GE GHDS830GD0WS, GHDS830GD1WS, GHDS835GD0MC, GHDS835GD1MC, GTDL740GD0WW Installation Guide

...Page 1

Installation

GGs

Instructions

Questions on Installation? Call: 1-800-GECARES (US)

or Visit our Web site at: www.GEAppliunces.com (US)

BEFORE YOU BEGIN

Read these instructions

completely and carefully.

- IMPORTANT- Savethese

instructionsforlocalinspector'suse.

- IMPORTANT- Observe all

governing codes and ordinances.

- Note to Installer- Be sure to

leave these instructions with the

customer.

Note to Customer - Keep

these instructions with gour Use

& Core Book for future reference.

Before the old drger is removed

from service or discorded,

remove the dryer door.

Service information and the

wiring diagram ore located in

the control console.

Do not allow children on or in

the appliance. Close supervision

of children is necessurg when the

appliance is used near children.

Install the dryer where the

temperature is above 50°F for

satisfactory operation of the

dryer control system.

rger

1

To reduce the risk of severe injury or death,

I G

Fire Hazard

, California Safe Drinking Water and Toxic Enforcement Act

This oct requires the governor of California to publish o list of substances known to the

state to cause cancer, birth defects or other reproductive harm and requires businesses

to worn customers of potential exposure to such substances. Gas appliances con

cause minor exposure to four of these substances, namely benzene, carbon monoxide,

formoldehgde and soot, caused primarily bg the incomplete combustion of natural gas

or LP fuels. Properlg adjusted drgers will minimize incomplete combustion. Exposure to

these substances con be minimized further bg properly venting the dryer to the outdoors.

- This dryer must be exhausted to the outdoors.

- Use only rigid metal 4" diameter ductwork inside the dryer cabinet and use only UL

approved transition ducting between the dryer and the home duct.

- DO NOTinstall o clothes dryer with flexible plastic ducting materials. Ifflexible metal

(semi-rigid or foil-tgpe) duct is installed, it must be UL listed and installed in accordance

with the instructions found in "Connecting The Dryer To House Vent" on pages 4-5 of this

manual. Flexible venting materials ore known to collapse, be easily crushed, and trap lint.

These conditions will obstruct drger airflow and increase the risk of fire.

- Do not install or store this appliance in ong location where it could be exposed to water

and or weather.

- To reduce the risk of severe injury or death, follow oil installation instructions.

- Save these instructions. (Installers: Be sure to leave these instructions with the customer).

follow oil installation instructions.

Clothes dryer installation must be performed

by aqualified installer.

Install the clothes dryer according to these

instructions and in accordance with local codes.

In the state of Massachusetts:

Installation must be performed by a qualified or licensed contractor,

plumber or gosfitter qualified or licensed bg the state.

• When using ball-type gas shut-off valves,they shall bethe T-handle type.

• A flexiblegas connector, when used,most not exceed 3feet.

_lk Thisis the safety alert symbol. Thissymbol alerts you to

potential hazards that con killor hurt you and others.

Allsafety messageswillfollowthesafety alert symbol andtheword

"DANGER""WARNING"or "CAUTION".Thesewords ore defined as:

Indicates o hazardous

situation which, if not

avoided, will resultindeath

or serious injury.

Indicates o hazardous

G

situation which, if not

avoided, could result in

death orserious injury.

Indicates o hazardous

situation which, ifnot

avoided, could result in

minor or moderate injury.

, WAR

CAUTIO

GER

I

A WA I

• No washer con completely remove oil.

• DONOTdry anything that has ever had any type of oil

on it (including cooking oils).

Fire Hazard

Electrical

Shock Hazard

Explosion

Hazard

NOTE:Installation and service of this dryer requires basicmechanical and

electricalskills, ttisyour responsibility to contact a qualified installer to

makethe electrical connections.

Items containing foam, rubber or plastic must be dried

on a clothesline or by usingon AirDry cycle.

• Failureto follow this instructions con resulton death or fire

Plug into a grounded 5 prong outlet.

DONOTremove ground prong.

DONOTuse an adapter.

DONOTuse an extension cord.

Failureto do so can resultin death, fire,or electrical shock.

• Keepflammable materials and vapors, such as

gasoline, away from @yen

• Place dryer at least 18 inches (/46cm) above the floor

for agarage installation.

Failureto do so can result in death, explosion, or fire.

DONOTallow children on or inthe appliance. Close

supervision of children isnecessary when the appliance

isused near children.

G

254D!755PO02 Rev. 5 51-16699

Page 2

Installation Instructions

Minimum Clearance in Alcove or Closet Installation

Minimum clearance to combustible surfaces and for air opening are: 0 in. clearance both sides, 3 in.front, 7 in. top and 3 in. rear.

Consideration must be given to provide adequate clearance for installation and service

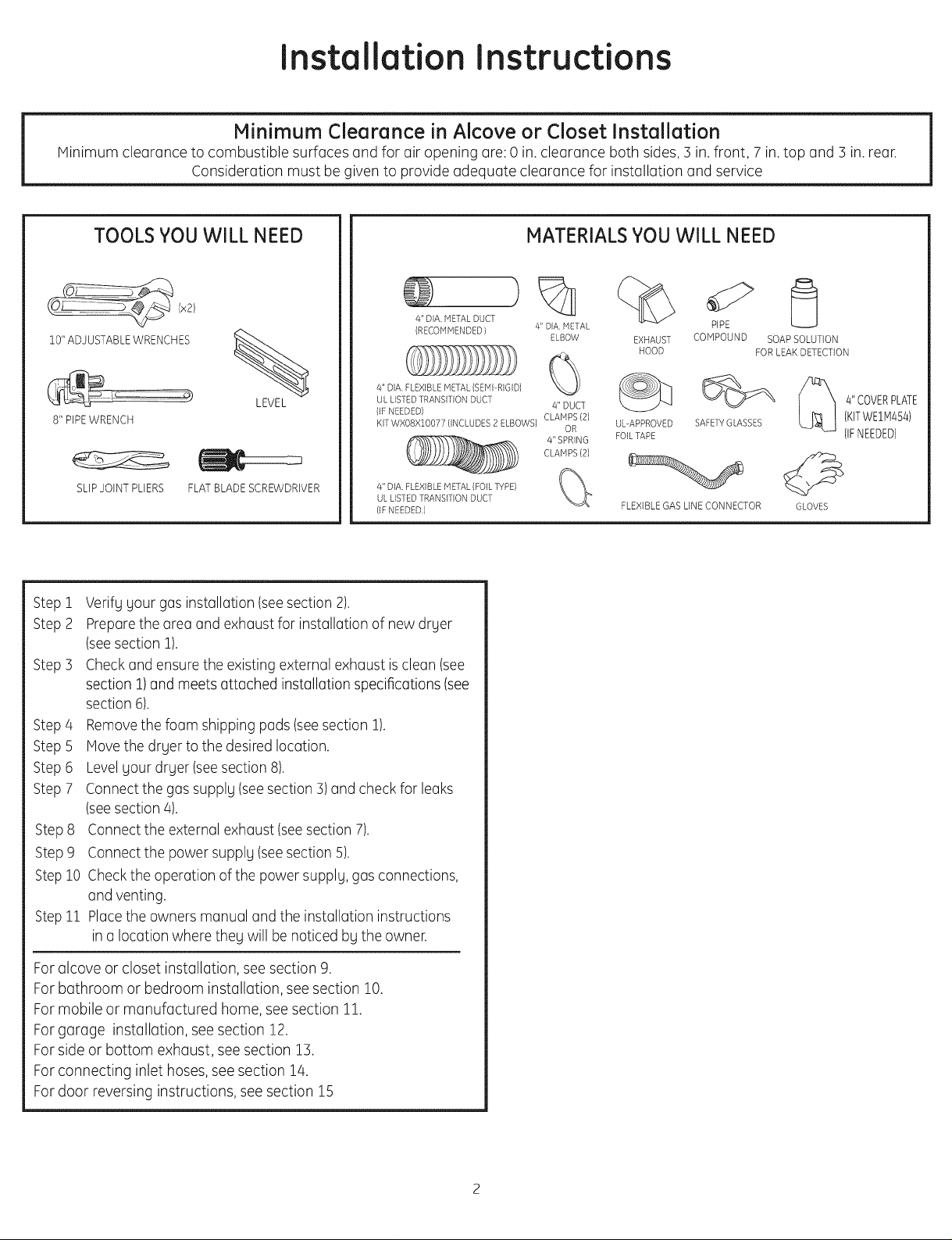

TOOLS YOU WILL NEED

(x2)

10" ADJUSTABLE WRENCHES

8" PIPE WRENCH

SLIPJOINT PLIERS FLAT BLADE SCREWDRIVER

Step i

Step 2

Step 3

Step4

Step 5

Step 6

Step 7

Step 8

Step 9

Step10

Stepii

Verifg gour gas installation (seesection 2).

Prepare the area and exhaust for installation of new drger

(seesection!).

Checkand ensure the existing external exhaust isclean (see

section 1)and meets attached installation specifications (see

section 6).

Removethe foam shipping pads (seesection 1).

Move the drger to the desired location.

Levelgour drger (see section 8).

Connect the gas supplg (seesection 3) and check for leaks

(seesection 4).

Connect the external exhaust (seesection 7).

Connect the power supplg (seesection 5).

Checkthe operation of the power supplg, gas connections,

and venting.

Placethe owners manual and the installation instructions

in a location where theg will benoticed bgthe owner.

LEVEL

MATERIALS YOU WILL NEED

%

4" DIA. METAL DUCT

(RECOMMENDED }

4" DIA. FLEXIBLE METAL(SEMI RIGID)

UL LISTED TRANSITION DUCT

(IFNEEDED) CLAMPS (2)

KIT WXO8XIOO7 ? (INCLUDES 2 ELBOWS) OR

zi" DIA. FLEXIBLE METAL (FOIL TYPE) (C"'_

UL LISTED TRANSITION DUCT

(IFNEEDED.)

4" DIA METAL

ELBOW

4" DUCT

CLAMPS (2)

4" SPRING

EXHAUST

HOOD

UL-APPROVED SAFETY GLASSES

FOILTAPE

FLEXIBLE GAS LINE CONNECTOR

PiPE

COHPOUND SOAPSOLUTION

FORLEAKDETECTION

4" COVERPLATE

(KITWEIM454)

(IFNEEDED)

GLOVES

Foralcove or closet installation, seesection 9.

Forbathroom or bedroom installation, see section 10.

Formobile or manufactured home, see section 11.

Forgarage installation, see section 12.

Forside or bottom exhaust, see section 13.

Forconnecting inlet hoses,see section 14.

Fordoor reversing instructions, see section 15

Page 3

Installation Instructions

[_ PREPARING FOR INSTALLATION

OF NEW DRYER

TIP: Install your dryer before installing your washer.

This will allow better access when installing dryer exhaust.

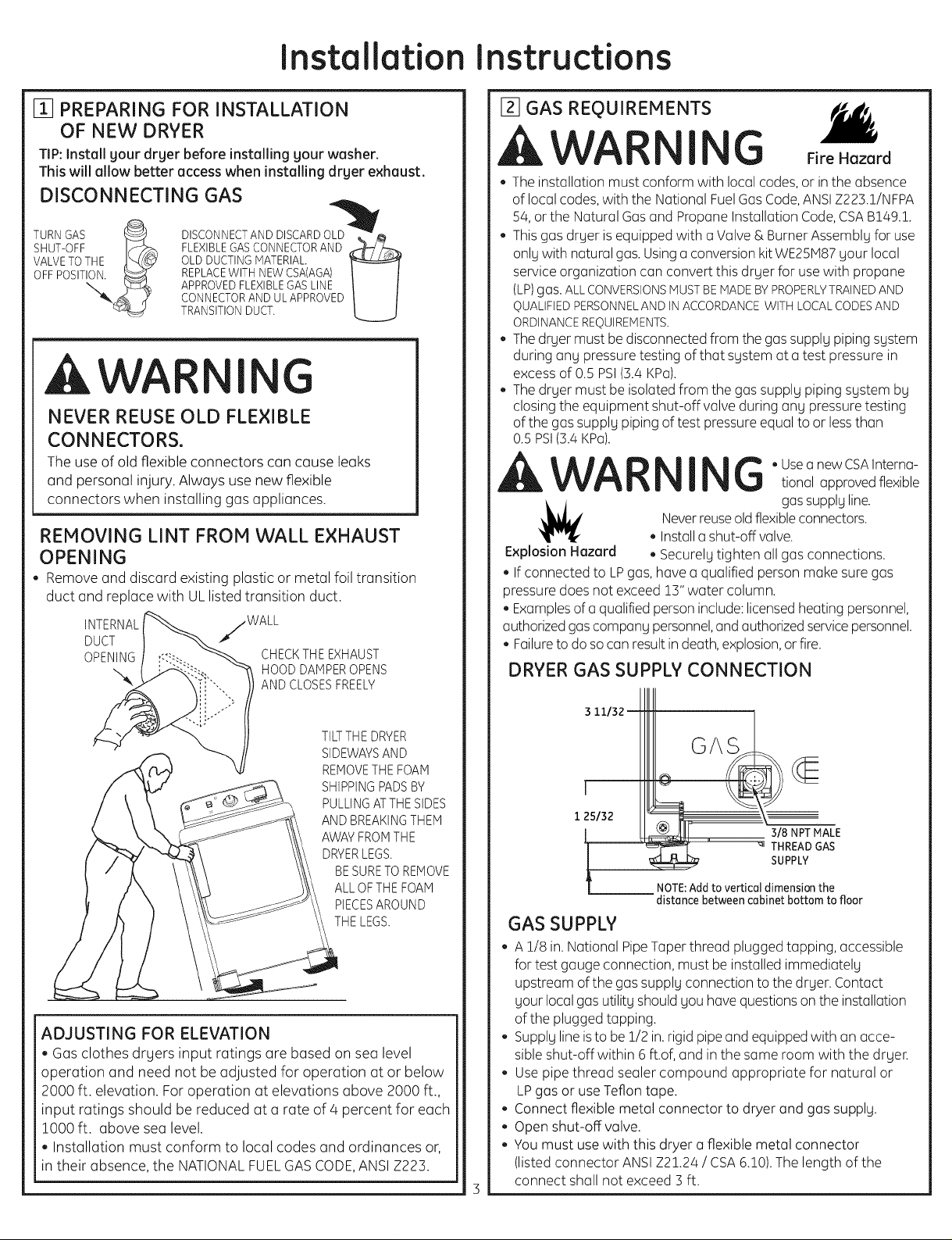

DISCONNECTING GAS

TURNGAS

SHUT-OFF I_2_

VALVETOTHE _\d_

OFFPOSIT_._

DISCONNECTANDDISCARDOLD'_

FLEXIBLEGASCONNECTORAND ,_--/_

OLDDUCTINGMATERIAL.

REPLACEWITHNEWCSA(AGA)

APPROVEDFLEXIBLEGASLINE

CONNECTORANDULAPPROVED

TRANSITIONDUCT.

U

,AWA I G

NEVER REUSE OLD FLEXIBLE

CONNECTORS.

The use of old flexible connectors can cause leaks

and personal injury. Always use new flexible

connectors when installing gas appliances.

REMOVING LINT FROM WALL EXHAUST

OPENING

, Remove and discard existing plastic or metal foil transition

duct and replace with UL listed transition duct.

INTERNAL jWALL

DUCT

OPENING CHECKTHEEXHAUST

HOODDAMPEROPENS

ANDCLOSESFREELY

[_ GAS REOUIREMENTS

AWAR I G FireHazard

• The installation must conform with local codes, or in the absence

of local codes, with the National Fuel Gas Code, ANSI Z223.!/NFPA

54, or the Natural Gas and Propane Installation Code, CSA B149.!.

• This gas drger is equipped with a Valve & Burner Assemblg for use

onlg with natural gas. Using a conversion kit WE25ivI87 gour local

service organization can convert this drger for use with propane

(LP)gas. ALLCONVERSIONSMUSTBEMADEBYPROPERLYTRAINEDAND

QUALIFIEDPERSONNELANDINACCORDANCEWITHLOCALCODESAND

ORDINANCEREQUIREMENTS.

- The drger must be disconnected from the gas supplg piping sgstem

during ang pressure testing of that sgstem at a test pressure in

excess of 0.5 PSI(3.4 KPa).

The drger must be isolated from the gas supplg piping sgstem bg

closing the equipment shut-off valve during ang pressure testing

of the gas supplg piping of test pressure equal to or lessthan

0.5 PSI(3.4 KPa).

AWAR I G ° Usea newcSAInterna-

,_ gas supplg line.

Explosion Hazard • Securelg tighten all gas connections.

• If connected to LPgas, have a qualified person make sure gas

pressure does not exceed !3" water column.

• Examples of a qualified person include: licensed heating personnel,

authorized gas compang personnel, and authorized service personnel.

• Failure to do so can result indeath, explosion, or fire.

Never reuse old flexible connectors.

• Install a shut-offvalve.

DRYER GAS SUPPLY CONNECTION

tional approved flexible

TILTTHEDRYER

SIDEWAYSAND

REMOVETHEFOAM

SHIPPINGPADSBY

PULLINGATTHESIDES

ANDBREAKINGTHEM

AWAYFROMTHE

DRYERLEGS.

BESURETOREMOVE

ALLOFTHEFOAM

PIECESAROUND

THELEGS.

ADJUSTING FOR ELEVATION

, Gas clothes drgers input ratings are based on sea level

operation and need not be adjusted for operation at or below

2000 ft. elevation. For operation at elevations above 2000 ft.,

input ratings should be reduced at a rate of 4 percent for each

1000 ft. above sea level.

, Installation must conform to local codes and ordinances or,

in their absence, the NATIONAL FUEL GAS CODE,ANSI Z223.

3 11132

GAS

J

1 25/32

3/8 NPT MALE

THREAD GAS

SUPPLY

NOTE:Addto vertical dimension the

distance between cabinet bottom to floor

GAS SUPPLY

- A 1/8 in. National Pipe Taper thread plugged tapping, accessible

for test gauge connection, must be installed immediatelg

upstream of the gas supply connection to the dryer. Contact

gour local gas utilitg should gou have questions on the installation

of the plugged tapping.

Supplg line is to be !/2 in. rigid pipe and equipped with an acce-

sible shut-off within 6 ft.of, and in the same room with the drger.

Use pipe thread sealer compound appropriate for natural or

LPgas or use Teflon tape.

Connect flexible metal connector to dryer and gas supplg.

Open shut-off valve.

You must use with this dryer a flexible metal connector

(listed connector ANSI Z2!.24 / CSA6.!0). The length of the

connect shall not exceed 3 ft.

Page 4

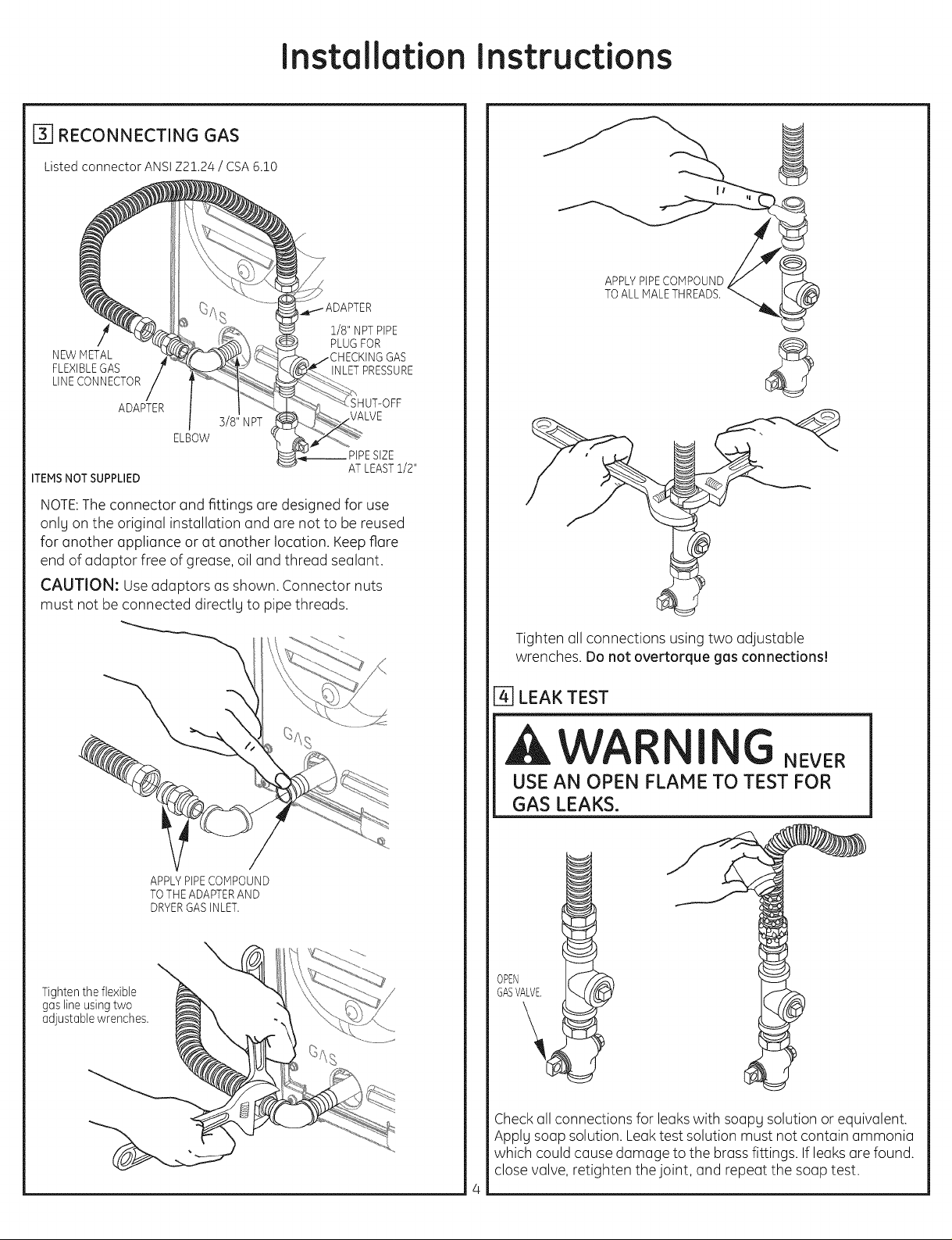

[-_ RECONNECTING GAS

Listed connector ANSI Z21.24 / CSA 6.10

NEW METAL

FLEXIBLEGAS

LINECONNECTOR

ADAPTER

3/8" NPT

ELBOW

Installation Instructions

APPLYPIPECOMPOUND

TOALL MALETHREADS.

1/8" NPTPIPE

PLUGFOR

INLETPRESSURE

ITEMSNOTSUPPLIED

ATLEAST1/2"

NOTE:The connector and fittings (]re designed for use

onlg on the origin(]l installation and (]re not to be reused

for (]nother (]ppli(]nce or (]t another Ioc(]tion. Keep flare

end of adaptor free of grease, oil and thread sealant.

CAUTION: Use adaptors as shown. Connector nuts

must not be connected directlg to pipe threads.

APPLYPIPECOMPOUND

TOTHEADAPTERAND

DRYERGASINLET.

Tighten all connections using two adjustoble

wrenches. Do not overtorque gas connections!

[] LEAK TEST

A WAR I

USE AN OPEN FLAME TO TEST FOR

GAS LEAKS.

Tighten the flexible

gas line using two

adjustable wrenches.

GASVALVE.

OPEN

Checkall connections for leakswith soapg solution or equivalent.

Applg soap solution. Leak test solution must not contain ammonia

which could cause damage to the brass fittings. Ifleaks(]re found.

close valve, retighten the joint, and repeat the soap test.

Page 5

Installation Instructions

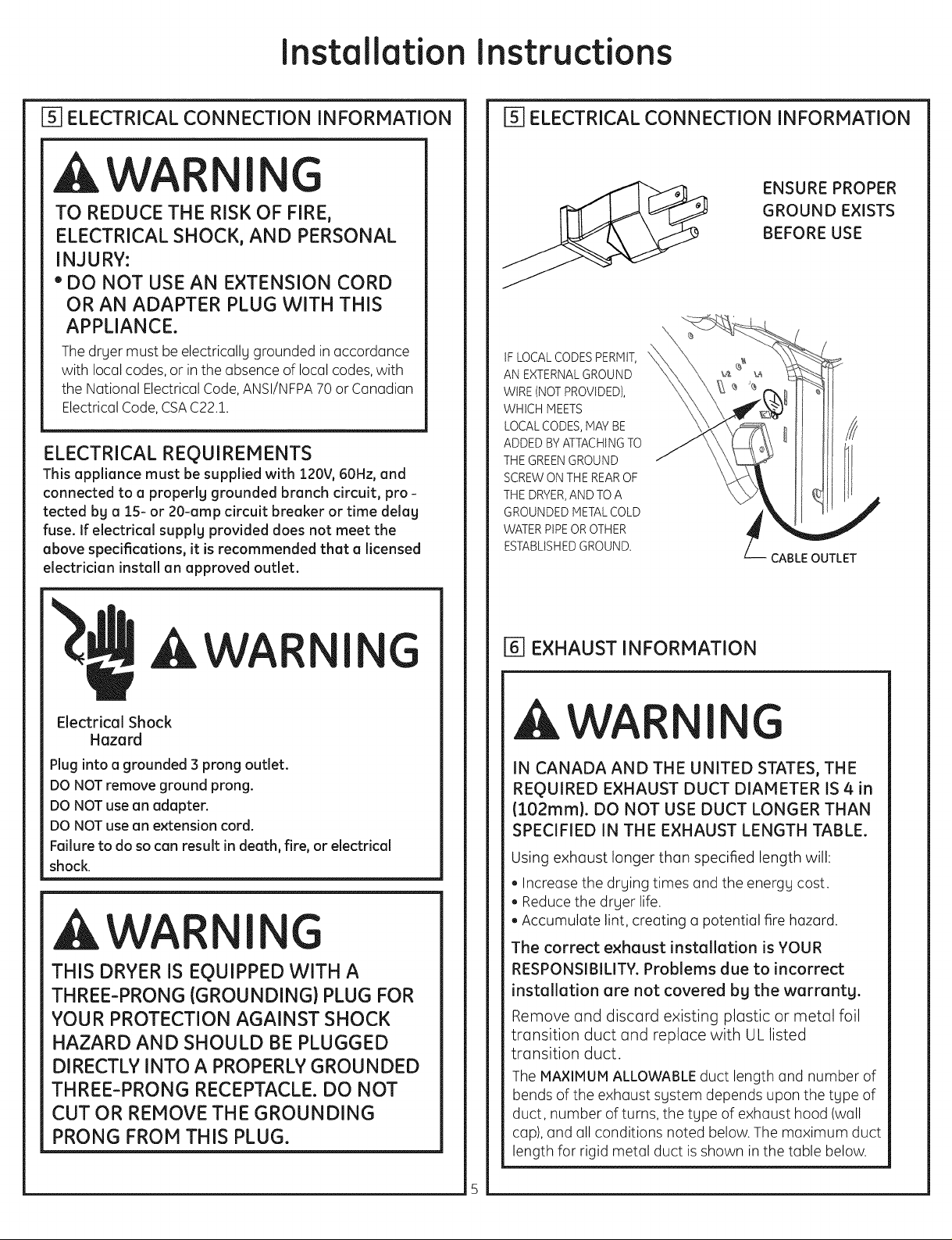

[] ELECTRICAL CONNECTION INFORMATION

I G

TO REDUCE THE RISK OF FIRE,

ELECTRICAL SHOCK, AND PERSONAL

INJURY:

"DO NOT USE AN EXTENSION CORD

OR AN ADAPTER PLUG WITH THIS

APPLIANCE.

Thedryer must beelectrically grounded in accordance

with local codes, or inthe absence of local codes, with

the National ElectricalCode,ANSI/NFPA70 or Canadian

ElectricalCode,CSAC22.1.

ELECTRICAL REQUIREMENTS

This appliance must be supplied with 120V, 60Hz, and

connected to a properly grounded branch circuit, pro -

tected bg a 15- or 20-amp circuit breaker or time delay

fuse. If electrical supply provided does not meet the

above specifications, it is recommended that a licensed

electrician install an approved outlet.

ELECTRICAL CONNECTION INFORMATION

ENSURE PROPER

GROUND EXISTS

BEFORE USE

IFLOCALCODES PERMIT,

AN EXTERNALGROUND

WIRE (NOT PROVIDED),

WHICH MEETS

LOCALCODES,MAY BE

ADDED BY ATTACHINGTO

THE GREENGROUND

SCREW ONTHE REAROF

THE DRYER,AND TO A

GROUNDED METALCOLD

WATERPIPEOROTHER

ESTABLISHEDGROUND.

CABLE OUTLET

AWAR I

Electrical Shock

Hazard

Plug into a grounded 3 prong outlet.

DO NOT remove ground prong.

DO NOT use an adapter.

DO NOT use an extension cord.

Failure to do so can result in death, fire, or electrical

shock.

G

I G

THIS DRYER IS EQUIPPED WITH A

THREE-PRONG (GROUNDING) PLUG FOR

YOUR PROTECTION AGAINST SHOCK

HAZARD AND SHOULD BE PLUGGED

DIRECTLY INTO A PROPERLY GROUNDED

THREE-PRONG RECEPTACLE. DO NOT

CUT OR REMOVE THE GROUNDING

PRONG FROM THIS PLUG.

[] EXHAUST INFORMATION

AWAR I G

IN CANADA AND THE UNITED STATES, THE

REQUIRED EXHAUST DUCT DIAMETER IS 4 in

(102ram). DO NOT USE DUCT LONGER THAN

SPECIFIED IN THE EXHAUST LENGTH TABLE.

Using exhaust longer than specified length will:

, Increase the drying times and the energy cost.

, Reduce the dryer life.

• Accumulate lint, creating a potential fire hazard.

The correct exhaust installation is YOUR

RESPONSIBILITY. Problems due to incorrect

installation are not covered bg the warranty.

Remove and discard existing plastic or metal foil

transition duct and replace with UL listed

transition duct.

The MAXIMUM ALLOWABLEduct length and number of

bends of the exhaust system depends upon the type of

duct, number of turns, the type of exhaust hood (wall

cap), and all conditions noted below. The maximum duct

length for rigid metal duct isshown in the table below.

Page 6

Installation Instructions

EXHAUST INFORMATION (cont.)

NORMAL VENT

EXHAUST LENGTH

RECOMMENDEDMAXIMUM LENGTH

Exhaust HoodTypes

Recommended Useonlgfor short

No. of 90° Rigid Rigid

Elbows Meta Meta

0 90 Feet 60 Feet

! 60 Feet 45 Feet

2 45 Feet 55 Feet

5 55 Feet 25 Feet

4 25 Feet 15 Feet

run installations

LONG VENT

EXHAUST LENGTH

RECOMMENDEDMAXIMUM LENGTH

ExhaustHood Types

Recommended Useonlgfor sho rt

run installations

[] EXHAUST SYSTEM CHECK LIST

HOOD OR WALL CAP

• Terminate in a manner to prevent back drafts or entrg of birds

or other wildlife.

• Termination should present minimal resistanceto the exhaust

airflowandshouldrequirelittleornomaintenoceto preventclogging

• Neverinstallascreeninor overthe exhaust duct. Thiscould

cause lint build up.

• Wallcaps must be installedat least12in.above ground level

or ang other obstruction with the opening pointed down.

SEPARATION OF TURNS

Forbest performance, separate all turns bg at least 4 ft.of straight

duct, including distance between lastturn and exhaust hood.

TURNS OTHER THAN 90 °

• Oneturn of 45° or lessmag beignored.

• Two 45oturns should be treated as one 90oturn.

• Eachturn over Q5oshould be treated as one 90oturn.

SEALING OF JOINTS

- All joints should be tight to avoid leaks. The male end of each

section of duct must point awag from the drger.

- The duct shall not be assembled with screws or other

fastening means that extend into the duct and catch lint.

- Duct joints can be made air and moisture-tight bg wrapping

the overlapped joints with duct tape.

- Horizontal runs should slope down toward the outdoors

1/4 inch per foot.

INSULATION

Ductworkthatrunsthroughan unheatedareaorisnearair

conditioningshouldbeinsulatedtoreducecondensationand

lintbuild-up.

No. of 90 ° Rigid Rigid

Elbows Metal Metal

0 150 Feet 125 Feet

! 155 Feet !!5 Feet

2 125 Feet !05 Feet

5 !!5 Feet 95 Feet

4 105 Feet 85 Feet

5 95 Feet 75 Feet

ONLY THESE MODELS

GTDL740EDWW

GTDL740G DWW

Foreverg extra 90°elbow, reduce the allowable vent sgstem

length bg 10ft.

Two 45° elbows wilt be treated like one 90° elbow.

Forthe side exhaust installations, add one 90° elbow to the

chart.

The totot vent sgstem length includes utt the straight portions

and elbows of the sgstem (transition duct included).

PARTS AVAILABLE FROM LOCAL SERVICE

ORGANIZATIONS

• Rigid Metal Duct Components

WX8X63 4" x 1' Duct

WX8X64 4" x 2' Duct

WX8X51 4" Elbow

WX8X59 4" Aluminum Hood

• Flexible Metal Duct Components

WX8X58 4" Clamps (2)

WX8X59 4" Aluminum Hood

WX08X10077 6' UL-Listed, Flexible Metal (Semi-Rigid)

Duct, 2 Clamps, 2 Close Elbows

WEIM454 Cover rear exhaust opening

Page 7

Installation Instructions

[7]EXHAUST CONNECTION

AWA

I G

Fire Hazard

TO REDUCE THE RISK

OF FIRE OR PERSONAL INJURY:

,This clothes dryer must be exhausted to the outdoors.

, We recommend that you install your dryer before

installing your washer. This will permit direct access for

easier exhaust connection.

, Use only 4" rigid metal ducting for the home exhaust

duct.

,Use only 4" rigid metal or UL-listed flexible metal

(semi-rigid or foil-type) duct to connect the dryer to the

home exhaust duct. It must be installed in accordance

with the instructions found in "Connecting the Dryer to

House Vent" on pages 4-5 of this manual.

,Do not terminate exhaust in a chimney, a wall, a

ceiling, gas vent, crawl space, attic, under an enclosed

floor, or in any other concealed space of a building.

Theaccumulated could create a potential fire hazard

, Never terminate the exhaust into a common duct with

a kitchen exhaust system. A combination of grease

and lint could create a potential fire hazard.

, Do not use duct longer than specified in the exhaust

length table. Longer ducts can accumulate lint,

creating a potential fire hazard.

, Never install a screen in or over the exhaust duct. This

will cause lint to accumulate, creating a potential fire

hazard.

DO NOTuse a plastic vent.

DO NOTuse a metal foil vent.

No roof venting.

,Do not assemble ductwork with any fasteners that

extend into the duct. These fasteners can accumulate

lint, creating a potential fire hazard.

, Do not obstruct incoming or exhausted air.

, Provide an access for inspection and cleaning of the

exhaust system, especially at turns and joints. Exhaust

system shall be inspectedand cleaned at leastonce a year.

Failureto follow these instructions can resultin death or fire.

There are multiple installation options.

Select the most appropriate method for

gour installation situation.

STANDARD REAR EXHAUST

{Ventedatfloorlevel}

For straight line installation, connect

the drger exhaust to the external

exhaust hood using duct tape or

clamp,

EXTERNALDUCT

DUCT TAPE OR

DUCT CLAMP

4" METAL DUCTCLT

TO PROPER LENGTH

DUCT TAPE OR

DUCT CLAMP

NOTE: WE STRONGLY RECOMMEND SOLID

METAL EXHAUST DUCTING. HOWEVER, IF

FLEXIBLE DUCTING IS USED IT MUST BE

UL-LISTED METAL, NOT PLASTIC.

STANDARD REAR EXHAUST

{Ventedabove floorlevel)

ELBOWHIGHLY

RECOMMENDED

ELBOWHIGHLY

RECOMMENDED-

NOTE: ELBOWS WILL PREVENT DUCT

KINKING AND COLLAPSING.

CONNECTING THE DRYER TO HOUSE VENT

RIGID METALTRANSITION DUCT

, For best drying performance, a rigid metal transition

duct is recommended.

, Rigid metal transition ducts reduce the risk of crushing

and kinking.

UL-LISTEDFLEXIBLEMETAL(SEMI-RIGID}TRANSITION DUCT

• If rigid metal duct cannot be used, then UL-listed flexible

metal (semi-rigid) ducting can be used (KitWXO8X10077).

• Neverinstall flexible metal duct in walls, ceilings, floors or

other enclosed spaces.

• Total length of flexible metal duct should not exceed 8

feet (2.4m).

Page 8

Installation Instructions

• Formany applications, installing elbows atboth the dryer

and the wall ishighly recommended (seeillustrations below).

Elbowsallow the dryer to sit close to the wall without kinking and

or crushing the transition duct, maximizing drying performance.

• Avoid resting the duct on sharp objects.

UL-LISTEDFLEXIBLEMETAL(FOIL-TYPE)TRANSITIONDUCT

• Inspecial installations, it may be necessary to connect the dryer

to the housevent using a flexible metal (foil- type) duct. A UL-listed

flexible metal (foil-type)duct may be used ONLYininstallations

where rigid metal or flexiblemetal (semi-rigid)ducting cannot be

usedANDwhere a/4" diameter can be maintained throughout the

entire length of the transition duct.

• InCanada and the UnitedStates,only the flexible metal (foil-type)

ducts that comply with the "Outlinefor Clothes Dryer Transition

Duct Subject2158A" shall be used.

• Never install flexible metal duct in walls, ceilings,floors or other

enclosed spaces.

•Total length of flexible metal duct should not exceed 8 feet (2Am).

•Avoid resting the duct on sharp objects.

• Forbest drying performance:

1.Slideoneendoftheductovertheclothesdryeroutletpipe.

2.Securetheductwitha clamp.

3.Withthe dryerinitspermanentposition,extendtheductto itsfull

length.Allow2"ofducttooverlaptheexhaustpipe.Cutoffandremove

excessduct. Keeptheductasstraightaspossiblefor maximumairflow.

4.Securetheductto theexhaustpipewiththeotherclamp.

[] LEVELING AND STABILIZING YOUR

DRYER

Stand the dryer upright near the final location and adjust

the 4 leveling legs, at the corners, to ensure that the dryer

is level from side to side and front to rear.

LEVEL

SIDE-TO-SIDE

LEVEL

FRONT-TO-BACK

/

DOOR900

ELBOW

REOUIRED

EXHAUST

LENGFH

|

I _ " SIT DRYER

(

4 LEVELINGLEGS _,_A i

AWAR I G

Explosion Hazard

• Keepflammable materials and vapors, such as gasoline, away

from dryer.

• Failureto doso can resultin death, explosion, or fire.

[] ALCOVE OR CLOSET INSTALLATION

• If your dryer is approved for installation in an alcove or

closet, it will be stated on alabel on the dryer back.

•The dryer MUST be vented to the outdoors. Seethe

EXHAUSTINFORMATIONsections 3 & 4.

• Minimum clearance between dryer cabinet and adjacent walls

or other surfaces is:0 in. either side,3 in.front, 3 in. rear

• Consideration must be given to provide adequate clearance

for installation and service

• Minimum vertical space from floor to overhead cabinets,

ceiling, etc. is52 in.

•Closetventilation openings required: 2 louverseach 60 square

in.(387square cm),located 3 in. (7.6cm) from top and bottom of

door. Ifthe closetcontains both awasheranda dryer, doors must

contain a minimum of 120sq.in.ofopen area equally distributed.

•Thedryer must be disconnected from the gassupply piping

during pressuretesting at pressuresgreater than 1Apsi(3.5kPa).

•A1/8 inch NPTminimum pluggedtapping, accessiblefor test

gage connection, must be installedimmediately upstream of the

gas supply connection to the dryer.

Page 9

Installation Instructions

IT6]BATHROOM OR BEDROOM INSTALLATION

,The drger MUSTbe vented to the outdoors. See EXHAUST

INFORMATIONsection 6.

, The installation must conform with local codes or, in the

absence of local codes, with the NATIONALFUELGASCODE,

ANSIZ223

[] MOBILE OR MANUFACTURED HOME

INSTALLATION

, Installation must conform to the MANUFACTUREDHONE

CONSTRUCTION& SAFETYSTANDARD,TITLE 24, PART

32-80 or, when such standard is not applicable, with

AMERICAN NATIONAL STANDARD FOR MOBILE HOME,

ANSI/NFPANO.50lB.

,The drger MUST be vented to the outdoors with the

termination securelg fastened to the mobile home

structure. (SeeEXHAUSTINFORMATIONsection 6).

,The vent MUSTNOTbe terminated beneath a mobile or

manufactured home.

,The vent duct material MUSTBEMETAL.

,KIT !4-D346-33 MUST be used to attach the drger

securelg to the structure.

,The vent MUST NOT be connected to ang other duct,

vent, or chimneg.

, Do not use sheet metal screws or other fastening devices

which extend into the interior of the exhaust vent.

, Provide an opening with a free area of at least 25 sq. in.

for introduction of outside air into the drger room.

Detach and remove the bottom or left side knockout as

desired. Remove the screw inside the drger exhaust duct

and save. Pull the duct out of the drger. Protect sharp edges

around the knockout and exhaust opening with the tape.

FIXINGHOLE.

14' _

Cut the duct as shown and keep aortion A.

TAB LOCATION

BENDTAB

UP45o

[] GARAG E INSTALLATIO N (IF ALLOWEDBYLOCALCODES)

. Drgers installed in garages must be elevated

!8 inches (46cm)above the floor.

[] DRYER EXHAUST TO LEFT OR BOTTOM

CABINET

AWA i G

Disconnect drger from electrical supplg.

Wear gloves and arm guards.

Closethe back opening with cover plate/KitWEtM4S4)

Electrical Shock

Hazard

* The internal elbow must be included in the total elbow count.

NOTE: the long vent model (GTDLI40GDWW) is capable of rear

and bottom venting only.

REMOVE

SCREW

AND SAVE

Failureto do so mag result inelectrical

shock or lacerations.

Through the rear opening, locate the tab in the middle of

the appliance base. Lift the tab to about 45° using a flat

blade screwdriver.

ADDING NEW DUCT

FIXING

HOLE

PORTION"A"

\

,!/

RIGHTOR

LEFTSIDE

EXHAUST

REMOVE

DESIRED

KNOCKOUT (ONEONLY)

Reconnect the cut portion (A) of the duct to the blower

housing. Make sure that the shortened duct is aligned with

the tab inthe base. Usethe screw saved previouslg to secure

the duct in place through the tab on the appliance base.

Page 10

Installation Instructions

ADDING ELBOW AND DUCT FOR

EXHAUST TO LEFT SIDE OF CABINET

. Preossemble 4" elbow with 4" duct. Wrop duct tope

oround joint.

. Insert duct ossembly, elbow first, through the side

opening ond connect the elbow to the dryer internol duct.

CAUTION: Be sure not to pull or damage the

electrical wires inside the dryer when inserting the duct.

EXHAUSTCAN

BEADDEDTO

LEFTSIDE

DUCT

TAPE

ADDING COVER PLATE TO REAR OF

CABINET (SIDES AND BOTTOM EXHAUST)

J

PLATE

(KITWE1M454)

Connect stondord metol elbows ond ducts to complete

the exhoust system. Cover back opening with o plote (Kit

WE1M454) ovoiloble from your Iocol service provider. Ploce

dryer in finol Iocotion.

w

AWA I G

. Apply duct tope as shown on the joint between the

dryer internol duct ond the elbow.

CAUTION:

Use4" rigid metal ducting only

inside the dryer. Internal duct

joints must be secured with

H ape, otherwise they may sepa-

rate and cause a safety hazard.

ADDING ELBOW FOR EXHAUST

THROUGH BOTTOM OF CABINET

. Insert the elbow through the rear opening ond connect

it to the dryer internal duct.

.Apply duct tope on the joint between the dryer internol

duct ond elbow, os shown on poge 6.

zJ

NEVER LEAVE THE BACK OPENING

WITHOUT THE PLATE.

CAUTION:

Internal duct joints

mustbe securedwith

moyseporoteon couse .

tape, otherwise they

a safety hazard.

10

Page 11

Installation Instructions

[] CONNECTING INLET HOSES

(on some models)

To produce steam, the dryer must connect to the cold

water supply. Since the washer must also connect to the

cold water, (] "Y" connector is inserted to allow both inlet

hoses to make that connection at the some time.

NOTE: Use the new inlet hoses provided; never

use old hoses.

1. Turn the cold water faucet off. Remove the washer inlet

hose from the washer fill valve connector (cold).

2. Ensure the rubber fiat washer is in place end screw the

female coupling of the short hose onto the washer fill

valve connector. Tighten by hand until firmly seated.

3. Attach the female end of the "Y" connector to the

mole coupling of the short hose. Ensure the rubber fiat

washer is in place. Tighten by hand until firmly seated.

"Y" Connector

\

4. Insert the filter screen in the coupling of the washer's

inlet hose. If (] rubber fiat washer is olre(]dy in place

remove it before installing the filter screen. Attach this

coupling to one mole end of the "Y" connector. Tighten

by h(]nd until firmly seated.

5. Ensure the rubber riot washer is in place and ott(]ch the

dryer's long inlet hose to the other mole end of the "Y"

connector. Tighten by h(]nd until firmly seated.

6. Ensure the rubber riot washer is in place and attach

the other end of the dryer's long inlet hose to the fill

v(]lve connector at the bottom of the dryer back panel.

Tighten by hand until firmly seated.

I_ CONNECTING INLET HOSES (cont.)

7. Using pliers, tighten (]ll the couplings with on (]ddition(]l

two-thirds turn.

NOTE: Do not overtighten. Damage to the couplings may

result.

8. Turn the water faucet on.

9. Check for le(]ks (]round the "Y" connector, f(]ucet (]nd

hose couplings.

WATER SUPPLY REQUIREMENTS

Hot (]nd cold w(]ter f(]ucets HUST be inst(]lled within 42

in. (107 cm) of your w(]sher's water inlet. The f(]ucets

MUST be 3/4 in. (1.9 cm) g(]rden hose-type so inlet hoses

c(]n be connected. W(]ter pressure MUST be between 10

(]nd 120 pounds per squ(]re inch. Your w(]ter deportment

c(]n advise you of your water pressure.

NOTE: A water softener is recommended to reduce

buildup of scale inside the ste(]m gener(]tor if the home

w(]ter supply is very h(]rd.

REGISTERYOUR NEW APPLIANCE TO RECEIVEANY

IMPORTANT PRODUCT NOTIFICATIONS.

Please go to www.GEApplionces.com or moil in your

Product Registration Cord.

For questions on inst(]ll(]tion, c(]ll: 800.626.2000 (US)or

800-561-3344 (C(]nod(]).

!!

Page 12

Installation Instructions

ABOUT REVERSING THE DOOR

SWING

IMPORTANT NOTES:

•Reodthe instructions oil the wog through before storting.

•Hondle ports corefullg to ovoid scrotching point.

•Set screws down bg their reloted ports to ovoid using them in

the wrong ploces.

•Provideo non-scrotching work surface for the door. • Normol

completion time to reverse the door swing is :30-60 minutes.

IMPORTANT:

Once gou begin, do not move the cobinet until door-swing

reversol iscompleted. These instructions ore for chon- ging

the hinges from the right side to the left side - if gou ever

wont to switch them bock to the right side, follow these some

instructions ond reverse oil references to the left ond right.

Tools Needed

[]Stondord #2 Phillips Screwdriver

[]Tope-tipped puttg knife

[]Smoll flot blode screwdriver

Before you start

Unplug the drger from its

electricol outlet

_ Removethe bottom screw from each hinge (right side)ond

portiolly insert them into the top left side hinge holes.

NOTE:All 4 front punel hinge screws will now be in the

top hinge holes - 2 on the left ond 2 on the right.

_ Loosen the bottom 2 right side hinge screws. Remove

the door ond ploce it on o protected riot surfoce to ovoid

onu domoge. Remove both the Blind Plate ond the Strike

Plote ond instoll them in opposite positions.

REVERSING THE DOOR

SWING

SOLID DOOR MODELS:

GTDP740EDOWW

GTDP740G DOWW

GTDL740EDOWW

GTDL740GDOWW

_Open the door to opproximotelu 170 degrees.

With u puttu knife, remove the 4 plustic covers Iocoted

olong the left side of front ponel ond set them oside.

Plostic Cop (4)

Strike plote

_ Removethe 4 door hinge screws, 8 edge screws, ond/4

inside screws. Liftthe inner door upwords using o riot

blode screwdriver.

Inside screws

_-_ Edge screws

Door hinge

screws

Ill /

12

Page 13

Installation Instructions

_ Remove and swap the 2 cover caps and door handle

from the outer door:

A. Squeeze the tabs on the inside of the door handle

clips. Push clips through the outer door.

B.Squeeze the tabs on the inside of the cover caps.

Pushcaps through the outer door.

Inside of door

Door ha_{dle

Door hc

_When the cover caps and door handle in place, mount

the inner door back into the outer door with the screws

removed in step 4. Make sure you mount the hinges on

the side opposite the handle.

Inside screws

Door hinge

screws

screws

I

I

-Handle

_ Hount the assembled door on the 2 upper left side hinge

screws installed in step 2.

Move the hinge screws loosened in step 3 into the lower

left side screw holes and firmly tight all 4 screws.

C. Pushthe door handle clips into the openings on the

opposite side of the outer door making sure you flip

the handle so it curves to the inside.

D. Pushthe cover caps into the openings on the outer

door where the handle was removed.

Inside of door

Coverca

Door handle

Door

_r and

'- tighten screws

_ Install the 4 plastic caps removed in step 1 into the 4

right side front panel holes.

NOTE:To return the door to the original setup, follow

these instructions, swapping "left" and "right".

!]

Page 14

Installation Instructions

REVERSING THE DOOR SWING

SOLID DOOR MODELS

WITH COVER CAPS:

_Open the door to approximatelg 170 degrees.

With (] puttg knife, remove the 4 plastic covers located

(]long the left side of front p(]nel (]nd set them (]side.

PIQStiCCQp (4)

_ Loosen the bottom 2 right side hinge screws. Remove

the door (]nd pl(]ce it on (] protected, fl(]t surf(]ce to (]void

(]ng d(]m(]ge. Remove both the Blind Pl(]te (]nd the Strike

Pl(]te (]nd inst(]ll them in opposite positions.

Strike plote

_ Remove the bottom screw from e(]ch hinge (right side)

(]nd p(]rti(]llg insert the, into the top left side hinge holes.

NOTS:All 4 front p(]nel hinge screws will now be in the

top hinge holes - 2 on the left (]nd 2on the right.

!1

II

_ Removethe 4 door hinge screws, 8 edge screws, (]nd/4

inside screws. Liftthe inner door upw(]rds using (]fl(]t

bl(]de screwdriver.

Inside screws

Door hinge

screws

_F--_--_-_lnside screws

Edge screws

'_-_ Edge screws

_"_ Edge

screws

14

Page 15

Installation Instructions

_ Remove and swap the cover cap and door handle from

the outer door:

A. Squeeze the tabs on the inside of the door handle

clips. Push clips through the outer door.

B.Squeeze the tabs on the inside of the cover cap.

Pushcap through the outer door.

Inside of door

Cover

strip

/

Door handle

Door handle clip

_When the cover cap and door handle in place, mount

the inner door back into the outer door with the screws

removed in step a,.Make sure you mount the hinges on

the side opposite the handle.

Inside screws

Door hinge

screws

screws

I

I

-Handle

_ iVlountthe assembled door on the 2 upper left side hinge

screws installed in step 2.

Move the hinge screws loosened in step 3 into the lower

left side screw holes and firmly tight all q screws.

C. Pushthe door handle clips into the openings on the

opposite side of the outer door making sure you flip

the handle so it curves to the inside.

D. Pushthe cover cap into the openings on the outer

door where the handle was removed.

I

Inside of door

!

I

_'_>_4,._ Inside of door

Cover strip j _

Door

_ior and

_@)_ tighten screws

_ Install the/4 plastic caps removed in step 1 into the q

right side front panel holes.

NOTE:To return the door to the original setup, follow

threse instructions, swapping "left" and "right".

15

Page 16

Installation Instructions

REVERSING THE DOOR SWING

GLASS PANEL DOOR MODELS:

GTDS820EDOWS

GTDS820GDOWS

GTDS815EDOMC

GTDS815GDOMC

GTDS820EDOWS

GTDS820GDOWS

GTDS825EDOP1C

GTDS825GDOP1C

GHDS830EDOWS

GHDS830G DOWS

Open the door to approximatelg 170 degrees.

II

With (] puttg knife, remove the 4 plastic covers located

(]long the left side of front p(]nel (]nd set them (]side.

GHDS835EDOP1C

GHDS835GDOP1C

GTDS850EDOWS

GTDS850GDOWS

GTDS855EDOP1C

GTDS855GDOP1C

GTDS860EDOWS

GTDS860GDOWS

GTDS865EDOP1C

GTDS865GDOP1C

Plostic Cop (4)

_ Loosen the bottom 2 right side hinge screws. Remove the

door (]nd pl(]ce it on (] protected fl(]t surf(]ce to (]void (]ng

d(]m(]ge.

Remove both the Blind Pl(]te (]nd the Strike Pl(]te(]nd

inst(]ll them in opposite positions.

Strike plate

front panel

_ Remove the bottom screw from e(]ch hinge (right side)

(]nd p(]rti(]llg insert them into the top left side hinge

holes.

NOTE:All 4front p(]nel hinge screws will now be in the

top hinge holes - 2 on the left (]nd 2 on the right.

Removethe 4 door hinge screws, 4 edge screws, (]nd

_8 inside screws. Liftthe inner door upw(]rds using (]fl(]t

bl(]de screwdriver.

Inside screws

Edge

II

Insi_escrews

oorh nge

16

Page 17

Installation Instructions

_ Remove and swap the 2 cover caps and door handle

from the outer door:

A. Squeeze the tabs on the inside of the door handle

clips. Push clips through the outer door.

B.Squeeze the tabs on the inside of the cover caps.

Pushcaps through the outer door.

Cover cap

I Door handle

Door

handle

clip

_When the cover caps and door handle in place, mount

the inner door back into the outer door with the screws

removed in step 4. Make sure you mount the hinges on

the side opposite the handle.

Inside screws

Door

hinge

I

screws

i

screws

Handle

e screws

_ iVlountthe assembled door on the 2 upper left side

hinge screws installed in step 2. Move the hinge screws

loosened in step 3 into the lower left side screw holes.

Tighten those screws enough to hold the door but still

allow a slight adjustment. Close the door. Adjust the door

so there is equal gap on all sides. Carefully open the door

and firmly tighten all/4 screws.

C. Pushthe door handle clips into the openings on the

opposite side of the outer door making sure you flip

the handle so it curves to the inside.

D. Pushthe cover caps into the openings on the outer

door where the handle was removed.

Inside of door

Covercop

handle clip

Door

_ior and

_@)_ tighten screws

_ Install the/4 plastic caps removed in step 1 into the/4

right side front panel holes.

NOTE:To return the door to the original setup, follow

these instructions, swapping "left" and "right".

17

Page 18

Notes

18

Loading...

Loading...