Page 1

g GE Consumer & Industrial Appliances

Service Manual & Installation Manual

Split System Air Conditioner

Model numbers:

PRO AIR 107

PRO AIR 109

PRO AIR 112

PRO AIR I109

PRO AIR I112

PRO AIR 218

GE AIR 326

GE AIR 428

Page 2

—1—

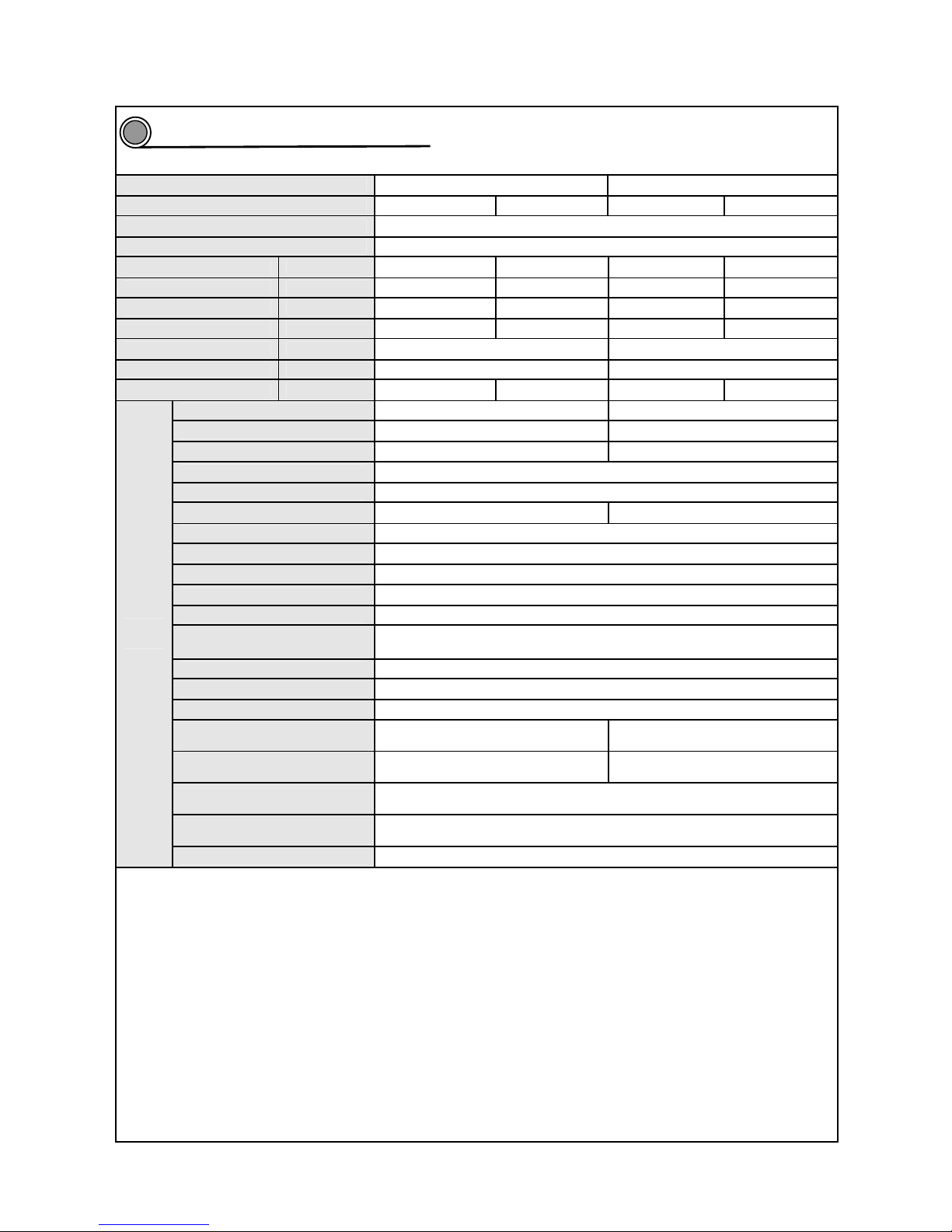

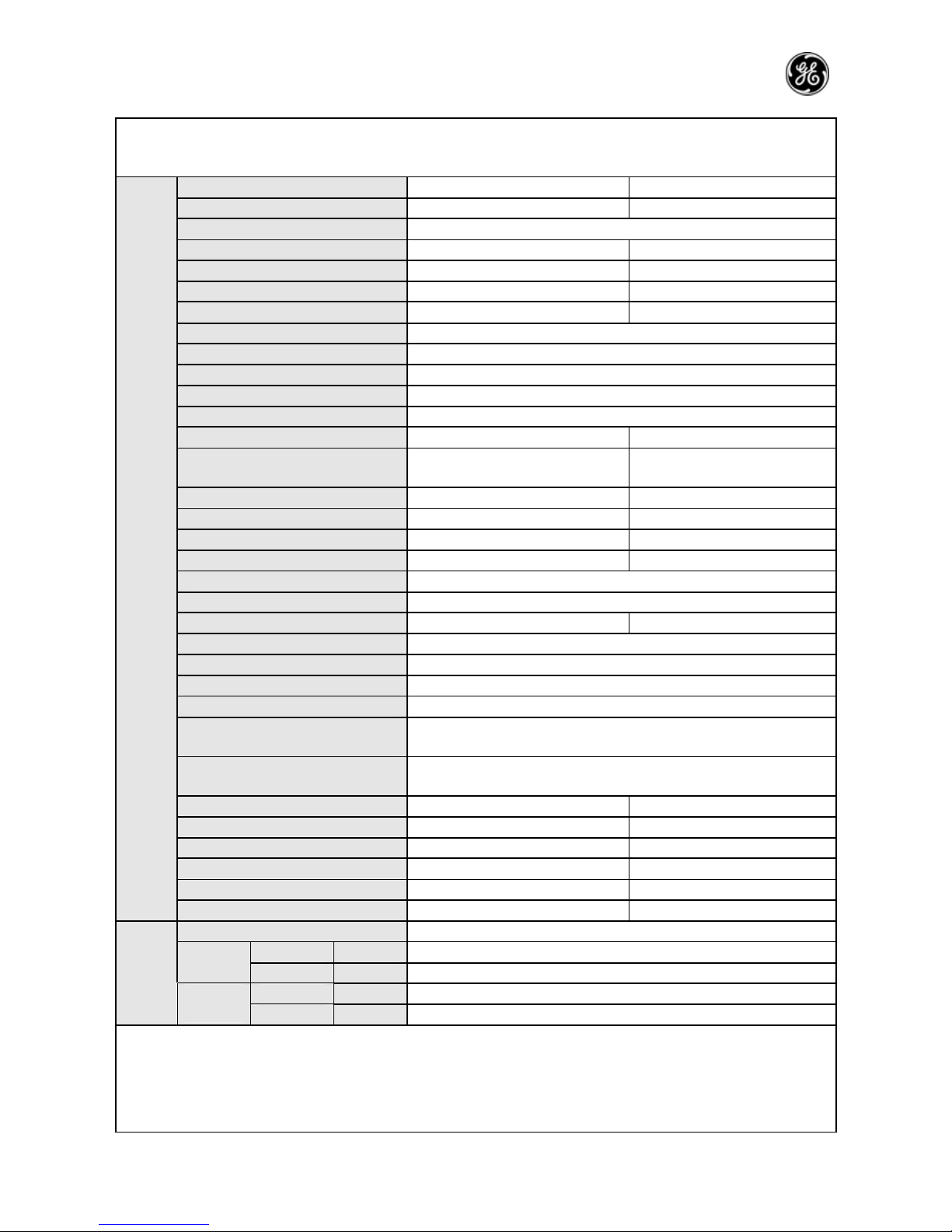

Summary and features

Model Remark

PRO AIR 107 IN / PRO AIR 107 OUT

1Ph 230V 50Hz R410A

1

Page 3

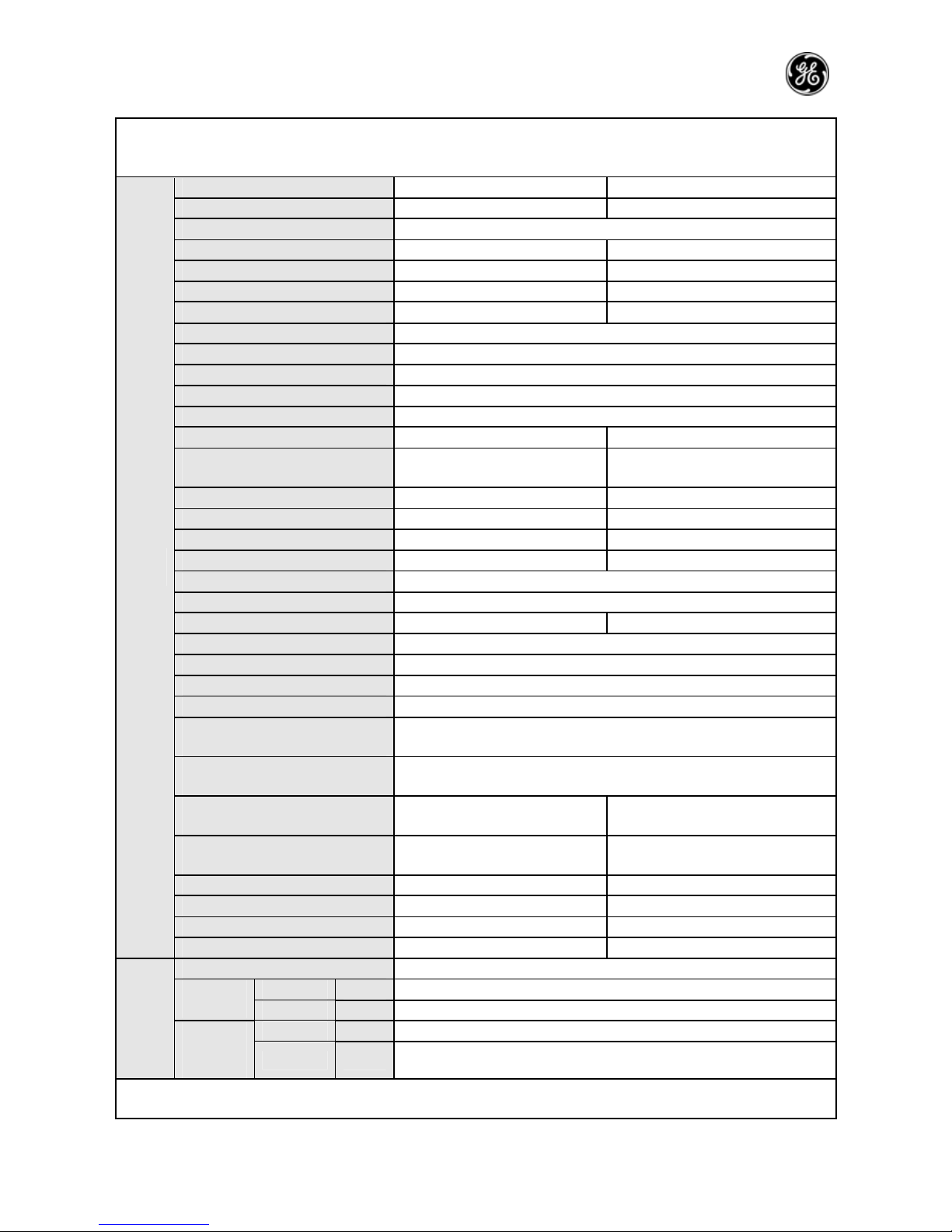

—2—

Model Remark

PRO AIR 109 IN / PRO AIR 109 OUT PRO AIR 112 IN / PRO AIR 112 OUT

PRO AIR I109 IN / PRO AIR I109 OUT PRO AIR I112 IN / PRO AIR I112 OUT

1Ph 230V 50Hz R410A

Page 4

—3—

Model Remark

PRO AIR 218 IN / PRO AIR 218 OUT

1Ph 230V 50Hz R410A

Page 5

—4—

Model Remark

GE AIR 326 IN1 / GE AIR 326 IN2 / GE AIR 326 OUT

1Ph 230V 50Hz R407C

Page 6

—5—

Model Remark

GE AIR 428 IN / GE AIR 428 OUT

1Ph 230V 50Hz R407C

Page 7

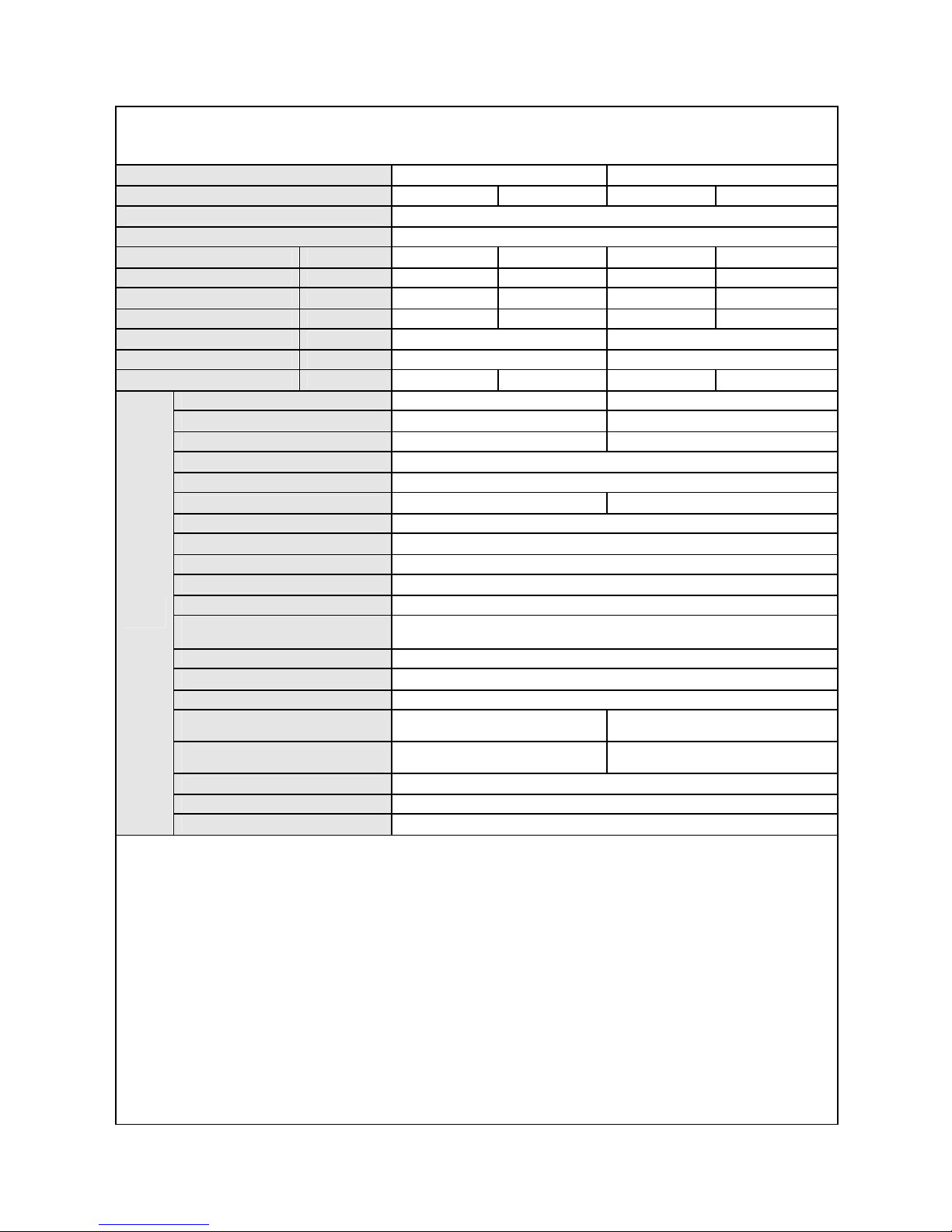

—6—

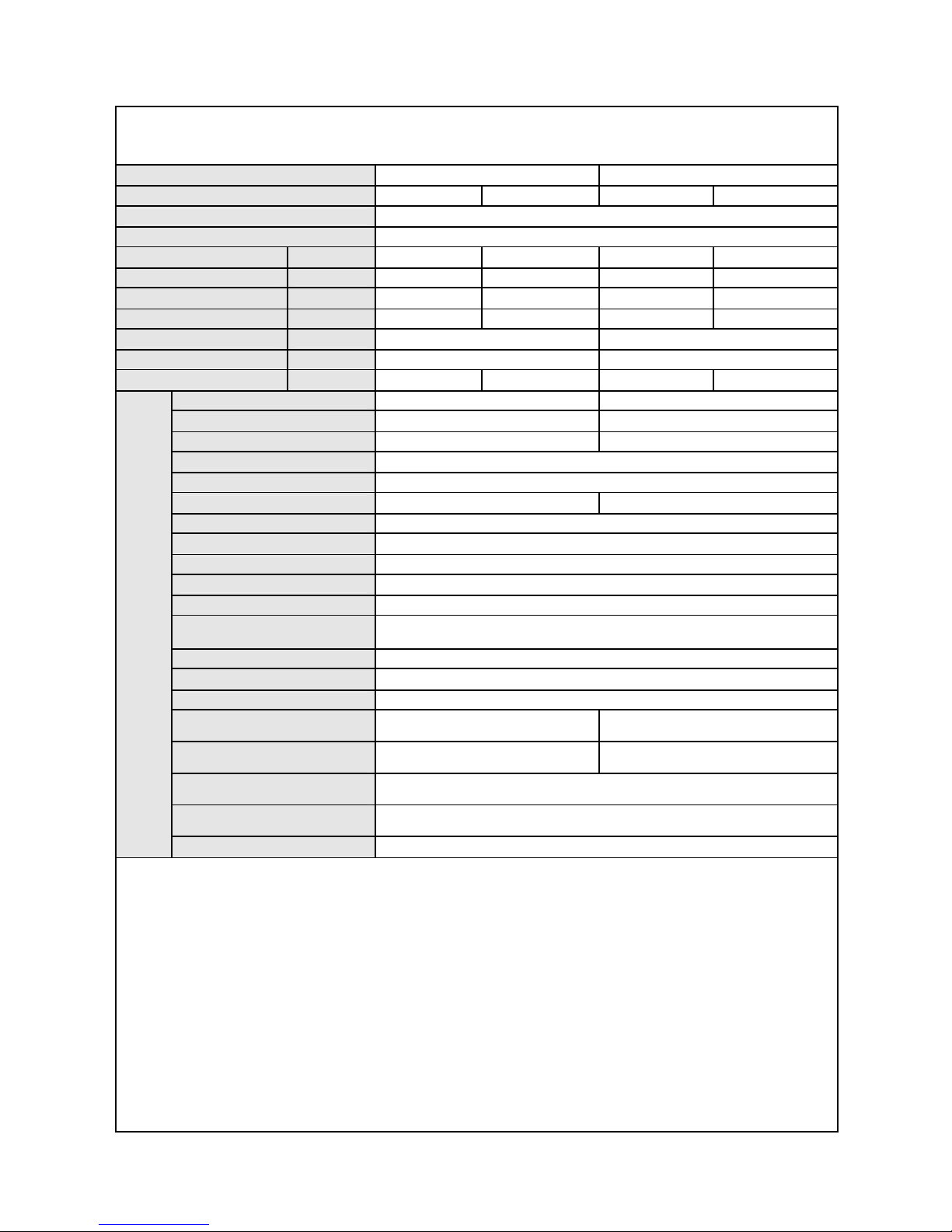

Technical and specifications

Model

PRO AIR 107 IN / PRO AIR 107 OUT PRO AIR 109 IN / PRO AIR 109 OUT

Function Cooling Heating Cooling Heating

Rated voltage 230V

Rated frequency 50Hz

Capacity (W) 2000 2200 2500 2600

Nominal power (W) 660 700 765 800

Max. power (W) 900 920 990 1050

Greatest currency (A) 4.1 4.3 4.8 5.5

Air flow (m3/h) 360 450

Dry capacity (L/h) 0.7 1.2

C.O.P/EER (W/W) 3.05 3.15 3.2 3.2

Model KFR-20G/NaA121-E KFR-25G/NaA121-E

Fan speed (r/min)(H/M/L) 1000/940/880 1160/1010/890

Output power (W) 8 14

Auxiliary electric heater power /

Fan capacitor 1

Fan motor running current 0.035 0.12

Fan type-piece

Axial flow fan-1

Diameter-length (mm) Φ97×583

Evaporator Aluminum fin-copper tube

Pipe diameter Φ7

Row-fin distance (mm) 2-1.4

Developed area of heat

exchanger (I×H×L)

580mm ×228.6mm×25.4mm

Swing motor model MP24GA

Motor power (W) 2

Fuse (A) PCB3.15A Transformer 0.2A

Noise (sound pressure level)

dB(A)

41/38/35

42/39/36

Noise (sound pressure level)

dB(A)

51/49/45

52/49/46

Outline dimension (W/D/H)

(mm)

770×180×250

Package dimension (W/D/H)

(mm)

855×270×336

Indoor

unit

Net weight/gross weight (kg) 8.5/12.5

2

Page 8

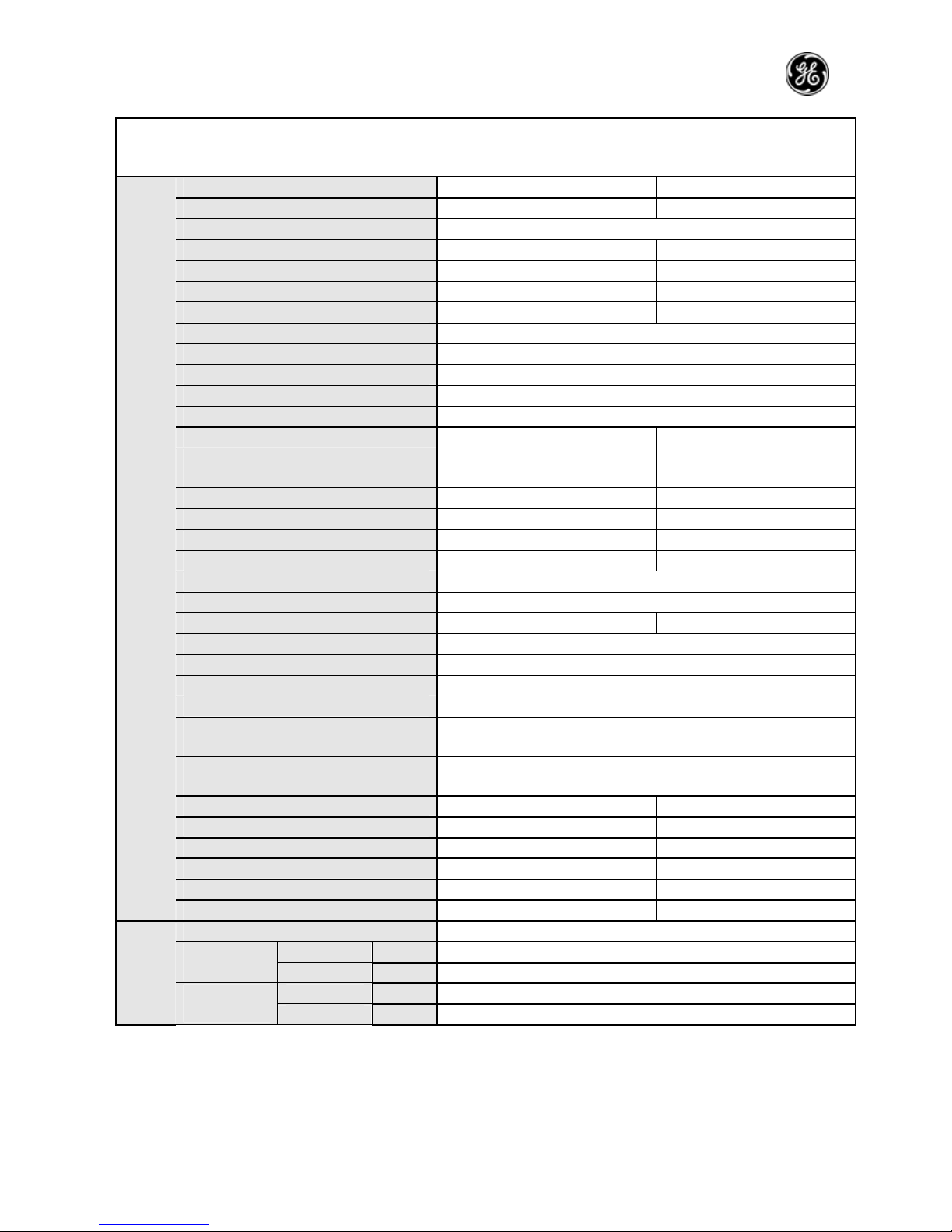

—7—

Model

PRO AIR 107 IN / PRO AIR 107 OUT PRO AIR 109 IN / PRO AIR 109 OUT

Compressor type GK080PAD C-1RV096H1A

Compressor type Rotary type

Locked rotor current 17 17

Compressor running current 3.2 3.8

Compressor input power 682 810

Compressor overload model M RA12009-12026 M RA98635-9201

Throttling method Capillary

Starting mode Capacitor CBB65 (22.5uF/450VAC)

Working temperature range -7~43℃

Condenser Aluminum fin-copper tube

Pipe diameter Φ9.52

Row-fin distance (mm) 2-1.6 2-1.4

Developed area of heat exchanger

(I×H×L)

673×406×44 791×508×44

Fan motor speed (rpm) 950 830

Motor rated power (W) 20 30

Fan motor running current (A) 0.42 0.26

Fan capacitor (μf) 1.5 2

Fan type-piece /

Fan type-piece Axial flow fan -1

Fan diameter (mm) Φ320 Φ400

Defrosting method Auto

Climate type T1

Insulation class I

Waterproof level IP24

Maximum working pressure of

exhaust side (Mpa)

3.8

Maximum working pressure of

exhaust side (Mpa)

1.2

Noise(sound pressure level)

dB(A)

52 56

Noise (sound pressure level)

dB(A)

62 66

Outline dimension (W/D/H)(mm) 660×260×430 848×320 ×540

Package dimension (W/D/H)(mm) 765×350×500 878×360 ×600

Net weight/gross weight (kg) 25/29 30/34

Outdoor

unit

Refrigerant/refrigerant charge (kg) R410A /0.88 R410A /1.1

Length 4

Liquid pipe (mm) Φ6 Outer

diameter

Gas pipe (mm) Φ9.52

Height (m) 5

Connection pipe

Maximu

m

distance

Length (m) 10

Page 9

—8—

Model PRO AIR 112 IN PRO AIR I109 IN

Function Cooling Heating Cooling Heating

Rated voltage 230V

Rated frequency 50Hz

Capacity (W) 3200 3400 2500 2700

Nominal power (W) 1060 1220 730 800

Max. power (W) 1390 1370 1246 1297

Greatest currency (A) 7.2 7.4 5.7 6

Air flow (m3/h) 450 450

Dry capacity (L/h) 1.2 1.2

C.O.P/EER (W/W) 3 2.8 3.4 3.4

Model KFR-32G/NaA121-E KFR-25G/NaA12F-E

Fan speed (r/min)(H/M/L) 1160/1010/890 1190/1090/990

Output power (W) 14 14

Auxiliary electric heater power /

Fan capacitor 1

Fan motor running current 0.12 0.12

Fan type-piece Cross flow fan-1

Diameter-length (mm) Φ97×583

Evaporator Aluminum fin-copper tube

Pipe diameter Φ7

Row-fin distance (mm) 2-1.4

Developed area of heat exchanger

(I×H×L)

580mm ×228.6mm×25.4mm

Swing motor model MP24GA

Motor power (W) 2

Fuse (A) PCB3.15A Transformer 0.2A

Noise (sound pressure level)

dB(A)

42/39/36

42/39/36

Noise (sound pressure level)

dB(A)

52/49/46 52/49/46

Outline dimension (W/D/H) (mm) 770×180×250

Package dimension (W/D/H) (mm)

855×270×336

Indoor

unit

Net weight/gross weight (kg) 8.5/12.5

Page 10

—9—

Model PRO AIR 112 OUT PRO AIR 109 OUT

Compressor type C-RV133H1A EU1011DV

Compressor type Rotary type

Locked rotor current 24 33.5

Compressor running current 5.25 4

Compressor input power 1125 628

Compressor overload model B210-145-241E 4CYC11233

Throttling method Capillary

Starting mode Capacitor

Working temperature range -7~43℃

Condenser Aluminum fin-copper tube

Pipe diameter Φ9.52

Row-fin distance (mm) 2-1.4 2-1.4

Developed area of heat exchanger

(I×H×L)

791×508×44 645×508×44

Fan motor speed (rpm) 830 830

Motor rated power (W) 30 30

Fan motor running current (A) 0.26 0.3

Fan capacitor (μf) 2.5 2.5

Fan type-piece /

Fan type-piece Axial flow fan-1

Fan diameter (mm) Φ400 Φ400

Defrosting method Auto

Climate type T1

Insulation class I

Waterproof level IP24

Maximum working pressure of

exhaust side (Mpa)

3.8

Maximum working pressure of

exhaust side (Mpa)

1.2

Noise (sound pressure level) dB(A) 56 54

Noise (sound pressure level) dB(A) 66 64

Outline dimension (W/D/H) (mm) 848×320 ×540 848×320 ×540

Package dimension (W/D/H) (mm) 878×360 ×600 878×360 ×600

Net weight/gross weight (kg) 30/34 41/43

Outdoo

r unit

Refrigerant/refrigerant charge (kg) R410A /1.3 R410A /1.2

Length 4

Liquid pipe (mm) Φ6 Outer

diameter

Gas pipe (mm) Φ9.52

Height (m) 5

Connection

pipe

Maximum

distance

Length (m) 10

Page 11

—10—

Model PRO AIR I112 IN PRO AIR 218 IN

Function Cooling Heating Cooling Heating

Rated voltage 230V

Rated frequency 50Hz

Capacity (W) 3200 3400 2500×2 2800×2

Nominal power (W) 1000 1100 830×2 900×2

Max. power (W) 1361 1383 1120×2 1100×2

Greatest currency (A) 5.9 6.1 5.9×2 5.4×2

Air flow (m3/h) 450 450

Dry capacity (L/h) 1.2

1.2×2

C.O.P/EER (W/W) 3.2 3.1 3 3.1

Model

KFR-32G/NaA12F-E KFR-25X2G/NaA121-E

Fan speed (r/min)(H/M/L) 1190/1090/990 1160/1010/890

Output power (W) 14 14

Auxiliary electric heater power /

Fan capacitor 1

Fan motor running current 0.12 0.12

Fan type-piece Cross flow fan-1

Diameter-length (mm) Φ97×583

Evaporator Aluminum fin-copper tube

Pipe diameter Φ7

Row-fin distance (mm) 2-1.4

Developed area of heat

exchanger (I×H×L)

580mm ×228.6mm×25.4mm

Swing motor model MP24GA

Motor power (W) 2

Fuse (A) PCB3.15A Transformer 0.2A

Noise (sound pressure level)

dB(A)

42/39/36

42/39/36

Noise (sound pressure level)

dB(A)

52/49/46 52/49/46

Outline dimension (W/D/H)

(mm)

770×180×250

Package dimension (W/D/H)

(mm)

855×270×336

Indoor

unit

Net weight/gross weight (kg) 8.5/12.5

Page 12

—11—

Model PRO AIR I112 OUT PRO AIR 218 OUT

Compressor type EU1011DV 5PS108EAA22

Compressor type Rotary type

Locked rotor current 33.5 18

Compressor running current 4 4.05

Compressor input power 628 880

Compressor overload model 4CYC11233 7100819 (KA-122-LPD021A)

Throttling method Capillary

Starting mode Capacitor

Working temperature range -7~43℃

Condenser Aluminum fin-copper tube

Pipe diameter Φ9.52

Row-fin distance (mm) 2-1.4 2-1.8

Developed area of heat exchanger (I×H

×L)

645×508×44 730×660×44

Fan motor speed (rpm) 830 815

Motor rated power (W) 30 60

Fan motor running current (A) 0.3 0.6

Fan capacitor (μf) 2.5 3

Fan type-piece /

Fan type-piece Axial flow fan-1

Fan diameter (mm) Φ400 Φ400

Defrosting method Auto

Climate type T1

Insulation class I

Waterproof level IP24

Maximum working pressure of exhaust

side (Mpa)

3.8

Maximum working pressure of exhaust

side (Mpa)

1.2

Noise (sound pressure level) dB(A) 54 60

Noise (sound pressure level) dB(A) 64 70

Outline dimension (W/D/H) (mm) 848×320 ×540 950×340×685

Package dimension (W/D/H) (mm) 878×360 ×600 1100×450×750

Net weight/gross weight (kg) 41/43 65/70

Outdoo

r unit

Refrigerant/refrigerant charge (kg) R410A /1.2 R410A /0.9×2

Length 4

Liquid pipe (mm) Φ6 Outer

diameter

Gas pipe (mm) Φ9.52

Height (m) 5

Connection

pipe

Maximum

distance

Length (m) 10

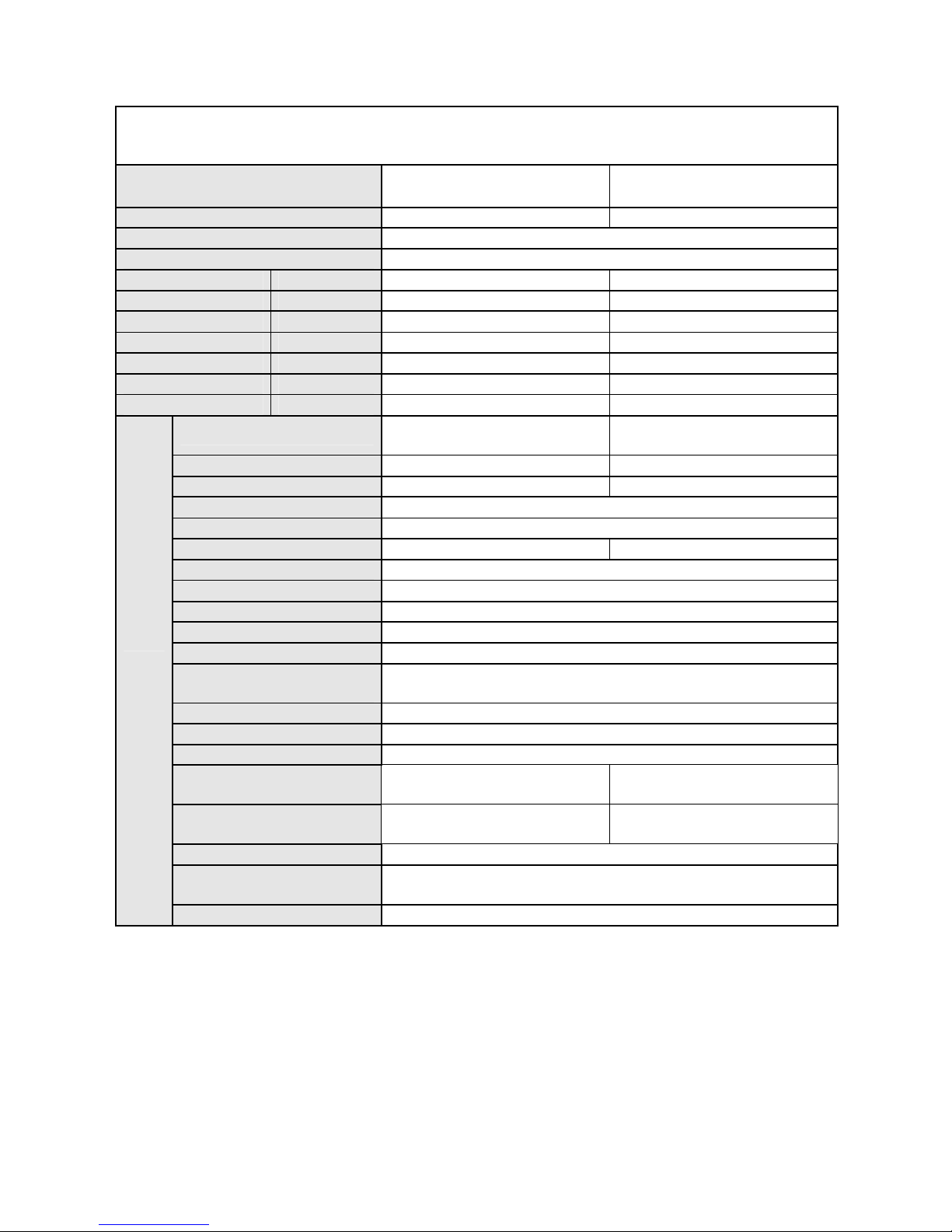

Page 13

—12—

Model

GE AIR 326 IN1 / GE AIR 326 IN2 / GE

AIR 326 OUT

GE AIR 428 IN / GE AIR 428 OUT

Function Cooling Cooling

Rated voltage 230V

Rated frequency 50Hz

Capacity (W)

6800 (3200+1800×2) 7200 (1800X4)

Nominal power (W) 6800 (3200+1800×2) 2900 (1450X2)

Max. power (W)

3400 (1700×2) 3400 (1700X2)

Greatest currency (A) 6.5+6.5 6.5+6.5

Air flow (m3/h) 450 450

Dry capacity (L/h) 1.2×2 1.2×2

C.O.P/EER (W/W) 2.4 2.5

Model

KF-18X2G/NA12-E /

KF-32G/NA12-E

KF-18X4G/NA12-E

Fan speed (r/min) (H/M/L) 1160/1010/890 1160/1010/890

Output power (W) 14 14

Auxiliary electric heater power /

Fan capacitor 1

Fan motor running current 0.12 0.12

Fan type-piece Cross flow fan-1

Diameter-length (mm) Φ97×583

Evaporator Aluminum fin-copper tube

Pipe diameter Φ7

Row-fin distance (mm) 2-1.4

Developed area of heat

exchanger (I×H×L)

580mm ×228.6mm×25.4mm

Swing motor model MP24GA

Motor power (W) 2

Fuse (A) PCB3.15A Transformer 0.2A

Noise (sound pressure level)

dB(A)

42/39/36

42/39/36

Noise (sound pressure level)

dB(A)

52/49/46

52/49/46

Outline dimension (W/D/H) (mm) 770×180×250

Package dimension (W/D/H)

(mm)

855×270×336

Indoor

unit

Net weight/gross weight (kg) 8.5/12.5

Page 14

—13—

Model

GE AIR 326 IN1 / GE AIR 326 IN2 /

GE AIR 326 OUT

GE AIR 428 IN / GE AIR 428 OUT

Compressor type C-RV237H01AA C-RV237H01AA

Compressor type Rotary type

Locked rotor current 31 31

Compressor running current 6.3 6.3

Compressor input power 1100 1100

Compressor overload model MRA98619-9200 MRA98619-9200

Throttling method Capillary

Starting mode Capacitor

Working temperature range -5~43℃

Condenser Aluminum fin-copper tube

Pipe diameter Φ9.52

Row-fin distance (mm) 2-1.8 2-1.8

Developed area of heat exchanger

(I×H×L)

791×508×44 791×508×44

Fan motor speed (rpm) 780 780

Motor rated power (W) 60 60

Fan motor running current (A) 0.56 0.56

Fan capacitor (μf) 3 3

Fan type-piece /

Fan type-piece Axial flow fan-1

Fan diameter (mm) Φ460 Φ460

Defrosting method Auto

Climate type T1

Insulation class I

Waterproof level IP24

Maximum working pressure of

exhaust side (Mpa)

2.5

Maximum working pressure of

exhaust side (Mpa)

0.6

Noise (sound pressure level) dB(A) 58 58

Noise (sound pressure level) dB(A) 68 68

Outline dimension (W/D/H) (mm) 950×412 ×840 950×412 ×840

Package dimension (W/D/H) (mm) 1100×450×920 1100×450×920

Net weight/gross weight (kg) 72/77 72/77

Outdoo

r unit

Refrigerant/refrigerant charge (kg) R407C /1.27×2 R407C /1.27×2

Length Length of connecting tube

Liquid

pipe

(mm) Φ6 Outer

diameter

Gas pipe (mm) Φ9.52

Height (m) 5

Connection pipe

Maximum

distance

Length (m) 10

The above data is subject to change without notice. Please refer to the nameplate of the unit.

Page 15

—14—

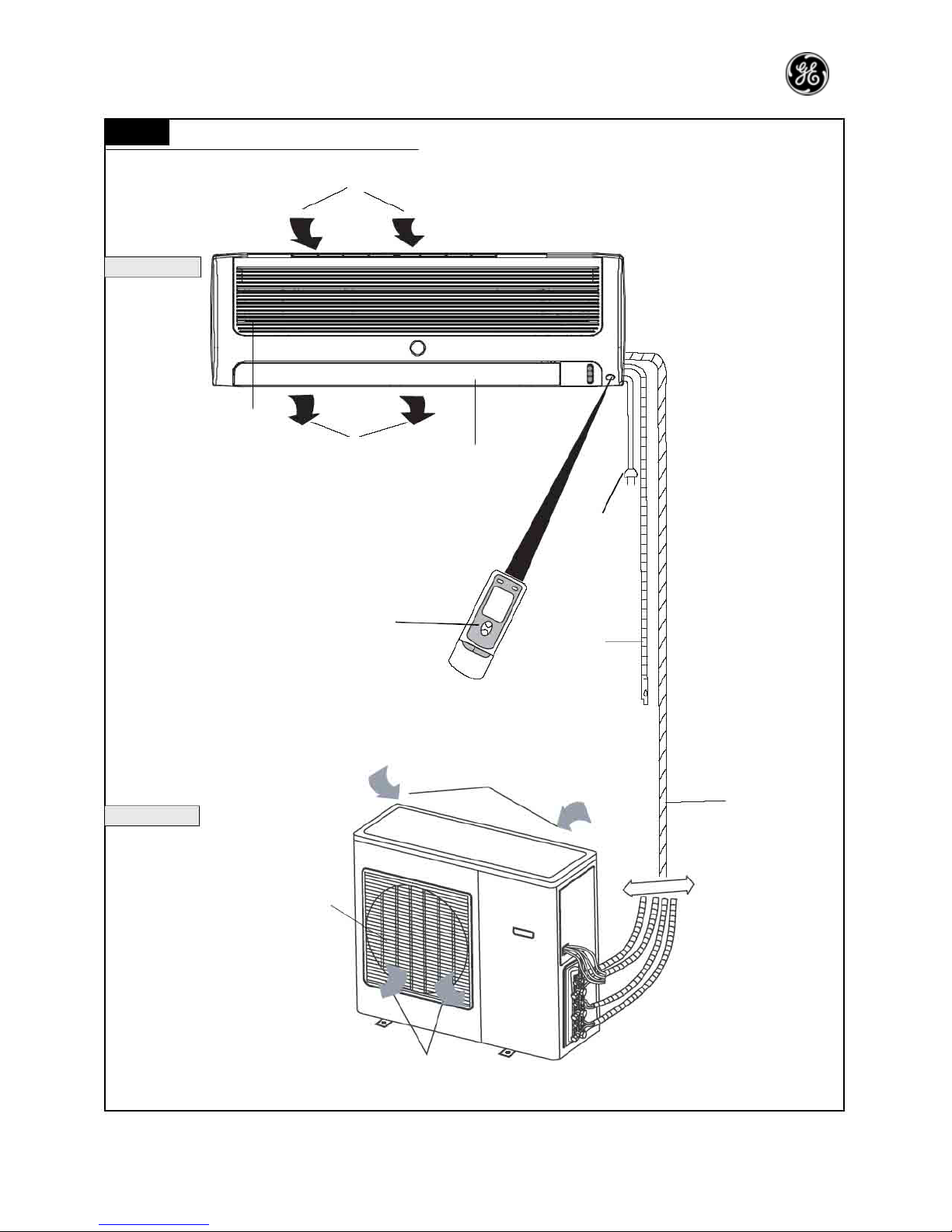

Part name

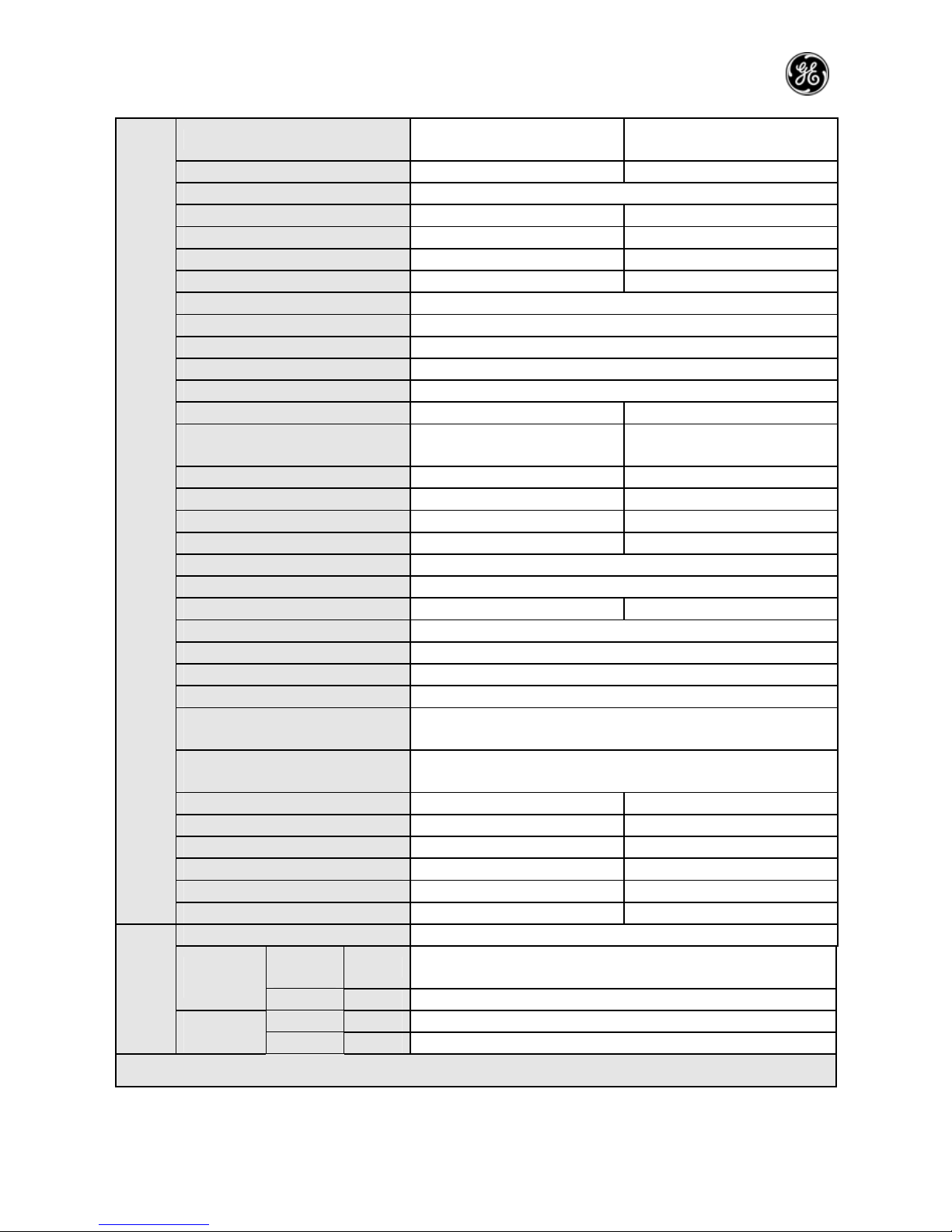

Part name of one driving one unit

Air in

Indoor unit

Panel

Air out Air guide board

Power plug

Remote controller

Drainage pipe

utdoor unit Air in

Connecting pipe and

connecting wire

Air outlet vent grill

Air out

3

3.1

Page 16

—15—

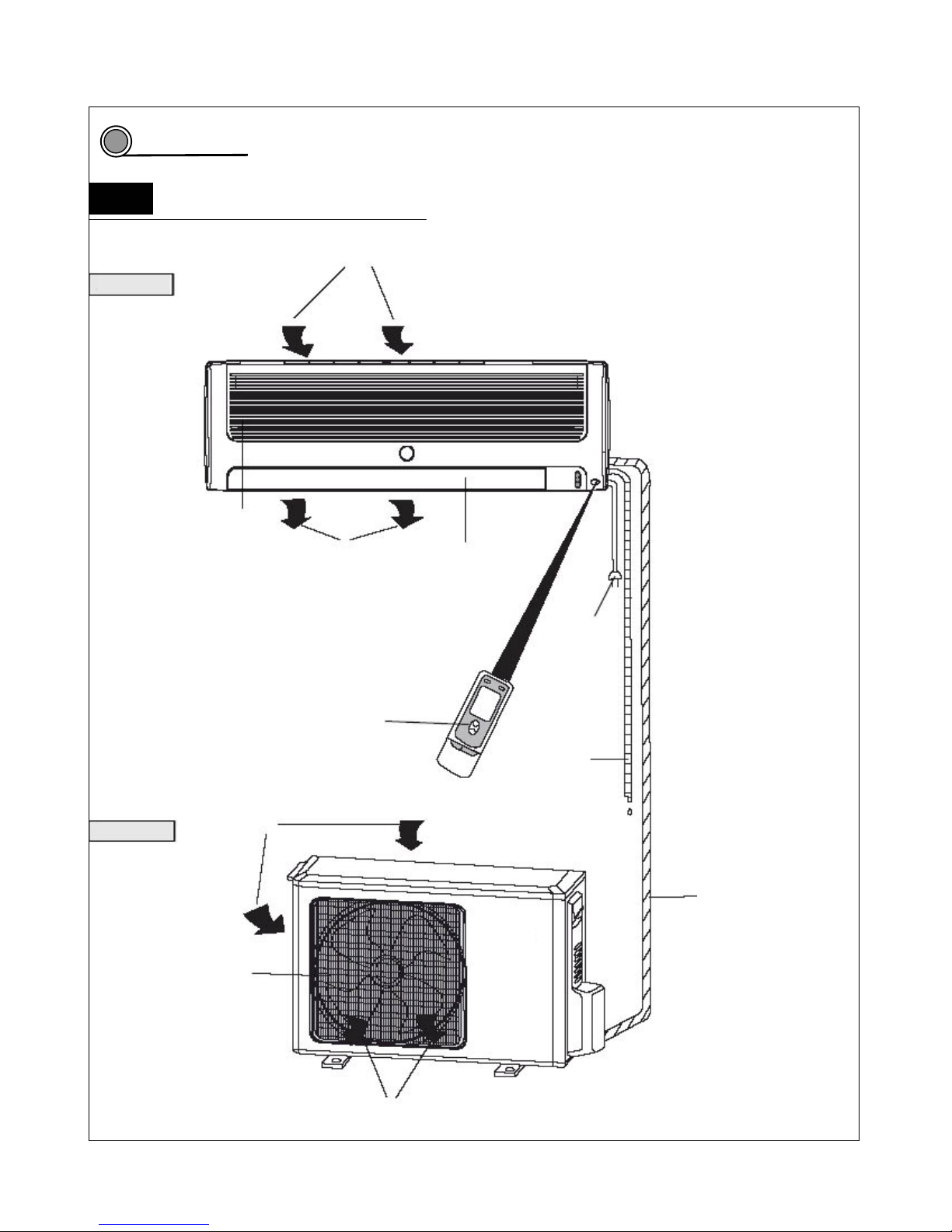

3.2 Part name of one driving two unit

Air in

Indoor unit A

Wrapping tape

Air out

Indoor unit B

Panel

Air guide board

Remote controller

Drainage pipe

Outdoor unit

Air in

Air outlet vent grill

Air out

Page 17

—16—

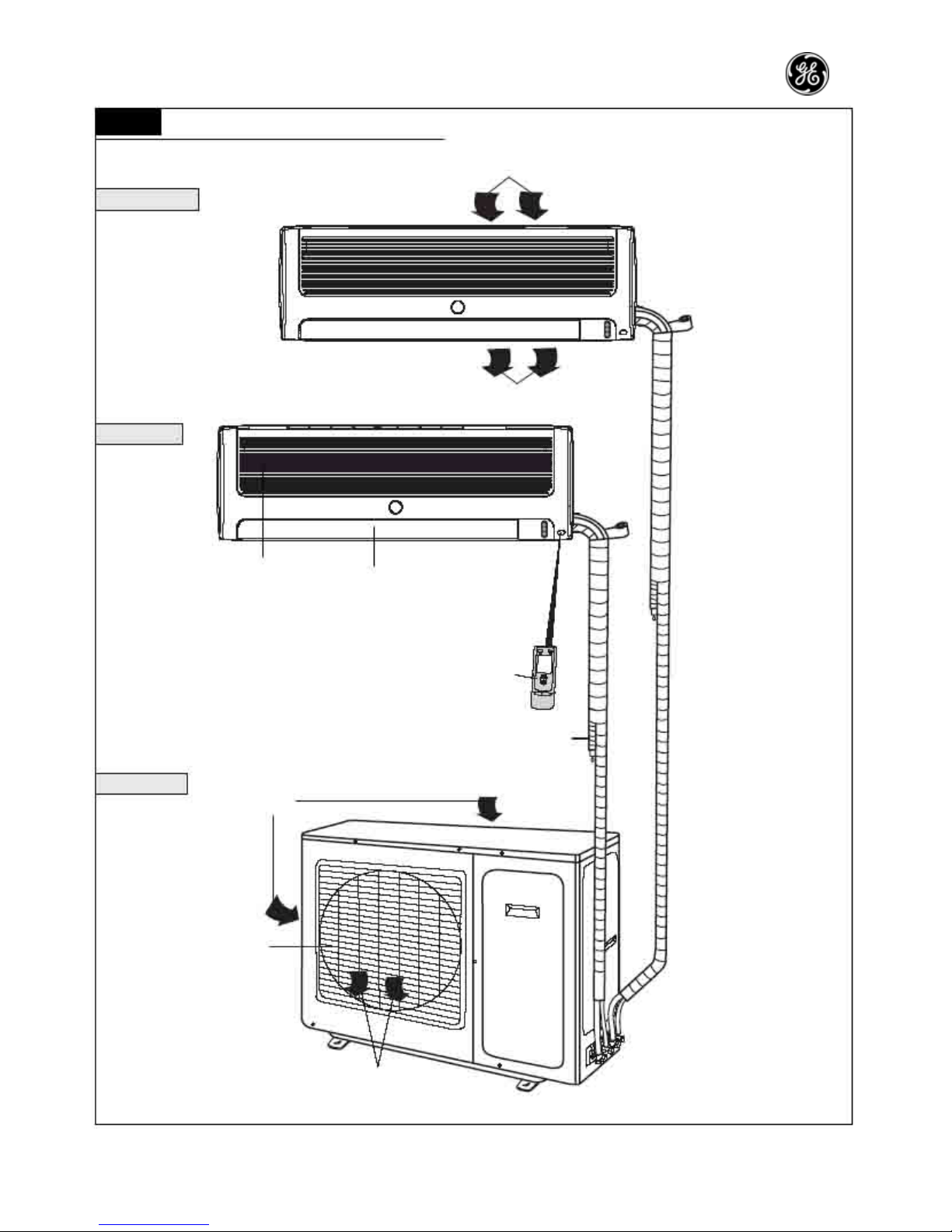

3.3 Part name of one driving three unit

Air in

Indoor unit

Panel

Air out Air guide board

Power plug

Remote controller

Drainage pipe

Air in

Outdoor unit

Air outlet vent grill

Air out

Connecting

pipe and

connecting

wire

Page 18

—17—

P17

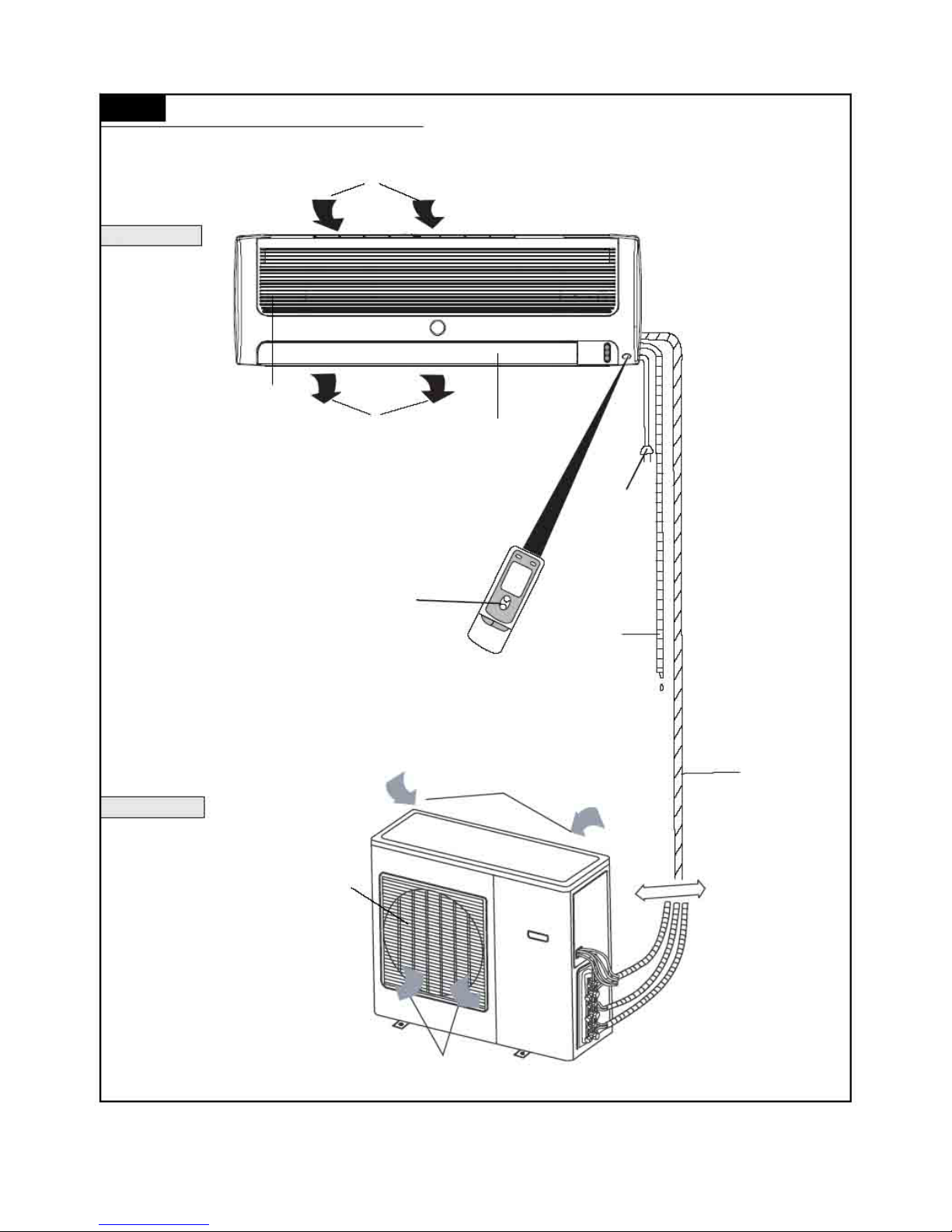

3.4

Part name of one driving four unit

Air in

Indoor unit

Panel

Air out Air guide board

Power plug

Remote controller

Drainage pipe

Air in

Outdoor unit

Air outlet vent grill

Air out

Connecting

pipe and

connecting

wire

Page 19

—18—

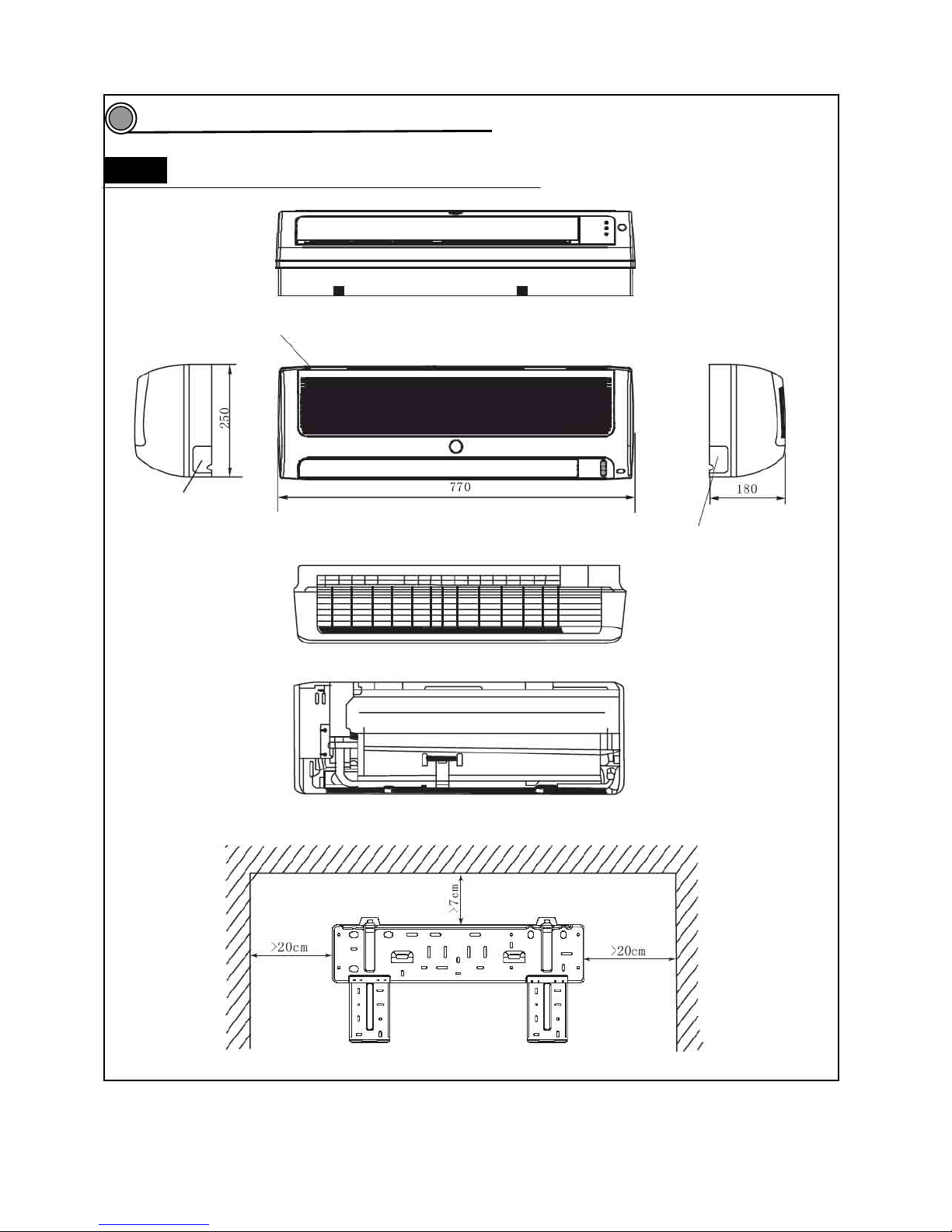

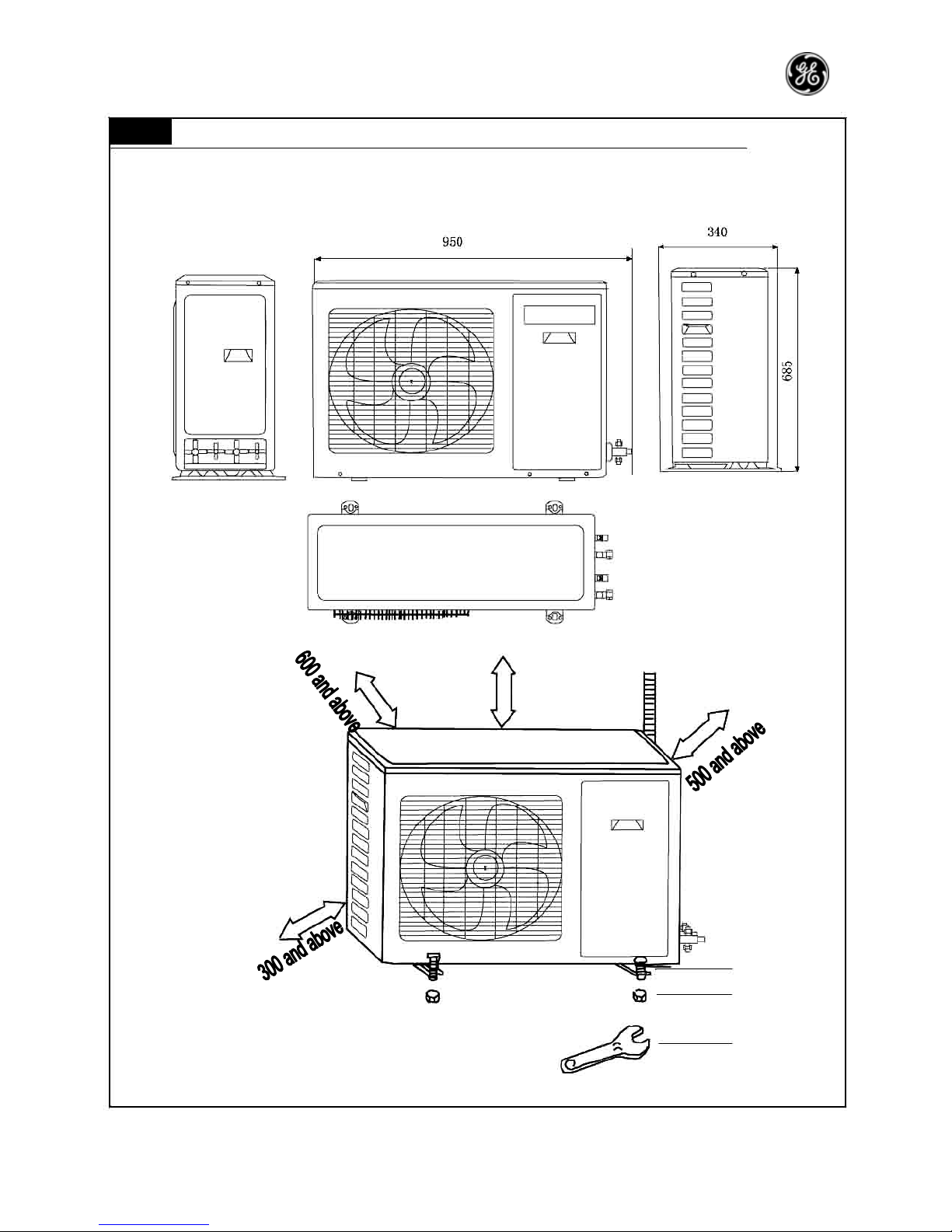

Outline and installation dimensions

4.1 Outline and installation dimensions of indoor unit

Air inlet vent

Left pipe outlet

Right pipe outlet

Rear view

Ceiling

Left side Right side

Installation dimensions

4

Page 20

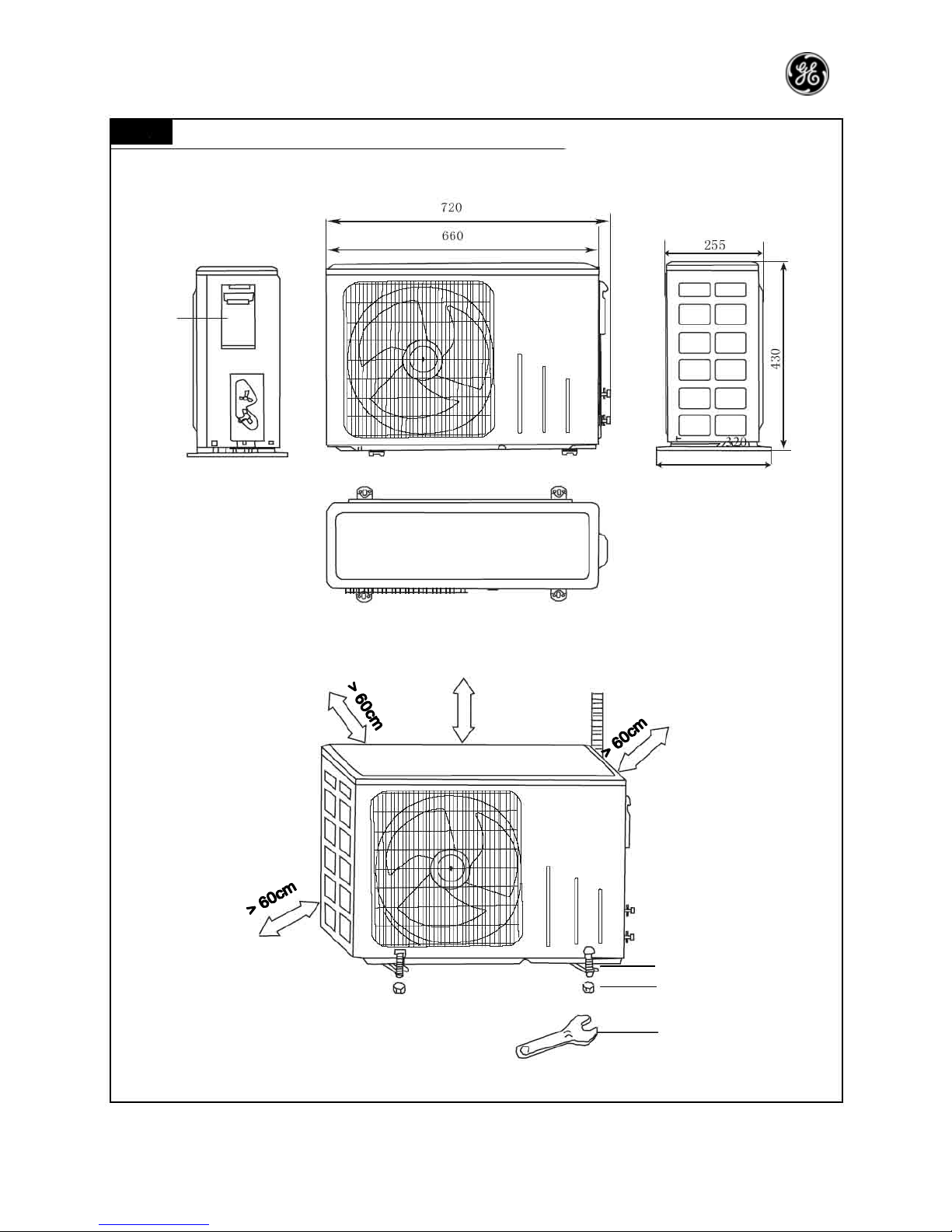

—19—

4.2 Outline and installation dimensions of indoor unit 20

Handle

> 60cm

Bolt

Nut

Spanner

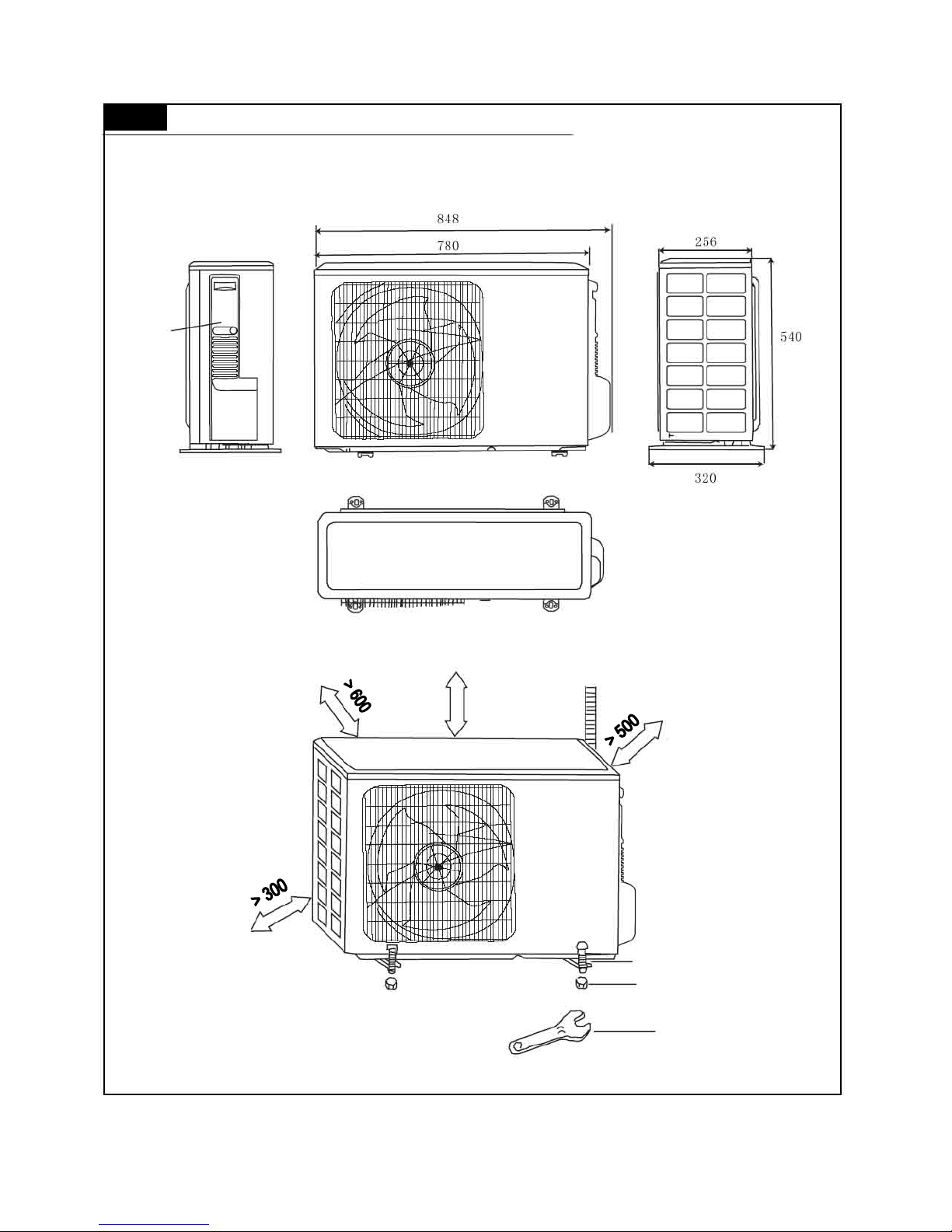

Page 21

—20—

4.3 Outline and installation dimensions of indoor units 2 5, 32

Handle

Unit: mm

> 500

Bolt

Nut

Spanner

Page 22

—21—

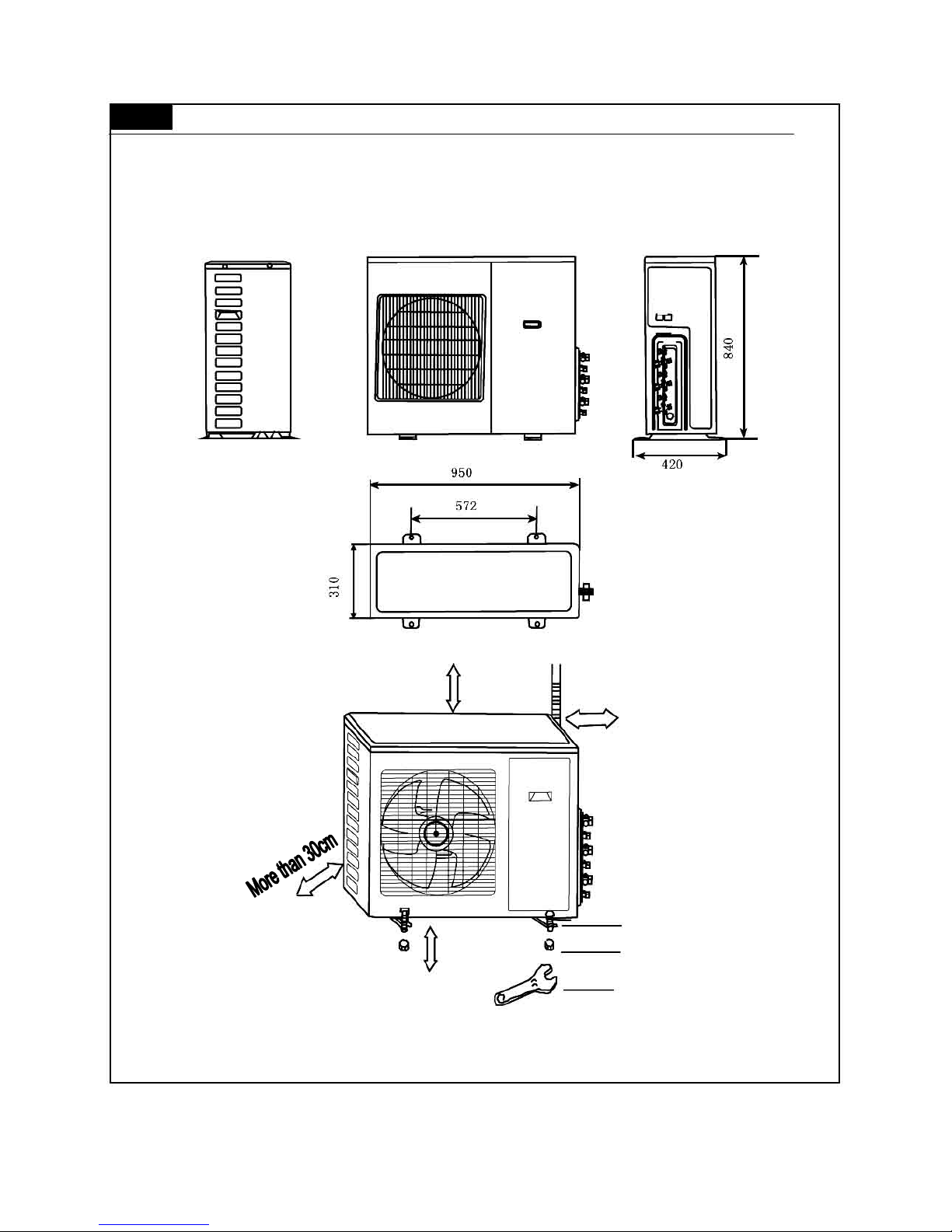

4.4 Outline and installation dimensions of one driving two outdoor unit

Unit: mm

500 and above

Bolt

Nut

Spanner

Page 23

—22—

4.5 Outline and installation dimensions of one driving three outdoor unit

More than 50cm

More than 30cm

Bolt

More than 200cm Nut

Spanner

Page 24

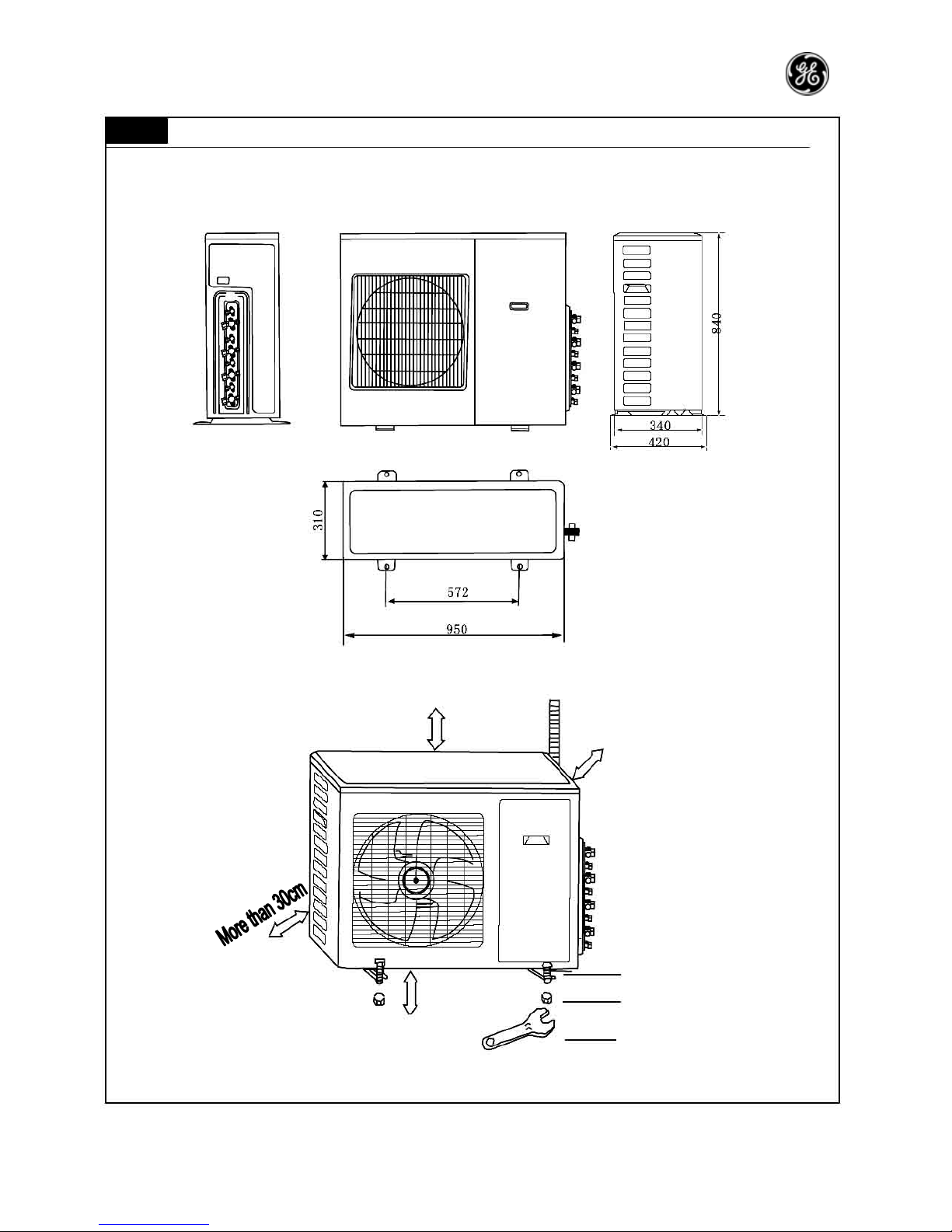

—23—

4.6 Outline and installation dimensions of one driving four outdoor unit

More than 50cm

More than 30cm

Bolt

More than 200cm Nut

Spanner

Page 25

—24—

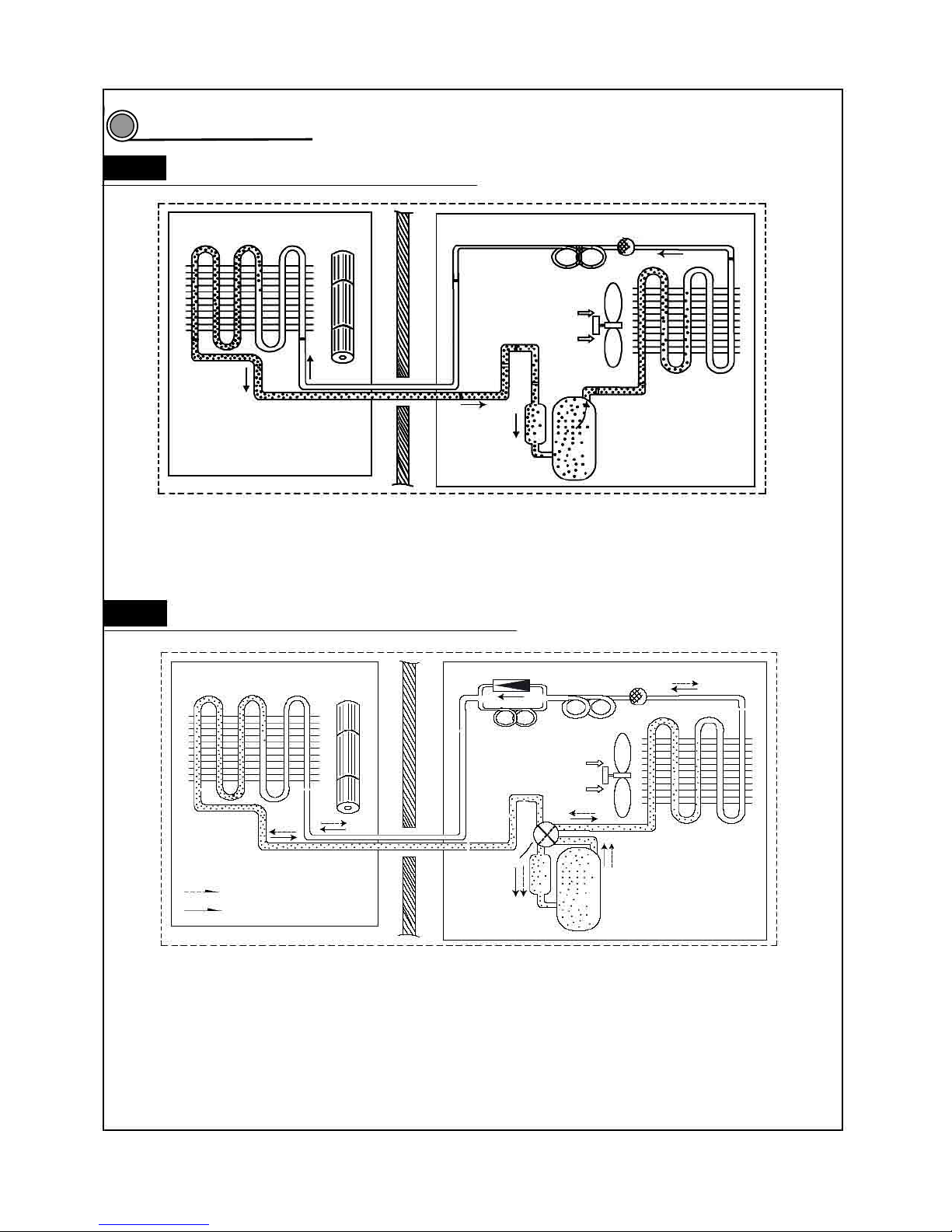

5

System diagram

5.1 Cool only system circuit diagram

Evaporator Cross flow fan

Capillary Filter

Axial flow fan

Condenser

Gas liquid

separator Compressor

When the power is on, indoor and outdoor units will start to run. The compressor sucks low-pressure refrigerant gas from

the evaporator of indoor unit and then discharges high-temperature, high-pressure refrigerant gas into outdoor

condenser. Then air exchanges the heat with outdoor air and becomes refrigerant liquid. The liquid is throttled by the

capillary and changes into low-temperature and low-pressure liquid and then flows into indoor evaporator. Then liquid

exchanges the heat with the required air and changes into low-temperature and low-pressure refrigerant gas. The cycle

introduced above goes on and on, and the demanded low temperature environment is maintained

5.2 Cool/Heat system circuit diagram

Evaporator Cross flow fan

Flow direction of refrigerant when heating

Flow direction of refrigerant when cooling

One-way valve

Main capillary Filter

Auxiliary Capillary

Axial flow fan

Condenser

Electromagnetic

four-way valve

Gas liquid

Separator Compressor

When the power is on, indoor and outdoor units will start to run. When the system operates in cool mode, the

compressor sucks low-temperature, low-pressure refrigerant gas from indoor evaporator and then discharges

high-temperature, high-pressure refrigerant gas into outdoor heat exchanger. With the help of axial flow fan, the gas

transfers its latent heat into outdoor air and becomes high-pressure refrigerant liquid. The liquid is throttled by the

capillary and changes into low-temperature and low-pressure liquid and then flows into indoor heat exchanger. With the

help of centrifugal fan, the liquid evaporates into low-temperature refrigerant gas and indoor air is cooled down. The

refrigerant gas is sucked into the compressor and the cycle introduced above goes on and on, and the demanded low

temperature environment is maintained. When the system operates in heat mode, four-way valve changes its way and

the refrigerant flows into the reversible cycle as the cool mode. The refrigerant discharges its latent heat in the indoor

heat exchanger, and sucks heat from outdoor heat exchanger and forms the heat pump cycle. This cycle goes on and on,

and the demanded high temperature environment is maintained.

5

Page 26

—25—

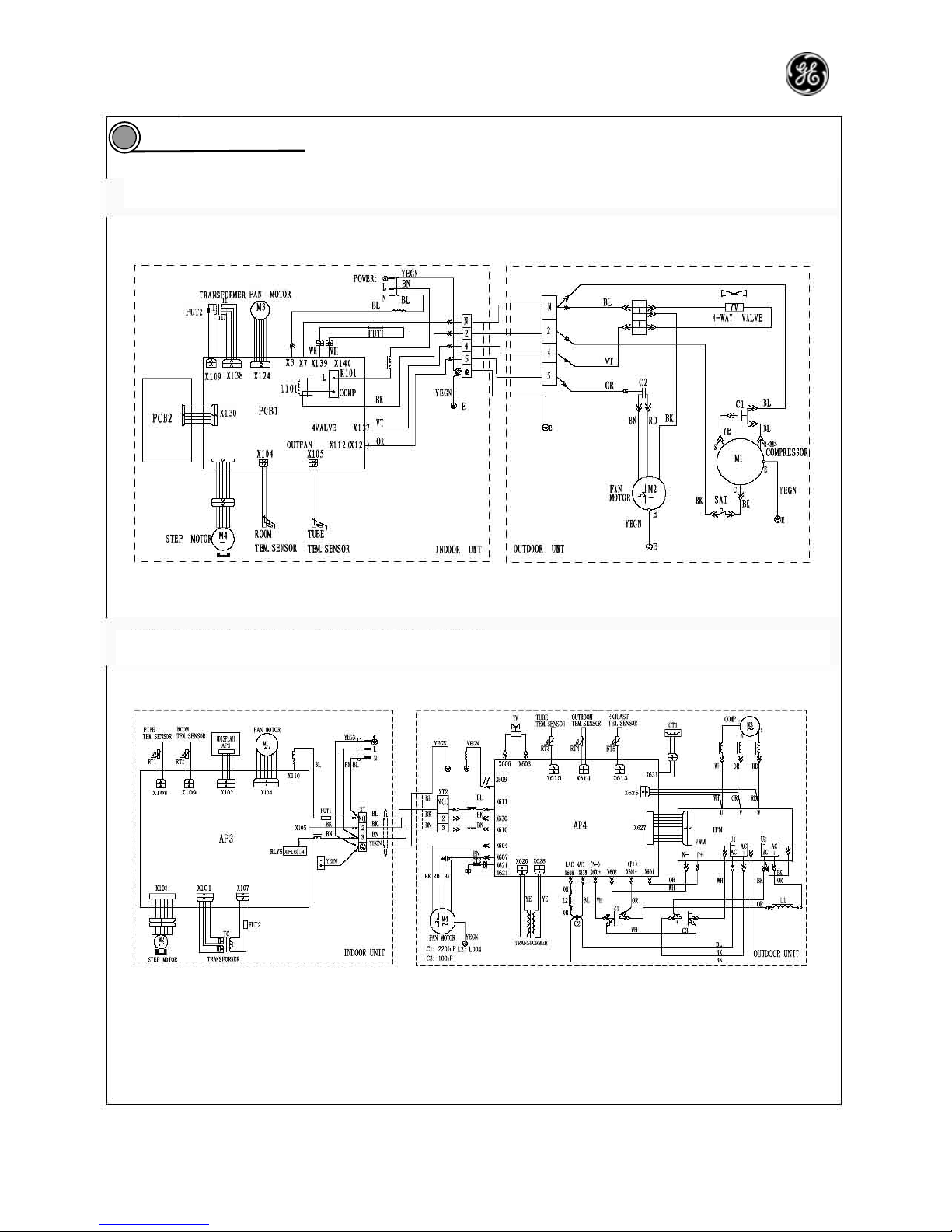

Circuit diagram

6

PRO AIR 107 IN / PRO AIR 107 OUT; PRO AIR 109 IN / PRO AIR 109 OUT; PRO AIR 112 IN / PRO

PRO AIR I109 IN / PRO AIR I109 OUT; PRO AIR I112 IN / PRO AIR I112 OUT

Page 27

—26—

Circuit

diagram is

same as

above.

Circuit

diagram is

same as

above.

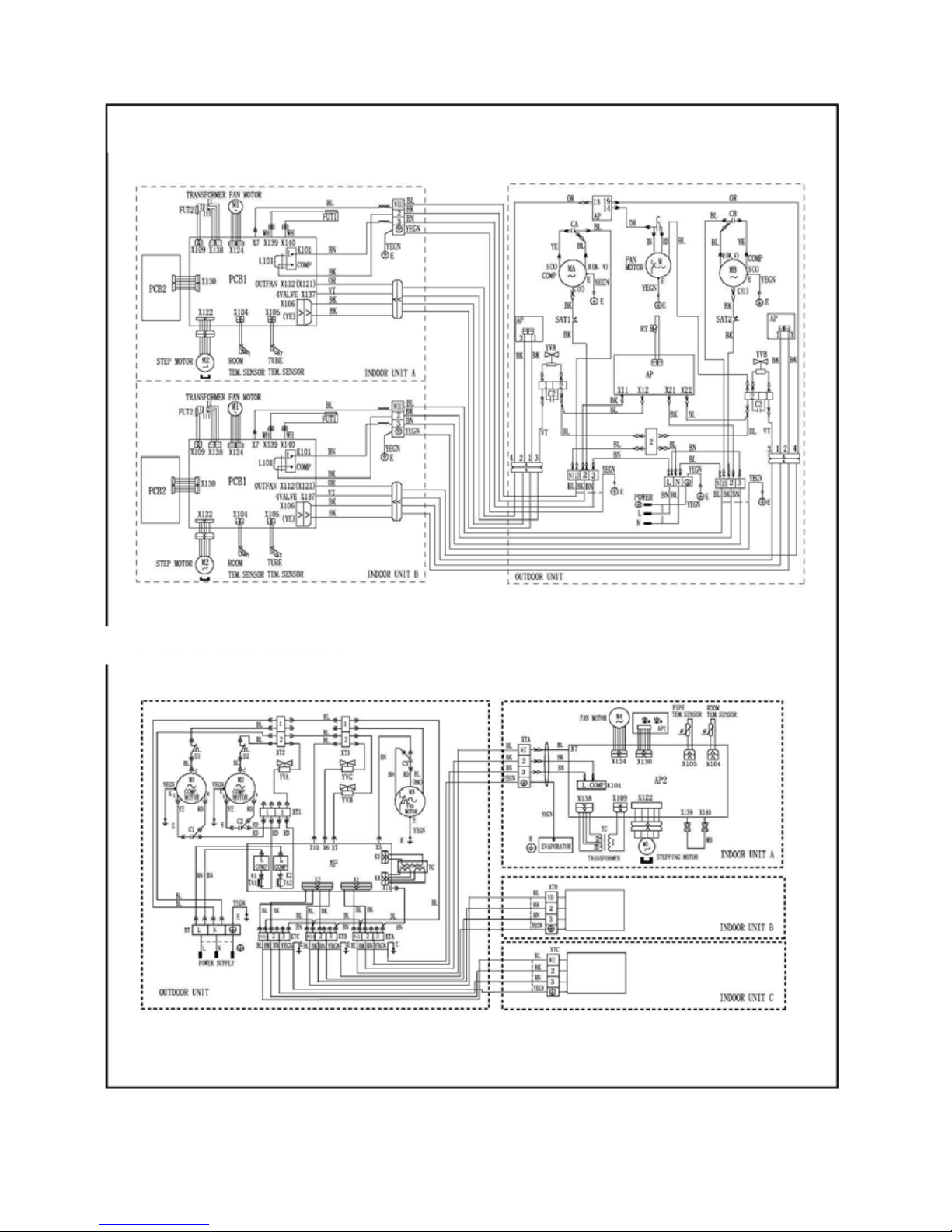

PRO AIR 218 IN / PRO AIR 218 OUT

GE AIR 326 IN1 / GE AIR 326 IN2 / GE AIR 326 OUT

Page 28

—27—

Circuit

diagram is

same as

above.

Circuit

diagram is

same as

above.

Circuit

diagram is

same as

above.

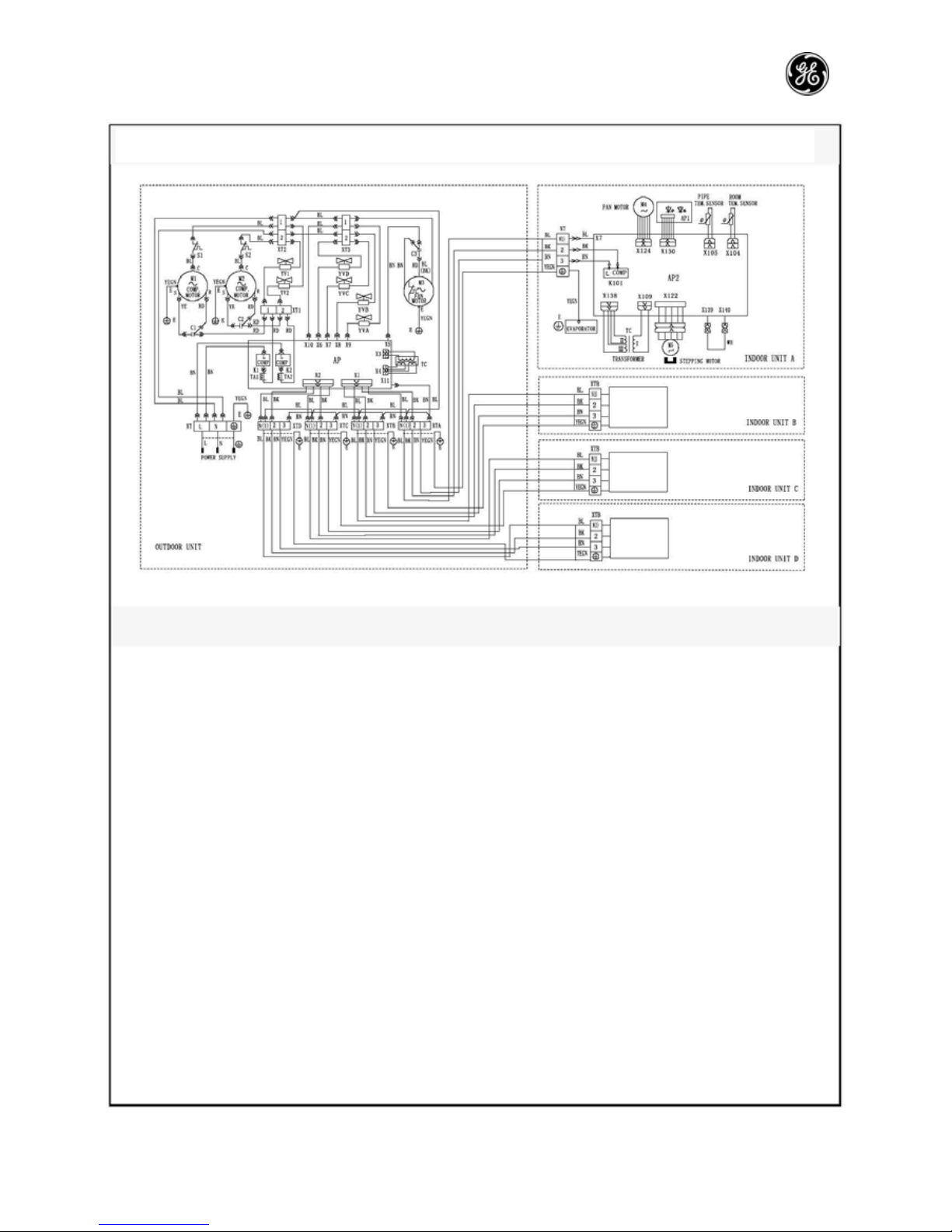

These circuit diagrams are subject to change without notice. Please refer to the one supplied with the unit.

GE AIR 428 IN / GE AIR 428 OUT

Page 29

—28—

Function manual and operation method of remote controller

PRO AIR I112 IN / PRO AIR I112 OUT, suitable for frequency converter

Function manual of remote controller

7.1.1 Temperature parameter

Room set temperature: (T

set

)

Room ambient temperature: (T

amb

)

7.1.2 Basic function of system

No matter what mode the compressor is in, the minimum time interval between two startups should be 3

minutes after it is powered on.

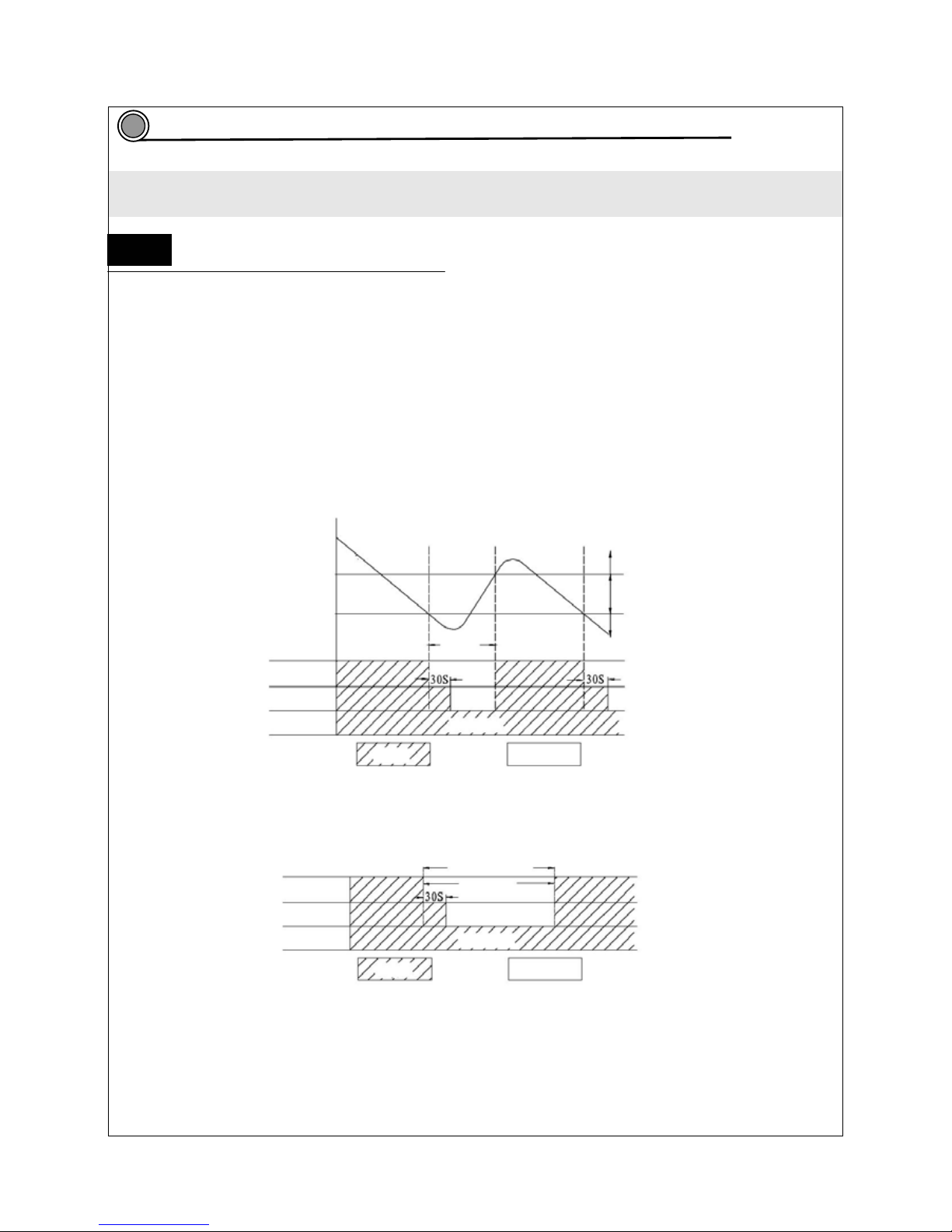

7.1.2.1 Cooling mode

7.1.2. 1.1 The condition and process of cooling

If T

amb>Tset

, COOL mode will act, compressor and external fan will run, the indoor fan will run at the set

speed.

If T

amb≤Tset

-2℃, compressor will stop and external fan will stop after a delay of 30s. The indoor fan will

run at the setting speed.

If Tset-2℃<T

amb<Tset

, the unit will keep ℃ on running in the original mode.

¾ In this mode, the reversal valve will not be powered on and the temperature setting range is

16 ~30℃℃.

T

set

+1℃ T

amb

Start cooling

T

set

-1℃ Keep running in the original mode

Stopping cooling

≥3min

Compressor

Outdoor fan

Indoor fan Set fan speed

Run Stop

7.1.2.1.2 Protection function

Anti-freezing Protection

When the anti-freezing protection is detected, the compressor will stop, the outdoor fan will stop after a

delay of 30 seconds. The indoor fan and swing motor will keep on running in the original mode. When

anti-freezing protection is eliminated and compressor has stopped for 3min, the machine restores its

former operation mode.

Anti-freezing Protection

Compressor ≥3min

Outdoor fan

Indoor fan Set fan speed

Run Stop

Over current protection

The compressor will run at a limited frequency when the total current is high. The compressor will stop

when the total current is too high and the outdoor unit will stop after a delay of 30s.

7.1.2.2 Dry mode

7.1.2.2.1 The condition and process of dry mode

If T

amb>Tset

, the drying mode will act. The compressor and external fan will run, and the indoor fan will run

at a low speed.

7

7.1

Page 30

—29—

If T

set

-2℃≤T

amb≤Tset

, the unit will keep on running in the original mode.

If T

amb≤Tset

-2℃, the compressor will stop. The external fan will stop after a delay of 30s, and the indoor

fan will run at a low speed.

¾ In this mode, the reversal valve will not be powered on and the temperature setting range is

16 ~30℃℃

T

amb

T

set

T

set

-2℃

Compressor

Outdoor fan

Indoor fan Low fan speed

Run Stop

Cooling running

Dry running

Stop running

7.1.2.2.2 Protection function

Anti-freezing protection

Anti-frost protection same as cooling

Over current protection

Over current protection is the same as the cooling mode.

7.1.2.2.3 SWING mode

At this mode, the inner fan will select among high, medium, low and auto modes and the compressor,

outer fan and 4-way fan will stop running.

¾ In this mode, the reversal valve will not be powered on and the temperature setting range is

16 ~30℃℃

7.1.2.3 HEAT mode

7.1.2.3.1 Running condition and process of heating mode

If T

amb≤Tset

+2 , HEAT mode will act, the compressor, outdoor fan and reversal valve will run at the same ℃

time, the indoor fan will run after 3 minutes’ delay at the latest.

If T

amb≥Tset

+4 , the compressor will stop℃ first and 15s later, the outdoor unit will stop. The reversal valve

will keep power-on and the indoor fan will run at a low speed and will stop 30s later.

If T

set

+2℃<T

amb<Tset

+4 ,℃ the unit will keep running in the previous mode.

¾ In this mode, the temperature setting range is 16 ~30 .℃℃

¾ The air conditioner will adjust the running frequency of the compressor automatically according to the

change of ambient temperature.

¾ The 4-way valve will be cut off 2min after the compressor stops operation when heating cut-off, or

heating mode changed to other mode.

T

set

+5℃

T

set

+2℃ T

amb

≥3min

Stop heating

Original running state

Start heating

Compressor

Outdoor fan

Indoor fan ≤3min Set fan speed ≤3min Set fan speed

Reversal valve

Run Stop

7.1.2.3.2 The condition and process of defrosting

When frost is detected in the condenser, the system will enter into defrosting mode. When the defrosting starts,

the compressor and indoor fan stop running. The outdoor fan will stop after a delay of 30s, and the four-way

Page 31

—30—

valve will stop running after a delay of 30s. The defrosting will start 15s later. After the compressor runs for 7

min or when the defrosting is finished, the compressor will stop, and 30s later the four-way valve will run. 30s

later, the compressor and outdoor fan resume to operation and indoor fan will run after a delay of 3min. Prior to

entering into defrost, if the auxiliary heating is running, then, for defrosting, the auxiliary heating will be stopped

firstly, and 5s later the indoor fan will stop. The indoor fan will run at blowing residual heat mode when the

compressor stops due to failure at heating mode.

¾ In this mode, the reversal valve will not be powered on and the temperature setting range is 16 ~30℃℃

7.1.2.3.3 Protection function

Anti-high temperature protection

If the evaporator is detected with a high pipe temperature, the outer fan stops running and if the evaporator

recovers to a normal pipe temperature, the outer fan resumes running.

Noise immunization protection

When "RUN/STOP" is used to turn off the unit, the reversal valve will delay 2 minutes to stop.

Over current protection

Over current protection is the same as the cooling mode

Auxiliary electrical heating power

Operation condition of auxiliary electric heating: for heating mode and when compressor is powered on, and

when the pipe temperature is detected to be too low with the indoor fan running at medium or high speed, the

auxiliary electric heating will be put into operation. When the compressor is powered on, and when the pipe

temperature is detected to be too low with the indoor fan running at low speed, the auxiliary electric heating will

be put into operation.

Stop condition of auxiliary electric heating: when the compressor stops or the pipe temperature is too high or

the environmental temperature is too high, the auxiliary electric heating stops operation. The auxiliary electric

heating will stop when there is failure in the communications. Once it stops, it will require 2min to recover the

operation.

7.1.2.4 Dry mode

For air delivery mode, the indoor fan will run at the setting wind speed and the swing motor will run at the

setting mode and the running indicator will be lit.

7.1.2.5 Auto mode

In this mode, the system will automatically select its running mode based on the change of the ambient

temperature (cooling, dry , heating and air supply). The protection function is same as HEAT/COOL mode.

7.1.2.6 Failure indication of general protection functions at various modes

1 Overload protection

When evaporator pipe temperature is detected high, if it is still higher after the compressor runs in a limited

frequency, the compressor will stop running. In auto HEAT or HEAT mode, the indoor fan will blow for 60

seconds and then stop, In other modes, the indoor fan will run at the setting speed and display H4.

¾ Evaporator pipe temperature is the temperature of outdoor heat exchanger when cooling or temperature of

indoor heat exchanger when heating.

2 Compressor delay protection

The compressor will delay 3min to start again after stopping.

3 Compressor discharge temperature protection

When discharge temperature is too high, the compressor will stop and it will resume running after 3 minutes

and display E4.

4 Communications malfunction

Communications malfunction means that no correct signal can be received continuously within 3 minutes. In

this case, the outdoor unit stops operation. The residual heat blowing will be stopped at auto heating or heating

mode. As to other modes, the indoor fan will run at the setting wind speed.

5 Module protection

The compressor will stop at module protection and the compressor will resume back to operation when it has

stopped for 3min.

6 Status of indicator at receiver board of indoor unit

The receiver board indicator at running is at normal status and when the indicator signal received three times

continuously within 6 seconds are not the same as the previous one will be recognized as pressing one time

the indicator button. In this case, the indicator of receiver board will enter into detection mode and will

automatically exit from the detection mode in 3 minutes.

7.1.3 Other controls

7.1.3.1 Power ON/OFF

Each time the On/Off button of the remote controller is pressed, the On/Off mode will be changed over once.

7.1.3.2 Mode selection

Press the MODE button on the remote controller to select and display the following modes: AUTO, COOL, DRY,

FAN, and HEAT.

7.1.3.3 T emperature setting selection button

Each time TEMP or TEMP button is pressed, the setting temperature will be increased or decreased by 1℃,

with the adjusting range being 16~30 . In AUTO mode, this button does not function.℃

7.1.3.4 Time setting button

Time setting button of remote controller: the time selection range is 0-24h, with the minimum unit being 0.5h.

Page 32

—31—

7.1.3.5 Auto button

The system will be stopped if the button is pressed down when the remote controller is powered on, with

the system being operated by remote controller. If the remote controller is powered off, pressing the button

will enter auto run mode and the swing will be turned on. The system will be running in accordance with

the remote controller if there is remote control command.

7.1.3.6 Sleep function

If the sleep function is set up at cooling or drying mode, T

set

will be raised automatically for 1℃ after one

hour, and will be raised for another 1℃ 2 hours later. Then, it will be running at such a setting temperature

and such a setting wind speed.

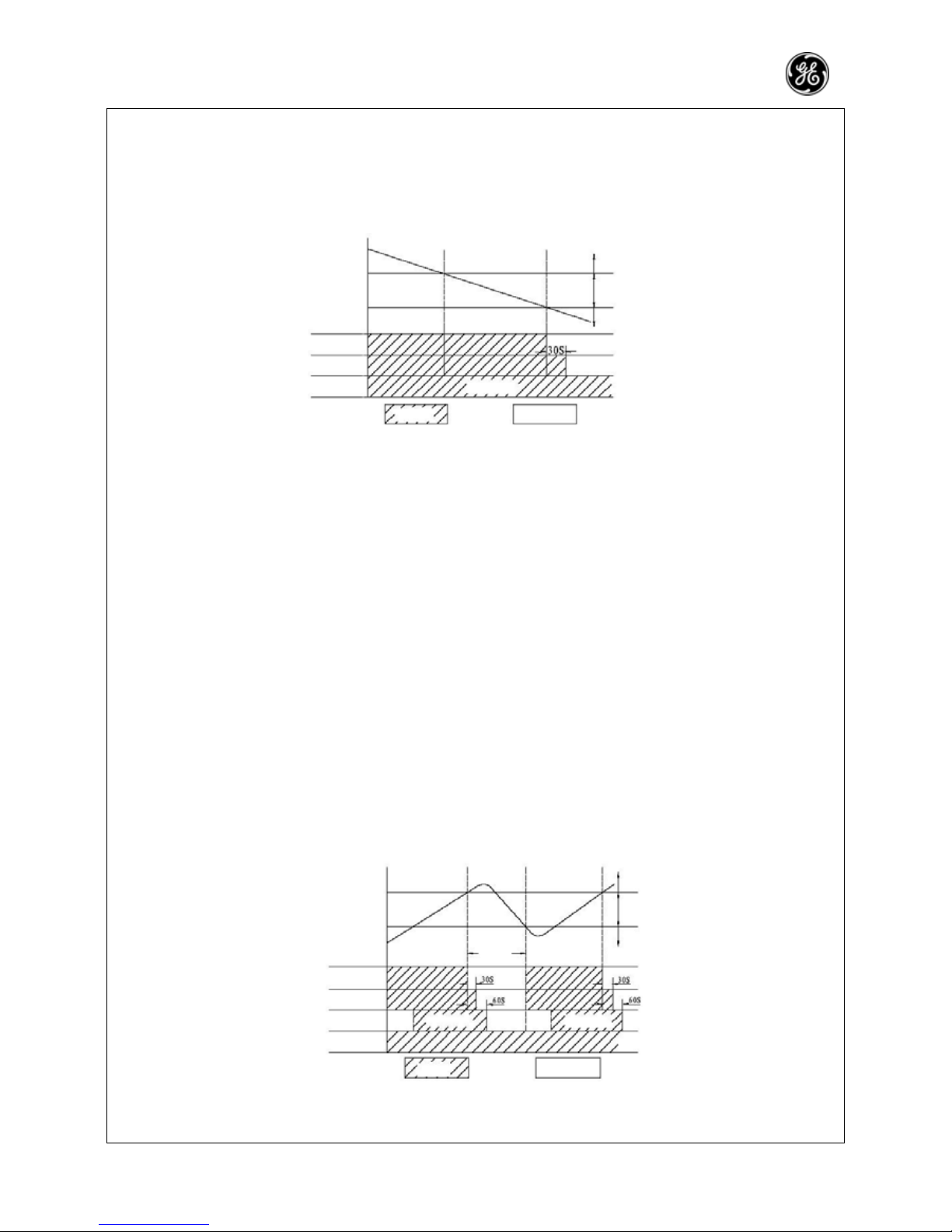

set

Temperature setting T

set

set

set

1 hour 2 hour Over 2 hour

If the sleep function is set up at heating mode, T

set

will be decreased for 1℃ after one hour, and will be

decreased for 2℃ 2 hours later. Then, it will be running at such a setting temperature and such a setting

wind speed.

1 hour 2 hour Over 2 hour

set

set

Temperature setting T

set

set

In FAN and AUTO mode, the set temperature is fixed.

7.1.3.7 Swing motor control

Use the SWING button of the wireless remote controller to controller SWING On/Off. Swing will only act

when indoor fan is running.

After power on, the stepping motor turns back to 0 position and closes the air outlet vent; after the unit is

turned on, it will turn back to the max. air outlet I position; when in swinging state, it will swing between L

and D position. When the unit is turned off, it will turn back to 0 position.

7.1.3.8 Measurement of maximum cooling capacity, name heating/cooling

Select cooling mode power on with remote controller and press “Light” button to turn on the light. In this

case, a sound from buzzer should be heard. Press “Change air” button to set up for air change 1 (air

change 2), a sound from buzzer should be heard, entering the maximum cooling mode (name cooling).

Afterwards, it is not allowed to press any other button of remote controller. Otherwise, the system will exit

from the maximum cooling mode (name cooling). Select heating mode power on with remote controller

and press “Light” button to turn on the light. In this case, a sound from buzzer should be heard. Press

“Change air” button to set up for air change 1 (air change 2), a sound from buzzer should be heard,

entering the maximum heating mode (name heating). Afterwards, it is not allowed to press any other

button of remote controller. Otherwise, the system will exit from the maximum heating mode (name

heating).

In case the maximum cooling, name cooling and name heating have been properly set up, cancel the

maximum cooling, name cooling and name heating 2 hours later.

Page 33

—32—

7.1.3.9 Power supply of outdoor unit

The power supply for outdoor unit is turned on in AUTO, COOL, HEAT and DRY mode under turn-on state.

The power supply for outdoor unit will delay 3 minutes to turn off under turn-off state or in the FAN mode

under turn-on state.

7.1.3.10 Buzzer

The buzzer will deliver a sound when the remote controller is powered on or an effective remote control

signal is received or when there is button input signal.

7.1.3.11Control of electric heater belt

The two electric heater belts will stop operation when there is failure in environmental temperature sensor of

outdoor unit, otherwise, the control will be carried out in accordance with the following logic:

① If the outdoor environmental temperature is very low and the compressor is not turned on, the electric

heater belt of compressor will operate: otherwise, if the compressor is turned on or the compressor is

not turned on but the outdoor environmental temperature is very high, the electric heater belt will not

operate. If the compressor it not turned on and is in between lower and higher, the electric heater belt of

compressor will keep on the original state.

② If the outdoor environmental temperature is low but higher than mentioned in the above paragraph, the

electric heater belt of compressor will operate: otherwise, if the electric heater belt of compressor does

not operate when the outdoor environmental temperature is very high. If it is between the two

temperatures, the electric heater belt of compressor will keep on the original state.

7.1.3.12 Indoor fan control

The indoor fan may be set up with remote controller to HIGH, MED and LOW, in this case, the fan will run

respectively at high, medium and low speed.

The auto wind speed of indoor fan:

① For cool/heat mode: if the frequency is low, the indoor fan runs at low wind speed;if the frequency is high,

the indoor fan runs at high wind speed.

② For air delivery mode: the auto wind speed is forcedly set up to low wind speed.

7.1.3.13 Power-off memory function

Mode, swing, temperature setting, wind speed setting and timing (in case the power is off when the timer is

due and the power is turned on again, the timer will re-start counting. If the power is turned on again, the

system will operate at the mode after the timer is due).

Page 34

—33—

Suitable to systems except for PRO AIR I109 IN / PRO AIR I109 OUT PRO AIR I112 IN / PRO AIR I112

OUT frequency converter

Function manual of remote controller

7.2.1 Temperature parameter

Room set temperature: (T

set

)

Room ambient temperature (T

amb

)

7.2.2 Basic function of the system

No matter what mode the compressor is in, the minimum time interval between two startups should be 3

minutes after it is powered on.

7.2.2.1 COOL mode

7.2.2.1.1 Running condition and process of cooling

If T

amb≥Tset

+1℃, COOL mode will act, compressor and outdoor fan will run, the indoor fan will run at the

set speed;

If T

amb≤Tset

-1℃, the system enters stop mode. In this case, the compressor will stop first, and the

indoor/outdoor fans will stop after a delay of 15s.

If T

set

-1℃<T

amb<Tset

+1℃, the unit will keep running in the previous mode.

¾ In this mode, the reversal valve will not be powered on and the temperature setting range is 16℃~30

℃

T

amb

T

set

+1℃

T

set

+2℃

≥3 min

Compressor

Outdoor fan

Indoor fan Set fan spee

d Set fan speed

Start cooling

Original running state

Stop cooling

Run Stop

7.2.2.1.2 Protection function

Anti-freezing Protection

When system anti-freezing protection is detected, the compressor and outdoor fan stop running, and the

indoor fan runs at the preset speed. When anti-freezing protection is eliminated and compressor has

stopped for 3min, the machine restores its former operation mode.

Anti-freezing Protection

Compressor ≥3min

Outdoor fan

Indoor fan Set fan speed

Run Stop

Over current protection

When the system current is detected to be higher than the specified value for 3 consecutive seconds, the

system will enter the operation mode of fan only. After 3 minutes, the system resumes back to the original

running mode. If the over current protection is detected for three times consecutively in 30 minutes, the

system will stop running and it is required to turn on the system with remote controller.

7.2.2.2 Dry mode

7.1.2.2.1 The condition and process of dry mode

If T

amb>Tset

+2℃, the cooling mode will act. The compressor and external fan will run, and the indoor fan

will run at an adjustable speed.

7.2

Page 35

—34—

If T

set

-2℃≤T

anp≤Tset

+2℃, the drying mode will act. In this case, the indoor fan will run at low speed. The

compressor and the outdoor fan will stop 6min later. The indoor fan will stop 30s later. The compressor and

the outdoor fan will run 3.5 min later and the indoor fan will run at low speed. The drying process then will

run periodically as given above.

If T

amb<Tset

-2 , ℃ the system enters stop mode. In this case, the compressor will stop first, and the outdoor

fan will stop after a delay of 15s, and then, the indoor fan will stop after another delay of 15s.

¾ In this mode, the reversal valve will not be powered on and the temperature setting range is

16 ~30℃℃

T

amb

T

set

+2℃

T

set

-2℃

6 min 6 min

4 min 4 min

Cooling running

Dry running

Stop running

Compressor

Outdoor fan

Indoor fan

Set fan speed Low speed Low speed

Run Stop

7.2.2.2.2 Protection function

Anti-freezing Protection

If system anti-freezing protection is detected, the compressor will stop, but the outdoor fan will stop after a

delay of 15s. The indoor fan will run at low speed. If the anti-freezing protection is released and the

compressor has stopped for 3 min, the system will resume to original operation mode.

Anti-freezing Protection

Compressor

Outdoor fan

Indoor fan Low fan speed

Run Stop

7.2.2.3 heating mode

7.2.2.3.1 The condition and process of heating

If T

amb≤Tset

+2 , HEAT mode will act℃ . In this case, the compressor, outdoor fan and reversal valve will run at

the same time, the indoor fan will run in accordance with anti-cool condition.

If T

amb ≥Tset

+4 , the compressor ℃ will firstly stop, and the outdoor fan will stop running 15s later. But the

reversal valve is still with power on. The indoor fan will stop after running at low fan speed for 30s.

If T

set

+2℃<T

amb<Tset

+4 ,the unit will keep running in the previous mode.℃

In this mode, the reversal valve will be powered on and the temperature setting range is 16 ~30℃℃.

T

set

+4℃

T

set

+2℃ T

amb

≥6 min ≥3 min ≥6 min

Compressor

Outdoor fan

Indoor fan

≤2 min ≤2 min

Reversal valve

Stop heating

Original running mode

Start heating

Run Stop

7.2.2.3.2 The condition and process of defrosting

When frost is detected in the condenser, the system will enter into defrosting state. At this time the compressor

continues to run and the outdoor fan, four-way valve and indoor fan will stop running. The run indicator blinks.

When it's detected that defrosting in the condenser is completed, the outdoor fan and four-way valve will run

simultaneously.

≥3 min

Page 36

—35—

The indoor fan will run after a delay of 3min and the compressor keeps on the running mode. In this case,

the run indicator stops blinking.

¾ The defrosting time is 10 min for the first time power on and the defrosting time afterwards depends

on the practical frost condition, the more the frost, the longer the defrosting time (Max. 12min, min.

3min). Exit from the defrosting mode if the frost removal is ended.

Defrosting time

Compressor

Outdoor fan 3min~12min

Indoor fan ≤3 min

4-way valve

Run Stop

7.2.2.3.3 Protection function

Anti-high temperature protection

If the evaporator is detected with a high pipe temperature, the outer fan stops running and if the evaporator

recovers to a normal pipe temperature, the outer fan resumes running.

Noise immunization protection

When "RUN/STOP" is used to turn off the unit, the reversal valve will delay 2 minutes to stop.

Over current protection

When the system current is detected to be higher than the specified value for 3 consecutive seconds, the

compressor and outdoor fan will stop and the indoor fan will stop. 3 minutes later, the system will resume

back to the original running mode. The indoor fan will run in accordance with anti-cool air condition: If the

over current protection is detected for three times consecutively in 30 minutes, the system will stop running

and it is required to turn on the system with remote controller

Anti-cold air

To prevent cool air from discharging when heating is started, the indoor fan may lag behind the

compressor for operation, with the latest of 2 minutes and will change over automatically the wind speed in

accordance with the temperature variation.

7.2.2.4 SWING mode

Running light

7.2.2.5 Auto mode

In this mode, the system will automatically select its running mode based on the change of the ambient

temperature (cooling, dry, heating and air supply). The protection function as HEAT/COOL mode

7.2.3 Other controls

7.2.3.1 Sleep function

If the sleep function is set up at cooling or drying mode, T

set

will be raised automatically for 1℃ after one

hour, and will be raised another 1℃ 2 hours later.

set

Temperature setting T

set

set

set

1 hour 2 hour Over 2 hour

If the sleep function is set up at heating mode, T

set

will be decreased automatically by 1℃ after one hour, and

will be decreased by 2℃ 2 hours later.

1 hour 2 hour Over 2 hour

set

set

Temperature setting T

set

set

Page 37

—36—

7.2.3.2 Swing motor control

7.2.3.3 Timer function

7.2.3.3.1 Timer ON

When TIMER ON is set, the system will be set under TIMER ON mode. When it's time to turn on, the

controller will run in the set mode. Time interval is 0 hour and the setting range is from 0.5 to 24 hours.

7.2.3.3.2 Timer off

TIMER OFF can be set under running state. When it's time to turn off, the system will be turned off. Time

interval is 0.5 hour and the setting range is from 0.5 to 24 hours.

7.2.3.3.3 Toggle switch (opening panel of indoor unit)

a. Run in auto mode, and will run according to the signal from remote controller, if any.

b. For test position, the main system will run at cooling mode. The indoor fan will run at high speed and

the swing will run at SWING: if there is a remote control command, the main system will run according

to the remote controller. If there is open or short circuit in the temperature sensor, the buzzer will deliver

an alarm at a frequency of 2Hz.

c. In case the toggle switch is set to running position, the main unit runs in accordance with the received

remote control command

d. The system will stop running at the stop position.

Toggle switch

7.2.3.4 Buzzer

The buzzer will deliver an alarm when the controller is powered on or a signal from remote controller is

received.

If there is open or short circuit in the temperature sensor, and the encoder switch is turned to TEST

postion, the buzzer will deliver an alarm at a frequency of 2HZ.

7.2.3.5 Indicator

Running indicator light (red)

Cooling indicator (green)

Heating indicator (yellow)

7.2.3.7 Auto wind speed control

In this mode, according to ambient temperature, indoor fan will select High, Middle and Low fan speed

automatically.

7.2.3.8 Memory function

If the system is turned on again after it is cut off, the system will start to run at the original operation mode

prior to power cut off.

Page 38

—37—

7.3 Names and functions of each part of the remote controller

Note:

z Be sure that there are no obstructions

Swing button

The guide louver will swing

at a certain angle each time

the swing button is pressed

and will stop operation

when the button is pressed

again.

Swing button

Press the button once,

and the air speed changes

in the order of

AUTO fan speed

Remarks: At mode,

the wind speed of fan is

not adjustable.

TEMP. button

Press once and it rises by

1 degree. Press once and

it drops by 1 degree.

In mode,

room temp. can be adjusted

in the range of 16℃-30 ℃

COOL mode operation

Dry mode

Ventilation mode

HEAT mode operation

MODE button

Press this button in turns to

change the operational

mode in the below order.

Auto

ON/OFF button:

Press this button, the unit

will start to run, when

repressed it, it will stop

running.

Page 39

—38—

7.4 Names and function of wireless remote controller (After cover is opened)

Note: This type of wireless remote control is a kind of new current control. Some buttons of the control

not available to this air conditioner will not be described below.

Liquid crystal display

It shows all the setting contents.

Sleeping mode button

Press the button once to enter sleep

mode, and press it another time, to exit

from the sleep mode.

Note: No sleep function at “auto”

and “air delivery” modes

TIMER OFF button

If the button is pressed

during operation, the auto

stop time may be set up

at the range of 0-24

hours.

Timer cancel

Light button

Press the button once to turn on the light

mode, and press it another time, to turn off

the light mode.

TIMER ON button

If the button is pressed at system off

mode, the auto start time may be set

up with a step of 0.5h each time at the

range of 0-24 hours.

Timer cancel

Page 40

—39—

7.5 Battery installation for the remote controller

z Guide to operational controls

General steps:

1 Plug to power supply and press ON/OFF button to start the unit.

2. Press MODE button to select the suitable operation mode.

3. Press the SWING button to make the swing blades swing at a certain angle. Press the button

once again to stop the swing

4. Press fan button, to set the desired fan speed.

5. Press +/- button to select the needed temperature.

Selectable steps:

6. To set up the sleep mode by pressing the sleep button at the remote controller.

7. Press TIMER button, and then press +/- button to set scheduled time.

Remarks: To select auto mode, the air conditioner will select automatically the suitable

running mode in accordance with the indoor temperature so that a comfortable ambient is

given.

z

Replace the batteries of the remote controller

The wireless remote controller uses two AAA alkali batteries

1. Slide downward the cover of battery compartment of remote controller and remove the used

batteries and replace with two pieces of new batteries (paying attention to the polarities).

2. Close the back cover of the remote controller

Note:

z Don't mix new and used or different

types of two batteries to insert.

z If the remote controller is not to be

used for several weeks, please take

out the battery to prevent the leakage

damaging the remote controller.

z The operation of remote controller

should be in its operation range.

z Remote controller should be more

than one meter's distance to TV or

sound equipment.

Cover of battery compartment

Reset button

Put in 2 Size 7 batteries

Page 41

—40—

Disassembly procedures

8.1 Disassembly procedures for indoor unit

Operation procedures/pictures

Disassembling panel

Push the panel with hand and release the

movable latch on the panel, and then lift it

upward to take out the panel.

As shown in Fig.8-1

Disassembling filter

screen and wire clamp

Top the medium section of filter to shed off

catches at the both sides. Pull forward to

disassemble the filter.

Screw out with a screwdriver one screw that

fixes the wire clamp and remove the wire

clamp.

As shown in Fig.8-2

Disassembling air

guide louver board

Firstly remove the middle section of the

guide louver from the support frame and

then bend slightly the guide louver to remove

the guide louver.

As shown in Fig. 8-3

Latch Panel

Fig.8-1

Filter net

Tension disc

Fig.8-2

Air guide board

Fig.8-3

8

Page 42

—41—

Operation procedures/pictures

Disassembling panel body

Open the three taping screws fixing the panel

body with a screw driver. Pull upward the

panel body and then lift it backward to take out

the panel body.

As shown in Fig.8-4

Disassemble electric box cover

Press down the latches around the cover of

electric box to remove the cover of electric

box as shown in Fig.8-5.

Disassembling water-tray

Pull away the terminals of guide louver motor

and divide the lower right latch of the water

tray with a screw driver. Rotate the water tray

to disengage it from the side latch. Remove

the water tray as shown in Fig.8-5

Screw Panel body Screw Cover

Fig.8-4

Clamp

Fig.8-5

Clamp

Water-tray Connecting

terminal

Fig.8-6

Page 43

—42—

Operation procedures/pictures

Disassembling the electric box

Firstly screw off 2 screws at the indicator board

and disassemble the indicator board. Then, pull

away the terminals of motor. Screw off grounding

screw and 2 screws fixing the electric box with a

screw driver. Open a latch of the electric box to

remove the electric box. as shown in Fig.8-7, 8-8.

Disassembling evaporator assembly

Firstly use a screwdriver to unscrew the screws in

the rear pipe-clamping bar of evaporator. Remove

the rear pipe clamp bar.

Unscrew the 2 screws at the right side of

evaporator.

Unscrew the screw on the left side of the

evaporator, and loosen the clasp. Turn the

evaporator for a certain angle, and remove the

evaporator as shown in Fig.8-8, 8-9, 8-10, 8-11.

Screw

Indicator board

Fig.8-7

Screw

Grounding screws Clamp

Fig.8-8

Rear pipe

clip board

Fig.8-9

Page 44

—43—

Operation procedures/pictures

Disassembling the motor

Firstly use a screwdriver to unscrew the 2

screws in the board choking of motor, pop

up the clasp as shown in the figure, and

remove the board choking of the motor as

shown in Fig.8-12.

Screw

Fig.8-10

Screw Clamp

Fig.8-11

Motor clamp Screw

Fig.8-12

Page 45

—44—

Operation procedures/pictures

And then unscrew the set screw for fixing

the motor, lift it up backward, and remove

the motor as shown in Fig.8-13

Remove cross flow fan

After taking out the motor, take out the ring

of bearing on the left end of the fan to take

off the cross flow fan as shown in Fig.8-14.

Taping screw

Motor

Fig.8-13

Cross flow fan

Rubber seat of bearing

Fig.8-14

Page 46

—45—

8.2 Disassembling procedure of outdoor unit 20

Operation procedures/pictures

Disassembling top cover and handle

Screw off one fixing screw that fixes the handle

with screwdriver to take out the handle. Screw

off 3 screws around the top cover to remove

the top cover as shown in Fig.8-15.

Disassembling the rear grill

Screw off 4 screws around the rear grill with a

screw driver to remove the rear grill as shown

in Fig.8-16.

Remove the front panel

Screw off 6 screws fixing the front panel with a

screw driver to remove front panel as shown in

Fig.8-17.

Top cover Handle

Screw

Fig. 8-15

Rear grill

Fig.8-16

Screw

Fig.8-17

Page 47

—46—

Operation procedures/pictures

Disassembling the electric box

Screw off 3 screws of the electric box with a

screw driver to remove the electric box as

shown in Fig.8-18.

Disassembling the right

sideboard

Screw off 5 screws at the right sideboard with a

screw driver to remove the right sideboard as

shown in Fig.8-19.

Disassembling axial flow fan

Screw off the nut fixing the axial fan with a

spanner to pull outward and remove the axial

fan as shown in Fig.8-20.

Screw

Fig.8-18

Screw

Fig.8-19

Nut

Fig.8-20

Page 48

—47—

Operation procedures/pictures

Disassembling the motor and motor support

With a screw driver, screw off the screw fixing

the motor and motor frame to remove the motor

and motor frame as shown in Fig.8-21.

Disassembling capillary

assembly

Weld off the welding spots between the

capillary assembly and other pipeline

connection and take off the capillary assembly

as shown in Fig. 8-22.

Disassembling valve

With a screw driver, screw off the screw fixing

the valve, and then weld off the connecting pipe

of the valve to remove the valve as shown in

Fig.8-23.

Motor

Motor bracket

Screw

Fig. 8-21

Capillary

assembly

Fig. 8-22

Valve

Fig.8-23

Page 49

—48—

Operation procedures/pictures

Disassembling compressor

Weld off two ends of compressor and screw

off 3 base screws with a spanner to remove

the compressor as shown in Fig.8-24.

Welded point

Base screw

Fig.8-24

Page 50

—49—

8.3 Disassembly procedures for outdoor unit 25, 32

Suitable for PRO AIR 109 IN / PRO AIR 109 OUT, PRO AIR 112 IN / PRO AIR 112 OUT

Operation procedures/pictures

Disassembling the top cover

Screw off the one piece of fixing screw that fixes

the handle with screwdriver and push down with

strength to take out the handle.

Screw off the 3 pieces of screws around the top

cover and then lift it upward to take out the top

cover as shown in Fig.8-25.

Disassembling the net cover

Unscrew 4 tapping screws in the screen

enclosure, and remove the screen enclosure as

shown in Fig.8-26.

Disassembling panel

sub-assembly

Unscrew the 5 tapping screws at the valve

support chassis and sideboard of the condenser

to take off panel assembly as shown in Fig.8-27.

Top cover Screw Screw Handle

Fig.8-25

Screw

Net cover

Fig.8-26

Panel

Screw

Fig.8-27

Page 51

—50—

Operation procedures/pictures

Dismount the electric mounting board

Screw off the 3 screws fixing the electric device

installation board, and pull out the inserting

contacts for leads of compressor and fan motor,

and remove the electric device installation board

as shown in Fig.8-28.

Disassembling right sideboard

Unscrew the 5 screws that fix the right sideboard

to take out the right sideboard as shown in

Fig.8-29.

Disassembling axial flow fan

Loosen the fixing nut with a spanner, remove the

nut, spring washer and flat washer. Remove the

lower axial flow fan with force as shown in

Fig.8-30.

Electric installation board

Screw

Fig.8-28

Screw

Fig.8-29

Fixing nut

Axial flow fan

Fig.8-30

Page 52

—51—

Operation procedures/pictures

Disassembling the motor and motor support

SCREW off 4 tapping screws that fix the motor to

take out the motor. Unscrew 2 tapping screws for

fixing the motor bracket, pull it upward, and take

out the motor bracket as shown in Fig.8-31.

Disassembling four-way valve

Unscrew the fixing nut of the four-way valve coil

and remove the coil. Wrap the four-way valve

with wet sponge and weld off the four welding

spots on the four-way valve to take off the

four-way valve. The welding process should be

performed as quick as possible, ensure that the

wrapped spun cotton should be moistened all

along; ensure that the pin cords etc. of

compressor must not be burnt out by thin flame

as shown in Fig.8-32.

Capillary assembly

Weld off the welding spots between the capillary

assembly and other pipeline connection and take

off the capillary assembly as shown in Fig.8-33.

Motor bracket

Taping screw

Motor

Fig.8-31

Four-way valve

Welded point

Fixing nut

Fig.8-32

Capillary assembly

Fig.8-33

Page 53

—52—

Operation procedures/pictures

Disassemblling big and small valves

Screw off 2bolts that fix the big valve, weld off

the welding point between the big valve and

the air return pipe to take down the big valve.

(Note: when welding off the welding spots,

wrap the big valve with wet cloth completely to

avoid high-temperature from damaging the

valve body.)

Screw off 2 bolts that fix the small valve, weld

off the welding point between the small vale

and the forked type pipe and take down the

small valve as shown in Fig.8-34.

Disassembling compressor

Screw off 3 nuts with wash at the base legs of

compressor (Remarks: it is required to firstly

discharge completely the freon.) Weld off the

welding spots as shown in the sucking and

exhausted pipings of the compressor. Remove

away carefully the pipings and remove the

compressor as shown in Fig.8-35.

Small valve gate

Big valve gate

Bolt

Fig.8-34

Compressor bolt

Fig.8-35

Page 54

—53—

8.4 Disassembling procedures for outdoor unit

Suitable for PRO AIR I109 IN / PRO AIR I109 OUT, PRO AIR I112 IN / PRO AIR I112 OUT

Operation procedures/pictures

Disassemble the top cover

Screw off the one piece of fixing screw that fixes

the handle with screwdriver and push down with

strength to take out the handle.

Screw off the 3 pieces of screws around the top

cover and then lift it upward to take out the top

cover as shown in Fig.8-36.

Disassembling net cover

Screw off 4 taping screws at the rear sideboard

and valve support chassis and condensor

sideboard to remove the net cover as shown in

Fig.8-37.

Disassembling panel assembly

Screw off the 5 pieces of tapping screws at the

valve support chassis and sideboard of the

condenser to take off panel assembly as shown

in Fig.8-38.

Top cover Screw Screw Handle

Fig.8-36

Rear grill

Screw

Fig.8-37

Panel

Screw

Fig.8-38

Page 55

—54—

Operation procedures/pictures

Disassembling right sideboard

Unscrew the 7 screws that fix the right

sideboard to take out the right sideboard as

shown in Fig.8-39.

Disassembling reactor box

and electric box assembly

Screw off the 2 screws that fix the electric box

cover to remove the cover of electric box.

Screw off 2 screws fixing the reactor box

assembly and remove the frame for

temperature sensor to remove the reactor box.

Screw off 4 screws fixing the reactor to remove

the reactor box.

Screw off 2 screws fixing the electric box and

unloose each wire bundle and unplug the

connection wire to take off the electric box as

shown in Fig.8-40, 8-41, 8-42.

Screw

Fig. 8-39

Screw Electric box cover

Fig.8-40

Sensor support

Reactor box

Reactor

Screw

Fig.8-41

Page 56

—55—

Operation procedures/pictures

Screw Electric box

Fig. 8-42.

Disassembling axial flow fan

Unloose the fixing nut that fixes the axial flow

fan with spanner and take out the nut, spring

gasket and flap gasket in sequence as shown

in Fig. 8-43.

Nut

Fig. 8-43.

Disassembling the motor and motor support

Screw off the 4 pieces of tapping screws that

fix the motor, and take out the motor. Screw off

the 2 screws that fix the motor frame, and take

out the motor frame as shown in Fig. 8-44.

Motor

Screw

Fig. 8-44

Axial flow fan

Screw

Page 57

—56—

Operation procedures/pictures

Disassembling four-way valve

Screw off the fixing nut of the four-way valve

coil and remove the coil. Wrap the four-way

valve with wet sponge and weld off the four

weld joints on the four-way valve to take off

the four-way valve (Remarks: it is required to

discharge completely the freon inside).

Welding process should be as quickly as

possible and the wetness of the wrapping

sponge should be maintained all the time. Be

sure not to burn out the lead wire of the

compressor as shown in Fig.8-45. Fig. 8-45.

Disassembling Capillary

Weld off each weld joint of the main capillary

and auxiliary capillary to take off the capillary

as shown in Fig.8-46.

Fig. 8-46.

Disassembling big valve and small valve

Screw off 2 bolts that fix the big valve, weld off

the welding point between the big valve and

the air return pipe to take down the big valve.

Note: when welding off the welding spots,

wrap the big valve with wet cloth completely to

avoid high-temperature damage to the valve

body. Screw off 2 bolts that fix the small valve,

and weld off the welding point between the

small vale and the forked type pipe and take

down the small valve as shown in Fig. 8-47.

Fig. 8-47.

Four-way

valve

Four-way

valve coil

welded

p

oint

Capillar

y

Small valve gate

Big valve gate

Bolt

Page 58

—57—

Operation procedures/pictures

Disassembling compressor

Unloose the 3 pieces of bottom nuts of the

compressor, weld off the suction and

discharge pipe and remove the pipeline

carefully to take out the compressor as shown

in Fig. 8-48.

Bottom nut

Fig. 8-48

Compressor

Page 59

—58—

Disassembly procedures for outdoor unit (one driving two)

Operation procedures/pictures

Disassembling the front sideboard

Screw off 4 fixing screws fastening the front

sideboard to disassemble the front sideboard

as shown in Fig. 8-49.

Screw Front

sideboard

Fig. 8-49

Disassemble the top cover board

Screw off the screws that fix around the top

cover to take off the top cover as shown in Fig.

8-50.

Fig. 8-50.

Disassembling the rear grill

Screw off 4 taping screws fastening the rear

sideboard to disassemble the rear grill as

shown in Fig. 8-51.

Screw Rear grill

Fig. 8-51

Top cover board

Screw

Page 60

—59—

Operation procedures/pictures

Disassembling the cabinet assembly

Screw off the 8 tapping screws on the cabinet,

chassis and condenser sideboard to take off

the cabinet assembly as shown in Fig. 8-52.

Screw

outer cover

Fig. 8-52.

Disassembling the electric box

Screw off the 2 screws that fix the electric

installation board and unplug the lead wire

insert of compressor, fan motor and four-way

valve (not for cooling only) to take off the

electric box as shown in Fig. 8-53.

Fig. 8-53

Disassembling rear sideboard

Screw off the screws on the rear sideboard,

valve support and chassis assembly and lift it

upward to take off the rear sideboard as

shown in Fig. 8-54.

Electric box

Fig. 8-54

Screw

Electric box

Rear sideboard

Page 61

—60—

Operation procedures/pictures

Disassembling axial flow fan

Screw off the fixing nut of axial flow fan with a

spanner to pull outward the axial flow fan as

shown in Fig. 8-55.

fixing nut

Fig. 8-55

Disassembling the motor and motor support

Screw off the motor fixing bolt on the motor

bracket pull out the motor backwards. Then

screw off the tapping screws that fix the motor

support, lift it upward and take out the motor

support as shown in Fig. 8-56.

Motor bracket

Fixing bolt of motor bracket

Fig. 8-56

Disassembling Four-way valve

Screw off the fixing nut of the coils of four-way

valves (2 pieces) and remove the coil. Wrap

the four-way valve with wet sponge and weld

off the weld joints on the four-way valve to

take off the four-way valve. The welding

process should be performed as quick as

possible, ensure that the wrapped spun cotton

should be moistened all along; ensure that the

pin cords etc. of compressor must not be burnt

out by thin flame. (Note: it is required to

completely discharge freon firstly.)as shown in

Fig. 8-57.

Fig .8-57

Axial flow fan

Motor fixing bolt

Four-way valve

Welded point

Page 62

—61—

Operation procedures/pictures

Disassembling Capillary

Wrap the capillary with wet sponge and weld

off its weld joints with other pipeline. The

welding process should be performed as

quickly as possible, ensure that the wrapped

spun cotton should be moistened all along;

ensure that the leading of compressor must

not be burnt out by flame. (Note: it is required

to completely discharge freon prior to welding

the capillary.)as shown in Fig. 8-58.

Fig. 8-58

Disassembling valve

Screw off 2 bolts that fix the big valve, weld off

the welding point between the big valve and

the air return pipe to take down the big valve.

Screw off the 2 pieces of bolts that fix the

small valve and weld off the welding spots

connecting the small valve and the connecting

pipe to take off the small valve. (Note: when

welding off the welding spots, wrap the big

valve with wet cloth completely to avoid

high-temperature damage to the valve

body)as shown in Fig. 8-59. Fig. 8-59

Disassembling compressor

Screw off the 3 washer nuts at the (2) base

legs of the compressor. Weld off all the

welding points of sucking/discharging pipes for

the compressor, and remove carefully the

piping. Remove the compressor as shown in

Fig. 8-60.

Compressor bolt

Fig. 8-60

Capillary

Small valve Big valve Bolt Bolt

Compressor

Page 63

—62—

Disassembling procedures for outdoor unit (one driving two)

Operation procedures/pictures

Disassembling the front sideboard

Screw off the 4 pieces of fixing screws of the

front sideboard and pull the handle upward to

take off the front sideboard as shown in Fig.

8-61.

Screw Front sideboard

Fig. 8-61

Disassemble the top cover board

Screw off the screws that fix around the top

cover to take off the top cover as shown in Fig.

8-62.

Screw

Top cover

Fig. 8-62

Disassembling the rear grill

Screw off the 4 pieces of tapping screws on

the rear sideboard and cabinet to take off the

rear grill.

Fig. 8-63

Rear grill Screw

Fig. 8-63

Page 64

—63—

Operation procedures/pictures

Screw

Disassembling the cabinet assembly

Screw off the 8 tapping screws on the cabinet,

chassis and condenser sideboard to take off

the cabinet assembly as shown in Fig. 8-64.

Cabinet assembly

Fig. 8-64

Disassembling the electric box

Screw off the screws fixing the electric device

installation board, and pull out the inserting

contacts for leads of compressor and fan

motor, and remove the electric device

installation board as shown in Fig. 8-65.

Screw

Fig. 8-65

Disassembling rear sideboard

Screw off the screws (14 pieces) that fix the

rear sideboard, valve support and chassis

assembly and lift it upward to take off the rear

sideboard as shown in Fig. 8-66, 8-67.

Screw

Fig. 8-66 Fig.8-67

Rear

sideboard

Frame for

electromagnetic valve

Page 65

—64—

Operation procedures/pictures

Disassembling axial flow fan

Screw off the tapping screws on the cabinet,

chassis and condenser sideboard to take off

the cabinet assembly as shown in Fig. 8-68.

Lock washer of external gear

Fig. 8-68

Disassembling the motor and motor support

Screw off the motor fixing bolt on the motor

bracket, pull out the motor backwards. Then

screw off the tapping screws that fix the motor

support, lift it upward and take out the motor

support as shown in Fig. 8-69.

Motor bracket

Fixing bolt of motor bracket

Fig. 8-69

Disassembling valve

Screw off 2 bolts that fix the big valve, weld off

the welding point between the big valve and

the air return pipe to take down the big valve.

Note: when welding off welding spots, wrap

the big valve with wet cloth completely to

avoid high-temperature damage to the valve

body. Screw off 2 bolts that fix the small valve,

and weld off the welding point between the

small vale and the forked type pipe and take

down the small valve as shown in Fig. 8-70.

Fig. 8-70

Axial flow fan

Fixing nut

Motor fixing bolt

(6 pieces)

Bolt

Valve bracket

Big valve gate

Small valve gate

Page 66

—65—

Operation procedures/pictures

Disassembling the compressor

Release the 3 washer nuts at the legs of

compressors (2 sets)(Remarks: it is required

to completely discharge freon). Weld off the

welding spots on suction /exhaust piping of

compressor, take away pipeline with care, and

take out the compressor as shown in Fig.

8-71.

Fig. 8-71

Air discharge

pipe

Compressor

(2 pieces)

compressor bolts (3 pcs)

Compressor bolt

Liquid

distributing pipe

Electromagnetic

valve

Page 67

—66—

Disassembling procedures for outdoor unit (one driving four)

Operation procedures/pictures

Disassembling the front sideboard

Screw off the 4 pieces of fixing screws of the

front sideboard and pull the handle upward to

take off the front sideboard as shown in Fig.

8-72.

Screw Front sideboard

Fig. 8-72

Disassemble the top cover board

Screw off the screws that fix around the top

cover to take off the top cover as shown in Fig.

8-73.

Screw

top cover

Disassembling the rear grill

Screw off the 4 pieces of tapping screws on

the rear sideboard and cabinet to take off the

rear grill as shown in Fig. 8-74.

Rear grill Screw

Fig. 8-74

Page 68

—67—

Operation procedures/pictures

Disassembling the cabinet assembly

Screw off the 8 tapping screws on the cabinet,

chassis and condenser sideboard to take off

the cabinet assembly as shown in Fig. 8-75.

Cabinet assembly

Fig. 8-75

Disassembling the electric box

Screw off the screws fixing the electric device

installation board, and pull out the inserting

contacts for leads of compressor and fan

motor, and remove the electric device

installation board as shown in Fig. 8-76.

Screw

Fig. 8-76

Disassembling rear sideboard

Screw off the screws (14 pieces) that fix the

rear sideboard, valve support and chassis

assembly and lift it upward to take off the rear

sideboard as shown in Fig. 8-77, 8-78.

Screw

Fig. 8-20 Fig. 8-21

Rear

sideboard

Frame for

electromagnetic valve

Page 69

—68—

Operation procedures/pictures

Disassembling axial flow fan

Screw off the tapping screws on the cabinet,

chassis and condenser sideboard to take off

the cabinet assembly as shown in Fig. 8-79.

Lock washer of external gear

Fig. 8-79

Disassembling the motor and motor support

Screw off the motor fixing bolt on the motor

bracket, pull out the motor backwards. Then

screw off the tapping screws that fix the motor

support, lift it upward and take out the motor

support as shown in Fig. 8-80.

Fixing bolt of motor bracket

Fig. 8-80

Disassembling valve

Screw off 2 bolts that fix the big valve, weld off

the welding point between the big valve and

the air return pipe to take down the big valve.

Note: when welding off welding spots, wrap

the big valve with wet cloth completely to

avoid high-temperature damage to the valve

body. Screw off 2 bolts that fix the small valve,

and weld off the welding point between the

small vale and the forked type pipe and take

down the small valve as shown in Fig. 8-81.

Fig. 8-81

Axial flow fan

Fixing nut

Motor fixing bolt

Motor bracket

Small valve gate

Bolt

Big valve gate

Valve bracket

Page 70

—69—

Operation procedures/pictures

Disassembling the compressor

Release the 3 washer nuts at the legs of

compressors (2 sets)(Remarks: it is required

to completely discharge freon). Weld off the

welding spots on suction /exhaust piping of

compressor, take away pipeline with care, and

take out the compressor as shown in Fig.

8-82.

Fig. 8-82

Air

discharge

pipe

Compressor

(2 pieces)

Compressor

bolt (3 pcs)

Liquid

distributing pipe

Electromagneti

c valve

Page 71

—70—

Explosive view and parts list

Explosive view of parts and components of indoor unit

9

Page 72

—71—

9.2 Explosive view of parts of outdoor unit

Code No. of parts Qty.

No. Name of parts

PRO AIR 107 IN PRO AIR 109 IN PRO AIR 112 IN

1 Hanging board 01252220 01252220 01252220 1

2 Bottom case 22202447 22202447 22202447 1

3 Water chute, evaporator 06122001 06122001 06122001 1

4 Pressure board of connecting pipe 24242001 24242001 24242001 1

5 Cross flow fan 10352001 10352001 10352001 1

6 Fan bearing 76512210 76512210 76512210 1

7

Rubber ring of cross flow fan

76512203 76512203 76512203 1

8 Water-tray 20182006 20182006 20182006 1

9 Swing blade 10512002 10512002 10512002 12

10 Connecting lever 1 10582002 10582002 10582002 1

11 Connecting lever 2 10582003 10582003 10582003 1

12 Drainage pipe 05232411 05232411 05232411 1

13 Separating lever 10582001 10582001 10582001 2

14 Water leading plate of evapurator / / / 1

15 Evaporator parts 010020935 010020935 010020936 1

16 Angular bracket, evaporator 24212016 24212016 24212016 1

17 Panel body 20002345 20002345 20002345 1

18 Screw Cover 242520012 242520012 242520012 3

19 Panel 20002346 20002346 20002346 1

20 Filter net (left) 11122041 11122041 11122041 1

21 Support for purifier 24222001 24222001 24222001 2

22 Air cleaner A 11012002 11012002 11012002 1

23 air guide board 10512070 10512070 10512070 1

24 Guide board axle sleeve 10542011 10542011 10542011 3

25 Remote controller Y512 30512506 30512506 30512506 1

26 Filter screen B, cleaning cartridge 11012003 11012003 11012003 1

27 Filter net (right) 11122040 11122040 11122040 1

28 Housing of indicator board 22262008 22262008 22262006 1

29

Indoor pipe temperature sensor

390000595 390000595 390000595 1

30 Sensor insert B 42020063 42020063 42020063 1

31 Stepping motor MP24GA 15212102 15212102 15212102 1