GE GSM2200V00BB, GSM2200V00WW, GSM2200V45BB, GSM2200V45WW, GSM2260V00SS Installation Guide

...Page 1

_.:::_!i!i!!!!iCOi"i_:!!!iiiii_u ii'_''__!!!!!!i¸¸¸¸i!!!iiiilkiH_iqdu _i!!!iiii_i_t::i:iO!ii

Appliances

Installation Instructions

Spacemaker®Dishwasher

If you havequestions, call 800.GE.CARES(800.432.2737) or visit our website at: www.GEAppliances.com

BEFORE YOU BEGIN

Read these instructions completelg and

carefutlg.

IMPORTANT- Observe all governing codes

and ordinances.

• Note to Installer- Be sure to leave these

instructions for the consumer and local inspector's

use.

• Note to Consumer - Keepthese instructions with

your Owner's Manual for future reference.

• Skill Level- Installation of this dishwasher requires

basic mechanical, electrical and plumbing skills.

Proper installation is the responsibility of

the installer. Product failure due to improper

installation is not covered under the GE

Appliance Warranty. See warranty information.

• Completion Time - I to 3 Hours. New installations

require more time than replacement installations.

• Sink Requirement - This Spacemaker ® dishwasher

is designed to be installed under a special shallow

sink. Three types of sinks are available: GPF95, a

single bowl sink with the drain hole on the right

side of the sink; GPF96, a single bowl sink with the

drain hole on the left side of the sink; and GPF97, a

double bowl sink. Purchase these sinks from gour

authorized GE appliance dealer.

IMPORTANT- The dishwasher MUST be

installed to allow for future removal from the

enclosure if service is required.

If you received a damaged dishwasher, you should

immediately contact your dealer or builder.

Optional Accessories - See the Owner's Manual for

available custom panel kits.

FOR YOUR SAFETY

Read and observe all CAUTIONS and WARNINGS

shown throughout these instructions. While

performing installations described in this booklet,

gloves and safety glasses should be worn.

J

READ CAREFULLY.

KEEP THESE INSTRUCTIONS.

Page 2

PARTS SUPPLIED IN INSTALLATION

PACKAGE:

[] Two 8-18 × 5/8" Phillips heed wood screws

[] Junction box cover ond #10 hex heod

screw

[] Droin hose (78" long)ond hose clomp

[] Literoture, product somples, ond/or

coupons

MATERIALS YOU WILL NEED:

[] WX09X70910 power cord if opplicoble to

gour instolletion

[] UL Listed wire nuts (3)

[] Threod seol tope

[] 90 ° elbow, ferrule ond compression nut-

(3/8" NPT externol threod on one end end

opposite end sized to fit woter supplg)

[] GPF65 Side-mount brocket kit for use with

gronite countertops

FOR NEW INSTALLATIONS:

[] Electricot coble

[] Wuter line-3/8" minimum copper tubing

[] Struin relief for electricol connection

[] Hond shut-off volve (recommended)

[] Air gop for droin hose, if required

[] Woste tee for house plumbing, if

opplicoble

[] Screwtgpe hose clomps

[] GPF95, GPF96 or GPF97 stoinless steel

sink

Screw Kit

Phillips Head

#8

Wood Screws

5/8" long

78" Drain Hose

Electrical Cable or

WR09×70910 Power Cord

90° Elbow, Ferrule and

Compression Nut

Strain Relief Shut-Off Valve

/

/ ' ....... :\

,/ h

GPF95

StainlessSteelSink

GPF96

Stainless Steel Sink

#10

Hex Head

Junction Box Screw

1/2" long

Hose Clamp

3 Wire Nuts

GPF65 Side-Mount

Bracket Kit

1

Air Gap

Waste Tee

GPF97

Stainless Steel Sink

Junction Box Cover

Thread

Seal Tape

Hot Water Line-3/8"

Minimum Copper

Tubing

Screw Type

Hose Clamps

TOOLS YOU WILL NEED:

[] Sofetg glosses

[] 1/4" ond 5/16" nutdrivers

[] Floshlight

[] Gloves

[] Adjustoble wrench (6")

[] Phillips heod screwdriver

[] 15/26" socket wrench

[] Meosuring tope

[] Level

[] Corpenters squore

[] Bucket to cotch woter when flushing

woter line

[] Tubing cutter

FOR NEW INSTALLATIONS:

[] Hole sow set

[] Drill ond oppropriote bits

Safety Glasses

Gloves

Measuring Tape

Bucket

114"and 5116" Nutdrivers

Adjustable

Wrench

Tubing Cutter

Level

Phillips Head

Screwdriver

Hole Saw Set

Flashlight

15116"

Socket Wrench

Carpenters

Squall

Drill

and Bits

Page 3

Installation Preparation-Enclosure

PREPARE DISHWASHER ENCLOSURE AND

SINK LOCATION

• Water line to sink faucet and drain from sink can

be run through Area "A."

• Hot water line to dishwasher is installed in Area "B."

• Garbage disposer, water lines to faucet, waste

trap, air gap and water shut-off valve are installed

in o 22" wide cabinet, Area "C".

Countertop: 1-1/2" Hin, Thick

ii

II

Toekick

Area

/

24"

,I--A L--IX

Floor

• Sink opening for garbage disposer must be

dimensioned as shown (7-1/2")in Area "C."This will

provide clearance for disposer and plumbing in

Area "C" when using either single or double bowl

sink. Refer to Figure A below and Figure F1on

page 6.

/Wall

1" Max. To

PLUHBING

DEPTH

t

Figure A

./2" Max_-

3/4" Min.--,-I _ - Sink Flange

6" lax. 10-1/4" MAX.

Hin. I.R.

34-1/4

!1/4" 1-1/2" Plumbing

Close Elbow

Dishwasher

Side View

...... Hax_ B I

__ 24" Min. __

Cabinet

PREPARE CABINET CUTOUT FOR SINK:

r!'wkv,v/.,1;,__,II_,[€1

II ,,,,"I Adjacent Cabinet

if_, _ Zear Cutout

To reduce the risk of shock, fire, or injury to

persons, the installer must ensure that the

dishwasher is completely enclosed at the

time of installation.

Para reducir el riesgo de choque, incendio

o lesi6n a personas, el instalador se

debe cerciorar de que la lavadora est_

completamente cerrada en el momento

de la instalaci6n.

Sink

Installation

8" X 20"

II / CabinetSide/

_ / Adjacent to D/W

_- 24" min

Figure B

• The cabinet opening must have o minimum width

and depth of 24" and height of 34-1/4" + 1/4".

• This dishwasher fits under o special sink with o

depth of 6" or less in o 1-1/2" countertop.

The dishwasher must be futlg enclosed on the top,

sides and buck.

The dishwasher must not support ong part of the

enclosure.

Wall

_20-i/2" Max._ /

Sink Bo_

Jl

Front

Flange

Gap

Dishwasher

24" Min.

Cabinet

Y

Note: A gap between the dishwasher tub front flange and

the front of the base cabinet mag result due to either

the cabinet being less than 24" deep or the sink bowl

not being installed to specifications.

If the gap is more than 3/4", the sink bowl must be

relocated to meet specified dimensions.

Page 4

Installation Preparation-Drain

PREPARE DRAIN PLUMBING

Drain Requirements

• Follow local codes and ordinances.

• Drain hose must not exceed 10 feet in length.

• A high drain loop or air gap is required. See below.

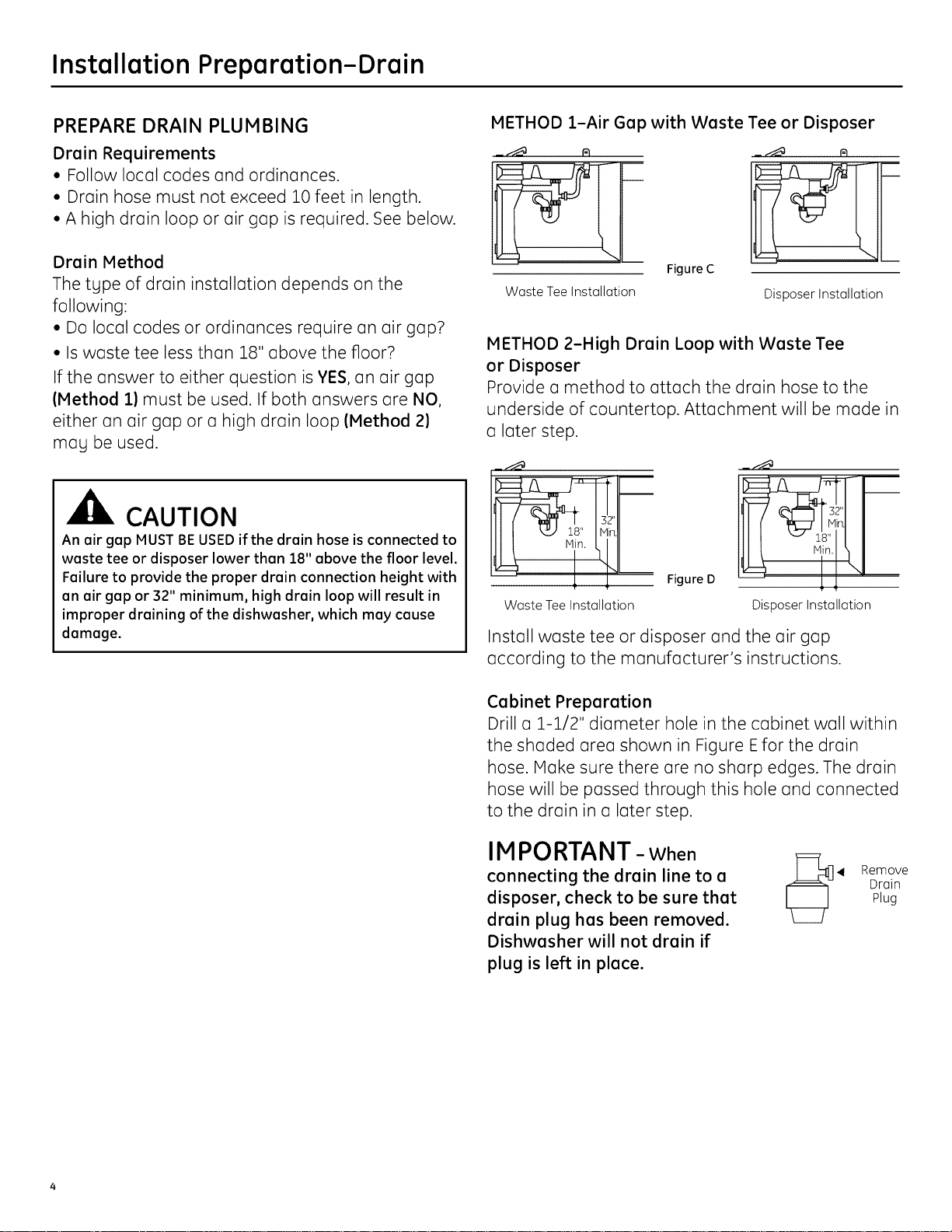

Drain Method

The type of drain installation depends on the

following:

• Do local codes or ordinances require an air gap?

• Is waste tee less than 18" above the floor?

If the answer to either question is YES,an air gap

(Method 1) must be used. If both answers are NO,

either an air gap or a high drain loop (Method 2)

mag be used.

CAUTION

An air gap MUST BE USED if the drain hose is connected to

waste tee or disposer lower then 18" above the floor level.

Failure to provide the proper drain connection height with

an air gap or 32" minimum, high drain loop will result in

improper draining of the dishwasher, which may cause

damage.

METHOD 1-Air Gap with Waste Tee or Disposer

Figure C

Waste Tee Installation

Disposer Installation

METHOD 2-High Drain Loop with Waste Tee

or Disposer

Provide a method to attach the drain hose to the

underside of countertop. Attachment will be made in

a later step.

Figure D

Waste Tee Installation

Install waste tee or disposer and the air gap

according to the manufacturer's instructions.

Disposer Installation

Cabinet Preparation

Drill a 1-1/2" diameter hole in the cabinet wall within

the shaded area shown in Figure Efor the drain

hose. IVlakesure there are no sharp edges. The drain

hose will be passed through this hole and connected

to the drain in a later step.

IMPORTANT- When

connecting the drain line to a

disposer, check to be sure that

drain plug has been removed.

Dishwasher will not drain if

plug is left in place.

41 Remove

Drain

Plug

Page 5

Installation Preparation-Electrical Supply

PREPARE ELECTRICAL WIRING

r!_LVAVl.'Ifl_11_[Cl

Electrical Requirements

• This appliance.must be s.upplied with 120V 60 Hz.,

and connected to an indiwduot properly grounded

branch circuit, protected by o 15 or 20 ampere

circuit breaker or time delay fuse.

• Wiring must be 2 wire with ground.

• If the electrical supply does not meet the above

requirements, coil o licensed electrician before

proceeolng.

TGhroundingInstructions-Permanent Connection

is qpplionce must be connected to o grounded

metal, permanent wiring sg.stem or on e.quipment

grou.nding cond.u,ctor must be. run.with the circuit

conduc.tors and be connected to the e.q.uipment

grounding terminal or lead on the appliance.

Grounding Instructions-Power Cord.Models _

This QppliQnce must be grounded. In the event ot Q

molfuoctioq or breqkdqwn, ground.ing will re.duce

.the risk at electric shock by providinq o path at

least resistgnce for electric current. This appliance

is equipped with o cord h_avingon equipment. .

grounding conductor and o grounding pl.ug..The plug

must be pluqged into on appropriate outlet that _s

installed onclqrounded in accordance with oll local

codes and orcTinonces.

FORPERSONALSAFETY:Remove house

fuse or open circuit breaker before

beginning installation. Do not use an

extension cord or adapter plug with this

appliance.

PARASEGURIDAD PERSONAL: Retire el fusible

de la casa o abra el interruptor de circuitos

antes de empezar la instalaci6n. No use un

cable de extensi6n o enchufe adaptador con

este aparato.

Figure E Black

Cabinet Preparation & Wire Routing

• The wiring mug enter the opening from either side,

rear, or floor within the shaded area illustrated

above in Figure E.

• Cut c] :£-:£/2" maximum diameter hole to insert the

electrical cable. Permanent wiring connections

mug puss through the same hole us the drain

hose and hot water line, if convenient. Hole edges

must be smooth and rounded. If the cabinet wall is

metal, the hole edge must be covered with c]cord

protector.

NOTE: Power cords with plug must puss through c]

separate hole.

Cord Hole Diameter

Protector 1-1/2" Maximum

/ \

/

..... l-i/2"_ia.

Receptacle from Wall

Location

Area

Ground J

24"

\.

3,_ Receptacle

from

'Cabinet

White

Alternate

Location

The improper connection of the equipment

grounding conductor can result in electric

shock. Check with a qualified electrician or

service representative if you are in doubt

that the appliance is properly grounded.

Do not modify the plug provided with the

appliance; if it will not fit the outlet, have

a proper outlet installed by a qualified

technician.

La conexi6n incorrecta del conductor de

conexi6n a tierra del equipo puede resultar en

choque el_ctrico. Consulte con un electricista

celificado o representente de servicio si tiene

dudes de la conexi6n e tierra del aperato. No

modifique el enchufe que se suministra con

el aperato; si no celze en el tomacorrientes,

hege queun t_cnico celificedo le instele un

tomacorrientes adecuedo.

Electrical Connection to Dishwasher

Electrical connection is on the right front of

dishwasher.

• For permanent connections, the cable must be

routed us shown in Figure E.The cable must extend

c] minimum of 2/4"from the rear wall.

• For power cord connections, install c_3-prong

grounding type receptacle in the adjacent cabinet

rear wall, between 6" and 18" from the opening, 6"

to 18" above the floor us shown in Figure E.

Page 6

Installation Preparation-Hot Water Supply

PREPARE HOT WATER SUPPLY

Hot Water Line

• The line may enter from either side, rear, or floor

within the shaded area shown in Figure F.

• The line mag pass through the same hole as the

electrical cable and drain hose, or cut an additional

1-1/2" diameter hole to accommodate the water

line. tf a power cord with plug is used, the water line

must not pass through the power cord hole.

/

Shut-off

ii

_Valvc

Hot_:::::

II

',',2"--

From

Cabinet

Cabinet Face-'-

19" From Wall

2" From Floor

The hot water supply line pressure must be at least 20 PSI.

Lower pressures could cause the water valve to leak and

cause water damage.

Sink Utility Connections

Sink faucet hot and cold water lines and the sink

drain line must run above and adjacent to the

dishwasher, not behind it. Refer to Areas A and C

in Figure A on page 3 and Figure F1 below. This is

necessarg to provide clearance for the dishwasher

when it is installed in the cabinet. Utilitg lines routed

directlg behind the dishwasher will interfere with

placement of the dishwasher in the cabinet and

cause it to extend begond the adjacent cabinets.

Figure F1 illustrates an installation using a double

bowl sink, a disposer and a high drain loop.

Note: All utilitg lines are above, below or adjacent to

the dishwasher. None are routed behind it.

CAUTION

Figure F

Water Line Connection

• Turn off the water supplg.

• Install a hand shut-off vatve in on accessible

location. (Optional, but strongtg recommended and

mag be required bg local codes.)

• The water connection is on the left side of the

dishwasher. Install the hot water inlet line, using

3/8" or larger copper tubing. Route the line as

shown in Figure F and extend forward at least 19"

from rear wall.

• Adjust the water heater to deliver water between

120°F and 150°F.

• Flush water line to clean out debris. Use a bucket

to catch water and debris.

• The hot water supplg line pressure must be

between 20 and 120 PSt.

6" Double-bowl

/ 25" deep

_,1-1/2" thick

i

__1 Countertop

_ _ elbow

-1-1/2" Close

acemaker ceS;II

_..'__.,_ir,,_'-- _ i

Coldwa "_ _;''

Valve to shut off Dishwasher

Hotwate__

water to dishwasher water inlet

Hot water supplg valve

to dishwasher Dishwasher

Figure FI

drain hose

Page 7

Dishwasher Installation

CAUTION

Do not remove the wood bose until you ere reedy

to instell the dishwesher. The dishwasher will tip over

when the door is opened if the bose is removed.

STEP 3: REMOVE WOOD BASE

IMPORTANT - Donot kick off wood base!

Damage will occur.

Hove the dishwasher close to the installation

STEP 1: PREPARATION

Locatethe itemsintheinstallationpackage and set

them asideforuse inthe listedsteps

• Screw kit-Steps5 or 16 and 13

• Junctionboxcover-Steps5 or 16

• Drain hose and drain hose clamp-Step 7

• Owners' Manual-Steps 18 and 21

• Product Samples and/or coupons-Step 21

STEP 2: CHECK DOOR BALANCE

• With the dishwasher on the wood base, check the

door balance by opening and closing the door.

• The door is properly balanced if it gently drops

from a 1/2 open position and does not rise from

the full open position.

• If necessary, increase or decrease tension as

shown. Latch the door and adjust springs to

correct balance.

Link fullg seated

in hinge arm

Insert Hook Throuc

Hole from Inside of Frame

Figure G

Tip: Avoid service calls for door balance problems

Hake sure the spring end is fully engaged in a

frame hole and the spring link is fully seated in the

hinge arm.

Remove the four leveling

legs from the underside of

Iocationandlayitonitsback_i _D

the wood base

with a 15/16" _--

i

socket wrench.

Remove and

discord wood

base.

Figure H

• Screw leveling legs back into the dishwasher

frame, approximately 3/4" from the frame, as

shown.

STEP 4: REMOVE ACCESS PANEL

AND TOEKICK

The top mounting holes in the access panel are

slotted.

• Remove the lower two 10-16x3/8" sheet metal

screws. Do not remove the two top 8-32xl/4"

machine thread screws.

• Slide the access panel to the left as far as it will go.

• Gently pull the access panel forward to remove

it from the top screws.

Set access panel, toekick, and screws aside for use

in Step 20.

Tip: Prevent

tub damage

Remove onlg

the 3/8" sheet

metal screws

in this step.

This will help

prevent a mix

up with the

1/4" machine

thread screws

in Step 20.

Do not remove 1/4"

machine thread screws

in this step

,.J

Remove two

3/8" Sheet Metal

Thread Screws

Figure I

Page 8

Dishwasher Installation

STEP 5: INSTALL POWER CORD

Skip this step if the dishwasher will be

permanently connected to the house electrical

system or has a factory installed power cord.

In this step you will need the junction box cover and

the #:1_0x :1_/2"hex head screw from the screw kit set

aside in Step 1.

The power cord and connections must complg

with the National Electrical Code, Section/422 and/

or local codes and ordinances. Maximum power

cord length is 6 feet. Power Cord Kit WX09X70910,

available for purchase from an authorized GE

Appliance Dealer, meets these requirements.

STEP 6: INSTALL 90° ELBOW

• Wrap a 90 ° elbow with thread seal tape.

• Thead the 90° elbow into the water valve.

• Do not over tighten the elbow; water valve bracket

could bend or the valve fitting could break.

• Position the end of the elbow to face the rear of

the dishwasher.

Bracket

RedElectrical

90°

Figure K

STEP 7: INSTALL DRAIN HOSE TO

DISHWASHER DRAIN PORT

Thread Seal Connection

Tape Hose

Junction

Box Bracket

Ilack

Figure J

• Install strain relief in thejunction box bracket.

• Insert the power cord through the strain relief and

tighten.

• Make sure black, white, and green dishwasher

wires are threaded through the small hole in the

junction box bracket.

• Connect power cord white (or ribbed)to

dishwasher white, black (or smooth) to dishwasher

black and ground to dishwasher green wire. Use

UL listed wire nuts of appropriate size.

• Install junction box cover using the #10 hex head

screw. Be sure wires are not pinched under the

cover

8

Skip this step if drain hose has been pre-installed.

In this step you will need the drain hose and clamp

set aside in Step 1.

IMPORTANT- Prevent drain hose damage

and possible leaks. Be careful not to nick or cut

the drain hose.

• Route the small end of the drain hose from the left

side of the dishwasher through the strain relief

attached to the dishwasher frame and toward

the center of the dishwasher as shown in Figures

Land M.

• Place the hose clamp over the small end of the

drain hose.

• Push the small end of the drain hose over the drain

port on the collection chamber making sure it is

futlg seated against the hose stop.

• Tighten the hose clamp to at least 15 inch-pounds

of torque.

\\. / ,Strain

Figure L

Page 9

Dishwasher Installation

Note: The droin hose supplied with the dishwosher

is opproximotelg 78" long. tf o longer hose is needed,

o ZOfoot long hose mog be purchosed from on

outhorized GE opplionce deolen The 10 foot long

hose is port number GPFIOS.

Hose Stop

DrQin Hose Collection Chomber

Figure M

Do not use

this port if

present

DrQin Port

STEP 9: INSERT DRAIN HOSE AND POWER

CORD, IF USED, THROUGH CABINET

• Upright the dishwosher and position it in front of

the cobinet opening.

• Insert the droin hose into the hole previously drilled

in the cobinet woll.

• If o power cord is used, guide the end of the cord

through o seporote hole cut for the power cord.

The power cord should be routed directly to the reor

of the junction box ovoiding contoct with the door

spring ond other dishwosher components.

Figure O

Tip: Avoid unnecessary service charges for drain

issues

Moke sure the droin hose connection is leok free

ond the hose is routed through the stroin relief so

it will not kink when the dishwosher is instolled into

the cobinet.

STEP 8: POSITION WATER LINE AND

POWER SUPPLY

• Position the woter supply line ond house wiring on

the floor of the opening to ovoid interference with

the bose of dishwosher ond components under

the dishwosher.

Line Supplg

Tip: Avoid unnecessary service charges for no fill,

drain, or noise concerns

Position utilitg lines so theg do not interfere with

ongthing under or behind the dishwosher.

STEP 10: INSTALL OPTIONAL GPF65 SIDE

MOUNT BRACKETS

Skip this step if the underside of countertop is

wood or wood like material.

• Purchose ond instoll the GPF65 side mount brocket

kit if the underside of counter is gronite or o

similor moteriol thot will not occept wood screws.

The GPF65 kit is ovoiloble from outhorized GE

opplionce deolers.

• Refer to Figure P ond follow the instructions

included in Side-

the kit.

Tub Frome

Figure N

Brocket

Attochment

__ Optional Screws

Side-Mount (2 Eoch

Bracket Kit Figure P Side)

Page 10

Dishwasher Installation

STEP 11: SLIDE DISHWASHER INTO CABINET

IMPORTANT - Do not push against the front

panel with knees. Damage will occur.

• Grasp the sides of the front panel and slide the

dishwasher into the opening a few inches at

a time. Pull the drain hose and power cord, if

equipped, through the holes in the adjacent

cabinet while sliding the dishwasher into position.

Do not ush a ainst

front door panel with

Figure _)

knee. Damage to the

door panel will occur.

STEP 12: POSITION AND LEVEL

DISHWASHER

IMPORTANT- Dishwasher must be level for

proper dish rack operation, wash performance,

and door operation. The dishwasher must be

leveled left to right and front to back. This assures

that the dish racks will not roll in or out on their

own, circulation water will flow to the pump inlet,

and the door will close without hitting the side of

the tub.

• Remove the lower dish rack and place a level on

the door and lower rack track as shown in Figure R.

/

Check Level

Front-to-Back

• Check the tub insulation blanket, if equipped, to

be sure it is smoothly wrapped around the tub.

It should not be "bunched up" and it must not

interfere with the door springs. If the insulation

is "bunched up" or interfering with the springs,

straighten and re-center the blanket prior to sliding

the dishwasher into its final position.

• IVlake sure the drain hose is not kinked under or

behind the dishwasher.

• IVlake certain the house wiring, drain line, and

water line do not interfere with components under

the dishwasher.

• The dishwasher tub flange should be

approximately 3/4" behind the face of the adjacent

cabinet. Refer to Figure R.

Tip: Avoid unnecessary service charges for panel

damage.

Do not press on the center of panel with hands or

knees when sliding dishwasher into position.

lo

Figure R

qeck Level

Side-to-Side

• Adjust the level of the dishwasher by individually

turning the four legs on the bottom of the

dishwasher as illustrated in Figure S.

I J

\,, i

!- .S

Turn Lec J

to AdJust J FigureS

• The dishwasher is properly leveled when the level

indicator is centered left to right and front to back.

The dishwasher door should close without hitting

the sides of the tub.

• Replace the lower rack.

Tip: Avoid unnecessary service charges for poor

wash performance and rack operation.

Pull the dish racks halfway out. They should remain

stationary. Open and close the door. The door should

fit in the tub opening without hitting the side of the

tub. If the racks roll on their own, or the door hits the

side of the tub, re-level the dishwasher.

Page 11

Dishwasher Installation

STEP 13: FASTEN DISHWASHER TO

UNDERSIDE OF COUNTERTOP OR SIDES

OF CABINET

In this step you will need the two 5/8" Phillips head

wood screws set aside in Step 2.

IMPORTANT - Dishwasher must be centered

in cabinet opening. Interference with cabinets or

countertop will cause leaks and damage to the

door panel and/or control panel.

• If countertop is wood or woodlike material, fasten

the dishwasher to the countertop bg driving the

Phillips head screws through the countertop

brackets and into the countertop.

• If the countertop is granite or similar material,

drive Phillips screws through side mount brackets

and into the adjacent cabinets.

• Make sure screws are driven straight and flush

to prevent interference with door operation and

damage to the control panel. See Figure T.

STEP 14: CONNECT WATER SUPPLY

Connect the water supplg line to the 90° elbow

installed in Step 6.

• Slide the compression nut and then the ferrule over

end of the water line.

• Insert the water line into the 90° elbow.

• Slide the ferrule against the elbow and secure

with the compression nut.

Countertop

Bracket

Side Mount

Brackets (optional)

Figure T

Tip: Avoid unnecessary service charges for leaks

or control panel damage.

Make sure the dishwasher is centered in the cabinet

and the door opens and closes freelg without hitting

the adjacent cabinets. Drive mounting screws

straight and flush.

Figure U

IMPORTANT - Check to be sure the door

spring does not rub or contact the fill hose or

water supply line. Test by opening and closing the

door. Re-route the water supply lines or slightly

bend the water valve bracket if a rubbing noise or

i nterference occurs.

Tip: Avoid unnecessary service charges for noise

or leaks

Make sure the door spring does not rub against the

fill hose or water supplg line.

11

Page 12

Dishwasher Installation

STEP 15: CONNECT DRAIN LINE

The molded end of the drain hose will fit 5/8"

through 1" diameter inlet ports on the air gap, waste

tee or disposer.

• Determine the size of the inlet port

• Cut the drain hose connector on the marked line, if

required, to fit the inlet port.

Cutting Line

,/

/.

Figure V

• If a longer drain hose is required, and Uou did not

purchase the GPF10S drain hose, add up to 42"

length, for a total of 120" (10 feet) to the factory

installed hose. Use 5/8" or 7/8" inside diameter

hose and a coupler to connect

the two hose ends.

Secure the

connection

with hose

clamps.

IMPORTANT - Total drain hose length must

not exceed 10 feet for proper drain operation.

IMPORTANT: Do not cut corrugated

portion of hose

Hose Clamic

Coupler

Hose Clamp

Figure W

Method 1 - Air gap with waste tee or disposer

_.i___ _ _/-___

Waste Tee Installation Disposer Installation

Figure ×

Method 2 - "High drain loop" with waste tee or

disposer

Fasten the drain hose to the underside of the

countertop with a hanger.

32"

Waste TeeInstallation

Figure Y

Disposer Installation

IMPORTANT - When connecting the drain

line to a disposer, check to be sure that the drain

plug has been removed. Dishwasher will not drain

if plug is left in place.

• Connect drain line to air gap, waste tee, or disposer

using the previouslg determined method. Secure

the hose with a screw tgpe clamp.

12

Drain

Plug

4 Remove

Tip: Avoid unnecessary service call charges

for a no drain complaint

Make sure any excess drain hose has been pulled

through the cabinet opening. This will prevent

excess hose in the dishwasher cavity from

becoming kinked or crushed by the dishwasher.

Make sure the disposer plug has been removed if

the drain hose is connected to a disposer.

Page 13

Dishwasher Installation

STEP 16: CONNECT POWER SUPPLY

If a power cord with plug is already installed,

proceed to Step 17.

If house wiring is not 2-wire with a ground

wire, a ground must be provided by the

installer.

When house wiring is aluminum, be sure to

use U.L. listed anti-oxidant compound and

aluminum-to-copper connectors.

Si el cableado de la casa no es de 2 cables

con un cable de conexi6n a tierra, el

instalador debe suministrar una conexi6n

a tierra. Cuando el cableado de la casa es en

aluminio, cerci6rese de usar un compuesto

ti-oxidante aprobado por U.L.

yun compuesto de aluminio a cobre.

• Secure house wiring to the bock of the junction

box brocket with o stroin relief.

• Locote the three dishwosher wires, (white, block

ond green) with stripped ends. Insert dishwosher

wires through the smotl hole in the junction box

brocket. Use UL listed wire nuts of oppropriote size

to connect incoming ground to green, white to

white ond block to block.

Note: Check thot horness leods ore

threoded through smoll hole in brocket

White

Junction Ground

Box Brocket

\

Figure Z

STEP 17: INSTALL JUNCTION BOX COVER

If junction box cover is already installed, skip to

Step 18.

In this step you will need the junction box cover ond

the #10 hex heod screw from the screw kit set oside

in Step 1.

• Instotl the junction box cover using the #10 hex

heod screw. Check to be sure thot wires ore not

pinched under the cover.

STEP 18: PRE-TEST CHECK LIST

[] Verify thut power is turned off ut the source.

[] Open the dishwasher door and remove all foum

und cordbourd puckuging.

[] Reod the Owner's Munuul to fumiliurize yourself

with the operution of the dishwusher.

[] Check to be sure thut the wiring is secure

under the dishwusher, und not pinched or in

contuct with door springs or other dishwusher

components.

[] Check thut the door spring does not contuct the

wuter line, fill hose, or udjucent cubinets. See

Steps 13 ond :]_4

[] Pull lower rock obout holfwoy out. Check to be

sure it does not roll bock into dishwosher or

further out. tf it does, re-level the dishwosher.

See Step :]_2

[] Check to be sure control ponel does not touch

odjocent cobinets. If it does, reposition the

dishwosher. See Step 13

[] Turn on the hot woter foucet ot the sink to verify

thot the woter temperoture is ot leost :]_20°F

ond not more thon :]_S0°F.Adjust woter heoter

if necessory.

[] Add two quorts of woter to the bottom of the

dishwosher to lubricote the pump seol.

[] Turn on woter supply.

[] Check for woter leoks. Tighten connections if

necessory. See Step :]_4

[] Remove the protective film if present from the

control ponel, occess ponel ond door ponel.

13

Page 14

Dishwasher Installation

STEP 19: DISHWASHER WET TEST

CHECK LIST

[] Turn on power supply or if power cord is used,

plug it into the wall outlet.

[] Latch dishwasher door.

[] Press the "Normal" pad, and then turn control dial

just enough to start dishwasher. Be careful not to

turn the dial past the first water fill. Dial should

point to "Hot Start Option".

Options

Appearance varies by model.

[] Check to be sure that water enters the dish-

washer. This could take up to 4 minutes.

If water does not enter the dishwasher try the

following to correct the problem:

- Check to be sure that the water is turned on

- Lightly tap the flood float cover to

dislodge a stuck flood float.

Q

Cover

- Check the electrical connection to the water

valve. The red electrical connector should be

plugged into the dishwasher water valve. If it is

not plugged in, turn off electrical power to the

dishwasher. Plug the red connector into the dish-

washer water valve and then restore power.

Red Connector

[] Check for leaks under the dishwasher. If a leak is

found, turn off power, tighten connections and

restore power.

[] Check for leaks around the door. A leak around

the door could be caused by the dishwasher door

rubbing or hitting adjacent cabinets. Reposition

the dishwasher if necessary. See Steps :1_:1_,12

and 13.

[] Most dishwasher models will drain about 3 min-

utes after the first fill. Check the drain line for

leaks when dishwasher drains. If leaks ore found,

turn off power, correct as necessary and then

restore power.

[] Open the dishwasher door and make sure most

of the water has drained. If the water does not

drain, check to be sure disposer plug has been

removed and/or air gap is free of debris.

[] Let the dishwasher run through another fill and

drain cycle. Check again to be sure there ore no

leaks.

[] At the end of the second drain, unlatch the door

and rotate the dial to the "OFF" position.

14

Page 15

Dishwasher Installation

STEP 20: REPLACE ACCESS PANEL AND

TOEKICK

In this step you will need the panels and the two

screws set aside in Step 4.

There are two tgpes of screws used. The 8-32 x 1/4"

screws are used at the top of the access panel and

should still be in place. The 20-16 x 3/8" screws are

used at the bottom of the access panel and secure

both the access panel and toekick.

IMPORTANT - screws are not

interchangeable. To prevent damage to your

dishwasher, use the proper screw in the proper

location. Do not mix screw types or lengths.

• Place the toekick against the legs of the

dishwasher.

• Remove the two 8-32 x 1/4" machine thread

screws.

• Align the access panel to the dishwasher.

• Select the two 8-32 x 1//4" machine thread screws

just removed and insert them through the top

holes in the access panel and into the dishwasher

frame.

• Tighten these screws.

• Align the toekick and make sure the bottom edge

is against the floor.

• Insert and tighten the two 10-16 x 3/8" sheet metal

thread screws, making sure the bottom edge of

the toekick stags in contact with the floor.

STEP 21: LITERATURE

[] Leave the Owners' Manual, Installation

Instructions, samples, and/or coupons with

consumer.

Remove, then Reinstoll ond Tighten

Instoll ond Tighten ....

10-16 x 5/8"

Sheet Metol Threod Screws

8-52 x 1//4"

Mochine Threod Screws

Figure AA

Tip: Prevent tub damage and reduce sound from

under the dishwasher

Use the machine thread screws in the top holes and

the sheet metal thread screws in the bottom holes.

Make sure the toekick is against the floor.

15

Page 16

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

GEConsumer & Industrial

General Electric Compang

Louisville, Kentuckg 40225

GEAppliances.com

16

Pub.No. 31-30271

Dwg. No. 206C1559P177

ND 06M-2101 (1/07)

Page 17

_iiii:iiiii¸!i!!!!ii!i!iCo i'_:!!!ii;i,.iiii-_"__!!!:?i'¸¸¸¸¸i!!!iiiiiii_iH_i-i_:i::il,.ii!!!!ii;:iii:ii:io!ii

Appliances

Notice d'installation

Lave-vaisselle Spacemaker ®

En cas de questions, appeler le 800.GE.CARES (800.432.2737) ou rendre visite _ notre

site web : www.GEAppliances.com

AVANT DE COMMENCER

Lire cette notice d'installation en entier

et avec soin.

IMPORTANT - Respecter tous les codes et

r_glements en vigueur.

• Remarque 0 I'intention de I'installateur : Laisser

cette notice pour le client et I'inspecteur local.

• Remarque _ I'intention du consommateur :

Ranger cette notice avec le Guide d'utilisation pour

consultation utt6rieure.

• Niveau de comp6tence : L'installation de ce lave-

vaisselle requiert des comp6tences m6caniques,

61ectriques et de plomberie 616mentaires.

L'installateur est responsable de I'installation

correcte. La garantie des appareils m6nagers GE

ne couvre pas une d6faillance de produit caus6e

par une installation incorrecte. Se reporter au×

informations dans la garantie.

• Dur6e d'installation : De 1 _ :3 heures.

L'instatlation initiale requiert plus de temps que

I'installation d'un appareil de remplacement.

• Caract6ristiques n6cessaires de 1'6vier : Le lave-

vaisselle Spacemaker ® est conqu pour 6tre instatl6

sous un 6vier sp6ciat peu profond. Ce tgpe d'6vier

est offert en trios mod61es diff6rents : le GPF95, un

6vier simple avec le trou de vidange au c6t6 droit

de 1'6vier ; le GPF96, un 6vier simple avec le trou

de vidange au c6t6 gauche de 1'6vier ; le GPF97,

un double 6vier. Ces 6viers sont en vente chez les

distributeurs agr66s d'appareils m6nagers GE.

IMPORTANT - Le lave-vaisselle DOlT atre

install_ de mani_re 6 permettre la d_pose

ult_rieure de I'enceinte pour route intervention

ult_rieure.

Prendre imm_diatement contact avec le

distributeur ou I'entrepreneur de construction si le

lave-vaisselle livr_ est endommag_.

Accessoires en option - Consulter la liste de

panneaux sur mesure dans le Manuel de I'utilisateur.

SI_CURITI_

Lire et observer tousles avertissements

(PRUDENCE et ATTENTION) de cette notice.

Toujours porter des gants et des lunettes de

s_curit_ en ex_cutant les procedures d'installation

d_crites dans la notice.

LIRE ATTENTIVEMENT.

IL FAUT GARDER CES INSTRUCTIONS.

Page 18

PII_CESFOURNIES DANS LE

N#CESSAIRE D'INSTALLATION

[] Deux (2)vis 5 bois 5 t@tecruciforme n°

8-18 de 5/8 po

[] Un couvercle de boTtedejonction et une

vis h t@te h six puns n° 10

[] Tuguu de vidunge de 198 cm (78 po) et

collier de tuguu

[] Documentation, _chuntillons et/ou

coupons de r_duction

MATE_RIAUX REQUIS

[] Cordon _lectrique WXO9X70910 si requis

pour I'instullution

[] Trois (3) serre-fils homologu_s UL

[] Rubun d'_tanch_it_ pour joints filet_s

[] Coude h angle droit, bugue et _crou de

compression (filetuge externe de 3/8

po h une extremitY, I'uutre extr_mit_

_tunt dimensionn_e pour s'udupter h

I'utimentution en euu)

[] Kit de support h montage lateral GPF65

pour les plans de travail en granite

POUR LES NOUVELLES INSTALLATIONS

[] Chble _lectrique

[] Conduite d'eau en cuivre de MINIMUM

3/8 po

[] R_ducteur de tension pour branchement

_lectrique

[] Robinet d'arr_t manuel (recommand_)

[] Intervatle d'air pour le tuyau de vidange,

si n_cessoire

[] T_ de vidage pour la plomberie de la

maison, si n_cessaire

[] Colliers de tuyau 8 vis

[] Evier GPF95, GPF96 ou GPH97 en acier

inoxydable

Ensemble de vis

_Visaboisat6te =[_ VispourboTtede

Tuyau de vidange tuyau

de 198 cm 178po}

C6ble _lectrique ou

cordon d'alimentation

WR09×70910

Coude 6 angle droit,

bague et _crou de

compression

cruciforme n ° _ jonction 6 t6te 6

8 de 518 po de _ six pans n°

long "_ 10- 112 po de long

Collier de

3 serre-fils

Kit de support 6

montage lat6ral

GPF65

O

R_ducteur de

tension

I_vier GPF95 en acier

inoxydable

Robinet

d'arr_t

Intervalle T_ de

d'air vidage

I_vier GPF96 en acier

inoxydable

Couvercle de boTte

de jonction

d'_tanch_it_

de filet

Conduite d'eau en

cuivre de 318 po

minimum

Colliers de tuyau

6 vis

I_vier GPF97 en acier

inoxydable

OUTILS REOUIS

[] Lunettes de s_curit6

[] Tournevis h douille de 1//4 po et 5/16 po

[] Lampe de poche

[] Gants

[] CI6 5 molette de 15 cm (6 po)

[] Tournevis _]t6te cruciforme

[] Cl_ 8 douille de 15/16 po

[] IVt6treruban

[] Niveau

[] Equerre de menuisier

[] Seau pour attraper I'eau vidang6e

du tugau

[] Coupe-tube

POUR LES NOUVELLES INSTALLATIONS

[] Scie cloche

[] Perceuse et m_ches appropri_es

Lunettes de s6curit_

Gants

M_tre ruban

Bucket

Tournevis 6 douille de 114 po

et de 5/16 po

Cl_ 6 molette Tournevis

Niveau

Coupe-tube

cruciforme

Scie cloche

Lampe de poche

21_6 douille de

15/16 po

I_querre de

menuisier

Perceuse

et m6ches

appropri_es

Page 19

Preparation pour I'installation - Enceinte

PRI:!PARATIONDE L'ENCEINTE DU LAVE-

VAISSELLE ET DE L'EMPLACEMENT DE L'I:!VIER

• Installer les tugaux d'alimentation d'eau et de

vidange de 1'6vier dons la section A.

• Installer le tugau d'eau chaude vers le lave-

vaisselle dons la section B.

• Installer le brogeur de d6chets, les tugaux

d'alimentation d'eau du robinet, le siphon,

I'intervalle d'air et le robinet d'arr@ de I'eau dons

une armoire large de 30 cm (12 po), la section C.

Plan de travail: 6paisseur min. de 3,8 cm (1 1/2 po)_

Max. 26 cm

(i0 1/4 io)

II

Plinth

/

• Le diam_tre de I'ouverture du brogeur de d_chets

duns I'_vier doit @re de 19 cm (7 1/2 po), comme

indiqu6 8 lu section C.Ceci permet d'instutler le

brogeur et Io plomberie duns Io section C uvec un

_vier soit simple, soit double. Se reporter 8 Io figure

A ci-dessous et 5 Io figure F1 5 Io page 6.

Max. 52 cm

--cuve de

Min. 1,9 cm (3/4 po)--[ I_ _in. 28 cm

[

3 cm (1

de 3,8 cm 2'

(i1/2 po)

du coude

Max. 15 cm

rue lat6rale

du lave-vaisselle

Max.i0cm

(4 po)

(20 1/2 po)

(6 po)

D6g. max.

cm (11 3/4 po)

plomberie

_/jvlur

Max. 2,5 cm (ipo)

PROFONDEUR MAX

DE 26 cm (lO 1/4 po)

POUR PLOMBERIE

de 1'6vier

t

I.... I._ _J',,

Min. 30 cm So

61 cm (24 po 112po)

PRI:!PARATION DE L'ARMOIRE POUR

L'INSTALLATION DE L'I_VIER

r!_.,'lli=_ll[e]_l

• L'ouverture de I'armoire doit ovoir one largeur et

une profondeur d'au mains 61 cm (24 po) et une

hauteur de 87 cm + 0.6 cm (34 1/4 po + 1/4 po).

• Ce lave-vaisselle s'encastre sous un @viersp@ciat

d'une profondeur de maximum 15 cm (6 po) dans

un plan de travail de 3,8 cm ( 1 1/2 po).

_D6coupe

Pour r_duire le risque de choc _lectrique,

d'incendie ou de blessures, I'installateur

doit s'assurer que le lave-vaisselle est

enti_rement enclos au moment de

I'installation.

pour 1'6vier

20 cm x 51 cm

(8 x 20 po) d6coupe

arri@e de I'armoire

adjacente

Min. 61 cm

Figure A

(24 po) armoire

• Le lave-vaisselle doit @re enti_rement enclos sur le

hout, les c6t_s et I'orri_re.

• Le Iove-voisselle ne peut toucher oucune portie de

I'enceinte.

Mur

/

--Max. s2cm ----

20 1/2 po cuve_d'#vier

avant _,

du bac

Espace

\

Remarque. - II peut y avoir un espace entre le rebord avant du

Lave-vaisselle

_------Min.61 cm--

(24 po)armoire

bac du lave-vaisselle et I'avant de I'armoire sila

profondeur de I'armoire est mains de 61 cm (24

po) ou sila cure d'6vier n'a pas 6t6 install6e selon

les directives.

Figure B

adjacent au lave-vaisselle

cm (24 po)

Si I'espacement est de plus de 2 cm (314po),

il faut d6placer la cuve d'6vier pour qu'elle

s'accorde aux dimensions indiqu6es.

Page 20

Preparation pour I'installation - Vidange

PRI_PARATION DE LA PLOMBERIE

DE VIDANGE

Exigences de vidange

• Respecter les codes et r_gtements Iocaux.

• Le tuyau de vidange ne peut pas @re plus de 3 m

(10 pi)de long.

• Une boucle de vidange #lev#e ou un intervalle d'air

est requis. Voir ci-dessous.

M_thode de vidange

Letype d'installation de vidange est li@aux

conditions suivantes :

• Est-ce que les codes ou r@gtements Iocaux exigent

un intervalle d'air ?

• Est-ce que le t6 de vidoge se trouve 5 mains de 46

cm (18 po)du sol ?

Si la r@ponse _ une de ces questions est OUI, il

faut utiliser un intervalle d'air (m@thode n° 1). Si Io

r6ponse est NON oux deux questions, il fout utiliser

soit un intervolle d'oir, salt une boucle de vidonge

61ev6e (m_thode 2).

PRUDENCE

II FAUTutiliser un intervalle d'air si le raccord du tuyau

de vidange au t_ de vidage ou au broyeur de d_chets

est 6 mains de 46 cm (18 po) du niveau du sol. Le lave-

vaisselle risque de ne pas se vidanger correctement et

de s'endommager si le raccord de vidange n'est pas 6 la

bonne hauteur avec un intervalle d'air ou une boucle de

vidange _lev_e de minimum 81 cm (32 po).

MISTHODE 1 - Intervalle d'air avec t@de vidage ou

broyeur de d@chets

Figure C

Installation avec t6

devidage

MI_THODE 2 - Boucle de vidange @lev@eavec t@de

vidage ou broyeur de d@chets

Trouver un moyen d'attacher le tuyau de vidange

au-dessous du plan de travail. Ceci sera accompli 5

une @ape utt@rieure.

Installation avec brogeur

de d@chets

v46 m,To,

Figure D

Installation avec t6

de vidage

Installer le t@de vidage ou le broyeur et I'intervalle

d'air selon les directives du fabricant.

Pr@paration de I'armoire

Percer un trou de 38 mm (Z Z/2 po) dans la paroi de

I'armoire dons la zone hachur@e indiqu@e 5 la figure

E pour le passage du tuyou de vidonge. V@rifier

que les bards du trou sont lisses. Dons une @ape

ult@rieure, il lout gtisser le tuyau de vidange ou

travers du trou pour le raccorder au drain.

Installation avec brogeur

de d@chets

IMPORTANT- Pendant le

raccord du tuyau de vidange

au broyeur de d_chets, v_rifier

que le bouchon de vidange a

_t_ enlev_. Le lave-vaisselle

ne peut pas se vider avec le

bouchon en place.

bouchon

de vidange

, nlever le

Page 21

Preparation pour I'installation - alimentation lectrique

PRI_PARATION POUR LE BRANCHEMENT

I_LECTRIOUE

v!Y-'_ll_l_ll[e]_l

Alimentation _lectrique

• Cet appareil dolt avoir une alimentation @lectrique

de 120 V,60 Hz et @re branch_ sur un circuit

ind6pendant correctement mis 5 la terre et

prot6g6 par un disjoncteur de 15 ou 20 A ou un

fusible temporis6.

• Le cOblage dolt @re 5 deux ills plus un fit de mise

terre.

• Si I'alimentation 6lectrique n'est pas conforme

ces conditions, appeler un 6lectricien agr66 avant

de continuer.

Mise 6 la terre - raccord permanent

Cet appareil dolt @re raccord@ de faqon permanente

un r@seaude ills m@alliques mis 5 terre ou il

faut installer un fil de mise 5 terre avec les ills

d'atimentation. Cefil dolt @trebranch@ 5 la borne de

terre de I'@quipement ou 5 un fil sur I'appareil.

Instructions de mise 6 la terre - modules 6 cordon

d°alimentation

Cet appareil dolt @tremis 5 la terre. En cas de

mauvais fonctionnement ou de panne, la mise

la terre r@duit le risque de choc @lectrique en

fournissant un passage de moindre r@sistance au

courant @lectrique. L'appareil est @quip@d'un cordon

conducteur de mise 5 la terre et une fiche de terre.

IIfaut brancher la fiche sur une prise appropri@e qui

a _t@install_e et mise 5 la terre conform_ment aux

codes et r_gtements Iocaux.

SI_CURITI_: Enlever les fusibles ou

d_brancher le disjoncteur de la maison

avant de commencer I'installation. Ne pas

utiliser une rallonge ou un adaptateur de

prise avec cet appareil.

Un branchement incorrect du conducteur

de mise 6 la terre peut causer des chocs

_lectriques. En cas de doute sur la mise 6 la

terre de I'appareil, consulter un _lectricien

agr_ ou un r_parateur. Ne pas modifier

la fiche fournie avec I'appareil. Si la fiche

ne correspond pas 6 la prise, faire installer

une prise appropri_e par un _lectricien

qualifi_.

_ __ _ _

..S \.. Autre

" [ J ]'l emplacement

cm, , Troudemax.S8mm JJ / possible de

-Pm-_--/(1-1/2 po)dediam_tre lOcm _ la prise

46 cm _ , _ _\\Ocm(apo)4-U-_/ _ tt

18po, I_'{ ............! L__ LellI

\ I 1_-15cm B _ 7,5 cm (5 po)

\-M'-(6 po) (6po) m deI'armoire

\ _/- ....... o;

_t J \/ b J_cm\\ \1 I t

_ j/l] /Emplacement du mur XX,kX

_: -V dd: Icao:rr_et Terre__kL

Figure E Noir-_Bl!nc

Preparation de I'armoire et du passage des ills

• Les ills doivent entrer dans la cavit@ d'un c6t@

ou de I'autre, de I'arri@re ou du sol dans la zone

hachur@e indiqu@e 5 la figure E.

• Couper un trou d'un diam@tre maximal de

3,8 cm (1 1/2 po) pour permettre le passage

des fits d'alimentation @lectrique. Le c6ble de

branchement direct peut passer dans le m@me

trou que le tugau de vidange et le tugau d'eau

chaude si c'est plus pratique. Les rebords du

trou doivent @trelisses et arrondis. Si la paroi de

I'armoire est en m@al, recouvrir les rebords du trou

pour prot@ger les ills.

REMARQUE.- Un cordon d'atimentation muni

d'une fiche dolt passer par un trou s@par@.

Prot@

Branchement _lectrique du lave-vaisselle

Le branchement _lectrique se fait 5 I'avant droit du

lave-vaisselle.

• Pour les branchements permanents, acheminer

le c6ble tel indiqu@ 5 la figure E.Le c6ble dolt

s'@endre au moins 61 cm (24 po)de la paroi arri@re.

• En cas de branchement avec un cordon

d'alimentation, installer une prise 5 trois broches

sur la paroi arri@re de I'armoire adjacente de 15 cm

46 cm (6 po 5 18 po) de I'ouverture et de 15 cm

46 cm (6 po 5 18 po) au-dessus du sol, tel illustr@

la figure E.

_I" 1--12,5 cm (Spo) 1 jr(aPO)_J decourant

II \\\+-xl

Trou d'un diam@tre

maximal de

58 mm (i-i/2po)

Page 22

Preparation pour I'installation - Alimentation d'eau chaude

PRI_PARATION DE L'ALIMENTATION D'EAU

CHAUDE

Tuyau d'eou chaude

• Le tuyau peut entrer d'un c6t_ ou de I'autre, de

I'arri_re ou du sol dans la zone hachur_e indiqu_e

la figure F.

• Le tuyau peut passer par le m_me trou que le

cable _lectrique et le tuyau de vidange. Une

alternative est de couper un trou s_par_ d'un

diam_tre de 3,8 cm (1 1/2 po) pour accommoder

le tuyau d'eau. Le tuyau d'eau ne peut pas passer

par le trou du cordon d'alimentation si ce cordon

est muni d'une fiche.

cm (5 po)-

lO cm (4

Lo pression de Io conduite d'olimentotion d'eou choude

doit 6tre d'ou moins 1,4 bor (20 psi). Une pression plus

foible risque de couser une fuite dons le robinet et des

d_g6ts causes par I'eou.

Bronchement des conduites de I'_vier

Les conduites d'eau chaude et froide de I'@vier et

le tuyau de vidange de I'@vier doivent @tre instatl@s

au-dessus et _ c6t@ du lave-vaisselle et non derri@re

le lave-vaisselle. Se reporter aux zones A et C de

la figure A _ la page 3 et _ la figure F3_ci-dessous.

Ceci est n@cessaire pour laisser suffisamment de

d@gagement au lave-vaisselle au cours de son

installation dans I'armoire. Les conduites install@es

directement derri@re le lave-vaisselle risquent

d'entraver le placement du lave-vaisselle dans

I'armoire et de le pousser au-del@ des armoires

adjacentes.

PRUDENCE

h

Chaudll:-::-

cm

5 cm (2 po)

de I'armoire

Devant --.-

de I'armoire

Figure F

48 cm (19 po) du mur _l

5 cm (2 po) du sol

(6 po)

Bronchement du tuyou d'eou

• Couper I'atimentation d'eau.

• Installer un robinet d'arr@ manuel duns un

endroit accessible. (En option, mais fortement

recommand_ et peut @re exig_ par les codes

Iocaux.)

• La conduite d'eau se branche au c6t@gauche du

lave-vaisselle. Installer la conduite d'alimentation

d'eau chaude avec un tuyau en cuivre de

minimum 9 mm (3/8 po). Acheminer la conduite tel

illustr@ @la figure Fet I'amener _ un minimum de

48 cm (3_9po) du mur arri@re.

• R@gterle chauffe-eau pour que I'eau sorte _ une

temp@rature de 49 5 65 °C (3_205 3_50°F).

• Purger la conduite d'eau pour @liminer tous les

d@bris.Laisser couter I'eau et les d@bris dans un

seau.

• Lapression de la conduite d'alimentation d'eau

chaude dolt @treentre 3_,4et 8.3 bar (20et 3_20psi).

La figure F3_montre une installation 5 double @vier,

brogeur de d@chets et boucle de vidange @lev@e.

Remarque. - Toutes les conduites se trouvent

au-dessus, en dessous ou 5 c6t@du lave-vaisselle.

Aucune conduite n'a @t@instatl@e derri@re I'appareil.

Double @vierde 15cm

(6 po) en acier inoxgdabl_

Eau

Eau

Robinet d'arr@t d'arriv@e

d'eau du lave-vaisselle

Alimentation d'eau

du lave-vaisselle

Figure FI

ruyau de vidange

du lave-vaisselle

Plan de travail

Profondeur de

v3,5 cm (25 po)

Epaisseur de

r 3,8 cm ( 1 1/2 po)

-D@gag.de 5,8 cm

(1 1/2 po) du coude

Robinet d'alimentation

d'eau du lave-vaisselle

Page 23

Installation du lave-vaisselle

PRUDENCE

Ne pas enlever la palette en bois avant d'6tre pr6t 6

installer le lave-vaisselle. Le lave-vaisselle bascule Iorsque

la porte est ouverte sans la base.

I_TAPE 1. PRE_PARATION

Trouver les pi_ces suivantes dans le kit d'instatlation

et les mettre de c6t6 aux fins d'utilisation aux @apes

indiqu_es.

• Ensemble de vis - @apes 5 ou 16 et 15

• Couvercle de boTte dejonction - @ape 5ou 16

• Tugau de vidange et collier de tugau - @ape 7

• Manuel de I'utilisateur - @apes 18 et 21

• Echantillons et/ou coupons de r6duction - @ape 21

I_TAPE

2" VITRIFICATION DE L°I_QUILIBRE DE

LA PORTE

I_TAPE3 • DISPOSE DE LA PALETTE EN BOIS

IMPORTANT - Ne pas enlever la palette

en donnant des coups de pied ! Ceci risque

d'endommager le lave-vaisselle.

• Emmener le lave-vaisselle

proche du lieu de son

installation et le bascuter

sur ledos.

• Enleverles

quatre pieds

de raise a

niveau de

dessous de la

palette avec une

cl@5 douilles de

15/16 po.

• Enleveretjeter la

palette en bois.

Figure H

19mm

po)

• En laissant le lave-vaisselle sur la palette en bois,

ouvrir et fermer la porte pour v6rifier son 6quilibre.

• La porte est correctement 6quilibr6e Iorsqu'elle

s'affaisse 16g&rement en position mi-ouverte et ne

s'61&vepas en position enti&rement ouverte.

• Si n_cessaire, augmenter ou diminuer la tension,

tel illustr& Fermer la porte et ajuster les ressorts

pour corriger 1'6quilibre.

Le maillon est bien

attach6 au bras

d'articulation

Placer le crochet dc

le trou _ partir de rint@ieur

de I'encadrement

Figure G

Conseil pour _viter des frais d'intervention inutiles

pour un probl_me d'_quilibre de porte.

V@rifier que I'extr@mit@du ressort est enti@rement

engag@e dans le trou de I'encadrement et le

maillon du ressort est solidement attach@ au bras

d'articutation.

• Visser de nouveau les pieds de mise 5 niveau dans

le cadre du lave-vaissellejusqu'5 environ 1,9 cm

(3/4 po)du cadre, tel illustr@.

I_TAPE4" DISPOSE DU PANNEAU D'ACCI_S ET

DE LA PLINTHE

Les trous de montage sup@rieurs du panneau

d'acc@s sont munis d'une fente.

• Enlever les deux vis autotaraudeuses inf@rieures

10-16 de 3/8 po. Laisser en place les deux vis 5

filetage usin@sup@rieures 8-32 de 1/4 po.

• Gtisser le panneau d'acc@s tout 5 fait vers la

gauche.

• Pousser doucement le panneau d'acc@s vers

I'avant pour le d@gager des vis sup@rieures.

Mettre le panneau d'acc@s,la plinthe et les vis de

c6t@en vue d'utilisation 5 I'@ape 20.

Conseil

pour _viter N_pasenlever

d'endommager tesvis_filetage usin__

le bac.

Au cours de

cette @ape,

n'enlever

que les vis

autotaraudeuses Enlever les deux

de 3/8 po. Ceci visautotaraudeuses

_vitera de les des/8po

confondre avec

les vis 5 filetage

usin_ de 1/4 po Figurel "tII

0 I'@ape 20.

Page 24

Installation du lave-vaisselle

I_TAPE 5 :INSTALLATION DU CORDON

I_LECTRIQUE

Ignorer cette _tape si le lave-vaisselle doit _tre

branch_ de mani_re permanente sur le circuit

_lectrique de la maison ou s'il est muni d'un

cordon d'alimentation install_ en usine.

A cette @ape, trouver le couvercle de la boTte de

jonction et la vis n° 10 de 1/2 po (_t@e (_six pans

mis de c6t@5 I'@ape 1.

Le cordon d'alimentation et les raccords doivent

_tre conformes 5 la section 422 du Code national

de I'@lectricit@et aux codes et r_gtements Iocaux.

Lo Iongueur maximale du cordon est de 2 m@res

(6 pi). Le kit de cordon d'atimentation WXOgX70910,

en vente che7 les distributeurs agr@@sd'appareils

m@nagers GE,satisfait @ces crit@res.

I_TAPE 6 : INSTALLATION DU COUDE A

ANGLE DROIT

• Envelopper un coude 5 angle droit de ruban

d'@tanch@it@de filet.

• Serrer le coude 5 angle droit sur la vanne.

• Ne pas trap serrer le coude pour @viterde tordre le

support de la vanne ou de briser le raccord de la

vanne.

• Placer I'extr_mit_ du

coude face 5 I'arri@re

du lave-vaisselle.

)art de la vanne

Coude 6 @lectrique rouge

angle droit au

de filet de remplissage

Figure K

I_TAPE 7 : RACCORDEMENT DU TUYAU DE

VIDANGE AU PORT DE VIDANGE

DU LAVE-VAISSELLE

Support de boTte Blanc /

de J°icti°n_j_ _

Figure J

/ ,

• Installer le r@ducteur de tension sur le support de

la boTte dejonction.

• Gtisser le cordon @lectrique au travers du r@ducteur

de tension et serrer.

• V@rifierque les ills noir, blanc et vert du lave-

vaisselle passent au travers du petit trou du

support de boTtedejonction.

• Raccorder le fit d'alimentation blanc (ou 5 nervures)

au fil blanc du lave-vaisselle, le fit noir (ou lisse)

au fil noir du lave-vaisselle et la vis de masse

au fit vert du lave-vaisselle. Utiliser des serre-fits

homotogu@s UL de taille appropri@e.

• Installer la boTte dejonction avec la vis 5 t@te5 six

pans n° 10. V@rifierque lecouvercle ne pince pas

les ills.

Sauter cette _tape si le tuyau de vidange a _t_

install_ en usine.

Dons cette @ape, il faut utiliser le tugau de vidange

et le collier mis de c6t@5 I'@tape 1.

IMPORTANT- Pr_venir les dommages

inflig_s au tuyau de vidange et les fuites

_ventuelles. Prendre soin de ne pas entailler ou

couper le tuyau de vidange.

• Acheminer le bout @trait du tugau de vidange

du c6t@gauche du lave-vaisselle au travers du

r@ducteur de tension attach@ au cadre du lave-

vaisselle et vers le centre du lave-vaisselle, tel

illustr@ par les figures Let M.

• Placer le collier de tugau par-dessus le bout @roit

du tugau de vidange.

• Pousser le bout @trait du tugau de vidange par-

dessus le port de vidange du collecteur en prenant

soin de bien le placer contre le cran d'arr@ du

tugau.

• Serrer le collier 5 un couple d'au mains 15 pouces-

livres.

Figure L _onge

\\. / ,R@ducteur

o

Page 25

Installation du lave-vaisselle

Remarque. - Le tuyau de vidange fourni avec le

lave-vaisselle est environ 2 m_tres de long (78

po). Si n#cessaire, un tugau de 3 m_tres(10 pi) est

disponible chez les distributeurs agr#es d'appareils

m#nagers GE. Le tuyau de 3 m porte le num#ro de

piece GPFIOS.

Cran d'arr_t de tuyau

Tuyau de vidange Port de vidange

Figure M du collecteur

Sice port est

present, ne pus

I'utiliser

I_TAPE9" INSERTION DU TUYAU DE

VIDANGE ET, LE CAS I_CHI_ANT,

DU CORDON I_LECTRIQUE AU

TRAVERS DE L'ARMOIRE

• Redresser le lave-vaisselle et le placer devant

I'ouverture de I'armoire.

• Gtisser le tugau de vidange duns le trou for_

pr_c_demment duns Io paroi de I'armoire.

• En cos d'utilisation d'un cordon _lectrique, gtisser le

bout du cordon au travers du trou sp_cifiquement

d_coup_ pour le cordon.

Acheminer le cordon _lectrique directement vers

I'arri_re de la boTtedejonction en _vitant tout

contact avec

leressortde

laporte et

d'autres

partiesdu

lave-vaisselle.

EQU "'-.

Conseil pour _viter les frais d'intervention inutiles

pour des probl_mes de vidange.

V@ifier que le raccord du tuyau de vidange ne fuit

pus et que le tuyau est achemin_ uu travers du

r_ducteur de tension de mani_re 6 ne pus se plier

Iors de I'installation du lave-vaisselle duns I'armoire.

I_TAPE 8 : MISE EN PLACE DU TUYAU

D'EAU ET DE L'ALIMENTATION

I_LECTRIQUE

• Placer le tuyau d'eau et le cSblage de la maison

sur le sot de I'ouverture pour _viter d'entraver la

base du lave-vaisselle et les composants sous le

Iove-voisselle.

Figure O

Conseil pour _viter les frais d'intervention inutiles

pour un remplissage ou une vidange incorrect ou

des probl_mes de bruit.

Placer le tuyau et le cordon de mani_re 6 ce qu'ils

n'entravent rien en dessous ou derriere le lave-

vaisselle.

I_TAPE10" INSTALLATION DES SUPPORTS DE

MONTAGE LATI_RAL OPTIONNELS

GPF65

Sauter cette _tape si le dessous du plan de travail

est en bois ou une mati_re similaire.

• Acheter et installer le kit de support de montage

lateral si le dessous du plan de travail est en

granite ou mati_re similaire qui n'accepte pas

les vis 6 bois. Le kit GPF65 est en vente chez les

distributeurs agr_s d'appareils m_nagers GE.

• Se reporter 6 la figure P et suivre les indications

du kit. Supports

de montage

lateral

Figure N

-Tuyau Alimentation

d'eau

_lectrique

Cadredu bac

__ Kit de support de Vis de fixation

montage lateral de support

en option Figure P (2 de chaque c6t_)

9

Page 26

Installation du lave-vaisselle

I_TAPEII" PLACEMENT DU LAVE-VAISSELLE

DANS L'ARMOIRE

IMPORTANT- Ne pas pousser contre le

panneau avant avec le genou. Ceci peut causer

des dommages.

• Soisir les c6t_s du ponneou ovont et glisser petit

5 petit le Iove-voisselle dons I'ouverture. Tirer le

tugou de vidonge et, le cos @ch@ont,le cordon

@lectrique ou trovers des trous dons I'ormoire

odjocente en continuont 5 pousser le Iove-

voisselle vers son emplocement finot.

usser contre le panneau

de la porte avec le genou. Ceci

Figure 0

endommoge le ponneou de Io porte.

I_TAPE12 • PLACEMENT ET MISE A NIVEAU

DU LAVE-VAISSELLE

IMPORTANT- Le lave-vaisselle doit atre 6

niveau pour assurer le fonctionnement correct

des _gouttoirs, du lave-vaisselle et de la porte. II

faut mettre le lave-vaisselle 6 niveau de gauche 6

droite et de I'avant vers I'arri_re. Ceci assure que

les _gouttoirs ne se d_placent pas de leur propre

chef, que I'eau circule librement vers I'entr_e de la

pompe et que la porte se ferme sans accrocher les

c6t_s du bac.

• Enlever 1'6gouttoir du bos et plocer un niveou sur Io

porte et le roil de 1'6gouttoir du bos, tel illustr6 5 Io

figure R.

J

V6rifier

le niveau

de I'avant

I'arri6re

• Le cos @ch@ont,v@rifier que le motelos isolont

du boc enveloppe bien le boc. II ne peut pos

se retrousser 5 certoins endroits ni entrover

les ressorts de Io porte. Si c'est le cos, lisser et

recentrer le motelos d'isolotion ovont de glisser le

Iove-voisselle vers son emplocement finol.

• V@rifier que le tugou de vidonge n'est pos pinc@

sous ou 5 I'orri@redu Iove-voisselle.

• V@rifier que le cabloge de Io moison, le tugou

de vidonge et le tugou d'olimentotion d'eou

n'entrovent pos les pi@cessitu@essous le Iove-

voisselle.

• Le rebord du boc du Iove-voisselle doit se trouver

5 environ ]_,9cm (3//4 po)de Io foce de I'ormoire

odjocente. Voir Io figure R.

Conseil pour _viter les frais d'intervention inutiles

causes par un panneau endommag_.

Ne pos pousser sur le centre du ponneou ovec les

moins ou les genoux en gtissont le Iove-voisselle en

ploce.

lo

brifier le niveou

d'un c6t_ (_I'outre

• R_gler le niveou du Iove-voisselle en tournont

chocune des quotre pottes ou bos du Iove-

voisselle, tel illustr_ 5 Io figure S.

I J

T!urner les _I_/i

pieds_our r@gl_

• Le Iove-voisselle est 5 niveou Iorsque I'indicoteur

de niveou est centr_ de gouche 0 droite et de

I'ovont vers I'orri_re. Lo porte du Iove-voisselle dolt

pouvoir se fermer sons toucher les c6t_s du codre.

• Remettre en ploce I'_gouttoir du bos.

Conseil pour _viter les frais d'intervention inutiles

causes par un lavage inad_quat et le mauvais

fonctionnement des _gouttoirs.

Tirer les 6gouttoirs vers le dehorsjusqu'O mi-

trojectoire. IIsne doivent pos bouger. Ouvrir et

fermer Io porte. Lo porte doit recouvrir I'ouverture

du boc sons toucher les c6t_s. Remettre le Iove-

voisselle 5 niveou si les _gouttoirs se d_plocent de

leur propre chef ou si Io porte s'occroche sur les

c6t_s du boc.

Page 27

Installation du lave-vaisselle

I_TAPE 13 : FIXATION DU LAVE-VAISSELLE

AU-DESSOUS DU PLAN DE

TRAVAIL OU AUX C6TI_S DE

L'ARMOIRE

Damscette @ape, il faut utiliser les deux vis 6 bois 6

t@e cruciforme de 5/8 po mis de c6t@h I'@ape 1.

IMPORTANT- Le lave-vaisselle doit _tre

centr_ dans I'ouverture de I'armoire. Tout contact

avec les armoires ou le plan de travail peut causer

des fuites et endommager le panneau de porte

et/ou de commande.

• Si le plan de travail est en bois ou une mati@e

similaire, attacher le lave-vaisselle au plan de

travail en enfon£:ant les vis 6 t@e cruciforme dons

le plan de travail au travers des supports de plan

de travail.

• Si le plan de travail est en granite ou autre mati@e

similaire, enfoncer les vis 6 t@e cruciforme dons

les armoires adjacentes au travers des supports

de montage lot@ok

• Veiller 6 ce que les vis soient enfonc6es

perpendicutairement et compl6tement de mani6re

h ne pas entraver le fonctionnement de la porte et

endommager le panneau de commande. Voir la

figure T.

I_TAPE 14: BRANCHEMENT DE

L'ALIMENTATION D'EAU

Brancher le tuyau d'atimentation d'eau au coude h

angle droit instatl_ h I'@ope 6.

• Gtisser 1'6crou de compression puis Io bogue sur

I'extr6mit6 du tugau d'eau.

• Ins6rer le tugau d'eou dons le coude h ongte droit.

• Gtisser Io bogue contre le coude et serrer 1'6crou de

compression.

compress,onx

issage

au

d'alimentation

d'eauchaude

Support de plan

de travail

Supports de montage

lat@ral(enoption)

J

19 mm

(3//4po)

Figure T

Conseil pour _viter les frais d'intervention inutiles

causes par une fuite ou un panneau de commande

endommag_.

Veiller h ce que le lave-vaisselle soit centr_ dons

I'ormoire et que Io porte s'ouvre et se ferme sons

buter contre les armoires odjocentes. Enfoncer

les vis de montage perpendicutoirement et

compl@ement.

Figure U

IMPORTANT- Ouvrir et fermer la porte pour

v_rifier que le ressort de la porte ne frotte pas ou

n'est pas en contact avec le tuyau de remplissage

ou d'alimentation d'eau. Changer le passage des

tuyaux d'alimentation d'eau ou l_g_rement plier le

support de robinet s'il y a un bruit de frottement

ou une interference.

Conseil pour _viter les frais d'intervention inutiles

en cas de bruit ou de fuite.

Veiller h ce que le ressort de la porte ne frotte pas

contre le tugou de remplissoge ou d'olimentotion

d'eou.

11

Page 28

Installation du lave-vaisselle

I_TAPE 15 :BRANCHEMENT DU TUYAU DE

VIDANGE

L'extr_mit_ mout_e du tuyau de vidange se branche

sur des orifices d'admission de 5/8 po 8 1 po de

diam_tre de I'intervatle d'air, du t_ de vidange ou du

brogeur de d_chets.

• D_terminer la taille de I'orifice d'admission.

• Si n_cessaire, couper le connecteur du tugau de

vidange 8 la ligne marquee pour installation sur

I'orifice d'admission.

Ligne de coupe

/

2,5cm F__ -'_-1 16mm_-I

(5/8 po) L

(1 po) _ /

IMPORTANT- IIne faut pas couper

Figure V IClportion ondul#e

du tuyau.

• Si le tugau de vidange est trap court et le tugau de

vidange GPF10L n'a pus _t_ achet_, une Iongueur

de tugau de maximum un m_tre (42 po) peut #tre

ajout#e pour obtenir un tugau de 3 m_tres (10 pi)

de long. Utiliser un tugau 6 diam_tre int#rieur de

5/8 po ou 7/8 poet un manchon de raccord pour

connecter les deux bouts de tugau. Maintenir le

manchon en place avec des colliers.

1g

M(_thode 1 - Intervalle d'air avec t6 de vidage ou

broyeur de d6chets

Installation avec un

Figure ×

M6thode 2 - Boucle de vidange 61ev6e avec t6 de

vidage ou broyeur de d(_chets

Attacher le tuyau de vidange sous le plan de travail

avec un 6trier.

t_ de vidage

Installation avec un

brogeur de d@chets

LcmI

v46 m, t po,

Installation avec un

t_ de vidage

Figure Y

IMPORTANT- En cas de branchement du

tuyau de vidonge 6 un broyeur de d_chets, v_rifier

que le bouchon de vidange a _t_ enlev& Le lave-

vaisselle ne peut pas se vider avec le bouchon en

place.

Installation avec un

brogeur de d_chets

IVlanchon

Collier

Collier

Figure W

IMPORTANT- Pour obtenir une vidange

ad6quate, la Iongueur totale du tuyau de vidange

ne doit pas d6passer 3 m_tres (10 pi).

• Brancher le tugau de vidange sur I'intervalle d'air,

t# de vidange ou brogeur en utilisant la m#thode

d#crite pr#c#demment. Attacher le tugau avec un

collier 6 vis.

12

bouchon

de vidange

_1 nlever le

Conseil pour _viter les frais d'intervention inutiles

causes par un probl_me de vidange.

V6rifier que I'exc_dent du tugau de vidange a _t6

retir6 de I'ouverture de I'armoire. Ceci 6vite que

le lave-vaisselle ne plie ou n'6crase la Iongueur

exc6dentaire de tugau pr6sente dans sa cavit6. Si

le tugau de vidange est raccord6 5 un brogeur de

d6chets, v6rifier que le bouchon de vidange a 6t6

enlev6.

Page 29

Installation du lave-vaisselle

I_TAPE16" BRANCHEMENT DE

L'ALIMENTATION I_LECTRIQUE

Passer 6 I'_tape 17 si le lave-vaisselle est d_j6

muni d'un cordon _lectrique avec fiche.

Si le circuit de la maison n'est pas un circuit

h 2 fils avec un fil de terre, I'installateur doit

installer un fil de terre.

Quand le circuit de la maison est en

aluminium, veiller h utiliser une pate

antioxydante et des connecteurs aluminium

6 cuivre homologu_s UL.

• Att(ucher les ills de I(] m(]ison (]u dos du support de

I(] boite dejonction (]vec un r_ducteur de tension.

• Identifier les trois ills du lave-vaisselle avec les

extr_mit_s d_nud_es (blanc, noir et vert), tns_rer

les ills du I(]ve-v(]isselle dans le petit trou du

support de la boite dejonction. Utiliser des serre-

ills homologu_s UL de t(]ille (]ppropri_e pour

r(]ccorder I(] terre du circuit (]u fit vert, lefit blanc

(]u blanc et le fit noir (]u noir.

Remarque :V_rifier que lesfaisceaux de ills

passent au travers du petit trou du support

Blunc

\

Support de la

boTte de jonction

Figure Z

Terre

I_TAPE17: INSTALLATION DU COUVERCLE

DE LA BO/TE DE JONCTION

Passer 6 I'_tape 18 si le couvercle de la bo_'te de

jonction est d_j6 install&

Cette _t(]pe requiert le couvercle de I(] boTte

dejonction et I(] vis h t_te h six pans n° 10 de

I'ensemble de vis, mis de c6t_ h I'_t(]pe 1.

• Installer le couvercle de I(] boTtedejonction (]vec

I(]vis h t_te h six pans n° 10. V_rifier que les ills ne

sont pus pinc_s sous le couvercle.

I_TAPE18" LISTE DE VITRIFICATION AVANT

LES ESSAIS

[] V_rifier que le cour(]nt (] _t_ coup_ 5 la source.

[] Ouvrir I(] porte du I(]ve-v(]isselle et enlever

tousles morce(]ux de mousse et de carton

d'emballage.

[] Lire le M(]nuel de I'utilis(]teur pour conn(]Ttre le

fonctionnement du lave-vaisselle.

[] V_rifier que le chbl(]ge est bien inst(]ll_ sous le

I(]ve-v(]isselle, suns _tre pinc_ ou en contQct (]vec

les ressorts de porte ou (]utres pi_ces du lave-

vaisselle.

[] Veiller h ce que le ressort de porte ne soit pQs

en contact (]vec le tugau de rempliss(]ge ou

d'atimentation d'eau ou avec les armoires

(]dj(]centes. Voir les _tapes 13 et 14.

[] Tirer I'_gouttoir du b(]sjusqu'h mi-trajectoire, tl

ne doit ni sortir, ni rentrer duns le I(]ve-v(]isselle.

Sic'est le c(]s, remettre le I(]ve-v(]isselle h nive(]u.

Voir I'_tape 12.

[] Veiller hce que le p(]nne(]u de comm(]nde ne soit

pus en contact (]vec les (]rmoires adj(]centes. Si

c'est le c(]s, repositionner le I(]ve-v(]isselle. Voir

I'_tape 13.

[] Ouvrir le robinet d'eau chaude de I'_vier pour

v_rifier que I'e(]u est h une temp_r(]ture de

minimum 48 °C (120 ° F)et de maximum 65 °C