GE AF-650 GP, GP AF-650 Quick Manual

GE

TM

AF-650 GP

General Purpose Drive

Quick Guide

Guia rapida

Kurzanleitung

Guide rapide

Guida rapida

Safety AF-650 GP Quick Guide

1Safety

1

1

1.1.1 Safety

WARNING

HIGH VOLTAGE!

Adjustable frequency drives contain high voltage when

connected to AC line power. Installation, start-up, and

maintenance should be performed by qualified personnel

only. Failure to perform installation, start-up, and

maintenance by qualified personnel could result in death

or serious injury.

High Voltage

Adjustable frequency drives are connected to hazardous

AC line voltage. Extreme care should be taken to protect

against shock. Only trained personnel familiar with

electronic equipment should install, start, or maintain this

equipment.

WARNING

UNINTENDED START!

When the adjustable frequency drive is connected to AC

line power, the motor may start at any time. The

adjustable frequency drive, motor, and any driven

equipment must be in operational readiness. Failure to be

in operational readiness when the adjustable frequency

drive is connected to AC line power could result in death,

serious injury, equipment, or property damage.

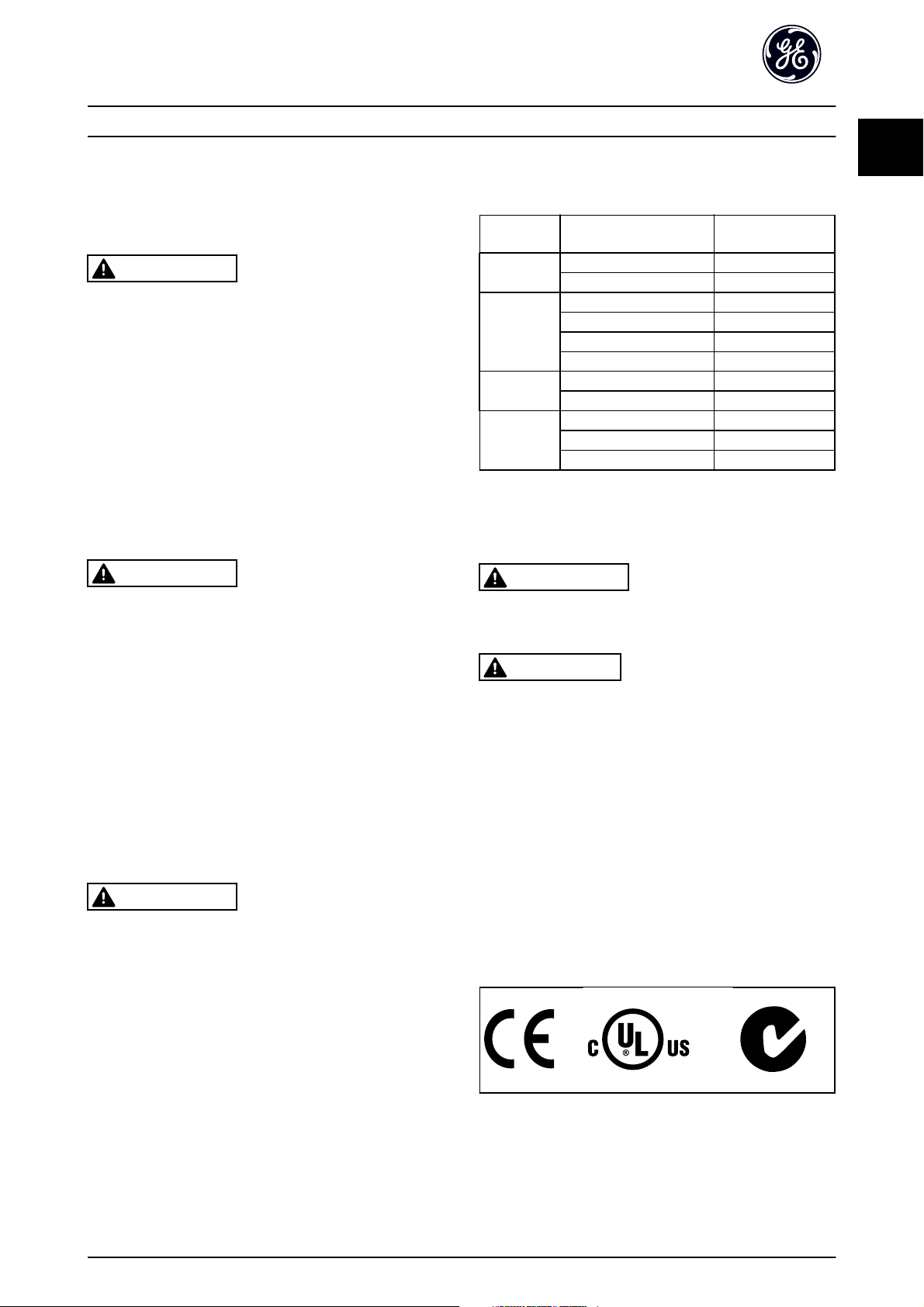

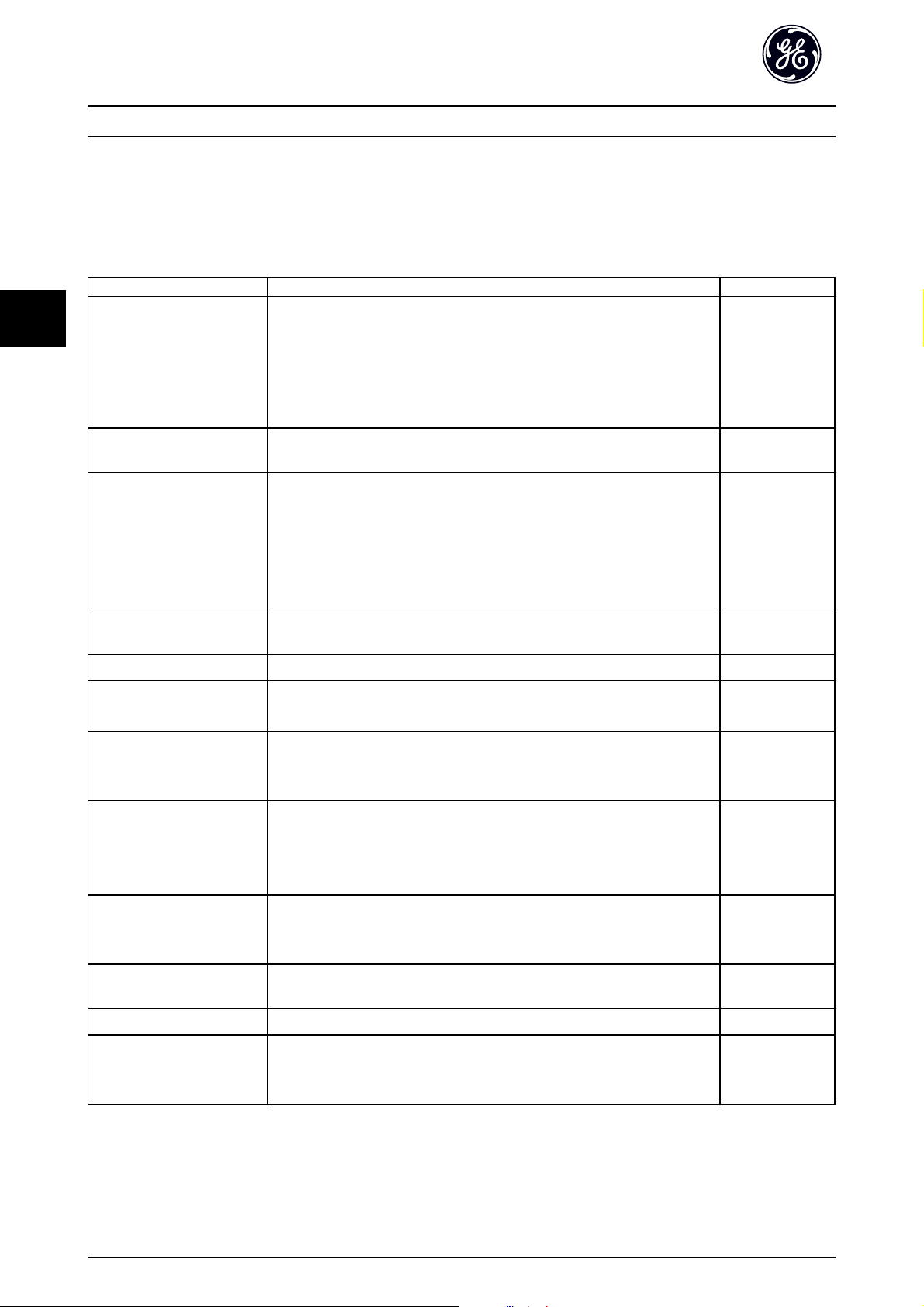

Voltage Power Size

200–240V

380–480V

525–600V

525–690V

Table 1.1 Discharge Time

Symbols

The following symbols are used in this manual.

0.25–3.7kW 0.33–5HP 4 minutes

5.5–37kW 7.5–50HP 15 minutes

0.37–7.5kW 0.5–10HP 4 minutes

11–75kW 15–100HP 15 minutes

90–200kW 125–300HP 20 minutes

250–800kW 350–1200HP 40 minutes

0.37–7.5kW 0.5–10HP 4 minutes

11–75kW 15–100HP 15 minutes

11–75kW 15–100HP 15 minutes

90–315kW 125–400HP 20 minutes

355–1200kW 500–1350HP 30 minutes

Minimum Waiting

Time

WARNING

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may

also be used to alert against unsafe practices.

Unintended Start

When the adjustable frequency drive is connected to the

AC line power, the motor may be started by means of an

external switch, a serial bus command, an input reference

signal, or a cleared fault condition. Use appropriate

precautions to guard against an unintended start.

WARNING

DISCHARGE TIME!

Adjustable frequency drives contain DC link capacitors that

can remain charged even when AC line power is disconnected. To avoid electrical hazards, remove AC line power

from the adjustable frequency drive before doing any

service or repair and wait the amount of time specified in

Table 1.1. Failure to wait the specified time after power has

been removed prior to doing service or repair on the unit

could result in death or serious injury.

CAUTION

Indicates a situation that may result in equipment or

property damage-only accidents.

NOTE

Indicates highlighted information that should be observed

in order to avoid mistakes or operate equipment at less

than optimal performance.

Approvals

DET-759A 1

2

Introduction AF-650 GP Quick Guide

2Introduction

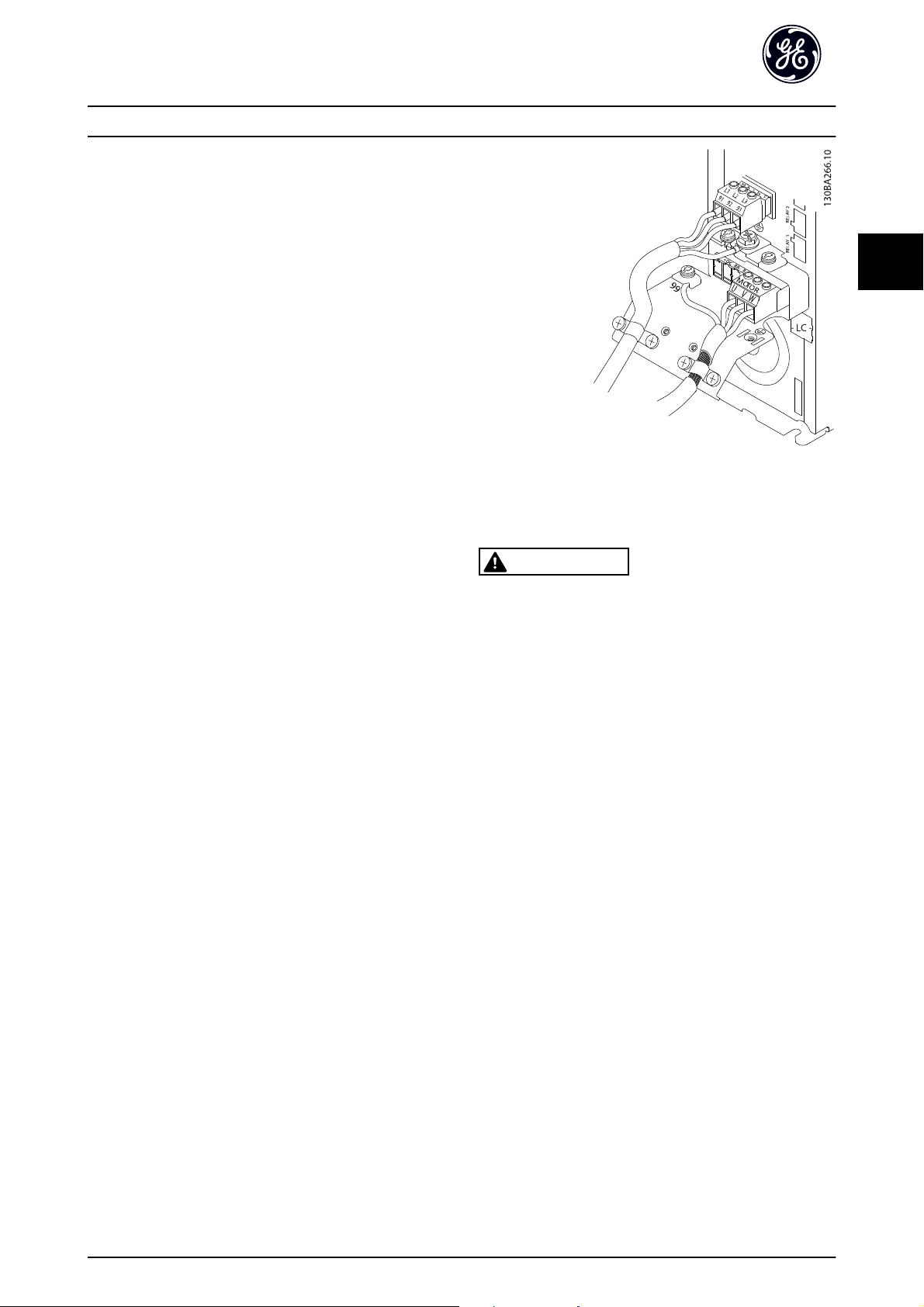

Illustration 2.1 Exploded View Unit Sizes 12-13, IP20

NOTE

Please consult the AF-650 GP Instruction Manual for other unit sizes.

1 Keypad 10 Motor output terminals 96 (U), 97 (V), 98 (W)

2 RS-485 serial bus connector (+68, -69) 11 Relay 1 (01, 02, 03)

3 Analog I/O connector 12 Relay 2 (04, 05, 06)

4 Keypad input plug 13 Brake (-81, +82) and load sharing (-88, +89) terminals

5 Analog switches (A53), (A54) 14 Line power input terminals 91 (L1), 92 (L2), 93 (L3)

6 Cable strain relief / PE ground 15 USB connector

7 Decoupling plate 16 Serial bus terminal switch

8 Grounding clamp (PE) 17 Digital I/O and 24 V power supply

9 Shielded cable grounding clamp and strain relief 18 Control cable coverplate

2DET-759A

Installation AF-650 GP Quick Guide

3

3 Installation

3.1 Installation Site Checklist

The drive relies on the ambient air for cooling.

•

Observe the limits on ambient air temperature for

optimal operation

Ensure that the installation location has sufficient

•

support strength to mount the drive

Keep the drive interior free from dust and dirt.

•

Ensure that the components stay as clean as

possible. In construction areas, provide a

protective covering. Optional IP54 (NEMA 12)

enclosures may be necessary.

Keep the manual, drawings, and diagrams

•

accessible for detailed installation and operation

instructions. It is important that the manual is

available for equipment operators.

Locate equipment as near to the motor as

•

possible. Keep motor cables as short as possible.

Check the motor characteristics for actual

tolerances. Do not exceed

1000 ft [300 m] for unshielded motor

•

leads

500 ft [150 m] for shielded cable.

•

3.3 Mechanical Installation

3.3.1 Cooling

To provide cooling airflow, mount the unit to a

•

solid flat surface or to the optional backplate (see

3.3.3 Mounting)

Top and bottom clearance for air cooling must be

•

provided. Generally, 4–10 in [100–225 mm] is

required. See Illustration 3.1 for clearance

requirements

Improper mounting can result in overheating and

•

reduced performance.

Derating for temperatures starting between 104°F

•

[40°C]) and 122°F [50°C] and elevation 3,300 ft

[1,000 m] above sea level must be considered.

See the equipment Design Guide for detailed

information.

3

3.2 Adjustable Frequency Drive and Motor

Pre-installation Checklist

Compare the model number of unit on the

•

nameplate to what was ordered to verify the

proper equipment

Ensure each of the following are rated for the

•

same voltage:

Line power

Drive

Motor

Ensure that drive output current rating is equal to

•

or greater than motor full load current for peak

motor performance.

Motor size and drive power must match

for proper overload protection.

If drive rating is less than motor, full

motor output cannot be achieved.

Illustration 3.1 Top and Bottom Cooling Clearance

DET-759A 3

3

Installation AF-650 GP Quick Guide

Voltage Power Size Clearance a/b

0.25–3.7kW 0.33–5HP 100mm / 4in

200–240V

380–480V

525–600V

525–690V all 225mm / 10in

Table 3.1 Minimum Airflow Clearance Requirements

5.5–22kW 7.5–30HP 200mm / 8in

> 22kW / 30HP 225mm / 10in

0.37–7.5kW 0.5–10HP 100mm / 4in

11–45kW 15–60HP 200mm / 8in

> 45kW / 60HP 225mm / 10in

0.37–7.5kW 0.5–10HP 100mm / 4in

11–45kW 15–60HP 200mm / 8in

> 45kW / 60HP 225mm / 10in

3.3.2 Lifting

Illustration 3.2 Proper Mounting with Backplate

Check the weight of the unit to determine a safe

•

lifting method

Ensure that the lifting device is suitable for the

•

task

If necessary, plan for a hoist, crane, or forklift with

•

the appropriate rating to move the unit

For lifting, use hoist rings on the unit, when

•

provided

3.3.3 Mounting

Mount the unit vertically

•

The drive allows side by side installation.

•

Ensure that the strength of the mounting location

•

will support the unit weight

Mount the unit to a solid flat surface or to the

•

optional backplate to provide cooling airflow (see

Illustration 3.2 and Illustration 3.3).

Improper mounting can result in overheating and

•

reduced performance.

Use the slotted mounting holes on the unit for

•

wall mounting, when provided.

Item A is a backplate properly installed for required airflow

to cool the unit.

Illustration 3.3 Proper Mounting with Railings

NOTE

Backplate is needed when mounted on railings.

4DET-759A

Installation AF-650 GP Quick Guide

3

3.4 Electrical Installation

This section contains detailed instructions for wiring the drive. The following tasks are described.

Wiring the motor to the drive output terminals

•

Wiring the AC line power to the drive input terminals

•

Connecting control and serial communication wiring

•

After power has been applied, checking input and motor power; programming control terminals for their intended

•

functions

3

Illustration 3.4 Basic Wiring Schematic Drawing.

A=Analog, D=Digital

Terminal 37 is used for Safe Stop. For Safe Stop installation instructions, refer to the Design Guide.

*The brake chopper factory option must be ordered to use dynamic braking resistors.

**This is available when ordering the brake chopper option on unit size 23 and above drives.

DET-759A 5

Installation AF-650 GP Quick Guide

3

3.4.1 Requirements

WARNING

EQUIPMENT HAZARD!

Rotating shafts and electrical equipment can be hazardous.

All electrical work must conform to national and local

electrical codes. It is strongly recommended that installation, start-up, and maintenance be performed only by

trained and qualified personnel. Failure to follow these

guidelines could result in death or serious injury.

CAUTION

WIRING ISOLATION!

Run input power, motor wiring and control wiring in three

separate metallic conduits or use separated shielded cable

for high frequency noise isolation. Failure to isolate power,

motor and control wiring could result in less than

optimum adjustable frequency drive and associated

equipment performance.

For your safety, comply with the following requirements.

Electronic controls equipment is connected to

•

hazardous AC line voltage. Extreme care should

be taken to protect against electrical hazards

when applying power to the unit.

Run motor cables from multiple adjustable

•

frequency drives separately. Induced voltage from

output motor cables run together can charge

equipment capacitors even with the equipment

turned off and locked out.

Overload and Equipment Protection

An electronically activated function within the

•

adjustable frequency drive provides overload

protection for the motor. The overload calculates

the level of increase to activate timing for the trip

(controller output stop) function. The higher the

current draw, the quicker the trip response. The

overload provides Class 20 motor protection. See

7 Warnings and Alarm for details on the trip

function.

Because the motor wiring carries high frequency

•

current, it is important that wiring for line power,

motor power, and control is run separately. Use

metallic conduit or separated shielded wire.

Failure to isolate power, motor, and control

wiring could result in less than optimum

equipment performance.

All adjustable frequency drives must be provided

•

with short-circuit and overcurrent protection.

Input fusing is required to provide this

protection, see Illustration 3.5. Fuses must be

provided by the installer as part of installation.

See maximum fuse ratings in 9.1.2 CE Compliance.

Illustration 3.5 Fuses

Wire Type and Ratings

All wiring must comply with local and national

•

regulations regarding cross-section and ambient

temperature requirements.

GE recommends that all power connections be

•

made with a minimum 167°F [75°C] rated copper

wire.

3.4.2 Grounding Requirements

WARNING

GROUNDING HAZARD!

For operator safety, it is important to ground drive

properly in accordance with national and local electrical

codes as well as instructions contained within these

instructions. Ground currents are higher than 3.5 mA.

Failure to ground drive properly could result in death or

serious injury.

NOTE

It is the responsibility of the user or certified electrical

installer to ensure correct grounding of the equipment in

accordance with national and local electrical codes and

standards.

Follow all local and national electrical codes to

•

ground electrical equipment properly.

Proper protective grounding for equipment with

•

ground currents higher than 3.5 mA must be

established, see Leakage Current (>3.5 mA)

A dedicatedground wire is required for input

•

power, motor power and control wiring

Use the clamps provided with on the equipment

•

for proper ground connections

6DET-759A

Installation AF-650 GP Quick Guide

3

Do not ground one drive to another in a “daisy

•

chain” fashion

Keep the ground wire connections as short as

•

possible

Use of high-strand wire to reduce electrical noise

•

is recommended

Follow the motor manufacturer wiring

•

requirements

3.4.2.1 Leakage Current (>3.5 mA)

Follow national and local codes regarding protective

grounding of equipment with a leakage current > 3.5 mA.

Drive technology implies high frequency switching at high

power. This will generate a leakage current in the ground

connection. A fault current in the drive at the output

power terminals might contain a DC component which can

charge the filter capacitors and cause a transient ground

current. The ground leakage current depends on various

system configurations including RFI filtering, shielded

motor cables, and drive power.

EN/IEC61800-5-1 (Power Drive System Product Standard)

requires special care if the leakage current exceeds 3.5m A.

Grounding must be reinforced in one of the following

ways:

Ground wire of at least 0.0155 in2 [10mm2]

•

Two separate ground wires both complying with

•

the dimensioning rules

See EN 60364-5-54 § 543.7 for further information.

Using RCDs

Where residual current devices (RCDs), also known as

ground leakage circuit breakers (ELCBs), are used, comply

with the following:

Use RCDs of type B only which are capable of

detecting AC and DC currents

Use RCDs with an inrush delay to prevent faults

due to transient ground currents

Dimension RCDs according to the system configuration and environmental considerations

3.4.2.2 Grounding Using Shielded Cable

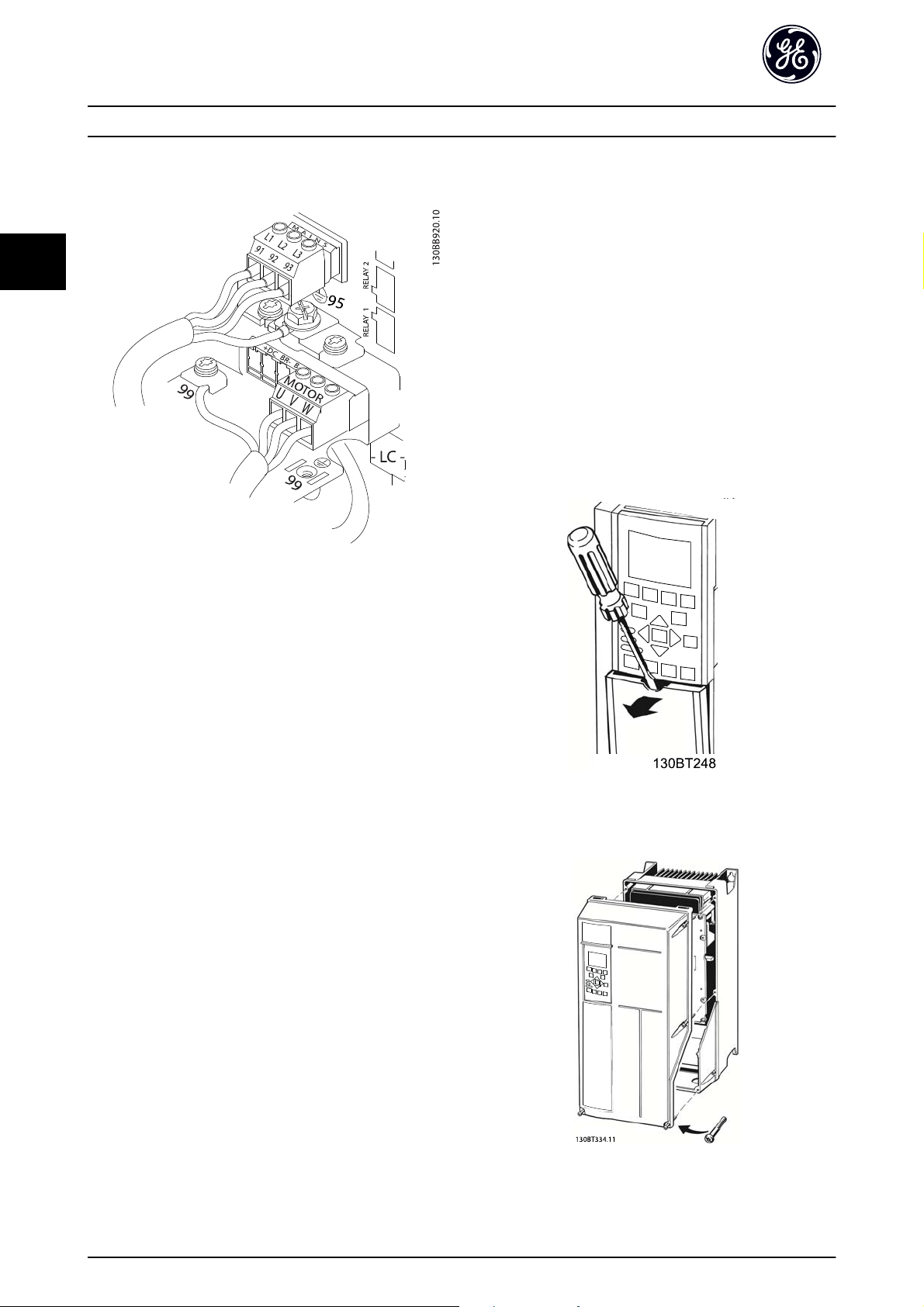

Grounding clamps are provided for motor wiring (see

Illustration 3.6).

Illustration 3.6 Grounding with Shielded Cable

3.4.3 Motor Connection

WARNING

INDUCED VOLTAGE!

Run output motor cables from multiple adjustable

frequency drives separately. Induced voltage from output

motor cables run together can charge equipment

capacitors even with the equipment turned off and locked

out. Failure to run output motor cables separately could

result in death or serious injury.

For maximum wire sizes, see Table 10.1

•

Comply with local and national electrical codes

•

for cable sizes.

Motor wiring knockouts or access panels are

•

provided at the base of IP21 and higher (Nema 1,

12, and 4/4X Indoor) units

Do not install power factor correction capacitors

•

between the adjustable frequency drive and the

motor

Do not wire a starting or pole-changing device

•

between the adjustable frequency drive and the

motor.

Connect the 3-phase motor wiring to terminals

•

96 (U), 97 (V), and 98 (W).

Ground the cable in accordance with grounding

•

instructions provided.

Torque terminals in accordance with the

•

information provided in

Follow the motor manufacturer wiring

•

requirements

Illustration 3.7 represents line power input, motor, and

ground grounding for basic adjustable frequency drives.

3

DET-759A 7

Installation AF-650 GP Quick Guide

3

Actual configurations vary with unit types and optional

equipment.

Illustration 3.7 Example of Motor, Line Power and Ground Wiring

3.4.5 Control Wiring

Isolate control wiring from high power

•

components in the adjustable frequency drive.

If the adjustable frequency drive is connected to

•

a thermistor, for PELV isolation, optional

thermistor control wiring must be reinforced/

double insulated. A 24 VDC supply voltage is

recommended.

3.4.5.1 Access

Remove access coverplate with a screwdriver. See

•

Illustration 3.8.

Or remove front cover by loosening attaching

•

screws. See Illustration 3.9.

Tightening torque for front cover is 2.0Nm for

unit size 15 and 2.2Nm for unit sizes 2X and 3X.

3.4.4 AC Line Power Connection

Size wiring based upon the input current of the

•

drive. For maximum wire sizes, see Table 10.1.

Comply with local and national electrical codes

•

for cable sizes.

Connect 3-phase AC input power wiring to

•

terminals L1, L2, and L3 (see Illustration 3.7).

Depending on the configuration of the

•

equipment, input power will be connected to the

line power input terminals or the input

disconnect.

Ground the cable in accordance with grounding

•

instructions provided in 3.4.2 Grounding

Requirements

All adjustable frequency drives may be used with

•

an isolated input source as well as with ground

reference power lines. When supplied from an

isolated line power source (IT line or floating

delta) or TT/TN-S power line with a grounded leg

(grounded delta), set 14-50 RFI Filter to OFF.

When off, the internal RFI filter capacitors

between the chassis and the intermediate circuit

are isolated to avoid damage to the intermediate

circuit and to reduce ground capacity currents in

accordance with IEC 61800-3.

Illustration 3.8 Control Wiring Access for IP20 / Open Chassis

Enclosures

Illustration 3.9 Control Wiring Access for IP55 / Nema 12 and

IP66 / Nema 4/4X Indoor

8DET-759A

Installation AF-650 GP Quick Guide

3

3.4.5.2 Control Terminal Types

Illustration 3.10 and shows the removable adjustable

frequency drive connectors. Terminal functions and default

settings are summarized in Table 3.2.

Illustration 3.10 Control Terminal Locations

Illustration 3.11 Terminal Numbers

Connector 1 provides four programmable digital

•

input terminals, two additional digital terminals

programmable as either input or output, a 24V

DC terminal supply voltage, and a common DC

voltage for optional customer-supplied 24 V. A

digital input for STO (Safe Torque Off) function.

Connector 2 terminals (+)68 and (-)69 are for an

•

RS-485 serial communications connection

Connector 3 provides two analog inputs, one

•

analog output, 10V DC supply voltage, and

commons for the inputs and output

Connector 4 is a USB port available for use with

•

the DCT-10

Also provided are two Form C relay outputs that

•

are in various locations depending upon the

adjustable frequency drive configuration and size.

Some options available for ordering with the unit

•

may provide additional terminals. See the manual

provided with the equipment option.

See 8.1 General Technical Data for terminal ratings details.

Terminal description

Default

Terminal Parameter

12, 13 - +24V DC 24 V DC supply

18 E-01 [8] Start

19 E-02 [10] Reversing

32 E-05 [0] No

33 E-06 [0] No

27 E-03 [0] No

29 E-04 [14] JOG

20 - Common for digital

37 - Safe Torque

39 -

42 AN-50 [0] No

50 - +10V DC 10V DC analog supply

53 AN-1# Reference Analog input.

54 AN-2# Feedback

55 -

setting Description

Digital inputs/outputs

operation

operation

operation

Off (STO)

Analog inputs/outputs

operation

voltage. Maximum

output current is

200mA total for all

24V loads. Usable for

digital inputs and

external transducers.

Digital inputs.

Selectable for either

digital input or

output. Default setting

is input.

inputs and 0V

potential for 24V

supply.

Safe input. Used for

STO.

Common for analog

output

Programmable analog

output. The analog

signal is 0–20 mA or

4–20 mA at a

maximum of 500

voltage. 15mA

maximum commonly

used for potentiometer or thermistor.

Selectable for voltage

or current. Switches

A53 and A54 select

mA or V.

Common for analog

input

3

Ω

DET-759A 9

Installation AF-650 GP Quick Guide

3

Terminal description

Default

Terminal Parameter

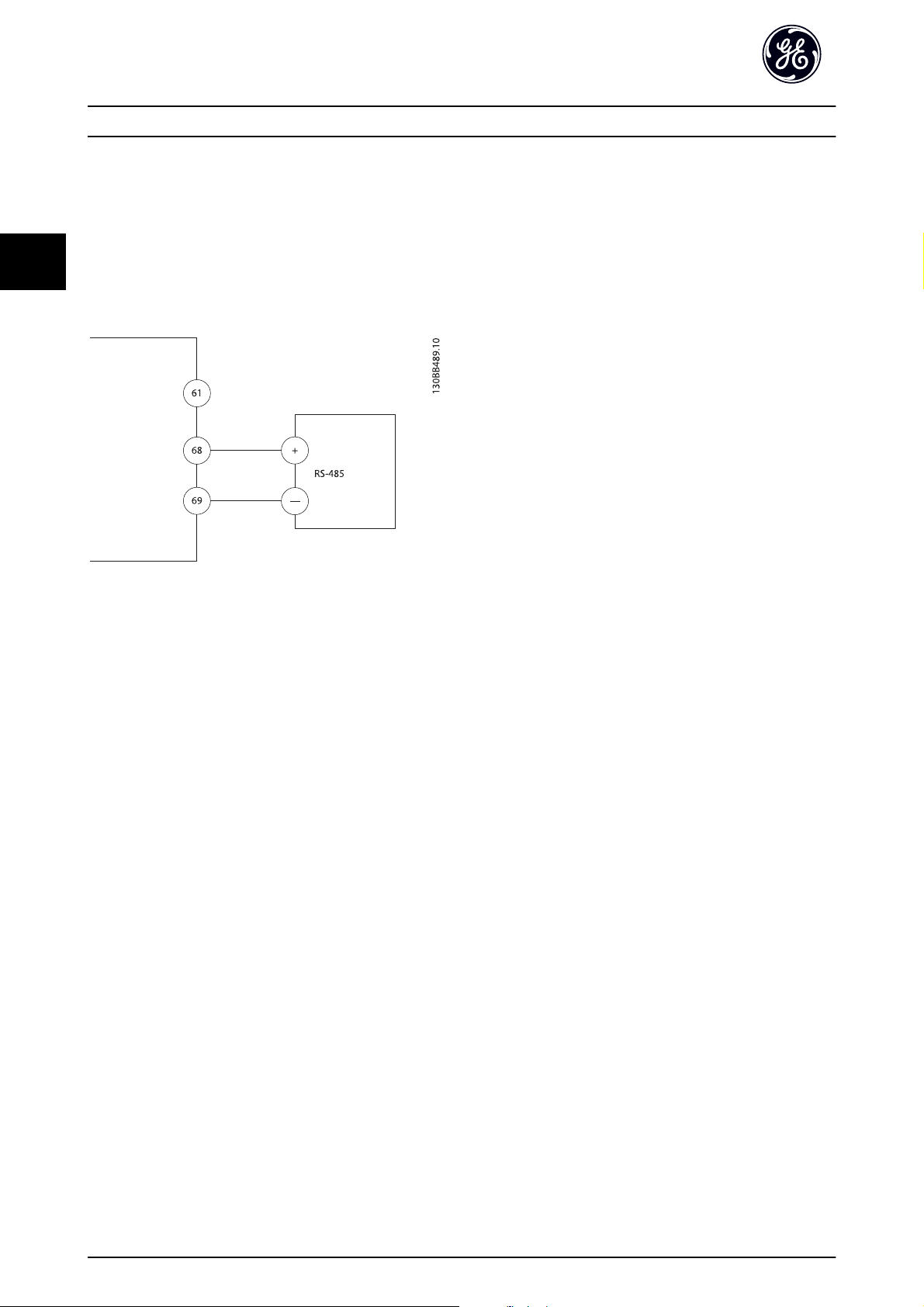

61 -

68 (+) O-3# RS-485 Interface. A

69 (-) O-3#

01, 02, 03 E-24

04, 05, 06 E-24 [0] No

Table 3.2 Terminal Description

setting Description

Serial communication

Relays

[0] No

operation

operation

Integrated RC filter for

cable screen. ONLY for

connecting the shield

when experiencing

EMC problems.

control card switch is

provided for

termination resistance.

Form C relay output.

Usable for AC or DC

voltage and resistive

or inductive loads.

3.4.5.3 Wiring to Control Terminals

Control terminal connectors can be unplugged from the

drive for ease of installation, as shown in Illustration 3.10.

1. Open the contact by inserting a small screwdriver

into the slot above or below the contact, as

shown in Illustration 3.12.

2. Insert the bared control wire into the contact.

3. Remove the screwdriver to fasten the control wire

into the contact.

4. Ensure the contact is firmly established and not

loose. Loose control wiring can be the source of

equipment faults or less than optimal operation.

If the ground potential between the adjustable frequency

drive and the PLC is different, electric noise may occur that

will disturb the entire system. Solve this problem by fitting

an equalizing cable next to the control cable. Minimum

2

cable cross-section: 0.025 in

(16 mm2).

50/60Hz ground loops

With very long control cables, ground loops may occur. To

eliminate ground loops, connect one end of the shield-toground with a 100nF capacitor (keeping leads short).

Avoid EMC noise on serial communication

This terminal is grounded via an internal RC link. Use

twisted-pair cables to reduce interference between

conductors. The recommended method is shown below:

Alternatively, the connection to terminal 61 can be

omitted:

3.4.5.5 Control Terminal Functions

Drive functions are commanded by receiving control input

signals.

Illustration 3.12 Connecting Control Wiring

3.4.5.4 Using Shielded Control Cables

Correct shielding

The preferred method in most cases is to secure control

and serial communication cables with shielding clamps

provided at both ends to ensure best possible high

frequency cable contact.

10 DET-759A

Each terminal must be programmed for the

•

function it will be supporting in the parameters

associated with that terminal. SeeTable 3.2 for

terminals and associated parameters.

It is important to confirm that the control

•

terminal is programmed for the correct function.

See 5 User Interface for details on accessing

parameters and for details on programming.

Installation AF-650 GP Quick Guide

3

The default terminal programming is intended to

•

initiate drive functioning in a typical operational

mode.

3.4.5.6 Terminal 53 and 54 Switches

Analog input terminals 53 and 54 can select

•

either voltage (-10–10V) or current (0/4–20mA)

input signals

Remove power to the drive before changing

•

switch positions

Set switches A53 and A54 to select the signal

•

type. U selects voltage, I selects current.

The switches are accessible when the Keypad has

•

been removed (see Illustration 3.13). Note that

some option cards available for the unit may

cover these switches and must be removed to

change switch settings. Always remove power to

the unit before removing option cards.

Terminal 53 default is for a speed reference signal

•

in open-loop set in DR-61 Terminal 53 Switch

Setting

Terminal 54 default is for a feedback signal in

•

closed-loop set in DR-63 Terminal 54 Switch

Setting

130BT310.10

Illustration 3.13 Location of Terminals 53 and 54 Switches and

Bus Termination Switch

3.4.5.7 Terminal 37

Terminal 37 Safe Stop Function

The AF-650 GP and is available with safe stop functionality

via control terminal 37. Safe stop disables the control

voltage of the power semiconductors of the drive output

stage which in turn prevents generating the voltage

required to rotate the motor. When the Safe Stop (T37) is

activated, the drive issues an alarm, trips the unit, and

coasts the motor to a stop. Manual restart is required. The

safe stop function can be used for stopping the drive in

emergency stop situations. In the normal operating mode

when safe stop is not required, use the adjustable

frequency drive’s regular stop function instead. When

automatic restart is used – the requirements under ISO

12100-2 paragraph 5.3.2.5 must be fulfilled.

Liability Conditions

It is the responsibility of the user to ensure personnel

installing and operating the Safe Stop function:

Read and understand the safety regulations

•

concerning health and safety/accident prevention

Understand the generic and safety guidelines

•

given in this description and the extended

description in the Design Guide

Have a good knowledge of the generic and safety

•

standards applicable to the specific application

User is defined as: integrator, operator, servicing,

maintenance staff.

Standards

Use of safe stop on terminal 37 requires that the user

satisfies all provisions for safety including relevant laws,

regulations and guidelines. The optional safe stop function

complies with the following standards.

EN 954-1: 1996 Category 3

IEC 60204-1: 2005 category 0 – uncontrolled stop

IEC 61508: 1998 SIL2

IEC 61800-5-2: 2007 – safe torque off (STO)

function

IEC 62061: 2005 SIL CL2

ISO 13849-1: 2006 Category 3 PL d

ISO 14118: 2000 (EN 1037) – prevention of

unexpected start-up

The information and instructions of the instruction manual

are not sufficient for a proper and safe use of the safe stop

functionality. The related information and instructions of

the relevant Design Guide must be followed.

3

DET-759A 11

Installation AF-650 GP Quick Guide

3

Protective Measures

Safety engineering systems may only be installed

•

and commissioned by qualified and skilled

personnel

The unit must be installed in an IP54 cabinet or

•

in an equivalent environment

The cable between terminal 37 and the external

•

safety device must be short circuit protected

according to ISO 13849-2 table D.4

If any external forces influence the motor axis

•

(e.g. suspended loads), additional measures (e.g. a

safety holding brake) are required in order to

eliminate hazards.

Safe Stop Installation and Set-up

WARNING

SAFE STOP FUNCTION!

The safe stop function does NOT isolate AC line voltage to

the drive or auxiliary circuits. Perform work on electrical

parts of the drive or the motor only after isolating the AC

line voltage supply and waiting the length of time

specified under Safety in this manual. Failure to isolate the

AC line voltage supply from the unit and waiting the time

specified could result in death or serious injury.

the jumper is not sufficient to avoid shortcircuiting. (See jumper on Illustration 3.14.)

2. Connect an external Safety monitoring relay via a

NO safety function (the instruction for the safety

device must be followed) to terminal 37 (safe

stop) and either terminal 12 or 13 (24V DC). The

safety monitoring relay must comply with

Category 3 (EN 954-1) / PL “d” (ISO 13849-1).

It is not recommended to stop the drive by using

•

the Safe Torque Off function. If a running drive is

stopped by using the function, the unit will trip

and stop by coasting. If this is not acceptable,

e.g. causes danger, the drive and machinery must

be stopped using the appropriate stopping mode

before using this function. Depending on the

application, a mechanical brake may be required.

Concerning synchronous and permanent magnet

•

motor adjustable frequency drives in case of a

multiple IGBT power semiconductor failure: In

spite of the activation of the Safe torque off

function, the drive system can produce an

alignment torque which maximally rotates the

motor shaft by 180/p degrees. p denotes the pole

pair number.

This function is suitable for performing

•

mechanical work on the drive system or affected

area of a machine only. It does not provide

electrical safety. This function should not be used

as a control for starting and/or stopping the

drive.

The following requirements have to be met to perform a

safe installation of the drive:

1. Remove the jumper wire between control

terminals 37 and 12 or 13. Cutting or breaking

Illustration 3.14 Jumper between Terminal 12/13 (24V) and 37

12 DET-759A

Installation AF-650 GP Quick Guide

3

3

Illustration 3.15 Installation to Achieve a Stopping Category 0 (EN 60204-1) with Safety Cat. 3 (EN 954-1) / PL “d” (ISO 13849-1).

1 Safety device Cat. 3 (circuit interrupt device, possibly

with release input)

2Door contact 8 Motor

3 Contactor (Coast) 9 5V DC

4Drive 10 Safe channel

5 Line power 11 Short-circuit protected cable (if not inside installation cabinet)

6 Control board

Safe Stop Commissioning Test

After installation and before first operation, perform a commissioning test of the installation making use of safe stop. In

addition, perform the test after each modification of the installation.

7Inverter

DET-759A 13

3

Installation AF-650 GP Quick Guide

3.4.6 Serial Communication

Connect RS-485 serial communication wiring to terminals

(+)68 and (-)69.

A shielded serial communication cable is

•

recommended

See 3.4.2 Grounding Requirements for proper

•

grounding

Illustration 3.16 Serial Communication Wiring Diagram

For basic serial communication set-up, select the following

1. Protocol type in O-30 Protocol.

2. Adjustable frequency drive address in

O-31 Address.

3. Baud rate in O-32 Drive Port Baud Rate.

Two communication protocols are internal to the

•

drive.

Drive profile

Modbus RTU

Functions can be programmed remotely using

•

the protocol software and RS-485 connection or

in parameter group O-## Options / Comms

Selecting a specific communication protocol

•

changes various default parameter settings to

match that protocol’s specifications along with

making additional protocol-specific parameters

available.

Option cards which can be installed in the

•

adjustable frequency drive are available to

provide additional communication protocols. See

the option card documentation for installation

and operation manual.

14 DET-759A

Start Up and Functional Tes... AF-650 GP Quick Guide

4

4 Start Up and Functional Testing

4.1 Pre-start

4.1.1 Safety Inspection

WARNING

HIGH VOLTAGE!

If input and output connections have been connected

improperly, there is potential for high voltage on these

terminals. If power leads for multiple motors are

improperly run through the same conduit, there is a

potential for leakage current to charge capacitors within

the drive, even when disconnected from line power input.

For initial start-up, make no assumptions about power

components. Follow pre-start procedures. Failure to follow

pre-start procedures could result in personal injury or

damage to equipment.

1. Input power to the unit must be OFF and locked

out. Do not rely on the drive disconnect switches

for input power isolation.

2. Verify that there is no voltage on input terminals

L1 (91), L2 (92), and L3 (93), phase-to-phase and

phase-to-ground,

3. Verify that there is no voltage on output

terminals 96 (U), 97 (V), and 98 (W), phase-tophase and phase-to-ground.

4. Confirm continuity of the motor by measuring

ohm values on U-V (96-97), V-W (97-98), and W-U

(98-96).

5. Check for proper grounding of the drive as well

as the motor.

6. Inspect the drive for loose connections on

terminals.

7. Record the following motor nameplate data:

power, voltage, frequency, full load current, and

nominal speed. These values are needed to

program motor nameplate data later.

8. Confirm that the supply voltage matches voltage

of drive and motor.

4

DET-759A 15

Start Up and Functional Tes... AF-650 GP Quick Guide

4.1.2 Start-up Check List

CAUTION

Before applying power to the unit, inspect the entire installation as detailed in Table 4.1. Check mark those items when

completed.

4

Inspect for Description

Auxiliary equipment

Cable routing

Control wiring

Cooling clearance

EMC considerations

Environmental considerations

Fusing and circuit breakers

Grounding

Input and output power wiring

Panel interior

Switches

Vibration

Look for auxiliary equipment, switches, disconnects, or input fuses/circuit

•

breakers that may reside on the input power side of the adjustable frequency

drive or output side to the motor. Ensure that they are ready for full speed

operation.

Check function and installation of any sensors used for feedback to the drive.

•

Remove power factor correction caps on motor(s), if present.

•

Ensure that input power, motor wiring, and control wiring are separated or in

•

three separate metallic conduits for high frequency noise isolation.

Check for broken or damaged wires and loose connections.

•

Check that control wiring is isolated from power and motor wiring for noise

•

immunity.

Check the voltage source of the signals, if necessary.

•

The use of shielded cable or twisted pair is recommended. Ensure that the

•

shield is terminated correctly.

Measure to make sure that the top and bottom clearance is adequate to

•

ensure proper airflow for cooling.

Check for proper installation regarding electromagnetic compatibility.

•

See equipment label for the maximum ambient operating temperature limits.

•

Humidity levels must be 5%–95% non-condensing.

•

Check for proper fusing or circuit breakers.

•

Check that all fuses are inserted firmly and in operational condition and that all

•

circuit breakers are in the open position.

The unit requires a ground wire from its chassis to the building ground.

•

Check for good ground connections that are tight and free of oxidation.

•

Grounding to conduit or mounting the back panel to a metal surface is not a

•

suitable ground.

Check for loose connections.

•

Check that motor and line power are in separate conduits or separated

•

shielded cables.

Inspect to ensure that the unit interior is free of dirt, metal chips, moisture, and

•

corrosion.

Ensure that all switch and disconnect settings are in the proper positions.

•

Check that the unit is mounted solidly or that shock mounts are used, as

•

necessary.

Check for an unusual amount of vibration.

•

☑

Table 4.1 Start-up Check List

16 DET-759A

Start Up and Functional Tes... AF-650 GP Quick Guide

4

4.2 Applying Power to the Adjustable Frequency Drive

WARNING

HIGH VOLTAGE!

Adjustable frequency drives contain high voltage when

connected to AC line power. Installation, start-up and

maintenance should be performed by qualified personnel

only. Failure to perform installation, start-up and

maintenance by qualified personnel could result in death

or serious injury.

WARNING

UNINTENDED START!

When adjustable frequency drive is connected to AC line

power, the motor may start at any time. The drive, motor,

and any driven equipment must be in operational

readiness. Failure to be in operational readiness when the

drive is connected to AC line power could result in death,

serious injury, equipment, or property damage.

1. Confirm input voltage is balanced within 3%. If

not, correct input voltage imbalance before

proceeding. Repeat procedure after voltage

correction.

2. Ensure optional equipment wiring, if present,

matches installation application.

3. Ensure that all operator devices are in the OFF

position. Panel doors closed or cover mounted.

4. Apply power to the unit. DO NOT start the drive

at this time. For units with a disconnect switch,

turn to the ON position to apply power to the

drive.

4.3 Basic Operational Programming

Adjustable frequency drives require basic operational

programming prior to running for best performance. Basic

operational programming requires entering motor

nameplate data for the motor being operated and the

minimum and maximum motor speeds. Enter data in

accordance with the following procedure. Parameter

settings recommended are intended for start-up and

checkout purposes. Application settings may vary. See

5 User Interface for detailed instructions on entering data

through the Keypad.

Enter data with power ON, but prior to operating the

adjustable frequency drive.

1. Press [Quick Menu] on the Keypad.

2. Use the navigation keys to scroll to Quick Start

and press [OK].

3. Select language and press [OK]. Then enter the

motor data in parameters P-02, P-03, P-06, P-07,

F-04 and F-05. The information can be found on

the motor nameplate.

P-07 Motor Power [kW] or P-02 Motor

Power [HP]

F-05 Motor Rated Voltage

F-04 Base Frequency

P-03 Motor Current

P-06 Base Speed

4. Enter 3-15 Reference Resource 1 and press [OK].

5. Enter 3-13 Reference Site. Local, Remote, or Linked

to Hand/Auto. In local, the reference is entered

on the keypad, and in remote, that reference is

sourced depending on .

6. Enter the accel/decel time in 3-41 Ramp 1 Ramp

up Time and 3-42 Ramp 1 Ramp Down Time.

7. For 1-90 Motor Thermal Protection enter Elec OL

Trip 1 for Class 20 overload protection. For

further information, please see 3.4.1 Requirements.

8. For 4-13 Motor Speed High Limit [RPM] or

4-14 Motor Speed High Limit [Hz], enter the

application requirements.

9. For 4-11 Motor Speed Low Limit [RPM] or

4-12 Motor Speed Low Limit [Hz], enter the

application requirements.

10. Set 4-10 Motor Speed Direction to Clockwise,

Counterclockwise or Both directions.

11. In 1-29 Automatic Motor Adaptation (AMA), select

Reduced Auto Tune or Full Auto Tune and follow

on-screen instructions. See 4.4 Auto Tune

This concludes the quick set-up procedure. Press [Status]

to return to the operational display.

4.4 Auto Tune

Auto tune is a test procedure that measures the electrical

characteristics of the motor to optimize compatibility

between the drive and the motor.

The drive builds a mathematical model of the

•

motor for regulating output motor current. The

procedure also tests the input phase balance of

electrical power. It compares the motor characteristics with the data entered in parameters P-0#.

It does not cause the motor to run or harm to

•

the motor

4

DET-759A 17

Start Up and Functional Tes... AF-650 GP Quick Guide

4

Some motors may be unable to run the complete

•

version of the test. In that case, select Reduced

Auto Tune

If an output filter is connected to the motor,

•

select Reduced Auto Tune.

If warnings or alarms occur, see 7 Warnings and

•

Alarm

4.5 Check Motor Rotation

Prior to running the adjustable frequency drive, check the

motor rotation.

1. Press [Hand].

2. Press [►] for positive speed reference.

3. Check that the speed displayed is positive.

When H-48 Clockwise Direction is set to [0]* Normal (default

clockwise):

4a. Verify that the motor turns clockwise.

5a. Verify that the Keypad direction arrow is

clockwise.

When H-48 Clockwise Direction is set to [1] Inverse (counterclockwise):

4b. Verify that the motor turns counterclockwise.

5b. Verify that the Keypad direction arrow is

counterclockwise.

4.6 Local Control Test

3. Note any acceleration problems.

4. Press [OFF].

5. Note any deceleration problems.

If acceleration problems were encountered

If warnings or alarms occur, see 7 Warnings and

•

Alarm

Check that motor data is entered correctly

•

Increase the ramp time in F-07 Accel Time 1

•

Increase current limit in F-43 Current Limit

•

Increase torque limit in F-40 Torque Limiter

•

(Driving)

If deceleration problems were encountered

If warnings or alarms occur, see 7 Warnings and

•

Alarm

Check that motor data is entered correctly

•

Increase the ramp time in F-08 Decel Time 1

•

Enable overvoltage control in B-17 Over-voltage

•

Control

See 7.4 Warning and Alarm Definitions for resetting the

drive after a trip.

NOTE

4.1 Pre-start through 4.6 Local Control Test in this chapter

conclude the procedures for applying power to the drive,

basic programming, set-up, and functional testing.

CAUTION

MOTOR START!

Ensure that the motor, system, and any attached

equipment is ready for start. It is the responsibility of the

user to ensure safe operation under any operational

condition. Failure to ensure that the motor, system, and

any attached equipment is ready for start could result in

personal injury or equipment damage.

NOTE

The Hand key on the Keypad provides a local start

command to the drive. The OFF key provides the stop

function.

When operating in local mode, the up and down arrows

on the Keypad increase and decrease the speed output of

the drive. The left and right arrow keys move the display

cursor in the numeric display.

1. Press [Hand].

2.

Accelerate the drive by pressing [

Moving the cursor left of the decimal point

provides quicker input changes.

] to full speed.

▲

4.7 System Start-up

The procedure in this section requires user-wiring and

application programming to be completed. The following

procedure is recommended after application set-up by the

user is completed.

CAUTION

MOTOR START!

Ensure that the motor, system, and any attached

equipment is ready for start. It is the responsibility of the

user to ensure safe operation under any operational

condition. Failure to ensure that the motor, system, and

any attached equipment is ready for start could result in

personal injury or equipment damage.

18 DET-759A

Start Up and Functional Tes... AF-650 GP Quick Guide

4

1. Press [Auto].

2. Ensure that external control functions are

properly wired to the drive and all programming

completed.

3. Apply an external run command.

4. Adjust the speed reference throughout the speed

range.

5. Remove the external run command.

6. Note any problems.

If warnings or alarms occur, see 7 Warnings and Alarm.

4

DET-759A 19

User Interface AF-650 GP Quick Guide

5 User Interface

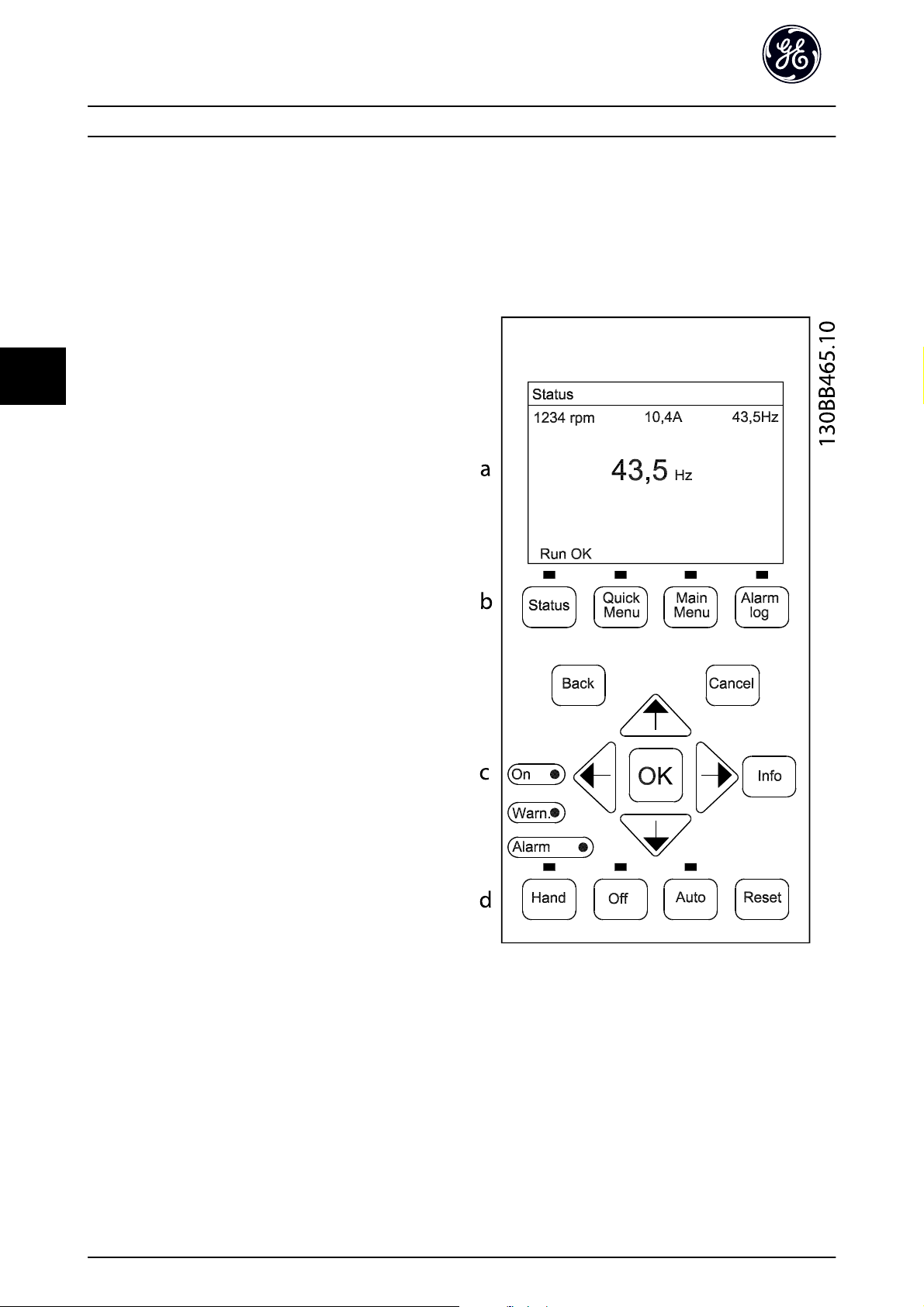

5.1.1 Keypad Layout

5

5.1 Local Control Panel Keypad

The Keypad is the combined display and keys on the front

of the unit. The Keypad is the user interface to the

adjustable frequency drive.

The Keypad has several user functions.

Start, stop, and control speed when in local

•

control

Display operational data, status, warnings and

•

cautions

Programming adjustable frequency drive

•

functions

Manually reset the adjustable frequency drive

•

after a fault when auto-reset is inactive

NOTE

The display contrast can be adjusted by pressing [STATUS]

and the up/down key.

The Keypad is divided into four functional groups (see

Illustration 5.1).

20 DET-759A

Illustration 5.1 Keypad

a. Display area.

b. Display menu keys for changing the display to

show status options, programming, or error

message history.

c. Navigation keys for programming functions,

moving the display cursor, and speed control in

local operation. Also included are the status

indicator lights.

d. Operational mode keys and reset.

User Interface AF-650 GP Quick Guide

5

5.1.2 Setting Keypad Display Values

The display area is activated when the adjustable

frequency drive receives power from AC line voltage, a DC

bus terminal, or an external 24 V supply.

The information displayed on the Keypad can be

customized for user application.

Each display readout has a parameter associated

•

with it.

Options are selected in main menu K-2#

•

The adjustable frequency drive status at the

•

bottom line of the display is generated automatically and is not selectable.

Display Parameter number Default setting

1.1 K-20 Speed [RPM]

1.2 K-21 Motor Current

1.3 K-22 Power [kW] [HP]

2 2.7 K-23 Frequency

3 K-24 Reference [%]

5.1.3 Display Menu Keys

Menu keys are used for menu access for parameter set-up,

toggling through status display modes during normal

operation, and viewing fault log data.

Key Function

Status Press to show operational information.

Press repeatedly to scroll through each

•

status display.

•

Press and hold [Status] plus [▲] or [▼] to

adjust the display brightness

The symbol in the upper right corner of the

•

display shows the direction of motor

rotation and which set-up is active. This is

not programmable.

Quick Menu Allows access to programming parameters for

initial set-up instructions and many detailed

application instructions.

Press to access Quick Start for sequenced

•

instructions to program the basic frequency

controller set up

Press to access Trending for realtime logging

•

on the keypad display.

Press to access Parameter Data Check for

•

changes in the parameter data set.

Follow the sequence of parameters as

•

presented for the function set-up

Main Menu Allows access to all programming parameters.

Press twice to access top level index.

•

Press once to return to the last location

•

accessed.

Press and hold to enter a parameter

•

number for direct access to that parameter.

Alarm Log Displays a list of current warnings, the last 10

alarms, and the maintenance log.

For details about the adjustable frequency

•

drive before it entered the alarm mode,

select the alarm number using the

navigation keys and press [OK].

5.1.4 Navigation Keys

5

Navigation keys are used for programming functions and

moving the display cursor. The navigation keys also

provide speed control in local (hand) operation. Three

drive status indicator lights are also located in this area.

DET-759A 21

5

User Interface AF-650 GP Quick Guide

Key Function

Hand Press to start the drive in local control.

Use the navigation keys to control drive

•

speed

An external stop signal by control input or

•

serial communication overrides the local hand

Off Stops the motor but does not remove power to

the drive.

Auto Puts the system in remote operational mode.

Responds to an external start command by

•

control terminals or serial communication

Speed reference is from an external source

•

Reset Resets the drive manually after a fault has been

cleared.

Key Function

Back Reverts to the previous step or list in the menu

structure.

Cancel Cancels the last change or command as long as

the display mode has not changed.

Info Press for a definition of the function being

displayed.

Navigation

Keys

OK Use to access parameter groups or to enable a

Light Indicator Function

Green ON The ON light activates when the

Yellow WARN When warning conditions are met,

Red ALARM A fault condition causes the red

Use the four navigation arrows to move between

items in the menu.

choice.

drive receives power from AC line

voltage, a DC bus terminal, or an

external 24V supply.

the yellow WARN light comes on

and text appears in the display

area identifying the problem.

alarm light to flash and an alarm

text is displayed.

5.1.6 Setting Keypad Display Values

The display area is activated when the adjustable

frequency drive receives power from AC line voltage, a DC

bus terminal, or an external 24 V supply.

The information displayed on the Keypad can be

customized for user application.

Each display readout has a parameter associated

•

with it.

Options are selected in main menu K-2#

•

The adjustable frequency drive status at the

•

bottom line of the display is generated automatically and is not selectable.

Display Parameter number Default setting

1.1 K-20 Speed [RPM]

1.2 K-21 Motor Current

1.3 K-22 Power [kW] [HP]

2 2.7 K-23 Frequency

3 K-24 Reference [%]

5.1.5 Operation Keys

Operation keys are found at the bottom of the Keypad.

22 DET-759A

User Interface AF-650 GP Quick Guide

5

5.2 Backup and Copying Parameter Settings

Programming data is stored internally in the drive.

The data can be uploaded into the Keypad

•

memory as a storage backup

Once stored in the Keypad, the data can be

•

downloaded back into the drive

Data can also be downloaded into other

•

adjustable frequency drives by connecting the

Keypad into those units and downloading the

stored settings. (This is a quick way to program

multiple units with the same settings.)

Initialization of the drive to restore factory default

•

settings does not change data stored in the

Keypad memory

WARNING

UNINTENDED START!

When the drive is connected to AC line power, the motor

may start at any time. The drive, motor, and any driven

equipment must be in operational readiness. Failure to

comply could result in death, serious injury, equipment or

property damage.

5.3 Restoring Default Settings

CAUTION

Initialization restores the unit to factory default settings.

Any programming, motor data, localization, and

monitoring records will be lost. Uploading data to the

Keypad provides a backup prior to initialization.

Restoring the drive parameter settings back to default

values is done by initialization of the adjustable frequency

drive. Initialization can be through H-03 Restore Factory

Settings or manually.

Initialization using H-03 Restore Factory Settings

•

does not change drive data such as operating

hours, serial communication selections, personal

menu settings, fault log, alarm log, and other

monitoring functions

Using H-03 Restore Factory Settings is generally

•

recommended.

Manual initialization erases all motor,

•

programming, localization, and monitoring data

and restores factory default settings.

5

5.2.1 Uploading Data to the Keypad

1. Press [OFF] to stop the motor before uploading

or downloading data.

2. Go to K-50 Keypad Copy.

3. Press [OK].

4.

Select All to Keypad.

5. Press [OK]. A progress bar shows the uploading

progress.

6. Press [Hand] or [Auto] to return to normal

operation.

5.2.2 Downloading Data from the Keypad

1. Press [OFF] to stop the motor before uploading

or downloading data.

2. Go to K-50 Keypad Copy.

3. Press [OK].

4. Select All from Keypad.

5. Press [OK]. A progress bar shows the

downloading process.

6. Press [Hand] or [Auto] to return to normal

operation.

5.3.1 Recommended Initialization

1. Press [Main Menu] twice to access parameters.

2.

Scroll to H-03 Restore Factory Settings.

3. Press [OK].

4. Scroll to [2] Restore Factory Settings.

5. Press [OK].

6. Remove power to the unit and wait for the

display to turn off.

7. Apply power to the unit.

Default parameter settings are restored during start-up.

This may take slightly longer than normal.

8. Alarm 80 is displayed.

9. Press [Reset] to return to operation mode.

5.3.2 Manual Initialization

1. Remove power to the unit and wait for the

display to turn off.

2. Press and hold [Status], [Main Menu], and [OK] at

the same time and apply power to the unit.

Factory default parameter settings are restored during

startup. This may take slightly longer than normal.

DET-759A 23

5

User Interface AF-650 GP Quick Guide

Manual initialization does not reset the following drive

information

ID-00 Operating Hours

•

ID-03 Power Up's

•

ID-04 Over Temp's

•

ID-05 Over Volt's

•

24 DET-759A

Parameter Menu Structure AF-650 GP Quick Guide

6

H-52 Min Speed Normal Magnetizing [Hz]

H-53 Model Shift Frequency

H-54 Voltage reduction in fieldweakening

H-55 U/f Characteristic - U

H-56 U/f Characteristic - F

H-58 Flystart Test Pulses Current

H-59 Flystart Test Pulses Frequency

H-6# Load Depend. Settings

H-61 High Speed Load Compensation

H-64 Resonance Dampening

H-65 Resonance Dampening Time Constant

H-66 Min. Current at Low Speed

H-7# Adj. Warnings

H-70 Warning Current Low

H-71 Warning Current High

H-72 Warning Speed Low

H-73 Warning Speed High

H-74 Warning Reference Low

H-75 Warning Reference High

H-76 Warning Feedback Low

H-77 Warning Feedback High

H-78 Missing Motor Phase Function

H-8# Stop Adjustments

H-87 Load Type

H-88 Minimum Inertia

H-89 Maximum Inertia

H-80 Function at Stop

H-81 Min Speed for Function at Stop [RPM]

H-82 Min Speed for Function at Stop [Hz]

H-83 Precise Stop Function

H-84 Precise Stop Counter Value

Delay

H-85 Precise Stop Speed Compensation

H-9# Motor Temperature

H-95 KTY Sensor Type

H-96 KTY Thermistor Input

H-97 KTY Threshold level

AN-## Analog In / Out

AN-0# Analog I/O Mode

AN-00 Live Zero Timeout Time

AN-01 Live Zero Timeout Function

AN-1# Analog Input 53

AN-10 Terminal 53 Low Voltage

AN-11 Terminal 53 High Voltage

AN-12 Terminal 53 Low Current

AN-13 Terminal 53 High Current

AN-14 Terminal 53 Low Ref./Feedb. Value

AN-15 Terminal 53 High Ref./Feedb. Value

AN-16 Terminal 53 Filter Time Constant

AN-2# Analog Input 54

AN-20 Terminal 54 Low Voltage

AN-21 Terminal 54 High Voltage

AN-22 Terminal 54 Low Current

AN-23 Terminal 54 High Current

AN-24 Terminal 54 Low Ref./Feedb. Value

AN-25 Terminal 54 High Ref./Feedb. Value

AN-26 Terminal 54 Filter Time Constant

AN-3# Analog Input X30/11

AN-30 Terminal X30/11 Low Voltage

6

C-23 Quick Stop Decel Time

E-24 Function Relay

F-11 Motor External Fan

C-24 Quick Stop Ramp Type

C-25 Quick Stop S-ramp Ratio at Decel. Start

E-26 On Delay, Relay

E-27 Off Delay, Relay

F-12 Motor Thermistor Input

F-18 Motor Speed Low Limit [RPM]

C-26 Quick Stop S-ramp Ratio at Decel. End

E-3# X46 Digital Inputs

F-16 Motor Speed Low Limit [Hz]

C-3# Frequ. Set. 2 and 3

C-30 Frequency Command 2

E-30 Terminal X46/1 Digital Input

E-31 Terminal X46/3 Digital Input

F-17 Motor Speed High Limit [RPM]

F-15 Motor Speed High Limit [Hz]

C-34 Frequency Command 3

P-## Motor Data

E-32 Terminal X46/5 Digital Input

E-33 Terminal X46/7 Digital Input

F-2# Fundamental 2

F-24 Holding Time

P-0# Motor Data

P-07 Motor Power [kW]

P-02 Motor Power [HP]

E-34 Terminal X46/9 Digital Input

E-35 Terminal X46/11 Digital Input

E-36 Terminal X46/13 Digital Input

F-25 Start Function

F-22 Start Speed [RPM]

F-23 Start Speed [Hz]

P-03 Motor Current

P-06 Base Speed

P-05 Motor Cont. Rated Torque

E-5# I/O Mode / Add On I/O

E-51 Terminal 27 Mode

E-52 Terminal 29 Mode

F-29 Start Current

F-26 Motor Noise (Carrier Freq)

F-27 Motor Tone Random

P-04 Auto Tune

P-01 Motor Poles

E-53 Terminal X30/2 Digital Input

E-54 Terminal X30/3 Digital Input

F-28 Dead Time Compensation

F-3# Fundamental 3

P-09 Slip Compensation

P-10 Slip Compensation Time Constant

E-55 Terminal X30/4 Digital Input

E-56 Term X30/6 Digi Out (OPCGPIO)

F-37 Adv. Switching Pattern

F-38 Overmodulation

P-2# Motor Selection

P-20 Motor Construction

E-57 Term X30/7 Digi Out (OPCGPIO)

E-6# Pulse Input

F-4# Fundamental 4

F-40 Torque Limiter (Driving)

P-3# Adv. Motor Data

E-60 Term. 29 Low Frequency

F-41 Torque Limiter (Braking)

P-30 Stator Resistance (Rs)

P-31 Rotor Resistance (Rr)

E-61 Term. 29 High Frequency

E-62 Term. 29 Low Ref./Feedb. Value

F-43 Current Limit

F-5# Extended References

P-33 Stator Leakage Reactance (X1)

P-34 Rotor Leakage Reactance (X2)

P-35 Main Reactance (Xh)

P-36 Iron Loss Resistance (Rfe)

P-37 d-axis Inductance (Ld)

H-## High Perf Parameters

H-0# High Perf Operations

H-09 Start Mode

H-07 Accel/Decel Time 1 Type

H-08 Reverse Lock

H-04 Auto-Reset (Times)

H-05 Auto-Reset (Reset Interval)

H-03 Restore Factory Settings

H-2# Motor Feedback Monitoring

H-20 Motor Feedback Loss Function

H-21 Motor Feedback Speed Error

H-22 Motor Feedback Loss Timeout

H-24 Tracking Error Function

H-25 Tracking Error

H-26 Tracking Error Timeout

H-27 Tracking Error Ramping

H-28 Tracking Error Ramping Timeout

H-29 Tracking Error After Ramping Timeout

H-4# Advanced Settings

H-40 Configuration Mode

H-41 Motor Control Principle

H-42 Flux Motor Feedback Source

H-43 Torque Characteristics

H-44 Constant or Variable Torque OL

H-45 Local Mode Configuration

H-48 Clockwise Direction

H-46 Back EMF at 1000 RPM

H-47 Motor Angle Offset

H-5# Load Indep. Settings

H-50 Motor Magnetization at Zero Speed

H-51 Min Speed Normal Magnetizing [RPM]

E-63 Term. 29 High Ref./Feedb. Value

E-64 Pulse Filter Time Constant #29

E-65 Term. 33 Low Frequency

E-66 Term. 33 High Frequency

E-67 Term. 33 Low Ref./Feedb. Value

E-68 Term. 33 High Ref./Feedb. Value

E-69 Pulse Filter Time Constant #33

E-7# Pulse Output

E-70 Terminal 27 Pulse Output Variable

E-72 Pulse Output Max Freq #27

E-73 Terminal 29 Pulse Output Variable

E-75 Pulse Output Max Freq #29

E-76 Terminal X30/6 Pulse Output Variable

E-78 Pulse Output Max Freq #X30/6

E-8# 24V Encoder Input

E-80 Term 32/33 Pulses Per Revolution

E-81 Term 32/33 Encoder Direction

E-9# Bus Controlled

E-90 Digital & Relay Bus Control

E-93 Pulse Out #27 Bus Control

E-94 Pulse Out #27 Timeout Preset

E-95 Pulse Out #29 Bus Control

E-96 Pulse Out #29 Timeout Preset

E-97 Pulse Out #X30/6 Bus Control

E-98 Pulse Out #X30/6 Timeout Preset

C-## Freq Ctrl Functions

C-0# Freq Ctrl Functions

C-05 Multi-step Frequency 1 - 8

C-02 Jump Speed From [RPM]

C-01 Jump Frequency From [Hz]

C-03 Jump Speed To [RPM]

C-04 Jump Frequency To [Hz]

C-2# Jog Setup

C-20 Jog Speed [Hz]

C-21 Jog Speed [RPM]

C-22 Jog Accel/Decel Time

F-50 Reference Range

F-51 Reference/Feedback Unit

F-52 Minimum Reference

F-53 Maximum Reference

F-54 Reference Function

F-6# References

F-62 Catch up/slow-down value

F-64 Preset Relative Reference

F-68 Relative Scaling Reference Resource

F-9# Digital Potentiometer

F-90 Step Size

F-91 Accel/Decel Time

F-92 Power Restore

F-93 Maximum Limit

F-94 Minimum Limit

F-95 Accel/Decel Ramp Delay

E-## Digital In/Out

E-0# Digital Inputs

E-00 Digital I/O Mode

E-01 Terminal 18 Digital Input

E-02 Terminal 19 Digital Input

E-03 Terminal 27 Digital Input

E-04 Terminal 29 Digital Input

E-05 Terminal 32 Digital Input

E-06 Terminal 33 Digital Input

E-07 Terminal 37 Safe Stop

E-1# Additional Accel Decel Ramps

E-10 Accel Time 2

E-11 Decel Time 2

E-12 Accel Time 3

E-13 Decel Time 3

E-14 Accel Time 4

E-15 Decel Time 4

E-2# Digital Output

E-20 Terminal 27 Digital Output

E-21 Terminal 29 Digital Output

Structure

Keypad Set-up

6.1.1 Main Menu

Parameter Data Set

K-0# Keypad Basic Set.

K-01 Language

K-02 Motor Speed Unit

K-03 Regional Settings

K-04 Operating State at Power-up

K-09 Performance Monitor

K-1# Keypad Set-up Ops

K-10 Active Set-up

K-11 Edit Set-up

K-12 This Set-up Linked to

K-13 Readout: Linked Set-ups

K-14 Readout: Edit Set-ups / Channel

K-2# Keypad Display

K-20 Display Line 1.1 Small

K-21 Display Line 1.2 Small

K-22 Display Line 1.3 Small

K-23 Display Line 2 Large

K-24 Display Line 3 Large

K-25 Quick Start

K-3# Keypad Custom Readout

K-30 Unit for Custom Readout

K-31 Min Value of Custom Readout

K-32 Max Value of Custom Readout

K-37 Display Text 1

K-38 Display Text 2

K-39 Display Text 3

K-4# Keypad Buttons

K-40 [Hand] Button on Keypad

K-41 [Off] Button on Keypad

K-42 [Auto] Button on Keypad

K-43 [Reset] Button on Keypad

K-44 [Off/Reset] Key on Keypad

K-5# Copy/Save

K-50 Keypad Copy

K-51 Set-up Copy

K-6# Password Protect.

K-60 Main Menu Password

K-61 Access to Main Menu w/o Password

K-65 Quick Menu Password

K-66 Access to Quick Menu w/o Password

K-67 Bus Password Access

F-## Fundamental Params

F-0# Fundamental 0

F-05 Motor Rated Voltage

F-04 Base Frequency

F-09 Torque Boost

F-02 Operation Method

F-01 Frequency Setting 1

F-07 Accel Time 1

F-08 Decel Time 1

F-03 Max Output Frequency 1

F-1# Fundamental 1

F-10 Electronic Overload

DET-759A 25

6

Parameter Menu Structure AF-650 GP Quick Guide

EN-20 Control Instance

EN-21 Process Data Config Write

EN-22 Process Data Config Read

EN-28 Store Data Values

EN-29 Store Always

EN-3# EtherNet/IP

EN-30 Warning Parameter

EN-31 Net Reference

EN-32 Net Control

EN-33 CIP Revision

EN-34 CIP Product Code

EN-35 EDS Parameter

EN-37 COS Inhibit Timer

EN-38 COS Filter

EN-4# Modbus TCP

EN-40 Status Parameter

EN-41 Slave Message Count

EN-42 Slave Exception Message Count

EN-8# Other Ethernet Services

EN-80 FTP Server

EN-81 HTTP Server

EN-82 SMTP Service

EN-89 Transparent Socket Channel Port

EN-9# Advanced Ethernet Services

EN-90 Cable Diagnostic

EN-91 MDI-X

EN-92 IGMP Snooping

EN-93 Cable Error Length

EN-94 Broadcast Storm Protection

EN-95 Broadcast Storm Filter

EN-96 Port Mirroring

Parameter Data Check

Last 10 Changes

Since Factory Setting

Drive Information

EN-98 Interface Counters

EN-99 Media Counters

EC-## Feedback Option

EC-1# Inc. Enc. Interface

EC-10 Signal Type

EC-11 Resolution (PPR)

EC-2# Abs. Enc. Interface

EC-20 Protocol Selection

EC-21 Resolution (Positions/Rev)

EC-24 SSI Data Length

EC-25 Clock Rate

EC-26 SSI Data Format

EC-34 HIPERFACE Baud rate

EC-6# Monitoring and App.

EC-60 Feedback Direction

EC-61 Feedback Signal Monitoring

RS-## Resolver Interface

RS-50 Poles

RS-51 Input Voltage

RS-52 Input Frequency

RS-53 Transformation Ratio

RS-59 Resolver Interface

ID-0# Operating Data

ID-00 Operating Hours

DN-31 Store Data Values

O-10 Control Word Profile

SP-43 Motor Cos Phi

DN-32 Devicenet Revision

O-13 Configurable Status Word STW

SP-5# Environment

DN-33 Store Always

DN-34 DeviceNet Product Code

DN-39 Devicenet F Parameters

DN-5# DeviceNet Proc Data

PB-## Profibus

K-11 Edit Set-up

PB-00 Setpoint

PB-07 Actual Value

PB-15 PCD Write Configuration

PB-16 PCD Read Configuration

PB-18 Node Address

PB-22 Telegram Selection

PB-23 Parameters for Signals

PB-27 Parameter Edit

PB-28 Process Control

PB-44 Fault Message Counter

PB-45 Fault Code

PB-47 Fault Number

PB-52 Fault Situation Counter

PB-53 Profibus Warning Word

PB-63 Actual Baud Rate

PB-64 Device Identification

PB-65 Profile Number

PB-67 Control Word 1

PB-68 Status Word 1

PB-71 Profibus Save Data Values

PB-72 ProfibusDriveReset

PB-80 Defined Parameters (1)

PB-81 Defined Parameters (2)

PB-82 Defined Parameters (3)

PB-83 Defined Parameters (4)

PB-84 Defined Parameters (5)

PB-90 Changed Parameters (1)

PB-91 Changed Parameters (2)

PB-92 Changed Parameters (3)

PB-93 Changed parameters (4)

PB-94 Changed parameters (5)

PB-99 Profibus Revision Counter

EN-## Ethernet IP

EN-0# IP Settings

EN-00 IP Address Assignment

EN-01 IP Address

EN-02 Subnet Mask

EN-03 Default Gateway

EN-04 DHCP Server

EN-05 Lease Expires

EN-06 Name Servers

EN-07 Domain Name

EN-08 Host Name

EN-09 Physical Address

EN-1# Ethernet Link Parameters

EN-10 Link Status

EN-11 Link Duration

EN-12 Auto Negotiation

EN-13 Link Speed

EN-14 Link Duplex

EN-2# Process Data

O-14 Configurable Control Word CTW

O-3# Drive Port Settings

O-30 Protocol

O-31 Address

O-32 Drive Port Baud Rate

O-33 Drive port parity

O-34 Estimated cycle time

O-35 Minimum Response Delay

O-36 Max Response Delay

O-37 Max Inter-Char Delay

O-4# Drive MC Port Set.

O-40 Telegram Selection

O-41 Parameters for Signals

O-42 PCD Write Configuration

O-43 PCD Read Configuration

O-5# Digital / Bus

O-50 Coasting Select

O-51 Quick Stop Select

O-52 DC Brake Select

O-53 Start Select

O-54 Reversing Select

O-55 Set-up Select

O-56 Preset Reference Select

O-57 Profidrive OFF2 Select

O-58 Profidrive OFF3 Select

O-8# Drive Port Diagns

O-80 Bus Message Count

O-81 Bus Error Count

O-82 Slave Messages Rcvd

O-83 Slave Error Count

O-9# Bus Jog / Feedback

O-90 Bus Jog 1 Speed

O-91 Bus Jog 2 Speed

DN-## Devicenet serial communication bus

DN-0# Common Settings

DN-00 DeviceNet Protocol

DN-01 Baud Rate Select

DN-02 MAC ID

DN-05 Readout Transmit Error Counter

DN-06 Readout Receive Error Counter

DN-07 Readout Bus Off Counter

DN-1# DeviceNet

DN-10 Process Data Type Selection

DN-11 Process Data Config Write

DN-12 Process Data Config Read

DN-13 Warning Parameter

DN-14 Net Reference

DN-15 Net Control

DN-18 internal_process_data_config_write

DN-19 internal_process_data_config_read

DN-2# COS Filters

DN-20 COS Filter 1

DN-21 COS Filter 2

DN-22 COS Filter 3

DN-23 COS Filter 4

DN-3# Parameter Access

DN-30 Array Index

Start

End

Start

End

Start

End

Start

End

Start

End

Start

End

Start

End

Start

End

SP-50 RFI Filter

SP-51 DC Link Compensation

SP-52 Fan Operation

SP-53 Fan Monitor

SP-55 Output Filter

SP-56 Capacitance Output Filter

SP-57 Inductance Output Filter

SP-59 Actual Number of Inverter Units

SP-6# Automatic Derate

SP-63 Option Supplied by External 24VDC

SP-7# Add ACC/DEC settings

SP-71 Accel Time 1 S-ramp Ratio at Accel.

SP-72 Accel Time 1 S-ramp Ratio at Accel.

SP-73 Decel Time 1 S-ramp Ratio at Decel.

SP-74 Decel Time 1 S-ramp Ratio at Decel.

SP-76 Accel/Decel Time 2 Type

SP-79 Accel Time 2 S-ramp Ratio at Accel.

SP-80 Accel Time 2 S-ramp Ratio at Accel.

SP-81 Decel Time 2 S-ramp Ratio at Decel.

SP-82 Decel Time 2 S-ramp Ratio at Decel.

SP-84 Accel/Decel Ramp 3 Type

SP-87 Accel Time 3 S-ramp Ratio at Accel.

SP-88 Accel Time 3 S-ramp Ratio at Accel.

SP-89 Decel Time 3 S-ramp Ratio at Decel.

SP-90 Decel Time 3 S-ramp Ratio at Decel.

SP-92 Accel/Decel Ramp 4 Type

SP-95 Accel Time 4 S-ramp Ratio at Accel.

SP-96 Accel Time 4 S-ramp Ratio at Accel.

SP-97 Decel Time 4 S-ramp Ratio at Decel.

SP-98 Decel Time 4 S-ramp Ratio at Decel.

O-## Options / Comms

O-0# General Settings

O-01 Control Site

O-02 Control Word Source

O-03 Control Word Timeout Time

O-04 Control Word Timeout Function

O-05 End-of-Timeout Function

O-06 Reset Control Word Timeout

O-07 Diagnosis Trigger

O-08 Readout Filtering

O-1# Control Settings

AN-31 Terminal X30/11 High Voltage

AN-34 Term. X30/11 Low Ref./Feedb. Value

AN-35 Term. X30/11 High Ref./Feedb. Value

AN-36 Term. X30/11 Filter Time Constant

AN-4# Analog Input X30/12

AN-40 Terminal X30/12 Low Voltage

AN-41 Terminal X30/12 High Voltage

AN-44 Term. X30/12 Low Ref./Feedb. Value

AN-45 Term. X30/12 High Ref./Feedb. Value

AN-46 Term. X30/12 Filter Time Constant

AN-5# Analog Output 42

AN-50 Terminal 42 Output

AN-51 Terminal 42 Output Min Scale

AN-52 Terminal 42 Output Max Scale

AN-53 Terminal 42 Output Bus Control

AN-54 Terminal 42 Output Timeout Preset

AN-55 Terminal 42 Output Filter

AN-6# Analog Output X30/8

AN-60 Terminal X30/8 Output

AN-61 Terminal X30/8 Min. Scale

AN-62 Terminal X30/8 Max. Scale

AN-63 Terminal X30/8 Bus Control

AN-64 Terminal X30/8 Output Timeout Preset

AN-7# Analog Output X45/1

AN-70 Terminal X45/1 Output

AN-71 Terminal X45/1 Min. Scale

AN-72 Terminal X45/1 Max. Scale

AN-73 Terminal X45/1 Bus Control

AN-74 Terminal X45/1 Output Timeout Preset

AN-8# Analog Output X45/3

AN-80 Terminal X45/3 Output

26 DET-759A

AN-81 Terminal X45/3 Min. Scale

AN-82 Terminal X45/3 Max. Scale

AN-83 Terminal X45/3 Bus Control

AN-84 Terminal X45/3 Output Timeout Preset

SP-## Special Functions

SP-0# Fault Settings

SP-00 Fault Level

SP-1# Line On/Off

SP-10 Line failure

SP-11 Line Voltage at Input Fault

SP-12 Function at Line Imbalance

SP-13 Line Failure Step Factor

SP-2# Reset Functions

SP-23 Typecode Setting

SP-24 Trip Delay at Current Limit

SP-25 Trip Delay at Torque Limit

SP-26 Trip Delay at Drive Fault

SP-28 Production Settings

SP-29 Service Code

SP-3# Current Limit Ctrl.

SP-30 Current Limit Cntrl, Proportional Gain

SP-31 Current Limit Cntrl, Integration Time

SP-32 Current Lim Ctrl, Filter Time

SP-35 Stall Protection

SP-4# Energy Savings

SP-40 VT Level

SP-41 Energy Savings Min. Magnetization

SP-42 Energy Savings Min. Frequency

Parameter Menu Structure AF-650 GP Quick Guide

6

SF-09 Wobble Random Function

SF-10 Wobble Ratio

SF-11 Wobble Random Ratio Max.

SF-12 Wobble Random Ratio Min.

SF-19 Wobble Delta Freq. Scaled

SF-2# Adv. Start Adjust

SF-20 High Starting Torque Time [s]

SF-21 High Starting Torque Current [%]

SF-22 Locked Rotor Protection

SF-23 Locked Rotor Detection Time [s]

PI-## PID Controls

PI-0# Speed PID Control

PI-00 Speed PID Feedback Source

PI-03 Speed PID Integral Time

PI-04 Speed PID Differentiation Time

PI-05 Speed PID Diff. Gain Limit

PI-06 Speed PID Low-pass Filter Time

PI-07 Speed PID Feedback Gear Ratio

PI-08 Speed PID Feed Forward Factor

PI-02 Speed PID Proportional Gain

PI-1# Torque PI Ctrl.

PI-12 Torque PI Proportional Gain

PI-13 Torque PI Integration Time

PI-2# Process PID Feedback

PI-20 Process CL Feedback 1 Resource

PI-22 Process CL Feedback 2 Resource

PI-3# Process PID Control

PI-30 Process PID Normal/ Inverse Control

PI-31 Process PID Anti Windup

PI-32 Process PID Start Speed

PI-33 Process PID Proportional Gain

PI-34 Process PID Integral Time

PI-35 Process PID Differentiation Time

PI-36 Process PID Diff. Gain Limit

PI-38 Process PID Feed Forward Factor

PI-39 On Reference Bandwidth

PI-4# Adv. Process PID I

PI-40 Process PID I-part Reset

PI-41 Process PID Output Neg. Clamp

PI-42 Process PID Output Pos. Clamp

PI-43 Process PID Gain Scale at Min. Ref.

PI-44 Process PID Gain Scale at Max. Ref.

PI-45 Process PID Feed Fwd Resource

6

Ctrl.

SF-00 Wobble Mode

SF-01 Wobble Delta Frequency [Hz]

SF-02 Wobble Delta Frequency [%]

SF-03 Wobble Delta Freq. Scaling Resource

SF-04 Wobble Jump Frequency [Hz]

SF-05 Wobble Jump Frequency [%]

SF-06 Wobble Jump Time

SF-07 Wobble Sequence Time

PI-46 Process PID Feed Fwd Normal/ Inv.

PI-49 Process PID Output Normal/ Inv. Ctrl.

PI-5# Adv. Process PID II

PI-50 Process PID Extended PID

PI-51 Process PID Feed Fwd Gain