Page 1

Global Sales & Service Network

GEP

3-5KW SINGLE PHASE

USER MANUAL

99 Walker Street North Sydney NSW 2060

T: +61 284159833

support.au@gesolarinverter.com

sales.au@gesolarinverter.com

* GE is a registered trademark of General Electric Company and is used under license by Jiangsu GoodWe Power Supply Technology Co., Ltd.

© 2020 All Rights Reserved

340-00438-03

Ver.1.3

SOLAR INVERTER

www.gesolarinverter.com

Page 2

1 Symbols ........................................................................................................................... 01

2 Safety Measures & Warning ................................................................ 02

3 Product Introduction ........................................................................................ 04

3.1 Inverter Overview .................................................................................................................. 04

3.2 Package .................................................................................................................................... 05

4 Installation .................................................................................................................... 06

4.1 Mounting Instructions .......................................................................................................... 06

4.2 Equipment Installation ........................................................................................................ 06

4.3 Electrical Connection .......................................................................................................... 08

4.4 Communication Connection ............................................................................................. 12

5 System Operation .............................................................................................. 16

5.1 LCD Panel ............................................................................................................................... 16

5.2 User Interface And System Configuration .................................................................... 17

5.3 Wi-Fi/LAN Reset And Reload............................................................................................ 24

5.4 Precaution For Initial Startup ............................................................................................ 26

5.5 Special Adjustable Setpoints ............................................................................................ 26

6 Troubleshooting .................................................................................................... 29

7 Caution............................................................................................................................ 31

7.1 Checking The DC Switch.............................................................................. 31

7.2 Checking The Electrical Connection............................................................. 31

8 Technical Parameters .................................................................................. 32

TABLE OF CONTENTS

Page 3

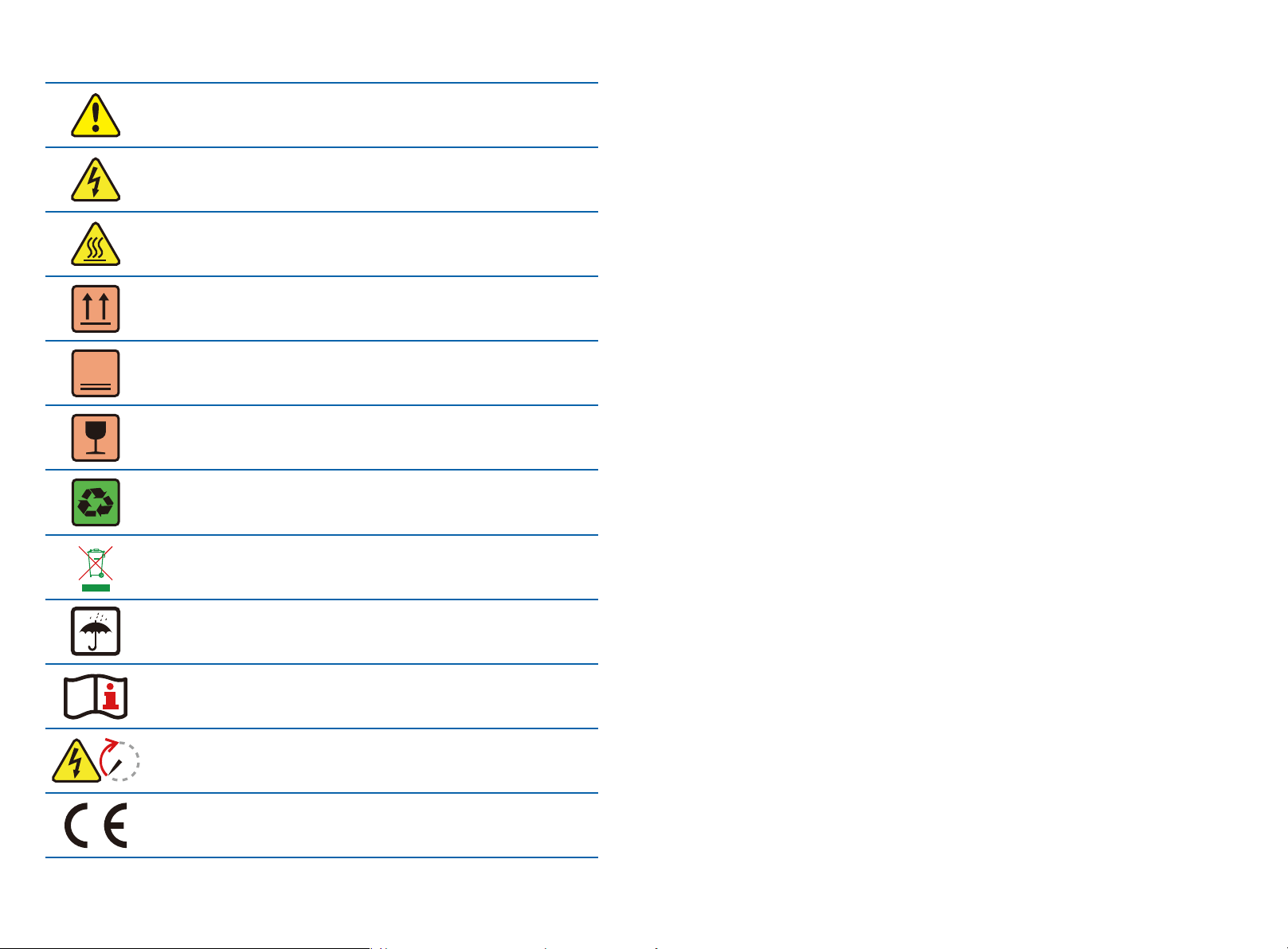

1 Symbols

Failure to observe a warning indicated in this manual may result in

injury.

Danger of high voltage & electric shock

Don't touch, hot surface!

This side up - The package must always have the

arrows point up

6

01 02

No more than six (6) identical packages

stacked on each other.

Fragile

Recyclable materials

Special disposal instructions

Keep Dry

Refer to operation instructions

Wait at least 5 minutes after disconnecting the inverter before

handling internal parts

5min

CE mark.

2 Safety Measures & Warning

• The GEP inverter strictly conforms and has been tested according to international safety

regulations.

• The manufacturer strongly advises installers to follow local safety regulations during

commissioning, operation and maintenance of the GEP inverter. Improper operation may result

in electric shocks or damage to equipment and property.

• The installation, maintenance and connection of the inverters must be performed by qualified

personnel, in compliance with local electrical standards, regulations and following the regulations

of the local power suppliers, companies and related authorities.

• If the GEP inverter is unpacked but not put into use immediately, please put it back to the

original package with the desiccant bag and seal it with tape.

• To avoid electric shocks, the DC input and AC output port of the inverters must be disconnected

for at least 5 minutes before performing any installation or maintenance.

• The temperature of some components of the inverters may exceed 60℃ during operation. To

avoid burns, do not touch the inverter during operation. Let the inverter cool before operating.

• Keep children away from the inverter.

• Touching or changing inverter components without following manual instructions may cause

personal injury, damage the inverters and could ultimately invalidate the warranty.

• The electronic components of the inverter could be damaged by static electricity. Appropriate

methods must be adopted to prevent such damage, otherwise the warranty may be null and

void.

• Ensure the output voltage of the proposed PV array is lower than the maximum rated input

voltage of the inverter, otherwise the inverter may be damaged and the warranty may be null

and void.

• When exposed to sunlight, the PV array generates dangerously high DC voltage. We strongly

advise operators strictly follow instructions and avoid actions that put lives at risk.

• The PV modules should have as a minimum an IEC61730 class A rating protection.

• If the equipment is used in a way not authorized by the manufacturer, the equipment built-in

protections may be damaged.

• In order to achieve complete equipment isolation: turn off the AC switch first, then turn off the DC

switch.

• Do not insert or pull the AC or DC terminals when the inverter is in operation.

• An Arc Fault Detector is recommended to be installed on the DC side of an earthing photovltaic

system.

• The inverter can exclude the possibility of DC residual currents to 6mA in the system, Where an

external RCD is required in addition to the built-in RCMU, type A RCD must be used to avoid

tripping.

• The PV is not grounded as default configuration.

Page 4

To ensure IP65 protection is maintained, please make sure that the inverter is rigorously

packed and its components are sealed properly. GE strongly suggests to install the

inverter at most one day after it has been unpacked. If this is not the case and the

installation takes longer, please re-seal all the unused terminals and ensure that the

inverter and its components are not exposed to water or dust.

The manufacturer provides a standard warranty which comes with the inverter product and

prepaid warranty extension solution for our customer. For further details please visit

www.gesolarinverter.com

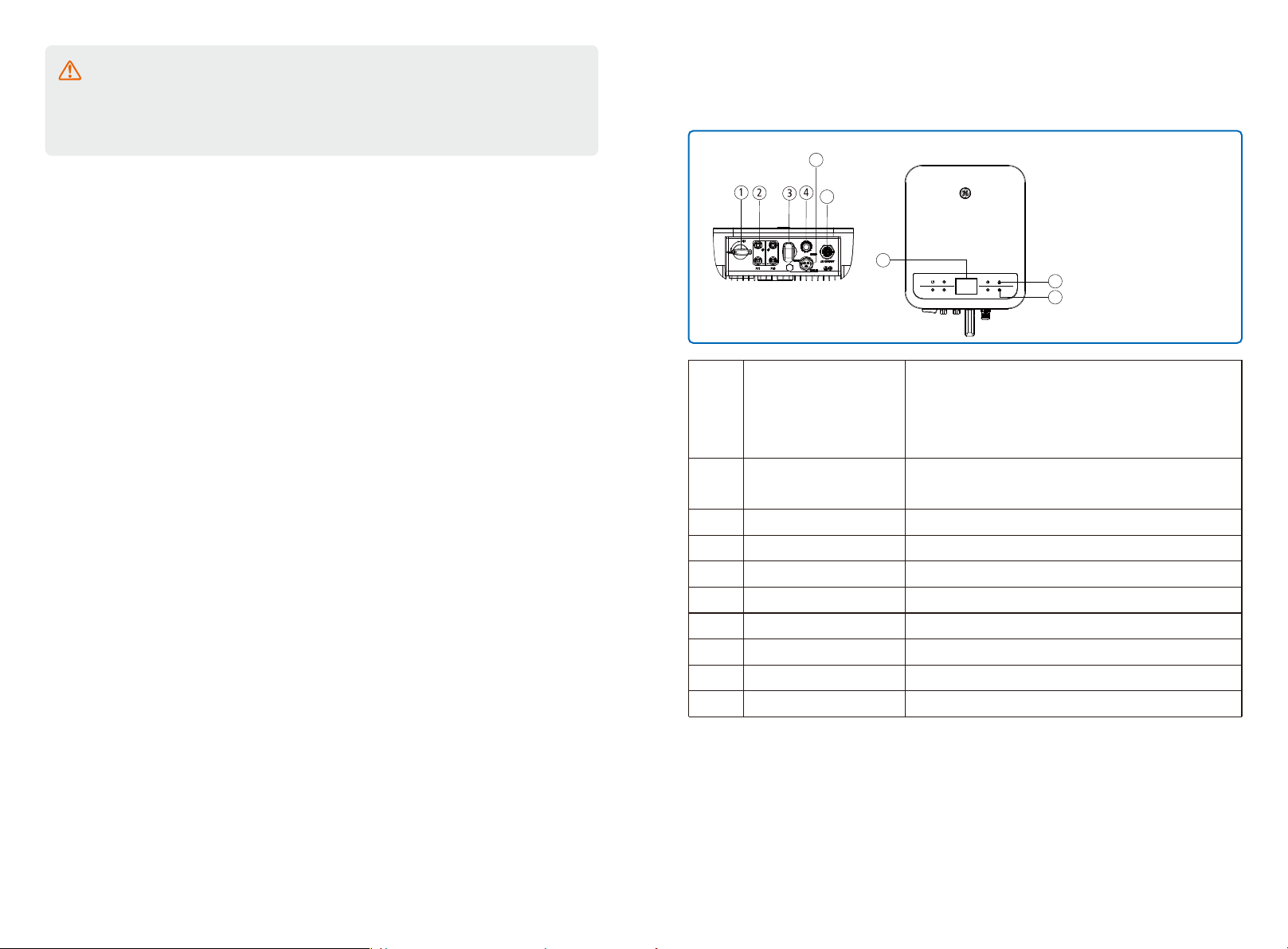

3 Product Introduction

3.1 Inverter Overview

GEP inverter illustration.

5

6

7

Item

Name

Description

1. DC Switch

2. PV Input Terminals

3. Wi-Fi /LAN Module (Optional)

4. DRED Function (Optional)

5. CT and RS485 (Optional)

6. AC Output Terminal

7. LCD Display

8. Indicator Lights

8

9. Buttons

9

DC Switch

1

PV Input Terminal

2

Wi-Fi /LAN Module (Optional)

3

DRED Function (Optional)

4

CT and RS485 (Optional)

5

6

7

8

9

AC Output Terminal

LCD Display

Indicator Lights

Buttons

During normal operation, it is in "on" state and it can shut down

the inverter after it is disconnected from the grid by the AC breaker.

For PV string connection

For Wi-Fi or LAN communication

For DRED communication

For CT and RS485 Communication

For AC cable connection

Inverter operation data overview and parameter configuration.

Display the state of the inverter

For configuration and viewing parameters.

03 04

Page 5

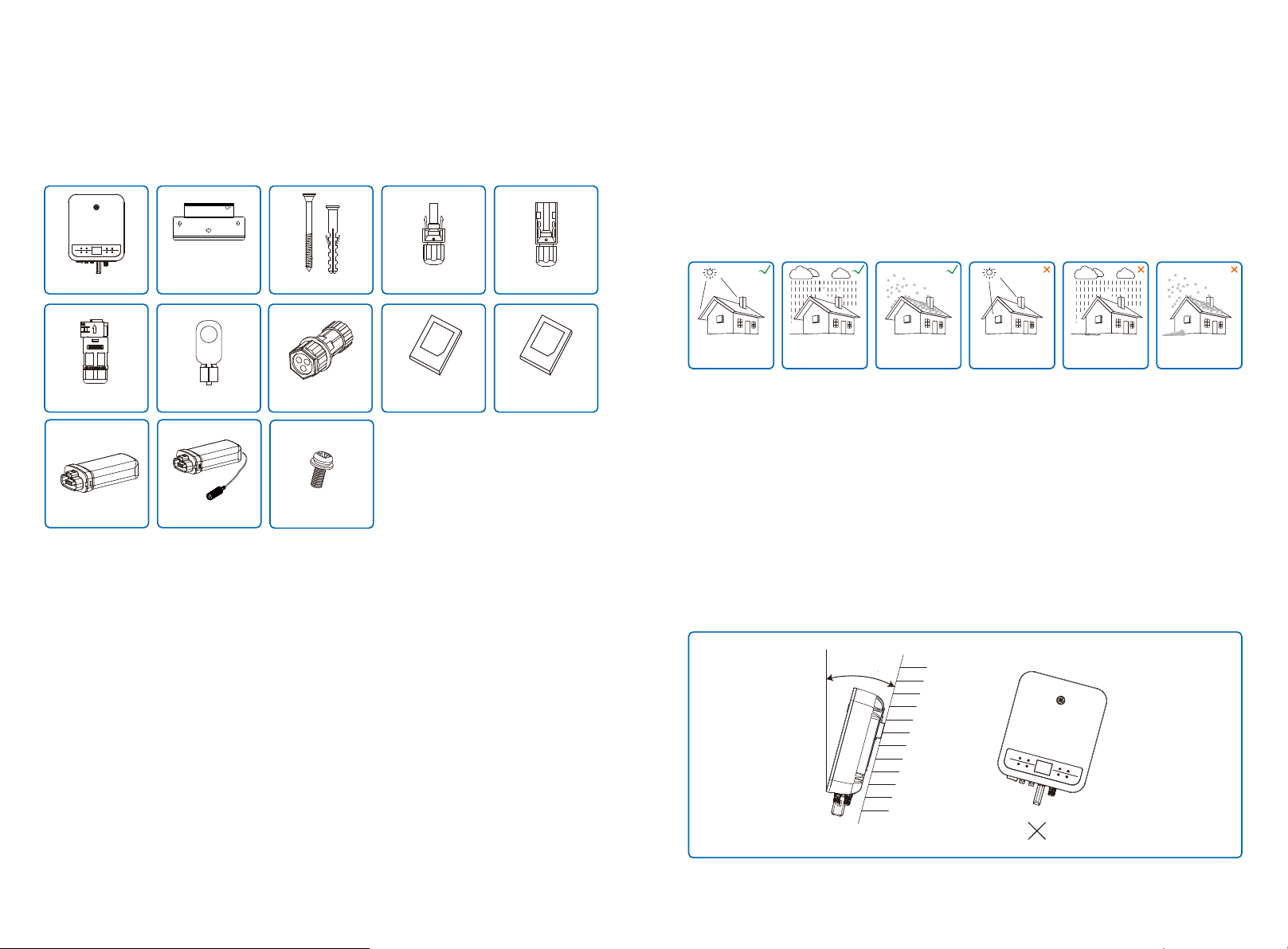

3.2 Package

The unit is thoroughly tested and strictly inspected before delivery. Damage may still occur during

shipping.

1. Check the package for any visible damage upon receiving.

2. Check the inner contents for damage after unpacking.

3. Check the package list below.

4 Installation

4.1 Mounting Instructions

1. In order to achieve optimal performance, the ambient temperature should be lower than 45℃.

2. For easy maintenance, we suggest to install the inverter at eye level.

3. Inverters should not be installed near flammable and explosive items. Strong electro-magnetic

charges should be kept away from installation site.

4. Product label and warning symbols should be located and placed in a manner that can be easily

ready by users.

5. Ensure the inverter is installed in a location that is protected from direct sunlight, rain and snow.

AC Terminal x1

Wi-Fi Module x1

Wall-mounted

Bracket x1

PE Terminal x1

LAN Module

(optional) x1

Expansion Bolts x6

CT/RS485 Terminal x1

Grounding Screw x1

Positive DC Plug x2 Negative DC Plug x2Inverter

User Manual x1

Wi-Fi/LAN

Configuration

Instruction x1

Keep away

from sunlight

Keep dry

Keep it clear

of snow

Sun Rain

Accmulated snow

4.2 Equipment Installation

4.2.1 Select installation location

Please take the following points into consideration when you selecting a proper location to install

inverter.

1. Please choose appropriate mounting methods and installation location taking into account the

weight and dimension of inverter.

2. The location must be well ventilated and sheltered from direct sunlight.

3. Install the inverter vertically or with a backward tilt up to 15 degrees maximum. No lateral tilt is

allowed. The inverter should not be tilted sideways. The area of the connectors should point

downwards.

MAX

15°

05 06

Page 6

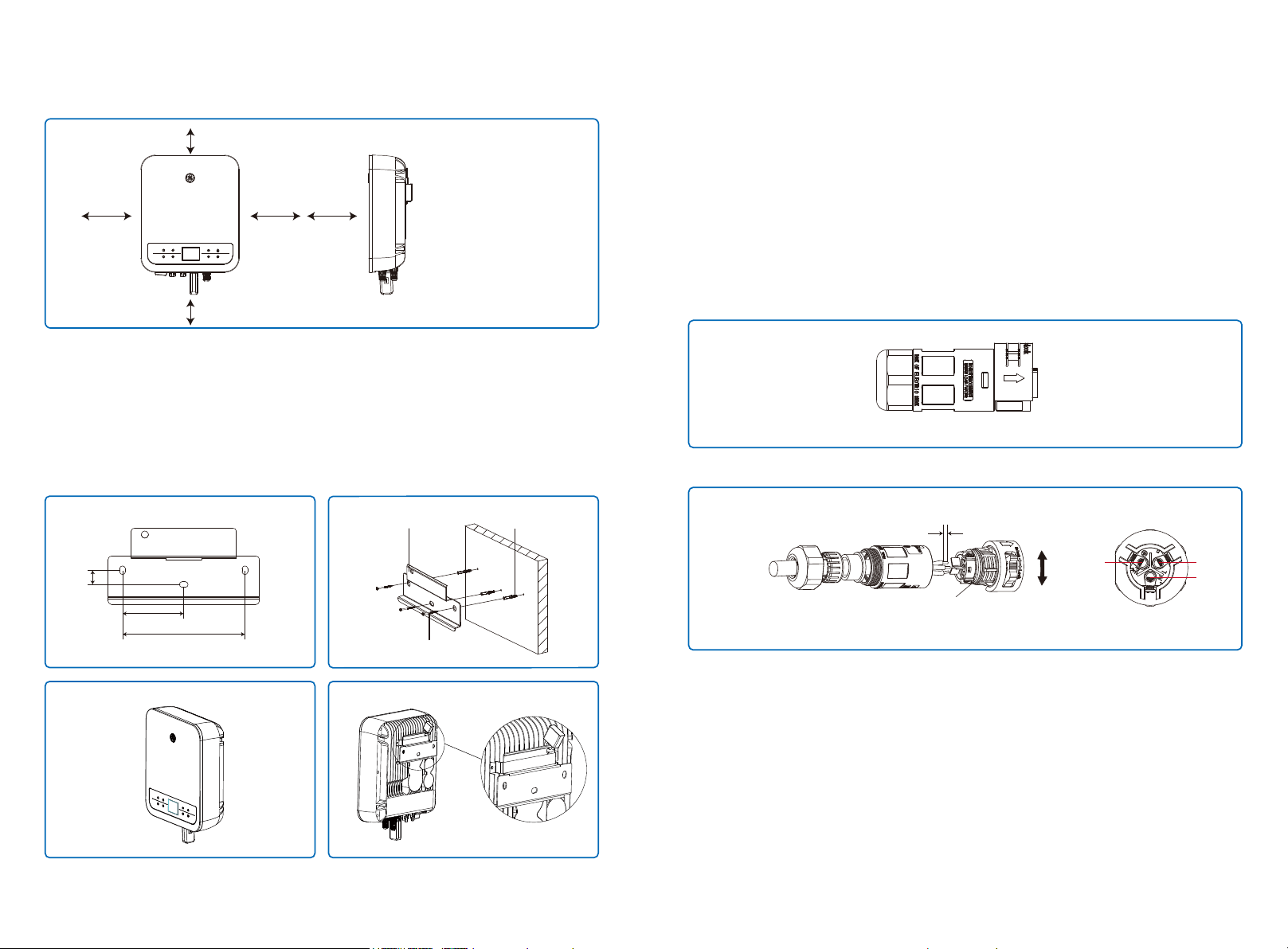

4. To guarantee the enough space for heat dissipation and facilitate the installation and removal,

the spacing around the inverter should meet the requirements as demonstrated in the following

illustration.

300mm

Upward

-------------- 300mm

200mm

300mm200mm

Downward

Front

Both sides

---------- 500mm

----------------- 300mm

---------- 200mm

500mm

4.2.2 Mounting procedure

1. Use the wall-mount bracket as a template and drill holes with 10mm in diameter and 80 mm in

depth on the wall.

2. Fix the wall-mount bracket on the wall with the expansion bolts in the accessories bag.

3. Hold the inverter by the side groove.

4. Mount the inverter onto the wall-mount bracket.

4.3 Electrical Connection

4.3.1 AC Side Connection

1. When connecting the inverter, please make sure both the voltage and the frequencey of the

inverter installed are complied with grid regulations and the inverter’s specification.

2. Add a breaker or fuse to the AC side. Please note that the specification should be more than 1.25

times the rated AC output current.

3. The PE wire of the inverter should be connected to earth. Make sure the impedance of neutral

wire and earth wire is less than 10Ω.

4. Disconnect the breaker or fuse between the inverter and the utility.

5. The AC connector brand compatible with the inverters is Exceedconn.

6. When laying the AC Wire make sure that the protective earthing conductor is not strained.

The Actual AC Connector is shown in the accessory box.

Exceedconn

Exceedconn connectors installation instruction

When unplugging the AC terminals, press the

button and hold it to unlock

Torque 0.7~0.9N.m

Make sure the terminal is rotated to the lock position before the inverter is powered on.

7-9mm

unlock

lock

PE Wire

L Wire

N Wire

20mm

85mm

170mm

Mounting Bracket Expansion Pipe

Self-tapping Screws

07 08

Page 7

AC cable specification

There are four types of DC connectors, DEVALAN, MC4, AMPHENDL H4 and QC4.10 series.

A B C

Annealed copper wire

Grade

Description

A

O.D.

B

Conductor Material Sectional Area

C

Bare Wire Length

Value

10~12mm

2

2.5~4mm

10mm around

* Neutral wire is blue, live wire is brown (preferred) or black and protective earth wire is yellow-green.

* Rotate (tightening torque: 0.6N.m) the connector of AC cable into the corresponding terminal.

4.3.2 AC circuit breaker and leakage current protection device

Please install an independent two pole circuit breaker to protect the inverter and make sure it is

safe to disconnect it from the grid.

In addition to the built-in RCMU, an external RCD is required to ensure that the inverter system

does not carry DC residual currents. To avoid tripping, the types A can be used.

Inverter Model

GEP3.6-1-10

GEP4.2-1-10/GEP5.0-1-10

Recommended Circuit Breaker Specifications

25A

32A

Note: it is not recommended that multiple inverters share a single circuit breaker.

The integrated leakage current detection device of the inverter can detect external leakage current

in real time. When the detected leakage current exceeds the limit value, the inverter will quickly

disconnect from the grid. If the leakage current protection device is installed externally, the action

current should be 300mA or higher.

DEVALAN SERIES MC4 SERIES

AMPHENOL SERIES QC4.10 SERIES

Note: The actual DC connector used is shown in the accessory box.

DC cable specification:

A B

Label

Description

A

External diameter of wire stock

B

Please use solar PV cable in DC

C

connection.(4mm PV1-F wire recommended)

Cross-sectional area of conductor material

C

Length of bare wire

The installation method of DC connector.

Positive connector

Inverter side

Value

4~5mm

2.5~4mm

About 7mm

2

4.3.3 DC Side Connection

1. Before connecting the PV strings, please ensure the plug connectors have the correct polarity.

Incorrect polarity has the potential risk to cause permanent damage to the inverter.

MC4 & QC4.10 DEVALAN & AMPHENOL

Negative connector

2. The open circuit voltage of the PV strings cannot exceed the maximum input voltage of the

inverter.

3. Only the DC connectors supplied by the manufacturer are suitable for use.

4. The positive and negative pole should not be connected to the PE wire (ground wire). Not follow-

Please use special tools to do crimping

Do not crimp wire

into the limit buckle.

ing this instruction may cause damage to the inverter.

5. Red wire represents positive, black wire represents negative.

6. For the GE series the minimum insulation resistance to the ground of the PV panels must exceed

20kΩ(R=600/30mA). There is risk of electric shock if this minimum resistance requirement is not

met.

Note:There is risk of burning if the DC connector is not connect tightly,you can hear the

“Click” sound to confirm the connectivity.

09 10

Page 8

4.3.4 Earth Terminal Connection

The inverter is equipped with earth terminal according to the requirement of EN 50178.

All non-current carrying exposed metal parts of the equipment and other enclosures in the PV

power system must be grounded.

Please follow the steps below to connect "PE" cable to ground.

Step 1

Strip the wire insulation sheet of a suitable length with a wire stripper.

L1

L2 = L1 + (1~2mm)

Step 2

Insert the stripped wire into the terminal and compress it tightly by crimping pliers.

4.4 Communication Connection

After the replacement of the Wi-Fi/LAN, the new module can work only after restarting PV array

connected to the inverter.

This port is used for connection of Wi-Fi or LAN module only. No connection to USB is

allowed. Do not connectPC or other device to this port.

4.4.1 Wi-Fi Communication

Wi-Fi communication option is only applicable to Wi-Fi version inverter and Wi-Fi communication

module is required. Please refer to "Wi-Fi Configuration Instruction" in the accessory box for

detailed instruction.

The Wi-Fi module installation of the GEP inverter is shown as below:

Step 3

Fix the earth wire

In order to improve the corrosion resistance of the terminal, it is recommended to apply

4.4.2 LAN Communication (optional)

LAN Communication is only application to LAN version inverter and LAN Communication module is

required.

silica gel on the earth terminal for corrosion protection after the grounding cable connec-

tion is completed.

NO.

Name

A

Cold-pressed terminal

B

Screw

C

Green & Yellow Cable

Explanation

(1~1.5Nm)

M5*14

4mm2 / 10AWG

A

B

C

11 12

Page 9

4.4.3 DRED / CT(Power Limit Device) /RS485 Connection

DRED (Demand Response Enabling Device) is only for Australia and New Zealand installations,

in compliance with Australian and New Zealand safety requirements, and DRED is not provided

by the manufacturer.

DRED should be connected to the COM port with 6-Pin as illustrated below.

Please connect the cables in order as shown in the right table.

CT(Power Limit Device) and RS485 communication ports are optional based on the demand of

the clients.

Step 1:

Unplug the terminal.

DRED

CT/RS485

Step 3:

Connection of DRED

Please connect the cables in order as shown in the right table.

6.5mm

25mm

Step 4:

Connection of CT(Power Limit Device)/RS485

Detailed operation is shown below:

6.5mm

25mm

NO.

NO.

NO.

1

2

3

4

5

6

1

2

3

4

5

6

Function

DRM1/5

DRM2/6

DRM3/7

DRM4/8

REFGen

Com/DRM0

RS485

Function

RS485 B

RS485 B

RS485 A

RS485 A

CT

Function

CT +

CT -

Step 2:

Dismount the terminal.

Note: There is an 6-Pin terminal in the accessory box.

1.DRED connection is only available for Australia and New Zealand.

2.Supported DRM command: DRM0, DRM5, DRM6, DRM7, DRM8.

For 6-Pin terminal

Single Hole Seal Ring

3.After installation is completed, please set up power limiting function referring to section 5.2.

4.Please pay attention to the direction of CT when wiring. CT clip should be locked tightly. The

white&black cable should connect Wire 2, the black cable should connect Wire 1. Tighten them

with a screwdriver. Make sure CT cables connected to the right output phase wires of inverter

when in use.

Screw Cap The Insulator

If any of the terminals is not used, please use the corresponding waterproof rubber gland

or cap to seal it.

13 14

Page 10

4.4.4 Export Power Limit Connection Diagram

The methods of connecting the Power Limiting device CT is shown below.

For the detailed installation procedure of CT, please refer to Step 4 of 4.4.3.

white & Black Wire

CT

Black

Wire

Inverter

L N

Switch Board

5 System Operation

5.1 LCD Panel

Green / green /green / red light respectively correspond to:

Router

4.4.5 Earth Fault Alarm(Only for Australia and New Zealand)

In compliance with the section 13.9 of IEC62109-2, the GEP inverter is equipped with an

earth fault alarm. When earth fault occurs, the fault indicator at the front LED screen will light up. On

inverters with Wi-Fi communication, the system sends an email with the fault notification to the

customer. For inverters without Wi-Fi, the buzzer of the inverter will keep ringing for one minute and

ring again at 30-minute intervals until the fault is resolved. (This function is only available in Austra-

lia and New Zealand).

4.4.6 Monitoring Portal

Portal is an on-wire monitoring system. After completing the installation of commu-

nication connection, you can access

portal.gesolarinverter.com or download the

‘Power Sight’ App by scanning the QR code to monitor your PV plant and device.

Please contact after-sales for further details.

Power Sight

INDICATOR STATUS

EXPLANATION

ON = INVERTER POWER-ON

OFF = INVERTER POWER-OFF

ON = INVERTER IS FEEDING POWER

OFF = INVERTER IS NOT FEEDING POWER

SINGLE SLOW FLASH = SELF CHECK BEFORE GRID CONNECT

SINGLE FLASH = WILL CONNECT WITH GRID

ON = COMMUNICATION SUCCESS

BLINK 2 = ROUTER COMMUNICATION FAILURE

BLINK 4 = SERVER COMMUNICATION FAILURE

BLINK = RS485 CONNECTED

ON = FAULT OCCURRED

OFF = NO FAULT

15 1615 16

Page 11

5.2 User Interface And System Configuration

5.2.2 Home Introduction

5.2.1 Overview of Menu Architecture

Use the Up, Down, Enter and Esc buttons to toggle the main menus. Press the Enter Esc key to

toggle the 123 menu, use the up and down keys to select the item and change the parameters, and

long press the Enter (short press is also ok for some items) to set the parameters. The display and

keys of the GEP inverter is shown as below:

x

20.5

E-DAY

/ /

3500

E-TOTAL

W

CARBON

Normal

x

W

CARBON

Normal

G

M

L

A B DC E F

H

I

20.5

E-DAY

/ /

J

3500

E-TOTAL

K

A: Communication information icon: Wi-Fi show the signal strength, RS485 shows the communica-

tion address.

B: Communication icon: This icon indicates the current communication method including Wi-Fi and

LAN and RS485.

C: LVRT/HVRT icon: The icon indicates that the system LVRT/HVRT function is on.

D: Grid Type icon: The icon indicates the grid type selected including Delta Grid/Star Grid.

E: Power limit icon: The Power limit icon indicates that the Power limit function is on.

F: Shadow icon: The Shadow icon indicates that the shadow function is on.

G: Safety icon: The number represents the safety code.

H: Real-time power.

J: System time and date.

I: E-day icon: The number represents the power generation for the current day.

K: E-Total: Historical cumulative power generation.

L: System status information.

M: Carbon: Energy conservation and emission reduction.

17 18

Page 12

5.2.3 Main Menu

Level 1 menu interface through the up and down key cycle, in the historical information, configura-

tion, advanced settings interface, press the Enter key will enter the Level 2 menu. To enter the Level

2 menu, select the item from the up and down keys. Press Enter to enter the project setup menu,

go to the Level 3 menu, change the setting contents by pressing the up and down keys, and press

the Enter key to set the contents. If safety country is not selected (shows Configure Safety on

display at home page) , press any key to enter Safety Country page.

The main menus interfaces are presented below:

5.2.4 Basic Settings

Basic Settings is mainly used to set the commonly used parameters, including language settings,

time settings, communication settings and safety setting. And these parameters can be set in the

APP.

Configuration

Vac 230.0V

Iac 21.3A

Fac 50.00Hz

Vpv1/ 2

Ipv1/ 2

Running Info

History Info

300.0/300.0V

5.0/5.0A

YearMonthDayHour

Configuration

Device Info

VERSION : V1.02.02.00.06

SERIA NO.: 95000PSB207W8007

/ /

Normal

/

/ /

19 20

Page 13

Netherlands

5.2.5 Advanced Settings

Advanced settings are mainly used to set the function parameters of the equipment running. In

order to prevent improper operation from customers, all advanced settings require a password to

obtain advanced permission to operate advanced settings (Once password has bene entered, you

can set the advanced settings menu for all items) .The default password is : 1111.In order to

prevent customers from forgetting the password, all devices have a unique super password, bound

to the serial number. Advanced settings items include Power limit settings, PF value settings, LVRT

settings,HVRT settings,Shadow settings, Password modification settings and Factory data

reset.Additional settings can be found on the ‘SolarGo’ APP. Please download ‘SolarGo’, connect

to the inverter via the App and complete the setup accordingly.

Power Limit

PF Value

Shadow

LVRT

Power Limit

CT Ration

PF Value

Shadow

LVRT

CT 40

CT 200

CT 1000

CT Unknown

CT Ration

21 22

Page 14

Power Limit

CT Ration

PF Value

Shadow

LVRT

5.2.6 History Information

The history information mainly includes the information of the generating capacity of the equipment,

the power generation information mainly includes the amount of electricity generation, daily power

generation, monthly power generation and annual power generation information.

Power Limit

CT Ration

PF Value

Shadow

LVRT

Power Limit

CT Ration

PF Value

Shadow

LVRT

HVRT

Grid Type

Password

Factory Data Reset

HVRT

Grid Type

Password

Factory Data Reset

HVRT

Grid Type

Password

Factory Data Reset

Old

New

0 0 0 0

0 0 00

√

5.3 Wi-Fi/LAN Reset And Reload

These functions are only available for Wi-Fi/LAN model inverters.

W/L Reset will reboot the Wi-Fi/LAN module without erasing the existing settings.

W/L Reload will recover the Wi-Fi/LAN module back to factory settings.

5.3.1 Reset&Reload of Wi-Fi/LAN Module on LCD

1. Press ‘Up’ / ‘Down’ to select ‘Basic’ and press ‘Enter’.

2. Press ‘Up’ / ‘Down’ to select ‘Communication’ and press ‘Enter’.

3. Press ‘Up’ / ‘Down’ to select ‘W/L Set’ and press ‘Enter’.

4. Press ‘Up’ / ‘Down’ to select ‘W/L reset / W/L Reload’ and long press ‘Enter’.

Wi-Fi Configuration

Basic Advanced

01/01/2020 00:00:00

22

Wi-Fi

Configuration

Language

Data&Time

Communication

Country Code

Grid Connection

Fault

01/01/2020 00:00:00

22

Wi-Fi

Communication

Modbud Address

W/L Set

01/01/2020 00:00:00

Fault

22

Wi-Fi

Wi-Fi Set

W/L ReloadW/L Reset

Fault

01/01/2020 00:00:00

22

Fault

23 24

Page 15

5.3.2 Reload of Wi-Fi/LAN Module using Button

Long press the button on the Wi-Fi/LAN module for at least 5 seconds and then release to restore

factory settings when the inverter is powered on.

Reload Button

5.4 Precaution For Initial Startup

1. Make sure the AC circuit is connected and AC the breaker is turned off.

2. Make sure the DC cable between inverter and PV string is connected, and the PV voltage is

normal.

3. Turn on the DC switch, and set safety country according to the local regulation.

4. Turn on the AC breaker. Check the inverter work is working normally.

5.5 Special Adjustable Setpoints(Only for Australia and New Zealand)

The inverter has a field in which the user can set functions, such as trip points, trip times, reconnect

times, active and inactive QU curves and PU curves. It is adjustable through special software. If

needed, please contact after-sales. To obtain software manuals, you can download them from the

official website or contact after-sales.

5.5.1 PF Power Curve Mode

PF power curve mode can be modified by Modbus communication method, specifically according

to the inverter Modbus address and Modbus register value, according to the set range in the set the

corresponding value.

cosФ

0.95

LEADINGLAGGING

1.0

0.95

B

0%

25%

A

LEGEND:

cosФ

50%

75%

Power, (%P/P

100%

C

rated

)

25 26

Page 16

Function

PF curve mode enable or disable

B %P/Prated

C Power factor

Default value (Australia)

0

50 (50%)

0.9

PF Power Curve Mode

Default value (New Zealand)

0

50 (50%)

0.9

Setting range

“0”or“1”

30%~80%

0.8~1

Register

40600

40603

40606

5.5.3 QU Curve Mode

QU curve mode can be modified by Modbus communication, specifically according to the

inverter Modbus address and Modbus register value, according to the set range to set the

corresponding value.

5.5.2 PU Curve Mode

The PU curve mode can be modified by Modbus communication method, specifically according

to the inverter Modbus address and Modbus register value, according to the set range to set the

corresponding value.

V1 V2 V3 V4 V1 V2 V3 V4

100%

80%

60%

POWER, P/Prated%

40%

20%

0%

200 210 220 230 240 250 260 270

Example curve for a volt-watt response mode (Australia) Example curve for a volt-watt response mode (New Zealand)

100%

80%

60%

POWER, P/Prated%

40%

20%

0%

200 210 220 230 240 250 260 270

PU curve Mode

Function

Default value (Australia)

PU curve mode enable or disable

V1 voltage ratio

P1 power ratio

1000(100%*Pn )

V2 voltage ratio

P2 power ratio

1000(100%*Pn )

V3 voltage ratio

P3 power ratio

1000(100%*Pn

V4 voltage ratio

P4 power ratio

200(20%*Pn )

1

900(207V)

956(220V)

1087(250V)

1152(265V)

Default value (New Zealand)

1

900(207V)

1000(100%*Pn )

956(220V)

1000(100%*Pn )

1061(244V)

1000(100%*Pn

1109(255V)

200(20%*Pn )

Setting range

““0”or“1”

0~2000

0~1500

0~2000

0~1500

0~2000

0~1500

0~2000

0~1500

Register

40680

40683

40684

40685

40686

40688

40689

40690

40691

Example: set the ratio of V1 voltage to 1100V, corresponding to the rated voltage of 230V, V1 = 230V

* 110% = 253V.

Example: set P1 power ratio to 900 and the corresponding power to 0.9* rated power.

V1 V2 V3 V4

40%

30%

LEADINGLEADING VAR/RATED, VA (%)

20%

10%

0%

10%

20%

30%

40%

200

210

220

230

INVERTER VOLTAGE, V

LEGEND:

var characteristic curve

250

240

260

270

V1 V2 V3 V4

40%

30%

LEADINGLEADING VAR/RATED, VA (%)

20%

10%

0%

10%

20%

30%

40%

200

210

220

INVERTER VOLTAGE, V

LEGEND:

230

240

var characteristic curve

250

260

QU curve Mode

Function

Default value (Australia)

QU curve mode enable or disable

V1 voltage ratio

Q1 reactive power ratio

300(30%*Pn )

V2 voltage ratio

Q2 reactive power ratio

300(30%*Pn )

V3 voltage ratio

Q3 reactive power ratio

300(30%*Pn )

V4 voltage ratio

Q4 reactive power ratio

300(30%*Pn )

0

900(207V)

957(220V)

1087(250V)

1152(265V)

Default value (New Zealand)

0

900(207V)

300(30%*Pn )

957(220V)

300(30%*Pn )

1061(244V)

300(30%*Pn )

1109(255V)

300(30%*Pn )

Setting range

“0”or“1”

0~2000

0~600

0~2000

0~1500

0~2000

0~1500

0~2000

0~600

Register

40650

40653

40654

40655

40656

40657

40658

40659

40660

Example: set the ratio of V1 voltage to 1100V, corresponding to the rated voltage of 230V, V1 = 230

* 110% = 253V.

Example: set Q1 reactive power ratio to 300, corresponding reactive power Q1=30%* rated

power.

5.5.4 Power Recovery Rate

The power recovery rate can be modified by Modbus communication, specifically according to

the inverter Modbus address and Modbus register value, according to the set range to set the

corresponding value.

270

Function

Power recovery rate Settings

The default value (Australia & New Zealand)

16(16%Pn/min)

Setting range

5~100

Register

40536

If you need to change the above Settings, please contact our after-sales service.

27 28

Page 17

6 Troubleshooting

If the Inverter is not able to work properly, please refer to the following instructions before

contacting your local service. If any problems arise, the red (FAULT) LED indicator on the front

panel will light up and the LCD screen will display relevant information. Please refer to the

following table for a list of error messages and associated solutions.

Type of fault Troubleshooting

1. Disconnect DC switch, take off DC connector, check the impedance between

PV (+) & PV(-) to earth.

Isolation Failure

Ground I Failure

Vac Failure

System

Failure

Fac Failure

2. If impedance is less than 100 kΩ, please check the insulation of PV string

wiring to earth.

3. If impedance is large than 100 kΩ, please contact local service office.

4. Take off AC connector, measure the impedance between neutral wire and PE

line. If it is larger than 10KΩ, please check AC wiring.

1. The ground current is too high.

2. take off the inputs from the PV generator and check the peripheral AC

system.

3. When the problem is cleared, reconnect the PV panel and check the Inverter

status.

4. Contact local service office for help if the problem still persist.

1. The PV Inverter will automatically restart within 5 minutes if the grid returns to

normal.

2. Make sure grid voltage conforms to specifications.

3. Make sure neutral (N) wire and PE wire are well connecteds.

4. Contact local service office for help if the problem still persist.

1. Grid is not connected.

2. Check grid cable connection.

3. Check availability of grid.

Type of fault Troubleshooting

Relay-Check Failure

DCI Injection High

EEPROM R/W Failure

SCI Failure

Inverter

Failure

Others

SPI Failure

DC BUS High

BUS Unbalance

GFCI Failure

Ifan Fault

Efan Fault

Afan Fault

No display

Wi-Fi module fail to

connect to network

1. Turn off DC switch of the inverter.

2. Wait till the inverter's LCD light is off.

3. Turn on DC switch and make sure it is connected.

4. If the problem still exists, contact local service office for help.

1. Turn off DC switch, take off DC connector, measure the voltage of PV array.

2. Plug in DC connector, and turn on DC switch.

3. If PV array voltage is lower than 250V , please check configuration of inverter

module.

4. If PV array voltage is higher than 250V , please contact local service office.

1. If the Wi-Fi module fails to connect to network after choosing the right router

hotspot and entering the right password,it's possible that there are special

characters not supported by the module in the hotspot password. Please

modify the password so that it consists of only Arabic numerals or uppercase /

lowercase letters.

2. If the problem still persists, contact local service office for help.

Utility Loss

1. Not connect to the grid.

2. Check if the power cable is connected with grid.

3. Check the availability of power from the grid.

Note: When sunlight is insufficient, the inverter may continuously start up and shut down

automatically due to insufficient power generation from the PV panels, This should not

lead to inverter damage.

1. Check whether PV open circuit voltage is higher or too close to the maximum

PV Over Voltage

Over Temperature

input voltage.

2. If the problem still persist when PV voltage is less than the maximum input

voltage, contact local service office for help.

1. The internal temperature is higher than normal specified value.

2. Reduce ambient temperature.

3. Move the inverter to a cool place.

4. If the problem still exists, contact local service office for help.

29 30

Page 18

7 Caution

7.1 Checking The DC Switch

DC switch does not require any maintenance.

It is recommended, though not compulsory, to:

• Check the DC switch regularly.

• Activate the DC switch 10 times in a row once a year.

Operating the switch will clean the contacts and will extend the life of the DC switch.

Boot order:

1. Turn on the breaker on AC side.

2. Turn on the DC switch.

3. Turn on the breaker on DC side.

Caution: if there is no switch, step 2 is not required.

Shutdown order:

1. Turn off the breaker on AC side.

2. Turn off the DC switch.

3. Turn off the breaker on DC side.

Caution: if there is no switch, step 2 is not required.

7.2 Checking The Electrical Connection

1. Check if the AC or DC wire is loose.

2. Check if the earth wire is reliably grounded.

3. Check if the waterproof covers of RS485 /WiFi port are fasten.

Caution: Maintenance cycle is once every half a year.

4. Please use torque wrench to tighten the AC terminal wiring connection once a year.

Caution: Maintenance cycle is once every half a year.

31 32

8 Technical Parameters

Technical Data

PV String Input Data

Max. DC Input Power (W)

Max. DC Input Voltage (V)

MPPT Range (V)

Start-up Voltage (V)

Min. Feed-in Voltage(V)

Nominal DC Input Voltage (V)

PV Input Operating Voltage range(V)

Max. Inverter Backfeed Current To The array (A)

Max. Input Current (A)

Max. Short Current (A)

No. of MPP Trackers

No. of Input Strings per Tracker

AC Output Data

Nominal Output Power (W)

Max. Output Apparent Power (VA) [1]

Nominal Output Voltage (V)

Nominal Output Frequency (Hz)

Max. Output Current (A)

Output Power Factor

Output THDi (@Nominal Output)

Current(inrush)

Maximum output fault current

Maximum output over current protection(A)

Efficiency

Max. Efficiency

Europen Efficiency

Protection

Anti-islanding Protection

Input Reverse Polarity Protection

Insulation Resistor Detection

DC SPD Protection

AC SPD Protection

Residual Current Monitoring Unit

Output Over Current Protection

Output Short Protection

Output Over Voltage Protection

Protective Class

Decisive Voltage Classification(DVC)

General Data

Operating Temperature Range (℃)

Relative Humidity

Operating Altitude (m)

Cooling

User Interface

Communication

Weight (kg)

Size (Width*Height*Depth mm)

Protection Degree

Night Self Consumption (W)

Topology

Model

*1:For Brazil Nominal Output Frequency GEP3.6-1-10 is 60Hz, GEP5.0-1-10 is 60Hz.

*4:For Brazil Nominal Output Voltage GEP3.6-1-10 is 220V, GEP5.0-1-10 is 220V.

GEP3.5S

5500

600

80~550

80

100

360

80~600

0

13/13

16.3/16.3

2

1

3500

3500

230V

50

15.2

~1 (Adjustable from 0.8 leading to 0.8 lagging)

<3%

130

155

50

98.3%

97.5%

Integrated(Type Ⅱ)

Integrated(Type Ⅱ)

Natural Convection

Wi-Fi / RS485 / LAN(Optional)

GEP3.5-1-10 GEP4.2-1-10

GEP3.6S

5500

600

80~550

80

100

360

80~600

0

13/13

16.3/16.3

2

1

3600

3960

*4

230V

*1

50

18

<3%

130

155

50

98.3%

97.5%

Integrated

Integrated

Integrated

Integrated

Integrated

Integrated

Integrated

ClassⅠ

C

-25~60

0~100%

≤4000

LCD & LED

11

336*400*124

IP65

<1

Transformerless

GEP3.6-1-10

GEP4.2S

6300

600

80~550

80

100

360

80~600

0

13/13

16.3/16.3

2

1

4200

4620

230V

50

21

<3%

130

155

50

98.3%

97.6%

Page 19

Technical Data

PV String Input Data

Max. DC Input Power (W)

Max. DC Input Voltage (V)

MPPT Range (V)

Start-up Voltage (V)

Min. Feed-in Voltage(V)

Nominal DC Input Voltage (V)

PV Input Operating Voltage range(V)

Max. Inverter Backfeed Current To The array (A)

Max. Input Current (A)

Max. Short Current (A)

No. of MPP Trackers

No. of Input Strings per Tracker

AC Output Data

Nominal Output Power (W)

Max. Output Apparent Power (VA) [1]

Nominal Output Voltage (V)

Nominal Output Frequency (Hz)

Max. Output Current (A)

Output Power Factor

Output THDi (@Nominal Output)

Current(inrush)

Maximum output fault current

Maximum output over current protection(A)

Efficiency

Max. Efficiency

Europen Efficiency

Protection

Anti-islanding Protection

Input Reverse Polarity Protection

Insulation Resistor Detection

DC SPD Protection

AC SPD Protection

Residual Current Monitoring Unit

Output Over Current Protection

Output Short Protection

Output Over Voltage Protection

Protective Class

Decisive Voltage Classification(DVC)

General Data

Operating Temperature Range (℃)

Relative Humidity

Operating Altitude (m)

Cooling

User Interface

Communication

Weight (kg)

Size (Width*Height*Depth mm)

Protection Degree

Night Self Consumption (W)

Topology

Model

*1: For Brazil Nominal Output Frequency GEP3.6-1-10 is 60Hz, GEP5.0-1-10 is 60Hz.

*2: For Australia Max. Output Apparent Power GEP5.0-1-10 is 4999VA.

*3: For Australia Max. Output Current GEP5.0-1-10 is 21.7A.

*4: For Brazil Nominal Output Voltage GEP3.6-1-10 is 220V, GEP5.0-1-10 is 220V.

*5: For Australia Nominal Output Power GEP5.0-1-10 is 4999W.

GEP4.6S

7500

600

80~550

100

360

80~600

13/13

16.3/16.3

4600

4600

230V

~1 (Adjustable from 0.8 leading to 0.8 lagging)

<3%

130

155

98.3%

97.6%

GEP4.6-1-10 GEP5.0-1-10

33

80

0

2

1

50

20

50

Integrated

Integrated

Integrated

Integrated(Type Ⅱ)

Integrated(Type Ⅱ)

Integrated

Integrated

Integrated

Integrated

ClassⅠ

-25~60

0~100%

≤4000

Natural Convection

LCD & LED

Wi-Fi / RS485 / LAN(Optional)

336*400*124

IP65

Transformerless

GEP5.0S

7500

600

80~550

80

100

360

80~600

0

13/13

16.3/16.3

2

1

5000

5500

230V

*1

50

*3

25

<3%

130

155

50

98.3%

97.8%

*5

*2

*4

Note:Overvoltage Category Definition

Category I:

applies to equipment connected to a circuit where measures have been taken to reduce transient

overvoltage to a low level.

Category II:

applies to equipment not permanently connected to the installation. For example, appliances,

portable tools and other plug-connected equipment;

Category III:

applies to fixed downstream equipment, including the main distribution board. For example, switchgear and other equipment in an industrial installation;

Category IV:

applies to equipment permanently connected at the origin of an installation (upstream of the main

distribution board).For example, electricity meters, primary overcurrent protection equipment and

other equipment connected directly to outdoor open wires.

Moisture Location Category Definition

Environment Category Definition

Outdoor : the ambient air temperature is -20~50℃. Relative humidity range is from 4% to 100%,

applied to PD3.

Indoor unconditioned:

the ambient air temperature is -20~50 ℃. Relative humidity range is from 5% to 95%, applied to

PD3.

Indoor conditioned:

the ambient air temperature is 0~40 ℃. Relative humidity range is from 5% to 85%, applied to PD2.

C

Pollution Degree Definition.

Pollution degree 1:

No pollution or only dry, non-conductive pollution occurs. The pollution has no influence.

Pollution degree 2:

Normally only non-conductive pollution occurs. However, a temporary conductivity occasionally

caused by condensation should be expected.

11

Pollution degree 3:

Conductive pollution occurs. Or dry, non-conductive pollution becomes conductive due to

<1

condensation, which is expected.

Pollution degree 4:

Persistent conductive pollution occurs. For example, pollution caused by conductive dust, rain or

snow.

34

Loading...

Loading...