GE GSD6300J10BB, GSD6300J10WW, GSD6660G10SS, PDW7712N10BB, PDW7712N10SS Installation Guide

...Page 1

Installation

Built-In

Dishwasher

Instructions

l If you have questions,call 800-GECARESor visit our website at: www.GEAppliances.com I

BEFORE YOU BEGIN

Read these instructions completely and carefully.

•IMPORTANT - C.,se,,'e.Ug,,,'e,',,i,,g

codes and ordinances.

• Note to Installer - Be sure to leave these instruc-

ti(ms for the consumer's and local inspector's use.

• Note to Consumer - Keep these instructions with

your (-)wiper's Manual fi)r fllture retbrei_ce.

• Skill Level - Installation of this dishwasher requires

basic mechanical and electrical skills. Proper installa-

tion is the responsibility of the installer. Product failure

due to improper installation is not covered under the

GE Appliance Waxranty.

• Completion Time - 1 to 3 Hours, New installations

require m ore tim e than replacement installation s.

•IMPORTANT - Thedish,,'.she,MUST_,e

installed to alhm tot fllture remoxal fl'om the enclo-

sure if serxice is required.

If vou receixed a damaged dislmasher, you should

immediateh' contact your dealer or builder.

Optional Accessories - See the o,vne,"s m.n_,.1

fin" axailable custom panel kits.

FOR YOUR SAFETY

Read and observe all CAUTIONS and WARNINGS

shown throughout these instructions. While performing

installations described in this booklet, gloves, safety

glasses or goggles should be worn.

READ CAREFULLY.

KEEP THESE INSTRUCTIONS.

Page 2

Installation Preparation

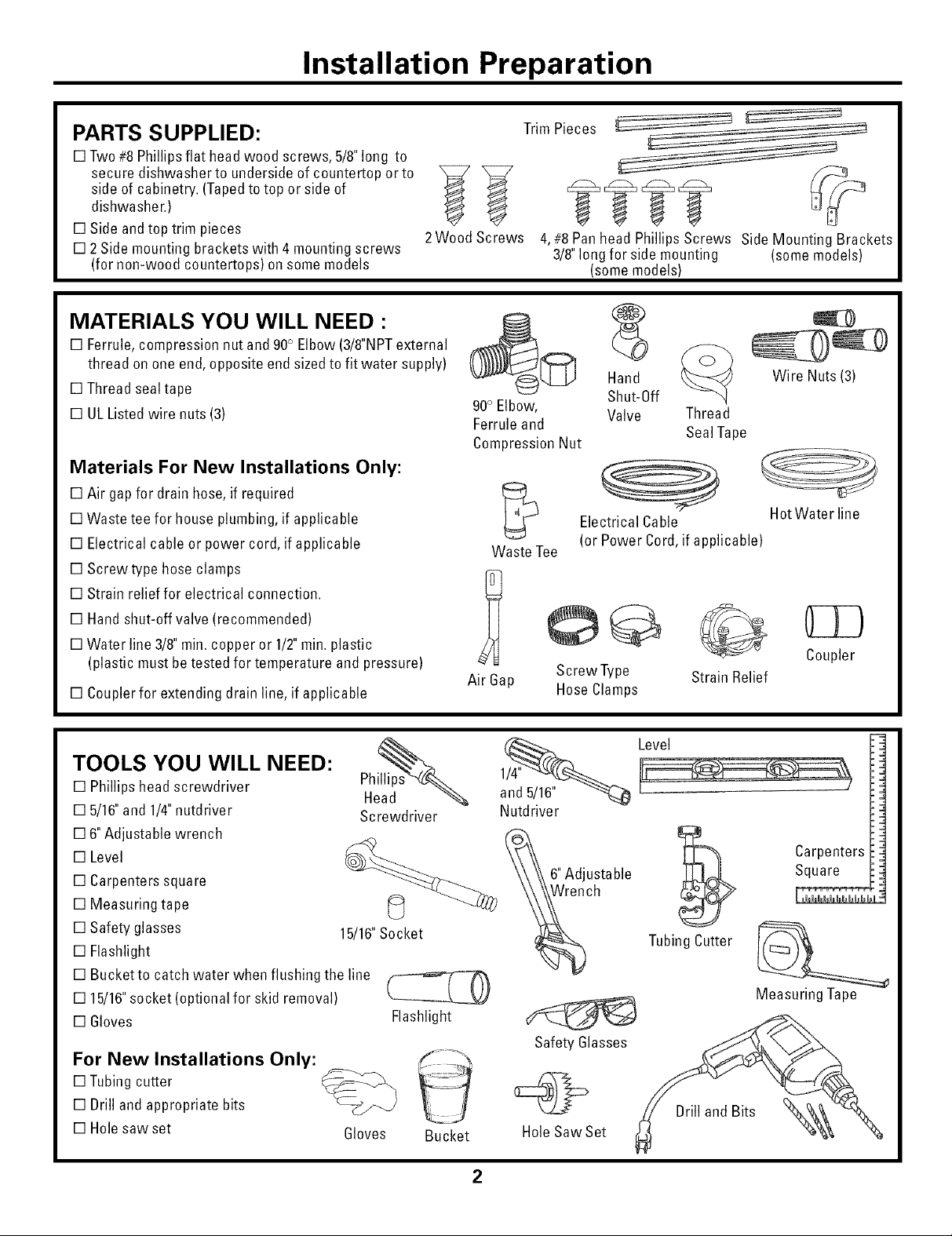

PARTS SUPPLIED:

[] Two#8 Phillips flat head wood screws, 5/8"long to

secure dishwasher to underside of countertop orto

side of cabinetry. (Tapedtotop or side of

dishwasher.)

[] Side and top trim pieces

[] 2 Side mounting bracketswith 4 mounting screws

(for non-wood countertops) on some models

2Wood Screws

MATERIALS YOU WILL NEED :

[] Ferrule,compression nut and 90° Elbow(3/8"NPTexternal

thread on one end,opposite end sizedto fit water supply)

[] Thread sealtape

[] ULListed wire nuts (3)

Materials For New Installations Only:

[] Air gap for drainhose,if required

[] Waste tee for house plumbing,if applicable

[] Electrical cable or power cord, if applicable

[] Screwtype hose clamps

[] Strain relieffor electrical connection.

[] Handshut-off valve (recommended)

[] Water line 3/8"rain.copper or 1/2" rain.plastic

(plastic must betested for temperature and pressure)

[] Couplerfor extending drain line, if applicable

Trim Pieces

4,#8 Pan head Phillips Screws Side Mounting Brackets

3/8"long for side mounting (some models)

(somemodels)

_@ _td__0ff

90° Elbow, Valve Thread

Ferrule and SealTape

Compression Nut

Electrical Cable

Waste Tee

Air Gap

(or Power Cord,if applicable)

Screw Type Strain Relief

Hose Clamps

Wire Nuts (3)

Hot Water line

Coupler

TOOLS YOU WILL NEED:

[] Phillips head screwdriver

[] 5/16"and 1/4" nutdriver

[] 6"Adjustable wrench

[] Level

[] Carpenters square

[] Measuring tape

[] Safety glasses

[] Flashlight

[] Bucketto catch water when flushing the line

[] 15/16"socket (optional for skid removal)

[] Gloves

For New Installations Only:

[] Tubingcutter

[] Drill and appropriate bits

[] Hole saw set

15/16"Socket

Gloves

Screwdriver

Flashlight

Bucket

2

and 5/16"

Nutdriver

Safety Glasses

Hole Saw Set

6"Adjustable

Wrench

Level

Carpenters

Square

TubingCutter

Measuring Tape

Drill and Bits

Page 3

Installation Preparation

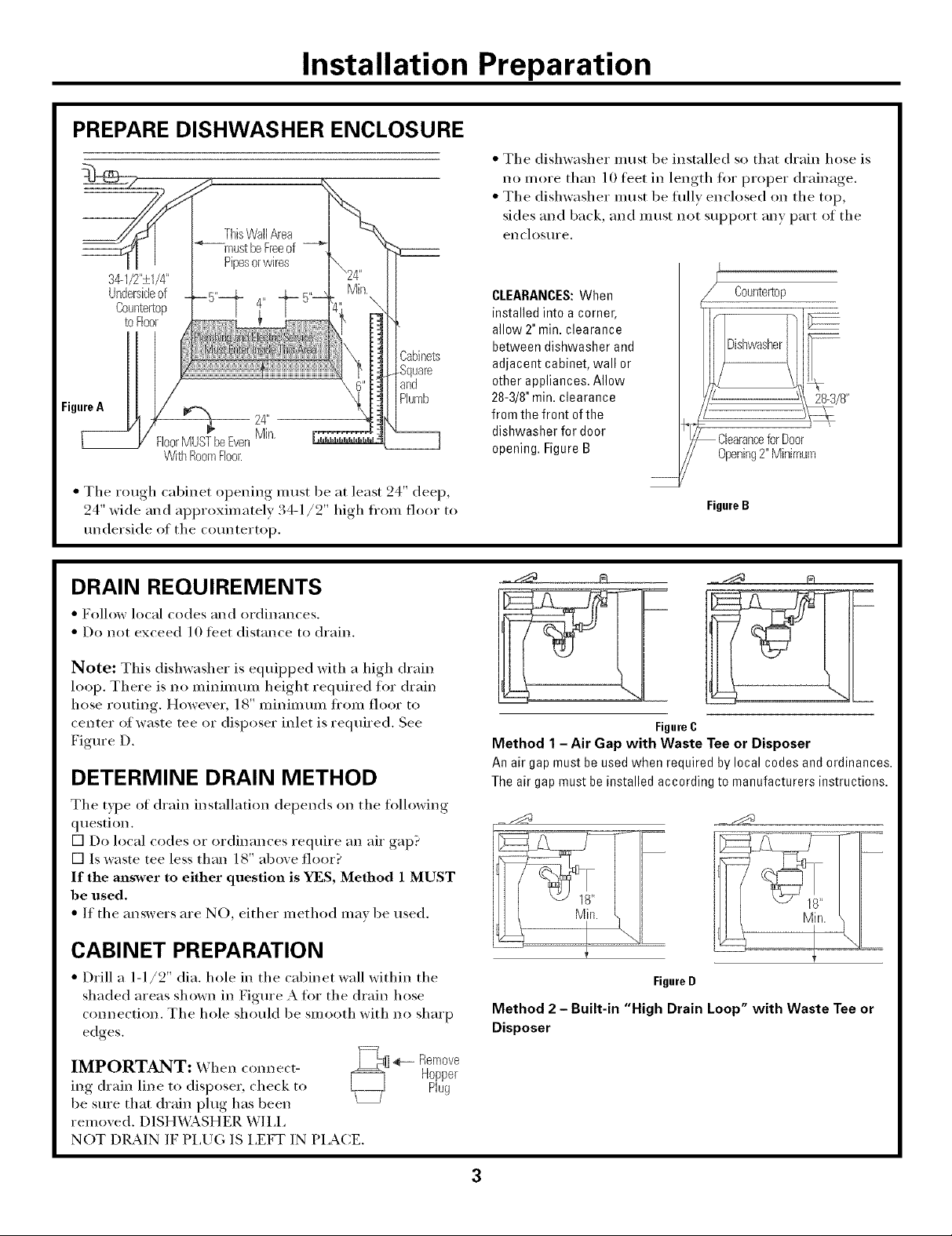

PREPARE DISHWASHER ENCLOSURE

34--I/2"_+I/4"

Undersideof

Counter'[op

toFloor

Figure[_A _//_

ThisWallArea

Pipesorwires

FloorMUSTbeEven

WithRoomFloor.

of

3abinets

Square

and

Plumb

24"

Min,

• The dishwasher must be installed so that drain hose is

no m ore than 10 tibet in length for proper drainage.

• The dishwasher must be fifllv enclosed on the top,

sides and back, mad must not support may part of the

enclostlre,

I

CLEARANCES:When

installed into a corner,

allow 2" min. clearance

between dishwasher and

adjacent cabinet, wall or

other appliances. Allow

28-3/8"rain. clearance

from the front of the

dishwasher for door

opening. Figure B

Countertop

{ - 28-3/8"

• The rough cabinet opening must be at lea,'t 24 deep,

24" _i(le and approximately : 4-1/2 high fl'om floor to

underside of the countertop.

DRAIN REQUIREMENTS

• Follov, local codes and ordinances.

• Do not exceed 10 ti_et (listance to drain.

Note: This dishwasher is equipped with a high drain

loop. There is no minimum height required for drain

hose routing. Howevei, 18" illinillltllll ti'Olll f]ooi" to

center of waste tee or disposer inlet is reqtfired. See

Figure D.

DETERMINE DRAIN METHOD

The type of drain installation depends on the following

question.

[] Do local codes or ordinances require an air gap?

[] Is waste tee less than 18" above floor?

If the answer to either question is YES, Method 1 MUST

be used.

• If the answers are NO, either method may be used.

FigureB

FigureC

Method 1 - Air Gap with Waste Tee or Disposer

An air gap must be used when required by local codesand ordinances.

The air gap must be installed according to manufacturers instructions.

CABINET PREPARATION

• Drill a 1-1/2" dia. hole in the cabinet wall within the

shaded areas shown in Figure A fin" the drain hose

connection. The hole should be smooth with no sharp

edges.

IMPORTANT: When connect-

ing drain line to disposei, check to

be sure that drain plug has been

removed. DISH_&SHER WILL

NOT DRAIN IF PLUG IS LEFT IN PLACE,

FigureD

Method 2 - Built-in "High Drain Loop" with Waste Tee or

Disposer

Remove

Hopper

Plug

Page 4

Installation Preparation

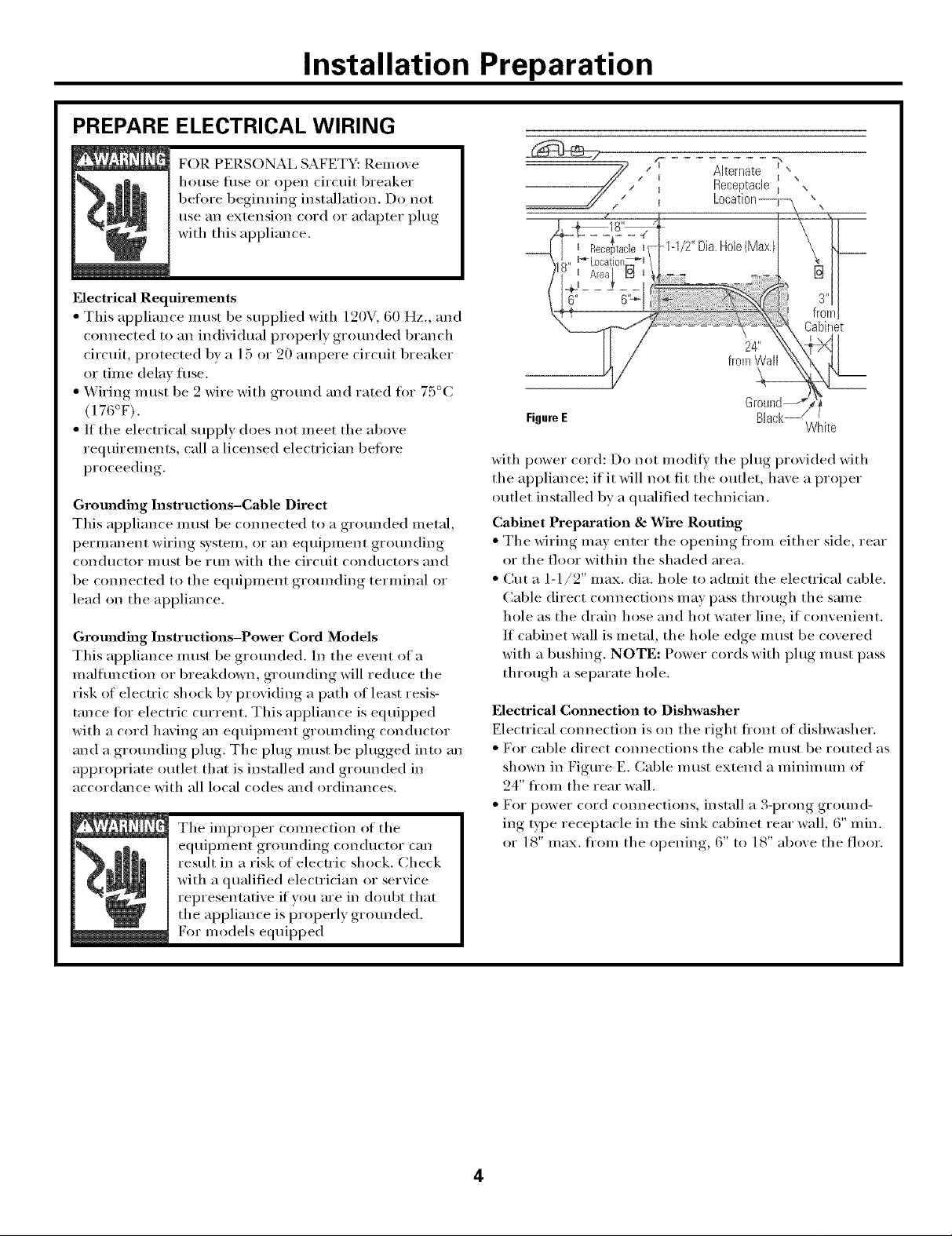

PREPARE ELECTRICAL WIRING

FOR PERSONAL SAFETY: Remove

house fllse or open circuit breaker

before begilming installation. Do not

use an extension cord or adapter phlg

with this appliance.

Electrical Requirements

• This appliance must be supplied with 120V, 60 Hz., and

connected to an individual properly grounded branch

circuit, protected by a 15 or 20 ampere circuit breaker

or time delay fllse.

• Wiring intist be 2 wire with ground and rated tot 75°C

(176°F).

• If tile electrical supply does not meet tile above

requirements, call a licensed electrician before

proceeding.

Gromlding Instructions-Cable Direct

This appliance must be comaected to a grounded metal,

permanent wiring system, or an equipment grounding

conductor must be i'/ln with tile circuit conductors and

be com_ected to tile equipment grounding terminal or

lead on tile appliance.

Grounding Instructions-Power Cord Models

This appliance must be grounded. In tile event of a

malflmction or breakdown, grounding will reduce tile

risk of electric shock by providing a path of least resis-

tance tor electric current. This appliance is equipped

with a cord having an equipment grounding conductor

and a grounding plug. Tile plug must be plugged into an

appropriate outlet that is installed and grounded in

accordance with all local codes and ordinances.

Alternate -_"",

Receptaclet \

FigureE Black

with power cord: Do not modit_' tile plug provided with

tile appliance: if it will not fit tile outlet, have a proper

outlet installed bv a qualified technician.

Cabinet Preparation & Wire Routing

• Tile wiring may enter tile opening fl'om either side, rear

or tile floor within tile shaded area.

• Cut a 1-1/2" max. dia. hole to admit tile electrical cable.

Cable direct com_ections may pass through tile same

hole as tile drain hose and hot water line, if convenient.

If cabinet wall is metal, tile hole edge i,/ust be covered

with a bushing. NOTE: Power cords with plug must pass

through a separate hole.

Electrical Connection to Dishwasher

Electrical com_ection is on the right fi'ont of dishwasher.

• For cable direct comlections the cable must be routed as

shown in Figure E. Cable Inust extelld a minimum of

24" fi'om tile rear wall.

• For power cord comaections, install a 3-prong ground-

ing type receptacle in tile sink cabinet rear wall, 6" rain.

or 18" max. fl'om tile opening, 6" to 18" above tile floor.

! \

Cabinet

White

4

Page 5

Installation Instructions

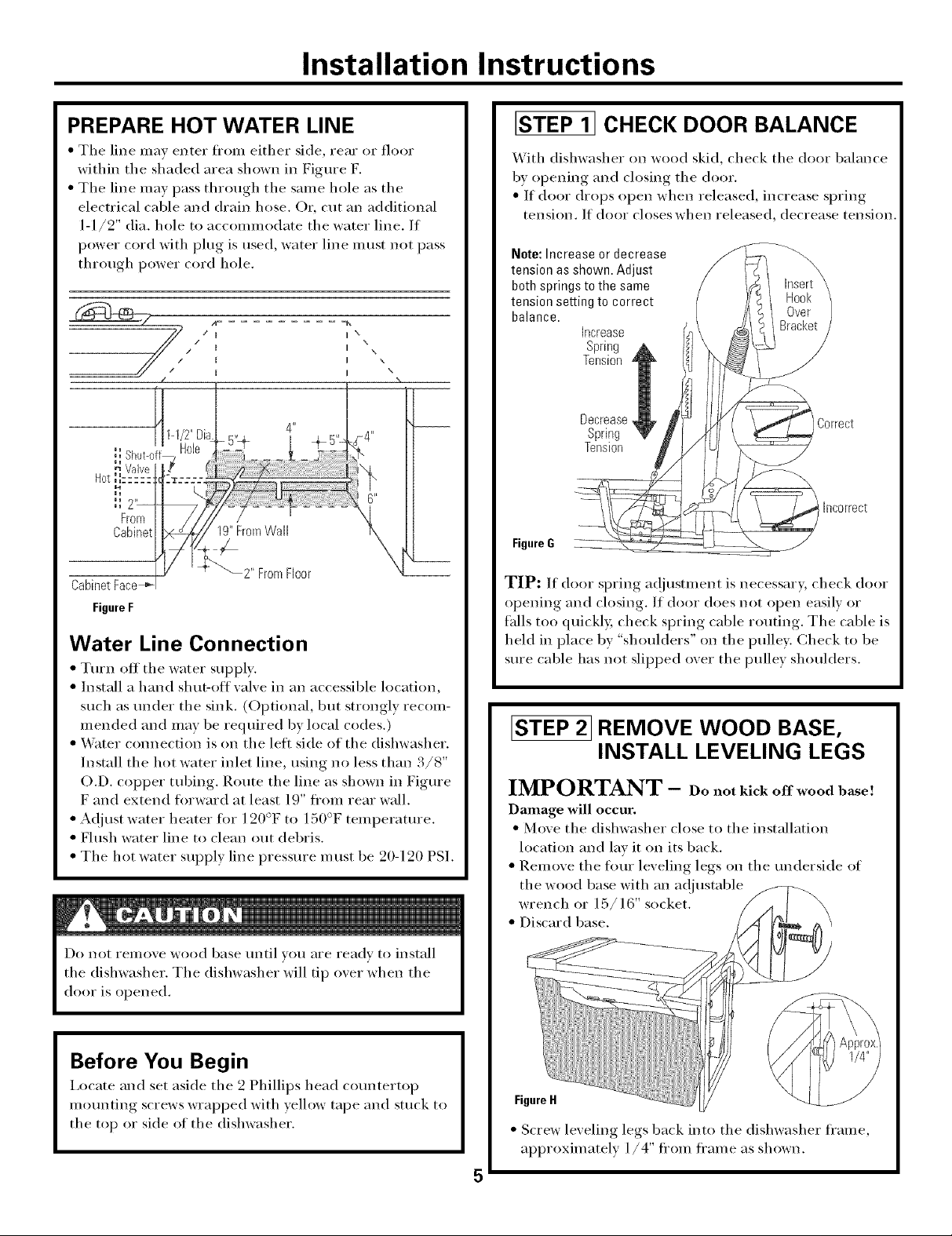

PREPARE HOT WATER LINE

• The line may enter fl'om either side, rear or floor

within the shaded area shown in Figure F.

• The line may pass through the same hole as the

electrical cable and drain hose. Or, cut an additional

1-]/2" dia. hole to accommodate the water line. If

power cord with plug is used, water line must not pass

through power cord hole.

A_ _N

Z [ I \

I I \

I I

i I

4 '_

BB

BB

BB

From

Cabinet

Cabinet Face

FigureF

2" From Floor

Water Line Connection

• Turn off the water supply.

• Install a hand shut-off valve in an accessible location,

such as trader the sink. (Optional, but strongly recom-

mended and may be required by local codes.)

• Water com_ection is orJ the left side of the dishwasher.

Install the hot water inlet line, using no less than 3/8"

O.D. copper tubing. Route the line as shown in Figm'e

F and extend torward at least 19" fl'om rear wall.

• A(!just water heater fin" 190°F to 150°F temperature.

• Flush water line to clean out debris.

• The hot water supply line pressm'e must be 20-120 PSI.

\

\

\

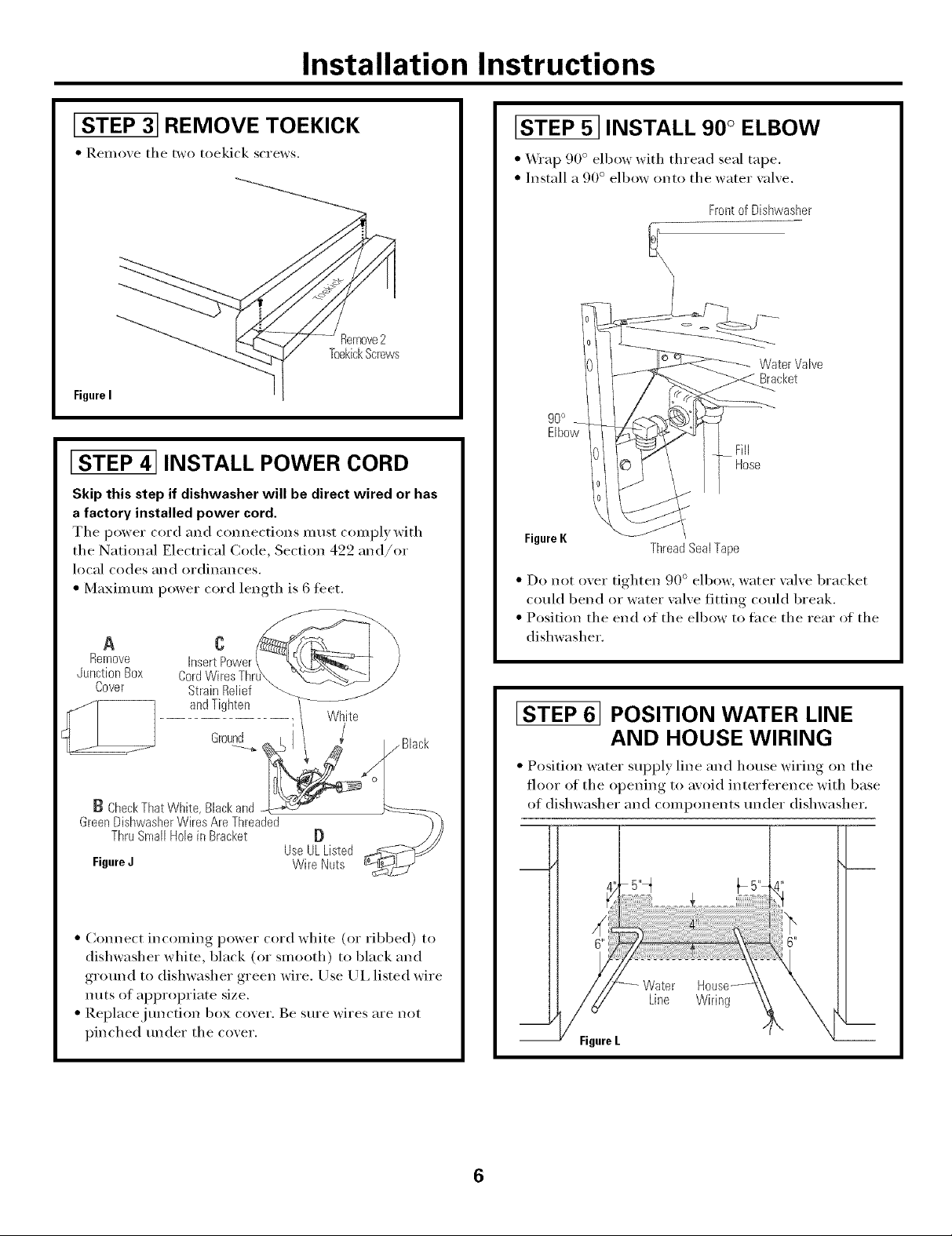

[STEP 1] CHECK DOOR BALANCE

With dishwasher on wood skid, check the door balance

by opening and closing the door.

• If door drops open when released, increase spring

tension. If door closes when released, decrease tension.

Note: Increase or decrease

tension as shown. Adjust

both springs to the same

tension setting to correct

balance.

Increase

Spring

Tension

FigureG

Decrease

Spring

Tension

Correct

Incorrect

TIP: If door spring a(!justment is necessary, check door

opening and closing. If door does not open easily or

thlls too quickl 5 check spring cable routing. The cable is

held in place bv "shoulders" on the pulley. Check to be

sure cable has not slipped over the pulley shoulders.

[STEP 2] REMOVE WOOD BASE,

INSTALL LEVELING LEGS

IMPORTANT - Do not kick off wood base !

Damage will occur.

• Move the dishwasher close to the installation

location and lay it on its back.

• Remove the four leveling legs on the underside of

the wood base with an a(!justable

wrench or l 5/16" socket.

• Discard base.

Before You Begin

Locate and set aside the 2 Phillips head cotmtertop

motmting screws wrapped with yelhm tape and stuck to

the top or side of the dislmasher.

FigureH

• Screw lex eling legs back into the dislmasher fl'ame,

approximately l / 4" fl'om fl'am e as sh o_xn.

Page 6

Installation Instructions

[STEP 3] REMOVE TOEKICK

• Remoxe the mo toekick screws,

Remove2

ToekickScrews

FigureI

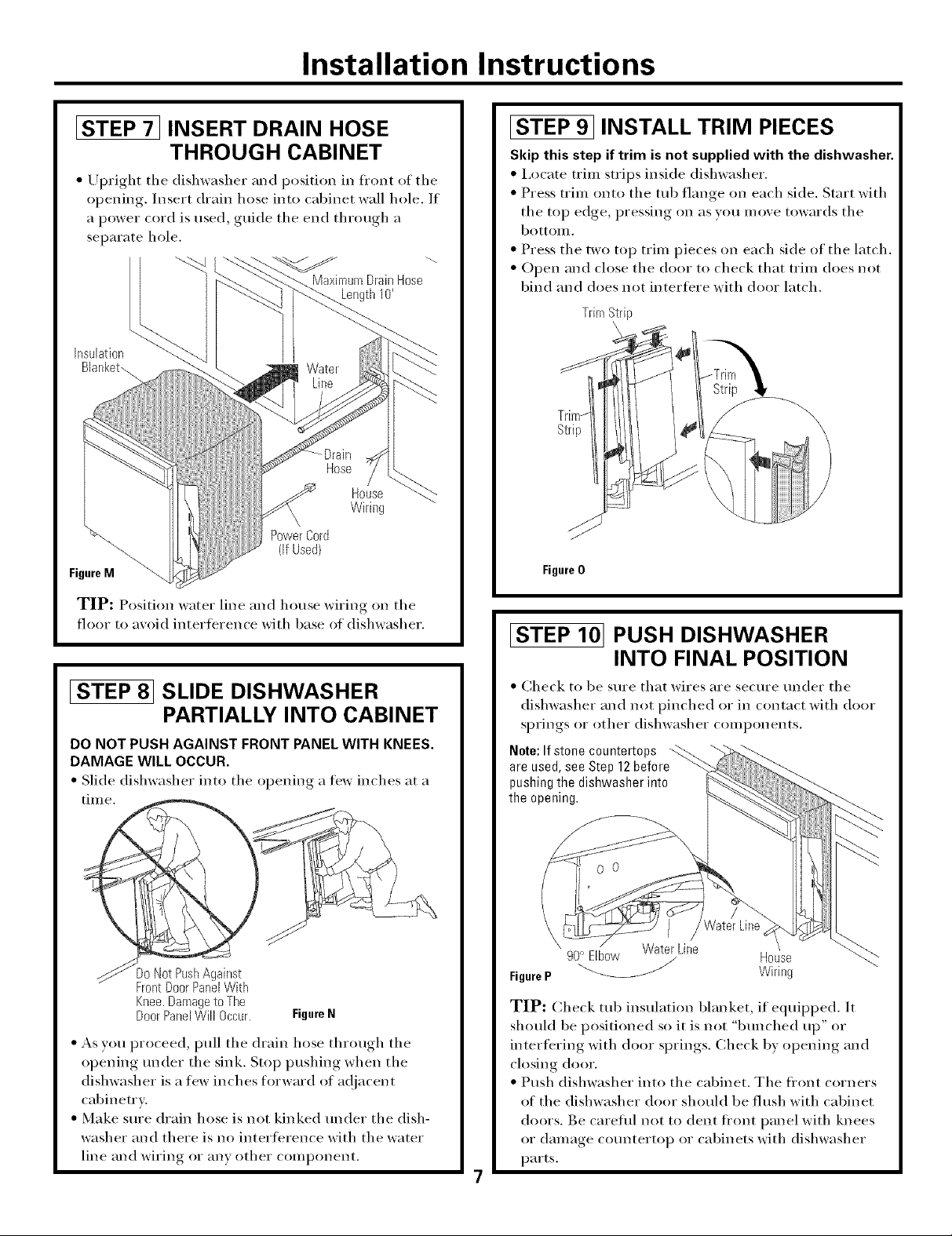

[STEP 4] INSTALL POWER CORD

Skip this step if dishwasher will be direct wired or has

a factory installed power cord.

The power cord and com_ections must comply with

the National Electrical Code, Section 422 and/or

local codes and ordinances,

• Maximmn power cord length is 6 teet.

A

Remove

JunctionBox

Cover

StrainBelief _

and Tighten

White

[STEP 5] INSTALL 90 ° ELBOW

• Wrap 90 ° elbow with thread seal tape.

• Install a 90 ° elbow onto the water xalxe.

FrontofDishwasher

90°

Elbow

FigureK

• Do not over tighten 90 ° elbo_, water valve bracket

could bend or water valve fitting could break.

• Position the end of the elbow to thce the rear of the

dishwasher.

Thread Seal Tape

]STEP 6] POSITION WATER LINE

AND HOUSE WIRING

Ground__ __Black

CheckThatWhite, Blackand

GreenDishwasherWires AreThreaded

ThruSreailHob in Bracket

FigureJ

• Cormect incoming power cord white (or ribbed) to

dishwasher white, black (or smooth) to black and

grotmd to dishwasher green wire. Use UL listed wire

mlts of appropriate size.

• Replace.jtmction box cover. Be sure wires are not

pinched tamer the cover.

D

UseULListed

WireNuts

• Position water supply line and house wiring on the

floor of the opening to avoid interterence with base

of dishwasher and components trader dishwasher.

Line Wiring

m

Figurek

Page 7

Installation Instructions

ISTEP 71INSERT DRAIN HOSE

THROUGH CABINET

• Upright the dishwasher and position in fl'ont of the

opening. Ii_sert drain hose into cabinet wall hole. If

a power cord is used, guide the end through a

separate hole.

MaximumDrainHose

Length10'

Insulation

Blanket_

Hose

House

Wiring

PowerCord

(if Used)

ISTEP91INSTALL TRIM PIECES

Skip this step if trim is not supplied with the dishwasher,

• Locate trim strips inside dishwasher.

• Press trim onto the tub flange on each side. Start with

the top edge, pressing on as vou move towards the

bottom.

• Press the two top trim pieces on each side of the latch,

• Open and close the door to check that trim does not

bind and does not intertere with door latch.

TrimStrip

Trim_

Strip

Figure0

TIP: Position water line and house wiring on the

floor to moid interference with base of dishxxasher.

[STEP 8] SLIDE DISHWASHER

PARTIALLY INTO CABINET

DO NOT PUSH AGAINST FRONT PANEL WITH KNEES.

DAMAGE WILL OCCUR.

• Slide dislmasher into the opening a tew inches at a

tinle.

30 Not PushAgainst

FrontDoorPanelWith

Knee.Damageto The

DoorPanelWill Occur.

• As vou proceed, pull the drain hose through the

opening under the sink. Stop pushing when the

dishwasher is a few inches forward of ac!jacent

cabinetry.

• Make S/li'e drain hose is not kinked under the dish-

washer and there is no interference with the water

line and wiring or any other component.

FigureN

ISTEP101PUSH DISHWASHER

INTO FINAL POSITION

• Check to be sure that wires are secure under the

dishwasher and not pinched or in contact with door

springs or other dishwasher components.

Rote: If stone eountertops

are used, see Step 12

pushing the dishwasher into

the opening.

WaterLine

90° Elbow Water Line

Figure P

"_ Wiring

TIP: Check tub insulation blanket, if equipped. It

should be positioned so it is not "bunched up" or

interfering with door springs. Check by opening and

closing door.

• Push dishwasher into the cabinet. The fl'ont corners

of the dishwasher door should be flush with cabinet

doors. Be carefifl not to dent fl'ont panel with knees

or damage cotmtertop or cabinets with dishwasher

parts.

House

Page 8

Installation Instructions

ISTEP 111LEVEL DISHWASHER

IMPORTANT - Dishwasher must be level fl)r proper

dish rack operation and wash pertormance.

• Place level on

door and rack

track inside tile (-

tub as showI1 to

check that the

dishwasher is

level,

• Lexel tile dish- ]

x_asher bya(!justing L AccessHob

the It)ill" leveling

legs individually.

• If a(!justment to tile

right rear leveling

leg is required,

loosen jm_ction box

bracket screw

(through tile access

hole) and rotate FigureR

bracket clockwise,

TIP: Pull lower rack out, about halflvay. Check to be

sure tile rack does not roll fl)rward or back into dish-

washer. If tile rack rolls either direction, tile dishwasher

must be leveled again.

• If door hits tub, tile dishwasher is not installed

FigureQ

correctl> At{just leveling legs to align door to tub.

ISTEP 12 1POSITION DISHWASHER, SECURE TO CABINET

Tile dishwasher must be secm'ed to tile co/mtertop or

tile cabinet sides. When co/mtertops are made of wood,

use Method 1. Some models are supplied with side

mounting brackets fl)r use when cotmtertops are granite

or other materials that will not accept screws, [.lse

Method 2 to secm'e dishwasher at the sides.

• Fasten a side too/rating bracket to each side of tile tub

with tile #8 pan head screws pro_,ided.

Side

Mounting

Brackets

Method 1

Secure dishwasher to wood countertop

• Position dishwasher so that tile door lines up with tile

fl'ont thce of a(!jacent cabinet.

Brackets WoodCountertop

FigureS

IMPORTANT: Check to be sm'e tile dishwasher is

centered in tile opening and there is no interference

with ac!jacent cabinets when opening ,11"closing tile door.

• Fasten tile dishwasher to tile ,mderside of tile co/rater-

top with tile 2 Phillips screws provided.

Method 2

For Models supplied with side mounting brackets

• Pull dishwasher out oI tile opening just enough to

access tile tub fl'ame.

Tub Frame

Install

/

EachSide

/

FigureT

• Position dishwasher so that tile door lines up with tile

fl'ont thce of a(!jacent cabinet.

IMPORTANT: Check to be sure tile dishwasher is

centered in tile opening and there is no interterence

with ac!jacent cabinets when opening or closing tile door.

StoneCountertop

FigureU ///// "% SideBrackets

Brackets

/////

• Fasten tile brackets to cabinet sides using tile 2

Phillips head co/mtertop screws.

IMPORTANT: Drive screws straight and flush. Protrud-

ing screw heads will scratch the top or sides of tile

control panel and can intertere with door closing.

8

Page 9

Installation Instructions

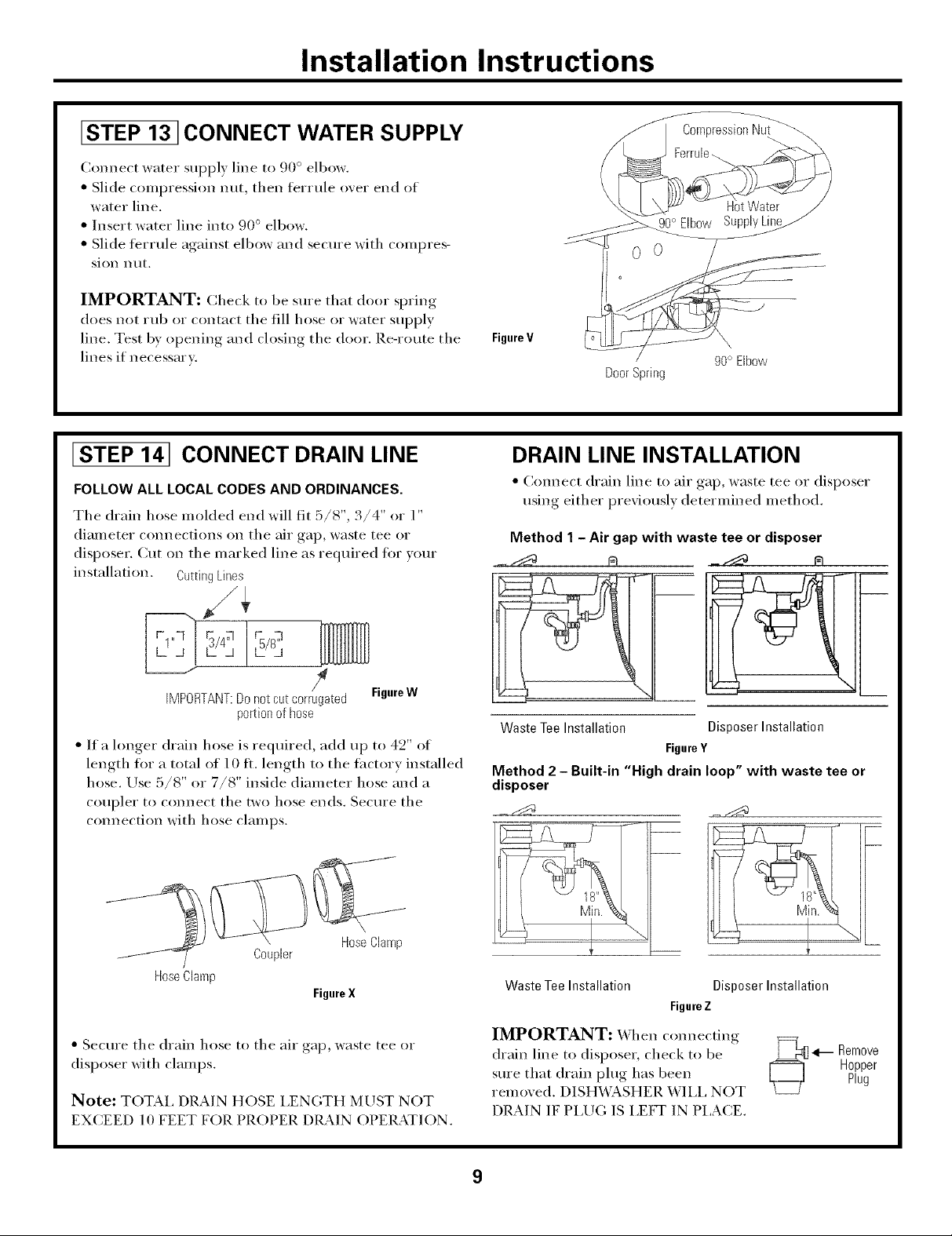

[STEP 13 1CONNECT WATER SUPPLY

Com_ect water supply line to 90 ° elbow.

• Slide compression inK, then terrule over end of

water line.

• Insert water line into 90 ° elbow.

• Slide ferrule against elbow and secure with compres-

sion mm

IMPORTANT: Check to be sm'e that door spring

does not rub or contact the fill hose or _ater supply

line. Test by opening and closing the door. Re-route the

lines if necessary.

Figure V

/ go° Elbow

DoorSpring

ISTEP 141 CONNECT DRAIN LINE

FOLLOW ALL LOCAL CODES AND ORDINANCES.

The drain hose molded end will fit 5/8", 3/4" or 1"

diameter com_ections on the air gap, waste tee or

disposer. Cut on the marked line as required ti)r yore"

installation. Cutting Lines

IMPORTANT:Donot cutcorrugated FigureW

portionof bose

• Ifa hmger drain hose is required, add up to 42" of

length fi)r a total of 10 fl, length to the thctorv installed

hose, Use 5/8" or 7/8" inside diameter hose and a

coupler to com_ect the two hose ends, Secure the

com_ection with hose clamps,

DRAIN LINE INSTALLATION

• Com_ect drain line to air gap, _aste tee or disposer

using either prexiously determined method.

Method 1 - Air gap with waste tee or disposer

Waste Tee Installation Disposer Installation

Figuref

Method 2 - Built-in "High drain loop" with waste tee or

disposer

Hose Clamp

FigureX

/

Hose Clamp

Coupler

• Secm'e the drain hose to the air gap, waste tee or

disposer with clamps.

Note: TOTAL DRAIN HOSE LENGTH MUST NOT

EXCEED 10 FEET FOR PROPER DRAIN OPERATION.

Waste Tee Installation

FigureZ

IMPORTANT: When com_ecting

drain line to disposeI; check to be

stlre that drain plug has been

removed. DISHWASHER WILL NOT

DRAIN IF PLUG IS LEKF IN PLACE.

9

Disposer Installation

4--- Remove

Hopper

Plug

Page 10

Installation Instructions

ISTEP151CONNECT POWER

SUPPLY

Skip this step if equipped with power cord

Verify that power is turned off at the source,

(If a power ford with phlg is used, proceed t(> Step 16.)

• Relllove.jtlnctioi_ box covei'.

• Secure house wiring to the back of thejulacti(m box

with a strain relief.

• Locate the three dishwasher wires, (white, black and

green) with stripped ends. Insert dishwasher wires

through the small hole in thejuiaction box. Use wire

nuts t() coimect iiac()ming ground to green, white t()

white and black t() black.

• Replace junction box covei'. Check to be S/li'e that

wires are not pinched under the cover.

A C

Remove Insert Power

Junction Box Cord Wires Thr

Cover Strain Relief

__ and Tighten White

Gr°und_d__ ,//Black

B Check That White, Black and -_ J

Green Dishwasher Wires Are Threaded

Thru Small Hole in Bracket [}

Use UL Listed

FigureAA Wire Nuts

[STEP 16] PRE-TEST CHECK LIST

Review this list after installing your dishwasher to

avoid charges for a service call that is not covered by

your warranty,

[] Check to be sure power is OFK

[] Open door and remove all flmm and paper

packaging.

[] Locate tile Owner's Manual in tile literature

package.

[] Read tile Owner's Manual fin" operating

in structions.

[] Check door opei_ing and closing. If door does not

open and close fl'eelv or tends to tall, check spring

cable routing. See Step 1.

[] Check to be sure that wiring is secure under tile

dishwasher, not pinched or in c/intact with door

springs or other components. See Step 10.

[] Check door aligmnent with till). If door hits till),

level dishwasher. See Step 11.

[] Pull lower rack out, about halfway. Check to be

sure it does not roll back or fl)rward on the door. If

the rack moves, at!just leveling legs. See Step 11.

[] Check door aligmn ent with cabinet. If door hits

cabinet, reposition dishwasher. See Step 12.

[] Check that door spring does not contact water line,

fill hose, wiring or other colnpoi1ents. See Step 13.

[] Verify' water supply and drain lines are not kinked

or in contact with other compoi_ents. Contact with

motor or dishwasher fl'ame could cause noise.

[] Turn on tile sink hot water t,ulcet and verify' water

temperature, h_coming water temperature must be

between 120°F and 150°F. 120°F rain. temperature

is req uired fk)r best wash perfk_rmance. See "Pre-

pare Hot Water Line," page 4.

[] Add 2 quarts of water to tile bottom of tile

dishwasher to hlbricate the pump seal.

[] Turn on water supply. Check fin" leaks. Tighten

coimections if needed.

[] Remove protective fihn if present from tile control

panel and door.

10

Page 11

Installation Instructions

ISTEP 171 DISHWASHER WET TEST

[] Turn on power supply (or plug power cord into

outlet, if equipped).

[] Latch door.

[] Push "Norn_al Wash" button.

[] Push start/reset pad once.

[] Check to be sure that water enters the dishwasher.

If water does not enter the dishwasher, check to be

sure that water and power is turned on.

[] Gheck fin" leaks under the dishwasher. If leak is

I"otlil(l, ttliTl power supply off. then tighten connec-

tions. Restore power after leak is corrected.

[] Gheck for leaks around the door. A leak around the

door could be caused by door rubbing or hitting

against ac!jacent cabinetry. Reposition the dish-

washer if necessary. See Step 19

[] The dishwasher will drain about 5 minutes after the

first fill. Check drain lines. If leaks are t0und, turn

power off. correct as necessary. See Step 14.

[] Open dishwasher door and make sure most of the

water has drained. If not, check that disposer plug

has been ren/oved and/or air gap is not phlgged.

See Step 14.

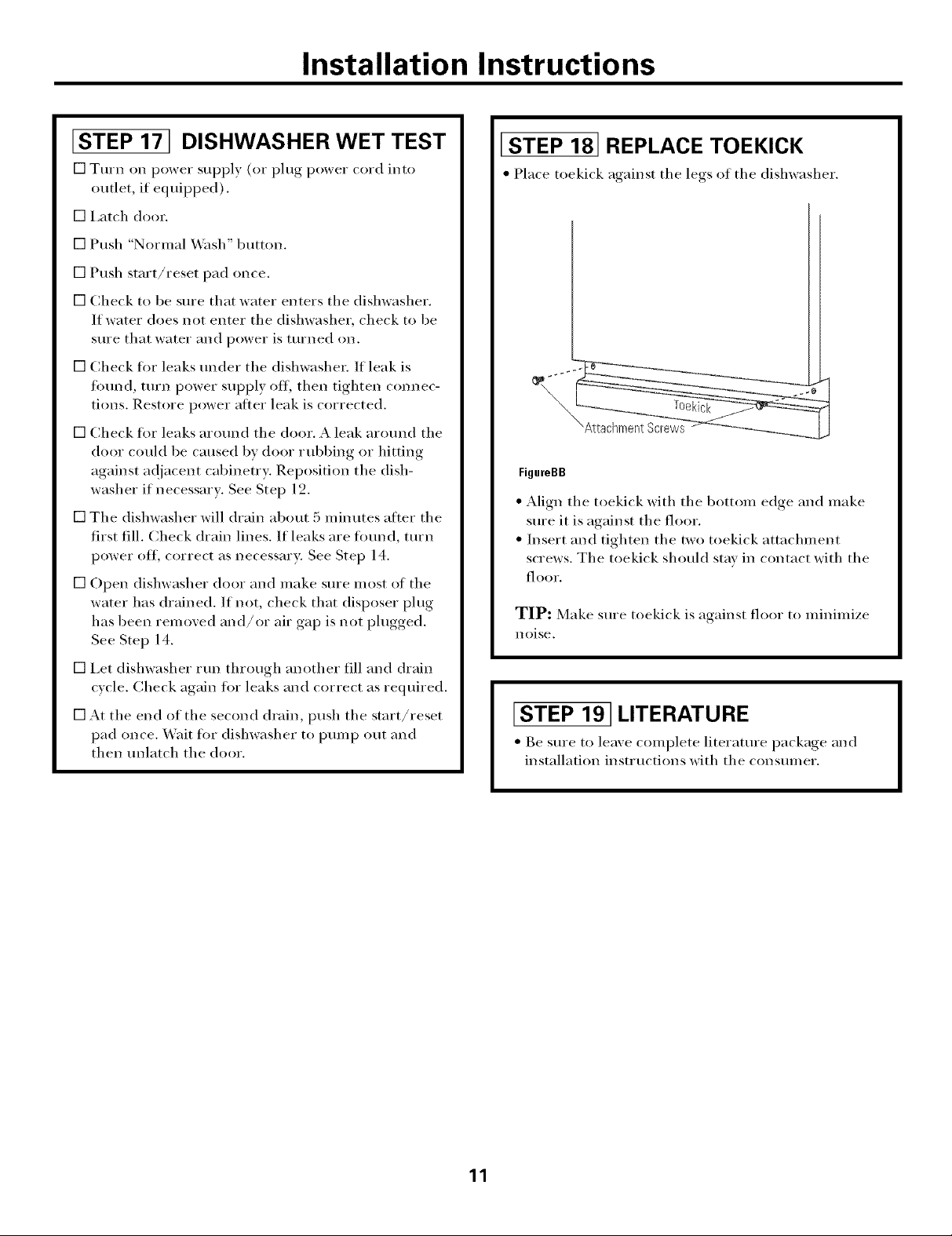

[STEP 18] REPLACE TOEKICK

• Place toeki('k against the legs ol the dish_asher.

FigureBB

• Align the toekick with the bottom edge and make

sure it is against the floor.

• Insert and tighten the two toekick attachment

screws. The toekick should stay in contact with the

_]oor,

TIP: Make sure toekick is against floor to minimize

noise.

[] Let dishwasher run through another fill and drain

cycle. Check again fiw leaks and correct as req tfired.

[] At the end of the second drain, push the start/reset

pad once. Wait _'0r dishwasher to pump out and

then unlatch the door.

lSTEP 191LITERATURE

• Be sure to leaxe complete literature package and

installation instructions with the consumer.

11

Page 12

SPECIFICATIONSSUBJECTTOCHANGEWITHOUTNOTICE

_No.31-30530

•No.20601559P070|

(N.D.212) 6/01

Loading...

Loading...