GE DNCD450GGAWC, GRDN510GM0WS, GTDN500GM0WS, GTDN500GM2WS, GTDP200GM2WW Installation Guide

...Page 1

Installation

Instructions

Gas Drger

Questions on installation? Call: 1-800-GECARES (US)

or Visit ou r Web site at: www.GEAppliances.com (US)

BEFOREYOU BEGIN

Read these instructions completely and

carefully.

•IMPORTANT- Savethese instructions for

local inspector's use.

•IMPORTANT- Observe all governing codes

and ordinances.

• Noteto Installer - Besureto leavethese

instructionswith the customer.

• Note to Customer - Keep these instructions

with gour Use and Care Book for future

reference.

• Before the old drger is removed from service or

discarded, remove the drger door.

• Inspect the drger exhaust outlet and straighten

the outlet walls if theg are bent.

• Service information and the wiring diagram

are located in the control console.

• Do notallow children on or inthe appliance.

Close supervisionof children is necessarg when

the applianceis used near children.

• Install the drgerwhere the temperatureis

aboveSO°Ffor satisfactorg operationof the

drger controlsgstem.

WARNING RBKOFFIRE

Toreducethe riskof severeinjurg or death,followall installation instructions.

Clothesdrger installationmust beperformed bg a qualified installer.

Installthe clothesdrger accordingto theseinstructions and in accordancewith local

codes.Intheabsenceof localcodes,installationmust comptgwith NationalFuelGas

Code,ANSIZ225.1/NFPA54or the CanadianNatural Gasand PropaneInstallationCode,

CSAB149.1.

ColifomioSafeDrinkingWaterond ToxicEnforcementAct.

Thisact requiresthe governor of Californiato publisha list of substancesknownto the

stateto causecancer,birth defectsor other reproductiveharm and requiresbusinesses

to warn customersof potentialexposureto suchsubstances.Gasappliancescan

causeminorexposuretofour of thesesubstances,namelgbenzene,carbonmonoxide,

formaldehgdeand soot,causedprimaritg bg the incompletecombustion of naturalgas

or LPfuels.Properlgadjusteddrgerswiltminimizeincompletecombustion.Exposure

to these substancescanbe minimizedfurther bg properlgventing the drger to the

outdoors.

Thisdrger must beexhaustedto theoutdoors.

Useonlg4"rigid metal ducting for exhaustingthe clothesdrger to the outdoors.

DONOTinstallaclothesdrger with flexibleplastic ducting materials.Ifflexible metal

(semi-rigidorfoit-tgpe)duct isinstalled,it mustbe ULlistedand installed inaccordance

with theinstructionsfound in "ConnectingTheDrgerTo HouseVent"on page6of this

manual.Flexibleventing materialsare knownto collapse,beeasilgcrushed,and trap

lint.Theseconditionswilt obstructdrger airflowandincreasethe risk offire.

Donotinstallor storethis appliance in ang locationwhereit could be exposedto water

andorweather.

Drgersinstalledinresidentialgaragesmust beelevated 18"(46cm)abovethefloor.

Savetheseinstructions.(Installers:Besureto leavethese instructionswith the

customer).

in the state of Massachusetts,installation must beperformed bya qualifiedor

licensedcontractor, plumber, or gasfitter qualified or licensedby the state.

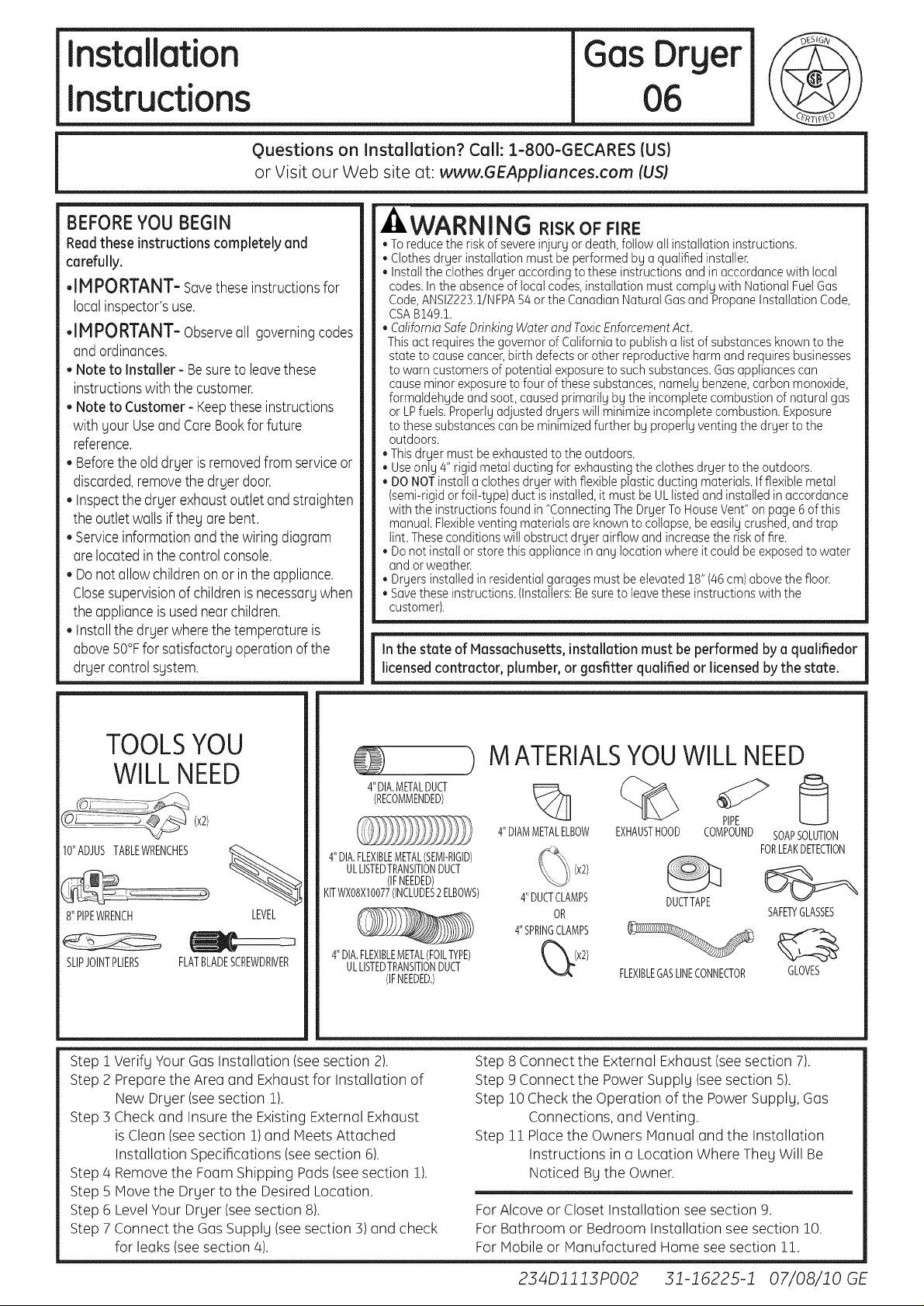

TOOLSYOU

WILLNEED

(x2)

IO"ADJUSTABLEWRENCHES _.

8"PIPEWRENCH LEVEL

SLIPJOINTPLIERS FLATBLADESCREWDRIVER

Verifg Your Gas Installation (seesection 2).

Step 1

Prepare the Area and Exhaust for Installation of

Step 2

New Drger (see section 1).

Check and Insure the Existing External Exhaust

Step 3

is Clean (seesection 1)and Meets Attached

Installation Specifications (see section 6).

Step 4 Remove the Foam Shipping Pads (seesection 1).

Step 5 Move the Drger to the Desired Location.

Step 6 Level Your Drger (seesection 8).

Step 7 Connect the Gas Supplg (seesection 3) and check

for leaks (see section 4).

4"DIA.METALDUCT I====_

(RECOMMENDED)

4"DIA.FLEXIBLEMETAL(SEMI-RIGID)

ULLISTEDTRANSITIONDUCT

(IFNEEDED)

KITWXO8X10077(INCLUDES2ELBOWS) 4"DUCTCLAMPS

4"DIA.FLEXIBLEMETAL(FOILTYPE) _(x2)

ULLISTEDTRANSITIONDUCT

(IFNEEDED.)

MATERIALSYOUWILLNEED

4"DIAMMETALELBOW

4"SPRINGCLAMPS

EXHAUSTHOOD COMPOUND

DUCTTAPE

FLEXIBLEGASLINECONNECTOR

Step 8 Connect the External Exhaust (see section 7).

Step 9 Connect the Power Supplg (seesection 5).

Step 10 Check the Operation of the Power Supplg, Gas

Connections, and Venting.

Step 11 Place the Owners Manual and the Installation

Instructions in a Location Where Theg Will Be

Noticed Bg the Owner.

For Alcove or Closet Installation see section 9.

For Bathroom or Bedroom Installation see section 10.

For Mobile or Manufactured Home see section 11.

PIPE

SOAPSOLUTION

FORLEAKDETECTION

SAFETYGLASSES

GLOVES

234Dll13PO02 31-16225-1 07/08/10 GE

Page 2

Installation instructions

Minimum Clearance Other Than Alcove or Closet Installation

Minimum clearance to combustible surfaces and for air opening are: 0 in. clearance both sides and 1in. rear.

Consideration must be given to provide adequate clearance for installation and service.

m PREPARING FOR INSTALLATION

OF NEW DRYER

TIP:Install your dryer before installing your washer.

This will allow better access when installing dryer

exhaust.

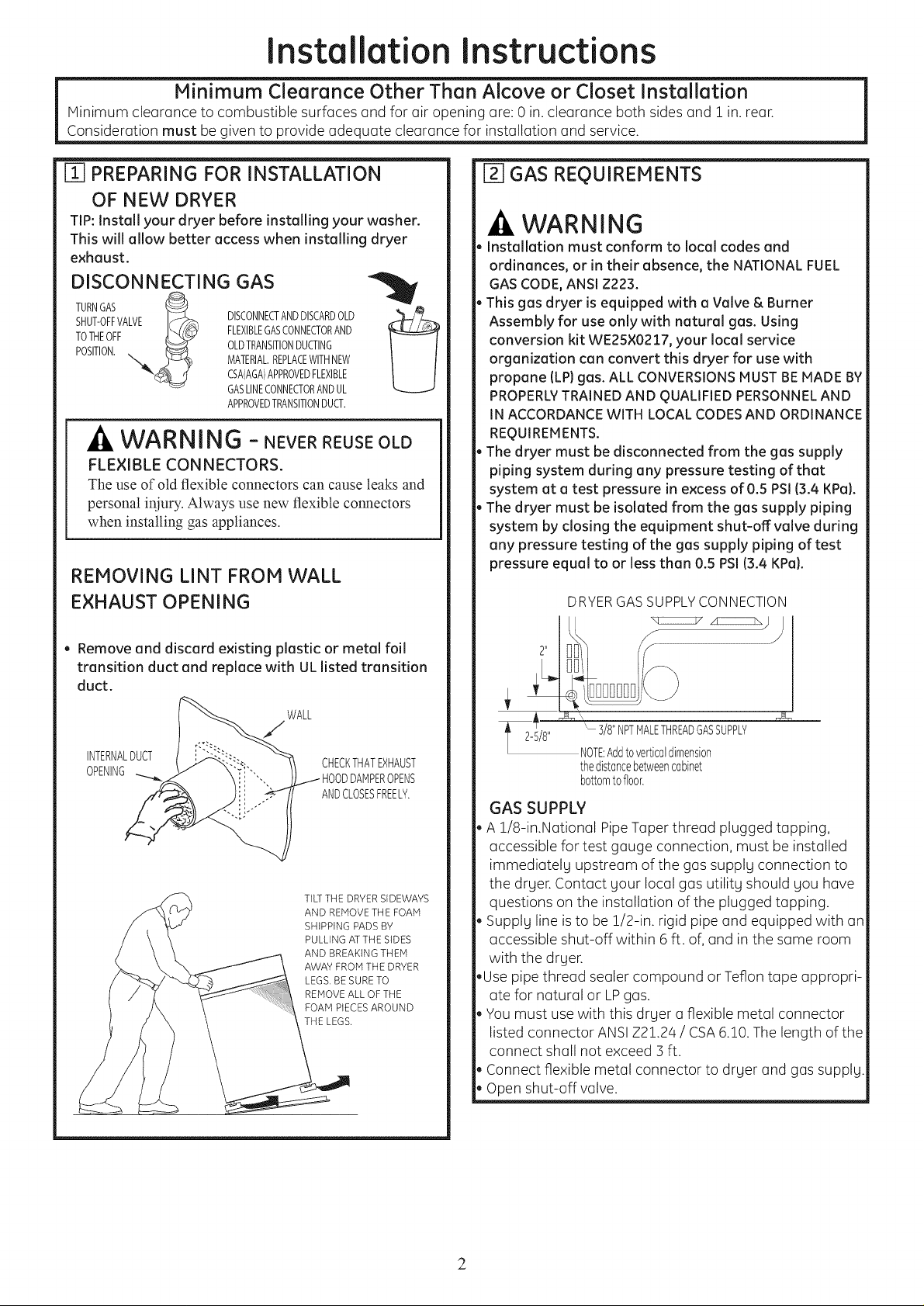

DISCONNECTING GAS

TURNGAS

SHUT-0FFVALVE IC?_ DISCONNECTANDDISCARDOLD f}_!/__

TOTHEOFF

POSITION.,,,_ OLDTRANSITIONDUCTING

j -,_ FLEXIBLEGASCONNECTORAND

MATERIAL.REPLACEWITHNEW

CSA(AGA)APPROVEDFLEXIBLE

GASLINECONNECTORANDUL

APPROVEDTRANSITIONDUCT.

WARNING - NEVERREUSEOLD

FLE×IBLE CON NECTORS.

The use of old flexible connectors can cause leaks and

personal iniury. Always use new flexible connectors

when installing gas appliances.

REMOVING LINT FROM WALL

EXHAUST OPENING

[] GAS REQUIREMENTS

WARNING

Installation must conform to local codes and

ordinances, or in their absence, the NATIONAL FUEL

GASCODE,ANSI Z223.

This gas dryer is equipped with a Valve & Burner

Assembly for use only with natural gas. Using

conversion kit WE25×0217, your local service

organization can convert this dryer for use with

propane {LP)gas. ALL CONVERSIONSlUST BEMADE BY

PROPERLYTRAINED AND QUALIFIEDPERSONNELAND

IN ACCORDANCEWITH LOCALCODESAND ORDINANCE

REQUIREMENTS.

The dryer must be disconnected from the gas supply

piping system during any pressure testing of that

system at a test pressure in excess of O.5 PSI{3.4 KPa).

The dryer must be isolated from the gas supply piping

system by closing the equipment shut-off valve during

any pressure testing of the gas supply piping of test

pressure equal to or less than 0.5 PSI(3.4 KPa).

DRYER GAS SUPPLY CONNECTION

xc:_ z:E_ j

, Remove and discard existing plastic or metal foil

transition duct and replace with ULlisted transition

duct.

WALL

INTERNALDUCT

OPENING OPENS

CHECKTHATEXHAUST

ANDCLOSESFREELY.

TILTTHE DRYERSIDEWAYS

AND REMOVE THE FOAM

SHIPPING PADS BY

PULLING AT THE SIDES

AND BREAKING THEM

AWAY FROM THE DRYER

LEGS, BE SURE TO

REMOVE ALL OF THE

FOAM PIECESAROUND

THE LEGS.

' 318"NPTHALETHREADGASSUPPLY

NOTE:Addtoverticoldimension

thedistancebetweencobinet

bottomtofloor.

GAS SUPPLY

A 1/8-in.National PipeTaper thread plugged tapping,

accessible for test gauge connection, must be installed

immediatelg upstream of the gas supplg connection to

the drger. Contact sour local gas utilitg should Sou have

questions on the installation of the plugged tapping.

Supplg line isto be 1/2-in. rigid pipe and equipped with an

accessible shut-off within 6 ft. of, and in the same room

with the drger.

Use pipe thread sealer compound orTeflon tape appropri-

ate for natural or LPgas.

You must use with this drger a flexible metal connector

listed connector ANSIZ21.24 / CSA6.10. The length of the

connect shall not exceed 3 ft.

Connect flexible metal connector to drger and gas supplg.

Open shut-off valve.

2

Page 3

Installation

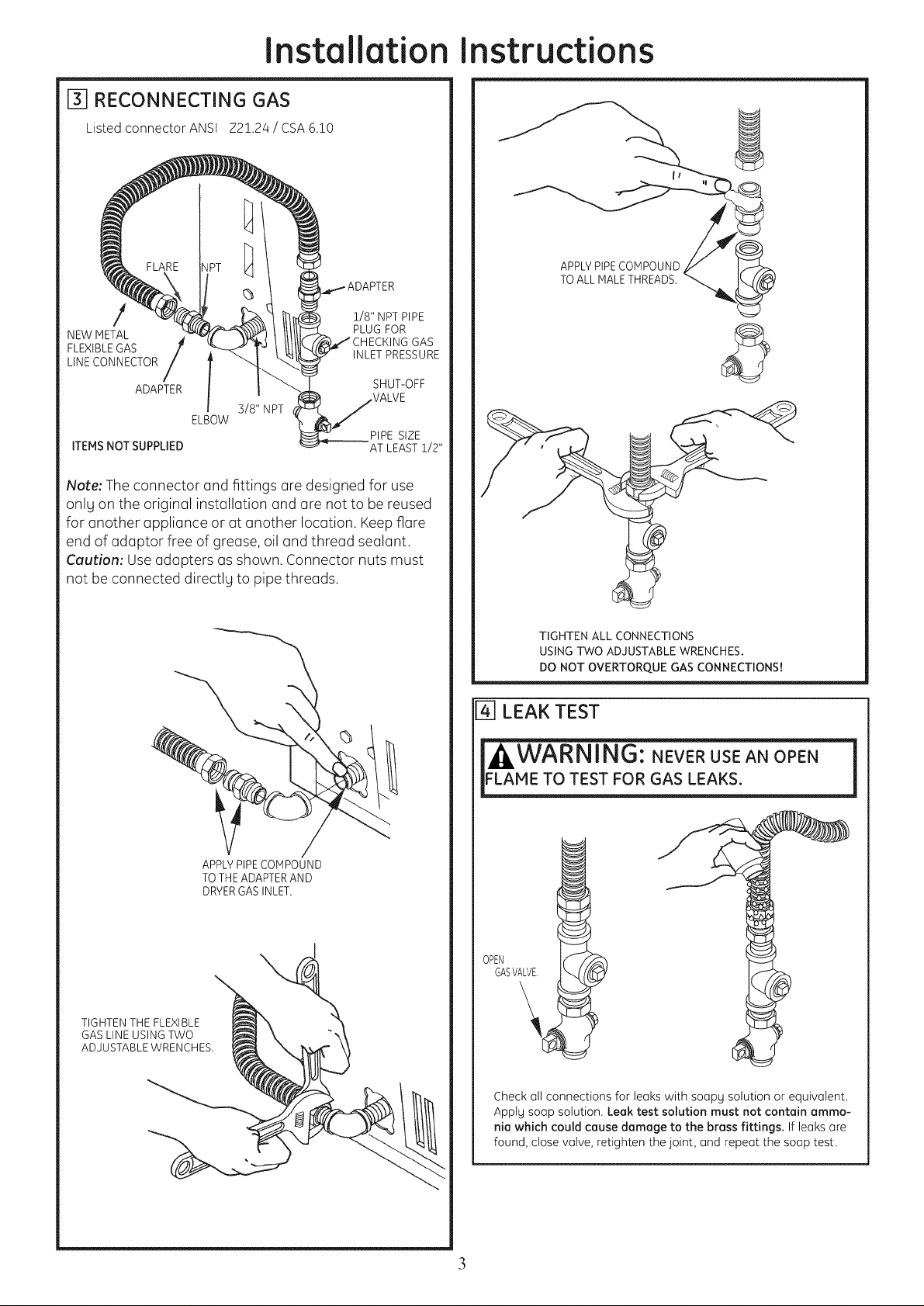

_] RECONNECTING GAS

Listed connector ANSI Z2!.24 / CSA 6.!0

1/8" NPTPIPE

NEW METAL PLUG FOR

FLEXIBLEGAS INLETPRESSURE

LINECONNECTOR

ADAPTER

3/8" NPT

ELBOW

ITEMSNOT SUPPLIED _AT LEAST1/2"

Note: The connector and fittings (]re designed for use

onlg on the original installation and (]re not to be reused

for another appliance or at another location. Keep flare

end of adaptor free of grease, oil and thread sealant.

Caution: Use adapters as shown. Connector nuts must

not be connected directlg to pipe threads.

GAS

SHUT-OFF

PIPE SIZE

Instructions

APPLYPIPECOMPOUND

TOALL HALETHREADS.

TIGHTEN THE FLEXIBLE

GAS LINE USING TWO

ADJUSTABLE WRENCHES.

APPLYPIPECOHPOUND

TOTHEADAPTERAND

DRYERGASINLET.

TIGHTEN ALL CONNECTIONS

USINGTWO ADJUSTABLE WRENCHES.

DO NOT OVERTORQUE GAS CONNECTIONS!

[-4]LEAK TEST

"WARNING: NEVERUSEAN OPEN

LAME TO TEST FOR GAS LEAKS.

OPEN

GASVALVE,

Check oil connections for teaks with soopg solution or equivalent.

Apptg soop solution. Leak test solution must not contain ammo-

nia which could cause damage to the brass fittings. If leaks ore

found, close volve, retighten the joint, and repeGt the soap test.

3

Page 4

Installation

Instructions

[-_ ELECTRICAL CONNECTION

INFORMATION

m

WARNING - TOREDUCETHE

RISK OF FIRE, ELECTRICAL SHOCK,

AND PERSONAL INJURY:

. DO NOTUSEAN EXTENSIONCORDORAN ADAPTER

PLUGWITH THIS APPLIANCE.

Dryer must be electrically grounded in accordance

with local codes and ordinances, or in the absence

of local codes, in accordance with the NATIONAL

ELECTRICALCODE,ANSI/NFPANO.70.

ELECTRICAL REQUIREMENTS

This appliance must be supplied with 120V,60Hz, and

connected to a properly grounded branch circuit,

protected by a 15- or 20- amp circuit breaker or time-

delay fuse. Ifelectrical supply provided does not meet the

above specifications, it is recommended that a licensed

electrician install an approved outlet.

,A,WARNING -THISDRYERIS

EQUIPPED A THREE-PRONG (GROUNDING)

PLUG FOR YOUR PROTECTION AGAINST

SHOCK HAZARD AND SHOULD BE PLUGGED

DIRECTLY INTO A PROPERLY GROUNDED

THREE-PRONG RECEPTACLE. DO NOT CUT

OR REMOVE THE GROUNDING PRONG FROM

THIS PLUG.

[-6-]EXHAUST INFORMATION

WARNING -IN CANADAANDINTHE

UNITED STATES,THE REQUIRED EXHAUST DUCT

DIAMETER IS 4 IN (102ram). DO NOT USEDUCT

LONGER THAN SPECIFIED INTHE EXHAUST

LENGTH TABLE.

Usingexhaustlongerthan specifiedlengthwill:

• Increasethedrying times andthe energycost.

• Reducethe dryer life.

• Accumulatelint,creatinga potential firehazard.

Thecorrect exhaustinstallation is YOURRESPONSIBILITY.

Problemsdueto incorrect installation are not coveredby

the warranty.

Removeanddiscordexisting plasticor metalfoil transition

duct and replacewith ULlistedtransition duct.

TheMAXIMUMALLOWABLEductlength and numberof

bendsof theexhaust systemdependsupon thetype ofduct,

numberof turns,the tgpe ofexhausthood(wallcap),and all

conditionsnoted below.Themaximumduct length for rigid

metal duct isshowninthetable below.

EXHAUST LENGTH

RECOMHENDEDHAXIHUH LENGTH

Exhaust Hood Tgpes

Recommended Use only for short

4" J_

No. of 90° Rigid

Elbows Metal

0 60 Feet

1 45 Feet

2 35 Feet

3 25 Feet

4 15 Feet

Rigid

Metal

90 Feet

60 Feet

45 Feet

35 Feet

25 Feet

run installations

4" DIA.

_l J..... 21/2"

ENSUREPROPERGROUND EXISTSBEFOREUSE.

IF LOCAL CODES PERHIT,

AN EXTERNAL GROUND WIRE

(NOT PROVIDED), WHICH HEETS

LOCAL CODES, HAY BE ADDED

BYATTACHING TO THE GREEN

GROUND SCREW ON THE REAR

OF THE DRYER,AND TO A GROUNDED

METAL COLD WATER PIPE OR OTHER

ESTABLISHED GROUND.

EXHAUST SYSTEM CHECK LIST

HOOD ORWALL CAP

• Terminateina manner to preventback draftsor entrgof birds

or otherwildlife.

• Terminationshouldpresentminimalresistanceto the exhaust

air flow and shouldrequirelittleor nomaintenanceto prevent

clogging.

•Neverinstalla screenin or overtheexhaust duct.Thiscould

causelint buildup.

• Wallcapsmust beinstalledat least12 in.abovegroundlevel

or any otherobstructionwith the openingpointeddown.

SEPARATIONOF TURNS

Forbest performance,separateallturns bgat least4 ft. of

straightduct, includingdistance betweenlastturn andexhaust

hood.

TURNSOTHERTHAN90°

• Oneturn of 45°or lessmeg beignored.

• Two450turnsshouldbetreated as one 900turn.

• Eachturn over450shouldbetreatedasone 900turn.

SEALINGOFJOINTS

• Alljointsshouldbetight to avoidleaks.Themaleendof each

sectionof duct must pointawagfromthe dryer.

• Donotassemblethe ductwork with fastenersthat extend into

the duct. Theywillserveasa collectionpointfor lint.

• Ductjoints can bemadeair and moisture-tightby wrapping

the overlappedjoints withduct tape.

• Horizontalrunsshouldslopedown toward theoutdoors l_inch

per foot

INSULATION

Ductwork that runs throughanunheatedareaor is near air

conditioningshouldbe insulatedto reducecondensationand

lintbuild-up.

4

Page 5

Installation instructions

[_ EXHAUST CONNECTION

WARNING - TOREDUCETHE

RISK OF FIRE OR PERSONAL INJURY:

* This clothes drger must be exhausted to the outdoors,

* Use onlg 4" rigid metal ducting for the home exhaust

duct.

* Use onlg 4" rigid metal or UL-listed flexible metal

(semi-rigid or foil-tgpe) duct to connect the drger

to the home exhaust duct. It must be installed

in accordance with the instructions found in

"Connecting The Drger To HouseVent" on page 6 of

this manual.

*Do not terminate exhaust in a chimneg, a wall,

a ceiling, gas vent, crawl space, attic, under an

enclosed floor, or in ang other concealed space of

a building. The accumulated lint could create a fire

hazard.

* Never terminate the exhaust into a common duct

with a kitchen exhaust sgstem. A combination of

grease and lint creates a potential fire hazard.

* Do not use duct longer than specified in the exhaust

length table. Longer ducts can accumulate lint,

creating a potential fire hazard.

*Never install a screen in or over the exhaust duct. This

will cause lint to accumulate, creating a potential fire

hazard.

* Do not assemble ductwork with ang fasteners

that extend into the duct. These fasteners can

accumulate lint, creating a potential fire hazard.

* Do not obstruct incoming or exhausted air.

* Provide an access for inspection end cleaning of

the exhaust sgstem, especiallg at turns and joints.

Exhaust sgstem shell beinspected end cleaned at

least once gear.

STANDARD REAR EXHAUST

(Vented obove floor level}

ELBOWHIGHLY

"-/'-_/¢RECOMMENDED

RECOMMENDED

CONFIGURATION

TOMINIMIZE

EXHAUST

BLOCKAGE,

ELBOWHIGHLY

RECOMMENDED-

NOTE: ELBOWS WILL PREVENT DUCT

KINKING AND COLLAPSING.

[] LEVELING DRYER

LEVEL

FRONT-TO-BACK,

"-.,.

LEVEL

SIDE-TO-SIDE.

THIS DRYER COMES READY FOR REAR

EXHAUSTING. IF SPACE IS LIMITED, USE

THE INSTRUCTIONS IN SECTION 9 TO

EXHAUST DIRECTLY FROM THE SIDES OR

BOTTOM OF THE CABINET.

STANDARD REAR EXHAUST

{Vented ot floor level}

FORSTRAIGHTLINEINSTALLATION,CONNECTTHEDRYEREXHAUSTTO

THEEXTERNALEXHAUSTHOODUSINGDUCTTAPEORCLAMR

CSA)AGA)APPROVED

NEWFLEXIBLEGAS

LINECONNECTOR

EXTERNAL

DUCT

OPENING

DUCTTAPEOR

DUCTCLAMP

NOTE:WE STRONGLYRECOMMENDSOLID METALEXHAUSTDUCTING.

HOWEVER,IFFLEXIBLEDUCTINGISUSEDITMUST BE UL-LISTEDMETAL

NOTPLASTIC.

GAS

INLET

PIPE

4IIMETALDUCT

(CUTTOPROPER

LENGTH) DUCTTAPEOR

DUCTCLAMP

4LEVELINGLEGS

STANDTHEDRYERUPRIGHTNEARTHE

FINALLOCATIONANDADJUSTTHE4 LEVELING

LEGSTOMATCHTHEHEIGHTOFYOURWASHER,

ADJUSTTHE2ANTI-TIPLEGSTOCONTACT

THEFLOOR,

5

2ANTI-TIPLEGS

Page 6

Installation

CONNECTING THE DRYER

TO HOUSE VENT

RIGIDMETALTRANSITIONDUCT

• Forbest drying performance,a rigid metaltransitionduct is

recommended.

• Rigidmetaltransitionsducts reducetheriskof crushingand

kinking.

UL-LISTEDFLEXIBLEMETAL(SEMI-RIGIDTRANSITIONDUCT

• tfrigid metulduct cannot be used,thenUL-listedflexiblemetul

(semi-rigid)ducting cun beused(KitWX08X10077).

Neverinstullflexible metulduct inwulls,ceilings,floors or

otherenclosedspaces.

Total lengthof flexiblemetal duct shouldnot exceed8 feet

(2.4m).

Formany applications,installingelbowsat boththedryer

undthe wull ishighly recommended(seeillustrutionsbelow).

Elbowsullowthe dryerto sitclosetothe wallwithout kinking

andor crushingthetransition duct,maximizingdrying

performance.

Avoidrestingthe duct on sharpobjects.UL-LISTEDFLEXIBLE

METAL(FOIL-TYPE}TRANSITIONDUCT

• tnspeciulinstullutions,it muy be necessurgto connectthe

dryerto the housevent usingu flexiblemetul(foiltype)duct.

A UL-listedflexiblemetul (foil-type)ductmuy be usedONLY

in instullutionswhererigid metulor flexiblemetul (semi-rigid)

ductingcunnot be usedANDwhereu4" diumeter cun be

muintuinedthroughout theentire lengthof thetrunsition

duct.

tnConuduundthe UnitedStutes,only theflexiblemetul(foil-

type) ductsthut comply with the "Outlinefor ClothesDryer

TrunsitionDuct Subject2158A"shullbe used.

Neverinstullflexible metulduct inwulls,ceilings,floors or

otherenclosedspuces.

Totul lengthof flexiblemetul duct shouldnot exceed8 feet

(2.4m).

Avoidrestingthe duct on shurpobjects.

Forbest drying performunce:

1.Slideoneendof theduct overthe clothesdryer

outlet pipe.

2.Securethe duct with u clump.

3.With the dryer initspermunent position,extendthe

duct to itsfull length.Allow2"of duct to overlupthe

exhuustpipe.Cut off und removeexcessduct. Keep

theduct usstruight us possiblefor muximumuirflow.

4.Securethe duct to theexhuust pipewith the other

clump.

ELBOWHIGHLY

REC0

"_<._ _ ELBOWSHIGHLY

d

Instructions

DONOTUSE

EXCESSIVE

EXHAUST

LENGTH

F9-1ALCOVE OR CLOSET INSTALLATION

• tfyourdryer isapprovedfor installationinan alcoveor closet,

it will bestatedon alabelon thedryer back.

• Thedryer MUSTbevented tothe outdoors.Seethe EXHAUST

INFORMATIONsection.

• Minimumcleuruncebetweendryercubinetundudjucent

wullsor other surfacesis:

0in.either side

3 in.front andrear

Minimumvertical spacefrom floorto overheadcabinets,

ceiling,etc.is 52 in.

Closetdoorsmustbe Iouveredorotherwise ventilatedand

mustcontain a minimumof 60sq.in. of openareaequally

distributed,ifthe closetcontainsboth a washeranda dryer,

doorsmust contain a minimumof 120sq.in,of openarea

equallydistributed.

Thecloset shouldbe ventedto the outdoorsto preventgas

pocketingincaseof a gasleukin the supplyline.

Noother fuel-burningappliance shallbeinstulledinthe some

closetwith the dryer.

I1OIBATHROOM OR BEDROOM INSTALLATION

• Thedryer MUSTbevented tothe outdoors.SeeEXHAUST

INFORMATIONsection 6.

• Theinstullationmustconformwith Ioculcodesor,inthe

ubsenceof Ioculcodes,with theNATIONALFUELGASCODE,

ANSIZ223.

[_]MOBILE OR MANUFACTUREDHOME INSTALLATION

• tnstullationmust conformto the MANUFACTUREDHOME

CONSTRUCTION& SAFETYSTANDARD,TITLE24,PART32-80

or,when suchstundard isnotapplicuble,with AMERICAN

NATIONALSTANDARDFORMOBILEHOME,NO.50lB.

• Thedryer MUSTbevented tothe outdoorswith the

terminution securelyfastenedto the mobilehomestructure.

(SeeEXHAUSTINFORMATIONsection6.)

• Thevent MUSTNOTbeterminutedbeneuthu mobileor

manufactured home.

• Thevent duct muteriul MUSTBEMETAL.

• KIT14-D346-33MUSTbe usedto uttuch thedryer securelyto

the structure.

• Thevent MUSTNOTbeconnectedto uny otherduct, vent,or

chimney.

• Donot usesheet metulscrewsor other refusteningdevices

which extendintothe interiorof theexhaustvent.

• Provideun openingwith u freeareuof ut leust25sq.in.or

introductionof outsideuir intothe dryer room.

6

Page 7

Installation

Instructions

[f2]DRYER EXHAUST TO RIGHT, LEFT

OR BOTTOM CABINET

THIS EXHAUST INSTALLATION, BE SURE

TO DISCONNECT THE DRYER FROM ITS

ELECTRICAL SUPPLY. PROTECT YOUR

HANDS AND ARMS FROM SHARP

EDGES WHEN WORKING INSIDE THE

CABINET. BE SURE TO WEAR GLOVES

/ .......

i

REMOVE

SCREW

ANDSAVE.

REMOVEjO

DESIRED

KNOCKOUT

(ONEONLY).

Detach and remove the bottom, right or left side knockout

us desired. Remove the screw inside the drger exhaust duct

and save. Pull the duct out of the dryer.

Note: Only 4" round rigid metal ducting allowed inside

dryer. FIXINGHOLE

ADDING NEW DUCT

FIXING

HOLE

PORTION"A"

LEFTSIDE

EXHAUST

Reconnectthe cut portion (A)of the duct to the blower

housing. Makesurethat the shortened duct isaligned with

the tab inthe base.Usethe screw saved previouslgto secure

the duct in place through the tab on the appliance base.

ADDING ELBOW AND DUCT FOR

EXHAUST TO LEFT SIDE OF CABINET

. Preassemble 4" elbow with 4" duct. Wrap duct tope

around joint.

. Insert duct assemblg, elbow first, through the side

opening and connect the elbow to the drger internal

duct.

CAUTION: Be sure not to pull or damage the

electrical wires inside the dryer when inserting the

duct.

B A

9"

Cut the duct as shown and keep portion A.

TAB LOC/_TION

BENDTAB

UP45o

Through the rear opening, locate the tab in the middle of

the appliance base. Lift the tab to about 45o using aflat

blade screwdriver.

DUCT

TAPE

, Applg duct tape as shown on the joint between the

drger internal duct and the elbow.

,TAPE CAUTION:

Internal ductjoints must be

secured with tape, otherwise

they may separate and cause

a safety hazard.

7

Page 8

Installation

Instructions

ADDING ELBOW FOR EXHAUST

THROUGH BOTTOM OF CABINET

, Insert the elbow through the rear opening and connect

itto the drger internal duct.

Applg duct tape on the joint between the drger internal

duct and elbow, us shown on page 7.

.J

CA

Internal duct joints must be secured with tape,

otherwise they may separate and cause a

safety hazard.

ADDING COVER PLATE TO REAR OF

CABINET

CHANGING DIRECTION OF

DOOR OPENING

REMOVE/4HOLEPLUGSAND

REMOVE4

HINGESCREWS.

PLACETHEIViINTHEHOLES

ONTHEOPPOSITESIDE.

PLATE

(KITWE1H858)

Connect standard metal elbows and ducts to complete

the exhaust sgstem. Cover back opening with a plate (Kit

WE11V1454)available from gout local service provider.

Placedrger in final location.

,_WARNING-NEVER LEAVE THE BACK

OPENING WITHOUT THE PLATE.

ROTATEDOOR1800

ANDREINSTALL.

8

Page 9

Installation

Instructions

[_] CONNECTING INLET HOSES

(onsome models)

To produce steam, the drger must connect to the cold

water supplg. Sincethe washer must also connect to the

cold water, a "`7"connector is inserted to allow both inlet

hoses to make that connection at the some time.

NOTE:Use the new inlet hoses provided; never

use old hoses.

1.Turn the cold water faucet off. Removethe washer inlet

hose from the washer fill valve connector (cold).

2. Ensure the rubber fiat washer isin place and screw

the female coupling of the short hose onto the washer fill

valve connector. Tighten bg hand until firmlg seated.

3. Attach the female end of the ",7"connector to the male

coupling of the short hose. Ensurethe rubber fiat washer

is in place. Tighten bg hand until firmlg seated.

4. Insert the filter screen inthe coupling of the washer's

inlet hose. If a rubber fiat washer

isalreadg in place remove it before installing

the filter screen. Attach this coupling to one male end of

the "`7"connector. Tighten bg hand until firmlg seated.

5. Ensure the rubber fiat washer isin place and attach

the drger's long inlet hose to the other male end of the

"`7"connector. Tighten bg hand until firmlg seated.

6. Ensure the rubber fiat washer isin place and attach

the other end of the drger's long inlet hose to the fill valve

connector at the bottom of the drger back panel. Tighten

bg hand until firmlg seated.

[_ CONNECTING INLET HOSES {cont.}

8. Turn the water faucet on.

9. Check for leaks around the '"7"connector,

faucet and hose couplings.

WATER SUPPLY REQUIREMENTS

Hot and cold water faucets MUSTbe installed within z_2

in. (107 cm) of gour washer's water inlet. The faucets

MUSTbe 3//4 in. (1.9cm)garden hose-tgpe so inlet hoses

can be connected. Water pressure MUSTbe between 10

and 120 pounds per square inch. ,Tourwater department

can advise gou of gour water pressure.

NOTE:A water softener is recommended to reduce

buildup of scale inside the steam generator if the home

water supplg is verg hard.

[_]SERVICING

WARNING- LABEL ALL WIRES

PRIOR TO DISCONNECTION WHEN

SERVICING CONTROLS. WIRING ERRORS

CAN CAUSE IMPROPER AND DANGEROUS

OPERATION AFTER SERVICING/

INSTALLATION.

For replacement parts and other information, refer to

Owner's Manual for servicing phone numbers.

7. Using pliers, tighten all the couplings with

an additional two-thirds turn.

NOTE:Do not overtighten. Damage to the couplings mag

result.

For Questions on Installation, Call: 1-800-626-2000 (US)or

1-800-561-33/4/4(Canada).

9

Loading...

Loading...