Page 1

SAFETY INFORMATION . . . . . . . . 3

SPECIFICATIONS . . . . . . . . . . . . . . 5

USING THE REVERSE

OSMOSIS SYSTEM. . . . . . . . . . . . . 6

INSTALLATION INSTRUCTIONS

Tools and Materials Required . . . . . . . . . . 8

Before Beginning Installation . . . . . . . . . . 9

Plan the Installation . . . . . . . . . . . . . . . . . 10

Feed Water Supply . . . . . . . . . . . . . . . . . 11

Drain Adapter . . . . . . . . . . . . . . . . . . . . . 12

Storage Tank and Faucet . . . . . . . . . . . . 14

Faucet Electronics. . . . . . . . . . . . . . . . . . 15

Connect Tubes . . . . . . . . . . . . . . . . . . . . 16

Sanitize the System . . . . . . . . . . . . . . . . 18

Test and Purge the System . . . . . . . . . . . 19

CARE AND CLEANING

Cartridge Life and Replacement . . . . . . . 20

Change Faucet Battery . . . . . . . . . . . . . . 21

Drain Flow Control . . . . . . . . . . . . . . . . . 22

TROUBLESHOOTING TIPS . . . 23

OWNER’S MANUAL

& INSTALLATION

INSTRUCTIONS

GXRQ18NBN

GNRQ18NBN

ENGLISH

PARTS LIST . . . . . . . . . . . . . . . . . . . 24

WARRANTY . . . . . . . . . . . . . . . . . . . 26

CONSUMER SUPPORT . . . . . . . 28

Systems tested and certified by NSF

FILTRATION SYSTEM

Write the model and serial numbers here:

Model # __________________________

Serial # __________________________

You can find them on the bracket.

International against NSF/ANSI

Standards 58 and 42 for the

reduction of claims as specified on

the Performance Data Sheet

Systems certified by IAPMO R&T

against NSF/ ANSI Standards

42, 53, 58, 401 and P473 for the

reduction of claims as specified

on the Performance Data Sheet.

REVERSE OSMOSIS

GE is a trademark of the General Electric Company. Manufactured under trademark license.

7375456 5HY*($

Page 2

THANK YOU FOR MAKING GE APPLIANCES A PART OF YOUR HOME.

Whether you grew up with GE Appliances, or this is your first, we’re happy to have you in the family.

We take pride in the craftsmanship, innovation and design that goes into every GE Appliances

product, and we think you will too. Among other things, registration of your appliance ensures that

we can deliver important product information and warranty details when you need them.

Register your GE appliance now online. Helpful websites and phone numbers are available in the

Consumer Support section of this Owner’s Manual. You may also mail in the pre-printed registration

card included in the packing material.

2

Page 3

IMPORTANT SAFETY INFORMATION

READ ALL INSTRUCTIONS BEFORE USING THE APPLIANCE

Read, understand, and follow all safety information contained in these instructions prior to installation and use of the

GE Appliances Reverse Osmosis system. Retain these instructions for future reference.

Intended use:

The GE Appliances Reverse Osmosis system is intended for use in filtering potable water in Residential applications,

and has not been evaluated for other uses. The system is typically installed at the point of use, and must be installed

as specified in the installation instructions. Contact a plumbing professional if you are uncertain how to install.

SAFETY PRECAUTIONS

Be sure the water supply conforms with the Specification Guidelines. If the water supply conditions are unknown,

contact your municipal water company or your local health department for a list of contaminants in your area and a

list of laboratories certified by your state to analyze drinking water.

SAFETY INFORMATION

WARNING

■ Do not allow children under 3 years of age to have access to small parts during the installation of this product.

WARNING

■ Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection

before or after the system. Systems certified for cyst reduction may be used on disinfected water that may

contain filterable cysts.

WARNING

■ Do not install if water pressure exceeds 100 psi (689 kPa). If your water pressure exceeds 80 psi (552 kPa),

you should install a pressure limiting valve. Contact a plumbing professional if you are uncertain how to check

your water pressure.

■ Do not install where water hammer conditions may occur. If water hammer conditions exist you should install

a water hammer arrester. Contact a plumbing professional if you are uncertain how to check for this condition.

■ Where a backflow prevention device is installed on a water system, a device for controlling pressure due to

thermal expansion should be installed.

WARNING

■ Keep batteries away from children. This product contains a lithium button cell battery. If a new or used lithium

button cell battery is swallowed or enters the body, it can cause severe internal burns and can lead to death in

as little as 2 hours. If you think batteries might have been swallowed or placed inside any part of the body, seek

immediate medical attention. Always completely secure the battery compartment. If the battery compartment

does not close securely, stop using the product, remove the battery and keep it away from children. Properly

dispose of used batteries, keeping them away from children.

To reduce the risk associated with choking:

To reduce the risk associated with the ingestion of contaminants:

To reduce the risk of physical injury due to hydropneumatic tank rupture:

Chemical Burn Hazard:

To reduce the risk associated with ingesting of water contaminated with sanitizer:

■ After installation, sanitizer MUST be flushed from the system before first use as directed within the installation

instructions.

This system has been tested for the treatment of water containing pentavalent arsenic (also known as As(V), As(+5)

or arsenate) at concentrations of 0.050 mg/L or less. This system reduces pentavalent arsenic, but may not remove

other forms of arsenic. This system is to be used on water supplies containing a detectable free chlorine residual or

on water supplies that have been demonstrated to contain only pentavalent arsenic. Treatment with chloramine

(combined chlorine) is not sufficient to ensure complete conversion of trivalent arsenic to pentavalent arsenic.

Please see the Arsenic Facts section of the Performance Data Sheet for further information.

This reverse osmosis system contains a replaceable component critical to efficiency of the system. Replacement of

the reverse osmosis component should be with one of identical specifications, as defined by the manufacturer, to

assure the same efficiency and contaminant reduction performance.

READ AND SAVE THESE INSTRUCTIONS

3

Page 4

IMPORTANT SAFETY INFORMATION

READ ALL INSTRUCTIONS BEFORE USING THE APPLIANCE

SAFETY PRECAUTIONS (continued)

This system has a lithium battery containing perchlorate. Per California Regulation:

Perchlorate Material – Special handling may apply. See www.dtsc.ca.gov/hazardouswaste/perchlorate.

Extended non-use of the Reverse Osmosis system:

■ If the system has not been used for one week or more, open the RO water faucet and allow the system to

drain. Close the RO water faucet and allow the system to regenerate the water supply..

Recommended installation is under the sink. However, the unit can be installed in a remote location, up to 20 feet

away from the sink.

• However, additional materials will be required. See parts list to obtain additional materials from GE Appliances.

• Locating the tank on a basement floor, with the faucet at a first floor sink may result in some loss of flow rate and

SAFETY INFORMATION

capacity (approximately 20%). Installing a second tank will improve this performance.

If Reverse Osmosis system is connected to a refrigerator icemaker, do not use copper tubing for the connection

between the Reverse Osmosis system and the refrigerator.

Sanitize upon installation of the Reverse Osmosis system and after servicing inner parts, including replacement of

prefilter, postfilter and Reverse Osmosis cartridge. It is important to have clean hands while handling inner parts of

the system. See the Sanitizing the System section.

This Reverse Osmosis system contains a replaceable treatment component critical for effective reduction of total

dissolved solids. This product water shall be tested periodically to verify that the system is performing satisfactorily.

See the The Water Test Kit section.

BE SURE TO FOLLOW ALL APPLICABLE STATE AND LOCAL CODES.

NOTICE: To reduce the risk associated with property damage due to water leakage:

■ Read and follow these instruction before

installation and use of this system.

■ Installation and use MUST comply with all state

and local plumbing codes.

■ Protect from freezing, remove filter cartridge when

temperatures are expected to drop below 40° F

(4.4° C).

■ Do not install systems in areas where ambient

temperatures may go above 110° F (43.3° C).

■ Do not install if water pressure exceeds 100 psi

(689 kPa). If your water pressure exceeds 80 psi

(552 kPa), you should install a pressure limiting

valve. Contact a plumbing professional if you are

uncertain how to check your water pressure.

■ Do not install where water hammer conditions may

occur. If water hammer conditions exist, you

should install a water hammer arrester. Contact a

plumbing professional if you are uncertain how to

check for this condition.

■ Where a backflow prevention device is installed on

a water system, a device for controlling pressure

due to thermal expansion should be installed.

■ Do not use a torch or other high temperature

sources near filter system, cartridges, plastic

fittings or plastic plumbing.

■ On plastic fittings, never use pipe sealant or pipe

dope. Use PTFE thread sealing tape only, as pipe

dope properties may deteriorate plastic.

■ Take care when using pliers or pipe wrenches to

tighten plastic fittings, as damage may occur if

over tightening occurs.

■ Do not install in direct sunlight or outdoors.

■ Locate the system in such a position as to prevent

it from being struck by other items used in the area

of installation.

■ Ensure that the location will support the weight of

the system when installed and full of water.

■ Ensure all tubing and fittings are secure and free

of leaks.

■ Do not install unit if any collets (parts 14 and 15 on

page 25) are missing. Contact 877.959.8688 if

collets are missing from any fittings to obtain

replacements.

■ Replace the disposable prefilter and postfilter

cartridges every 6 months, at the rated capacity, or

sooner if a noticeable reduction in flow rate occurs.

■ Replace the disposable RO cartridge every 24

months, or sooner if a noticeable reduction in

filtration efficiency occurs.

READ AND SAVE THESE INSTRUCTIONS

4

Page 5

Specifications

Reverse Osmosis System

Models: GXRQ18NBN and GNRQ18NBN

Supply water pressure limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-100 psi (280-689 kPa)

Supply water temperature limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-100 °F (4-38 °C)

Maximum total dissolved solids (TDS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2000 ppm

Maximum water hardness @ 6.9 pH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 gpg

Maximum iron, manganese, hydrogen sulfide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0

Chlorine in water supply (max. ppm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0

Supply water pH limits (pH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Product (quality) water, 24 hours1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14.76 gal. (55.9 liters)

Percent rejection of TDS, minimum (new membrane)1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86.5

Automatic shutoff control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . yes

Efficiency2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.6 %

Recovery3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21.2 %

This system conforms to NSF/ANSI 58 for the specific performance claims as verified and substantiated by test data.

1

@ Feed water supply at 50 psi, 77°F, and 750 TDS. Quality water production, amount of waste water and percent rejection all

vary with changes in pressure, temperature and total dissolved solids.

2

Efficiency rating means the percentage of the influent water to the system that is available to the user as reverse osmosis

treated water under operating conditions that approximate typical daily usage.

3

Recovery rating means the percentage of the influent water to the membrane portion of the system that is available to the user

as reverse osmosis treated water when the system is operated without a storage tank or when the storage tank is bypassed.

SPECIFICATIONS

Non-potable Water Sources: Do not attempt to use this product to make safe drinking water from non-potable water sources.

Do not use the system on microbiologically unsafe water, or water of unknown quality without an adequate disinfection before or

after the system. This system is certified for cyst reduction and may be used on disinfected water that may contain filterable

cysts.

Arsenic Reduction: This system shall only be used for arsenic reduction on chlorinated water supplies containing detectable

residual free chlorine at the system inlet. Water systems using an inline chlorinator should provide a one minute chlorine contact

time before the reverse osmosis system.

Nitrate/Nitrite Test Kit: This system is supplied with a nitrate/nitrite test kit. Product water should be monitored periodically

according to the instructions provided with the test kit.

Installations In the Commonwealth of Massachusetts: The Commonwealth of Massachusetts requires installation be

performed by a licensed plumber and do not permit the use of saddle valves. Plumbing code 248-CMR of the Commonwealth of

Massachusetts must be followed in these cases.

Product Water Testing: The Reverse Osmosis system contains a replaceable treatment component critical for the effective

reduction of total dissolved solids. Product water should be tested periodically to verify that the system is performing properly.

Replacement of the reverse osmosis component: This reverse osmosis system contains a replaceable component critical to

the efficiency of the system. Replacement of the reverse osmosis component should be with one of identical specifications, as

defined by the manufacturer, to assure the same efficiency and contaminant performance.

Dimensions:

14”

14"

9-1/4”

9-1/4"

12-1/2”9” dia.

9" dia.

Storage Tank Reverse Osmosis Assembly

12-1/2" 3-5/8"

3-5/8”

RO Product

Water Faucet

9-3/4"

9-3/4”

5

Page 6

Using the Reverse Osmosis System

How the Reverse Osmosis System Works

Reverse Osmosis reduces Total Dissolved Solids (TDS) and organic matter from water by diffusing it through a

special membrane (see Performance Data Sheet). The membrane separates minerals and impurities from the water

and they are flushed to the drain. For the reduction of the claims specified, see Performance Data Sheet. High

quality product water goes directly to the drinking water faucet or to the storage tank. The system makes a good

supply of drinking water each day. How much it makes depends on the feed water supply pressure, temperature

and quality.

The prefilter and postfilter are replaceable cartridges. The carbon prefilter reduces chlorine while also filtering

sediments. The postfilter reduces any other undesirable tastes and odors before you use the water.

The system includes an electronic faucet assembly with a prefilter and postfilter change reminder. When six months

have passed, a flashing light will remind you to change the two filters.

Description of the Reverse Osmosis System

Prefilter - Water from the cold supply pipe is

directed to the prefilter cartridge. The prefilter is a

replaceable sediment cartridge containing activated

carbon. The prefilter reduces chlorine taste and odor

in the feed water because CHLORINE DESTROYS

THE REVERSE OSMOSIS MEMBRANE. Filtered,

clean, chlorine-reduced water flows from the prefilter to

the Reverse Osmosis cartridge.

Reverse Osmosis Cartridge - The middle

cartridge includes a tightly wound, special membrane.

Water is forced through the cartridge where the

membrane reduces the dissolved solids and organic

matter. High quality product water exits the Reverse

Osmosis cartridge and goes to the storage tank.

Reject water, with the dissolved solids and organic

matter, leaves the cartridge and is discharged to the

drain through 1/4” tubing.

Storage Tank - The storage area holds up to 1-3/4

gallons of product water. A diaphragm inside the tank

keeps water pressurized, when the tank is full, for fast

flow to the faucet when drinking water is needed.

When the tank is empty of water, the pressure at the

air valve is 5 - 7 psi.

Postfilter - After leaving the storage tank, but before

going to the system faucet, product water goes to the

post filter cartridge. The postfilter is an enhanced

replaceable sediment cartridge containing activated

carbon designed to reduce select pharmaceuticals,

select herbicides/pesticides, VOCs, BPA and PFOA/

PFOS as well as remaining tastes, odors, and

sediments. Clean, high quality drinking water flows

through the tubing and to the system faucet.

USING THE REVERSE OSMOSIS SYSTEM: How the System Works

RO Product Water Faucet - The countertop

faucet dispenses filtered drinking water when opened.

It has a variable flow handle. To comply with plumbing

codes, an air gap is built into the faucet drain water

connection.

Faucet Electronics - Inside the faucet handle is a

battery operated 6 month timer. The faucet LED will

light blue for a few seconds whenever the faucet

handle is operated. When 90% of the filter lifetime has

elapsed, the LED will flash blue 3 times whenever the

faucet handle is operated. It will flash red continuously

when 100% (6 months) has elapsed, to indicate that

the prefilter and postfilter cartridges must be changed.

Automatic Shutoff Assembly - To conserve

water, the drinking water system has an automatic

shutoff. When the storage tank has filled to capacity

and the drinking water faucet is closed, pressure

closes the shutoff. Water flow to the Reverse Osmosis

cartridge is shut off until drinking water is used again,

and pressure drops in the Reverse Osmosis system.

Check Valve - The check valve in the manifold

assembly prevents a backward flow of product water

from the storage tank. A backward flow could cause

the Reverse Osmosis membrane to rupture.

Flow Control - The flow control regulates the flow

of water through the Reverse Osmosis cartridge at the

required rate to produce high quality water. The

control is located in the elbow fitting where the red 1/4”

drain line exits the manifold.

6

Page 7

Using the Reverse Osmosis System

PRODUCT

WATER FAUCET

Air Gap

6

PRODUCT WATER

BLACK

Gravity

DRAIN WATER

Drain

USING THE REVERSE OSMOSIS SYSTEM: How the System Works

WATER

IN

AUTOMATIC

SHUTOFF

GREEN

Drain Flow

Control

Check

Valve

8

BLUE

1

PRODUCT

POSTFILTER

3

7

YELLOW

WATER

STORAGE

TANK

4

RED

PREFILTER

5

RO

MEMBRANE

2

Reverse Osmosis Water Flow Schematic

Water Flow Description

1. Water enters prefilter. Sand, silt and other sediments are reduced. Chlorine is also reduced.

2. Water leaves prefilter and proceeds to the Reverse Osmosis cartridge.

3. Water enters the Reverse Osmosis membrane. Dissolved solids are reduced.

4. Processed water leaves the Reverse Osmosis membrane and flows to the storage tank.

5. Drain water with dissolved solids leaves the Reverse Osmosis membrane and flows to the drain.

6. Faucet is activated.

7. Processed water leaves the storage tank and flows to the postfilter, where it is filtered to ensure fresh taste.

8. Water flows to the Reverse Osmosis faucet.

7

Page 8

Installation

Reverse Osmosis Filtration System

Instructions

Models GXRQ18NBN and GNRQ18NBN

Questions? Call 800.626.2005

?

or visit our Website at: GEAppliances.com/ge/service-and-support/contact.htm

WARNING

■ Check with your state and/or local public works department for plumbing codes. You

must follow their guides as you install the Reverse Osmosis system.

NOTE: Failure to comply with these installation instructions will void the product warranty,

and the installer will be responsible for any service, repair or damages caused thereby.

TOOLS AND MATERIALS

REQUIRED FOR INSTALLATION

INSTALATION INSTRUCTIONS

■ Electric Drill and 1-3/8” Drill Bit (type as required)

if mounting hole is needed for faucet

■ Electric Drill and 3/8” Drill Bit (type as required) if

installing the included drain adapter

■ Two (2) Adjustable Wrenches

■ Tape Measure

■ Phillips and Flat Blade Screwdrivers

■ Utility Knife

■ PTFE Thread Sealing Tape

■ If your main water line is a rigid pipe, you will

require a compression fitting and possibly other

plumbing hardware to complete the installation.

IMPORTANT: To avoid damaging the sink,

consult a qualified plumber or installer for drilling

procedures. Special drill bits may be needed for

stone, porcelain or stainless steel.

Read entire manual. Failure to follow all guides and rules could cause

personal injury or property damage.

BEFORE YOU BEGIN

Read these instructions completely and

carefully.

■ IMPORTANT: Save these instructions for local

inspector’s use.

■ IMPORTANT: Observe all governing codes

and ordinances.

■ Note to Installer: Be sure to leave these

instructions with the consumer.

■ Note to Consumer: Keep these instructions for

future reference.

■ Proper installation is the responsibility of the

installer.

■ Product failure due to improper installation is not

covered under the warranty.

■ A shutoff valve must be available or added near

the installation point.

Items in Parts Bag

CONTENTS INCLUDED WITH SYSTEM

■ Reverse Osmosis Assembly and Tubing

■ Product Literature (Owner’s Manual and

Installation Instructions)

■ Performance Data Sheet

■ Water Supply Fitting

■ Faucet Assembly with Electronic Timer and

Tubing

■ Storage Tank

■ Tank Connector

■ Drain Adapter

Drain Adapter

Nitrate / Nitrite Test Kit

Water Supply

Fitting

Ta nk

Connector

Eye

Dropper

8

Page 9

Installation Instructions

THINGS TO CHECK BEFORE BEGINNING INSTALLATION

INSTALATION INSTRUCTIONS

FEED WATER

The water supply to the Reverse Osmosis system

must have the qualities listed in the specifications.

Municipal water supplies most often will have

these qualities. Well water may need conditioning;

have the water tested by a water analysis

laboratory and get their recommendations for

treatment.

IMPORTANT: For water with a hardness greater

than 10 grains (at 6.9 pH) the use of a softener is

recommended. Failure to install a softener will

reduce the life of the Reverse Osmosis cartridge.

RO DRAIN CONNECTION

A suitable drain point and air gap (check your

state and/or local codes) are needed for reject

water from the Reverse Osmosis membrane

cartridge.

RO FAUCET

The RO product water faucet installs on the sink or

on the countertop next to the sink. It may be

installed in an existing sink spray attachment hole,

or a hole may be drilled. Space is required

underneath for tubing to and from the faucet, and

for securing the faucet in place. All three faucet

tubes are supplied already connected at one end

to the faucet.

BASEMENT INSTALLATION

If installing in a basement, leave enough tubing in

place during installation to be able to move unit to

floor for ease at servicing and making filter/

membrane changes. Additional tubing and fittings

required.

NOTE: See parts list on page 25 for optional parts

that may be required for a basement installation.

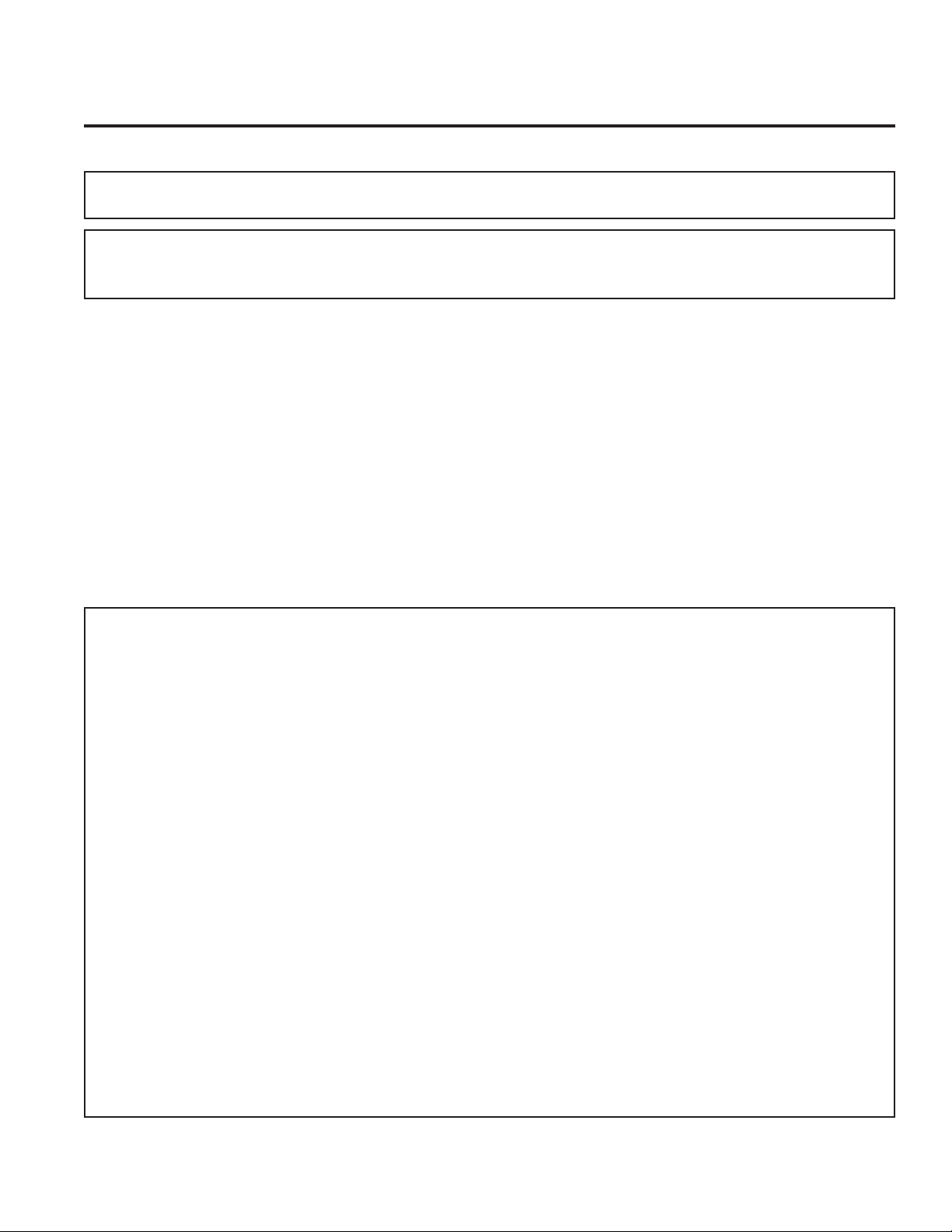

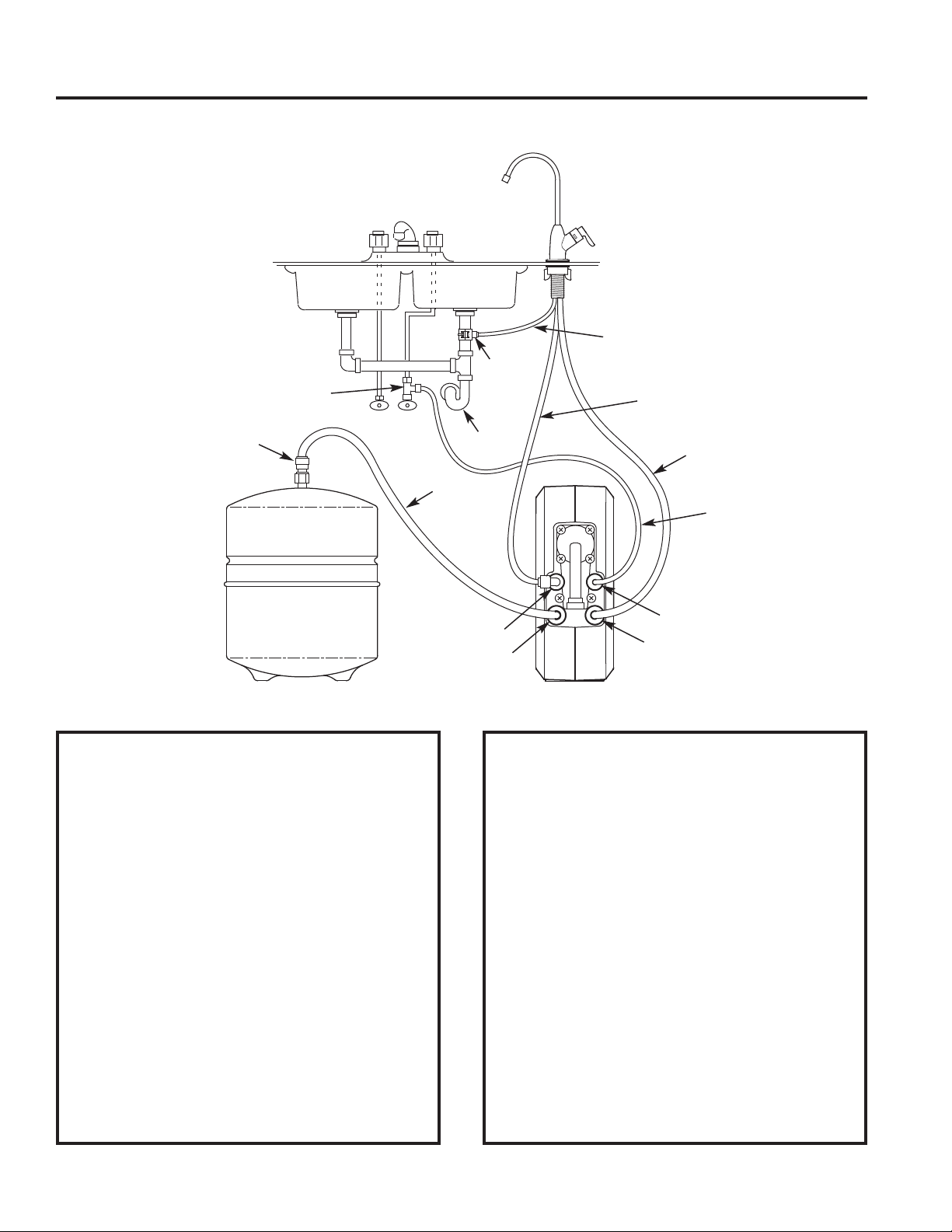

RO Product

Water Faucet

Tank

Connector

3/8” Black

Drain

Water Supply

Fitting

HOT COLD

3/8” Yellow

Tube

Red Collet

Yellow Collet

Storage Tank Reverse Osmosis Assembly

Adapter

Sink

P–Trap

Tube

1/4” Red

Tube

3/8” Blue

Tube

1/4” Green

Tube

Green Collet

Blue Collet

9

Page 10

Installation Instructions

PLAN THE INSTALLATION

The Reverse Osmosis System can be installed under a sink or in a remote location. Typical remote sites are a

laundry room or utility room. Review the location options below and determine where to install the system.

UNDER THE SINK LOCATION

The Reverse Osmosis Filter Assembly and

storage tank may be installed in a kitchen or

bathroom sink cabinet.

REMOTE INTERIOR LOCATION

The Reverse Osmosis Filter Assembly and

storage tank may also be installed in a

remote interior location away from the

Reverse Osmosis faucet. A nearby water

source and drain point are required.

PREPARE FOR INSTALLATION

1. Before starting, close the hot and cold

water shutoff valves.

INSTALATION INSTRUCTIONS

2. Temporarily place tank and filter assembly

into planned location. Check position of

items and space required for installation.

Ensure tubes may be routed without

kinking.

3. Remove tank and filter from planned

location and set aside.

Outside Faucet

(Hard Water)

Soft, Cold Water

Cold Water

Supply

Hard Water Line

Drain Adapter

for Reverse

Osmosis

Reject Water

HOT COLD

Storage

Tank

Sink Drain

Shutoff Valve

P-Trap

Typical Under Sink Installation

Installation items included in parts bag.

Outside Faucet

(Hard Water)

To Faucet

Reverse

Osmosis

Faucet

Reverse

Osmosis

Assembly

10

Soft, Hot Water

Water

Heater

Typical Remote Installation

Additional parts required.

Shutoff

Valve

Water

Softener

Hard

Water

House

Floor

Drain

to

1-1/2”

Air Gap

Water

Meter

Soft water to

Reverse Osmosis

System

Reverse Osmosis

System

Reverse Osmosis

Drain

Storage

Ta nk

Main

Shutoff

Valve

Page 11

Installation Instructions

FEED WATER SUPPLY

Check and comply with local plumbing codes as you plan, then install a cold water supply fitting.

INSTALATION INSTRUCTIONS

A. PREFERRED INSTALLATION

A typical connection using the included water

supply fitting is shown in the illustration below.

1. Close the cold water shutoff valve and open the

faucets to relieve pressure and drain water from

the sink cold water pipe.

cold water

pipe

water supply

fitting

gasket

cold water

shutoff

2. Disconnect the existing cold water line from the

water shutoff valve.

3. Make sure that the water supply fitting’s gasket

is inside the female threaded portion of the

fitting.

4. Install the water supply fitting onto the cold

water shutoff valve, where the existing cold

water line was removed, and hand tighten. Be

careful not to cross thread or overtighten.

5. Connect the existing cold water line to the male

threaded portion of the water supply fitting and

hand tighten. Be careful not to cross thread or

overtighten.

Cold Water

Shutoff Valve

1/4” green

tubing to

Reverse

Osmosis inlet

B. OPTIONAL INSTALLATION

A typical connection using a compression type

fitting (not included).

NOTE: Be sure to turn off the water supply and

open a faucet to drain the pipe.

Complying with plumbing codes, install a fitting on

the cold water pipe to adapt 1/4" OD tubing. A

typical connection is shown in the illustration

below.

Cold Water

Shutoff Valve

1/4” compression

fitting

insert

ferrule

1/4” green

cold water

pipe

NOTE: If threaded fittings are used, be sure to use

pipe joint compound (metal fittings only) or

thread sealing tape on outside threads.

tubing to

Reverse

Osmosis inlet

11

Page 12

Installation Instructions

REVERSE OSMOSIS DRAIN ADAPTER (for under sink installation)

INTRODUCTION

A suitable drain point is needed for the drain water

from the Reverse Osmosis system. Options are:

• Install the included Drain Adapter

As shown below, install the included drain

adapter onto the sink’s drain pipe above the Ptrap. This is normally used for under sink

installations.

Double Basin Sink

Garbage

Disposal

Drain

Adapter

INSTALATION INSTRUCTIONS

NOTE: Do not install drain adapter on a line

coming from a garbage disposal.

• Use another existing drain in the home

Run the drain tube from the RO system directly

to an open drain. This is often used for remote

location installations.

NOTE: An incorrectly connected drain point can

cause water to leak from the faucet’s air gap.

NOTE: Local code may restrict the type of drain

installation to use. Either drain installation

type, if permitted by code, may be used in

under sink or remote location installations.

Consult a plumber if you are not familiar

with plumbing procedures.

P–Trap

Single Basin

P–Trap

Sink

Drain

Adapter

INSTALL DRAIN ADAPTER (Cont.)

RO

Faucet

Drain

Tube

Drain Adapter

P–Trap

2. Using the hole through the drain fitting as a guide,

mark the pipe where a 3/8” hole will be drilled,

and remove the drain adapter from the pipe.

NOTE: Do not drill through the drain adapter’s Q.C.

fitting, as this could damage the o-ring.

Nuts

Drain

Adapter

Halves

Sink Drain Pipe

3/8” Hole - Do not drill

through Q.C. Fitting

3/8” Quick

Connect

Fitting

Screws

P-Trap

12

INSTALL DRAIN ADAPTER

The drain adapter included with the RO system is

designed to fit around a standard 1-1/2” O.D. drain

pipe. In the following procedure, install the drain

adapter above (upstream of) the P-trap. Be sure

to comply with local plumbing codes.

NOTE: Before starting this procedure, inspect the

drain pipe under the sink for corrosion, and replace

if necessary, before continuing with installation.

1. Test fit the two halves of the drain adapter onto

the sink drain pipe, about 6 inches above the Ptrap. Make sure that the quick connect (Q.C.)

fitting is toward the direction of the RO faucet.

NOTE: Locate so that the drain tubing from the

Reverse Osmosis faucet will run straight to

the adapter, with no dips, loops, or kinks.

3. Drill a 3/8” dia. hole in the pipe and remove flash.

4. Clean the sink tailpiece to assure a leak-tight fit.

5. Place the halves of the drain fitting back onto

the sink drain pipe. Use a pencil or similar

pointed object to align the Q.C. fitting so that it

is centered on the hole you drilled.

6. Assemble the nuts and screws, as shown in the

illustration above, and tighten both sides equally

to secure the drain adapter halves onto the pipe.

Do not overtighten.

7. Do not connect black tubing to the Q.C. fitting at

this time. It is done after the RO faucet is installed.

Page 13

Installation Instructions

ALTERNATIVE DRAIN INSTALLATION (for a remote location)

Outside Faucet

Outside Faucet

(Hard Water)

Hard

Water

to

House

Soft, Cold Water

Soft, Hot Water

(Hard Water)

Hard Water Line

Shutoff

Valve

Water

Heater

Water

Softener

Water

Meter

INSTALATION INSTRUCTIONS

BLUE Tubing

to Reverse

Osmosis Faucet

Soft Water GREEN Tubing

to Reverse

Osmosis System

Reverse Osmosis

System

Reverse Osmosis

Drain - RED

Tubing to Drain

YELLOW Tubing

to Storage Tank

Storage Tank

Main Shutoff

Valve

1/4'' RED Tubing

1-1/2”

Air Gap

Air Gap

Laundry

Tub

1-1/2”

Air Gap

Stand pipe

Sump

1-1/2”

Air Gap

INSTALL A DRAIN POINT AND AIR GAP

(for a remote location)

Route the drain tubing to an existing drain in the

house. A floor drain, laundry tub, standpipe, sump,

etc. are suitable drain points. Be sure to provide a

1-1/2” air gap between the end of the hose and the

drain point. This will prevent water from backing

up into the system.

NOTE: Check your local plumbing codes.

To install a remote drain point, complete the

following steps:

1. Locate the 1/4” red tube and determine whether

it is long enough to reach from the Reverse

Osmosis assembly to the drain point.

RED

Tubing to

Drain

1-1/2”

Floor

Drain

2. If longer tubing is required, see parts list in back

of manual and replace the red tube with an

adequate length of 1/4” tubing.

3. Cut one end of the drain tube square.

4. Insert this tube all the way into the red collet

fitting on the Reverse Osmosis filter assembly.

See illustration on page 17.

5. Pull on the tubing to be sure it is held firmly in

the fitting.

NOTE: A flow control insert is located inside the

elbow fitting that the drain tube connects

to. Leave this fitting in place.

6. Route the tubing to the drain point and secure at

the end with a bracket (not included). Provide a

1-1/2” air gap between the end of the tube and

the drain.

13

Page 14

Installation Instructions

STORAGE TANK AND FAUCET

STORAGE TANK INSTALLATION

1. Apply thread sealing tape (2 wraps clockwise) to

the threads on the nipple at the top of the tank.

Ta nk

Nipple

Wrap thread

sealing tape

on threads

Tank Connector

INSTALATION INSTRUCTIONS

2. Locate the included tank connector. Slowly

tighten the tank connector onto the tank nipple

7-8 full turns, so as not to cross thread or

overtighten.

3. Do not connect the tube at this time. This will

occur later in the assembly.

4. Place the storage tank next to the Reverse

Osmosis assembly. The tank can be placed

upright or on its side.

Storage

Ta nk

INSTALL THE FAUCET (Cont.)

1. If drilling is needed, drill a 1-3/8" diameter hole

in the mounting surface. Be sure to use the

proper procedure for drilling stone, porcelain or

stainless steel. Special drill bits may be

needed. Consult a qualified plumber.

RO

Faucet

Base Ring

Gasket

Threaded

Stud

Counter

To p

Washer

Wing

Nut

Tubing

14

INSTALL THE FAUCET

Select the location of the Reverse Osmosis

product water faucet. Be sure there is room

underneath and above the sink to make the

needed connections. Options are:

• Use an existing sink top hole for the spray hose

or soap dispenser (Must be between 1-1/4” and

1-1/2” in diameter)

• Drill a new hole in the sink top

• Drill a new hole in the countertop next to the sink

NOTE: Check to ensure the Reverse Osmosis

faucet will mount flat against the mounting

surface.

NOTE: Visually review the routing of the tubes

from the Reverse Osmosis assembly to the

faucet. Check to ensure there is adequate

tube routing space between the faucet and

Reverse Osmosis assembly.

2. Unscrew the plastic wing nut from the RO

faucet’s threaded stud. Slide this wing nut and

the adjacent metal washer off the tubing ends

and set them aside to reinstall in step 4, below.

NOTE: Be sure the black rubber gasket and metal

base ring remain in place on the faucet

stud.

3. Work tubing and the faucet stud down into the

mounting hole. Be sure that the faucet body

seats squarely into the base ring, and that the

black rubber gasket sits flat against the sink or

countertop.

4. On the underside of the sink or countertop, slide

the metal washer and wing nut (removed in step

2) back over the tubing ends and onto the stud.

With the washer in place between the

countertop and wing nut, tighten the wing nut

securely.

Page 15

Installation Instructions

FAUCET ELECTRONICS

Inside the faucet handle is a battery operated 6 month timer. On a new Reverse Osmosis system, the product water

faucet is shipped with a battery in the holder. After the faucet has been installed, the thin plastic strip must be

removed, as described below, to power up the 6 month timer.

POWER UP THE FAUCET TIMER

1. On the faucet handle, locate the battery cover.

There should be a thin plastic strip that sticks

out from the battery cover.

Faucet

Handle

Plastic Strip pull out and

discard

INSTALATION INSTRUCTIONS

Battery

Cover

2. Grasp the plastic strip, pull it all the way out and

discard it.

3. The LED on the faucet handle will briefly flash

red, then blue, to indicate the 6 month timer is

powered up.

The faucet LED will light blue for a few seconds whenever the faucet handle is operated. When 90% of the filter

lifetime has elapsed, the LED will flash blue 3 times whenever the faucet handle is operated. It will flash red

continuously when 100% (6 months) has elapsed, to indicate that the prefilter and postfilter cartridges must be

changed.

Always change the battery, as shown on page 21, when replacing the prefilter / postfilter cartridges (every 6 months).

15

Page 16

Installation Instructions

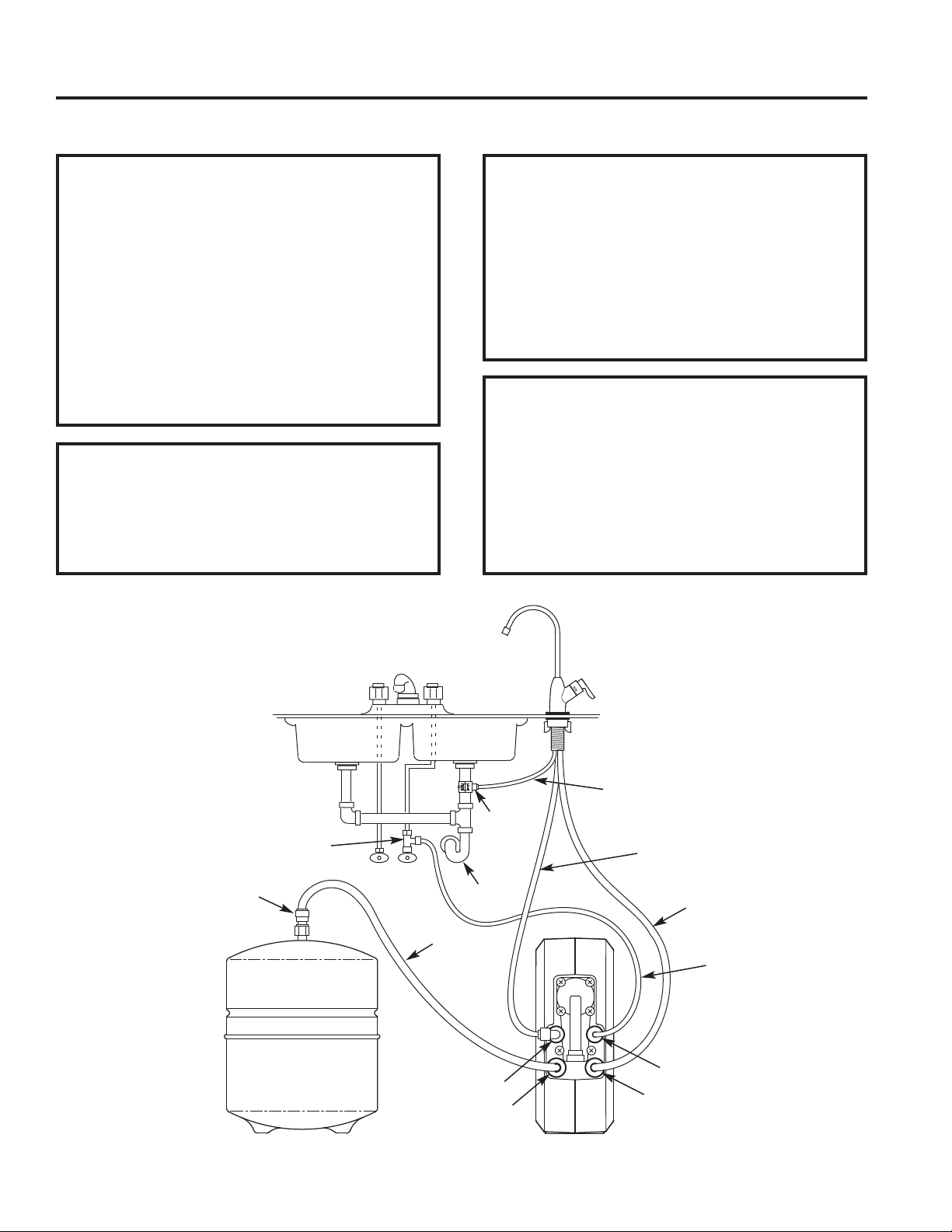

HOW TO CONNECT TUBES

The Reverse Osmosis system includes push-in

fittings for quick tubing connection. Review the

following instructions before connecting the tubes

in the next step. Failure to follow these

instructions may lead to future leaks.

CUT TUBES TO LENGTH

1. Use a sharp cutter or knife to cut the end of

tubing. Always cut the tubing end square and

smooth, with no nicks or rough spots.

Tube

NOTE: Tubing lengths should allow the RO

INSTALATION INSTRUCTIONS

2. Inspect the tube up to 1” from the end to be sure

assembly to be moved for servicing.

there are no nicks, scratches or other rough

spots. If needed, cut the tubing again.

Push-in Fitting

CONNECT TUBES

1. Push tubing through collet, until it engages the

o-ring. Continue pushing until the tube bottoms

out against the back of the fitting. Do not stop

pushing when the tube engages the o-ring.

Failure to follow these instructions may lead to

future leaks. When a 1/4” tube is fully engaged,

11/16” of the tube has entered the fitting. When

a 3/8” tube is fully engaged, 3/4” of the tube has

entered the fitting. Mark tube with a piece of

tape or marker.

2. If additional tubing is required, see parts list at

the end of this manual.

Collet O-Ring

Tube Partially Engaged

Collet O-Ring

Tube Fully Engaged

TO DISCONNECT TUBES (If necessary)

1. Push the collet inward with a finger tip.

Collet (depress to

remove tubing)

Tubing

2. Continue holding collet inward while pulling the

tubing out.

MAKE TUBING CONNECTIONS

YELLOW TUBE

from Reverse Osmosis assembly to

storage tank

1. Locate the 3/8” yellow tube and cut one end

square. See above.

2. Insert all the way into the yellow collet fitting on

the Reverse Osmosis assembly.

3. Route the other end of this tube to the fitting on

top of the storage tank.

4. Cut tube square and to length.

5. Do not connect at this time. This will occur in

the sanitizing step.

16

GREEN TUBE

from cold water supply pipe to

Reverse Osmosis assembly

1. Locate the 1/4” green tube and cut one end

square.

2. Connect to cold water supply fitting. See “Feed

Water Supply” illustrations on page 11.

3. Route the other end of this tube to the green

collet fitting on the Reverse Osmosis assembly.

4. Cut tube square and to length.

5. Insert all the way into the fitting.

6. Pull on the tube to be sure it is held firmly in the

fitting.

Page 17

Installation Instructions

MAKE TUBING CONNECTIONS (Cont.)

Water Supply

Fitting

HOT COLD

Ta nk

Connector

Drain

Adapter

Sink

P–Trap

3/8” Yellow

Tube

INSTALATION INSTRUCTIONS

RO Product

Water Faucet

3/8” Black

Tube

1/4” Red

Tube

3/8” Blue

Tube

1/4” Green

Tube

Storage Tank Reverse Osmosis Assembly

BLUE TUBE

from Reverse Osmosis faucet to

Reverse Osmosis assembly

1. Locate the 3/8” blue tube attached to the faucet.

2. Route the loose end of this tube to the blue

collet fitting on the Reverse Osmosis assembly.

3. Cut tube square and to length.

4. Insert all the way into the fitting.

5. Pull on the tube to be sure it is held firmly in the

fitting.

BLACK TUBE

from Reverse Osmosis faucet to

drain adapter

1. Locate the 3/8" black tube attached to the

faucet.

2. The loose end needs to be attached to the quick

connect fitting on the sink drain adapter.

Red Collet

Yellow Collet

Green Collet

Blue Collet

3. Cut this tube as needed to route it as straight as

possible, without loops, dips, or kinks.

4. Cut the end of the tube square.

5. Insert all the way into the fitting.

6. Pull on the tube to be sure it is held firmly in the

fitting.

RED TUBE

f

rom Reverse Osmosis faucet to

Reverse Osmosis assembly

1. Locate the 1/4” red tube attached to the faucet.

2. Route the loose end of this tube to the red collet

fitting on the Reverse Osmosis assembly.

3. Cut tube square and to length.

4. Insert all the way into the fitting.

5. Pull on the tube to be sure it is held firmly in the

fitting.

17

Page 18

Installation Instructions

SANITIZE THE SYSTEM

SANITIZING THE SYSTEM

Sanitizing is recommended immediately after

installation of the Reverse Osmosis system. It Is

also recommended after servicing inner parts. It is

important that the person installing or servicing the

system have clean hands while handling inner

parts of the system.

Complete the following steps to sanitize the

system.

1. Make sure that the water supply to the Reverse

Osmosis system is off.

2. Open the Reverse Osmosis faucet. If the tank

is not already empty, allow the water to empty.

3. Locate the included eyedropper and common

household bleach (5.25%).

INSTALATION INSTRUCTIONS

Yellow

Tube

Tank

Connector

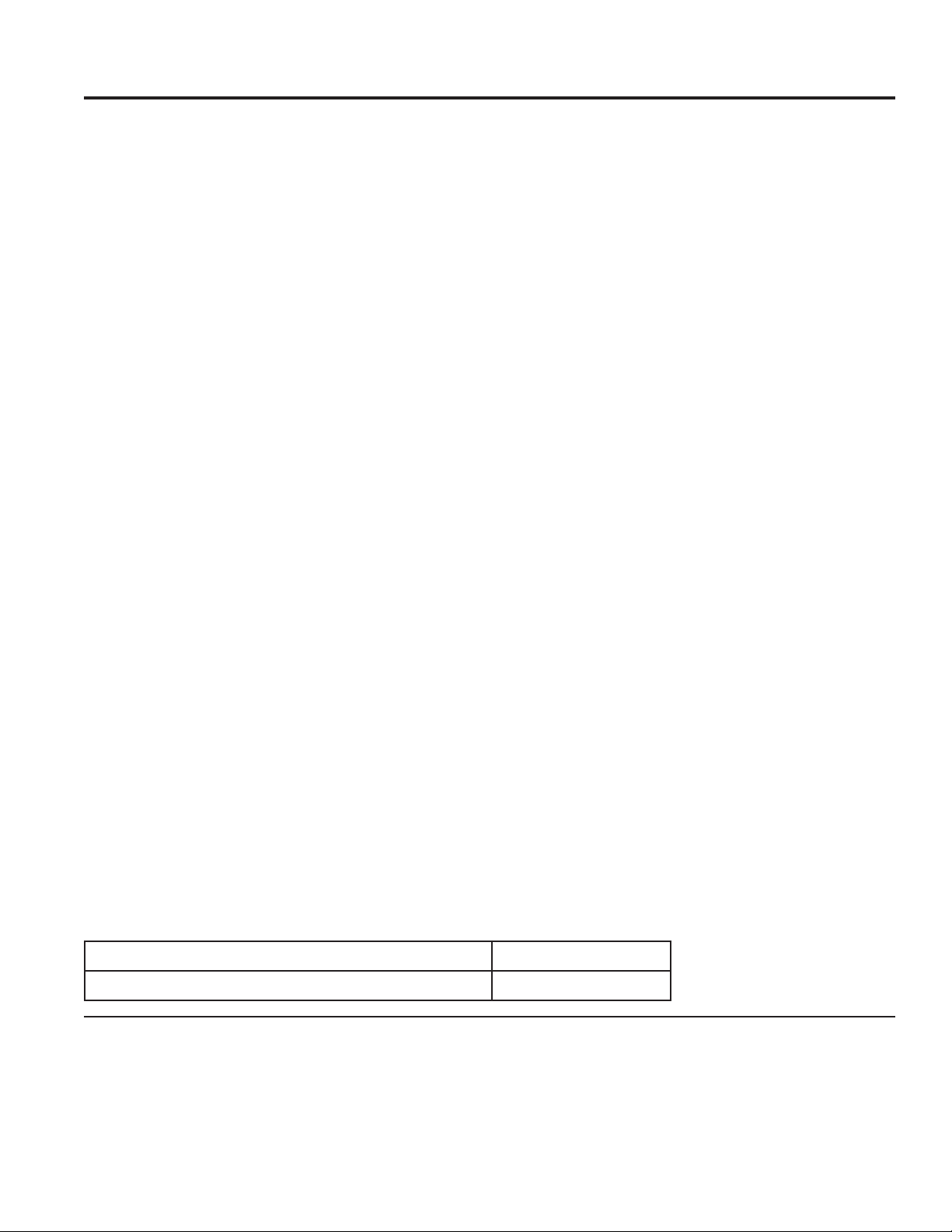

OPTIONAL SANITIZING KIT

The reusable sanitizing kit (P/N WS35X22001), not

included) is recommended to easily and completely

sanitize the Reverse Osmosis system annually.

Prefilter

Sanitization

Cartridge

RO

Sanitization

Cartridge

Postfilter

Sanitization

Cartridge

The kit includes the following:

• Prefilter sanitization cartridge

(contains no filtration media)

• Postfilter sanitization cartridge

(contains no filtration media)

• RO sanitization cartridge

(contains no RO membrane)

• Syringe, 1 oz.

• Complete instructions

18

4. Add 3 ml. of bleach into open end of yellow

tube. Handle bleach according to bleach

manufacturer’s recommendations.

5. Connect yellow tube to tank connector.

6. Sanitizing the system will be completed during

the pressure test and purging steps on the

following page.

NOTE: The bleach must be removed from the

system before drinking the water. See

purging instructions, following.

Uses standard 5.25% household bleach (not

included) to completely sanitize the Reverse

Osmosis system.

To order, call toll-free GE Appliances Parts and

Services at 877.959.8688.

Page 19

Installation Instructions

TEST AND PURGE THE SYSTEM

INSTALATION INSTRUCTIONS

PRESSURE TEST THE SYSTEM

NOTE: Complete the sanitizing procedure on the

preceding page before pressure testing.

To pressure test the system, complete the

following steps.

1. Open the water supply valve to the Reverse

Osmosis system (see illustration below).

2. Purge air from the house plumbing by opening

several house faucets. Close faucets when

water runs smooth, with no spurting.

3. Pressure will start to build in the RO system. In

about 2 hours check all fittings and connections.

Check for water leaks. Fix leaks if any are

found. If problems exist, refer to the

troubleshooting chart or call the toll free number

below it.

NOTE: When the system is first pressurized, water

may “'spurt”' from the faucet air gap hole

until air is expelled from the RO system.

Reverse

Osmosis

Kitchen

Faucet

Cold Water

Supply

Storage

Tank

Water Supply Shutoff

Valve to Reverse

Osmosis System

Faucet

HOT COLD

PURGE THE SYSTEM

To purge the system, complete the following steps.

1. Open the Reverse Osmosis faucet and let water

flow through the system for a 24 hour period.

Water flow will be a slow trickle at this time.

NOTE: Do not consume water from the RO system

until purging is complete.

2. Close the Reverse Osmosis faucet after the 24

hour purging period is complete.

3. When the purging is finished, your Reverse

Osmosis system is ready for use.

NOTE: As with all other water system applications,

leaks may occur. Because the system

pressure builds slowly, leaks may not be

immediately apparent. Recheck for leaks

24 hours after purging the system is

complete.

OPERATING FEATURES

Please review the following operating

features before using the Reverse

Osmosis system:

• Filtered water will not be available

immediately. It may take several hours to

fill the storage tank and create maximum

flow from the Reverse Osmosis faucet.

• Water Pressure from the Reverse Osmosis

faucet will be less than with a standard

faucet.

• Water will run to the drain while the

Reverse Osmosis system is producing

water, even when water is not being drawn

from the Reverse Osmosis faucet. A small

quantity of water may be heard trickling to

the drain at times when water is not being

drawn from the faucet. This is normal.

Water will automatically stop going to the

drain when the storage tank is full.

19

Page 20

Care and Cleaning

CARTRIDGE LIFE AND REPLACEMENT

PREFILTER / POSTFILTER CARTRIDGE

LIFE

NOTE: It is recommended to replace the battery,

prefilter and postfilter cartridges at least every

6 months of product water use. Replace more

often if they begin to plug with sediment.

The prefilter and postfilter are replaceable sediment

cartridges with activated carbon in their composition.

The prefilter and postfilter cartridges must be

periodically replaced. This will protect the RO

membrane from being destroyed by chlorine. It will

also prevent the filters from plugging with sediment.

Slower output of product water may be noticed as the

prefilter and postfilter build up with sediment. Replace

the prefilter and postfilter cartridges when this occurs.

Replace the faucet battery whenever you replace the

cartridges.

PREFILTER / POSTFILTER CARTRIDGE

REPLACEMENT (every 6 months)

Complete the following steps to replace the prefilter

and postfilter cartridges.

1. Remove (turn counterclockwise) the prefilter

cartridge from the manifold. Then remove the

postfilter cartridge.

2. Discard the cartridges in a proper manner.

3. Install new cartridges in reverse order: postfilter first,

then prefilter. Turn cartridges clockwise to reattach

to the manifold. Do not overtighten.

4. Remove and replace the faucet timer battery. See

next page for instructions.

5. Purge the Reverse Osmosis system. See previous

page for instructions.

REVERSE OSMOSIS MEMBRANE CARTRIDGE

LIFE

The Reverse Osmosis cartridge is a tightly wound

special membrane. The membrane reduces the

dissolved solids and organic matter. The life of the

Reverse Osmosis membrane cartridge depends mostly

on the pH and hardness of the supply water (see

Specifications). Cartridge life is shorter with higher

pH. For example, if supply water pH is from 6.8 to 7.7,

the cartridge may last for well over one year.

However, cartridge life may be as short as 6 months if

the pH is as high as 8.5 to 10. Higher pH weakens the

cartridge membrane and causes pinhole leaks. It Is

time to replace the Reverse Osmosis cartridge when

the production rate and/or quality of product water

drops. Product water may begin to taste different,

indicating solids and organics are passing through the

Reverse Osmosis membrane. See Reverse Osmosis

cartridge replacement.

REVERSE OSMOSIS MEMBRANE CARTRIDGE

REPLACEMENT

Complete the following steps to replace all cartridges

when replacing the RO membrane.

1. Remove (turn counterclockwise) the prefilter

cartridge from the manifold to stop flow to the

Reverse Osmosis cartridge.

2. Remove the Reverse Osmosis cartridge.

3. Remove the postfilter cartridge.

4. Discard the cartridges in a proper manner.

5. Install new cartridges in reverse order: postfilter,

Reverse Osmosis and then prefilter. Turn cartridges

clockwise to reattach to the manifold. Do not

overtighten.

6. Remove and replace the faucet timer battery. See

next page for instructions.

7. Purge the Reverse Osmosis system. See previous

page for instructions.

To obtain replacement filters, call toll-free GE Appliances Parts and Services at 877.959.8688, or

visit the store where you purchased your reverse osmosis system.

Prefilter / Postfilter Cartridge Replacement FQ18PN Carbon Block

CARE AND CLEANING: Cartridge Maintenance and Replacement

Reverse Osmosis Cartridge Replacement FQ18MN Thin Film Polyamide

THE WATER TEST KIT

To obtain an independent laboratory water test kit, please call Legend Technical Services at 1.800.949.8220 and

leave your contact details. They will contact you to find out what water tests you are interested in, and inform you of

the cost of the testing. You will then receive a kit that will include all necessary tests to properly indicate the

performance level of your system. Product water should be tested a minimum of every six months.

NOTE: When the TDS reduction of the system falls below 75%, it is time to replace the reverse osmosis cartridge in

addition to the prefilter and postfilter.

20

Page 21

Care and Cleaning

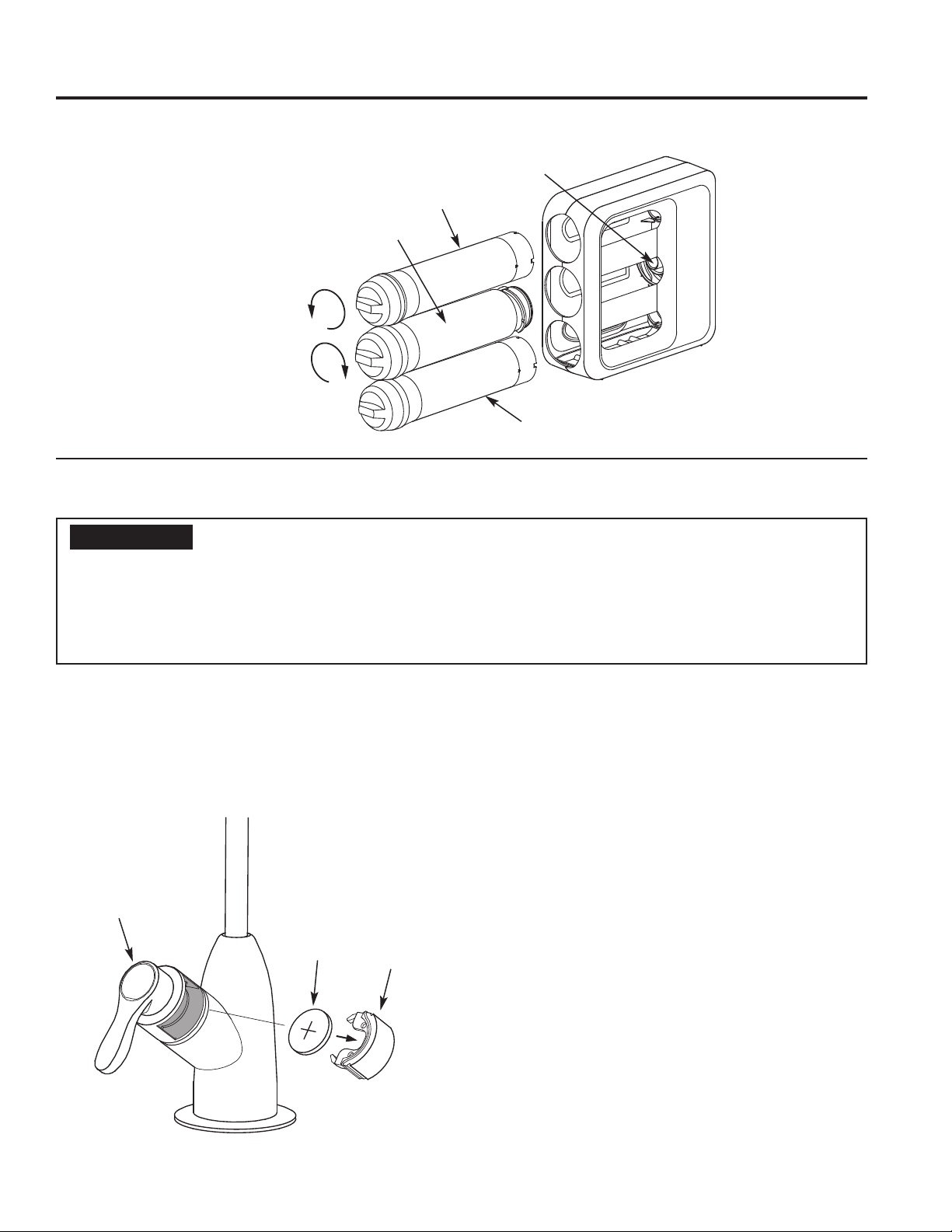

CARTRIDGE REPLACEMENT (Cont.)

CARE AND CLEANING: Cartridge Replacement and Faucet Battery

Prefilter

Cartridge

RO

Cartridge

Turn filter cartridges

counterclockwise

to remove from manifold

Turn filter cartridges

clockwise

to attach to manifold

Manifold

Postfilter

Cartridge

CHANGE FAUCET BATTERY

WARNING

■ Keep batteries away from children. This product contains a lithium button cell battery. If a new or used lithium

button cell battery is swallowed or enters the body, it can cause severe internal burns and can lead to death in

as little as 2 hours. If you think batteries might have been swallowed or placed inside any part of the body, seek

immediate medical attention. Always completely secure the battery compartment. If the battery compartment

does not close securely, stop using the product, remove the battery and keep it away from children. Properly

dispose of used batteries, keeping them away from children.

Chemical Burn Hazard:

A new battery is included with the replacement prefilter

/ postfilter cartridge kit. Always change the battery, as

shown below, when replacing the prefilter/ postfilter

cartridges (every 6 months).

1. Locate the battery holder cover on the RO product

water faucet’s handle.

Faucet

Handle

Battery

(CR 2032)

Battery

Holder

Cover

2. Grip the cover by the gaps at each side, and firmly

pull it all the way out of the faucet. A screwdriver

may be used to pry up the cover, but be careful not

to scratch or nick the finish.

3. Pull the old battery out of the holder and replace it

with the new battery from the replacement prefilter /

postfilter cartridge kit (Lithium CR 2032 button battery

or equivalent). Place battery into the holder with the

positive (+) side facing up, or away from the faucet’s

base.

4. Slide the battery holder back into the opening in the

faucet’s handle, making sure it is oriented correctly

(it will not fit if upside-down). Push it all the way in

until the cover is flush.

5. When the battery is installed, the faucet LED will

briefly flash red then blue. The timer begins its 6

month countdown. Whenever the faucet handle is

operated, the blue LED will light for a few seconds.

The LED will not light if the battery was placed into

the holder upside-down.

21

Page 22

Care and Cleaning

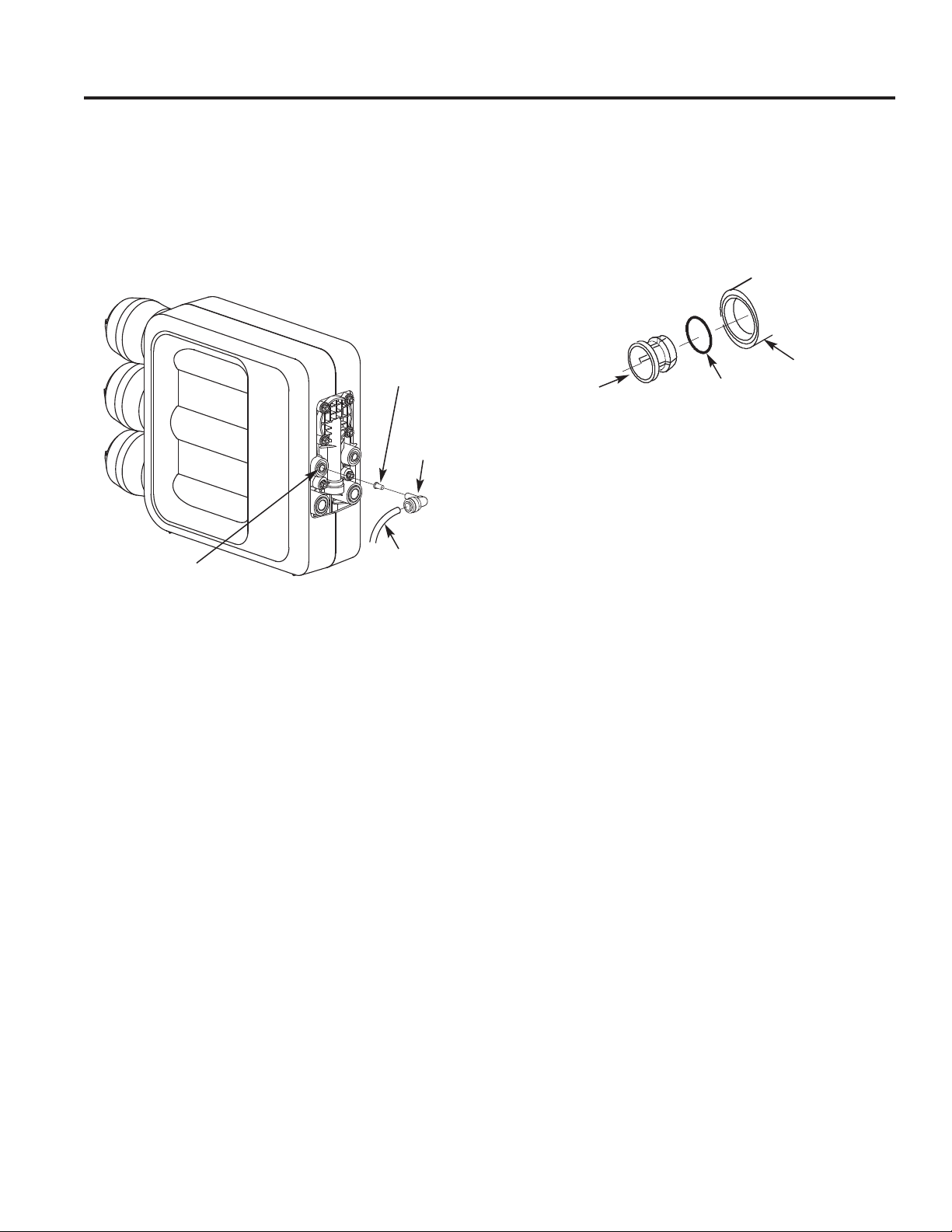

DRAIN FLOW CONTROL

The flow control is required for proper operation of the

Reverse Osmosis system. See illustration below. The

flow control, located inside the push-in elbow fitting on

the drain port of the Reverse Osmosis assembly,

keeps water flowing through the membrane at the

required rate. This ensures that the system produces

the best quality product water.

Flow Control

Insert

Push-in

Elbow

Fitting

Drain Port

1/4” Red

Tubing to Drain

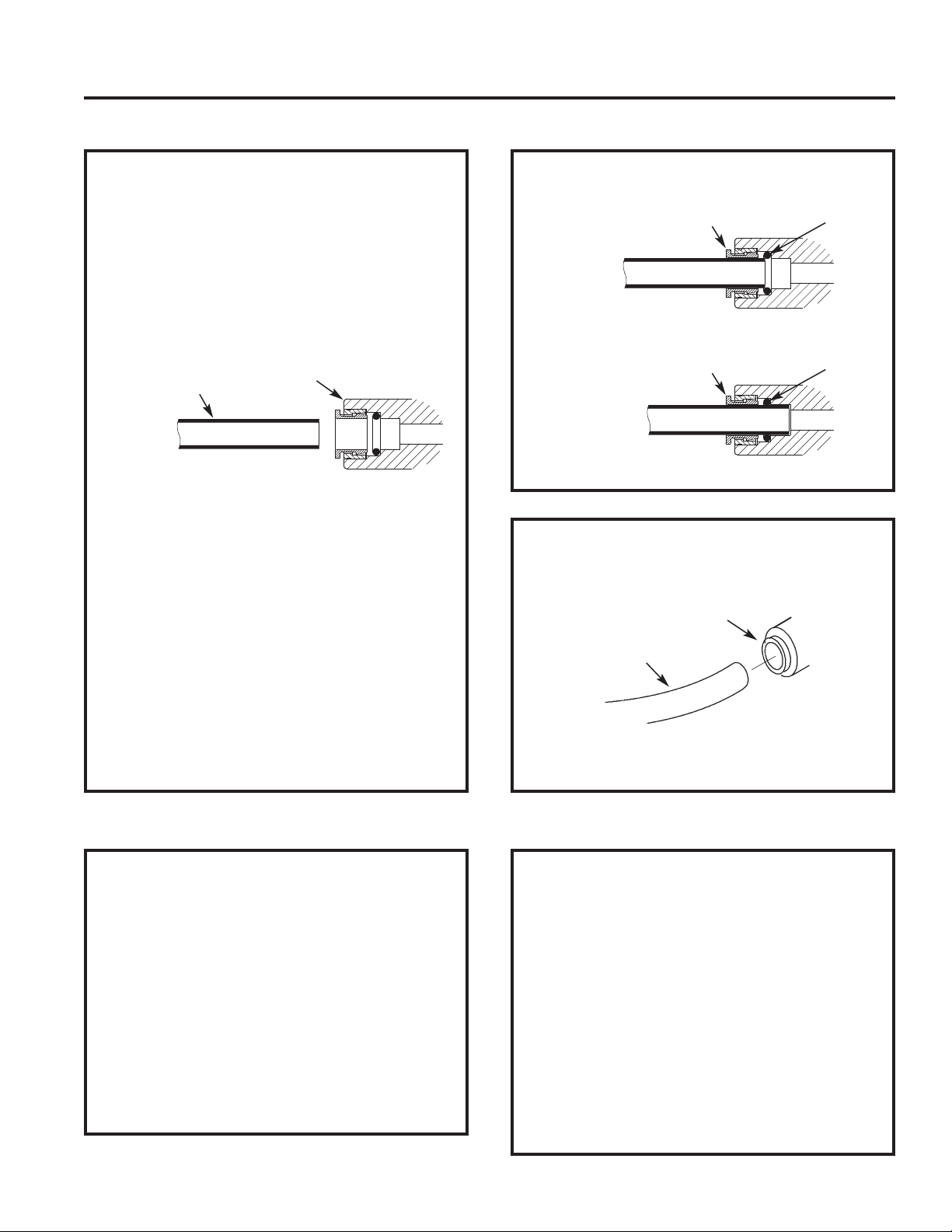

ASSEMBLING COLLET AND O-RING

1. Remove the collet and o-ring from the fitting with a

small screwdriver. Do not scratch the internal walls

of the fitting port.

2. Clean collet port, lubricate with silicone-based

lubricant, and insert the o-ring seal into the bottom

of the port.

Fitting Port

Collet

3. Push the collet inward until it locks in place.

O-Ring Seal

Periodically check the flow control to be sure the small

hole through it is clean and unrestricted.

If the flow control requires service, review the

CARE AND CLEANING: Drain Flow Control

exploded view above. Assemble and disassemble as

shown. If the flow control remains in the manifold

when the push-in elbow fitting is removed, it will be

necessary to remove the drain port’s collet and o-ring,

as shown in the next section, to retrieve it.

22

Page 23

Troubleshooting Tips... Before you call for service

Save time and money! Review the following chart first and you may not need to call for service.

Problem Possible Causes What To Do

Water has air bubbles

and is cloudy

Indicator light on

faucet handle not

working

Chlorine taste and/or

odor in the Reverse

Osmosis product

water

Other taste and/or

odor

Water leaking from

faucet air gap hole

System makes

product water slowly

No water

Leaks at fittings

Sounds you may hear

Air in system after installation. Will go away after it runs for a while.

Battery installed incorrectly. Observe orientation on page 21 and install correctly.

Battery is dead. Replace with new Lithium CR 2032, 3-volt battery.

The ppm of chlorine in your water

supply exceeds maximum limits

and has destroyed the Reverse

Osmosis membrane.

The prefilter is no longer reducing

chlorine from the water supply.

High quality product water may

have a different taste than what

you’re used to.

Low water usage. Completely drain system and allow to refill.

Contamination in product water

storage.

Prefilter and postfilter need to be

changed.

Drain side of faucet air gap (3/8”

tubing) plugged, restricted or

incorrectly connected to the

drain.

This is normal. Water flow rate will be lower than a regular faucet. It takes

Water supply to the Reverse

Osmosis system not within

specifications.

Prefilter cartridge plugged with

sediments.

Reverse Osmosis membrane

plugged with sediments.

Water supply valve not turned on. Turn water supply valve on. See illustration on page 19.

After filter change, tank is empty. It takes several hours for RO system to provide enough water

Improperly installed. Reinstall. See Installation Instructions.

Sink drain, drain water from

system.

Faucet air gap drain water flowing

through the faucet air gap. This

may be associated with high

pressure water supply, generally

80 psi or greater.

If the water supply contains more than 2.0 ppm of chlorine,

additional filtering of the water supply to the Reverse Osmosis

is needed. Correct this condition before doing maintenance on

the Reverse Osmosis system.

Replace the Reverse Osmosis membrane cartridge, prefilter,

postfilter and battery in the faucet handle.

This is normal.

Use sanitizing procedure.

Replace the prefilter and postfilter. Sanitize system.

Inspect and eliminate restriction or plug. It is important that

there are no dips, loops or low spots in the drain line from the

faucet air gap to the drain pipe. Refer to Installation Instructions

for proper drain connection. If drain line adapter was used as

the drain point, periodic inspection/cleaning is recommended.

several hours to fill the tank.

Increase water pressure, precondition the water, etc., as

needed to conform before doing maintenance on the Reverse

Osmosis system.

Replace the prefilter. If rate does not increase, replace the

postfilter, Reverse Osmosis membrane cartridge and battery in

the faucet handle.

Replace Reverse Osmosis membrane cartridge and battery in

the faucet handle.

to fill the tank.

This is normal.

Drain line can be installed to an alternate drain, such as a

basement drain. See page 13 for alternate drain

configurations.

Install a pressure regulator in the house water supply system to

reduce the pressure below 80 psi.

TROUBLESHOOTING TIPS

If you are still having trouble, please visit www.GEAppliances.com/ge/service-and-support/contact.htm or

call us at 800.626.2005.

23

Page 24

Parts List

PARTS LIST

2

3

GXRQ18NBN and GNRQ18NBN

1

4

5

11

12

8

9

10

6

7

13

15

14

24

Page 25

Parts Catalog

PARTS CATALOG

QUANTITY

G

X

R

Q

1

GE

REF.

NO.

0001 WS19X21938 CABINET ASSEMBLY, LEFT HALF, RIGHT HALF,

0002 FQ18PN PRE AND POST FILTER CARTRIDGE SET,

0003 FQ18MN RO CARTRIDGE 1 1

0004 WS19X21937 MANIFOLD ASSEMBLY

0005 WS03X21933 DIAPHRAGM KIT 1 1

0006 WS15X21935 CHECK VALVE KIT 1 1

0007 WS15X21932 AUTOMATIC SHUTOFF KIT 1 1

0008 WS15X21988 COLLET KIT, 1/4” (SET OF 2) 1 1

0009 WS15X21989 COLLET KIT, 3/8” (SET OF 2) 1 1

0010 WS02X21934 FLOW CONTROL KIT 1 1

0011 WS32X10012 STORAGE TANK 1 1

0012 WS22X21939 TANK CONNECTOR 1 1

0013 WS15X21941 FAUCET 1 1

0014 WS18X21940 DRAIN ADAPTER 1 1

0015 WS18X21936 WATER SUPPLY FITTING 1 1

0016 WS35X22001 SANITIZATION KIT (OPTIONAL - SEE SANITIZING

0017 WS35X22002 AUXILIARY STORAGE TANK (OPTIONAL -

0018 WS07X10006 TUBING, 1/4” O.D. X 20 FEET LONG, WHITE

0019 WS07X10008 TUBING, 3/8” O.D. X 20 FEET LONG, WHITE

0020 WS01X22003 DROPPER 1 1

0999 Manual Online OWNER’S MANUAL & INSTALLATION

APPLIANCES

PART NO. PART DESCRIPTION

AND DRIP TRAY

INCLUDING BATTERY (NOT SHOWN)

(INCLUDES REF. NO. 0001 AND 0005 THRU 0009)

INSTRUCTIONS FOR ILLUSTRATION)

INCLUDES REF. NO. 0011 AND FITTINGS TO

PLUMB IN PARALLEL WITH ORIGINAL TANK)

(OPTIONAL FOR REMOTE INSTALLATION)

(OPTIONAL FOR REMOTE INSTALLATION)

INSTRUCTIONS

8

N

B

N

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

G

N

R

Q

1

8

N

B

N

25

Page 26

GE Appliances Reverse Osmosis System Warranty

GEAppliances.com

All warranty service provided by our SmartWater™ Authorized Servicer Network. To schedule service, contact us

toll free at 800.GE.CARES. Please have serial number and model number available when calling for service.

For the period of GE Appliances will replace

WARRANTY

One year

from the date of the original purchase

What GE Appliances will not cover

■ Service trips to your home to teach you how to use

the product.

■ Improper installation, delivery, or maintenance.

■ Failure of the product if it is abused, misused,

modified, or used for other than the intended

purpose or used commercially.

■ Use of this product where water is microbiologically

unsafe or of unknown quality, without adequate

disinfection. Systems certified for cyst reduction

may be used on disinfected water that may contain

filterable cysts.

Any part of the Reverse Osmosis Filtration System which fails due to a

defect in materials or workmanship.

■ Filter cartridges, membrane cartridges and batteries

after 30 days from date of purchase.

■ Damage to the product caused by accident, fire,

floods or acts of God.

■ Incidental or consequential damage caused by

possible defects with this appliance.

EXCLUSION OF IMPLIED WARRANTIES

Your sole and exclusive remedy is product repair as provided in this Limited Warranty. Any implied warranties,

including the implied warranties of merchantability or fitness for a particular purpose, are limited to one year or

the shortest period allowed by law.

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home use

within the USA. If the product is located in an area where service by a GE Appliances Authorized Servicer is not

available, you may be responsible for a trip charge or you may be required to bring the product to an Authorized GE

Appliances Service location for service. In Alaska, the warranty excludes the cost of shipping or service calls to your

home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state. To know what your legal

rights are, consult your local or state consumer affairs office or your state’s Attorney General.

Warrantor: GE Appliances

date is needed to obtain service under the warranty.

Staple your receipt here. Proof of the original purchase

26

Page 27

Notes

NOTES

27

Page 28

Consumer Support

GE Appliances Website

Have a question or need assistance with your appliance? Try the GE Appliances Website 24 hours a day, any day

of the year! You can also shop for more great GE Appliances products and take advantage of all our on-line support

services designed for your convenience. In the US: GEAppliances.com

Register Your Appliance

Register your new appliance online at your convenience! Timely product registration will allow for enhanced

communication and prompt service under the terms of your warranty, should the need arise. You may also mail in

the pre-printed registration card included in the packing material. In the US: GEAppliances.com/register

Schedule Service

Expert GE Appliances repair service is only one step away from your door. Go online and schedule your service at

your convenience any day of the year. In the US: GEAppliances.com/ge/service-and-support/service.htm or

call 800.432.2737 during normal business hours.

CONSUMER SUPPORT

Extended Warranties

Purchase a GE Appliances extended warranty and learn about special discounts that are available while your

warranty is still in effect. You can purchase it online anytime. GE Appliances Services will still be there after your

warranty expires. In the US: GEAppliances.com/ge/service-and-support/shop-for-extended-service-plans.htm

or call 800.626.2224 during normal business hours.

Parts and Accessories

Individuals qualified to service their own appliances can have parts or accessories sent directly to their homes

(VISA, MasterCard and Discover cards are accepted). Order online today 24 hours every day. In the US:

GEAppliances.com or call 877.959.8688 during normal business hours.

Instructions contained in this manual cover procedures to be performed by any user. Other servicing

generally should be referred to qualified service personnel. Caution must be exercised, since improper

servicing may cause unsafe operation.

Contact Us

If you are not satisfied with the service you receive from GE Appliances, contact us on our Website with all the

details including your phone number, or write to:

In the US: General Manager, Customer Relations | GE Appliances, Appliance Park | Louisville, KY 40225

GEAppliances.com/ge/service-and-support/contact.htm

28

Printed in the United States

Loading...

Loading...