Page 1

GE

g

Lighting Solutions

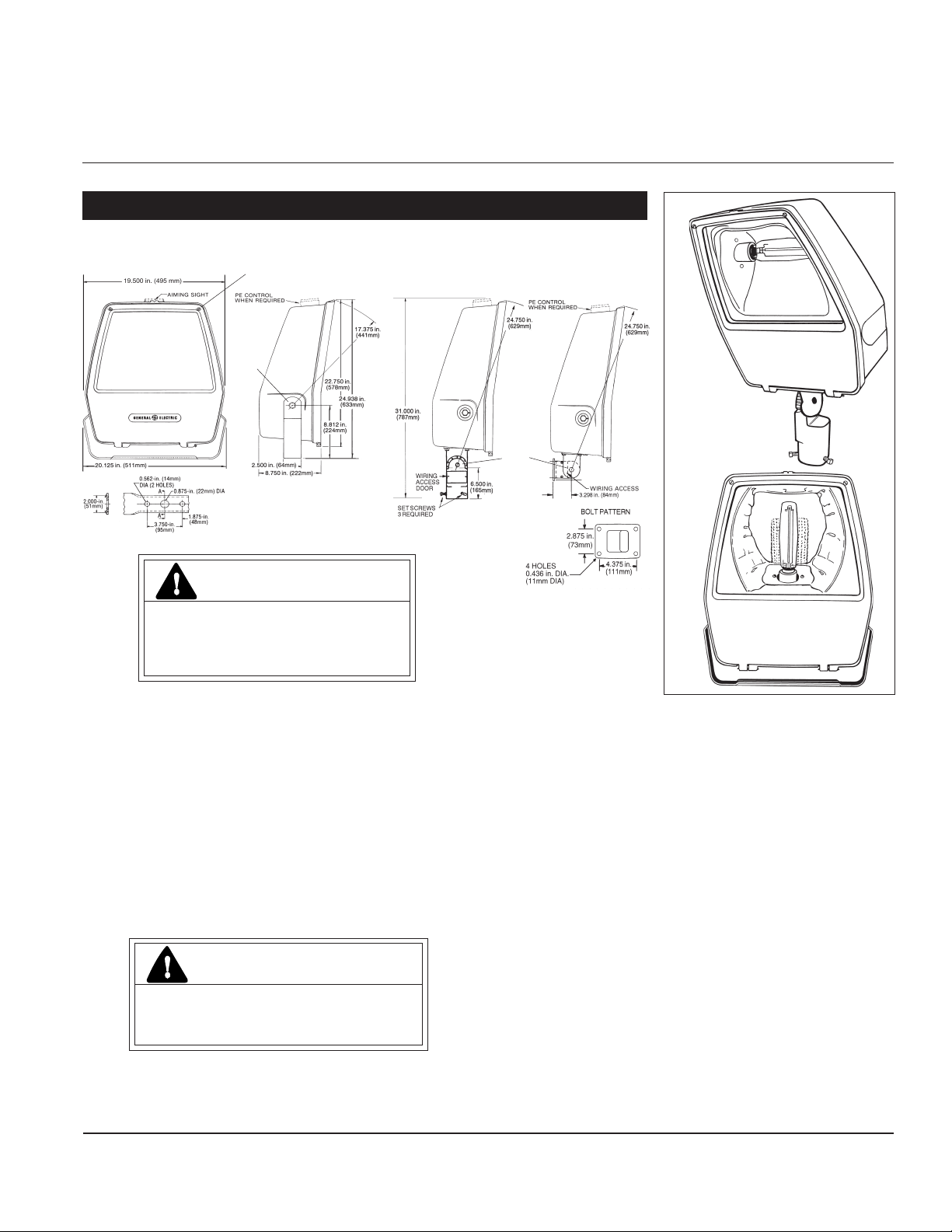

HLU, VLU Powerflood® Floodlight

READ THOROUGHLY BEFORE INSTALLING

GEH-5829

INSTRUCTIONS

Trunnion Mounted

(Standard)

Risk of electric shock

• Turn power off before servicing

– see instructions

SCREW B

BOLT A

WARNING

Slipfitter Mounted

(Options K or S)

BOLT A

Wall Mounted

(Option V)

HLUF

VLUF

GENERAL

This luminaire is designed for outdoor lighting

applications, and should not be used in areas of limited

ventilation or in high ambient temperature enclosures.

Best results will be obtained if installed and maintained

according to the following recommendations.

UNPACKING

This luminaire has been properly packed so that no

parts should have been damaged during transit. Inspect

to confirm.

MOUNTING

CAUTION

Unit will fall if not installed properly

• Follow installation instructions

This floodlight is provided with either trunnion

mounting, pipe mounting, or wall mounting means.

These instructions do not purport to cover all details or variations in equipment nor to provide for every possible contingency to be met in connection with installation, operation or

maintenance. Should further information be desired or should particular problems arise which are not covered sufficiently for the purchaser’s purposes, the matter should be referred

to GE Lighting Solutions.

TRUNNION MOUNTED UNITS — Mounted directly

on a flat surface. Mounting adapters are available for

installation on poles, crossarms, pipes, etc. The trunnion

bracket has a clearance hole for a 3/4-inch bolt used for

attachment to such mountings. The 0.562-inch holes on

either side permit additional anchoring, where required.

Tighten side trunnion bolts to 18 - 22 foot pounds.

PIPE MOUNTED UNITS — The slipfitter can be

mounted on 1-7/8-inch O.D. through 2-3/8-inch O.D. or

2-7/8-inch O.D. through 3-inch O.D. pipes. Three set

screws are used to clamp the floodlight securely to the

pipe. Tighten set screws to 18 - 22 foot pounds.

WALL MOUNTED UNITS - The wall mounting plate

is provided with four (4) 0.438-inch clearance holes

spaced 4.375(H)x2.875(V) inches for mounting.

AIMING

Slightly loosen bolt "A" (two on trunnion, one on

slipfitter), tilt luminaire to desired position, and retighten bolts. Both trunnions and slipfitters have vertical

degree scales which permit setting the floodlight at a

Page 2

selected angle and facilitate repositioning to the original

setting after having moved the floodlight for servicing.

Also, a sight has been cast into the top of the housing as

an aid in aiming the unit during daylight hours.

PHOTOELECTRIC CONTROL

Photoelectric control receptacle (if present) should be

oriented before control is installed. Loosen the two

holding screws and rotate receptacle until "North" is

directed as near as possible to true north. Tighten

holding screws and install control.

SLIPFITTER-MOUNTED AND WALL-MOUNTED

UNITS — Splice supply leads to three leads inside wiring

box. Splice line lead to black lead, neutral lead to white

lead, and ground lead to green lead, which is electrically

connected to floodlight housing.

LAMPS

Use only lamps specified on nameplate. Observe

lamp manufacturer’s recommendations and

restrictions on lamp operation, particularly ballast

type, burning position, etc.

WIRING

Make all electrical connections in accordance with

the National Electrical Code and any applicable

local code requirements.

Verify that supply voltage is correct by comparing

it to nameplate.

If unit is designated as multivolt or multiwatt,

follow specific instruction.

Connect ground lead to the green lead, green

ground screw on housing or terminal block

provided.

Do not remove insulated connectors from wires

not needed for required voltage connection.

When changing voltage on reconnectable units,

move only the lead with the insulated connector.

IF SINGLE VOLTAGE:

All single voltage ballasts are pre-wired such that

user need only connect the supply conductors.

IF MULTIVOLT: (120/208/240/277 volts)

Connect the ballast lead with the insulated termi-

nal to the desired voltage terminal as indicated on

the ballast terminal nameplate.

IF MULTIWATT:

Multiwatt ballasts are available in various combi-

nations of wattage. See wiring instructions on

wiring tag inside the luminaire.

TRUNNION MOUNTED LUMINAIRES — Threeconductor No. 14 cable (with 90°C minimum insulation)

is recommended for making electrical connections to

these units. Open the floodlight by loosening two screws

"B" and pulling the door forward. Remove the insulation

shield from the reflector to expose the wiring entrance

and terminal board. Loosen screws in pressure plate,

insert cable through grommet, and retighten screws.

(Notice that grommet fits cable of approximately 9/16inch diameter.) Grommet and pressure plate form a

weatherproof seal and strain relief. To maintain this seal,

screws in pressure plate must be retightened whenever

seal is disturbed.

Connect line lead to first (#1) terminal board position

and neutral lead to last (#3) position and connect

ground lead to the terminal with the green lead attached.

Before closing luminaire, be sure insulation shield is

properly attached to the reflector.

The VLU is designed for high pressure soduim (HPS),

"Deluxe White" mercury, and metal halide lamps of 400

watts and less, depending upon the ballast installed. The

HLU is designed for HPS lamps only.

Lamp Tightness – Mogul Base Lamp: The lamp

should be securely inserted to the NEMA-EEI specified

torque of 35 inch-pounds, which is best achieved by very

firmly tightening to insure application of sufficient

torque. Tightening must be sufficient to fully depress and

load the center contact of the socket.

MAINTENANCE

CAUTION

Risk of burn

• Allow lamp/fixture to cool before

handling

WARNING

Risk of burn

• Do not touch operating luminaire

This unit has a ballast tray which can be removed for

easy replacement of the ballast, ignitor or capacitor. To

remove the tray, disconnect the supply leads from the

terminal board, separate the disconnect to the lamp and

photoelectric control, loosen the screws at the top of the

ballast tray and slide the tray to the left so that the tray

can be pulled free over the keyhole slots. Reverse this

procedure for installation.

The ALGLAS® finished reflector and door glass may

be cleaned with any suitable non-abrasive glass cleaning

solution, soap or detergent, and rinsed with clean water.

Page 3

GE

g

Lighting Solutions

Lampe à faisceau large Powerflood®HLU, VLU

À LIRE AVEC SOIN AVANT D’INSTALLER

GEH-5829

INSTRUCTIONS

Montage tourillon

Trunnion Mounted

(Standard)

VISÉE

TROUS 2

VIS B

COMMANDE PE

S'IL Y A LIEU

BOULON A

Montage collier

(Options K ou S)

PORTE ACCES

CABLÂGE

PORTE ACCES

CABLÂGE

DANGER

Risque d'électrocution

• Mettre hors tension avant d'intervenir

– Suivez les instructions

PRÉSENTATION

Ces luminaires sont conçus pour fournir un éclairage à

l’extérieur, et ne doivent pas être utilisé dans des zones à

ventilation limitée ou sous des températures ambiantes élevées. Les

meilleurs résultats sont obtenus avec une installation et un

entretien conformes aux recommandations qui suivent.

DÉBALLAGE

Le luminaire a été emballé correctement de façon à ce

qu’aucune de ses pièces ne soit endommagée pendant son

transport. Veuillez procéder à une vérification pour le confirmer.

MONTAGE

ATTENTION

Montage mural

(Option V)

COMMANDE PE

S'IL Y A LIEU

HLUF

BOLT A

ACCÈS CÂBLAGE

DISPOSITION

DES BOULONS

TROUS 4

MODÈLES MONTÉS SUR TOURILLON — Le

montage se fait sur une surface plane. Des adaptateurs sont

disponibles pour l'installation sur poteaux, traverses, tuyaux, etc.

Le support de tourillon a un orifice de dégagement pour un

boulon de 3/4 de pouce pour la fixation avec de tels montages.

Les trous de 14,3 mm (0,562") de chaque côté permettent un

ancrage supplémentaire si c'est nécessaire. Serrez les boulons

latéraux de tourillon à 27-33 mKg (18-22 livre-pied).

MODÈLES MONTÉS SUR TUYAUTERIE — Le

collier pour emboîtage peut être monté sur des tuyauteries de

diamètre externe de 47 à 60 mm (1-7/8 à 2-3/8") ou de 73 à 76

mm (2-7/8 à 3"). Trois vis de blocage sont utilisées pour fixer la

lampe de façon sûre sur la tuyauterie. Serrez ces vis de blocage à

27-33 mKg (18-22 livre-pied).

VLUF

Risque de chute en cas de mauvais

montage • Suivez les instructions

Cette lampe est livrée avec les accessoires pour un montage sur

tourillon, sur tuyauterie ou sur mur.

Ces instructions n'ont pas pour destination de couvrir tous les détails ou variantes de l'équipement, ni de répondre à toutes les éventualités que vous pourriez rencontrer pendant l'installation,

le fonctionnement ou l'entretien. Si vous souhaitez des informations complémentaires, ou si vous rencontrez un problème particulier qui ne soit pas adressé de votre point de vue d'acheteur,

le sujet doit être remonté jusqu'à la société GE Lighting Solutions

MODÈLES MONTÉS SUR MUR - La plaque pour

montage mural est fournie avec quatre (4) trous de dégagement

de 12,4 mm (0,438") espacés de 111 mm en H x 73 mm enV(4.375

x 2.875") pour la fixation.

VISÉE

Desserrez légèrement le(s) boulon(s) "A" (deux sur tourillon,

un sur collier), inclinez le luminaire en position voulue, et

resserrez. Les tourillons et colliers ont des échelles graduées en

Page 4

degrés verticaux qui permettent un réglage de la lampe à un angle

sélectionné et facilitent son repositionnement après un

déplacement pour l'entretien. De plus un viseur est moulé sur le

dessus du caisson pour aider à l'orientation de la lampe à la

lumière du jour.

COMMANDE PHOTOÉLECTRIQUE

Le réceptacle de la commande photoélectrique, si elle est

présente, doit être orienté avant d'installer le module de

commande. Desserrez ses deux vis de maintien et tournez-le

jusqu'à ce que son indication"North" soit dirigée au mieux vers le

Nord vrai. Resserrez les vis de maintien et installez le module PE.

CÂBLAGE

Effectuez tous les raccordements en conformité avec les

normes nationales et les éventuels règlements locaux

applicables.

Vérifiez que la tension secteur disponible est la bonne en

comparant avec l'indication de tension sur la plaque

d'identification.

Reliez le fil de terre sur le fil vert, sur la vis verte de terre

du châssis ou la borne spécifique de terre.

Si l'appareil est conçu pour être multi-tensions ou multi-

puissances, suivez les instructions spécifiques.

N'enlevez pas les connecteurs isolés des fils non

concernés par le raccordement de la tension.

En changeant la tension des unités reconfigurables, ne

bougez que le fil avec la cosse isolée.

LUMINAIRES SUR TUYAUTERIE OU MURAUX —

Raccordez les fils d'alimentation aux trois fils du

luminaire dans sa boîte de câblage. Reliez la phase

secteur sur le fil noir, le neutre sur le fil blanc, et la terre

sur le vert, qui est électriquement relié au caisson de la

lampe.

LAMPES

N’utilisez que le type de lampe spécifié sur la plaque

d’identification. Observez les recommandations et restrictions du fabricant sur le fonctionnement de la lampe, en

particulier pour le type de ballast, la position d’utilisation,

etc.

Le modèle VLU est conçu pour recevoir des lampes à vapeur de

sodium haute pression(HPS), à vapeur de mercure "Deluxe

White", et aux halogènures métalliques, de 400 watts et moins, en

fonction du ballast qui est installé. Le modèle HLU est conçu

uniquement pour recevoir des lampes à vapeur de sodium haute

pression(HPS).

Serrage de lampe - culot goliath : La lampe doit être

insérée de façon sûre avec un couple de serrage NEMA-EEI

spécifié à 4,4 mkg (35 livre-pouce), ce qui est le mieux réalisé en

serrant fortement à la main pour mettre un couple suffisant. Le

serrage doit complètement appuyer et charger le contact central

de la douille avec le culot de la lampe.

MONO-TENSION :

Tous les ballasts sont précâblés et l'utilisateur n'a qu'à

relier les fils d'alimentation pour la tension prévue.

MULTI-TENSIONS : (120/208/240/277 volts)

Reliez le fil de ballast avec sa terminaison isolée sur la

borne de tension adéquate comme indiqué sur la plaque

du ballast.

MULTI-PUISSANCES :

Les ballasts multi-puissances sont disponibles en diverses

combinaisons de wattages. Reportez-vous aux instructions

de câblage sur l'étiquette à l'intérieur du luminaire.

LUMINAIRES SUR TOURILLON — Un câble à trois

conducteurs N° 14 (avec isolation thermique à 90°C minimum)

est recommandé pour réaliser le raccordement d'alimentation.

Ouvrez la lampe en desserrant deux vis "B" et en tirant la porte

vers l'avant. Enlevez l'écran d'isolation du réflecteur pour exposer

l'accès au câblage et au bornier. Desserrez les vis de la plaque de

pression, insérez le câble dans le passe-fil (qui accepte un câble

jusqu'à 14 mm ou 9/16" de diamètre) et reserrez les vis. Le passefil et la plaque de pression constituent une étanchéité contre les

intempéries et évitent les contraintes. Pour maintenir cette

étanchéité il faut resserrer les vis de la plaque de pression chaque

fois que l'étanchéité aura été perturbée.

Connectez la phase secteur sur la première (#1) position du

bornier, et le neutre sur la dernière (#3), et reliez le fil de terre au

bornier là où est câblé le fil vert de l'appareil.

Avant de refermer le luminaire, assurez-vous que l'écran

d'isolation est bien attaché au réflecteur.

ATTENTION

Risque de brûlure

Laissez le bloc d'ampoule refroidir

avant d'y toucher

DANGER

Risque de brûlure

• Ne touchez pas le luminaire allumé

ENTRETIEN

Ce produit a un plareau de ballast qui peut être déposé pour

faciliter le remplacement du ballast, de l'inductance ou du

condensateur. Pour enlever le plateau, débranchez les fils

d'alimentation au bornier, séparez la prise à déconnexion rapide

pour la lampe et la commande photoélectrique éventuelle,

desserrez les vis sur le dessus du plateau de ballast et tirez le

plateau vers la gauche pour qu'il puisse être libéré en le soulevant

par dessus les orifices en trou de serrure. Effectuez la procédure

inverse au remontage.

Le réflecteur en finition ALGLAS

être nettoyés avec toute solution convenable pour vitres non

abrasive, à base de savon ou de détergent, puis il faut les rincer à

l'eau claire.

®

et la porte vitrée peuvent

g

GE Lighting Solutions • 1-888-MY-GE-LED • www.gelightingsolutions.com

16943533----888

GE Lighting Solutions is a subsidiary of the General Electric Company. Evolve and other trademarks belong to GE Lighting Solutions. The GE brand and logo are trademarks of the General Electric Company.

© 2011 GE Lighting Solutions. Information provided is subject to change without notice. All values are design or typical values when measured under laboratory conditions.

35-201578-3K (11/00)

Loading...

Loading...