GE ADW1000K00BB, EDW2050F02CC, EDW3060G02SS, EDW3060G03SS, GSD1900J01WH Installation Guide

...Page 1

Ifyouhaveaquestionconcerningtheinstallationofthis

product,calltheGEAnswerCenter<R_ConsumerInformation

Serviceat800.626.2000,24hoursaday,7daysaweek.

Ifyoureceivedadamageddishwasher,

youshouldimmediatelycontactyour

dealerorbuilder.

[] Two Phillips head countertop mounting screws taped to dishwasher

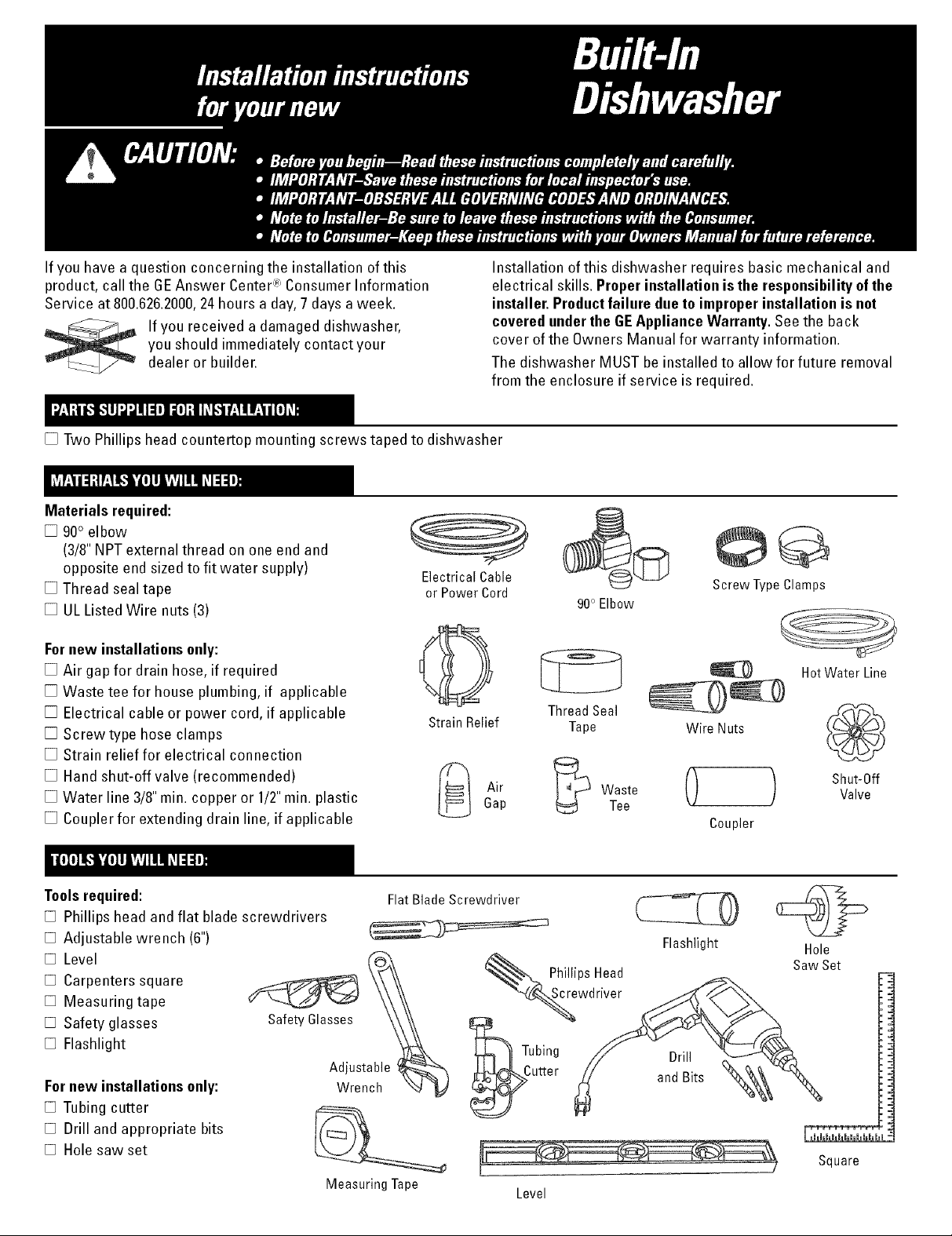

Materials required:

[] 90° elbow

(3/8"NPT external thread on one end and

opposite end sized to fit water supply)

[] Thread seal tape

[] UL Listed Wire nuts (3)

Fornew installations only:

[] Air gap for drain hose, if required

[] Waste tee for house plumbing, if applicable

[] Electrical cable or power cord, ifapplicable

[] Screwtype hose clamps

[] Strain relief for electrical connection

[] Hand shut-off valve (recommended)

[] Water line 3/8"min. copper or 1/2"min. plastic

[] Coupler for extending drain line, ifapplicable

Electrical Cable

or Power Cord

StrainRelief Tape

A,r Waste() )

Gap Tee

Installationofthisdishwasherrequiresbasicmechanicaland

electricalskills.Properinstallation is the responsibilityof the

installer. Productfailure dueto improperinstallation is not

coveredunderthe GEAppliance Warranty.See the back

cover of the Owners Manual for warranty information.

The dishwasher MUST beinstalledto allow for future removal

from the enclosure if service isrequired.

Screw Type Clamps

HotWaterLine

ThreadSeal

Wire Nuts

Shut-Off

Valve

Coupler

Toolsrequired:

[] Phillips head and flat blade screwdrivers

[] Adjustable wrench (6")

[] Level

[] Carpenters square

[] Measuring tape

[] Safety glasses

[] Flashlight

Fornew installations only:

[] Tubing cutter

[] Drill and appropriate bits

[] Holesaw set

SafetyGlasses

FlatBlade Screwdriver

Adjustable

Wrench

Measuring Tape

Flashlight Hole

Saw Set

__Sc rePhillipsHead

wdri_

_Tubing // Drill

_Cutter _/ andBits _-_

Square

Level

Page 2

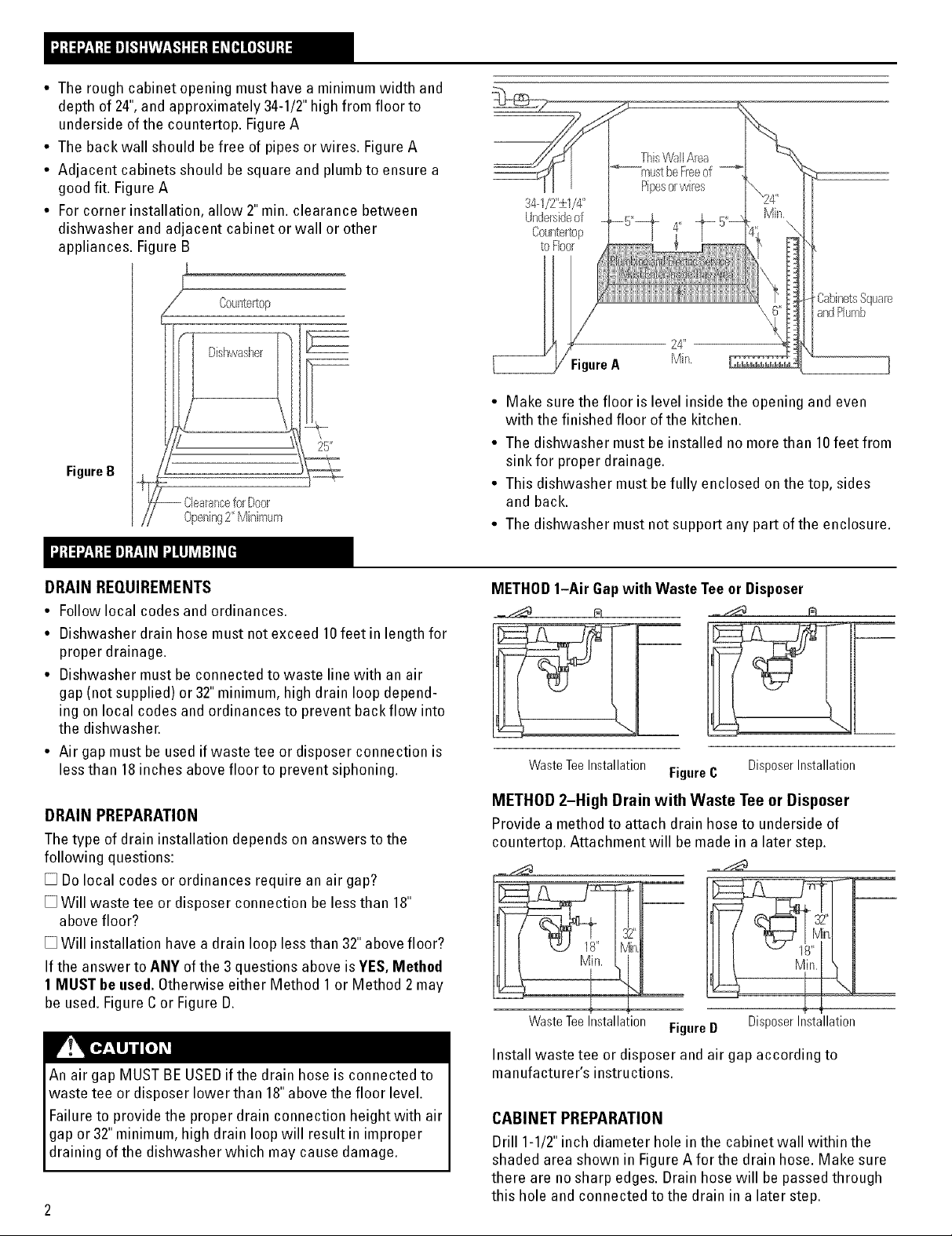

• The rough cabinet opening must have a minimum width and

depth of 24",and approximately 34-1/2"high from floor to

underside of the countertop. Figure A

• The backwall should be free of pipes or wires. Figure A

• Adjacent cabinets should be square and plumbto ensure a

good fit. Figure A

• For corner installation, allow 2" min. clearance between

dishwasher and adjacent cabinet or wall or other

appliances. Figure B

This'v%ll Area

)[

Ppesorwires

34--1/2":_1/4"

UndersideoF

Countertop

to%or

Countertop

E

Dishwasher _\l

25"

FigureB

Clearancefor Door

Openi_g2" Min}mum

DRAIN REQUIREMENTS

• Follow local codes and ordinances.

• Dishwasher drain hose must not exceed 10feet in length for

proper drainage.

• Dishwasher must be connected to waste line with an air

gap (not supplied) or 32" minimum, high drain loop depend-

ing on local codes and ordinances to prevent backflow into

the dishwasher.

• Air gapmust be used if waste tee or disposer connection is

less than 18inches above floor to prevent siphoning.

Cab}_etsSquae

a_dPlumb

• Make sure the floor is level inside the opening and even

with the finished floor of the kitchen.

• The dishwasher must be installed no more than 10feet from

sink for proper drainage.

• This dishwasher must befully enclosed onthe top, sides

and back.

• The dishwasher must not support any part of the enclosure.

METHOD1-Air Gapwith Waste Teeor Disposer

WasteTeeInstallation

FigureC

DisposerInstallation

DRAIN PREPARATION

The type of drain installation depends onanswers to the

following questions:

[] Do local codes or ordinances require an air gap?

[] Will waste tee or disposer connection be less than 18"

abovefloor?

[] Will installation have a drain loop lessthan 32"above floor?

If the answer to ANY of the 3 questions above is YES, Method

1 MUST be used. Otherwise either Method 1 or Method 2 may

be used. Figure C or Figure D.

An air gap MUST BE USEDif the drain hose is connected to

waste tee or disposer lower than 18"above the floor level.

Failure to provide the proper drain connection height with air

gap or 32"minimum, high drain loop will result in improper

dra n ng of the d shwasher wh ch may cause damage.

METHOD 2-High Drain with Waste Tee or Disposer

Providea method to attach drain hose to underside of

countertop. Attachment will be made in a later step.

g:--

Waste Tee Installation Figure D

Install waste tee or disposer and air gap according to

manufacturer's instructions.

CABINET PREPARATION

Drill 1-1/2"inch diameter hole in the cabinet wall within the

shaded area shown in Figure A for the drain hose. Make sure

there are no sharp edges. Drain hose will be passedthrough

this hole and connected to the drain in a later step.

DisposerInstallation

Page 3

WARNING

FORPERSONALSAFETY:REMOVEHOUSE

FUSEOROPEN CIRCUITBREAKERBEFORE

BEGINNINGINSTALLATION.

DONOTUSEAN EXTENSIONCORDDRADAPTER PLUG

WITH THIS APPLIANCE.

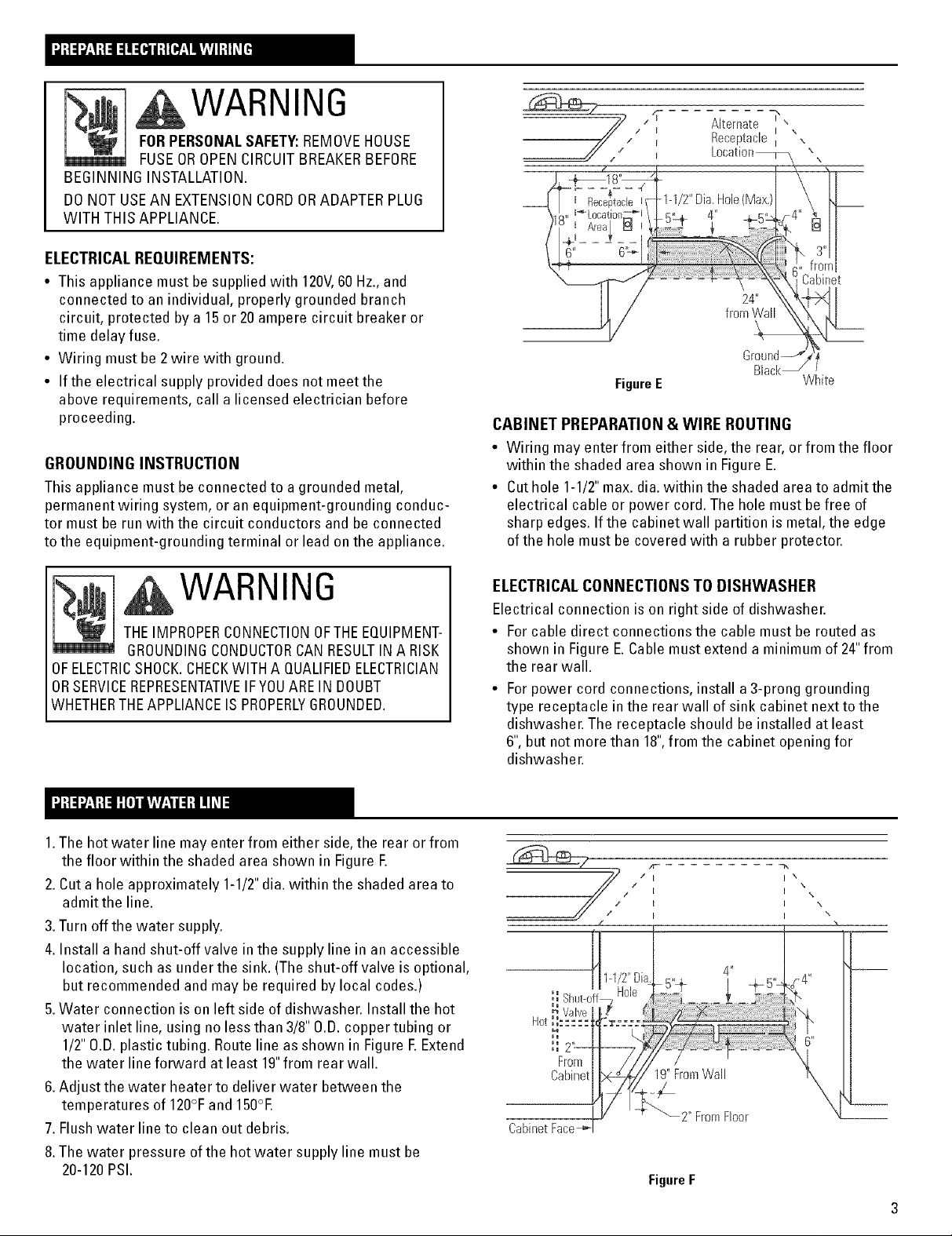

ELECTRICALREQUIREMENTS:

• This appliance must be supplied with 120V,60 Hz.,and

connected to an individual, properly grounded branch

circuit, protected by a 15or 20ampere circuit breaker or

time delay fuse.

• Wiring must be 2wire with ground.

• Ifthe electrical supply provided does not meet the

above requirements, call a licensed electrician before

proceeding.

GROUNDING INSTRUCTION

This appliance must be connected to a grounded metal,

permanent wiring system, or an equipment-grounding conduc-

tor must be run with the circuit conductors and be connected

to the equipment-grounding terminal orlead on the appliance.

-1-1/2"Dia.Flole(Max,)

FigureE

CABINET PREPARATION & WIRE ROUTING

• Wiring may enter from either side, the rear, or from the floor

within the shaded area shown in Figure E.

• Cuthole 1-1/2"max. dia.within the shaded area to admit the

electrical cable or power cord. The hole must be free of

sharp edges. If the cabinet wall partition is metal,the edge

ofthe hole must be covered with a rubber protector.

4"

Cabinet

Black_"

White

WARNING

THEIMPROPERCONNECTIONOFTHEEQUIPMENT-

GROUNDINGCONDUCTORCAN RESULTINA RISK

OFELECTRICSHOCK.CHECKWITH A QUALIFIEDELECTRICIAN

ORSERVICEREPRESENTATIVEIFYOUAREINDOUBT

WHETHERTHEAPPLIANCEIS PROPERLYGROUNDED.

1.The hot water line may enter from either side, the rear or from

the floor within the shaded area shown in Figure E

2.Cut a hole approximately 1-1/2"dia. within the shaded area to

admit the line.

3.Turn off the water supply.

4. Install a hand shut-off valve in the supply line in anaccessible

location, such as under the sink. (The shut-off valve is optional,

but recommended and may be required by local codes.)

5.Water connection is on left side of dishwasher. Install the hot

water inlet line, using no less than 3/8" O.D.copper tubing or

1/2"O.D.plastic tubing. Route line as shown in Figure E Extend

the water line forward at least 19"from rear wall.

6.Adjust the water heater to deliver water between the

temperatures of 120°Fand 150°E

7. Flushwater line to clean out debris.

8.The water pressure of the hot water supply line must be

20-120PSI.

ELECTRICALCONNECTIONS TO DISHWASHER

Electrical connection is on right side of dishwasher.

• Forcable direct connections the cable must be routed as

shown in Figure E.Cable must extend a minimum of 24"from

the rear wall.

• Forpower cord connections, install a3-prong grounding

type receptacle in the rear wall of sink cabinet next to the

dishwasher. The receptacle should be installed at least

6", but not more than 18",from the cabinet opening for

dishwasher.

Cabinet Face

2" FromFloor

FigureF

Page 4

If you need help with any of the following steps, call the

GEAnswer Center':R_Consumer Information Service, 800.626.2000

Do not remove the wood base until you are ready to install

the dishwasher. The dishwasher will tip over when the door

is opened.

Step1checkdoorbalancebeforewoodbaseisremoved

Locate the 2 Phillips head countertop mounting screws

wrapped with yellow tape and stuck to the top or side of the

dishwasher. Set aside for use in Step 12.

Check door balance by opening and closing door. If neces-

saw latch door and adjust one or both springs before the

wood base is removed.

Moving spring hookto rear

hole increases spring tension.

MOreTension

Step4 Remove access panel and toekick

Removethe two screws below the access panel and set aside

for reuse. Remove access panel by backing out the two

screws located between the door and access panel.These

screws are secured to access panel with plastic retainers.

BackOut

2Screws

Remove2

Screws

Figure I

FigureGG

nsertSprhrg

ThroughInsideof Frame

[Step2 Remove leveling legs and wood base:I

Move thedishwasherclosetothecabinet

andlayiton itsback.Remove thefourleveling

legswithan adjustablewrench.Remove

and discard the wood base.Do not"Kick"

wood base off,damagewill occur.

FigureG

lStep3 Install leveling legs J

Screw leveling legs back into the dishwasher

frame. The legs should extend approximately

3/4"away from the frame.

FigureH

[Step5 Install power cord (when used)

For power cord installation only. Skip this step if dishwasher

will bedirectly wired.

Removethe junction box

cover and install strain

relief. The power cord

and connections must

comply with the National

Electrical Code, Section

422and/or local codes

and ordinances. The cord

must be no longer than

6 ft. from the junction

boxto the receptacle.

Locate the three dish-

washer wires (white,

black and green) with

the stripped ends. Using ULListed wire nuts of appropriate

size, connect incoming white to white, black to black, and

incoming ground to green wire. Replace the junction box

cover. Checkthatwires are not pinched under cover.

Step 6 ,nStai, e,how

Install the 90° elbow

fitting to the water

valve using thread seal

tape on the threads.

Thewater valve

requires 3/8"NPT

fitting with external

threads. The opposite

end should fit water Thread

supply line. Position the Seal

end ofthe elbowto face Tape

the rear of the dishwasher.

Donot bend the dishwasher Figure K

frame when installing the 90° elbow fitting to the water

valve as this could cause the door spring to come in

contact with the fill hose.

Note: CheckThat Harness Leads Are

Threaded Thru Small Hole in Bracket

\ White

\ Neutral

=l__ Live

Page 5

continued

Step 7 Positionwaterline and power supply

Position the water supply line and house wiring on the floor of

the opening to avoid interference with base of dishwasher

and components underdishwasher.

Line Supply

FigureL

Step8 "se.drain hosethroughcabinet

Upright dishwasher and position in front of the cabinet

opening. Insert the drain hose into the hole previously drilled in

the cabinet wall. If a power cord is used,guide the end

through a separate hole cut for the electrical cord.

Power cord should be routed directly to the rear of junction box

avoiding contact with spring or other dishwasher components.

lStep9 Slidedishwasherintocabinet J

Slide the dishwasher into the opening afew inches at a time.

Asyou proceed, pull the drain hose through the opening and

under the sink. Make sure drain hose is not kinked under

dishwasher. Check to be sure there is no interference with

water line and wiring.

DONOTPUSH

AGAINSTFRONT

DOORPANEL

WITH YOUR

KNEE.Damageto

the doorpanel

will occur.

Step10 Alignwater and electrical lines j

Routethe water line and

electrical supply to their

connection locations

under the dishwasher.

Do not connect water

and electrical inthis step.

FigureN

RearView

_!ater

FigureM

/

Step8A InstallTrimPieces (onsomemodels)

• Press the trim onto the tub flange on each side of the

dishwasher. Start even with the top edge and press in as

you move to the bottom.

• Press trim piece onto top dishwasher flange.

• Open and close the doorto checkthat trim does not bind.

Note:Tubtrim is located in

dishwasher upper rack.

Step 11Leveldishwasher ]

Levelthe dishwasher by adjusting the

four leveling legs individually for correct

alignment. See Figure O.

Dishwasher should be level left to right

and front to backfor proper dish rack

operation and dishwasher performance.

Dishwasher door should be in alignment

with adjacent cabinets. See Figure P.

@

Figure0

Step12Positiondishwasher andfasten to cabinet]

Openthe door and position the dishwasher tub flange 3/4"

from the cabinet opening. Fastenthe dishwasher to the

underside of the countertop, using the 2 Phillips screws

provided in Step 1.Be sure screws are driven straight and

flush to avoid interference with door operation. See Figure P.

Important:

Make sure that /_

dishwasher is

centered in the

opening and

there is no

interference with

cabinets when

opening or closing

the door. Interfer-

ence may cause a

water leak when

dishwasher is in

operation.

FigureP

Page 6

lStep 13 Connect water supply

contmued

Connect water supply line to 90° elbow installed in Step 6.

Open and close the door. Checkto besure door spring does

not rub against fill hose or water supply line.

[Step 14co..ectdrain line

Follow all local codes and ordinances.

DRAIN LINE PREPARATION

The molded end is designed to fit 5/8",3/4"or 1" diameter

connections to the air gap, waste tee or disposer. Cut on

premarked line as required for your installation as illustrated

in Figure R.

Note: DONOTCUTCORRUGATEDPORTIONOFHOSE.

Bracket Impertanr: When opening and

blot Water

Supply Line

closing the door, the door

spring should not touch the fill

hose. If it does, bend water

valve bracket slightly to

provide clearance between

the spring and the fill hose,

Figure Q

Method 1-Air gap with waste tee or disposer

___ r_ __ N

Cutting Lines

FigureR Donot (;utcorrugated

portionof hose

If the location requires a longer drain hose, add up to 42" of

length to the factory installed hose. Use5/8"or 7/8"inside

diameter hose and a short section of copper water pipe of

appropriate length and diameter to connect the two hose

ends. Secure connection with appropriate clamps (not

supplied).

Nete: TOTALDRAIN HOSELENGTHMUSTNOT EXCEED

10FEETFORPROPERDRAIN OPERATION.

DRAIN LINE INSTALLATION

Connect drain line to air gap, waste tee or disposer using

either Method 1or Method 2 as previously determined. Refer

to Figure S or Figure T.

Secure connection using appropriate clamps (not supplied).

Make sure drain hose is not kinked.

Waste tee installation Disposer Installation

FigureS

Method 2-High drain loopwith waste tee or disposer

Fasten to underside Fasten to underside

.__ ofcountertop _ _ of countertop

Waste tee installation Disposer Installation

FigureT

Nete: BE SURETO REMOVEDRAIN PLUGFROMDISPOSER

BEFOREATTACHINGDRAIN LINE.DISHWASHERWILL NOT

DRAIN IFPLUG IS LEFTIN PLACE.

Page 7

[Step15 Connect power supply

continued

Verify that power is turned off at source. If power cord is

used, plug itintothe wall outlet and go to Step 16. Ifdish-

washer is to be directly wired to house wiring, continuewith

this step.

Remove junction box cover.

Secure the power supply cable to the back of the junctionbox

with a strain relief (notsupplied).

Locate the three dishwasher wires (white, black, and green)

with the stripped ends. Insert the three wires through the

small hole in the junction box bracket. Using wire nuts of

appropriate size, connect incoming ground to green wire,

white to white and blackto black, as shown in Figure U.

Replace the junction box cover. Checkto make sure that wires

are not pinched under junction box cover.

White

Neutral

Gro!_ \ _

.... .Black

WARNING

If house wiring is not 2-wire with a ground wire,

a ground must beprovided bythe installer.

When house wiring is aluminum, be sure to use U.L.Listed

anti-oxidant compound and aluminum-to-copper connectors.

Step16 Pre4est check liSt

[] Checkto besure power is off. [] Pull lower rack about halfway out. Check to be sure it does

[] Open dishwasher door and remove all foam and card- not roll back intodishwasher or further out. If itdoes,

board packaging.

[] Remove literature package with Use& Care manual.

[] Readthe Use & Caremanual to familiarize yourself with

the operation of the dishwasher.

[] Add two quarts of water to the bottom of the dishwasher

to lubricate the pump seal.

[] Removethe protective film if present from the control

panel, access panel and door panel.

[] Checkto be sure that wiring is secure under the dish-

washer, and not pinched or in contact with door springs or

other dishwasher components.

relevel dishwasher.

[] Turn on water supply.

[] Check for plumbing leaks. lighten connections if

necessary.

[] Check that door spring does not contact water line, fill

hose, wiring or dishwasher components.

[] Turn on the hot water faucet at the sink andverify water

temperature. Water going to dishwasher must be between

the temperatures of 120°Fand 150°E

__ Live FigureU

I I Note:CheckThat

HarnessLeadsAre

ThreadedThruSmall

HoleinBracket

[Step 17 Dishwasher wet test check list

[] Turn on power supply. [] Check for leaks around the door. A leak around the door

[] Latch door.

[] Select normal cycle on push-button or electronic models.

[] On dial models, turn control dial just enough to start

dishwasher. Be careful notto turn the dial past the first

water fill. On electronic models, push start pad.

[] Checkto be sure that water enters the dishwasher. This

could take upto 4 minutes.

If water does not enter the dishwasher, check to be sure

that water isturned on.

[] Checkfor leaks under the dishwasher. If a leak isfound,

turn off power supply, tighten connections and restore

power.

could be caused by dishwasher door rubbing or hitting

against adjacent cabinetry. Reposition the dishwasher if

necessary.

[] The dishwasher will drain about 5minutes after the first fill,

Check drain lines. If leaks are found, turn off power, correct

as necessary and restore power.

[] Open dishwasher door andmake sure most of the water

has drained. If not, checkthat disposer plug has been

removed and/or air gap is not plugged.

[] Letthe dishwasher run through another fill and drain cycle.

Check again to be sure there are no leaks.

[] Atthe end ofthe second drain, pushthe reset padon

electronic models. Ondial models, unlatch the door and

rotate the dial to the "OFF" position.

Page 8

contmued

Step 18Replace accesspanel and toekick 1

Refer to FigureV.Place the toekick against the legs of the

dishwasher. Align the access panel to the dishwasher and

tighten the two access panel screws. Align the toekick and

make sure the bottom edge is against the floor. Insert and

tighten the two toekick attachment screws, making sure the

bottom edge of the toekick stays in contact with the floor.

FigureV

Step 19 Literature

Tighten2

AccessPanelScrews

Access Panel

[] Be sure to leave complete literature package and installa-

tion instructions with consumer.

Pub, No. 31-30515 DW6. NO. 206C1559P054

SPECIFICATIONSSUBJECTTOCHANGEWITHOUT NOTICE

(N.D. 558) 2/00

Loading...

Loading...