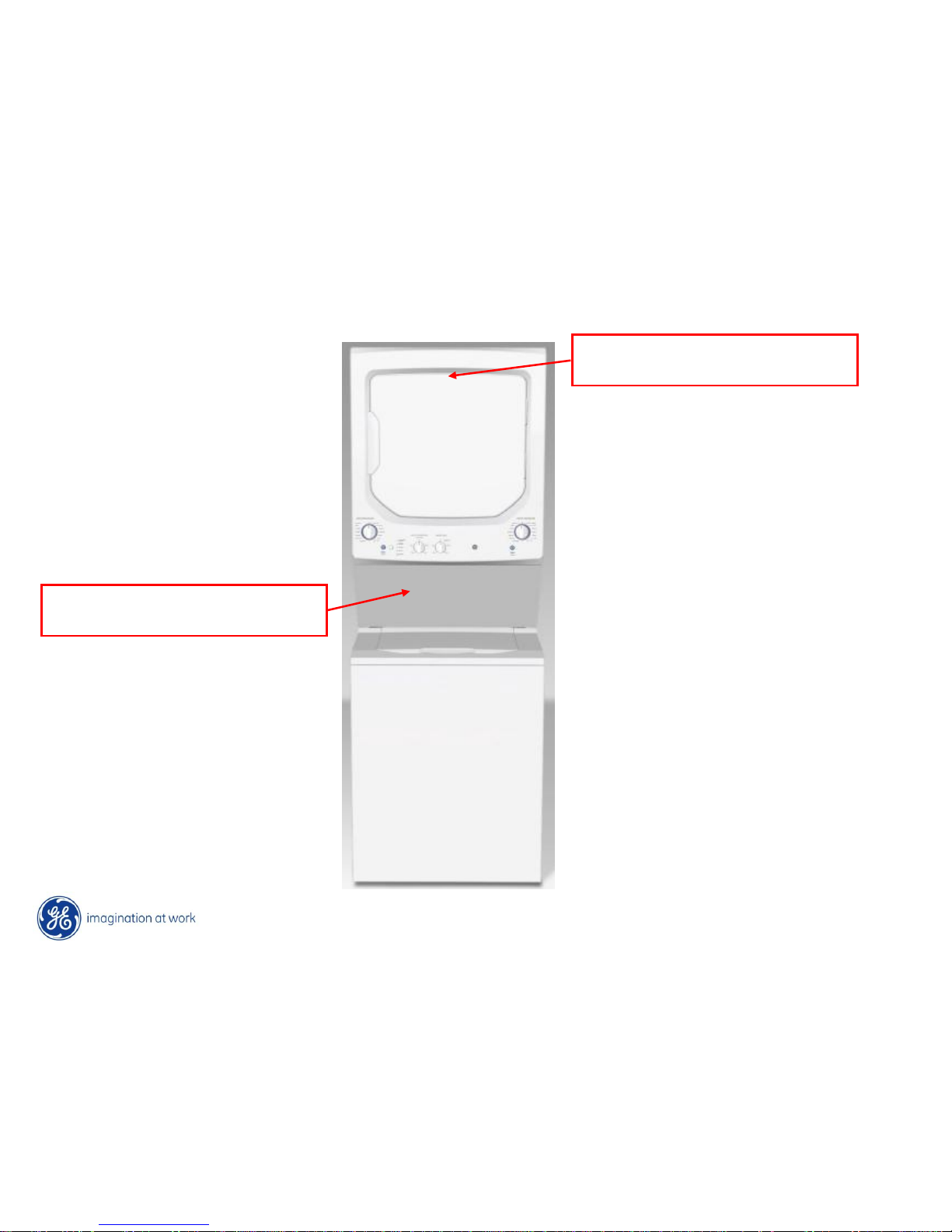

GE GTUP270EMWW, GTUP270GMWW, GTUP240EMWWGTUP240GMWW, GTUP240EMWW, GTUP240GMWW Service Manual

24” & 27” Unitized Laundry Centers

GTUP270EMWW

GTUP270GMWW

GTUP240EMWW

GTUP240GMWW

IMPORTANT SAFETY NOTICE

The information in this presentation is intended for use by individuals

possessing adequate backgrounds of electrical, electronic, &

mechanical experience. Any attempt to repair a major appliance may

result in personal injury & property damage. The manufacturer or seller

cannot be responsible for the interpretation of this information, nor can it

assume any liability in connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing this product.

If electrical power is required for diagnosis or test purposes, disconnect

the power immediately after performing the necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to

complete a path to ground are removed for service, they must be

returned to their original position & properly fastened.

Copyright General Electric 2010

GE Factory Service Employees are required to use safety glasses with side

shields, safety gloves & steel toe shoes for all repairs.

Dyneema® Cut

Resistant Glove

Safety Glasses

must be

compliant with

ANSI Z87.1-2003

Prescription Safety Glasses

Plano Safety Glasses

Steel Toe Shoes

VR Gloves – provide shock protection

Copyright General Electric 2010

Model/Serial Tag

Located inside dryer on front panel

Mini-Manual

Taped on the inside of the service panel

Product Information

Copyright General Electric 2010

• Drum capacity 5.9 ft3

• Drum access area: 303 in

2

• Heater power : 5400W

• 4 drying cycles (Timed, Auto

Cottons, Easy care, Delicate)

• Auto cottons cycle available

• Wrinkle care option

• Exhaust max. length: 48 ft

• Drum capacity 5.7 ft3

• Drum access area: 234 in2

• Heater power : 4500W

• 3 drying cycles (Timed,

Permanent press, Delicate)

• No auto cottons cycle available

• No wrinkle care option

• Exhaust max. length: 48 ft

New 27” Old 27”

DRYER 27’’ Design Differences

Unitized Laundry Center

Product Weight 240 Lbs

Copyright General Electric 2010

• Capacity 3.18 ft

3

• Index rinse(w/basket spin) & Deep

rinse

• Adaptive fill and Manual Fill

capability

• ATC temperature control

• Washer Electronic Control

• LED status indicators

• Quick Release Lid Lock

• Capacity 2.7 ft

3

• Deep rinse only

• Manual fill capability

• Discrete water temperatures

• Washer Electromechanical

Timer

• Cycle indicator thru timer

• Slow release Lid Lock (ptc)

New 27” Old 27”

27” Washer Design Differences

Unitized Laundry Center

Copyright General Electric 2010

• Capacity 4.4 cu. ft .

• Drum access area: 150 in2

• 4 Heat levels available

• Delicate cycle available

• Lint filter in the door

• Front serviceable as per spec.

• EOC removed

• Height 3” taller

• Capacity 3.4 cu. ft .

• Drum access area: 133 in2

• 3 Heat levels available.

• No delicate cycle available

• Lint filter at the rear of the

drum

• Some parts require rear access

to service

• EOC signal

New 24”

Old 24”

DRYER 24’’ Design Differences

Unitized Laundry Center

Product Weight 214 Lbs

“End Of Cycle Signal”

Copyright General Electric 2010

24” Washer Design Diferences

• Capacity 1.87 ft

3

• Index rinse(w/basket spin) & Deep

rinse

• Adaptive fill and Manual Fill

capability

• ATC temperature control

• Washer Electronic Control

• LED status indicators

• Quick Release Lid Lock

• Capacity 1.75 ft3

• Deep rinse only

• Manual fill capability

• Discrete water temperatures

• Washer Electromechanical Timer

• Cycle indicator thru timer

• Mechanical Brake

• Transmission + I Motor

New 24” Old 24”

Unitized Laundry Center

Copyright General Electric 2010

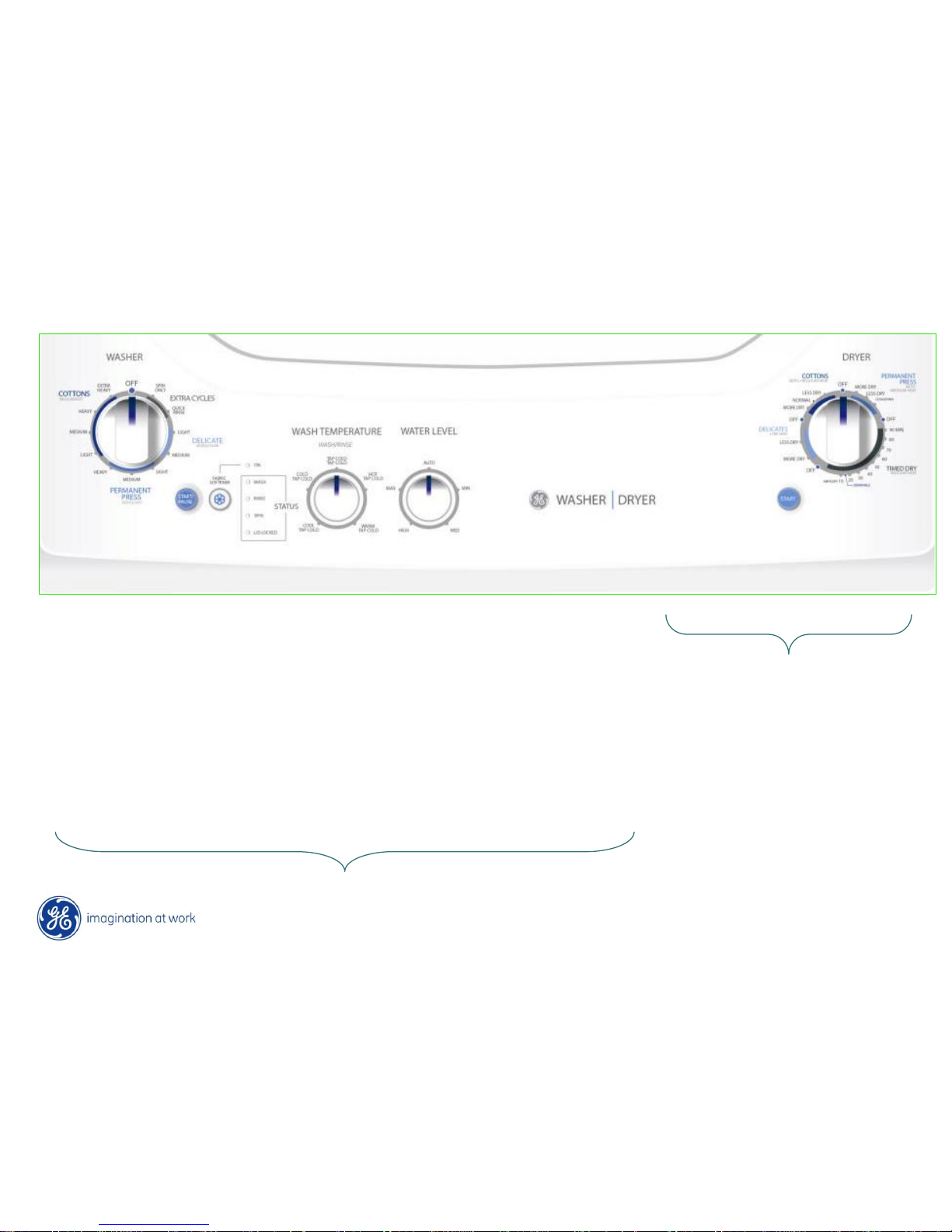

Water Level

• Automatic

(if Adaptive

Fill is needed)

• Minimum

• Medium

• High

• Maximum

T Board

2 buttons

• Start / Pause

• Options

5 Leds

• “Shower Rinse”

• “Deep Rinse”

• Wash (Indicator)

• Rinse (Indicator)

• Spin (Indicator)

Temperature

• Cold - 60

• Cool - 70

• Warm – 80

• Hot – 110

Programs

• OFF

• Heavy duty

• Whites

• Colors

• Easy care

• Delicates

• Speed Cycle

• Extra Spin

Start Button Timer

Product Controls

Washer Controls

Dryer Controls

Copyright General Electric 2010

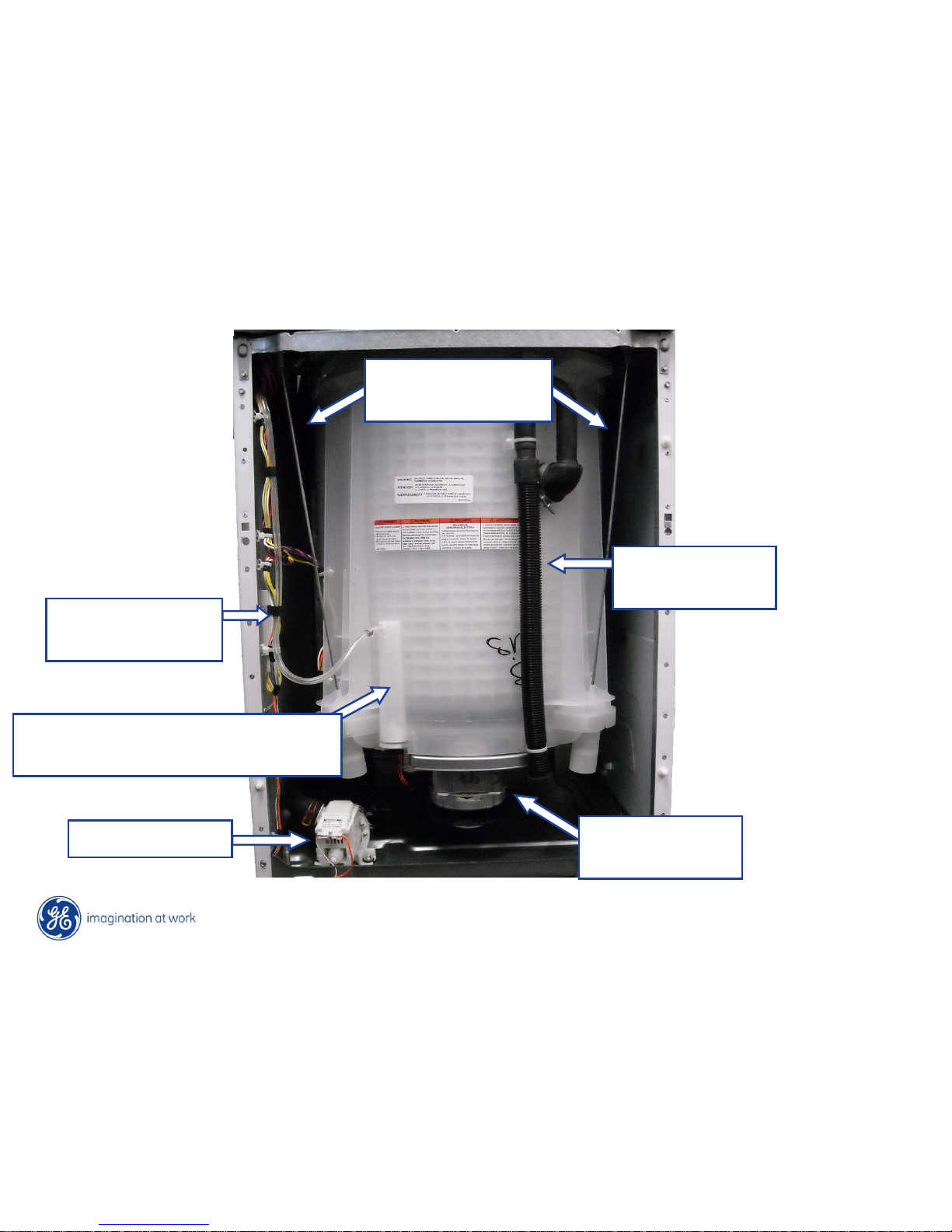

Washer Components

Over flow

pipe

Motor &

Transmission

Drain Pump

Motor

Capacitor

Suspension

Rods

Pressure Switch Dome & Hose

Copyright General Electric 2010

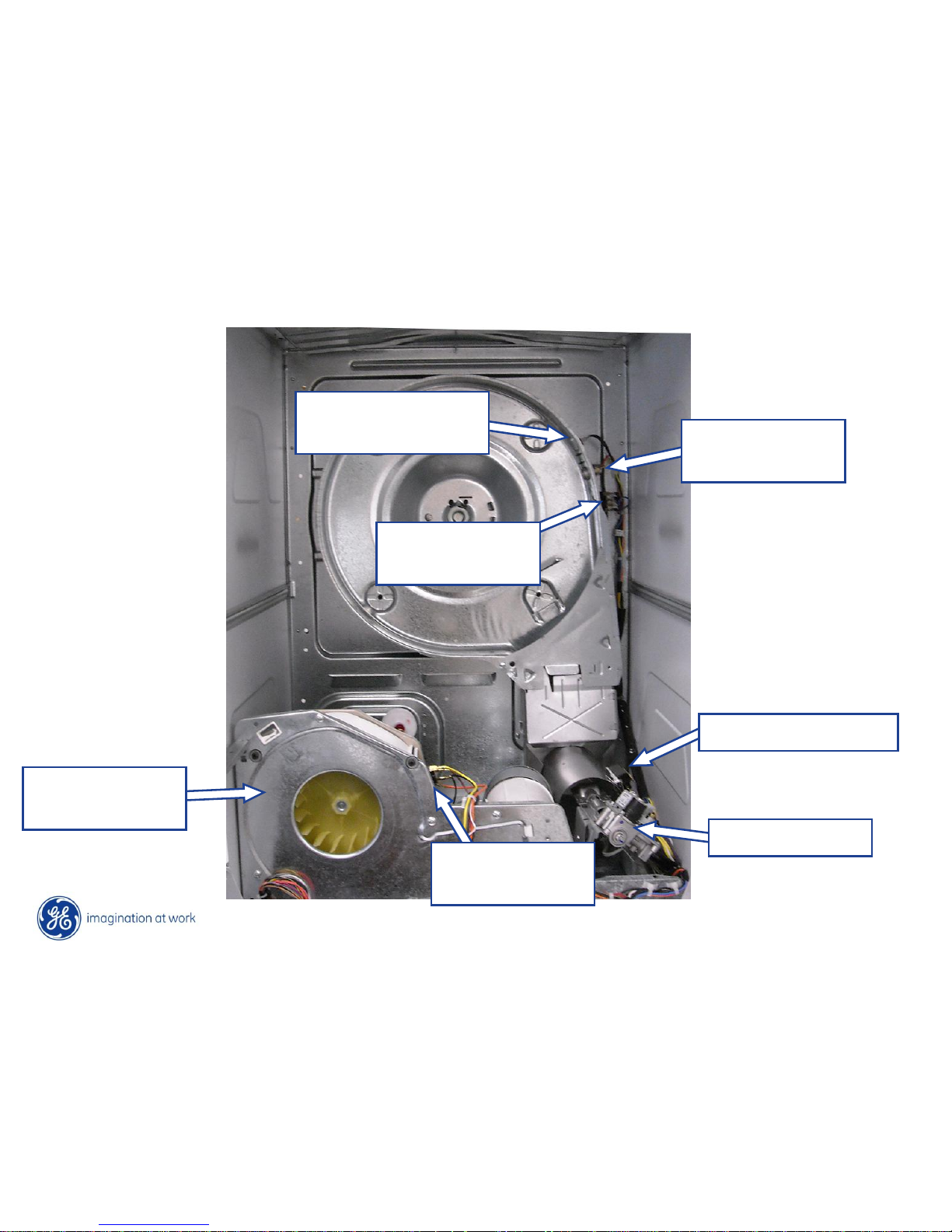

Gas Dryer Components

Motor &

Blower Assy

Gas Valve

Flame Detector

High Limit

Thermostat

Safety

Thermostat

Control Inlet

Thermostat

Outlet

Thermostat

Copyright General Electric 2010

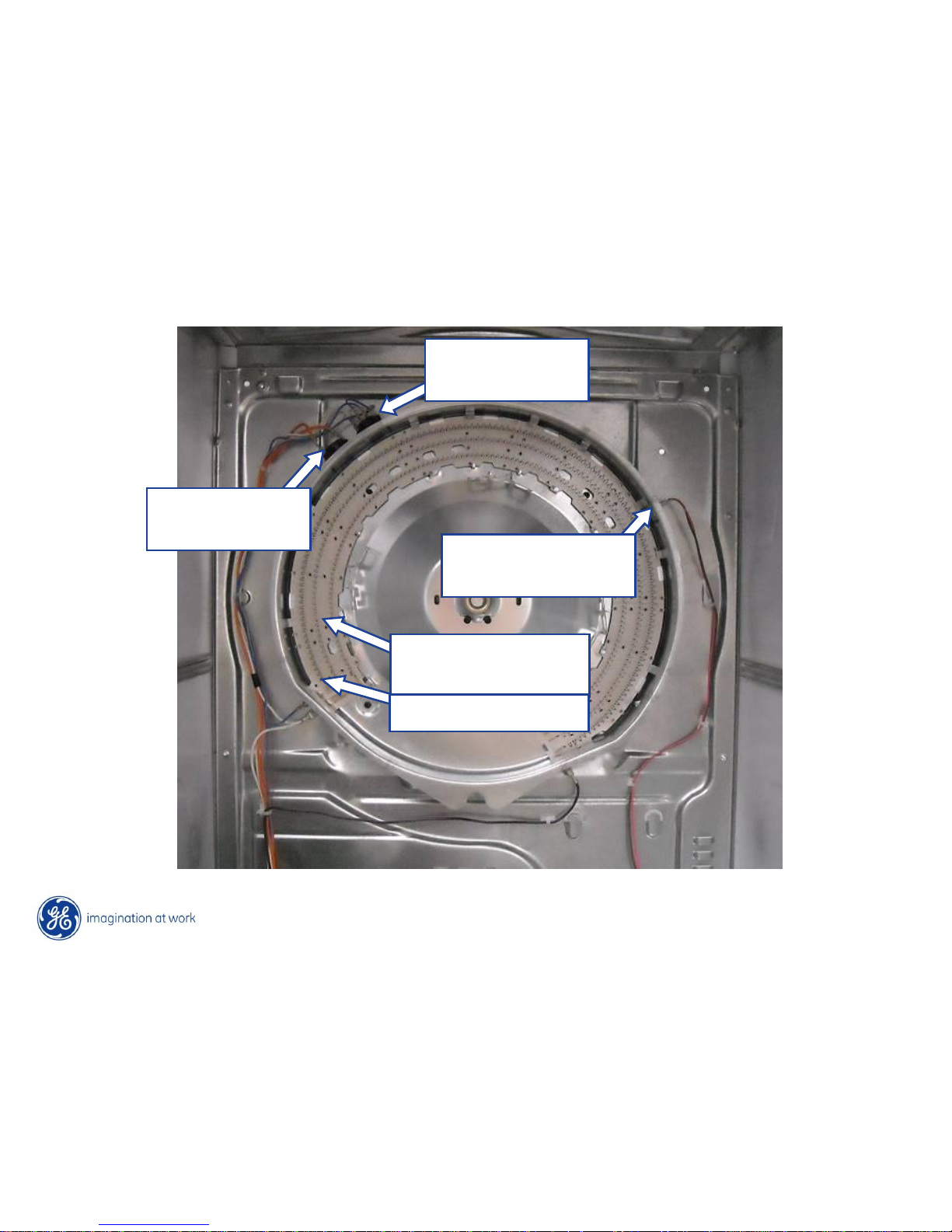

Electric Dryer Components

Safety

Thermostat

High Limit

Thermostat

Control Inlet

Thermostat

Inner Heater

Coils

Outer Heater Coil

Copyright General Electric 2010

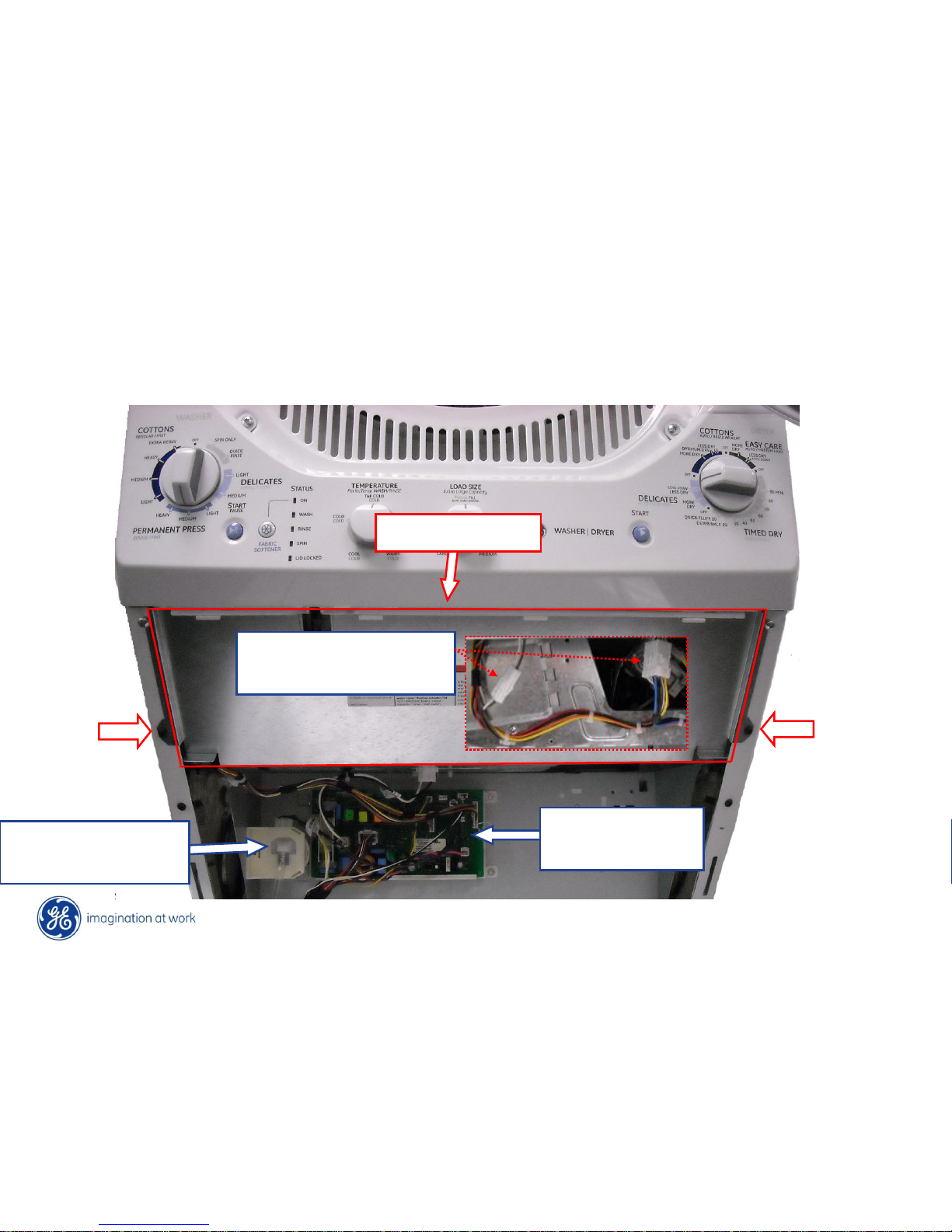

Control Panel Access

To access the service panel; remove the two Phillips screws at the top left and right of

the panel. Lift up on the panel and pull forward to release the panel from the cabinet.

The mini manual is taped to the backside of the service panel.

Mini

Manual

Copyright General Electric 2010

Control Panel Access

The washer control and pressure switch are accessible after removing the service panel.

To access the dryer harness wiring connectors; remove two Phillips screws from the

heat shield and pull the shield forward to remove.

Washer

Control Board

Water Pressure

Sensor

Dryer Harness

Connectors

Heat Shield

Copyright General Electric 2010

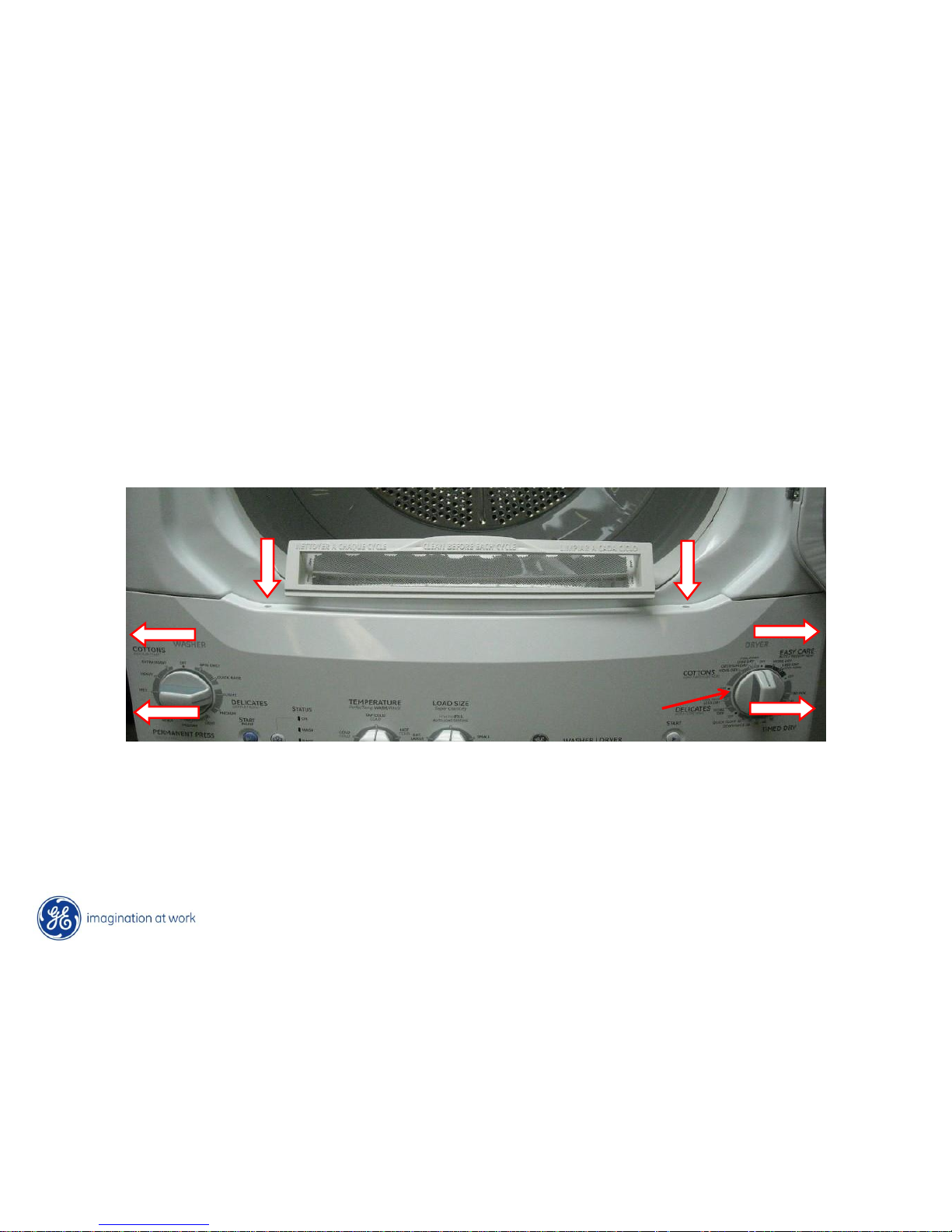

24” Control Panel Access

To access the washer/dryer controls; remove five Phillips screws, one on each side of

the control panel and three on the front opening. Remove the dryer control knob and tilt

the panel forward.

Copyright General Electric 2010

27” Control Panel Access

To access the washer/dryer controls; remove six Phillips screws, two on each side of the

control panel and two on the front bottom door opening. Remove the dryer control knob

and tilt the panel forward.

Copyright General Electric 2010

Control Panel

Washer Controls

Dryer Timer &

Start Switch

To remove the control panel from the cabinet; slide the panel to the right to release the

locking tabs from the slots. The washer controls are installed on the control panel, dryer

timer and start switch remain on the dryer front panel.

Copyright General Electric 2010

Control Panel

To replace any of the washer controls; remove the selection knob from the front, lift the

locking lever and rotate the control to the left to release from the control panel.

Copyright General Electric 2010

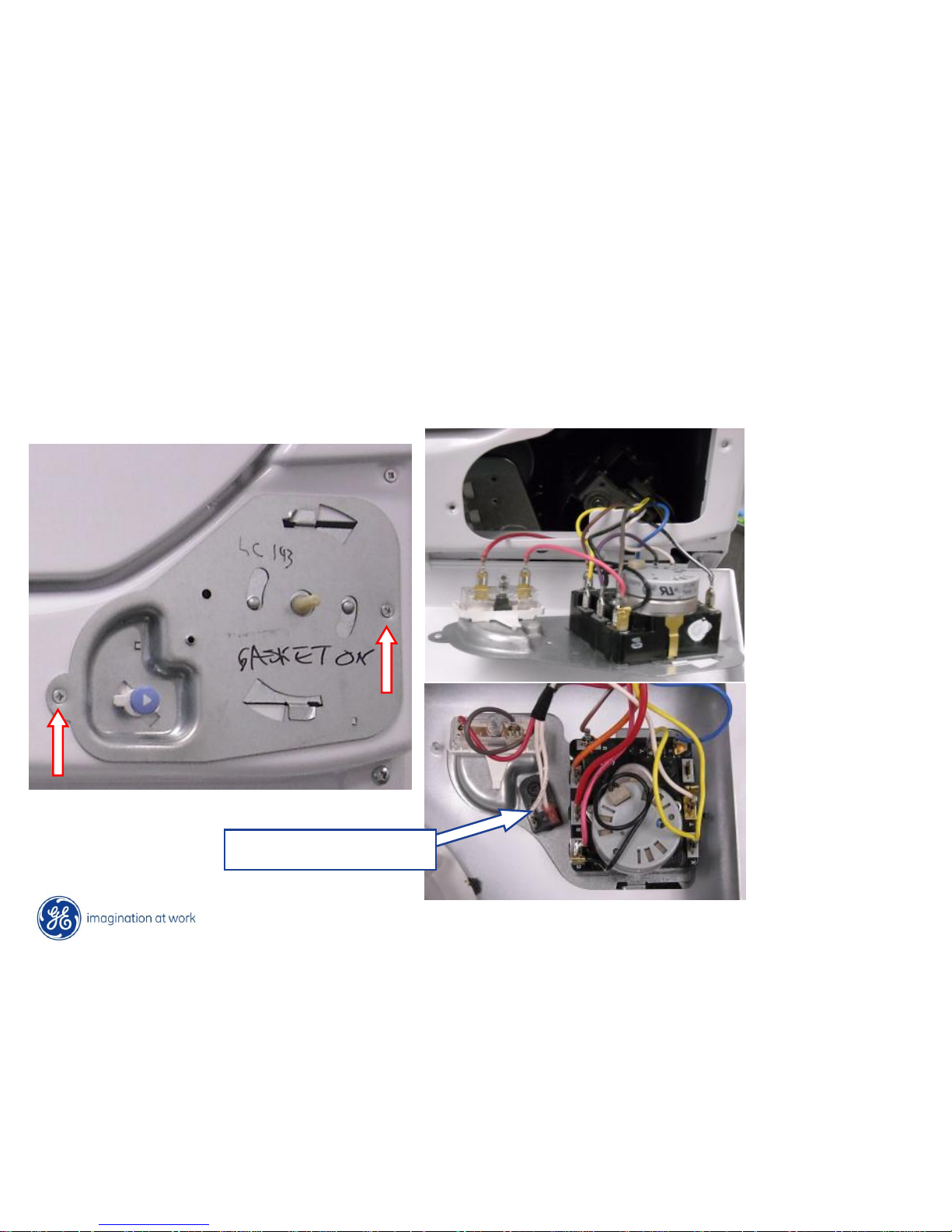

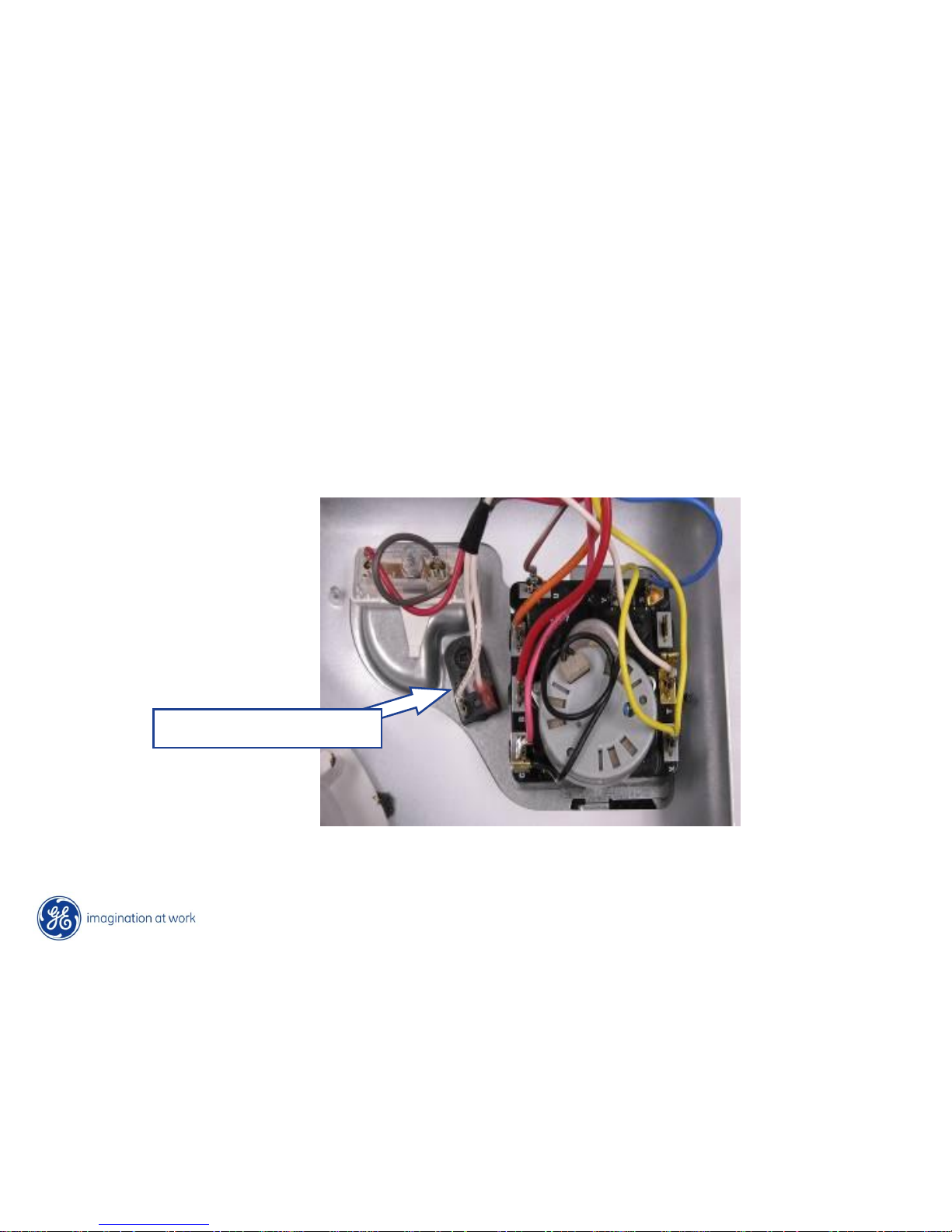

Control Panel

To replace the dryer timer or start switch (Timer motor dropping resistor EL); remove two

Phillips screws from the control bracket and remove the bracket from the front panel.

Both the dryer timer and start switch are twist lock connected to the control bracket.

Gas Model

Electric Model

Dropping Resistor

Copyright General Electric 2010

Control Panel

The timer dropping resistor (on electric models) controls the run time during automatic

cycles. This 4500 ohm resistor is in series with the timer motor, when the thermostat

trips turning off the heat – the resistor drops the 240 vac heater circuit to 120 vac to run

the timer motor. The resistor is held in place on the bracket with a single Phillips screw.

Dropping Resistor

Copyright General Electric 2010

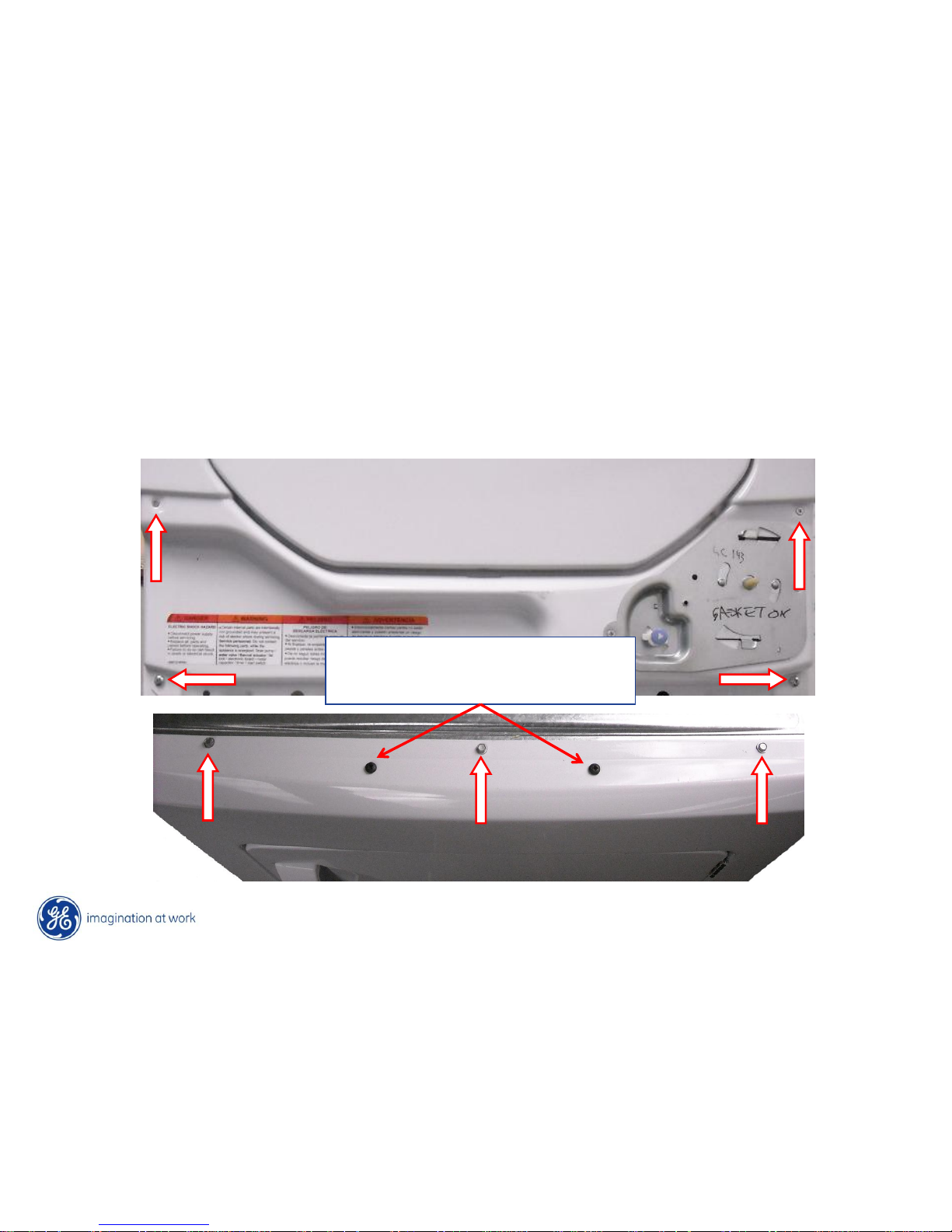

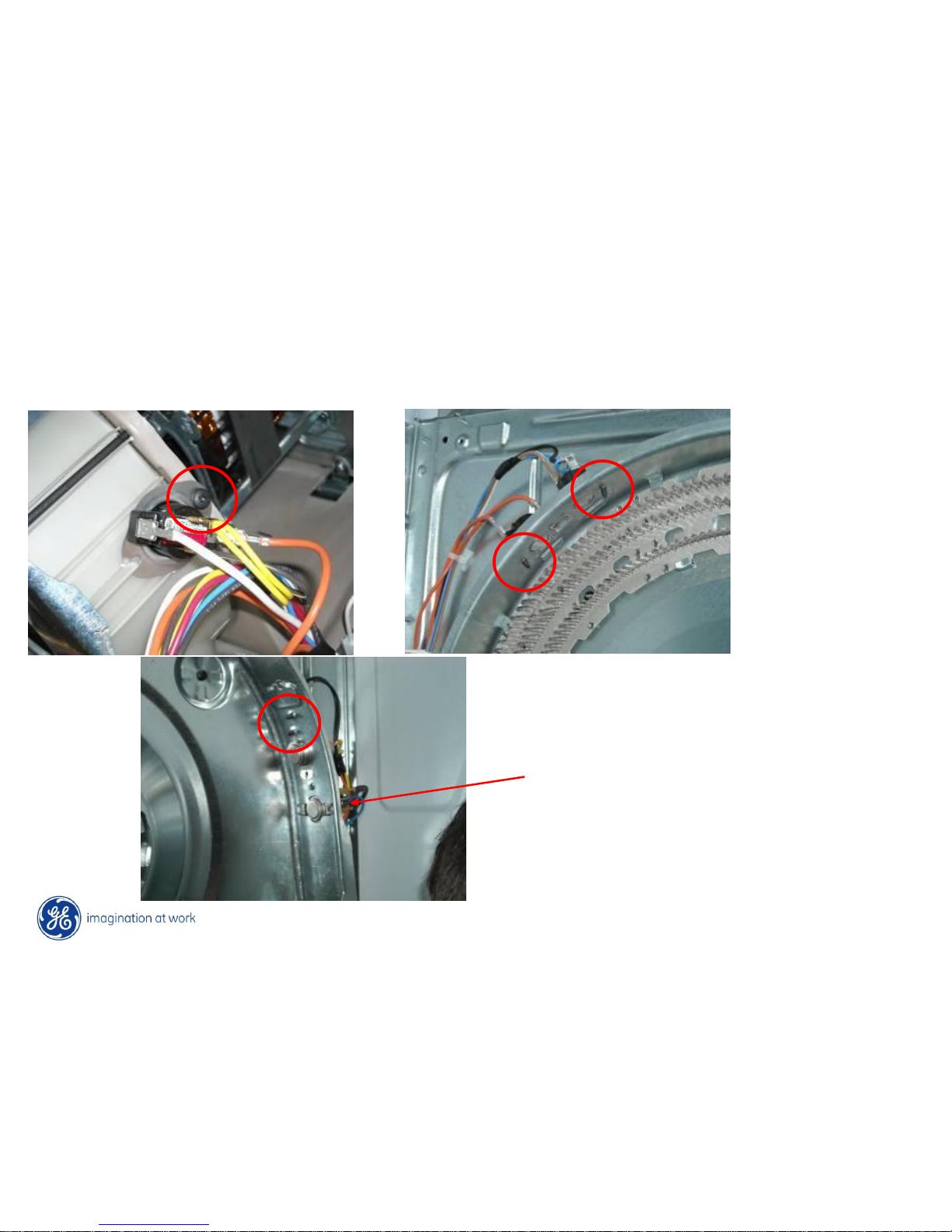

Dryer Front Panel Removal

To remove the dryer front panel; unplug the harness connectors behind the heat shield.

Remove the four Phillips screws from the front of the panel and three ¼” hex head

screws from the panel top. Pull out on the bottom of the panel and lift to release the

panel from the dryer drum.

Top Drum Bearing Screws

Do Not Remove

Copyright General Electric 2010

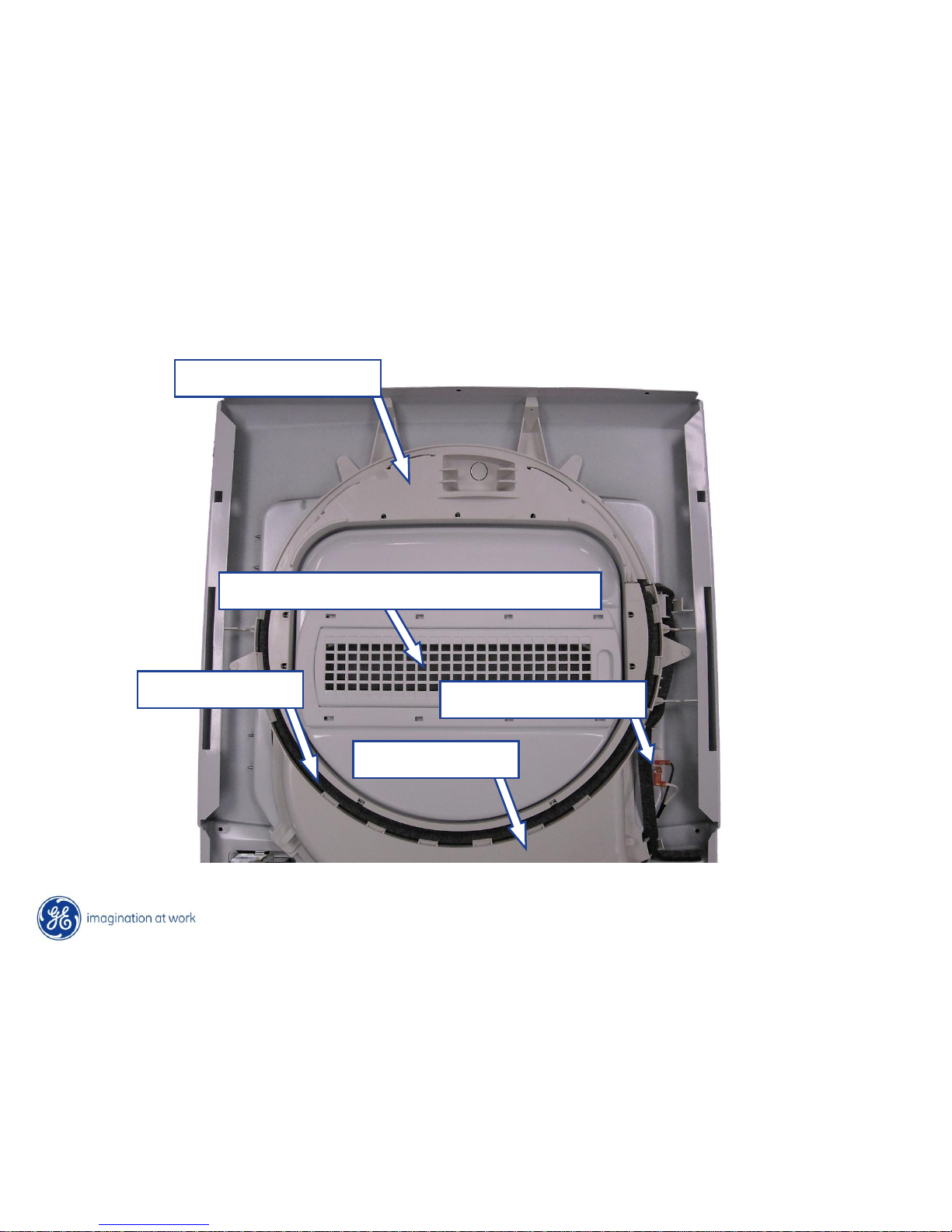

Lint Filter – not on 27” models

Door Switch

Drum Bearing

Drum Felt

24” Dryer Front Panel

Air Duct

Copyright General Electric 2010

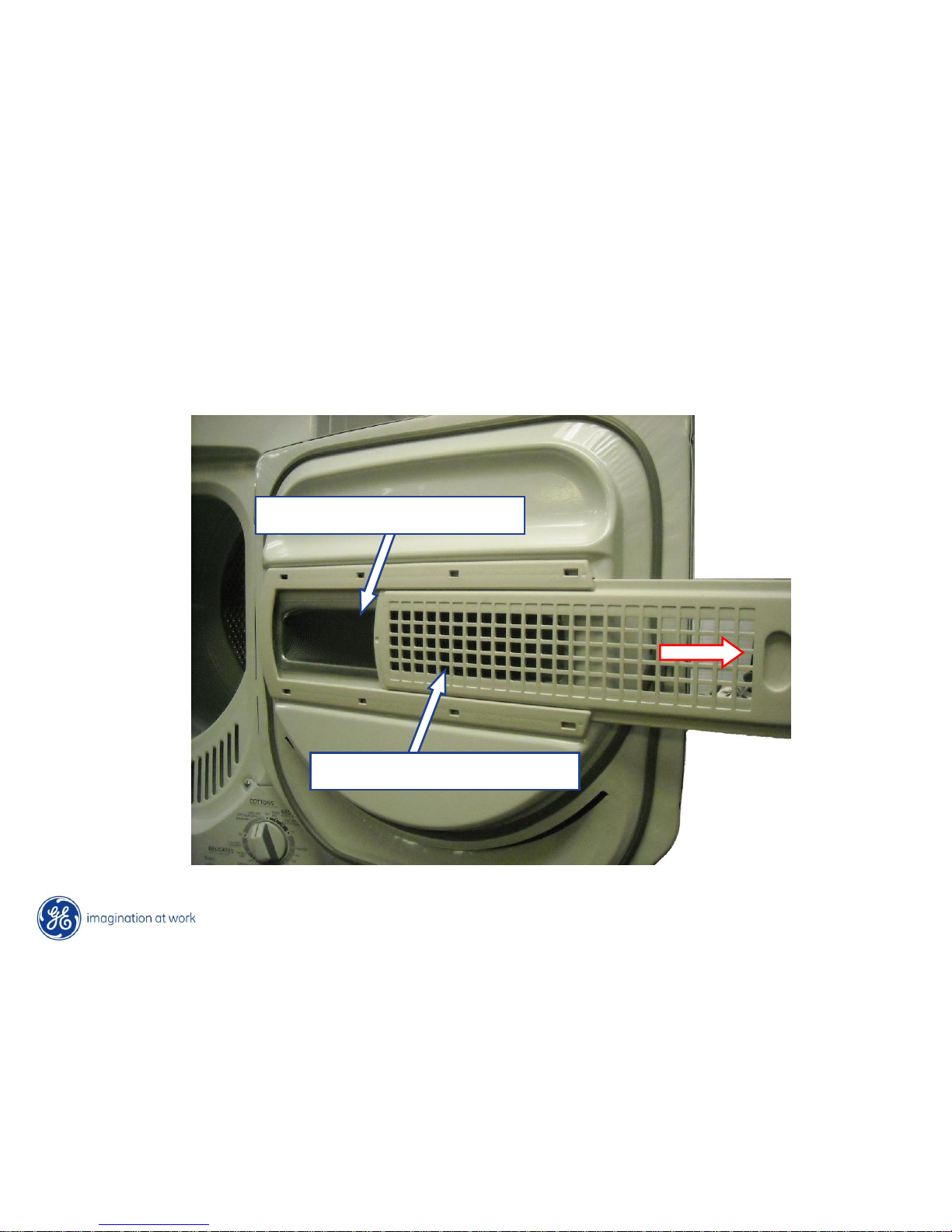

24” Dryer Front Panel

Screen Mesh Lint Filter

The lint filter is housed in the dryer door. To clean the lint filter, slide the cover from the

screen mesh filter and wipe off the lint from the mesh screen after each cycle.

Lint Filter Cover

Copyright General Electric 2010

27” Dryer Front Panel

The lint filter is housed in the dryer front. To clean the lint filter, slide the filter up from the

front panel and wipe off the lint screen after each cycle.

Standard Lint Filter

Copyright General Electric 2010

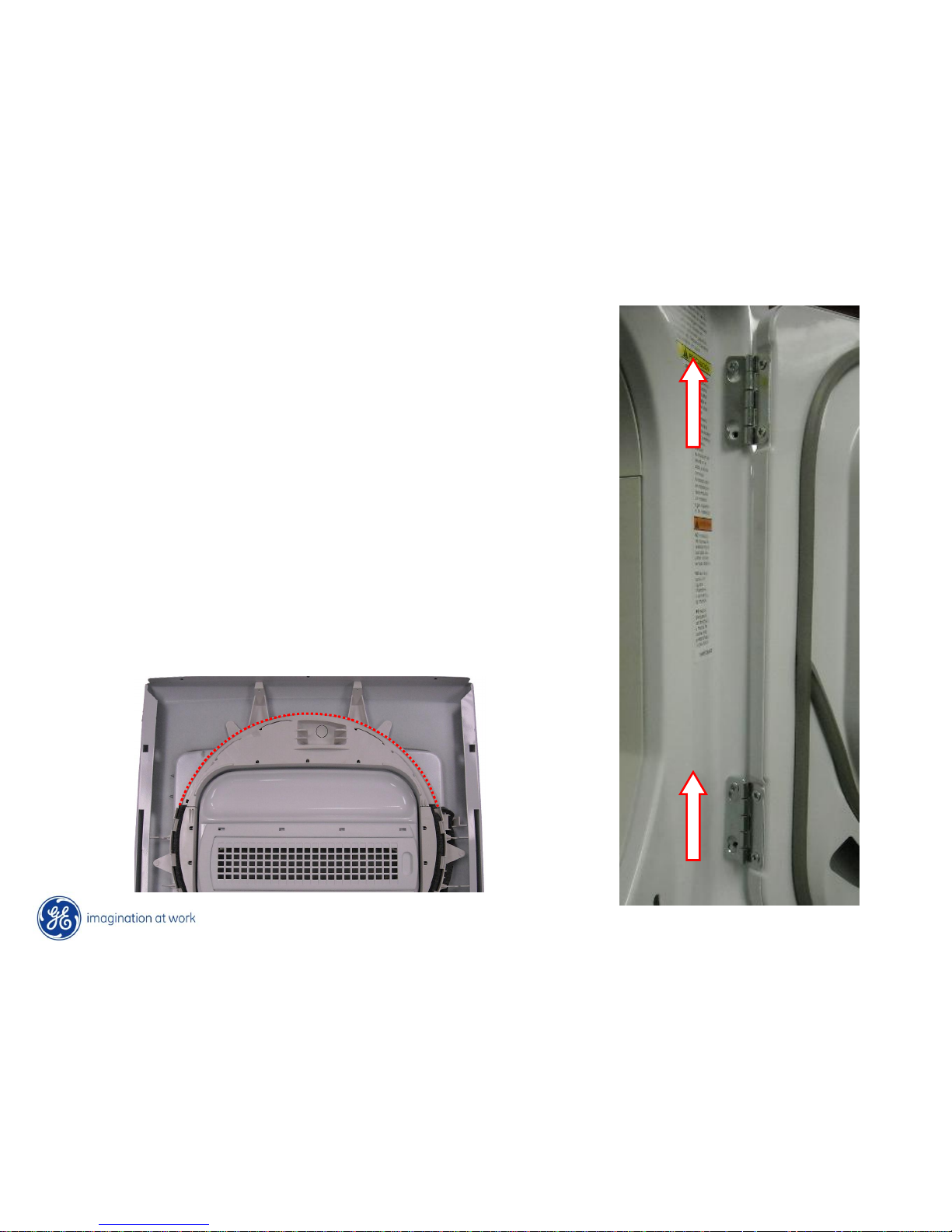

Dryer Front Panel Installation

When removing or re-installing the dryer front panel;

remove the dryer door. Remove the bottom screw

from each hinge and loosen the second screw, lift the

door off of the dryer front.

Removing the dryer door allows for easier

manipulation of the dryer front as you place the dryer

front on the top of the cabinet and reach through the

door opening to push up on the dryer drum for

placement on the front top bearing.

Copyright General Electric 2010

Dryer Drum Removal

To remove the dryer drum; lift up on the drum and push the idler pulley to the right

locking it onto the motor bracket, releasing tension on the belt for removal. The dryer

drum can then be removed from the dryer by pulling it forward. When re-installing the

dryer belt, position the belt on the drum and pulleys and unlock the idler to tension the

belt. Rotate the drum by hand CCW several times to ensure proper belt alignment.

Copyright General Electric 2010

Dryer Thermostats

The dryer thermostats can be replaced by removing a single Phillips screw and

removing the stat from a locking tab.

The control inlet thermostat on

gas models utilize two locking

tabs instead of a Phillips screw.

Copyright General Electric 2010

Motor & Blower

The blower wheel is mounted to the motor shaft with an integral threaded nut. To

remove the blower wheel; lock the motor shaft and turn the blower nut CCW with a

15/16” (24mm) socket.

Copyright General Electric 2010

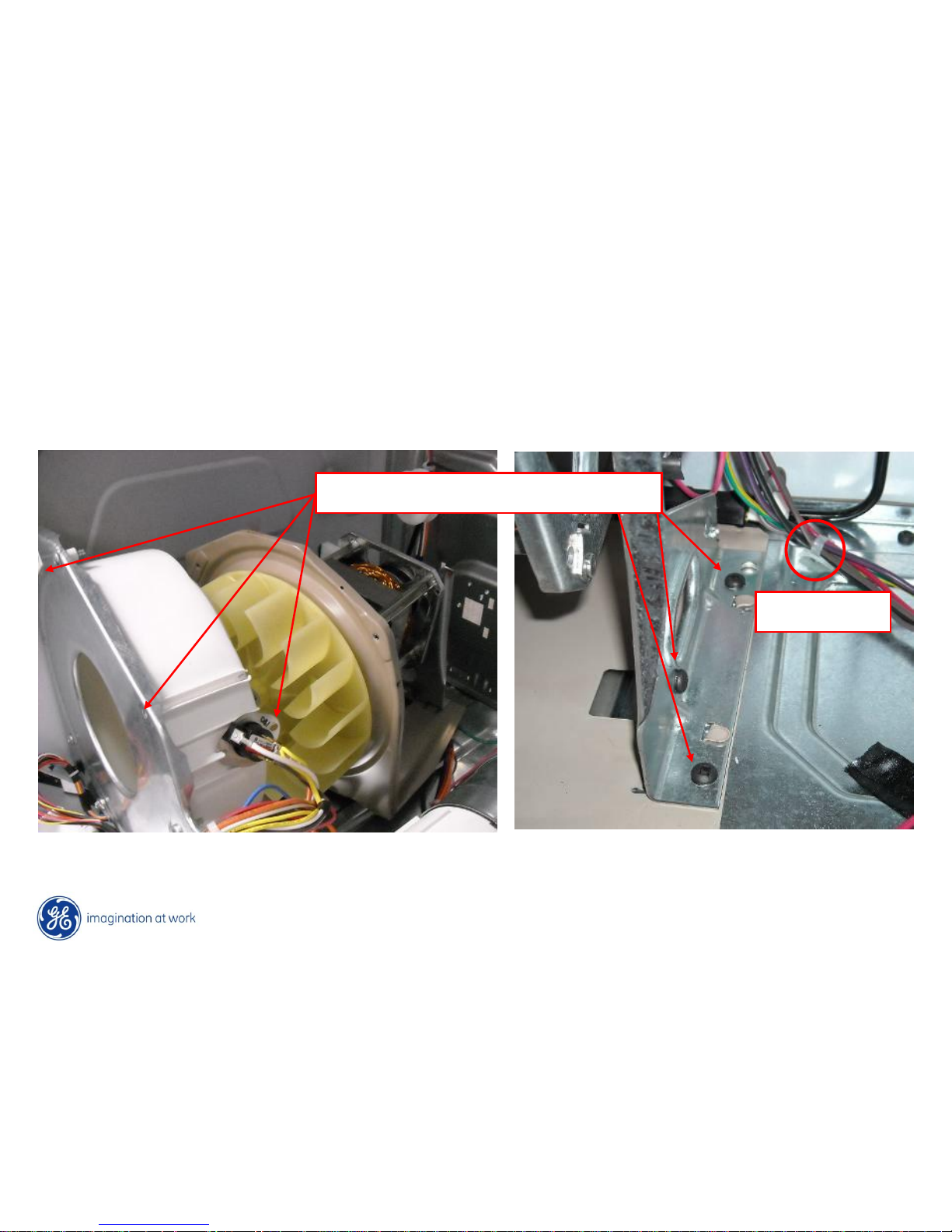

Motor & Blower

To remove the motor/blower assembly; remove three Phillips screws from the front

blower housing and the control thermostat. Remove three Phillips screws from the

rear motor bracket, disconnect the motor harness wire tie and move the assembly

to the rear of the dryer.

Six Phillips Screws

Wire Tie

Copyright General Electric 2010

Motor & Blower

To replace the drive motor; you can pull the assembly as previously mentioned or,

loosen the front motor clamp and compress the rear clamp to unsnap it from the

rear motor bracket. Remember to unscrew the blower wheel.

Rear Clamp

Loading...

Loading...