GE GNWH38S User Manual

REQUIRED TOOLS AND ACCESSORIES FOR INSTALLATION

■ 2 Adjustable wrenches

■ Pipe cutter

■ Ruler or tape measure

■ Cordless drill

■ File

■ Emery paper

■ Screwdriver

Optional accessories are available (Visa, MasterCard or Discover cards accepted)

by visiting our Website at www.GEAppliances.com or from Parts and Accessories,

call 800.626.2002 (U.S.) or 800.663.6060 (Canada).

CONTENTS INCLUDED WITH PRODUCT

■ Filter system (head and canister)

■ Product literature

■ Canister wrench

■ Timer and batteries

■ Mounting bracket

■ Four 5/16″ Hex-head screws and four 5/16″ Hex washer-head

screws

■ 2 sets of fitting, ferrule, and nut

■ 2 UL-approved grounding clamps and a #6 AWG grounding

wire

■ White sealing tape

1

GE SmartWater

™

INSTALLATION INSTRUCTIONS

Heavy Duty Water Filtration System—GNWH38F

SAFETY PRECAUTIONS

■ Check with your state and local public works department for

plumbing and sanitation codes. You must follow these guidelines

as you install the Heavy Duty Water Filtration System. Using a

qualified installer is recommended.

■ Be sure the water supply conforms with the Performance Data.

If the water supply conditions are unknown, contact your

municipal water company.

WARNING:Do not use with water that is

microbiologically unsafe or of unknown quality without

adequate disinfection before or after the system.

■ It is highly recommended that a water shut-off valve be placed

directly upstream of your household filter.

■ Check with your local public works department for plumbing codes.

You must follow their guides as you install the Heavy Duty Water

Filtration System.

■ Use the Heavy Duty Water Filtration System on a potable, safe-to-

drink, home COLD water supply only. The filter cartridge will not

purify water or make unsafe water safe to drink. DO NOT use on

HOT water (100°F max).

■ Protect the Heavy Duty Water Filtration System and piping from

freezing. Water freezing in the system will damage it.

■ Your Heavy Duty Water Filtration System will withstand up to

100 psi water pressure. If your house water supply pressure is

higher than 100 psi during the day (it may reach higher levels

at night), install a pressure reducing valve before the system

is installed.

■ Do not install on HOT WATER. The temperature of the water

supply to the Heavy Duty Water Filtration System must be

between the minimum of 40°F and the maximum of 100°F.

See the Filter Cartridge Life section.

■ Do not install the Heavy Duty Water Filtration System using

copper solder fittings. The heat from the soldering process

will damage the unit.

■ If making a soldered copper installation, do all sweat soldering

before connecting pipes to the system. Torch heat will damage

plastic parts.

WARNING:Discard all unused parts and packaging

material after installation. Small parts remaining after installation

could be a choke hazard.

■ Do not install filter in an outside location or anywhere it will be

exposed to sunlight.

PROPER INSTALLATION

This Heavy Duty Water Filtration System must be properly installed and located in accordance with the Installation Instructions

before it is used.

GNWH38F is

Tested and Certified by NSF International

against NSF/ANSI

Standard 42 for materials and

structural integrity requirements only.

184D1064P001 (04--04 JR) 49-50125

www.GEAppliances.com

GENERAL ELECTRIC COMPANY, Appliance Park, Louisville, KY 40225

COMPONENT

GNWH38F is tested and certified by NSF International

against NSF/ANSI Standard 42 with cartridge FXHTC

for the reduction of Chlorine: Taste and Odor.

2

Filter Cartridge Replacement

You should change your filter when the water flow is noticeably reduced or at least every 3 months.

Turn off water to filter. Water must be shut off from

an upstream valve.

Press the red pressure release button to release

pressure.

Unscrew the filter canister and discard used filter.

Wash the filter canister with mild soap and water.

Do not use harsh cleaners or hot water.

Inspect the filter canister O-ring. Make sure it is

lightly lubricated with clean food grade silicone

grease (silicone grease is available through GE

Parts and Service: 1.800.626.2002, part number

WS60X10005). Be sure the o-ring is seated in the

groove. It is recommended that you replace the

O-ring if it is damaged.

Place a new filter cartridge into the canister,

making sure it is centered and completely seated

on the bottom seal.

Reinstall the filter canister to the unit. Use the

canister wrench to tighten the canister. DO NOT

OVERTIGHTEN.

Slowly turn on water to the filter by using the

upstream shut-off valve.

Press the red pressure release button to remove

trapped air.

After installation, flush the cartridge for

10 minutes, wait one hour, then flush again

for 10 minutes before using the water.

9

8

7

6

5

4

3

2

1

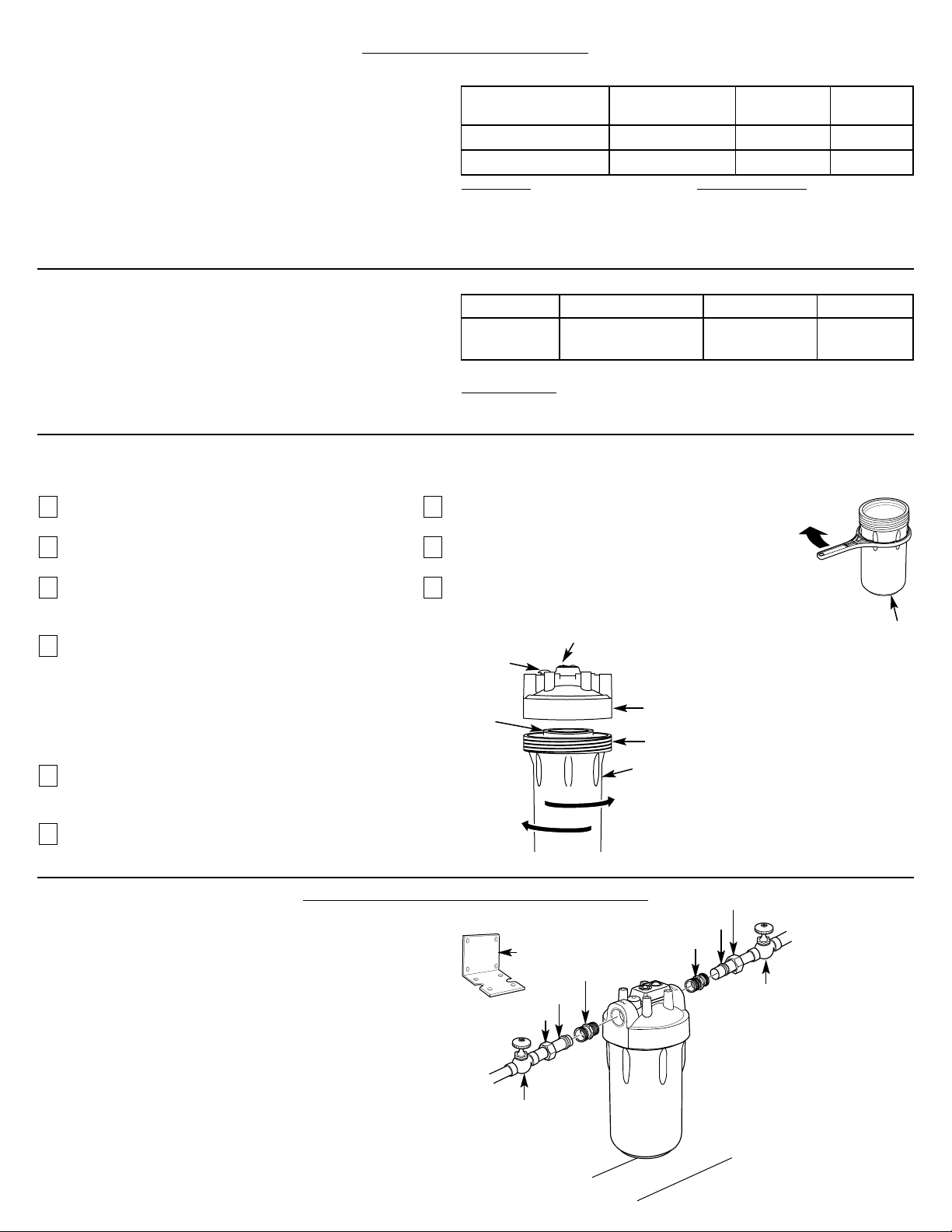

Installation Overview

NOTE: Be sure to allow a minimum space of 11⁄2 ″–2″ under

the filter for removing the sump to change the cartridge.

Turn canister wrench

clockwise to remove

Canister

Turn

clockwise

to remove

canister

Turn

counterclockwise

to tighten

Red pressure

release button

Filter

cartridge

O-ring seal

Filter canister

Head

STEP-BY-STEP INSTALLATION INSTRUCTIONS

Recommended

shut-off valve

Recommended

shut-off valve

Fitting

Ferrule

Hex nut

Fitting

Ferrule

Hex nut

11⁄2 ″–2″

Typical installation

Remote timer

Mounting

bracket

CARTRIDGE SPECIFICATIONS

Influent Challenge Reduction Average

Substance Concentration Requirements Reduction

Standard 42

Chlorine: Taste and Odor 2.0 mg/L ± 10% ≥ 50% 95.5%

Performance Data

This system has been tested according to NSF/ANSI 42

for the reduction of the substances listed below. The

concentration of the indicated substances in water

entering the system was reduced to a concentration

less than or equal to the permissible limit for water

leaving the system, as specified in NSF/ANSI 42.

FXHTC Cartridge

Test Conditions

Flow Rate: 3 gpm (11.4 Lpm)

pH: 7.5±1

Inlet Pressure: 60 PSI (4.1 bar)

Temperature: 68°F ± 5°F (19.8°C ± 2.5°C)

Operating Requirements

Pressure: 30–125 psi (2.1–6.9 bar)

Turbidity: 5 NTU Max.

Temperature: 40°F–100°F (4.4°C–37.7°C)

Capacity: 5,000 gallons (18,927L) or 3 months

Testing was performed under standard laboratory conditions, actual performance may vary.

GE Model Function Life Construction

FXHSC Sediment* 3 months/ Pleated

30 Micron* 24,000 gallons

Additional Replacement Filter

FXHSC Filter could be used as a replacement filter.

FXHSC Cartridge

Operating Guidelines

Minimum–Maximum Supply Water Pressure: 20–125 psi

Minimum–Maximum Supply Water Temperatures: 40°F–100°F

*Based on manufacturer’s internal testing.

3

STEP-BY-STEP INSTALLATION INSTRUCTIONS (cont.)

Select Location

Select a location for the filter that is:

■ protected from freezing.

■ not exposed to direct sunlight.

It is recommended that a shut-off valve be placed on both sides of the filter.

It is recommended that a mounting bracket be used.

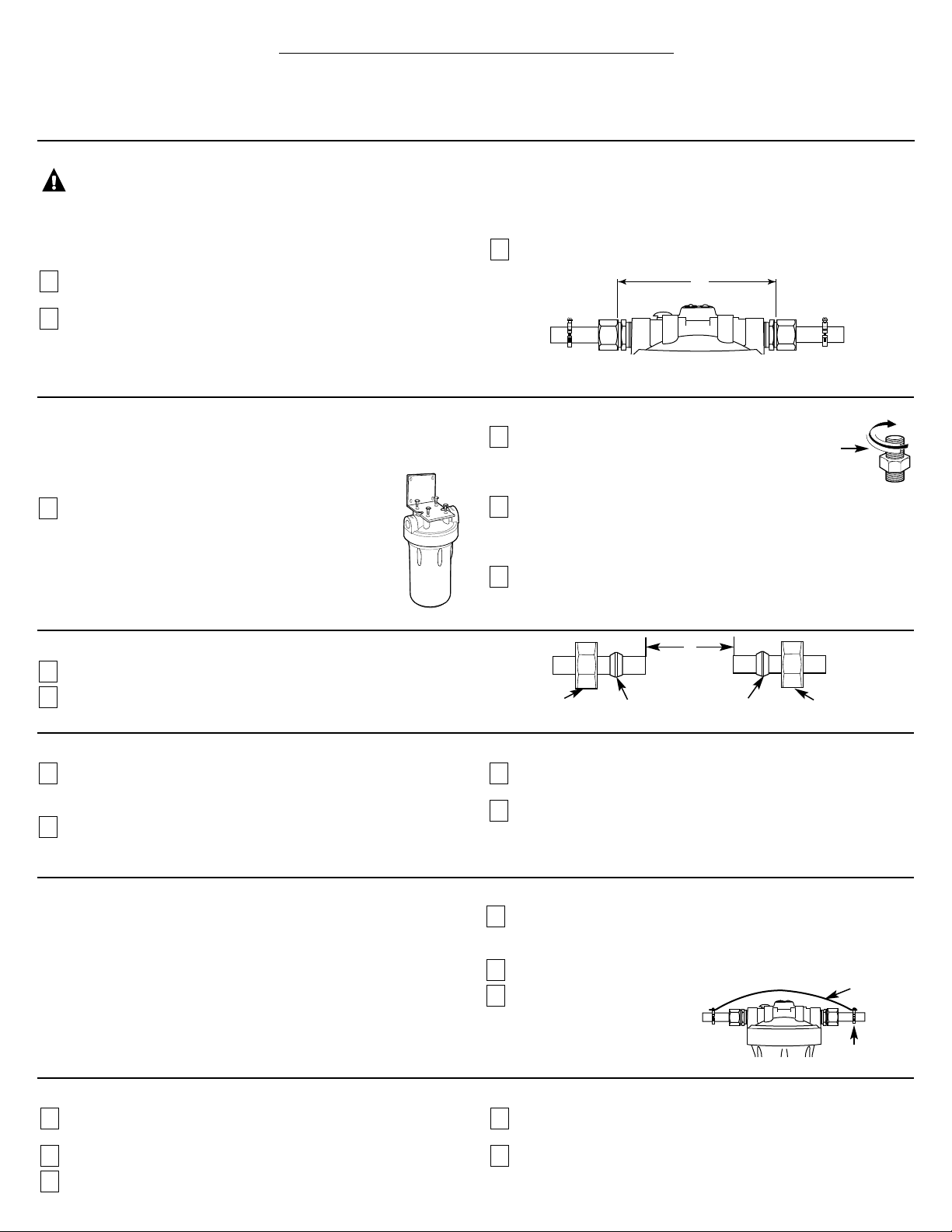

Install Mounting Bracket and Fittings

Instructions are for installing fittings supplied with the filter system or

similar fittings onto copper plumbing. If the unit is to be installed on

any other type of tubing (plastic, PVC, galvanized), consult a

qualified plumber for additional hardware.

Attach heavy duty mounting bracket to head assembly

with four hex-head screws as shown in illustration.

Failure to use the bracket may result in a leak over time.

The bracket can be used as a template for marking the

location of the mounting screws.

Apply 4 or 5 wraps of white sealing tape, in a

clockwise direction, to the pipe threads of each

fitting. DO NOT use joint compound on any parts

connecting to filter system.

Assemble fitting to the inlet and outlet of the head. Start each

fitting by hand to make sure they don’t cross thread. Use an

adjustable wrench to tighten fittings. DO NOT OVERTIGHTEN.

About 1–2 thread(s) should remain visible.

Use four hex washer-head screws to mount bracket to the wall firmly.

Use proper anchors on wall. Anchors are NOT included.

4

3

2

1

Cut Water Line

WARNING: A copper or galvanized cold water pipe may

be used to ground electrical outlets in the home. Failure to maintain this

ground path may result in an electric shock hazard. If the cold water

pipe is used to ground electrical outlets, please refer to the Installing the

Ground Wire section before cutting the pipe.

Turn off the water supply and open a nearby faucet to drain the

water out of pipes.

Using a tape measure or ruler, measure the distance “D” as shown.

■ NOTE: It is recommended that the shut-off valve be placed before and

after the filter as shown in the Installation Overview illustration.

■ Select a secure location surface to install filter and mounting bracket.

The location should align the filter system with inlet and outlet pipe

and should not cause the pipes to bend or damage. Mark the distance

“D” on the pipe. D is about 7

3

⁄4″.

Using a pipe cutter, cut pipe. Sand (file) cut ends of pipe to assure

that they are square and smooth.

■ NOTE: Have a bucket and towel available to collect excess water.

3

2

1

Installing the Unit

Align filter assembly with pipe ends making certain that the incoming

water supply is going into the filter opening marked “IN”. It may be

necessary to spread the pipe ends apart to install filter assembly.

Using two adjustable wrenches, hold incoming fitting securely with

one wrench and tighten nut with second wrench. Repeat this

procedure for outgoing fitting.

If mounting bracket is not used, support the water pipe on either

side of the filter unit.

Install a filter and tighten canister to seal (see filter cartridge

replacement section).

4

3

2

1

Final Check

Install filter, if not already done (see Filter Cartridge Replacement

Section).

Slowly turn on water supply.

Check entire system for leaks.

If leaking from fittings, shut off water flow and tighten or reseal

fittings. If leaking from the canister, tighten canister with a wrench.

After installation, flush the cartridge for 10 minutes, wait one hour,

then flush again for 10 minutes before using the water.

5

4

3

2

1

White

sealing

tape

Attach Fittings to Water Line

Slip a compression nut onto each pipe.

Next, slip the brass ferrule onto each pipe.

2

1

Hex Nut

Brass ferrule

Hex Nut

Brass ferrule

D

Installing the Ground Wire

NOTE: If your house plumbing is plastic, it would not be used as a

grounding path, and this step should be skipped.

IMPORTANT: A copper or galvanized house cold water pipe is often used

to ground electrical outlets in the home. Grounding protects you from

electrical shock. The water filter system may have broken this ground

path. To restore connection, install an 16″ long, 6-gauge copper wire

across the filter, tightly clamped using UL approved 1/2″–1″ bronze

grounding clamps at both ends as shown.

Clean copper pipe and ends of wire with emery paper. Bare wire is

recommended. If insulated wire is used, it should be stripped 1″ at

each end before cleaning with emery paper.

Attach bronze clamps to pipe. Tighten screws.

Attach wire to clamps as shown.

Tighten screws firmly to the

copper wire at stripped end.

3

2

1

Clamp

Ground wire

D

Loading...

Loading...