GE GTS21SCXASS, GTS21SBXASS, GTS21KCXAWW, GTS21KCXABB, GTS21KBXAWW Owner’s Manual

...

¢)

¢)

4..0

GEPpp/iances.com

Safety Instructions ............ 2-4

Operating Instructions

Automatic Icemaker ............. 9

Controls ....................... 5

Crispers and Pans ............. 7, 8

Shelves and Bins ................ 6

Care and Cleaning

Care and Cleaning .......... 10, 11

Replacing the i,ight Bulb ........ 11

Installation Instructions

Icemaker Installation ........ 13-16

Preparing to Install

the Refrigerator ............... 12

Reversing the Door Swing .... 21-25

Water i Jne Installation ....... 17-21

Moo#Is G7"t-12 I, GTL2 l

and G7"5"2l

Congdlateur supdrieur

Rdfrigdrateurs

La section frangaise commence _ la page 32

Congelador superior

®

Troubleshooting Tips ....... 26-29

Normal Operating Sounds ....... 26

Consumer Support

Consumer Support ..... Back Cover

Warranty fi)r

Canadian Customers ............ 30

Warranty for U.S. Customers ..... 31

Note to Installer - Be sure to leave

fllese instructions wifll file Consumer

Note to Consumer - Keep these

instructions f_n"fl_alre reference.

Note/_ l'installateur - Assurez-vous

de laisser ces insuucfions au

consolnlna[eilI-

Note au consommateur -

Conservez ces instructions pour

r_f_rence fl_U_re.

Nora al instalador - asegfirese

de dejar estas insmmciones con el

cons tltIlidoI_

Nora aL!consumidor - Conserve

estas instrucciones para refe.rencia fimm_.

Refrigeradores

Lasecci6n en espa_o/empieza en/apagina 65

Writethemodelandserial numbershere:

Model #

Serial #

Find these numbers on the gray label

on the lef_ side, near the top of the

refrigerator compartment.

_9707733P00_ 49-60505-2 04-09 JR

iMPORTANTSAFETYINFORMATION.

READALLiNSTRUCTiONSBEFOREUSING.

A WA

Use this appliance only for its intended purpose as described in this Owner's Manual

,!

m

SAFETYPRECAUTIONS

When using electrical appliances, basic safety precautions should be followed, including the following:

}}_This refligerator must be properly installed

and located in accordance with the Installation

Instructions before it is used.

Do not allow children to climb, stand or hang

on the shelves in the reflJgerator They could

dmnage the reflJgemtor and seriously i_jure

themselves.

}}_Do not touch the cold surfitces in the fleezer

compartment when hands are damp or wet.

Skin may stick to these extremely cold surf_tces.

}}_Do not store or use gasoline or other flammable

xapors and liquids in the vicinity of this or any

other appliance.

',_ In refligerators widl automatic icemake_,

avoid contact with the moving parts of the

eiector mechanism, or with the heating element

located on the bottom of the icemaker Do not

place finge_ or hands on the automatic

icemaldng mechanism while the refligemtor

is plugged in.

,,_Keep fingers out of file "pinch point" areas;

clearances between the doors and bet_,veen the

doors and cabinet are necessarily stuN1. Be carefhl

closing doors when chiMren are in the area.

}}_Unplug the refligerator before cleaning and

making repai_.

NOTE:Westronglyrecommendthatanyservicingbe

performedbyaqualifiedindividual

}}{_Setting either or both controls (some models only

have one control) to the 1 (Off) position does not

remove power to the light circuit.

}}{_Do not refleeze flozen foods which have

thawed completely.

2

GEPpp/iance&com

A

OF ,B

PROPERDISPOSALOFTHEREFRIGERATOR

Child entrapment and suftbcafion are not

problems of the past. Junked or abandoned

refligerators are still dangerous...even if they will

sit fbr 'just a few days." If you are getting rid of

your old refligeratox; please follow the instructions

below to help prevent accidents°

Before You7",hrowAway YourOld

Refrigeratoror Freezer:

} Take off the doors°

}i_i,eave the shelves in place so that children

may not easily climb inside.

Refrigerants

All refrigeration products contain refiigerams,

which under federal law must be removed prior

to product disposal If you are getting rid of an

old refiigeradon product, check with the company

handling the disposal about what to do.

USEOFEXTENSIONCORDS

Because of potential safety hazards under certain conditions, we strongly recommend against the

use of an extension cord,

However; if you must use an extension cord, it is absolutely necessary that it be a UL-listed (in the United

States) or a CSA-listed (in Canada), 3-wire grounding type appliance extension cord having a grounding

type plug and outlet and that the elecuJcal rating of the cord be 15 amperes (minimum) and 120 volts.

3

iMPORTANTSAFETYINFORMATION.

READALLiNSTRUCTiONSBEFOREUSING.

A WA

,!

m

HOWTOCONNECTELECTRICITY

Do not, under any circumstances, cut or remove the third (ground) prong from the power cord,

For personal safety, this appliance must be properly grounded,

The power cord of dlis appliance is equipped widl

a 3-prong (grounding) plug which mates wit1 a

standard 3-prong (grotmding) wall outlet to

minimize the possibility of elecuic shock hazard

fiom this appliance°

Have the wall oudet and drcuit checked by a

qualified electrician to make sure the outlet is

properly grounded.

Where a standard 2-prong wall oudet is

encotmmred, it is your pet_onN responsibility and

obligadon to have it replaced with a properly

grounded 3-prong wall outlet.

The refligerator should ah,vays be plugged into its

own individual electrical outlet which has a voltage

rating that matches the rating plate.

This proxides the best performance and also

prevents overloading house wiring circuits which

could cause a fire hazard fiom overheated wires.

Never unplug your refligerator by pulling on the

power cord° Ah,vays g_ip plug firefly and pull

straight out fiom the otlflet.

Repair or replace immediately all power cords flint

have become fiwed or otherwise damaged. Do not

use a cord that shows crocks or abrasion damage

along its length or at either end.

When moving the refligerator away flom the

wall, be careflfl not to roll over or damage the

power cord.

READANDFOLLOWTHISSAFETYINFORMAtiONCAREFULLY.

SAVETHESEINSTRUCTIONS

4

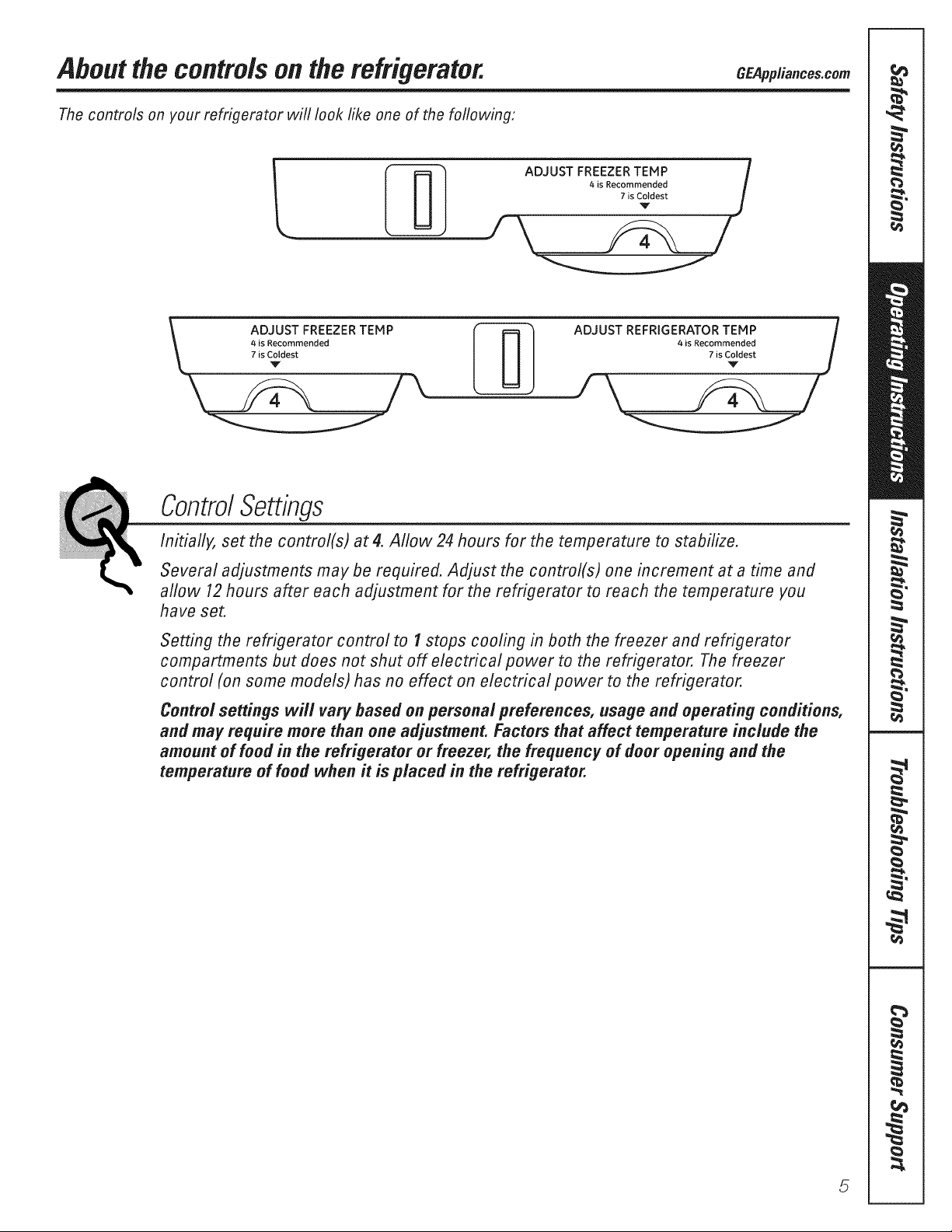

About the controlsonthe refrigerator.

Thecontrols on your refrigerator will looklikeone of the following:

GEApp/iances.com

i _ ADJUST FREEZER TEMP i

I _ | I 4iS Recommended #

I I III ,,sCCdestj

ADJUST FREEZER TEMP _ ADJUST REFRIGERATOR TEMP /

4 is Recommended l I l I 4is Recommended l

7 is Coldest J I I I zis Coldest

v

ControlSettings

Initially, set the control(s) at 4. Allow 24 hours for the temperature to stabilize.

Several adjustments may be required. Adjust the control(s) one increment at a time and

allow 12hours after each adjustment for the refrigerator to reach the temperature you

have set.

Setting the refrigerator control to I stops cooling in both the freezer and refrigerator

compartments but does not shut off electrical power to the refrigerator. The freezer

control (on some models) has no effect on electrical power to the refrigerator.

Control settings will vary based on personal preferences, usage and operating conditions,

and may require more than one adjustment. Factors that affect temperature include the

amount of food in the refrigerator or freezer, the frequency of door opening and the

temperature of food when it is placed in the refrigerator.

5

Aboutthe shelves andbins.

Not all features are on all models,

Rearranging the Shelves

Shelves in the refligerator and fleezer compamnents are adjustable.

Refrigerator Compartment

Half-WidthShelves

One end of the shelf rests on a

molded side-wall support; a bracket

on file oilier end hooks into a track

on file rear cabinet wall.

TOremove:

O Tilt the shelf up at the flont.

0 i,iff the support off and out of the track.

d_Titt up

o- 4

f./---

Toreplace:

0 While tilting the shelf up, insert the top

hook at the back of the shelf in a slot

on the track.

0 Lower the flont of the shelf undl the

bottom of the shelf locks into place.

NOTE:Theshelf to theright of the trackis

designedtohookinto theright-handslot,the

shelf to theleft isdesignedtohookinto the

left-handslot

Freezer Compartment

Toremove:

Lift up the left side of the shelf and

slide it left into the center of the shelf

supports.

Rotate the fight side of the shelf up and

out of the shelf supports.

Toreplace:

il

i _!i!

6

0 HoMing the shelf diagonally; insert the

left end of the shelf into the center of

the shelf supports on the side wail.

0 Insert the right end of the shelf into

the shelf supports on the side wall.

Rest each end of the shelf on the

bottom of the shelf supports.

Aboutthecrispersandpans. C App,ia,ces.com

Not all features are on all models,

Fruit and Vegetable Crispers

Excess water that may accmmflate in the

bottom of the dra\,ve_ or under the dm\,ve_

shoukt be wiped d_T.

Pdjustab/e Humidity Crisper

Slide the control all the way to the

H/GHsetting to provide high lmmidity

recommended K_r most vegetables.

Snack Pan

Slide the control all the way to the LOW

setting to provide lower humidity levels

recommended fbr most fluits.

This pan can be moved to the most useflfl

location fbr your fhmily's needs.

Toremove,slide the pan out to the stop

position, lif_ the pan up and past the stop

position, and lif_out.

7

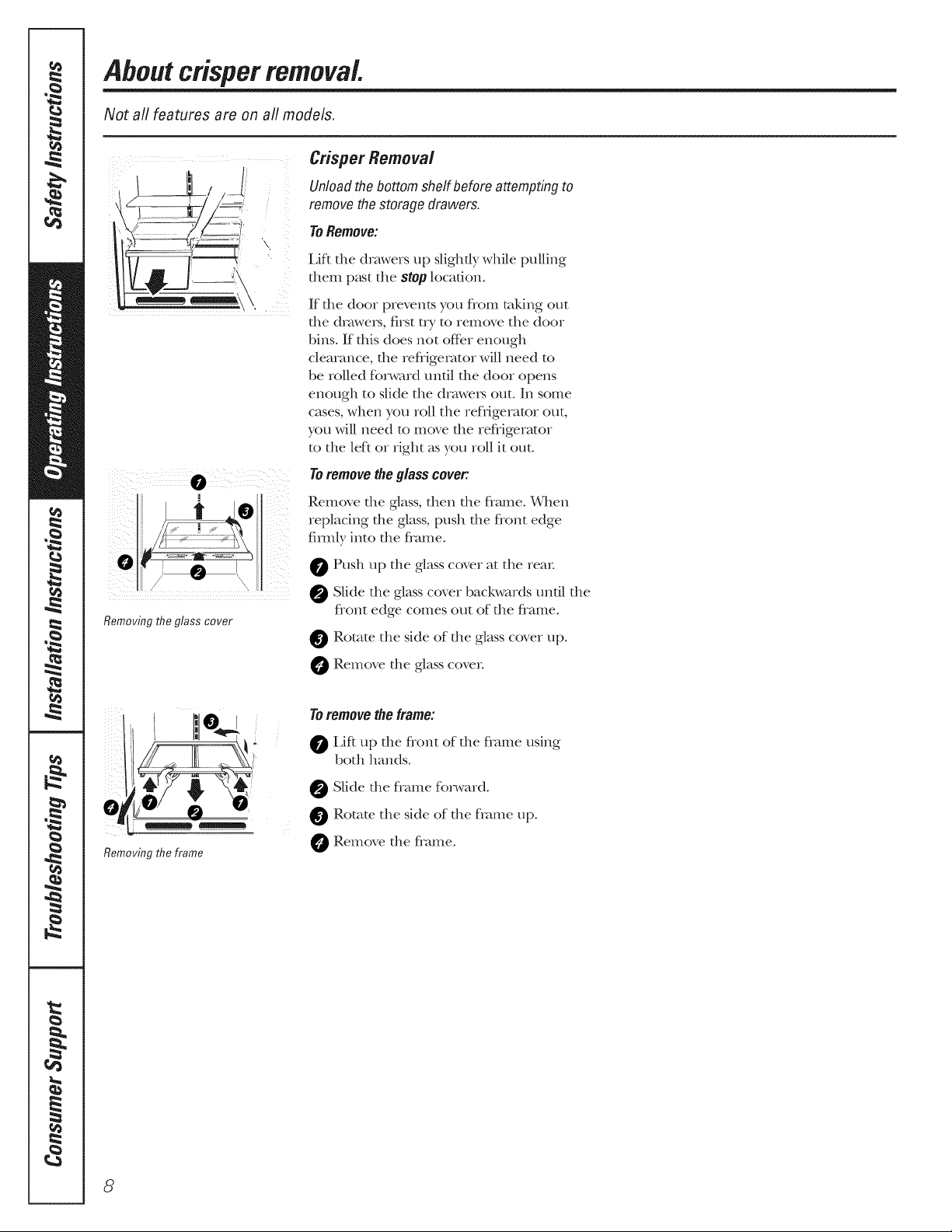

Aboutcrisperremoval

Not all features are on all models,

Crisper Removal

ii! I "

Unload the bottom shelf before attempting to

remove the storage drawers.

ToRemove:

l,if_ the drawers tap slightly while pulling

them p_Lstthe stop locafiono

If file door prevents you flom taldng out

the drawea_, first try to rein<we the door

bins° If this does not offbr enough

clearance, the refligemtor will need to

be rolled fbrward until the door opens

enough to slide the drawea_ out. In some

cases, when you roll the refligerator out,

you will need to re(we the refligerator

to the left or right as you roll it ()tat.

Toremovetheglasscover:

Remove the glass, then the flame. _,rhen

replacing the glass, push the flont edge

firefly into the flame.

Removingtheglasscover

Removing the frame

0 Push tap the glass cover at the rein:

0 Slide the glass cover backwards until the

flont edge comes out of the flame.

0 Rotate the side of the glass cover tap.

Remove the glass covea;

Toremove the frame:

0 Lif_ up the flont of the flame using

both hands°

Slide the f}ame fbn,vard.

0 Rotate the side of the flame tap.

O Remove the flame.

8

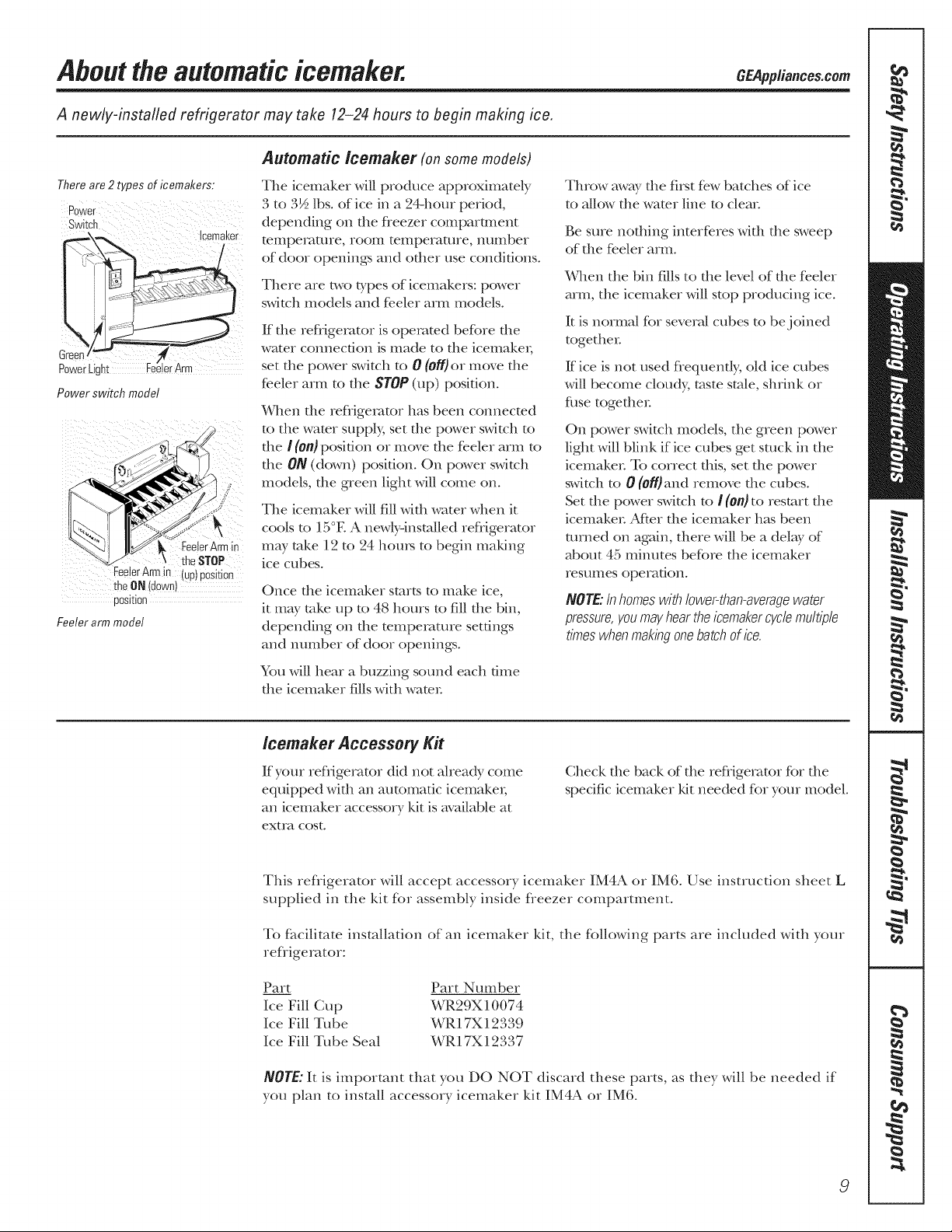

Abouttheautomaticicemaker. CEA,,,ia.ce .com

A newly-installed refrigerator may take 12-24 hours to begin making ice,

Automatic lcemaker (onsomemodels)

There are 2 types of icemakers:

Power

Switch

_x_. !cemaker

G;)

Po;er

Power switch model

FeelerArmin

FeelerArm n

theON ieowm

ooskion

Feeler arm model

theSTOP

uoJDOSkion

The icemaker will produce approximately

3 to 3½ lbs. of ice in a 24-hour period,

depending on the fleezer compartment

telnperat/]re, rooIll telllperat/lre, ntl[llbei

of door openings and other use conditions.

There are two types of icemakers: power

switch models and fe.eler arIn models.

If tlle refligerator is operated before tile

water connection is made to the icemake_;

set tile power switch to 0 (off) or move the

feeler arI-n to tile STOP(up) position.

¼qlen file refligemtor has been connected

to tile wamr supply, set tlle power switch to

the I (On}posidon or IIlove the feeler arm to

tile ON (down) position. On power swimh

models, die green light will come on.

The icemaker will fill widl water when it

cools to 15°E A new/y-installed refligerator

may rake 12 to 24 hom_ to begin making

ice cubes.

Once file icemaker starts to make ice,

it may rake up to 48 hours to fill file bin,

depending on the mmpemmre settings

and nmnber of door openings.

You will hear a buzzing sound each dine

the icemaker fills with wate,:

Throw away tile first few batches of ice

to allow the water line to clear

Be sure nothing interfe.res with tile sweep

of tile feeler arm.

When the bin fills to the level of tile feeler

arIn, tile icemaker will stop producing ice.

It is normal for several cubes to be joined

together

ff ice is not used flequently; old ice cubes

will become cloudy, taste stole, shrink or

fuse together

On power switch Inodels, tile green power

light will blink if ice cubes get stuck in tlle

icemake_: To correct this, set die power

switch to 0 (0ff)and remove the cubes.

Set tile power switch to / (Oft)to restart die

icemaker After the icemaker has been

turned on again, there will be a del W of

about 45 minutes before tile icemaker

res uIIles operation.

NOTE:Inhomeswithlower@an-averagewater

pressure,youmayheartheicemakercyclemultiple

timeswhenmakingonebatchof lee.

/cemaker Accessory Kit

If your refligerator did not aheady come

equipped with an automatic icemake_;

an icemaker accesso_ T ldt is available at

extra cost.

This refligerator will accept accessory icemaker IM4A or IM6. Use instruction sheet L

supplied in the kit for assembly inside fleezer compamnent.

To facilitate installation of an icemaker kit, the fbllowing parts are included with your

refligerator:

Part Part Number

Ice Fill Cup WR29X10074

Ice Fill Tube WR17X 12339

Ice Fill Tube Seal WR l7X 12337

NOTE:It is important that you DO NOT discard these parts, as they will be needed if

you plan to install accessory icemaker kit IM4A or IM6.

Check tile back of tile refligerator for tile

specific icemaker kit needed for your model.

9

Careandcleaningoftherefrigerator.

Cleaning the Outside

Thedoorhandlesandtrim.Clean with

a clod1 dampened widl soapy water:

Dry with a soR cloth.

Keep theoutsideclean.Wipe with a clean

clod1 ligbdy dampened with kitchen

appliance wax or mild liquid dish

dem_gent. Dry and polish with a clean,

soR clodL

Thestainless steel panels and doorhandles

(on some models) can be cleaned with

Cleaning the Inside

a commercially available stainless steel

cleaner. Do not use appliance wax or polish

on the stainless smel.

Donot wipetherefrigeratorwithasoileddishcloth

orwettowel Thesemayleavea residuethat

canerodethepaint Donotusescouringpads,

powderedcleaners,bleachorcleanerscontaining

bleachbecausetheseproductscanscratchand

weakenthepaintfinish.

Tohelp prevent odors,leave an open box of

baldng soda in file flesh food and fleezer

compartments.

Unplug the refrigerator before cleaning. If this

is not practical, wring excess moisture out

of sponge or cloth when cleaning around

switches, lights or conuols.

Use/,vaiIi}./,vilteI and baking soda solution--

about a tablespoon (15 ml) of baldng soda

to a quart (1 limr) of wam_: Tiffs both cleans

and neutralizes odors. Thoroughly IJnse

and wipe dry.

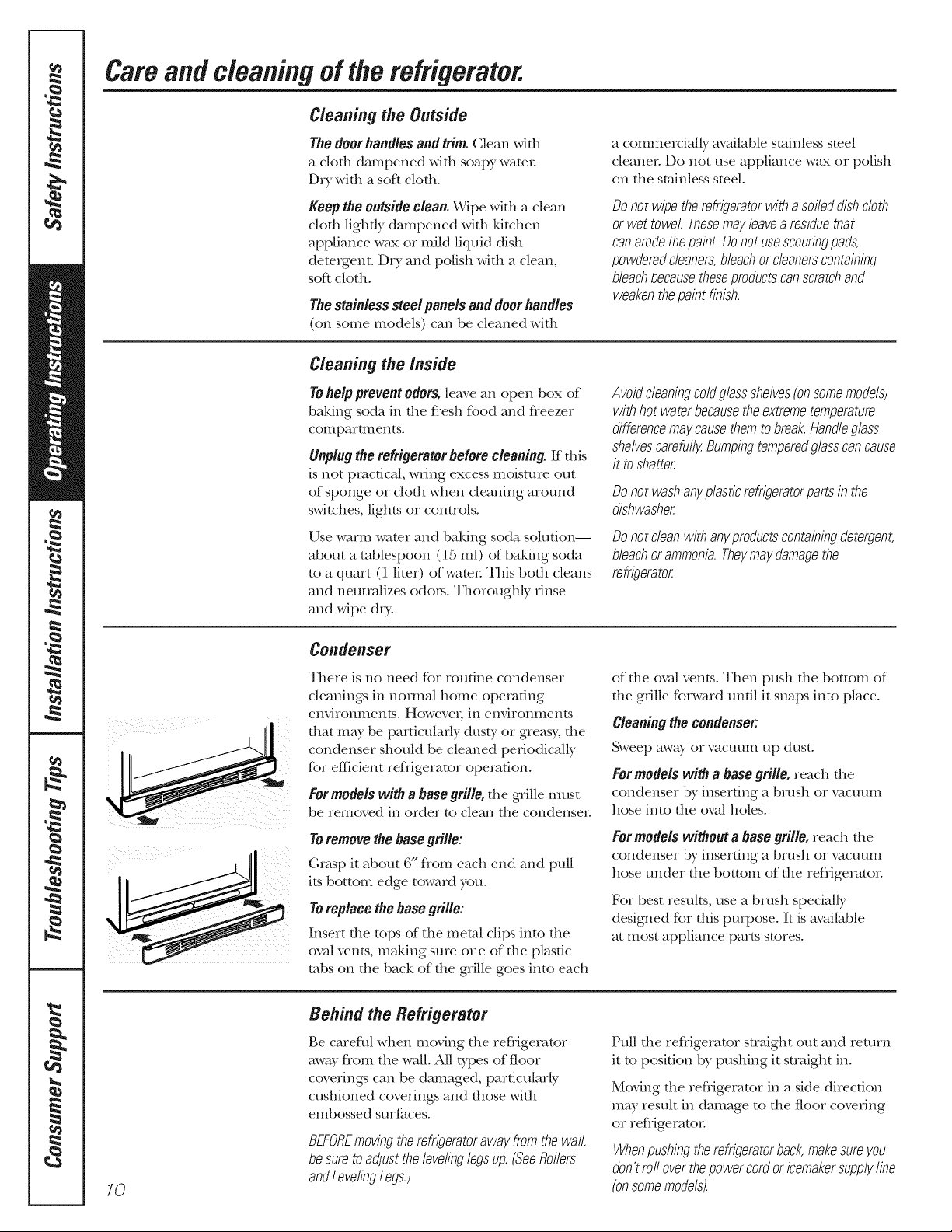

Condenser

There is no need for roudne condenser

cleanings in nomm/home opemdng

environments. Howevei; in environI_Ttents

that may be particularly dusty or greasy; the

condenser should be cleaned periodically

for efficient reflJgemtor operation.

Formodelswitha basegrille,d_e gqille must

be removed in order to clean die condenser

Toremovethebase grille:

Grasp it about 6" flom each end and pull

its bottom edge toward you.

Toreplacethebasegrille:

Insert tlle tops of the metal clips into the

ova/vents, making sure one of the plastic

tabs on tile back of tile grille goes into each

Avoid cleaning cold glass shelves(onsomemodels)

with hot water becausethe extreme temperature

difference maycausethem tobreak.Handleglass

shelvescarefully Bumpingtemperedglasscan cause

it to shatter

Donot washangplasticrefrigeratorpartsinthe

dishwasher

Donotcleanwithangpreductscontainingdetergent,

bleachorammonia.Theymaydamagethe

refrigerator

of die oval vents. Then push die bottom of

the grille fbrward until it snaps into place.

Cleaningthecondenser:

Sweep away or vacuum up dust.

For models win a base grille, reach d_e

condenser by inserting a brush or vacuum

hose into the ova/boles.

For models wiNout a base grille, reach d_e

condenser by inserting a brush or vacuum

hose under tile bottom of the reflJgerator

For best results, use a brush specially

designed for dfis purpose. It is available

at most appliance parts stores.

10

Behind the Refrigerator

Be careflfl when moving the refligerator

away flom the wall. All t),pes of floor

coverings can be damaged, particularly

cushioned coverings and those with

embossed smfaces.

BEFOREmovingtherefrigeratorawayfromthewall,

besuretoadjustthelevelinglegsup.(SeeRollers

andLevelingLegs.)

Pull die refligerator smdght out and return

it to posidon by pushing it straight in.

McMng file refligerator in a side direction

may result in damage to the floor covering

or reflJgerator

Whenpushingtherefrigeratorback,makesureyou

don'trefloverthepowercordoricemakersupplyline

(onsomemodels).

Preparing for Vacation

GEPpp/iance&com

For long V_tCa[ioIIS Of _bsences_ ielnove

food and mlplug the refligeratoT. Move

file refligerator control to file 1 (Off}position

and clean file interior wifll a baking soda

solution of one tablespoon (15 ml) of

baking soda to one quart (1 limr) of wamr

i,eave the doo_ open.

Set the icemaker power switch to file 0 (Off)

position or move the feeler am1 to the STOP

(up) position (depending on model) and

shut off file water supply to file refligemtor

If the temperature can drop below fleezing,

have a qualified servicer drain the water

supply system (on some models) to prevent

serious property damage due to flooding.

Preparing to Move

Secure all loose items such as grille,

shelves and drawexs by taping them

securely in place to prevent damage.

Besuretherefrigeratorstaysin anuprightposition

&ring moving

Replacingthe fightbulb.

Setting either or both controls to 1 (off) does not remove power to the light circuit.

Refrigerator Compartment--Upper tight

A CAUTION:Light_u/_maybeh0t. 0 _epl.ce,,_l,_,,,.ppH.,,cet>,,lt>of

Unplug the refrigerator. _ Plug the refligerator back in.

The bulb is located at the top of file

compamnent near the opening.

the same or lower wattage.

11

st llati

m

rato

I structi

BEFORE YOU BEGIN

Read these instructions completely and carefully.

" IMPORTANT - S.ve hese

instructions if)r local inspector's use.

" IMPORTANT - Obse,ve.ll

governing codes and ordinances.

* Note to Installer - Be sure to leave these

instructions with tile ConsuH-ter

. Note to Consumer - Keep these instructions

for future reference.

* Skill level - Installation of this appliance requires

basic mechanical skills.

* Completion time - Refligerator Installation

15 minutes.

* Proper installation is the responsibility of the

installer.

* Product failure due to improper installation is not

covered under the Warranty.

WATER SUPPLY TO THE ICENIAKER

{ON SOME MODELS)

If the refligerator has an icemakm; it will have

to be connected to a cold water line. AGE water

supply kit (containing robing, slmtoff valve, fittings

and instructions) is available at extra cost flom your

dealer or by visiting our Website at GEAppliances.com

or Parts and Accessories, 800.626.2002.

REFRIG ERATOR LOCATION

" Do not install file refligerator where the mmperamre

will go below 60°F (16°C) because it will not run often

enough to maintain proper temperatures.

" Do not install file refligerator where the mmperatme

will go above 100°F (37°C) because it will not perfbrxn

properly:

- Install it on a floor strong enough to support it flflly

loaded.

Models GTH21,GT/_21and GTS21

CLEARANCES

Allow the ff>llowing clearances fin ease of installation,

proper air circulation and plumbing and electrical

COllllectioIls.

"Sides 1/8" (3 ram)

"Top 1"(25 ram)

"Back 1" (25 ram)

If the refligerator is to be installed next to a wall on the

binge side, allow 5/16" (8 ram) door clearance.

ROLLERS AND LEVELING LEGS

Rollers allow you to mcwe file refligemtor away flom file

wall for cleaning.

Leveling Legs near each flont corner of file refligerat(n;

next to the rollers, shouM be adj usmd if any of the

fbllowing occurs:

" Refligerator wobbles due to flont roller not being firefly

positioned on the floor

" Door(s) do not close easily when opened to 45 °.

NOTE:

" BEFORE moving die refligemtor away flom file wall,

be sure to turn the leveling legs cotmterclockwise so that

the weight of the reflJgerator is fiflly mmsfe.rred to the

flont rolle_.

" The refligemtor will not be level flora flont to back. It

will have a slight backward flit for proper doo>closing.

To adjust the leveling legs,

turn the two flont leveling

legs dockwise to raise the

flont of the refligerator and

counterclockwise to lower it.

__4)iiwi seto

raise

refrigerator

12

Installation instructions

ICENIAKER iNSTALLATiON

BEFORE YOU BEGIN

Read each step thoroughly before proceeding.

CAUTION - U,,pl.:the

Refligerator To eliminate the danger

of electric shock during installation,

you must unplug the refligerator flom

its electrical outlet.

TOOLS YOU WILL NEED

FlatbladeandPhillips Pliers

screwdrivers

PARTS INCLUDED

iNSTRUCTIONS

_] REMOVE THE OUTLET COVER

• Remove the outlet cover

with a fiat-blade screwdriver

Side Back

_PREPARE FOR INSTALLATION

Inside the fleezeL loosen the h,vo mounting screws,

but do not screw them all the way out. If your model

does not have the screws aheady in the fieezer wall,

look for t_,vo plug buttons. Remove the plug buttons

and insert the two Phillips head screws. The screws

should extend approximately 1/2" (13ram) out

flom the fleezer wall

©

2

NO. DESCRIPTION QUANTITY

1 WaterFill Tube 1

2 IceFill Guide 1

3 WaterFill TubeSeal 1

m INSTALL FILL TUBE

• If the refligerator aheady has a

water tube inlet on the back of the

refiigerator, go to Step 2.

• Remove and discard the white plug

flom the lower left back corner of

the fleezer wall.

* Go to the back of the refligerator. Find the small

label in the upper right band corner and peel it

off_Then discard the label.

Peel one side of the paper away _ Seat

flom the water fill tube seal, slide Ir'___

the seal along the tube and affix u -_-o4_._,'X,x

to the back side of the water

robe inlet flange.

Remove the adhesive

bacMng on the opposite side

of the water fill robe sea/and

slide the robe into the hole _

near the top at the back of the refiigeratcn: Fhmly

press on the inlet to secure it to the refligerator

Mounting

screws

3

[-4-]SETPOWER SWITCH TO 0 (off)

Set the icemaker power switch to O (of_). Leave

the power switch in the O (offc) position undl the

refiigerator is connected to the water supply to

prevent premature operation.

_ Holef?r

wiretie

SwitchP°wer ......__+...........- -%

(Appearance may vary)

13

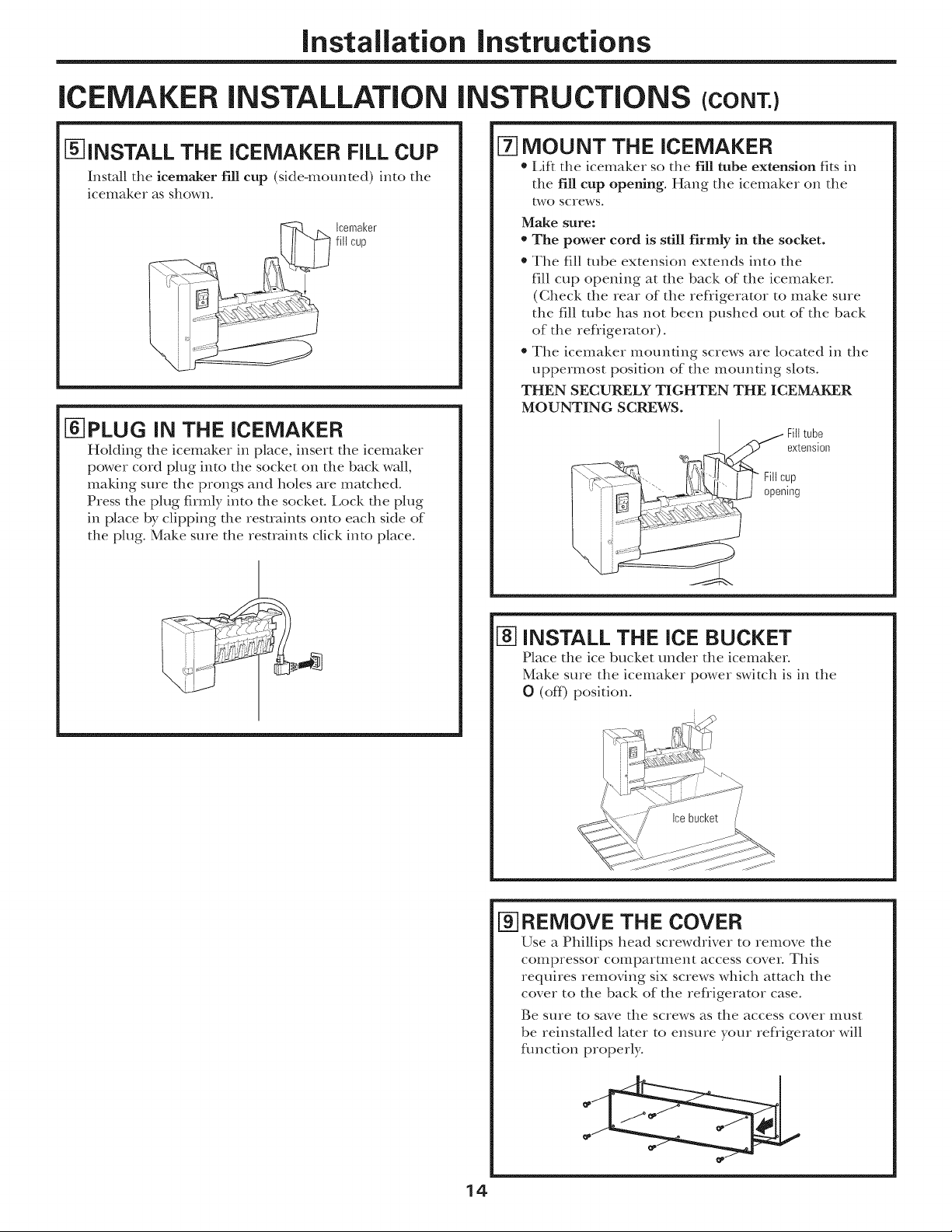

Installation instructions

ICEMAKER

iNSTALLATiON iNSTRUCTiONS (CONT.I

[_INSTALL THE ICEMAKER FiLL CUP

Install tile icemaker fill cup (skte-mounted) into tile

icemaker as shown.

Icemal<er

fill cup

[_PLUG IN THE ICEMAKER

Hokling die icemaker in place, insert tile icemaker

power cord plug into the socket on tile back wall,

maMng sure tile prongs and boles are matched.

Press tile plug firmly into tile socket, i,ock the plug

in place by clipping the resuaints onto each side of

tile plug. Make sure tile restraints click into place.

[-/-]MOUNT THE ICEMAKER

, Lift tile icemaker so tile fill tube extension fits in

tile fir cup opening. Hang tile icemaker on tile

two screws.

Make sure:

*The power cord is still firmly in the socket.

* Tile fill tube extension extends into the

fill cup opening at tile back of tile icemaker

(Check tile rear of file refligerator to make sure

tile fill tube has not been pushed out of tile back

of tile refligerator).

* Tile icemaker Illotlnfing sclews are located in tile

uppermost position of tile mounting slots.

THEN SECURELY TIGHTEN THE ICEMAKER

MOUNTING SCREWS.

[_ INSTALL THE ICE BUCKET

Place tile ice bucket under tile icemaker.

Make sure tile icemaker power switch is in tile

0 (off) position.

_]REMOVE THE COVER

Use a Phillips head screwdriver to remove tile

conlpressor compartulent access cover. This

requires removing six screws which attach tile

cover to tile back of tile refligerator case.

Be sure to save tile screws as the access cover must

be reinstalled later to ensure your refligerator will

flmcdon properl>

14

Installation instructions

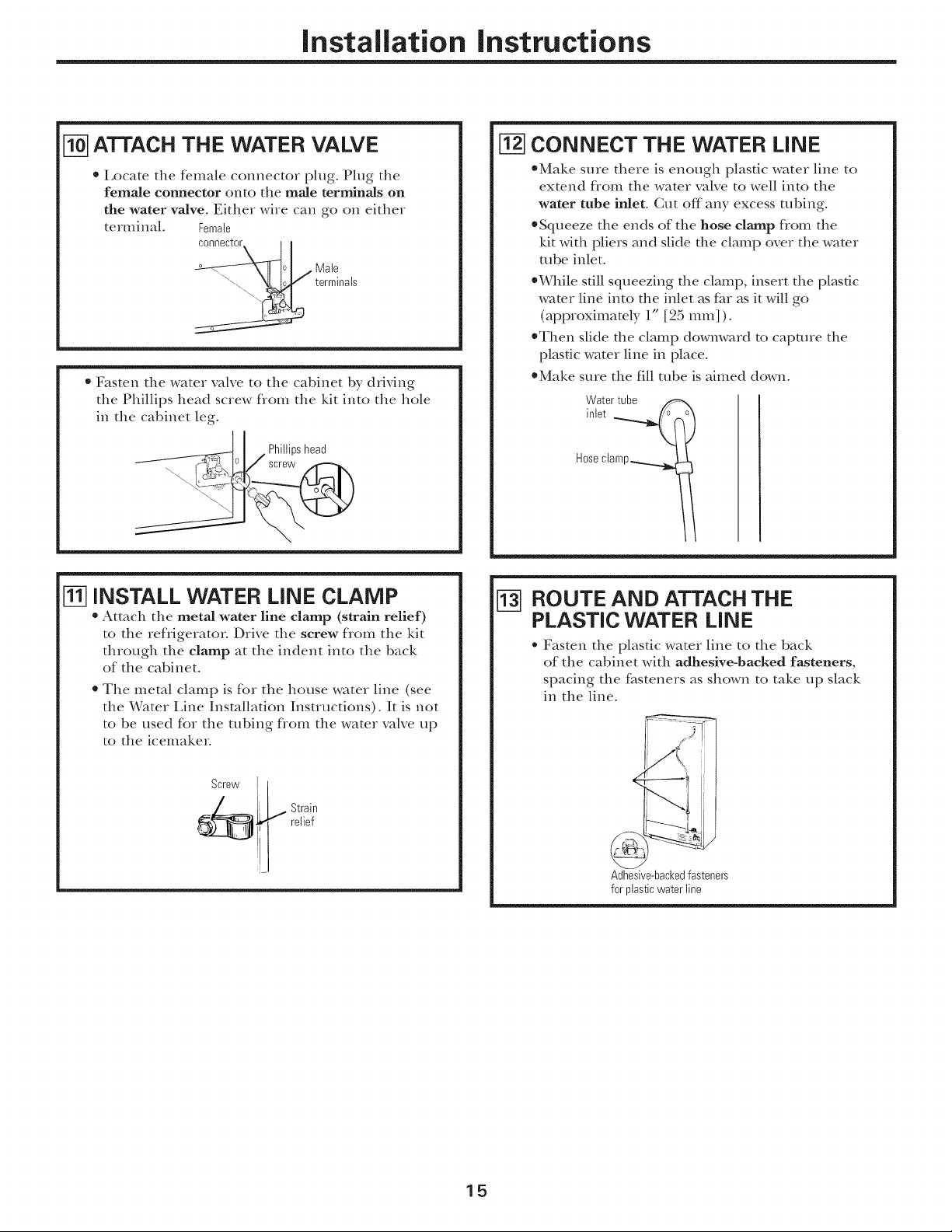

[TO-]ATTACH THE WATER VALVE

* Locate the female connector plug. Plug the

female connector onto the male terminals on

the water valve. Either wire can go on either

terminal. Female

0I/Male

_,_ terminals

* Fasten the water valve to the cabinet by driving

the Phillips head screw flom the kit into the hole

in the cabinet leg.

_ I Phiitipshead

o / screw

[i-27CONNECT THE WATER LINE

*Make sure there is enough plastic water line to

extend flom the water valve to well into the

water tube inlet. Cut off any excess robing.

*Squeeze the ends of the hose clamp flom the

ldt with pliers and slide the clamp over the wamr

robe inlet.

*While still squeezing the clamp, insert the plastic

water line into the inlet as flu as it will go

(approximately 1" [25 IIlIIl]).

*Then slide the clamp dowm,vard to capture the

plasdc water line in place.

*Make sure the fill robe is aimed down.

Water tube

inlet __

Hose clamp._

[_] INSTALL WATER LINE CLAMP

• Attach the metal water line clamp (strain relief)

to the refligerator. Drive the screw flom the kit

through the clamp at the indent into the back

of the cabinet.

* The metal clamp is for the house water line (see

the Water Line Installation Instructions). It is not

to be used for the robing flom the water valve up

to the icemaker.

ROUTE AND ATTACH THE

PLASTIC WATER LINE

Fasten the plastic water line to the back

of the cabinet with adhesive-backed fasteners,

spacing the f_steners as shown to take up slack

in the line.

Adhesive-backedfasteners

for plasticwater line

15

Installation instructions

ICEMAKER iNSTALLATiON iNSTRUCTiONS (CONT.)

WATER VALVE iNSTALLED

Refer to the Water i,ine Installation Instructions

for connection to the home water supply: After

water line installation is completed, set the

icemaker power switch to I (on).

The icemahing cycle will not begin until the icemaher

and freezer compartment reach operating temperature,

then icemahing will begin automatically.

[_ATTACH WARRANTY LABEL

A label is provided with this kit to record the date

of installation for warran V purposes. Apply it to the

back of the rehigerato_: The icemaker installation

inside the heezer is now complem.

16

Installation instructions

iNSTALLiNG THE WATER LiNE (ONSOMEMODELS)

BEFORE YOU BEGIN

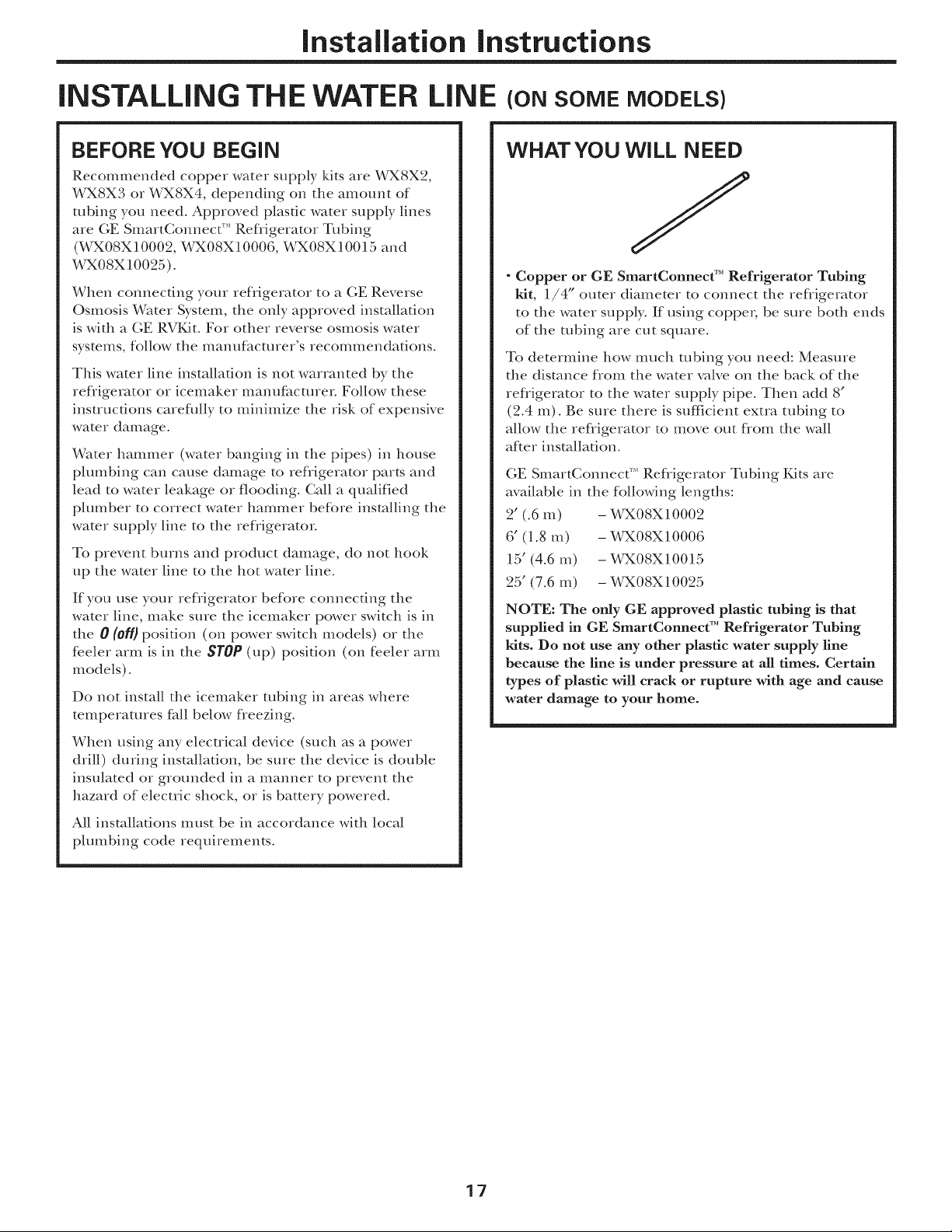

Recommended copper water supply kits are WX8X2,

WX8X3 or WX8X4, depending on the amount of

ulbing you need. Approved plastic water supply lines

are GE SmartConnect F''Refiigerator Tubing

(WX08X10002, WX08X10006, WX08X10015 and

WX08X10025).

When connecting your refligerator to a GE Reverse

Oslnosis Water System, the only approved installation

is with a GE RVKIt. For other reverse osmosis water

systems, follow the manufhcmrer's recommendations.

This water line installation is not warranted by the

refiigerator or icemaker manufacturer. Follow these

instructions careflflly to minimize the risk of expensive

water damage.

Water hammer (water banging in the pipes) in house

plumbing can cause damage to refiigerator parts and

lead to water leakage or flooding. Call a qualified

plumber to correct water hammer before installing the

water supply line to the refiigerator.

To prevent burns and product damage, do not hook

up the water line to the hot water line.

If you use your refligerator before connecting the

water line, make sme the icemaker power switch is in

the 0 (off} position (on power switch models) or the

feeler arm is in the STOP (up) position (on feeler arIll

models).

Do not install the icemaker robing in areas where

temperatures f_dl below fieezing.

When using any electrical device (such as a power

drill) during installation, be sure the device is double

insulated or grounded in a manner to prevent the

hazard of electric shock, or is battery powered.

All installations Inust be in accordance with local

plumbing code requirements.

WHAT YOU WiLL NEED

J

" Copper or GE SmartConnect TM Refrigerator Tubing

kit, 1/4" outer diameter to connect the refligerator

to the water supply. If using coppm; be stue both ends

of the robing are CUt square.

To determine how much tubing you need: Measure

the distance fiom the water valve on the back of the

refiigerator to the water supply pipe. Then add 8"

(2.4 m). Be sure there is sufficient extra robing to

allow the refiigerator to move out flom the wall

after installation.

GE SmartConnect _"Refligerator Tubing Kits are

available in the following lengths:

2' (.6 m) - %_X08X10002

6" (1.8 m) - %PX08X10006

15' (4.6 m) - %PX08X10015

25' (7.6 m) - %_X08X10025

NOTE: The only GE approved plastic tubing is that

supplied in GE SmartConnect TM Refrigerator Tubing

kits. Do not use any other plastic water supply line

because the line is under pressure at all times. Certain

types of plastic will crack or rupture with age and cause

water damage to your home.

17

Installation instructions

iNSTALLiNG THE WATER LiNE

WHAT YOU WiLL NEED (CONT.)

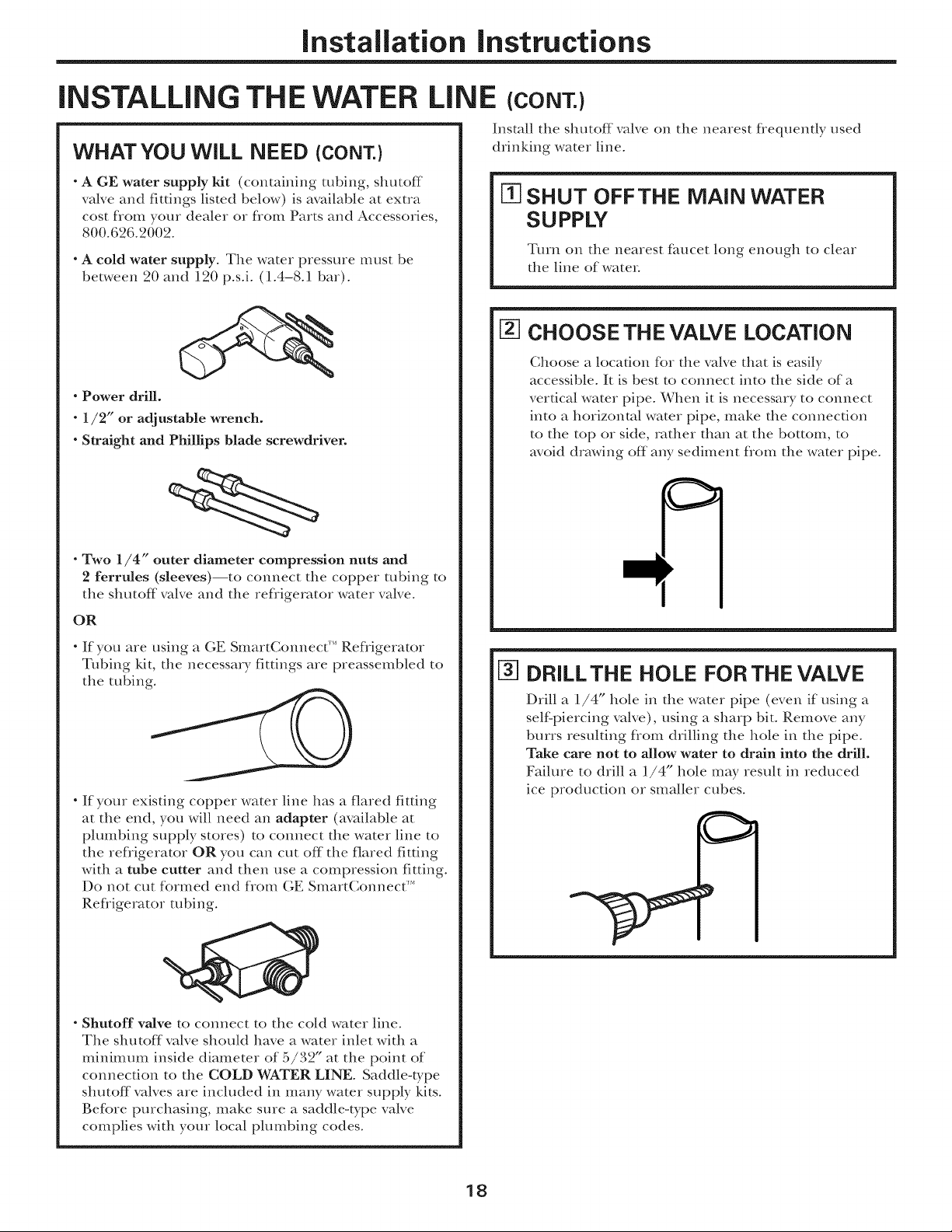

" A GE water supply Mt (containing tubing, shutoff

valve and fittings listed below) is available at extra

cost flom your dealer or flom Parts and Accessories,

800.626.2002.

" A cold water supply. The water pressme must be

between 20 and 120 p.s.i. (1.4-8.1 bar).

- Power drill.

- 1/2" or adjustable wrench.

- Straight and Phillips blade screwdriver.

(CONT.)

Install the shutoff valve on the nearest f_equendy used

drinking water line.

m SHUT OFFTHE MAiN WATER

SUPPLY

Tmn on the nearest faucet long enough to clear

the line of water

[2-]CHOOSE THE VALVE LOCATION

Choose a location for the valve that is easily

accessible. It is best to connect into the side of a

vertical water pipe. When it is necessary to connect

into a horizontal water pipe, make the connection

to the top or side, rather than at the bottom, to

avoid drawing off any sediment flom the water pipe.

" Two 1/4" outer diameter compression nuts and

2 ferrules (sleeves)--to connect the copper robing to

the shutoff valve and the refligerator water valve.

OR

" If you are using a GE SmartConnect '_'Refiigerator

Tubing kit, the necessary fittings are preassembled to

the tubing.

" If your exisdng copper water line has a flared fitting

at the end, you will need an adapter (available at

plumbing supply stores) to connect the water line to

the refligerator OR you can cut off the flared fitting

with a tube cutter and then use a compression fitdng.

Do not cut formed end flom GE SmartConnect _''

Refligerator robing.

[-3-]DRILLTHE HOLE FOR THE VALVE

Drill a 1/4" hole in the water pipe (even if using a

self'piercing valve), using a sharp bit. Remove any

burrs resulting fiom drilling the hole in the pipe.

Take care not to allow water to drain into the drill.

Faihue to drill a 1,/4" hole may result in reduced

ice production or smaller cubes.

- Shutoff valve to connect to the cold water line.

The shutoff valve should have a water inlet with a

minimum inside diameter of 5/32" at the point of

connection to the COLD WATER LINE. Saddle-type

shutoff valves are included in many water supply kits.

Before purchasing, make sure a saddle-type valve

complies with your local phunbing codes.

18

Installation instructions

[] FASTEN THE SHUTOFF VALVE

Fasten the shutoff valve to the cold water pipe with

the pipe clamp.

PipeClamp_

Saddle-Type_/' l

ShutoffValve

NOTE: Commonwealth of Massachusetts Plumbing

Codes 248CMR shall be adhered to. Saddle valves

are illegal and use is not permitted in Massachusetts.

Consult with your licensed plumber.

VerticalCold

WaterPipe

_] TIGHTEN THE PIPE CLAMP

Tighten the clamp screws until the sealing washer

begins to swell.

NOTE: Do not overtighten or you may crush the

tubing.

PipeClamp--

Clamp

Washer

CONNECTTHE TUBING

TO THE VALVE

Place the compression nut and ferrule (sleeve)

for copper tubing onto the end of the tubing and

connect it to the shutoff valve.

Make sure the tubing is flflly inserted into the valve.

Tighten the compression nut securely.

For plastic tubing flom a GE SmartConnect _'*

Ref_igerator Tubing kit, insert the molded end

of the robing into the shutoff valve and tighten

compression nut until it is hand-fight; then tighten

one additional mrn with a wrench. Overflghtening

may cause leaks.

r-----Compression

Saddle-Type_ J_

ShutoffValve _,

PackingNut_

OutletValve.-/

NOTE: Commonwealth of Massachusetts Plumbing

Codes 248CMR shall be adhered to. Saddle valves

are illegal and use is not permitted in Massachusetts.

Constflt with your licensed plumber.

Nut

|SmartConnect _

[] ROUTETHETUBING

Route the robing between the cold water line and

the refligerator.

Route the robing through a hole drilled in the wall

or floor (behind the refrigerator or adjacent base

cabinet) as close to the wall as possible.

NOTE: Be sure there is sufficient extra tubing

to allow the refligerator to move out flom the wall

af*er installation.

FLUSH OUTTHETUBING

Turn the main water supply on and flush out the

robing until the water is clear

Shut the water off at the water valve after about

one quart (1 liter) of water has been flushed

through the robing.

19

Installation instructions

iNSTALLING THE WATER LINE (CONT.)

N-ICONNECTTHE TUBING TO THE

REFRIGERATOR

NOTES:

Before making the connection to the refligeratcm

be sure the refligerator power cord is not

plugged into the wall outlet.

We recommend installing a water filter if your

water supply has sand or particles that coukt clog

the screen of the refligerator's water valve° Install

it in the water line near the ref?igemtor. If using

GE SmartConnect r'' Refligerator Tubing kit, you

will need an additional robe (WX08X10002) to

connect the filter. Do not cut plastic tube to

install filter.

Remove the screws holding the right side of the

access cover Fold back the cover.

Remove the plastic flexible cap

flom the water valve

(refligerator connection).

Place the compression nut and

ferrule (sleeve) onto the end of

the tubing as shown. On (;E

SmartConnect'" Refligerator

Tubing kit, the nuts are aheady

assembled to the tubing.

Insert the end of the tubing into the water valve

connection as flu as possible. While holding the

tubing, tighten the fitting.

©

NI CONNECT THE TUBING TO THE

REFRIGERATOR (CONT.)

One of the illustrations below will look like the

connection on your refrigerator.

1/4"Tubing

3ressionNut

Ferrule(sleeve)

- Refrigerator

Tubing

Connection

[1-07TURN THE WATER ON ATTHE

SHUTOFF VALVE

Tighten any connections that leak.

For plastic robing flom a GE SmartConnect'"

Refligerator Tubing kit, insert the molded end

of the robing into the water valve connection and

tighten compression nut until it is hand-tight;

then tighten one additional turn with a wrench.

Overtightening may cause leaks.

Fasten the robing into the clamp provided to hokt

it in a vertical position. You may need to P_T open

the clamp.

Reatmch the access cover.

2O

Installation instructions

[] PLUG iN THE REFRIGERATOR

Arrange the coil of tubing so that it does not vibrate

against the back of the refrigerator or against the

wall. Push the refligerator back to the wall.

Makesureproper

groundexists

beforeuse.

IMPORTANT: PLEASE READ CAREFULLY

FOR PERSONAL SAFETY, THIS APPLIANCE

MUST BE PROPERLY GROUNDED.

Tile power cord of this appliance is equipped

with a 3-prong (grounding) plug that mates with

a standard 3-prong (grounding) wall receptacle

to minimize the risk of electric shock hazard f_om

this appliance. The customer should have the

wall receptacle and circuit checked by a qualified

electrician to make sure the receptacle is properly

grounded.

Where a standard two-prong wall receptacle is

encountered, it is the personal responsibility and

obligation of the customer to have it replaced with

a properly grounded 3-prong wall receptacle.

DO NOT, UNDER ANY CIRCUMSTANCES, CUT

OR REMOVE THE THIRD (GROUND) PRONG

FROM THE POWER CORD.

STARTTHE ICEMAKER

On power switch models, set the icemaker power

switch to the I (on}position. Oil feeler arm models,

move the feeler arm to the ON (down) position. The

icemaker will not begin to operate until it reaches

its operating temperauue of 15°F (-9°C) or below.

It will then begin operation automatically.

Powerswitch model

/7

//

........_ FeelerArminthe

...... STOP(up)position

FeelerArm in

the ON(down)position

Feelerarmmodel

NOTE: In lower water pressure conditions, the

water valve may Qun on tip to 3 times to deliver

enough water to the icemal<er.

REVERSING THE DOOR SWING

IMPORTANT NOTES

When reversing the door swing:

* Read the instructions all the way through before

starting.

* Handle parts carefldly to avoid scratching paint.

* Set screws down by their related parts to avoid using

them in the wrong places.

* Provide a non-scratching work surface for

the doors.

IMPORTANT: Once you begin, do not move the

cabinet until door-swing reversal is completed.

These instructions are for changing the binges flom

the right side to the lef_ side--if you ever want to change

the binges back to the right side, fbllow these same

instructions and reverse all references to lef* and right.

Unplug the refrigerator from its electrical outlet.

Empty all door shelves, including the dairy

compartment.

21

TOOLS YOU WILL NEED

5/16" socketandratchet

Phillipsscrewdriver

Maskingtape

Puttyknifeor

thin-bladescrewdriver

Installation instructions

REVERSING THE DOOR SWING (CONT.)

TRANSFER TOP HINGE TO

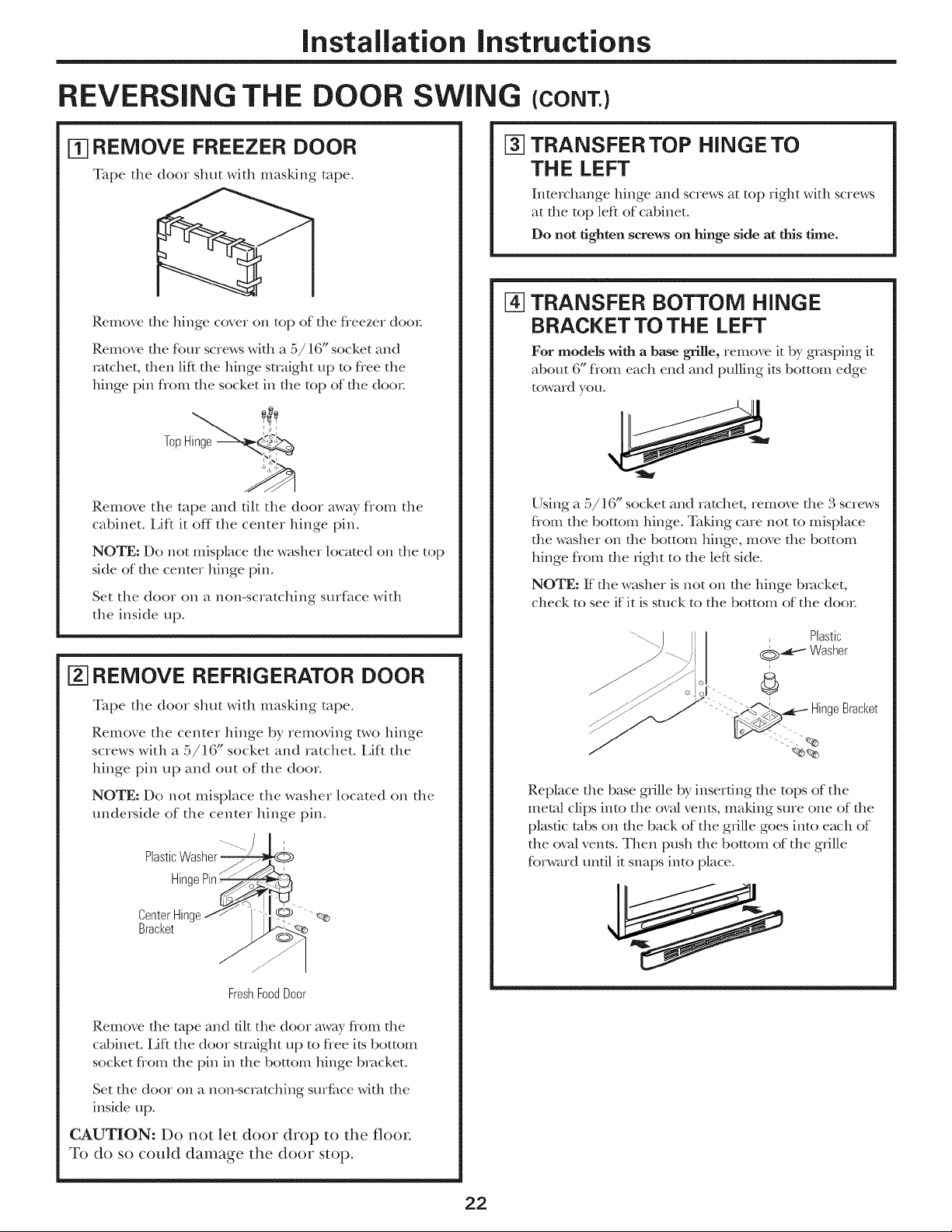

[_ REMOVE FREEZER DOOR

Tape the door shut with masking tape.

Remove the binge cover on top of the fleezer doom

Remove the four screws with a 5/16" socket and

ratchet, then lift the binge straight up to flee the

binge pin flom the socket in the top of the door

TopHinge

%

THE LEFT

Interchange binge and screws at top right with screws

at the top left of cabinet.

Do not tighten screws on hinge side at this time.

[-4]TRANSFER BOTTOM HINGE

BRACKET TO THE LEFT

For models with a base grille, reIIlove it by grasping it

about 6" flom each end and pulling its bottom edge

toward you.

Remove the tape and tilt the door away flom the

cabinet, i,iR it off the center binge pin.

NOTE: Do not misplace the washer located on the top

side of the center binge pin.

Set the door on a non-scratching smf_tce with

the inside up.

REMOVE REFRIGERATOR DOOR

Tape the door shut with masking tape.

Remove the center binge by removing two binge

screws with a 5/16" socket and ratchet. Elf1 the

binge pin up and out of the door

NOTE: Do not misplace the washer located on the

underside of the center binge pin.

Plastic

'""--- I

Hinc

Using a 5/16" socket and ratchet, reiD.ore die 3 screws

flom the bottom binge. Taking care not to misplace

the washer on the bottom binge, move the bottom

binge flom the Hgbt to the left side.

NOTE: ff the washer is not on the binge bracket,

check to see if it is stuck to the bottom of the doo_:

Plastic

i

©_--_ Washer

Bracket

Replace die base grille by inserting die tops of the

metal clips into the ova/vents, maMng sure one of the

plasdc tabs on the back of the grille goes into each of

the ova/vents. Then push the bottom of the gnlle

fbrward until it snaps into place.

/

FreshFoodDoor

Remove the rope and flit the door away flom the

cabinet. Lift the door straight up to flee its bottom

socket flom the pin in the bottom binge bracket.

Set the door on a non-scratching smf_ce with the

inside up.

CAUTION: Do not let door drop to the floor.

To do so could damage the door stop.

22

Installation instructions

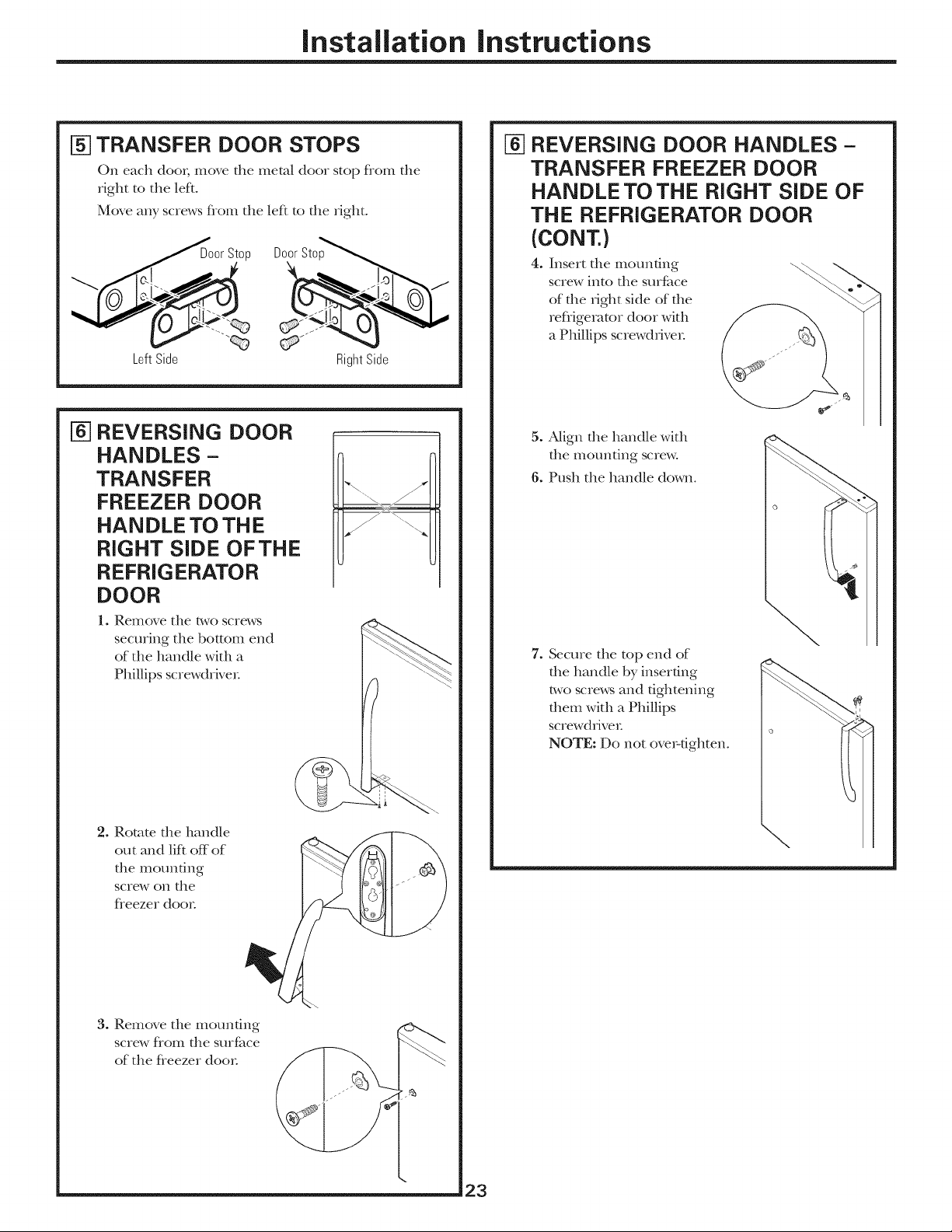

N1TRANSFER DOOR STOPS

On each do()/; move the metal door stop fiom the

right to the lefL

Move any screws fiom the leR to the _ight.

Door Stop Door Stop

LeftSide RightSide

[] REVERSING DOOR

HANDLES -

TRANSFER

FREEZER DOOR

HANDLE TO THE

RIGHT SIDE OF THE

REFRIGERATOR

DOOR

1. Remove the two screws

securing the bottom end

of the handle with a

Phillips screwdriver:

[] REVERSING DOOR HANDLES-

TRANSFER FREEZER DOOR

HANDLE TO THE RIGHT SiDE OF

THE REFRIGERATOR DOOR

(CONT.)

4. Insert file mounting

screw into the surface

of the IJght side of the

refiigemtor door with

a Phillips screwd_Jve,:

5. Align the handle with

the mounting screw°

6. Push the handle down°

7. Secure the top end of

die handle by inserting

two screws and tightening

them with a Phillips

screwdriver:

NOTE: Do not over-tighten.

2. Rotate file handle

out and lif* off of

file mounting

screw on the

fieezer do(n:

3. Remove the mounting

screw flom the surface

of the fieezer do(n:

\

23

Installation instructions

REVERSING THE DOOR SWING

_-] REVERSING DOOR HANDLES -

TRANSFER REFRIGERATOR

DOOR HANDLE TO THE RIGHT

SiDE OFTHE FREEZER DOOR

1. Remove the t_,voscrews

securing the top end of

file handle widl a Phillips

scre_,vdrive_:

2. Rotate die

handle out

and lift off of

the mounting

screw on file

reflJgerator

dooi:

(CONT.)

REVERSING DOOR HANDLES-

[]

TRANSFER REFRIGERATOR

DOOR HANDLE TO THE RIGHT

SiDE OFTHE FREEZER DOOR

(CONT.)

4. Insert file mounung screw

into the surfitce of the right

side of the fleezer door

with a Phillips screwdriver:

5. Align the handle with

the mounting screw°

6. Rotate the handle°

3. Remove the mounting

screw flom the surfime

of the reflJgemtor

dooi:

7. Secme the bottom end

of the handle by inserung

two screws and tightening

them with a Phillips

screwdriver

NOTE: Do not ore>tighten.

24

Installation instructions

NI REHANG THE REFRIGERATOR

DOOR

Lower the refligerator door onto the bottom

hinge pin°

Plastic

Screw die b,,voscrews into die center hinge location

on die left side with a 5/16" socket and ratchet.

Smdghten file door and place the center hinge pin

into the opening on top of file door Remember to

include tlle washer

Move the door into place, so you can align tlle center

hinge bracket over tlle center hinge holes on die left

side. Insert and tighten the two screws with a 5/16"

socket and ratchet.

NOTE: Ensure die washer is in place on top of die

hinge pin.

PlasticWasher_b

CenterHinge

Bracket

Hinge

I ..............

RefrigeratorDoor

[TO-]ADJUSTTHE DOORS

(IF NEEDED)

If the freezer door is too high:

Remove the hinge

cover on top of the

fleezer door and

loosen the four

screws with a 5/16"

socket and ratchet.

Replace tlle hinge

covei:

Loosenscrews. 5/16" __

%

I

If both doors are too high:

1. Remove

the hinge Loosenscrews.

cover on

top of tlle

door and

loosen the

f}om screws

with a

5/16"

fleezer _

socket and

ratchet.

.

Loosen die two center hinge screws wkh a 5/16"

socket and ratchet.

3. Slide tlle center hinge to die left to lower

tlle doors.

4. Fully tighten all screws and replace top hinge cove,:

%

5/16

_ oosen

5/16"

screwsand

slideleft to

lowerdoors.

[] REHANG THE FREEZER DOOR

Lower die fleezer door onto die center hinge pin.

Be sure die washer is in place.

igePin

Washer

iJfl die top hinge so die pin fits into die door socket.

Support the door on the handle side and make sme

the door is straight and the gap bet_,veen the doo_s is

even across the flont. While holding the door in

place, dghmn the top hinge screws.

25

If both doors are too low:

1. Remove die

hinge cover

on top of

the fleezer

door and

loosen the t

fbur screws

with a 5/16"

socket and t

ratchet.

2. Loosen the

bwo cenmr

hinge screws

wkh a a/16 socket and ratchet.

3.

Slide tlle center hinge to die fight to raise

the doors.

4. Fully dghten all screws and replace

top hinge cove_:

NOTE: Save the door spacer

Doo_ may settle with use. DoorSpacer

Loosenscrews. 5/16'_'

<&Loosen

5/16"

screwsand

sliderightto

raisedoors.

Normal operatingsounds.

Newer refrigerators sound different from older refrigerators, Modern refrigerators

have more features and use newer technology,

Do you hear what / hear? These sounds are normal

HUMMM.,

-- WHOOSH...

[] The new high efficiency compressor may run faster

and longer than yore old refligerator and you may

hear a high-pitched hum or pulsating sound while

it is operating.

[] You m W hear a whooshing sound when the doors close.

This is due to pressure equalizing within the refligerator

[] You may hear the rims spinning at high speeds.

This happens when the refrigerator is first plugged

in, when the doors are opened f}equently or when

a large amount of food is added to the ref_igerator

or freezer compamnents. The rims are helping to

maintain the correct temperatures.

CLICKS, POPS,

CRACKS and CHIRPS

[] You may hear cracking or popping sounds when the

refiigerator is first plugged in. This happens as the

refligerator cools to the correct temperature.

[] The compressor may cause a clicMng or chirping

sound when attempting to restart (this could rake

up to 5 minutes).

[] Expansion and contraction of cooling coils during

and after defrost can cause a cracking or popping

so/xxld.

[]

On models with an icemakm, after an icemaking

cycle, you may hear the ice cubes dropping into

the ice bucket.

[]

On models with a dispenser, during water dispense,

you may hear the water lines move at initial dispense

and af*er dispenser button is released.

WATERSOUNDS

6

[] The flow of refligeram fllrough file fleezer cooling

coils may make a gurgling noise like boiling water.

[] Water dropping on die deflost heater can cause a

sizzling, popping or buzzing sound during die

deflost cycle.

[] A water dripping noise may occur dming the deflost

cycle as ice melts flom the evaporator and flows into

the drain pan.

[] Closing the door may cause a gurgling sound due to

pressure equalization.

26

Beforeyouca//for service...

GEPpp/iances.com

Troubleshooting tips

Save time and money! Review the charts on the following

pages first and you may not need to call for service,

Possible Causes What ToDo

Freezer doorpops open This is normal if, after = This h_dk:ates that there is a good sea| on the fleezer

when refrigerator door popping open, the freezer docn: If the fleezer door does not automatically close after

is closed door closed on its own. popping open, the rollers need adjusting. See Rollers and

Leveling Legs.

Boor does not close Leveling legs need adjusting. • See Rollers and Leveling Legs.

by itself

Refrigerator does Refrigerator in defrost cycle. • Wak about 40 minutes for deft ost cycle to end.

not operate Refrigerator control in • Move the refligerator and fleezer control to a

1(Off)position. temperature setting.

Refrigerator is unplugged. • Push the plug completely into the Buffet.

The fuse is blown/ekcnit • Replace disc or reset the breaker:

breaker is tripped.

Vibration or rattling Refrigerator is not resting • Adjust leveling legs (See Rollers and Leveling Legs).

(slight vibration on all four rollers.

is normafl

Motor operates for Normal when refrigerator = Wait 24 hours for the refligerator to completely

long periods or cycles is first plugged in. coo/down°

on and off frequently

(Modern refrigerators Often occurs when large • This is nom_al.

with more storage

space and a larger placed in refrigerator.

freezer require more Door left open. + Check to see if package is hokting door open°

operating time. They

start and stop often Hot weather or frequent • This is nomlal.

tomaintain even door openings.

temperatures.) Temperature controls set + See About the controls.

Refrigerator orfreezer Temperature control not set • See About the controls.

compartment too warm cold enough.

Froster ice cn/stals Door left open. +Check to see if package is holdh_g door open.

on frozenfood

(frost within package

is normal) door openings.

amounts of food are

at the coldest setting.

Warm weather or frequent • Set the temperature control one step coldeL

door openings. See About the controls.

Door left open. • Check to see if package is hoMing door open.

Freezer door popped open. • See the problem Freezer door pops open when

refrigerator door is closed.

Too frequent or too long

Food blocking freezer air vents. • Move items away flom the back wall of the fleeze_:

Frequent"buzzing"

sound

Smallorhollow cubes

Icemaker power switch is in

the I (on) position, but the

water supply to the refrigerator

has not been connected.

Water f'flter clogged. *Replace filter cartridge with new cartridge or with plug.

*Set the power switch to the 0 (off) position. Keeping it

in the I(on)position will damage the water valve.

27

Beforeyoucall forservice..,

Troubleshooting tips

Possible Causes What ToDo

Automatic icemaker Icemaker power switch is = On power swkch models, set the power switch to the

(on some models) not on. I (on) position. On feeler am1 models, move the feeler

does not work am_ to the ON ((to\,_q_) position.

Water supply turned off or • See Installing the water line.

not connected.

Freezer compartment • Wait 24 hours fin the refligerator to completely

too warnl, coo[ down°

Piled up cubes in the storage • Level cubes by hand.

bin cause the icemaker

to shut off.

Ice cubes stuck in icemaker. • Turn off the icemake_; remove cubes and turn the

(Green power fight on icemaker back on.

icemaker blh_dng.)

Ice cubes have Ice storage bin needs cleaning. • Empty and wash bin. Dhcard oM cubes.

odor/taste

Food transmitting odor/taste = Wrap fbods well.

to ice cubes.

Interior of refrigerator • See Care and cleaning.

needs cleaning.

Slow ice cube freezing Door left open. • Check to see if package is hoMing door open.

Temperature control not set • See About the controls.

cold enough. • A newly insm|led refligerator may tnke l2-24 hours

to begin making ice cubes.

Moisture forms on Not unusual{ during • Wipe surfhce dry; then adjust the flesh fbod control

cabinet surface periods of high humidity, setting one nunlber higher and check again in 24 hours.

between the doors

Refrigerator has odor Foods transmJtting • Foods with strong o(kns should be tightly wrapped.

odor to refrigerator. • Keep an open box of baking soda in the refligerator;

replace every t]uee months.

Interior needs cleaning. • See Care and cleaning.

Moisture collects inside Too frequent or too

(in humid weather, air long door openings.

carries moisture into

refrigerator when doors Open containers of water or = Cover or seal open contnine_. DuAng a deflost cycle,

are opened) return with long or flequent door openings.

Refrigerator compartment No power at outlet. • Replace fl_se or reset the breaken

light doesnot work Light bulb burned out or loose. • See Replacing the light bulbs.

warm food in the refrigerator, moisture will be removed flom the refligerato_, but may

28

Possible Causes What ToDo

GEPpp/iance&com

Hotair frombottom

ofrefrigerator

Food freezing in Food too close to the air vent • Move the fbod mvay flora the ah vent (near the

the refrigerator at the back of the refrigerator, controls).

in the freezer

Boor bins do not fit The freezer door bins are • Try to inst_dl the |)ins in both doox_.

in the door a different size than the

Controlsdo aotlightup Some models do not have •l[f yo/_ can read whke m_tnbex_ on the control setting,

Normal air flow coofing

motor. In the refrigeration

process, it is normal that

heat be expelled in the

area under the refrigerator.

Some floor coverings will

discolor at these normal

and safe temperatures.

Refrigerator control is set * Move the refiigerator control to a warmer

too cold. temperature setting one increment at a time.

Defrost heater is on. * This is n(nmal.

refrigerator door bins.

lighted controls, the model does not have lighted controls.

Refrigerator light bulb burned • See Replacing the light bulbs.

out or loose.

Water has poor Water dispenser has not been * Dispense water until all water in system is

taste/odor used for a long time. replenished.

Water in firstglass Normal when refrigerator • Wak 24 hours for the refligemtor to completely

iS warm is first installed, coo/down.

Water dispenser has not been • Dispense water undl all water is system is

used for a long time. replenished.

Water system has been drained. • Allow several hours hn replenished supply to chill°

No water orice cube Supply line or shutoff valve • (]all a plumbe_:

production is clogged.

29

Loading...

Loading...