Page 1

GE HA Dryer Upgrade – GFDS350 Series

GE® 7.5 cu. ft. stainless steel capacity dryer with Steam Options

Models:

GFDS350ELWW

GFDS350GLWW

GFDS355ELMV

GFDS355GLMV

GFDS355ELMS

GFDS355GLMS

Service Guide

31-9209

GWS2011

Page 2

GE HA Dryer Upgrade – GFDN240 Series

GE® 7.0 cu. ft. stainless steel capacity dryer

Models:

GFDN240ELWW

GFDN240GLWW

GFDN245ELMS

GFDN245GLMS

GFDN245ELMV

GFDN245GLMV

NOTE: 240 series is the same as

the 350 series but without steam &

a slightly smaller drum.

GWS2011

Page 3

IMPORTANT SAFETY NOTICE

The information in this presentation is intended for use by individuals

possessing adequate backgrounds of electrical, electronic, & mechanical

experience. Any attempt to repair a major appliance may result in

personal injury & property damage. The manufacturer or seller cannot be

responsible for the interpretation of this information, nor can it assume

any liability in connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing this product.

If electrical power is required for diagnosis or test purposes, disconnect

the power immediately after performing the necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to complete

a path to ground are removed for service, they must be returned to their

original position & properly fastened.

Copyright 2011

3

Page 4

GE Factory Service Employees are required to use safety glasses with

side shields, safety gloves & steel toe shoes for all repairs.

Plano Type Safety Glasses

Dyneema® Cut

Dyneema® Cut

Resistant Glove

Resistant Glove

Electrically Rated Glove

Electrically Rated Glove

and Dyneema® Cut

and Dyneema® Cut

Resistant Glove Keeper

Resistant Glove Keeper

Plano Type Safety Glasses

Steel Toe Work

Steel Toe Work

Boot

Boot

Brazing Glasses

Brazing Glasses

Copyright 2011

Prescription Safety Glasses

Prescription Safety Glasses

Safety Glasses must be

Safety Glasses must be

ANSI Z87.1-2003 compliant

ANSI Z87.1-2003 compliant

4

Page 5

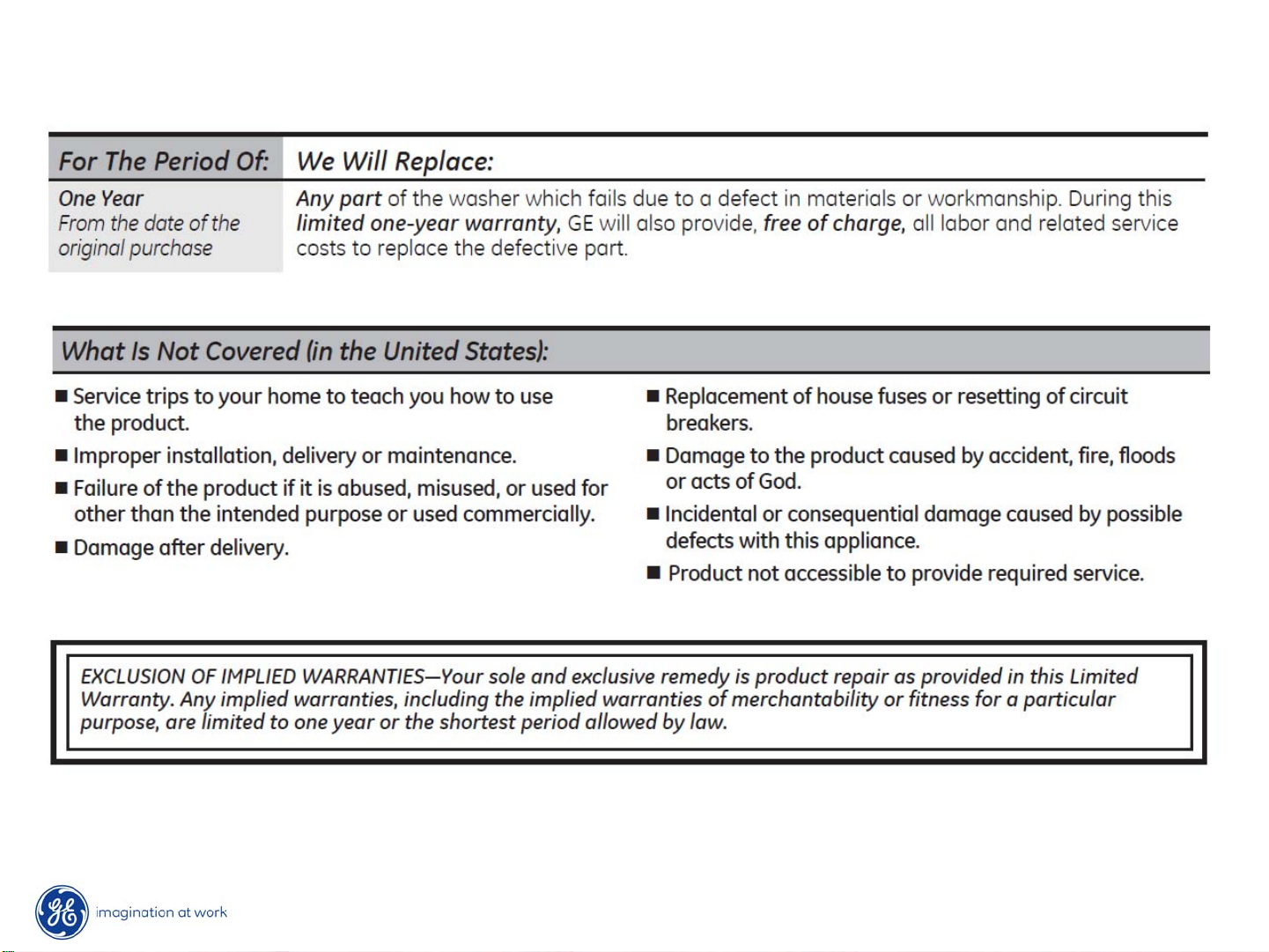

Warranty

Copyright 2011

5

Page 6

Model / Serial

The full model / serial tag is located on the front panel inside the

door opening.

There is also a barcode sticker that displays the model & serial and

is located on the left, front of the top panel.

Copyright 2011

6

Page 7

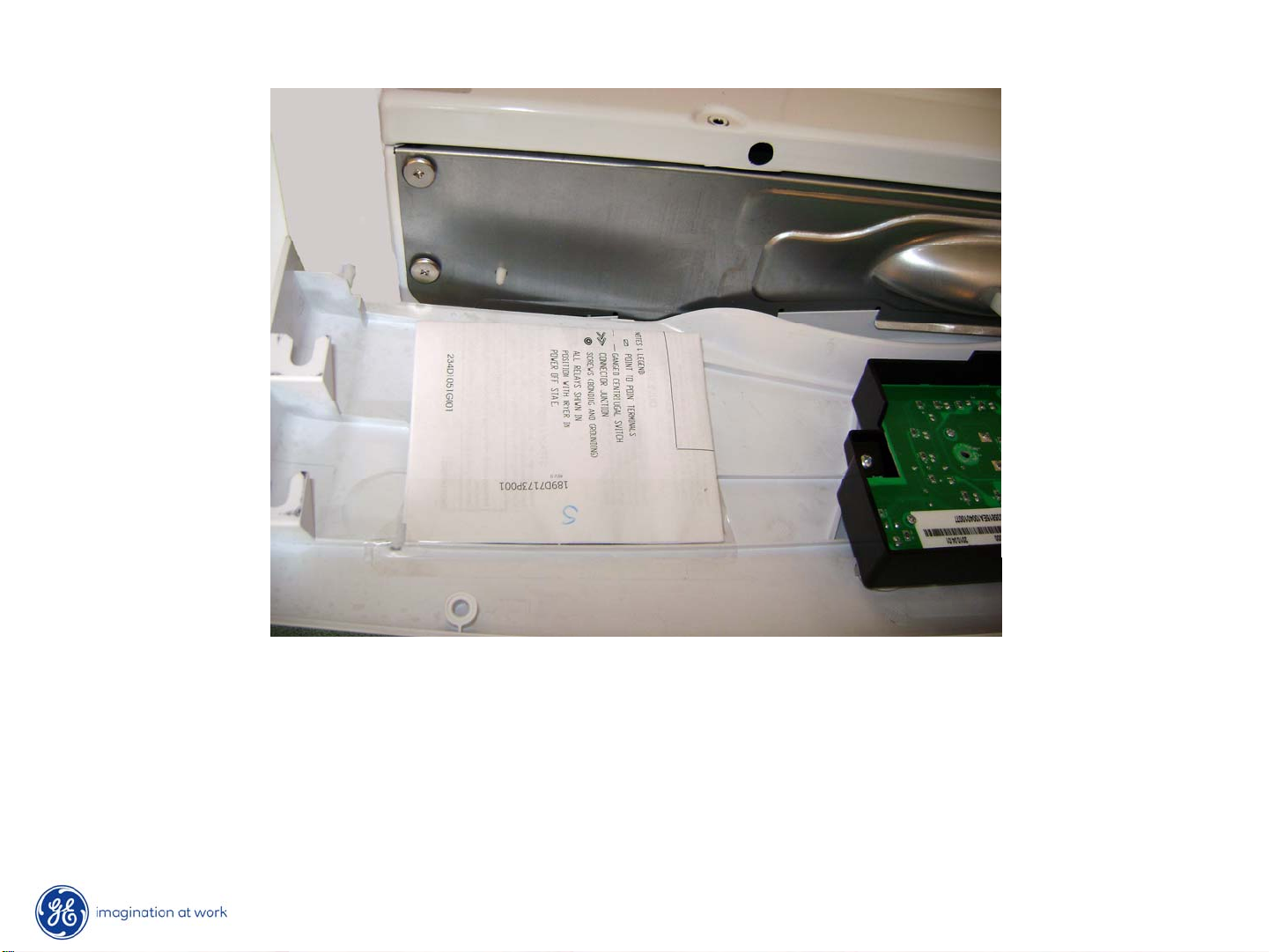

Mini-Manual

Mini-Manual is located inside control housing.

Copyright 2011

7

Page 8

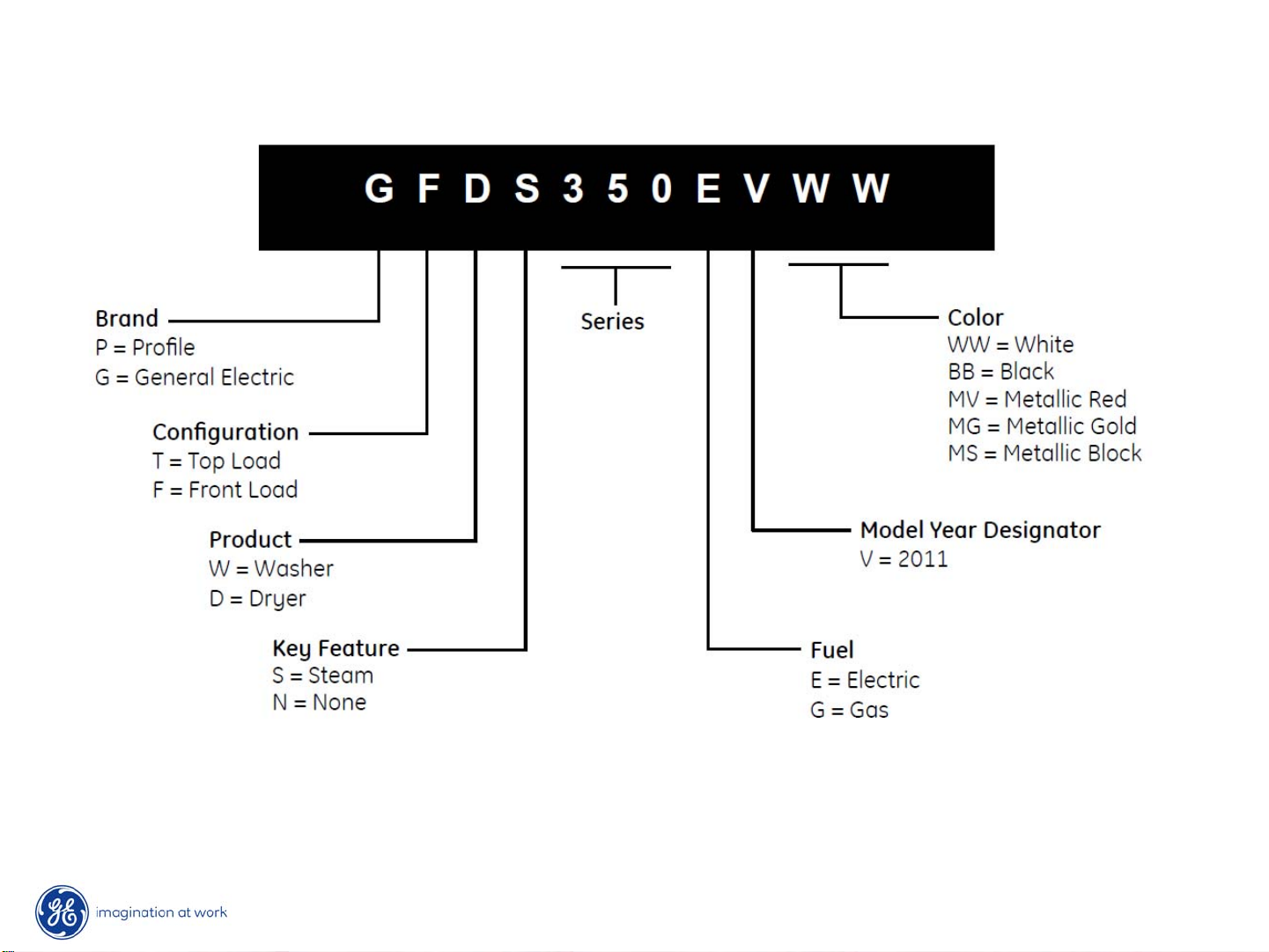

Nomenclature

Copyright 2011

8

Page 9

Installation

These Laundry products can be installed

in several different configurations:

Undercounter

Side-by-Side.

Pedistal

Stacked

Dryer can be stacked on the washer.

Kit for stacking dryer over washer is not

included with the washer.

Order GEFLSTACK.

Machines can be stacked on a

pedestal. These can be ordered separately.

SPSD157JMV – Vermillion

SPSD157JMS - Silver

SPSD157JWW - White

Adobe Acrobat

Stacking Instructions.

Open in “Normal View”.

Document

Copyright 2011

9

Page 10

Installation – Water Line

To produce steam, the dryer must connect to the cold water supply. Since the

washer must also connect to the cold water, a “Y” connector is inserted to

allow both inlet hoses to make that connection at the same time.

NOTE: Use the new inlet hoses & “Y”

connector provided; never use old

hoses. (Hose kit - Long & short hoses, washers & “Y” connector - WE25M53)

Copyright 2011

10

Page 11

Installation - Venting

These dryer models can be vented through the rear, the side or the bottom

of the cabinet.

STANDARD REAR EXHAUST

Dryer Exhaust to the rear of cabinet for Gas and Electric models.

SIDE VENTING:

Dryer Exhaust to right of cabinet for Electric models only.

Dryer Exhaust to left of cabinet for Gas and Electric models.

BOTTOM VENTING:

Dryer Exhaust to the bottom of cabinet for Gas and Electric models.

Copyright 2011

11

Page 12

Installation – Demo Mode

To enter demo mode:

Turn the unit off so the screen is blank.

Then unplug the unit, wait 10 seconds.

Plug the unit back in.

Within 30 seconds after plugging in the unit, press the Start/Pause

button 4 times within 3 seconds with the door open.

To exit Demo Mode:

Repeat the above sequence.

Note: In the Demo Mode, the control will proceed through the

selected cycle but will not actually activate any components.

Copyright 2011

12

Page 13

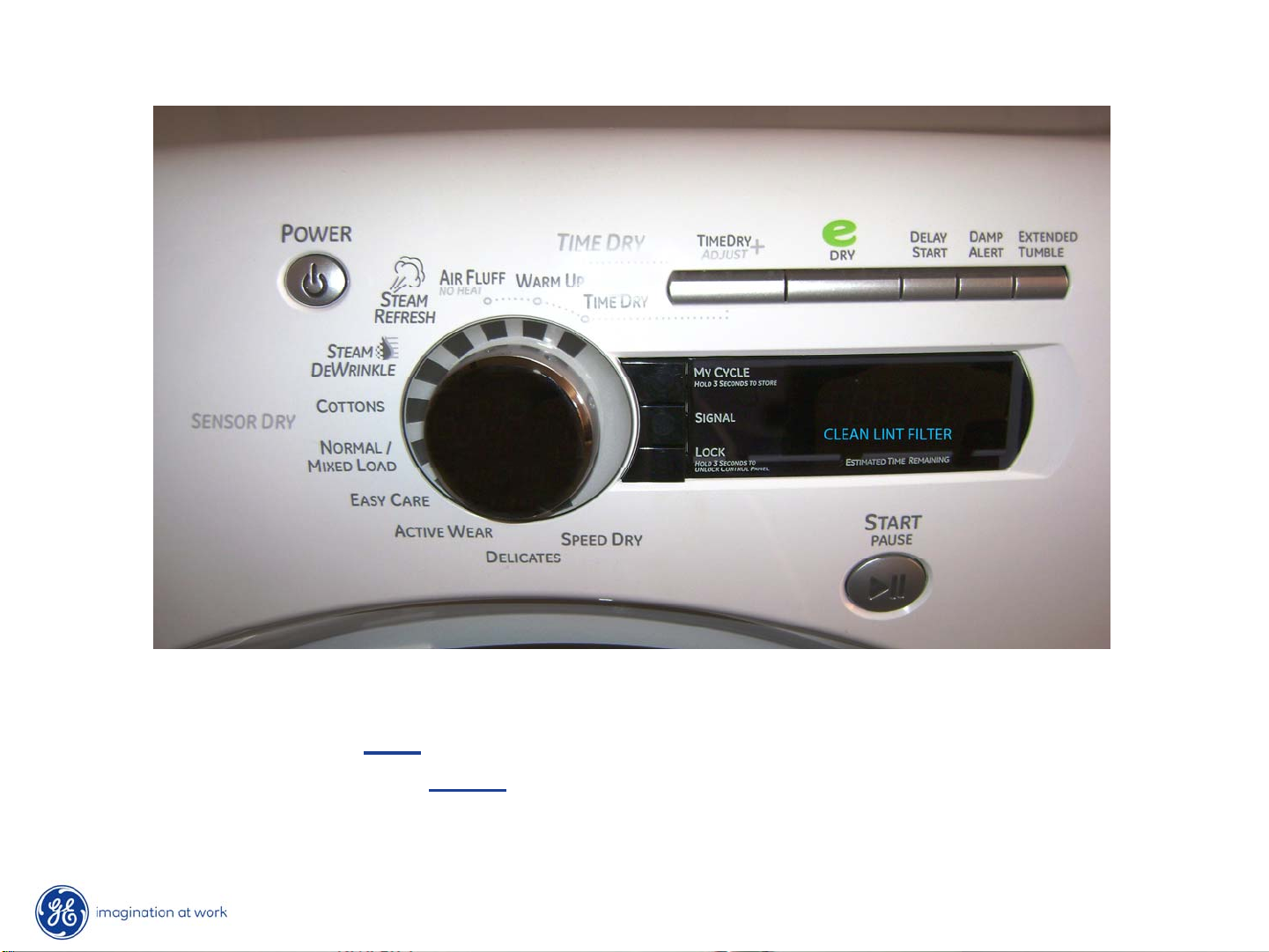

Features – Steam Cycles

Steam Refresh

For slightly wrinkled dry garments. Significantly reduces wrinkles on 1–5

garments.

Selecting a higher number of garments for the cycle (e.g., selecting 5garment load for a 1-garment load) may result in excessive wetting of

clothes. After the STEAM REFRESH Cycle, the unit will beep and display

“Garments Ready” and “0:00.” If the unit is not turned off or if the door is not

opened, the dryer will continue to tumble for 30 minutes. At the end of 30

minutes, it will display “0:00” and “Cycle Complete.”

NOTE: When STEAM REFRESH is selected, “EXTENDED TUMBLE” will

automatically turn on and cannot be turned off.

A single extremely light fabric item may need to have an additional item

included in the steam refresh cycle to

achieve optimum results.

Copyright 2011

13

Page 14

Features – Steam Cycles

Steam Dewrinkle

For use with larger loads than STEAM REFRESH. Ideal for

loads left in dryer for an extended time. Selecting a larger cycle

than needed (e.g., selecting Large Load for a half-full dryer)

may result in excessive wetting of clothes.

Copyright 2011

14

Page 15

Features – Lint Filter Message

“CLEAN LINT FILTER” (message) This message represents only a

reminder and does not

should be cleaned after every drying cycle is complete.

This message will disappear after the START button is pressed. Message may

appear even though you may have already cleaned the filter.

always appear when the filter needs cleaning. The filter

Copyright 2011

15

Page 16

Features – e Dry

Reduces the total energy consumption of specific dryer cycles by

adjusting certain heat settings and extending dry times.

NOTE: Cycle times will change when e-Dry is selected.

This cycle can be used with DELICATES, ACTIVE WEAR, EASY

CARE, NORMAL/MIXED LOADS and COTTONS.

Copyright 2011

16

Page 17

Features – Drying Rack

• The drying rack is designed for use with the TIMED DRY cycles.

• Use with sensor cycles may result in damp items or extended cycle times.

• Do not use this drying rack when there are other clothes in the dryer

that are not placed on the rack.

Copyright 2011

17

Page 18

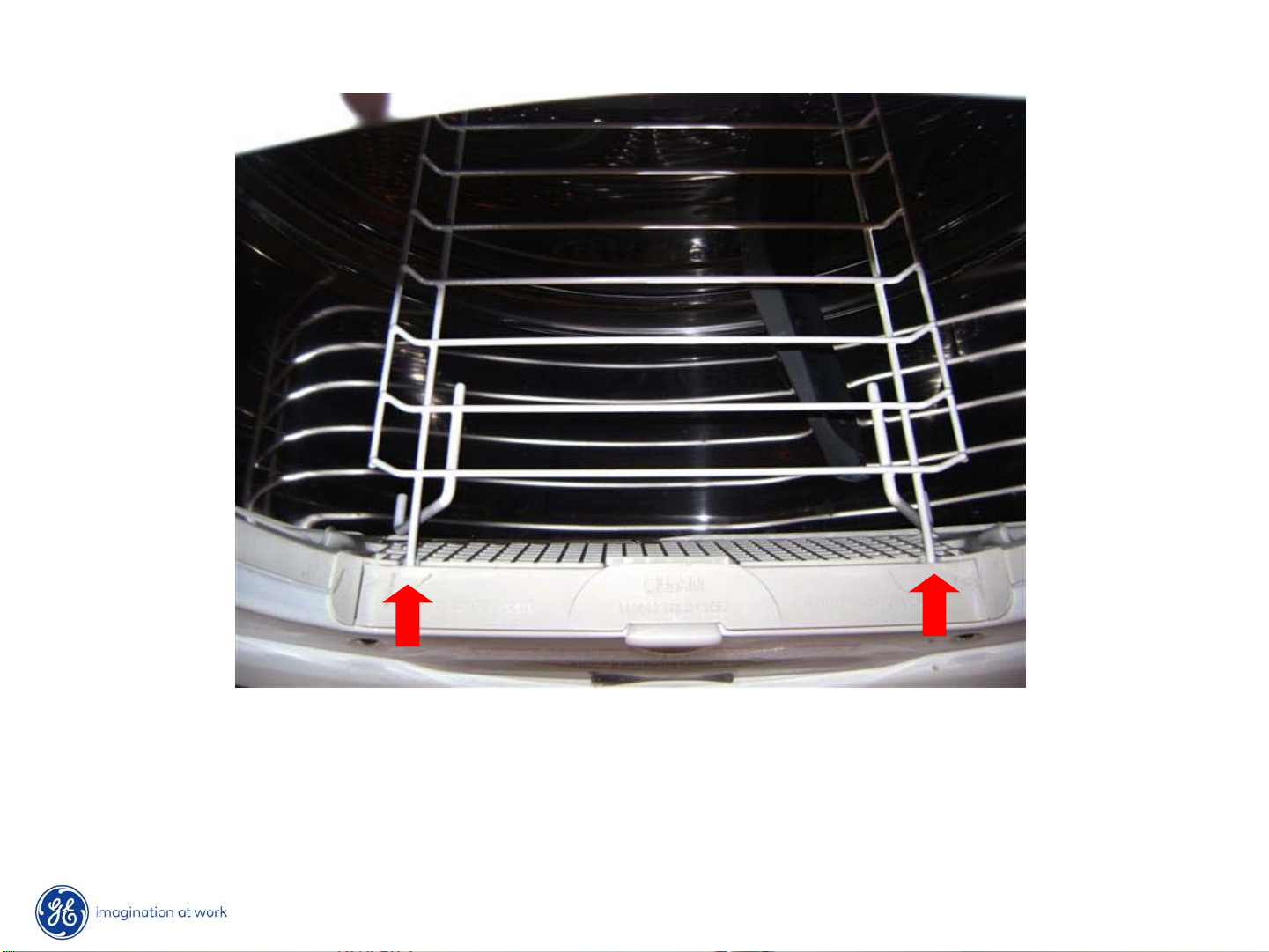

Features – Drying Rack

• To install the drying rack, pull up the lint filter slightly.

• Insert the drying rack into the slots, then push the filter

back into place.

Copyright 2011

18

Page 19

Features – Door Swing Reversal

Instructions for reversing door swing

are included in the Use & Care.

• Read the instructions all the way through

before starting.

• Handle parts carefully to avoid scratching

the paint.

• Set screws down by their related parts to

avoid using them in the wrong places.

• Provide a non-scratching work surface for

the door.

• Normal completion time to reverse the door

swing is 30-60 minutes.

Adobe Acrobat

Door Reversal Instructions.

Open in “Normal View”.

Copyright 2011

Document

19

Page 20

Disassembly – Top Panel

1. Remove the Phillips-head screw that attaches the control panel

rear trim. Pull the trim piece backward and remove.

Note: It may be helpful to place a putty knife along the top seam

between the trim and the control panel, then tap lightly backward.

Copyright 2011

20

Page 21

Disassembly – Top Panel

2. Remove the 2 Phillips-head screws that attach the top panel to the

cabinet.

3. Raise the front of the top panel approximately 3 inches, then pull

forward to clear the rear tabs. Lift off top panel.

Copyright 2011

21

Page 22

Disassembly – Control Panel

Removal of the control panel provides access to the

control board assembly.

To remove the control panel:

1. Remove the cycle selector knob by pulling outward.

Copyright 2011

22

Page 23

Disassembly – Control Panel

2. Remove the Phillips-head screw underneath the cycle select knob.

Copyright 2011

23

Page 24

Disassembly – Control Panel

Disconnect

3. Lift the control panel off vertically to disengage hooks from

grommets on washer front.

4. Disconnect the wire harness.

Copyright 2011

24

Page 25

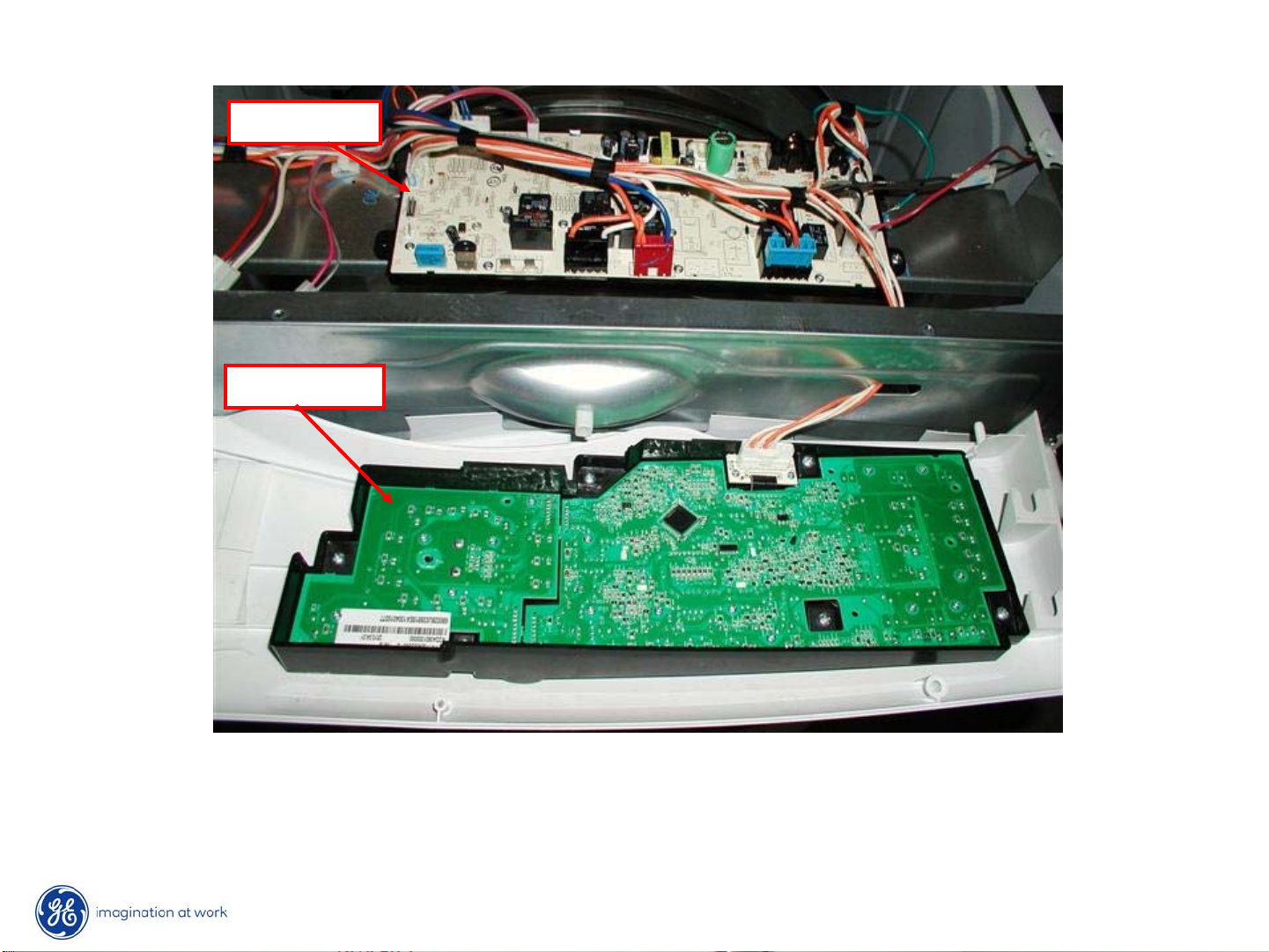

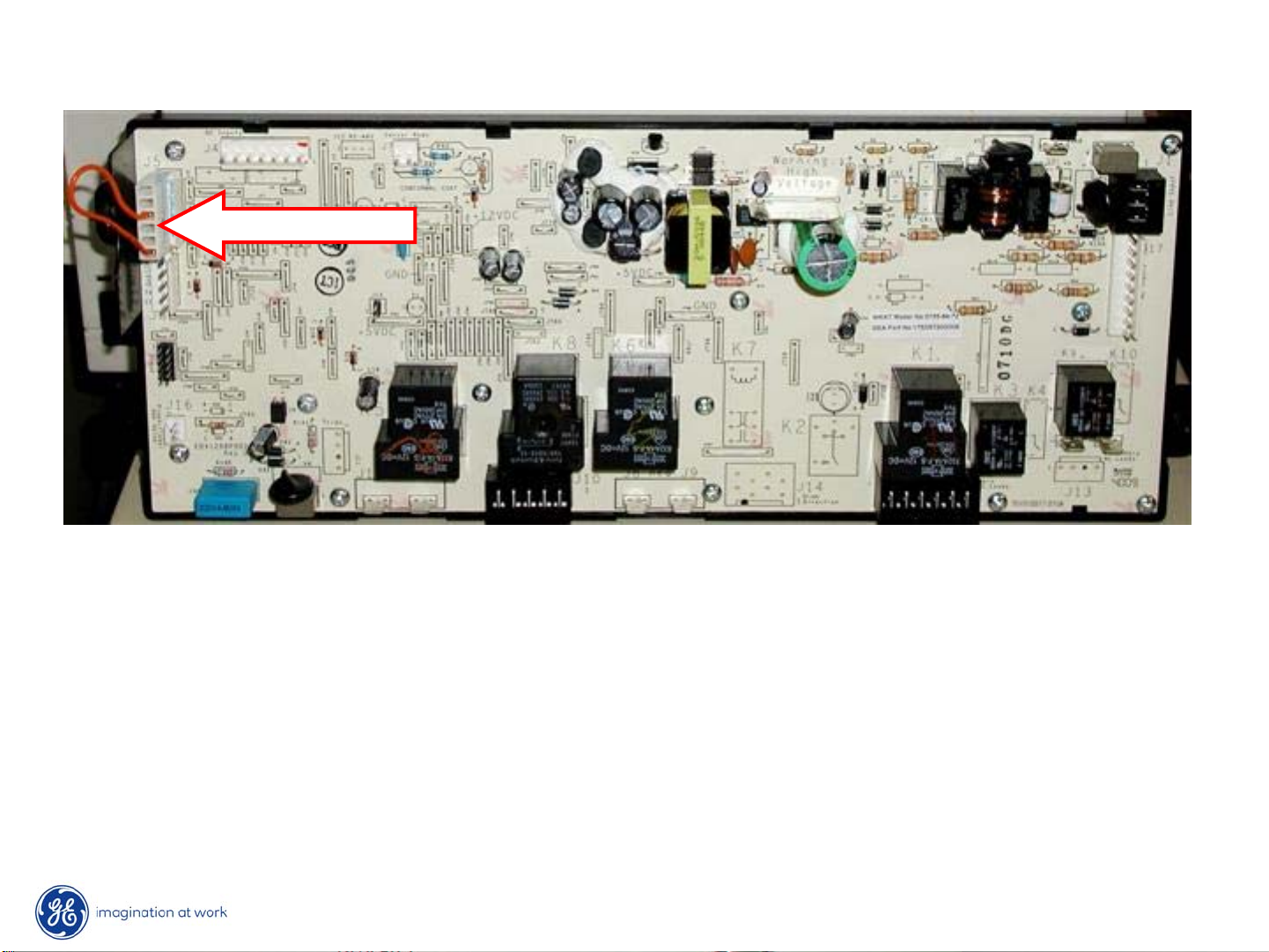

Electronic Control System

Power Board

Control Board

The electronic control consists of a control board (UI) and a power board.

Copyright 2011

25

Page 26

Electronic Control System

To remove the electronic control board:

1. Set the control panel in the service position.

2. Remove the 6 Phillips-head screws that attach the selector board to the

control panel.

Copyright 2011

26

Page 27

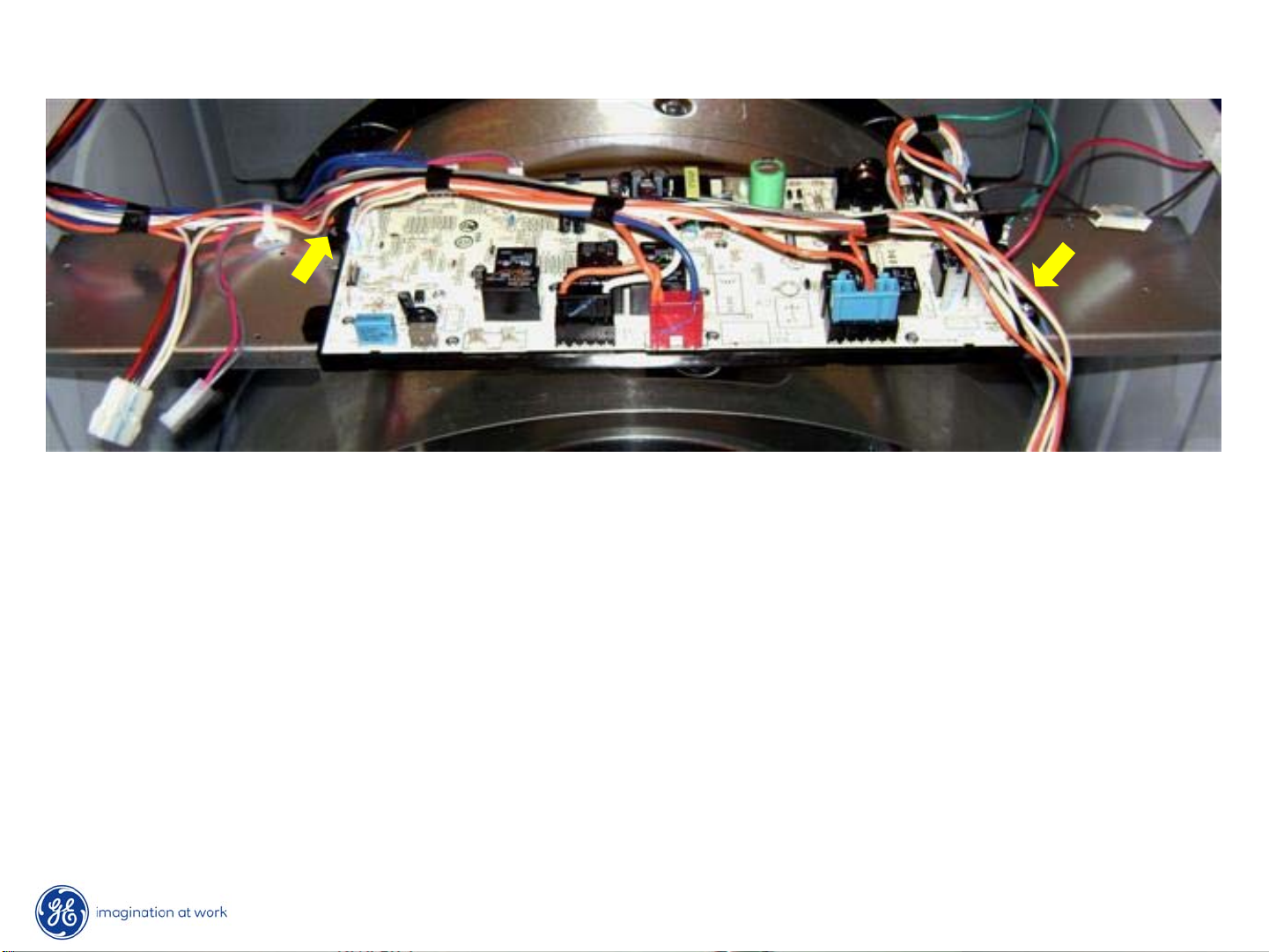

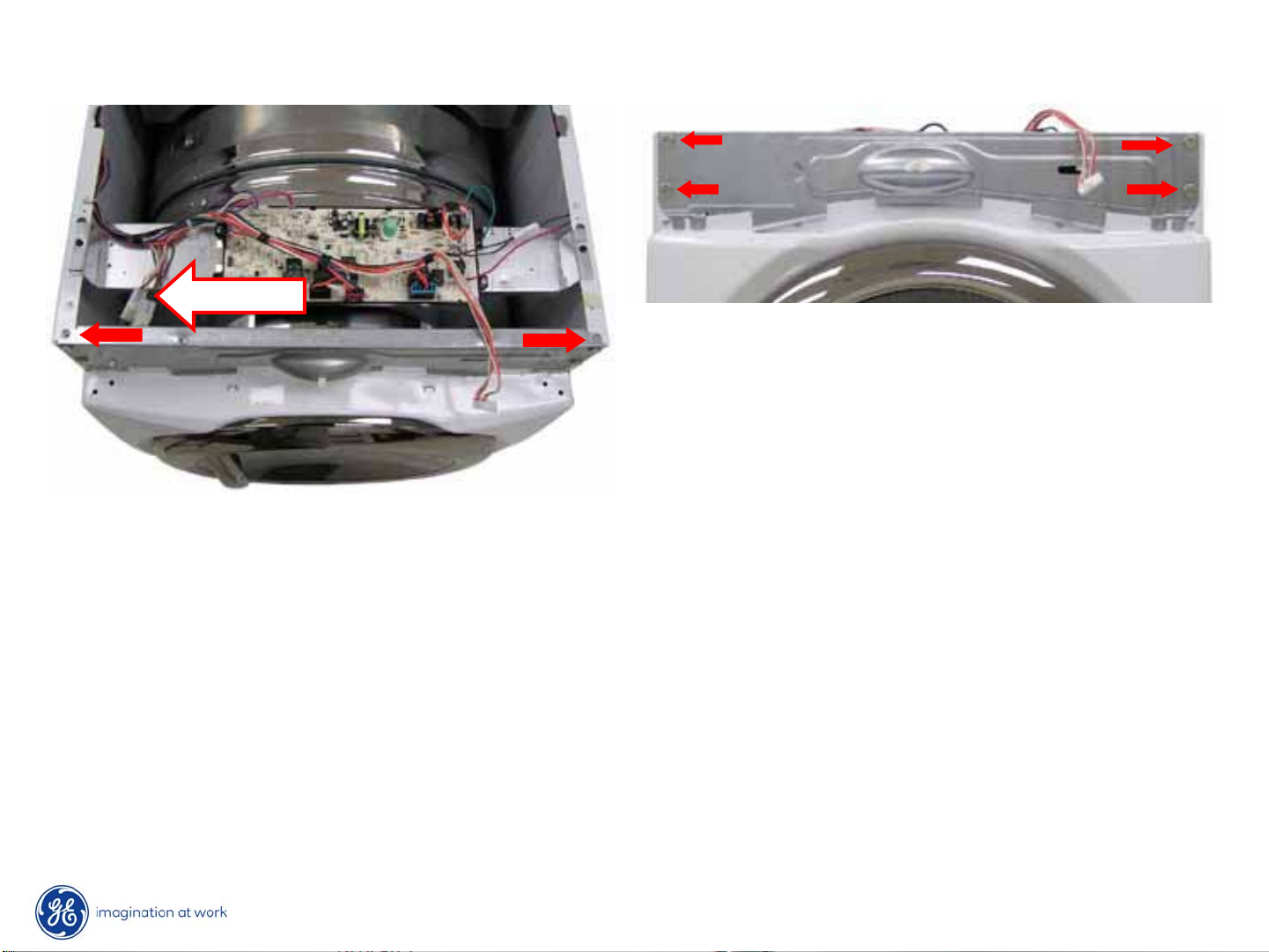

Electronic Control System

To remove the electronic power board:

1. Remove the top panel.

2. Disconnect 11 wires and wiring harnesses from the power board.

3. Remove the 2 Phillips-head screws to release the power board from the

power board bracket.

Copyright 2011

27

Page 28

Electronic Control System (Model Select plug)

J5 Model Select Plug

Note: If replacing the electronic control, transfer the model selector

harness

at J5, to the replacement control board in the same location as on the

original.

Copyright 2011

28

Page 29

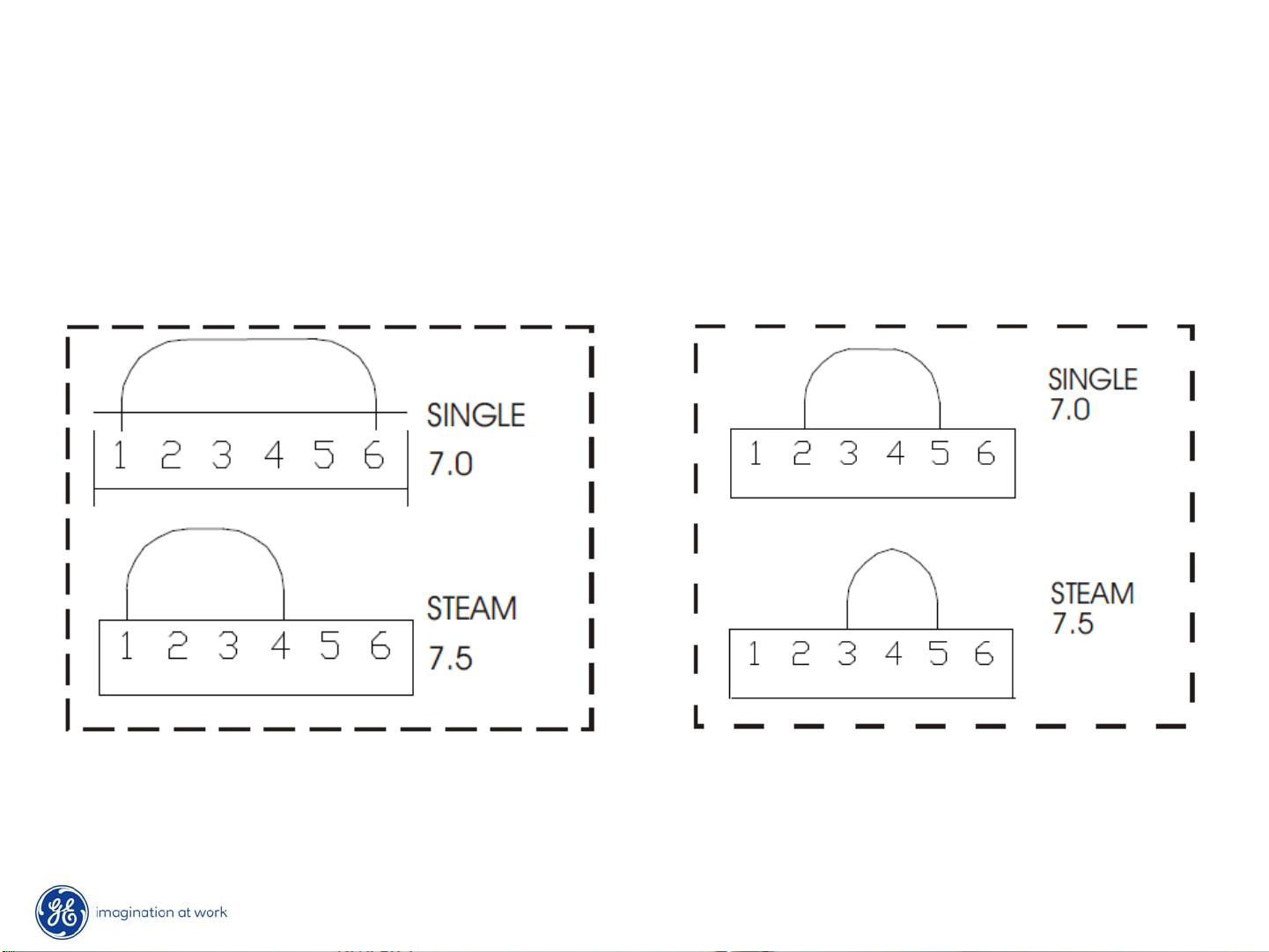

Electronic Control System (Model Select plug)

J5 Plug Configurations:

Electric Models

Gas Models

(Non – Steam)

(Non – Steam)

Copyright 2011

29

Page 30

Disassembly – Front Panel

Disconnect

To remove the front panel:

1. Remove the top panel and control panel.

2. Disconnect the drum lamp / door switch wire harness and the sensor rod

wire harness connected to the power board.

3. Remove the 2 Phillips-head screws from the front panel bracket.

4. Remove 4 Phillips-head screws from the front panel bracket.

5. Lift the bracket out of the hinges and set aside.

Copyright 2011

30

Page 31

Disassembly – Front Panel

Bottom of Front Panel

6. Loosen several turns but do not remove the 2 Phillips head screws

from the bottom of the front panel.

7. Remove 2 Phillips-head screws from the top of the front panel.

Copyright 2011

31

Page 32

Disassembly – Front Panel

8. Tilt the top edge of the front panel out and press on the John Guest

connector collar to release the water line.

9. Lift front panel from the bottom two screws and set aside.

Copyright 2011

32

Page 33

Disassembly – Air Duct Assembly

NOTE:

The trap duct felt seal can be

Trap Duct Felt Seal

Sensor Rod Ground Wire

replaced by extracting the seal

from the channel located on the

air duct assembly.

The air duct assembly houses the lint filter, steam nozzle, drum seal,

and the 2 sensor rods. It is located on the back side of the front panel.

To remove the air duct assembly:

1. Remove the front panel.

2. Remove the single Phillips-head screw that attaches the sensor

ground wire to the cabinet.

Copyright 2011

33

Page 34

Disassembly – Air Duct Assembly

3. Remove the 2 Phillips-head screws that attach the air duct assembly to

the front panel.

4. Grasp each side of the air duct assembly and unsnap the air duct from

the front panel.

Caution: Upon reassembly, ensure that the door switch, drum light, and

sensor wiring are retained and routed properly to avoid contact with the

drum.

Copyright 2011

34

Page 35

Disassembly – Air Duct Assembly

4. Grasp each side of the

air duct assembly and

unsnap the air duct from the

front panel at the points

indicated.

Caution: Upon reassembly,

ensure that the door switch,

drum light, and sensor

wiring are retained and

routed properly to avoid

contact with the drum.

Copyright 2011

35

Page 36

Disassembly – Drum Slides

e

d

i

Sl

rt

o

p

p

Su

u

G

e

d

i

l

S

e

d

i

e

d

i

Sl

rt

o

p

p

Su

u

G

e

d

i

l

S

e

d

i

The drum slide assembly is located on the back side of the front panel and utilizes

4 drum slides. Two white outer slides are used as guides, and 2 dark color center

(top) slides are used to support the weight of the drum. When replacing the slides,

the dark-colored support slides must be used to replace the top support slides.

Guide slides may also be replaced with support slides.

Caution: Do not replace the center (top) support slides with the white guide slides.

Damage to the dryer will result.

Copyright 2011

36

Page 37

Disassembly – Drum Slides

abbed

T

end

To Remove Drum Slides: (Remove top panel, control panel then tilt the

front panel outward.

1. Grasp individual slides at the non-tabbed end and pry up slide.

2. Release slide from tab on duct assembly and remove.

Copyright 2011

37

Page 38

Disassembly – Steam Nozzle

The steam nozzle is located inside the front of the dryer on the right side

of the air duct assembly. The steam nozzle consists of a brass orifice and

a fine filter screen. If the orifice should become plugged or restricted, it

should not be cleaned. Replace a plugged or restricted steam nozzle.

Copyright 2011

38

Page 39

Disassembly – Steam Nozzle

Nozzle with Thread Lock Applied

The steam nozzle can be replaced without disassembly of the dryer.

Replacement can be performed by opening the dryer door to access

the steam nozzle. A 7/16” or 11-mm nut driver can be used to unscrew

the nozzle from the air duct assembly.

Note: The replacement steam nozzle will have thread lock pre-applied to

the screw threads.

Copyright 2011

39

Page 40

Disassembly – Steam Nozzle Connector

1. Remove the air duct assembly.

2. Press on the John Guest

connector collar and release the

water line from the steam nozzle

connector.

3. Remove the Phillips-head

screw that attaches the nozzle to

the nozzle housing.

4. Pull the nozzle connector out

of the housing.

Copyright 2011

Jo

r

a

l

l

o

C

r

o

ct

e

n

n

o

C

st

e

u

G

n

h

40

Page 41

Disassembly – Door Switch

Locking Tabs

Door Switch Front View

Door Switch Rear View

The door switch is fastened to the front panel by 2 locking tabs (1 on each

side). When the dryer door is closed, the switch will complete the drum

motor circuit, allowing dryer operation. When the door is open, the switch

will open the drum motor circuit, interrupting dryer operation. Opening the

dryer door will also cause the door switch to close the drum light circuit,

allowing the drum light to be energized.

Copyright 2011

41

Page 42

Disassembly – Moisture Sensor

Moisture Sensor Rods (2)

The moisture-sensing circuit consists of 2 sensor rods. They are mounted

beneath the lint filter on the drum side of the air duct.

Operation of the moisture sensor can be checked by using service test

mode T07.

Copyright 2011

42

Page 43

Disassembly – Moisture Sensor

Plug connecting sensor

rods to J7 on control

board.

The dryer will signal when the clothes are at 17% moisture level if

equipped with a damp signal that has been selected.

Approximate values for dryness level:

Damp = 17%

Less dry = 12%

Dry = 2-6%

More dry = <2%

Copyright 2011

43

Page 44

Disassembly – Moisture Sensor

The sensor rods are connected to

the main control board. The rods

are spaced approximately ½-in.

apart, which creates an open

circuit to the control.

The control board utilizes a lowvoltage capacitor that charges to

approximately 5 VDC when the

circuit is open and discharges to

less than 1 VDC when the circuit

is shorted.

When wet clothes tumble across the two rods, the clothes create a very

low resistance between the rods, which discharges the capacitor.

As the clothes become dry, their resistance value increases and the

charge across the capacitor builds to approximately 5 VDC.

Copyright 2011

44

Page 45

Drive Belt

Pulley shown

in locked

position

Idler Pulley

Idler Arm

The drive belt (Part #WE12M29) is a 4-rib belt and extends from under the

motor pulley, over the top of the idler pulley, and around the perimeter

of the dryer drum. (See belt diagram.) Belt tension is maintained by the idler

pulley and driven by a pulley attached to the motor shaft.

Copyright 2011

45

Page 46

Drive Belt

Pulley shown in locked

position with motor cover

removed.

WARNING: The idler arm

is under high tension. To

prevent injury, do not let

the idler arm snap back

.

Idler Arm Locking Tab

To remove the drive belt:

1. Remove the front panel.

2. Reach under the left-hand side of the drum, push the idler pulley down

and to the right, and lock the idler arm on the top corner of the motor

bracket to release belt tension.

3. Remove the belt from the motor pulley and remove through the front of

the dryer.

Copyright 2011

46

Page 47

Installing the Drive Belt

1. Remove the front panel.

2. Reach under the left-hand side of

the drum, push the idler pulley down

and to the right, and lock the pulley

shaft on the top corner of the

motor bracket.

3. Place the belt in position around the

center of the drum through the front of

the dryer.

4. Place the belt in position around the

motor pulley (see diagram), release

View from rear of dryer

the idler pulley from the motor bracket,

and guide onto the belt.

Note: Check to make sure the belt is

in place and not twisted before

installing the top and front panels.

Copyright 2011

47

Page 48

Belt Switch (Idler Switch)

A belt switch, activated by the idler arm, is fastened to the motor bracket by

2 screws. Should the drive belt break, the belt switch will open the drive

motor circuit, interrupting dryer operation.

Note: The drum lamp will operate with an open belt switch.

Copyright 2011

48

Page 49

Belt Switch

Switch shown in closed position

The belt switch is fastened to the motor base plate with 2 Phillips-head

screws. The belt switch is activated by the movement of the idler arm. If the

drive belt breaks or comes off the idler pulley, the belt switch opens power

to the motor interrupting dryer operation. The drum lamp will operate with

an open belt switch.

To remove the belt switch:

1. Remove the motor and blower wheel.

2. Remove the 2 Phillips-head screws that attach the belt switch to the

motor base plate.

Copyright 2011

49

Page 50

Drum

Drum Baffle Screws

The drum is made of 304 stainless steel and has three replaceable baffles.

The drum rotates counterclockwise, as viewed from the front, at a speed of

47 to 51 rpm.

Copyright 2011

50

Page 51

Drum

To remove the drum:

1. Remove the drive belt from the motor.

2. Using the belt as a handle, pull the drum forward and guide out of the

cabinet.

Copyright 2011

51

Page 52

Drum Shaft & Bearing

Drum Shaft

Drum Bearing

“O” Ring

The drum shaft is attached to the rear of the drum with three T-20 Torx

screws. The bearing can be removed by pulling it off the shaft. The drum

shaft and bearing fit into the bearing retainer in the center of the heater

assembly (electric models) or diffuser assembly (gas models).

To access the drum shaft and bearing, it is necessary to remove the drum.

Copyright 2011

52

Page 53

Drum Bearing Retainer & Ground Strap Assembly

The drum shaft and bearing fit into the bearing retainer in the center of the

heater assembly (electric models) or diffuser assembly (gas models).

The assembly is held to the back side of the heater housing or diffuser

assembly by four screws.

Copyright 2011

53

Page 54

Idler Assembly

The idler arm is positioned on

the chassis and inserted in a

slot in the motor base plate.

The assembly is located to the

left of the motor.

To remove the idler assembly:

1. Remove the drum.

WARNING: The idler arm is under high tension. To prevent injury, do not

let the idler arm snap back.

2. Release tension on the idler assembly by unlocking the idler arm from

the top right corner of the motor support.

Copyright 2011

54

Page 55

Idler Assembly

Slot in Motor Base Plate

3. Remove the idler arm from the slot in the motor base plate.

4. Remove the idler assembly from the dryer.

Copyright 2011

55

Page 56

Water Valve

The water inlet valve is

located inside the cabinet

at the bottom right hand

corner.

The water valve is

Water Valve / Cover

enclosed under a metal

cover.

The cover is attached to

the dryer with a Phillipshead screw and a tab

located at the bottom.

The valve has an approximate resistance value of 406 .

Operation of the water inlet valve can be checked by using service test

mode T07.

Copyright 2011

56

Page 57

Water Valve

To replace the inlet water valve:

1. Remove the drum.

2. Remove the 2 Phillips-head screws that hold the cover to the cabinet and

remove the cover by lifting up and out.

Copyright 2011

57

Page 58

Water Valve

Water Inlet Hose

Disconnect

John Guest

Connector

Collar

Water Outlet Tubing

Note: In the following steps, capture any residual water that may escape

from the valve, fill hose, and tubing.

3. Disconnect the water inlet hose.

4. Disconnect the coil wiring.

5. Press the John Guest connector collar and remove the water outlet

tubing.

Copyright 2011

58

Page 59

Motor & Blower Wheel

The motor is a single-speed, dual-shaft, 1/4-hp, 1725-rpm motor with an

automatic reset overload protector. The overload protector is an internal

component of the motor and cannot be replaced separately. The motor

contains a centrifugal switch that serves three purposes: It disengages the

motor start winding (6), engages the motor run winding (8), and closes the

circuit contacts (1 to 3) for the heat source.

Copyright 2011

59

Page 60

Motor & Blower Wheel

Turn nut

Counterclockwise

To remove.

The blower wheel is held to the motor shaft with a 15/16-in. (24-mm)

molded nut.

Motor resistance values:

Start winding = 2.3 ohms

Run winding = 2.3 ohms

Copyright 2011

60

Page 61

Motor & Blower Wheel

Thermostat

Moisture

Shield

To remove the motor:

1. Disconnect power to the unit.

2. Remove the drum. (See Drum.)

3. Remove the Phillips-head screw and the thermostat moisture shield from

the front frame.

Copyright 2011

61

Page 62

Motor & Blower Wheel

Outlet Control Backup Thermostat

4. Remove the Phillips-head screw and the outlet control backup

thermostat from the blower housing.

Copyright 2011

62

Page 63

Motor & Blower Wheel

Motor Support

Disconnect

Belt Switch

5. Remove the idler pulley assembly from the motor bracket.

6. Disconnect the motor wire harness.

7. Disconnect the wires attached to the belt switch.

8. Remove the single vertical and single horizontal Phillips-head screws that

attach the motor bracket and motor support to the chassis.

Copyright 2011

63

Page 64

Motor & Blower Wheel

9. Remove the 2 Phillips-head screws and 2 washers that hold the top of

the motor base plate to the blower housing.

Copyright 2011

64

Page 65

Motor & Blower Wheel

10. Remove the Phillips-head

screw, then disengage the motor

moisture shield from the motor

bracket.

11. Raise the rear of the motor bracket to clear the tab protruding from the

bottom of the chassis. Slide the motor bracket back until the bracket tabs

clear the slots in the chassis. Remove the motor and blower wheel

assembly from the chassis.

Note: When installing the motor and blower wheel assembly, ensure that

the 2 rear tabs on the motor bracket are inserted into the slots in the motor

support, and the 2 front tabs on the motor bracket are inserted into slots

provided in the chassis.

Copyright 2011

65

Page 66

Motor & Blower Wheel

t

u

N

d

e

d

l

o

. M

in

-

6

/1

5

1

Mo

t

f

a

Sh

r

o

t

12. Hold the motor shaft from turning and use a 15/16-in. (24-mm) socket

to remove the blower wheel from the motor shaft.

Copyright 2011

66

Page 67

Motor & Blower Wheel

13. Compress and remove

the rear motor strap from

the motor support.

14. Loosen the two 1/4-in.

hex-head screws on the

front motor strap.

15. Lift and remove the

motor from the motor

bracket.

Rear Motor Strap

Front Motor Strap

NOTES:

• When installing the motor to the motor bracket, install the motor with the

motor harness terminals at the 9:30 o'clock position.

• After installing the motor, ensure both moisture shields are properly

installed.

Copyright 2011

67

Page 68

Blower Housing

The blower housing is attached to the dryer with 7 screws and 3 tabs.

To remove the blower housing:

1. Remove the motor and blower wheel.

2. Remove the single Phillips-head screw located inside the outlet of the

exhaust pipe. Remove the exhaust tube from the blower housing.

Copyright 2011

68

Page 69

Blower Housing

Tabs

3. Remove the 7 Phillips-head screws that attach the blower housing to the

base plate.

4. Slide the blower housing to the right.

Note: When reinstalling the blower housing, ensure the 3 tabs are inserted

into the front base plate.

Copyright 2011

69

Page 70

Heater Assembly

The heater assembly is located behind the drum. It consists of inner and

outer open-wire elements, each formed in a zigzag pattern fastened to a

single housing. The inner element consists of 2 elements wired in parallel

with each. The inner element and the outer element are controlled by

separate relays on the control board.

Copyright 2011

70

Page 71

Heater Assembly

When energized, the outer element draws approximately 12.5 amps at 240

VAC. The outer element has a resistance value of 19.2 . When energized,

the 2 inner elements draw approximately 12.5 amps at 240 VAC. The 2

inner elements have a combined resistance value of 19.2 .

Copyright 2011

71

Page 72

Heater Assembly

To access the heater assembly, it is necessary to remove the drum. Lead

wires can then be removed from the elements, inlet safety

thermostat, inlet control thermistor, and high limit thermostat. The heater

assembly is attached to the cabinet with 4 Phillips-head screws.

Copyright 2011

72

Page 73

Heater Assembly

Heater is available in the

following manners:

512 – Heater & housing asm (includes

hi-limit and bearing retainer)

WE11M42

513 – Heater housing

WE11M43

514 – Mica heater asm

WE11M32

Copyright 2011

73

Page 74

Heater Assembly

To Remove Mica Heater Assembly:

1. Remove leads from heater assembly.

2. Bend back single metal tab on housing holding heater in place.

Copyright 2011

74

Page 75

Heater Assembly

Tab & Gap

p

a

G

&

b

a

T

3. Rotate mica assembly slightly counterclockwise to align numerous

gaps on mica surface with tabs on housing.

4. Lift mica heater assembly from housing.

Copyright 2011

75

Page 76

Burner Assembly & Conversion

The burner assembly consists of

the gas valve coils, gas valve,

burner, and inlet pipe

Burner assembly can be

converted to LP gas by installing

a WE25X217 Conversion Kit.

Burner assembly can be

converted back to natural gas by

installing a WE25X218

Conversion Kit.

Copyright 2011

76

Page 77

Gas Valve Coils

The burner assembly has a gas

valve that utilizes 3 coils.

A double coil (safety and booster

coils combined) and a single main

coil are located on top of the gas

valve in front of the combustion

chamber opening.

All coils can be replaced separately.

Gas valve coil assembly resistance

values:

• Safety coil terminals - 1400

• Booster coil terminals - 580

• Main coil terminals - 1300

Copyright 2011

77

Page 78

Valve Coil Replacement

1. Remove the drum.

2. Remove 2 Phillips-head screws from the front frame and the Phillipshead screw from the rear of the gas valve cover.

Copyright 2011

78

Page 79

Valve Coil Replacement

3. Disconnect the wire harness from both coils.

4. Note the position of the locator pins inserted in the coil bracket.

5. Remove the 2 Phillips-head screws that attach the coil bracket to the

valve body.

6. Lift the bracket vertically. Lift coils to remove.

Note: Upon reassembly, ensure the locator pins are inserted into the

holes

provided in the coil bracket.

Copyright 2011

79

Page 80

Gas Valve

The gas valve is attached to a

bracket located in the bottom,

right, front corner of the dryer

cabinet.

To remove the gas valve:

1. Shut off the gas supply to

the unit.

2. Disconnect gas supply from

the burner inlet pipe.

3. Remove the drum.

4. Remove 2 Phillips-head

screws from the front frame

and the Phillips-head screw

from the rear of the gas valve

cover.

Copyright 2011

80

Page 81

Gas Valve

5. Disconnect the ignitor wire

harness and the 2 wires from

the flame detector.

6. Disconnect the coil wire

harness from each coil.

7. Remove the 2 Phillips-head

screws that attach the gas

valve bracket to the dryer floor.

8. Pull the bracket toward the

front of the dryer to disengage

tabs from dryer floor.

Copyright 2011

81

Page 82

Gas Valve

9. Remove the coils from the gas valve.

10. Turn the bracket over. Remove the 3 Phillips head screws that attach

the gas valve to the gas valve bracket.

Caution: The ignitor

is very fragile. To prevent breaking the ignitor, care

must be taken when installing the gas valve.

Note: Upon reassembly, ensure the gas valve bracket is inserted under the

2 tabs located in the dryer floor.

Copyright 2011

82

Page 83

Ignitor

The ignitor is located at the end of the burner assembly in the combustion

chamber opening and has a maximum rating of .4 amps. The ignitor has

an approximate resistance value of 300 to 500 .

The ignitor is attached to the gas valve bracket with a Phillips-head screw.

To access the ignitor, it is necessary to remove the burner assembly. (See

Gas Valve , steps 1 through 8.)

Copyright 2011

83

Page 84

Flame Detector

The flame detector is attached

to the right side of the

combustion chamber. It is

necessary to remove the flame

detector moisture shield to

remove the flame detector.

To remove the flame

detector:

1. Remove the drum.

2. Remove 2 Phillips-head

screws from the front frame

and the Phillips-head screw

from the rear of the gas valve

cover.

Copyright 2011

84

Page 85

Flame Detector

3. Disconnect the 2 wires from

the flame detector.

4. Remove the Phillips-head

screw that holds the flame

detector to the combustion

chamber.

5. Remove the flame detector

from the tab at the bottom.

Note: Upon reassembly,

ensure the tab at the bottom of

the flame detector is inserted

into the slot located on the

combustion chamber.

Copyright 2011

85

Page 86

Inlet Safety Thermostat

On electric models, the inlet

safety thermostat is located on

the top left area of the heater

housing, to the left of the inlet

control thermistor.

On gas models, the inlet safety

thermostat is located on the right

side of the diffuser, above the

inlet control thermistor.

The thermostat monitors

incoming air temperature.

Inlet Control

Thermistor

Inlet Safety

Thermostat

Electric Model Shown

If the thermostat reaches a temperature beyond its maximum temperature

rating, it will trip and disable power to the heating elements (electric

models) or burner assembly (gas models).

Copyright 2011

86

Page 87

Inlet Safety Thermostat

On electric dryers, the inlet

safety thermostat opens at

225°F (7.5cu ft) or 210°F (7.0

cu ft) and will automatically

reset at 195°F or 180°F

respectfully.

On gas dryers, the inlet

safety thermostat opens at

300°F and will automatically

reset at 260°F.

To remove the inlet safety thermostat:

1. Remove the drum.

Inlet Safety

Thermostat

Electric Model Shown

2. Disconnect the 2 wires from the inlet safety thermostat.

3. Remove the Phillips-head screw that attaches the inlet safety thermostat

to the heater assembly or diffuser.

4. Lift and slide the thermostat from the heater assembly or diffuser.

Copyright 2011

87

Page 88

Inlet Control Thermistor

On electric models, the inlet

control thermistor is located on

the top left area of the heater

housing, to the right of the inlet

safety thermostat.

On gas models, the inlet control

thermistor is located on the right

side of the diffuser, below the

Inlet Safety

Thermostat

Inlet Control

Thermistor

inlet safety thermostat.

Electric Model Shown

The thermistor monitors incoming air temperature and will respond to

temperature changes of 3 °F.

The thermistor relays this information to the control board.

The thermistor has a negative coefficient. As the temperature increases,

the thermistor's resistance decreases.

Copyright 2011

88

Page 89

Inlet Control Thermistor

To remove the inlet control

thermistor:

1. Remove the drum.

2. Disconnect the 2 wires from

Inlet Control

Thermistor

the inlet control thermistor.

3. Remove the Phillips-head

screw that attaches the inlet

control thermistor to the heater

assembly or diffuser.

4. Lift and slide the thermistor

from the heater assembly or

diffuser.

Operation of the inlet control thermistor can be checked by using service

test mode T06.

Specific failures associated with the inlet control thermistor can initiate

error codes E3 and E4.

Copyright 2011

89

Page 90

Outlet Control Thermistor

Shield in Place

Outlet Control

Thermistor

Shield Removed

The outlet control thermistor is located on the lower rear area of the blower

housing. It is below the moisture shield and the outlet control backup

thermostat.

The outlet control thermistor measures outgoing air temperature and will

respond to temperature changes of 3°F. The thermistor relays this

information to the control board.

Copyright 2011

90

Page 91

Outlet Control Thermistor

Operation of the outlet control

thermistor can be checked by using

service test mode T05.

Specific failures associated with the

outlet control thermistor can initiate

error codes E5 and E6.

To remove the outlet control thermistor:

1. Remove the drum.

2. Remove the Phillips-head screw and the thermostat moisture shield from

the front frame.

3. Disconnect the 2 wires from the outlet control thermistor.

4. Remove the 2 Phillips-head screws that attach the outlet control

thermistor to the blower housing.

Copyright 2011

91

Page 92

Thermistor Characteristics

If the control reads a thermistor value too high

or too low then it will log an error code, and

switch to a setting where the heaters are on a

duty cycle. The dryer then relies on the

backup thermostats to control the heater.

Dryer goes into this fall back mode when it

has determined that it can no longer rely on

thermistor temperature to control applied

heat. This can occurs when a thermistor

cannot sense heat (failed open) or always

read hot (failed closed).

The fall back mode consist of reducing the maximum heating power

(typically 50%) so that thermostats are fast enough to shut down heater in

case of overheating. On these GE Model Dryers, both heaters are cycled

ON and OFF every minute.

Copyright 2011

92

Page 93

Outlet Control Backup Thermostat

Outlet Control

Backup Thermostat

Shield in Place

Shield Removed

The outlet control backup thermostat is located on the upper, rear area of

the blower housing. It is below the moisture shield and above the outlet

control thermistor. The outlet control backup thermostat monitors the

outgoing air temperature. If the thermostat reaches a temperature beyond

its maximum temperature rating, it will trip and disable power to the heating

elements or burner assembly.

Copyright 2011

93

Page 94

Outlet Control Backup Thermostat

The outlet control backup

thermostat opens at

165°F and will

automatically reset at

155°F.

To remove the outlet control backup thermostat:

1. Remove the drum.

2. Remove the Phillips-head screw and the thermostat moisture shield from

the front frame.

3. Disconnect the 2 wires from the outlet control backup thermostat.

4. Remove the Phillips-head screw that attaches the outlet control backup

thermostat to the blower housing.

Copyright 2011

94

Page 95

High Limit Thermostat

On electric models, the high

limit thermostat is located on

the top right area of the heater

housing.

On gas models, the high limit

thermostat is located on the

upper right side of the

diffuser.

High Limit

Thermostat

The high limit thermostat monitors incoming air temperature.

If the high limit thermostat trips it will take out the L1 circuit to the motor

which, in turn, will disable the heat source.

Copyright 2011

95

Page 96

High Limit Thermostat

For both the electric and gas

models, the high limit thermostat

opens at 315°F and will

automatically reset at 250°F.

To remove the high limit thermostat:

1. Remove the drum.

2. Disconnect the 2 wires from the high limit thermostat.

3. Remove the Phillips-head screw that attaches the high limit thermostat to

the heater assembly or diffuser.

4. Slide the thermostat from the heater assembly or diffuser.

Copyright 2011

96

Page 97

Service Mode Test

How to enter to service mode and navigate:

From idle state, press and alternate between the “My cycle” and “Delay

Start” buttons twice to enter service mode.

Upon entering the service mode, the Control shall be in test selection mode

and display the first test number (t01). Rotating the knob counter clockwise

(CCW) shall decrement the test number in the display. Rotating the knob

clockwise (CW) shall increment the test numbers in the display.

Once the test number is selected, pressing [Start/Pause] shall begin the

selected test.

During a test, pressing power button shall terminate that test and bring the

control to the test selection mode (test number is displayed on the display).

Pressing Power key during the test selection mode shall exit the Service

mode.

Copyright 2011

97

Page 98

Service Mode Test Sequences

Copyright 2011

98

Page 99

Service Mode Test Sequences

Copyright 2011

99

Page 100

Error Codes

Copyright 2011

100

Loading...

Loading...