GE GNULQ01 Installation Guide

I stallation

Kitchenand BathMain Faucet

I structio

Filtration System- G×ULQ/GNULQ

SAFETY PRECAUTIONS

• Check with gour state and local public works

department for plumbing and sanitation codes.

You must follow these guidelines as gou install

the Kitchen and Bath Main Faucet Filtration

Sgstem. Using a qualified installer is recommended.

• Besure the water supplg conforms with the

Performance Data. If the water supplg conditions are

unknown, contact gour municipal water compang.

WARNING- Donotuse withwaterthatis

microbiologicallg unsafe or of unknown qualitg without

adequate disinfection before or after the sgstem.

• Itis highlg recommended that a water shut-off valve

be placed directlg upstream of gout Kitchen and Bath

Main Faucet Filtration System.

PARTS INCLUDED

• Filter Cartridge

• Filter Head/Bracket

• 6 Feet of 3/8" Tubing

• 3/8" x 1/2" Faucet Adapter

• 3/8" Compression Hex Nut

• 3/8" Ferrule

• 3/8" Tube Insert

• Mounting Screws

• 1/2" Compression to 3/8" Adapter

• 7/16" Compression to 3/8" Adapter

Optionalaccessoriesare availableMisa,MasterCardor

Discovercards accepted)5g visitingourWeSsiteat ge.com

or from PartsandAccessories,calf800.626.2002(U.S.)or

800.663.6060(Canada).

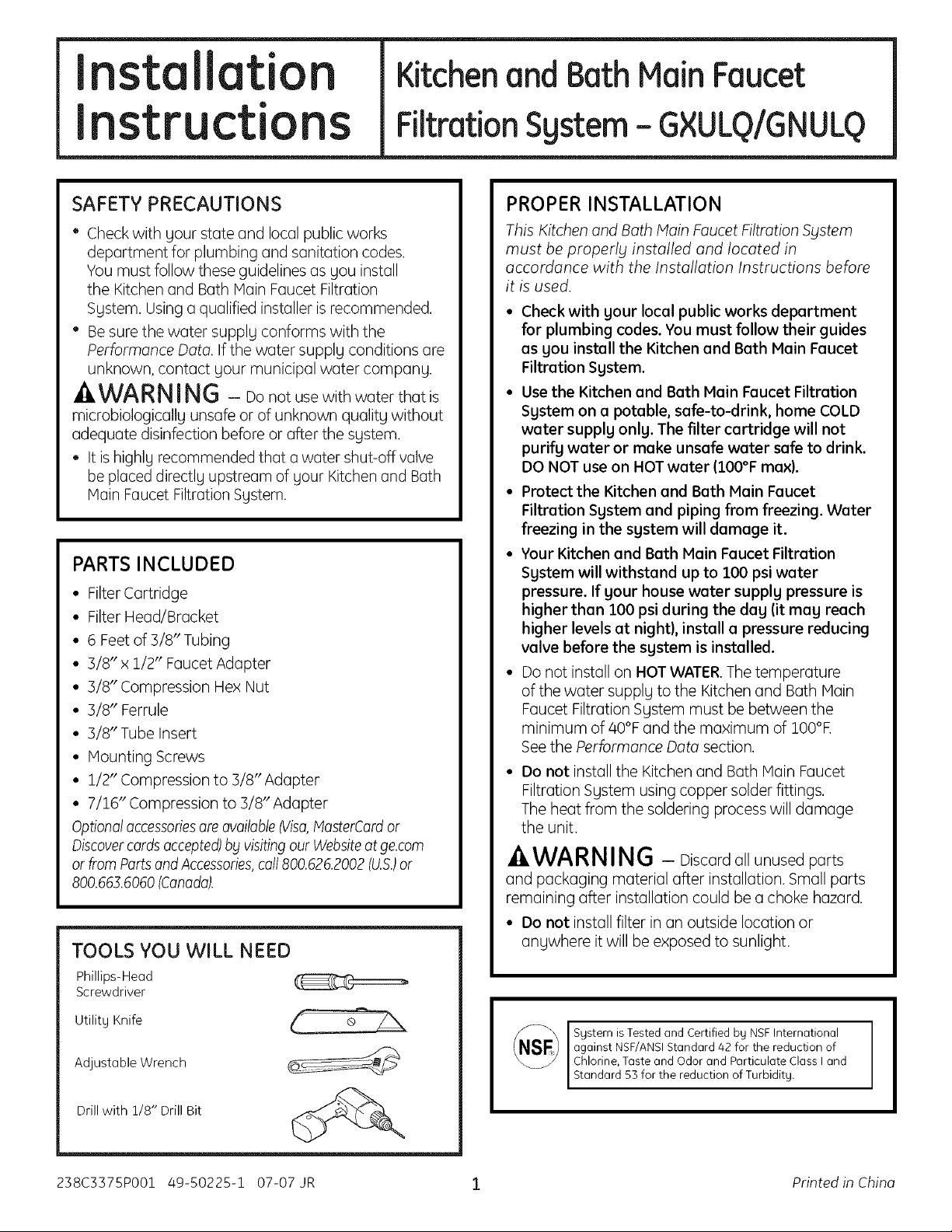

TOOLS YOU WILL NEED

PROPER INSTALLATION

This Kitchen and Bath Main Faucet Filtration Sgstem

must be properly installed and located in

accordance with the Installation Instructions before

it is used.

• Check with gour local public works department

for plumbing codes. You must follow their guides

as gou install the Kitchen and Bath Main Faucet

Filtration System.

• Use the Kitchen and Bath Main Faucet Filtration

Sgstem on a potable, safe-to-drink, home COLD

water supplg onlg. The filter cartridge will not

purifg water or make unsafe water safe to drink.

DO NOT use on HOT water (IO0°F max).

• Protect the Kitchen and Bath Main Faucet

Filtration Sgstem and piping from freezing. Water

freezing in the sgstem will damage it.

• Your Kitchen and Bath Main Faucet Filtration

Sgstem will withstand up to 100 psi water

pressure. If gour house water supplg pressure is

higher than 100 psi during the dag (it mag reach

higher levels at night), install a pressure reducing

valve before the sgstem is installed.

• Do not install on HOT WATER. The temperature

of the water supplg to the Kitchen and Bath Main

Faucet Filtration Sgstem must be between the

minimum of 40°F and the maximum of 100°E

See the Performance Data section.

Do not install the Kitchen and Bath Main Faucet

Filtration Sgstem using copper solder fittings.

The heat from the soldering process will damage

the unit.

IkWARNING - Discard all unused parts

and packaging material after installation. Small parts

remaining after installation could be a choke hazard.

• Do not install filter in an outside location or

angwhere it will be exposed to sunlight.

Phillips-Head

Screwdriver

UtilitUKnife

Adjustable Wrench

Drill with 1/8" Drill Bit

238C3375P001 49-50225-1 07-07 JR :1 Printedin Chino

Sgstem is Tested and Certified bg NSF International

against NSF/ANSI Standard 42 for the reduction of

Chlorine, Taste and Odor and Particulate Class I and

Standard 53 for the reduction of Turbiditg.

Installation Instructions

CARTRIDGE SPECIFICATIONS

Performance Data - Filtration Sgstem GXULQ Using Filter GXULQR

• ThisSystemhasbeentestedaccordingtoNSF/ANS142and53forthereductionofthe substanceslistedbelow.Theconcentrationofthe

indicatedsubstancesinwaterenteringthe systemwasreducedto a concentrationlessthanor equaltothepermissiblelimitforwaterleaving

thesystem,asspecifiedinNSF/ANS142and53.

• Actualperformancemayvarywith localwaterconditions.

• Donotusewithwaterthat ismicrobiologicallyunsafeor withwaterof unknownqualitywithoutadequatedisinfectionbeforeor after

the system.

USEPA Influent

Parameter MCL Challen_te Concentration

Chlorinetaste and odor -- 2,0 mg/L _+10%

Particulate Class I

partices 0 5to <lum** - ->i0000 porticles/mL

Parameter

Turbidity

*Tested using a flow rate of 2 gpm (7,6 I/min); pressure of 60 psrg;

pH of 75 _+0,5;temp. of 68° _+5°F (20°_+3°C)

**Measurement in particles/mL Particles usedwere 0.5-1 microns.

***NTU--Nephelometric Turbidity Units

USEPA Influent

MCL Challen_te Concentration

1 NTU*** 11 ± 1 NTU***

Standard No. 42: Aesthetic Effects

Influent Effluent

Avera_/e Avera_te Maximum

1.9 mg/L <005 mg/L O.O5 mg/L

10333333 #/mL 20,500 #/mL 41,0OO #/mL

Standard No. 53: Health Effects

Influent

Averacle Avera_te

11.O0 NTU 0,1 NTU

Effluent

Maximum Average Minimum Requirement

O1 NTU 991% 991% O.5NTU

Operating Specifications

Capacity: certified for up to 2000 gallons (7,571 I);upto six months

Pressure requirement: 35-100 psi (2,8-6 9 bar}

Temperature: 33°-1OO°F(0,6°-38°C)

% Reduction

Avera_te Minimum

>974% 974%

998% 996%

% Reduction

Reduction

Requirement

->50%

->85%

Reduction

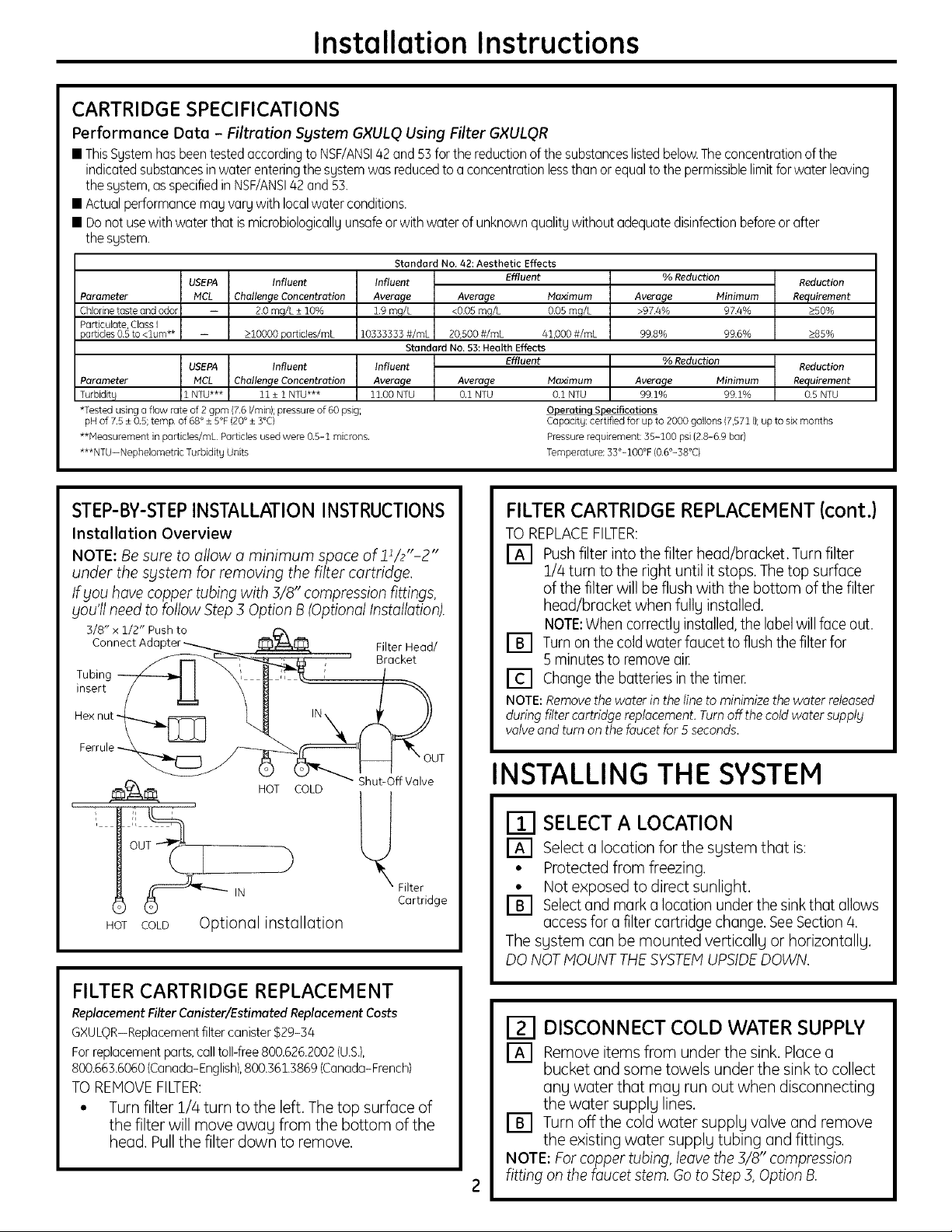

STEP-BY-STEPINSTALLATION INSTRUCTIONS

Installation Overview

NOTE: Be sure to allow o minimum space of11/8"-2"

under the system for removing the filter cartridge.

lf b!ouhave copper tubing with 3/8" compression fittings,

gou'tt need to follow Step 3 Option B (Optional Installation).

3/8" x 1/2" Push to

Connect Ado Filter Head/

Tubing

insert

Hex nut

Ferrule

HOT COLD

IN Filter

HOT COLD Optional installation

Bracket

Shut-Off Valve

Cartridge

FILTER CARTRIDGE REPLACEMENT (cont.)

TO REPLACEFILTER:

[] Push filter into the filter head/bracket. Turn filter

1/4 turn to the right until it stops. The top surface

of the filter will be flush with the bottom of the filter

head/bracket when fully installed.

NOTE:When correctly installed, the label willface out.

[] Turnon the cold water faucet to flush the filter for

5 minutesto remove air.

[] Changethe batteriesinthe timer.

NOTE: Remove the water in the line to minimize the water released

duringfiltercartridgereplacement.TurnoffthecoldwatersupplbJ

valveandturnon thefaucetfor5seconds.

INSTALLING THE SYSTEM

ITI SELECT A LOCATION

[] Select a location for the sgstem that is:

• Protected from freezing.

• Notexposed todirect sunlight.

[] Select and murk a location under the sink that allows

access for u filter cartridge change. SeeSection 4,

The sgstem can be mounted verticallg or horizontallg.

DO NOT MOUNT THESYSTEMUPSIDEDOWN.

FILTER CARTRIDGE REPLACEMENT

Replacement Filter Canister/Estimated Replacement Casts

GXULQR--Replacement filter canister $29-34

For replacement parts, call toll-free 800.626.2002 (U.S.),

800.663.6060 (Canada-English), 800.361.3869 (Canada-French)

TO REMOVEFILTER:

• Turn filter 1/4 turn to the left. The top surface of

the filter will move away from the bottom of the

head. Pull the filter down to remove.

DISCONNECT COLD WATER SUPPLY

[] Remove items from under the sink. Place a

bucket and some towels under the sink to collect

any water that may run out when disconnecting

the water supply lines.

[] Turn offthe cold water supply valve and remove

the existing water supply tubing and fittings.

NOTE: For copper tubing, leave the 3/8" compression

fitting on the faucet stem. Go to Step 3, Option B.

Installation Instructions

[] INSTALL FAUCET ADAPTER

Installthe 3/8" x 1/2" faucet adapter to the faucet

threads.

DO NOT OVERTIGHTEN,

Option A - Typical Installation

x

_ Faucet Threads

---- Adapter

Option B - Optional Installation

If you have copper tubing with a compression

adapter, you will NOTuse the 1/2" faucet adapter.

Use a section of tubing, slide the compression

hex nut and 3/8" ferrule (tapered end away from

the compression nut) onto the tubing, and put in

the tubing insert.

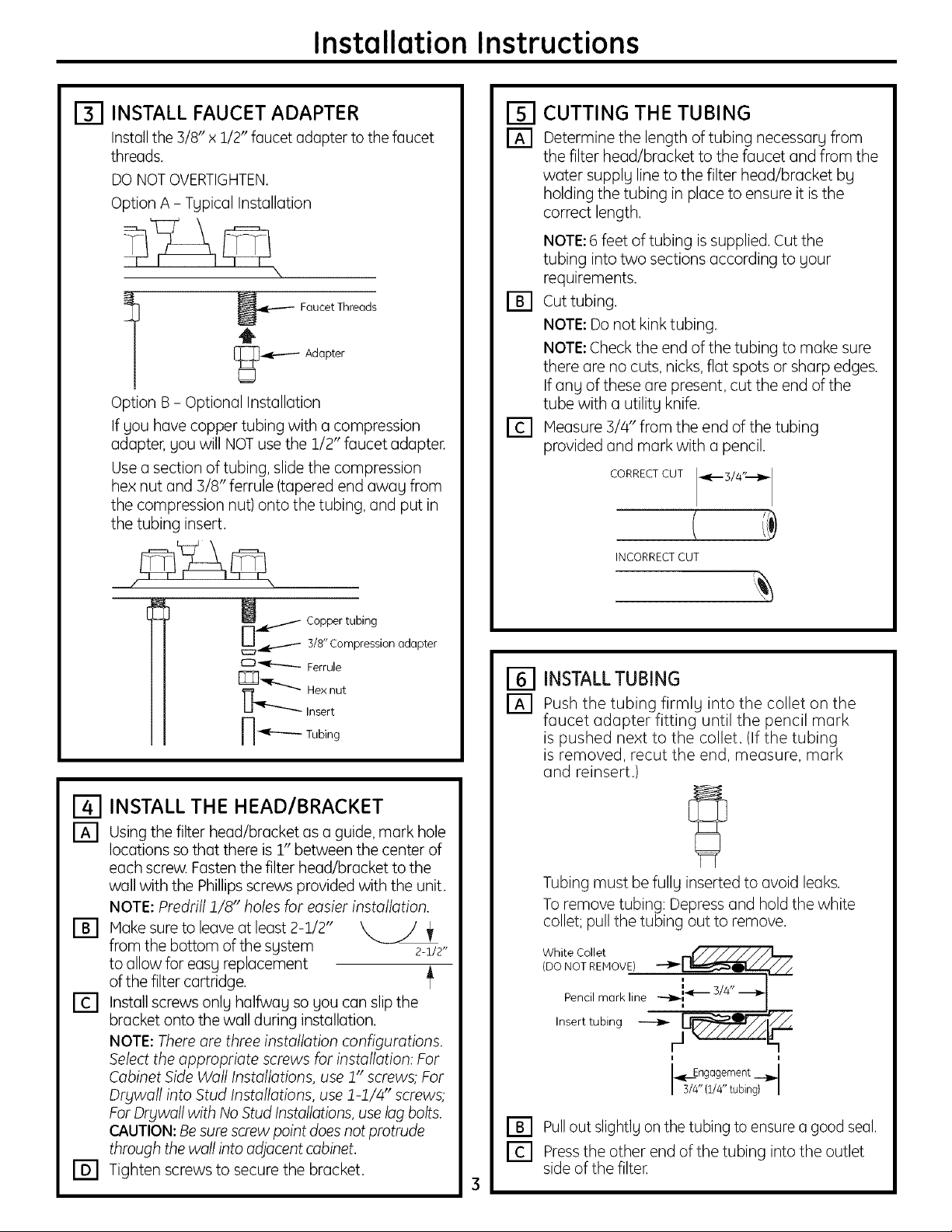

CUTTING THE TUBING

[]

Determine the length of tubing necessary from

the filter head/bracket to the faucet and from the

water supply line to the filter head/bracket by

holding the tubing in place to ensure it is the

correct length.

NOTE: 6 feet of tubing is supplied. Cut the

tubing into two sections according to your

requirements.

[] Cut tubing.

NOTE: Do not kink tubing.

NOTE: Check the end of the tubing to make sure

there are no cuts, nicks, flat spots or sharp edges.

If any of these are present, cut the end of the

tube with a utility knife.

[] Measure 3/4" from the end of the tubing

provided and mark with a pencil.

INCORRECT CUT

l ...I Copper tubing

_ _.-_---- 3/8"Compression adapter

CD _---_.._ Ferrule

::r:t

H _'----- Tubing

[] INSTALL THE HEAD/BRACKET

[] Using the filter head/bracket as a guide, mark hole

locations so that there is 1" between the center of

each screw. Fasten the filter head/bracket to the

wall with the Phillips screws provided with the unit.

NOTE: Predrill 1/8" holes for easier installation.

[] Make sure to leave at least 2-1/2" _, i,/

from the bottom of the sgstem 2-1/2"

to allow for easg replacement

of the filter cartridge. '_

[] Install screws onlg halfwag so gou can slip the

bracket onto the wall during installation.

NOTE: There ore three installation configurations.

Select the appropriate screws for installation: For

Cabinet Side Wall Installations, use 1" screws; For

Drywall into Stud Installations, use 1-1/4" screws;

For Drywall with No Stud Installations, use log bolts.

CAUTION: Be sure screw point does not protrude

through the wall into adjacent cabinet.

[] Tighten screws to secure the bracket.

A

r_ INSTALLTUBING

[] Push the tubing firmlg into the collet on the

faucet adapter fitting until the pencil mark

is pushed next to the collet. (If the tubing

is removed, recut the end, measure, mark

and reinsert.)

Tubing must be fully inserted to avoid leaks.

To remove tubing: Depress and hold the white

collet; pull the tubing out to remove.

White Collet

(DONOT REMOVE) ___

Pencil mark line ---:1_1_'_

Insert tubing ._

[] Pull out slightlg on the tubing to ensure a good seal.

[] Pressthe other end of the tubing into the outlet

side of the filter.

i

' 3/4"

i

i

._ngagement

I 3/4" (1/4"tubing)

Installation Instructions

J-_ iNSTALLCOMPRESSIONFiTTiNGS

[] Take the remaining section of tubing, slide the

compression hex nut and 3/8" ferrule (tapered

end awag from the compression nut) onto the

tubing, and put in the tube insert.

Shut-Off Valve Tubing Insert Ferrule Hex Nut Tubing

[] Fasten the assemblg onto the cold water supplg

valve. Do not overtighten.

Shut-Off Valve Tubing Insert Ferrule Hex Nut Tubing

NOTE: Overtightening will cause the tubing to

separate from the fitting.

NOTE: For shut-off valves with 1/2" or 7/16"

compression fittings, please use appropriate

adapters provided in the kit.

[] Connect the other end to the inlet side as

indicated bg the arrow on the filter head/bracket.

FINAL CHECK

[] Insert the filter into the filter head/bracket, Turn

the filter 1/4 turn to the right until it stops. The

top surface of the filter will become flush with

the bottom of the filter head/bracket when it is

fullg installed.

[] Slowly turn on the water supplg.

[] Check the entire sgstem for leaks. If there are

leaks, refer back to the Cut the Tubing section

to reinsert the tubing.

[] If leaking from fittings, shut off water pressure

and tighten or reseal fittings. If leaking from the

filter, tighten the filter.

[] After installation, let water run for approximatelg

5 minutes to flush the filter and to remove air.

NOTE: It is normal for there to be air in the

sgstem causing bubbles in the wate[

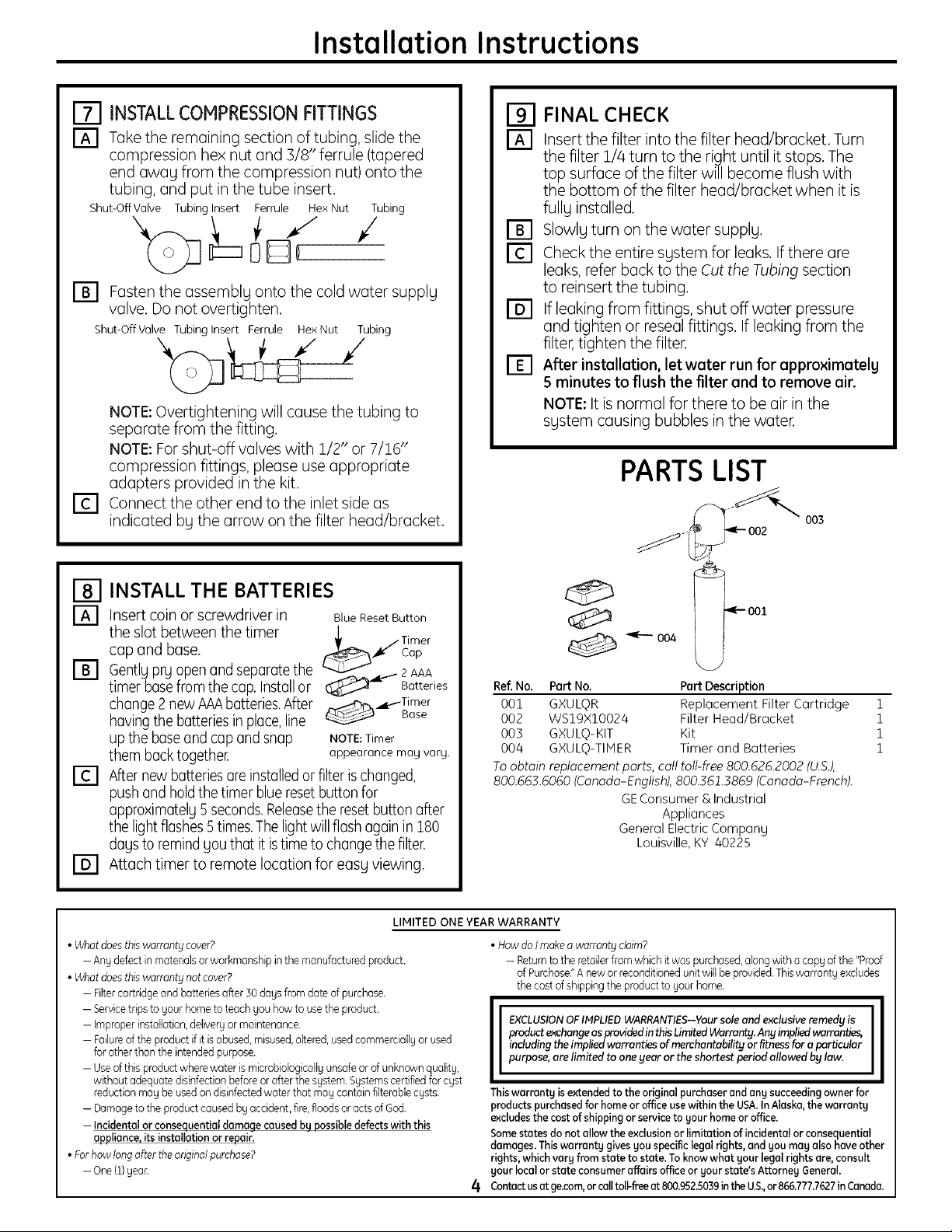

PARTS LIST

[] INSTALL THE BATTERIES

] Insert coin or screwdriver in Blue Reset Button

the slot between the timer _,_ /Timer

cap and base.

[] Gently pry open and separatethe _" CP2aAA

timer bosefrom the cap. Installor _ Batteries

change2 new AAAbatteries.After _.._.----Timer

havingthe batteries in place,line _ Base

up the baseandcap and snap NOTE:Timer

them backtogether, appearance man vary.

[] Afternewbatteriesareinstalledorfilterischanged,

pushand holdthe timer blue resetbutton for

approximately5seconds.Releasetheresetbuttonafter

the lightflashes5times,Thelight willflash againin 180

days to remind youthat it istime to change thefilter.

[] Attachtimer to remotelocationfor easy viewing.

LIMITED ONE YEAR WARRANTY

• Whatdoesthiswarranty cover?

- Angdefectinmaterialsorworkmanshipinthe manufacturedproduct.

• Whatdoesthiswarranty notcover?

- Filtercartridgeandbatteriesafter 30dagsfromdate of purchase.

- Servicetripsto gour hometoteach gouhowto usethe product.

- Improperinstallation,delivergor maintenance.

- Failureof the productifit isabused,misused,altered,usedcommerciallgor used

forotherthan theintendedpurpose.

- Useofthis productwherewateris microbiologicallgunsafeor ofunknown qualitg,

withoutadequatedisinfectionbeforeorafterthesgstem.Sgstemscertifiedfor cgst

reductionmag beusedondisinfectedwater thatmag containfilterablecgsts.

- Damageto the productcausedbgaccident,fire,floodsoractsof God.

- Incidental or consequentialdamaqecausedbtl possibledefectswith this

appliance,its installation or repair.

• Forhowlongafter theoriginalpurchase?

- One(1)geac

_-- -__ 003

_ 004

Ref.No. Part No. Part Description

001 GXULQR Replacement Filter Cartridge

002 WS19X10028 Filter Head/Bracket

003 GXULQ-KIT Kit

00/4 GXULQ-TIIVlER Timer and Batteries

To obtain replacement parts, call toll-free 800.626.2002 (U.S.),

800.663.6060 (Canada-English), 800.361.3869 (Canada-French).

GE Consumer & Industrial

Appliances

General Electric Compang

Louisville, KY /40225

• HowdoI makea warrantyclaim?

- Retumtothe retailerfromwhich itwas purchased,alongwith acopgof the"Proof

of Purchase/'Anewor reconditionedunitwill beprovided.Thiswarrantg excludes

thecost ofshippingthe producttogour home.

EXCLUSIONOFIMPLIEDWARRANTIES-Yoursoleend exclusiveremedy is

productexchangeasprovidedin thisLimitedWarronty.Anyimpli_=dworranties,

includingthe implied worrantiesof merchantability or fitnessfor o porticular

purpose,ore limited to oneyeor or the shortest period ollowed by low,

Thiswarrantg isextendedto the original purchaserandang succeedingownerfor

productspurchasedfor homeor office usewithin the USA.InAlaska,the warrantg

excludesthecost ofshippingor serviceto gour homeor office.

Somestatesdo not allowthe exclusionor limitation of incidental orconsequential

damages.Thiswerrantg gives gouspecificlegal rights,and gou magalso haveother

rights, whichvarg from state to state.To knowwhat gour legalrights are,consult

gout localor state consumer affairs officeor gourstate's AttornegGeneral.

Contactusatge.com,orcalltoll-fi,eeat800.952.5039inthe U.S.,or866,777.7627inCanada.

1

1

1

1

instatlation instructions

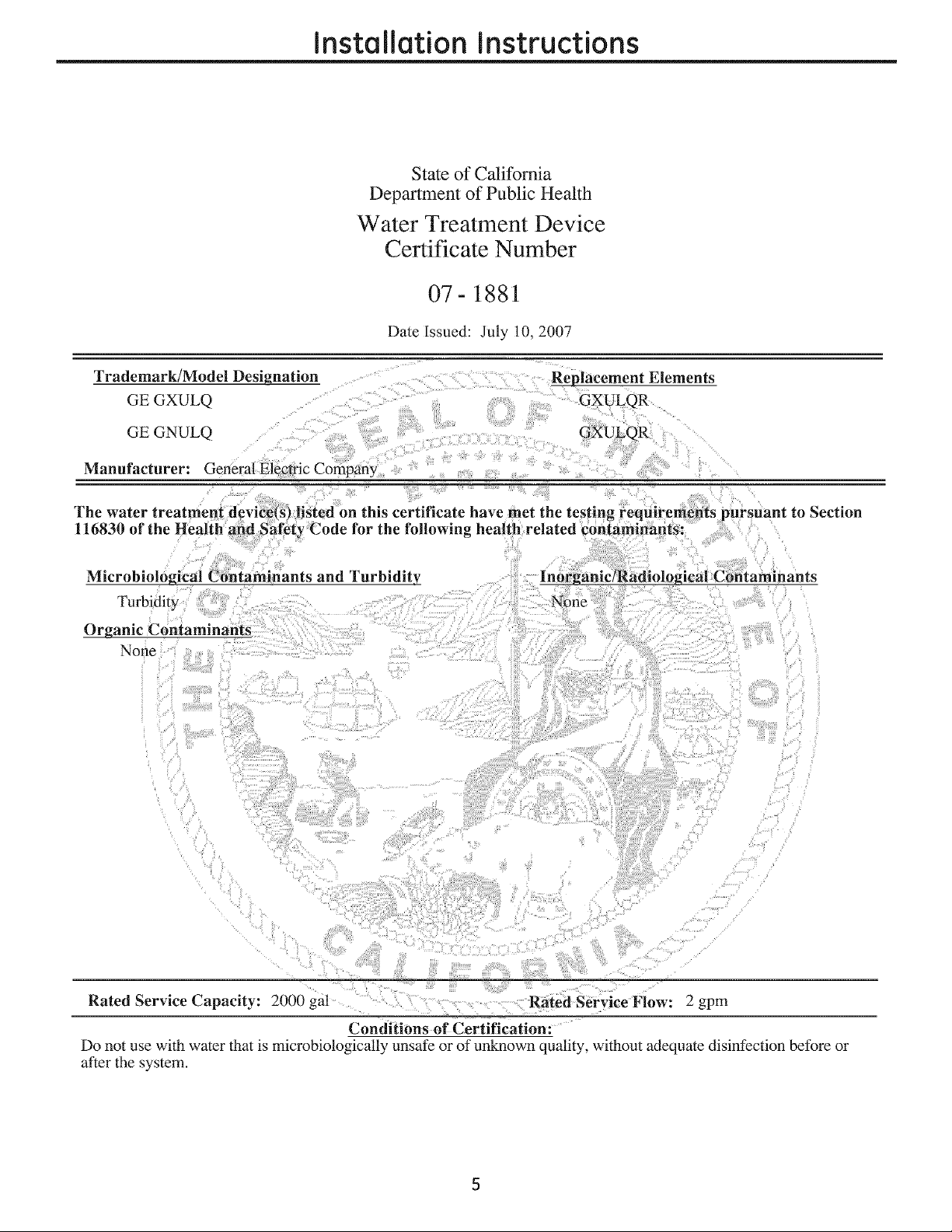

State of California

Department of Public Health

Water Treatment Device

Certificate Number

07-1881

Date issued: July 10, 2007

Trademark!ModelDesi_nation

GEGXULQ

GEGNULQ

Manufacturer: General Elecaric Company

Turbidity

Organic Contaminants

None

Re_placement Elements

Rated Service Capacity: 2000 gal Rated Service Flow: 2 gpm

Conditions of Certification:

Do not use with water that is microbiologically unsafe or of unknown quality, without adequate disinfection before or

after the system.

Loading...

Loading...