GE GNSF18Z01, GNSF23Z01, GNSF35Z01, PNSF31Z01 Installation Instructions

WARNING: Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before

or after the system. The water should be tested periodically to verify that the system is performing satisfactorily.

Small parts remaining after the installation could be a choke hazard. Discard safely.

GE & PROFILE

SmartWater™ Softener Systems

INSTALLATION INSTRUCTIONS

GE Models GNSF18Z01, GNSF23Z01, GNSF35Z01 & Profile Model PNSF31Z01

TABLE OF CONTENTS: Page #

Important Installation Recommendations 1

Plan How You Will Install the Softener 2

Where to Install the Softener 2

Tools and Materials Required for Installation 2

Step-by-Step Installation Instructions

— Bypass valve 4

— Softener assembly 4

— Plumb piping 4

— Brine tank overflow fittings 4

— Valve drain hose 4, 5

— Connecting brine tank overflow hose 5

— Grounding clamps and wires 5

— Testing for water leaks 5

— Programming the control 6, 7

— Specifications/Dimensions 7

Parts List 8–11

7193812 (1-98) 215C1001P001-2 For Use and Care questions call: GE Answer Center® 800.626.2000

Pub. No. 49-5806-2 GENERAL ELECTRIC COMPANY, Appliance Park, Louisville, KY 40225

CAUTION: Certain plumbing skills are

needed for installation. If you are unsure

about any part of the installation of this

product, consult a professional plumber.

UNPACKING AND INSPECTION

The softener is shipped in one master carton.

The softener is completely assembled at the

factory, except as required at installation.

Be sure to check the entire softener for any

shipping damage or parts loss. Also note

damage to the shipping cartons. Contact the

transportation company for all damage and

loss claims. The manufacturer is not

responsible for damages in transit.

Small parts, needed to install the softener,

are on a skin-packed cardboard piece. To

avoid loss of the small parts, keep them on

the skin-pack until you are ready to use them.

1

IMPORTANT INSTALLATION RECOMMENDATIONS

Read entire manual. Failure to follow all guidelines and rules could cause personal injury or property damage.

• Follow the installation instructions carefully. Failure to properly install the softener voids the warranty.

• Before you begin installation, read these Installation Instructions completely. Then, obtain all the materials and tools you will need to

make the installation.

• Check local codes. The installation must conform to them.

• Use only lead-free solder and flux for all sweat-solder connections, as required by state and federal codes.

• Connect the softener to the main water supply pipe BEFORE or AHEAD OF the water heater. DO NOT RUN HOT WATER

THROUGH THE SOFTENER. Temperature of water passing through the softener must be less than 100° F.

• Use care when handling the softener. Do not turn upside down, drop, drag, or set on sharp protrusions.

• The softener requires a minimum water flow of 3 gallons per minute at the inlet. Maximum allowable inlet water pressure is 125 psi. If

daytime pressure is over 80 psi, nighttime pressure may exceed the maximum. Use a pressure reducing valve if necessary. (Adding a

pressure reducing valve may reduce the flow.)

• The softener works on 24 volt-60 Hz electrical power only. Be sure to use the included transformer. Be sure the electric outlet and

transformer are in an inside location to protect from wet weather.

• See “WHERE TO INSTALL THE SOFTENER” section for more details.

PLAN HOW YOU WILL INSTALL THE SOFTENER

You must first decide how to run in and out pipes to the softener. Look at the house main water pipe at the point where you will connect

the softener. Is the pipe soldered copper, glued plastic, or threaded galvanized? What is the pipe size?

WARNING: Use only lead-free solder and flux to prevent lead poisoning.

Look at Fig. 1 for models GNSF18, GNSF23 and GNSF35 or Fig. 2 for model PNSF31. Use this as a guide when planning your particular

installation. Be sure to direct the incoming hard water supply to the softener valve inlet fitting. The valve is marked IN and OUT. See

below to help you prepare.

NOTE: The state of Massachusetts requires a licensed plumber to perform the installation.

2

•In and out pipes to the softener must be at least 3/4″size. Some

local codes require a minimum of 1″pipe size. To plumb with 1″

pipes, buy adapters to fit the 1″pipe threads on the bypass valve

(see Figures 1 and 2).

• Use copper, brass or galvanized pipe and fittings. Some codes

may also allow CPVC plastic pipes.

•Use the included bypass valve to install the softener. The bypass

valve allows you to turn off water to the softener for servicing, but

still have water in the house pipes.

•Drain hose is needed for valve and salt tank drains. A 20′ length

of drain tubing is included. If a longer length is needed, it can be

ordered from GE Parts at 800.626.2002.

•If a rigid valve drain is needed to comply with plumbing codes,

you can buy the parts needed (Fig. 4A) to connect a 1/2″copper

tubing or plastic pipe drain.

•Clean nugget or pellet water softener salt is needed to fill the

brine tank, see step 9.

TOOLS AND MATERIALS REQUIRED FOR INSTALLATION

•Place the softener as close as possible to a sewer drain, or other

acceptable drain point or standpipe.

•It is recommended to keep outside faucets on hard water to save

soft water and salt.

•Do not install the softener in a place where it could freeze. Freeze

damage is not covered by the warranty.

•Do not install the softener where it would block access to the

water heater or access to the main water shutoff.

•Put the softener in a place where water damage is least likely to

occur if a leak develops. The manufacturer will not repair or pay

for water damage.

•A 120 volt electric outlet is needed to plug in the included

transformer. The softener has a 10 foot power cable. If the outlet

is remote (up to 100 feet), use 18 gauge wire to connect. Be sure

the electric outlet and transformer are in an inside location, to

protect from wet weather. Be sure the outlet is unswitched to

prevent accidental shutoff.

•If installing in an outside location, you must take the steps

necessary to assure the softener, installation plumbing, wiring,

etc., are as well protected from the elements (sunlight, rain,

wind, heat, cold), contamination, vandalism, etc., as when

installed indoors.

•Keep the softener out of direct sunlight. The sun’s heat may

distort non-metallic parts and may damage the electronics.

WHERE TO INSTALL THE SOFTENER

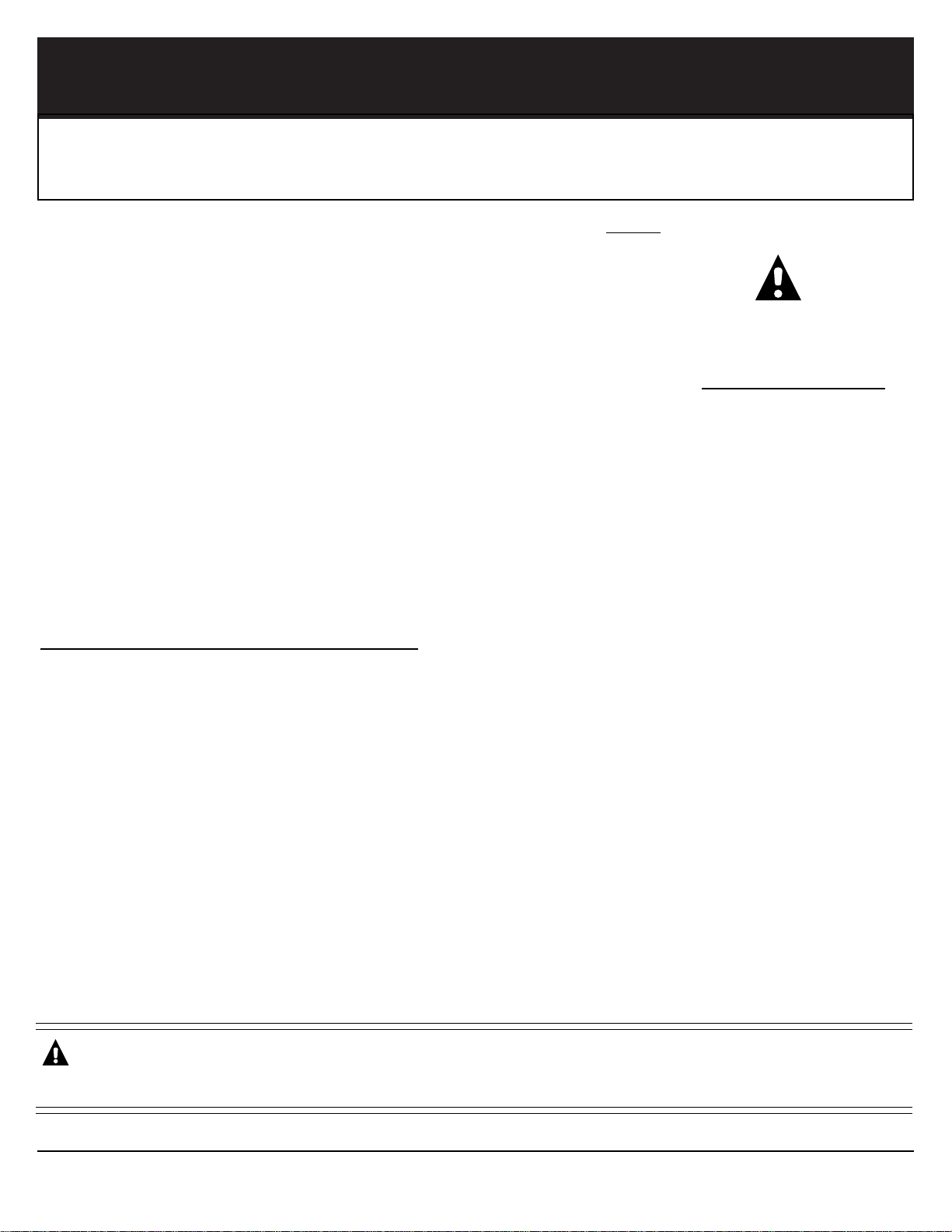

TYPICAL INSTALLATION ILLUSTRATION

3

Fig. 1

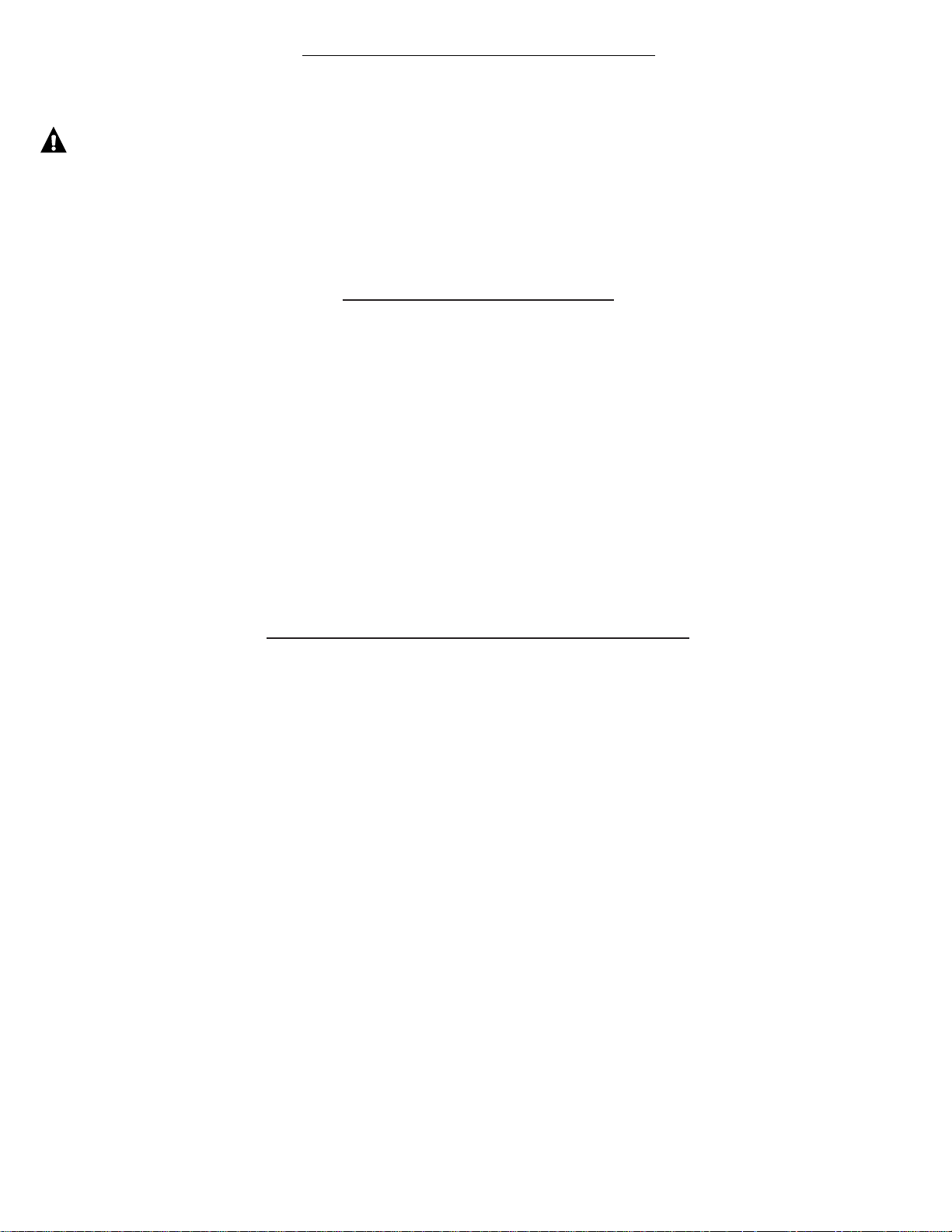

OPTIONAL 3-VALVE BYPASS INSTALLATION ILLUSTRATION

Adapters for this installation are not supplied with the softener.

Fig. 2

Soft water

Hard water to

outside faucets

MAIN WATER PIPE

Hard water

Installation nut (2)

Copper tube, 3/4″ (2)

Washer (2)

Bypass Valve

•Pull out for service

•Push in for bypass

NOTE: Threads on the bypass

valve are 1″ male pipe. If 1″ pipes

are needed, do not use the

copper tubes and nuts included.

Buy adapters and plumb directly

to the 1″threads.

INLET

Brinewell

Note: See drain hose

connections, page 6.

SALT

GOES HERE

Salt hole

cover

removed

24V transformer

120-volt outlet

Hard water

Soft water

From softener

outlet

To softener

inlet

CROSS-OVER

Use if water supply flows from

the left. Include single or

3-valve bypass.

CROSS-OVER

Use if water supply flows from

the left. Include single or

3–valve bypass.

To softener

inlet

From softener

outlet

Hard water

Soft water

MAIN WATER PIPE

Soft water

Hard water

Copper tube, 3/4″ (2)

Washer (2)

Installation adapter (2)

INLET

NOTE: Threads on the installation adapters are

1″ male pipe. If 1″ pipes are needed, do not use

the copper tubes and nuts included. Buy adapters

and plumb directly to the 1″threads.

24V transformer

120-volt outlet

Bypass valve

Hard water to

outside faucets

Inlet valve

Outlet valve

Nut (2)

For soft water service:

- Open the inlet and outlet valves

- Close the bypass valve

For bypass hard water:

- Close the inlet and outlet valves

- Open the bypass valve

3-valve bypass system

Turn off the water supply to pipes to be cut and drain the house water pipes. Open both

hot and cold faucets.

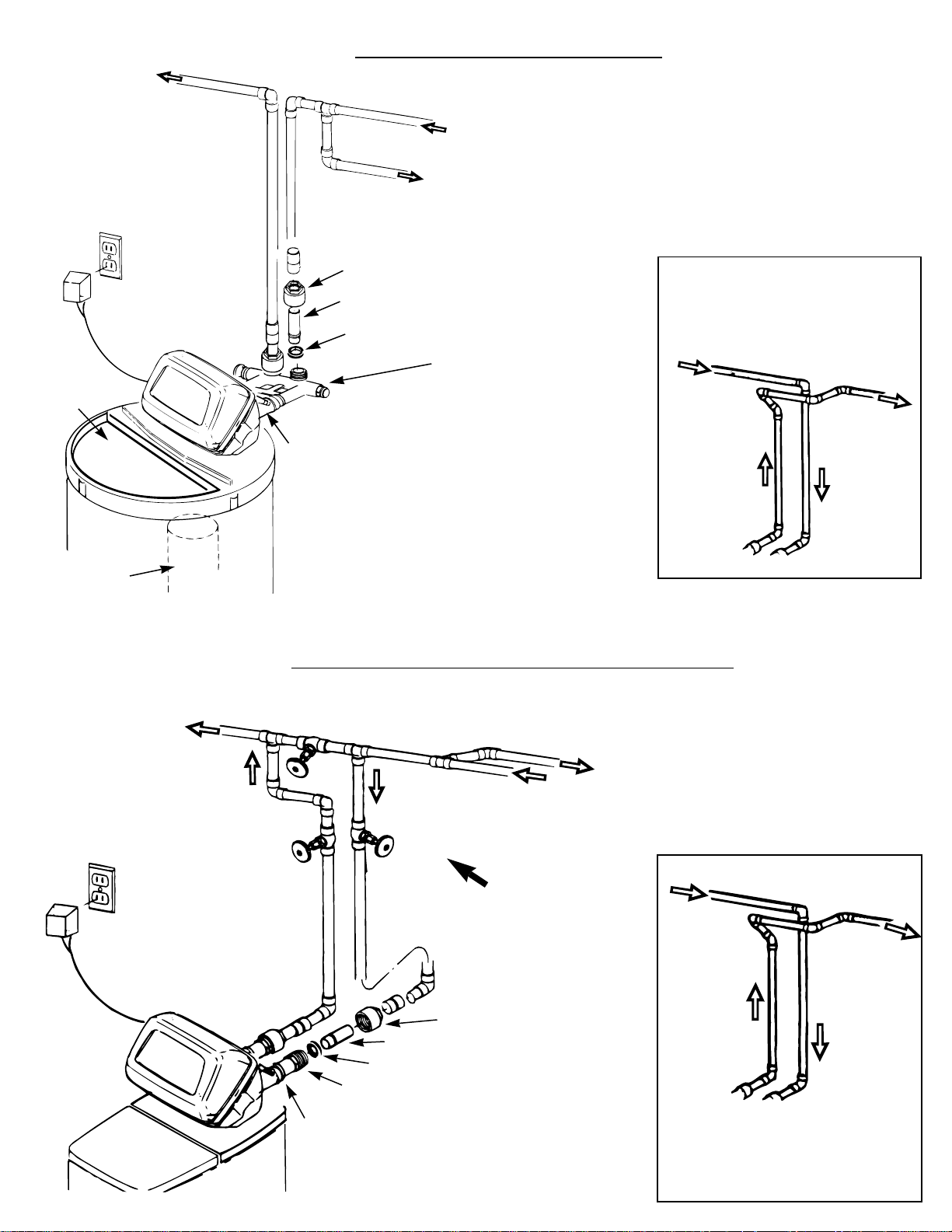

1. INSTALL BYPASS VALVE

•Remove plastic shipping plug and wire from valve outlet.

•Push the bypass valve (lubricate o-ring seals with silicone grease) into both ports of the

valve as shown in Fig. 3A.

•Snap the 2 large plastic clips in place, from the top, down as shown in Figures 3A and 3B.

Be sure they snap into place. Pull on the bypass valve to make sure it is held securely in

place.

2. MOVE THE SOFTENER ASSEMBLY INTO INSTALLATION POSITION:

•Be sure the installation surface is level and smooth. Sharp objects under the tank may

puncture it. If needed, place the tank on a section of 3/4″thick (minimum) plywood.

Then, place shims under the plywood as needed to level the softener.

3. PLUMB IN AND OUT PIPES TO AND FROM SOFTENER:

CAUTION: Observe all of the following cautions as you connect inlet and outlet

plumbing.

•BE SURE INCOMING HARD WATER SUPPLY IS DIRECTED TO THE SOFTENER

VALVE INLET PORT. If house water flow is from the left, use a plumbing cross-over as

shown in Fig. 1.

•If making a soldered copper installation, do all sweat soldering before connecting pipes

to the bypass valve. Torch heat will damage plastic parts.

•When turning threaded pipe fittings onto plastic fittings, use care not to cross-thread.

•Use pipe joint compound on all external pipe threads.

•Support inlet and outlet plumbing in some manner (use pipe hangers) to keep the

weight off of the valve fittings.

4. INSTALL THE BRINE TANK OVERFLOW FITTINGS:

•Insert the rubber grommet into the 3/4″ diameter hole in the brine tank sidewall as

shown in Fig. 5.

•Push the end of the hose adapter elbow into the grommet as shown in Fig. 5.

5. CONNECT AND RUN THE VALVE DRAIN HOSE:

•Use the provided drain hose (20′ length included) to attach to the valve drain fitting.

To keep water pressure from blowing the hose off, use a hose clamp to secure in place.

•Locate the other end of the hose at a suitable drain point (floor drain, sump, laundry

tub, etc.) that terminates at the sewer. Check and comply with local codes.

IMPORTANT: If more drain hose is needed, it can be ordered from GE Parts at

800.626.2002. The water softener will not work if water cannot exit this hose during

regenerations.

•Tie or wire the hose in place at the drain point. High water pressure will cause it to whip

during the back-wash and fast rinse cycles of regeneration. Also provide an air gap of at

least 1–1/2″between the end of the hose and the drain point. An air gap prevents

possible siphoning of sewer water into the softener, if the sewer should “back-up.”

•If raising the drain hose overhead is required to get to the drain point, do not raise

higher than 8′above the floor. Elevating the hose may cause a back-pressure that could

reduce brine draw during regenerations.

Fig. 3A.

Fig. 3B.

Fig. 3C.

Fig. 4.

STEP-BY-STEP INSTALLATION INSTRUCTIONS

NOTE: Be sure the turbine

and support are firmly in

place in the valve outlet.

Blow into the valve port and

observe the turbine

for free rotation.

4

Drain

fitting

on

valve

Valve drain hose

To sewer drain

Turbine

Valve outlet

Turbine shaft

and support

IN

OUT

Turn bypass valve

up-side down to

connect to floor

level plumbing

Valve body

inlet or outlet

Bypass valve

(push all the way in)

Clip

END

VIEW

Clip

Outlet

Inlet

O-ring seal goes into the outer

groove only. The clip snaps into

the inner groove (see below).

Bypass valve

NOTE: Threads

on the valve are 1″

male pipe. If 1″

pipe is needed,

buy adapters and

plumb to the 1″

threads.

SIDE

VIEW

Loading...

Loading...