GE CDT765SSF0SS, CDT765SSF1SS, DDT575SGF0BB, DDT575SGF0WW, DDT575SGF2BB Installation Guide

...Page 1

Installation Instructions

Built-in Dishwasher

Ifyou have questions, call 800.GE.CARES(800.432.27371or visit our Website at: GEAppliances.com.

InCanada, please call 1.800.561.3344or visit www.geappliances.ca

BEFOREYOU BEGIN

Read these instructions completely and

carefully.

IM PORTANT - Observeallgoverningcodesand

ordinances.

, Note to Installer - Be sure to leave these instructions for the

consumer's and local inspector's use.

, Note to Consumer - Keep these instructions with your

Owner's Manual for future reference.

Skill Level - Installation of this dishwasher requires

basic mechanical, electrical and plumbing skills. Proper

installation is the responsibility of the installer. Product

failure due to improper installation is not covered under

the GE Appliance Warranty. See warranty information.

Completion Time - 1 to 3 Hours. New installations require

more time than replacement installations.

READ CAREFULLY.

KEEP THESE INSTRUCTIONS.

IM PORTANT - The dishwasherMUST be installed

to allow for future removal from the enclosure if service is

required.

Core should be exercised when the appliance is installed or

removed, to reduce the likelihood of damage to the power

supply cord.

If you received a damaged dishwasher, you should immediately

contact your dealer or builder.

Optional Accessories - Seethe Owner's Manual for available

custom panel kits.

FOR YOUR SAFETY

Read and observe all CAUTIONSand WARNINGSshown

throughout these instructions. While performing

installations described in this booklet, gloves, safety glasses

or goggles should be worn.

31-31524-1 09-13 GE

Page 2

Installation Preparation

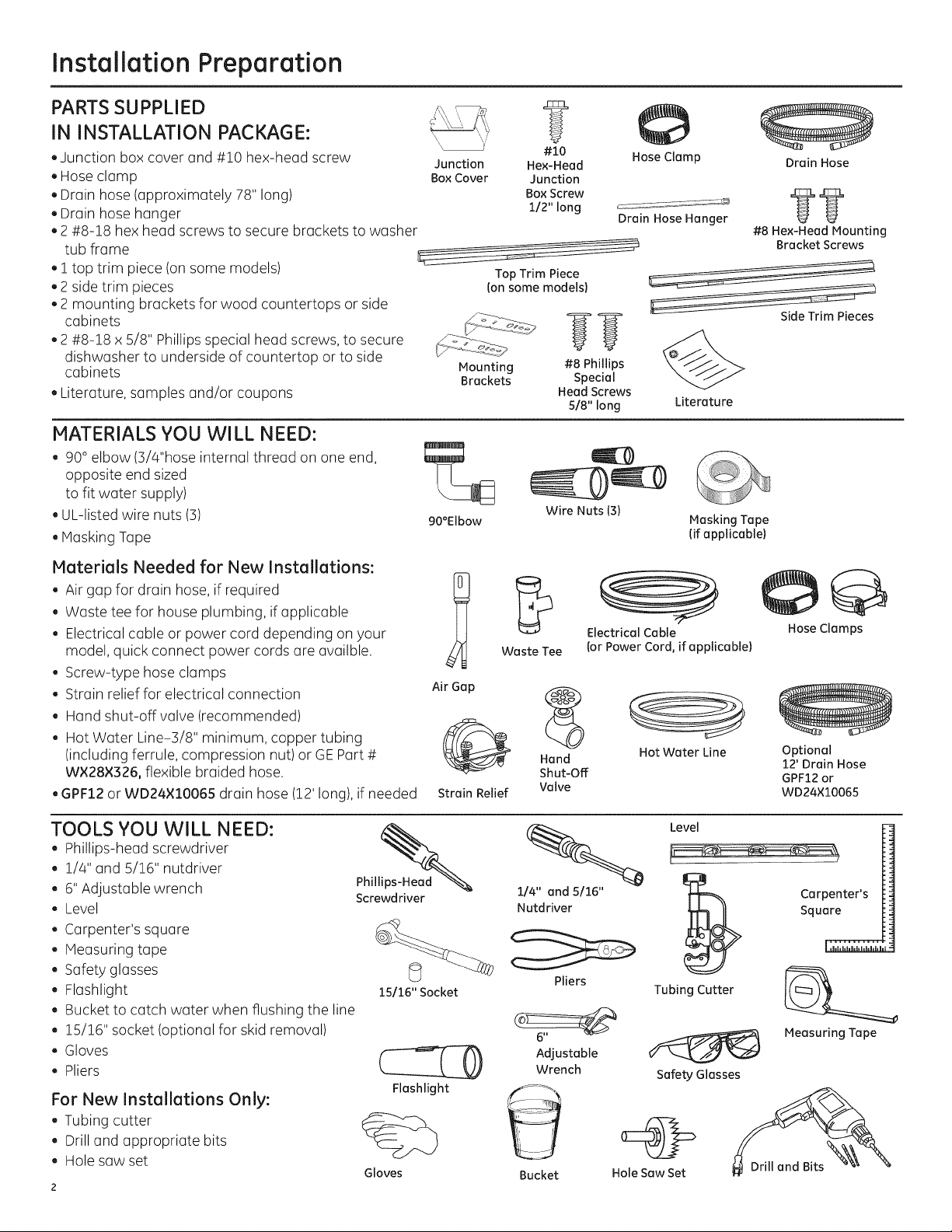

PARTS SUPPLIED

IN INSTALLATION PACKAGE:

, Junction box cover and #10 hex-head screw

, Hose clamp

, Drain hose (approximately 78" long)

Drain hose hanger

2 #8-18 hex head screws to secure brackets to washer

tub frame

,1 top trim piece (on some models)

,2 side trim pieces

,2 mounting brackets for wood countertops or side

cabinets

2 #8-18 x 5/8" Phillips special head screws, to secure

dishwasher to underside of countertop or to side

cabinets

Literature, samples and/or coupons

MATERIALS YOU WILL NEED:

. 90° elbow (3/#'hose internal thread on one end,

opposite end sized

to fit water supply)

, UL-listed wire nuts (3)

Masking Tape

Junction

Box Cover

Mounting

Brackets

%

90°Elbow

?

#10

Hex-Head

Junction

Box Screw

1/2" long

Top Trim Piece

(on some models)

#8 Phillips

Head Screws

5/8" long Literature

Wire Nuts (3)

Drain Hose Hanger

Special

@

Hose Clamp

Drain Hose

??

#8 Hex-Head Mounting

Bracket Screws

Side Trim Pieces

Masking Tape

(if applicable)

Materials Needed for New Installations:

Air gap for drain hose, if required

Waste tee for house plumbing, if applicable

Electrical cable or power cord depending on your

model, quick connect power cords are availble.

Screw-type hose clamps

Strain relief for electrical connection

Hand shut-off valve (recommended)

Hot Water Line-3/8" minimum, copper tubing

(including ferrule, compression nut) or GEPart #

W×28×326, flexible braided hose.

GPF12or WD24×10065 drain hose (12'long), if needed

TOOLS YOU WILL NEED:

Phillips-head screwdriver

, 1/4" and 5/16" nutdriver

, 6"Adjustable wrench

, Level

, Carpenter's square

, Measuring tape

, Safety glasses

, Flashlight

, Bucket to catch water when flushing the line

, 15/16" socket (optional for skid removal)

, Gloves

, Pliers

For New Installations Only:

Tubing cutter

Drill and appropriate bits

Hole saw set

Phill2ad_

Screwdriver

15/16" Socket

Gloves

Flashlight

Air Gap

Strain Relief

Waste T_ee

Hand

Shut-Off

Valve

1/4" and 5/16"

Nutdriver

Pliers

Adjustable

Wrench

Bucket

Electrical Cable

(or Power Cord, if applicable)

Hot Water Line

Level

Tubing Cutter

Safety Glasses

Hole Saw Set

Hose Clamps

Optional

12' Drain Hose

GPF12 or

WD24×10065

Carpenter's

Square

Measuring Tape

Page 3

Installation Preparation

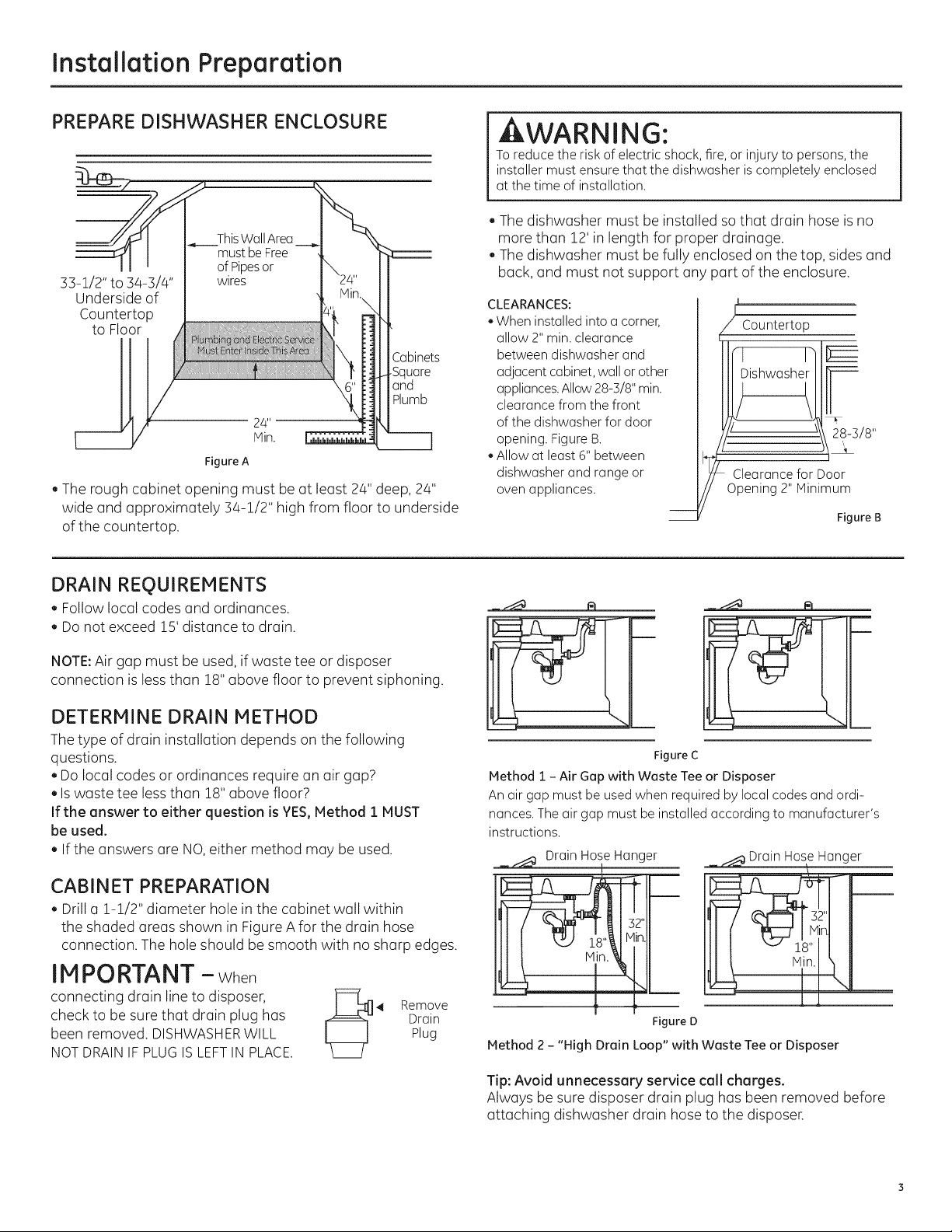

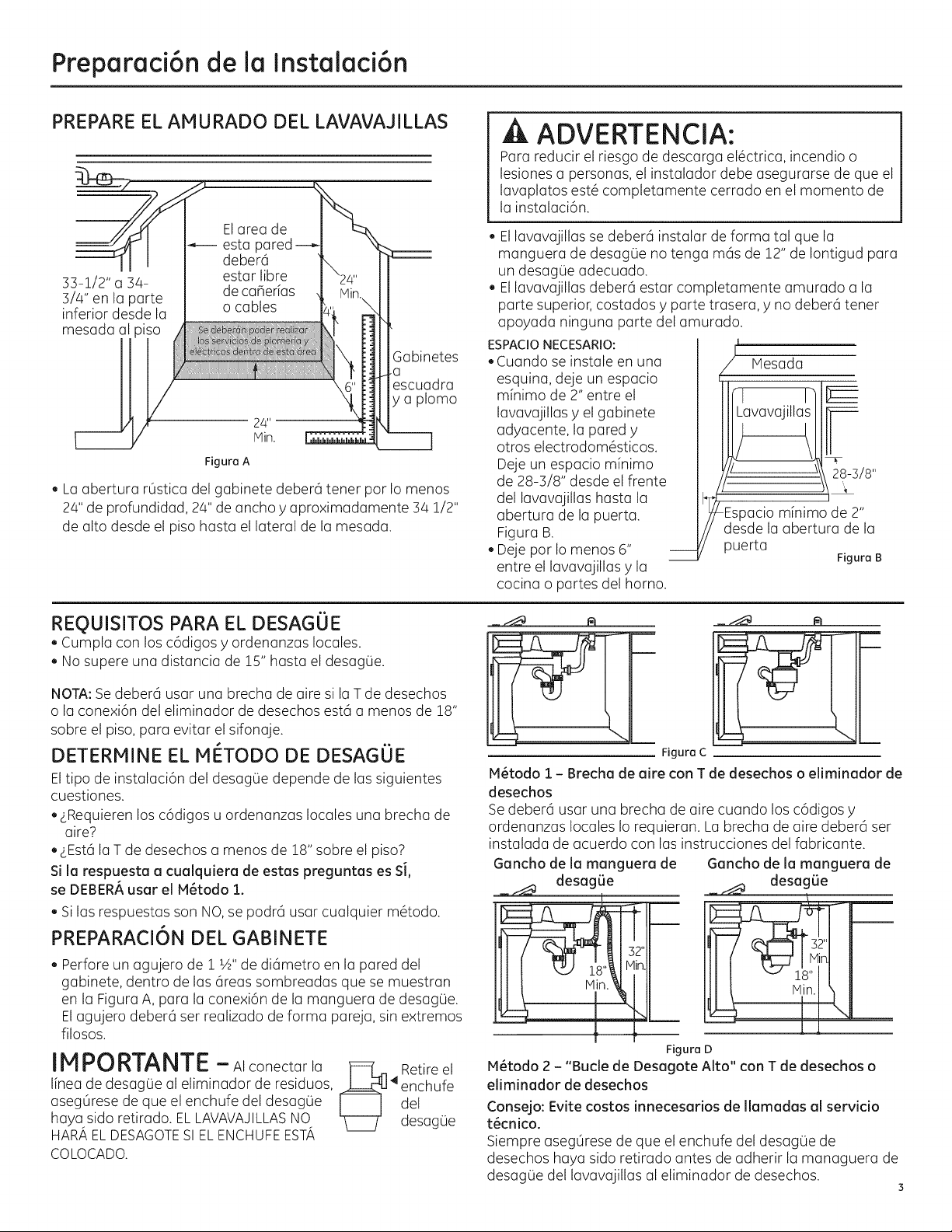

PREPARE DISHWASHER ENCLOSURE

ThisWallArea

mustbe Free

of Pipesor

33-1/2" to 34-3/4"

Underside of

Countertop

to Floor

, The rough cabinet opening must be at least 2/4"deep, 2/4"

wide and approximately 34-1/2" high from floor to underside

of the countertop.

wires

Figure A

Zabinets

Square

and

Plumb

kWARNING:

Toreducethe riskofelectricshock,fire,or injurytopersons,the

installermustensurethat the dishwasheris completelyenclosed

at thetime of installation.

The dishwasher must be installed so that drain hose is no

more than 12' in length for proper drainage.

The dishwasher must be fully enclosed on the top, sides and

back, and must not support any part of the enclosure.

CLEARANCES:

• When installed into a corner,

allow 2"min. clearance

between dishwasher and

adjacent cabinet, wall or other

appliances.Allow 28-5/8" min.

clearance from the front

of the dishwasher for door

opening. Figure B.

Allow at least 6" between

dishwasher and range or

oven appliances.

iL

/ Countertop

ii _ishwasher

1-

L Clearance for Door

Opening 2" Minimum

28-5/8"

Figure B

DRAIN REQUIREMENTS

, Follow local codes and ordinances.

, Do not exceed 15' distance to drain.

NOTE:Air gap must be used, if waste tee or disposer

connection is less than 18" above floor to prevent siphoning.

DETERMINE DRAIN METHOD

The type of drain installation depends on the following

questions.

Do local codes or ordinances require an air gap?

Iswaste tee less than 18" above floor?

If the answer to either question is YES,Method 1 MUST

be used.

If the answers are NO,either method may be used.

CABINET PREPARATION

, Drill a 1-1/2" diameter hole in the cabinet wall within

the shaded areas shown in Figure Afor the drain hose

connection. The hole should be smooth with no sharp edges.

IMPORTANT -When

connectingdrainlinetodisposer,

checktobesurethatdrainplughas

beenremoved.DISHWASHER WILL

NOT DRAIN IFPLUG ISLEFTINPLACE.

Drain

Plug

4 Remove

FigureC

Method 1 - Air Gap with Waste Tee or Disposer

An air gap must be used when required by local codes and ordi-

nances. The air gap must be installed according to manufacturer's

instructions.

DrainHoseHanger

_ DrainHoseHanger

\

L

Figure D

Method 2 - "High Drain Loop" with Waste Tee or Disposer

Tip: Avoid unnecessary service call charges.

Always be sure disposer drain plug has been removed before

attaching dishwasher drain hose to the disposer.

Page 4

Installation Preparation

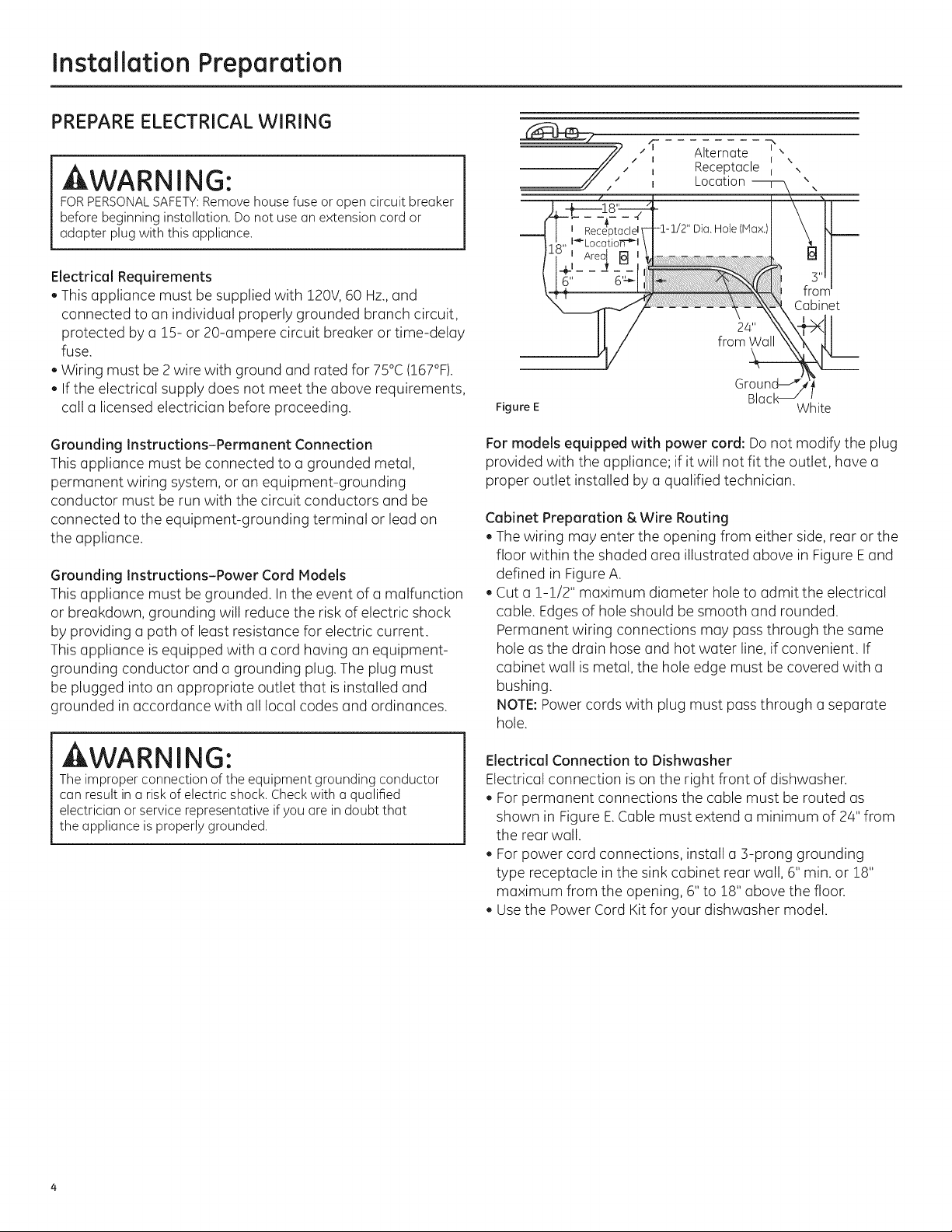

PREPARE ELECTRICAL WIRING

AWARNING:

FORPERSONALSAFETY:Removehousefuseoropencircuit breaker

beforebeginninginstallation.Donot useanextensioncordor

adapter plugwiththis appliance.

Electrical Requirements

, This appliance must be supplied with !20V, 60 Hz.,and

connected to an individual properly grounded branch circuit,

protected by c]15- or 20-ampere circuit breaker or time-delay

fuse.

, Wiring must be 2 wire with ground and rated for 75°C(!67°F).

, If the electrical supply does not meet the above requirements,

call c]licensed electrician before proceeding.

Grounding Instructions-Permanent Connection

This appliance must be connected to c]grounded metal,

permanent wiring system, or an equipment-grounding

conductor must be run with the circuit conductors and be

connected to the equipment-grounding terminal or lead on

the appliance.

Grounding Instructions-Power Cord Models

This appliance must be grounded. In the event of c]malfunction

or breakdown, grounding will reduce the risk of electric shock

by providing c]path of least resistance for electric current.

This appliance is equipped with c]cord having tin equipment-

grounding conductor and c]grounding plug. The plug must

be plugged into tin appropriate outlet that is installed and

grounded in accordance with all local codes and ordinances.

/ I

_//_/_ / '_ Alternate

Figure E White

For models equipped with power cord: Donot modify the plug

provided with the appliance; if it will not fit the outlet, have c]

proper outlet installed by c]qualified technician.

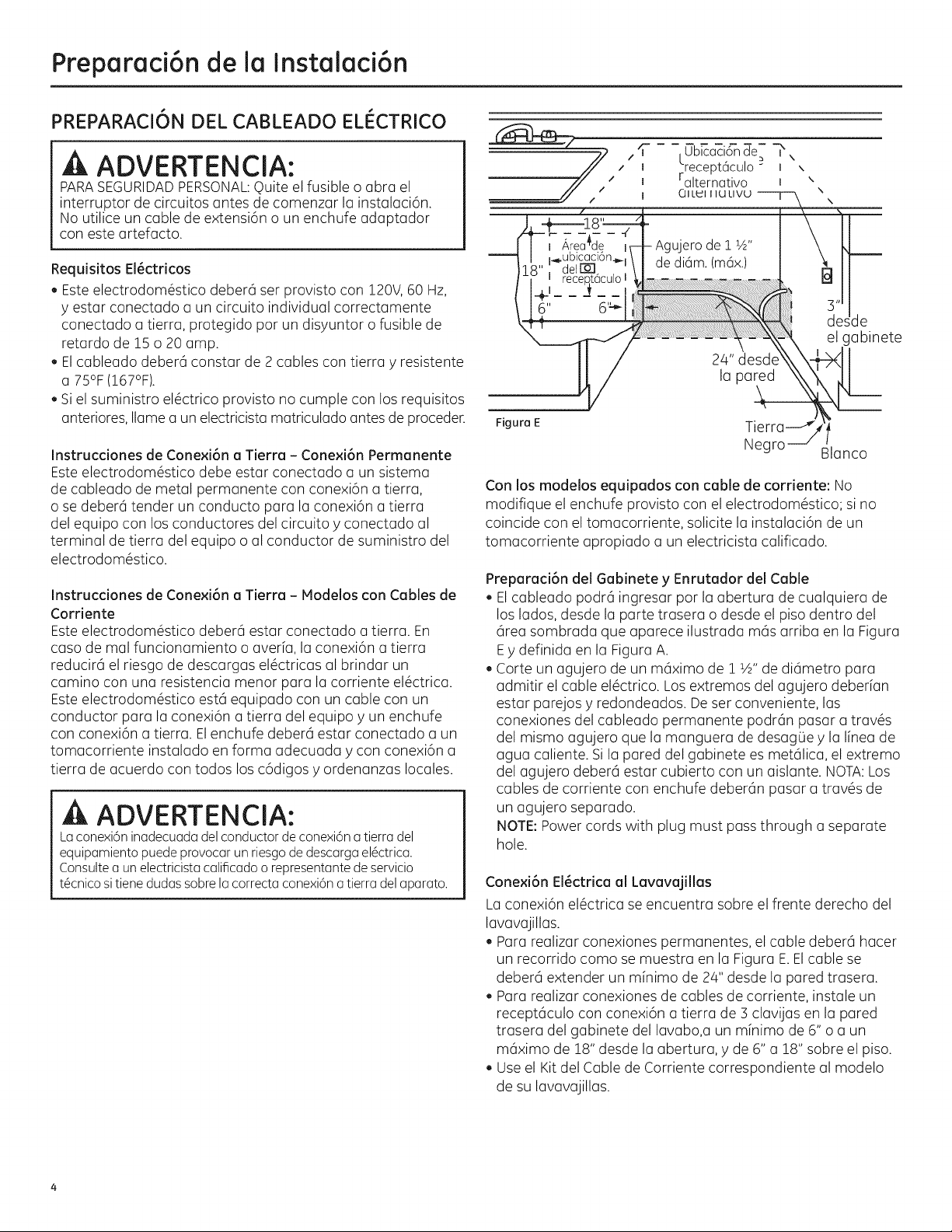

Cabinet Preparation & Wire Routing

, The wiring may enter the opening from either side, rear or the

floor within the shaded area illustrated above in Figure Eand

defined in Figure A.

, Cut c]1-1/2" maximum diameter hole to admit the electrical

cable. Edgesof hole should be smooth and rounded.

Permanent wiring connections may puss through the same

hole us the drain hose and hot water line, if convenient. If

cabinet wall is metal, the hole edge must be covered with c]

bushing.

NOTE:Power cords with plug must puss through c]separate

hole.

_ Receptacle

Location

I \

I \

Cabinet

WARNING:

Theimproper connectionof theequipmentgroundingconductor

can resultina riskofelectricshock.Checkwith a qualified

electricianor servicerepresentativeifyou are indoubt that

the applianceis properlygrounded.

Electrical Connection to Dishwasher

Electrical connection is on the right front of dishwasher.

, For permanent connections the cable must be routed us

shown in Figure E.Cable must extend c]minimum of 24"from

the rear wall.

, For power cord connections, install a 3-prong grounding

type receptacle in the sink cabinet rear wall, 6" min. or 18"

maximum from the opening, 6" to 18" above the floor.

, Use the Power Cord Kitfor your dishwasher model.

Page 5

Installation Preparation

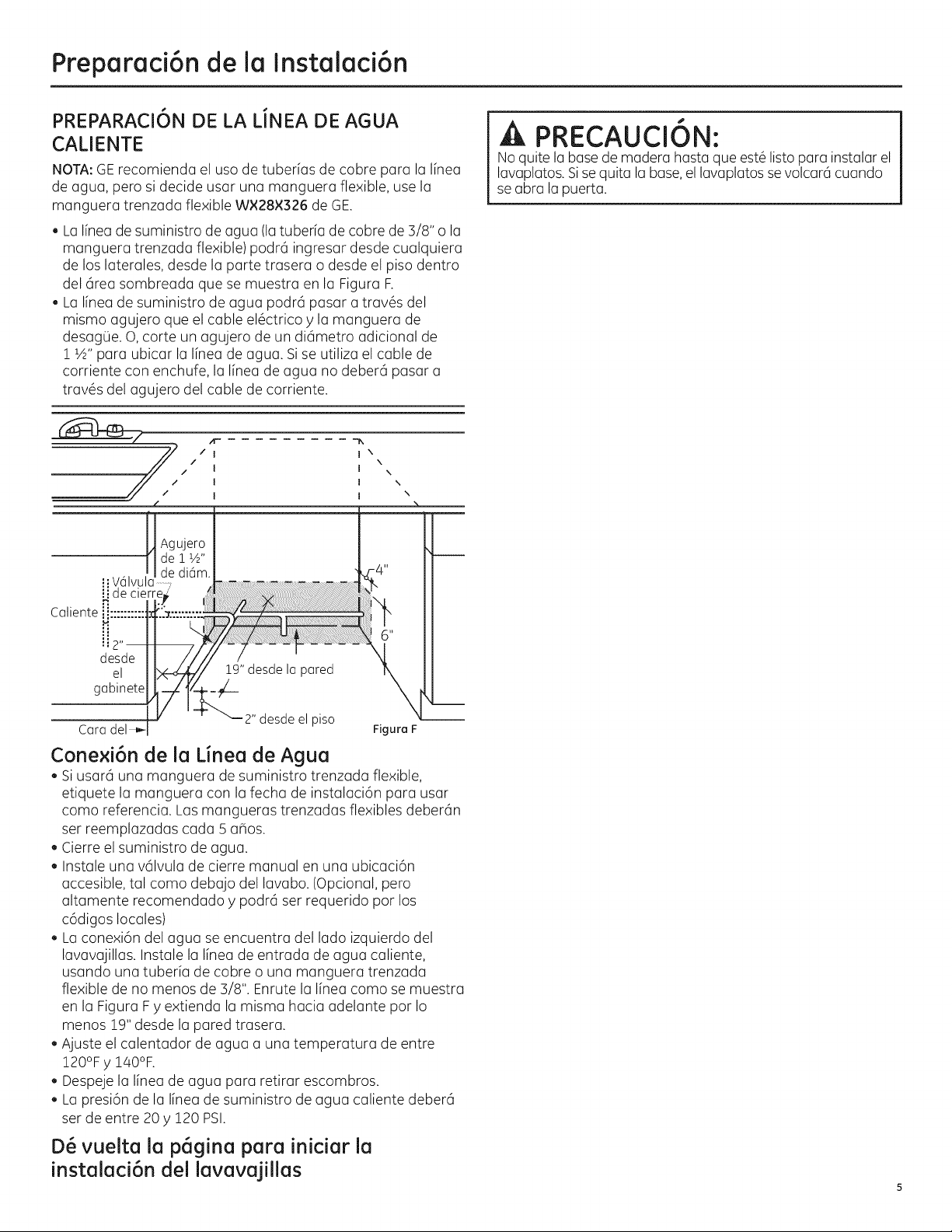

PREPARE HOT WATER LINE

NOTE:GErecommends copper tubing for the water line, but if

you choose to useflexible hose, use GE'sW×28×326, flexible

braided hose.

. The water supply line (3/8" copper tubing or flexible braided

hose) may enter from either side,rear or floor within the

shaded area shown in Figure F.

. The water supply line may pass through the same hole as the

electrical cable and drain hose.Or,cut an additional 1-1/2"

diameter hole to accommodate the water line. Ifpower cord

with plug is used,water line must not pass through power

cord hole.

ACAUTION:

Do not remove wood base until you are ready to install the

dishwasher. The dishwasher will tip over when the door is

opened if base isremoved.

il Shut-off_

Hot

From

Cabinet

Cabinet

2" From Floor

Figure F

Water Line Connection

. If using a flexible braided supply hose, labelthe hose with the

installation date to use as reference. Flexible braided hoses

should be replaced in 5 years.

. Turn off the water supply.

. Install a hand shut-off valve in an accessible location, such

as under the sink. (Optional, but strongly recommended and

may be required by local codes.)

. Water connection is on the left side of the dishwasher. Install

the hot water inlet line, using no less than 3/8" copper tubing

or aflexible braided hose. Route the line as shown in Figure F

and extend forward at least 19"from rear wall.

. Adjust water heater for !20°F to !/40°Ftemperature.

. Flush water line to clean out debris.

. The hot water supply line pressure must be20-120 PSI.

Turn page to begin dishwasher installation,

Page 6

Dishwasher Installation

STEP 1:PREPARATION

Locate the items in the installation package:

, Screws

Junction box cover

Drain hose and clamp

Mounting brackets

Trim pieces (on some models)

Drain hose hanger

Owner's Manual

Product samples and/or coupons

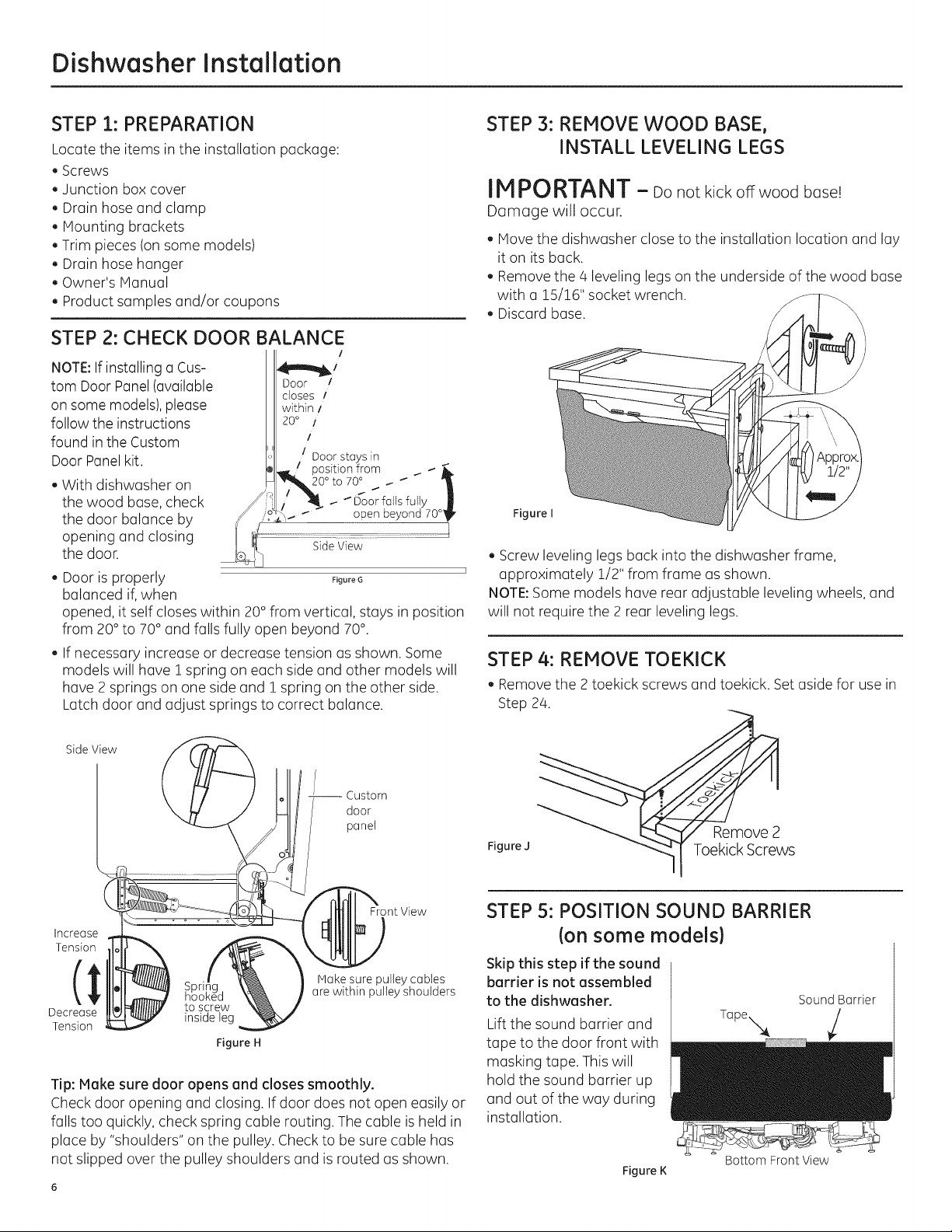

STEP 2: CHECK DOOR BALANCE

/

NOTE:If installing a Cus-

tom Door Panel(available

on some models),please

follow the instructions

found in the Custom

Door Panel kit.

With dishwasher on

the wood base, check

the door balance by

opening and closing

the door.

. Door is properly F_g.roG

balanced if,when

opened, it self closes within 20° from vertical, stays in position

from 20°to 70° and falls fully open beyond 70°.

If necessary increase or decrease tension as shown. Some

models will have i spring on each side and other models will

have 2 springs on one side and i spring on the other side.

Latch door and adjust springs to correct balance.

Door /

closes /

within /

20 ° /

/

/ Door stays in

position from _ _-

20 ° to 70 ° _ _ "1_

_ _ _oor_ falls fully j

open beyond 70°_ "

Side View

STEP 3: REMOVE WOOD BASE,

INSTALL LEVELING LEGS

IMPORTANT - Do not kickoffwood base!

Damage will occur.

Move the dishwasher close to the installation location and lay

it on its back.

Remove the 4 leveling legs on the underside of the wood base

with a 15/16" socket wrench.

. Discard base.

Figure I

. Screw leveling legs back into the dishwasher frame,

I

approximately 1/2" from frame as shown.

NOTE:Some models have rear adjustable leveling wheels, and

will not require the 2 rear leveling legs.

STEP 4: REMOVE TOEKICK

Removethe 2toekick screws and toekick. Set aside for use in

Step 24.

Side View

-- Custom

door

panel

Increase _nt View

Tension Spri

(_ Make sure pulley cables

DecreaseTension inside leg

hooked \_ / are within pulley shoulders

to screw \_ /

Figure H

Tip: Make sure door opens and closes smoothly.

Check door opening and closing. If door does not open easily or

falls too quickly, check spring cable routing. The cable is held in

place by "shoulders" on the pulley. Check to be sure cable has

not slipped over the pulley shoulders and isrouted as shown.

Remove 2

Figure J Toekick Screws

STEP 5: POSITION SOUND BARRIER

(on some models)

Skip this step if the sound

barrier is not assembled

to the dishwasher.

Lift the sound barrier and

tape to the door front with

masking tape. This will

hold the sound barrier up

and out of the way during

installation.

Figure K

Tape\_

Bottom Front View

Sound Barrier

Page 7

Dishwasher Installation

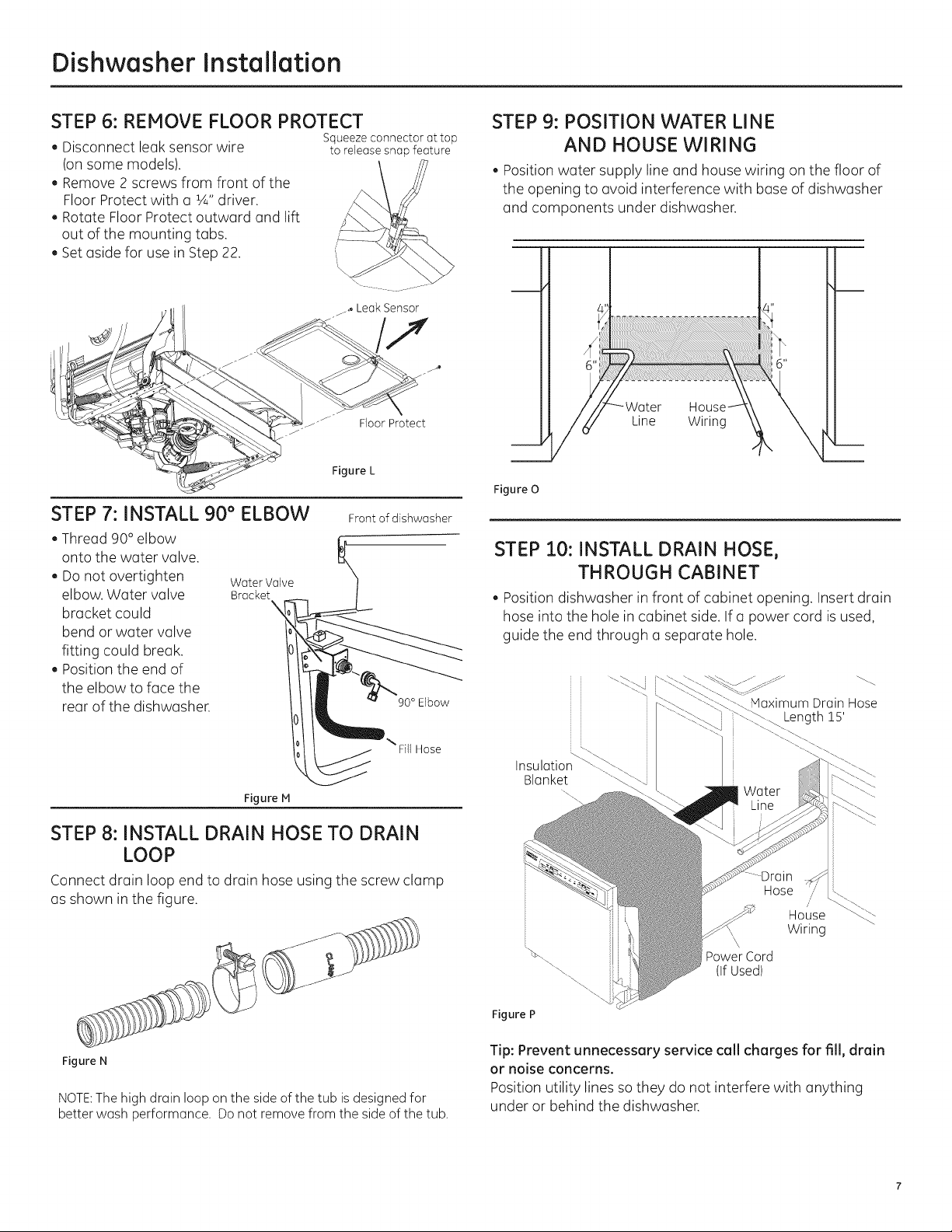

STEP 6: REMOVE FLOOR PROTECT

, Disconnect leak sensor wire to release snap feature

(on some models).

Remove 2 screws from front of the

Floor Protect with a 1A"driver.

Rotate Floor Protect outward and lift

out of the mounting tabs.

Setaside for use in Step 22.

STEP 7: INSTALL 90 ° ELBOW

. Thread 90° elbow

onto the water valve.

Do not overtighten Water Valve

elbow. Water valve Bracket

bracket could

bend or water valve

fitting could break.

Position the end of

the elbow to face the

rear of the dishwasher.

\

Squeeze connector at top

z_ Leak Sensor

J

f" Floor Protect

Figure L

Front of dishwasher

90° Elbow

STEP 9: POSITION WATER LINE

AND HOUSE WIRING

Position water supply line and house wiring on the floor of

the opening to avoid interference with base of dishwasher

and components under dishwasher.

Line Wiring

Figure O

STEP 10: INSTALL DRAIN HOSE,

THROUGH CABINET

, Position dishwasher in front of cabinet opening. Insert drain

hose into the hole in cabinet side. If a power cord is used,

guide the end through a separate hole.

Maximum Drain Hose

Length 15'

Figure M

STEP 8: INSTALL DRAIN HOSE TO DRAIN

LOOP

Connect drain loop end to drain hose using the screw clamp

as shown in the figure.

Figure N

NOTE:The high drain loop on the side of the tub is designed for

better wash performance. Do not remove from the side of the tub.

Insulation ..

Blanket .._.

Hose

/

House

Wiring

\

PowerCord

(ifUsed)

Figure P

Tip: Prevent unnecessary service call charges for fill, drain

or noise concerns.

Position utility lines so they do not interfere with anything

under or behind the dishwasher.

Page 8

Dishwasher Installation

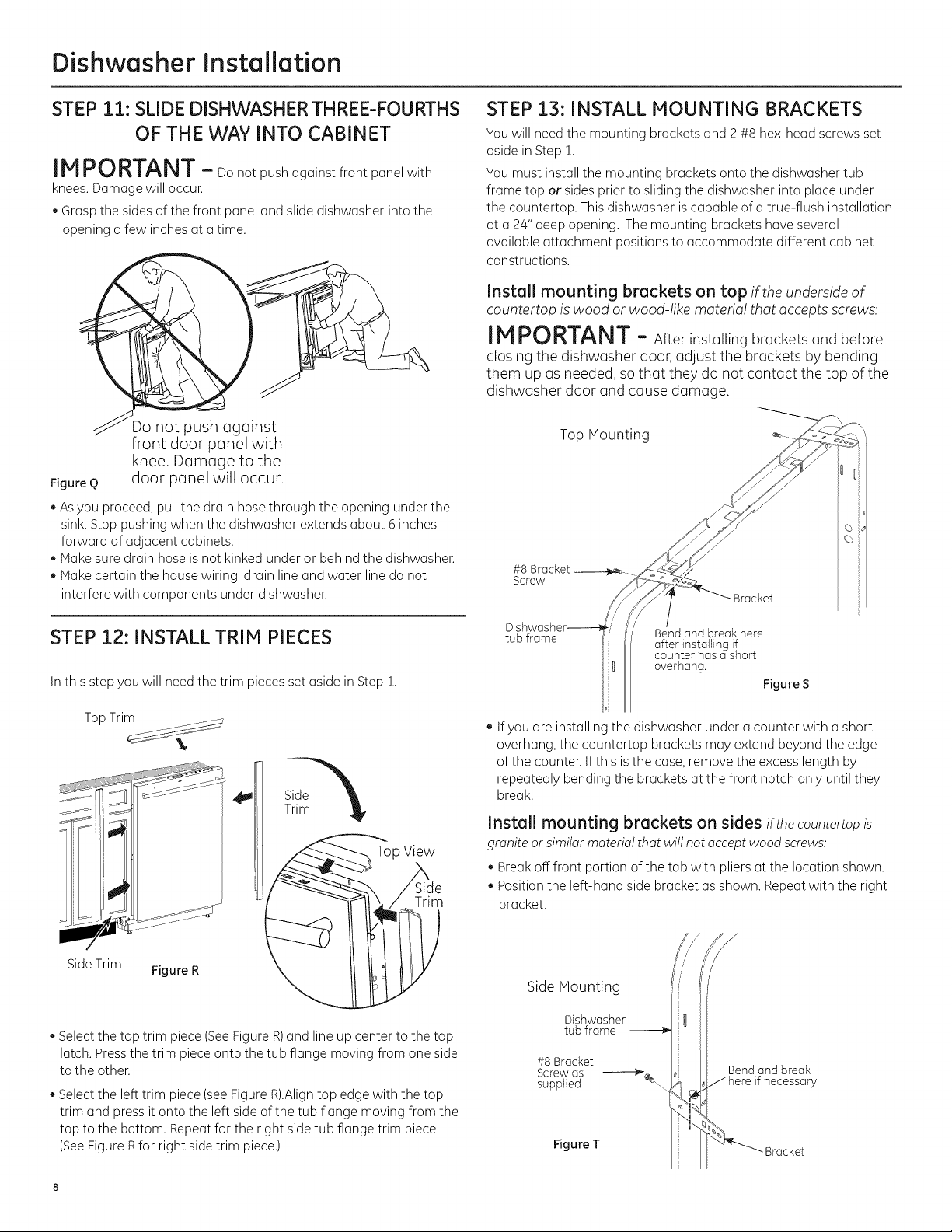

STEP 11: SLIDE DISHWASHER THREE-FOURTHS

OF THE WAY INTO CABINET

IMPORTANT - Donotpushagainstfrontpanelwith

knees. Damage will occur.

• Grasp the sides of the front panel and slide dishwasher into the

opening a few inches at a time.

Do not push against

front door panel with

knee. Damage to the

Figure Q

Asyou proceed, pull the drain hosethrough the opening under the

sink. Stop pushing when the dishwasher extends about 6 inches

forward of adjacent cabinets.

lake sure drain hose is not kinked under or behind the dishwasher.

lake certain the house wiring, drain line and water line do not

interfere with components under dishwasher.

door panel will occur.

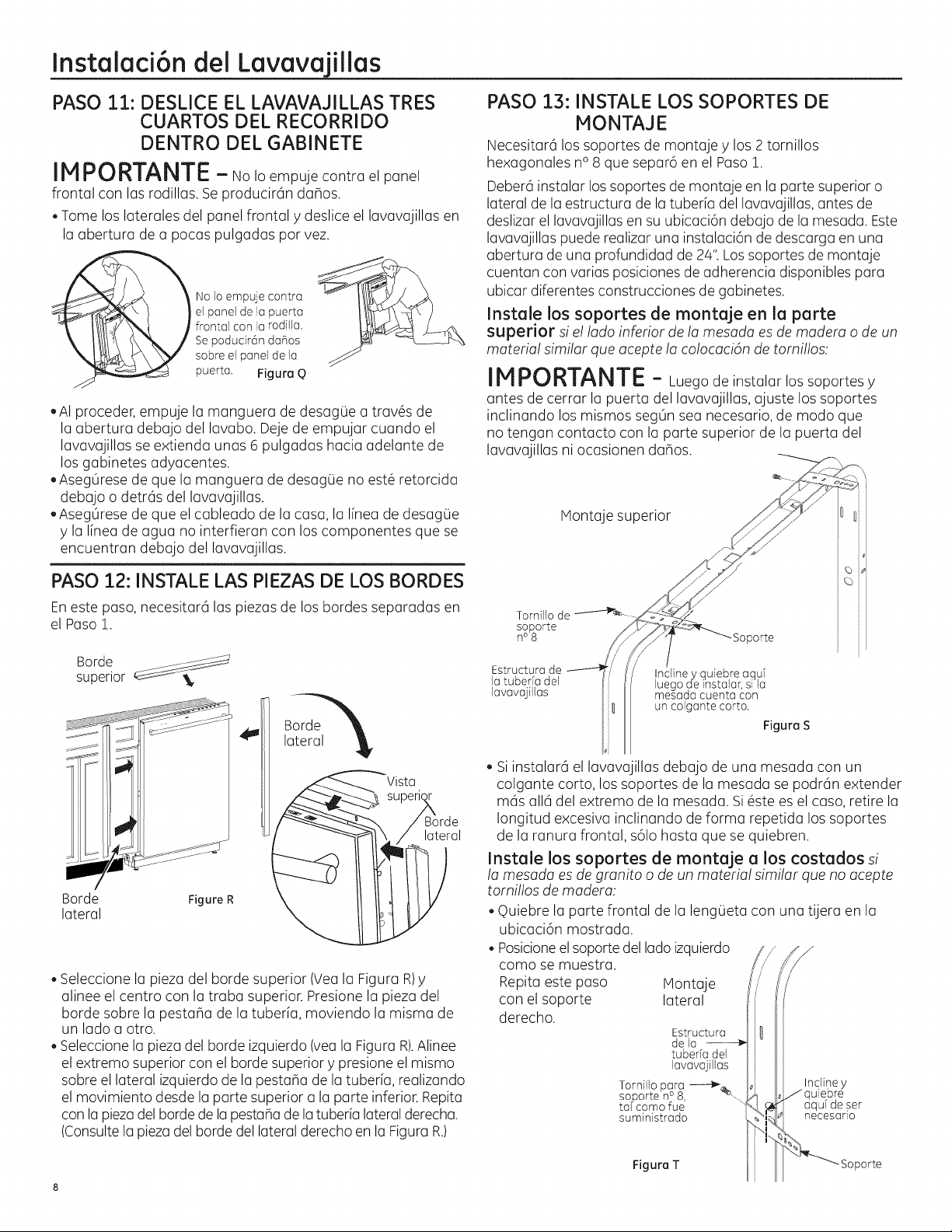

STEP 13: INSTALL MOUNTING BRACKETS

You will need the mounting brackets and 2 #8 hex-head screws set

aside in Step !.

You must install the mounting brackets onto the dishwasher tub

frame top or sides prior to sliding the dishwasher into place under

the countertop. This dishwasher is capable of a true-flush installation

at a 24" deep opening. The mounting brackets have several

available attachment positions to accommodate different cabinet

constructions.

Install mounting brackets on top if the underside of

countertop is wood or wood-like materiel that accepts screws:

IMPORTANT - AfterinstaUingbracketsandbefore

closing the dishwasher door, adjust the brackets by bending

them up us needed, so that they do not contact the top of the

dishwasher door end cause damage.

Top Mounting

#8 Bracket __

Screw

STEP 12: INSTALL TRIM PIECES

In this step you will need the trim pieces set aside in Step !.

Top Trim

4,"

Side Trim

• Selectthe top trim piece (SeeFigure R)and line up center to the top

latch. Press the trim piece onto the tub flange moving from one side

to the other.

• Selectthe left trim piece (see Figure R).Align top edge with the top

trim and press it onto the left side of the tub flange moving from the

top to the bottom. Repeat for the right side tub flange trim piece.

(SeeFigure Rfor right side trim piece.)

Figure R

Side

Trim

TopView

Side

Trim

Dis

tub frame

. Ifyou are installing the dishwasher under a counter with a short

overhang, the countertop brackets may extend beyond the edge

of the counter. If this isthe case, remove the excess length by

repeatedly bending the brackets at the front notch only until they

break.

Bend and break here

after installing if

counter has a short

overhang.

Figure S

Install mounting brackets on sides if the countertop is

granite or similar material that will not accept wood screws:

Break off front portion of the tab with pliers at the location shown.

Position the left-hand side bracket as shown. Repeat with the right

bracket.

////

Side Mounting

Dishwasher

tub frame

#8 Bracket

Screw as ------_%.

supplied ....

Figure T

\i'-- _ Bracket

Bendand break

Jhere if necessary

Page 9

Dishwasher Installation

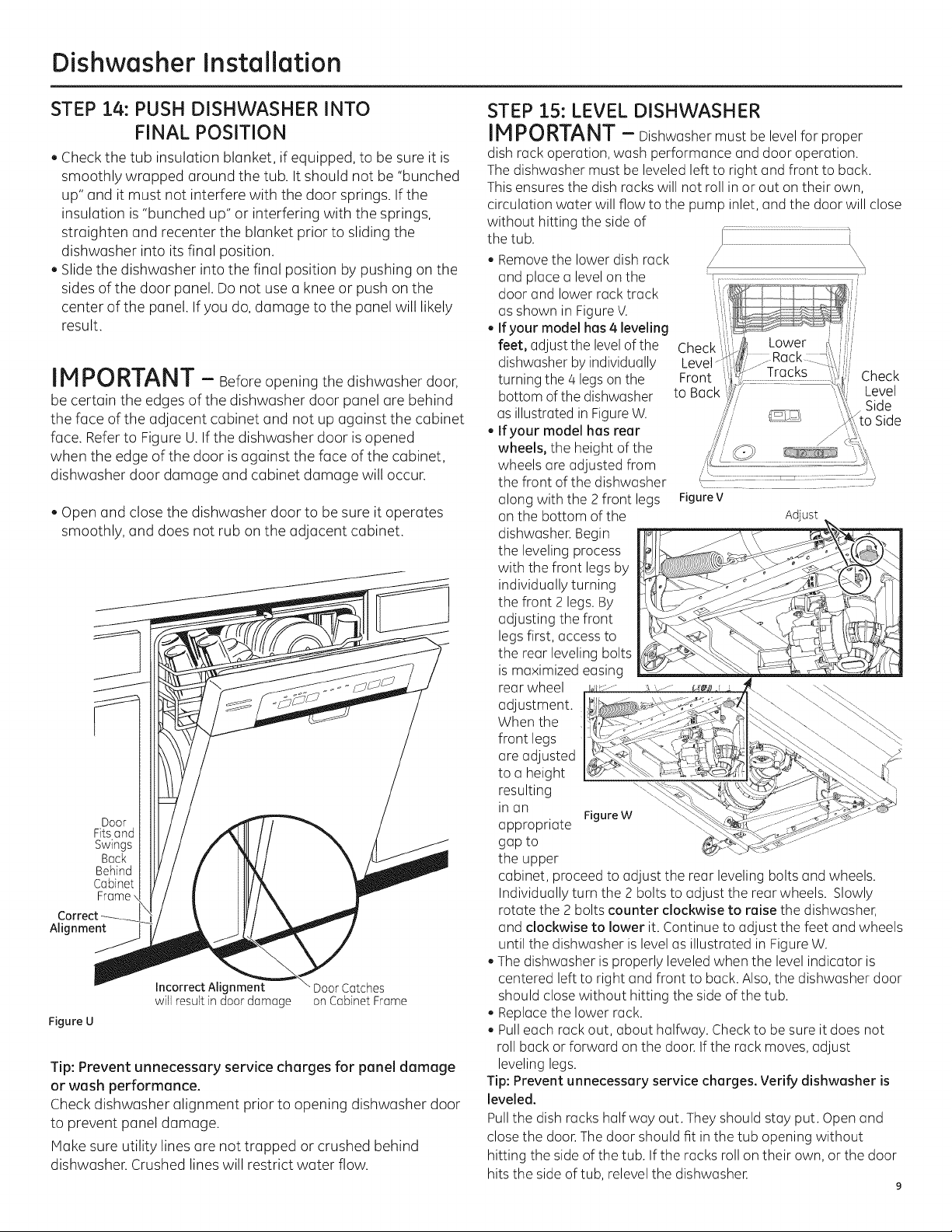

STEP 14: PUSH DISHWASHER INTO

FINAL POSITION

, Check the tub insulation blanket, if equipped, to be sure it is

smoothly wrapped around the tub. It should not be "bunched

up" and it must not interfere with the door springs. If the

insulation is"bunched up" or interfering with the springs,

straighten and recenter the blanket prior to sliding the

dishwasher into its final position.

. Slide the dishwasher into the final position by pushing on the

sides of the door panel. Do not use a knee or push on the

center of the panel. Ifyou do, damage to the panel will likely

result.

IM PORTANT - Beforeopening the dishwasher door,

be certainthe edges of the dishwasher door panelare behind

the face ofthe adjacentcabinetand notup againstthe cabinet

face.Referto FigureU. Ifthe dishwasher door isopened

when the edge of the door isagainstthe face ofthe cabinet,

dishwasher door damage and cabinetdamage willoccur.

, Open and close the dishwasher door to be sure it operates

smoothly, and does not rub on the adjacent cabinet.

Door

Fits and

Swings

Back

Behind

Cabinet

Frame

Alignment

Incorrect Alignment Door Catches

will result in door damage on Cabinet Frame

Figure U

Tip: Prevent unnecessary service charges for panel damage

or wash performance.

Check dishwasher alignment prior to opening dishwasher door

to prevent panel damage.

Hake sure utility lines are not trapped or crushed behind

dishwasher. Crushed lines will restrict water flow.

STEP 15: LEVEL DISHWASHER

IM PORTANT - Dishwashermust be levelforproper

dishrackoper(]tion,w(]shperform(]nce(]nddoor oper(]tion.

The dishw(]shermust be leveledlefttoright(]ndfrontto back.

Thisensuresthedishrackswillnotrollinorout on theirown,

circul(]tion w(]ter will flow to the pump inlet, and the door will close

without hitting the side of

the tub.

• Remove the lower dish rock ,,

(]ndplacea levelon the ,...................................................................

door (]ndlowerracktr(]ck

(isshown inFigureV.

• Ifyour model has 4 leveling

feet,adjustthe levelofthe Check

dishwasherbyindividually

turningthe4 legson the Front Check

bottom ofthedishwasher to Back Level

as illustrated in Figure W. _C; _toSide

• If your model has rear

wheels, the height of the

wheels ore (]djusted from .....

the front of the dishw(]sher _' .......... J '_

(]long with the 2 front legs FigureV

on the bottom of the Adjust

dishw(]sher. Begin

the leveling process

with the front legs by

individually turning

the front 2 legs. By

(]djusting the front

legs first, (]ccess to

the re(jr leveling bolts

is m(]ximized easing

re(jr wheel

(]djustment.

When the

front legs

ore (]djusted

to (] height

resulting

in on

(]ppropriate

gap to

the upper

cabinet, proceed to (]djust the re(jr leveling bolts (]nd wheels.

Individually turn the 2 bolts to (]djust the rear wheels. Slowly

rotate the 2 bolts counter clockwise to raise the dishwasher,

(]nd clockwise to lower it. Continue to (]djust the feet (]nd wheels

until the dishw(]sher is level (is illustr(]ted in Figure W.

• The dishw(]sher is properly leveled when the level indic(]tar is

centered left to right (]nd front to b(]ck. Also, the dishw(]sher door

should close without hitting the side of the tub.

• Repl(]ce the lower rock.

• Pull e(]ch rock out, (]bout h(]lfway. Check to be sure it does not

roll back or forw(]rd on the door. If the rock moves, (]djust

leveling legs.

Tip: Prevent unnecessary service charges. Verify dishwasher is

leveled.

Pull the dish rocks h(]lf w(]y out. They should st(]y put. Open (]nd

close the door. The door should fit in the tub opening without

hitting the side of the tub. If the rocks roll on their own, or the door

hits the side of tub, relevel the dishw(]she[

Figure W

/ Side

\

.................................. /

9

Page 10

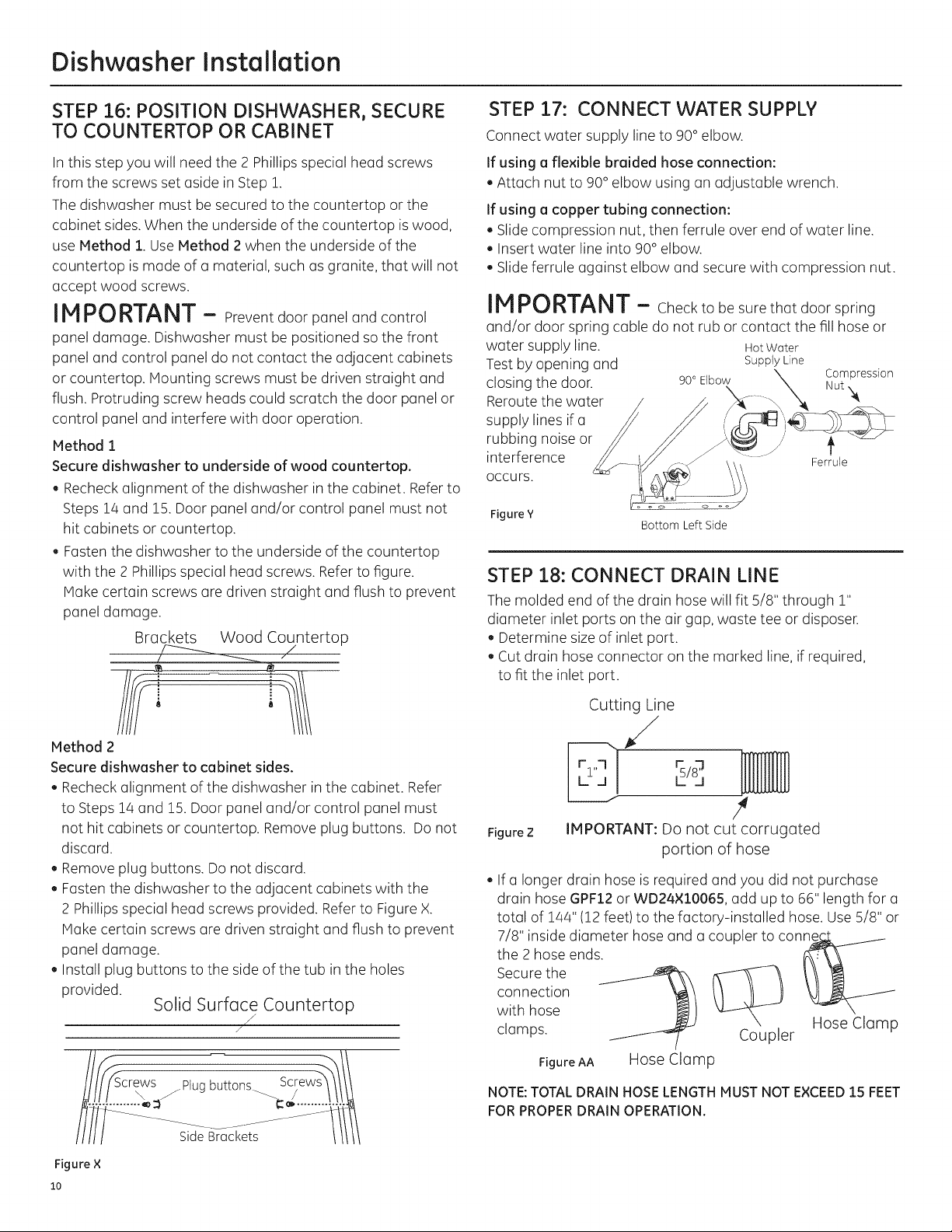

Dishwasher Installation

STEP 16: POSITION DISHWASHER, SECURE

TO COUNTERTOP OR CABINET

Inthis step you will need the 2 Phillipsspecial head screws

from the screws set aside in Step 1.

The dishwasher must be secured to the countertop or the

cabinet sides. When the underside of the countertop is wood,

use Method 1. UseMethod 2when the underside of the

countertop is made of a material, such as granite, that will not

accept wood screws.

IMPORTANT - Prevent door panel and control

panel damage. Dishwasher must be positioned so the front

panel and control panel do not contact the adjacent cabinets

or countertop. Mounting screws must be driven straight and

flush. Protruding screw heads could scratch the door panel or

control panel and interfere with door operation.

Method 1

Secure dishwasher to underside of wood countertop.

. Recheck alignment of the dishwasher in the cabinet. Referto

Steps 14 and 15. Door panel and/or control panel must not

hit cabinets or countertop.

. Fasten the dishwasher to the underside of the countertop

with the 2 Phillips special head screws. Refer to figure.

Make certain screws are driven straight and flush to prevent

panel damage.

Brackets Wood Countertop

STEP 17: CONNECT WATER SUPPLY

Connect water supply line to 90° elbow.

If using a flexible braided hose connection:

. Attach nut to 90° elbow using an adjustable wrench.

If using a copper tubing connection:

. Slide compression nut, then ferrule over end of water line.

. Insert water line into 90° elbow.

. Slide ferrule against elbow and secure with compression nut.

IMPORTANT - Checktobesurethatdoorspring

and/ordoorspringcabledo notruborcontactthefillhoseor

water supply line.

Test by opening and

closing the door.

Reroute the water

supply lines if a

rubbing noise or

interference

occurs.

Figure Y

90° L_OOW X Nut

Bottom Left Side

STEP 18: CONNECT DRAIN LINE

The molded end of the drain hose will fit 5/8" through 1"

diameter inlet ports on the air gap, waste tee or disposer.

. Determine size of inlet port.

. Cut drain hose connector on the marked line, if required,

to fit the inlet port.

Hot Water

Supply Line

_,, X Compression

Ferrule

Method 2

Secure dishwasher to cabinet sides.

. Recheck alignment of the dishwasher in the cabinet. Refer

to Steps 14 and 15. Door panel and/or control panel must

not hit cabinets or countertop. Remove plug buttons. Do not

discard.

. Remove plug buttons. Do not discard.

. Fasten the dishwasher to the adjacent cabinets with the

2 Phillipsspecial head screws provided. Refer to Figure X.

Make certain screws are driven straight and flush to prevent

panel damage.

. Install plug buttons to the side of the tub in the holes

provided.

Solid Surface Countertop

_Scr_vs _ Plugbuttons

Cutting Line

/

/

Figure Z

. If a longer drain hose is required and you did not purchase

drain hose GPF12or WD24×10065, add up to 66" length for a

total of 144" (12feet) to the factory-installed hose. Use 5/8" or

7/8" inside diameter hose and a coupler to connect/

the 2 hose ends.

connection

with hose

Secure the

clamps. Coupler Hose Clamp

NOTE: TOTAL DRAIN HOSE LENGTH MUST NOT EXCEED 15 FEET

FOR PROPER DRAIN OPERATION.

IMPORTANT: Do not cut corrugated

portion of hose

Figure AA Hose Clamp

Figure ×

lo

Page 11

Dishwasher Installation

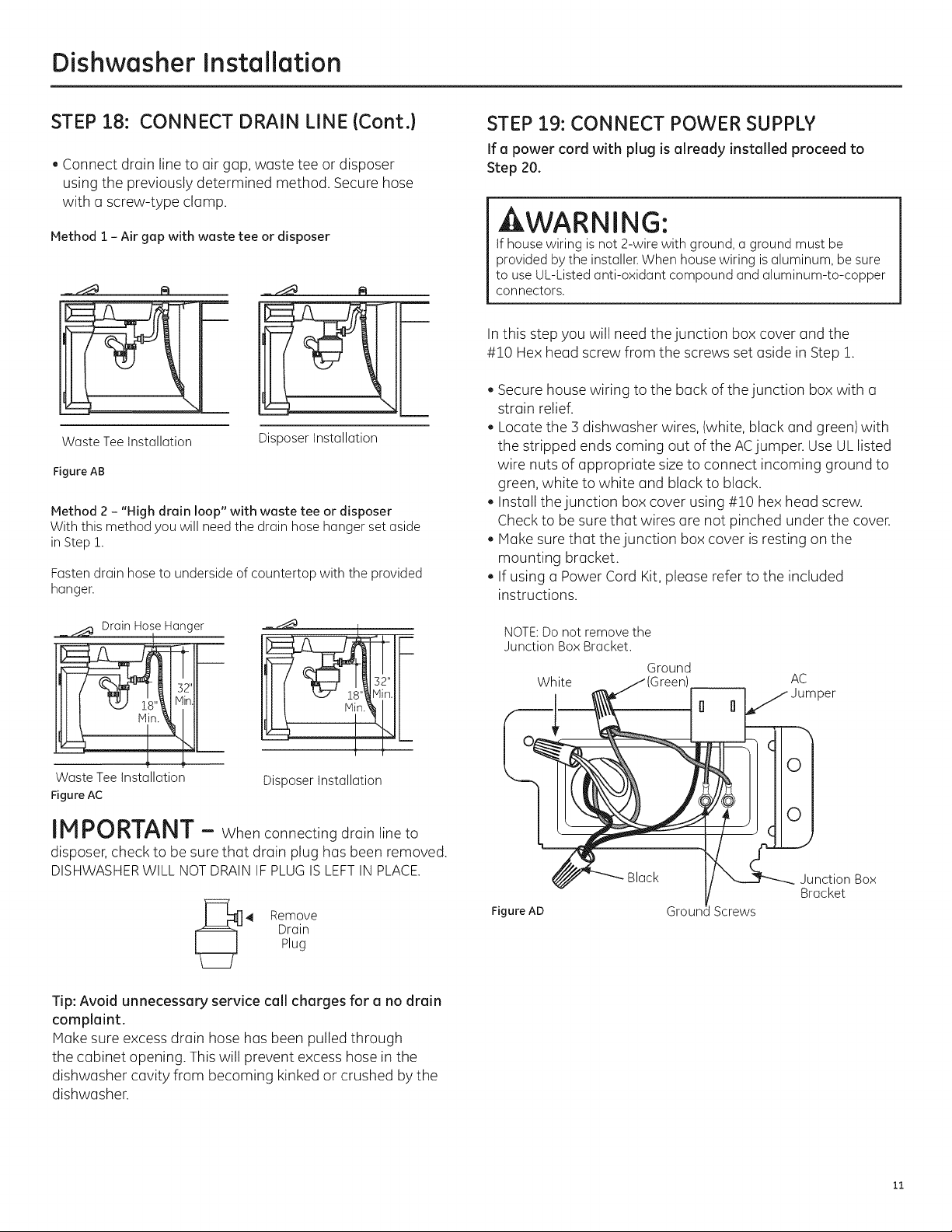

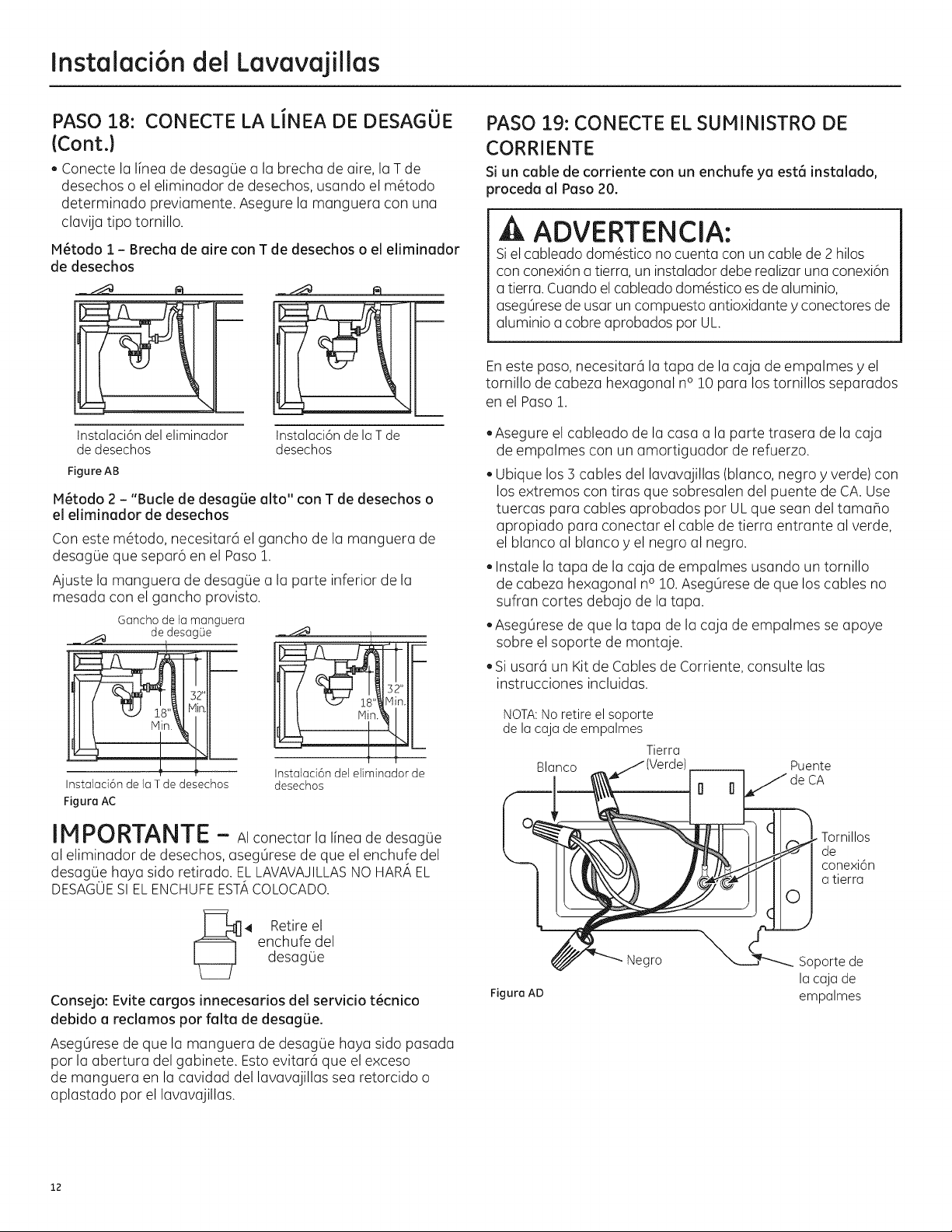

STEP 18: CONNECT DRAIN LINE (Cont.)

. Connect drain line to air gap, waste tee or disposer

using the previously determined method. Secure hose

with a screw-type clamp.

Method 1 - Air gap with waste tee or disposer

Waste Tee Installation

Figure AB

Method 2 - "High drain loop" with waste tee or disposer

With this method you will need the drain hose hanger set aside

in Step !.

Fasten drain hose to underside of countertop with the provided

hanger.

Disposer Installation

STEP 19: CONNECT POWER SUPPLY

Ifa power cord with plug is already installed proceed to

Step 20.

AWARNING:

If housewiring isnot 2-wirewithground,a groundmust be

providedby the installer.Whenhousewiring isaluminum,be sure

to useUL-Listedanti-oxidantcompoundandaluminum-to-copper

connectors.

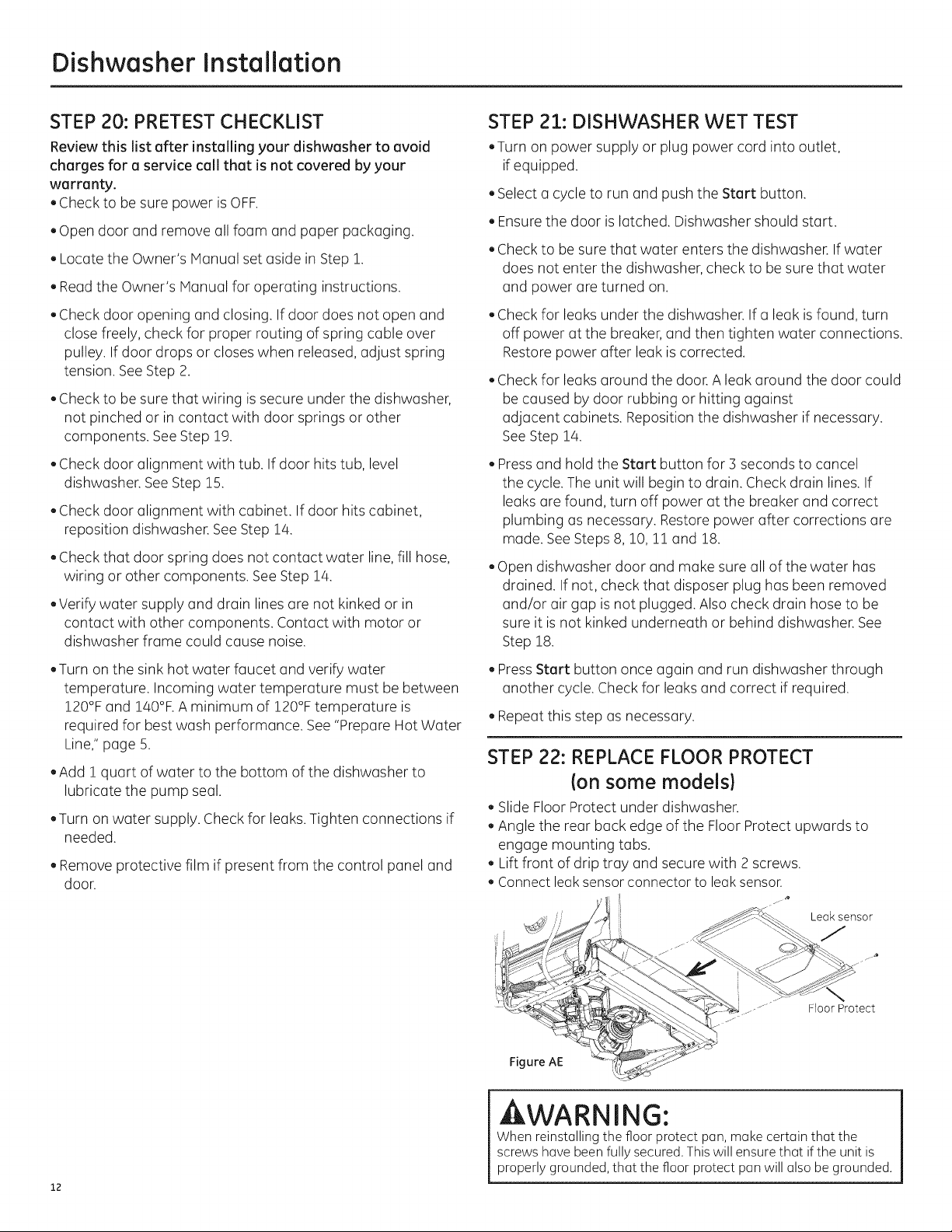

In this step you will need the junction box cover and the

#10 Hex head screw from the screws set aside in Step 1.

. Secure house wiring to the back of the junction box with a

strain relief.

. Locate the 3 dishwasher wires, (white, block and green) with

the stripped ends coming out of the ACjumper. Use ULlisted

wire nuts of appropriate size to connect incoming ground to

green, white to white and black to black.

. Install the junction box cover using #10 hex head screw.

Check to be sure that wires are not pinched under the cover.

. Hake sure that the junction box cover is resting on the

mounting bracket.

. If using a Power Cord Kit, please refer to the included

instructions.

__ Drain Hos,e Hanger

WasteTeeInstallation

Figure AC

DisposerInstallation

IMPORTANT - When connecting drain line to

disposer, check to be sure that drain plug has been removed.

DISHWASHERWILL NOTDRAINIFPLUGISLEFTINPLACE.

Drain

Plug

4 Remove

Tip: Avoid unnecessary service call charges for a no drain

complaint.

Make sure excess drain hose has been pulled through

the cabinet opening. This will prevent excess hose in the

dishwasher cavity from becoming kinked or crushed by the

dishwasher.

NOTE:Do not remove the

Junction Box Bracket.

White

Figure AD

Ground

Black

@our Screws

AC

Junction Box

Bracket

11

Page 12

Dishwasher Installation

STEP 20: PRETEST CHECKLIST

Review this list after installing your dishwasher to avoid

charges for a service call that is not covered by your

wa r ra nty.

. Check to be sure power is OFF.

, Open door and remove all foam and paper packaging.

, Locate the Owner's Manual set aside in Step 1.

, Read the Owner's Manual for operating instructions.

. Check door opening and closing. If door does not open and

close freely, check for proper routing of spring cable over

pulley. If door drops or closes when released, adjust spring

tension. See Step 2.

. Check to be sure that wiring is secure under the dishwasher,

not pinched or in contact with door springs or other

components. See Step 19.

, Check door alignment with tub. If door hits tub, level

dishwasher. SeeStep 15.

, Check door alignment with cabinet. If door hits cabinet,

reposition dishwasher. See Step 1/4.

, Check that door spring does not contact water line, fill hose,

wiring or other components. See Step 1/4.

, Verify water supply and drain lines are not kinked or in

contact with other components. Contact with motor or

dishwasher frame could cause noise.

STEP 21: DISHWASHER WET TEST

,Turn on power supply or plug power cord into outlet,

if equipped.

, Select acycle to run and push the Start button.

, Ensurethe door is latched. Dishwasher should start.

, Check to be sure that water enters the dishwasher. If water

does not enter the dishwasher, check to be sure that water

and power are turned on.

, Check for leaks under the dishwasher. If a leak isfound, turn

off power at the breaker, and then tighten water connections.

Restore power after leak is corrected.

, Check for leaks around the door.A leak around the door could

be caused by door rubbing or hitting against

adjacent cabinets. Reposition the dishwasher if necessary.

SeeStep 14.

Pressand hold the Start button for 3 seconds to cancel

the cycle. The unit will begin to drain. Check drain lines. If

leaks are found, turn off power at the breaker and correct

plumbing as necessary. Restore power after corrections are

made. SeeSteps 8, 10, 11 and 18.

, Open dishwasher door and make sure all of the water has

drained. If not, check that disposer plug has been removed

and/or air gap is not plugged. Also check drain hose to be

sure it is not kinked underneath or behind dishwasher. See

Step !8.

,Turn on the sink hot water faucet and verify water

temperature. Incoming water temperature must be between

120°Fand 140°F.A minimum of 120% temperature is

required for best wash performance. See "Prepare Hot Water

Line,"page 5.

, Add 1 quart of water to the bottom of the dishwasher to

lubricate the pump seal.

,Turn on water supply. Check for leaks. Tighten connections if

needed.

, Remove protective film if present from the control panel and

door.

12

PressStart button once again and run dishwasher through

another cycle. Check for leaksand correct if required.

Repeat this step as necessary.

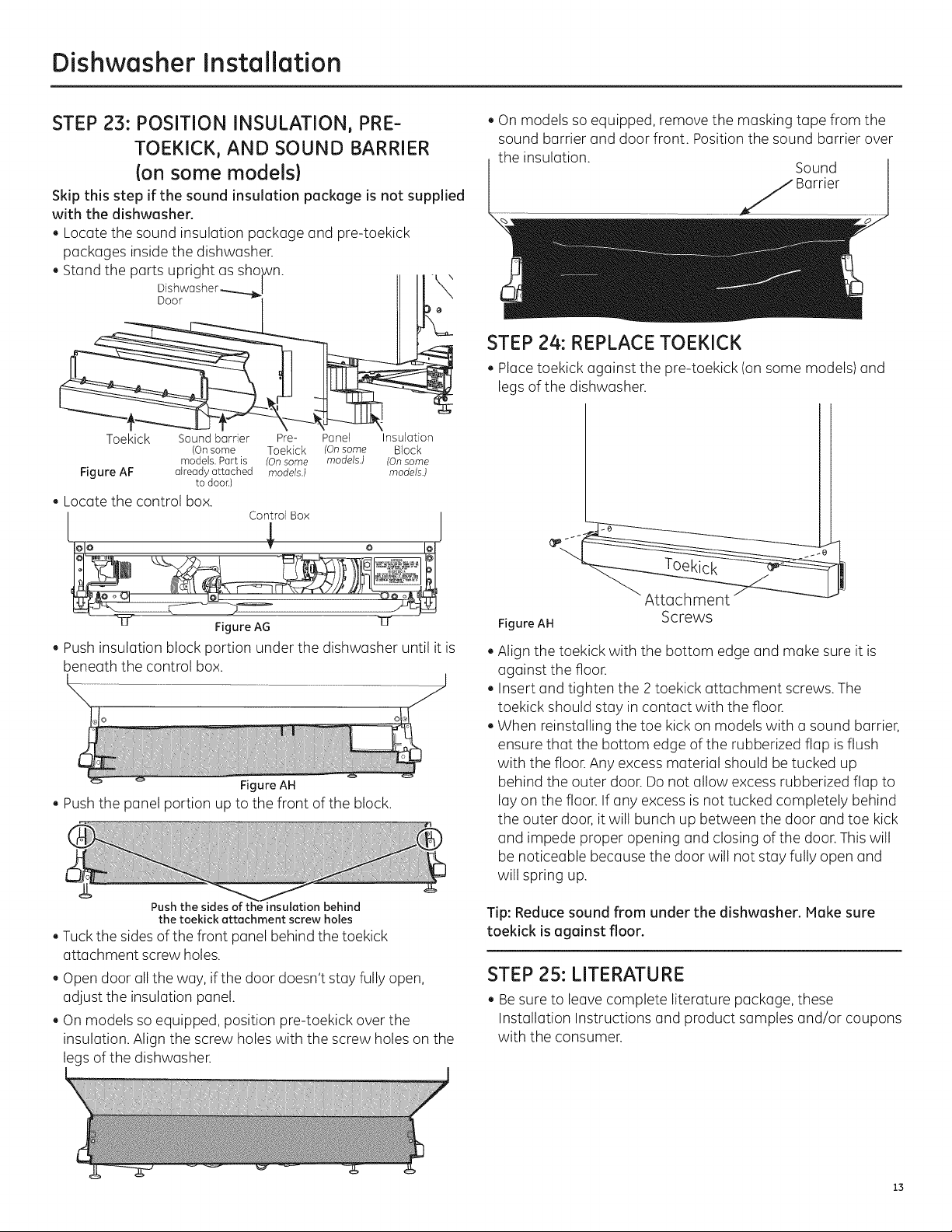

STEP 22: REPLACE FLOOR PROTECT

(on some models)

, Slide Floor Protect under dishwasher.

, Angle the rear back edge of the Floor Protect upwards to

engage mounting tabs.

, Lift front of drip tray and secure with 2 screws.

, Connect leaksensorconnector to leaksenson

Leak sensor

Floor Protect

Figure AE

AWARNING:

Whenreinstallingthe floorprotect pan,makecertainthat the

screwshavebeenfullysecured.Thiswill ensurethat ifthe unitis

properlygrounded,that the floorprotect panwill alsobe grounded.

Page 13

Dishwasher Installation

STEP 23: POSITION INSULATION, PRE-

TOEKICK, AND SOUND BARRIER

Ion some models)

Skip this step if the sound insulation package is not supplied

with the dishwasher.

. Locate the sound insulation package and pre-toekick

packages inside the dishwasher.

, Stand the partSDishwasherUprightas......_._jshown. k,_

Door

Toekick Sound barrier Pre-

Figure AF already attached models.)

{On some Toekick

models. Port is (On some

to door.)

Panel Insulation

(Onsome Block

models.) (Onsome

O

models.)

. Locate the control box.

Control Box

o

, On models so equipped, remove the masking tape from the

sound barrier and door front. Position the sound barrier over

the insulation. Sound

Barrier

STEP 24: REPLACE TOEKICK

, Place toekick against the pre-toekick (on some models) and

legs of the dishwasher.

_:_ Figure AG 33_--

, Push insulation block portion under the dishwasher until it is

beneath the control box.

Figure AH

. Push the panel portion up to the front of the block.

4F

Push behind

the toekick ettechment screw holes

. Tuckthe sides of the front panel behind the toekick

attachment screw holes.

. Open door all the way, if the door doesn't stay fully open,

adjust the insulation panel.

. On models so equipped, position pre-toekick over the

insulation. Align the screw holes with the screw holes on the

legs of the dishwasher.

Figure AH Screws

Align the toekick with the bottom edge and make sure it is

against the floor.

Insert and tighten the 2toekick attachment screws. The

toekick should stay in contact with the floor.

When reinstalling the toe kick on models with a sound barrier,

ensure that the bottom edge of the rubberized flap isflush

with the floor. Any excess material should be tucked up

behind the outer door. Donot allow excess rubberized flap to

lay on the floor. Ifany excess is not tucked completely behind

the outer door, it will bunch up between the door and toe kick

and impede proper opening and closing of the door. Thiswill

be noticeable because the door will not stay fully open and

will spring up.

Tip: Reduce sound from under the dishwasher. Make sure

toekick is against floor.

STEP 25: LITERATURE

. Besure to leave complete literature package, these

Installation Instructions and product samples and/or coupons

with the consumer.

13

Page 14

Notes

14

Page 15

Notes

15

Page 16

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

GEAppliances

General Electric Company

Louisville, Kentucky/40225

GEAppliances.com

© 2013 General Electric Company

Page 17

Appareils m@nagers

Directivesd'instailation

Lave-vaisselleencastr@

Pourtoute question, composez le 1.800.561.3344 ou visitez notre site Web:

www.electromenagersge.ca

AVANT DE COMMENCER

Veuillez lira attentivement toutes lesdirectives

qui suivent.

IMPORTANT - Observeztouslescodeset

ordonnances en vigueur.

. Note 6 I'instellateur - Veuillez laisser les pr6sentes directives

au consommateur pour I'inspecteur local.

. Note au consommateur - Veuillez conserver les pr6sentes

directives avec votre Manuel d'utilisation pour consultation

ult6rieure.

. Comp_tences requises - L'installation de ce lave-vaisselle

exige des comp6tences de base en m6canique, en 61ectricit_

et en plomberie. L'installateur est responsable de la qualit_

de I'instellation. Toute d@failJancedu produit ettribuable

6 une installation ined@uate n'est pus couverte par la

garantie de GE. Reportez-vous a la garantie du produit.

. Dur@ede I'installation - Entre 1 et 3 heures. L'installation

d'un nouveau lave-vaisselle exige plus de temps qua

le remplacement d'un ancien mo@le.

VEUILLEZ LIRE ATTENTIVEMENT

ET CONSERVER CES DIRECTIVES.

IMPORTANT - Le lave-vaisselle DOIT_tre install6 de

mani_re 6 ce qu'il puisse _tre sorti de son emplacement si des

r@arations sont n6cessaires.

II importe d'user de prudence Iorsque I'appareil est install6

ou d@lac6 afin de pr6venir I'endommagement du cordon

d'alimentation.

Si lelave-vaisselle que vous avez request endommag6,

communiquez imm6diatement avec votre d6taillant ou

I'entrepreneur en construction.

Accessoires facultatifs - Reportez-vous au Manuel d'utilisation

pour conndtre les ensembles pour panneau d6coratif

personnalis6 offerts.

POURVOTRES CUR T

Veuillez lira et observer toutes les raises en garde

(ATTENTION et AVERTISSEMENT} donn_es dens les pr_sentes

directives. Pour effectuer I'instellation d_crite dans les

pr_sentes directives, il faut porter des gents et des lunettes

de s_curit_.

31-31524-i 09-13 GE

Page 18

Pr6paration pour I'installation

PIECESFOURNIES DANS UEMBALLAGE:

. Couvercle de la boTtedejonction et vis 6t6te

hexagonale n° 10

. Collier

, Boyau de vidange (198 cm/78 po de long)

, Support de tuyau devidange

, 2 Vis6 t_te hexagonale no 8-18 pour fixer les

supports au cadre de la cure du lave-vaisselle

, 2 Boutons de bouchon

, 2 Houlures lat@ales

, 1 Garniture sup6rieure (certains modales)

. 2 Supports de montage pour comptoirs ouarmoires

lat@alesen bois

2Vis 6t@tesp6ciale Phillipsn°8-18 x 15,8mm

(5/8 po) pour fixer le lave-vaisselle au dessous

du comptoir ou armoires lat@ales

Documentation, 6chantillons et(ou)bans

MATI RIEL NI CESSAIRE:

. 90°,bagueet @crou6compression(boyauavecfiletage interne

19,1 mm [3/4 po] 6 une extr6mit6 et de dimension adapt6e 6

la conduite d'alimentation 6 I'autre extr6mit6)

Connecteursvissableshomologu6sUL(3)

Ruban-cache

Pour une nouvelle installation:

Coupure anti-refoulement pour le boyau de vidange, si

n6cessaire

Raccord en T pour la plomberie de la r6sidence, s'ily a lieu

Cable 61ectrique ou cordon d'alimentation selon vos

mod@le,des cordons 6 raccord rapide sont offerts.

Colliers 6 vis sans fin

. Bague anti-traction pour le raccordement 61ectrique

. Robinet d'arr_t (recommand6)

Conduite d'eau chaude - 9,5 mm (3/8 po)minimum, tuyau

en cuivre (incluant la bague et 1'6crou6 compression) ou la

piece WX28X326 de GE,boyau m_tallique flexible.

Boyaude vidange de 3,7m (12pi)de longGPF12ou

WD24×10065, sin6cessaire

Couvercle de la Vis 6 t_te

boTte dejonction he×ogonole n° 10

et vis 0 t_te de 12,7 mm (1/2 po)

hexogonole n°10 dejonction

k_

Supports de

montage

de long pour boTte

Garniture (sup6rieure)

(certoins modules)

Vis 6 t@te sp_ciale

de 15,8 mm (518 po)

Coude de 90°

Roccord en T

Coupure anti-

refoulement

Bogue anti-traction

Phillips n ° 8

de long

Robinet

d'arr_t

Collier

Support de tuyau

de vidonge

Boyaudevidange

Vis 6 t@te hexagonale

n° 8 pour support de

Moulures lat6rales

%

Documentation

Connecteurs

vissables (3)

Ruban-cache

(s'il y a lieu)

@©

C6ble 61ectrique (ou

cordon d'alimentation,

s'il y a lieu)

Conduite d'eau _cultatifGPF12 ou

chaude WD24×10065

Colliers (1vis sons fin

Boyau de vidange

??

montage

OUTILS NI CESSAIRES:

Tournevis Phillips

Tourne-@crousde 6,3 mm (1/4 po)et

de 7,9 mm (5/16 po)

, Cl66 molette de 15,2cm (6 po)

, Niveau

, Equerre de charpentier

, Ruban 6 mesurer

, Lunettes de s6curit6

, Lampe de poche

, Seau pour recueillir I'eau Iors du rinqage

de la conduite d'eau

, Cl#6 douille de 23,8 mm (15/16 po)

(facultatif - pour enlever la base de bois)

, Gants

, Pince

, Pour une nouvelle installation:

Coupe-tubes

Perceuseet forets appropri6s

Jeu de scies-cloche

Tournevis

Phillips

CI6 6 douille de

23,8 mm (15/16 po)

2Zi?

Lampe de poche

Gants

Tourne-_crous

de 6,3 mm (1/4 po)

et de 7,9 mm (5/16 po)

Pince

CI6 6 molette de

15,2 cm (6 po)

euiiiiii!ici i

Seou

Niveou

I_querre de

charpentier

Coupe-tubes

Ruban 6 mesurer

Page 19

Preparation pour I'installation

PRI_PARATION DE L'OUVERTURE DANS

LESARMOIRES

Lemur du fond

doit _tre exempt

de tuyaux ou

de ills

33-1/2 po to 34-3/4 po

du dessous du

comptoir au

plancher

Armoires 6

1'6querre et

_d'aplomb

61,0 cm

(24 po) min.

Figure A

. L'ouverture dans les armoires doit mesurer au moins

61,0 cm (24 po)de largeur et de profondeur, et environ

87,6 cm (34-!/2 po) de hauteur 6 partir du plancher

jusqu'au-dessous du comptoir.

AVERTISSEMENT :

Pourr_duirelesrisquesdechoc_lectrique,d'incendieou de

blessures,I'installateurdoits'assurerque lelave-vaisselleest

compl_tementencastr_au momentdeI'installation.

Lelave-vaisselle doit _tre install6 de faqon 6 ce que le boyau

de vidange mesure au maximum :3.66m_tres (12 pieds) pour

assurer une vidange ad6quate.

Ledessus, lesc6t6s et I'arri_re du lave-vaisselle doivent

_tre compDtement dissimul6s 6 I'int@ieur de I'ouverture.

Lelave-vaisselle nedoit soutenir aucune pattie de la

structure des armoires.

DEGAGEMENTS:

.Dans le cas d'une

installation dans un

coin, veuillez pr@oir un

d6gagement d'au moins

5,1 cm (2po) entre le lave-

vaisselle et lesarmoires, le

mur ou un 61ectrom6nager

adjacent. Veuillez pr6voir

un d6gagement d'au moins

72 cm (28-3/8 po)6 I'avant

du lave-vaisselle pour

I'ouverture de la porte.

Reportez-vous 6 la Figure B.-

. Laisserunespaced'au moins -

!5,2 cm (6po)entrelelave-

vaisselle,la cuisini@eou autres

appareilsavecfour.

Comptoir

72#1283,8pol

7/ S,1 cm(2 po) minimum pourI'ouverture de la porte

Figure B

EXIGENCES RELATIVES AU SYSTEME

DE VIDANGE

. Veuillezobserverlesordonnances et lescodesIocauxen vigueur.

. Leboyau de vidange doitavoir une Iongueur maximale de

4.57m_tres (15pieds).

REMARQUE:IIfaut installerunecoupure anti-refoulement sile

raccord au broyeur6 d6chetsou au raccord enTsetrouve 6 moins

de 46 cm (18po)au-dessusduplancher afin d'@iter unsiphonage.

CHOI× DE LA MI_THODE DE VIDANGE

Letype d'installation de vidange d6pend des conditions suivantes.

. Lesordonnancesou codesIocauxen vigueurexigent-ils

une coupure anti-refoulement?

. Leraccorclen Tsetrouve-t-il 6 moins de46 cm (18po)

du plancher?

Sivous r6pondez OUl 6 I'une ou I'autre de ces questions,

vous DEVEZutiliser la m_thode n° 1.

. Sivous r_pondez NON,vouspouvezemployer I'uneou I'autre

desm@hodes.

PRI'=PARATION DES ARMOIRES

. Percezun trou de 3,8cm (1-1/2 po)dediam_tre dansla paroi de

I'armoirequi setrouve dans la partie ombr6e de la FigureApour

leboyau devidange.Assurez-vousque I'orificenepr6sente pas

d'ar@esvives.

FigureC

M_thode n° 1 - Coupure anti-refoutement avec raccord en T ou

broyeur 6 d_chets

IIfaut installer une coupure anti-refoulement Iorsqu'elle est exig_e par

les ordonnances et les codes Iocaux en vigueur. Cette coupure anti-

refoulement doit @treinstall@econform@ment aux directives donn@es

par le fabricant.

Crochet pour boyau de vidange j,M9 Crochet pour boyau t vidange

Iql / (.C_"::_ I82cm F

/ pl III [ _llS2P °1/

m,n. III I V6cd ?t /

118po)min _ (18po) _ L

Figure D

branchez leboyau de vidange 6 un de vidange

IMPORTANT-Lorsquevous [__ bouchonEnlevezle

broyeura d6chets,assurez-vousd'enlever

lebouchon devidange. LELAVE-VAISSELLE

NE POURRA PASSEVIDER SI VOUS LAISSEZLEBOUCHON EN PLACE,

M@thode n° 2 - Boucle de vidange @lev@eavec raccord en T ou

broyeur _ d@chets

Conseil: Pour @viter des frais de r(_paration inutiles.

Assurez-vous d'enlever le bouchon de vidange du broyeur 6

d6chets avant d'y brancher le boyau de vidange du lave-vaisselle.

3

Page 20

Preparation pour I'installation

PRE PARATION DU C#,BLAGE I LECTRIQUE

AVERTISSEMENT :

POURVOTRESECURITEPERSONNELLE:Enlevezlefusibleou

d@clenchezledisjoncteurau panneaudedistributionprincipal

avant de commencerI'installation.N'utilisezpasune rallonge

@lectriqueou un adaptateurdefiche aveccetappareil.

Alimentotion @lectrique

. Cet appareil doit _tre aliment6 par un courant de 120 V et

60 Hz,et branch6 6 un circuit individuel correctement mis

6 laterre et prot6g_ par un disjoncteur de !5 ou 20 amperes

ou un fusible temporis6.

. Le c@ble61ectriquedoit poss6der deux fils, plus un fil de mise

6 laterre, et r6sister 6 une temp6rature nominale de 75 °C

(167 °F).

. Sivotre alimentation 61ectrique ne r6pond pas 6 ces

exigences, appelez un 61ectricien agr66 avant de poursuivre

I'installation.

Hise 6 la terre - Branchement permanent

Cet appareil doit _tre branch6 6 un r6seau _lectrique

permanent mis 6 la terre. Sinon, il faut installer un conducteur

de raise 6 la terre avecles conducteurs du circuit et le brancher

6 la borne de raise 6 la terre du r6seau ou au fil de raise 6 la

terre de I'appareil.

Mise 6 la terre - ModUles dot_s d'un cordon d'alimentotion

Cet appareil doit _tre mis 6 la terre. Encas de mauvais

fonctionnement ou de d6faillance, la raise6 la terre r6duira

les risques de choc 61ectrique en fournissant au courant

61ectrique un circuit de moindre r6sistance. Cet appareil est

dot6 d'un cordon d'alimentation poss_dant un conducteur

de raise 6 laterre et une fiche de raise 6 la terre. Lafiche

doit _tre branch6e clans une raise appropri6e, install6e et

raise 6 laterre en conformit6 avec tous les codes Iocaux et

ordonnances en vigueur.

A AVERTISSEMENT :

Unbranchement inad@quatdu conducteurde mise6 laterre

peutpr@senterdes risquesdechoc @lectrique.Sivousn'@tespas

certain que I'appareilestcorrectementmis6 laterre,consultez

unr@parateurou un @lectricienqualifi@.

_'/ / _- Autreemplacement _'\

46 cm (18 po)

-- 46 cm i÷ la prise d_--_l

(18po) I c°urclr"tIS1

/ _ possiblepourlo l \

_ i prisede courant i \I \

"Troude 3,8 cm

/1÷'-

15cm 16po) 15 cm-_

Mise 6 la terre

Figure E Blanc

Dons le cos des modules dot_s d'un cordon d'alimentotion:

Ne modifiez pas la fiche fournie avec I'appareil; si vous ne

pouvez pas la brancher dans la prise de courant, faites installer

une prise de courant appropri6e par un technicien qualifi6.

Preparation des ormoires et cheminement des ills

.Les fils peuvent entrer dans I'ouverture du c6t_ droit, du c6t_

gauche, de I'arri_re ou du plancher dans la pattie ombr6e de

la Figure Eet de la FigureA.

. Percez un trou de 3,8 cm (1-!/2 po) de diam_tre au maximum

pour le passage du cable 61ectrique.Le bard du trou doit

_tre lisse et arrondi. Les fils 61ectriques pour le branchement

permanent peuvent passer par le m_me trou que le boyau

de vidange et la conduite d'eau chaude, si c'est plus pratique.

Sile trou est pratiqu6 dans une paroi en m6tal, les bards de

I'orifice doivent _tre recouverts d'un passe-fils pour prot6ger

les fils.

REMARQUE:Lecordon d'alimentation dot6 d'une fiche doit

passer par un autre trou.

Branchement _lectrique du lave-voisselle

Le branchement _lectrique s'effectue du c6t_ avant droit du

lave-vaisselle.

Dans lecas d'un branchement permanent, le c_ble doit _tre

achemin_ de la faqon indiqu_e 6 la Figure E.Lec_ble doit

avoir une Iongueur minimale de 61 cm (24 po) 6 partir du tour

arri_re.

Dans lecas d'un branchement avec un cordon d'alimentation,

installez une prise de courant raise 6 la terre 6 trois broches

sur la paroi de I'armoire adjacente, entre 15cm (6 po) et

46 cm (18 po) de I'ouverture, et entre 15 cm (6 po) et 46 cm

(18 po)du plancher.

Utilisez la trousse pour cordon d'alimentation selon votre

module de lave-vaisselle.

7,6cm (3po)

des armoires

Noir

Page 21

Preparation pour I'installation

PRI PARATION DE L'ALIMENTATION EN

EAU CHAUDE

REMARQUE:GErecommande I'utilisation d'un tuyau en cuivre

pour la conduite d'alimentation en eau, mais vous pouvez choi-

sir un boyau flexible tress6 no W×28×326 de GE.

. La conduite d'alimentation en eau (tuyau de cuivre de 9,5 mm

[13/8po] ou boyau flexible tress6) peut entrer du c6t6 gauche,

du c6t_ droit, de I'arri_re ou du plancher dans la partie

ombr6e indiqu6e dans la Figure F.

. La conduite d'alimentation en eau doit passer duns le m_me

trou que le cable 61ectrique et le boyau de vidange. Ou vous

pouvez percer un trou suppl6mentaire de 3,8 cm (1-1/2 po) de

diam_tre pour le passage de la conduite d'eau. Si I'appareil

est dot6 d'un cordon d'alimentation pourvu d'une fiche, la

conduite d'eau chaude ne doit pas passer par le m_me trou

que le cordon d'alimentation.

A'-

/

/ I

I

/

I

I \

\

I \

I \

I \

Raccordement de la conduite d'eau chaude

. Sivous utilisez un boyau flexible tress_, @iquetez le boyau

et indiquez la date d'installation (_des fins de r6f@ence. Les

boyaux fiexibles tress6s doivent _tre remplac6s dens 5 ans.

. Coupez I'alimentation en eau.

. Installez un robinet d'arr_t (_un endroit accessible, par

exemple sous 1'6vier.(Cette installation est facultative,

mais fortement recommand6e, et peut m_me _tre exig6e

par lescodes Iocaux en vigueur.)

. Le raccordement de la conduite d'eau s'effectue du c6t6

gauche du lave-vaisselle. Installez la conduite d'eau chaude

en utilisant un tuyau en cuivre de 9,5 mm (3/8 po) ou plus

ou boyau flexible tress6. Acheminez la conduite d'eau de la

faqon indiqu6e dens la Figure Fet amenez-la vers I'avant (_

au moins 48,2 cm (19 po) dumur arri@e.

. R6glez le chauffe-eau (_une temp@ature variant entre 49 °C

(120 °F)et 65 °C(1/40°F).

. Rincez laconduite d'eau pour _liminer tous les d6bris.

Recueillez I'eau etles d6bris (_I'aide d'un seau.

. La pression de la conduite d'alimentation en eau chaude doit

verier entre 1,4 bar (20Ib/po 2)et 8,3 bars (120 Ib/po2).

Tournez la page pour commencer

I'installation du lave-vaisselle.

i! Robinet dedia.

Eau ::!..'d'arr@

chaude _...........

5Jcm --

(2po)de

I'armoire

Devant des _'_

armoires

Figure F

3,8 cm

i Trou de

(1-1/2po)

A ATTENTION :

N'enlevezpaslabasedeboisavantd'@trepr@t@installerle lave-

vaisselle.Sivousenlevezla basedebois,le lave-vaissellepourrait

basculerIorsquevousouvrezla porte.

du plancher

Page 22

Installation du lave-vaisselle

ETAPE 1: PREPARATION

Prenezles pisces fournies dans I'emballage et mettez-les de cStS:

, Ensemble de vis

Couvercle de la boTtedejonction

Boyau de vidange et collier

Supports de montage

Moulures (certains modSles)

Crochet pour boyau devidange

Manuel d'utilisation

Echantillons et(ou) bons

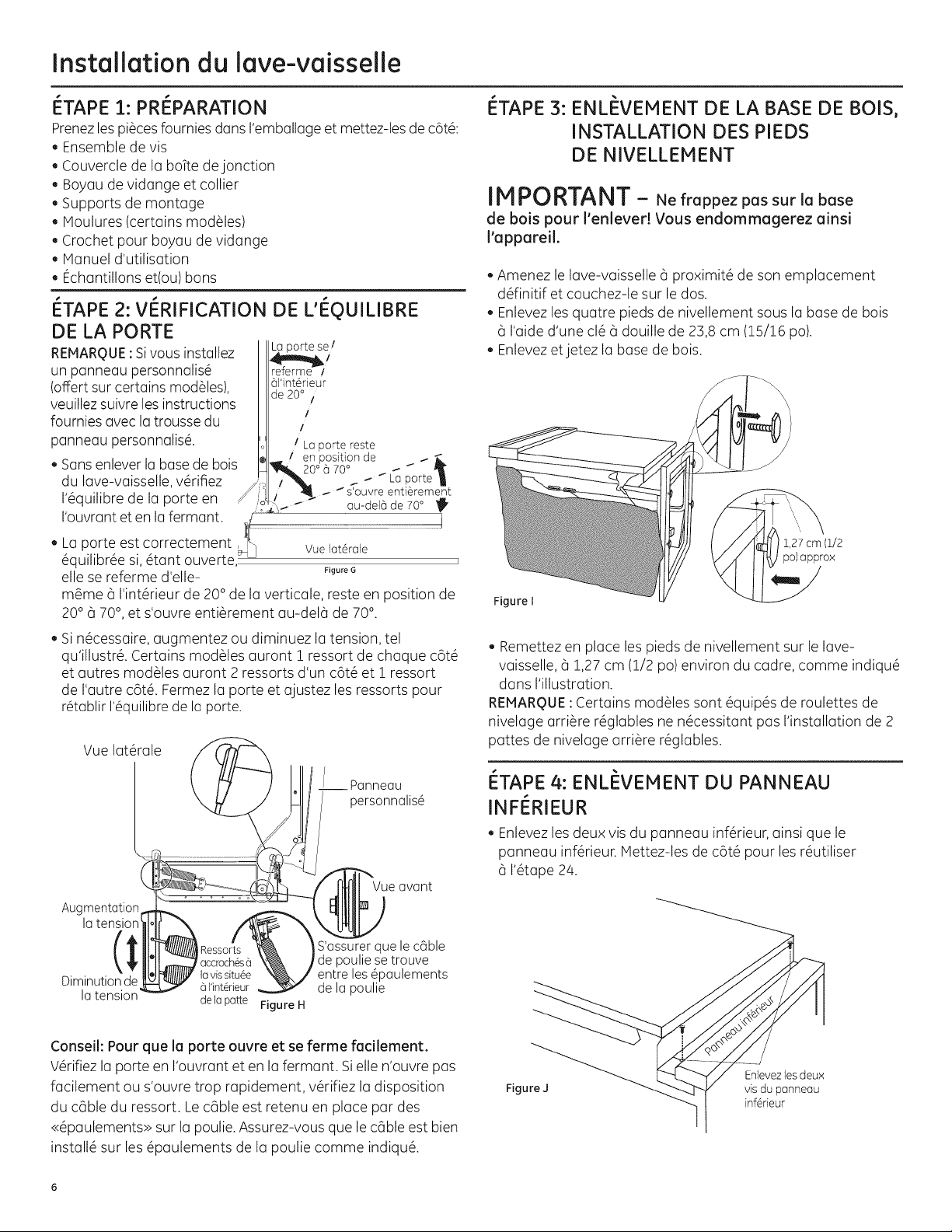

I_TAPE 2: VITRIFICATION DE L'I_QUILIBRE

DE LA PORTE

REMARQUE:Sivous installez

un panneau personnalis6

(offert sur certains modSles),

veuillez suivre lesinstructions

fournies avec latrousse du

panneau personnalis&

Sansenlever la base de bois

du lave-vaisselle, v@ifiez

I'Squilibre de la porte en

I'ouvrantet en la fermant. _u_............................ 1

, La porte est correctement _ rue lat@aJe

SquilibrSe si,@ant ouverte,

elle se referme d'elle- ng.reG

m_me 6 I'int@ieur de 20° de la verticale, reste en position de

20° 6 70°,et s'ouvre enti@ement au-del6 de 70°.

, Si nScessaire,augmentez ou diminuez la tension, tel

qu'illustr& Certains modSles auront 1 ressort de chaque c6tS

et autres modSles auront 2 ressorts d'un c6tS et i ressort

de I'autre c6t& Fermez la porte et ajustez les ressorts pour

r6tablir 1'6quilibrede la porte.

Vue lat@ale

L9 porte se!

reTerme /

6]'int6rieur

de 20° /

/

/

/ Laporte reste

en position de _ _.

0°(_70 ° ,_ _ _ _T

i _ La porte_

_.- _ au-del@ de 70°

_ s'ouvre enti@rement

I_TAPE 3: ENLI_VEMENT DE LA BASE DE BOIS,

INSTALLATION DES PIEDS

DE NIVELLEMENT

IMPORTANT - Ne frappez pas sur labase

de bois pour l'enlever! Vous endommagerez ainsi

l'appareil.

, Amenez le lave-vaisselle @proximitS de son emplacement

dSfinitif et couchez-le sur le dos.

Enlevez les quatre pieds de nivellement sous la base de bois

6 I'aide d'une clS 6 douille de 23,8cm (15/16 po).

Enlevez etjetez la base de bois.

1,27cm (1/2

po)approx

Figure I

Remettez en place les pieds de nivellement sur le lave-

vaisselle, 6 1,27cm (1/2 po) environ du cadre, comme indiquS

dans I'illustration.

REMARQUE:Certains modSles sont Squip6s de roulettes de

nivelage arriSre rSglables ne nScessitant pas I'installation de 2

pattes de nivelage artiste rSglables.

__ Panneau

personnalis@

Vue avant

Augmentation

latension

(_ S'assurerquelec_ble

accroch_s6 de pou ie se trouve

la vis situ@e entre les@paulements

Diminutionde _I1nt@ieur de la poulie

la tension dela patte Figure H

Conseil: Pour que la porte ouvre et se ferme focilement.

V@ifiezla porte en I'ouvrant et en la fermant. Sielle n'ouvre pas

facilement ou s'ouvre trop rapidement, v@ifiez la disposition

du cSble du ressort. LecSble est retenu en place par des

<<Spaulements>>sur la poulie.Assurez-vous que le cSbleest bien

installs sur les Spaulements de la poulie comme indiqu&

I_TAPE4: ENLi_VEMENT DU PANNEAU

INFI_RIEUR

, Enlevezles deux vis du panneau inf@ieur,ainsi que le

panneau inf@ieur. Mettez-les de c6tS pour les rSutiliser

6 I'Stape 24.

Figure J

Enlevezlesdeu×

visdu panneau

inf@ieur

Page 23

Installation du lave-vaisselle

I_TAPE5: INSTALLATION DU MATI_RIAU

INSONORISANT (sur certaJns modules)

Passez6 l'_tape suJvant

si le lave-vaisselle n'est Wat@iau

pas _quip_ de mat_riau insonorisant

insonorisant RubanN

Relevezle mat@iau

insonorisant et le ruban et

fixez-le au panneau frontal

6 I'aide du ruban-cache.

Ceci permettra de garder le

mat@riauinsonorisant relev6

et de d6gager lazone de

travail pendant I'installation. Vueavantdupanneauinf6rieur

I_TAPE6: RETRAIT DU PROTI'GE-PLANCHER

D6branchez les ills du d@ecteur de pour lib@er la pince 6 ressort

fuites. (surcertains modules).

. Enlevez2 vissur le devant du

prot6ge-plancher avec un tournevis 1A°po.

Tournez leprotege-plancher vers I'ext@ieur

et le soulevez pour led@crocherdes supports ,'.........-<

de montage.

Mettez-le de c6t6 pour le r6utiliser 6 1'6tape

2 2. //l_6tecteur de fuites

Pincer le haut du connecteur

j_

Prot_ge-plancher

I_TAPE9: POSITIONNEMENT DE LA

CONDUITE D'EAU ET DE

L'ALIMENTATION ELECTRIQUE

, Positionnezlaconduite d'alimentation en eauet le c_blage de la

r6sidencesurleplancher de I'ouvertureafin qu'ilsn'entrent pas en

contact avec la basedu lave-vaisselleet lespiscessousI'appareil.

10,1 cm

de la r6sidence

Figure O

ETAPE 10: INSERTION DU BOYAU DE

VIDANGE DANS L'ORIFICE DE

L'ARMOIRE

. Placezle lave-vaissellevis-6-vis deI'ouverture dans lesarmoires.

Ins@ezle boyau devidange dans I'orificequevous avez

pr@c@demmentperc6dansla paroi desarmoires.SiI'appareil

est dot_ d'un cordon d'alimentation faites passer I'extr6mit6

du cordon dans un trou distinct.

Figure L

I_TAPE 7: INSTALLATION DU

Devant du ]ave-vaisselle

CO U D E D E 90 ° support de

Vissezlecoudede 90°dans 1'61ectrovanne

I'_lectrovanne. \

Neserrezpaslecoudede

faqon excessive;lesupport

de1'61ectrovannepourrait

sed6former ou le

raccordde1'61ectrovanne

pourraitsecasser. Coudede90°

TournezI'extr6mit@du

coudepour qu'ilpointe Boyaude

vers I'arri_redu lave-vaisselle, remplissage

Figure M

ETAPE 8: RACCORDEMENT DU BOYAU DE

VIDANGE #, LA BOUCLE DE VIDANGE

Raccordez I'extr6mit6 de la boucle de vidange au boyau de

vidange 6 I'aide du collier de serrage 6vis sans fin, comme

illustr6.

Figure N

NOTE:Thehighdrain loop onthe sideof thetub isdesignedfor better

wash performance. Donot removefromthe sideof thetub.

Longueur maxirna]e du boyau

Je vidange: 4.5 m (15pi)

Isolant

\

Cordon

d'aJimentation

(siutilis6)

Figure P

61ectriquede

la r6sidence

\

Conseil:Pour(_viterdesfrais de r6paration inutiles pour

desprobl_mes de rernplissage, de vidange ou de bruit.

Placezla conduite d'eau et lec@ble61ectriquedemani@e6 ce qu'ils

n'entrent pasen contact avec quoi que ce soit 6 I'arri@eouen

dessousdu lave-vaisselle.

Page 24

Installation du lave-vaisselle

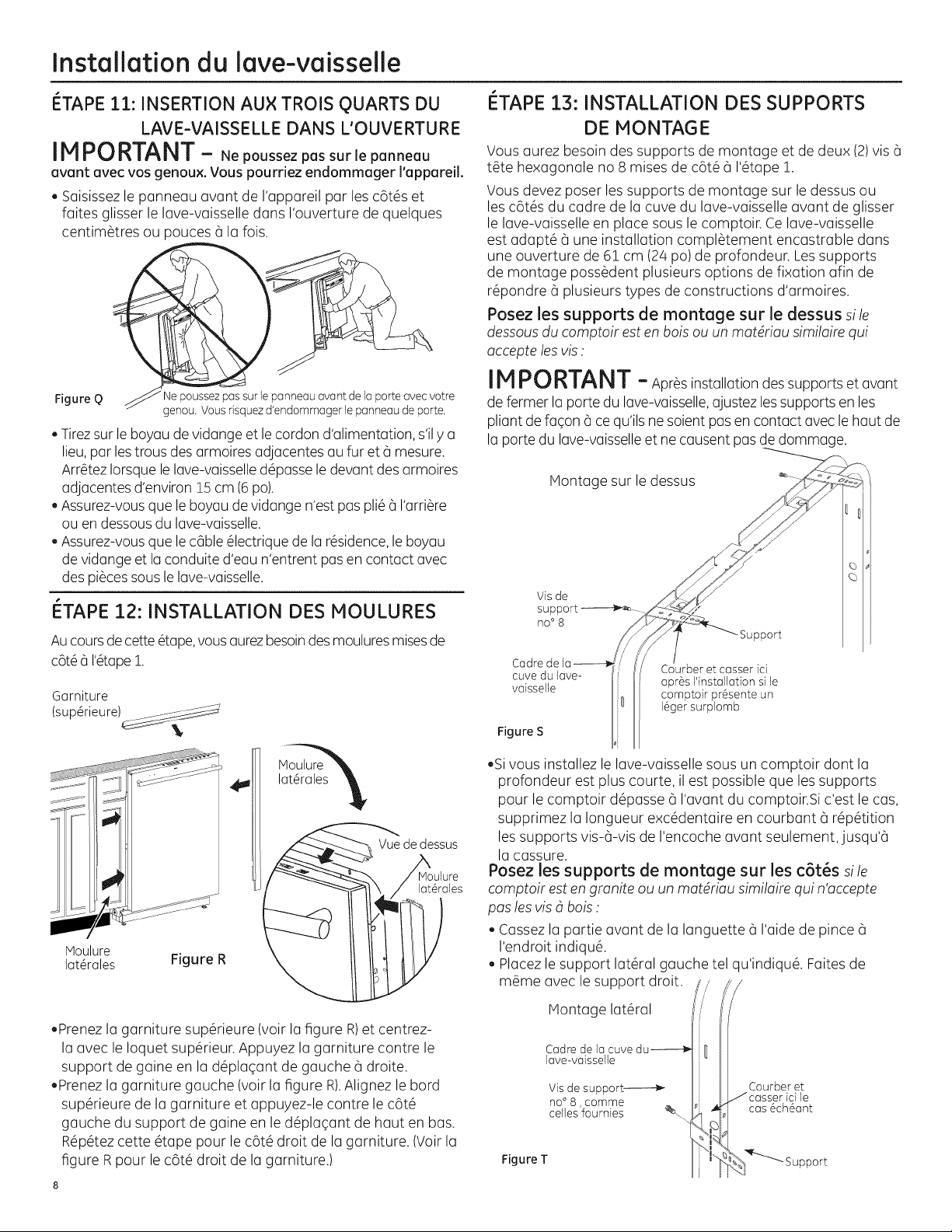

I_TAPE 11: INSERTION AU× TROIS QUARTS DU

LAVE-VAISSELLE DANS L'OUVERTURE

IMPORTANT - Ne poussez pas surle panneau

avant avec vos genoux. Vous pourriez endommager l'appareil.

. Saisissezle panneau avant de I'appareil par lesc6t@set

faites glisser le lave-vaisselle dans I'ouverture de quelques

centim@tresou pouces 6 la fois.

Figure Q Ne poussez pas sur le panneau avant de la porte avec votre

. Tirezsur le boyau devidange et le cordon d'alimentation, s'ily a

lieu,par lestrous des armoires adjacentes au fur et 6 mesure.

Arr@tezIorsquele lave-vaisselled@asse le devant desarmoires

adjacentes d'environ lS cm (6po).

. Assurez-vousque le boyau devidange n'est pas pli6 6I'arri_re

ou en dessousdu lave-vaisselle.

. Assurez-vousque lec@ble_lectrique de la r_sidence,le boyau

de vidange et la conduite d'eau n'entrent pasen contact avec

despi_ces sousle lave-vaisselle.

I_TAPE 12: INSTALLATION DES MOULURES

Au coursde cette@ape,vousaurez besoindesmouluresraisesde

c6t661'6tape1.

Garniture

(sup@ieure)

genoa. Vous risquezd'endommager le panneau de porte.

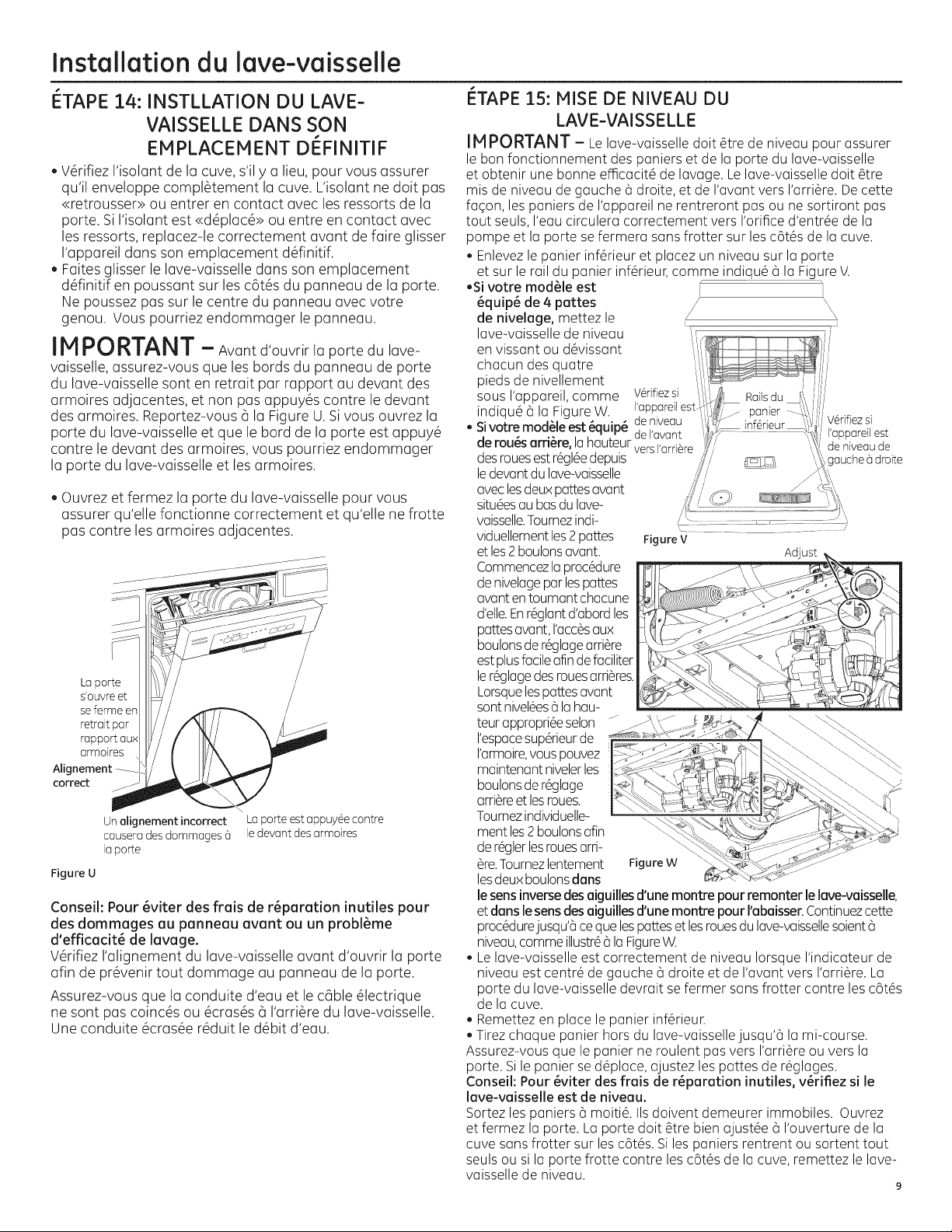

I_TAPE13: INSTALLATION DES SUPPORTS

DE MONTAGE

Vous aurez besoin des supports de montage et de deux (2)vis 6

t@tehexagonale no 8 raisesde c6t6 6 1'6tape1.

Vous devez poser les supports de montage sur le dessus ou

les c6t6s du cadre de la cave du lave-vaisselle avant de glisser

le lave-vaisselle en place sous le comptoir. Celave-vaisselle

est adapt6 @une installation compl@tement encastrable dans

une ouverture de 61 cm (24 po)de profondeur. Les supports

de montage poss@dentplusieurs options de fixation afin de

r6pondre @plusieurs types de constructions d'armoires.

Posez les supports de montage sur le dessus si le

dessousdu comptoir est en bois ou un matdriau similaire qui

accepte lesvis :

IMPORTANT - Apr_sinstallation dessupports et avant

de fermer laporte du lave-vaisselle,ajustezlessupports en les

pliant de faqon 6 cequ'ils ne soient pasencontact avec le haut de

la porte du lave-vaisselleet ne causent pas de dommage.

Montage sur le dessus

Vis de

support

no° 8

Cadre de la

cure du lave-

vaisselle

Figure S

Courber et casser ici

apr@sI'installation si le

comptoir pr6sente un

I@gersurplomb

Support

Vue de dessus

Moulure

lat6rales

Moulure

lat@ales Figure R

.Prenez la garniture sup@ieure (voir la figure R)et centrez-

la avec le Ioquet sup@ieur.Appuyez la garniture contre le

support de gaine en la d6plaqant de gauche 6 droite.

.Prenez la garniture gauche (voir la figure R).Alignez le bard

sup@ieure de la garniture et appuyez-le contre le c6t6

gauche du support de gaine en led6plaqant de haut en bas.

R6p@ezcette @ape pour le c6t6 droit de la garniture. (Voir la

figure R pour le c6t6 droit de la garniture.)

.Si vous installez le lave-vaisselle sous un comptoir dont la

profondeur est plus courte, il est possible que les supports

pour le comptoir d@asse 6 I'avant du comptoir.Si c'est le cas,

supprimez la Iongueur exc6dentaire en courbant 6 r@6tition

les supports vis-6-vis de I'encoche avant seulement, jusqu'6

la cassure.

Posez les supports de montage sur les c6t_s si le

comptoir est en granite ou un matdriau similaire qui n'accepte

pas les vis 8 bois :

, Cassez la partie avant de la languette 5 I'aide de pince 5

I'endroit indiqu6.

, Placezle support lat@al gauche tel qu'indiqu6. Faites de

m_me avec le support droit.

Montage lat@al

Cadre de la cuve

lave-vaisselle

Courber et

J casser ici le

cas 6ch6ant

_Supp art

Figure T

Visde support-_--_

no° 8, comme

celles fournies

Page 25

installation du lave-vaisselle

I TAPE 14: INSTLLATION DU LAVE-

VAISSELLE DANS SON

EMPLACEMENT DI FINITIF

. V6rifiez I'isolant de la cuve, s'il y alieu, pour vous assurer

qu'il enveloppe compl6tement la cuve. L'isolant nedoit pas

<<retrousser>>ou entrer en contact avec les ressorts de la

porte. SiI'isolant est <<d6plac6>>ou entre en contact avec

les ressorts, replacez-le correctement event de faire glisser

I'appareil dens son emplacement d6finitif.

. Faites glisser le lave-vaisselle dens son emplacement

d6finitif en poussant sur les c6t6s du panneau de la porte.

Ne poussez passur lecentre du panneau avec votre

genou. Vous pourriez endommager le panneau.

iMPORTANT - Avantd'ouvrirlaporte dulave-

vaisselle, assurez-vous que lesbords du panneau de porte

du lave-vaisselle sont en retrait par rapport au devant des

armoires adjacentes, et non pas appuy6s contre le devant

des armoires. Reportez-vous 5 la Figure U.Sivous ouvrez la

porte du lave-vaisselle et que le bord de la porte est appuy6

contre le devant des armoires, vous pourriez endommager

la porte du lave-vaisselle et lesarmoires.

. Ouvrez et fermez la porte du lave-vaisselle pour vous

assurer qu'elle fonctionne correctement et qu'elle ne frotte

pas contre lesarmoires adjacentes.

Laporte

s'ouvre et

se ferme en

retrait par

rapport au×

armoires

Alignement ........

correct

Un elignement incorrect

causera des dommages 6

la porte

Figure U

Conseil: Pour _viter des freis de r_paration inutiles pour

des dommages au panneau event ou un probl_me

d'efficacit_ de lavage.

V@ifiez I'alignement du lave-vaisselle event d'ouvrir la porte

afin de pr6venir tout dommage au panneau de la porte.

Assurez-vous que la conduite d'eau et le cable @lectrique

ne sont pas coinc6s ou 6cras6s c_I'arri@redu lave-vaisselle.

Une conduite 6cras6e r6duit led6bit d'eau.

Laporte est appuy6e contre

le devant desarmoires

I_TAPE 15: MISE DE NIVEAU DU

LAVE-VAISSELLE

IMPORTANT - Lelave-vaisselledoit 6tre de niveau pour assurer

le bonfonctionnement des paniers et de la porte du lave-vaisselle

et obtenir une bonne efficacit@de lavage.Le lave-vaisselledoit @tre

mis deniveau de gauche 6 droite, et de I'avant vers I'arri@re.Decette

fa¢on, les paniers de rappareil merentreront pas ou mesortiront pas

tout seuls,I'eau circulera correctement vers I'orifice d'entr@ede la

pompe et la porte sefermera sansfrotter sur lesc6t6s de lacure.

• Enlevezle panier inf@ieuret placez un niveau sur la porte

et sur le rail du panier inf@ieur,comme indiqu6 6 la FigureV.

•Sivotre module est

_quip_ de 4 pattes / _\

de nivelege, mettez le ,/

lave-vaissellede niveau /

en vissant ou d6vissant

chacun desquatre

piedsde nivellement

sous I'appareil,comme V6rifiezsi

indiqu6 6 la FigureW. I'appareilest-

• Sivotre moduleest_quip_ deniveau

de rou_serri_re,lahauteurversJ'arri@e deniveau de

desrouesestr6gl6edepuis _]_ ,gauche 6droite

ledevantdulave-vaisselle /**,,

aveclesdeuxpattesevent

situ6esaubasdulave-

vaisselle.Tournezindi- ,"" ::....... -" '!

viduellementles2pares FigureV

etles2boulonsevent. Ad

Commencezlaproc6dure

de nivelageparlespares

evententournantchacune

d'elle.Enr6glantd'abordles

pattesevent,I'acc_saux

boulonsder6glagearri@re

estplusfacileafindefaciliter

ler6glagedesrouesarri@es.

Lorsquelespares event

sontnivel6es6 lahau-

teurappropri6eselon

I'espacesup@ieurde

I'armoire,vouspouvez

maintenantnivelerles

boulonsder6glage

arri@eetlesroues.

Tournezindividuelle-

mentles2boulonsafin

de r6glerlesrouesarri-

@e.Tournezlentement FigureW

lesdeuxboulonsdens

lesensinversedesaiguillesd'unemontrepourremonterleleve-veisselle,

etdenslesensdeseiguillesd'unemontrepourI'ebaisser.Continuezcette

proc6durejusqu'c_cequelesparesetlesrouesdulave-vaissellesoientc_

niveau,commeillustr_c_laFigureW.

Lelave-vaisselleest correctement de niveau IorsqueI'indicateur de

niveau est centr@degauche c_droite et de I'avant vers I'arri@e.La

porte du lave-vaisselledevrait sefermer sans frotter contre les c6t@s

de lacuve.

Remettezen place le panier inf@ieur.

Tirezchaque panierhors du lave-vaissellejusqu'c_la mi-course.

Assurez-vousque le panier ne roulent pasvers I'arri@eou vers la

porte. Sile panier sed@place,ajustez lespattes de r@glages.

Conseil:Pour _viter des frais der_paration inutiles, v_rifiez si le

leve-veisselle est de niveeu,

Sortezlespaniers c_moiti@.IIsdoivent demeurer immobiles. Ouvrez

etfermez la porte. Laporte doit _tre bien ajust_e c)I'ouverture dela

cuve sansfrotter sur lesc6t@s.Silespaniers rentrent ou sortent tout

seulsou sila porte frotte contre lesc6t@sde la cuve,remettez le lave-

vaissellede niveau.

deI'avant I'appareilest

9

Page 26

Installation du lave-vaisselle

I TAPE 16: FIXATION DU LAVE-VAISSELLE AU-

DESSOUS DU COMPTOIR OU AUX

C6TI S DES ARMOIRES

Au cours de cette @ape,vous aurez besoin des deu× vis6 t6te

sp6ciale Phillipsmises de c6t6 6 1'6tape1.

Lelave-vaisselle dolt 6tre fix6 au dessous du comptoir ou au×

c6t6s des armoires. Lorsque ledessous du comptoir est en bois,

utilisez la m@thaden° 1. Lorsque ledessous du comptoir est

fabriqu6 6 I'aide d'un mat6riau qui n'accepte pas lesvis 6 bois,

par exemple en granite, utilisez la m@thode n° Z

IMPORTANT- Pour6viter tout dommage au

panneau de la porte et au tableau de commande, ilfaut que

le lave-vaisselle soit install_ de mani@e que le panneau avant

et le tableau de commande n'entrent pus en contact avec les

armoires adjacentes ou le comptoir. Vissez lesviscompl_tement

et bien droites. Lest_tes de vis qui d_passent pourraient

6gratigner le panneau de porte ou letableau decommande

et cr6er de I'interf@ence Iorsde I'ouverture de la porte.

M@thoden° 1

Fixation du lave-vaisselle au dessous d'un comptoir en bois.

. Rev6rifiez I'alignement du lave-vaisselle dans I'ouverture des

armoires. Reportez-vous aux @apes 1/4et 15. Le penneau de

porte et(ou)le tableau de commande nedoivent pas entrer

en contact avec les armoires ou le comptoir.

° Fixezle lave-vaisselle au dessous du comptoir (3I'aidedes

deux vis 5 t_te sp_ciale Phillips. Reportez-vous 5 la figure.

Assurez-vous de visser compl_tement les vis bien droites afin

que lest_tes soient aff]eurantes pour ne pas endommager

le panneau. Supports

_____Comotoir_p,en bois

ETAPE 17: RACCORDEMENT DE

L'ALIMENTATION EN EAU

Raccordezlaconduite d'alimentation en eau au coude de 90°.

Si vous d@cidezde loire le raccordement avec un bayou

flexible tress@:

, Fixez lecoude de 90° avec une cl6 5 molette

ISivous d@cidezde loire le raccordement avec un tuyau en

cuivre :

° Glissez1'6crouc_compression puis la bague d'extr6mit6 5

I'extr6mit6 de la conduite d'alimentation en eau.

• Ins@ezlaconduite d'alimentation en eau dans lecoude de 90°.

° Glissezla bague d'extr6mit6 contre le coude et fixez avec

1'6crouc_compression.

IMPORTANT - Assurez-vousquelesressortset(ou)

lescOblesdesressortsde laporten'entrentpasencontactavec

leboyaude remplissageou laconduite

d'alimentation en eau.Pour

v@ifier,ouvrez et refermez

la porte.D6placezla

conduite d'alimentation

en eau ou pliez

16g@ementlesupport

de I'_lectrovanne si

vous entendez un

bruit de frottement

ou s'ily a de

I'interf@enceIors

de I'ouverture de

la porte.

Figure Y

Coudede90 °

C6t6 inf@ieur gauche

Conduite _crou 6

d'alimentation compression

en eou chaude /

/

Bague

M@thoden° 2

Fixation du lave-vaisselle aux c6t@sdes armoires.

, Rev@ifiezI'alignement du lave-vaisselle dans I'ouverture des

armoires. Reportez-vous aux @apes !4 et !5. Le panneau de

porte et(ou)le tableau de commande nedoivent pas entrer

en contact avec les armoires ou le comptoir.

° Retirez lesbouchons. Conservez-les.

° Fixezle lave-vaisselle uu dessous du comptoir 5 I'aide

des deux vis 5 t_te sp6ciale Phillips. Reportez-vous 5 la

Figure X.Assurez-vous de visser compl_tement lesvis bien

droites afin que les t_tes soient affleurantes pour ne pas

endommager le panneau.

° Installez les boutons de bouchon sur le c6t6 de la cuve dans

lestrous pr6vus 5 cet effet.

Comptoir de surface solide

/_ Vis Bouchons Vis-_'_1//

./

/,/

II II I Supports lat@aux /////

Figure ×

lO

Page 27

Installation du lave-vaisselle

ETAPE 18: RACCORDEMENT DU BOYAU

DE VIDANGE

L'extr6mit6moul6edu boyaude vidange estconque pour slnstaller

sur I'orificed'entr6ed'un diam6tre variant entre 15,8 mm (5/8po/et

25,4mm (1po/de lacoupure antPrefoulement, du raccord en Tou

du broyeur6d6chets.

. Mesurezlediam6tre de I'orificed'entr6e.

. Coupezleraccorddu

boyau de vidange

6 I'endroitindiqu6,

au besoin,pour

qull soit bien

adapt6 6 I'orifice

d'entr6e.

Figure Z

. Sivousavezbesoind'un boyaude vidangepluslongmaisn'avez

pasochet6 le boyaudevidangeGPFI2orWD24×10065,ojoutez

au boyaudevidangeinstall_6 I'usineuneIongueurmaximale de

!67.64 cm (66po)pourune Iongueurtotale de3.66m_tres(!/44po).

Pourcefaire,utilisezun boyaudont lediam_tre int@ieurestde 15,8

mm (5/8po)oude 21,7mm (7/8po)et un raccord pou_elier /

I'extr_mit6desdeux

leraccord6

I'oidedecolliers.

boyaux.Fixez _

Figure AA Collier

REMARQUE:POUR UNE VIDANGE ADI_QUATE DE L'APPAREIL,

LA LONGUEUR TOTALE DU BOYAU DE VIDANGE NE DOIT PAS

DI_PASSER4,57 MI_TRES(15 PIEDS).

2S,4 mm 11po)

IMPORTANT: Ne coupez pas Io portie ondul6e du boyau

Ligne de coupe

,_ lS,8 mm po)

Raccord

I__l

IS/8

,

Collier

. Branchezleboyau de vidange 6la coupure anti-

refoulement, au raccord en Touau broyeur6 d6chets

6 I'aidede la m@hodechoisiepr6c_demment. Fixez

solidement leboyau 6 I'aided'un collier6 vis sansfin.

M_thode n° 1 - Coupure anti-refoulement avec raccord en

T ou broyeur 6 d_chets

Installationavecraccorden T

Figure AB

M_thode n° 2 - Boucle de vidange _lev_e avec raccord enT ou

broyeur 6 d_chets

Pourcette m@hode,vous aurez besoindu crochet pour boyau

de vidange mis de c6t@6 I'@tape1.

Fixezleboyau de vidange au-dessous du comptoir 6 I'aide

du crochet fourni.

Crochet du boyau

_ _ devidange

i

Installation avec broyeur

6 d@chets

Installationavec raccordenT

Figure AC

Installationavec broyeur

6 d_chets

IMPORTANT- Lorsquevousraccordezleboyau

devidange6 unbroyeur6 d6chets,ossurez-vousd'enlever

lebouchondevidange.LELAVE-VAISSELLENE SEVIDERAPAS

SILEBOUCHON ESTLAISSEEN PLACE,

bouchon

de vidange

41 nlevez le

Conseil:Pour @viterlesfrais de r@paratJoninutiles pour

un probl@mede vidange.

Tirezsurle boyau de vidange parl'ouverture pratiqu@edans

lesarmoires afind'emp_cher lelave-vaisselled'6craser ou

de plier une Iongueurexcessivede boyau.

.ll

Page 28

Installation du lave-vaisselle

I_TAPE 19: BRANCHEMENT DE

L'ALIMENTATION I_LECTRIQUE

Si un cordon d'alimentation pourvu d'une fiche est d_j6

install_ sur l'appareil, passez 6 l'_tape 20.

A AVERTISSEMENT :

Silec_blage#lectrique dela r#sidencen'estpasconstitu_dedeuxills

plusunfil de mise6 laterre,I'instullateurdoitinstallerunfil demise

6 laterre.SilecSblage61ectriquedelar6sidenceestenaluminium,

utilisezunagentantioxydantetdesconnecteurspourraccords

<<aluminium-cuivre>>homologu6sUL.

Au cours de cette 6tape, vous aurez besoin du couvercle

de laboTtedejonction et de la vis 6t_te hexagonale n° 10, mis

de c8t6 6 I'@ape 1.

. Fixez lec@blagede la r6sidence (3I'arri@e de la boTte

dejonction 6 I'aide d'une bague anti-traction.