Page 1

Installation

lectric Drger

Instructions

Questions on Installation? Call: 800.GE.CARES (US)

or visit our web site at: www.GEAppliances.com (US)

BEFORE YOU BEGIN

Readthese instructions completely and

carefully.

•IN PORTANT- savethese instructions

for local inspector's use.

•IMPORTANT- Observe all governing

codes and ordinances.

• Note to Installer - Besure to leave these

instructions with the customer.

• Note to Customer - Keep these instructions

with your Owner's Manual for future reference.

• Before the old dryer is removed from service

or discarded, remove the dryer door.

• Service information and the wiring diagram

are located in the control console.

• Do not allow children on or in the appliance.

Close supervision of children is

necessary when the appliance is used

near children.

• Install the dryer where the temperature

is above 50°Ffor satisfactory operation of

the dryer control system.

• Product failure due to improper installation

is not covered under the Warranty.

10

I

- WARNING RISK OF FIRE

•To reduce the risk of severe injury or death, follow all installation

instructions.

• Clothes dryer installation must be performed by a qualified installer.

• Install the clothes dryer according to these instructions and in

accordance with local codes.

• Thisdryer must be exhausted to the outdoors.

• Useonly rigid metal 4" diameter ductwork inside the dryer cabinet and use

only UL approved transition ducting between the dryer and the home duct.

• DONOTinstall a clothes dryer with flexible plastic ducting materials. If

flexible metal (semi-rigid or foil-type) duct is installed, it must be UL listed

and installed in accordance with the instructions found in "Connecting

The Dryer To House Vent" on pages 4-5 of this manual. Flexible venting

materials are known to collapse, be easily crushed, and trap lint. These

conditions will obstruct dryer airflow and increase the risk of fire.

• Do not install or store this appliance in any location where it could be

exposed to water and or weather.

• Save these instructions. (Installers: Be sure to leave these instructions

with the customer).

NOTE: Installation and service of this drger requires basic

mechanical and electrical skills. It is gour responsibilitg to

contact a qualified installer to make the electrical connections.

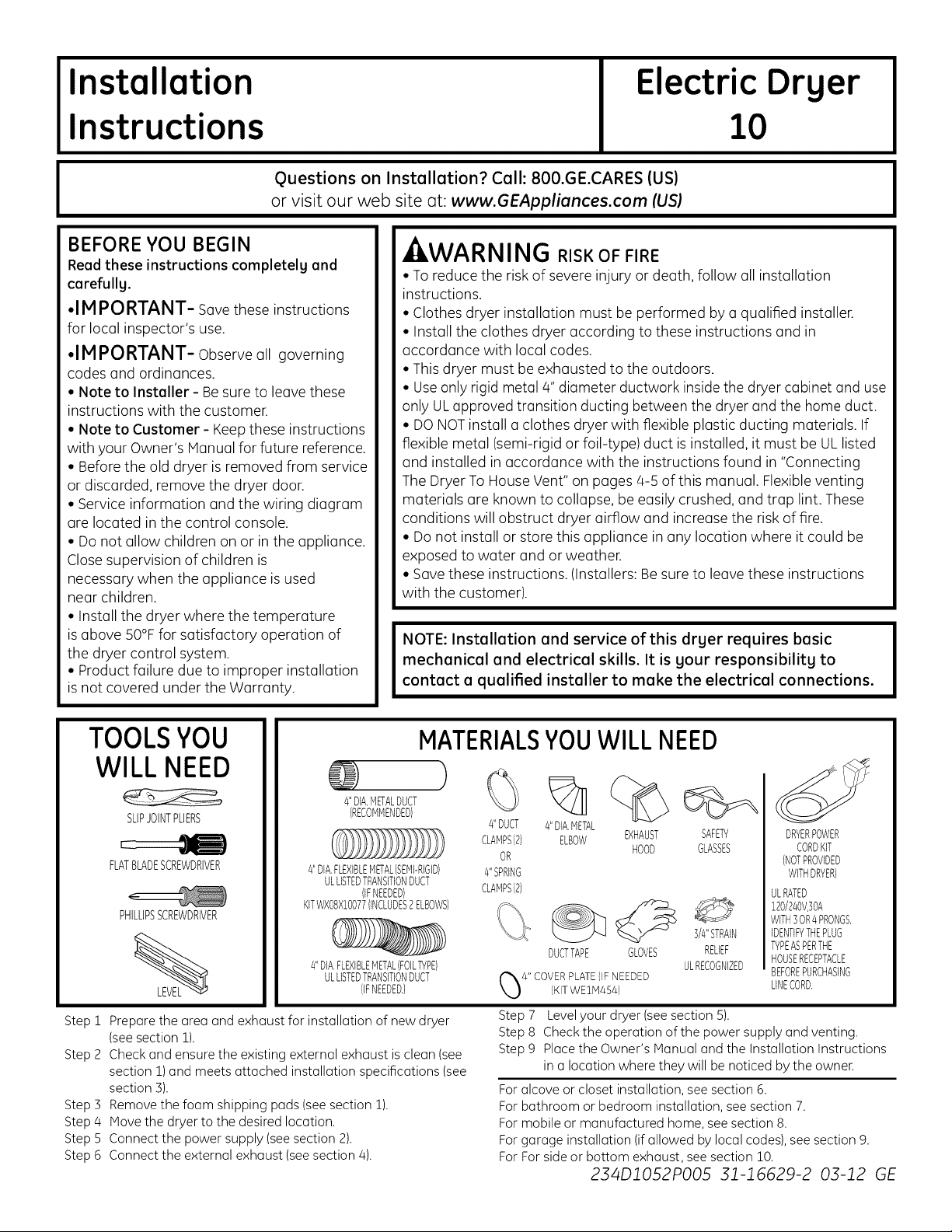

TOOLSYOU

WILL NEED

4"DIA.METALDUCT

SLIPJOINTPLIERS

FLATBLADESCREWDRIVER

PHILLIPSSCREWDRIVER

Prepare the area and exhaust for installation of new dryer

Step 1

(seesection 1).

Step 2

Check and ensure the existing external exhaust isclean (see

section 1)and meets attached installation specifications (see

section 3).

Remove the foam shipping pads (see section 1).

Step 3

Step 4

Move the dryer to the desired location.

Step 5

Connect the power supply (seesection 2).

Connect the external exhaust (seesection 4).

Step 6

(RECOMMENDED)

4"DIA,FLEXIBLEMETAL(SEMI-RIGID)

ULLISTEDTRANSITIONDUCT

KITWXB8XIBO77(INCLUDES2ELBOWSI

4"DIA.FLEXIBLEMETAL(FOILTYPEI

(IFNEEDED)

ULLISTEDTRANSITIONDUCT

(IFNEEDED,)

MATERIALSYOUWILL NEED

%

#'DUCT

CLAMPS(2) EXHAUST

4"SPRING

CLAMPS(2)

4"DIA.METAL

ELBOW

OR

DUCTTAPE GLOVES

4" COVERPLATE{IFNEEDED

{KITWE1M454)

Step7 Levelyour dryer (seesection5).

Step8 Checkthe operationofthe power supplyandventing.

Step9 PlacetheOwner'sManualandthe InstallationInstructions

in a locationwheretheywill benoticedbythe owner.

Foralcoveor closetinstallation,seesection6.

Forbathroom or bedroominstallation,seesection7.

Formobileor manufacturedhome,seesection8.

Forgarageinstallation(ifallowed by localcodes),seesection9.

ForForsideor bottom exhaust,seesection10.

HOOD

234DlO52PO05 31-16629-2 03-12 GE

%

SAFETY

GLASSES

3/4"STRAIN

RELIEF

ULRECOGNIZED

DRYERPOWER

CORDKIT

(NOTPROVIDED

WITHDRYER)

ULRATED

120/240V,]OA

WITH3OR4PRONGS,

IDENTIFYTHEPLUG

TYPEASPERTHE

HOUSERECEPTACLE

BEFOREPURCHASING

LINECORD,

Page 2

Installation Instructions

Minimum Clearance Other Than Alcove or Closet Installation

Minimum clearance to combustible surfaces and for air opening are: 0 in.clearance both sides, ] in. front and 3 in. rear.

Consideration must be given to provide adequate clearance for installation and service.

[] PREPARING FOR INSTALLATION

OF NEW DRYER

TIP:Install your dryer before installing your washer.

This will allow better accesswhen installing dryer exhaust.

REMOVING LINT FROM WALL EXHAUST

OPENING

• Remove and discard existing plastic or metal foil

transition duct and replace with UL listed transition duct.

WALL

INTERNALDUCT

OPENING OPENS

CHECKTHATEXHAUST

ANDCLOSESFREELY.

TILTTHE DRYER SIDEWAYS

AND REMOVE THE FOAM

SHIPPING PADS BY

PULLING AT THE SIDES

AND BREAKING THEM

AWAY FROM THE DRYER

LEGS.BE SURE TO

REMOVE ALL OF THE

FOAM PIECES AROUND

THE LEGS.

121ELECTRICAL CONNECTION INFORMATION

- kWARNING - TO REDUCE THE RISK OF

FIRE, ELECTRICAL SHOCK AND PERSONAL INJURY:

• DO NOT USE AN EXTENSION CORD OR AN

ADAPTER PLUG WITH THIS APPLIANCE.

Dryer must be electrically grounded in accordance with

local codes and ordinances, or in the absence of local

codes, in accordance with the NATIONALELECTRICAL

CODE,ANSI/NFPANO. 70.

ELECTRICAL REQUIREMENTS

This dryer must be connected to an individual branch

circuit, protected by the required time-delay fuses or

circuit breakers. A four or three-wire, single phase,

]20/240V or ]20/208V, 60Hz, 30 amp circuit is required.

GROUNDING INSTRUCTIONS

This dryer must be connected to a grounded metal, perma-

nent wiring system, or an equipment-grounding conductor

must be run with the circuit conductors and connected to

the equipment grounding terminal on the appliance.

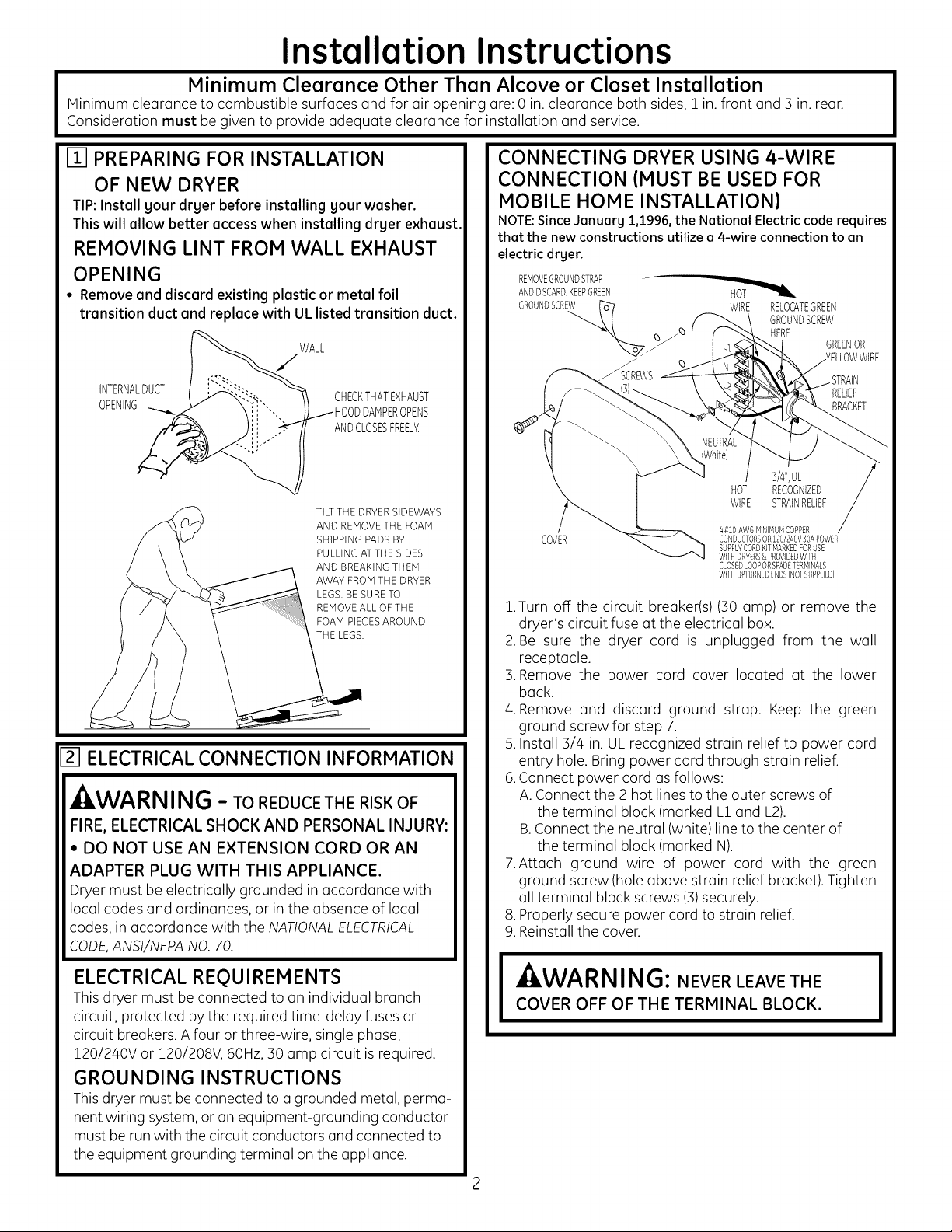

CONNECTING DRYER USING 4-WIRE

CONNECTION (MUST BE USED FOR

MOBILE HONE INSTALLATION)

NOTE: Since January 1,1996, the National Electric code requires

that the new constructions utilize a 4-wire connection to an

electric drger.

REMOVEGROUNDSTRAP --

ANDDISCARD.KEEPGREEN HOT

GROUNDSCREW

_SCREWS

COVER

].Turn off the circuit breaker(s) (30 amp) or remove the

dryer's circuit fuse at the electrical box.

2.Be sure the dryer cord is unplugged from the wall

receptacle.

3. Remove the power cord cover located at the lower

back.

4. Remove and discard ground strap. Keep the green

ground screw for step 7.

5.Install 3/4 in. UL recognized strain relief to power cord

entry hole. Bring power cord through strain relief.

6.Connect power cord as follows:

A.Connect the 2 hot lines to the outer screws of

the terminal block (marked L] and L2).

B.Connect the neutral (white) line to the center of

the terminal block (marked N).

7.Attach ground wire of power cord with the green

ground screw (hole above strain relief bracket). Tighten

all terminal block screws (3)securely.

8. Properly secure power cord to strain relief.

9. Reinstall the cover.

A, i I^ ,-, ,, , , ,, , ,-

,I:IiW/'AKI_III_I_: NEVER LEAVE THE

COVER OFF OF THE TERMINAL BLOCK.

WIRE RELOCATEGREEN

GROUNDSCREW

HERE

3/4",UL

HOT RECOGNIZED

WIRE STRAINRELIEF

/4#10AWG MINIMUMCOPPER

CONDUCTORSOR]20/240V30APOWER

SUPPLYCORDKITMARKEDFORUSE

WITHDRYERS&PROVIDEDWITH

CLOSEDLOOPORSPADETERMINALS

WITHUPTURNEDENDS(NOTSUPPLIED}

GREENOR

Page 3

Installation Instructions

CONNECTING DRYER USING 3-WIRE

CONNECTION

IFREQUIRED,BYLOCALCODE,

INSTALLEXTERNALGROUND

(NOTPROVIDED)TOGROUNDED

METALCOLDWATERPIPE,OR GREEN GROUND

OTHERESTABLISHEDGROUND GROUND STRAP

DETERMINEDBYAQUALIFIED SCREW

ELECTRICIAN. HOT

COVER CONDUCTORSOR120/240V30APOWER

s-wire Connection

Not for use in Canada.

DONOTuse for Mobile Home Installations.

NOTfor use on new construction.

NOTfor use on recreational vehicles.

NOTfor use in areas where local codes prohibit grounding

through the neutral conduction.

WIRE STRAINRELIEF

NEUTRAL

(White) HOT

] #10AWGMINIMUMCOPPER

SUPPLYCORDKITMARKEDFORUSE

WITHDRYERS& PROVIDEDWITHCLOSED

LOOPORSPADETERMINALSWITH

UPTURNEDENDS(NOTSUPPLIED).

BRACKET

3/4",UL

RECOGNIZED

WIRE

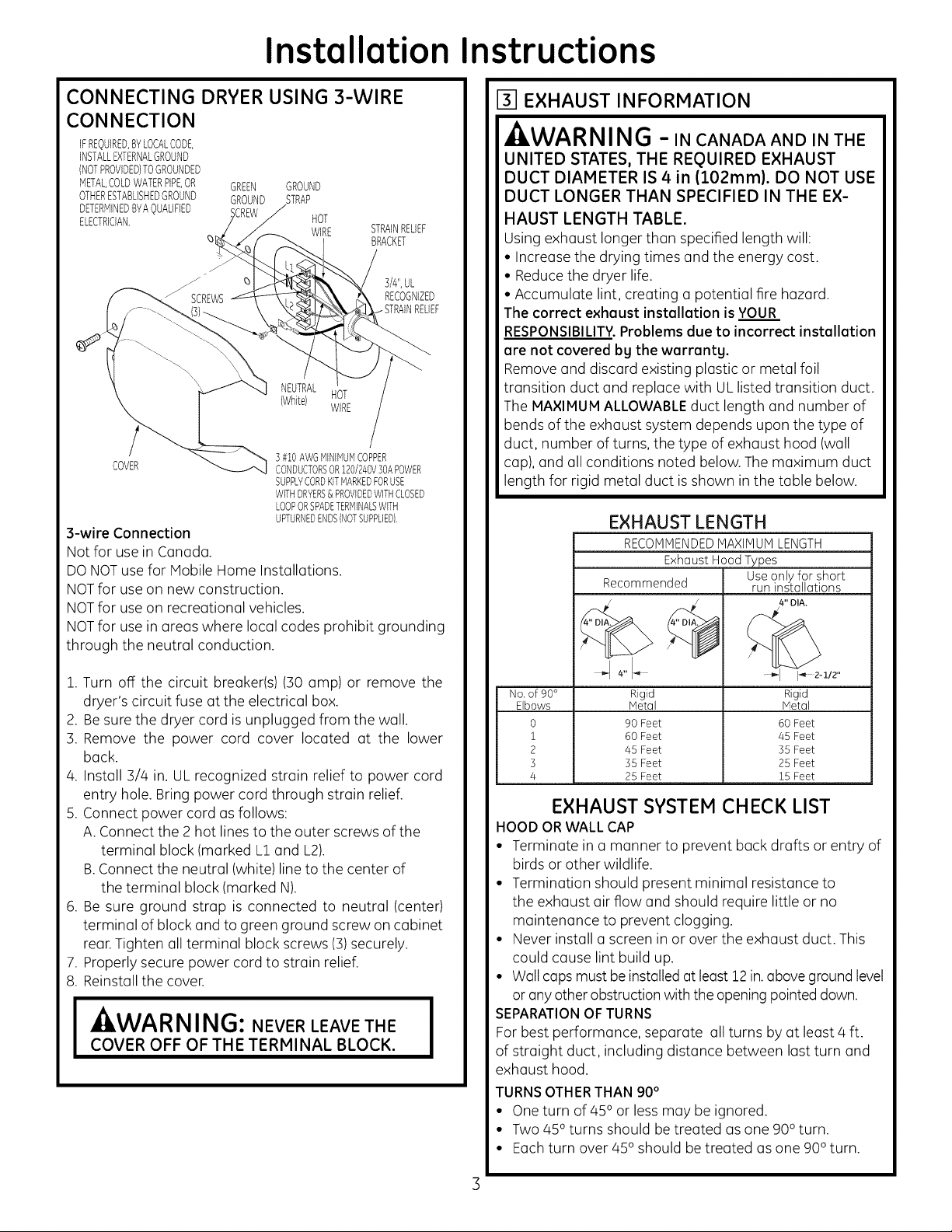

[] EXHAUST INFORMATION

,AWARNING -INCANADAANDINTHE

UNITED STATES, THE REQUIRED EXHAUST

DUCT DIAMETER IS 4in (102ram). DO NOT USE

DUCT LONGER THAN SPECIFIED IN THE EX-

HAUST LENGTH TABLE.

Using exhaust longer than specified length will:

• Increase the drying times and the energy cost.

• Reducethe dryer life.

• Accumulate lint, creating a potential fire hazard.

The correct exhoust instollotion is YOUR

RESPONSIBILITY.Problems due to incorrect instollotion

ore not covered by the werronty.

Remove and discard existing plastic or metal foil

transition duct and replace with ULlisted transition duct.

The MAXIMUM ALLOWABLEduct length and number of

bends of the exhaust system depends upon the type of

duct, number of turns, the type of exhaust hood (wall

cap), and all conditions noted below. The maximum duct

length for rigid metal duct isshown in the table below.

EXHAUST LENGTH

RECOMMENDEDMAXIHUI LENGTH

ExhaustHoodTypes

Recommended runinstallations

Useonly forshort

4" DIA.

1. Turn off the circuit breaker(s) (30 amp) or remove the

dryer's circuit fuse at the electrical box.

2. Besure the dryer cord is unplugged from the wall.

3. Remove the power cord cover located at the lower

back.

4. Install 3/4 in. UL recognized strain relief to power cord

entry hole. Bring power cord through strain relief.

5. Connect power cord as follows:

A. Connect the 2 hot lines to the outer screws of the

terminal block (marked L1 and L2).

B.Connect the neutral (white) line to the center of

the terminal block (marked N).

6. Be sure ground strap is connected to neutral (center)

terminal of block and to green ground screw on cabinet

rear.Tighten all terminal block screws (3)securely.

7. Properly secure power cord to strain relief.

8. Reinstall the cover.

I WARNING: NEVER LEAVE THE I

COVER OFF OF THE TERMINAL BLOCK.

No, of 90°

Elbows

0

1

2

3

4

Rigid Rigid

Metal Metal

90 Feet 60 Feet

60 Feet 45 Feet

45 Feet 35 Feet

35 Feet 25 Feet

25 Feet 15 Feet

EXHAUST SYSTEM CHECK LIST

HOOD OR WALL CAP

• Terminate in a manner to prevent back drafts or entry of

birds or other wildlife.

• Termination should present minimal resistance to

the exhaust air flow and should require little or no

maintenance to prevent clogging.

• Never install a screen in or over the exhaust duct. This

could cause lint build up.

• Wall caps must be installed at least 12 in.aboveground level

or anyother obstruction with the openingpointed down.

SEPARATIONOFTURNS

For best performance, separate all turns by at least 4 ft.

of straight duct, including distance between last turn and

exhaust hood.

TURNSOTHERTHAN 90°

• Oneturn of 45oor less may be ignored.

• Two 450 turns should be treated as one 900turn.

• Each turn over 450should betreated as one 900 turn.

Page 4

Installation

nstructions

SEALING OFJOINTS

• Alljoints should be tight to avoid leaks.The male end of

each section of duct must point away from the dryer.

• The duct shall not be assembled with screws or other

fastening means that extend into the duct and catch lint.

• Duct joints can be made air and moisture-tight by

wrapping the overlapped joints with duct tape.

• Horizontal runs should slope down toward the outdoors

1/4 inch per foot.

INSULATION

Duct work that runs through an unheated area or is

near air conditioning should be insulated to reduce

condensation and lint build-up.

[] EXHAUST CONNECTION

- WARNING - TO REDUCE THE RISK

OF FIRE OR PERSONAL INJURY:

•This clothes dryer must be exhausted to the outdoors.

• Use only 4" rigid metal ducting for the home exhaust

duct.

• Use only 4" rigid metal or UL-listed flexible metal

(semi-rigid or foil-type) duct to connect the dryer to the

home exhaust duct. It must be installed in accordance

with the instructions found in"Connecting the Dryer to

House Vent" on pages 4-5 of this manual.

• Do not terminate exhaust in a chimney, a wall, a

ceiling, gas vent, crawl space, attic, under an enclosed

floor, or in any other concealed space of a building. The

accumulated lint could create a potential fire hazard.

• Never terminate the exhaust into a common duct with

a kitchen exhaust system. A combination of grease

and lint creates a potential fire hazard.

• Do not use duct longer than specified in the exhaust

length table. Longer ducts can accumulate lint,

creating a potential fire hazard.

• Never install a screen in or over the exhaust duct. This

will cause lint to accumulate, creating a potential fire

hazard.

• Do not assemble ductwork with any fasteners that

extend into the duct. These fasteners can accumulate

lint, creating a potential fire hazard.

• Do not obstruct incoming or exhausted air.

• Provide an access for inspection and cleaning of the

exhaust system, especially at turns and joints. Exhaust

system shall be inspected and cleaned at least once a

year.

There are multiple installation options.

Select the most appropriate method for

your installation situation.

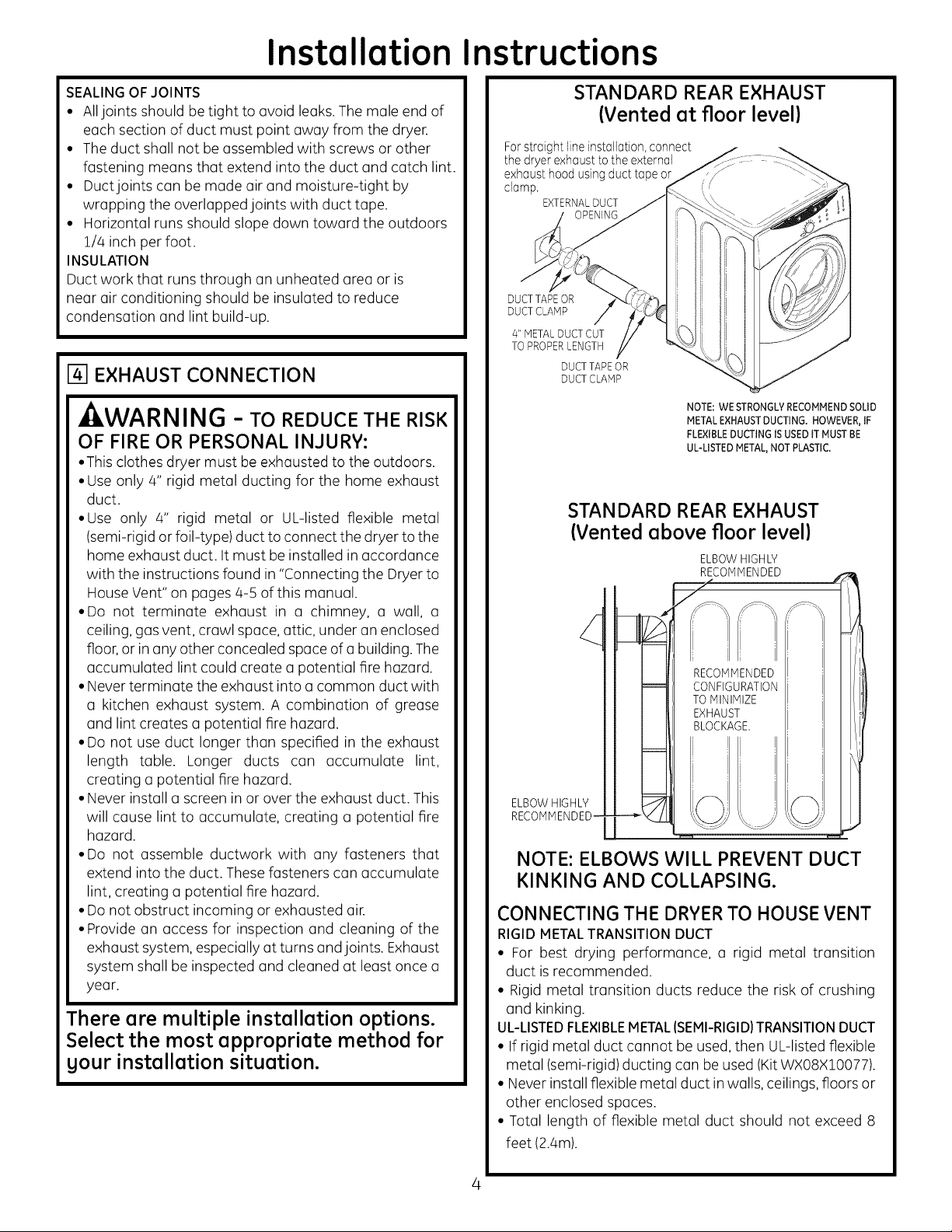

STANDARD REAR EXHAUST

(Vented at floor level)

For straight line installation, connect

the dryer exhaust to the external

exhaust hood using duct tape or

clamp.

EXTERNALDUCT

DUCT TAPEOR

DUCT CLAMP

4" METALDUCT CUT

TO PROPERLENGTH

DUCTTAPE OR

DUCTCLAMP

NOTE: WE STRONGLYRECOMMENDSOLID

METALEXHAUSTDUCTING. HOWEVER,IF

FLEXIBLEDUCTING ISUSEDtT MUST BE

UL-LISTED METAL,NOT PLASTIC.

STANDARD REAR EXHAUST

(Vented above floor level)

ELBOWHIGHLY

d

: i

C()[I-FIGUFATI_D-N I '

TOMINIMIZE I !

EXHAUST

BL J I :IOCKAGE I i

ELBOWHIGHLY

RECOMMENDED-

!

NOTE: ELBOWS WILL PREVENT DUCT

KINKING AND COLLAPSING.

CONNECTING THE DRYERTO HOUSE VENT

RIGID METALTRANSITION DUCT

• For best drying performance, a rigid metal transition

duct isrecommended.

• Rigid metal transition ducts reduce the risk of crushing

and kinking.

UL-LISTEDFLEXIBLEMETAL(SEMI-RIGID)TRANSITIONDUCT

• If rigid metal duct cannot be used, then UL-listed flexible

metal (semi-rigid) ducting can beused (KitWXO8XlO077).

• Neverinstall flexible metal duct in walls, ceilings, floors or

other enclosed spaces.

• Total length of flexible metal duct should not exceed 8

feet (2.4m).

Page 5

Installation Instructions

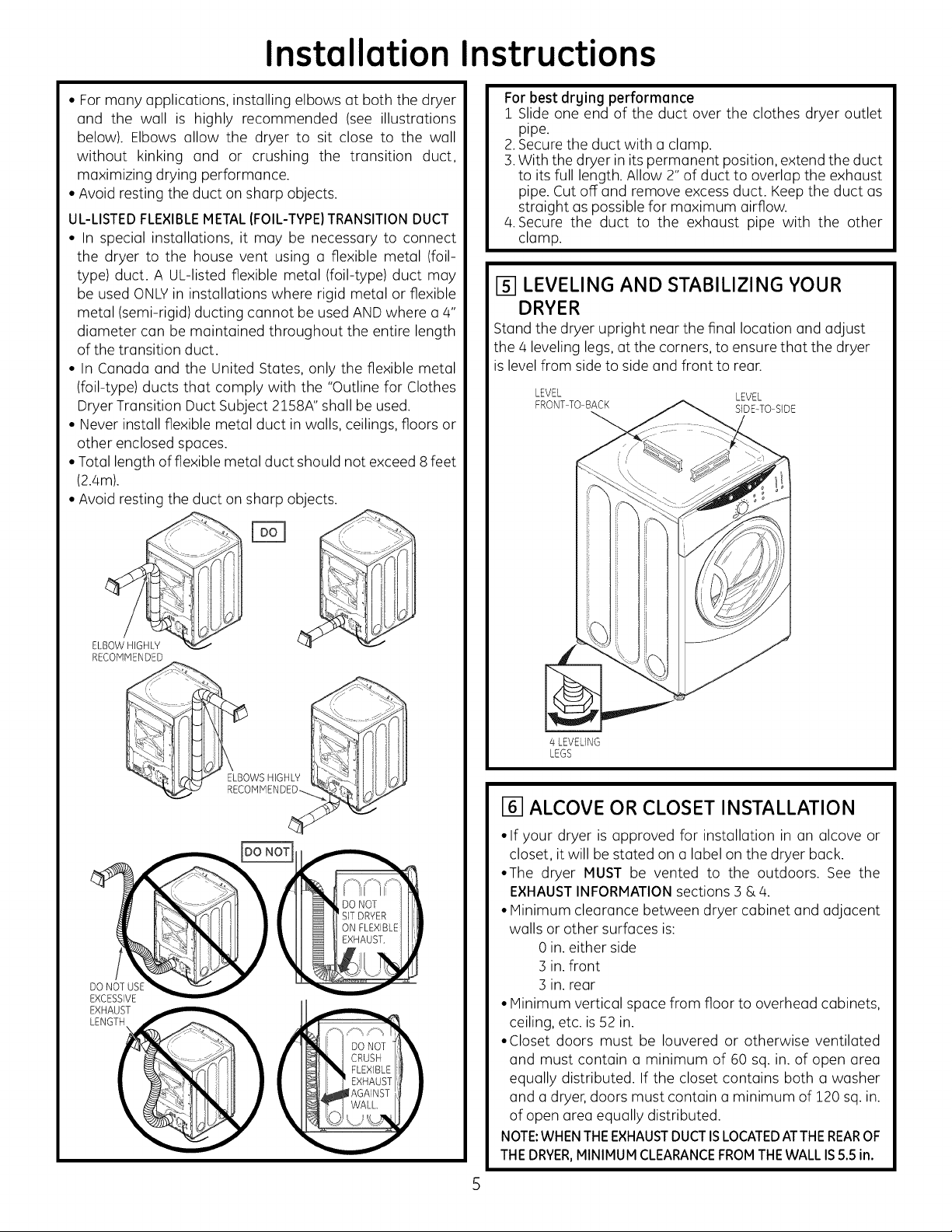

• For many applications, installing elbows at both the dryer

and the wall is highly recommended (see illustrations

below). Elbows allow the dryer to sit close to the wall

without kinking and or crushing the transition duct,

maximizing drying performance.

• Avoid resting the duct on sharp objects.

UL-LISTEDFLEXIBLEMETAL{FOIL-TYPE)TRANSITIONDUCT

• In special installations, it may be necessary to connect

the dryer to the house vent using a flexible metal (foil-

type) duct. A UL-listed flexible metal (foil-type) duct may

be used ONLYin installations where rigid metal or flexible

metal (semi-rigid) ducting cannot be used ANDwhere a4"

diameter can be maintained throughout the entire length

of the transition duct.

• In Canada and the United States, only the flexible metal

(foil-type) ducts that comply with the "Outline for Clothes

Dryer Transition Duct Subject 2158A" shall be used.

• Never install flexible metal duct in walls, ceilings, floors or

other enclosed spaces.

• Total length of flexible metal duct should not exceed 8feet

(2.4m).

• Avoid resting the duct on sharp objects.

For best drying performance

1 Slide one end of the duct over the clothes dryer outlet

pipe.

2.Secure the duct with mclamp.

3.With the dryer in its permanent position, extend the duct

to its full length. Allow 2" of duct to overlap the exhaust

pipe. Cut off and remove excess duct. Keep the duct as

straight as possible for maximum airflow.

4.Secure the duct to the exhaust pipe with the other

clamp.

[] LEVELING AND STABILIZING YOUR

DRYER

Stand the dryer upright near the final location and adjust

the 4 leveling legs, at the corners, to ensure that the dryer

islevel from side to side and front to rear.

LEVEL LEVEL

FRONTTO BACK SIDE-TO SIDE

ELBOWHIGHLY

RECOk_,MENDED

EXHAUST

LENGTH

(

4 LEVELING

LEGS

[] ALCOVE OR CLOSET INSTALLATION

• If your dryer is approved for installation in an alcove or

closet, it will be stated on a label on the dryer back.

•The dryer MUST be vented to the outdoors. See the

EXHAUSTINFORMATIONsections 3 & 4.

• Minimum clearance between dryer cabinet and adjacent

walls or other surfaces is:

0 in. either side

3 in.front

3 in.rear

• Minimum vertical space from floor to overhead cabinets,

ceiling, etc. is 52 in.

•Closet doors must be Iouvered or otherwise ventilated

and must contain o minimum of 60 sq. in. of open area

equally distributed. If the closet contains both o washer

and a dryer, doors must contain o minimum of 120 sq. in.

of open area equally distributed.

NOTE:WHENTHEEXHAUSTDUCTISLOCATEDATTHEREAROF

THEDRYER,MINIMUMCLEARANCEFROMTHEWALLIS5.5in.

Page 6

Installation Instructions

I-_ BATHROOM OR BEDROOM INSTALLATION

• The dryer MUST be vented to the outdoors. See EXHAUST

INFORMATION section :3& 4.

• The installation must conform with local codes or, in the

absence of local codes, with the NATIONAL ELECTRICAL

CODE, ANSI/NFPA NO. 70.

F-_MOBILE OR MANUFACTURED HOME

INSTALLATION

•Installation must conform to the MANUFACTURED HOME

CONSTRUCTION & SAFETY STANDARD, TITLE 24, PART

:32-80 or, when such standard is not applicable, with

AMERICAN NATIONAL STANDARD FOR MOBILE HOME,

ANSI/NFPA NO. 501B.

• The dryer MUST be vented to the outdoors with the

termination securely fastened to the mobile home

structure. (See EXHAUST INFORMATION section :3 & 4).

• The vent MUST NOT be terminated beneath a mobile or

manufactured home.

• The vent duct material MUST BE METAL.

• Do not use sheet metal screws or other fastening devices

which extend into the interior of the exhaust vent.

• See section 2 for electrical connection information.

FIXINGHOLE

B A

.

Cut the duct as shown and keep portion A.

TAB LOCATION

BENDTAB

UP45o

Through the rear opening, locate the tab in the middle of

the appliance base. Lift the tab to about 450 using a flat

blade screwdriver.

19IGARAGE INSTALLATION (IF ALLOWED

BY LOCAL CODES)

• Dryers installed in garages must be elevated 18 inches

(46cm) above the floor.

I1-O1DRYEREXHAUST TO RIGHT, LEFT OR

BOTTOM CABINET

, WARNING - BEFOREPERFORMING

THIS EXHAUST INSTALLATION, BESURE

TO DISCONNECT THE DRYER FROM ITS

ELECTRICAL SUPPLY.PROTECT YOUR

HANDS AND ARMS FROM SHARP EDGES

WHEN WORKING INSIDE THE CABINET.

BESURE TO WEAR GLOVES.

REMOVE

SCREW

ANDSAVE.

ADDING NEW DUCT

FIXING

HOLE

PORTION"A"

RIGHTOR

LEFTSIDE

EXHAUST

Reconnect the cut portion (A)of the duct to the blower

housing. Make sure that the shortened duct is aligned with

the tab in the base. Use the screw saved previouslg to secure

the duct in place throuqh the tab on the appliance base.

REMOVEDESIRED

KNOCKOUT(ONEONLY).

Detach and remove the bottom, right or left side knockout

as desired. Remove the screw inside the dryer exhaust duct

and save. Pull the duct out of the dryer.

Page 7

Installation Instructions

ADDING ELBOW AND DUCT FOR

EXHAUST TO LEFT OR RIGHT SIDE OF

CABINET

• Preassemble 4" elbow with 4" duct. Wrap duct tape

Ground joint.

• Insert duct assembly, elbow first, through the side

opening and connect the elbow to the dryer internal

duct.

-&CAUTION: Be sure not to pullor damage the

electrical wires inside the drger when inserting the duct.

EXHAUSTCAN

BEADDEDTO

LEFTORRIGHTSIDE

ADDING COVER PLATE TO REAR OF

CABINET (SIDES AND BOTTOM EXHAUST)

PLATE

{KITWE1M454)

Connect standard metal elbows and ducts to complete

the exhaust system. Cover back opening with a plate (Kit

WEllV]454) available from your local service provider. Place

dryer in final location.

-_WARNING-NEVER LEAVE THE

BACK OPENING WITHOUT THE PLATE

(Kit WEIM454).

• Apply duct tape as shown on the joint between the

dryer internal duct and the elbow.

DUCT CAUTION:

Internal duct joints must be

secured with tape, otherwise

theg mag separate and cause a

safetg hazard.

ADDING ELBOW FOR EXHAUST

THROUGH BOTTOM OF CABINET

• Insert the elbow through the rear opening and connect

it to the dryer internal duct.

•Apply duct tope on the joint between the dryer internal

duct and elbow, as shown above.

REGISTER YOUR NEW APPLIANCE TO RECEIVE ANY

IMPORTANT PRODUCT NOTIFICATIONS.

Please go to www.GEAppliances.com or mail in

your product registration curd.

For questions on installation, coil: 800.626.2000 (US) or

800-561-3344 (Canada).

CAUTION:

Internal duct joints must be secured with tape,

otherwise they may separate and cause a

safety hazard.

Page 8

Page 9

Instrucciones

Secadora El ctrica

de instalaci6n

2,Preguntas sabre la instalaci6n? Llame al: 1-800-GECARES (EE.UU.)

o visite nuestro sitio Web en: www.GEAppliances.corn (EE.UU.)

ANTES DE COMENZAR

Lea estas instrucciones par completo y con

detenimiento.

•IM PORTANTE - Guarde estas instruc-

ciones para el usa de inspectores locales.

•IMPORTANTE - Siga todos los c6digos

y ordenanzas vigentes.

• Nota al instalador - AsegOrese de dejar

estas instrucciones con el consumidor.

• Nota al consumidor - Mantenga estas

instrucciones con el Manual del propietario

para referencia futura.

• Antes de que la secadora antigua sea retirada

del servicio o eliminada, quftele la puerta.

• Lainformaci6n sabre reparaciones y el

diagrama del cableado se encuentran en la

consola de control.

• No permita que niflos sesuban o se metan

dentro del aparato. Se requiere una super-

visi6n estricta cuando el aparato es utilizado

cerca de nifios.

• Instale la secadora en lugares donde la

temperatura sea mayor a 50°F para un

funcionamiento satisfactorio del sistema de

control de la secadora.

• Lagarant[a no cubre las fallas del producto

debido a una instalaci6n incorrecta.

10

I

- ADVERTENCIA RIESGO DE INCENDIO

• Para reducir el riesgo de una lesi6n grave o de muerte, cumpla con

todas las instrucciones de instalaci6n.

• Lainstalaci6n de la secadora debe efectuarla un instalador calificado.

• Instale la secadora de ropa de acuerdo con estas instrucciones yen

cumplimiento de los c6digos locales.

• Estasecadora debe tener una salida al exterior.

• Utilice s61oun conducto r[gido de metal de un di6metro de 4" dentro del

gabinete de la secadora y use s61oun conducto detransici6n aprobado

par ULentre la secadora y el conducto dom#stico.

• NOinstale una secadora de ropa con conductos de pl6stico flexibles.

Si se instala un conducto flexible de metal (semi r[gido o de tipo papel de

aluminio), debe estar aprobado par ULe instalarse de acuerdo con las

instrucciones de "C6mo conectar la secadora a la ventilaci6n dom#stica"

de las p6ginas 4-5 de este manual. Los materiales de ventilaci6n

flexibles a menudo se desploman, se aplastan y atrapan pelusas. Estas

condiciones obstruyen la corriente de aire de la secadora e incrementan

el riesgo de incendio.

• No instale o almacene este aparato en un lugar donde se vea expuesto

al agua y/o alas inclemencias del tiempo.

• Guarde estas instrucciones. (Instaladores: AsegOrese de dejar estas

instrucciones al consumidor).

NOTA:La instalaci6n g reparaci6n de esta secadora requieren capaci-

dades mec6nicas y el_ctricas b6sicas. Essu responsabilidad contactar

a un instalador calificado para realizar las conexionesel_ctricas.

HERRAMIENTAS

NECESARIAS

CONDUCTODEMETALDE#' DEDIA

AUCATESDEJUNTADESLIZANTE

DESTORNILLADORPLANO

DESTORNILLADORDEESTRELLA

Paso 1

Prepareel6reay lasalidaparalainstalaci6nde lanueva

secadora (ver secci6n 1).

Paso 2

Verifique y asegOrese de que lasalida al exterior existente

est# limpia (ver secci6n 1)y que cumpla con las especifi-

caciones de instalaci6n incluidas (versecci6n 3).

Paso 3

Quite las almohadittas de espuma para envio (ver secci6n 1).

Paso Q

Desplace la secadora a la ubicaci6n deseada.

Paso 5

Conecte el suministro de energfa (ver secci6n 2).

Paso 6

Conecte la salida al exterior (ver secci6n 4).

Paso 7

Nivele su secadora (versecci6n 5).

Paso 8

Verifique el funcionamiento del suministro de energfa y

(RECOMENDADO)

CONDUCTODETR#NSIOONDEMET&L

FLEXIBLE(SEMIRIGIDO/DE4"DEDIA, DERESORTEDE4"(2)

APROBADOPORUL(SIFUERANECESARIO}

KITWXO8XIOO77(INCLUYE2CODOSI _ _ AUVIODETENSION

CONDUCTODETRANSIOONDEMETAL

FLEXIBLE(TIPOPAPELDEALUMINIO}DE4"DEDI#.

APROBADOPORUL(SIFUERANECESARIOI a "PLACADECUBIERTA

HATERIALES

)

ABRAZADERAS

DECONDUCTODE4"(2)

0

ABRAZADERAS

ONTAADHESIVA PORUL

de la ventilaci6n.

Paso 9 Coloque el manual del propietario y las instrucciones de

instalaci6n en un lugar de fcicil acceso para el propietario.

Para instalaci6n en nicho o closet, ver secci6n 6.

Para instalaci6n en baflos o dormitorios, ver secci6n 7.

Para casas m6viles o prefabricadas, ver secci6n 8.

Para instalaci6n en garaje (sipermitido por loscodigos locales),ver

secci6n 9.

Para salidas laterales o por la parte inferior, ver secci6n 10.

NECESARIOS

KITDECABLE

CODODEMETAL

DE4"DEDIA. CAMPANA GAFAS

DESALIDADESEGURIDAD

GUANTES DE3A"RECONOODO

LJ

234DlO52PO05 31-16629-2 03-12 GE

DEENERGIA

DELASECADORA

(NOPROVBTACON

LASECADORAI

CAPACIDAD UL DE

220/240V30A

CON 3 0 4 PUNTAS

ANTES DE COMPRAR EL

CORDON IDENTIFIQUE

EL TIPO DE ENCHUFE DE

ACUERDO CON EL

RECEPTACULO

DE LA CASA

Page 10

Instrucciones de instalaci6n

Espaciominimo diferente a instalaci6n en nichos oclosets

Losespacioslibresm[nimosrespectodesuperficiescombustiblesy deaberturasde aireson:Espaciode0 pulg.aamboslados,1 pulg.enel

frentey 3 pulg.enlapartetrasera. Oebetenerseencuentaunespaciolibreadecuadoparaunfuncionamientoy reparaci6ncorrectos

m PREPARACION PARA LA INSTALACION

DE UNA SECADORA NUEVA

CONSEJO:Instale su secadora antes de instalar la lava-

dora. Esto permitir6 un mejor acceso cuando instale la

salida de la secadora.

COMO OUITAR PELUSA DE LA ABERTURA

DE LA SALIDA DE LA PARED

• Quite y descarte el conducto de transici6n existente de

pl6stico o de papel de aluminio y coloque un conducto

de transici6n aprobado por UL.

ABERTURA DE

VERIFIQUE QUE

EL REGULADOR

DE TIRO DE LA CAMPANA

DE SALIDA SEABRA

Y CIERRE UBREMENTE

INCLINE LA SECADORA

DECOSTADO Y QUITE

LAS ALMOHADILLAS

DE ESPUJqA PARA ENV[O

TOMANDOLAS DE LOS

COSTADOS Y

ARRANCANDOLAS DE LAS

PATASDE LA SECADORA.

ASEGORESE DE OUITAR

TODAS LAS PIEZAS

DE ESPUJqA UBICADAS

ALREDEDOR DE LAS PATAS.

121INFORMACION SOBRE CONE×IONES

ELECTRICAS

- ADVERTENCIA - PARA RE DUCIR EL

RIESGO DE INCENDIO, DESCARGA ELECTRICA

V LESIONES PERSONALES:

• NO UTILICE UN CABLE DE EXTENSI6N O UN

ENCHUFE ADAPTADOR CON ESTE APARATO.

La secadora debe contar con una conexi6n el6ctrica a

tierra en cumplimiento con los c6digos y ordenanzas

locales, o si 6stos no existieran, de acuerdo con el

CODIGOELE_CTRICONACIONAL,ANSI/NFPAN°. 70.

REOUISITOS ELI_CTRICOS

Esta secadora debe conectarse a un circuito derivado

individual, con la protecci6n de los fusibles de tiempo

retardado o interruptores de circuito requeridos. Se requiere

un circuito de tres o cuatro cables, fase Onica, 120/280V 6

120/208V, 60Hz y 30 amperios.

INSTRUCCIONES DE CONEXI6N A TIERRA

Esta secadora debe conectarse a un sistema de cableado

permanente con conexi6n a tierra o debe utilizarse un con-

ductor de conexi6n a tierra del equipamiento con los con-

ductores de circuito y conectarse a la terminal de conexi6n

a tierra del aparato.

COMO CONECTAR LA SECADORA USAN-

DO UNA CONE×I6N DE 4 CABLES (DEBE

UTILIZARSE EN INSTALACIONES DE CASAS

M6VILES)

NOTA:Desdeel I de enero de 1996,el C6digoEl_ctricoNacional

exige que las nuevasconstrucciones utilicen una conexi6n de 4

cables a una secadorael_ctrica.

QUITE LA CINTA DE

CON EXl6N A TIERRA

Y DESCARTELA CONSERVE

EL TORNILLO VERDE

DE CONEXl6N ATIERR/_

TAPA

VIVO

VUELVA A COLOCAR

ELTORNILLO VERDE

DE CONEXl6N ATIERRA AOUi

CABLEVERDE

DE AUVIO

BRACKET

ALIVIO DE TENSI6N

CABLE DE ¾" RECONOCIDO

VIVO POR UL

4 CONDUCTORES DE COBRE #10 AWG

NiNINO O KIT DE CABLE DE SUNINISTRO

DE ENERGiA DE 120/240V 30A NARCADO

PARA USO EN SECADORAS Y PROVISTO

CON TERNINALES DE BUCLE CERRADO O

DE PALA CON EXTRENOS NACIA ARRIBA

(NO PROVISTOS}

i. Desactive el interruptor de circuitos (30 amperios) o

quite el fusible del circuito de la secadora de la caja

el#ctrica.

2.Verifique que elcable dela secadora est# desenchufado

del tomacorriente.

3. Quite la tapa del cable de energia ubicada en la parte

trasera inferior.

4.Quite y descarte la cinta de conexi6n a tierra. Conserve

el tornillo verde de conexi6n a tierra para el paso 7.

5. Instale un alivio de tensi6n de sApulgadas reconocido

por UL en el orificio de entrada del cable de energia.

Paseel cable de energia a trav@sdel alivio de tensi6n.

6.Conecte el cable de energia de la siguiente manera:

A. Conecte los dos cables vivos a los tornillos externos

del bloque terminal (marcado L1y L2).

B.Conecte el cable neutral (blanco) al centro del bloque

terminal (marcado N).

7. Conecte el cable a tierra del cable de energia con el

tornillo verde de conexi6n a tierra (orificio sobre el

soporte de alivio de tensi6n). Ajuste por firmemente

todos los tornillos (3)del bloque terminal.

8.Ajuste bien el cable de energia al alivio de tensi6n.

9.Vuelva a instalar la tapa.

- ADVERTENCIA: NUNCA OL-

VIDE DE VOWER A COLOCAR LA TAPA DEL

BLOQUE TERMINAL.

Page 11

Instrucciones de instalaci6n

C6MO CONECTAR LA SECADORA UTILI-

ZANDO UNA CONE×I6N DE 3 CABLES

SI ASi LO REOUIRIERAN LOS CODIGOS TORNILLO CINTA DE CONEXION

LOCALES, INSTALL UNA CONEXION VERDE

A TIERRA EXTERNA (NO PROVISTA) DE CONEXION /A

A METAL CON CONEXION A TIERRA, A TIERRA /

TUBERiAS DE AGUA FRiA CON CONEXION /

A TIERRA U OTRA CONEXION A TIERRA _ CABLE VWO

ESTABLECIDA PaR UN ELECTRICISTA

CAURCADO

/

TAPA

TIERRA

SOPORTE

DE ALIVIO

DE TENSION

ALWIO DE TENSION

DE %" RECONOQDO

PaR UL

MINIMa O KI] DE CABLE DE SUP11NISTRO

DE ENERG[A DE 120/2a0V }0A IV1ARCADO

DE PALA CON EXTREIV!OSHACIA ARRIBA

(NO PROVISTOS)

Conexi6n de 3 cables

NOusar en Canad6.

NOusar en instalaciones en casas m6viles.

NOusar en casas nuevas.

NOusar en vehiculos recreativos.

NO usar en 6reas donde los c6digos locales proh[ben

la connexi6n el6ctrica a tierra par el media del cable

neutral.

1. Desactive el interruptor de circuitos (30 amperios) o

quite el fusible del circuito de la secadora de la caja

el6ctrica.

2. Verifique que el cable de la secadora est6

desenchufado del tomacorriente.

3. Quite latapa del cable de energia ubicada en la parte

trasera inferior.

4. Instale un alivio de tensi6n de s4pulgadas reconocido

par ULen el orificio de entrada del cable de energia.

Paseel cable de energia a trav6s del alivio de tensi6n.

5.Conecte el cable de energia de la siguiente manera:

A. Conecte los dos cables vivos a los tornillos externos

del bloque terminal (marcado L1y L2).

B.Conecte el cable neutral (blanco) al centro del bloque

terminal (marcado N).

6. AsegOrese de que la cinta de conexi6n a tierra est6

conectada a la terminal neutral (central) del bloque

y al tornillo verde de conexi6n a tierra de la parte

trasera del gabinete. Ajuste par firmemente todos los

tornillos (3)del bloque terminal.

7.Ajuste bien el cable de energia al alivio de tensi6n.

8. Vuelva a instalar la tapa.

- ADVERTENCIA: NUNCA OL-

VIDE DE VOLVER A COLOCAR LA

TAPA DEL BLOQUE TERMINAL.

[] INFORMACION DE SALIDA

- ADVERTENCIA- EN CANAD/_ Y

LOS ESTADOS UNIDOS, EL DIAMETRO

DE CONDUCTO DE SALIDA REQUERIDO

ESDE 4 PULG. (102 mm). NO UTILICE UN

CONDUCTO DE UNA LONGITUD MAYOR

A LA ESPECIFICADA EN LA TABLA DE

LONGITUD DE SALIDA.

AIutilizar una salida de mayor Iongitud a la especificada se:

• Incrementardn lostiempos desecadoy el costa de energ[a.

• Reducir6 lavida 0til de la secadora.

• Acumular6 pelusa, Io que podria generar un riesgo

potencial de incendio.

La correcta instalaci6n de salida es SU

RESPONSABILIDAD. Los problemas generados por una

instalaci6n incorrecta no se encuentran cubiertos por

la garantia.

Quite y descarte el conducto detransici6n existente de

pl6stico o de papel de aluminio y coloque un conducto

de transici6n gprobado par UL.

La Iongitud MA×IMA PERMITIDAdel conducto y la

cantidad de codas del sistema de salida dependen

del tipo de conducto, la cantidad de curvas, laclase

de campana de salida (cubierta de pared) y todas las

condiciones indicadas acontinuaci6n. La Iongitud

m6xima del conducto para conductos r[gidos de metal

se indica en lasiguiente tabla.

LONGITUD DE SALIDA

LONGITUDIvI_,XIIV1ARECOMENDADA

Tipos de campana de salida

Recomendado

Cant. de

codas de 90°

0

1

2

3

Metal

Rigido

90 Pies

60 Pies

45 Pies

35 Pies

LISTADE CONTROL DEL SISTEMA DE SALIDA

CAMPANA 0 CUBIERTADEPARED

• Instale la salida de modo de evitar contracorrientes o el

ingreso de p6jaros u arras insectos o animales.

• La boca de salida debe presentar una resistencia

minima al flujo de salida y debe requerir poco o ningOn

mantenimiento para evitar las obstrucciones.

• Nunca instale un filtro dentro o sabre el conducto de

salida. Esto podrfa provocar una acumulaci6n de pelusa.

• Las cubiertas de pared deben instalarse par Io menos a

12" sabre el nivel del suelo o cualquier otra obstrucci6n

con la abertura apuntando hacia abajo.

SEPARACIONDECURVAS

Para un mejor desempeflo, separe todas las curvas con par

Io menos 4 pies de conducto recto, incluyendo la distancia

entre la Oltima curva y la campana de salida.

GIROSQUENO SON DE90•

• Un giro de 450 o menos puede ignorarse.

• Dos giros de 450deben tratarse coma ungiro de 90°.

• Todoslosgirosdemdsde450debentratarsecomaungirode90°.

Utilizar s61oen instaladones

de trayeeto corto

4" DIA.

I" z-tim+'

Metal

Rigido

60 Pies

45 Pies

35 Pies

25 Pies

Page 12

Instrucciones de instalaci6n

SELLADO DE JUNTAS

• Todas lasjuntas deben estar bien selladas para evitar p@didas.

Elextremo macho de cada secci6n de conducto debe apuntar

en direcci6n opuesta a la secadora.

• El conducto no debera instalarse con tornillos u otros medios de

sujeci6n que se extiendan dentro del conducto y enganchen

pelusas.

• Lasjuntas de los conductos deben ser herm@icas al aire y a

la humedad mediante la superposici6n de juntas con cinta

aislante.

• Los tramos horizontales deben tener una inclinaci6n hacia el

exterior de 1/4" por pie.

AISLACION

Los conductos instalados a trav_s de una cirea sin calefacci6n o

ubicados cerca de un acondicionador de aire deben aislarse para

reducir la condensaci6n y la acumulaci6n de pelusas.

CONE×I6N A LA SALIDA

ADVERTENCIA - PARA

REDUCIR EL RIESGO DE INCENDIO O

DE LESIONES PERSONALES:

• Esta secadora de ropa debe tener una salida al

exterior.

• Utilice s61oun conducto de metal rigido de 4" para el

conducto de salida dom6stico.

• Use s61o un conducto de metal rigido de 4"o de

metal flexible (semi rigido o de tipo papel de aluminio)

aprobado por UL para conectar la secadora al

conducto de salida dom6stico. Debe instalarse de

acuerdo con las instrucciones incluidas en "C6mo

conectar la secadora a la ventilaci6n dom6stica" de

las p6ginas 4-5 de este manual.

• No instale la boca de salida dentro de una chimenea,

pared, cielorraso, ventilaci6n de gas, espacio entre

pisos, 6tico, bajo un piso con cerramiento o en

cualquier otro espacio oculto de un edificio. La

acumulaci6n de pelusas podria provocar un riesgo

potencial de incendio.

• Nunca instale la boca de salida dentro de un conducto

com0n con el sistema de salida de la cocina. La

combinaci6n de grasa y pelusas podria provocar un

riesgo potencial de incendio.

• No utilice un conducto de una Iongitud mayor a la

especificada en la tabla de Iongitud de salida. Los

conductos m6s largos acumulan pelusa, Io que

genera un riesgo potencial de incendio.

• Nunca instale un filtro dentro o sobre el conducto de

salida. Esto provocar6 la acumulaci6n de pelusas, Io

que genera un riesgo potencial de incendio.

• No arme la red de conductos con sujeciones que

se extiendan dentro del conducto. Estas sujeciones

pueden acumular pelusa, Io que genera un riesgo

potencial de incendio.

• No obstruya el aire que entra y sale.

• Incluya un acceso para inspecci6n y limpieza del

sistema de salida, especialmente en las curvas y

juntas. El sistema de salida debe inspeccionarse y

limpiarse por Io menos una vez al aBo.

Existen opciones m61tiples de instalaci6n.

Seleccione el m_todo m6s apropiado para su

instalaci6n.

SALIDA TRASERA EST#,NDAR

(Ventilaci6n a nivel del suelo)

Para una instalad6n en linea recta, conecte

lasalidade la secadoraa la campana

desalidaal exteriorcondnta aislante

o una abrazadera

ABERTURA DE

CONDUCTO EXTERIOR

CINTA AISLANTE

O

DE CONDUCTO

CONDUCTO DE METAL

DE 4" CORTADO

CON LA LONGITUD ADECUADA

CINTA AISLANTE O

ABRAZADERA DE CONDUCTO

NOTA: RECOMENDAMOS ENFATICAMENTE EL USO

DECONDUCTOS DE SALIDA DE METAL SOLIDO.

SIN EMBARGO, SI SE USAN CONDUCTOS FLEXIBLES

ESTOSDEBEN SER DE METAL APROBADOS PORU[

NO DE PLASTICO.

SALIDA TRASERA ESTANDAR

(Ventilaci6n sobre el nivel del suelo)

SERECOMIENDA

ELUSO DECODOS-

NOTA: LOS CODOS EVITAN QUE LOS

CONDUCTOS SE DOBLEN O CAIGAN.

C6MO CONECTAR LA SECADORA A LA VEN-

TILACION DOMESTICA

CONDUCTODE TRANSlCION DE METALRIGIDO

• Para un mejor desempe_o de secado, se recomienda un

conducto de transici6n de metal rigido.

• Los conductos de transici6n de metal rigidos reducen el

riesgo de aplastamientos g torceduras.

CONDUCTODETRANSICIONDEMETALFLEXIBLE

(SEMI-RiGIDO)APROBADOPOR UL

• Si no puede utilizarse un conducto de metal r[gido, entonc-

es puede usarse un conducto de metal flexible (semi-r[gido)

aprobado por UL(KitWX08X10077).

• Nunca instale conductos de metal flexibles en paredes,

cielorrasos, pisos u otros espacios cerrados.

• La Iongitud total del conducto de metal flexible no deber6

superar los 8 pies (2./4m).

Page 13

Instrucciones de instalaci6n

• Para muchas aplicaciones, se recomienda enf6ticamente

la instalaci6n de codos en la secadora y en la pared

(ver ilustraciones de abajo). Los codos permiten que la

secadora se ubique cerca de la pared sintorcer o aplastar

el conducto de transici6n, Io que potencia al mOximo el

desempeflo de secado.

• No coloque el conducto sobre objetos afilados.

CONDUCTO DE TRANSICION DE METAL FLEXIBLE(SEMI-

RiGIDO)APROBADOPORUL

• Eninstalaciones especiales,puede sernecesario conectar la

secadora a la ventilaci6n dom@sticautilizando un conducto

de metal flexible (tipo papel de aluminio). Puede utilizarse

un conducto de metal flexible (tipo papel de aluminio)

aprobado por UL SOLO en instalaciones en las que no

pueden usarse conductos de metal rfgidos o flexibles (semi-

rigidos)Yen lasque puede mantenerse un didmetro de 4" a

Iolargo de todo el conducto de transici6n.

• En Canad6 y los Estados Unidos, solamente deberOn

utilizarse los conductos de metal flexibles (tipo papel de

aluminio) que cumplan con el "Resumen para conductos

de transici6n para secadoras de ropa, Tema 2158A".

• Nunca instale conductos de metal flexibles en paredes,

cielorrasos, pisos u otros espacios cerrados.

• La Iongitud total del conducto de metal flexible no deber6

superar los 8 pies (2.4m).

• No coloque el conducto sobre objetos afilados.

Poro un mejor desempe_o de secodo:

1.Deslice un extremo del conducto sobre latuberia de salida

de la secadora de ropa.

2.Fijeel conducto con una abrazadera.

3. Con la secadora en su posici6n permanente, extienda el

conducto en su Iongitud total. Dejeque se superpongan 2"

de conducto con la tuberia de salida. Corte y quite el tramo

de conducto que sobre. Mantenga el conducto Iom6s recto

posible para Iograr una corriente de aire m6xima.

4. Fijeel conducto a la tuberia de salida con la otra abraza-

dera.

E C6MO NIVELAR Y ESTABILIZAR SU

SECADORA

Coloque la secadora en posici6n vertical cerca de la

ubicaci6n definitiva y ajuste las cuatro patas de nivelaci6n,

en los extremos, para garantizar que lasecadora se

encuentre nivelada de lado a lado y del frente a la parte

trasera. N_VELAR N4VELAR

FRENTE A PARTE TRASERA LADO A LADO

NO UTILICE

UNA LONGITUD

DE SALIDA EXCESIVA

4 PATAS

DE NIVELACION

I-_ INSTALACI6N EN NICHO O EN CLOSET

•Su secadora puede instalarse en un nicho o closet,

como se indica en la etiqueta de la parte trasera del

aparato.

• Estasecadora DEBEtener una ventilaci6n al exterior.

Ver la INFORMACION SOBRE SALIDA secciones 3 y 4.

• Elespacio libre m[nimo entre el gabinete de la

secadora y las paredes adyacentes u otras superficies

es de:

0 pulg. sobre ambos lados

3 pulg. en el frente

4 pulg. en la parte trasera

• Elespacio vertical m[nimo desde el piso a los

gabinetes superiores, cielorraso, etc., es de 52 pulg.

• Laspuertas del closet deben contar con rejillas u

otro tipo de ventilaci6n y deben tener por Io menos

60 pulg. cuadradas de espacio abierto igualmente

distribuido. Si el closet incluye una lavadora y una

secadora, las puertas deben contener un m[nimo de

120 pulg. cuadradas de espacio abierto distribuido

uniformemente.

NOTA:CUANDO ELCONDUCTODESALIDA EST/_

UBICADO EN LA PARTETRASERADE LA SECADORA,EL

ESPACIOLIBREMiNIMO DESDELA PAREDDEBESER

5.5 PULGADAS.

Page 14

Instrucciones de instalaci6n

[] INSTALACION EN BAI_JOS0 DORMITORIOS

• Estasecadora DEBEtener una ventilaci6n alexterior. Ver

la INFORMACIONSOBRESALIDAsecciones 3 y 4.

• La instalaci6n debecumplir con c6digos locales o, si no

existieran, con el CODIGO ELI_CTRICONACIONAL,ANSI/

NFPAN° 70.

I-_INSTALACI6N EN CASAS M6VILES 0

PREFABRICADAS

• La instalaci6n debe cumplir con la NORMASOBRE

CONSTRUCCIONY SEGURIDADDECASASPREFABRICADAS,

TiTULO28, PARTE32-80 o, cuando dicha norma no sea

aplicable, con Ig NORMANACIONALESTADOUNIDENSE

PARACASASMOVILES,ANSI/NFPANo501B.

• La secadora DEBEtener ventilaci6n al exterior con la

terminaci6n bien sujeta a la estructura de la casa m6vil.

(Verla INFORI4ACIONSOBRESALIDAsecciones 3 y 4).

• La ventilaci6n NODEBEterminar debajo de una casa

m6vil o prefabricada.

• Elmaterial del conducto de ventilaci6n DEBESERMETAL.

• No utilice tornillos para placas de metal u otros

dispositivos de sujeci6n que se extiendan al interior de la

ventilaci6n de salida.

• Verlasecci6n2sobreinformaci6nsobreconexionesel@ctricas.

1-911NSTALACI6N EN GARAJE (SI PERMITI-

DO POR LOS CODIGOS LOCALES)

•Secadoras instaladas en garages deben ser

elevadas Z8pulgadas (46cm)del nivel del piso.

UBICACI6N DE LA LENGOETA

ORIFICIO DE MONTAJE

B A

(13 1/4" para ventilaci6n inferior)

131/2"

Corteelconductocomopuedeversegconservelaporci6nA.

GIRE LA LENGOETA

HASTA 45 °

A tray,s de la abertura trasera, ubique la lengOeta en

el medio de la base del aparato. Levante la teng0eta

hasta alrededor de 45 °, utitizando un destornillador de

lados ptanos.

C6MO AGREGAR CONDUCTOS NUEVOS

DE MONTAJE

ORIFICIO I

PORCION "A"

II--_SALIDA DE LA SECADORA HACIA LA

DERECHA, IZQ)UIERDA O PARTE INFE-

RIOR DEL GABINETE

- kADVERTENCIA - ANTESDE

EFECTUAR ESTA INSTALACION DE SALIDA,

ASEGURESE DE DESCONECTAR LA

SECADORA DEL SUMINISTRO ELECTRICO.

PROTEJA SUS MANOS Y BRAZOS DE LOS

LADOS AFILADOS CUANDO TRABAJE

DENTRO DEL GABINETE. ASEGURESE DE

USAR GUANTES

QUITE EL

TORNILLO

Y CONSERVEL

"_O_ QUIT E

EL RECORTE

DESEADO (SOLO UNO)

Despegue y quite el recorte inferior, derecho o izquierdo,

seg0n corresponda. Quite el tornillo ubicado dentro

del conducto de salida de la secadora ycons6rvelo.

Saque el conducto de la secadora.

s

s

SAUDA LATERAL

PORDERECHA O IZQUIERDA

Vuelvaaconectar la porci6ncortada(A)delconductoa la carcasa

delventilador. Aseg0resedeque elconductom6s cortose encuentre

aFneadocon laleng0eta dela base.Utiliceeltornillo conservado

conanterioridadparasujetarelconducto ensulugaratrav@sdela

lenq0etadela basedelartefacto.

Page 15

Instrucciones de instalaci6n

COMO AGREGAR CODOS Y CONDUCTOS

DE SALIDA HACIA LA IZQUIERDA O DERE-

CHA DEL GABINETE

• Arme previamente un codo de 4" con un conducto de 4".

Coloque cinta aislante alrededor de la junta.

• Introduzca el montaje del conducto, el codo primero,

a trav6s de la abertura lateral y conecte el codo al

conducto interno de la secadora.

_ZlPRECAUCI6N: Aseg6resedenotiraro

dafiar los cables el_ctricos ubicados dentro de la secadora

cuando introduzca el conducto.

LA SALIDA PUEDE

AGREGARSE A LOS

LADOS DERECHO

0 IZOUIERDO X

CINTA

AISLANTE

C6MOAGREGAR LA PLACA DE CUBIERTA A

LA PARTE TRASERA DEL GABI NETE (SALI DAS

POR LOS LADOS V LA PARTE INFERIOR)

(KIT WEIM454)

Conecte los codos y conductos de metal est6ndar para

completar el sistema de salida. Cubra laabertura trasera

con la placa (Kit WEIIV1454),disponible en su proveedor de

servicios local. Coloque la secadora en su ubicaci6n final.

ADVERTENCIA - NUNCADEJE

LA ABERTURA TRASERA SIN LA PLACA

EN SU LUGAR (Kit WEIM454).

• Aplique cinta aislante como puede verse en la junta

entre el conducto interno de la secadora y el codo.

CINTA

- PRECAUCION:

Lasjuntas del conducto

interno deben sujetarse con

cinta; caso contrario, pueden

separarse y provocar un

riesgo de seguridad.

C6MO AGREGARUN CODO DESALIDAA

TRAVF!SDE LA PARTEINFERIORDELGABINETE

• Introduzca el codo a trav6s de la abertura trasera y

con6ctelo al conducto interno de la secadora.

• Aplique cinta aislante en lajunta entre el conducto in-

terno de la secadora y el codo, como puede verse abajo.

k/,,lr.4d v

REGISTRE SU NUEVO APARATO PARA RECIBIR LAS

NOTIFICACtONES DE PRODUCTOS IlvtPORTANTES.

Por favor vaya a www.GEAppliances.com o

enviar por correo su tarjeta de inscripci6n.

Para preguntas sobre la instalaci6n, Ilame al:

800.626.2000 (EE.UU.)o 800-561-33/4/4 (Canad6).

t.as juntas delconducto interno deben

sujetarse con cinta; caso contrario, pueden

separarse y provocar un riesgo de seguridad.

Page 16

Loading...

Loading...