GE DHDSR46GG9WW, DNCK440GG9WC, GHDN520GD0WS, GHDN520GD1WS, GHDN520GD2WS Installation Guide

...Page 1

Installation

Instructions l'°so r'er1@

Questions on Installation? Call: 800.GE.CARES (US)

or visit our web site at: www.GEAppliances.com (US)

BEFOREYOU BEGIN

Read these instructions completely and

carefully.

•IN PORTANT-Save these instructions for

local inspector's use.

•IMPORTANT- Observe all governing codes

and ordinances.

• Note to Installer - Besureto leavethese

instructionswith the customer.

• Note to Customer - Keep these instructions

with your Owner's Hanual for future reference.

• Before the old dryer is removed from service or

discarded, remove the dryer door.

• inspect the dryer exhaust outlet and straighten

the outlet walls if they are bent.

• Service information and the wiring diagram

are locatedin thecontrolconsole.

• Donot allowchildren on or inthe appliance.

Closesupervisionof childrenis necessarywhen

theappliance isusednear children.

• installthe dryer wherethe temperatureis

aboveSO°Ffor satisfactory operationofthe

dryercontrol system.

• Productfailuredue to improper installationis

not coveredunderthe Warranty.

WARNING RISK OF FIRE

• To reducethe risk ofsevereinjuryor death, follow all installationinstructions.

• Clothesdryer installationmust be performed bya qualifiedinstaller.

• Installthe clothesdryer accordingto theseinstructionsand inaccordance with local

codes.Inthe absenceof localcodes,installationmust complywith National FuelGas

Code,ANSIZ22].l/NFPA54or the CanadianNaturalGasand PropaneInstallationCode,

CSAB149.1.

•CaliforniaSafeDrinkingWaterand ToxicEnforcementAct.

Thisact requiresthe governor of Californiato publish alistof substancesknownto the

state tocause cancer,birth defectsor other reproductiveharm and requiresbusinesses

to warn customersofpotential exposureto suchsubstances.Gasappliancescan

causeminor exposuretofour of thesesubstances,namelybenzene,carbonmonoxide,

formaldehydeand soot, causedprimarily by the incompletecombustionof naturalgas

or LPfuels.Properlyadjusted dryerswitiminimizeincompletecombustion. Exposure

to these substancescan beminimizedfurther byproperlyventingthe dryerto the

outdoors.

• Thisdryer must be exhaustedto the outdoors.

• Useonly4" rigid metalducting for exhaustingthe clothesdryer to the outdoors.

• DONOTinstall aclothesdryer with flexible plasticducting materials.If flexiblemetal

(semi-rigidorfoil-type) duct isinstalled,itmustbe ULlisted andinstalledin accordance

with the instructionsfound in "ConnectingTheDryerToHouseVent" onpage6 ofthis

manual.Flexibleventing materials areknownto collapse,beeasiiy crushed,and trap

lint.Theseconditionswilt obstruct dryerairflow and increasethe riskof fire.

• Donot installor store this appliancein any locationwhere it could beexposedto water

andorweather.

• Savetheseinstructions.(Installers:Besureto leavethese instructionswith the

customer).

In the state of Massachusetts:

• Installation must beperformed by a qualified or licensedcontractor,

plumber,or gasfitter qualified or licensedby the state.

• Whenusing ball-type gasshut-offvalves, they shall beT-handletype.

• Aflexible gasconnector, when used,must not exceed3 feet.

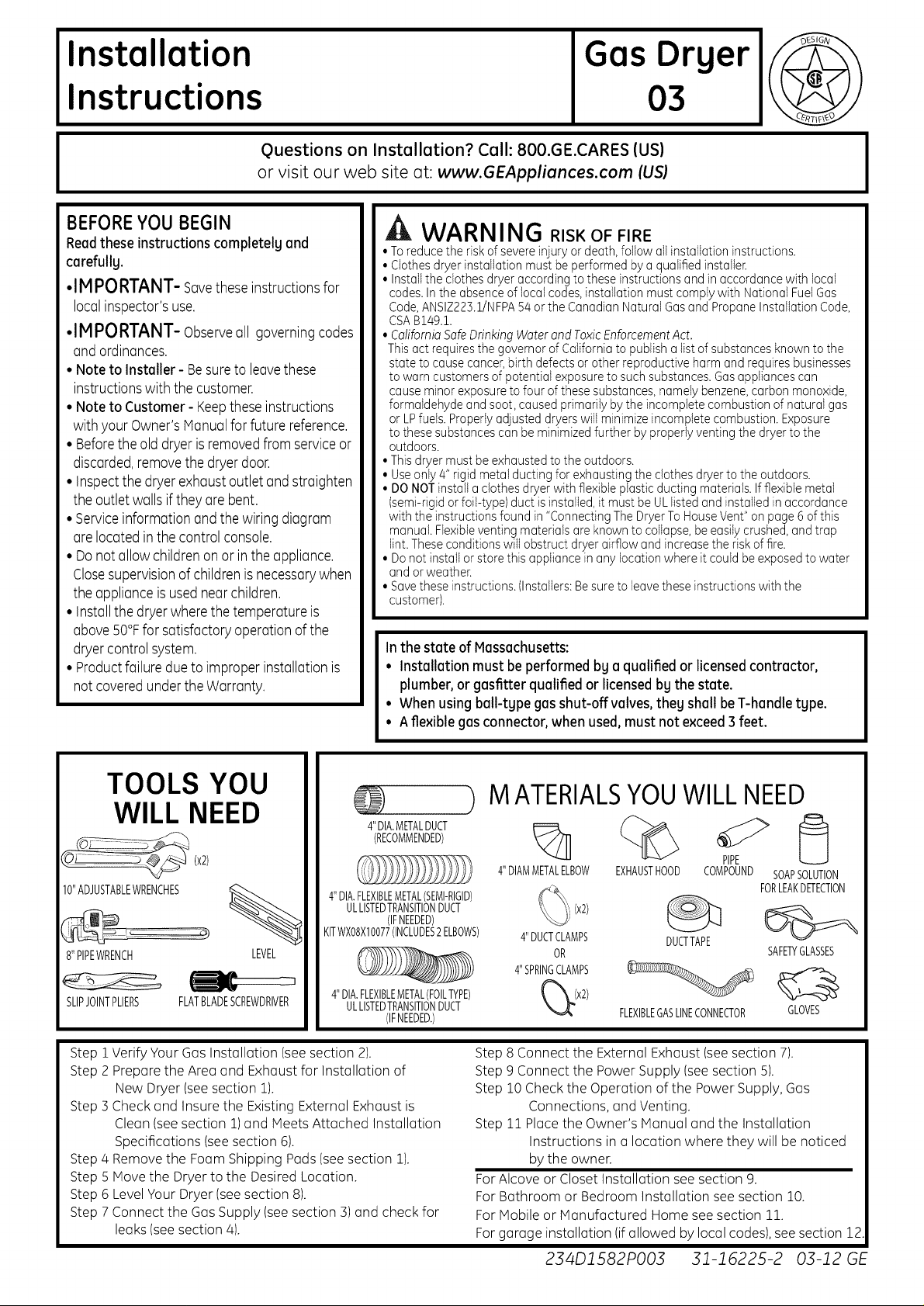

TOOLS YOU

WILL NEED

(x2)

10"ADJUSTABLEWRENCHES

, ic................._)

8"PIPEWRENCH LEVEL

SLIPJOINTPLIERS FLATBLADESCREWDRIVER

Step 1Verify Your Gas Installation (see section 2).

Step 2 Prepare the Area and Exhaust for Installation of

New Dryer (see section 1).

Step ] Check and Insure the Existing External Exhaust is

Clean (see section 1) and Meets Attached Installation

Specifications (see section 6).

Step 4 Remove the Foam Shipping Pads (see section 1).

Step 5 Move the Dryer to the Desired Location.

Step 6 Level Your Dryer (see section 8).

Step 7 Connect the Gas Supply (see section ]) and check for

leaks (see section 4).

4"DIA.METALDUCT I====_

(RECOMMENDED)

4"DIA.FLEXIBLEMETAL(SEMI-RIGID)

ULLISTEDTRANSITIONDUCT

KITWXO8X10077(INCLUDES2ELBOWS)

4"DIA.FLEXIBLEMETAL(FOILTYPE)

(IFNEEDED)

ULLISTEDTRANSITIONDUCT

(IFNEEDED.)

MATERIALSYOUWILLNEED

)

4"DIAMMETALELBOW

4"DUCTCLAMPS DUCTTAPE

OR SAFETYGLASSES

4"SPRINGCLAMPS

Step 8 Connect the External Exhaust (see section 7).

Step 9 Connect the Power Supply (see section 5).

Step 10 Check the Operation of the Power Supply, Gas

Connections, and Venting.

Step 11 Place the Owner's Manual and the Installation

Instructions in a location where they will be noticed

by the owner.

For Alcove or Closet Installation see section 9.

For Bathroom or Bedroom Installation see section 10.

For Mobile or Manufactured Home see section 11.

For garage installation (if allowed by local codes), see section 12.

EXHAUSTHOOD COMPOUND

FLEXIBLEGASLINECONNECTOR GLOVES

PIPE

SOAPSOLUTION

FORLEAKDETECTION

234D1582PO03 31-16225-2 03-12 GE

Page 2

Installation Instructions

Minimum Clearance Other Than Alcove or Closet Installation

Minimum clearance to combustible surfaces and for air opening are: 0 in. clearance both sides and J_in. rear.

Consideration must be given to provide adequate clearance for installation and service.

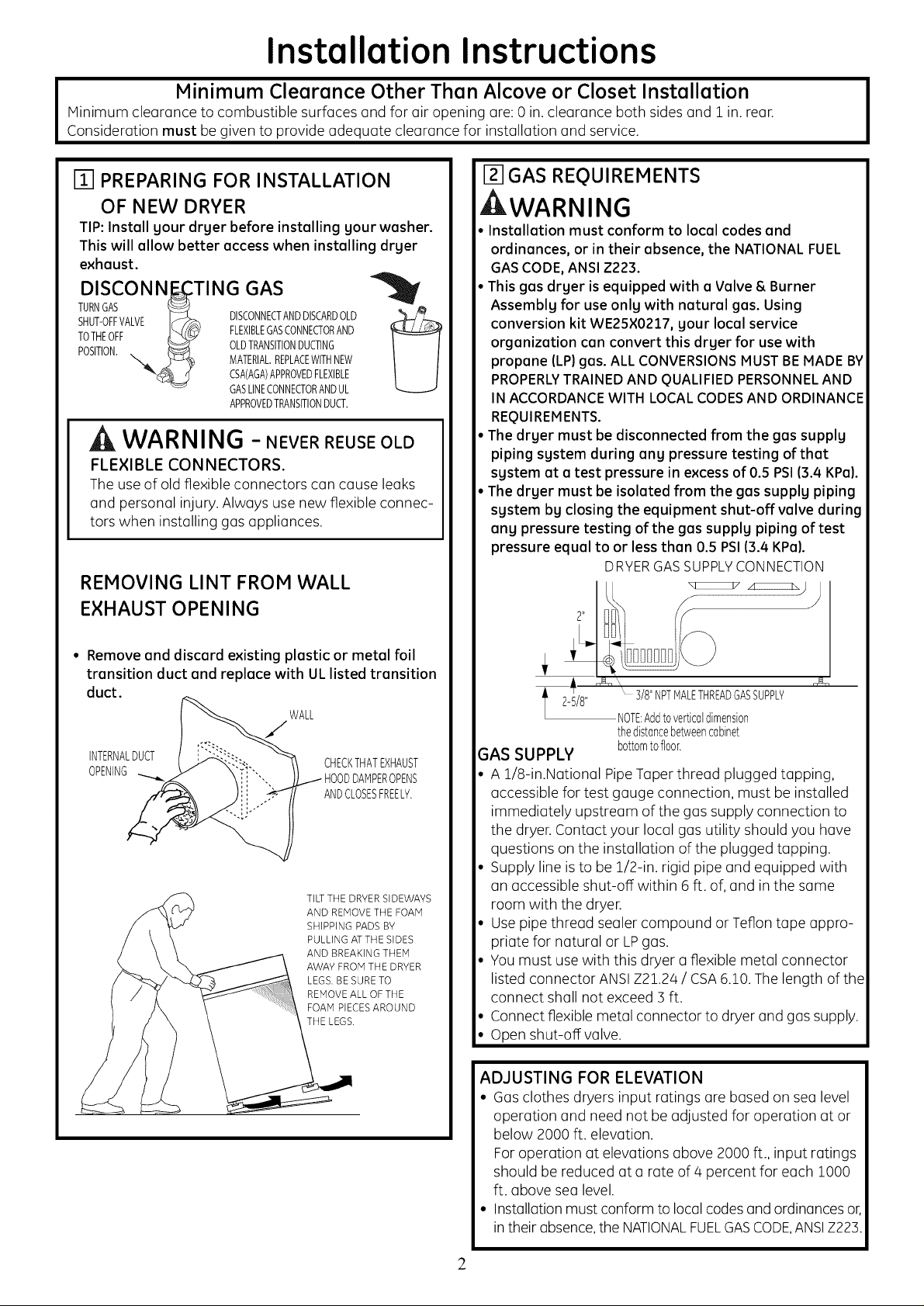

[] PREPARING FOR INSTALLATION

OF NEW DRYER

TIP:Install your dryer before installing your washer.

This will allow better access when installing dryer

exhaust.

DISCONN_TING GAS

TURNGAS

SHUT-OFFVALVE1(7_ DISCONNECTANDDISCARDOLD

TOTHEOFF

POSITION.x'_ _--_ OLDTRANSITIONDUCTING

_u FLEXIBLEGASCONNECTORAND

MATERIAL,REPLACEWITHNEW

CSA(AGA)APPROVEDFLEXIBLE

GASLINECONNECTORANDUL

APPROVEDTRANSITIONDUCT.

WARNING - NEVERREUSEOLD

FLEXIBLE CON NECTORS.

The use of old flexible connectors can cause leaks

and personal injury. Always use new flexible connec-

tors when installing gas appliances.

REMOVING LINT FROM WALL

EXHAUST OPENING

[] GAS REQUIREMENTS

tLWARNING

Installation must conform to local codes and

ordinances, or in their absence, the NATIONAL FUEL

GASCODE,ANSI Z223.

This gas drger is equipped with a Valve & Burner

Assemblg for use onlg with natural gas. Using

conversion kit WE25X0217, gour local service

organization can convert this drger for use with

propane (LP)gas. ALL CONVERSIONSMUSTBEMADE BY

PROPERLYTRAINED AND QUALIFIEDPERSONNELAND

IN ACCORDANCEWITH LOCALCODESAND ORDINANCE

REQUIREMENTS.

The dryer must be disconnected from the gas supply

piping system during any pressure testing of that

system at a test pressure in excess of O.5PSI(3.4 KPa).

The dryer must be isolated from the gas supply piping

system bg closing the equipment shut-off valve during

ang pressure testing of the gas supply piping of test

pressure equal to or less than 0.5 PSI(3.4 KPa).

DRYERGASSUPPLYCONNECTION

• Remove and discard existing plastic or metal foil

transition duct and replace with UL listed transition

duct.

WALL

INTERNALDUCT

OPENING HOODDAMPEROPENS

CHECKTHATEXHAUST

ANDCLOSESFREELY.

TILTTHE DRYERSIDEWAYS

AND REMOVE THE FOAM

SHIPPING PADS BY

PULLING ATTHE SIDES

AND BREAKING THEM

AWAY FROM THE DRYER

LEGS.BE SURETO

REMOVEALL OFTHE

FOAM PIECESAROUND

THE LEGS.

A 2-5/8" 3/8"NPTMALETHREADGASSUPPLY

NOTE:Addtoverticaldimension

thedistancebetweencabinet

;AS SUPPLY

bottomtofloor.

A 1/8-in.National PipeTaper thread plugged tapping,

accessible for test gauge connection, must be installed

immediately upstream of the gas supply connection to

the dryer. Contact your local gas utility should you have

questions on the installation of the plugged tapping.

Supply line is to be 1/2-in. rigid pipe and equipped with

an accessible shut-off within 6 ft. of, and in the same

room with the dryer.

Use pipe thread sealer compound or Teflon tape appro-

priate for natural or LPgas.

You must use with this dryer a flexible metal connector

listed connector ANSIZ21.24/CSA 6.10.The length of the

connect shall not exceed 3 ft.

Connect flexible metal connector to dryer and gas supply.

Open shut-off valve.

ADJUSTING FOR ELEVATION

• Gasclothes dryers input ratings are based on sea level

operation and need not be adjusted for operation at or

below 2000 ft. elevation.

For operation at elevations above 2000 ft., input ratings

should be reduced at a rate of 4 percent for each lO00

ft. above sea level.

• Installation must conform to local codes and ordinances or,

in their absence,the NATIONALFUELGASCODE,ANSIZ223.

2

Page 3

Installation Instructions

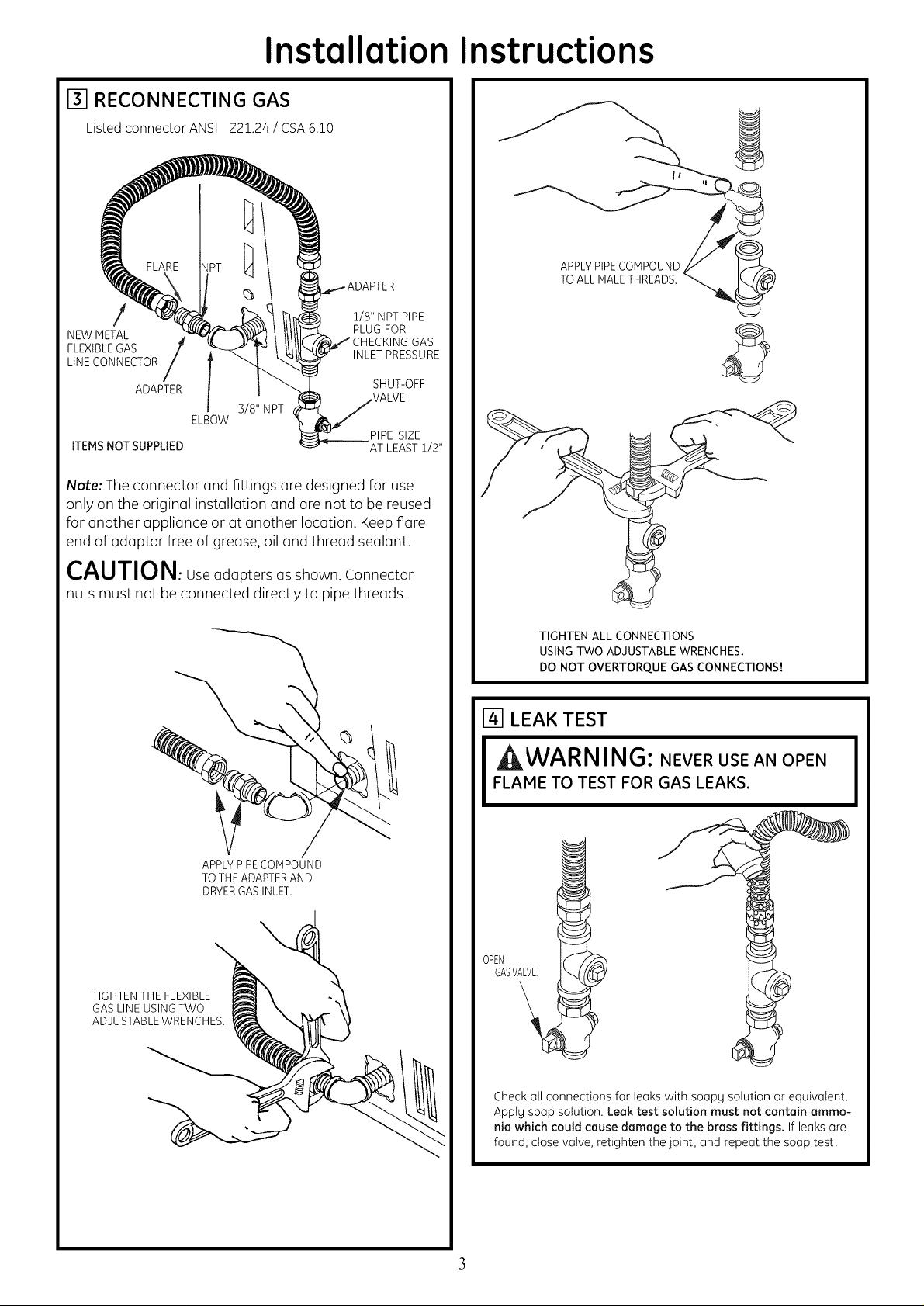

IYI RECONNECTING GAS

Listed connector ANSt Z21.24 / CSA 6.10

1/8" NPT PIPE

NEW METAL PLUG FOR

FLEXIBLEGAS INLETPRESSURE

LINECONNECTOR

ADAPTER

3/8" NPT

ELBOW

ITEMSNOT SUPPLIED _AT LEAST1/2"

Note: The connector and fittings are designed for use

only on the original installation and are not to be reused

for another appliance or at another location. Keep flare

end of adaptor free of grease, oil and thread sealant.

GAS

SHUT-OFF

PIPE SIZE

APPLYPIPECOMPOUND

TOALL MALETHREADS.

CAUTION: Use adapters as shown. Connector

nuts must not be connected directly to pipe threads.

APPLYPIPECOMPOUND

TOTHEADAPTERAND

DRYERGASINLET.

TIGHTENTHE FLEXIBLE"_

GASLINEUSINGTWO_ I

TIGHTEN ALL CONNECTIONS

USINGTWO ADJUSTABLE WRENCHES.

DO NOT OVERTORQUE GAS CONNECTIONS!

I%-1LEAK TEST

WARNING: NEVERUSEANOPEN

FLAME TO TEST FOR GAS LEAKS.

OPEN

GASVALVE.

ADJUSTABLEWRENCHE& _

Check all connections for teoks with soopg solution or equivalent.

Apptg soap solution. Leek test solution must not contain ammo-

niawhich could cause damage to the brass fittings.IfleaksGre

found, close v(]lve, retighten the joint, and repeat the soap test.

3

Page 4

Installation Instructions

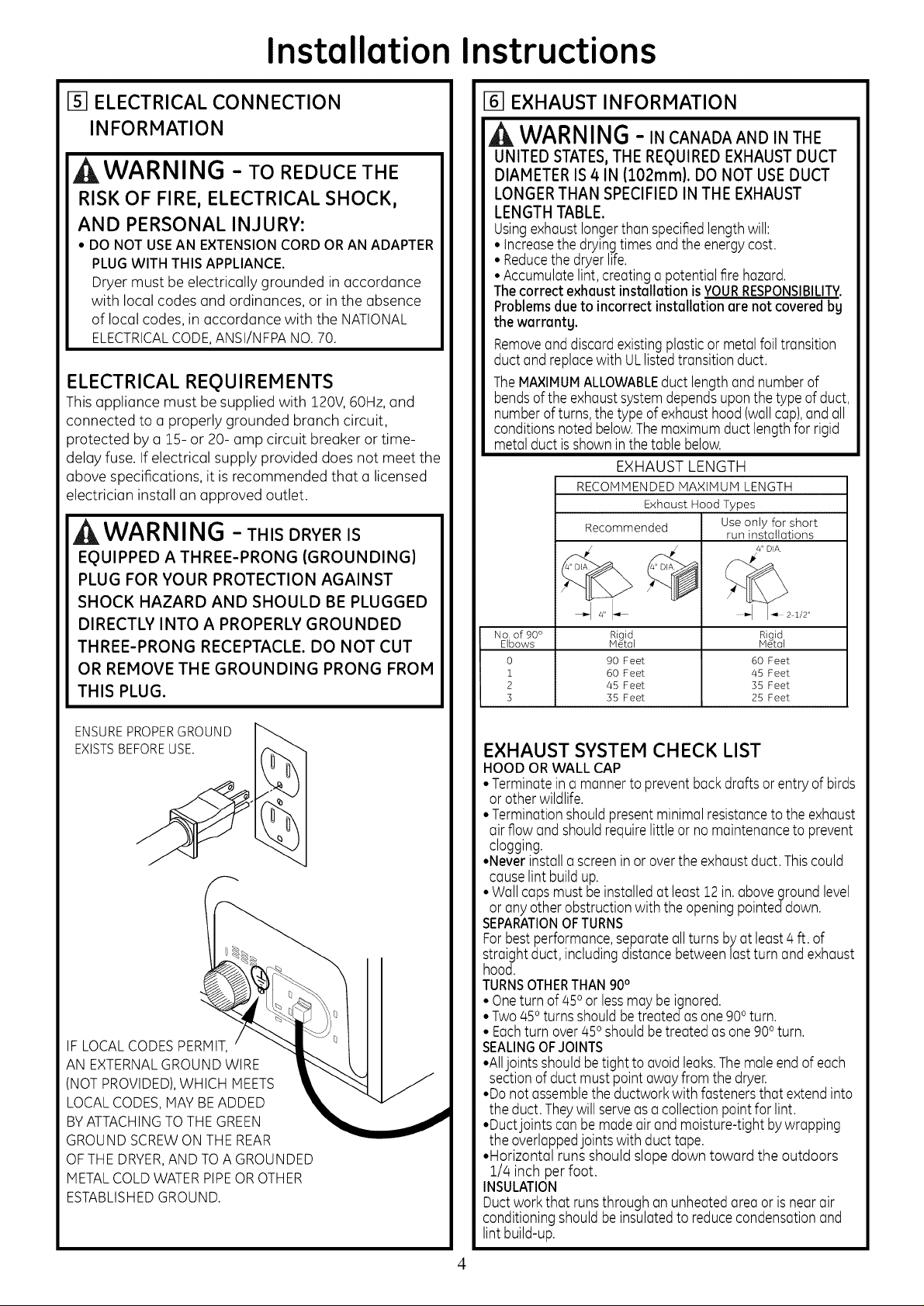

[] ELECTRICAL CONNECTION

INFORMATION

WARNING - TOREDUCETHE

RISK OF FIRE, ELECTRICAL SHOCK,

AND PERSONAL INJURY:

• DO NOT USEAN EXTENSIONCORDORAN ADAPTER

PLUGWITH THIS APPLIANCE.

Dryer must be electrically grounded in accordance

with local codes and ordinances, or inthe absence

of local codes, in accordance with the NATIONAL

ELECTRICALCODE,ANSI/NFPANO.70.

ELECTRICAL REQUIREMENTS

This appliance must be supplied with 120V,60Hz, and

connected to a properly grounded branch circuit,

protected by a 15- or 20- amp circuit breaker or time-

delay fuse. If electrical supply provided does not meet the

above specifications, it is recommended that (] licensed

electrician install an approved outlet.

WARNING - THISDRYERIS

EQUIPPED A THREE-PRONG (GROUNDING)

PLUG FOR YOUR PROTECTION AGAINST

SHOCK HAZARD AND SHOULD BE PLUGGED

DIRECTLY INTO A PROPERLY GROUNDED

THREE-PRONG RECEPTACLE. DO NOT CUT

OR REMOVE THE GROUNDING PRONG FROM

THIS PLUG.

I-_ EXHAUST INFORMATION

WARNING -IN CANADA AND IN THE

UNITED STATES,THE REQUIRED EXHAUST DUCT

DIAMETER IS 4 IN (102mm). DO NOT USEDUCT

LONGER THAN SPECIFIED IN THE EXHAUST

LENGTH TABLE.

Usingexhaustlongerthan specifiedlengthwill:

increasethedrying timesand theenergycost.

Reducethe dryerlife.

• Accumulatelint,creatinga potential firehazard.

Thecorrect exhaustinstallation isYOURRESPONSIBILITY.

Problemsdueto incorrect installation are not covered by

the warranty.

Removeanddiscardexisting plasticor metalfoil transition

duct and replacewith ULlistedtransition duct.

TheMAXIMUMALLOWABLEduct lengthand numberof

bendsof theexhaust systemdependsuponthetype of duct,

numberof turns,the type of exhausthood (wallcap),and all

conditionsnoted below.Themaximumduct length for rigid

metal duct isshowninthetable below.

EXHAUST LENGTH

RECOMMENDED MAXIMUM LENGTH

Exhaust Hood Types

Recommended

No. of 90° Rigid,

Elbows Hetal

0 60 Feet

1 45 Feet

2 35 Feet

3 25 Feet

Rigid,

Metal

90 Feet

60 Feet

45 Feet

35 Feet

Use only for short

run installations

4" DIA

.......II-.

ENSUREPROPERGROUND

EXISTSBEFOREUSE.

IF LOCAL CODES PERMIT,

AN EXTERNAL GROUND WIRE

(NOT PROVIDED), WHICH MEETS

LOCAL CODES, MAY BE ADDED

BYATTACHING TO THE GREEN

GROUND SCREW ON THE REAR

OF THE DRYER, AND TO A GROUNDED

METAL COLD WATER PIPE OR OTHER

ESTABLISHED GROUND.

EXHAUST SYSTEM CHECK LIST

HOOD ORWALL CAP

• Terminateina mannerto preventback draftsor entry of birds

or otherwildlife.

• Terminationshouldpresentminimalresistanceto the exhaust

air flow and shouldrequirelittleor nomaintenanceto prevent

clogging.

•Neverinstalla screenin or overtheexhaustduct.Thiscould

causelint buildup.

• Wallcapsmust beinstalledat least12in. abovegroundlevel

or anyother obstructionwith the openingpointeddown.

SEPARATIONOFTURNS

Forbest performance,separateallturns byat least4ft. of

straightduct, includingdistance betweenlastturn andexhaust

hood.

TURNSOTHERTHAN900

• Oneturn of 450or lessmaybe ignored.

• Two450turnsshouldbetreated as one 900turn.

• Eachturn over450shouldbetreated asone 900turn.

SEALINGOFJOINTS

•Alljointsshouldbetight to avoidleaks.Themale endof each

sectionof duct must pointawayfrom thedryer.

•Donotassemblethe ductwork with fastenersthat extend into

the duct. Theywill serveasa collectionpointfor lint.

•Ductjoints canbe madeair andmoisture-tightbywrapping

the overlappedjoints with duct tape.

•Horizontal runs should slope down toward the outdoors

1/4 inch per foot.

INSULATION

Ductwork that runsthroughanunheatedareaor is near air

conditioningshouldbeinsulatedto reducecondensationand

lintbuild-up.

4

Page 5

Installation Instructions

r-71EXHAUST CONNECTION

WARNING - TOREDUCETHE

RISK OF FIRE OR PERSONAL INJURY:

• This clothes dryer must be exhausted to the

outdoors.

• We recommend that you install your dryer before

installing your washer. This will permit direct access

for easier exhaust connection.

• Use only 4" rigid metal ducting for the home exhaust

duct.

• Use only 4" rigid metal or UL-listed flexible metal

(semi-rigid or foil-type) duct to connect the dryer

to the home exhaust duct. It must be installed

in accordance with the instructions found in

"Connecting The Dryer To HouseVent" on page 6 of

this manual.

• Do not terminate exhaust in a chimney, a wall,

a ceiling, gas vent, crawl space, attic, under an

enclosed floor, or in any other concealed space

of a building. The accumulated lint could create a

potential fire hazard.

• Never terminate the exhaust into a common duct

with a kitchen exhaust system. A combination of

grease and lint creates a potential fire hazard.

• Do not use duct longer than specified in the exhaust

length table. Longer ducts can accumulate lint,

creating a potential fire hazard.

• Never install a screen in or over the exhaust duct.

This will cause lint to accumulate, creating a

potential fire hazard.

• Do not assemble ductwork with any fasteners

that extend into the duct. Thesefasteners can

accumulate lint, creating a potential fire hazard.

• Do not obstruct incoming or exhausted air.

• Provide an access for inspection and cleaning of

the exhaust system, especially at turns and joints.

Exhaust system shall be inspected and cleaned at

least once year.

STANDARD REAR EXHAUST

(Vented above floor level}

ELBOWHIGHLY

_ RECOMMENDED

(

RECOMMENDED

CONFIGURATION

TOMINiMiZE

EXHAUST

BLOCKAGE.

ELBOWHIGHLY

RECOMMENDED-

m r'--

NOTE: ELBOWS WILL PREVENT DUCT

KINKING AND COLLAPSING.

[] LEVELING DRYER

LEVEL

FRONT-TO-BACK.

LEVEL

SIDE-TO-SIDE.

THIS DRYER COMES READY FOR REAR

EXHAUSTING. IF SPACE IS LIMITED, USE

THE INSTRUCTIONS IN SECTION 9 TO

EXHAUST DIRECTLY FROM THE SIDES OR

BOTTOM OF THE CABINET.

STANDARD REAR EXHAUST

(Vented ot floor level)

FORSTRAIGHTLINEINSTALLATION,CONNECTTHEDRYEREXHAUSTTO

THEEXTERNALEXHAUSTHOODUSINGDUCTTAPEORCLAMR

CSA(AGA)APPROVED

NEWFLEXIBLEGAS

LINECONNECTOR

EXTERNAL

DUCT

OPENING

DUCTTAPEOR

DUCTCLAMP

NOTE:WESTRONGLYRECOMMENDSOLIDMETALEXHAUSTDUCTING.

HOWEVER,IF FLEXIBLEDUCTING IS USEDITMUST BE UL-LISTEDMETAL

NOTPLASTIC.

GAS

INLET

PIPE

4" METALDUCT

(CUTTOPROPER

LENGTH) DUCTTAPEOR

DUCTCLAYP

4LEVELINGLEGS

STANDTHEDRYERUPRIGHTNEARTHE

FINALLOCATIONANDADJUSTTHE4LEVELING

LEGSTOMATCHTHEHEIGHTOFYOURWASHER.

ADJUSTTHE2ANTI-TIPLEGSTOCONTACT

THEFLOOR.

2ANTI-TIPLEGS

5

Page 6

Installation Instructions

CONNECTING THE DRYERTO HOUSE VENT

RIGID METALTRANSITION DUCT

• Forbestdrying performance,a rigid metaltransitionductis

recommended.

• Rigidmetaltransitionsductsreducethe riskofcrushingandkinking.

UL-LISTEDFLEXIBLEMETAL(SEMI-RIGIDTRANSITIONDUCT

• If rigid metalduct cannot be used,then UL-listedflexible

metal(semi-rigid)ductingcanbe used(KitWX08XZ0077).

• Neverinstallflexiblemetal duct in walls,ceilings,floorsor

otherenclosedspaces.

• Totallengthofflexiblemetalductshouldnotexceed8feet(2.4m).

• Formany applications,installingelbowsat boththedryer

andthe wall ishighlyrecommended(seeillustrationsbelow).

Elbowsallowthe dryerto sit closeto the wallwithout kinking

andor crushingthetransition duct,maximizingdrying

performance.

• Avoidrestingthe ducton sharpobjects.

UL-LISTEDFLEXIBLEMETAL(FOIL-TYPE)TRANSITION DUCT

° Inspecialinstallations,it maybenecessaryto connectthe

dryerto the housevent usingaflexiblemetal(foiltype)duct.

A UL-listedflexiblemetal(foil-type)duct maybeusedONLY

ininstallationswhererigidmetalor flexiblemetal(semi-rigid)

ductingcannotbeusedANDwherea4"diametercanbe

maintainedthroughoutthe entirelengthof thetransitionduct.

• InCanadaand the UnitedStates,onlytheflexible metal(foil-

type)ductsthat complywith the"Outlinefor ClothesDryer

TransitionDuct Subject2158A"shallbe used.

• Neverinstallflexiblemetal duct in walls,ceilings,floorsor

otherenclosedspaces.

• Totallengthofflexiblemetalductshouldnotexceed8feet(2.4m).

• Avoidrestingthe ducton sharpobjects.

• Forbestdrying performance:

Z.Slideoneendof the duct overthe clothesdryeroutlet

pipe.

2.Securethe duct with a clamp.

3.With the dryerinits permanentposition,extendthe duct

to its full length.Allow2"ofduct to overlapthe exhaust

pipe.Cutoff and removeexcessduct. Keeptheductas

straightas possiblefor maximumairflow.

4.Securethe duct to theexhaust pipewith the otherclamp.

DO

EXCESSIVE

EXHAUST

LENGTH

(

[ ,LCOVE OR CLOSETINSTALLATION

• If yourdryer isapprovedfor installationin an alcoveor closet,

it will bestatedonalabelon thedryer back.

• Thedryer MUSTbe ventedto theoutdoors.Seethe EXHAUST

INFORMATIONsection.

• Minimumclearancebetween dryercabinet and adjacent

wallsor other surfacesis:

0in.either side

3in.front and rear

• Minimumvertical spacefrom floor to overheadcabinets,

ceiling,etc.is 52 in.

• Closetdoorsmust beIouveredor otherwiseventilatedand

mustcontain a minimumof 60sq.in.of openareaequally

distributed.Ifthe closet containsboth a washerand a dryer,

doorsmust contain a minimumof 120sq.in,of openarea

equallydistributed.

• Thecloset shouldbeventedto the outdoorsto preventgas

pocketingincaseof a gasleak inthe supplyline.

• Noother fuel-burningapplianceshallbe installedin the same

closetwith the dryer.

[i--O]BATHROOM OR BEDROOM INSTALLATION

• Thedryer MUSTbe ventedto the outdoors.SeeEXHAUST

INFORMATIONsection6.

• Theinstallation mustconform with localcodesor,in the

absenceof local codes,withthe NATIONALFUELGASCODE,

ANSIZ223.

ELBOWHIGHLY

RECOMMENDED

_WS HIGHLY

- RECOMMENDE_

[_]MOBILE OR MANUFACTUREDHOME INSTALLATION

• Installationmustconform tothe MANUFACTUREDHOME

CONSTRUCTION& SAFETYSTANDARD,TITLE24,PART32-80

or,when suchstandard isnotapplicable,with AMERICAN

NATIONALSTANDARDFORMOBILEHOME,NO.501B.

• Thedryer MUSTbe ventedto theoutdoorswith the

termination securelyfastenedto the mobilehomestructure.

(SeeEXHAUSTINFORMATIONsection6.)

• Thevent MUSTNOTbeterminated beneatha mobileor

manufactured home.

• Thevent duct materialMUSTBEMETAL.

• KIT14-D346-33MUSTbeusedto attachthe dryersecurelyto

the structure.

• Thevent HUSTNOTbeconnectedto anyother duct,vent, or

chimney.

• Donot usesheetmetal screwsor other refasteningdevices

which extendintothe interiorof theexhaustvent.

• Provideanopeningwith a free areaof at least25sq.in.or

introductionof outsideair intothe dryerroom.

• Stackingof a gasdryerisnot permitted in a mobilehomeor

manufactured home.

6

Page 7

Installation Instructions

I_IGARAGE INSTALLATION (IF ALLOWED

BY LOCAL CODES)

• Dryers installed in garages must be elevated 18 inches

(46cm) above the floor.

IT3-1DRYEREXHAUST TO RIGHT, LEFT

OR BOTTOM CABINET

WARNING - BEFOREPERFORMING

THIS EXHAUSTINSTALLATION, BE SURE

TO DISCONNECT THE DRYER FROM ITS

ELECTRICAL SUPPLY. PROTECT YOUR

HANDS AND ARMS FROM SHARP

EDGES WHEN WORKING INSIDE THE

CABINET. BE SURE TO WEAR GLOVES

REMOVE

SCREW

ANDSAVE.

ADDING NEW DUCT

FIXING

HOLE

PORTION"A"

LEFTSIDE

EXHAUST

Reconnectthe cut portion (A)of the duct to the blower

housing. Makesurethat the shortened duct isalignedwith

the tab inthe base.Usethe screw saved previouslgto secure

the duct in placethrough the tab on the appliance base.

ADDING ELBOW AND DUCT FOR

EXHAUST TO LEFT SIDE OF CABINET

• Preassemble 4" elbow with 4" duct. Wrap duct tape

around joint.

• Insert duct assembly, elbow first, through the side

opening and connect the elbow to the dryer internal

duct.

REMOVE,_)

DESIRED

KNOCKOUT

lONEONLY).

Detach and remove the bottom, right or left side knockout

as desired. Remove the screw inside the drger exhaust duct

and save. Pull the duct out of the drger.

Note: Onlg 4" round rigid metal ducting allowed inside

drger.

FIXINGHOLE

B A

9"

Cut the duct as shown and keep portion A.

TAB LOCATION

BENDTAB

UP45o

CAUTION: Besure not to pullor damage

theelectricalwiresinsidethedryerwhen insertingthe

duct.

EXHAUSTCAN __ __

BEADDEDTO _!I/ -:Sj_j _Mf

LEFTORR]GHTSIDE _

• Apply duct tape as shown on the joint between the

dryer internal duct and the elbow.

DUCT

,TAPE

CAUTION:

Internal duct joints must be

secured with tape, otherwise

they may separate and cause

a safetg hazard.

Through the rear opening, locate the tab in the middle of

the appliance base. Lift the tab to about/450 using a flat

blade screwdriver.

7

Page 8

Installation Instructions

ADDING ELBOW FOR EXHAUST

THROUGH BOTTOM OF CABINET

• Insert the elbow through the rear opening and connect

it to the dryer internal duct.

• Apply duct tape on the joint between the dryer internal

duct and elbow, as shown on page 7.

CAUTION:

Internal duct joints must be secured with tape,

otherwise they may separate and cause a

safety hazard.

ADDING COVER PLATE TO REAR OF

CABINET

[] CHANGING DIRECTION OF DOOR

OPENING

REMOVE4 HOLEPLUGSAND

REMOVE4

HINGESCREWS.

PLACETHEMINTHEHOLES

ONTHE OPPOSITESIDE.

PLATE

(KITWEII454)

Connect standard metal elbows and ducts to complete

the exhaust system. Cover back opening with a plate (Kit

WEllV1454)available from your local service provider.

Placedryer in final location.

WARNING-NEVER LEAVE THE BACK

OPENING WITHOUT THE PLATE.

ROTATEDOOR1800

AND REINSTALL.

8

Page 9

Installation Instructions

1_ CONNECTING INLET HOSES

(on some models)

To produce steam, the dryer must connect to the cold

water supply. Since the washer must also connect to the

cold water, a "Y"connector is inserted to allow both inlet

hoses to make that connection at the same time.

NOTE: Usethe new inlet hoses provided; never

use old hoses.

1.Turn the cold water faucet off. Remove the washer inlet

hose from the washer fill valve connector (cold).

2. Ensure the rubber fiat washer isin place and screw the

female coupling of the short hose onto the washer fill

valve connector. Tighten by hand until firmly seated.

3. Attach the female end of the "Y"connector to the

male coupling of the short hose. Ensure the rubber fiat

washer is in place.Tighten by hand until firmly seated.

4. Insert the filter screen in the coupling of the washer's

inlet hose. If a rubber flat washer isalready in place

remove it before installing the filter screen. Attach this

coupling to one male end of the "Y" connector. Tighten

by hand until firmly seated.

5. Ensure the rubber fiat washer isin place and attach the

dryer's long inlet hose to the other male end of the "Y"

connector. Tighten by hand until firmly seated.

6. Ensure the rubber fiat washer isin place and attach

the other end of the dryer's long inlet hose to the fill

valve connector at the bottom of the dryer back panel.

Tighten by hand until firmly seated.

[] CONNECTING INLET HOSES (cont.)

8.Turn the water fauceton.

9. Check for leaks around the "Y" connector, faucet and

hose couplings.

WATER SUPPLY REQUIREMENTS

Hot and cold water faucets IvlUSTbe installed within 42

in. (107 cm) of your wosher's water inlet. The faucets

IvIUSTbe 3/4 in. (1.9 cm) garden hose-type so inlet hoses

con be connected. Water pressure IvIUSTbe between 10

and 120 pounds per square inch. Your water department

con advise you of your water pressure.

NOTE:A water softener is recommended to reduce

buildup of scale inside the steam generator if the home

water supply isvery hard.

I-i-61SERVICING

WARNING- LABEL ALL WIRES

PRIOR TO DISCONNECTION WHEN

SERVICING CONTROLS. WIRING ERRORS

CAN CAUSE IMPROPER AND DANGEROUS

OPERATION AFTER SERVICING/

INSTALLATION.

Forservicing phone numbers for replacement parts, and

other information, refer to Owner's Manual or visit our

Web site.

REGISTERYOUR NEW APPLIANCE TO RECEIVEANY

IMPORTANT PRODUCT NOTIFICATIONS.

7. Using pliers,tighten all the couplings with an additional

two-thirds turn.

NOTE: Do not overtighten. Damage to the couplings may

result.

Pleose go to www.GEAppliunces.com or moil in your

Product Registrotion Cord.

For questions on installation, coil: 800.626.2000 (US)or

800-561-3344 (Canada).

9

Page 10

Notes

10

Page 11

Notes

1!

Loading...

Loading...