GE GTDL740EDWW, GHDS830GDWS, GTDL740GDWW, GTDP740EDWW, GTDP740GDWW Technical Service Manual

...Page 1

GE Appliances

Technical Service Guide

December 2012

GE CleanSpeak™

Dryers

GHDS830EDWS/GDWS

GHDS835EDMC/GDMC

GTDL740EDWW/GDWW

GTDP740EDWW/GDWW

GTDS810EDWS/GDWS

GTDS815EDMC/GDMC

GTDS820EDWS/GDWS

GTDS825EDMC/GDMC

GTDS850EDWS/GDWS

GTDS855EDMC/GDMC

Sanitized

Normal

Mixed Loads

Jeans

Cottons

Quick Flu

No Heat

Timed Dry

STEAMselect

Select Steam Cycle and PUSH “STEAMselect” for garment amount

1 to2 3 to5 6 to7 8 to13

Casuals

Permanent Press

Active Wear

Delicates

Steam Refresh

Steam Dewrinkle

Towels / Sheets

Bulky Items

Quick Dry

Drum

High

Extra Dry

90 ~ 99

Medium

More Dry

70 ~ 80

L CYCLE TIME

TOTA

TED

ESTIMA

Low

Dry

DRYING

50 ~ 60

CLEAN

ER

T

LINT FIL

DAMP

Less Dry

Extra Low

30 ~ 40

COOL

DOWN

DELAY

No Heat

Damp

10 ~ 20

DRY

Energy Smart

Time TempLevel

Damp

Use Timed Dry

Rack

Extended

Delay

Cycles Only

Alert

Dry

Tumble

y

Dr

Hold 3 seconds

to CANCEL

t

Good Bes

Dry

monitor

e

GTDS860EDWS/GDWS

GTDS865EDMC/GDMC

31-9228

GE Appliances

General Electric Company

Louisville, Kentucky 40225

Page 2

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by individuals possessing

adequate backgrounds of electrical, electronic, and mechanical experience. Any

attempt to repair a major ap pli ance may result in personal injury and property

damage. The man u fac tur er or seller cannot be responsible for the in ter pre ta tion

of this in for ma tion, nor can it assume any liability in connection with its use.

WARNING

If the information in this manual is not followed exactly, fi re or ex plo sion may result

causing property damage, personal injury or death. If you smell gas:

– Do not try to light any appliance.

– Do not touch any electrical switch; do not use any phone in the building.

– Immediately call the gas supplier from a neighbor’s phone. Follow the

gas supplier’s instructions.

– If you cannot reach the gas supplier, call the fi re department.

WARNING

To avoid personal injury, disconnect power before ser vic ing this prod uct. If electrical

power is required for di ag no sis or test pur pos es, disconnect the power immediately

after per form ing the nec es sary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to complete a path

to ground are removed for service, they must be returned to their original position

and properly fastened.

GE Appliances

Technical Service Guide

Copyright © 2012

All rights reserved. This service guide may not be reproduced in whole or in part in

any form without written permission from the Gen er al Electric Com pa ny.

– 2 –

Page 3

Table of Contents

Back Panel ............................................................................................................................................................................30

Belt Switch............................................................................................................................................................................23

Blower Wheel ...................................................................................................................................................................... 23

Burner Assembly and Gas Conversion ...................................................................................................................26

Component Locator Views ...........................................................................................................................................14

Control Board Assembly ...............................................................................................................................................34

Control Board Connector Locator View ................................................................................................................. 16

Control Features ................................................................................................................................................................. 6

Control Panel.......................................................................................................................................................................17

Diagnostics from the Board ......................................................................................................................................... 40

Door Switch .........................................................................................................................................................................19

Drive Belt and Drum ........................................................................................................................................................ 20

Drum Motor .........................................................................................................................................................................24

Drum Rollers ........................................................................................................................................................................ 21

Dryer Components...........................................................................................................................................................17

Dryer Model Codes ..........................................................................................................................................................38

Error Codes .......................................................................................................................................................................... 39

Flame Detector ..................................................................................................................................................................28

Front Bulkhead ..................................................................................................................................................................19

Front Panel ........................................................................................................................................................................... 18

Gas Valve .............................................................................................................................................................................26

Gas Valve Coils ...................................................................................................................................................................27

Heater Assembly ...............................................................................................................................................................25

High Limit Thermostat ....................................................................................................................................................32

Ignitor .....................................................................................................................................................................................28

Ignitor Circuit Operation ................................................................................................................................................29

Inlet Control Thermistor .................................................................................................................................................32

Inlet Safety Thermostat ................................................................................................................................................. 31

Introduction ............................................................................................................................................................................5

LED Drum Light .................................................................................................................................................................. 19

Long Vent Motor ................................................................................................................................................................ 25

Misting Nozzle ....................................................................................................................................................................35

Moisture Sensor ................................................................................................................................................................22

Nomenclature .......................................................................................................................................................................4

Outlet Control Thermistor .............................................................................................................................................33

Outlet Control Thermostat ............................................................................................................................................ 33

Rear Bulkhead ...................................................................................................................................................................30

Reversing the Door Swing ............................................................................................................................................12

Schematics and Wiring Diagrams ............................................................................................................................ 48

Service Test Mode .............................................................................................................................................................37

Steam Components .........................................................................................................................................................35

Top Panel .............................................................................................................................................................................. 18

Troubleshooting ................................................................................................................................................................37

Warranty .............................................................................................................................................................................. 54

Water Valve ......................................................................................................................................................................... 36

– 3 –

Page 4

Model Number

Nomenclature

G T D S 8 6 0 E D O W W

Brand

D = General Electric

Confi guration

T = Top Load

Product

D = Dryer

Key Feature

S = Steam

Technical Sheet

Series

Specifi c Color

WW = White

WS = Silver Backguard

MC = Metallic Carbon

Engineering Digit

Model Year

D = 2012

Fuel

E = Electric

G = Gas

Color

0 = White

5 = Color

Serial Number

The fi rst two characters of the serial number

identify the month and year of manufacture.

Example:

ZZ123456S = December, 2012

Model Number

Nomenclature

Serial Number

The nomenclature tag is lo cat ed on

the front panel inside the door.

Note: The technical sheet is located

inside the control panel.

Z – DEC

A – JAN

D – FEB

F – MAR

G – APR

H – MAY

L – JUN

M –JUL

R – AUG

S – SEP

T – OCT

V – NOV

– 4 –

2012 – Z

2011 – V

2010 – T

2009 – S

2008 – R

2007 – M

2006 – L

2005 – H

2004 – G

2003 – F

2002 – D

2001 – A

The letter des ig nat ing

the year re peats every

12 years.

Example:

Z - 2012

Z - 2000

Z - 1988

Page 5

Introduction

GE CleanSpeak™ Dryer Features

GE CleanSpeak™ model dryers incorporate 2 steam features. These units do not utilize a separate steam

generator. These dryers use a water valve and a steam nozzle that functions as a “misting” orifi ce. It works in

conjunction with the heat generated by the dryer to de-wrinkle clothing.

Located in the Timed Dry Cycles, the steam cycles are:

• Steam Refresh – Freshens up to 5 slightly wrinkled dry garments, reducing wrinkles and odors to extend

for another wear.

• Steam Dewrinkle – Helps remove stubborn wrinkles from larger loads quickly and conveniently, even

from clothes left in the dryer from the day before.

A "Y" connector installed on the washer's cold water inlet hose supplies water to the dryer. The water valve

inlet is located at the bottom left area of the dryer. A hose carries the water to the misting orifi ce.

Other Features Include:

• CleanSpeak™ Communication System – Dryer can communicate with a compatible washer.

• Brillion Enabled Communication – Dryer can communicate with your Home Computer and/or iPhone®.

• 13 dryer cycles – Offer enhanced drying performance and fabric care.

• Energy Smart™ – Enables your dryer to reduce energy consumption during periods of high energy costs.

• HE SensorDry™ – Allows the control to monitor the fabric for moisture content and end the cycle at the

desired moisture level.

• My Settings – Selection saves a favorite cycle for future use.

• Cycle countdown display with LED indicators – Know exactly how much time is left for each cycle with

bright display and lights.

• Large 7.8 and 8.3-cubic foot dryer drum capacities.

• Integrated Drying Rack for drying delicate items, such as

washable sweaters.

• Dual Thermistors – Thermistors are more sensitive to

temperature changes and can relay the information

faster than thermostats. The dryer utilizes dual

thermistors to monitor incoming air temperature, as

well as air temperature leaving the drum. The sensors

work together with the heat and the blower to provide

consistent, even heat.

• LED Drum Lamp.

• Reversible door.

• Long Vent Models – Separate blower motor for long vent

applications.

• Built-in service test mode. Specifi c dryer components can

be operated. Error codes are recorded and accessible on

the control panel display.

– 5 –

Page 6

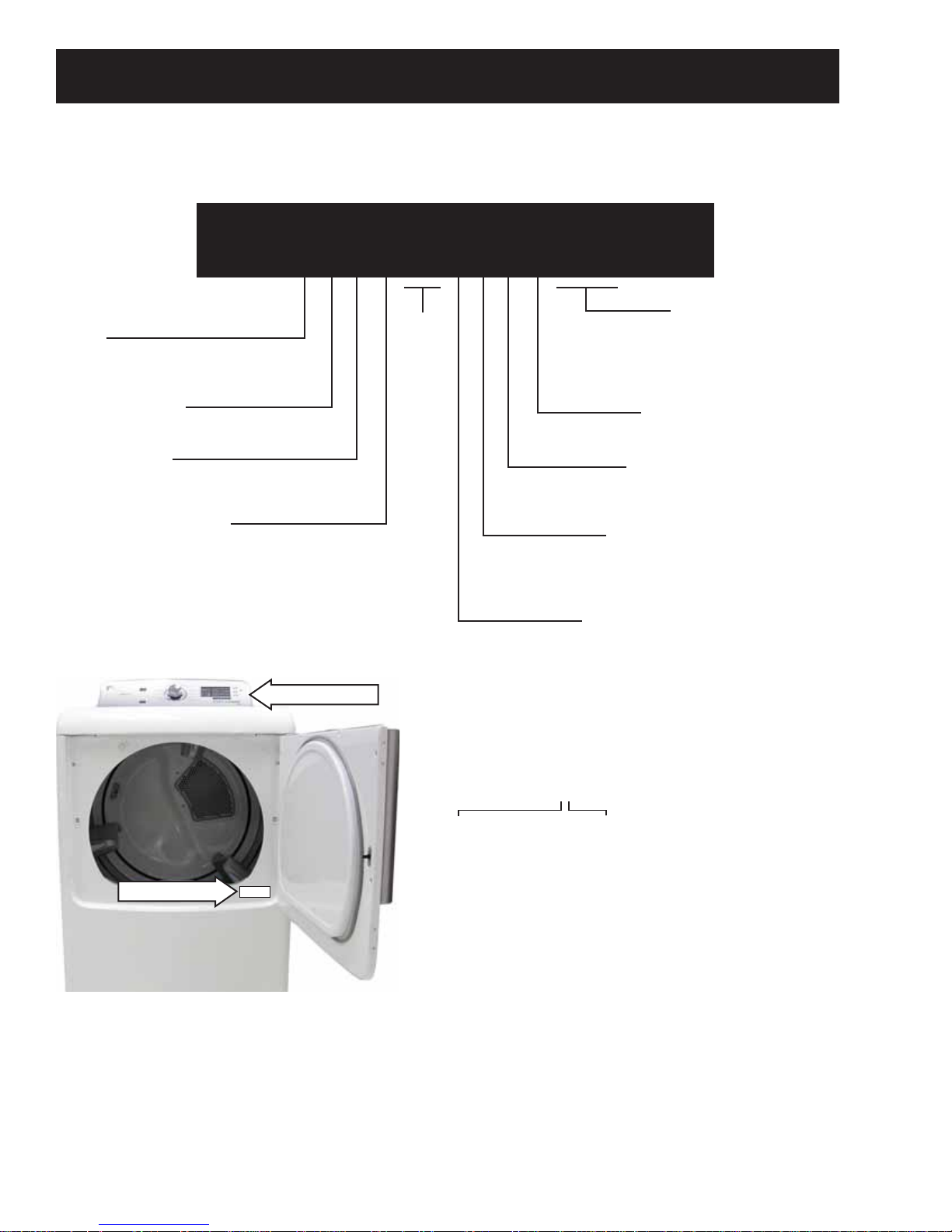

Control Features

Throughout this manual, features and appearance may vary from your model.

Controls

B CD

Sanitized

Towels / Sheets

Bulky Items

Quick Dry

Quick Fluff

No Heat

Timed Dry

Select Steam Cycle and PUSH “STEAMselect” for garment amount

A

Power

A

Press to “wake up” the display. If the display is active, press to put the dryer into idle mode.

Normal

Mixed Loads

Cottons

1 to2 3 to5 6 to7 8 to13

Jeans

STEAMselect

Casuals

Permanent Press

Active Wear

Delicates

Steam Refresh

Steam Dewrinkle

ESTIMATED TOTAL CYCLE TIME

DRYING

DAMP

COOL

DOWN

Energy Smart

E F

CLEAN

LINT FILTER

DELAY

DRY

Delay

Dry

Hold 3 seconds

to CANCEL

Extra Dry

90 ~ 99

70 ~ 80

More Dry

50 ~ 60

Less Dry

30 ~ 40

Damp

10 ~ 20

Time TempLevel

Damp

Extended

Tumble

Good Best

Dry

H

G

Dry

Alert

e

Drum

monitor

High

Medium

Low

Extra Low

No Heat

Rack

Dry

Use Timed Dry

Cycles Only

NOTE: Pressing Power does not disconnect the appliance from the power supply.

Start and Pause

B

Press Start to begin the cycle. NOTE: The door must be closed for the dryer to start the cycle. Pressing Pause will pause the

cycle, the Start will blink and “PAUSE” will scroll across the LCD.

To continue the cycle, press Start again. To stop the cycle, hold the button for 3 seconds.

Display and Status Lights

C

The display shows the approximate time remaining until the end of the cycle.

In addition, this display will, “scroll” the dryer status:

PAUSE The message “PAUSE” will scroll across the display when the dryer’s cycle is paused. The cycle may be

re-started by pressing the Start button.

door The message “door” will be displayed when the door is opened during the dryer’s cycle.

CyCLE The message “CyCLE” will be displayed when the clothes are dry and the washer is recommending a

preferred cycle for the next load (see CleanSpeak section).

dELAY The message “dELAY” will be displayed when the Delayed Dry is initiated. It will be replaced with the

estimated time when cycle starts.

ES Dryer in a delay start (4 hour maximum) awaiting lower energy rates (see About Appliance

Communication - Energy Smart section).

Cycle status lights

Shows whether the washer is in the DRYING, DAMP, or COOL DOWN cycle.

Feature status lights indicate:

The My Settings feature is on for this cycle.

The dryer is locked - will blink once if you press any button or turn the cycle knob.

The signal is on. See the Variable Signal description.

The Energy Smart feature is selected. See About Appliance Communication - Energy Smart section.

The Clean Lint Filter light will stay on for 15 seconds after the cycle stops.

The eDry feature is selected.

A Delay Dry time is set.

– 6 –

(Continued next page)

Page 7

Operating instructions

Drying Cycles-Sensor cycles automatically determine fabric dryness.

D

Timed cycles run for the selected time.

Timed Dry

Quick Fluff/ For freshening or fluffing up already dry clothing, fabric, linens and pillows. Use with No Heat.

No Heat Provides 10 minutes of no-heat tumbling.

Quick Dry For small loads that are needed in a hurry, such as sport or school uniforms. Can also be used if the

previous cycle left some items damp, such as collars or waistbands. NO TE: On some models, the time

remaining in the cycle will show counting down in the display.

Bulky Items For large coats, bed spreads, mattress covers, sleeping bags and similar large/bulky items such as

blankets, comforters, jackets, and small rugs.

Towels/Sheets* For most towels and linens.

Cottons* For cottons and most linens.

Normal/Mixed For loads consisting of cottons and poly-blends.

Jeans* For jeans.

Permanent Press*

Active Wear For sports and exercise wear.

Delicates For delicate items, special-care fabrics and knits.

Steam Refresh For slightly wrinkled dry garments. Significantly reduces wrinkles.

NOTE: A single extremely light fabric item may need to have an additional item included in

the Steam Refresh cycle to achieve optimum results.

Steam Dewrinkle For use with larger loads than Steam Refresh. Ideal for loads left in the dryer for an extended time.

STEAMselect The STEAMselect button is used in conjunction with Steam Refresh and Steam Dewrinkle. As you

press the button, it defines how many articles are in the dryer and adjusts the steam and cool down

times accordingly.

Steam Cycle ( & ) Notes:

Sanitized This option reduces certain types of bacteria by 99.9%, including: Staphylococcus aureus, Pseudomonas

aeruginosa and Klebsiella pneumoniae**. The anti-bacterial process occurs when high heat is used

during a portion of the drying cycle.

Sanitization Performance of

Residential Clothes Dryers

NOTE: The Sanitized cycle locks on (i.e. cannot be turned off) the Extra Rinse option.

NOTE: Do not use this cycle on delicate fabrics.

*Cycles available with Sanitized option.

**The Sanitized Cycle is Certified by NSF International (formerly National Sanitation Foundation) to NSF Protocol P154

Sanitization Performance of Residential Clothes Dryers.

Loads*

Casuals/ For wrinkle-free, permanent press, delicate items and knits.

Important - The temperature setting must be set to HIGH and water must be turned on before running the steam cycles.

The Extended Tumble option will be turned on.

After the steam cycle, th e unit will beep (if Variable Signal is on) and display “00”.

Do not use a steam cycle with items such as wool, leather, silk, lingerie, foam products or electric blankets.

Do not use steam cycles on new clothes without first washing.

Steam cycles are not intended for use with towels.

NSF Protocol P154

Set the Cycle Selector at the desired drying time.

Settings

E

Individual settings for Timed Dry cycle minutes (Time), dryness level (Level), and temperature (Temp) can be set from

the minimum (lowest in column) to maximum (highest in column). In general, the higher up the column, the more

energy will be used.

Time - Selection only for Timed cycles.

Each “setting” allows you to specify a lower (1 tap) or an upper (2 taps) time working your way from a

minimum 10 minute to a maximum 99 minute dry time (10, 20, 30, 40, . . . 80, 90, 99, 10 . . .)

Dryness Level - Selection only used for Sensor cycles. Timed cycles run for the selected time.

Extra Dry Use for heavy-duty fabrics or items that should be very dry, such as towels.

More Dry Use for heavy-duty or mixed type fabrics.

Dry Use for a normal dryness level suitable for most loads. This is the preferred cycle for energy savings.

Less Dry Use for lighter fabrics.

Damp

6

For leaving items partially damp.

– 7 –

(Continued Next Page)

Page 8

Temperature

E

High For regular to heavy cottons.

NOTE: Steam Dewrinkle and Steam Refresh require the High temperature setting.

Medium For synthetics, blends, delicates and items labeled permanent press.

Low For delicates, synthetics and items labeled tumble dry low.

Extra Low

No Heat For fluffing items without heat. For use only with the Timed Dry cycles.

Options

F

For delicates, synthetics and items labeled tumble dry low.

Delay Dry

As the Delay Dry button is repeatedly pressed, the delay time sets to from 1 to 9 hours, and back to clear (0). After selecting

the delay time, press Start and the delay time will count down the time remaining until the cycle starts.

If the Delay Dry button is pressed for 3 seconds, it clears (regardless of the delay time) or terminates a delaying cycle.

Extended Tumble

Use this option to minimize the wrinkles in clothes. It provides 1 hour of no-heat tumbling after the clothes are dry. If you are

using the cycle Signal and you select the Extended Tumble option, a signal will sound at the end of the drying time and every

5 minutes during the Extended Tumble cycle. This will remind you that it is time to remove the clothes.

Damp Alert

This option causes the dryer to beep when clothes have dried to a damp level. Remove items that you wish to hang dry. The

Damp Alert will only beep when this option is selected (but the dry cycle will keep running). Removing clothes and hanging them

when they are damp, can reduce the need to iron some items. The light beside the button will be lit when Damp Alert is on.

Rack Dry

Rack Dry is only allowed for timed cycles (Timed Dry & Quick Fluff). The light turns off if cycle knob is turned to a non-timed cycle.

My Settings

G

As the cycle selector knob is turned, the Time (Timed Dry), Level (Dryness Level), and Temp (Temperature) settings change to

automatic pre-set default settings. If you desire a different setting, press the appropriate button(s).

My Settings button for 3 seconds, the status heart and button lights will turn on, and the dryer will save these settings for that knob

selection. In the future, when you turn the selector knob to that cycle, your settings will be automatically recalled.

To temporarily (for this load) return to the pre-set default settings, depress the My Settings button for 1/2 second, the status heart

and button lights will turn off and the options will change back to these defaults. To make these default settings permanent, hold the

My Settings button again for 3 seconds to make them your preferred settings (the lights will turn back on).

NOTE: Variable Signal volume cannot be set for My Settings.

Variable Signal

Use the Variable Signal button to change the volume of the end of cycle and control signals. Press the button until you reach

the desired volume (low-med-high) or off. The clothes should be removed when the beeper goes off so wrinkles do not set in.

NOTE:

Remove garments promptly at the sound of signal. Place clothes on hangers so wrinkles will not set in.

Use the Variable Signal especially when drying fabrics like polyester, knits and permanent press. These fabrics should be

removed so wrinkles will not set in.

Drum Light

The drum light will go on if the Drum Light button is pushed or the door is opened. It will stay on until the door is shut or the

Drum Light or Power button is pushed.

Control Lock

You can lock the controls to prevent any selections from being made. Or you can lock the controls after you have started a

cycle. Children cannot accidentally start the dryer by touching buttons with this option selected.

7RORFNWKHGU\HUFRQWUROV press and hold the Control Lock button for 3 seconds. The control lock icon will light up when locked.

7RXQORFNWKHGU\HUFRQWUROV press and hold the Control Lock button for 3 seconds.

NOTE: The Power button can still be used when the machine is locked.

eDry

H

Available for %XON\,WHPV7RZHOV6KHHWV&RWWRQV1RUPDO0L[HG/RDGV-HDQV&DVXDOV3HUPDQHQW3UHVV$FWLYH:HDU,

and Delicates. When the eDry button is pressed, cycle settings change to reduce the total energy consumption of the

selected sensor cycle. NOTE: Cycle times will change when eDry is selected.

The eMonitor lights display the relative energy use of your selected cycle and options. They are provided as an energy guide

and range from Good (1 light) to Better (5 lights). Cycle (time), dryness level, temperature, and additional tumble options can

increase or decrease your energy efficiency. Some special cycles will not provide a display.

Then press and hold the

7

– 8 –

(Continued next page)

Page 9

About the dryer features.

Sensor Dry

Time Dry

Steam Cycle

Two back legs on the

rear wall angled ledge

Secure front two inner straight

legs into the oval holes on both

sides of the lint filter handle

This feature is activated in all but the Timed

(Timed Dry & Quick Fluff) and Steam (Steam

Refresh & Steam Dewrinkle) cycles.

The Sensor Dry provides greater drying

accuracy than standard machines, resulting

in shorter dry times and better clothes care.

As the clothes tumble, they touch a moisture

sensor. The sensor will stop the heating cycle

as soon as the clothes have reached the

selected dryness.

This feature is activated in Timed Dry & Quick

Fluff cycles. The time (10, 20, 30, 40, . . . 80, 90,

99) is specified via the Time button.

This feature is activated in Steam Refresh &

Steam Dewrinkle cycles. Use STEAMselect to

indicate the number articles.

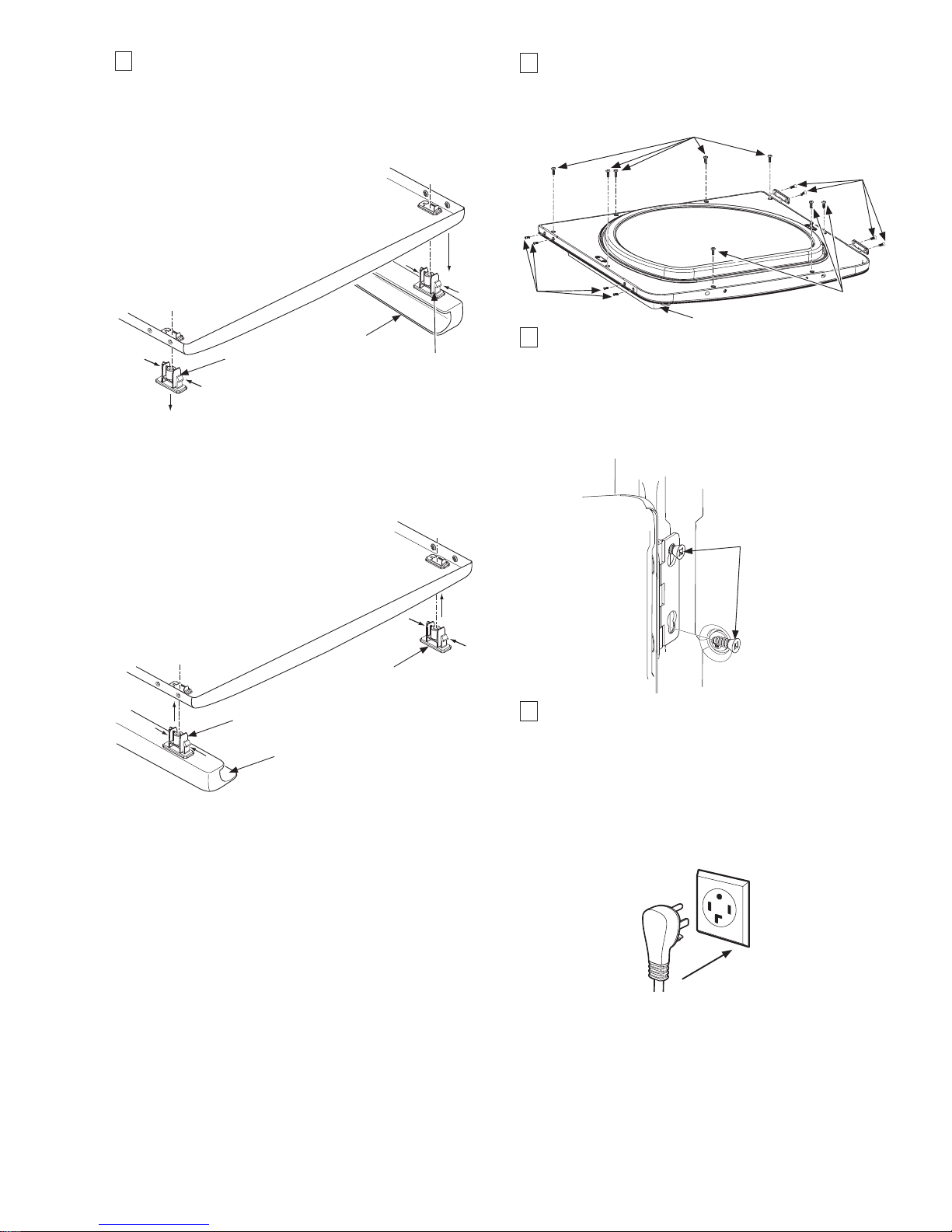

Drying Rack (on some models)

A handy drying rack may be used for drying

items such as tennis shoes.

Hook the rack over the lint filter so the rack

extends into the dryer drum.

NOTE:

The drying rack must be used with the

Do not use this drying rack when there are

Timed Cycle.

other clothes in the dryer.

This dryer will adjust the initial estimated

drying time of the sensor dry cycles as it

“learns” its installation and usage profile.

Please allow several weeks for the dryer to

customize itself to “you”.

To use the drying rack:

1

Insert the drying rack into the dryer

opening with the two leg side toward the

back and four leg side toward the front.

2

Place the two back legs on the rear wall

angled ledge.

3

Secure front two inner straight legs into

the oval holes on both sides of the lint

filter handle.

NOTE: Rotate the dryer drum by hand

clockwise to make sure the baffles clear the

rack.

Stainless Steel Drum

The stainless steel used to make the dryer drum

provides the highest reliability available in a GE

dryer. If the dryer drum should be scratched

Drum Light

The drum light is an LED light. Replacement must

be done by a qualified technician.

or dented during normal use, the drum will not

rust or corrode. These surface blemishes will not

affect the function or durability of the drum.

(Continued next page)

– 9 –

Page 10

Communication.

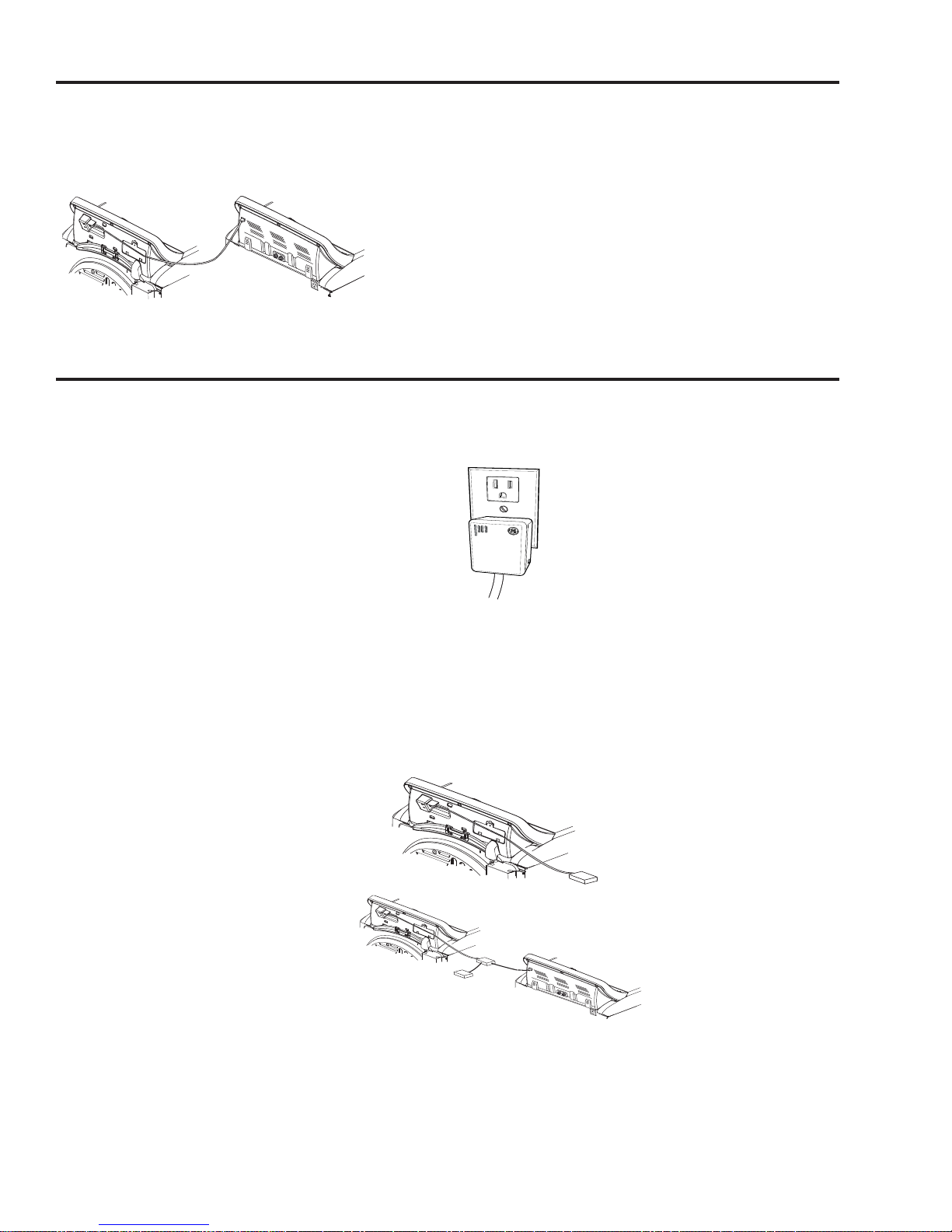

CleanSpeak

This dryer can communicate with a compatible

washer (one whose Owner’s Manual contains a

CleanSpeak description) via a cable between these

appliances. This cable comes with a CleanSpeak

dryer models or may be purchased separately.

Dryer

TM

Washer

Brillion Enabled Communication

This dryer (and/or compatible washer) can

communicate with your Home Computer and/or

®

iPhone

. By using the GE Nucleus™ Home Energy

Manager and Appliance Communication Module

(ACM) you will be able to see the following:

®

On your home computer or iPhone

:KLFKF\FOHLVUXQQLQJDQGZKDWLWVFXUUHQWF\FOH

segment is (example, “Cool Down”).

7KHHVWLPDWHGWLPHUHPDLQLQJRIWKHF\FOHWKDW

has been selected.

When a cycle has completed or if it requires

maintenance or servicing.

$OHUWVQRWLI\LQJ\RXLIWKHZDVKHUQHHGV

maintenance or servicing.

What your software allows you to do:

Cycle display will provide the current status of the

wash cycle:

'U\LQJ'DPS&RRO'RZQRU&RPSOHWH

Alerts will notify you of problems. Some examples:

,QOHW7KHUPRVWDWSUREOHP

2XWOHW7KHUPRVWDWSUREOHP

What you will need for two-way communication:

1XFOHXVKRPHHQHUJ\PDQDJHUPRGHO

$SSOLDQFHFRPPXQLFDWLRQ0RGXOHPRGHO

%URDGEDQGFRQQHFWLRQZLWKURXWHU:L)LIRU

&RPSXWHU0DF

iPhone

iPhone

®

connection)

®

®

.

or PC) and/or Internet capable

NOTE: If you also have a compatible Energy Smart

washer, see Installation Instructions for additional

parts.

:

At the end of the wash cycle, the washer sends a

signal to the dryer to indicated a preferred dry cycle.

When the dryer becomes idle (“End” display times

out - or- the door is opened) “CYCLE” will scroll

across its cycle time display, its current cycle knob

setting LED will be lit, and (if different) a second

recommended cycle LED will blink. If “CYCLE” times

out, pressing Power will refresh it and the LEDs. If

the dryer cycle knob is turned , the solid LED will

move accordingly. Pressing the dryer Start will

initiate the cycle knob setting (solid LED) and turn off

the recommended (blinking LED) if a different cycle

is started.

NOTE: Clean Speak CYCLE times out after

5 minutes. Pressing the power button will

refresh CYCLE and the LEDs no matter how

long it has been timed out.

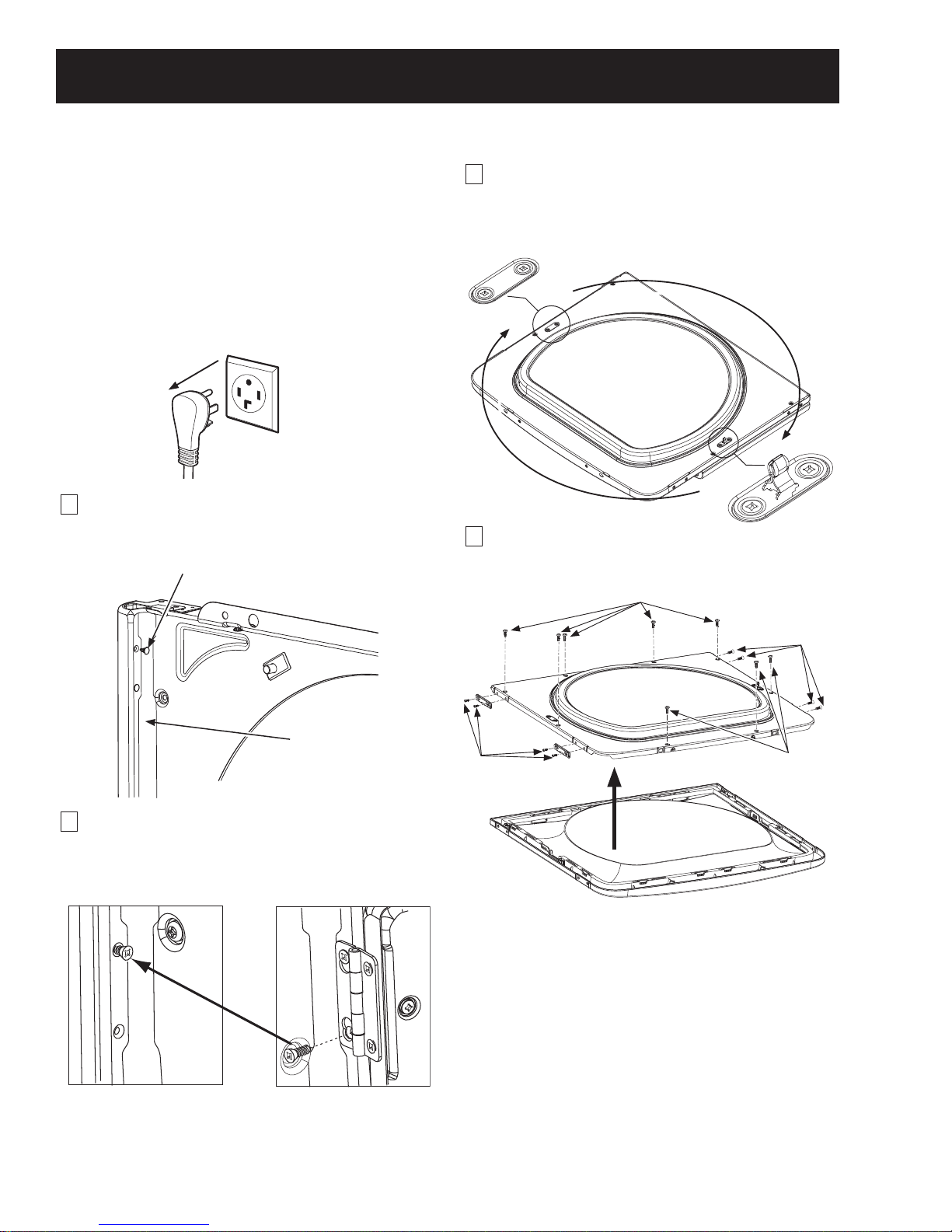

Installation

Step 1: Install your Nucleus Home Energy Manger/

Cable - near your internet router.

Refer to the Quick Start Guide/Installation

Instructions included with this device for

information needed to download software to a

desktop and/or iPhone

®

.

Step 2: Install your Appliance Communication

Module (ACM) in your Laundry area. Determine

the most convenient location for your ACM. Install

the ACM according to the Quick Start/Installation

Instructions included with the device.

Step 3: Connect your ACM to your dryer or dryerwasher.

ACM

Dryer

- OR -

Dryer

Spliter

ACM

Washer

The ACM comes with a splitter, two 6’ cables, and a

1’ cable (see Parts and Accessories section). If you

also have an Energy Smart washer, use the splitter

to connect both appliances. NOTE: If this dryer

did not come with a 6 foot cable, you will need to

purchase a second 6 foot cable (see Parts and

Accessories section).

For more information or questions, please visit:

www.gebrillion.com or call 1-800-220-6899.

(Continued next page)

– 10 –

Page 11

Energy Smart

Energy Smart enables your dryer to reduce energy

consumption during periods of high energy costs.

If you live in an area where your power provider

charges different rates at various times of the day,

your dryer will inform you of those times when you

are paying the highest rate. The Energy Smart icon

will illuminate on the dryer control panel, the cycle

time will display “ES”, and the operation will be in

a delay mode. The dryer will delay start (up to 4

hours) until the rate goes down. You can override

this feature by holding the Delay Dry button for 3

seconds to cancel and run it at your convenience

(immediately or delayed 1-9 hours).

TM

What you will need:

6PDUW0HWHUWRFRPPXQLFDWHZLWK\RXUZDVKHU

(call your power provider)

$QEnergy Smart dryer (like this one)

$Q$SSOLDQFH&RPPXQLFDWLRQ0RGXOH$&0

Installation:

Step 1: Power provider installs a Smart Meter

Steps 2 & 3: Install an ACM. See the Brillion Enabled

Communication section.

– 11 –

Page 12

Reversing the Door Swing

Note: These instructions are for changing the dryer so the door

opens from the right side.

Tools needed:

Standard #2 Phillips screwdriver

Tape-tipped putty knife

Small flat blade screwdriver

Before you Start

Unplug the dryer from its electrical outlet.

1

Open the door approximately 170 degrees. With a putty

knife, remove the 4 plastic covers located along the left

side of the front panel and set them aside.

Plastic Cover (4)

3

Loosen the bottom 2 right side hinge screws. Remove the

door and place it on a protected, flat surface to avoid

any damage. Remove both the Blind Plate and the Strike

Plate and install them in opposite positions.

Blind plate

Inner door

Strike plate

4

Remove the 4 door hinge screws, 4 edge screws, and 8

inside screws. Lift the inner door upwards using a flat

blade screwdriver.

Inside screws

Left side of

front panel

2

Remove the bottom screw from each hinge (right side)

and partially insert them into the top left side hinge

holes.

NOTE: All 4 front panel hinge screws will now be in the top

hinge holes - 2 on the left and 2 on the right.

Edge

screws

Inner door

Door hinge

screws

Outer door

Note: Some doors may have 4 inside screws and 4 additional

edge screws.

Inside screws

– 12 –

(Continued next page)

Page 13

5

Remove and swap the 2 cover caps and door handle

from the outer door:

A. Squeeze the tabs on the inside of the door handle

clips. Push clips through the outer door.

B. Squeeze the tabs on the inside of the cover caps. Push

caps through the outer door.

Inside of door

6

With the cover caps and door handle in place, mount the

inner door back into the outer door with the screws

removed in step 4. Make sure you mount the hinges on

the side opposite the handle.

Inside screws

Door

hinge

screws

Door handle

Cover cap

Door handle clip

C. Push the door handle clips into the openings on the

opposite side of the outer door making sure you flip

the handle so it curves to the inside.

D. Push the cover caps into the openings on the outer

door where the handle used to be installed.

Inside of door

Cover cap

Door handle clip

Door handle

Edge

screws

7

Mount the assembled door on the 2 upper left side hinge

Handle

Inside screws

screws installed in step 2. Move the hinge screws

loosened in step 3 into the lower left side screw holes.

Tighten those screws enough to hold the door but still

allow a slight adjustment. Close the door. Adjust the door

so there is equal gap on all sides. Carefully open the door

and firmly tighten all 4 screws.

Hang door and

Door

8

Install the 4 plastic caps removed in step 1 into the 4

tighten screws

right side front panel holes.

NOTE: To return the door to the original setup, follow these

instructions, swapping “left” and “right”.

When you finish

Plug the dryer back into its electrical outlet.

– 13 –

Page 14

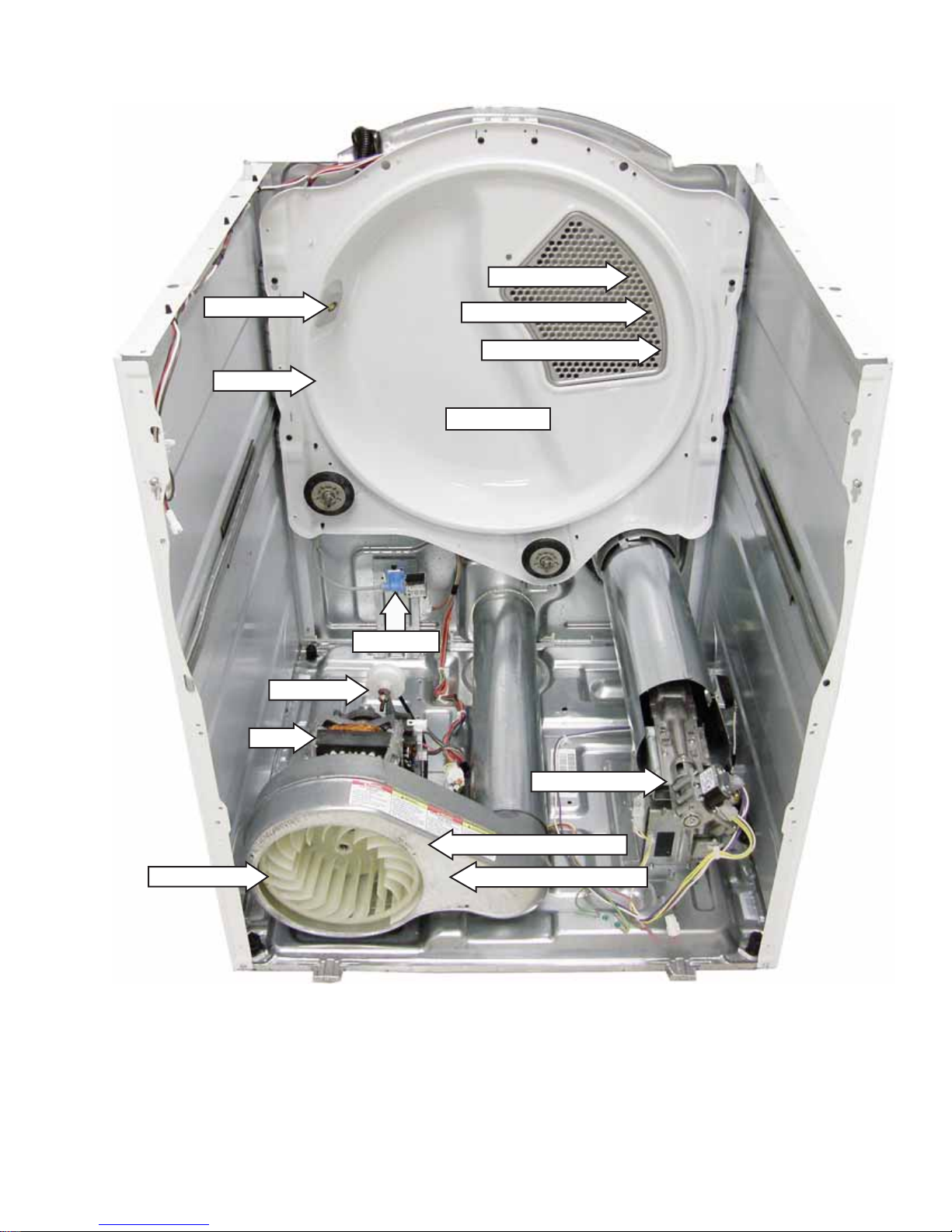

Electric Model

Misting Nozzle

Drum Back

Component Locator Views

Inlet Thermistor**

Rear Bulkhead

Water Valve

Idler Pulley

Motor

Blower Wheel

* Located on back of blower housing

** Located behind rear bulkhead

Inlet Safety

Thermostat

Outlet Control Thermostat*

Outlet Control Thermistor*

– 14 –

High Limit Thermostat

Heater Assembly

(Continued Next Page)

Page 15

Gas Model

Inlet Thermistor**

Misting Nozzle

Drum Back

Idler Pulley

Motor

Inlet Safety Thermostat**

High Limit Thermostat**

Rear Bulkhead

Water Valve

Blower Wheel

* Located on back of blower housing

** Located behind rear bulkhead

Burner Assembly

Outlet Control Thermostat*

Outlet Control Thermistor*

– 15 –

Page 16

J25

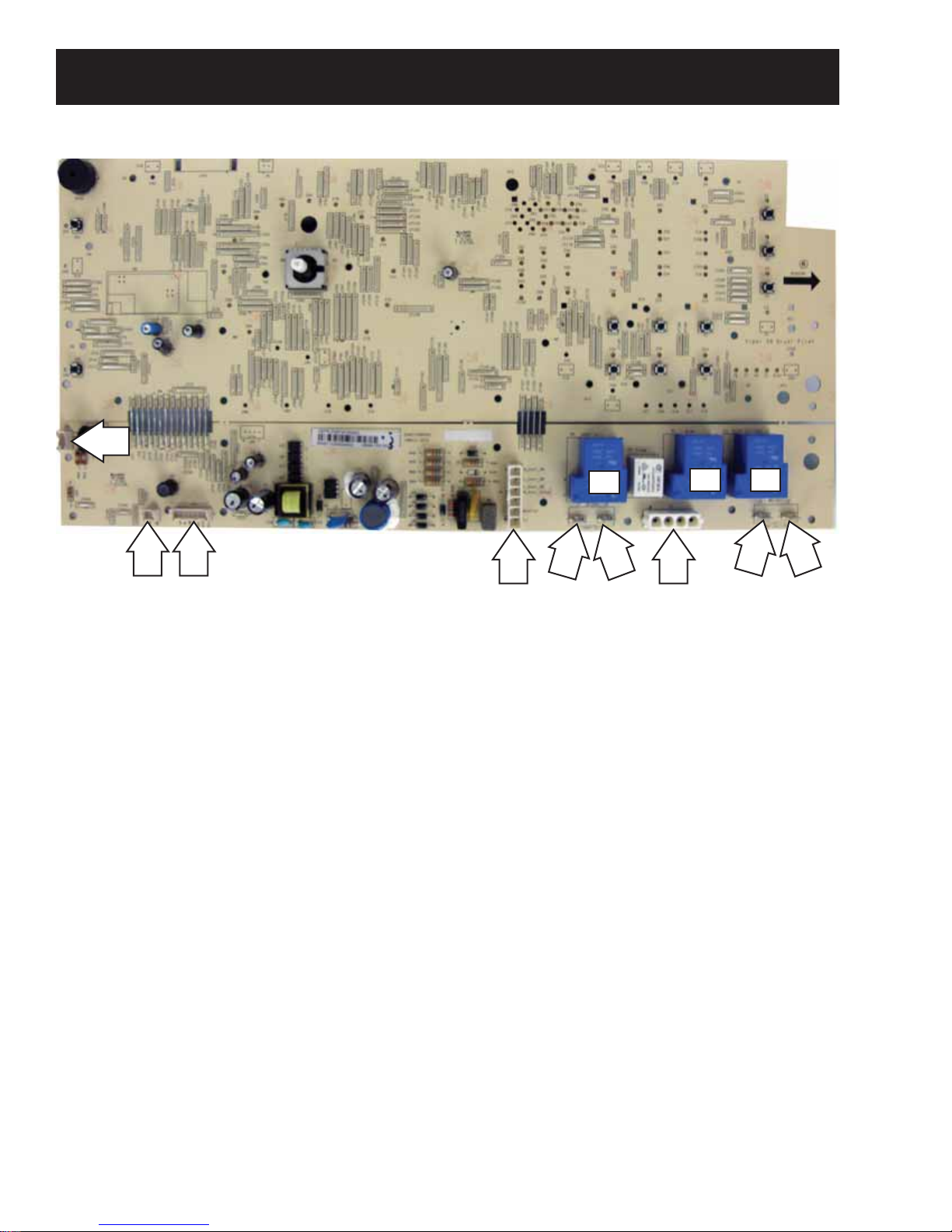

Control Board Connector Locator View

J10J11

J

2 - Outer Coil (Electric), Gas Valve

J4 - Outer Coil (Electric)

J5 - Drum Motor, L1, Steam, Long Vent Motor

J6 - Inner Coil (Electric)

J7 - Inner Coil (Electric)

J8 - L1, Neutral, Door Switch, Motor Centrifugal Switch

J10 - Outlet Control Thermistor, Inlet Control Thermistor,

DSM Module, ground, GEA, 12 VDC

J11 - Drum Light

J25 - Sensor Rods, Earth Ground

J8

J7

K4

J6

J5

J4

K3K1

J2

K1 - Outer Coil Relay (Electric), Gas Valve Relay

K2 - Drum Motor Relay

K3 - Inner Coil (Electric) Relay

SW1 - UI Control

– 16 –

Page 17

Dryer Components

WARNING: Sharp edges may be exposed when

servicing the dryer. Use caution to avoid injury.

Wear Kevlar® gloves or equivalent protection.

Note: Combined Phillips-head/square-drive recess

screws are utilized throughout this appliance. Either

Phillips or square-drive screwdrivers can be used to

extract or install these screws.

Control Panel

Removal of the control panel provides access to the

control board assembly. The control panel is held in

place with 3 screws located below the control panel

chrome trim and 2 key slots inside the control panel

that engage 2 shoulder screws attached to the main

top.

To remove the control panel:

1. Insert a fl at blade screwdriver and press in each

of the 2 release tabs (1 on each side) and slide

the chrome trim forward from the control panel.

2. Remove the chrome trim from the control panel.

3. Remove the three 1/4-in. hex-head screws that

attach the control panel to the main top.

4. Push the control panel back and remove it from

the 2 shoulder screws attached to the main top.

Tab

5. Carefully hang the control panel over the back

of the dryer.

– 17 –

Page 18

Top Panel

Front Panel

Removal of the top panel provides access to the

drum light.

To remove the top panel:

1. Remove the control panel from the top panel.

(See Control Panel.)

2. Remove the 2 Phillips-head screws (1 from

underneath each front corner) that attach the

top panel to the dryer.

3. Press up the 2 metal clips (1 from underneath

each front corner) and simultaneously push the

top panel forward approximately 2 inches.

Metal Clip

Removal of the front panel provides access to the

drum and drive belt. The front panel is held in place

by 6 screws and 2 bottom tabs on the frame.

To remove the front panel:

1. Remove the control panel. (See Control Panel.)

2. Remove the top panel. (See Top Panel.)

3. Disconnect the door switch wires.

4. Remove the top 2 Phillips-head screws (1 from

each top corner) that attach the front panel to

the dryer cabinet.

4. Lift the top panel from the dryer.

Disconnect

Disconnect

5. Remove the 4 Phillips-head screws that attach

the front panel to the front frame.

6. Close the door. Grasp the top of the front panel

on both sides, tilt it out, then lift the panel off the

2 bottom tabs.

– 18 –

Page 19

Door Switch

Front Bulkhead

The door switch is fastened to the front panel by 2

locking tabs (1 on each side). When the dryer door

is closed, the switch will complete the drum motor

circuit, allowing dryer operation. When the door is

open, the switch will open the drum motor circuit,

interrupting dryer operation. Opening the dryer door

will also cause the drum light to be energized.

The door switch can be removed by inserting a fl at

blade screwdriver behind the switch fl ange and

carefully prying the switch out from the front panel.

Two wires are connected to the switch.

The door switch circuit can be checked in the

service mode.

Door Switch

The front bulkhead houses the lint fi lter housing,

2 sensor rods, 2 front rollers, and drum light. It is

located behind the front panel.

To remove the front bulkhead:

1. Remove the control, top, and front panels. (See

Control Panel, Top Panel, and Front Panel.)

2. Remove the wire tie from the front bulkhead.

3. Disconnect the drum light wire harness.

4. Disconnect the sensor rods wire harness.

5. Loosen, but do not remove the top 2 Phillipshead screws that attach the front bulkhead to

the side panels.

6. Remove the remaining 6 Phillips-head screws

that attach the front bulkhead to the side

panels.

7. Remove the 2 Phillips-head screws that attach

the bottom of the front bulkhead to the blower

housing.

LED Drum Light

The LED drum light is attached to the front bulkhead

with 2 clips. It is necessary to disconnect the drum

light wire harness and squeeze both clips to remove

the LED drum light.

The LED drum light receives approximately 3.8 VDC

from the control board J11 connector.

Disconnect

8. Lift the front bulkhead off the top 2 screws.

Disconnect

Loosen

Wire Tie

Screw (below duct)

Loosen

Clip

Disconnect

Clip

– 19 –

Page 20

Drive Belt and Drum

The drum rotates clockwise, as viewed from the

front, at a speed of 46-50 rpm. The drive belt

extends from the motor pulley, past the idler pulley,

and around the perimeter of the dryer drum.

To remove the drive belt:

1. Remove the control, top, and front panels. (See

Control Panel, Top Panel, and Front Panel.)

2. Remove the front bulkhead. (See Front Bulkhead.)

3. To release belt tension, reach under the left side

of the drum, push the idler pulley to the left,

then lock the idler arm into the top indentation

on the idler arm bracket. (See photo. Drum

removed for clarity.)

Non-Long Vent Model

To install the drive belt:

1. Place the belt in position around the

circumference of the drum.

2. Reach under the left side of the drum and place

the belt in position around the motor and idler

pulleys.

3. Release the idler pulley and guide the belt into

position.

Note: The belt should be oriented so that the belt

grooves contact the motor pulley.

Non-Long Vent Model Drive Belt Installed

Idler Pulley

Idler Arm

Idler Pulley

Long Vent Model Drive Belt Installed

Idler Arm Bracket

Long Vent Model

Idler Arm

Idler Arm Bracket

4. Remove the belt from the motor pulley and idler

pulley.

5. Guide the belt out from the dryer cabinet.

– 20 –

(Continued Next Page)

Page 21

Note: Before installing the front panel, slowly rotate

drum in both directions to ensure belt is aligned and

not twisted.

To remove the drum:

1. Remove the belt from the motor pulley and idler

pulley. (See To remove the drive belt, follow

steps 1 through 3.)

2. Using the belt as a handle, pull the drum

forward and guide it out of the dryer cabinet.

Drum Rollers

The stainless steel drum rotates on 4 drum rollers (2

on the front drum support and 2 on the rear drum

support).

Each drum roller comes as a complete assembly.

Caution: To prevent damage to the dryer, the drum

must be installed with the blue threaded felt seal

toward the back of the dryer.

Blue Thread

To remove the drum rollers:

1. Remove the front bulkhead to access the front

drum rollers. Remove the drum (See Drive Belt

and Drum), to access the rear drum rollers.

2. Each drum roller is held in place by a plastic

triangular clip. Remove the triangular clip with a

small fl at-bladed screwdriver and slide the drum

roller off the roller shaft.

To remove the left side drum roller shaft from the

front bulkhead:

1. Remove the front bulkhead. (See Front Bulkhead.)

2. Remove the 9/16-in. hex nut that attaches the

shaft to the front bulkhead.

To remove the right side drum roller shaft from

the front bulkhead:

1. Remove the front bulkhead. (See

Front Bulkhead.)

2. Remove the lint fi lter.

3. Disconnect the sensor wires.

Note: The sensor rods are part of the lint fi lter

housing. To replace the sensor rods, the lint fi lter

housing must be replaced.

(Continued Next Page)

– 21 –

Page 22

4. Remove the 2 Phillips-head screws from the

metal duct.

5. Pull the metal duct off the lint fi lter housing.

6. Remove the 2 Phillips-head screws from the lint

fi lter housing.

Lint Filter Housing

Metal Duct

Moisture Sensor

The moisture-sensing circuit consists of 2 sensor

rods. They are mounted beneath the lint fi lter on the

drum side of the front bulkhead.

7. Lift the lint fi lter housing and remove it from the

front bulkhead.

8. Remove the 9/16-in. hex nut that attaches the

shaft to the front bulkhead.

To remove the drum roller shaft from the rear

bulkhead:

1. Remove the drum. (See

Drive Belt and Drum.)

2. For front service, tilt the bottom of the rear

bulkhead inward from the dryer frame (See

Bulkhead.), or remove the back panel for rear

service. (See

Back Panel.)

Rear

Note: The 2 sensor rods in the front bulkhead are

not replaceable. To replace the sensor rods, replace

the lint fi lter housing. (See Drum Rollers.)

• The sensor rods are connected to the

main control board. The rods are spaced

approximately 1/2 inch apart, creating an open

circuit to the control.

• The control board utilizes a low-voltage

capacitor that charges to approximately 5 VDC

when the circuit is open and discharges to less

than 1 VDC when the circuit is shorted.

• When wet clothes tumble across the 2 rods, the

clothes create a very low resistance between

the rods, discharging the capacitor.

• As the clothes become dry, their resistance

value increases and the charge across the

capacitor builds to approximately 5 VDC.

• Proper leveling of the dryer is vital for accurate

sensor drying. If the front of the dryer is raised

too high, clothes will tumble toward the rear of

the drum, preventing contact with the sensor

rods. This could produce a false dryness reading.

3. Remove the 9/16-in. hex nut that attaches the

drum roller shaft to the rear bulkhead.

– 22 –

Page 23

Belt Switch

Blower Wheel

The belt switch is located to the right of the drum

motor and is attached to the switch bracket with 2

Phillips-head screws. The switch is activated by the

movement of the idler arm. If the drive belt breaks

or comes off of the idler pulley, the belt switch

opens power to the drum motor, interrupting dryer

operation. The drum must be removed to access the

belt switch and wiring. (See Drive Belt and Drum.)

Belt Switch

The blower wheel is held to the motor shaft with

a 15/16-in. (24-mm) molded nut. To remove the

blower wheel, it is not necessary to remove the

motor from the dryer.

15/16-in. Molded Nut

To remove the blower wheel:

Note: Non-long vent model is shown below. The

procedure for the long vent model is similar.

(Shown with exhaust tube removed for clarity.)

1. Remove the drum. (See

Drive Belt and Drum.)

2. On non-long vent models, unlock the idler arm

from the idler arm bracket.

3. Hold the motor shaft from turning and use a

15/16-in. (24-mm) socket to rotate the blower

wheel clockwise from the motor shaft.

– 23 –

Page 24

Drum Motor

The drum motor is a single-speed, 120-VAC, 1/3hp, 5.0-amp rated motor with an automatic reset

overload protector. The overload protector is an

internal component of the motor and cannot

be replaced separately. The motor contains a

centrifugal switch that serves 2 purposes:

• Disengages the motor start winding.

• Closes the circuit contacts for the heat source.

The switch is an internal component of the motor

and cannot be replaced separately.

To remove the drum motor:

5. Using a fl at blade screwdriver, compress and

then remove the front and rear motor straps

from the motor bracket.

6. Lift the motor from the motor bracket.

Non-Long Vent Model

Motor Strap

1. Remove the drum. (See Drive Belt and Drum.)

2. Unlock the idler arm from the idler arm bracket.

3. Disconnect the motor wire harness.

Non-Long Vent Model

Idler Arm

Disconnect

Long Vent Model

Motor Strap

Long Vent Model

Motor Strap

Motor Strap

Idler Arm

4. On non-long vent models, remove the blower

wheel. (See

Blower Wheel.)

Disconnect

– 24 –

Page 25

Long Vent Motor

Heater Assembly

The long vent motor operates on 120-VAC and

rotates at 300 RPM. The motor has an approximate

resistance value of 15 Ω. A 10 ufd capacitor is

attached to the motor. The motor is attached to

the back of the blower housing with 3 Phillips-head

screws.

To remove the long vent blower motor:

1. Remove the blower wheel. (See

Blower Wheel.)

2. Disconnect the motor wire harness.

Long Vent Blower Motor

Disconnect

Capacitor

WARNING: Sharp edges may be exposed when

servicing the dryer. Use caution to avoid injury.

Wear Kevlar® gloves or equivalent protection.

The heater assembly is located below the drum

on the right side of the chassis. It consists of 2

open-wire elements, each fastened inside a single

housing. The elements are wired in parallel with

each other and controlled by a relays on the control

board.

When energized, each element draws

approximately 12.5 amps at 240 VAC. Each element

has a resistance value of approximately 20.6

When both are energized, the elements draw

approximately 25 amps at 240 VAC. The 2 inner

elements have a combined resistance value of

approximately 41.2

To remove the heater assembly:

1. Remove the drum. (See

Drive Belt and Drum.)

2. Note the wire locations, then disconnect all

wiring from the heater assembly.

3. Remove the 3 Phillips-head screws that attach

the motor to the blower housing.

4. Pull the motor out from the back of the blower

housing.

3. Remove the Phillips-head screw from the top on

the heater assembly.

4. Remove the two 1/4-in. hex-head screws that

attach the heater assembly to the chassis.

Disconnect

Disconnect

Disconnect

– 25 –

Page 26

Burner Assembly and Gas Conversion

The burner assembly consists of the gas valve with

attached gas inlet pipe, gas valve coils, and burner.

To convert the dryer from natural gas to LP gas,

refer to conversion kit Part #WE25M87. To convert

the dryer from LP gas to natural gas to, refer to

conversion kit Part #WE25M88.

Gas Valve

The gas valve is attached to the burner bracket.

To remove the gas valve:

1. Shut off the gas supply to the dryer.

6. Remove the two 1/4-in. hex-head screws from

the front of the burner bracket.

7. Pull the burner and the connected gas inlet pipe

as an assembly out from the dryer.

2. Remove the front bulkhead. (See

Front Bulkhead.)

3. Disconnect the ignitor wire harness.

4. Disconnect the wire harness from both coils.

5. Remove the wire retainer from the front of the

burner bracket.

Disconnect

Disconnect

Burner Bracket

Disconnect

Wire Retainer

8. Remove the three 1/4-in. hex head screws that

attach the gas valve to the burner bracket.

– 26 –

Page 27

Gas Valve Coils

The burner assembly gas valve utilizes 2 coils. A

double coil (safety and booster coils combined) and

a single main coil are located on top of the gas valve

in front of the combustion chamber opening. The

coils can be replaced separately.

Gas valve coil assembly resistance values:

• Safety coil terminals - 1400

To remove the double and main coils:

1. Remove the burner assembly from the dryer.

(See Gas Valve and follow steps 1 through 7.)

2. Note the position of the locator pins inserted in

the coil bracket.

3. Remove the 2 Phillips-head screws that attach

the coil bracket to the valve body.

• Booster coil terminals - 580

• Main coil terminals - 1300

Main Coil

Booster Coil

Safety Coil

Coil Bracket

Locator Pin

Locator Pin

4. Lift the coil bracket vertically.

5. Lift coils vertically from valve assembly.

Note: Upon assembly, ensure the locator pins are

inserted into the holes provided in the coil bracket.

– 27 –

Page 28

Ignitor

Flame Detector

WARNING: Sharp edges may be exposed when

servicing the dryer. Use caution to avoid injury.

Wear Kevlar® gloves or equivalent protection.

The ignitor is located at the end of the burner

assembly in the combustion chamber opening and

has a maximum rating of 4 amps. The ignitor has an

approximate resistance value of 40 to 200 Ω.

The ignitor is attached to the gas valve bracket

with a Phillips-head screw. To access the ignitor, it is

necessary to remove the burner assembly. (See Gas

Valve

and follow steps 1 through 7.)

Gas Valve Bracket

The fl ame detector is attached to the right side of

the combustion chamber.

To remove the fl ame detector :

1. Remove the front bulkhead. (See Front Bulkhead.)

2. Disconnect the 2 wires from the fl ame detector.

3. Remove the fl ame detector from the tab at the

bottom.

Note: When installing the ignitor, make sure the

ignitor wiring harness is routed through the opening

in the burner bracket.

Harness Opening

Ignitor Harness

Caution: The ignitor is very fragile. To prevent

breaking the ignitor, care must be taken when

installing the burner assembly.

Tab

Note: Upon reassembly, ensure the tab at the

bottom of the fl ame detector is inserted into the slot

located on the combustion chamber.

– 28 –

Page 29

Ignitor Circuit Operation

The glo-bar ignitor circuit is made up of the following components: a gas valve with safety and main valves,

ignitor, and a fl ame detector. The safety valve is actuated by a double coil that comprises a safety coil

(resistance approximately 1400 ohms) and a booster coil (resistance approximately 580 ohms). Both coils

are needed to open the safety valve. Once energized, the safety coil alone will hold the valve open. The main

valve has a single coil (resistance approximately 1300 ohms).

L1

IGNITOR

(GLOWING RED)

BOOSTER

SAFETY

Ignitor On

DETECTOR

MAIN

N

L1

IGNITOR

(NOT GLOWING)

BOOSTER

SAFETY

N

DETECTOR

MAIN

Gas Valve Open

The fl ame detector (< 1 ohm) is mounted on the combustion chamber. It is normally in the closed position

(N.C.). The fl ame detector is opened by the radiant heat produced by the glo-bar and once open, the fl ame

detector will be held open by the radiant heat produced by the gas fl ame.

When the control system calls for heat, the following circuits are energized:

1. N- through detector, ignitor, outlet control backup, inlet safety thermostats to L1

2. N- through detector, booster coil, outlet control backup, inlet safety thermostats to L1

3. N- through safety coil and outlet control backup, inlet safety thermostats to L1

When the glo-bar is heating, the booster and safety coils are both energized and will open the safety valve.

The main valve is closed as its coil is bypassed by the N.C. fl ame detector. When the glo-bar reaches ignition

temperature, in approximately 60 seconds or less, the fl ame detector is heated and opens, placing the main

coil in series with the glo-bar. The main valve opens, allowing gas to fl ow into the combustion chamber and

ignite. The main coil, now in series with the glo-bar, causes the glo-bar to cool down. However, the fl ame

detector is held open by the radiant heat from the gas fl ame. The booster coil is now also in series with the

main coil and is essentially inoperative. Should a momentary power failure occur, the gas valve will shut

off and an attempt to restart will not occur until the fl ame detector cools and resets, in approximately 30

seconds.

Valves Closed Valves Open

– 29 –

Page 30

Back Panel

Rear Bulkhead

It is necessary to remove the back panel to allow

access to the inlet thermistor, high limit and safety

thermostats (gas model), water tube, spray nozzle

housing, rear drum roller shafts, and wire harnesses.

Electric Model

To remove the back panel:

1. Remove the 1/4-in hex-head screw, then open

and remove the terminal block cover.

2. Remove the power cord from the terminal block.

3. Mark and disconnect the 3 dryer wires from the

terminal block.

4. Remove the sixeen 1/4-in. hex-head screws that

attach the back panel to the dryer.

The rear bulkhead is located between the drum and

the back panel. To allow front access to components

attached to the rear bulkhead, it is necessary to

remove and tilt the bulkhead inward from the dryer

frame.

Electric Model

To remove the rear bulkhead:

1. Remove the drum. (See Drive Belt and Drum.)

2. Remove the Phillips-head screw that attaches

the combustion tube to the inlet vent.

3. Remove the top 2 and bottom 3 Phillips-head

screws from the bulkhead.

4. Loosen, but do not remove the 2 Phillips-head

screws from the keyhole locations.

5. Remove the 3 plastic wire retainers from the top

left side of the bulkhead.

6. Lift and maneuver the bulkhead off the middle

screws and combustion tube.

Terminal Block

Cover Screw

Cover

7. To access the inlet thermistor, water tube, spray

nozzle housing, and wire harnesses, tilt the top

of the bulkhead inward from the dryer frame.

8. To access rear drum roller shafts, tilt the bottom

of the bulkhead inward from the dryer frame.

9. To remove the bulkhead from the cabinet,

remove all wiring and water tubing attached to

the back of the bulkhead.

Wire Retainers

Loosen

Loosen

Gas Model

The back panel is attached with sixteen 1/4-in. hexhead screws. The power cord wire harness can be

disconnected after removing the back panel.

Combustion

Tube

(Continued Next Page)

– 30 –

Page 31

Gas Model

To remove the rear bulkhead:

1. See Electric Model, To remove the rear

bulkhead, and follow steps 1 through 5.

2. Remove the gas valve. (See Gas Valve.)

3. Remove the two 1/4-in. hex-head screws and

the combustion tube from the burner pedestal.

Combustion Tube

Inlet Safety Thermostat

On electric models, the inlet safety thermostat is

located near the back of the heater housing, on the

left side. On gas models, the inlet safety thermostat

is located on the top right side of the inlet duct,

below the high limit thermostat. The thermostat

monitors incoming air temperature.

If the thermostat reaches a temperature beyond its

maximum temperature rating, it will trip and disable

power to the heating elements (electric model) or

burner assembly (gas model).

The inlet safety thermostat opens at 260°F (127°C)

and will automatically reset at 230°F (110°C).

To access the inlet safety thermostat, it is necessary

to remove the drum (electric model). On gas models,

remove the rear bulkhead for front service or back

panel for rear service.

The thermostat is attached to the heater housing or

inlet duct with a Phillips-head screw and a tab. Two

wires are connected to the thermostat.

Burner Pedestal

4. Lift and maneuver the rear bulkhead off the

middle screws and combustion tube.

5. To access the inlet thermistor, high limit and

safety thermostats, water tube, spray nozzle

housing, and wire harnesses, tilt the top of the

rear bulkhead inward from the dryer frame.

6. To access the rear drum roller shafts, tilt the

bottom of the rear bulkhead inward from the

dryer frame.

7. To remove the rear bulkhead from the cabinet,

remove all wiring and water tubing attached to

the back of the rear bulkhead.

Electric Model

Inlet Safety

Thermostat

Gas Model

Inlet Duct

Inlet Safety Thermostat

– 31 –

Page 32

Inlet Control Thermistor

High Limit Thermostat

The inlet control thermistor is located on the

top right side of the inlet duct. The thermistor

monitors incoming air temperature and relays the

information to the control board.

The thermistor has a negative coeffi cient . As the

temperature increases, the thermistor's resistance

decreases.

Inlet control thermistor approximate resistance

values:

• 59.4 - 65.7K at 69°F (20°C)

• 47.6 - 52.4K at 77°F (25°C)

• 38.4 - 42K at 86°F (30°C)

Operation of the inlet control thermistor can be

checked by using the inlet thermistor test in service

test mode. (See

Service Test Mode.)

Specifi c failures associated with the inlet control

thermistor can initiate error codes F01 and F03. (See

Service Test Mode.)

To access the inlet control thermistor, it is necessary

to remove the rear bulkhead for front service or

back panel for rear service.

On electric models, the high limit thermostat is

located near the back of the heater housing, on the

right side. On gas models, the high limit thermostat

is located on the top right side of the inlet duct,

between the inlet thermistor and the inlet safety

thermostat. The thermostat monitors incoming air

temperature.

If the thermostat reaches a temperature beyond its

maximum temperature rating, it will trip and disable

power to the heating elements (electric model) or

burner assembly (gas model).

The high limit thermostat opens at 300°F (149°C)

and will automatically reset at 270°F (132°C).

To access the high limit thermostat, it is necessary

to remove the drum (electric model). On gas models,

remove the rear bulkhead for front service or back

panel for rear service.

The thermostat is attached to the heater housing or

inlet duct with a Phillips-head screw and a tab. Two

wires are connected to the thermostat.

Electric Model

The thermostat is attached to the inlet duct with a

Phillips-head screw. A wire harness is connected to

the thermistor.

Note: Electric model safety and high limit

thermostats not located on the air duct.

Gas Model

Inlet Control Thermistor

High Limit

Thermostat

Gas Model

High Limit Thermostat

– 32 –

Page 33

Outlet Control Thermistor

Outlet Control Thermostat

The outlet control thermistor is located on the back

of the blower housing. The outlet control thermistor

measures outgoing air temperature and provides

temperature change information to the control

board.

The thermistor has a negative coeffi cient . As the

temperature increases, the thermistor's resistance

decreases.

Outlet control thermistor approximate resistance

values:

• 118 - 122K at 69°F (20°C)

• 98 - 102K at 77°F (25°C)

• 78 - 82K at 86°F (30°C)

Operation of the outlet control thermistor can

be checked by using the outlet thermistor test in

service test mode. (See

Service Test Mode.)

Specifi c failures associated with the outlet control

thermistor can initiate error codes F02 and F04. (See

Service Test Mode.)

To access the outlet control thermistor, it is

necessary to remove the drum.

The outlet control thermostat is located on the back

of the blower housing. The outlet control thermostat

measures outgoing air temperature and provides

temperature change information to the control

board.

If the thermostat reaches a temperature beyond its

maximum temperature rating, it will trip and disable

power to the heating elements (electric model) or

burner assembly (gas model).

The outlet control backup thermostat opens at

145°F (63°C) and will automatically reset at 130°F

(54°C).

To access the outlet control thermostat, it is

necessary to remove the drum.

The thermostat is attached to the blower housing

with a Phillips-head screw and a tab. Two wires are

connected to the thermostat.

Outlet Control

Thermostat

The thermistor is attached to the blower housing

with 2 Phillips-head screws. Two wires are

connected to the thermistor.

Outlet Control

Thermistor

– 33 –

Page 34

Control Board Assembly

The control board assembly is mounted in a plastic

housing that is attached to the inside of the control

panel. It consists of 2 circuit boards connected by a

wire spine. The boards and the plastic housing are

replaced as an assembly.

Operation of the control board assembly can be

checked by using the service test mode. (See Service

Test Mode.)

Error codes that are specifi c to the control board

can initiate error codes F05 and E06. (See Service

Test Mode.)

To remove the control board assembly:

6. Disconnect the DMS wire harness from the

control panel rear cover.

1. Remove the control panel. (See Control Panel and

follow steps 1 through 4.)

2. Pull the control knob straight out from the

control panel.

3. Place a protective surface on the top panel.

4. Lay the control panel face down on the

protected top panel.

5. Remove the 5 Phillips-head screws and the

control panel rear cover.

7. Disconnect the wire harnesses from the control

panel.

8. Remove the 8 Phillips-head screws and the

control board frame from the control panel.

– 34 –

Page 35

Steam Components

Misting Nozzle

The misting nozzle is located inside the dryer on the

left side of the rear bulkhead. The misting nozzle

consists of a brass orifi ce and a fi ne fi lter screen.

If the orifi ce should become plugged or restricted,

it should not be cleaned. Replace a plugged or

restricted misting nozzle.

Misting Nozzle

To access the misting nozzle, it is necessary to

remove the drum. (See

or 11-mm nut driver can be used to unscrew the

misting nozzle from the nozzle housing.

Drive Belt and Drum.) A 7/16”

To remove the misting nozzle connector and

housing:

1. Remove the misting nozzle. (See

Misting Nozzle.)

2. For front service, tilt the top of the rear bulkhead

inward from the dryer frame. (See Rear

Bulkhead.)

3. For rear service, remove the back panel. (See

Back Panel.)

4. Press on the John Guest connector collar and

release the water line from the misting nozzle

connector.

5. Remove the Phillips-head screw that attaches

the misting nozzle connector to the nozzle

housing.

6. Pull the misting nozzle connector out from the

nozzle housing.

Misting Nozzle

Connector

Nozzle Housing

Note: Tefl on® tape will be included with the

replacement misting nozzle.

John Guest

Connector

Collar

7. Remove the 2 Phillips-head screws that attach

the nozzle housing to the rear bulkhead.

Nozzle Housing

Misting Nozzle with Tefl on Tape Applied

– 35 –

Page 36

Water Valve

WARNING: The water valve is NOT grounded and

may present a risk of electric shock during servicing.

Disconnect electric power prior to servicing.

The water valve supplies water to the misting nozzle

on demand from the control board. The water valve

has a fl ow rate of 1/3 gallon per minute, operates on

120 VAC, and has an approximate coil resistance of

560 .

The water valve is front or rear serviceable. It is

attached to a bracket that is attached to the fl oor of

the dryer.

To remove the water valve (front service):

1. Turn off water supply to the dryer.

2. Remove the drum. (See Drive Belt and Drum.)

3. Disconnect the coil wire harness.

4. Press on the John Guest connector collar and

release the water line from the water valve.

To remove the water valve (rear service):

1. Turn off water supply to the dryer.

2. Disconnect the hose from the valve.

3. Remove the back panel. (See

Back Panel.)

4. Remove the two 1/4-in. hex-head screws that

attach the valve bracket to the dryer fl oor.

Note: In the following step, the bottom of the valve

bracket is inserted in a slot in the dryer fl oor.

5. Slide the valve bracket out from the dryer fl oor.

Valve Bracket

5. Remove the 2 Phillips-head screws that attach

the valve to the valve bracket.

John Guest

Connector

Collar

Disconnect

6. Pull the valve and the attached water supply

hose into the dryer.

7. Disconnect the hose from the valve.

6. Invert the valve bracket and disconnect the coil

wire harness.

7. Press on the John Guest connector collar and

release the water line from the water valve.

8. Remove the 2 Phillips-head screws that attach

the valve to the valve bracket.

Disconnect

Hose

John Guest

Connector

Collar

– 36 –

Page 37

Troubleshooting

Service Test Mode

The dryer control has a service test mode that can be utilized by the service technician in order to test

critical components and to access error codes. This test mode will help the service technician to quickly

identify certain failed or improperly operating dryer components.

To enter the service test mode and navigate:

From idle state, simultaneously press and hold the START button and rotate cycle select knob 180 degrees (8

clicks) and release the START button.

Upon entering the service mode, the control will be in service test selection mode and display the fi rst test

number (t1). Rotating the knob clockwise (CW) shall increment the test numbers in the display. Rotating the

knob counterclockwise (CCW) shall decrement the test number in the display.

Once the test number is selected, pressing START will begin the selected test. To exit that test, rotate the

cycle selection knob either CW or CCW.

To exit the service test mode:

Pressing the Power button will exit the machine from the service test mode.

The following tables shows the diagnostic tests and the button sequence that is required to perform them:

DISPLAY MODE PRESS START REMARK

t1 DRYER MODEL see DRYER MODEL

CODE

t2 SOFTWARE

and EEPROM

VERSION

t3 XML Check XML version number Checks Board Memory

t4 USER

INTERFACE

TEST

t5 ERROR CODE

see dryer

error code

table

t6 OUTLET

THERMISTOR

t7 INLET

THERMISTOR

t8 MOISTURE

SENSOR

t9 DOOR OPEN/

DOOR CLOSED

SOFTWARE VERSION

NUMBER

LIGHT ON ALL

SEGMENT

Clears displayed error

code and displays

next most recent error

code.

Display the

Outlet thermistor

temperature

Display the

inlet thermistor

temperature

Display moisture

sensor voltage

SERVICE TEST MODE

Second press start displays Jumper model.

Software programed in the Board

STOP WHEN RELEASE START

See Section - Error Code (t5)

First start allows entering in the mode

Displays “do” if the door is opened or “dc” if door is

closed.

(Continued Next Page)

– 37 –

Page 38

SERVICE TEST MODE

DISPLAY MODE PRESS START REMARK

ta CleanSpeak

Test

Checks the

communications to

Will display "On" if OK. Will display "Er" if no response

the washer

tb WATER VALVE

TEST

Toggles water valve

and motor states

If water valve and motor are on, then "On" is displayed

otherwise "Of" is displayed.

tc RESTORE

EEPROM

Default EEPROM

values are restore

td Set Model Blinks LEDs waiting

for input. Three sec

press of Time+Level

keys. Set model with

Time/Level keys, then

Press and Hold Start

key for 3 s.

Dryer Model Codes

DRYER MODEL NUMBER MODEL DESCRIPTION MODEL CODE ID#

GTDP740ED0WW Electric 7.8 cu ft, 2 digit, Led 1 E

GTDP740GD0WW Gas 7.8 cu ft, 2 digit, Led 2 G

GTDL740ED0WW Electric 7.8 cu ft, Long Vent, 2 digit, Led 3 E

GTDL740GD0WW Gas 7.8 cu ft, Long Vent, 2 digit, Led 4 G

GTDS810ED0WS

GTDS815ED0MC

GTDS820ED0WS

GTDS825ED0MC

GHDS830ED0WS

GHDS835ED0MC

GTDS810GD0WS

GTDS815GD0MC

GTDS820GD0WS

GTDS825GD0MC

GHDS830GD0WS

GHDS835GD0MC

GTDS850ED0WS

GTDS855ED0MC

GTDS850GD0WS

GTDS855GD0MC

GTDS860ED0WS

GTDS865ED0MC

GTDS860GD0WS

GTDS865GD0MC

If EEPROM restoration is successful, then "EP" is displayed,

if error occurs, then "Er" is displayed.