GE DNCD450EG9WC, GHDX100EM0WW, GRDN510EM0WS, GRDN510EM2WS, GRDN510GM2WS Installation Guide

...

Installation

ElectricDryer

Instructions

Questions on installation? calk 1-800-GECARES (US)

or Visit our Web site at: www.GEAppliunces.com (US)

BEFORE YOU BEGIN

Readtheseinstructionscompletelyandcarefully.

•IMPORTANT- Save these instructionsfor

localinspector'suse.

•IMPORTANT- Observeall governingcodes

andordinances.

• Note to Installer - Besureto leavethese

instructionswith the customer.

• Note to Customer - Keeptheseinstructions

with your Useand CoreBookforfuture

reference.

• Beforethe old dryeris removedfrom serviceor

discorded,removethe dryerdoor.

• Inspectthe dryerexhaustoutlet andstraighten

the outlet wallsif they arebent.

• Serviceinformation andthe wiringalia-gram

arelocated inthe controlconsole.

• Do notallowchildrenon or inthe appliance.

Closesupervisionofchildren isnecessary

whenthe applianceis usednearchildren.

• Installthe dryerwherethe temperature is

above50°Ffor satisfactory operationof the

dryercontrol system.

O5

WARNING ruSKOFFree

, Toreduce the risk of severe injury or death, follow all installation

instructions.

, Clothes dryer installation must be performed by a qualified installer.

, Install the clothes dryer according to these instructions and in

accordance with local codes.

, Thisdryer must be exhausted to the outdoors.

, Useonly 4" rigid metal ducting for exhausting the clothes dryer to the

outdoors.

, DO NOTinstall a clothes dryer with flexible plastic ducting materials.

If flexible metal (semi-rigid orfoil-type) duct is installed, it must be

ULlisted and installed in accordance with the instructions found in

"Connecting The Dryer To House Vent" on page 5 of this manual.

Flexible venting materials are known to collapse, be easily crushed,

and trap lint. These conditions will obstruct dryer airflow and increase

the risk of fire.

, Do not install or store this appliance in any location where it could be

exposed to water and or weather.

, Save these instructions. (Installers: Besure to leave these instructions

with the customer).

NOTE: Installation and service of this dryer requires basic

mechanical and electrical skills. It is your responsibility to

contact a qualified installer to make the electrical connections.

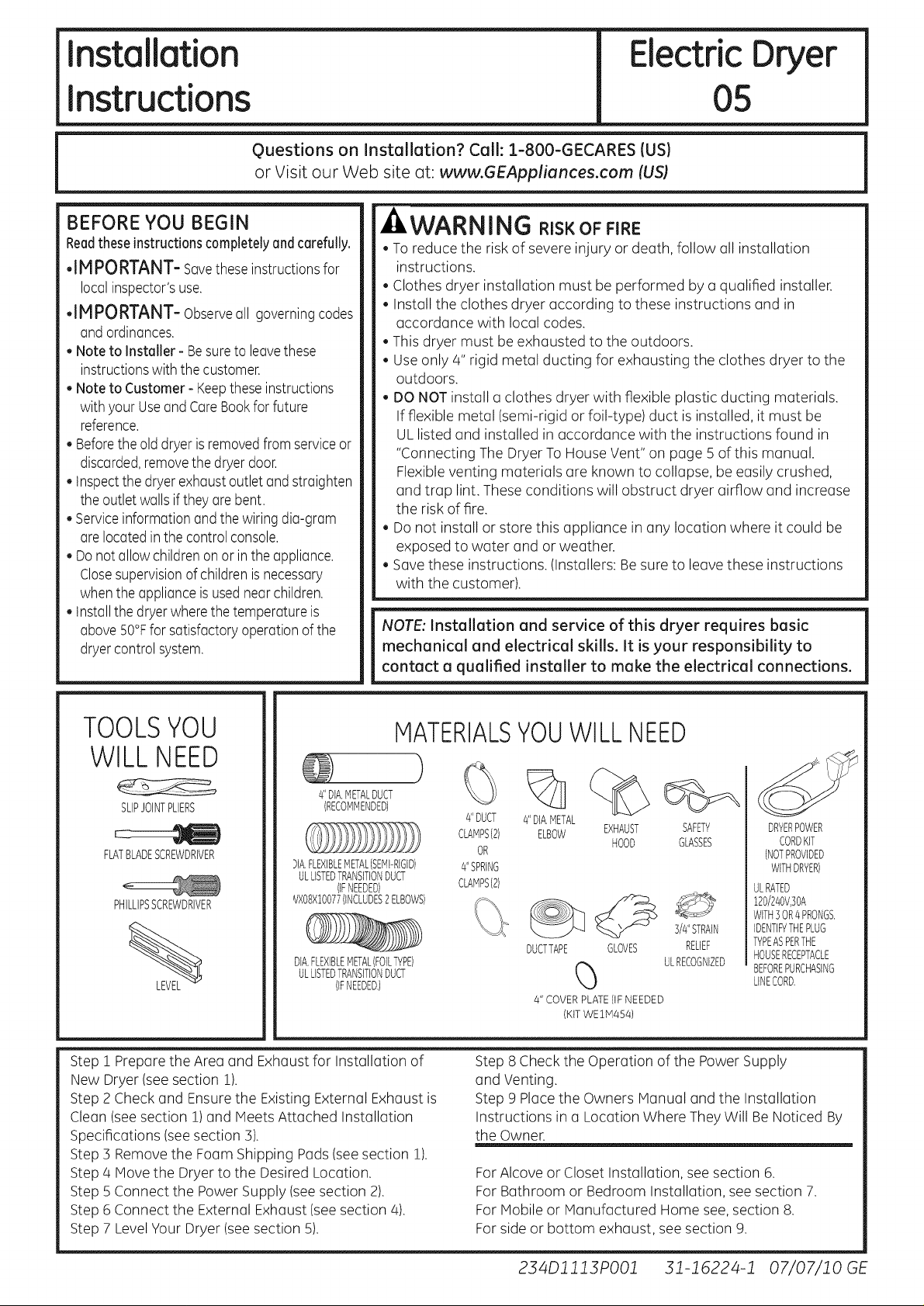

TOOLSYOU

MATERIALSYOUWILL NEED

WILLNEED

)

4IIDIA,METALDUCT

SLIPJOINTPLIERS

FLATBLADESCREWDRIVER

PHILLIPSSCREWDRIVER

Step 1 Prepare the Area and Exhaust for Installation of

New Dryer (seesection 1).

Step 2 Check and Ensurethe Existing External Exhaust is

Clean (seesection 1) and Meets Attached Installation

Specifications (seesection 3).

Step 3 Remove the Foam Shipping Pads(seesection 1).

Step 4 Move the Dryer to the Desired Location.

Step 5 Connect the Power Supply (see section 2).

Step 6 Connect the External Exhaust (see section 4).

Step 7 LevelYour Dryer (see section 5).

(RECOMMENDED)

}IA.FLEXIBLEMETAL(SEMI-RIGID)

ULLISTEDTRANSITIONDUCT

(IFNEEDED)

_,/XO8XlO077(INCLUDES2ELBOWS)

DIA.FLEXIBLEMETAL(FOETYPE)

ULLISTEDTRANSITIONDUCT

(IFNEEDED,)

%

4'IDUCT

CLAMPS(2) EXHAUST

4"SPRING

CLAMPS(2)

Step 8 Check the Operation of the Power Supply

and Venting.

Step 9 Place the Owners Manual and the Installation

Instructions in a Location Where They Will Be Noticed By

the Owner.

For Alcove or Closet Installation, see section 6.

For Bathroom or Bedroom Installation, see section 7.

For Mobile or Manufactured Home see, section 8.

For side or bottom exhaust, see section 9.

OR

4'1DIA,METAL

ELBOW

DUCTTAPE GLOVES RELIEF

4" COVERPLATE(IFNEEDED

(KITWEIM454)

HOOD

%

SAFETY

GLASSES

3/4"STRAIN

ULRECOGNIZED

DRYERPOWER

CORDKIT

(NOTPROVIDED

WITHDRYER)

ULRATED

120/240V,]OA

WITH3OR4PRONGS.

IDENTIFYTHEPLUG

TYPEASPERTHE

HOUSERECEPTACLE

BEFOREPURCHASING

LINECORD,

234Dll13PO01 31-16224-1 07/07/10 GE

Installation instructions

Minimum Clearance Other Than Alcove or Closet Installation

Minimum clearance to combustible surfaces and for air opening are: 0 in. clearance both sides and 1in. rear.

Consideration must be given to provide adequate clearance for installation and service.

ri] PREPARING FOR INSTALLATION

OF NEW DRYER

TIP:Install your dryer before installing your washer.

This will allow better access when installing dryer

exhaust.

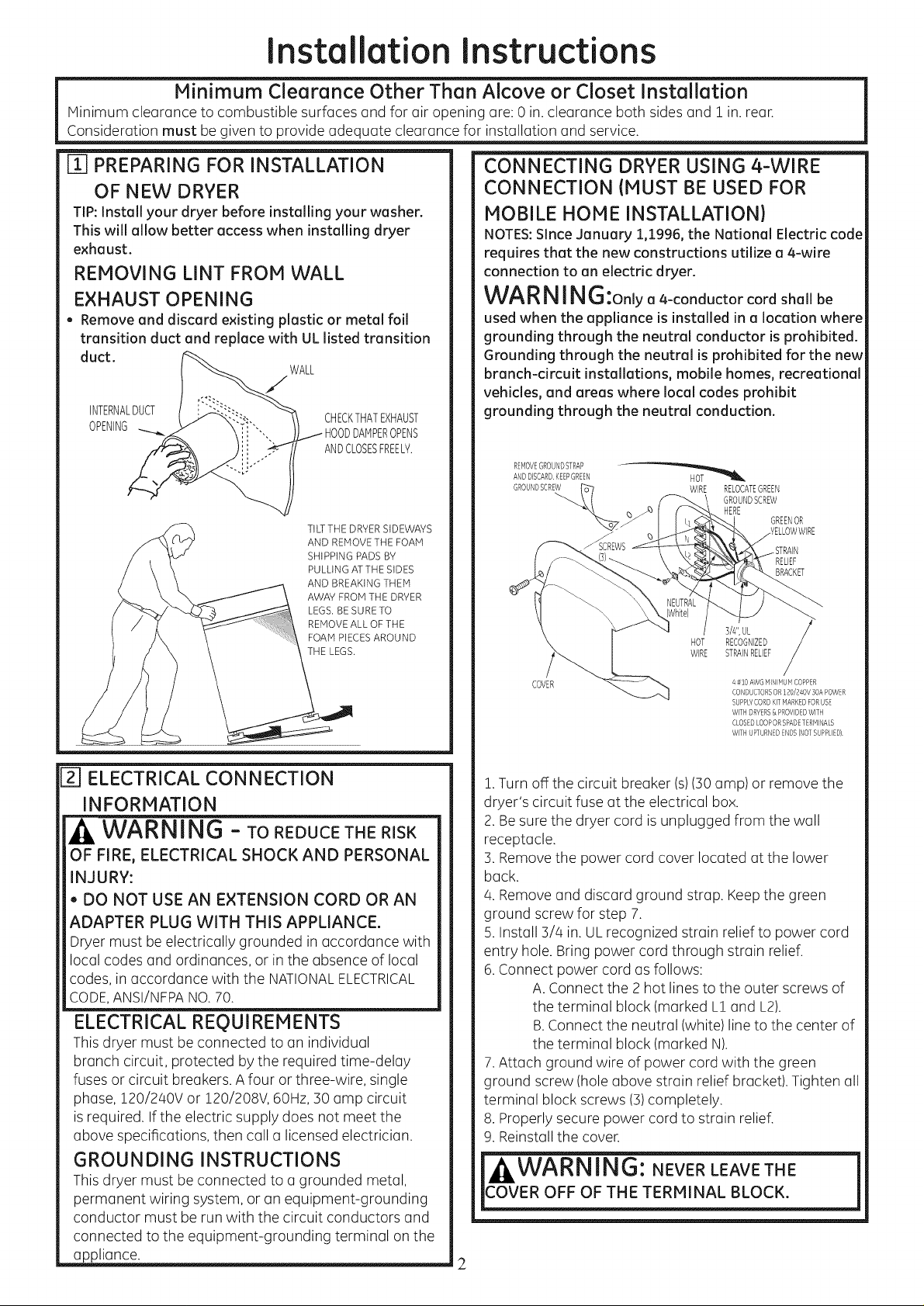

REMOVING LINT FROM WALL

EXHAUST OPENING

. Remove and discard existing plastic or metal foil

transition duct and replace with UL listed transition

duct.

WALL

/

INTERNALDUCT

OPENING i HOODDAMPEROPENS

CHECKTHATEXHAUST

ANDCLOSESFREELY.

TILTTHE DRYERSIDEWAYS

AND REMOVETHE FOAM

SHIPPING PADS BY

PULLING ATTHE SIDES

AND BREAKING THEM

AWAY FROM THE DRYER

LEGS, BE SURE TO

REMOVEALL OF THE

FOAM PIECESAROUND

THE LEGS,

CONNECTING DRYER USING 4-WIRE

CONNECTION (MUST BE USED FOR

MOBILE HONE INSTALLATION)

NOTES:Since January 1,1996, the National Electric code

requires that the new constructions utilize a 4-wire

connection to an electric dryer.

WARNING:onlya4-conductorcordshallbe

used when the appliance is installed in a location where

grounding through the neutral conductor is prohibited.

Grounding through the neutral is prohibited for the new

branch-circuit installations, mobile homes, recreational

vehicles, and areas where local codes prohibit

grounding through the neutral conduction.

REivIOVEGROUNDSTRAP

ANDDISCARDKEEPGREEN

GROU"@SCREW ('_-/ WIRE RELOCATEGREEN

-_::::::_:3 _ HERE GREENOR

COVER

GROUNDSCREW

HOT

RECOGNIZED

STRAINRELIEF

WIRE

s/4",UL

N#10 AWG HR'_iHUIVICOPPER

CONDUCTORSOR120/240V 30APOWER

SUPPLYCORDKITHARKEDFORUSE

WITHDRYERS& PROVIDEDWITH

CLOSEDLOOPORSPADETERHINALS

WITHUPTURNEDENDS(NOTSUPPLIED)

RELIEF

BRACKET

[_] ELECTRICAL CONNECTION

INFORMATION

WARNING - ToREDUCETHERISK

OF FIRE, ELECTRICAL SHOCK AND PERSONAL

INJURY:

, DO NOT USE AN EXTENSION CORD OR AN

ADAPTER PLUG WiTH THiS APPLIANCE.

Dryer must be electrically grounded inaccordance with

local codes and ordinances, or in the absence of local

codes, in accordance with the NATIONALELECTRICAL

CODE,ANSI/NFPANO.70.

ELECTRICAL REQUIREMENTS

This dryer must be connected to an individual

branch circuit, protected by the required time-delay

fuses or circuit breakers. A four or three-wire, single

phase, 120/240V or 120/208V, 60Hz, 30 amp circuit

is required. If the electric supply does not meet the

above specifications, then call a licensed electrician.

GROUNDING INSTRUCTIONS

This dryer must be connected to a grounded metal,

permanent wiring system, or an equipment-grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal on the

appliance.

1.Turn off the circuit breaker (s)(30amp) or remove the

dryer's circuit fuse at the electrical box.

2. Besure the dryer cord is unplugged from the wall

receptacle.

3. Removethe power cord cover located at the lower

back.

4. Remove and discard ground strap. Keepthe green

ground screw for step 7.

5. Install 3/4 in. UL recognized strain relief to power cord

entry hole. Bring power cord through strain relief.

6.Connect power cord as follows:

A. Connect the 2 hot lines to the outer screws of

the terminal block (marked L1 and L2).

B.Connect the neutral (white) line to the center of

the terminal block (marked N).

7.Attach ground wire of power cord with the green

ground screw (hole above strain relief bracket). Tighten all

terminal block screws (3)completely.

8. Properly secure power cord to strain relief.

9. Reinstall the cover.

,

2

Installation instructions

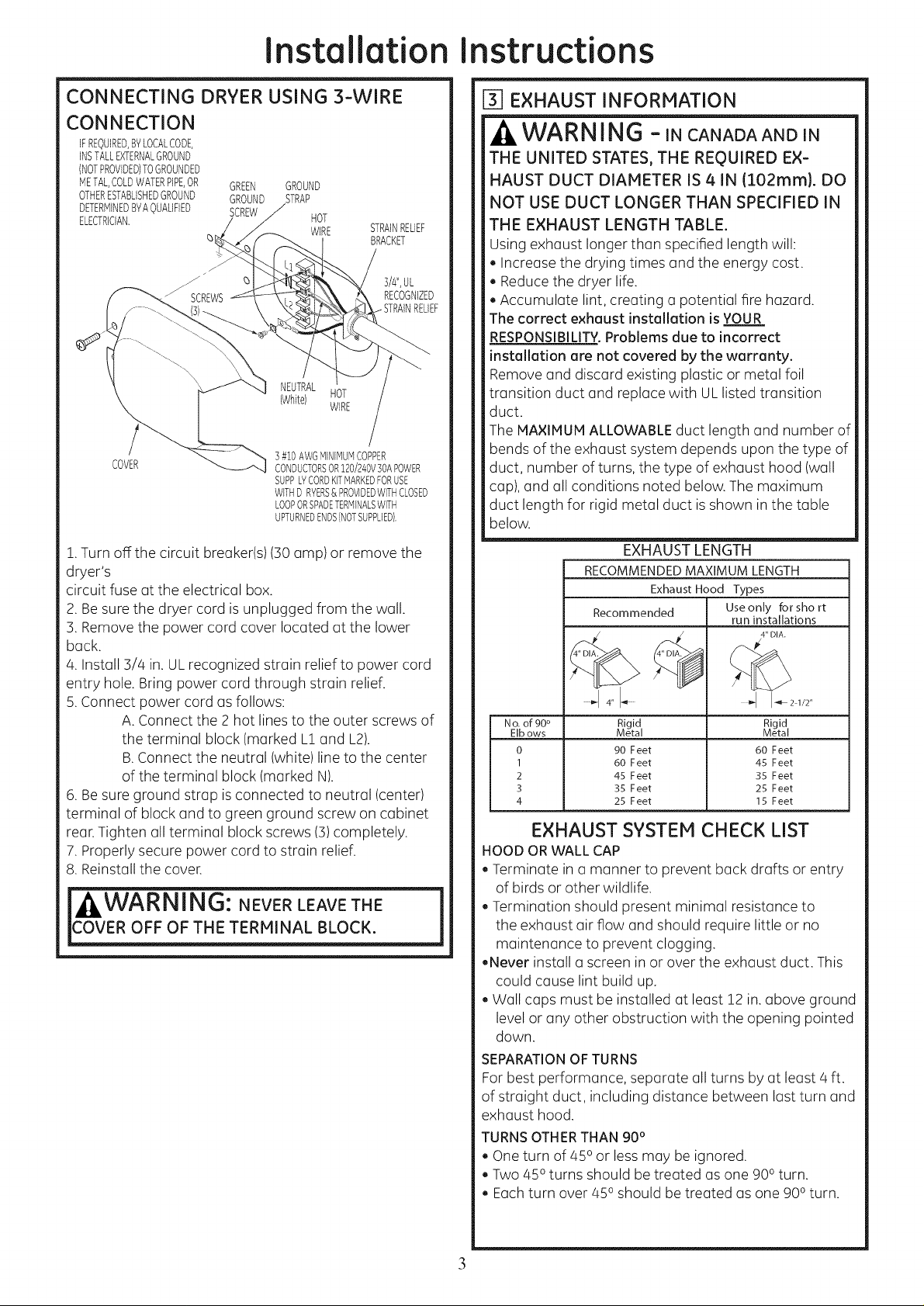

CONNECTING DRYER USING 3-WIRE

CONNECTION

IFREQUIRED,BYLOCALCODE,

iNSTALLEXTERNALGROUND

(NOTPROVIDED)TOGROUNDED

METAL,COLDWATERPIPE,OR GREEN GROUND

OTHERESTABLISHEDGROUND GROUND STRAP

DETERMINEDBYAQUALiFiED SCREW

ELECTRiCiAN. HOT

COVER

WiRE STRAINRELIEF

NEUTRAL

(White) HOT

] #10AWGMINIMUMCOPPER

CONDUCTORSOR120/240V30APOWER

SUPPLYCORDKiTMARKEDFORUSE

WiTHDRYERS&PROVIDEDWiTHCLOSED

LOOPORSPADETERMINALSWiTH

UPTURNEDENDS(NOTSUPPLIED}.

BRACKET

WIRE

3/#',UL

RECOGNIZED

EXHAUST INFORMATION

WARNING -IN CANADAANDIN

THE UNITED STATES, THE REQUIRED EX-

HAUST DUCT DIAMETER IS 4. IN (102mm). DO

NOT USE DUCT LONGER THAN SPECIFIED IN

THE EXHAUST LENGTH TABLE.

Using exhaust longer than specified length will:

, Increase the drying times and the energy cost.

, Reducethe dryer life.

, Accumulate lint, creating a potential fire hazard.

The correct exhaust installation is YOUR

RESPONSIBILITY.Problems due to incorrect

installation are not covered by the warranty.

Remove and discard existing plastic or metal foil

transition duct and replace with ULlisted transition

duct.

The MAXIMUM ALLOWABLE duct length and number of

bends of the exhaust system depends upon the type of

duct, number of turns, the type of exhaust hood (wall

cap), and all conditions noted below. The maximum

duct length for rigid metal duct is shown in the table

below.

1.Turn off the circuit breaker(s)(30amp) or remove the

dryer's

circuit fuse at the electrical box.

2. Besure the dryer cord isunplugged from the wall.

3. Removethe power cord cover located at the lower

back.

4. Install 3/4 in. ULrecognized strain relief to power cord

entry hole. Bring power cord through strain relief.

5.Connect power cord as follows:

A. Connect the 2hot lines to the outer screws of

the terminal block (marked L1 and L2).

B.Connect the neutral (white) line to the center

of the terminal block (marked N).

6. Besure ground strap isconnected to neutral (center)

terminal of block and to green ground screw on cabinet

rear.Tighten all terminal block screws (3)completely.

7. Properly secure power cord to strain relief.

8. Reinstall the cover.

j|WARNING'. NEVER LEAVE THE j

COVER OFF OF THE TERMINAL BLOCK.

EXHAUST LENGTH

RECOMMENDED MAXIMUM LENGTH

Exhaust Hood Types

Recommended

4" I-_ I-4_ 2 1/2"

No.of 90 ° Rigid Rigid

EIbows Metal Metal

0 90 Feet 60 Feet

1 60 Feet 45 Feet

2 45 Feet 35 Feet

3 35 Feet 25 Feet

4 25 Feet 15 Feet

Useonly for sho rt

run installations

4" DIA.

EXHAUST SYSTEM CHECK LIST

HOOD ORWALL CAP

, Terminate in a manner to prevent back drafts or entry

of birds or other wildlife.

, Termination should present minimal resistance to

the exhaust air flow and should require little or no

maintenance to prevent clogging.

,Never install a screen inor over the exhaust duct. This

could cause lint build up.

, Wall caps must be installed at least 12 in. above ground

level or any other obstruction with the opening pointed

down.

SEPARATIONOF TURNS

Forbest performance, separate all turns by at least 4 ft.

of straight duct, including distance between last turn and

exhaust hood.

TURNSOTHERTHAN 90°

, Oneturn of 45oor less may be ignored.

, Two 45oturns should be treated as one 90oturn.

, Eachturn over 45o should be treated as one 90oturn.

3

Loading...

Loading...