Page 1

OWNERS MANUAL

faucet and

base

%“

&

GENERAL ELECTRIC

UNDERCOUNTER

REVERSE OSMOSIS

SYSTEM

● GE/12 ●

Safety Guides

Maintenance

model

..

Installation

Repair Parts

Operation

GENERAL ELECTRIC Appliance Park

●

71XXXXX (–/96)

Page 2

TABLE OF CONTENTS

PG. NO.

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Whatthe Drinking Water System willdo .. . . . . . . 4

Components ofthe system . . . . . . . . . . . . . . . . . . . 4

Checks to make before installing . . . . . . . . . . . . . .

Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

4-5

SAFETY

ORead all steps, guides and rules carefully before in-

staliing and using the Drinking Water System. Follow

all steps exactly to correctly install.

Q BE SURE TO FOLLOW APPLICABLE STATE AND

LOCAL PLUMBING ANDSANITARYCODES WHEN

INSTALLING TI-IE DRINKING WATER SYSTEM. A

qualified installer is recommended.

@The Drinking Water System workson water pressures

of40 psi (minimum) to 125 psi (maximum). Seethe

table below. If house water pressure is over the maximum, install a pressure reducing valve in the water

supply to the Drinking Water System.

PG. NO.

Sanitizing, and pressure testing . . . . . . . . . . . . . . . 10

How the Drinking Water System works . . . . . . . . . 11

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...12-14

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Repair Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. I&17

GUIDES

+Do not install the Drinking Water System outside, or in

extreme hot or cold temperatures. Temperature of the

water supply to the Dtinking Water System must be

between 40”F (minimum) and 80 or 10O”F (maximum).

See the table below. DO NOT INSTALL ON HOT

WATER.

OReadtheotherlimits (pt+, hardness, etc.) belowand

be sure the water supply conforms.

O Do not use the system on microbioiogically unsafe

water, or water of unknown quality.

SPECIFICATIONS

re~ii U“itiiel :“ : ‘. ‘“--

Feed water temperature limits

Maximum total dissolved solids (TDS) – parts per million (ppm)

Maximum water hardness @ 6.9 pi-i (see chart pg. 3) – grains per gallon (gpg)

Maximum iron, manganese, hyd. sulfide

Chlorine in water supply

Feed water pt-f limits (pH)

Product (quality) water, 24 hrs. –

Waste water per gallon product water, 24 hrs. —

Percent recovery of feed water

Percent rejection of TDS (new membrane) @

Storage tank capacity – gallons

Automatic Shut-off Control

Feed water at 60 psi and 77°F with 750 parts per million sodium chloride. Quality water production, amount of waste water

(D

and percent rejection all vary with changes in pressure, temperature and total dissolved solids. See additional charts on

page 3.

Removed (maximum of 2.0 ppm) by RO Prefilter @ Water supply must be chlorinated... see page 4. Bac-

@

(REGULAR MAINTENANCE REQUIRED). Chlorine

will destroy the RO membrane... see page 4.

J.- ‘~mits– pounds per square inch (psi) ‘- ~ - “ ‘“

...

– minimum, maximum degrees F

gallons @ .

gallons @

teria will destroy the RO membrane.

MODEL

2.

Page 3

SPECIFICATIONS

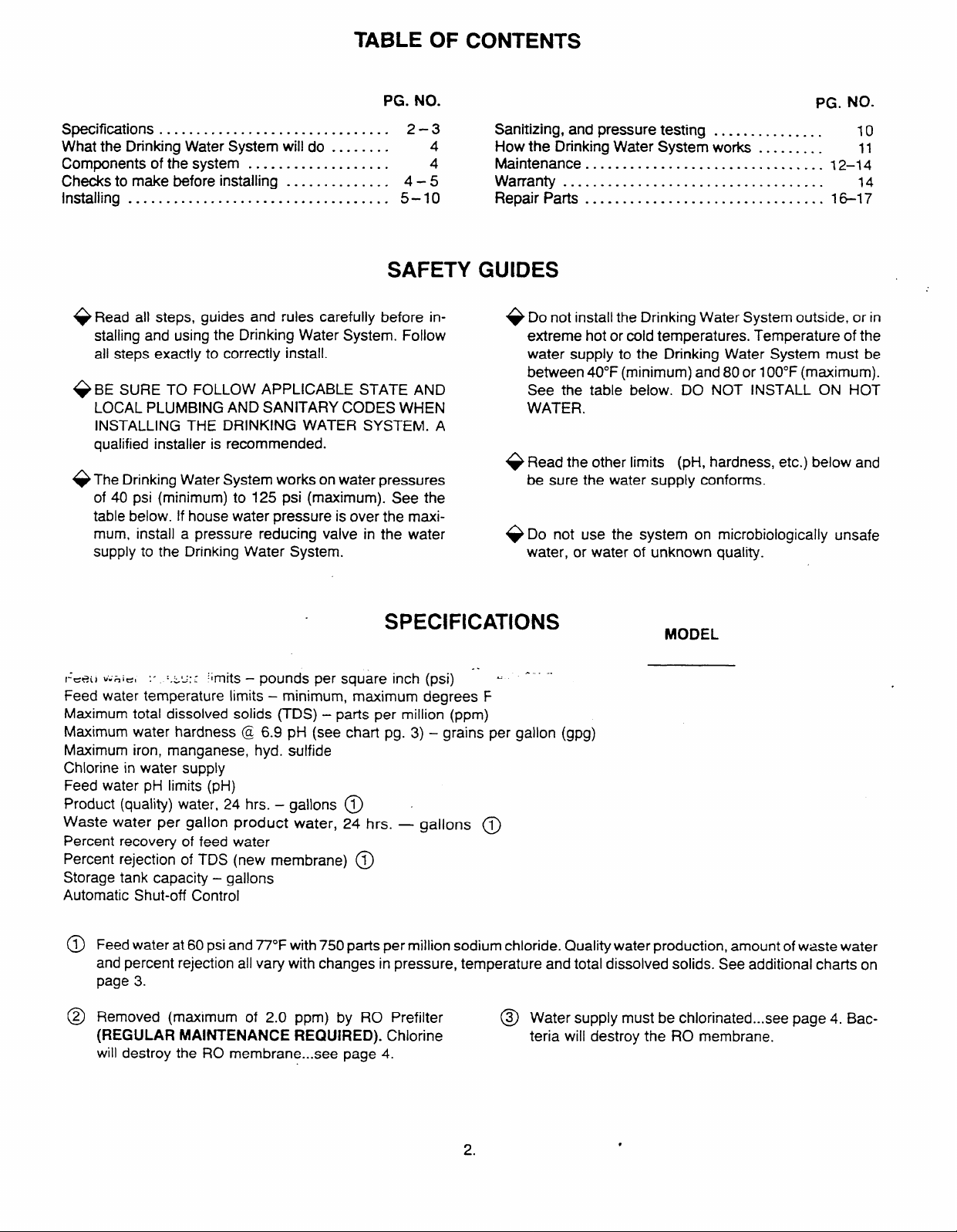

TYPICAL QUALITY WATER PRODUCTION,

24 HOURS (@ 77°F Feed Water Temperature)

12

8

@a‘“

$30

II

,

i

40 50 60 70 80 ~ 1~

FEED WATER PRESSURE (PS;;

I

I

i t

I

,

1

,

I

!

1

:18

I

i

i;

ERO

:20

200

ERO 300

TYPICAL REJECTION PERCENTAGE OF TDS

@ ~“F Feed water Temperature)

4C 5C & 7C 80 w 1~

‘EE2 “WATER ?!lESSURE (PSI)

110 120

u

t

7=-F

I

L

40 50 60 70 ~ ~ 1~

@ NOTE: To correcI gallons per aay for ddferent fed water tempera-

tures. mutuply gpd by the cmrrectton factor.

..”:~, . .

145150 :fil M)j65170175]~ !80

1.38~ 48i.571.67 [.76 !.851.9511.x)ll .)5 ]1.1511.2511 .311.t$3

FEED WATER TEMPERATURE (“F)

CORRECTION FACTOR

I

1

I I

FEED WATER PRESSURE (PSI)

.,

I

I

I

.-.

I

I I I

I

85j~i95i1m

I

!

1

I

110 120

I

I

PRETREATMENT OF THE WATER SUPPLY

NEEDED TO PREVENT SCALING

TO USE THE CHART...

...Locate the intersecting point of feed water hardness

and ~.

If this point falls within the shaded area, pretreatment*

is needed.

*Softening of the water is the suggested pretreatment

40 5C w 70 m w 1~

NOTE

. .

?e:cemages are Sasez an tes*5 using standard sodium Monde

FEECI WATER PRESSURE (PSI)

110 120

8

7.5

I

n

7 ‘

PRET&AT&T ‘. ‘.

.~~~

,SCALHNG .

6.5 ‘

I

6

=

I

I

NO PRETREATMENT

4 ,

I

10

20

1

I

I

30 40

FEED WATER HARDNESS (GPG)

I

I

I

50 60

3.

Page 4

WHAT THE DRINKING

WATER SYSTEM WILL DO

The drinking water system is a REVERSE OSMOSIS (RO)

water treating unit. Reverse osmosis is a way of removing

dissolved solids and organic matter from water by passing

it through a special membrane. The membrane separates

minerals and impurities from the water, and they are

flushed to the drain. Good tasting, high quality product

water goes directly to the drinking faucet. or to the storage

tank. The system makes a good supply of drinking water

each day (see specifications). How much i? will make

depends on the feed water suppiy pressure. temperature,

and quality.

The ERO systems include either a standard faucet. or an

electronic faucet assembly with a built-in water testing

feature. When water is taken from the faucet, a green

indicator light means TDS

limits, and that water quality is good.

Pre and postfilters have replaceable can’ridges. The sedi-

remova! k within the specified

COMPONENTS OF THE SYSTEM

ment prefiher removes sand, silt, difi, etc., from the feed

water before it can enter the RO

prefilter cartridge also has

move chlorine from the feed water.) The postiliter cartridge

removes any other undesirable tastes and odors just be-

fore you use the water.

NOTE: A product data sheet is available for each RO,

listing what the system will remove (or reduce) from the

water.

The drinking water system ftis nicely under the kitchen

or bathroom sink; however, you can install it where most

convenient. You do need a COLD water supply pipe and

drain point within a few feet. (You can buy long lengths

of tubing if needed to reach more distant points...BE

SURE TUBING IS ACCEPTABLE FOR USE ON

POTABLE WATER SUPPLIES.)

carbon in it’s composition to re

system. (The E~O 300

The RO system is shipped in 1 carton, consisting of:

(1) Storage Tank

(2) RO Assembly, with tubing lengths attached

(3) Ski~ack containing a faucet, ‘storage tank shutoff

valve, mounting washers and screws.

(4) Separate length of 1/4” tubing, atid a WY to 1/4” tubifi~ -” Z) are w:~!a~c f:”m”: E~~’?@?er ‘CT u:e :7 a~ee~ +PW

reducing union.

(5) ELECTRONIC MODELS include a separate bag of

electronic parts. These are: electronic box, faucet base,

and battery holder with batteries (4).

INSTALLER PROVIDES: (1) Ftiingsto tap cold water pipe

for feed water source to the RO...must adapt to 1/4” OD

tubing; (2) A drain point for RO discharge water...must

adapt to 3/8” OD tubing. Both items must comply with

state and /or local codes. Optional fittings (pages 5 and

codes permit.

THINGS TO CHECK BEFORE YOU START TO INSTALL

* FEED WATER-The water supply to the drinking water

system must have the qualities listed in the specifications.

If not, it will not make product water as it should andlife of

the RO membrane is shortened. City water most often will

have these qualities. Well water may need conditioning.

Have the water tested by a water analysis laboratory, and

get their recommendations for treatment. Observe plumb

ing codes when providing a water supply to the RO. A seif–

piercing saddle valve is available from EcoWater for tap

ping into a cold water pipe, see pages 5 and 15. Be sure

to check local codes.

CAUTIONS:

ERO 200 MODELS – Feed water must have ch/orine treat-

ment to kJ/ bacteria. Bacteria will destroy the RO membrane cartridge.

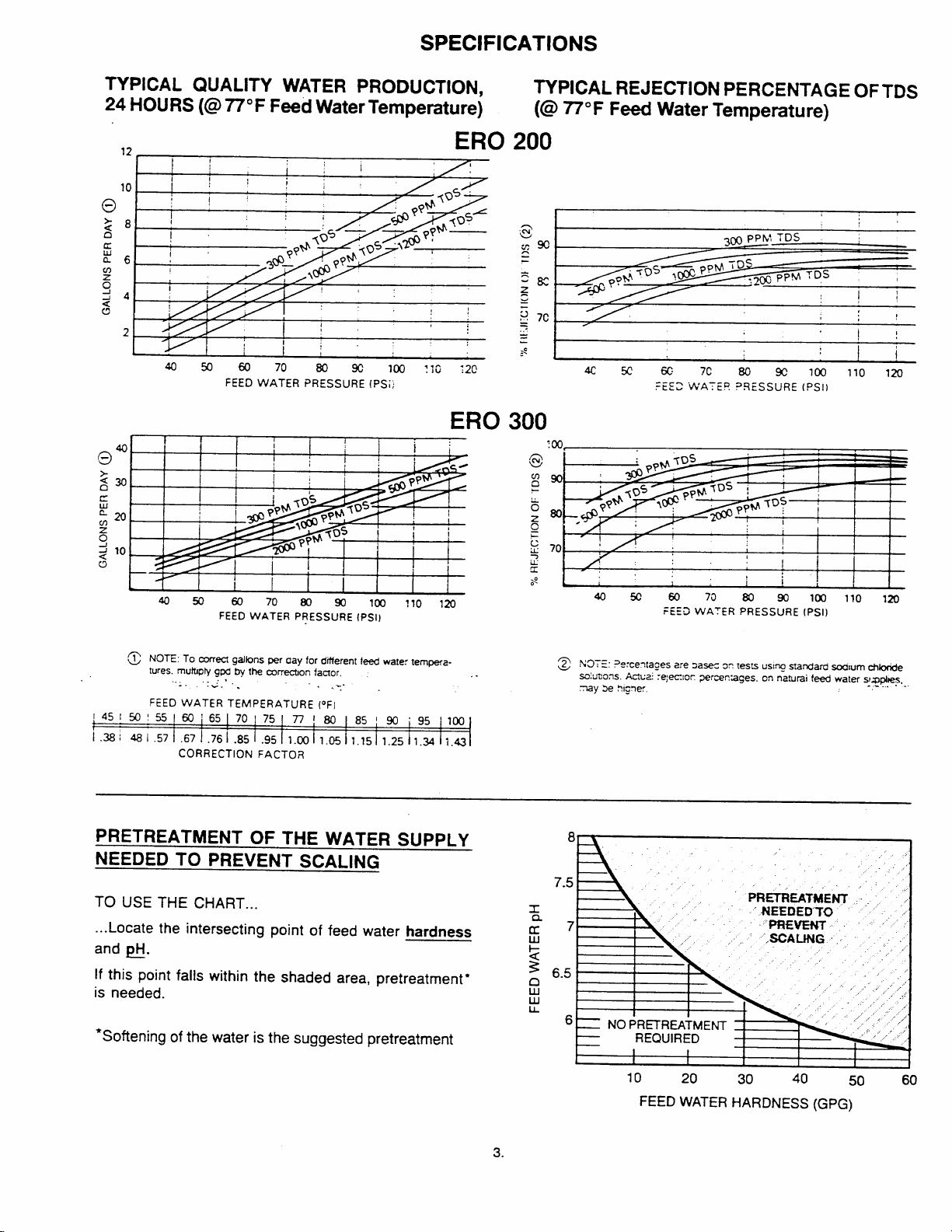

FIGURE 1

—---- .— . ..

—..

I H’JLllAJ’”ml I

1.

●

s

DtilN

STORAGE

TANK WATER SUPPLY

(SINK TRAP)

RO

.. —-

\

COLD ‘--

.

RO -

ERO 300 MODELS – Feed water must have all chlorine

removed (prefilter removes up to 2.0 ppm). Chlorine

will destroy the RO membrane cartridge. Be sure to

service the prefilter at suggested intervals, pages 12 and

14.

* DRAIN POINT - A suitable drain point (check your

local codes) is needed for reject water from the RO mem-

brane cartridge. We suggest using the sink P-trap drain

pipe. A drain clamp (drilling required) is available from Eco-

4.

Page 5

THINGS TO CHECK BEFORE

Water to use where codes permit. Refer to pages 6 and 15.

YOU START TO INSTALL

*

MOUNTiNG SURFACE -The RO assembly mounts on

a wall surface under the sink, or you cxm lay it on the bot-

* RO FAUCET - The RO

on the sink, or on

it’s installed in an existing

the countertop next to the sink. Often,

Space is required underneath

faucet.

ALL electronic faucet connections and installation

product water faucet installs

sink spray attachment hole.

for tubing to and from the

procedures are done on or above the sink or countertop.

tom of the cabinet. Special washers and screws are ineluded for wall mounting.

When the storage tank is full of water, it weighs about 30

pounds. Be sure to set on a surface that will support this

weight.

Refer to pages 7 and 9.

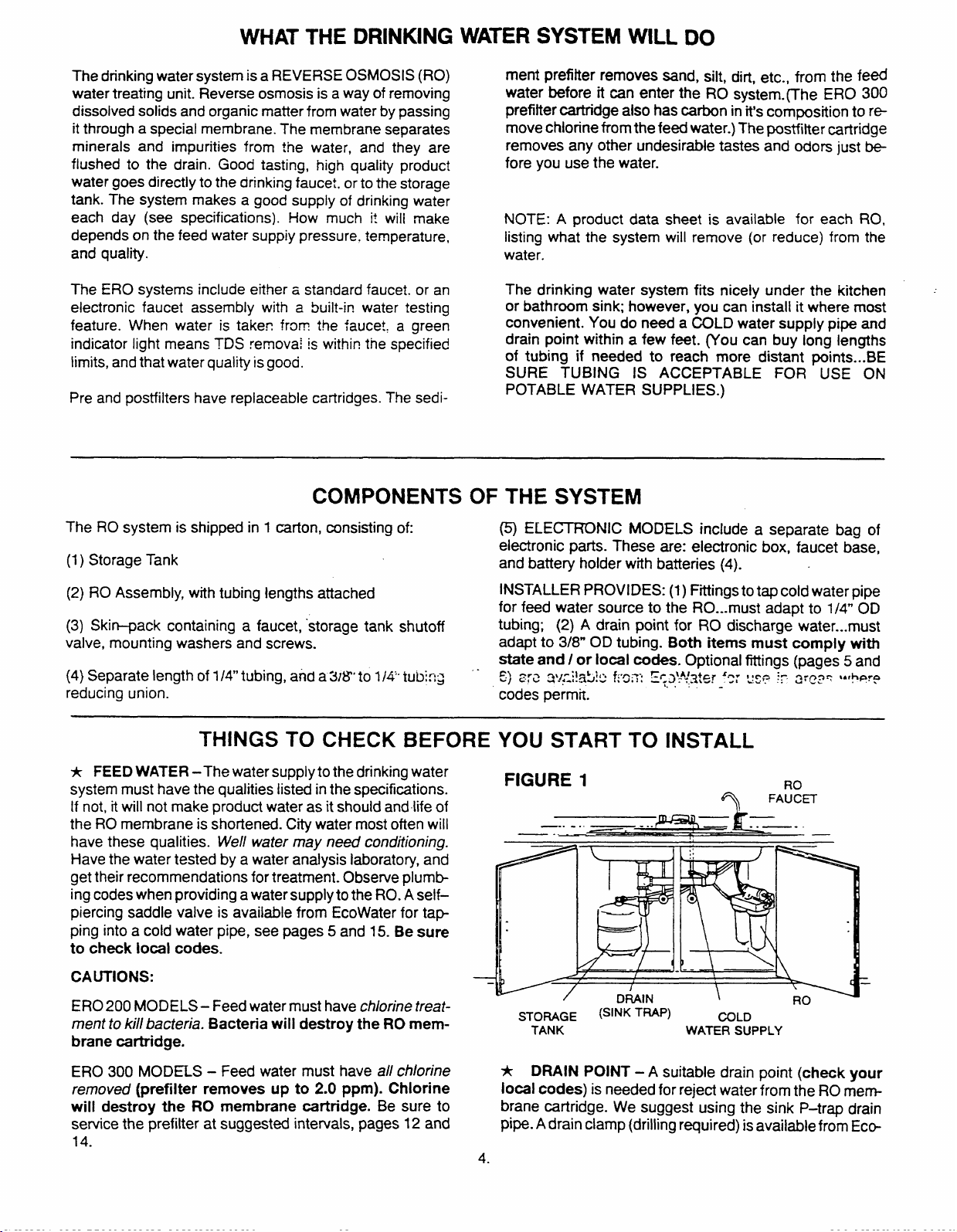

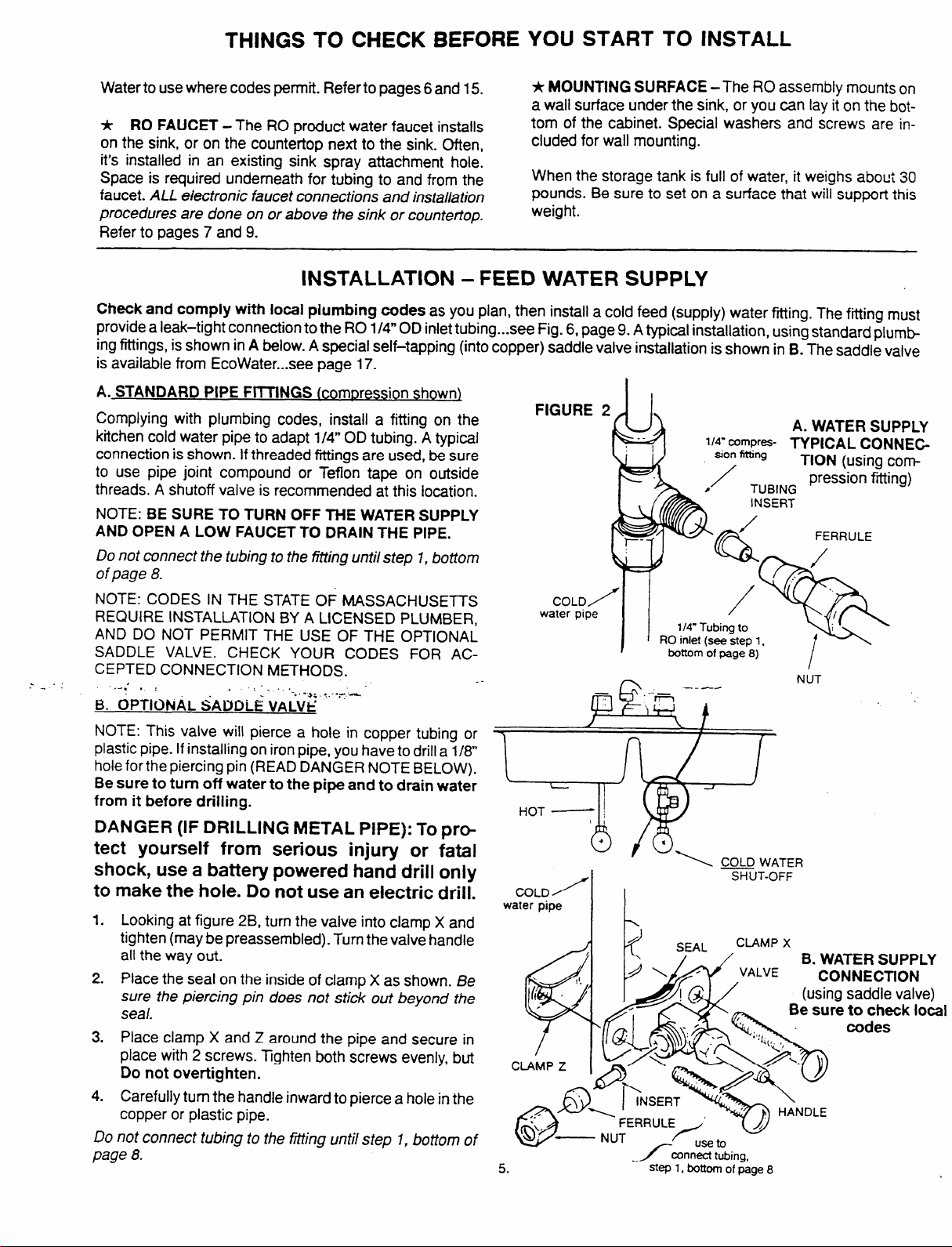

INSTALLATION - FEED WATER SUPPLY

Check and comply with local plumbing oodes as you plan, then install a cold feed (supply) water f~ing. The ftiing must

provide a leak-tight connection to the RO 1/4” OD inlet tubing...see Fig. 6, page 9. A typical installation, using standard plumb

ing fittings, is shown in A below. A special self–tapping (into copper) saddle valve installation is shown in B. The saddie valve

is available from EcoWater...see page 17.

. . ,

.

.-.

A. STANDARD PIPE FMINGS (cornDress

Complying with plumbing codes, install a fitting on the

kitchen cold water pipe to adapt 1/4 OD tubing. A typical

connection is shown. If threaded fittings are used, be sure

ion shown)

FIGURE 2

lJJOXV&S- TYPICAL CONNEG

to use pipe joint compound or Teflon tape on outside

threads. A shutoff valve is recommended at this location.

NOTE: BE SURE TO TURN OFF THE WATER SUPPLY

AND OPEN A LOW FAUCET TO DRAIN THE PIPE.

Do not mnnect the tubing to the fitting until step 1, bottom

of page 8.

NOTE: CODES IN THE STATE OF MASSACHUSETTS

REQUIRE INSTALLATION BY A LICENSED PLUMBER,

AND DO NOT PERMIT THE USE OF THE OPTIONAL

COLD

water pipe

/’

1/4”Tubingto

RO inlet (see step 1,

/

SADDLE VALVE. CHECK YOUR CODES FOR AC- botiomof page 8)

CEPTED CONNECTION METHODS.

,-, .,. . . . .

s. OpTl~NAL

SAUDL< vALv~’:””-r’-

.

..

n –--4

NOTE: This valve will pierce a hole in copper tubing or

plastic pipe. If installing on iron pipe, you have to drill a 1/8

hole for the piercing pin (READ DANGER NOTE BELOW).

Be sure to turn off water to the pipe and to drain water

from it before drilling.

DANGER (IF DRILLING METAL PIPE): To pro

tect yourself from serious injury or fatal

shock, use a battery powered hand drill only

to make the hole. Do not use an electric drill.

1. Looking at figure 2B, turn the valve into clamp X and

tighten (may be preassembled). Turn the valve handle

all the way out.

2. Place the seal on the inside of clamp X as shown. Be

sure the piercing pin does not stick out beyond the

seal.

3. Place clamp X and Z around the pipe and secure in

place with 2 screws. lighten both screws evenly, but

Do not overtighten.

4. Carefully turn the handle inward to pierce a hole in the

copper or plastic pipe.

Do not connect tubing to the ffling until step 1, bottom of

page 8.

COLD

water pipe

i-”-

.

9

CLAMP Z

5.

/

/

&

/:

--~ connecttubing,

\ COLD WATER

SEAL

.

!

>e

k

k\’ “ W

stepl, bottornof W~8

SHUT-OFF

CLAMP X

VALVE

A. WATER SUPPLY

TION (using com-

FERRULE

/

NUT

B. WATER SUPPLY

CONNECTION

(using saddie valve)

Be sure to check local

codes

Page 6

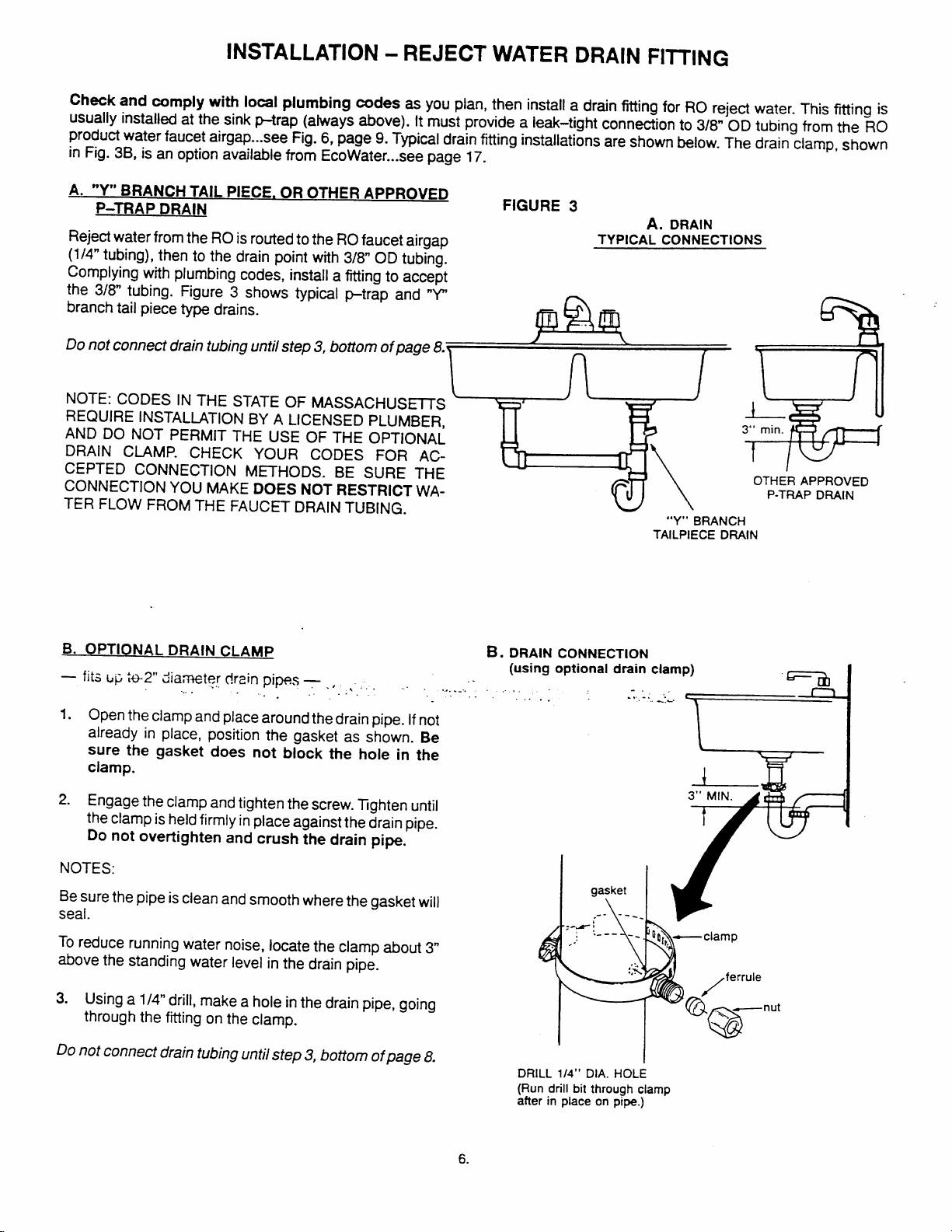

INSTALLATION - REJECT WATER DRAIN FITTING

Check and comply with local plumbing codes as you plan, then install a drain fitting for RO reject water. This f~ing is

usually installed at the sink ~rap (always above). It must provide a leak-tight connection to 3/8” 00 tubing from the RO

product water faucet airgap...see Fig. 6, page 9. Typical drain fitting installations are shown below. The drain clamp, shown

in Fig. 3B, is an option available from EcoWater...see page 17.

A. “Y” BRANCH TAIL PIECE. OR OTHER APPROVED

P-TRAP DRAIN

Reject water from the RO is routed to the RO faucet airgap

(1/4” tubing), then to the drain point with 3/8” OD tubing.

Complying with plumbing codes, install a fitting to accept

the 3/8” tubing. Figure 3 shows typical &trap and “Y”

branch tail piece type drains.

Do not connect drain tubing until step 3, bottom of page 8.\

NOTE: CODES IN THE STATE OF MASSACHUS~S

REQUIRE INSTALLATION BY A LICENSED PLUMBER,

AND DO NOT PERMIT THE USE OF THE OPTIONAL

DRAIN ClAMP. CHECK YOUR CODES FOR ACCEPTED CONNECTION METHODS. BE SURE THE

CONNECTION YOU MAKE DOES NOT RESTRICT WATER FLOW FROM THE FAUCET DRAIN TUBING.

FIGURE 3

DRAIN

TYPICAL CONNECTIONS

(

A.

R

(

(7

)

w

3“ min.

OTHER APPROVED

P-TRAP DRAIN

“Y” BRANCH

TAILPIECE DRAIN

B. OPTIONAL DRAIN CLAMP

—fit3~p t~2’’diawt~r drainpipes-, , ,,, .. . ‘- ,. .

....

1.

Open the clamp and place around the drain pipe. If not

. .

.. . .,

. . ..

~. DRAIN CONNECTION

(using optional drain clamp)

.......

. .. . .

already in place, position the gasket as shown. Be

sure the gasket does not block the hole in the

clamp.

2. Engage the clamp and tighten the screw. Tghten until

the clamp is held firmly in place against the drain pipe.

Do not overtighten and crush the drain pipe.

NOTES:

Be sure the pipe is clean and smooth where the gasket will

seal.

To reduce running water noise, locate the clamp about 3“

above the standing water level in the drain pipe.

3. Using a 1/4” drill, make a hole in the drain pipe, going

through the ftiing on the clamp.

Do not connect drain tubing until step 3, bottom of page 8.

DRiLL 114” DiA. HOLE

(Run dnii bit through ciamp

after in piace on pipe.)

gasket

,---- --

\

.,-.

-.

“=-l~:- ~

—ciamp

04}/

ferruie

i

/

G@

—nut

\

@

6.

Page 7

INSTALL THE FAUCET

(Install Standard Faucet, page 8)

Select one of the following places to install the faucet. Be

sure there’s room underneath so you can make the needed connections.

NOTE: Looking at Fig. 4D, be sure the faucet base

flat against the sutiace, at the selected location, so

fit

the

gasket will seal.

—

in an existing sink spray attachment hoie.

—

Drill a hole in the sink top.

—

Drill a hole in the countertop, next to the sink.

1.

If drilling is needed, make a 1-1/8” to 1–1/4” dia. hole.

Be sure to use proper procedures for drilling porcelain or stainless steel.

2.

Place plumbers putty around the drilled hole.

3.

Looking at Fig. 4A, insert a screw into the NON-

SLOITED base mounting hole. Turn a special nut a

few turns onto the screw.

4.

Position the base gasket over the mounting hole. Set

the base on the gasket, routing the leadwire through

the mounting hole. Holding the special nut under the

sink with 1 finger, tighten the screw until just snug.

Turn the remaining special nut a few turns onto the

5.

other screw. Position the screw in the slotted base

mounting hole, and tighten until snug. Carefully

tighten both screws until the base is held firmly in

place. Do not overtighten and break the base.

NOTE: if the faucet is unassembled. slide the lever over

the small cylindrical nut. Then, push or turn the spout into

the faucet body.

6.. ,4ssernNe the top gasket, top faucet base, and hex nut

~.~:~ :~~ f&@ ~+j!?....

snug. Any other faucet parts included are not used.

7. Using the washer, Fig. 4D, turn the tubing adaptor

onto the faucet stud and tighten securely.

8. Take the 27 length of 3/8” tubing and push 1 end onto

the 3/8” faucet barb ftiing...Fig. 4D.

.+ L”. L

~i~-

“.<C. T!2h+eP the .n[~t

will

Until

lever .

9

\ , / ~opg-

---

@

<.

.-.

G.

.-.

(

~

H hex nut

faucet

topgasket

. .

- ..

c.

B.

gasket

D.

M

1-1/4” hole

LOCATE BASE OVER

HOLE AS StlOWN

II

9. Move the RO system into position, under the sink.

Referring to page 9, hang the system on cabinet wall,

or lay on the floor surface, as desired.

10. Route the 1/4” tubing (marked “1/4 barb on faucet”),

and the 3/& tubing (marked “faucet”), from the bot-

tom, up through the mounting hole and faucet base.

Connect to the faucet as follows...see Fig. 4D:

a. Push the end of the 1/4” tubing onto the 1/4” barb on

the faucet.

b. Using the tubing adaptor nut, fasten the 3/8” tubing

to the tubing adaptor, and tighten the nut.

11.

Lower the faucet assembly and lock into place on the

faucet base.

faucet base

leadwire

\

Page 8

INSTALL STANDARD FAUCET

Select 1 of the following places to install the faucet. Be

sure there’s room underneath so you can make the needed connections.

—

—

—

1.

2.

NOTE: If the faucet is unassembled, slide the lever over

the cylindrical nut. Then, push or turn the spout into the

faucet body.

3.

4.

5.

6.

7.

8.

n

L“.

Note: For ease of service and maintenance, keep tubing

lengths long enough so removal of the RO system from under the sink is possible.

existing sink spray attachment hole.

In an

Drill a hole in the sink top.

Drill a hole in the countertop, next to the sink.

If drilling is needed, make a 1” dia. (minimum) hole.

Place plumbers putty around the drilled hole.

Slide the chrome washer and rubber washer, in that

order, onto the faucet stud.

Take the 27 length of 3/8 tubing and push 1 end onto

the 3/8” faucet barb f~ing.

Move the RO system into position, under the sink

(Referring to page 9, hang the system on cabinet wall,

or lay on the floor surface, as desired.) Route the 1/4”

tubing (marked “1/4 bati on faucet”), from the bottom, up through the faucet mounting hole. Push the

end onto the 1/4” barb ftiing.

Work tubing and the faucet stud down, into the mount-

ing hole.

On the underside of the sink or countertop, install the

plastic bushing, flat washer, and hex nut. Slide the

large steel washer in place, between the bushing and

the bottom of the sink or countertop. Then, tighten the

hex nut securely.

Using the washer, turn the tubing adaptor onto the

faucet stud and tighten securely.

u~x.x?”. he 3/8 tubing (marked “faucet”) from th’~ “ “

RO, to the tubing adaptor installed in step 8. Tighten

the tubing adaptor nut securely.

FIGURE 5

..

/

lever

chrome washer

rubber washer

3i8° barb ~

kit

QQbj

/\

. .

m

,\, ~

----

%

nut

spout

~ faucet

1/4” barb

\\

.

CONNECT WATER SUPPLY, FAUCET DRAIN TUBING, and

ELECTRONICS, if applicable

1. Connect “water supply” tubing, Fig. 2 and 6: A

length of 3/8” tubing (marked “water supply”) is attached

to the RO inlet. A separate length of 1/4” tubing and a 3/8”

by 1/4” reducing union are included to make this connec-

tion.

A. Connect the 1/4” tubing to the feed water supply fitting,

installed on page 5. Connect the tubing as applies (Fig. 2A

or 2B) and tighten the nut securely.

B. Standard Faucet Model: Connect the 1/4” tubing to

the 3/8” tubing coming from the RO (marked “water sup-

using the tubing reducing union. Be sure to use tub

ply”),

ing inserts at each connection.

C. Electronic Faucet Models: Using the tubing reducing

union, connect the 3/8 tubing from the RO (marked “water supply”), to the bottom, feed side of the electronic

box. Cut a short piece (3” to 5“) of 1/4” tubing from the

length, installed in A above, to use between the reducing

union and electronic box.

2. Electronic Faucet Models: Referring to Fig. 6, cut the

product water tubing as typically shown, and connect to

the top and bottom of the electronic box, product side.

Again, be sure to use tubing inserts at each connection.

8.

Page 9

3. All Models: Run the 3/8” tubing from the 3/8” faucet

barb, to the drain fitting installed on page 6. Keep this tub back cover and, looking at Fig. 6, fasten the battery con-

ing run as straight as possible, without loops, dips or nector to the battery pack (be sure batteries are installed

/ow+Pots. Cut the tubing as needed and fasten to the

drain fitting (Fig. 3A or 3B), securing as required. replace the back cover.

4. All Models: Run

ting on the RO module, to the shutoff valve at the top of the

storage tank.

‘,

3

T

b

i

\

a iength of 3/8” tubing from the tee fit-

SHUTOFF VALVE

—

\

TANK

2“ (MINIMUM CLEARANCE

FOR CHANGING CARTRIDGES)

L

5. Electronic Faucet Models: Remove the electronic box

correctly). Put the battery pack in the electronic box and

Fasten the electronic box leadwire to the faucet base lead-

wire... Fig. 6.

INSTALL RO ASSEMBLY AND STORAGE TANK

1.

Hold the RO assembly up to the wall where you will

install it. Position and mark locations for the mounting

screws and hanger

2. Fasten the hanger washers to the wall surface. Two

~

wood screws are included for fastening to a wood surface. Provide other screws as needed.

3. Hang the RO assembly on the washers.

4. Move both the RO assembly and tank into place. Set

the tank on the floor surface and install the fittings as

shown. Use teflon tape on fitting threads.

washers.

. .

TYPICAL INSTALLATION

. . .

1

AL

“am~ “‘“

supply /

%r-il-ils V21UP

--””. - .- .-

Note: On standard faucet models,

disreuard the electronic box. but “=, \ ‘,Mmule

conn&t all tubing betweenthe&me —;__

points.

/

‘T

~

..

f

.—-

l-l

.-..

-.. .

-m)

●Electronic

Ill Ill J*-n-

teodll I II

. -J

)

Tank

“1

Faucet

/

JiL

//

IWII ~. -~

\

tubing

reoucerumon,

348”x 1/4”

FIGURE 6

Faucet modelsonly.

al

1) Rr7A~

/~

lNLkT

ilnnl

“Battery

holder

Shutoff

Assembly

[ ....–J

9.

UY

lEFILTER

PF

POSTFILTER

Page 10

~ANITiZING THE RO SYSTEM

INSTALLATION

REFER TO PAGES 12 AND 16.

Sanitizing is recommended upon installation of the RO

system, and after servicing inner parts. IT IS IMPORTANT

FOR THE SERVICE PERSON TO

WHILE HANDLING INNER PARTS OF THE SYSTEM.

CAUTION: BE SURE TO REMOVE ALL CARTRIDGES,

AS FOLLOWS, BEFORE SANITIZING. CHLORINE WILL

DESTROY THE CARTRIDGES.

1. BE SURE WATER SUPPLY TO THE RO IS TURNED

OFF, AND THE RO FAUCET IS OPEN.

2. Remove the u-pin and pull the inlet cover, o-ring and RO

cartridge from the RO housing. PLACE THE CAFITRIDGE

IN A CLEAN PLASTIC BAG.

3. Replace the inlet cover, with o-ring, and re-insert the

u-pin.

4. Remove the POSTFILTER sump, turning to the left. Take

the cartridge from the sump and place in the plastic bag.

Replace the sump and TIGHTEN SECURELY.

HAVE CLEAN HANDS

5. Remove the PREFILTER sump and cartridge. Also place

this cartridge in the clean bag.

6. If needed, flush the prefilter sump with fresh water. Then,

fill with water to about 1” from the top. Add 1.0 oz. of

chlorine (ordinary 5.25%0household bieach... iilexex.Clorox,

etc.) and mix in the water. DO NOT ADD CHLORINE

FIRST. Concentrated, it will attack plastics.

7. Carefully replace the sump, on the prefiiter head, and

tighten securely.

8. Open the tank shutoff valve, and the water supply to the

RO. Open the RO faucet, locking the lever upward, against

the spout.

9. Allow water to circulate through the system until the

bieach odor is gone.

10. Turn off the water suppiy to the RO. Ciose the RO faucet

afier water fiow stops.

11. Repeat steps 1-5 and 7, oniy replace ali cartridges. BE

SURE YOUR HANDS ARE CLEAN.

PRESSURE TESTING

DO THE SANITIZING PROCEDURES ABOVE BEFORE PRESSURE TESTING.

1. Open the water suppiy shutoff vaive, page 5.

. .

2.Open the main water suppiy vaive. Open faucets to let tubing connections for any water leaks. Correct leaks

air out of the pipes and ciose when water runs smooth.

5. IMPORTANT PURGING INSTRUCTIONS: The RO cartridge contains a food grade presewative that you shouid ciean

from it before using the system. The presemative wiii give product water an unpleasant taste and odor. After the storage

tank has fiiied (takes about 12 hours), open the system faucet until the tank is empty. Aiiow the tank to fiii again for

12 hours, then open the faucet and empty. After 4 purgings, the system is ready to make product water for your use.

..

. .“.,..

3.Open the water shut-off valve on the storage tank. .

‘- 4.in about

system. At that time, carefuiiy cll~c~ aii iitiings end

if any are found.

4 hours, pressure wiii s?art :C bu~ld ;: the !?0

10.

Page 11

HOW THE RO DRINKING WATER SYSTEM WORKS

PREFILTER

Water from the cold supply pipe enters the RO assembly

prefilter first (Fig. 6).

ERO 200— The prefiiter has a 5

micron replaceable sedi-

ment cartridge. It removes sand, silt, dirt and other

sediments that may be in the water supply. Filtered, clean

flOWS from the prefiiter, to the RO membrane

water

cartridge.

300-

ERO

The prefilter is a replaceable sediment cartridge with activated carbon in its composition. The cartridge (1 to 2 micron) removes sand, silt, dirt, other sediments, and

Up to 2.0 ppm of chlorine from the feed water

(CHLORINE DESTROYS THE ERO 300 RO MEMBRANE). Filtered, clean,

Chlorine-free water ftows from

the prefilter, to the R() membrane cartridge. IMPORTANT:

SEE PREFILTER MAINTENANCE, PAGE 12.

REVERSE OSMOSIS

(RO) CARTRIDGE

The cartridge, inside the RO housing, includes a tightly

wound, speciaJ membrane. Water is forced through the

cartridge where the membrane removes the dissolved

solids and organic matter. High quality product water exits the RO housing and goes to the storage tank or to the

postfilter. Reject water, with the dissolved solids and

organic matter, ieaves the housing and goes to the drain

through the 1/4” tubing. .

The electronic faucet provides a buiit-in

ter.

As water is taken from the faucet, the indicator

water quality tes-

iights show how the RO system is operating to provide high

quaiity drinking water.

FLASHING GREEN LIGHT-The RO system is giving you

high quaiity drinking water.

FLASHING RED “FILT” LIGHT - The prefiiter and postfiiter cartridges need repiacing. This occurs after 6 months,

or 900 gaiions of product water use. Also replace the

controi box batteries ...see page 13.

FLASHING AMBER “ROY’ LIGHT – The RO cartridge no

ionger removes at ieast 75°/0 of the TDS from the suppiy

water and needs replacement.

NOTE: Disregard initial or short periods of the fiashing

“RO” iight.

SHUT-OFF ASSEMBLY

To conserve water, the drinking water system has an

automatic shut-off assembiy. When the storage tank has

filied to capacity, and the drinking water faucet is ciosed,

pressure cioses the shutdf. Water fiow to the RO housing is shut off untii drinking water is used again, and

pressure drops in the RO system.

CHECK VALVE

STORAGE TANK

The storage tank huids up to 2’.1 gaiions Ui pic)tiuc~ waier.

A diaphragm inside

when the tank is fuii) for fast fiow to the faucet when

30 psi

the tank keeps water pressurized (to

drinking water is needed. A 10 gaiion tank is an avaiiabie

option.

POSTFILTER

After ieaving the storage tank, but before going to the

faucet, product water goes through the postfiiter. The

postfiiter aiso has the activated carbon type sediment

filter. Any remaining tastes, odors or sediments are removed from the product water. Taste-free, odor free, ciean,

high quaiity drinking water fiows through the tubing to the

faucet.

FAUCET AND ELECTRONICS

The sink or countertop faucet vends the drinking water

when opened. it has a hand operated, spring-loaded

closed lever to prevent waste. You can also keep the faucet open by pushing upward on the lever and locking it

against the faucet spout.

To compiy with piumbing codes, an

the faucet drain water connection.

air-gap is buiit into

..

A check vaive (Fig. 8 and 9) is buiit into 1 end of the RO

hO!JS@, urder the tee fitting. The Check VaiVe prevents

ti&~kWiliU ~iOW 01 PICJJtiCt Wa;~~ ;iCi,, L, 4G d.=- ‘‘.’- - “-’rage tank.

a

.

..

A backward fiow couid rupture the FIO membrane.

FLOW CONTROL

The fiow controi (see Fig. 9, page 13) reguiates flow,

through the RO cartridge, to the required rate to get the de-

sired quaiity of product water. The controi is located in the

eibow fitting, at the RO housing drain port. A smali, con~

shaped screen fits over the front end of the flow control to

help prevent piugging with drain water sediments.

This reverse osmosis system contains a replaceable

treatment component critical for effective removai of

totai dissolved soiids. The water shouid be tested

periodically to verify the system is performing

satisfactorily.

11

Page 12

MAINTENANCE

(Also see Filter-Cartridae Redacement Guide on Paqe14)

To keep the drinking water system operating and making

high quality water, the prefilter cafiridge, RO cartridge. and

postfilter catiridge need replacing at certain intema!s.

When replacing patis, simply lift the RO assembly from the

mounting washers and lay on the floor sc you can easily

work on it. You can also remove the RO housing by pulling

out of mounting ,clamps.

CAUTION: BEFORE DISCONNECTING ANY PARTS,

CLOSE THE SHUTOFF VALVE ON THE STORAGE

TANK, CLOSE THE WATER SUPPLY SADDLE VALVE,

AND OPEN THE DRINKING WATER FAUCET.

seconds to 1 minute for pressure to relieve through the

system.

PREFILTER AND POSTFILTER CARTRIDGE

Allow 30

ERO 200- After a time, the sediment prefilter cartridge

begins to plug with sediments and water cannot get

through it as fast. You may notice a slower making of

quality product water. When this happens, anew sediment

cartridge is needed. Also replace the postfilter cartridge.

ERO 300 – YOUmust replace the prefilter cafiridge often

to protect the RO membrane from being destroyed by

ch/orine andior from plugging with sediments that are in

the water supply. If the water supply contains both chlorine

and sediments. replace the prefilter cartridge at least every

6 months, or more often if it begins to-plug with sediments.

If the water has sediments only, WITH NO CHLORINE,

then read RO 200 above. Also replace the postfilter cartridge.

ELECTRONIC MODELS – To signal correct replacement

intewal,

after 6 months. or 900 gallons of product water use, whichever

At the same time. replace the postfilter cartridge and the

batteries in the control box. Replacing the batteries resets

the 6 month or 900 gallon period, and assures proper

operation of the “ROWindicator light (see page 13).

REPLACING CARTRIDGES...Tum the sump out of the

filter head. BE CAREFUL... THE SUMP IS FULL OF WATER.

sump with fresh water and insert the new cartridge.

SURE THE lARGE O-RING IS IN PLACE ON THE TOP

OF THE SUMP, AND LUBRICATED (USE LUBRICANT

APPROVED FOR USE ON POTABLE WATER SUP-

PLIES). Turn the sump into the head and tighten securely.

Repeat this procedure on the other filter.

RO CARTRIDGE

The life of the RO cartridge depends mostly on the pH of

properly treated feed water... see pages 3 and 4.

the red “FIL~ indicator light will begin to flash

occurs first.

Remove and discard the inner cartridge. Flush the

. .

BE

11

!-/

1’

1

,:,

I

l::! ~

Ii .,:

TO REMOVE SUMP

TURN

THIS WAY

SUMP

w

The higher the pt-i, the shorter the cartridge life. For example, if feed water pH is from 6.8 to 7.7, the cartridge

last for well over 1 year. However, cartridge life maybe as

short as 6 months if the pH is as high

higher pH weakens the cartridge membrane and makes

pin hole leaks.

It’s time to replace the RO cartridge when the quality and/

or prockctim’”rate of product “~ate~-dIUK [.!’rst replace

prefilter and postfilter cartridge). Product water may begin

to taste different or even bad, indicating solids and organ-

ics are getting through the cartridge.

NOTE: When replacing the RO cartridge, also install the

new flow control (included). The prefilter and postfilter

cartridge should also be replaced,

ELECTRONIC MODELS - It’s time to replace the RO

cartridge when the amber “RO” light on the faucet base

begins to flash continually whiie RO water is taken from the

faucet (see page 11).

TO REPIACE THE CARTRIDGE..<

1.

Turn off the water suppiy (see the preceding caution

note, above ieft column).

2.

Remove the inlet cover from the housing. (Remove

the retainer ring and puli the u-pin.)

3.

Use a pliers to pull the cartridge from the housing.

4.

instali the new cartridge and repiace the inlet cover

(iubricate o-ring if needed).

Insert the u-pin and instali the retainer ring.

5.

as 8.5 or 11.0. The

may

IL.

Page 13

MAINTENANCE

6. Remove the old flow control and replace with the new

control included with the RO cartridge (see below).

7. PURGE THE CARTRIDGE AS INSTRUCTED ON

PAGE 10.

BAITERIES IN ELECTRONIC CONTROL BOX

Always replace the 4, “AA’” alkaline batteries in the control

box when changing the pre and postfilter ca~ridges. Good

batteries are needed to assure proper indicator light

operation. Weak batteries may give a false indicatio~.

Changing the batteries also resets the 6 month or 900

gallon period.

FLOW CONTROL AND SCREEN

The flow control is vital for proper operation of the RO

cartridge. The control must keep water fiow through the

cartridge at the proper rate to obtain the best quality

product water.

When servicing the RO, it’s good practice to check the fiow

control (and black tubing to it) to make sure the small tube

and surrounding surfaces are clean and unrestricted. A

small, coneshaped screen (Fig. 9) is located in front of the

flow control to help keep it clean. !f the flow control should

plug with foreign particles, the RO cartridge cannot

discharge minerals or impurities to the drain. it would only

take a short time for the cartridge to plug, making it

useless.

CAUTION: To install the screen, place the cone end into

the elbow fitting. Then, carefully push it in using the 1/4”

tubing as a tool. Do not force in after you feel resistance.

Visually check to be sure it is properly positioned.

.,

s..’.”’

.. ...

FIGURE 9

compression

nut

\

r

c}

Illf

..

screen

TO

DRAIN

1/4”

ontrol

tubing

When installing the flow control, tighten the nut by”hand.

then another 1

OVERTIGHTEN AND DISTORT OR CRUSH THE

TUBING AND FLOW CONTROL.

i4 to 1/2 turn with a pliers. DO NOT

13.

Page 14

FILTER-CARTRIDGE REPLACEMENT GUIDE

MODEL ERO 200

AT LEAST EVERY 6 MONTHS

– Replace prefilter sediment cartridge and postfilter

carbon cartridge.

– Make replacements indicated if any of the

following occur before the 6 months -

CHLORINE (OR OTHER) TASTE AND/OR ODOR

– Replace postfilter carbon cartridge

– If taste & odor persists, also replace prefilter

sediment cadridge, RO cartridge, flow control and

screen.

SLOW PRODUCTION RATE

– Replace prefilter sediment cartridge

– If rate does not increase, replace postfilter carbon

cartridge, RO cartridge, flow control and screen.

HIGH TDS

– Replace prefilter sediment cartridge, postfilter carbon

cartridge, RO cartridge, flow control and screen.

MODEL ERO 300

AT LEAST EVERY 6 MONTHS

- Replace

cartridges.

prefilter and postfilter sediment-carbon

– Make replacements indicated if any of the

following occur before the 6 months –

CHLORINE TASTE AND/OR ODOR

- Replace prefiiter cartridge, postfilter cartridge, RO

cartridge, flow control and screen.

OTHER

–

TASTE AND/OR ODOR

Replace postfilter cartridge

– If taste & odor persists, replace prefilter cartridge,

RO cartridge, flow control and screen.

SLOW PRODUCTION

Replace prefiiter cartridge

–

RATE

– If rate does not increase, replace postfilter cartridge,

RO cartridge, flow control and screen.

HIGH TDS

– Replace prefilter cartridge, postfilter cartridge, RO

cartridge, flow control and screen.

ELECTRONIC MODELS

..

fl.”r !.E.~.5T 5\lEpy 5 *.V251THCOR qoo G,4L1.cyvS ~~ pp M1.’ii k~ U,WT

— ------------- “ “ “

Replace the prefilter cartridge, postfilter cartridge, and batteries in the electronic box.

WHEN THE AMBER “RO” LIGHT FLASHES -

Replace the RO cartridge, flow control and screen.

RED “FIL~ LIGHT FLASHES –

14.

Page 15

..

Page 16

REPAIR PARTS

SADDLE VALVE

‘0 ‘-T---

ELEC.BOX

42

/

M! ~z”

DRAIN CLAMP

\

4

46

48

DRAIN WATER

TO FAUCET

Y

.-

,.-

<~’

45

6

d @-l ‘“

Iw

r’~ ,

1

I

c.=

\

.

\

“’’-_=””’ – 28

29

\

.

\

\

1

/’ ,’

)

/

.’

8

16,

Page 17

REPAIR PARTS

KEY ~

NO.

II

[2

3 [ 7112248 I Top, Faucet Base+

I

4 ~ 0900713 I Screw, %32x 1-3/8 (2) +

5

I

6

7 7115725 j Nut (2) +

8 I 9003203 / Nut, 3/8” Tubing (8)

9 7131349 ~Insert, 3/8” Tubing (9)

I

10 7115694 I Electronic Box + - incl’sthe following

—

—

—

11

12

13

I

14

15

16

I

17

I

L

18

19 90w801 ! Elbow, 1/8” NPT x 3/8” Tubing (2)

PART I

~ NUMBER /

~ 7095925 ~Faucet

I 7051206 ~Top Gasket+

7115686 i Base, Faucet+ @

7114614 ~Gasket+

1269800 i Spring (not illustrated)

7087477 j Magnet (not illustrated)

7127756

7115822 I Battery Holder ● (batteries not in-

1

7087223 I Screw, #1 O – 16 x 1/2” (4)

7078389 ~Head (2)

7098185 ~

7070323 ! Sediment-carbon Cartridge

7093494 ! Ring, 3- 5/8” I.D. x 3- 7/8 O.D. (2)

7065394 ! Sump (2)

7100770 ] Elbow

I Flow Washer (not illustrated)

eluded)

I

Elbow Assembiy (2)

DESCRIPTION

—-——--.--..-—..—-----.—.-

7112442 ~Valve Top

21 ‘--

r

22 71124WI

7014979 ~Plunger

23

7099296 ]

24

25 7112442 ~Valve Top

I

7030721 ~Screw, #10- 14x 1 – 3/4” (4)

26

—

7133838 I Shutoff Assembly- incls. 21 through 26

—

0020218 Tubing, 1/4” - order length needed

7105160 I Tee, 1/8” NPT x 3/8” Tubing

27

~Valve Center Body

Diaphragm (2)

KEY

NO.

28

29 I 7101726 ~Tank Shutoff Valve

30 ~ 7112523 ] Clip (2)

31 I 9006029 i

32 I 7112492 I Bracket

33

34 j 7048041

35

36 1289000

—

37 I 7030438 I RO Housiny includes 34,35 &36

38 9016001 RO Cartridge incls. 43 &44 ERO 200

39

40 ~ 1269800

41 I 7043554 I Tee, 3/8” Tubing

42

43 I 7095030 Cone Screen

44 7167764 I Flow Control,

45

46 7122798

.... ... . .___ .. . . .

, ~?

48

I

49

50 7056565

51 / 7131331

I

– I 9041700 Hanger Washer (2) (not illustrated)

—

—

—

PART ‘

; NUMBER , DESCRIPTION

7077464 ‘Tank,

7095983

9033600 I Sediment Cartridge ERO 200

I

~ 7070323 ~Sediment<atin Cartridge ERO 300

: 7093509 O-ring, 1 – 19f32° LD. x 2“ O.D.

, 0900288 , Retainer (not illustrated)

\ 7096086

9000702 Check Ball

I

9004504 [ Elbow, 1/8” NPT x 1/4”Tubing

I

9003204 Nut, 1/4” Tubing

I

7g797Q ?.

!

I

7011272

I

,

7ofYll 44

[ Insert, 1/4” Tubing (3)

9006062 I Woodscrew (2) (not illustrated)

7163396 Small Parts Skin-pack

0010251 Tubing, 3/8” – order length needed

2.1 gal. (standard)

Tank, 10 gal. (optional, not included)

screw (4)

inlet Cover

UPin

RO Cartridge incls. 43 & 44 ERO 300

Spring

1-3/4” long

Drain Clamp@

; [.}k=!q (Yyy @

I Saddle Valve@

Adaptor, 7/16“ -24

Reducing Union @

0 Includes key nos. 2,3,4,6 and 7.

@ Not included with RO - Not allowed in all

local codes).

areas (check you

@ Includes compression nuts-Also use with 1/4”and 3/8” tubing

inserts, key nos 9 and 51.

17

Loading...

Loading...