GE GDF650SFJ2DS, GDF650SFJ4DS, GDF650SGJ0BB, GDF650SGJ0WW, GDF650SGJ2BB Installation Guide

...Page 1

Installation Instructions

Built-In Dishwasher

If you have questions, call GE Appliances at 800.GE.CARES (800.432.2737) or visit our website

at: GEAppliances.com. In Canada, please call 1.800.561.3344 or visit www.geappliances.ca

BEFORE YOU BEGIN

Read these instructions completely and

carefully.

WARNING

• To reduce the risk of electric shock, fire, or injury to

persons, the installer must ensure that the dishwasher

is completely enclosed at the time of installation.

• FOR PERSONAL SAFETY : Remove house fuse or open

circuit breaker before beginning installation. Do not use

an extension cord or adapter plug with this appliance.

• The improper connection of the equipment grounding

conductor can result in a risk of electric shock. Check

with a qualified electrician or service representative if

you are in doubt that the appliance is properly grounded.

• If house wiring is not 2-wire with ground, a ground

must be provided by the installer. When house wiring

is aluminum, be sure to use UL-Listed anti-oxidant

compound and aluminum-to-copper connectors.

CAUTION

Do not remove wood base until you are ready to install

the dishwasher. The dishwasher will tip over when the

door is opened if base is removed.

FOR YOUR SAFETY

Read and observe all WARNINGS and CAUTIONS

shown throughout these instructions.

While performing installations described in this booklet,

gloves, safety glasses or goggles should be worn.

IMPORT ANT – Observe all governing codes and

• Note to Installer – Be sure to leave these instructions for

the consumer’s and local inspector’s use.

• Note to Consumer – Keep these instructions with your

Owner’s Manual for future reference.

• Skill Level – Installation of this dishwasher requires

basic mechanical, electrical and plumbing skills. Proper

installation is the responsibility of the installer. Product

failure due to improper installation is not covered under

the GE Appliances W arranty. See warranty information.

• Completion Time – 1 to 3 Hours. New installations

require more time than replacement installations.

IMPORTANT – The dishwasher MUST be installed to allow

for future removal from the enclosure if service is required.

Care should be exercised when the appliance is installed or

removed,

supply cord.

If you received a damaged dishwasher, you should

immediately contact your dealer or builder.

Optional Accessories – See the Owner’s Manual for

available custom panel kits.

Your dishwasher is a water heating appliance.

to reduce the likelihood of damage to the power

ordinances.

CHECK THE FOLLOWING

Tub trim does not interfere with the door

Dishwasher is square and level at both the top and

bottom of the cabinet opening, with no twisting or

distortion of the tub or door

All 4 legs of the dishwasher are firmly in contact with the

floor

Drain hose is not pinched between the dishwasher and

adjacent cabinets or walls

Tub trim is fully seated on the tub flange

READ CAREFULLY

KEEP THESE INSTRUCTIONS

31-31560-1 09-16 GEA

Page 2

Installation Preparation

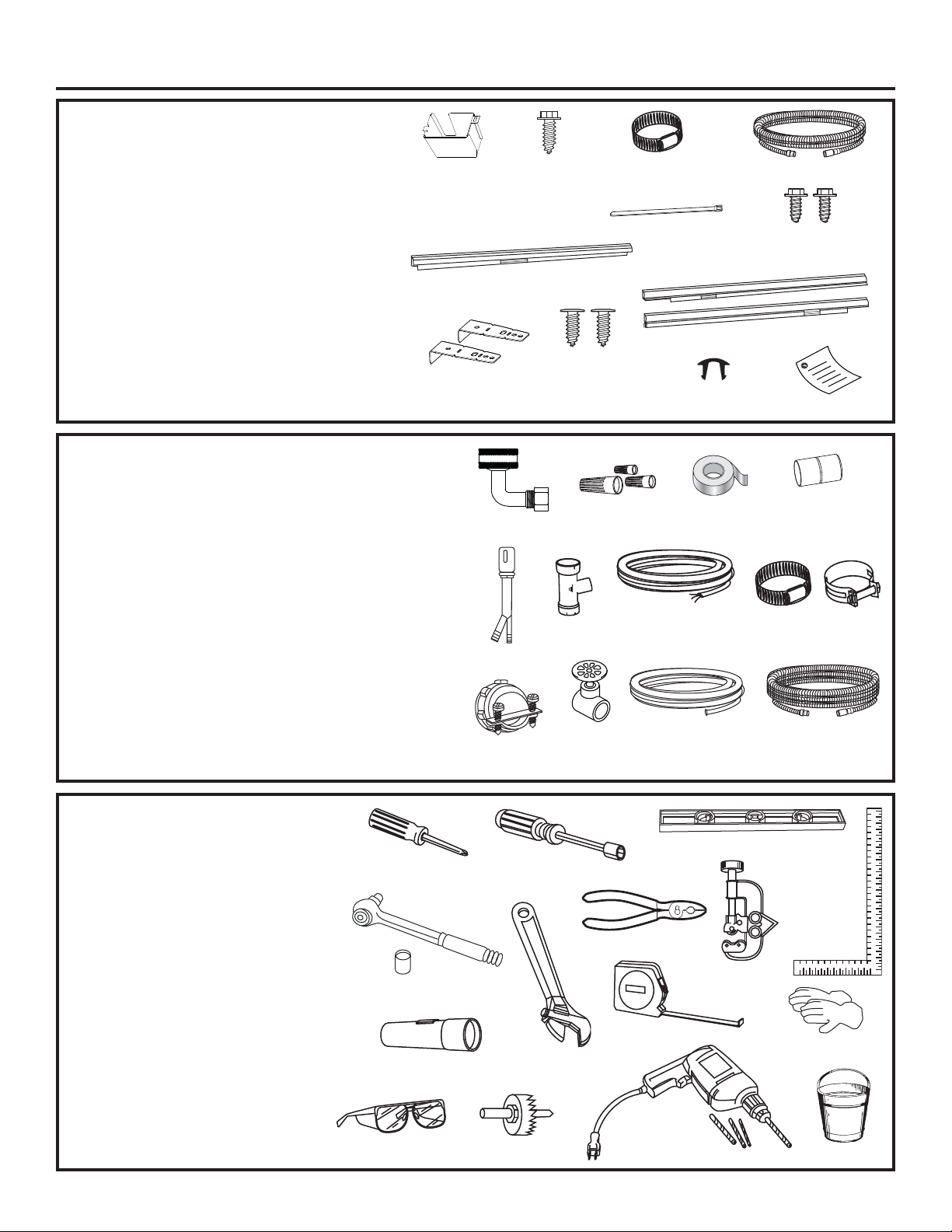

PARTS SUPPLIED IN

INSTALLATION PACKAGE:

• Junction box cover and #10 hex-head screw

• Hose clamp

• Drain hose (approximately 58” long)

• Drain hose hanger

• 2 #8-18 hex head screws to secure brackets to

washer tub frame

• 1 top trim piece (on some models)

• 2 side trim pieces

• 2 mounting brackets for wood countertops

or side cabinets

• 2 #8-18 x 5/8” Phillips special head screws,

to secure dishwasher to underside of

countertop or to side cabinets

• Plug buttons

• Literature, samples and/or coupons

MATERIALS YOU WILL NEED:

• 90° elbow (3/4”hose internal thread on one

end,opposite end sized to fit water supply)

• UL-listed wire nuts (3)

• Masking Tape

Materials For New Installations Only:

• Air gap for drain hose, if required

• Waste tee for house plumbing, if applicable

• Electrical cable or Power Cord Kit WX09X70910 (5.4 Ft)

or WX09X70911 (7.9 ft) depending on your installation.

• Screw-type hose clamps

• Strain relief for electrical connection

• Hand shut-off valve (recommended)

• Hot Water Line–3/8” minimum, copper tubing

(including ferrule, compression nut) or GE Appliances

Part # WX28X326, flexible braided hose.

• WD24X10065 drain hose (12’ long), if needed.

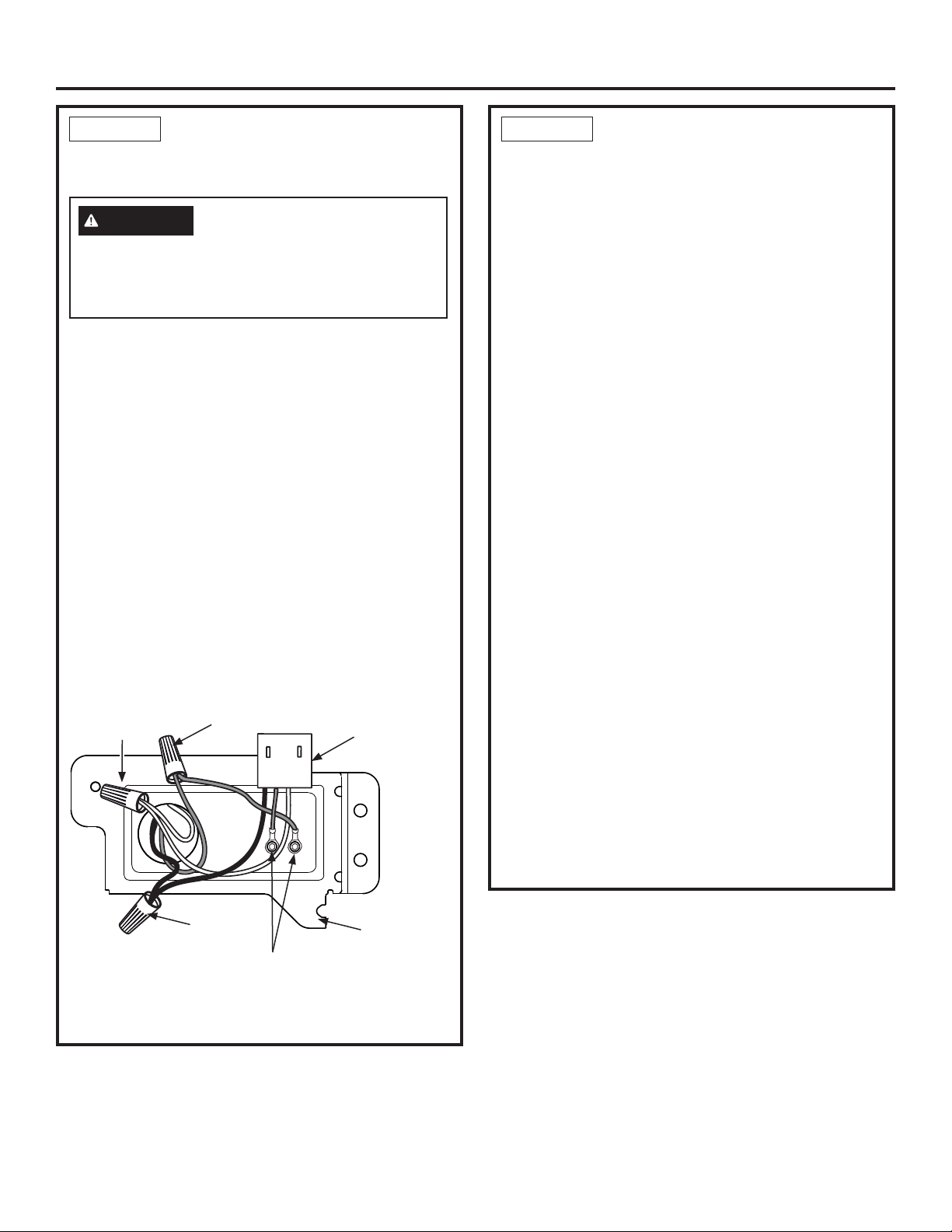

Junction

Box Cover

Mounting

Brackets

#10

Hex-Head

Junction

Box Screw

1/2" long

Top Trim Piece

(on some models)

#8 Phillips

Head Screws

90°Elbow

Waste Tee

Air Gap

Strain Relief

Drain Hose Hanger

Special

5/8" long

Wire Nuts (3)

Hand

Shut-Off

Valve

Hose Clamp

Plug Buttons

Masking Tape

Electrical Cable

(or Power Cord,

if applicable)

Hot Water Line

Drain Hose

#8 Hex-Head

Mounting Bracket

Screws

Side Trim Pieces

Literature

Coupler for

optional

drain hose

Hose Clamps

Optional

12' Drain Hose

WD24X10065

TOOLS YOU WILL NEED:

• Phillips-head screwdriver

• 1/4” and 5/16” nutdriver

• 6” Adjustable wrench

• Level

• Carpenter’s square

• Measuring tape

• Safety glasses

• Flashlight

• Bucket to catch water when flushing the line

• 15/16” socket (optional for skid removal)

• Gloves

• Pliers

For New Installations Only:

• Tubing cutter

• Drill and appropriate bits

• Hole saw set

Phillips-Head

Screwdriver

Safety Glasses

15/16” Socket

Flashlight

2

1/4” and 5/16”

Nutdriver

6” Adjustable

Hole Saw Set

Wrench

Pliers

Tubing Cutter

Measuring Tape

Drill and Bits

Level

Carpenter’s

Square

Gloves

Bucket

Page 3

Installation Preparation

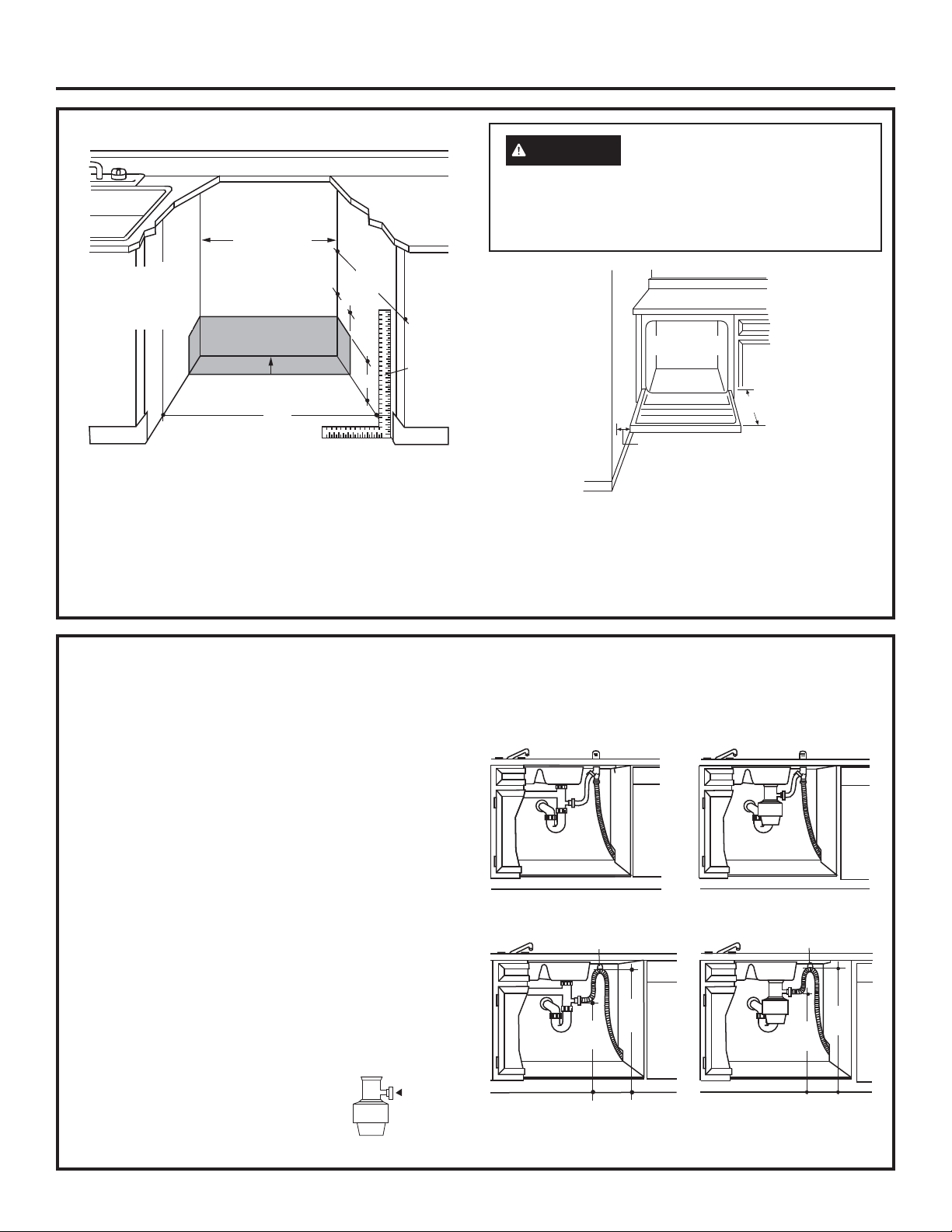

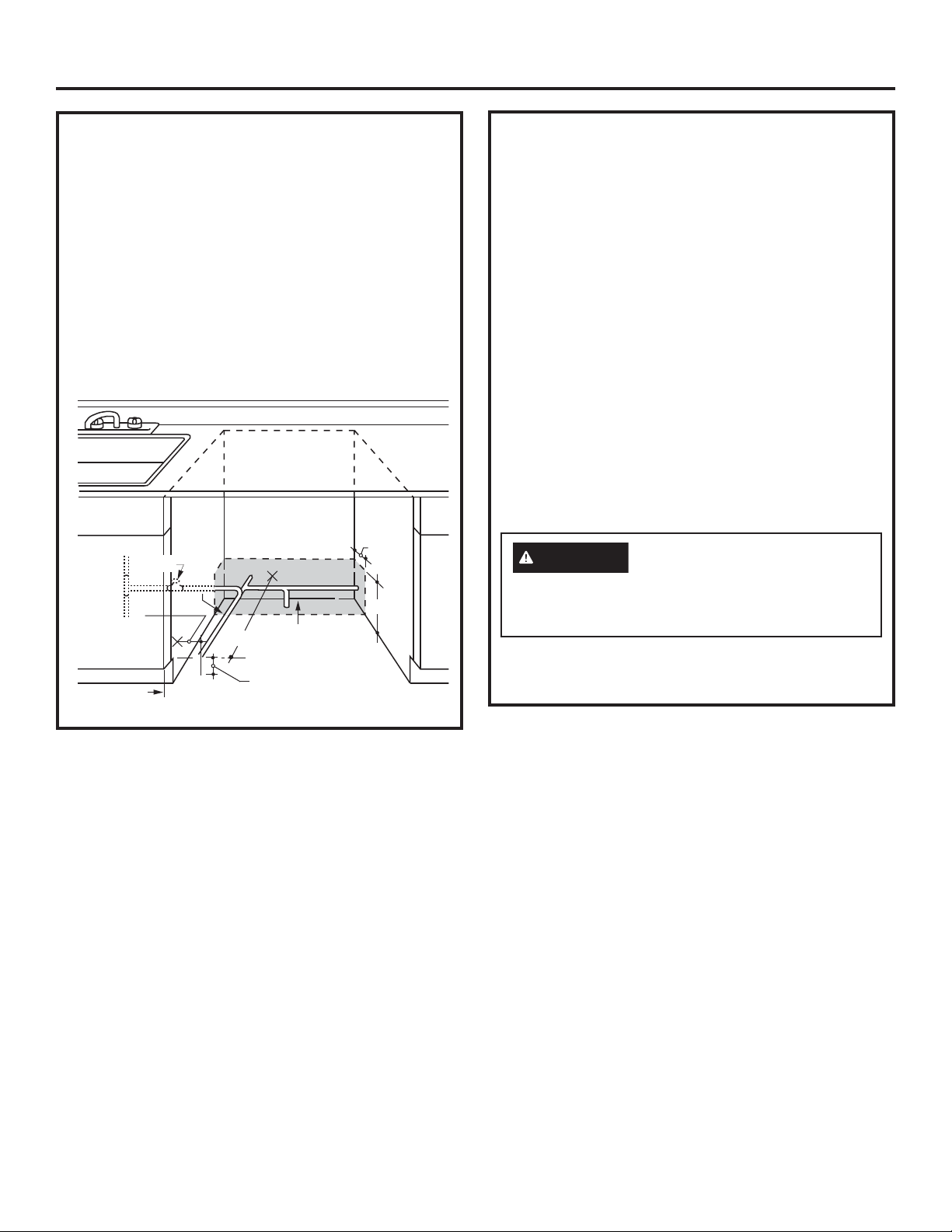

PREPARE DISHWASHER ENCLOSURE

This Wall Area

must be Free

33-1/2” to 34-3/4”

Underside of

Countertop

to Floor

+

34-1/2" 1/4"

Underside of

Countertop

to Floor

of Pipes or

wires

Plumbing and Electric Service

Must Enter Inside This Area

24"

Figure A

Min.

• The rough cabinet opening must be at least 24” deep,

24” wide and approximately 34-1/2” high from floor to

underside of the countertop.

• The dishwasher must be installed so that drain hose is

no more than 12’ in length for proper drainage.

• The dishwasher must be fully enclosed on the top,

sides and back, and must not support any part of the

enclosure.

24"

Min.

4"

Cabinets

Square

6"

and

Plumb

WARNING

To reduce the risk of electric shock, fire, or injury

to persons, the installer must ensure that the

dishwasher is completely enclosed at the time of

installation.

Countertop

Dishwasher

25-1/2"

Clearance for Door

Opening 2" Minimum

Figure B

CLEARANCES:

• When installed into a corner , allow 2” min. clearance

between dishwasher and adjacent cabinet, wall or other

appliances. Allow 25-1/2” min. clearance from the front of

the dishwasher for door opening. Figure B.

DRAIN REQUIREMENTS

• Follow local codes and ordinances.

• Do not exceed 12’ distance to drain.

• Drain connection height is not to exceed 72” above

bottom of dishwasher.

NOTE : Air gap must be used if waste tee or disposer

connection is less than 18” above floor to prevent

siphoning.

DETERMINE DRAIN METHOD

The type of drain installation depends on the following

questions.

• Do local codes or ordinances require an air gap?

• Is waste tee less than 18” above floor?

If the answer to either question is YES, Method 1

MUST be used.

•

If the answers are NO, either method may be used.

CABINET PREPARATION

• Drill a 1-1/2” diameter hole in the cabinet wall within

the shaded areas shown in Figure A for the drain hose

connection. The hole should be smooth with no sharp edges.

IMPORTANT – When connecting

drain line to disposer, check to be sure

that drain plug has been removed.

DISHWASHER WILL NOT DRAIN IF

PLUG IS LEFT IN PLACE.

Remove

Drain

Plug

Method 1 – Air Gap with Waste Tee or Disposer

An air gap must be used when required by local codes

and ordinances. The air gap must be installed according to

manufacturer’s instructions.

Figure C

Method 2 – “High Drain Loop” with Waste Tee or Disposer

Drain Hose Hanger

32"

Min.

18"

Min.

Figure D

Drain Hose Hanger

32"

Min.

18"

Min.

Tip: Avoid unnecessary service call charges.

Always be sure disposer drain plug has been removed

before attaching dishwasher drain hose to the disposer.

3

Page 4

Installation Preparation

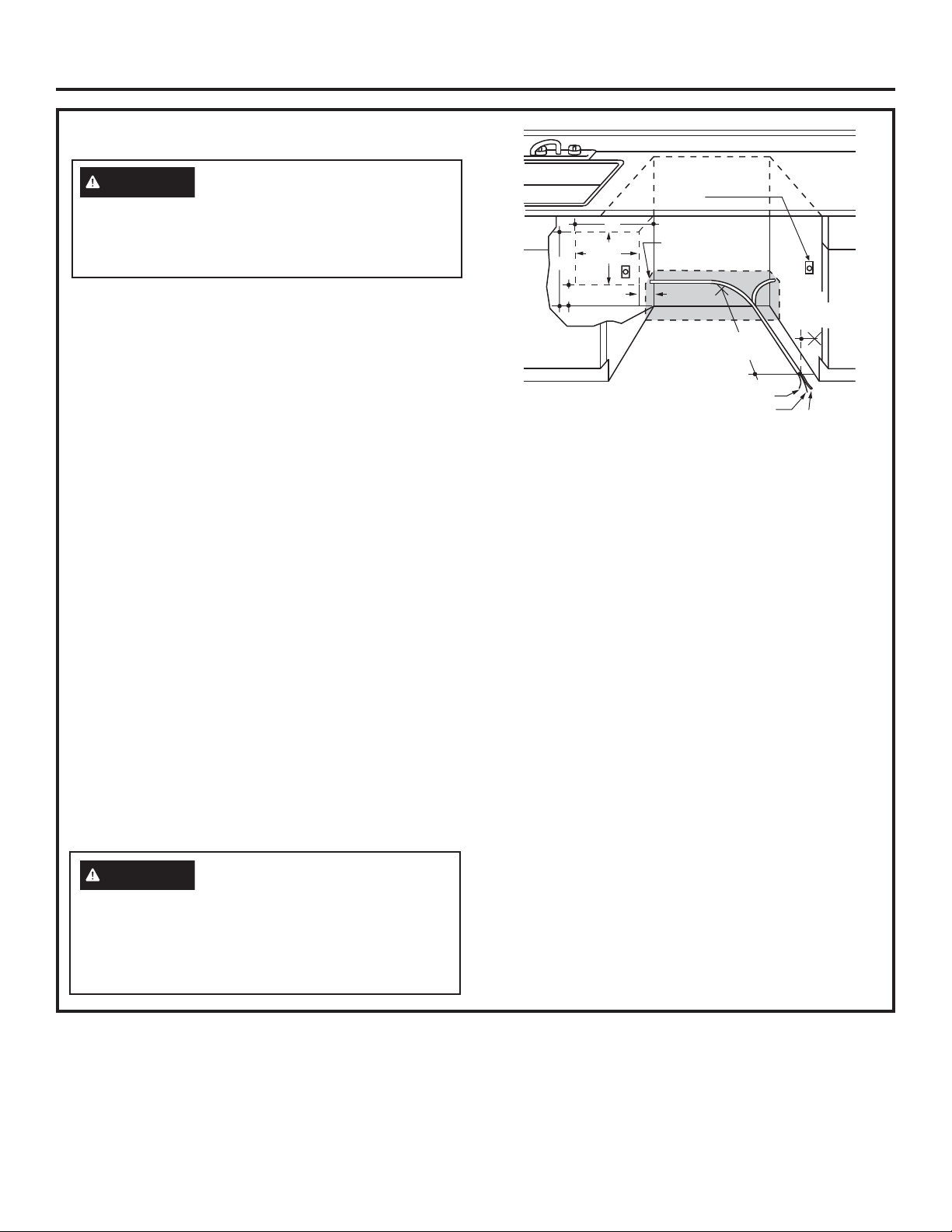

PREPARE ELECTRICAL WIRING

WARNING

FOR PERSONAL SAFETY: Remove house fuse or

open circuit breaker before beginning installation. Do

not use an extension cord or adapter plug with this

appliance.

Electrical Requirements

• This appliance must be supplied with 120V, 60 Hz.,

and connected to an individual properly grounded

branch circuit, protected by a 15- or 20-ampere circuit

breaker or time-delay fuse.

• Wiring must be 2 wire with ground and rated for 75°C

(167°F).

• If the electrical supply does not meet the above

requirements, call a licensed electrician before

proceeding.

Alternate Receptacle

Location in Adjacent

Cabinet

18"

1-1/2" Dia. Hole (Max.)

6"

24"

from Wall

Ground

Black

3"

from

Cabinet

White

Figure E

18"

6"

Receptacle

Location

Area

For models equipped with power cord: Do not modify the

plug provided with the appliance; if it will not fit the outlet,

have a proper outlet installed by a qualified technician.

Grounding Instructions–Permanent Connection

This appliance must be connected to a grounded metal,

permanent wiring system, or an equipment-grounding

conductor must be run with the circuit conductors and

be connected to the equipment-grounding terminal or

lead on the appliance.

Grounding Instructions–Power Cord Models

This appliance must be grounded. In the event of a

malfunction or breakdown, grounding will reduce the risk

of electric shock by providing a path of least resistance

for electric current. This appliance is equipped with a

cord having an equipment-grounding conductor and

a grounding plug. The plug must be plugged into an

appropriate outlet that is installed and grounded in

accordance with all local codes and ordinances.

WARNING

The improper connection of the equipment grounding

conductor can result in a risk of electric shock. Check

with a qualified electrician or service representative

if you are in doubt that the appliance is properly

grounded.

Cabinet Preparation & Wire Routing

•

The wiring may enter the opening from either side, rear

or the floor within the shaded area illustrated above in

Figure E and defined in Figure A.

• Cut a 1-1/2" maximum diameter hole to admit the

electrical cable. Edges of hole should be smooth and

rounded. Permanent wiring connections may pass

through the same hole as the drain hose and hot water

line, if convenient. If cabinet wall is metal, the hole

edge must be covered with a bushing.

NOTE:

Power cords with plug must pass through a

separate hole in the cabinet.

Electrical Connection to Dishwasher

Electrical connection is on the right front of dishwasher.

• For permanent connections the cable must be routed

as shown in Figure E. Cable must extend a minimum of

24" from the rear wall.

• For power cord connections, install a 3-prong

grounding type receptacle in the sink cabinet rear wall,

6" min. or 18" maximum from the opening, 6" to 18"

above the floor.

• Use only WX09X70910 or WX09X70911 Dishwasher

Power Cord Kit.

4

Page 5

Installation Preparation

PREPARE HOT WATER LINE

NOTE: GE Appliances recommends copper tubing for

the water line, but if you choose to use flexible hose,

use GE Appliances WX28X326, flexible braided hose.

• The water supply line (3/8” copper tubing or flexible

braided hose) may enter from either side, rear or

floor within the shaded area shown in Figure F.

• The water supply line may pass through the same

hole as the electrical cable and drain hose. Or, cut

an additional 1-1/2" diameter hole to accommodate

the water line. If power cord with plug is used, water

line must not pass through power cord hole.

Shut-off

Valve

Hot

2"

From

Cabinet

Cabinet Face

1-1/2" Dia.

Hole

19" From Wall

2" From Floor

Figure F

4"

6"

Water Line Connection

• If using a flexible braided supply hose, label

the hose with the installation date to use as

reference. Flexible braided hoses, elbows and

gaskets should be replaced in 5 years.

• Turn off the water supply.

• Install a hand shut-off valve in an accessible

location, such as under the sink. (Optional, but

strongly recommended and may be required by local

codes.)

• Water connection is on the left side of the

dishwasher. Install the hot water inlet line, using no

less than 3/8” copper tubing or a flexible braided

hose. Route the line as shown in Figure F and

extend forward at least 19” from rear wall.

• Adjust water heater for 120°F to 140°F temperature.

• Flush water line to clean out debris.

• The hot water supply line pressure must be 20-120

PSI.

CAUTION

Do not remove wood base until you are ready to

install the dishwasher. The dishwasher will tip over

when the door is opened if base is removed.

Turn page to begin dishwasher

installation.

5

Page 6

Dishwasher Installation

STEP 1

PREPARATION

Locate the items in the installation package:

• Screws

• Junction box cover

• Drain hose and clamp

• Mounting brackets

• Trim pieces (on some models)

• Drain hose hanger

• Owner’s Manual

• Product samples and/or coupons

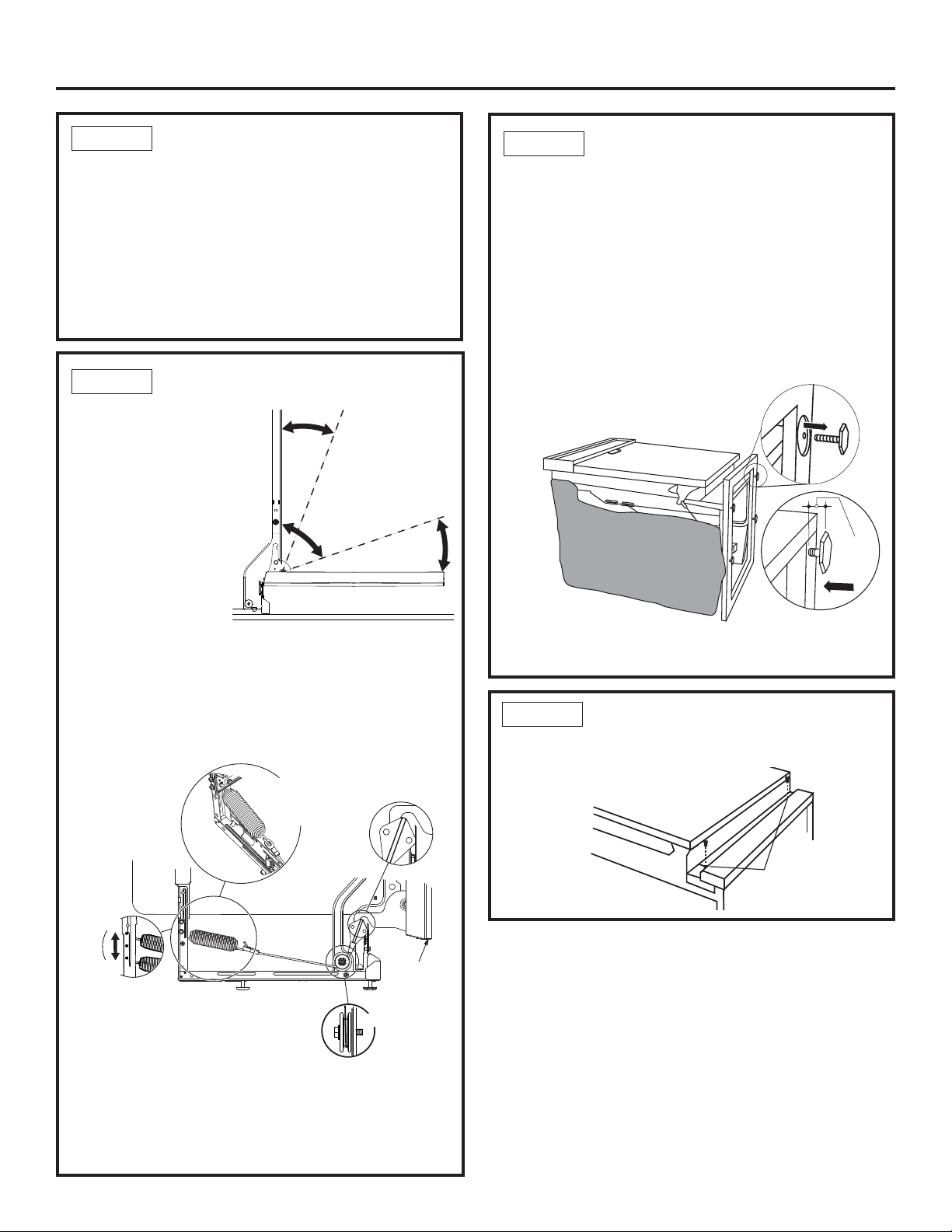

STEP 2

NOTE: If installing a

Custom Door Panel

(available on some

models), please

follow the instructions

found in the Custom

Door Panel kit

WD35X20417.

• With dishwasher

on the wood base,

check the door

balance by opening

and closing the door.

• Door is properly balanced if, when opened, it self

closes within 20° from vertical, stays in position from

20° to 70° and falls fully open beyond 70°.

• If necessary increase or decrease tension as shown.

Some models will have 2 springs on one side and

1 spring on the other side. Latch door and adjust

springs to correct balance.

CHECK DOOR BALANCE

Door

closes

within

20°

Door stays in

position from

20° to 70°

Door falls fully

open beyond 70°

Side View

Figure G

Figure G

Spring

hooked

to hole

inside rail

STEP 3

REMOVE WOOD BASE,

INSTALL LEVELING LEGS

IMPORTANT – Do not kick off wood base!

Damage will occur.

• Move the dishwasher close to the installation location

and lay it on its back. NOTE: Do not place the

dishwasher on its side.

• Remove the 4 leveling legs on the underside of the

wood base with a 15/16” socket wrench.

• Discard base.

• Screw leveling legs back into the dishwasher frame,

approximately 1/2” from frame as shown.

Approx.

1/2"

Figure I

NOTE: Some models have rear adjustable leveling

wheels, and will not require the 2 rear leveling legs.

STEP 4

• Remove the 2 toekick screws and toekick. Set aside

for use in Step 23.

REMOVE TOEKICK

Side View

Increase

Tension

Decrease

Tension

NOTE: The number of

springs, on each side,

will vary by model.

Figure H

Make sure pully

cables are within

pulley shoulders

Custom

door

panel

Front View

Tip: Make sure door opens and closes smoothly.

Check door opening and closing. If door does not open

easily or falls too quickly, check spring cable routing.

The cable is held in place by “shoulders” on the pulley.

Check to be sure cable has not slipped over the pulley

shoulders and is routed as shown.

Toekick

Remove 2

Figure J

Toekick Screws

6

Page 7

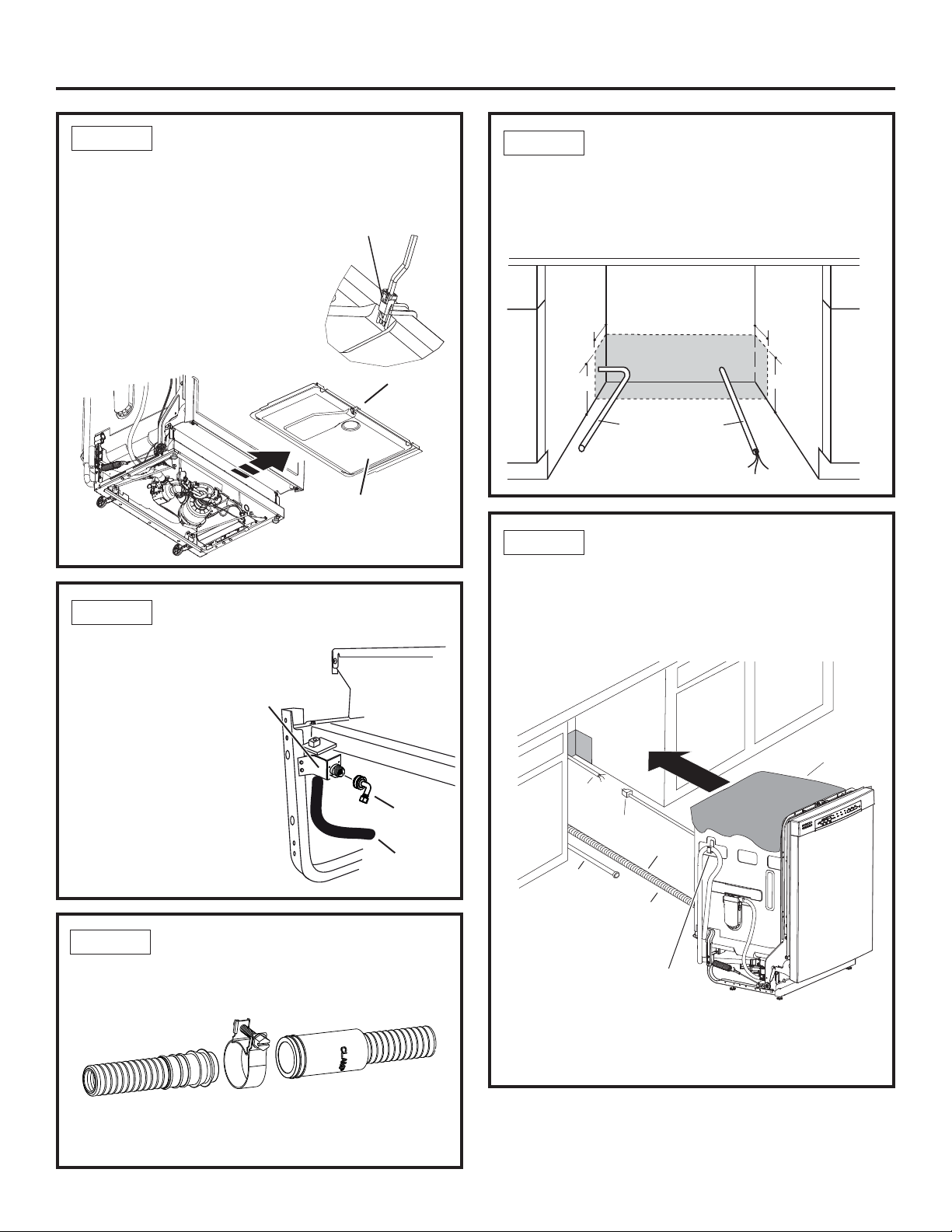

Dishwasher Installation

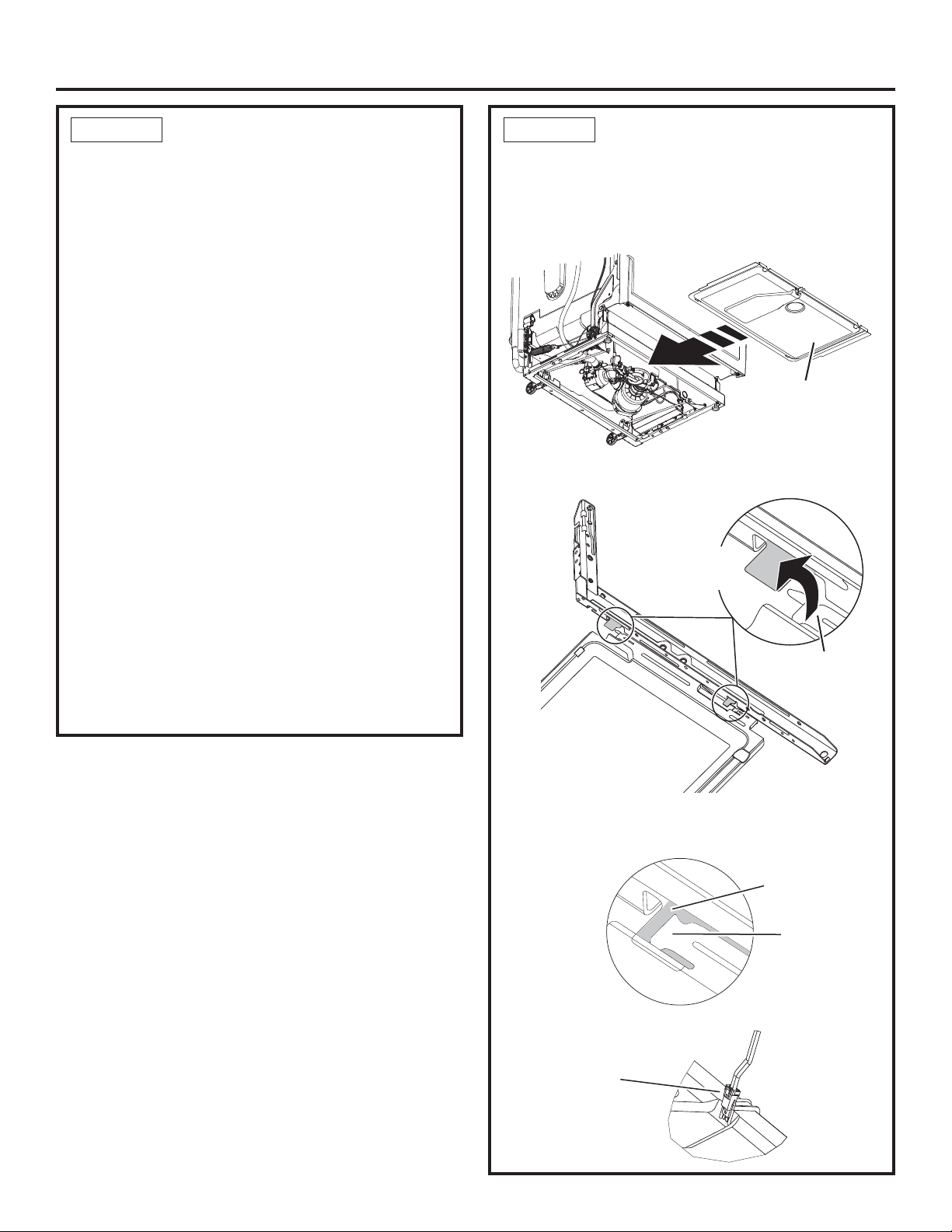

STEP 5

IF NECESSARY, REMOVE

FLOOR PROTE CT P AN

(On some models)

• Disconnect leak sensor wire

(on some models).

• Pull floor protect pan forward and

slide it from under the dishwasher.

• Set aside for use in Step 21.

STEP 6

• Thread 90° elbow

onto the water valve.

Ensure rubber gasket

is located between

valve and elbow.

• Do not overtighten

elbow. Water valve

bracket could bend

or water valve fitting

could break.

• Position the end

of the elbow to

face the rear of the

dishwasher.

STEP 7

INSTALL 90° ELBOW

Water

Valve

Bracket

INSTALL DRAIN HOSE TO

Squeeze connector at top

to release snap feature

Leak Sensor

Floor Protect Pan

Figure L

Front of dishwasher

90° Elbow

Fill Hose

Figure M

DRAIN LOOP

Connect drain loop end to drain hose using the screw

clamp as shown in the figure.

Figure N

NOTE: The high drain loop on the side of the tub is

designed for better wash performance. Do not remove

from the side of the tub.

STEP 8

POSITION WATER LINE

AND HOUSE WIRING

• Position water supply line and house wiring on the

floor of the opening to avoid interference with base

of dishwasher and components under dishwasher.

4"

6"

STEP 9

4"

6"

Water

Line

Figure O

INSTALL DRAIN HOSE,

House

Wiring

THROUGH CABINET

• Position dishwasher in front of cabinet opening.

Insert drain hose into the hole in cabinet side. If

a power cord is used, guide the end through a

separate cabinet opening.

House

Wiring

Power Cord

(If used)

Drain

Water

Line

Ensure drain hose is not

twisted or pinched

Maximum drain hose

length is 15'

Do not disconnect or remove high

drain loop from left side of dishwasher

Tip: Prevent unnecessary service call charges for

fill, drain or noise concerns.

Position utility lines so they do not interfere with

anything under or behind the dishwasher.

Hose

Insulation

Blanket

Figure P

7

Page 8

Dishwasher Installation

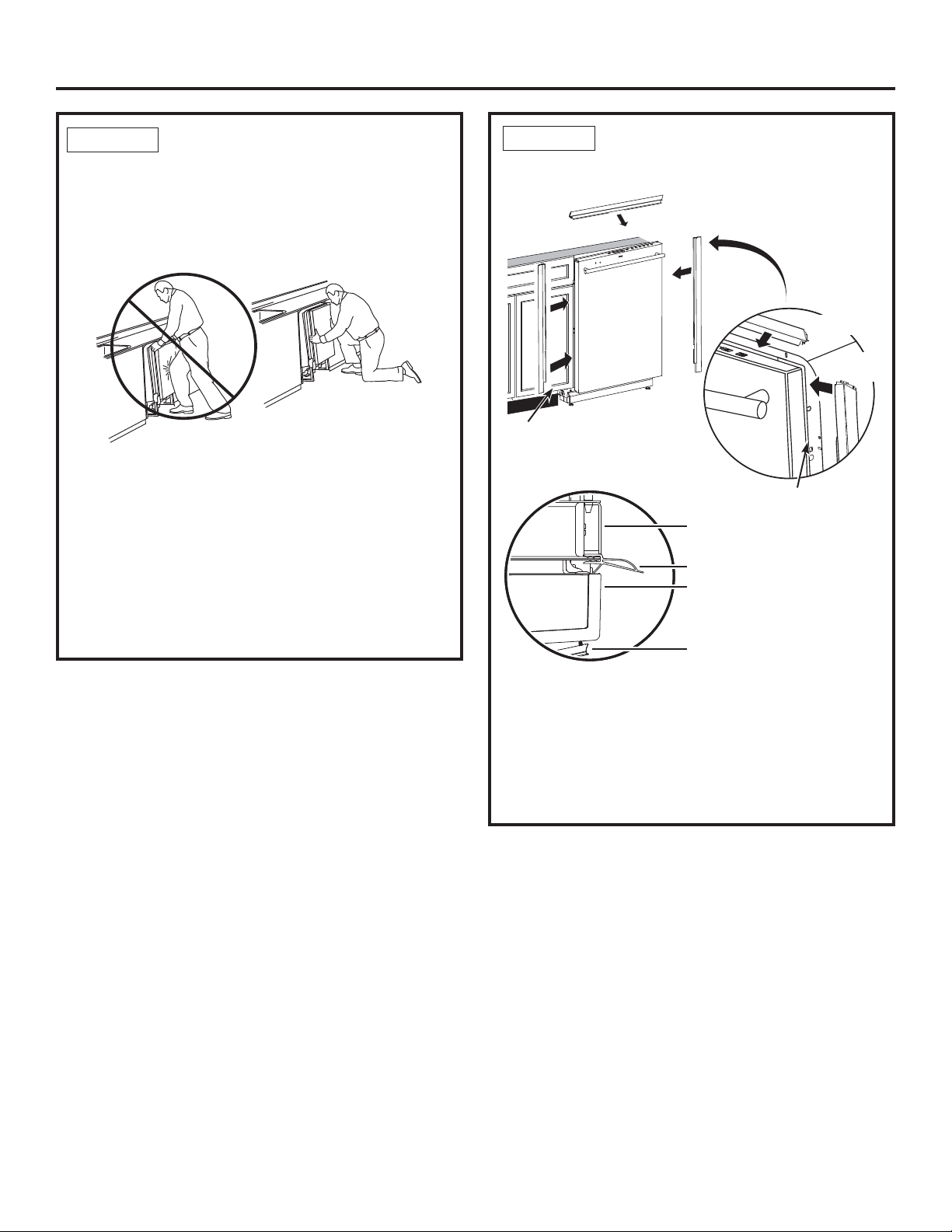

STEP 10

SLIDE DISHWASHER

THREE-FOURTHS OF

THE WAY INTO CABINET

IMPORTANT – Do not push against front panel with

knees. Damage will occur.

• Grasp the sides of the front panel and slide

dishwasher into the opening a few inches at a time.

Do not push against

front door panel with

knee. Damage to the

door panel will occur.

• As you proceed, pull the drain hose through the

opening under the sink. Stop pushing when the

dishwasher extends about 6 inches forward of

adjacent cabinets.

• Make sure drain hose is not kinked under or behind

the dishwasher.

• Make certain the house wiring, drain line and

water line do not interfere with components under

dishwasher.

Figure Q

STEP 11

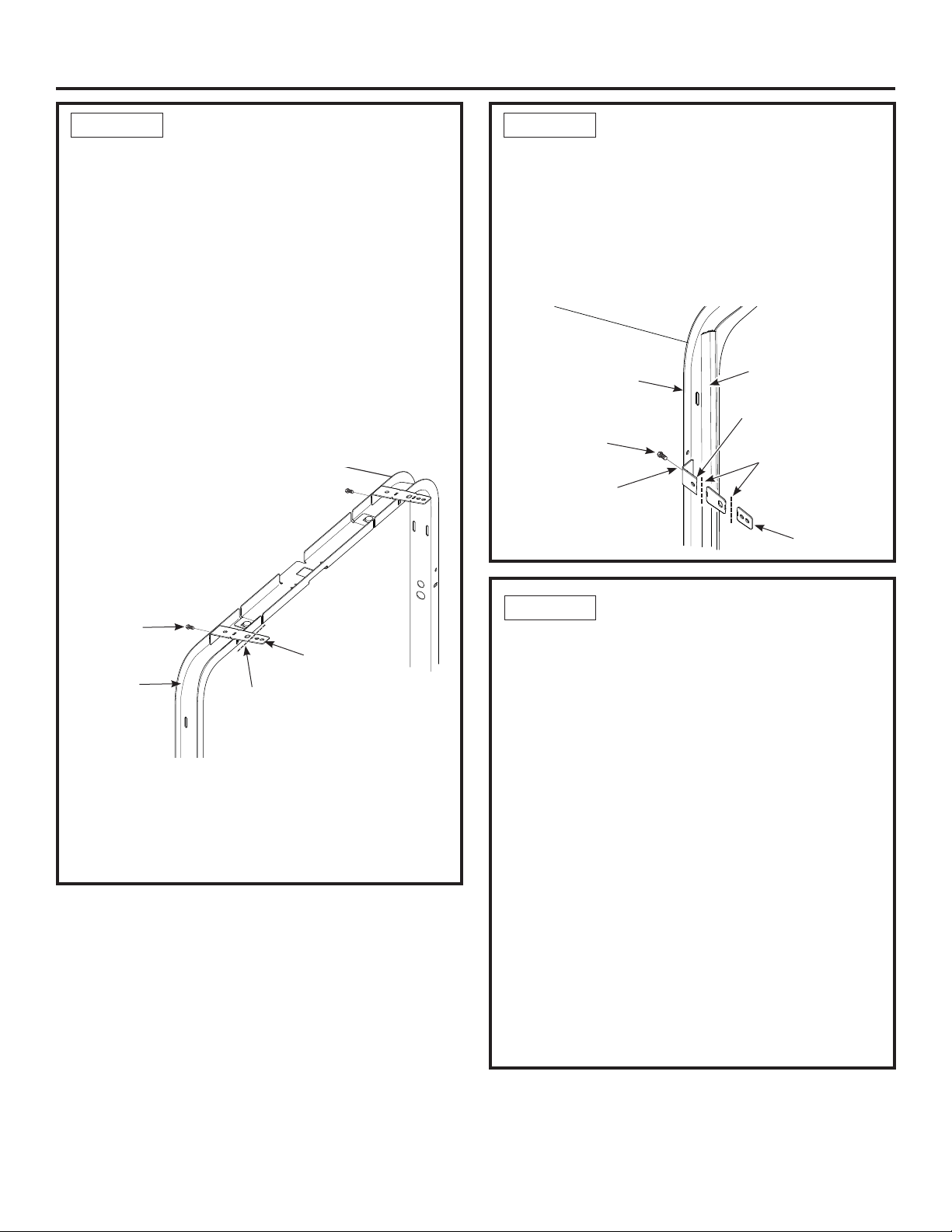

In this step you will need the trim pieces set aside in Step 1.

Top Trim

Side Trim

Top

View

INSTALL TRIM PIECES

Side

Trim

Figure R

Fully seat to tub flange

Tub frame

Tub trim

Door

Handle

Top View

Side

Trim

• Select the top trim piece (See Figure R) and line up

center to the top latch. Press the trim piece onto the

tub flange moving from one side to the other.

• Select the left trim piece (see Figure R). Align top

edge with the top trim and press it onto the left side

of the tub flange moving from the top to the bottom.

Repeat for the right side tub flange trim piece. (See

Figure R for right side trim piece.)

8

Page 9

Dishwasher Installation

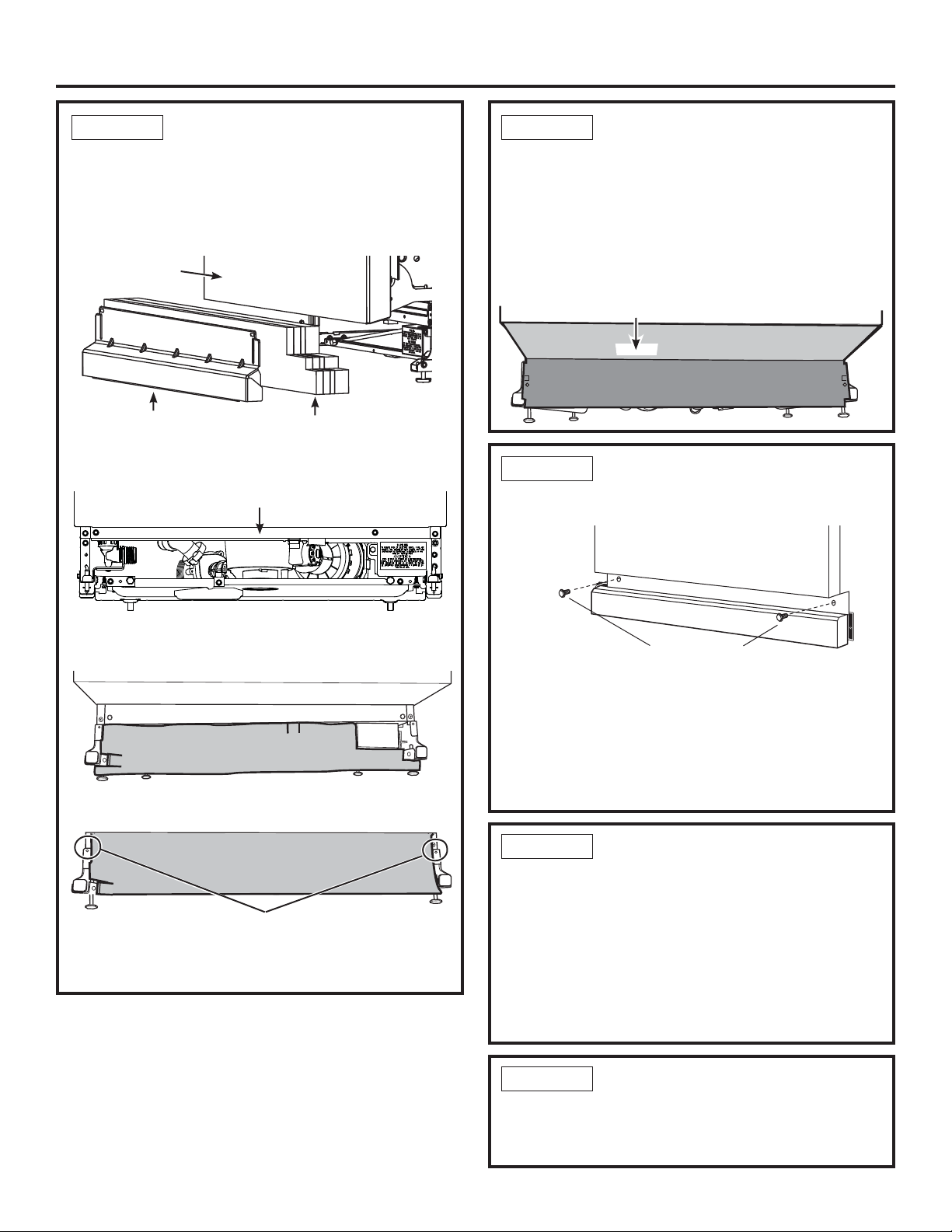

STEP 12

INSTALL MOUNTING

BRACKETS

You will need the mounting brackets and 2 #8 hexhead screws set aside in Step 1.

You must install the mounting brackets onto the

dishwasher tub frame top or sides prior to sliding

the dishwasher into place under the countertop. This

dishwasher is capable of a true-flush installation at a

24” deep opening. The mounting brackets have several

available attachment positions to accommodate different

cabinet constructions.

Install mounting brackets on top if the

underside of countertop is wood or wood-like

material that accepts screws:

IMPORTANT - After installing brackets and before

closing the dishwasher door, adjust the brackets

by bending them up as needed, so that they do not

contact the top of the dishwasher door and cause

damage.

Top Mounting

STEP 12

INSTALL MOUNTING

BRACKETS (CONT.)

Install mounting brackets on sides if the

countertop is granite or similar material that will

not accept wood screws:

• Break off front portion of the tab with pliers at the

location shown prior to attaching to dishwasher.

• Position the left-hand side bracket as shown. Repeat

with the right bracket.

Side Mounting

Dishwasher

tub frame

#8 Bracket

screw as

supplied

Do not pinch

the latch wires

in #8 bracket

screw

Figure T

Tub trim

Care should be taken

to ensure mounting

screws do not damage

cabinetry

Bend and break

here if necessary

Bracket

#8 Bracket

Screw

Bracket

Dishwasher

tub frame

• If you are installing the dishwasher under a counter

with a short overhang, the countertop brackets may

extend beyond the edge of the counter. If this is

the case, remove the excess length by repeatedly

bending the brackets at the front notch only until they

break.

Bend and break

here after installing if

counter has a short

overhang.

Figure S

STEP 13

PUSH DISHWASHER INTO

FINAL POSITION

• Check the tub insulation blanket, if equipped, to be

sure it is smoothly wrapped around the tub. It should

not be “bunched up” and it must not interfere with

the door springs. If the insulation is “bunched up” or

interfering with the springs, straighten and re-center

the blanket prior to sliding the dishwasher into its

final position.

• Slide the dishwasher into the final position by

pushing on the sides of the door panel. Do not push

or pull the door in a partially open or closed position

when moving the dishwasher. Do not use a knee or

push on the center of the panel. If you do, damage to

the panel will likely result. Check that the dishwasher

is squarely positioned in the cabinet opening at

both the top and the bottom of the appliance prior to

mounting to the cabinet.

IMPORTANT – Before opening the dishwasher door,

be certain the edges of the dishwasher door panel

are behind the face of the adjacent cabinet and not

up against the cabinet face. Refer to Figure U. If the

dishwasher door is opened when the edge of the door

is against the face of the cabinet, dishwas he r door

damage and cabinet damage will occur.

9

Page 10

Dishwasher Installation

STEP 13 STEP 14

• Open and close the dishwasher door to be sure it

operates smoothly, and does not rub on the adjacent

cabinet.

Tip: Prevent unnecessary service charges for

panel damage or wash performance.

Check dishwasher alignment prior to opening

dishwasher door to prevent panel damage.

Make sure utility lines are not trapped or crushed behind

dishwasher. Crushed lines will restrict water flow.

Door

Fits and

Swings

Back

Behind

Cabinet

Frame

Correct

Alignment

Figure U

Check that tub trim does not

contact the door at all points

Top

View

Tub trim may be trimmed if

necessary to ensure proper

door operation

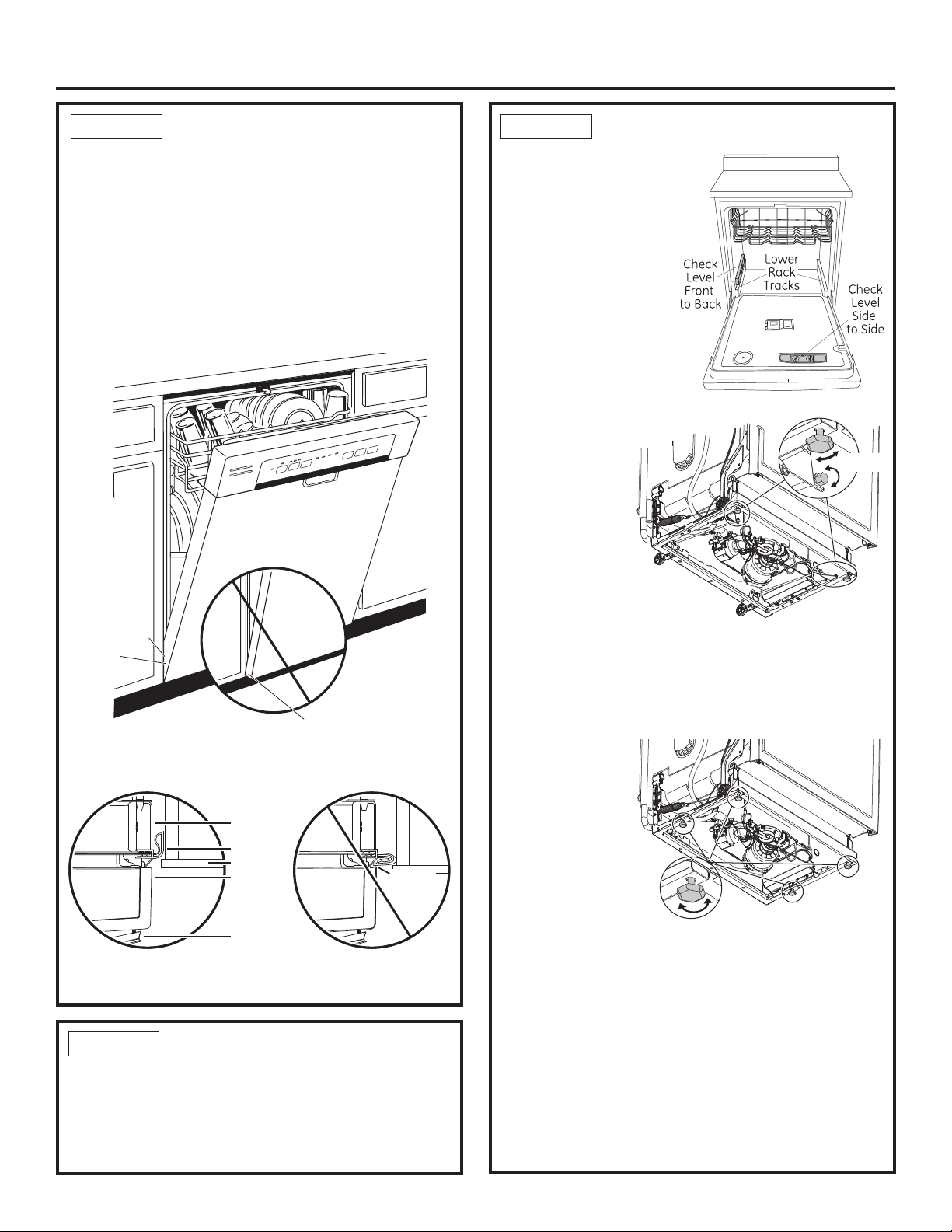

STEP 14

IMPORTANT – Dishwasher must be level for proper dish

rack operation, wash performance and door operation. The

dishwasher must be leveled left to right and front to back.

This ensures the dish racks will not roll in or out on their own,

circulation water will flow to the pump inlet, and the door will

close without hitting the side of the tub.

PUSH DISHWASHER INTO

FINAL POSITION (CONT.)

Incorrect Alignment

will result in door damage

Tub frame

Tub trim

Cabinet

Door

Handle

Door Catches

on Cabinet Frame

Do not allow tub trim to get

trapped by or come into

contact with the door

Top

View

Tub trim

trapped

by door!

LEVEL DISHWASHER

• Remove the lower dish

rack and place a level on

the door and lower rack

track as shown in Figure V.

• If your model has rear

wheels, the height of the

wheels are adjusted from

the front of the dishwasher

along with the 2 front

legs on the bottom of the

dishwasher. Begin the

leveling process with the

front legs by individually

turning the front 2 legs.

By adjusting the front

legs first,access to the

rear leveling bolts

is maximized

easing rear wheel

adjustment. When

the front legs are

adjusted to a height

resulting in an

appropriate gap to

the upper cabinet,

proceed to adjust

the rear leveling

wheels by adjusting

the leveling bolts as illustrated in Figure W. Individually turn

the 2 bolts to adjust the rear wheels. Slowly rotate the 2 bolts

counter clockwise to raise the back of the dishwasher, and

clockwise to lower it. Continue to adjust the feet and wheels

until the dishwasher is level as illustrated in Figure W. Ensure

all 4 legs/wheels are firmly in contact with the floor.

• If your model has

4 leveling feet,

adjust the level of

the dishwasher by

individually turning the

4 legs on the bottom

of the dishwasher as

shown in Figure WW.

• The dishwasher

is properly

leveled when the

level indicator is

centered left to right

and front to back. Also, the dishwasher door should close

without hitting the side of the tub.

• Replace the lower rack.

• Pull each rack out, about halfway. Check to be sure it does

not roll back or forward on the door. If the rack moves,

adjust leveling legs.

Tip: Prevent unnecessary service charges. Verify

dishwasher is leveled.

Pull the dish racks half way out. They should stay put. Open

and close the door. The door should fit in the tub opening

without hitting the side of the tub. If the racks roll on their

own, or the door hits the side of tub, re-level the dishwasher.

LEVEL DISHWASHER (CONT.)

Figure V

Adjust

Figure W

Figure WW

Adjust

10

Page 11

Dishwasher Installation

STEP 15

POSITION DISHWASHER,

SECURE TO COUNTERTOP

OR CABINET

In this step you will need the 2 Phillips special head

screws from the screws set aside in Step 1.

The dishwasher must be secured to the countertop

or the cabinet sides. When the underside of the

countertop is wood, use Method 1. Use Method 2

when the underside of the countertop is made of a

material, such as granite, that will not accept wood

screws.

IMPORTANT – Prevent door panel and control

panel damage. Dishwasher must be positioned so

the front panel and control panel do not contact the

adjacent cabinets or countertop. Mounting screws

must be driven straight and flush. Protruding screw

heads could scratch the door panel or control panel

and interfere with door operation.

Method 1

Secure dishwasher to underside of wood countertop.

• Recheck alignment of the dishwasher in the cabinet.

Refer to Steps 13 and 14. Door panel and/or control

panel must not hit cabinets or countertop.

• Fasten the dishwasher to the underside of the

countertop with the 2 Phillips special head screws.

Refer to figure. Make certain screws are driven

straight and flush to prevent panel damage.

Brackets

Wood Countertop

STEP 15

POSITION DISHWASHER,

SECURE TO COUNTERTOP

OR CABINET (CONT.)

• Re-check that the dishwasher is squarely positioned

in the cabinet at both the top and bottom of the

appliance after mounting to the cabinets/countertop.

Adjust if necessary.

• Confirm all leveling legs are in contact with the floor

to prevent the dishwasher from rocking and ensure

proper door and latch operation

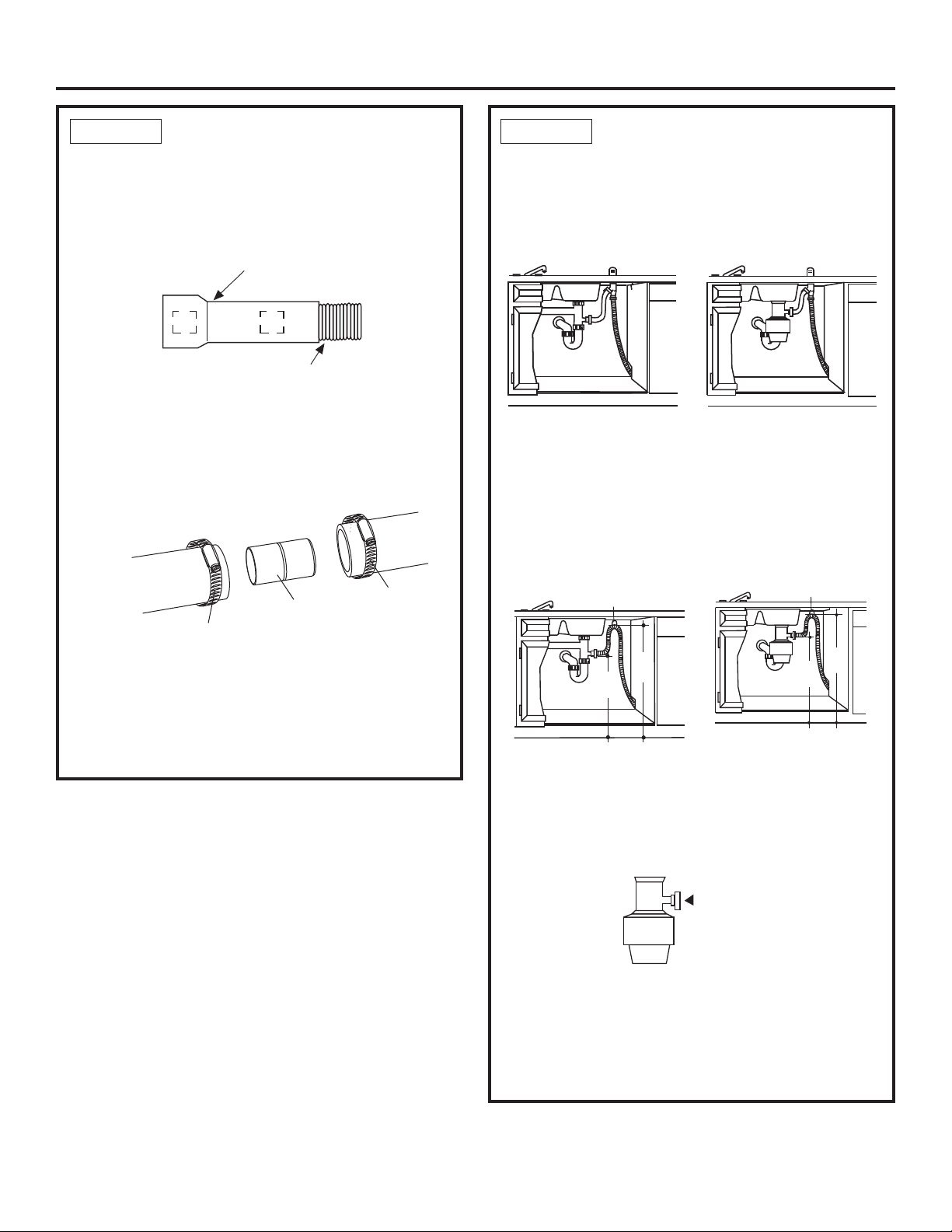

STEP 16

CONNECT WATER

SUPPLY

Connect water supply line to 90° elbow.

If using a flexible braided hose connection:

• Attach nut to 90° elbow using an adjustable wrench.

If using a copper tubing connection:

• Slide compression nut, then ferrule over end of water

line.

• Insert water line into 90° elbow.

• Slide ferrule against elbow and secure with

compression nut.

IMPORTANT – Check to be sure that door spring and/

or door spring cable do not rub or contact the fill hose

or water supply line. Test by opening and closing the

door. Re-route the water supply lines if a rubbing noise

or interference occurs.

Hot Water

90° Elbow

Supply Line

Compression

Nut

Method 2

Secure dishwasher to cabinet sides.

• Recheck alignment of the dishwasher in the cabinet.

Refer to Steps 13 and 14. Door panel and/or control

panel must not hit cabinets or countertop.

• Remove plug buttons. Do not discard.

• Fasten the dishwasher to the adjacent cabinets with

the 2 Phillips special head screws provided. Refer

to Figure X. Make certain screws are driven straight

and flush to prevent panel damage. Do not screw

into the cabinet face frame.

• Install plug buttons to the side of the tub in the holes

provided.

Solid Surface Countertop

Screw

Figure X

Plug buttons

Side Brackets

Screw

11

Bottom Left Side

Ferrule

Figure Y

Page 12

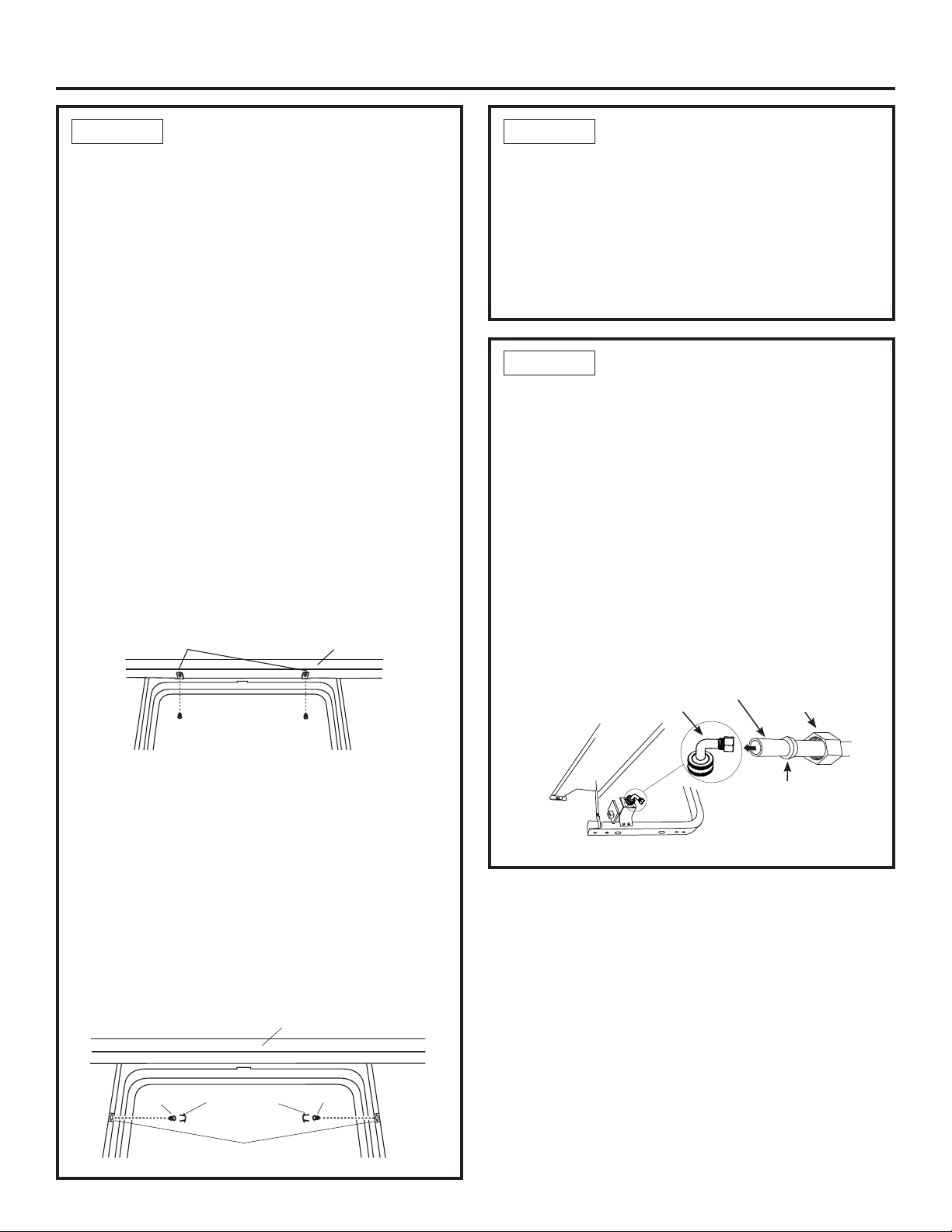

Dishwasher Installation

STEP 17 STEP 17

The molded end of the drain hose will fit 5/8” through 1”

diameter inlet ports on the air gap, waste tee or disposer.

• Determine size of inlet port.

• Cut drain hose connector on the marked line, if required,

to fit the inlet port.

Figure Z

• If a longer drain hose is required and you did not

purchase drain hose WD24X10065, add up to 66”

length for a total of 144” (12 feet) to the factory-installed

hose. Use 5/8” or 7/8” inside diameter hose and

a coupler to connect the 2 hose ends. Secure the

connection with hose clamps.

CONNECT DRAIN LINE

Cutting Line

1"

IMPORTANT: Do not cut corrugated

5/8"

portion of hose

• Connect drain line to air gap, waste tee or disposer

using the previously determined method. Secure

hose with a screw-type clamp.

Method 1 – Air gap with waste tee or disposer

Waste Tee Installation

Method 2 – “High drain loop” with waste tee or

disposer

With this method you will need the drain hose hanger

set aside in Step 1.

Fasten drain hose to underside of countertop with the

provided hanger.

CONNECT DRAIN LINE

(CONT.)

Disposer Installation

Figure AB

2^d_[Ta

Figure AA

NOTES:

• DRAIN CONNECTION HEIGHT IS NOT TO EXCEED

72” ABOVE BOTTOM OF DISHWASHER.

• TOTAL DRAIN HOSE LENGTH MUST NOT

EXCEED 12 FEET FOR PROPER DRAIN

OPERATION.

7^bT2[P\_

7^bT2[P\_

Drain Hose Hanger

32"

Min.

18"

Min.

Waste Tee Installation

Figure AC

IMPORTANT – When connecting drain line to

disposer, check to be sure that drain plug has been

removed. DISHWASHER WILL NOT DRAIN IF PLUG

IS LEFT IN PLACE.

Disposer Installation

18"

Min.

32"

Min.

Remove

Drain

Plug

Tip: Avoid unnecessary service call charges for a

no drain complaint.

Make sure excess drain hose has been pulled through

the cabinet opening. This will prevent excess hose

in the dishwasher cavity from becoming kinked or

crushed by the dishwasher.

12

Page 13

Dishwasher Installation

STEP 18

CONNECT POWER SUPPLY

If a power cord with plug is already installed

proceed to Step 19.

WARNING

If house wiring is not 2-wire with ground, a ground

must be provided by the installer. When house wiring

is aluminum, be sure to use UL-Listed anti-oxidant

compound and aluminum-to-copper connectors.

In this step you will need the junction box cover and

the #10 Hex head screw from the screws set aside in

Step 1.

• Secure house wiring to the back of the junction box

with a strain relief.

• Locate the 3 dishwasher wires, (white, black and

green) with the stripped ends coming out of the AC

jumper. Use UL listed wire nuts of appropriate size to

connect incoming ground to green, white to white and

black to black.

• Install the junction box cover using #10 hex head

screw. Check to be sure that wires are not pinched

under the cover.

• Make sure that the junction box cover is resting on

the mounting bracket.

• If using a Power Cord Kit, use GE Appliances part

number WX09X70910 or WX09X70911 and refer to

the included instructions.

NOTE: Do not remove the

Junction Box Bracket.

White

Ground

(Green)

AC

Jumper

STEP 19

Review this list after installing your dishwasher to

avoid charges for a service call that is not covered

by your warranty.

• Check to be sure power is OFF.

• Open door and remove all foam and paper

packaging.

• Locate the Owner’s Manual set aside in Step 1.

• Read the Owner’s Manual for operating instructions.

• Check door opening and closing. If door does not

open and close freely, check for proper routing of

spring cable over pulley. If door drops or closes

when released, adjust spring tension. See Step 2.

• Check to be sure that wiring is secure under the

dishwasher, not pinched or in contact with door

springs or other components. See Step 18.

• Check door alignment with tub. If door hits tub, level

dishwasher. See Step 14.

• Check door alignment with cabinet. If door hits

cabinet, reposition dishwasher. See Step 13.

• Check that door spring does not contact water line,

fill hose, wiring or other components. See Step 13.

• Verify water supply and drain lines are not kinked

or in contact with other components. Contact with

motor or dishwasher frame could cause noise.

• Turn on the sink hot water faucet and verify water

temperature. Incoming water temperature must be

between 120°F and 140°F. A minimum of 120°F

temperature is required for best wash performance.

See “Prepare Hot Water Line,” page 5.

• Add 1 quart of water to the bottom of the dishwasher

to lubricate the pump seal.

• Turn on water supply. Check for leaks. Tighten

connections if needed.

• Remove protective film if present from the control

panel and door.

• Check that tub trim does not contact the door.

PRETEST CHECKLIST

Black

Ground Screws

Figure AD

NOTE: All ground screws, brackets and wires must

remain intact.

Junction Box

Bracket

13

Page 14

Dishwasher Installation

STEP 20 STEP 21

• Turn on power supply or plug power cord into outlet,

if equipped.

• Select a cycle to run and push the START button.

• Ensure the door is latched. Dishwasher should start.

• Check to be sure that water enters the dishwasher.

If water does not enter the dishwasher, check to be

sure that water and power are turned on.

• Check for leaks under the dishwasher. If a leak

is found, turn off power at the breaker, and then

tighten water connections. Restore power after leak

is corrected.

• Check for leaks around the door. A leak around

the door could be caused by door rubbing or

hitting against adjacent cabinets. Reposition the

dishwasher if necessary. See Step 13.

• Press and hold the START button for 3 seconds to

cancel the cycle. The unit will begin to drain. Check

drain lines. If leaks are found, turn off power at the

breaker and correct plumbing as necessary. Restore

power after corrections are made. See Steps 7, 8, 9,

10 and 17.

• Open dishwasher door and make sure all of the

water has drained. If not, check that disposer plug

has been removed and/or air gap is not plugged.

Also check drain hose to be sure it is not kinked

underneath or behind dishwasher. See Step 17.

• Press START button once again and run dishwasher

through another cycle. Check for leaks and correct if

required.

• Repeat these steps as necessary.

DISHWASHER WET TEST

• Slide the floor protect pan under the dishwasher

until its side lock slots are close to engaging the side

mounting tabs on the dishwasher.

• Lift the pan until its lock slots contact the mounting

tabs and push the pan back to engage them.

Rear

REPLACE FLOOR

PROTECT PAN

(on some models)

Figure AE

Mounting Tab

Two on each side

of the dishwasher

Two on each side of

the floor protect pan

Floor Protect

Pan

Lock Slots

Floor Protect

Pan

Front

• When properly installed, the top of the lock slots will

be over the mounting tabs.

Mounting

Tab

Lock Slot

• Connect the leak sensor connector to the leak sensor

(on some models).

Leak Sensor

(on some models)

14

Page 15

Dishwasher Installation

STEP 22 STEP 22

• Locate the sound insulation package inside the

dishwasher.

• Stand the parts upright as shown.

Dishwasher

Door

Figure AF

• Locate the control box.

POSITION SOUND

INSULATION PIECE

(on some models)

Toekick

Insulation Block

(On some models.)

Control Box

• Open door all the way, if the door doesn’t stay fully

open, adjust the insulation panel.

• Align the screw holes with the screw holes on the

legs of the dishwasher.

• Ensure vent opening is not blocked by insulation.

Location and appearance will vary

STEP 23

• Place toekick against the legs of the dishwasher.

POSITION SOUND

INSULATION PIECE

(on some models)

Vent opening

REPLACE TOEKICK

(CONT.)

Figure AG

• Push insulation block portion under the dishwasher

until it is beneath the control box.

Figure AH

• Push the panel portion up to the front of the block.

(on some models)

Push the sides of the insulation behind

the toekick attachment screw holes

• Tuck the sides of the front panel behind the toekick

attachment screw holes.

Toekick

Figure AJ

• Align the toekick with the bottom edge and make

sure it is against the floor.

• Insert and tighten the 2 toekick attachment screws.

The toekick should stay in contact with the floor.

Tip: Reduce sound from under the dishwasher.

Make sure toekick is against floor.

STEP 24

• Tub trim does not interfere with the door

• Dishwasher is square and level at both the top and

bottom of the cabinet opening, with no twisting or

distortion of the tub or door

• All 4 legs of the dishwasher are firmly in contact with

the floor

• Drain hose is not pinched between the dishwasher

and adjacent cabinets or walls

• Tub trim is fully seated on the tub flange

CHECK THE FOLLOWING

Attachment

Screws

STEP 25

• Be sure to leave complete literature package, these Installation

Instructions and product samples and/or coupons with the

consumer.

LITERATURE

15

Page 16

NOTE: Product improvement is a continuing endeavor at GE Appliances.

Therefore, materials, appearance and specifications are subject to

change without notice.

Page 17

Directives d’installation

Lave-vaisselle encastré

Pour toute question, composez le 1.800.561.3344 ou visitez notre site web:

www.electromenagersge.ca

AVANT DE COMMENCER

ARRÊT

Veuillez lire attentivement toutes les directives

qui suivent.

AVERTISSEMENT

• Pour réduire les risques de choc électrique, d’incendie

ou de blessures, l’installateur doit s’assurer que le lavevaisselle est complètement encastré au moment de

l’installation.

• POUR VOTRE SÉCURITÉ PERSONNELLE: Enlevez

le fusible ou déclenchez le disjoncteur au panneau de

distribution principal avant de commencer l’installation.

N’utilisez pas une rallonge électrique ou un adaptateur

de fiche avec cet appareil.

• Un branchement inadéquat du conducteur de mise à la

terre peut présenter des risques de choc électrique. Si

vous n’êtes pas certain que l’appareil est correctement

mis à la terre, consultez un réparateur ou un électricien

qualifié.

• Si le câblage électrique de la résidence n’est pas

constitué de deux fils plus un fil de mise à la terre,

l’installateur doit installer un fil de mise à la terre. Si le

câblage électrique de la résidence est en aluminium,

utilisez un agent antioxydant et des connecteurs pour

raccords «aluminium-cuivre» homologués UL.

ATTENTION

N’enlevez pas la base de bois avant d’être prêt à installer

le lave-vaisselle. Si vous enlevez la base de bois, le lavevaisselle pourrait basculer lorsque vous ouvrez la porte.

VÉRIFIEZ LES POINTS SUIVANTS

La moulure de la cuve ne gêne pas la porte

Le lave-vaisselle est d'équerre et de niveau par rapport au bas et au haut de

l'ouverture de l'armoire, sans torsion ni déformation de la cuve ou de la porte

Les quatre (4) pieds reposent fermement sur le plancher

Le boyau de vidange n'est pas coincé entre le lave-vaisselle et les armoires

ou les murs adjacents

La moulure de cuve repose entièrement contre le bord de la cuve

POUR VOTRE SÉCURITÉ

Veuillez lire et observer toutes les mises en garde

(A VERTISSEMENT et ATTENTION) données dans les

présentes directives.

Pour effectuer l’installation décrite dans les présentes

directives, il faut porter des gants et des lunettes de

sécurité.

IMPORTANT – Observez tous les codes et ordonnances en

vigueur.

• Note à l’installateur – Veuillez laisser les présentes

directives au consommateur pour l’inspecteur local.

• Note au consommateur – Veuillez conserver les

présentes directives avec votre Manuel d’utilisation pour

consultation ultérieure.

• Compétences requises – L’installation de ce lave-

vaisselle exige des compétences de base en mécanique,

en électricité et en plomberie. L’installateur est

responsable de la qualité de l’installation. Toute

défaillance du produit attribuable à une installation

inadéquate n’est pas couverte par la garantie de GE

Appliances. Reportez-vous à la garantie du produit.

• Durée de l’installation – Entre 1 et 3 heures.

L’installation d’un nouveau lave-vaisselle exige plus de

temps que le remplacement d’un ancien modèle.

IMPORTANT – Le lave-vaisselle DOIT être installé de

manière à ce qu’il puisse être sorti de son emplacement si

des réparations sont nécessaires.

Il importe d'user de prudence lorsque l'appareil est installé

ou déplacé afin de prévenir l'endommagement du cordon

d'alimentation.

Si le lave-vaisselle que vous avez reçu est endommagé,

communiquez immédiatement avec votre détaillant ou

l’entrepreneur en construction.

Accessoires facultatifs – Reportez-vous au Manuel d’utilisation

pour connaître les ensembles pour panneau décoratif

personnalisé offerts.

Votre lave-vaisselle est un appareil qui chauffe l’eau.

VEUILLEZ LIRE ATTENTIVEMENT

CONSERVER CES DIRECTIVES

Page 18

Préparation pour l’installation

PIÈCES FOURNIES DANS

L’EMBALLAGE:

• C

ouvercle de la boîte de jonction et vis à tête hexagonale n° 10

• Collier

• Boyau de vidange (147 cm/58 po de long)

• Support de tuyau de vidange

• 2 Vis à tête hexagonale no 8-18 pour fixer les

supports au cadre de la cuve du lave-vaisselle

• 1 Garniture supérieure (certains modèles)

• 2 Moulures latérales

• 2 Supports de montage pour comptoirs ou

armoires latérales en bois

• 2 Vis à tête spéciale Phillips n° 8-18 x 15,8 mm (5/8 po) pour fixer

le lave-vaisselle au dessous du comptoir ou armoires latérales

• 2 Boutons de bouchon

• Documentation, échantillons et(ou) bons

MATÉRIAUX NÉCESSAIRES:

• 90°, bague et écrou à compression (boyau avec filetage interne

19,1 mm [3/4 po] à une extrémité et de dimension adaptée à

la conduite d’alimentation à l’autre extrémité)

• Connecteurs vissables homologués UL (3)

• Ruban-cache

Pour une nouvelle installation:

• Coupure anti-refoulement pour le boyau de vidange, si nécessaire

• Raccord en T pour la plomberie de la résidence, s’il y a lieu

•

Câble électrique ou Trousse de cordon d’alimentation

WX09X70910 (5,4 pi) ou WX09X70911 (7,9 pi) en fonction de

votre installation.

• Colliers à vis sans fin

• Bague anti-traction pour le raccordement électrique

• Robinet d’arrêt (recommandé)

• Conduite d’eau chaude – 9,5 mm (3/8 po) minimum, tuyau en

cuivre (incluant la bague et l’écrou à compression) ou la pièce

WX28X326 de GE Appliances, boyau métallique flexible.

• Boyau de vidange de 3,7 m (12 pi) de long WD24X10065,

si nécessaire

Couvercle de la

boîte de jonction

et vis à tête

hexagonale n° 10

Vis à tête

hexagonale n° 10

de 12,7 mm (1/2

po) de long pour

boîte de jonction

Garniture (supérieure)

(certains modèles)

Vis à tête spéciale

Phillips n° 8

de 15,8 mm (5/8 po)

de long

Coude de 90°

Coupure anti-

refoulement

Bague

anti-traction

Connecteurs

vissables (3)

Raccord

en T

Robinet

d’arrêt

Supports de

montage

Collier

Support de tuyau

de vidange

Ruban-cache

Câble électrique (ou

cordon d’alimentation,

s’il y a lieu)

Conduite d’eau

chaude

Boyau de vidange

Vis à tête hexagonale

n° 8 pour support de

montage

Moulures latérales

Boutons de

bouchon

Documentation

Raccord pour

boyau de vidange

facultatif

Colliers à vis

Boyau de

vidange facultatif

WD24X10065

sans fin

OUTILS NÉCESSAIRES:

• Tournevis cruciforme

• Tournevis à douille de 5/16 po et 1/4 po

• Clé à molette de 15 cm (6 po)

• Niveau

• Équerre de menuisier

• Ruban à mesurer

• Lunettes de sécurité

• Lampe de poche

• Seau pour attraper l’eau lors de la purge du tuyau

• Douille de 15/16 po (optionnelle pour

la dépose de la palette)

• Gants

• Pince

Pour une nouvelle installation:

• Coupe-tube

• Perceuse et mèches appropriées

• Jeu de scie-cloche

Pince

Lunettes de sécurité

Tournevis

cruciforme

Douille de 15/16

Tournevis à douille

de 5/16 po et 1/4 po

Lampe de poche

Scie-cloche

2

Clé à molette de

15 cm (6 po)

Ruban à mesurer

Perceuse et

mèches

Niveau

Équerre de

menuisier

Coupe-tube

Gants

Seau

Page 19

Préparation pour l’installation

PRÉPARATION DE L’OUVERTURE

DANS LES ARMOIRES

Le mur du fond

doit être exempt

de tuyaux ou

33-1/2 po to 34-3/4

po du dessous

du comptoir au

plancher

de fils

La partie ombrée est

réservée à la plomberie et

à l’électricité

15,2 cm (6 po)

61,0 cm

(24 po) min.

Figure A

• L’ouverture dans les armoires doit mesurer au moins 61,0 cm (24

po) de largeur et de profondeur, et environ 87,6 cm (34-1/2 po)

de hauteur à partir du plancher jusqu’au-dessous du comptoir.

• Le lave-vaisselle doit être installé de façon à ce que le boyau

de vidange mesure au maximum 3.66 mètres (12 pieds) pour

assurer une vidange adéquate.

• Le dessus, les côtés et l’arrière du lave-vaisselle doivent être

complètement dissimulés à l’intérieur de l’ouverture. Le lave-vaisselle

ne doit soutenir aucune partie de la structure des armoires.

61,0 cm

(24 po) min.

10,1 cm

(4 po)

Armoires à

l’équerre et

d’aplomb

AVERTISSEMENT

Pour réduire les risques de choc électrique, d’incendie

ou de blessures, l’installateur doit s’assurer que le

lave-vaisselle est complètement encastré au moment

de l’installation.

Countertop

Comptoir

Lave-vaisselle

Dishwasher

28-3/8"

65 cm (25-1/2 po)

5,1 cm (2 po) minimum

Clearance for Door

pour l’ouverture de la porte

Opening 2" Minimum

Figure B

DÉGAGEMENTS:

• Dans le cas d’une installation dans un coin, veuillez prévoir

un dégagement d’au moins 5,1 cm (2 po) entre le lavevaisselle et les armoires, le mur ou un électroménager

adjacent. Veuillez prévoir un dégagement d’au moins 65 cm

(25-1/2 po) à l’avant du lave-vaisselle pour l’ouverture de la

porte. Reportez-vous à la Figure B.

EXIGENCES RELATIVES AU

SYSTÈME DE VIDANGE

• Veuillez observer les ordonnances et les codes locaux en vigueur.

• Le boyau de vidange doit avoir une longueur maximale de 3.66

mètres (12 pieds).

• Le boyau de vidange ne doit pas être raccordé à une hauteur

dépassant 1,8 m (72 po) au-dessus du bas du lave-vaisselle.

REMARQUE: Il faut installer une coupure anti-refoulement si le

raccord au broyeur à déchets ou au raccord en T se trouve à moins

de 46 cm (18 po) au-dessus du plancher afin d’éviter un siphonage.

CHOIX DE LA MÉTHODE DE VIDANGE

Le type d’installation de vidange dépend des conditions suivantes.

• Les ordonnances ou codes locaux en vigueur exigent-ils une

coupure anti-refoulement?

• Le raccord T se trouve-t-il à moins de 46cm (18po) du plancher?

Si vous répondez OUI à l’une ou l’autre de ces

questions, vous DEVEZ utiliser la méthode n° 1.

• Si vous répondez NON, vous pouvez employer l’une ou l’autre

des méthodes.

PRÉPARATION DES ARMOIRES

• Percez un trou de 3,8 cm (1-1/2 po) de diamètre dans la paroi de

l’armoire qui se trouve dans la partie ombrée de la Figure A pour

le boyau de vidange. Assurez-vous que l’orifice ne présente pas

d’arêtes vives.

IMPORTANT – Lorsque vous

branchez le boyau de vidange à un

broyeur à déchets, assurez-vous d’enlever

le bouchon de vidange. LE LAVEVAISSELLE NE POURRA PAS SE VIDER

SI VOUS LAISSEZ LE BOUCHON EN PLACE.

Remove

Enlevez le

Drain

bouchon

Plug

de vidange

Méthode n° 1 – Coupure anti-refoulement avec raccord en

T ou broyeur à déchets

Il faut installer une coupure anti-refoulement lorsqu’elle est exigée par les ordonnances et les codes locaux en vigueur. Cette

coupure anti-refoulement doit être installée conformément aux

directives données par le fabricant.

Figure C

Méthode n° 2 – Boucle de vidange élevée avec raccord en

T ou broyeur à déchets

Crochet pour boyau de vidange

82 cm

32"

(32 po)

Min.

18"

46 cm

Min.

(18 po) min.

min.

Figure D

Crochet pour boyau

de vidange

82 cm

(32 po)

32"

min.

Min.

18"

46 cm

Min.

(18 po) min.

Conseil: Pour éviter des frais de réparation inutiles.

Assurez-vous d’enlever le bouchon de vidange du broyeur à

déchets avant d’y brancher le boyau de vidange du lave-vaisselle.

3

Page 20

Préparation pour l’installation

PRÉPARATION DU CÂBLAGE

ÉLECTRIQUE

AVERTISSEMENT

POUR VOTRE SÉCURITÉ PERSONNELLE: Enlevez

le fusible ou déclenchez le disjoncteur au panneau

de distribution principal avant de commencer

l’installation. N’utilisez pas une rallonge électrique ou

un adaptateur de fiche avec cet appareil.

Alimentation électrique

• Cet appareil doit être alimenté par un courant de 120 V et

60 Hz, et branché à un circuit individuel correctement

mis à la terre et protégé par un disjoncteur de 15 ou 20

ampères ou un fusible temporisé.

• Le câble électrique doit posséder deux fils, plus un fil de

mise à la terre, et résister à une température nominale de

75 °C (167 °F).

• Si votre alimentation électrique ne répond pas à ces

exigences, appelez un électricien agréé avant de

poursuivre l’installation.

Mise à la terre – Branchement permanent

Cet appareil doit être branché à un réseau électrique

permanent mis à la terre. Sinon, il faut installer un

conducteur de mise à la terre avec les conducteurs du

circuit et le brancher à la borne de mise à la terre du

réseau ou au fil de mise à la terre de l’appareil.

Mise à la terre – Modèles dotés d’un cordon

d’alimentation

Cet appareil doit être mis à la terre. En cas de mauvais

fonctionnement ou de défaillance, la mise à la terre réduira

les risques de choc électrique en fournissant au courant

électrique un circuit de moindre résistance. Cet appareil est

doté d’un cordon d’alimentation possédant un conducteur

de mise à la terre et une fiche de mise à la terre. La fiche

doit être branchée dans une mise appropriée, installée et

mise à la terre en conformité avec tous les codes locaux et

ordonnances en vigueur.

AVERTISSEMENT

Un branchement inadéquat du conducteur de

mise à la terre peut présenter des risques de choc

électrique. Si vous n’êtes pas certain que l’appareil est

correctement mis à la terre, consultez un réparateur

ou un électricien qualifié.

Autre emplacement

possible pour la prise

de courant dans une

armoire adjacente

46 cm

(18 po)

15 cm (6 po)

Figure E

46 cm (18 po)

Zone pour

la prise de

courant

15 cm

(6 po)

Trou de 3,8 cm

(1-1/2 po) de dia.

(max.)

61 cm (24

po) du mur

Mise à la terre

Noir

7,6 cm (3 po)

des armoires

Blanc

Dans le cas des modèles dotés d’un cordon

d’alimentation:

Ne modifiez pas la fiche fournie avec l’appareil; si vous ne

pouvez pas la brancher dans la prise de courant, faites

installer une prise de courant appropriée par un technicien

qualifié.

Préparation des armoires et cheminement des fils

• Les fils peuvent entrer dans l’ouverture du côté droit, du

côté gauche, de l’arrière ou du plancher dans la partie

ombrée de la Figure E et de la Figure A.

• Percez un trou de 3,8 cm (1-1/2 po) de diamètre au

maximum pour le passage du câble électrique. Le bord du

trou doit être lisse et arrondi. Les fils électriques pour le

branchement permanent peuvent passer par le même trou

que le boyau de vidange et la conduite d’eau chaude, si

c’est plus pratique. Si le trou est pratiqué dans une paroi

en métal, les bords de l’orifice doivent être recouverts d’un

passe-fils pour protéger les fils.

REMARQUE: Le cordon d’alimentation doté d’une fiche

doit passer par un autre trou dans l’armoire.

Branchement électrique du lave-vaisselle

Le branchement électrique s’effectue du côté avant droit du

lave-vaisselle.

• Dans le cas d’un branchement permanent, le câble doit

être acheminé de la façon indiquée à la Figure E. Le câble

doit avoir une longueur minimale de 61 cm (24 po) à partir

du mur arrière.

• Dans le cas d’un branchement avec un cordon

d’alimentation, installez une prise de courant mise à la

terre à trois broches sur la paroi de l’armoire adjacente,

entre 15 cm (6 po) et 46 cm (18 po) de l’ouverture, et entre

15 cm (6 po) et 46 cm (18 po) du plancher.

• Utilisez uniquement WX09X70910 ou WX09X70911

Trousse de cordon d’alimentation pour lave-vaisselle.

4

Page 21

Préparation pour l’installation

PRÉPARATION DE

L’ALIMENTATION EN

EAU CHAUDE

REMARQUE: GE Appliances recommande l’utilisation

d’un tuyau en cuivre pour la conduite d’alimentation en

eau, mais vous pouvez choisir un boyau flexible tressé no

WX28X326 de GE Appliances.

• La conduite d’alimentation en eau (tuyau de cuivre de

9,5 mm [3/8 po] ou boyau flexible tressé) peut entrer du

côté gauche, du côté droit, de l’arrière ou du plancher

dans la partie ombrée indiquée dans la Figure F.

• La conduite d’alimentation en eau doit passer dans

le même trou que le câble électrique et le boyau de

vidange. Ou vous pouvez percer un trou supplémentaire

de 3,8 cm (1-1/2 po) de diamètre pour le passage de

la conduite d’eau. Si l’appareil est doté d’un cordon

d’alimentation pourvu d’une fiche, la conduite d’eau

chaude ne doit pas passer par le même trou que le

cordon d’alimentation.

Trou de

Eau

chaude

5,1 cm

(2 po) de

l’armoire

Robinet

d’arrêt

3,8 cm

(1-1/2 po)

de dia.

48,2 cm (19 po)

du mur arrière

10,1 cm

(4 po)

15,2 cm

(6 po)

Raccordement de la conduite d’eau

chaude

• Si vous utilisez un boyau flexible tressé, étiquetez le

boyau et indiquez la date d’installation à des fins de

référence. Les boyaux flexibles, coudes et joints tressés

doivent être remplacés dans 5 ans.

• Coupez l’alimentation en eau.

• Installez un robinet d’arrêt à un endroit accessible, par

exemple sous l’évier. (Cette installation est facultative,

mais fortement recommandée, et peut même être

exigée

par les codes locaux en vigueur.)

• Le raccordement de la conduite d’eau s’effectue du côté

gauche du lave-vaisselle. Installez la conduite d’eau

chaude en utilisant un tuyau en cuivre de 9,5 mm (3/8

po) ou plus ou boyau flexible tressé. Acheminez la

conduite d’eau de la façon indiquée dans la Figure F et

amenez-la vers l’avant à au moins 48,2 cm (19 po) du

mur arrière.

• Réglez le chauffe-eau à une température variant entre

49 °C (120 °F) et 65 °C (140 °F).

• Rincez la conduite d’eau pour éliminer tous les débris.

Recueillez l’eau et les débris à l’aide d’un seau.

• La pression de la conduite d’alimentation en eau

chaude doit varier entre 1,4 bar (20 lb/po²) et 8,3 bars

(120 lb/po²).

ATTENTION

N’enlevez pas la base de bois avant d’être prêt à

installer le lave-vaisselle. Si vous enlevez la base de

bois, le lave-vaisselle pourrait basculer lorsque vous

ouvrez la porte.

Devant des

armoires

Figure F

5,1 cm (2 po)

du plancher

Tournez la page pour commencer

l’installation du lave-vaisselle.

5

Page 22

Installation du lave-vaisselle

ÉTAPE 1

PRÉPARATION

Prenez les pièces fournies dans l’emballage et mettez-les

de côté:

• Ensemble de vis

• Couvercle de la boîte de jonction

• Boyau de vidange et collier

• Supports de montage

• Moulures (certains modèles)

• Crochet pour boyau de vidange

• Manuel d’utilisation

• Échantillons et(ou) bons

ÉTAPE 2

VÉRIFICATION DE

L’ÉQUILIBRE DE LA PORTE

REMARQUE : Si vous

installez un panneau

personnalisé (offert sur

certains modèles), veuillez

suivre les instructions

fournies avec la trousse

du panneau personnalisé

WD35X20417.

• Sans enlever la base de

bois du lave-vaisselle,

vérifiez l’équilibre de la

porte en l’ouvrant et en

la fermant.

• La porte est

correctement équilibrée

si, étant ouverte, elle se

referme d’elle-même à l’intérieur de 20° de la verticale,

reste en position de 20° à 70°, et s’ouvre entièrement

au-delà de 70°.

• Si nécessaire, augmentez ou diminuez la tension, tel

qu’illustré. Certains modèles sont munis de 2 ressorts

d’un côté et d’un ressort de l’autre. Fermez la porte et

ajustez les ressorts pour rétablir l’équilibre de la porte.

Vue latérale

Side View

La porte se

referme

àl'intérieur

de 20°

La porte reste

en position de

20° à 70°

Vue latérale

Ressort

Spring

accroché

hooked

dans le trou

to hole

à l’intérieur

inside rail

du rail basal

s'ouvre

au-delà de 70°

Figure G

Vue de l'intérieur

La porte

entièrement

ÉTAPE 3

ENLÈVEMENT DE

LA BASE DE BOIS,

INSTALLATION DES

PIEDS DE NIVELLEMENT

IMPORTANT – Ne frappez pas sur la base de bois pour

l’enlever! Vous endommagerez ainsi l’appareil.

• Amenez le lave-vaisselle à proximité de son

emplacement définitif et couchez-le sur le dos.

REMARQUE : Ne placez pas le lave-vaisselle sur un de

ses côtés.

• Enlevez les quatre pieds de nivellement sous la base de

bois à l’aide d’une clé à douille de 23,8 cm (15/16 po).

• Retirez la base.

Remettez en place les pieds de nivellement sur le

•

lave-vaisselle, à 1,27 cm (1/2 po) environ du cadre,

comme indiqué dans l’illustration.

Approx.

1/8"

1,27 cm (1/2

Figure I

po) approx

REMARQUE : Certains modèles sont équipés de

roulettes de nivelage arrière réglables ne nécessitant pas

l’installation de 2 pattes de nivelage arrière réglables.

ÉTAPE 4

ENLÈVEMENT DU

PANNEAU INFÉRIEUR

• Enlevez les deux vis du panneau inférieur, ainsi que

le panneau inférieur. Mettez-les de côté pour les

réutiliser à l’étape 23.

Augmentation

la tension

Diminution

de la tension

NOTE: The number of

REMARQUE : Le

springs, on each side,

nombre de ressorts,

will vary by model.

de chaque côté, varie

selon le modèle.

Figure H

S'assurer que le

Make sure pully

câble de poulie

cables are within

se trouve entre

pulley shoulders

épaulements

les

de

la poulie

Panneau

Custom

personnalisé

Vue avant

Front View

door

panel

Conseil: Pour que la porte ouvre et se ferme

facilement.Vérifiez la porte en l’ouvrant et en la fermant.

Si elle n’ouvre pas facilement ou s’ouvre trop rapidement,

vérifiez la disposition du câble du ressort. Le câble est

retenu en place par des «épaulements» sur la poulie.

Assurez-vous que le câble est bien installé sur les

épaulements de la poulie comme indiqué.

Panneau inférieur

Enlevez

Figure J

les deux vis du

panneau inférieur

6

Page 23

Installation du lave-vaisselle

ÉTAPE 5

SI NÉCESSAIRE, RETRAIT

DU PAN PROTÈGE-PLANCHER

(certains modèles)

• Débranchez les fils du détecteur

de fuites. (sur certains modèles).

• Tirez le pan protège-plancher

vers l’avant et glissez-le depuis

le dessous du lave-vaisselle.

• Mettez-le de côté pour le réutiliser

à l’étape 21.

ÉTAPE 6

INSTALLATION DU COUDE

DE 90°

• Vissez le coude de 90° dans

l’électrovanne. Assurez-vous

que le joint d’étanchéité en

caoutchouc se situe entre

l’électrovanne et le coude.

• Ne serrez pas le coude de

façon excessive; le support

de l’électrovanne pourrait

se déformer ou le raccord

de l’électrovanne pourrait se

casser.

• Tournez l’extrémité du

coude pour qu’il pointe vers

l’arrière du lave-vaisselle.

ÉTAPE 7

RACCORDEMENT DU

l’électrovanne

Pincer le haut du connecteur

pour libérer la pince à ressort

Pan

Protège-plancher

Figure L

Devant du lave-vaisselle

Support

de

Figure M

Détecteur de

fuites

Coude de 90°

Boyau de

remplissage

BOYAU DE VIDANGE À LA

BOUCLE DE VIDANGE

Raccordez l’extrémité de la boucle de vidange au boyau

de vidange à l’aide du collier de serrage à vis sans fin,

comme illustré.

Figure N

REMARQUE : La boucle de vidange élevée sur le côté de

la baignoire est conçue pour améliorer les performances

de lavage. Ne retirez pas du côté de la baignoire.

ÉTAPE 8

POSITIONNEMENT DE

LA CONDUITE D’EAU

ET DE L’ALIMENTATION

ÉLECTRIQUE

• Positionnez la conduite d’alimentation en eau et le câblage

de la résidence sur le plancher de l’ouverture afin qu’ils

n’entrent pas en contact avec la base du lave-vaisselle et les

pièces sous l’appareil.

10,1 cm

(4 po)

15,2 cm

(6 po)

ÉTAPE 9

Alimentation

Conduite

d’alimentation

en eau

INSERTION DU BOYAU DE

électrique

de la résidence

Figure O

10,1 cm

(4 po)

15,2 cm

(6 po)

VIDANGE DANS L’ORIFICE

DE L’ARMOIRE

• Placez le lave-vaisselle vis-à-vis de l’ouverture dans les armoires.

Insérez le boyau de vidange dans l’orifice que vous avez

précédemment percé dans la paroi des armoires. Si l’appareil

est doté d’un cordon d’alimentation, faites passer l’extrémité du

cordon dans un l’ouverture dans les armoires distinct.

Alimentation

électrique de

la résidence

Conduite

d’eau

Assurez-vous que le boyau de

vidange n'est ni tordu ni coincé

Longueur maximale

du boyau de vidange:

4.57 m (15 pi)

Ne débranchez ni ne retirez la

boucle de vidange haute du côté

gauche du lave-vaisselle

Conseil: Pour éviter des frais de réparation inutiles pour

des problèmes de remplissage, de vidange ou de bruit.

Placez la conduite d’eau et le câble électrique de manière à ce

qu’ils n’entrent pas en contact avec quoi que ce soit à l’arrière

ou en dessous du lave-vaisselle.

Cordon

d’alimentation

(si utilisé)

vidange

Boyau

de

Isolant

Figure P

7

Page 24

Installation du lave-vaisselle

ÉTAPE 10

INSERTION AUX TROIS

QUARTS DU LAVEVAISSELLE DANS

L’OUVERTURE

IMPORTANT – Ne poussez pas sur le panneau

avant avec vos genoux. Vous pourriez endommager

l’appareil.

• Saisissez le panneau avant de l’appareil par les côtés

et faites glisser le lave-vaisselle dans l’ouverture de

quelques centimètres ou pouces à la fois.

Ne poussez pas sur le panneau avant de la porte avec

Do not push against

Figure Q

• Tirez sur le boyau de vidange et le cordon d’alimentation,

s’il y a lieu, par les trous des armoires adjacentes au fur

et à mesure. Arrêtez lorsque le lave-vaisselle dépasse le

devant des armoires adjacentes d’environ 15 cm (6 po).

• Assurez-vous que le boyau de vidange n’est pas plié à

l’arrière ou en dessous du lave-vaisselle.

• Assurez-vous que le câble électrique de la résidence, le

boyau de vidange et la conduite d’eau n’entrent pas en

contact avec des pièces sous le lave-vaisselle.

votre genou. Vous risquez d’endommager le panneau

de porte.

ÉTAPE 11

INSTALLATION DES

MOULURES

Au cours de cette étape, vous aurez besoin des moulures

mises de côté à l’étape 1.

Garniture

(supérieure)

Moulure

latérales

Vue de dessus

Moulure

latérales

Moulure

latérales

Vue de

dessus

• Prenez la garniture supérieure (voir la figure R) et

centrez-la avec le loquet supérieur. Appuyez la garniture

contre le support de gaine en la déplaçant de gauche à

droite.

• Prenez la garniture gauche (voir la figure R). Alignez

le bord supérieure de la garniture et appuyez-le contre

le côté gauche du support de gaine en le déplaçant

de haut en bas. Répétez cette étape pour le côté droit

de la garniture. (Voir la figure R pour le côté droit de la

garniture.)

Figure R

Contact total contre

le bord de cuve

Cadre de

la cuve

Moulure de cuve

Porte

Poignée

8

Page 25

Installation du lave-vaisselle

ÉTAPE 12

INSTALLATION DES

SUPPORTS DE MONTAGE

Vous aurez besoin des supports de montage et de deux

(2) vis à tête hexagonale no 8 mises de côté à l’étape 1.

Vous devez poser les supports de montage sur le dessus

ou les côtés du cadre de la cuve du lave-vaisselle avant

de glisser le lave-vaisselle en place sous le comptoir. Ce

lave-vaisselle est adapté à une installation complètement

encastrable dans une ouverture de 61 cm (24 po) de

profondeur. Les supports de montage possèdent plusieurs

options de fixation afin de répondre à plusieurs types de

constructions d’armoires.

Posez les supports de montage sur le dessus

si le dessous du comptoir est en bois ou un

matériau similaire qui accepte les vis :

IMPORTANT - Après installation des supports et avant de

fermer la porte du lave-vaisselle, ajustez les supports en

les pliant de façon à ce qu’ils ne soient pas en contact avec

le haut de la porte du lave-vaisselle et ne causent pas de

dommage.

Montage sur le dessus

ÉTAPE 12

INSTALLATION DES

SUPPORTS DE MONTAGE

(SUITE)

Posez les supports de montage sur les côtés si

le comptoir est en granite ou un matériau similaire

qui n’accepte pas les vis à bois :

• Cassez la partie avant de la languette à l’aide de pince à

l’endroit indiqué, avant la fixation sur le lave-vaisselle.

• Placez le support latéral gauche tel qu’indiqué. Faites de

même avec le support droit.

Montage latéral

Cadre de la cuve

du lave-vaisselle

Vis de support

no° 8

Ne coincez pas

les fils du loquet

en insérant la

vis de support

no 8

Figure T

Moulure de

cuve

Veillez à ce que les vis

de montage n’abîment

pas les armoires

Courber et

casser ici le

cas échéant

Support

Vis de

support

no° 8

Support

Cadre de la

cuve du lavevaisselle

Figure S

• Si vous installez le lave-vaisselle sous un comptoir dont

la profondeur est plus courte, il est possible que les

supports pour le comptoir dépasse à l’avant du comptoir.

Si c’est le cas, supprimez la longueur excédentaire en

courbant à répétition les supports vis-à-vis de l’encoche

avant seulement, jusqu’à la cassure.

Courber et casser ici

après l'installation si

le comptoir présente

un léger surplomb

INSTLLATION DU

ÉTAPE 13

LAVE-VAISSELLE DANS

SON EMPLACEMENT

DÉFINITIF

• Vérifiez l’isolant de la cuve, s’il y a lieu, pour vous

assurer qu’il enveloppe complètement la cuve. L’isolant

ne doit pas «retrousser» ou entrer en contact avec les

ressorts de la porte. Si l’isolant est «déplacé» ou entre

en contact avec les ressorts, replacez-le correctement

avant de faire glisser l’appareil dans son emplacement

définitif.

• Faites glisser le lave-vaisselle dans son emplacement

définitif en poussant sur les côtés du panneau de

la porte. Abstenez-vous de pousser ou tirer la porte

en position fermée ou partiellement ouverte lors du

déplacement du lave-vaisselle. Ne poussez pas sur le

centre du panneau avec votre genou. Vous pourriez

endommager le panneau. Avant de fixer le lave-vaisselle

sur l’armoire, assurez-vous qu’il est placé d’équerre

dans l’ouverture, aussi bien dans sa partie inférieure que

supérieure.

IMPORTANT – Avant d’ouvrir la porte du lave-vaisselle,

assurez-vous que les bords du panneau de porte du

lave-vaisselle sont en retrait par rapport au devant des

armoires adjacentes, et non pas appuyés contre le devant

des armoires. Reportez-vous à la Figure U. Si vous

ouvrez la porte du lave-vaisselle et que le bord de la porte

est appuyé contre le devant des armoires, vous pourriez

endommager la porte du lave-vaisselle et les armoires.

9

Page 26

Installation du lave-vaisselle

INSTLLATION DU

ÉTAPE 13 ÉTAPE 14

LAVE-VAISSELLE DANS

SON EMPLACEMENT

DÉFINITIF (SUITE)

• Ouvrez et fermez la porte du lave-vaisselle pour vous

assurer qu’elle fonctionne correctement et qu’elle ne

frotte pas contre les armoires adjacentes.

Figure U

La porte

s’ouvre et

se ferme

en retrait

par rapport

aux armoires

Alignement

correct

Un alignement incorrect

causera des dommages

à la porte

La porte est appuyée contre

le devant des armoires

Conseil: Pour éviter des frais de réparation inutiles

pour des dommages au panneau avant ou un

problème d’efficacité de lavage.

Vérifiez l’alignement du lave-vaisselle avant d’ouvrir la porte

afin de prévenir tout dommage au panneau de la porte.

Assurez-vous que la conduite d’eau et le câble électrique

ne sont pas coincés ou écrasés à l’arrière du lavevaisselle. Une conduite écrasée réduit le débit d’eau.

Assurez-vous que la

moulure de cuve ne touche

la porte en aucun point

Vue de

dessus

Si nécessaire, la moulure

de cuve peut être rognée

pour assurer le bon

fonctionnement de la porte

ÉTAPE 14

MISE DE NIVEAU DU

Cadre de

la cuve

Moulure

de cuve

Porte

Poignée

Ne laissez pas la moulure de

cuve se coincer dans la porte ou

entrer en contact avec celle-ci

Moulure de

Vue de

dessus

cuve coincée

dans la porte!

LAVE-VAISSELLE