GE GTDP301GL, GTDX200GM, GTDX205GM, PTDS650GMWT, GTDP301GLWS Installation Instructions Manual

WARNING RISK OF FIRE

• To reduce the risk of severe injury or death, follow all installation instructions.

• Clothes dryer installation must be performed by a qualied installer.

• Install the clothes dryer according to these instructions and in accordance with local

codes. In the absence of local codes, installation must comply with National Fuel Gas

Code, ANSIZ223.1/NFPA 54 or the Canadian Natural Gas and Propane Installation Code,

CSA B149.1.

• California Safe Drinking Water and Toxic Enforcement Act.

This act requires the governor of California to publish a list of substances known to the

state to cause cancer, birth defects or other reproductive harm and requires businesses

to warn customers of potential exposure to such substances. Gas appliances can

cause minor exposure to four of these substances, namely benzene, carbon monoxide,

formaldehyde and soot, caused primarily by the incomplete combustion of natural gas

or LP fuels. Properly adjusted dryers will minimize incomplete combustion. Exposure

to these substances can be minimized further by properly venting the dryer to the

outdoors.

• This dryer must be exhausted to the outdoors.

• Use only 4” rigid metal ducting for exhausting the clothes dryer to the outdoors.

• DO NOT install a clothes dryer with exible plastic ducting materials. If exible metal

(semi-rigid or foil-type) duct is installed, it must be UL listed and installed in accordance

with the instructions found in “Connecting The Dryer To House Vent” on page 6 of this

manual. Flexible venting materials are known to collapse, be easily crushed, and trap

lint. These conditions will obstruct dryer airow and increase the risk of re.

• Do not install or store this appliance in any location where it could be exposed to water

and or weather.

• Dryers installed in residential garages must be elevated 18” (46 cm) above the oor.

• Save these instructions. (Installers: Be sure to leave these instructions with the

customer).

In the state of Massachusetts, installation must be performed by a qualiedor

licensed contractor, plumber, or gastter qualied or licensed by the state.

Installation

Instructions

Gas Dryer

06

Questions on Installation? Call: 1-800-GECARES (US)

or Visit our Web site at: www.GEAppliances.com (US)

BEFORE YOU BEGIN

Read these instructions completely and

carefully.

•IMPORTANT- Save these instructions for

local inspector’s use.

•IMPORTANT- Observe all governing codes

and ordinances.

• Note to Installer - Be sure to leave these

instructions with the customer.

• Note to Customer - Keep these instructions

with your Use and Care Book for future

reference.

• Before the old dryer is removed from service or

discarded, remove the dryer door.

• Inspect the dryer exhaust outlet and straighten

the outlet walls if they are bent.

• Service information and the wiring diagram

are located in the control console.

• Do not allow children on or in the appliance.

Close supervision of children is necessary when

the appliance is used near children.

• Install the dryer where the temperature is

above 50°F for satisfactory operation of the

dryer control system.

LEVEL

8" PIPE WRENCH

10" ADJUS TABLE WRENCHES

(x2)

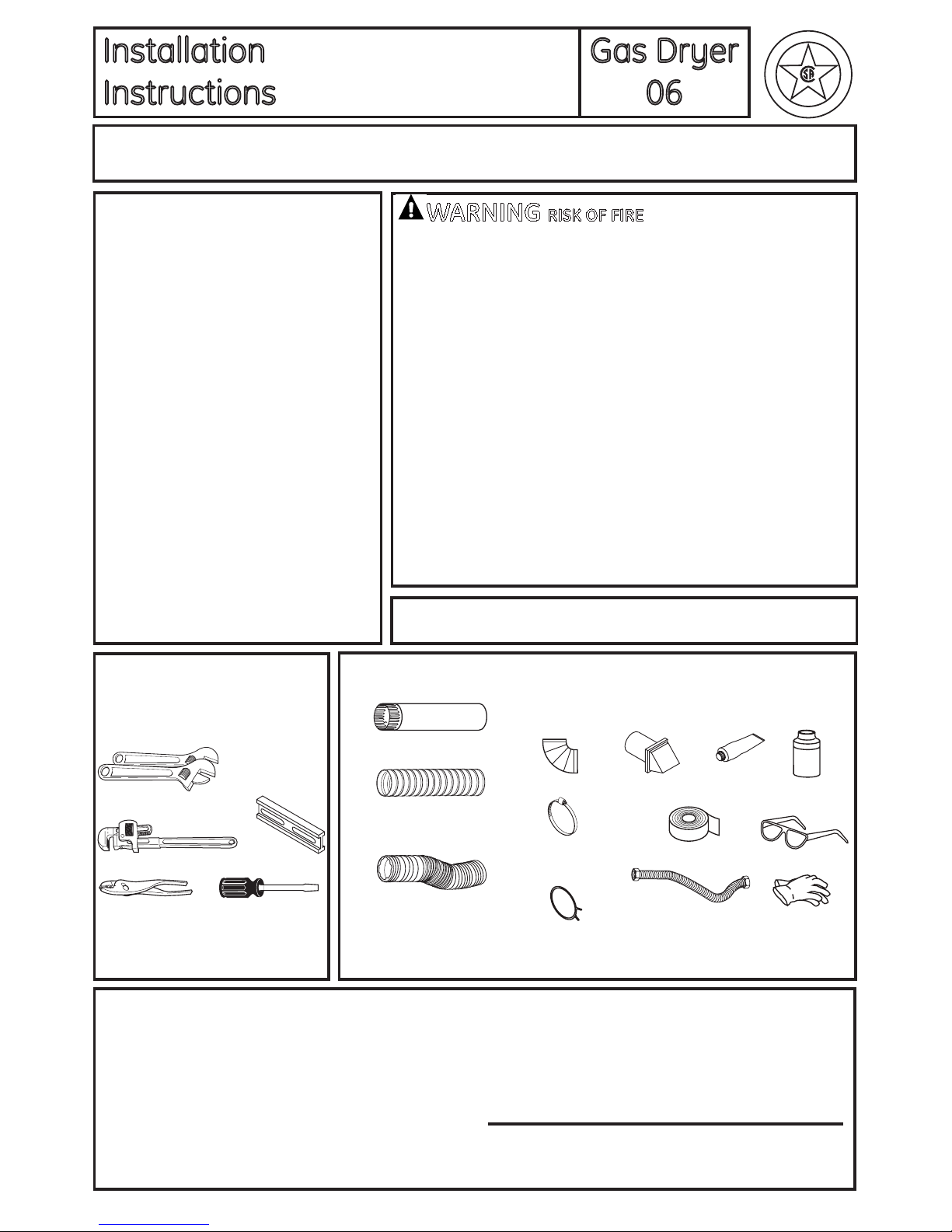

TOOLS YOU

WILL NEED

SLIP JOINT PLIERS

FLAT BLADE SCREWDRIVER

M ATERIALS YOU WILL NEED

EXHAUST HOOD

FLEXIBLE GAS LINE CONNECTOR

SOAP SOLUTION

FOR LEAK DETECTION

PIPE

COMPOUND

DUCT TAPE

GLOVES

SAFETY GLASSES

4" DIAM METAL ELBOW

4" DUCT CLAMPS

OR

4" SPRING CLAMPS

(x2)

(x2)

4" DIA. FLEXIBLE METAL (SEMI-RIGID)

UL LISTED TRANSITION DUCT

(IF NEEDED)

KIT WX08X10077 (INCLUDES 2 ELBOWS)

4" DIA. METAL DUCT

(RECOMMENDED)

4" DIA. FLEXIBLE METAL (FOIL TYPE)

UL LISTED TRANSITION DUCT

(IF NEEDED.)

234D1113P002 31-16225-1 07/08/10 GE

Step 1 Verify Your Gas Installation (see section 2).

Step 2 Prepare the Area and Exhaust for Installation of

New Dryer (see section 1).

Step 3 Check and Insure the Existing External Exhaust

is Clean (see section 1) and Meets Attached

Installation Specications (see section 6).

Step 4 Remove the Foam Shipping Pads (see section 1).

Step 5 Move the Dryer to the Desired Location.

Step 6 Level Your Dryer (see section 8).

Step 7 Connect the Gas Supply (see section 3) and check

for leaks (see section 4).

Step 8 Connect the External Exhaust (see section 7).

Step 9 Connect the Power Supply (see section 5).

Step 10 Check the Operation of the Power Supply, Gas

Connections, and Venting.

Step 11 Place the Owners Manual and the Installation

Instructions in a Location Where They Will Be

Noticed By the Owner.

For Alcove or Closet Installation see section 9.

For Bathroom or Bedroom Installation see section 10.

For Mobile or Manufactured Home see section 11.

D

E

S

I

G

N

C

E

R

T

I

F

I

E

D

Installation Instructions

2

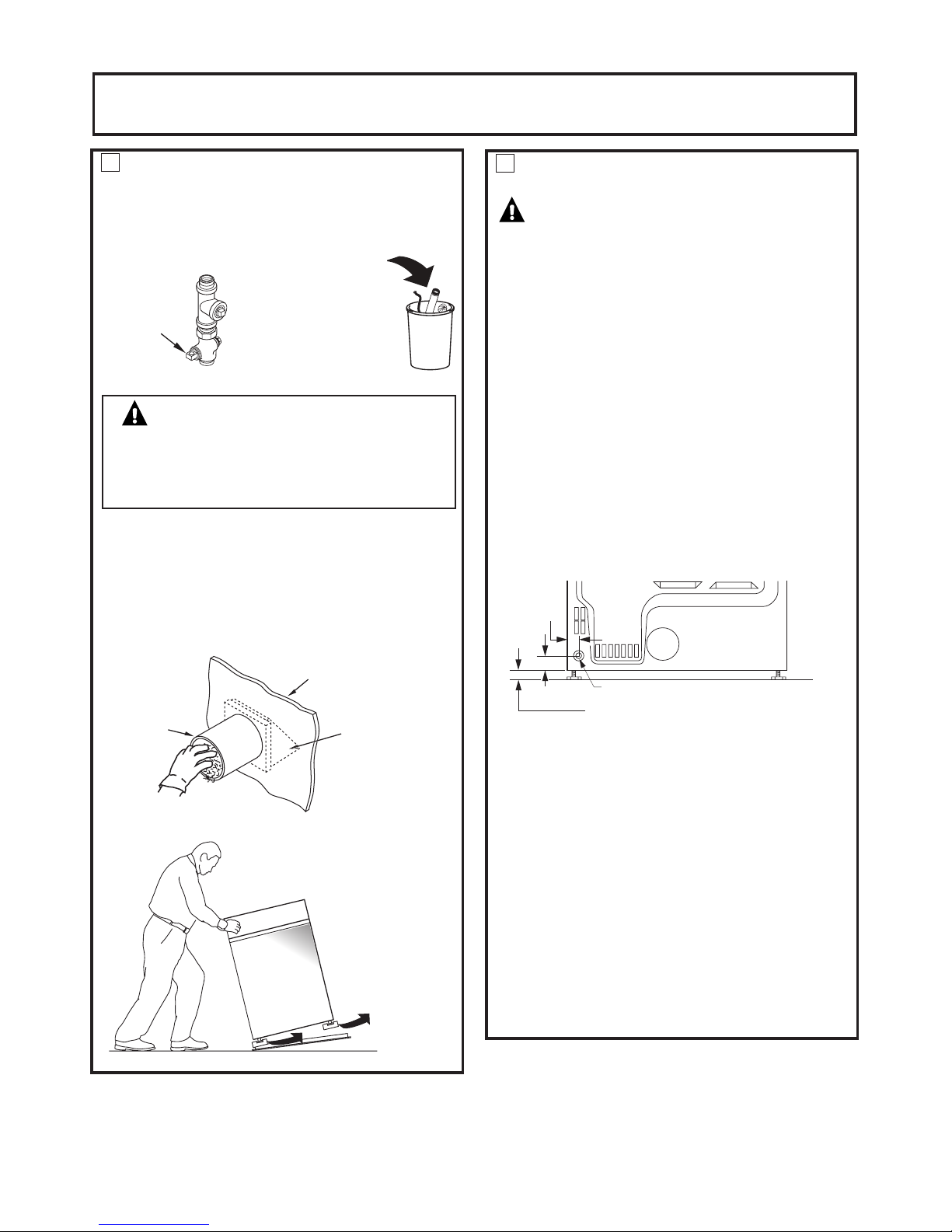

Minimum Clearance Other Than Alcove or Closet Installation

Minimum clearance to combustible surfaces and for air opening are: 0 in. clearance both sides and 1 in. rear.

Consideration must be given to provide adequate clearance for installation and service.

2

GAS REQUIREMENTS

WARNING

• Installation must conform to local codes and

ordinances, or in their absence, the NATIONAL FUEL

GAS CODE, ANSI Z223.

• This gas dryer is equipped with a Valve & Burner

Assembly for use only with natural gas. Using

conversion kit WE25X0217, your local service

organization can convert this dryer for use with

propane (LP) gas. ALL CONVERSIONS MUST BE MADE BY

PROPERLY TRAINED AND QUALIFIED PERSONNEL AND

IN ACCORDANCE WITH LOCAL CODES AND ORDINANCE

REQUIREMENTS.

• The dryer must be disconnected from the gas supply

piping system during any pressure testing of that

system at a test pressure in excess of 0.5 PSI (3.4 KPa).

• The dryer must be isolated from the gas supply piping

system by closing the equipment shut-o valve during

any pressure testing of the gas supply piping of test

pressure equal to or less than 0.5 PSI (3.4 KPa).

GAS SUPPLY

• A 1/8-in.National Pipe Taper thread plugged tapping,

accessible for test gauge connection, must be installed

immediately upstream of the gas supply connection to

the dryer. Contact your local gas utility should you have

questions on the installation of the plugged tapping.

• Supply line is to be 1/2-in. rigid pipe and equipped with an

accessible shut-off within 6 ft. of, and in the same room

with the dryer.

•Use pipe thread sealer compound or Teon tape appropriate for natural or LP gas.

• You must use with this dryer a exible metal connector

listed connector ANSI Z21.24 / CSA 6.10. The length of the

connect shall not exceed 3 ft.

• Connect exible metal connector to dryer and gas supply.

• Open shut-off valve.

INTERNAL DUCT

OPENING

CHECK THA T EXHAUST

HOOD DAMPER OPENS

AND CLOSES FREELY.

WALL

TILT THE DRYER SIDEWAYS

AND REMOVE THE FOAM

SHIPPING PADS BY

PULLING AT THE SIDES

AND BREAKING THEM

AWAY FROM THE DRYER

LEGS. BE SURE TO

REMOVE ALL OF THE

FOAM PIECES AROUND

THE LEGS.

1

PREPARING FOR INSTALLATION

OF NEW DRYER

TIP: Install your dryer before installing your washer.

This will allow better access when installing dryer

exhaust.

DISCONNECTING GAS

REMOVING LINT FROM WALL

EXHAUST OPENING

• Remove and discard existing plastic or metal foil

transition duct and replace with UL listed transition

duct.

DISCONNECT AND DISCARD OLD

FLEXIBLE GAS CONNECTOR AND

OLD TRANSITION DUCTING

MATERIAL. REPLACE WITH NEW

CSA(AGA) APPROVED FLEXIBLE

GAS LINE CONNECTOR AND UL

APPROVED TRANSITION DUCT.

TURN GAS

SHUT-OFF VALVE

TO THE OFF

POSITION.

WARNING - NEVER REUSE OLD

FLEXIBLE CONNECTORS.

The use of old exible connectors can cause leaks and

personal injury. Always use new exible connectors

when installing gas appliances.

DRYER GAS SUPPLY CONNECTION

2"

2-5/8"

3/8" NPT MALE THREAD GAS SUPPLY

NOTE: Add to vertical dimension

the distance between cabinet

bottom to floor.

Installation Instructions

3

3

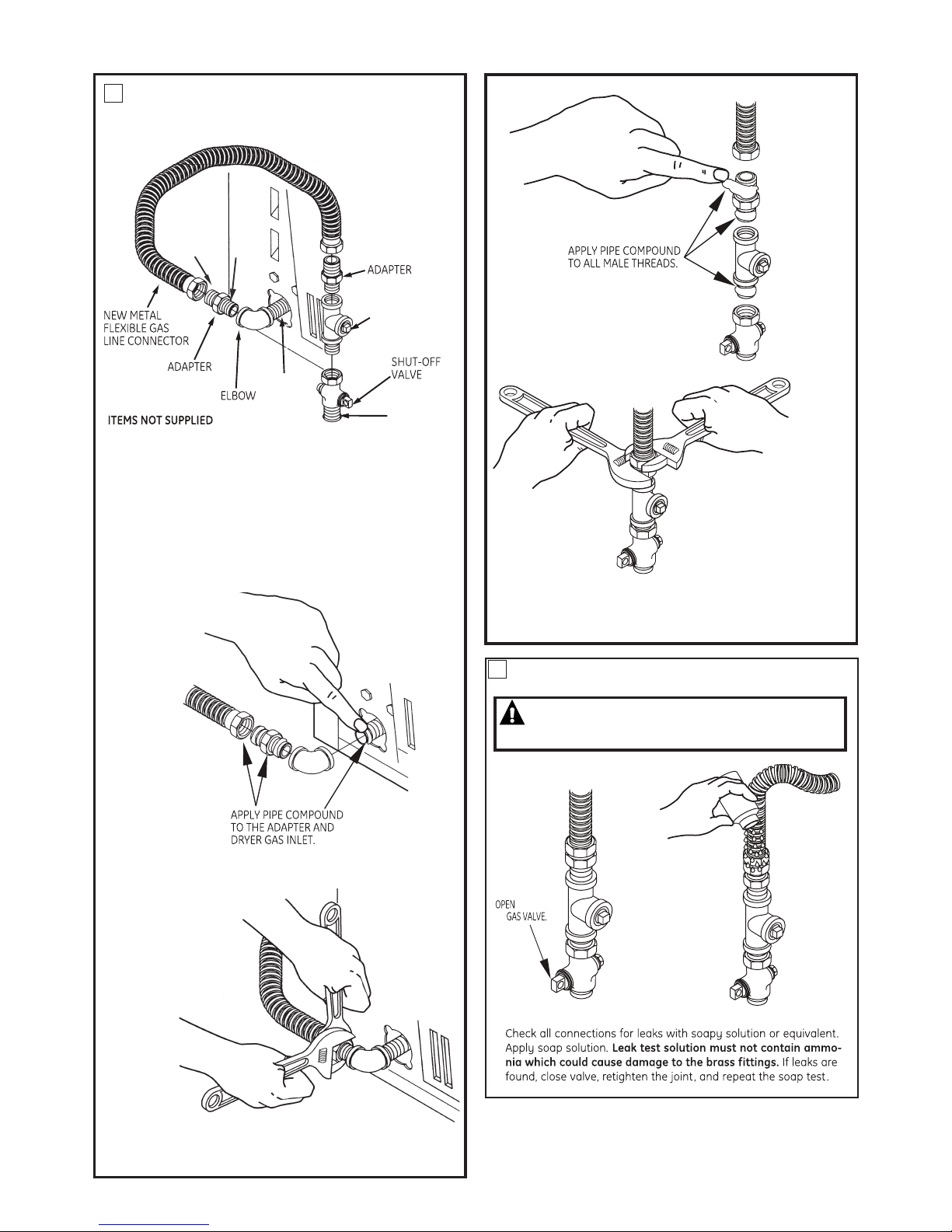

RECONNECTING GAS

Note: The connector and ttings are designed for use

only on the original installation and are not to be reused

for another appliance or at another location. Keep are

end of adaptor free of grease, oil and thread sealant.

Caution: Use adapters as shown. Connector nuts must

not be connected directly to pipe threads.

WARNING: NEVER USE AN OPEN

FLAME TO TEST FOR GAS LEAKS.

FLARE

NPT

PIPE SIZE

Listed connector ANSI Z21.24 / CSA 6.10

1/8" NPT PIPE

PLUG FOR

CHECKING GAS

INLET PRESSURE

AT LEAST 1/2"

3/8" NPT

TIGHTEN THE FLEXIBLE

GAS LINE USING TWO

ADJUSTABLE WRENCHES.

TIGHTEN ALL CONNECTIONS

USING TWO ADJUSTABLE WRENCHES.

DO NOT OVERTORQUE GAS CONNECTIONS!

4

LEAK TEST

Loading...

Loading...