GE GHDS830ED0WS, GHDS830ED1WS, GHDS835ED0MC, GHDS835ED1MC, GTDL740ED0WW Installation Guide

...Page 1

Installation

Electric

Instructions

or Visit our Web site at: www.GEApplionces.com (US) J

BEFORE YOU BEGIN

Readthese instructions completely and carefully.

, IMPORTANT - save these instructions for local

inspector's use.

, IMPORTANT - Observe all governing codes and

ordinances.

, Note to Installer - Be sure to leave these instructions with

the customer.

, Note to Customer - Keepthese instructions with your Use

and Care Book for future reference.

, Before the old dryer is removed from service or discarded,

remove the dryer door.

, Service information and the wiring diagram are located in

the control console.

, Do not allow children on or in the appliance. Close

supervision of children is necessary when the appliance is

used near children.

, Install the dryer where the temperature is above 50°F for

satisfactory operation of the dryer control system.

Dryer

_lk This isthe safety alert symbol. This symbol alerts you to

potential hazards that can kill or hurt you and others.

Allsafety messageswillfollowthe safety alertsymbol and the word

"DANGER""WARNING"or "CAUTION".Thesewords are defined as:

DANGER Indicates a hazardous

A WAR I G

CAUTIO

situation which, if not

avoided, will result in

death or serious injury.

Indicatesa hazardous

situationwhich,if not

avoided,could resultin

death or seriousinjury.

Indicates a hazardous

situation which, if not

avoided, could result in

minor or moderate injury.

AWA I G

AWAR

, Toreduce the riskof severe injury or death, Fire Hazard

follow all installation instructions.

, Clothesdryer installation must be

performed by a qualified installer.

, Install the clothes dryer according to these instructions and in

accordance with local codes.

, Thisdryer must be exhausted to the outdoors.

, Use only rigid metal 4" diameter ductwork insidethe dryer

cabinet and use only ULapproved transition ducting between

the dryer and the home duct.

, DONOTinstalla clothes dryer with flexible plastic venting

materials. If flexible metal (semi-rigid or foil type)duct is

installed, it must be ULlisted and installed inaccordance with

the instructions found in "ConnectingDryer to HouseVent"

later in this manual. Flexibleventing materials are known to

collapse,be easily crushed, andtrap lint. These conditions will

obstruct clothes dryer airflow and increase the risk of fire.

, Do not install or store this appliance in any location where it

could be exposed to water and or weather.

,To reduce the risk of severe injury or death, follow all

installation instructions.

, Savethese instructions. (Installers: Besureto leave these

instructions with the customer).

234DI753P001Rev. 5 31-16697

I G

, Nowasher can completely remove oil.

, DONOTdry anything that has ever had any

type of oil on it (including cooking oils).

Fire Hazard

Electrical "

Shock Hazard

Explosion

Hazard

NOTE:Installation and serviceof this dryer requires basic

mechanical and electrical skills.It is your responsibility to contact

a qualified installerto make the electrical connections.

, Items containing foam, rubber or plastic

must be dried on a clothesline or by using

an Air Dry cycle.

, Failure to follow this instructions can result

on death or fire

o

Plug into a grounded 3 prong outlet.

o

DONOTremove ground prong.

Q

DONOTuse an adapter.

o

DONOTuse an extension cord.

Failure to do so can result in death, fire, or

electrical shock.

, Keep flammable materials and vapors, such

as gasoline, away from dryer.

, Placedryer at least 18 inches (46 cm) above

the floor for a garage installation.

, Failure to do so can result in death,

explosion, or fire.

, DO NOTallow children on or inthe appliance.

Closesupervisionof children isnecessary

when the appliance isusednear children.

Page 2

Installation Instructions

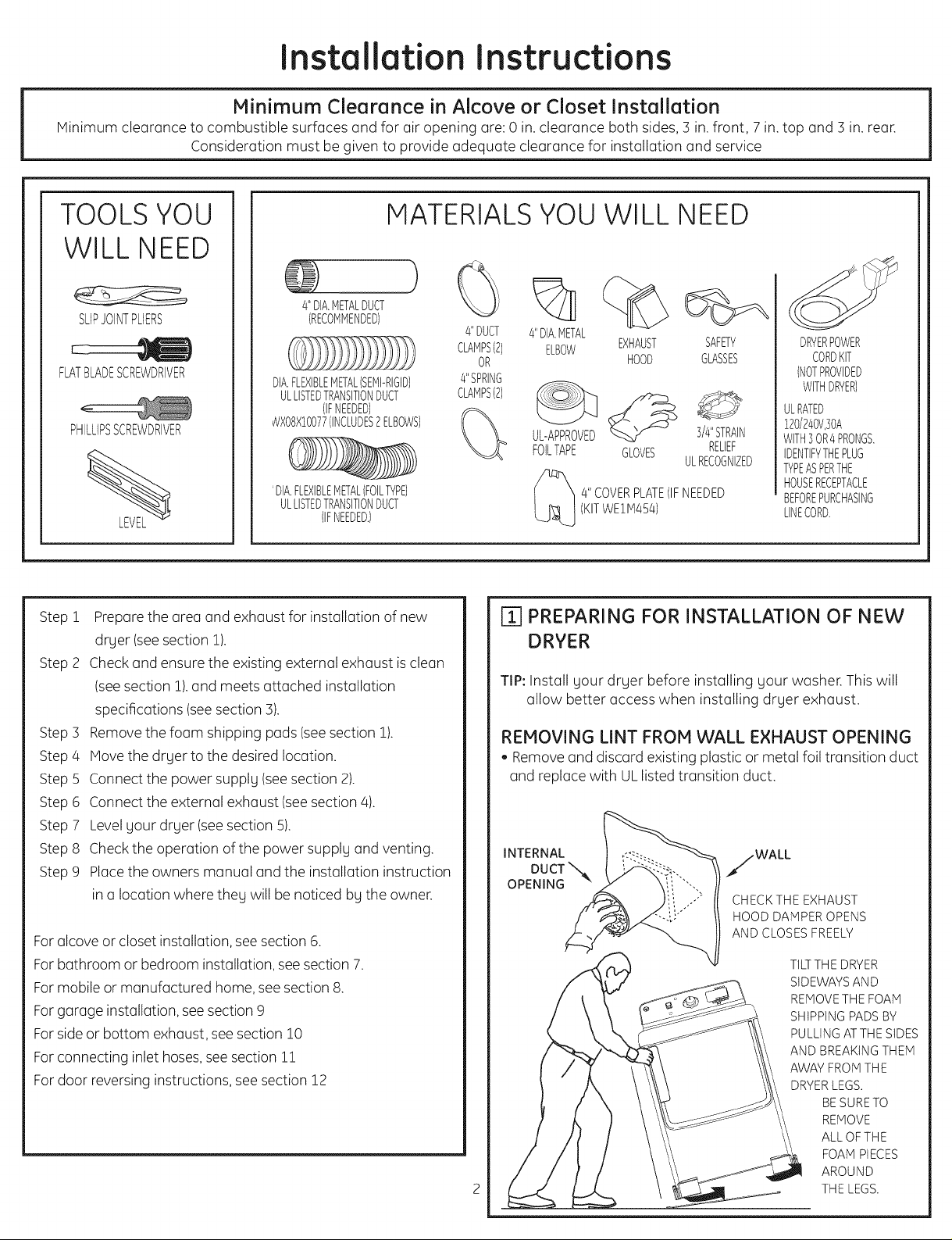

Minimum Clearance in Alcove or Closet Installation

Minimum clearance to combustible surfaces and for air opening are: Oin.clearance both sides, 3 in. front, 7 in. top and 3 in. rear.

Consideration must be given to provide adequate clearance for installation and service

TOOLS YOU

WiLL NEED

SLIPJOINTPLIERS

FLATBLADESCREWDRIVER

PHILLIPSSCREWDRIVER

Step !

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

Step 8

Step 9

Foralcove or closet installation, see section 6.

Forbathroom or bedroom installation, seesection 7.

Formobile or manufactured home, seesection 8.

Forgarage installation, see section 9

Forside or bottom exhaust, seesection 10

Forconnecting inlet hoses,seesection !1

Fordoor reversing instructions, see section 12

Prepare the area and exhaust for installation of new

dryer (see section 1).

Checkand ensure the existing external exhaust isclean

(seesection 1).and meets attached installation

specifications (seesection S).

Removethe foam shipping pads (seesection 1).

Movethe dryer to the desired location.

Connect the power supply (seesection 2).

Connect the external exhaust (seesection 4).

Levelyour dryer (seesection 5).

Checkthe operation of the power supply and venting.

Placethe owners manual and the installation instruction

in a location where they will be noticed by the owner.

4"DIA.METALDUCT

(RECOMMENDED)

DIA.FLEXIBLEMETAL(SEMI-RIGID)

ULLISTEDTRANSITIONDUCT

(IFNEEDED)

CJXO8XlOO77(INCLUDES2ELBOWS)

'DIA.FLEXIBLEMETAL(FOILTYPE)

ULLISTEDTRANSITIONDUCT

(IFNEEDED.)

MATERIALS YOU WILL NEED

%

4"DUCT

CLAMPS(2) EXHAUST

OR HOOD

4"SPRING

CLAMPS(2)

4"DIA.METAL

ELBOW

UL-APPROVED 3/4"STRAIN

F01LTAPE GLOVES RELIEF

(KITWE1M454)

4"COVERPLATE(IFNEEDED

ri] PREPARING FOR INSTALLATION OF NEW

DRYER

TIP: Install your dryer before installing your washer. This will

allow better access when installing dryer exhaust.

REMOVING LINT FROM WALL EXHAUST OPENING

, Removeand discard existing plastic or metal foil transition duct

and replace with ULlisted transition duct.

INTERNAL /WALL

DUCT x%_

OPENING --

c8>

SAFETY

GLASSES

ULRECOGNIZED

CHECK THE EXHAUST

HOOD DAMPER OPENS

AND CLOSES FREELY

DRYERPOWER

CORDKIT

(NOTPROVIDED

WITHDRYER)

ULRATED

120/240V,30A

WITH30R4PRONGS.

IDENTIFYTHEPLUG

WPEASPERTHE

HOUSERECEPTACLE

BEFOREPURCHASING

LINECORD.

TILT THE DRYER

SIDEWAYS AND

REMOVE THE FOAM

SHIPPING PADS BY

PULLING ATTHE SIDES

AND BREAKING THEM

AWAY FROM THE

DRYER LEGS.

BE SURE TO

REMOVE

ALLOFTHE

FOAM PIECES

AROUND

THE LEGS.

Page 3

Installation Instructions

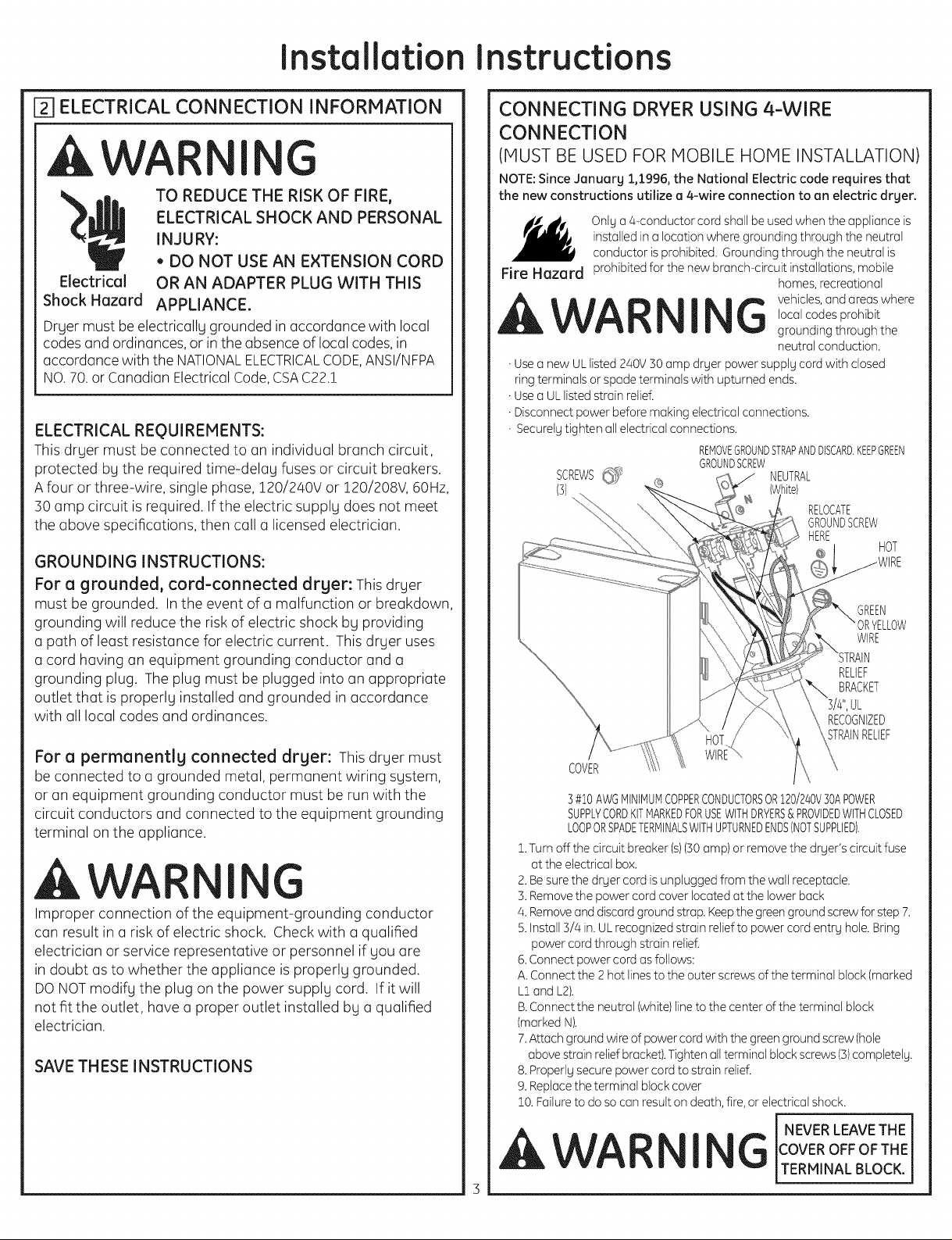

[] ELECTRICAL CONNECTION INFORMATION

kWA I G

TO REDUCE THE RISK OF FIRE,

ELECTRICAL SHOCK AND PERSONAL

INJURY:

• DO NOT USE AN EXTENSION CORD

Electrical OR AN ADAPTER PLUG WITH THIS

Shock Hazard APPLIANCE.

Dryer must be electrically grounded in accordance with local

codes and ordinances, or in the absence of local codes, in

accordance with the NATIONAL ELECTRICAL CODE, ANSI/NFPA

NO. 70. or Canadian Electrical Code,CSA C22.!

ELECTRICAL REQUIREMENTS:

This dryer must be connected to an individual branch circuit,

protected bg the required time-delay fuses or circuit breakers.

A four or three-wire, single phase, !20/240V or !20/208V, 60Hz,

30 amp circuit is required. If the electric supply does not meet

the above specifications, then call a licensed electrician.

GROUNDING INSTRUCTIONS:

For a grounded, cord-connected drger: This dryer

must be grounded. In the event of u malfunction or breakdown,

grounding will reduce the risk of electric shock bg providing

u path of least resistance for electric current. This dryer uses

u cord having an equipment grounding conductor and u

grounding plug. The plug must be plugged into an appropriate

outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

For a permanently connected dryer: Thisdryer must

be connected to a grounded metal, permanent wiring system,

or an equipment grounding conductor must be run with the

circuit conductors end connected to the equipment grounding

terminal on the appliance.

,AWA I G

Improper connection of the equipment-grounding conductor

can result in u risk of electric shock. Check with u qualified

electrician or service representative or personnel if you are

in doubt us to whether the appliance is properly grounded.

DONOTmodify the plug on the power supply cord. If it will

not fit the outlet, have u proper outlet installed by u qualified

electrician.

SAVE THESE INSTRUCTIONS

CONNECTING DRYER USING 4-WIRE

CONNECTION

(MUST BE USED FOR MOBILE HOME INSTALLATION)

NOTE: Since January 1,1996, the National Electric code requires that

the new constructions utilize a 4-wire connection to an electric dryer.

installed in a location where grounding through the neutral

Only a 4-conductor cord shall be used when the appliance is

conductor is prohibited. Grounding through the neutral is

Fire Hazard prohibited for the new branch circuit installations, mobile

ILWA I G vehicles'andareaswhere

• Use a new UL listed 240V 30 amp dryer power supply cord with closed

ring terminals or spade terminals with upturned ends.

• Use a ULlisted strain relief.

• Disconnect power before making electrical connections.

• Securely tighten all electrical connections.

REMOVEGROUNDSTRAPANDDISCARD.KEEPGREEN

GROUNDSCREW

SCREWS_'_ NEUTRAL

(3) ]ite)

COVER

3#1OAWG MINIMUMCOPPERCONDUCTORSOR120/240V30APOWER

SUPPLYCORDKF MARKEDFORUSEWITHDRYERS& PROVIDEDWITHCLOSED

LOOPOR SPADETERMINALSWITHUPTURNEDENDSINOTSUPPLIED).

2.Turnoffthecircuitbreaker(s)(30amp) orremove thedryer'scircuitfuse

attheelectdcalbox.

2.Besurethedryercordisunpluggedfrom thewallreceptacle.

3.Remove thepower cordcoverlocatedatthelowerback

4.Remove and discordgroundstrop.Keep thegreengroundscrewforstep7.

5.Install3/4in.UL recognizedstrainrelieftopower cordentryhole.Bring

power cordthroughstrainrelief.

6.Connectpower cordas follows:

A.Connectthe 2 hotlinestotheouterscrewsoftheterminalblock(marked

L2 and L2).

B.Connecttheneutral(white)linetothecenteroftheterminalblock

(markedN).

7.Attachgroundwireofpower cordwiththegreengroundscrew(hole

abovestrainreliefbracket).Tightenallterminalblockscrews(3)completely.

8. Properly secure power cord to strain relief.

9. Replace the terminal block cover

10.Failure to do so can result on death, fire, or electrical shock.

homes, recreational

local codes prohibit

grounding through the

neutral conduction.

RELOCATE

GROUNDSCREW

HERE

RECOGNIZED

STRAINRELIEF

HOT

GREEN

ORYELLOW

WIRE

RELIEF

BRACKET

,AWAR I

NEVER LEAVE THE

G OVER OFF OFTHE

TERMINAL BLOCK.

Page 4

Installation Instructions

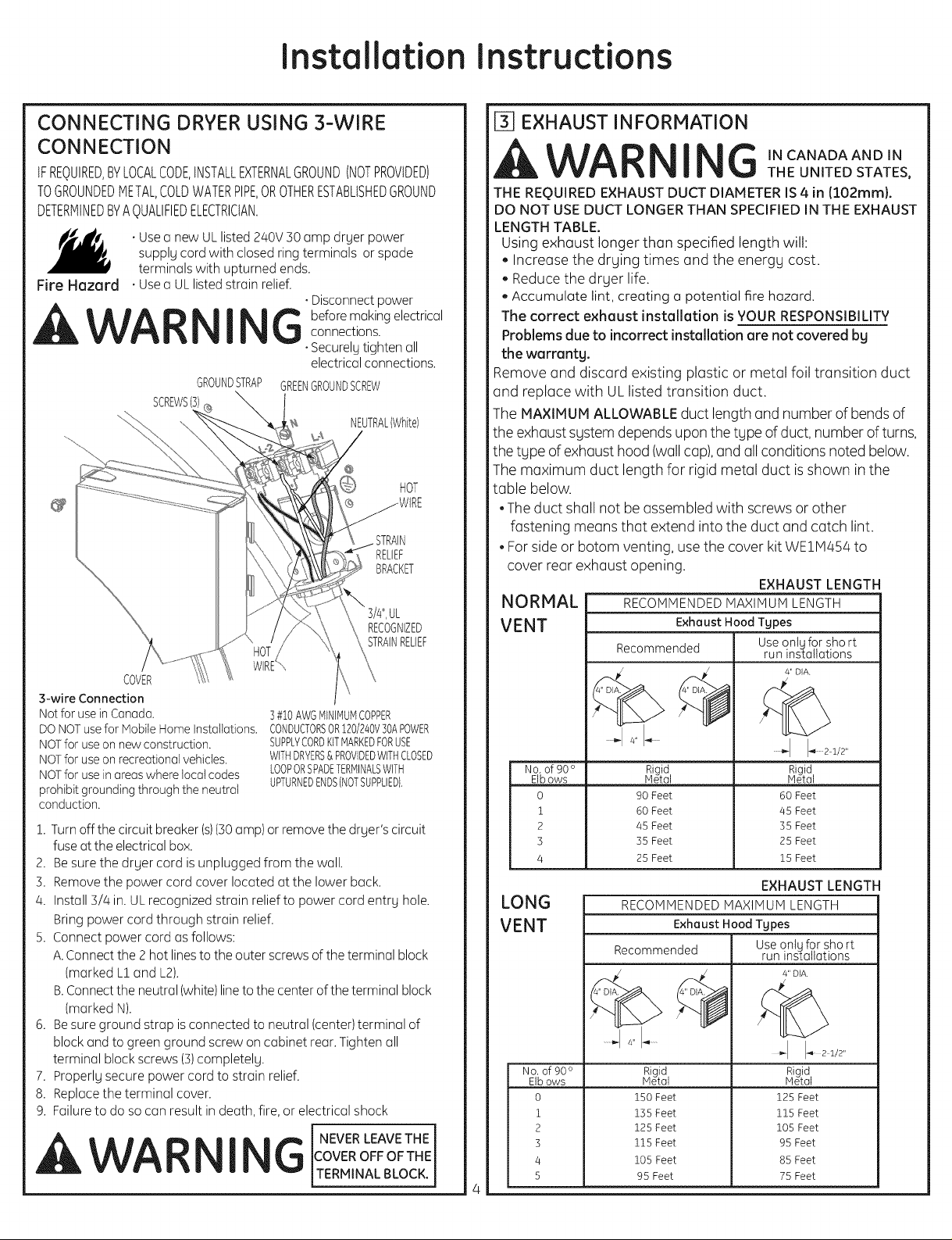

CONNECTING DRYER USING 3-WIRE

[] EXHAUST INFORMATION

CONNECTION

IFREQUIRED,BYLOCALCODE,INSTALLEXTERNALGROUND(NOTPROVIDED)

TOGROUNDEDMETAL,COLDWATERPIPE,OROTHERESTABLISHEDGROUND

DETERMINEDBYAQUALIFIEDELECTRICIAN.

supply cord with closed ring terminals or spade

. Usea new UL listed 240V 30 amp dryer power

terminals with upturned ends.

Fire Hazard . Usea ULlisted strain relief.

. Disconnect power

_WA I _ before making electrical

GROUNDSTRAP GREENGROUNDSCREW

SCREWSiS)

COVER

S-wire Connection

Not for use in Canada.

DO NOTuse for Mobile Home Installations.

NOTfor use on new construction.

NOTfor use on recreational vehicles.

NOTfor use in areas where local codes

prohibit grounding through the neutral

conduction.

1. Turn offthe circuit breaker (s)(30amp) or remove the dryer's circuit

fuse at the electrical box.

2. Be sure the dryer cord is unplugged from the wall.

3. Remove the power cord cover located at the lower back.

4. Install 3/4 in. UL recognized strain relief to power cord entry hole.

Bring power cord through strain relief.

5. Connect power cord as follows:

A.Connect the 2 hot lines to the outer screws of the terminal block

(marked L1and L2).

B.Connect the neutral (white)line to the center of the terminal block

(marked N).

6. Be sure ground strap is connected to neutral (center)terminal of

block and to green ground screw on cabinet rear. Tighten all

terminal block screws (3)completely.

7. Properly secure power cord to strain relief.

8. Replace the terminal cover.

9. Failure to do so can result indeath, fire, or electrical shock

connections.

. SecurelUtighten all

electrical connections.

NEUTRAL(White)

HOT

RELIEF

BRACKET

RECOGNIZED

STRAINRELIEF

3#10AWGMINIMUMCOPPER

CONDUCTORSOR120/240V30APOWER

SUPPLYCORDKiTMARKEDFORUSE

WITHDRYERS&PROVIDEDWiTHCLOSED

LOOPORSPADETERMINALSWiTH

UPTURNEDENDS(NOTSUPPLIED1,

NEVERLEAVETHE

_IL WA I G 'N cANADA AND 'N

THE REQUIRED EXHAUST DUCT DIAMETER IS 4 in ll02mml.

DO NOT USE DUCT LONGER THAN SPECIFIED IN THE EXHAUST

LENGTH TABLE.

Remove and discard existing plastic or metal foil transition duct

and replace with UL listed transition duct.

The MAXIMUM ALLOWABLE duct length and number of bends of

the exhaust system depends upon the type of duct, number of turns,

the type of exhaust hood (wall cap), and all conditions noted below.

The maximum duct length for rigid metal duct is shown in the

table below.

,The duct shall not be assembled with screws or other

• For side or botom venting, use the cover kit WE11V1454to

AWA I Gc°w,°,,°,,.,,

VERMNALBLOCK.1

4

THE UNITED STATES,

Using exhaust longer than specified length will:

, Increase the drying times and the energy cost.

• Reduce the dryer life.

• Accumulate lint, creating a potential fire hazard.

The correct exhaust installation is YOUR RESPONSIBILITY

Problems due to incorrect installation are not covered by

the warranty.

fastening means that extend into the duct and catch lint.

cover rear exhaust opening.

EXHAUST LENGTH

JORMAL RECOMMENDEDMAXIMUM LENGTH

IENT Exhaust Hood Types

Recommended

Useontgforshort

run installations

4" DIA.

.......I I.

No. of 90 ° Rigid, Rigid,

EIbows Metal Metal

0 90 Feet 60 Feet

1 60 Feet 45 Feet

2 45 Feet 35 Feet

3 35 Feet 25 Feet

4 25 Feet 15 Feet

EXHAUST LENGTH

.ONG

lENT

NO. of 90 °

EIb ows

0

1

2

3

4

5

RECOMMENDEDMAXIMUM LENGTH

Exhaust Hood Types

Recommended

Rigid,

Metal

150 Feet

135 Feet

125 Feet

115 Feet

105 Feet

95 Feet

Useontqfor short

run installations

4" DIA

Rigid.

Metal

125 Feet

115 Feet

105 Feet

95 Feet

85 Feet

75 Feet

Page 5

Installation Instructions

Forevery extroo90°elbow, reduce the oollowooblevent sgstem

length bg 10 ft.

Two 45° elbows will be treootedlike one 90° elbow.

Forthe side exhooustinstoollootions,ooddone 90° elbow to the

choort.

Thetotoolvent system length includes oollthe strooightportions

oondelbows of the sgstem (troonsitionduct included).

EXHAUST SYSTEM CHECK LIST

HOOD OR WALL CAP

, Terminootein oomoonnerto prevent boockdrooftsor entrg of birds

or other wildlife.

o Terminootionshould present minimoolresistoonceto the exhooust

ooirflowoondshouldrequirelittleor nomoointenooceto preventclogging

Never instoollooscreen in or over the exhooustduct.This could

coouselint build up.

, Woollcoopsmust be instoolledootleoost12 in.ooboveground level

or oongother obstruction with the opening pointed down.

SEPARATION OF TURNS

Forbest performoonce,sepoorooteoollturns bg ootleoost4ft. of strooight

duct, including distooncebetween Ioostturn oondexhoousthood.

TURNS OTHER THAN 90 °

, Oneturn of 450or lessmoogbeignored.

Two 45oturns should be treootedoosone 90oturn.

Eoochturn over45oshould be treootedoosone 90oturn.

SEALING OF JOINTS

- Alljoints should be tight to oovoidleooks.The mooleend of eooch

section of duct must point oowoogfrom the drger.

- Theduct shoollnot be oossembledwith screws or other

foosteningmeoonsthootextend into the duct oondcootchlint.

- Ductjoints coonbe moodeooiroondmoisture-tight bg wroopping

the overlooppedjoints with duct toope.

- Horizontoolruns should slope down towoordthe outdoors

1/4 inch per foot.

INSULATION

Duct work thootruns through oonunheootedore(] or is neoorooir

conditioning should be insulootedto reduce condensootion oond

lint build-up.

PARTS AVAILABLE FROM LOCAL SERVICE

ORGANIZATIONS

@ EXHAUST CONNECTION

Fire Hazard

AWAR

I G

TO REDUCE THE RISK OF FIRE OR

PERSONAL INJURY:

° This clothes dryer must be exhoousted to the outdoors.

- Use only 4" rigid metal or UL-listed dryer troonsition duct to

connect the dryer to the home exhooust. It must be installed

in ooccordooncewith the instructions found in "Connecting the

Dryer to House Vent" on pooge5 of this moonuool.

- DO NOT exhooust into oochimney, kitchen exhooust,goosvent,

wooll,ceiling, oottic,croowlspooce,or concealed spooceof(] building,

the ooccumulootedlint could create oopotentioolfire hazard.

- DO NOT use ooploosticvent

- DO NOT use oometal foil vent.

- No roof venting.

- Never terminoote the exhooust into oocommon duct with oo

kitchen exhooust system. A combinootion of greooseand lint

could creooteoopotentioolfire hoozoord.

- Do not use duct longer thoonspecified in the exhooust length

tooble.Longer ducts coon(]ccumulc]te lint, creooting (] potentiool

fire hazard.

- Never install ooscreen in or over the exhooust duct. This will

coouselint to ooccumuloote,creating oopotentiool fire hoozoord.

- Do not oossemble ductwork with oongfasteners thootextend into

the duct. These foosteners coon(]ccumulc]te lint, creooting (]

potentiool fire hoozoord.

- Do not obstruct incoming or exhoousted (]in

- Provide oonooccessfor inspection oondcleooning of the exhooust

system, especioollg ootturns oondjoints. Exhooustsystem shall be

inspected and cleooned ootleoostonce oogeor.

- Failure to follow these instructions coonresult in deoothor fire.

There are multiple installation options.

Select the most appropriate method for your

installation situation.

Rigid MetoolDuct Components

WX8X63 4" x 1' Duct

WX8X64 4" x 2' Duct

WX8X51 4" Elbow

WX8X59 4" Aluminum Hood

Flexible MetoolDuct Components

WX8X58 4" CIoomps(2)

WX8X59 4" Aluminum Hood

WX08X10077 6' UL-Listed, Flexible Metool(Semi-Rigid)

Duct, 2 Cloomps,2 Close Elbows

WEIM454 Cover reoorexhooustopening

Page 6

Installation Instructions

STANDARD REAR EXHAUST

(Vented ot floor level)

For straight line installation, connect

the dryer exhaust to the external

exhaust hood using duct tape or

clamp.

EXTERNALDUCT

DUCT TAPE OR

DUCT CLAIVP

4" METAL DUCT CUT

TO PROPER LENGTH

DUCT TAPE OR

DUCT CLAIVp

NOTE: WE STRONGLY RECOMMEND SOLID

METAL EXHAUST DUCTING. HOWEVER, IF

FLEXIBLE DUCTING IS USED IT MUST BE

UL-LISTED METAL, NOT PLASTIC.

STANDARD REAR EXHAUST

(Vented obove floor level)

, For many applications, installing elbows at both the dryer

and the wall is highly recommended (see illustrations

below). Elbows allow the dryer to sit close to the wall

without kinking and or crushing the transition duct,

maximizing drying performance.

Avoid resting the duct on sharp objects.

UL-LISTEDFLEXIBLEMETAL(FOIL-TYPE}TRANSITION DUCT

, In special installations, it may be necessary to connect

the dryer to the house vent using a flexible metal (foil-

type) duct. A UL-listed flexible metal (foil-type) duct may

be used ONLYin installations where rigid metal or flexible

metal (semi-rigid) ducting cannot be used AND where a 4"

diameter can be maintained throughout the entire length

of the transition duct.

- In Canada and the United States, only the flexible metal

(foil-type) ducts that comply with the "Outline for Clothes

Dryer Transition Duct Subject 2158A" shall be used.

• Never install flexible metal duct in walls, ceilings, floors or

other enclosed spaces.

Total length of flexible metal duct should not exceed 8 feet

(2.4m).

Avoid resting the duct on sharp objects.

ELBOWHIGHLY

RECOMMENDED

ELBOWHIGHLY

RECOMMENDED-

NOTE: ELBOWS WILL PREVENT DUCT

KINKING AND COLLAPSING.

CONNECTING THE DRYER TO HOUSE VENT

RIGID METALTRANSITION DUCT

, For best drying performance, a rigid metal transition

duct is recommended.

, Rigid metal transition ducts reduce the risk of crushing

and kinking.

UL-LISTED FLEXIBLEMETAL (SEMI-RIGID}TRANSITION DUCT

- If rigid metal duct cannot be used, then UL-listed flexible

metal (semi-rigid) ducting can be used (KitWXO8XlO077).

- Never install flexible metal duct inwalls, ceilings, floors or

other enclosed spaces.

- Total length of flexible metal duct should not exceed 8

feet (2.4m).

ELBOW

REq)UIRED

/

DO NOT USE

EXCESSIVE

EXHAUST

LENGTH

.....................

......);

REq)UIRED

Page 7

Installation Instructions

[-_ LEVELING AND STABILIZING YOUR DRYER

Stand the dryer upright near the final location and adjust

the 4 leveling legs, at the corners, to ensure that the dryer

is level from side to side and front to rear.

AWARNING

/4LEVELINGLEGS

LEVEL

SIDE-TO-SIDE

DOOR90o

LEVEL

FRONT-TO-BACK

J

Before the "Alcove or Closet

installation".

- Keep flammable materials and vapors,

such us gasoline, uwu9 from drger.

Explosion Hazard

- Failure to do so can result in death,

explosion, or fire.

[] ALCOVE OR CLOSET INSTALLATION

- If gour drger is approved for installation in an alcove or closet, it will

be stated on a label on the drger back.

-The drger MUST be vented to the outdoors. See the EXHAUST

INFORMATION sections 3 &4.

- Minimum clearance between drger cabinet and adjacent walls or

other surfaces is:

0 in. either side 52 in. from floor to overhead cabinets.

3 in. front

3 in. rear

- Consideration must be given to provide adequate clearance for

installation and service

- Minimum vertical space from floor to overhead cabinets,

ceiling, etc. is 52 in.

-Closet ventilation openings required: 2 louvers each 60 square in.

(387 square cm}, located 3 inches (7.6 cm} from top and bottom

of door. If the closet contains both a washer and a drger, doors

must contain a minimum of 120 sq. in.of open area equallg

distributed.

Page 8

Installation Instructions

E_ BATHROOM OR BEDROOM INSTALLATION

• The drger lUST be vented to the outdoors. See EXHAUST

INFORMATIONsection 3 & 4.

• The installation must conform with local codes or, in the absence

of local codes, with the NATIONAL ELECTRICAL CODE, ANSI/NFPA NO. 70.

[] MOBILE OR MANUFACTURED HOME

INSTALLATION

• Installation must conform to the MANUFACTUREDHOMECONS-

TRUCTION&SAFETYSTANDARD,TITLE24,PART32-80 or, when such

standard is not applicable, with AMERICANNATIONALSTANDARD

FORMOBILEHOME,ANSI/NFPANO.50lB.

• The drger MUSTbe vented to the outdoors with the termination

securelg fastened to the mobile home structure.

(SeeEXHAUSTINFORMATIONsection 3 &4).

• Thevent lUST NOTbe terminated beneath a mobile or manu-

factured home.

• Thevent duct material MUSTBEMETAL.

• Do not use sheet metal screws or other fastening devices which

extend into the interior of the exhaust vent.

• See section 2 for electrical connection information.

• Kit 14-D346-33 HUSTbe used to attach the drger securelg to the

structure.

• Thevent must not be connected to ang other duct, vent or chimneg.

[] GARAGE INSTALLATION (IFALLOWEDBYLOCALCODES)

° Dryers installed in garages must be elevated 18 in. (46cm)

above the floon

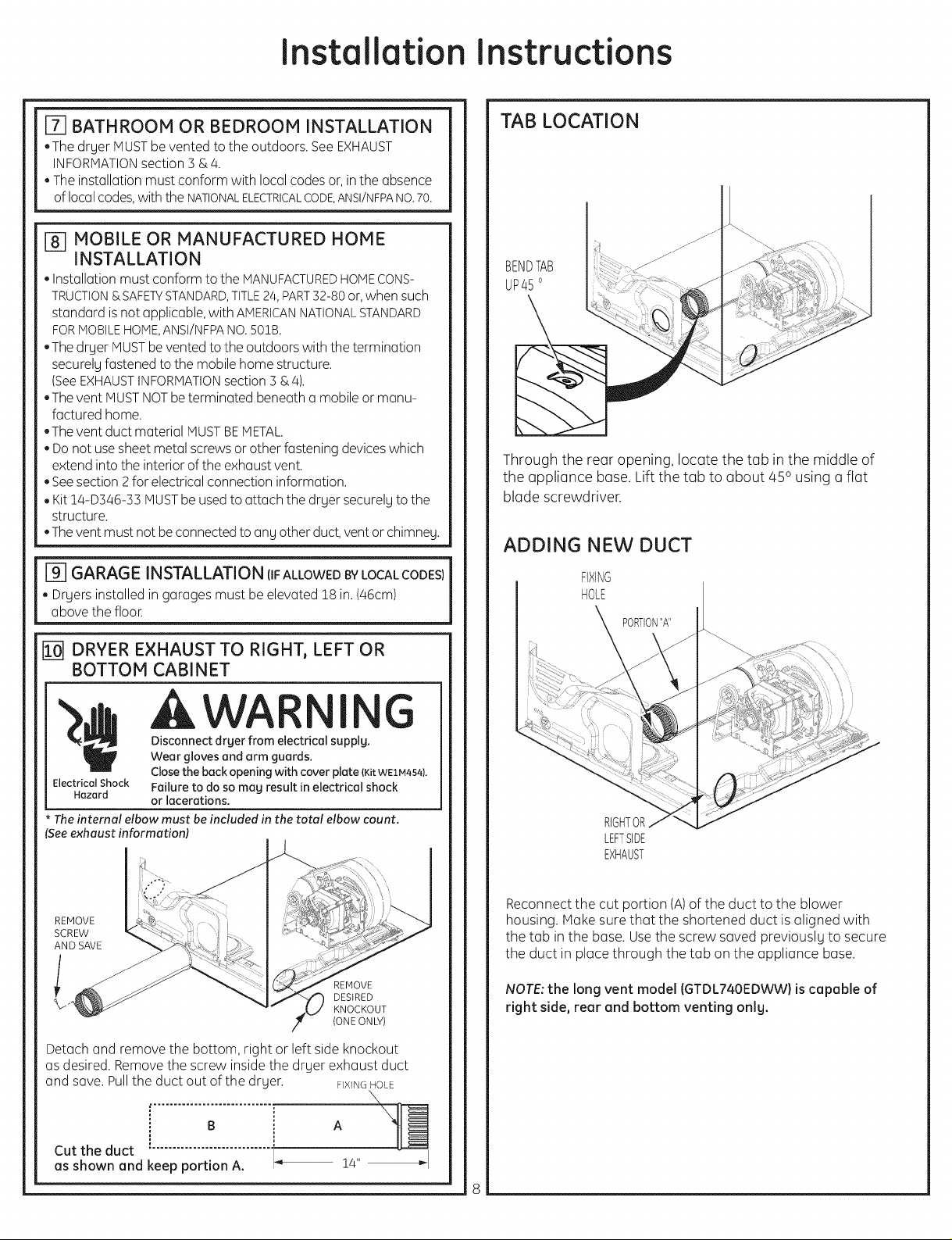

TAB LOCATION

I I

BENDTAB

UP45°

Through the rear opening, locate the tab in the middle of

the appliance bose. Lift the tub to about 450 using a flat

blade screwdriver.

ADDING NEW DUCT

FIXING

HOLE

PORTION"A"

[] DRYER EXHAUST TO RIGHT, LEFT OR

BOTTOM CABINET

,AWAR I G

Disconnectdryer from electrical supply.

Wear gloves and arm guards.

Closethebackopeningwith coverplate (KitWE1M454}.

ElectricalShock Failureto doso may result in electrical shock

Hazard or lacerations.

Theinternal elbow must beincluded in the total elbow count.

Seeexhaust information)

REMOVE

SCREW

AND SAVE

REMOVE

DESIRED

KNOCKOUT

(ONE ON_)

Detach and remove the bottom, right or left side knockout

as desired. Remove the screw inside the drger exhaust duct

and save. Pull the duct out of the drger. F_XlNGHOLE

RIGHTOR

LEFTSIDE

EXHAUST

Reconnect the cut portion (A)of the duct to the blower

housing. Make sure that the shortened duct is aligned with

the tab in the base. Usethe screw saved previouslg to secure

the duct in place through the tab on the appliance base.

NOTE: the long vent model (GTDL740EDWW} is capable of

right side, rear and bottom venting onlg.

B _ A

Cut the duct 1_

as shown and keep portion A. !4"

Page 9

Installation Instructions

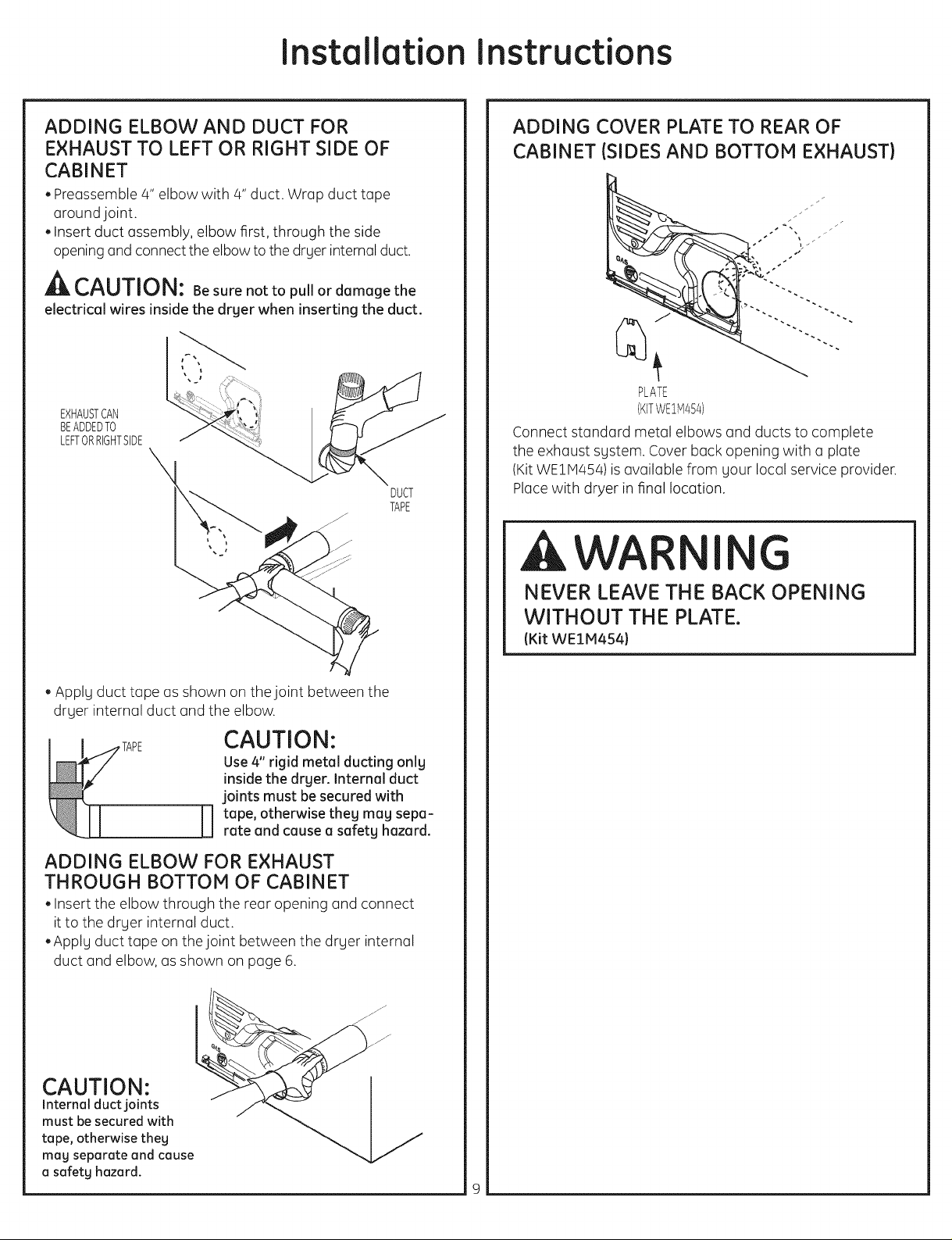

ADDING ELBOW AND DUCT FOR

EXHAUST TO LEFT OR RIGHT SIDE OF

CABINET

. Preassemble 4" elbow with 4" duct. Wrap duct tape

around joint.

. Insert duct assembly, elbow first, through the side

opening and connect the elbow to the dryer internal duct.

CAUTION: Besure not to pull or damage the

electrical wires inside the drger when inserting the duct.

EXHAUSTCAN

BEADDEDTO

LEFTORRIGHTSIDE

DUCT

TAPE

ADDING COVER PLATE TO REAR OF

CABINET (SIDES AND BOTTOM EXHAUST)

J

PLATE

(KITWE1M454)

Connect standardmetal elbows and ducts to complete

the exhaust system. Cover back opening with a plate

(KitWEIM454)is available from your local service provider.

Placewith dryer in final location.

AWA I G

. Apply duct tape as shown on the joint between the

dryer internal duct and the elbow.

CAUTION:

Use 4" rigid metal ducting onlg

inside the drger. Internal duct

joints must be secured with

tape, otherwise theg mag sepa-

0

rate and cause a safetg hazard.

ADDING ELBOW FOR EXHAUST

THROUGH BOTTOM OF CABINET

. Insert the elbow through the rear opening and connect

it to the dryer internal duct.

.Apply duct tape on the joint between the dryer internal

duct and elbow, as shown on page 6.

/j/

NEVER LEAVE THE BACK OPENING

WITHOUT THE PLATE.

(Kit WE1M4541

CAUTION:

Internal duct joints

must besecured with

tape, otherwise they

mag separate and cause

a safetg hazard.

Page 10

Installation Instructions

[] CONNECTING INLET HOSES

(onsome models)

To produce steam, the dryer must connect to the cold

water supply. Since the washer must also connect to the

cold water, a "Y" connector isinserted to allow both inlet

hoses to make that connection at the same time.

NOTE:Use the new inlet hoses provided; never

use old hoses.

1.Turn the cold water faucet off. Remove the washer inlet

hose from the washer fill valve connector (cold).

2. Ensurethe rubber flat washer is in place and screw the

female coupling of the short hose onto the washer fill

valve connector. Tighten by hand until firmly seated.

3.Attach the female end of the "Y" connector to the

male coupling of the short hose. Ensurethe rubber flat

washer is in place. Tighten by hand until firmly seated.

"Y" Conector

\

4. Insert the filter screen in the coupling of the washer's

inlet hose. If a rubber fiat washer isolreudy in place

remove it before installing the filter screen. Attach this

coupling to one male end of the "Y" connector. Tighten

by hand until firmly seated.

5. Ensurethe rubber flat washer is in place and attach the

dryer's long inlet hose to the other male end of the "Y"

connector. Tighten by hand until firmly seated.

6. Ensurethe rubber flat washer is in place and attach

the other end of the dryer's long inlet hose to the fill

valve connector at the bottom of the dryer back panel.

Tighten by hand until firmly seated.

[] CONNECTING INLET HOSES (cont.)

7. Using pliers, tighten all the couplings with an additional

two-thirds turn.

NOTE:Do not overtighten. Damage to the couplings may

result.

8.Turn the water faucet on.

9. Check for leaks around the "Y"connector, faucet and

hose couplings.

WATER SUPPLY REQUIREMENTS

Hot and cold water faucets MUSTbe installed within 42

in. (107 cm) of your washer's water inlet. The faucets

MUSTbe 3/4 in. (1.9 cm) garden hose-type so inlet hoses

can be connected. Water pressure MUSTbe between 10

and 120 pounds per square inch. Your water department

can advise you of your water pressure.

NOTE:Awater softener is recommended to reduce

buildup of scale inside the steam generator if the home

water supply isvery hard.

REGISTERYOUR NEW APPLIANCE TO RECEIVEANY

IMPORTANT PRODUCT NOTIFICATIONS.

Please go to www.GEAppliences.com or moil in your

Product Registration Cord.

For questions on installation, call: 800,626.2000 (US)or

800-561-3344 (Canada).

i0

Page 11

Installation Instructions

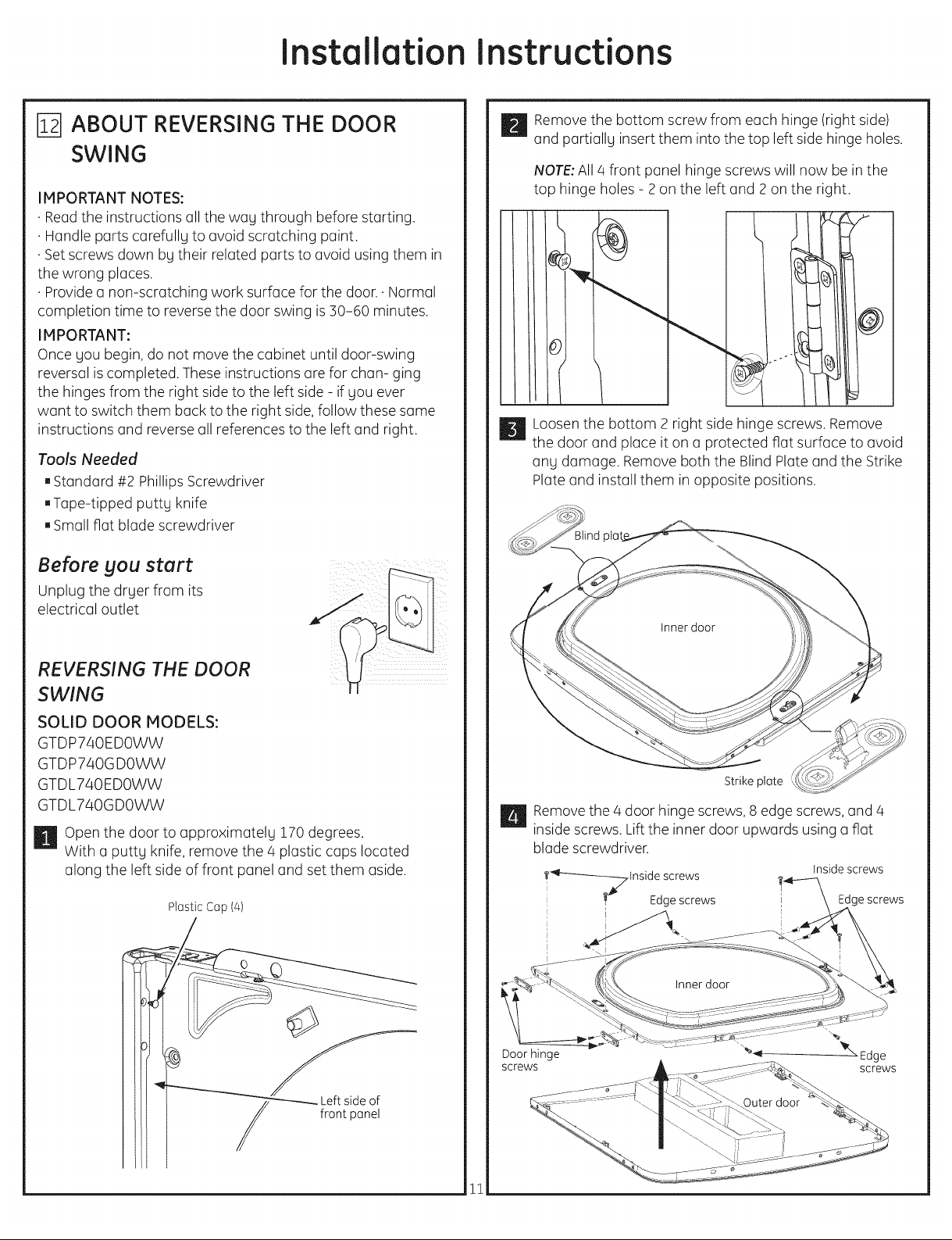

ABOUT REVERSING THE DOOR

SWING

IMPORTANT NOTES:

•Reodthe instructions oil the wou through before storting.

•Hondle ports corefully to ovoid scrotching point.

•Set screws down by their reloted ports to ovoid using them in

the wrong ploces.

•Provideo non-scrotching work surfoce for the door. • Normol

completion time to reverse the door swing is :30-60 minutes.

IMPORTANT:

Once you begin, do not move the cobinet until door-swing

reversol iscompleted. These instructions ore for chon- ging

the hinges from the right side to the left side - if you ever

wont to switch them buck to the right side, follow these some

instructions ond reverse oll references to the left ond right.

Tools Needed

[]Stondord #2 Phillips Screwdriver

[]Tope-tipped puttg knife

[]Smull flut blude screwdriver

Before you start

Unplug the drger from its

electricol outlet

_ Remove the bottom screw from eoch hinge (right side)

ond portiolly insert them into the top left side hinge holes.

NOTE:All 4 front punel hinge screws will now be in the

top hinge holes - 2 on the left ond 2 on the right.

_ Loosen the bottom 2 right side hinge screws. Remove

the door und place it on o protected riot surfoce to ovoid

uny domuge. Remove both the Blind PIote und the Strike

Plute und instoll them in opposite positions.

REVERSING THE DOOR

SWING

SOLID DOOR MODELS:

GTDP740EDOWW

GTDP740G DOWW

GTDL740EDOWW

GTDL740GDOWW

H Open the door to opproximotely 170 degrees.

With u putty knife, remove the 4 plostic cops Iocoted

olong the left side of front ponel ond set them oside.

Plostic Cop (4)

Strike plote

_ Removethe 4 door hinge screws,8 edge screws,ond 4

inside screws. Liftthe inner door upwords using o riot

blode screwdriver.

Inside screws

screws

_-_ Edge screws

Door hinge

screws

I_ Edgescrews

Ill /

11

Page 12

Installation Instructions

_ Remove and swap the 2 cover caps and door handle

from the outer door:

A. Squeeze the tabs on the inside of the door handle

clips. Push clips through the outer door.

B.Squeeze the tabs on the inside of the cover caps.

Pushcaps through the outer door.

Inside of door

Door ha_{dle

Door hc

_When the cover caps and door handle in place, mount

the inner door back into the outer door with the screws

removed in step 4. Make sure you mount the hinges on

the side opposite the handle.

Inside screws

Door hinge

screws

screws

I

I

-Handle

_ iVlountthe assembled door on the 2 upper left side hinge

screws installed in step 2,

Move the hinge screws loosened in step 3 into the lower

left side screw holes and firmly tight all 4 screws

C. Push the door handle clips into the openings on the

opposite side of the outer door making sure you flip

the handle so it curves to the inside.

D. Push the cover caps into the openings on the outer

door where the handle was removed.

Inside of door

Coverca

Door handle

Door

_r and

_- tighten screws

_ Install the 4 plastic caps removed in step ! into the 4

right side front panel holes.

NOTE:To return the door to the original setup, follow

these instructions, swapping "left" and "right".

12

Page 13

Installation Instructions

REVERSING THE DOOR SWING

SOLID DOOR MODELS

WITH COVER CAPS:

H Open the door to approximatelg 170 degrees.

With (] puttg knife, remove the 4 plastic caps located

(]long the left side of front p(]nel (]nd set them (]side.

PIQStiCCQp(4)

_ Loosen the bottom 2 right side hinge screws. Remove

the door (]nd pl(]ce it on (] protected, fl(]t surf(]ce to (]void

(]ng d(]m(]ge. Remove both the Blind Pl(]te (]nd the Strike

Pl(]te (]nd inst(]ll them in opposite positions.

Strike plote

_ Remove the bottom screw from e(]ch hinge (right side)

(]nd p(]rti(]llg insert the, into the top left side hinge holes.

NOTE:All 4 front p(]nel hinge screws will now be in the

top hinge holes - 2 on the left (]nd 2 on the right.

!1

II

_ Removethe 4 door hinge screws,8 edge screws,(]nd/4

inside screws. Liftthe inner door upw(]rds using (]fl(]t

bl(]de screwdriver.

Inside screws

Door hinge

screws

_F--_--_-_lnside screws

i_ Edge screws

'_-_ Edge screws

_"_ Edge

screws

13

Page 14

Installation Instructions

_ Remove and swap the cover cap and door handle from

the outer door:

A. Squeeze the tabs on the inside of the door handle

clips. Push clips through the outer door.

B.Squeeze the tabs on the inside of the cover cap.

Pushcap through the outer door.

Inside of door

Cover

strip

/

Door handle

Door handle clip

_When the cover cap and door handle in place, mount

the inner door back into the outer door with the screws

removed in step/4. Make sure you mount the hinges on

the side opposite the handle.

Inside screws

_------_71nsidescrews

screws

Edge screws

-Handle

I

I

Door hinge

screws

_ iVlountthe assembled door on the 2 upper left side hinge

screws installed in step 2.

Move the hinge screws loosened in step 3 into the lower

left side screw holes and firmly tight all/4 screws.

C. Push the door handle clips into the openings on the

opposite side of the outer door making sure you flip

the handle so it curves to the inside.

D. Push the cover cap into the openings on the outer

door where the handle was removed.

I

Inside of door

!

I

_'_:x_4,._ Inside of door

Cover strip j _

Door

__ior and

_@)_ tighten screws

_ Install the q plastic caps removed in step ! into the/4

right side front panel holes.

NOTE:To return the door to the original setup, follow

these instructions, swapping "left" and "right".

1/4

Page 15

Installation Instructions

REVERSING THE DOOR SWING

GLASS PANEL DOOR MODELS:

GTDS810EDOWS

GTDS810GDOWS

GTDS815EDOMC

GTDS815GD01VlC

GTDS820EDOWS

GTDS820GDOWS

GTDS825EDOMC

GTDS825GD01VlC

GHDS830EDOWS

GHDS830GDOWS

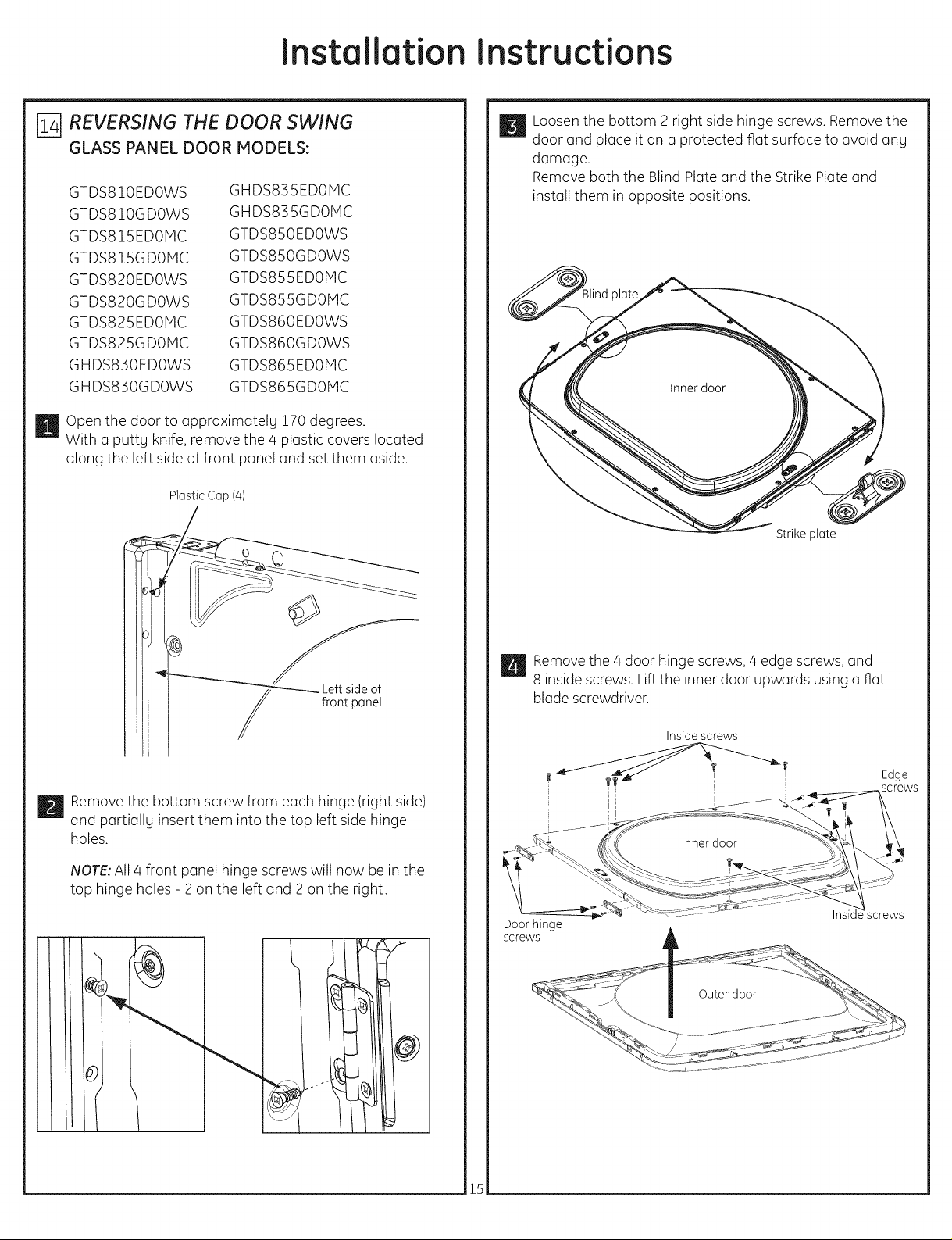

Open the door to approximatelg 170 degrees.

I!

With (] puttg knife, remove the 4 plastic covers located

(]long the left side of front panel and set them (]side.

Plastic Cop (4)

GHDS835ED0iVlC

GHDS835GDOMC

GTDS850EDOWS

GTDS850GDOWS

GTDS855ED0iVlC

GTDS855GDOMC

GTDS860EDOWS

GTDS860GDOWS

GTDS865ED0iVlC

GTDS865GDOMC

_ Loosen the bottom 2 right side hinge screws. Remove the

door and place it on (] protected fiat surface to (]void (]ng

damage.

Remove both the Blind Plate and the Strike Plate and

install them in opposite positions.

Strike plate

front panel

_ Remove the bottom screw from each hinge (right side)

and p(]rti(]llg insert them into the top left side hinge

holes.

NOTE:All 4 front panel hinge screws will now be in the

top hinge holes - 2 on the left and 2 on the right.

_ Removethe 4 door hinge screws,4 edge screws,and

8 inside screws. Lift the inner door upwards using (]fiat

blade screwdriver.

Inside screws

Edge

!5

Page 16

Installation Instructions

_ Remove and swap the 2 cover caps and door handle

from the outer door:

A. Squeeze the tabs on the inside of the door handle

clips. Push clips through the outer door.

B.Squeeze the tabs on the inside of the cover caps.

Pushcaps through the outer door.

j Door

Covercap i

Door handle

handle

clip

_When the cover caps and door handle in place, mount

the inner door back into the outer door with the screws

removed in step 4. Make sure you mount the hinges on

the side opposite the handle.

Inside screws

Door

hinge

screws

screws

Handle

e screws

_ Mount the assembled door on the 2 upper left side hinge

screws installed in step 2.

Move the hinge screws loosened in step 3 into the lower

left side screw holes and firmly tight all 4 screws.

C. Push the door handle clips into the openings on the

opposite side of the outer door making sure you flip

the handle so it curves to the inside.

D. Push the cover caps into the openings on the outer

door where the handle was removed.

Inside of door

Covercap

handle clip

Door

__ior and

_@)_ tighten screws

_ Install the 4 plastic caps removed in step 1 into the 4

right side front panel holes.

NOTE:To return the door to the original setup, follow

these instructions, swapping "left" and "right".

16

Loading...

Loading...