Page 1

SEARS

3EPT.731A

TECHNICAL

FLASH

DISTRICT

MANAGER

CENTRAL

MANAGER

BRANCH

MANAGER

CALL

CENTRE

MANAGER

PARTS

MANAGER

T.

F.

46-106

JUNE

2OO4

CLAUDE

BABINEAU_

DEPARTMENT

73IA

DIVISION

46

SOURCE

C978

ERVICE

MANUA

DIVISION

46

G.E.

REFRIGERATORS

2OO3

ELBCTRONIC

BOTTOM-MOUNT

Page 2

GE

Consumer

& lndustrial

TECHNICAL

SERVICE

GUIDE

2003

Electron

ic

Bottom-Mou nt

Refrigerators

MODEL

SERIES:

GBS22_

_P

GBS20__P

PDS22__P

PDS2O

P

-=:

PUB # 31-9112

1tM

Page 3

IMPORTANT

SAFETY

NOTICE

The information

in this service

guide

is intended

for

use by

individuals

possessing

adequate backgrounds

of electrical,

electronic, and

mechanical

experience. Any attempt

to repair a

major appliance may

result

in

personal

injury

and

property

damage.

The manufacturer

or

seller cannot

be responsible

for the

interpretation

of this information,

nor can

it

assume

any

liability in

connection

with ib

use.

WARNING

To

avoid

personal

injury

disconnect

polver

before seMcing

this

product.

lf

elestrical

power

is required

for

diagnosis

or test

purposes,

disconnect the

power

immediately

after

performing

the

necessary

checks.

RECONNECT ALL GROUNDING DEVICES

lf

grounding

wires, screws,

Sfraps,

clips, nuts, or

washers used

to complete a

path

to

ground

are removed

for service, they must

be retumed

totheiroriginal

position

and

prcperlyfastened.

GE Consumer &

lndustial

TechnialServloe

Guide

Copynght@2004

All rights

reserved.

This

service

gufule

may not be reproduced

in whole

or

in

part

in

any

form without

written

permission

fiorn tte

Genenal Elecfic Comparry.

-2-

Page 4

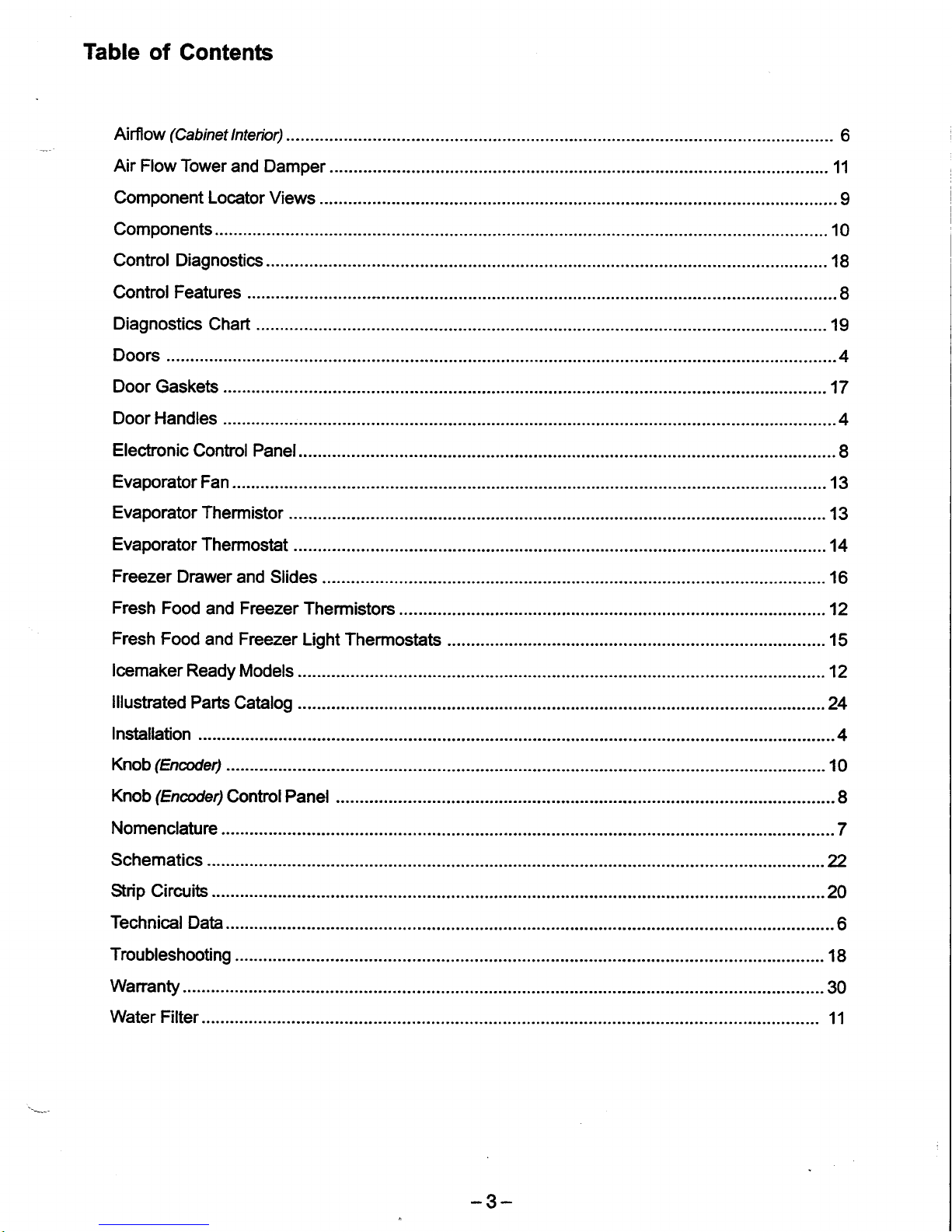

Table

of

Contents

-3-

Page 5

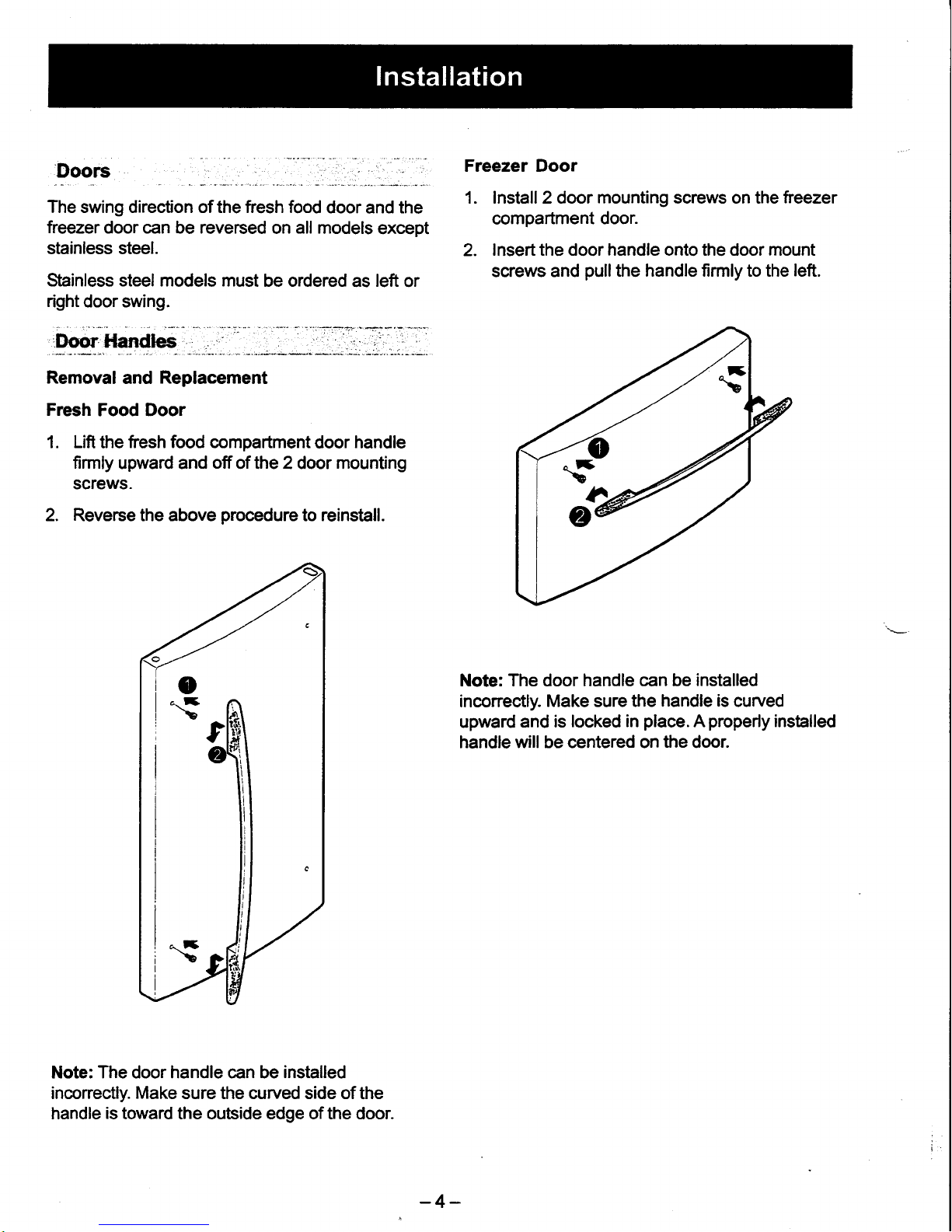

Doors

The swing direction of the fresh food

door

and

the

freezer

door can be reversed

on

all

models

except

stainless steel.

Stainless steel models must

be ordered

as

left

or

right

door swing.

Removal

and

Replacement

Fresh Food Door

1. Lifi

the

tresh food compartment

door handle

firmly

upward and

off

of the 2door mounting

screws.

2. Reverse the above

procedure

to reinstiall.

Note: The door handle can be

installed

inconectly.

Make

sure the curved side of

the

handle

is

toward the outside edge of the door.

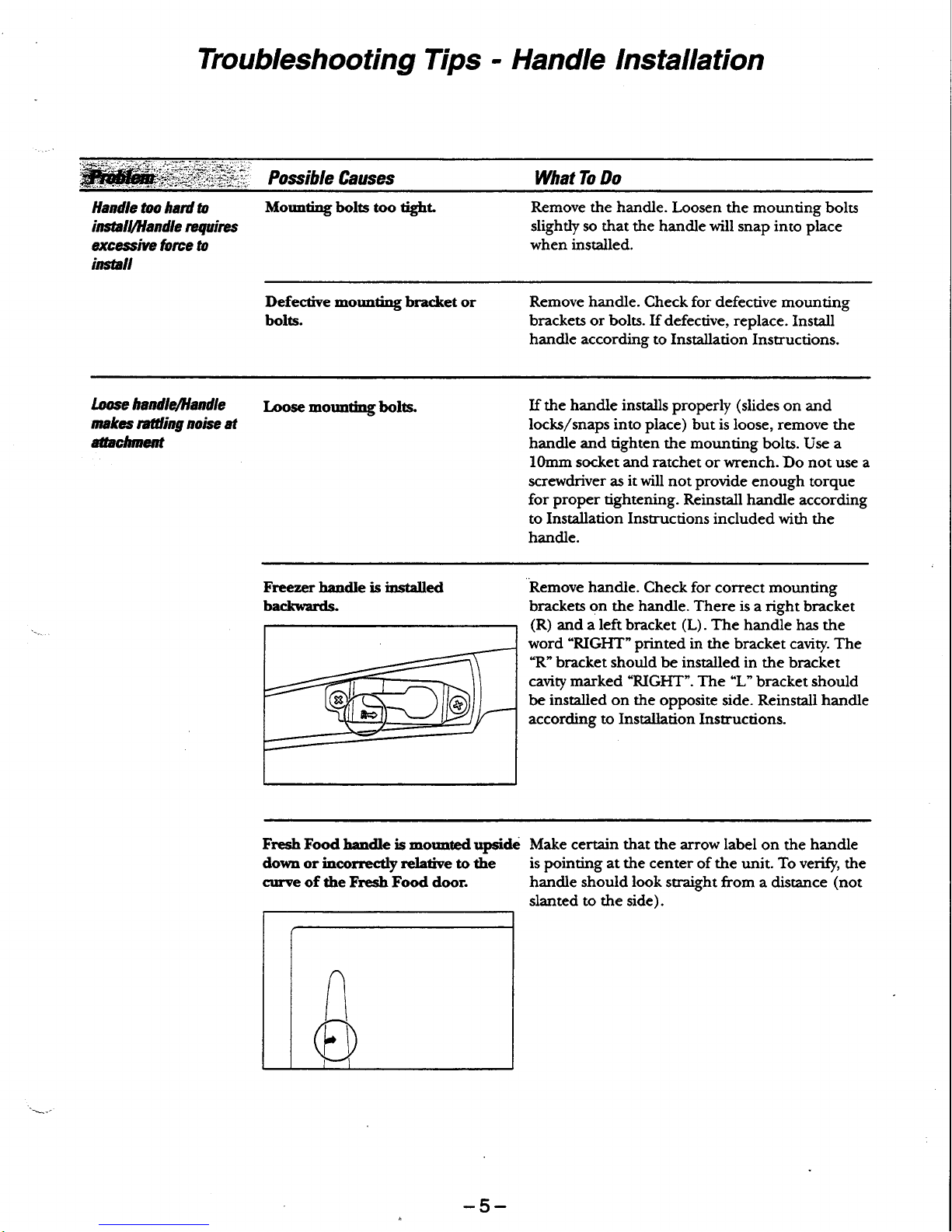

Freezer Door

1. Install 2 door mounting screws on the

treezer

compartment

door.

2.

lnsert the door handle onto the door mount

screws and

pullthe

handle firmly to the

left.

Note: The door

handle can be installed

inconectly.

Make

sure

the

handle is

curved

upward

and is

locked in

place. A properly

installed

handle will be centered on

the

door.

-4-

Page 6

Troubleshooting

Tips - Handle Installation

Handle too hard b

instrlUHandle tequircs

excesive torce to

itlr;fg, l

Mormting

bolts too tight- Remove

the handle.

Loosen the mounting

bola

sltghtly so that the handle will

snap

into place

when installed.

Defective normting bracket

or

bolts.

Remove

handle.

Check for defective

mounting

brackets or bols. If defective, replace.

Install

handle according to Installation

Instructions.

Larce handle/l{andle

rmkes

ratiling noise

at

fficlnretrt

Loose

normtingbolts

If the

handle installs properly

(slides

on and

locks/snaps into place)

but

is

loose, remove the

handle and tighten the mounting

bola. Use

a

lomm

socket

and ratchet

or wrench. Do not use a

screwdriver as

it will

not provide

enough torque

for

proper tightening.

Reinstall handle

according

to Insrallation Instructions included wi&

the

handle.

Freezer

handle is installed

baclmtards.

Remove handle.

Check for correct mounting

brackets

on

the

handle. There is

a right bracket

(R)

and a left bracket

(L).

The

handle has the

word

'RIGHT"

printed

in the bracket

cavity.

The

"R'bracket

should

be

installed in

the bracket

cavity marked

"RIGI{T".

The

"L"

bracket should

be

insr^lled on the

opposite side. Reinstall handle

according

to

Installation Instructions.

Fresh Foodhandle is mormtedupside

dorrn

or

incorrectly

relative to the

curve

ofthe Fresh Food door.

Make certain that the arrow label

on the

handle

is pointing at the center

of

the

unit. To

veri$,

the

handle should

look

straight from a

distance

(not

slanted to the side).

-5-

Page 7

ELECTRICAL

SPECIFICATIONS

Temperature

Control

(Position

5)...............

........32 - 4"F

Detrost Conhol...

60 hrs @ 40

mins with

no dooropening

OvertemperatureThermostat.............

140-110"F

Defrost Thermistor..

..--..-....70'F

Electrical Rating: 115V.

AC,

60 H2.................1

-

5Amp.

Maximum

Cunent Leakage.....

........0.5

mA

Maximum

Ground Path Resistan@...............0.

14 Ohms

Energy Consumption.......507

k\rVh/yr for

20

culft

models

Energy Consumption.......520

kWh/yr for

22 cuftmodels

NO LOADPERFORITIANCE

Control

Position:5€

And Ambient

of;..........

.....

90'F

Fresh

Food,

"F.....

.---...32

-

42

Frozen Food,

"F.....

.......

-5 -

5

Percent

Running Time...........

.........

45

-

65

REFRIGERANONSYSTETTI

Minimum

Compressor Gapacity Vacuum......

........

22 in.

Minimum

Equalized Pressure

@

70"F

38

PS|G

@

90"F......

49 PStc

Reftigerant- R- 134a..

4.06o2-

Compressor................

690 BTU/hr

INSTALLANON

Clearance

must

be

provided

at top, sides

and rear

of the

refrigerator

for

air circulation.

ATTOP......

.1

inch

AT SIDES..

0.125

inch

AT REAR...

1

inch

The evaporatorfan forces air through

the

evaporator

into the fteezer

compartment.

Air from the

evaporator

is

also

forced through

the

electronic damper to

the top

of the

air

tunnel,

through the fresh food compartment, and retums

to the evaporator.

The fresh

food

compartment

receives

chilled

air

through an electronic damper at the bottom, rear

of the

ftesh

food compartment. The damper is

controlled by the

main

control board. When

open,

the damper allows

chilled

air

ftom

the

freezer

to

move

into

the

fresh

food compartment.

Air retums

from

the ftesh

food

compartment

to the

freezer compartment

via two vents located

to the

left

and

right

of

the

airtunnel.

r

coLD

AtR

*=

MIXED AIR

r r r

flfl REIURN TO

EVAPOMTOR

\

1

.-&

\

FRESH

FOOD'

\.

\

i-$

-

FREEZER

t

,

!>

AIR FLOW

-6-

Page 8

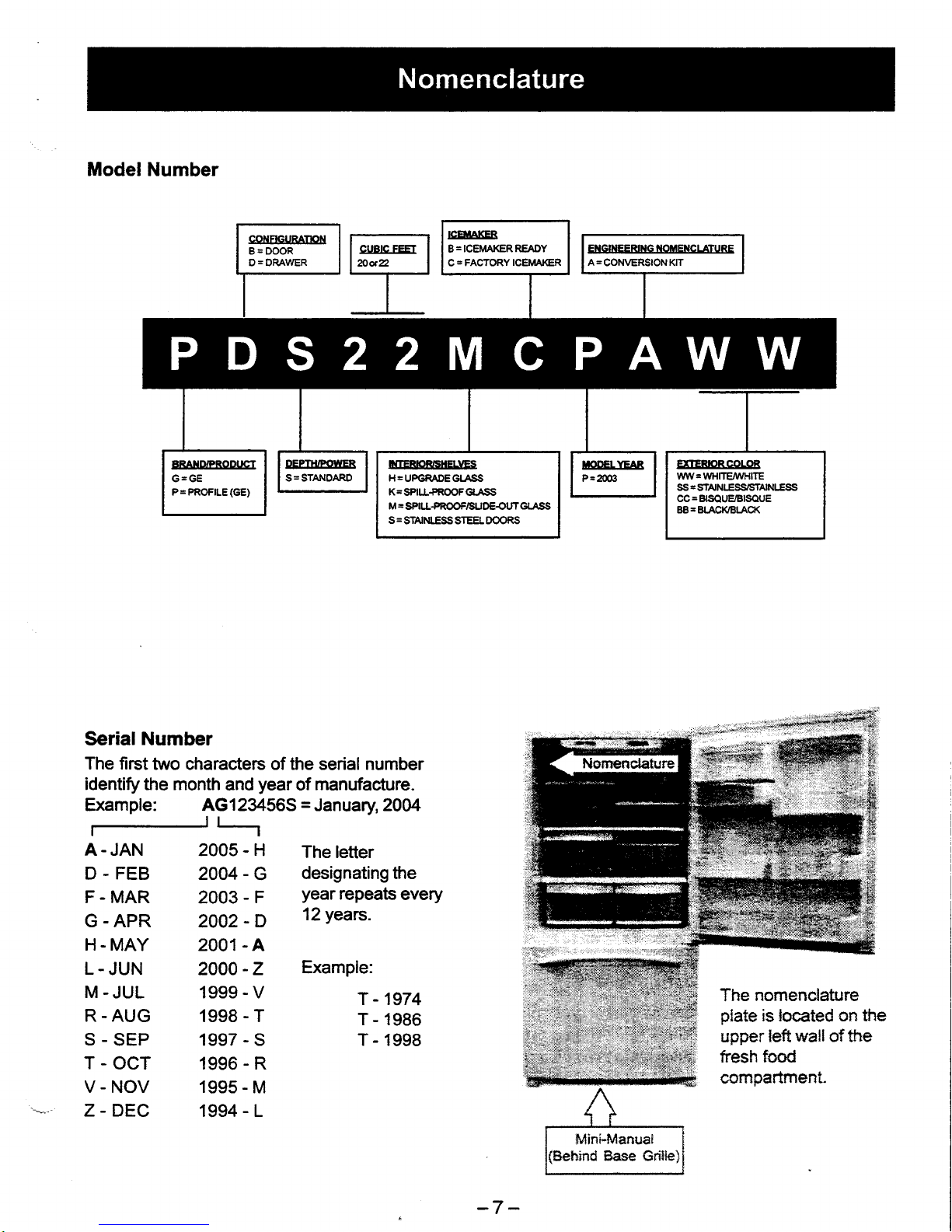

Model Number

V-NOV

Z-DEC

L.

JUN

M.JUL

1999 - V

R.

AUG 1998 - T

s-sEP

1997-S

T-OCT

1996-R

2O0O

-Z

ExamPle:

Serial Number

The first

two characters of the serial number

identify the month

and

year

of

manufacture.

Example: AG123456S = January 2004

A. JAN

2005-H

Theletter

D

-

FEB

2004

-

G

designating the

F - MAR

2003

-

F

year

repeats

every

G - ApR

2OO2

_D

1?years.

H

-

MAY 2OO1

-A

T - 1974

T - 1986

T - 1998

The nomenclaftlre

plate

is located on the

upper left wall

of

the

fresh

food

connpartment.

1995

-

M

1994 - L

i{TERICIR'SHELIGS

H=UPGMDEGT

SS

K=SPI!+ROOFG|.ASS

M

=

SPILIL'rPf{OOF/SUDEOUT

GLASS

S

=

STAINIESS STEEL DOORS

EITERbRCOLOR

WW= WHTTE/VI/HITE

Ss = SrANLESS,SfAINLESS

CC = BISOUE/BISOUE

BB=BLACKtsl-ACK

-7-

Page 9

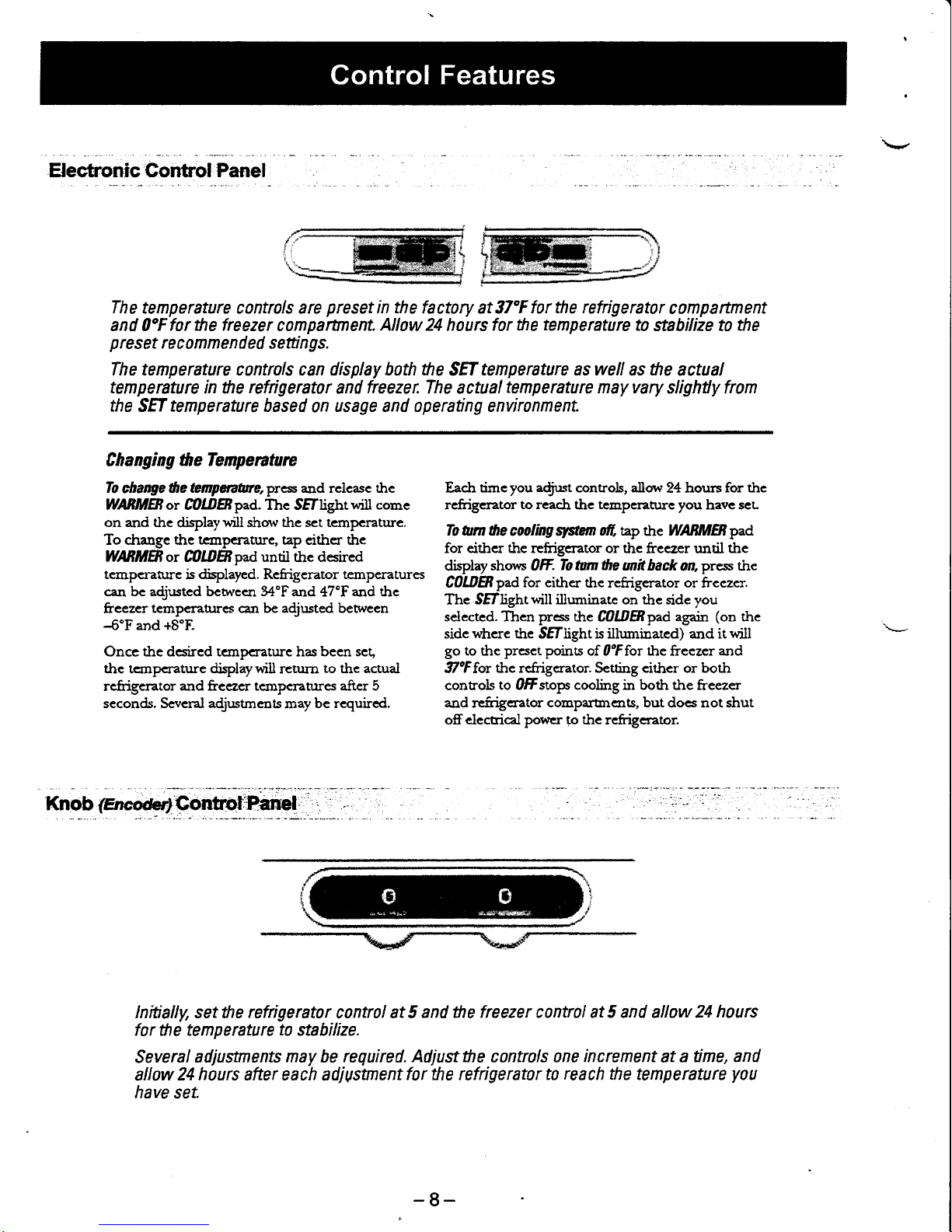

H ectronic Gontrol Panel

The tenperature controls are

preset

in

the

factory at 37"F

for the refrigerator

clmpartment

and OoF

for the freezer

compartnenL

Allow 24

hours

for the

temperature

ta

stahilize t0

the

p

res

et

re

c om

me n d

ed setti

n

gs.

The temperature

controls

can display both he

SEf

tenperature as well as the

actual

temperature

in the

refrigerator

and

freezer.

The actual

tenperature

nay vary

slighfly fron

the

SEf rcnperature based

0n

usage and operating envirlnment

C h a

ng i ng the Tempe

nta

re

To

change

the Eflrpqaane,press and

rclcase

thc

WBMBoT fiOl0Bpad. Thc SEf[ghtwill

come

on and the

displaywill

show the set tcmpcrature.

To drange the tcanperature, tap eithcr the

WAfrMBor C0lD8paduntjl the desired

temperahJre

is

displayed. Rcfrigerator temperatures

c:n be a{usted bcmeen 34'F

and 47'F

and

the

frcczcr

temperahrres can be adjusted betwccn

4"Fand

+8'F.

Once the dcsircd temperaturc has been set,

the tcrnpcrature

display wiil

r€turn

to

the actual

refrigerator

and

freezer tcmpcratures

after 5

seconds. Scveral adjr:stmens

nray

be required.

Each

timeyou

adjrrst

controls, allow

24 hours

for thc

rcfrigerator

to reach the tempcrahrrc you

have

seu

To

turn 6e cooling

qrsi/et,

fr,

ttp the

WABMB

pad

for either the refrigerator or the

freezer until

the

display

shom Otr.

To tum ,he

mit hack

on,

press the

C0UBpad

for either

the refrigerator or frcczcr.

Thc

Sff[ghtwill illuminate on the side

you

selectcd. Tlren press

the

C0o.ffipad again

(on

the

sidc

vihere the

SEllight is illnnrinated) and it

will

go to thc

prcsct poins

of OoFfor the

freezer

and

illoF

for

thc refrigerator. Setting cithcr or both

controls

to OfFstops cooling in both the

fi'eezer

and

rcfrigcrator

comparbrcns, but docs

not

shut

offdeccicai

power

to thc refrigerator.

Knob

(mcwlGontrol'Panel

lnitially, setthe

refrigerator

contrll

at 5 and

the freezer czntrol at 5 and

allow

24

hours

for the temperature

to

stabilize.

Several

adjustnents nay be

required. Adjustthe contrlls one

increment

at

a time,

and

allow

24 hours after each

adjUstnentfor

the refrigerat1r to

reach the

temperature

yTu

have

set.

-8-

Page 10

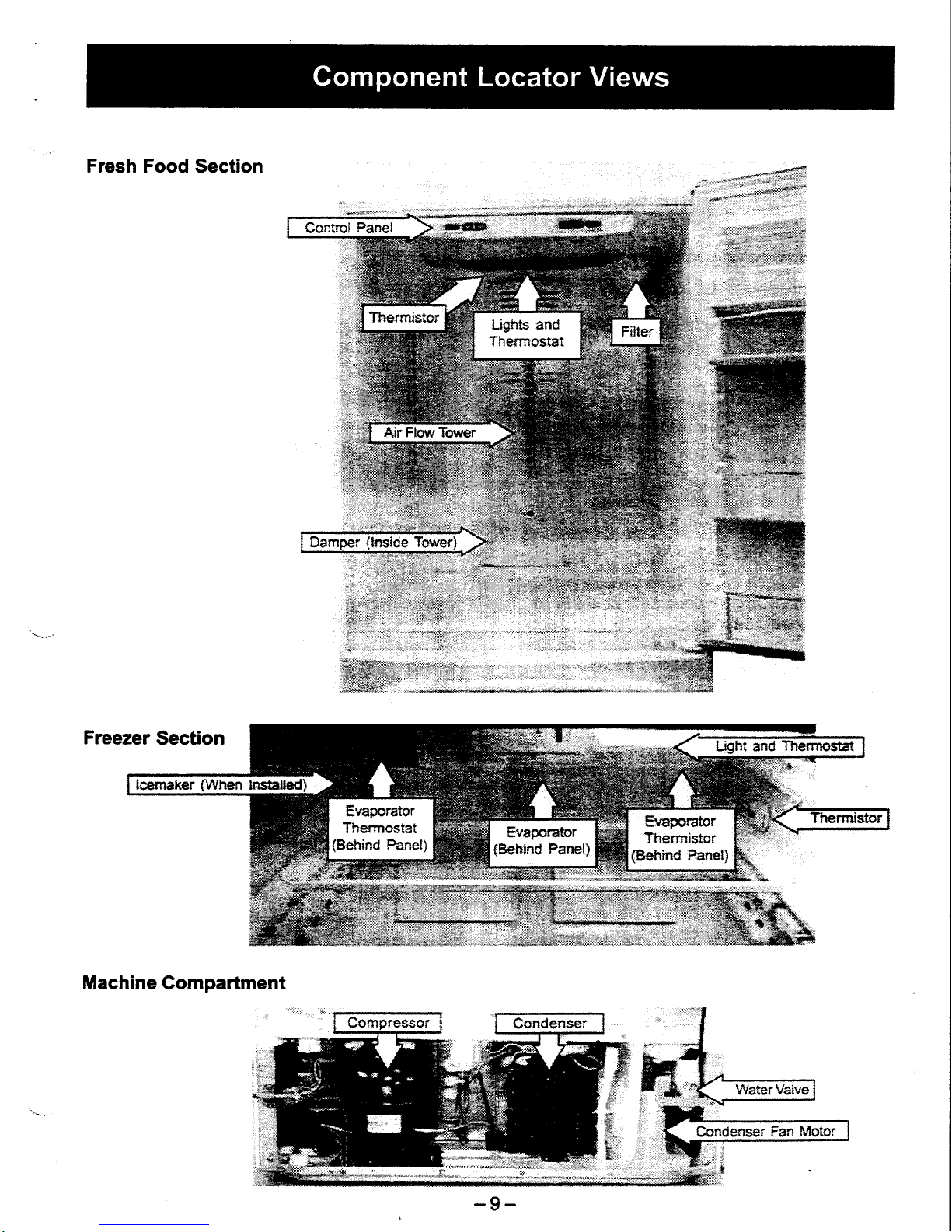

Fresh Food

Section

Machine

Gompartment

#

#

s,

i:is

#,

-9-

Page 11

Knob

(Encoder)

"

.

Electronic

and

mechanical

control

panels

are

removed in

the same manner.

Removal and Replacement

1. Remove

the fresh food light

cover.

2. Remove

the 2 screws that hold the rear

of the

control housing

to the liner ceiling.

3. There

are 3

posts

inserted into the liner

ceiling

holding

the front of the

control

in

place.

Firmly

pullthe

control housing down atthe ftont

edge

to release the

posts.

Pull the housing

towards

the front

to release the trabs in the

back.

Note: The foam

may be holding the

posts

and

tabs in the liner.

4. Unplug

the fesh food

light

connector

from the

compartment ceiling.

The fresh food light housing is held in

place

by

4 tabs. Press the tabs

to remove

the housing.

Unplug

the connectorfrom the control board.

Press

the

tab

on the

door

switch

and

push

the

switch through the

hole in

the control

panel

housing.

6.

7.

-

10-

Page 12

Air Flow

Tower

and

Damper:

'

The

air

flow

tower

contains

an intemal

damper.

The

damper

and tower

are replaced

as one

unit.

Removal

and

Replacement

1. Remove

the

2 screws

on the top

and bottom

of

the center

shelf bracket.

Remove

the bracket.

2.

Remove the

screw

from

the

bottom of the

air

flow

tower.

Lean the tower forward

to access

the

connector

at the bottom

of the tower.

Water Filter

On

ice

maker models, the water

filter is located

in

the upper, right

comer of the fresh food

compartment. The water

filter should

be changed

every 6 months.

To

access

the water filter,

press

the tab on

the

front

of

the water filter

cover

and allow the cover

to

drop

down.

Water

Filter

Part

# GSWF

3.

Unplug the connector;

then

remove the

airflow

tower.

Turn the water

filter counterclockwise

to

remove

and clockwise to

install.

Remove Install

Note: lf a new filter

is not

available, a filter bypass

must be

installed

to

supply unfiltered water

to the

icemaker.

Filter bypass

part

# WR02X11613

-11-

Page 13

.lcemaker

Ready

Models

The

accessory icemaker

can be

purchased

through

parts, parl#

lM6 or

as a sales accessory

part#

lM4Athrough

a dealer. The icemaker

must

be

installed

with

the filltube shipped with

the

refrigerator.

The

slot in the filltube must

be

on

top

of the tube.

The water fill

tube is

packaged

with

the use

and

care

manual

in

a

plastic

bag

in

the vegetable

drawer.

The

fill tube

part

number is WR02X11712.

-,fr9sn

Food

and Freezer Thermistors

Thermistor

Values

Temperature

Degrees

(F)

Resislance in

KiloOhms

Temperature

Degrees

(C)

-40

166.8 kO

-40

-31

120.5 kO

-35

-22

88 kO

-30

-13

65

kO

-25

4

48.4 kO

-20

5

36.4 K)

-15

14

27.6 kO

-10

23 21 U,O

-5

32 16.3 ko 0

41

12.7 t&

5

50 10 ko

10

59 7.8

kO 15

68 6.2 kO

20

T7

5ko 25

86

4ko

30

95 3.2

kO

35

1U

2.6

kO

40

113 2.2ko, 45

122 1.8

kO

50

55

1.5 kO 40

60 1.2k4

-35

The fresh food thermistor

is located

on the

ceiling

of

the fresh food compartment behind the light

assembly.

-

The freezer thermistor

is located

on

the rear

of the

right hand wall in the freezer section.

Note:

Fresh food

and

freezer thermistors are

removed

in the same manner.

To remove

the thermistor cover,

insert a flat

blade

screwdriver

under the

front of the cover

and

genfly

lift

the cover. Squeeze and

lift the cover from the

boftom until

it releases from the compartment wall.

-

12-

Page 14

Note:

Some of the foam insulation

may need

to

be

removed

to expose

the thermistor

and

wire.

i{.

Thernristor

When replacing

the thermistor,

cut the thermistor

wires

and splice the new

thermistor

using bell

connectors

as shown.

Always

use

RTV102

silicone sealant to seal the

end of the

connector

from moisture.

Note:

The

thermistor must

be

inside

the

thermistor

cover but is not required

to

be

inserted

back

into

the insulation

or

inside

the

cabinet frame.

Evaporator Fan

The

evaporator fan is located

above the

evaporator

behind the

rear

panel

of the

treezer

compartment.

The

evaporator

fan

is held in

place

by 2 screws.

To

access the fan, remove

the

drawers, shelves,

and

icemaker

(if

installed)

from the freezer

compartment. Remove the

back

panel.

The fan, motor,

and

mount

come out

as one unit.

Shown with

Back

Panel

Removed

Evaporator Thermistor

The evaporator

thermistor

is located

on top of the

evaporator behind the rear

panel

of the

lreezer

compartment. The thermistor is held

in

place

by

a

tie strap.

To

access the thermistor, remove the

drawers,

shelves, and icemaker

(if

installed) from

the

lreezer

compartment.

Remove

the back

panel.

Shown

with Back

Panel Removed

When replacing

the thermistor, cut the thermistor

wires

and splice the

new

thermistor using bell

connectors

as shown.

Always

use

RTV102

silicone sealant to seal the end of the connector

from moisture.

Use

a new tie

strap to secure

the

thermistor to the evaporator tubing.

ti"=.1

t

":,

":

i#.,

':

.

:,:

r". ..,'-

.

t'^

-13-

Page 15

Evaporator

Thermostat

The

defrost

heater is controlled

by the

evaporator

thermistor

and normally

tums offat

70'F. lf

the

evaporator

thermistor

fails,

the evaporator

thermostat

will

turn off

the defrost

heater

at 140"F

and will

reset

at 110"F.

The

evaporator

thermostat

is

located

on the

top,

left

side of the

evaporator

behind

the back

panel

of

the freezer

compartment.

To

access

the

thermostat,

remove

the

drawers,

shelves,

and

icemaker

(if

installed)

from

the

freezer

compartment.

Remove

the

back

panel.

Shownwith

Back

Panel Removed

The

thermostat is

held

in

place

by

a spring tab.

To

remove

it,

squeeze

the

tab.

Note:

The

resistance

of the

thermostat

and

defrost

heater

can be taken

by removing

the

access

panel

located in

the upper left

section

of the

evaporator

cover. Remove the

screw and

pullthe

cover

forward

to expose the two-wire

connector.

Unplug

the

connector

and

read

the resistance

between

the

two terminals.

Since the

thermostat

and heater

are

in

series, the reading

should be approximately

32 0.

When replacing

the

thermostat,

cut the thermostat

wires and

splice the new

thermostat

using bell

connectors

as shown. Always

use RTV102

silicone sealant to

seal the end

of the

connector

from moisture.

-14-

Page 16

Fresh

FoddAifti

Fresh

Food

LightThermostat

\*

The

fesh food

light

thermostat

intemlpts

power

to

the fresh

food

lights when

the

temperature

reaches

175"F.

Power

is

restored

when

the

thermostat

temperature

cools

to 155'F.

The

thermostat

is located

on the

back

of the

fresh

food

light

housing.

To

access

the

thermostiat,

remove

the

control

panel

(see

Control Panel).

The

thermostat

is held

in

place

by 2

screws.

:reezer

Light

Thermostat

The

freeze

r

fl ight

thermostat

i ntemr

pts

power

to

the freezer

lights

when

the

temperature

of

the

disk

reaches

175'F.

Power

is restored

when

the

thermostat

temperature

cools

to

155"F.

The

thermostat

is located

behind

the

freezer light

housing.

To

acoess

the

thermostat,

remove

the fteezer

light

cover

and housing.

The

housing

is

held in

place

by

5

screws.

Note: To

gain

better

access

to

the

thermostat,

pull

the

housing

down

untilthere

is enough

room

to

remove

the thermostat.

\ffhen

replacing

the thermostiat,

cut the thermostat

wires

and splice

the

new

thermostat

using bell

connectors

as shown. Always

use RTV102

silicone

sealant to

seal the

end of the

connector

from

moisture.

-15-

Page 17

Removal

and Replacement

1.

Open the freezer

drawer

until it

stops.

2. The bottom

basket

rests

on a frame

inside

the

lreezer

drawer.

To remove

it, liftthe

basket

ftom

the

back and

slide it toward

the

freezer

compartment.

3.

Remove

the single Phillips-head

screw on

each side

of

the

rail.

Note: Do not

remove

the

hex-head

screws from

the

rail

assemblies.

The

tabs on the side of

the drawer

rails

fit into

the front

slots of the

guide

rails.

Lift

the

drawer

by the handle to

separate the

drawer

rails

ftom

the

guide

rails.

Set

the

drawer

on a

non-scratching

surface.

Remove

the middle

basket, top

basket, ice

tray

shelf, dnd

ice

bin.

The

center rail

assembly is held

in

place

by

a

molded

channel in

the

treezer

ceiling and

notches in

the metal

support rails.

Remove

the

center rail assembly

by

pressing

down

on the

metal

support

rails while

rotating

the

bottom

edge of

the

center rail assembly.

To remove

the metal support rails,

press

the

tabs

on the

plastic

support housing.

Remove the 3 Phillips

screws that

hold

the

plastic

support housing

in

place.

5.

6.

7.

8.

4.

o

IXt

t{OTnmow

ter headccnua

Page 18

10. Pullthe

front

edge

of the

plastic

support

housing

away from

the

side wall. Pull

the

housing

forward

to

disengage

the rear

tabs.

Note:

The

plastic

housing

may

be tight

against

the

side wall,

and the tabs

may

be

foamed

in

place.

Some force

may

be

required

to remove

it.

11.

To remove

the

guide

rails

trom the

plastic

support housing,

lift

the

tab

on

the

back

side

of

the housing

with

a

smallflathead

screwdriver.

Freezer

Drawer Shim

lf

the

drawer is

not sealing

correctly

and the

gasket

is

not

damaged,

the

door alignment

can

be

adjusted.

Remove

the Phillips

screws holding

the rail

connector

to the

drawer front.

Using the necessary

number

of

stainless steel

washers,

shim the

drawer

to

provide

the

correct

alignment.

The

door

gaskets

are fttted tightly

into the door

channel.

They

should not

be removed

unless they

need

to

be replaced.

Note: When

replacing

a

gasket,

a wide

blade

screw

driver may

be necessary

to

remove

the

gasket.

-17-

Page 19

--'--'..T:--

-:''

-"

r.'-.:'

-:-

::..*.?

:"'-'

i

:-.'

::- ::;'i--i.a.'i-;l:.-

Gontr.ol

Diagnpstbs

_,

.,,

_-l_1,.-..--,.i;,',:ir..;:=.

A

diagnostic

aid

can

be assembled

which

consists

of a control

board,

membrane

and wiring

hamess.

The

parts

required

are WR55X10120,

WR55X1

0068

and

WX05X14999.

The

control

diagnostics

allow

the

technician

to

functionally

test individual

components

to

aid

in

troubleshooting.

On the electronic

bottom

mount

models,

the

diagnostics

are

performed

by removing

the

existing

temperature

control

board

and

plugging

in

the diagnostic

aid or by accessing

the main

board

on the back

of

the reftigeratorand

plugging

into

the

J4 connector.

Note: Refrigerators

with

an electronic

temperature

control must

have

the control

disconnected

before

attempting

the

diagnostics

test from

the main

controlboard.

1. Enter the

diagnostic mode

by

pressing

both

the feezer temperature

(cor-oen

and

wnnuen)

pads

and the

refrigerator

temperature

(cor-oen

and

wnnuen)

pads

simultaneously.

Note: All four

pads

must be held for

approximately

3 seconds.

Blinking

"0's"

in

both displays indicate

the refrigerator

has

entered the test mode.

3. Press

and release

any

pad

other

than

the

temperature

pads

to

active the test mode.

4. Enterthe

display numbers

as shown

in

the

diagnostics

chart on the next

page

for

the test

desired.

5. Press

and release

any

pad

otherthan the

temperature

pads

to

active the test mode.

Note: Selected models have limited

test

capability.

See

the COMMENTS

column in the Diagnostics

Chart

on the next

page

for

clarification.

-

18-

Page 20

FREEZER

DISPLAY

FRESH

FOOD

DISPI-AY

DIAGNOSTICS

RESULTS

COMMENTS

0

c

Encoder

Test

As

the knob is

rotated

the

d'splay will

show the

corresponding

setting

Only

for models

with

temperature

control knobs

0

7

Control

and

Sensor

System

Test

Checks

each

thermistor

and

displays

"P"

for

pass

and

"0"

for fail

See Note

1

below

for display

order

1

0

Dampers

Test

Opens

each damper,

pauses

briefly

and then

closes.

lncludes

Custom

Cool

dampers if

applicable

1

Fan Test

Runs

each fian

in

sequence

for 10

seconds

each.

1

2

100%

Run Time

Sealed

system

on

100%

ofthe

time.

Times out

after t hour.

1

3

Prechill

Test

Starts

Prechill

mode.

Unit

retums

to normal

on its

own.

,|

4

Defrost Test

Toggles

on the Defrost

cycle.

See

Note

2 below

Must

press

again to tum

heaters

off. See Note

2

1

5

Main

Confol Reset

Causes

a system reset

1

6

Exit Diagnostic

Mode

Causes a temperature

control board reset

1

7

Degrees

C'/Fo

Changes

ftom F'to

C' or C'

to

F"

on

temperature

display

See Note

3

belour

Note

1 .

#1

-

Single Fresh

Food

Thermistor

#3

-

Custom

Cool #4 - Evaporator

#5 - Freezer

Thermistortestresultsare:

P

=

Pass

0 = Fail

S

=

Shortto

5VDC B

=

Bad

amplifier(replace

main

control)

Note

2. You

must

enter

the

defrost test

again

to toggle

the defrost

heater

off

at the

end of the

test. The

heater

will

not

come

on if the

evaporator

thermistor

is

warm.

Note

3. Press

FF

temperatrire pad

(warmer/colder)

to

toggle.

Using the

service

test

board,

you

can

change

the

temperature

display

from Fahrenheit

to Centigrade

on the refrigerator

display,

but the

customer

will

be

unable to

change

it back

without

using

a service

test

board.

Refer

to Service

Guide

31-9072 for

additional information

Gondenser

Fan

Noise

Symptom:

Loud

airflow

noise

coming

from

the

condenser

fan

compartment.

Problem:

The

plenum

is

bent

out of

position

due

to

the screw

tab being

tightened

at an

angle.

Solution:

Release

the

tension

off the

plenum

by

loosening

the

screw

tab.

Straighten

the

plenum

to

the

proper

position

around the

fan

blade.

Tighten

the screw

so the

tab is

straight.

Photo

Shown

with

Plenum

in the

Bent Position

-19-

Page 21

Strip

Gircuits

3-Wre Electronic Temperature

Control

Damper

6-Wire

Encoder

Temperature Control

Thermistorc

Condenser and

Enaporator

Fan

MOTHERBOARD

8

I

t0

MOTHERBOARD

MOTHERBOARD

MODEL

lD

(20)

rfr)oEr

rD

(22)

+s\rDC

FFI

FFl

F2

EVAP

rcIHERBOARD

FAN COM

5 COi{D

FAN

EVAP

FAN

FYAP

RPM

I'IOTHERBOARD

-20 -

Page 22

FreezerUght

Fresh Food Light

Gomprcssor

Defrost

Heater

DOOROPEN ?

NEI'TRAL

TIOTHERBOARD

-21 -

Page 23

Drawer Models

CIRCUIT

DIAGRAM/

(DRAWER

20,nCUFD

LEGEND

BK: BIACK

BN: BROWN

RD:

RED

BO: BRIGHT

ORANGE

BL: BLUE

GY GREY

GN: GREEN

YL:

YELLOW

WH: WHITE

PR:

PURPLE

SB: SI(Y

BLUE

PK: PINK

FngBoAE)

DOORO?ET

EI/AP

oooRoPEll

EUIRAL

araP trt

R'APRPT

oYtLroaD

'\-l-lZl.rJe|(

GI,YL€

il.*^cno*

|cEtA|GR

FZOOORilTCH

4

?B{tn

F{JGT'[G)

r{.OIIl

nm3

-22-

Page 24

Door

Models

CIRCUIT

DIAGRAM/

(swlNG

20,22CUF\

IEI'TRAL

EVAPnfl

o,ERtoaD

AA-l-j:L.Lslpr

Gtrvl?-

frducnon

,I\

taurr

FF.I,IGHITz}

ffi

ilTB

LEGEND

BK: BLACK

BN:

BROWN

RD: RED

BO: BRIGHT ORANGE

BL: BLUE

GY GREY

GN: GREEN

YL: YELLOW

WH: WHITE

PR: PURPLE

SB: SKY BLUE

PK: PINK

-23-

Page 25

Note: Exploded views

and

parts

list

are

for

illustration

only. Refer to

parF

catalog for specific model

information.

PDS22AMBPAVi|W

Shown

504

-l-

.v

-

-\-

I

\

352

I

795

4L7

-24-

(AFT

NO.

Wrt9€6 e[)

Page 26

437

637

a- s'

832

833

830

-@,

24(E

310

\@

415

w

\9

812

h

pr

t*fi

74tr-K

fl-,

639

24L

,4

310

'

729

-o

813t

60

122

4r-?

I

i

(ART

NO. WRr9437

C2)

-25-

Page 27

&4

\

,::::.::

-26

-

(ART

NO- U'Rr9438

C2)

Page 28

PDS22AMBPAWW

Shown

vtEw

NUMBER

CATALOG

NUMBER

DESCRIPTION

QUANTITY

1

3146043

HANDLE

INSTRUCTIONS

1

1

31-46169

INSTALL

INSTRUCTION

1

1

31-51515

MINIMANUAL

1

1

49-60282

USE AND

CARE

1

11

wR78X10943

DOOR

FOAM

ASSY.FZ

1

14

wR14X10184

GASKET

ASSEMBLY.F

1

25

wR14X10185

GASKET

ASSEMBLY.R

1

26

wR17X11585

GUIDE,RAIL(ICE)BIN

1

u

wR78X10944

DOOR FOAM

ASSY.R

1

35

wR04x10138

NAME P|..ATE

1

38

wR02x11722

CAP.HINGE(C)

'l

39

wRo2x11721

CAP.HINGEru)

1

40

wR02x11684

GUIDE

RAILruIDDLE

TA/)

1

41

wR74X10170

FRONT

GRILLE

ASS'Y

1

46

wR30x10050

SHELF

ICE TRAY

1

48

wR17X11584

GUIDE

AIR

1

50

wRl7X11591

RAIL ASSEMBLY

2

58

wR02x11676

LEVELING

LEG

2

59

wR02x11673

LINK.HUMIDITY(L)

I

60

wR02x11696

RUBBER.DAMPING

1

61

wR02x11674

LINK.HUMIDITY(R)

1

70

wR02x11701

RAIL SLIDE(C)

2

75

wR17X11589

RAIL

ASS'Y.SLIDE(RH

FZ)

1

77

wR17X11590

RAIL ASS'Y.SLIDE(LH FZ)

1

79

wR02x11753

BRACKET.WTRruALVE

1

79

wR02x11753

BRACKET.WTRA/ALVE

,l

80

wR23X10347

GROUND

WIRE.WTR

VALVE

'l

82

wR84X10057

CONDENSER

ASSY

1

u

wR14X10176

MIDDLE

GASKET

1

85

wR14X10175

FRONT

GASKET

2

86

wR60x10147

FAN

ASSY

BLADE

1

89

wR32x10465

LOWER

PAN

1

93

wR02x11697

DRAIN TUBE

1

102

wR02x11694

GROMMET.

RUBBER

2

103

wR02x11750

PLUG

BUTTON.\A^/v

2

105

wR01x10446

BOLT.DOOR

HNDL

4

106

wR02x11665

DAIRY

DOOR CVR

1

107

wR12X10670

HANDLE,FZR

DOOR

1

108

wR12X10669

HANDLE,FF

DOOR

1

109

wR71X10536

DAIRY

BIN

1

110

wR13X10303

HINGE

ASSEMBLY.U

1

111

wR13X10305

HINGE

ASS'Y

2

't12

wR02x11719

COVER.HINGE(U)

1

115

wR13X10307

HINGE

ASSEMBLY.C

1

121

wR02x11720

STOPPER,DOOR

1

122

wR02x11306

STOPPER.COMP

4

126

wR02x11686

GUIDE

ASSEMBLY.RAIL

1

128

wR02x11680

SNUGGER

2

141

wR21X10081

CAN DISPENSER

1

-27 -

Page 29

PDS22AMBPAWW

Shown

vtEw

NUMBER

CATALOG

NUMBER

DESCRIPTION OUANTTTY

14

wR02x11687

CONNECTOR.DOOR

2

200 wR02x11689 SHUTTER SLIDE

1

202

wR72X10148

SLIDE

ASS'Y LEFT

1

206

wR02x11679 BRACKET.HANDLE

FF 2

212 wR02x11678 BRACKET.HANDLE

FZR[)

1

219 wR02x11672 LEVER,SHUTTER

1

228

wR85X10057

EVAPORATORASS'Y

1

241 wR55X10025

SENSOR TEMP FF

3

2M wR02x11677 BRACKET.HANDLE

FZR

1

251

wR02x11703 SUPPORTOR COVER

TA/

1

265 wR02x11698

ROLLER

4

268

wR02x11671 ADJUSTER

1

270

wR02x11690 GROMMET FILL TUBE

1

310

wR02x116&t COVER.SENSOR

2

311 wR02x11666 FRAME - LOWER

PAN

1

315 wR02x11741

ROLLER PIN

4

331

wR12X10657 FZR BSKT UPPER

HANDLE

1

332 wR12X10658

FZR

BSKT WffRIM

1

336

wR02x11669 COVER.GRILLE

FAN

1

u'l wR02x11663 COVER.P.T.C

1

352 wR30x10052 ICE BIN

1

387

wR02x11662

COVER

ICE BIN

1

407

wR32X10463 VEG PAN

2

408 wR32X10464 MEAT PAN

1

409

wR02x11670

ACCESS

COVER

1

412 wR21X10080

FZR

BSKT. UPPER

1

414

wR21X10079

FZR

BSKT - CTR

1

415

wR02x11659 MAIN

CVR

1

417 wR21X10078

FZR

BSKT

1

430

wR17X11592 HOUSING CONTROL

1

435 60A BULB 6OW

3

436

wR02x11656 REFLECTOR.I-AMP(FZ)

1

437

wR02x11657 REFLECTOR.I.AMP(FF)

1

503

wR71X10562

SHELF

ASSEMBLY.R

1

504

wR71X10563

SHELF ASSEMBLY.R

1

505

wR71X10564

SHELF

ASSEMBLY.R

1

506

wR71X10565

SHELF

ASSEMBLY.FOLDING

1

512

wR72X10151 HOLDER.SHELF

FYL

2

522

wR02x11682 RAIL

SUPPORT.

L

1

524

wR02x11681

RAIL

SUPPORT

-

R

1

527

wR71X10541

HOLDER,SHELF C

1

536

wR02x11704 HOLDER,RAIL

1

il1 wR02x11683 VEG PAN FRT SUPPORT

2

603

wR09x10114

DAMPER

ASS'Y

1

619

wR17X11587

CONNECTOR

ASSEMBLYR)

1

620

wR50x10044 THERMOSTAT-BI.METAL

I

621

wR50x10047

THERMODISC(FUSE-M)

1

622

wR17X11588

CONNECTOR ASSEMBLY(L)

1

-28

-

Page 30

PDS22AMBPAWW

Shown

VIEW

NUMBER

CATALOG

NUMBER

DESCRIPTION

QUANTITY

623

wR02x11699

SOCKET ASSEMBLY.LAMP(F)

1

624

wR02x11700

SOCKET ASSEMBLY.

LAMP(R)

1

625

wR50x10050

THERMODISC

FF

1

636 wR23X10341

SWITCH L]GHT FZ

1

637

wR23X10342

SWITCH LIGHT FF

1

638

wR02x11661

COVER I.AMP FF

1

639

wR02x11658

COVER LAMP FZ

1

714

WR3OX1OM8

TRAY

DRIP

1

722

wR60x10146

EVAP MOTOR

ASSY

1

728

wR02x11702

HOLDER.DRIER

'l

732

wR17X11594

EVAP FAN

CVR ASS'Y

1

740

wR86X0093

DRIER

1

742

wR02x11695

COMP.

GROMMET

4

74

wRl7X11583

GUIDE.FAN

1

756

wR02x11688

SHUTTER

SLIDE

1

795

wR30x10051

SUPPORTOR,DIVIDER

2

801

wR55X10339

BOARD

ASM MAIN

CONTROL

1

802

wR55X10340

BRD

ASM TEMP

1

806

wR17X11586

DOOR

BIN

1

807

wR71X10532

DOOR

BIN

4

810

wR07x10080

P.T.C

REIAY

1

811

wR08x10048

OVER

LOAD

1

812

wR84X10055

CONDENSER FAN

MOTOR

1

813 wR87X10097

COMP. REPL. KIT

1

814

wR60x10148

FAN

CONDENSER

ASS'Y

1

820 tM6

IM KIT.IM6

1

821

WR62X1OMO

CAPACITOR

1

822

wR17X11607

FILTER ASSEMBLY.HEAD

1

821

wR62X0079

CAPACITOR

1

823

wR57X10049

WATER VALVE

1

824

wR02x11712

TUBE,INJECT

1

825

wR02x11711

GUIDE.WATER

1

823

wR57X10033

WATER VALVE

1

826 wR50x10042

DEFROST

HEATER

1

827

wR02x11710

HOLDER

5

828

wR02x11709

BAND(MECH)

4

829

wR02x11708

COVER.TUBE

1

830

wR02x11713

COVER,FILTER(LOWER)

1

832

wRozx11714

COVER.FILTER(UPPER)

1

833

GSWF

WATER FILTER

CATRIDG

1

1730

wR23X10300

POWER

CORD

1

623 wR02x11699

SOCKET

ASSEMBLY.LAMP(F)

1

624 wR02x11700

SOCKET

ASSEMBLY,LAMP(R)

1

625 wR50x10050

THERMODISC

FF

1

636

wR23X10341

SWITCH LIGHT FZ

1

637

wR23X10342

SWITCH L]GHT FF

1

638

wR02x11661

COVER LAMP FF

1

639

wR02x11658

COVER

LAMP FZ

1

714

wR30x10048

TRAY

DRIP

1

-29 -

Page 31

ReffigefatOf

WaffatftTf.

(tur

cusfrmers

in

the united

Svrls)

Allwarranty

seruice

provided

by our Factory Seruice

Cente$,

or an

autharized

Customer CarP technician. To

schedule seryice,

on-line,24 hours

a day,

visit

us

at

dEAppliancescom,

or

call

ap.GEcAnEs

wn.$2273il.

..ffiGEWinRqtae:

&teYec,r

f.rptrrfipd*.cdilre

ot@lrtrdrarr.'

Atry

ptot

te

rcfrigeraor wbidr

Ails &rc to a dcftct in marcriab or nor*manstrip

During

ftis

ftil

u*pwraly,GE

rrin

abo

provi<te, t:eddrrgeall labor

and irhome

senice to repac€

the

ddective paru

fihre Ysrs

.'^

l';

tuirttre&tsoffrb

ofigtrl r.dlq9a1,l

'-.:

.

fuV

Ft

o, h W

ffiigsdirrysJffin

(the

@mpressor, cqrdenseg a,aporator

and dl conneaing

urbing) whidr Aib

drc oa

dcfectin marcrials orrrcr*manship.

During

hb frtil finaw

ffi ffipa*U

W

wrdr,GE will atso

providc,

te

d

@

all hborandin*romeserrice

o rephce

thedc&oirepartin

trescalcdrdigeratrrgsystem.

Illdf'Myc

-':,

:

Ftwr llroilgful..: ,

prdlrsrdr6.dft:

A@r

, .,

Awptotdoevaarfltercaruidge

whidt

Aib &rc oa dc&ctin marcriab

orrrorlsnanstrip.

D'udng

dris ffi

ffiley wtfi,@,wil,abo

prwide, te d dzgea replacemcut

rrarcr

filrcrcartidge.

Ffirc of rhepro&rcifitb*ln4

ter*4 credfor

Pofecrghtbubc

cwufu crtidge

o6crftnfu-inadcdprpcccd*;d"ry.

-

otcr6mesDdedsoG'

Serrice

trips

to

yorr

hme

16 te-t ynr

bow to u*

eeprcdra

Iryopcr

t".i.lltdcb

defEllGl'y

or

nr;-t-a.ce.

roas

of food dr to

qroilege.

R€da-€ot of

hous frscs

or nscdiog

of

cirurit

brcakes.

nd.ccod

of thc wu ftcr caciftc ee b €cr

grsuc

ttet b

ostdde

&c

+Gd6ed

opcr:dbg rage

c

dE b cloo..*ge sdtncrtin ee

watcr

sryplt

Duage

lo lbc

Frc&rr

@scd bt.ocidcnt,

firc,

f,oods

oraosofGod.

Incirhl

a Gequdat

dm.ge cntsd bt poo$lc

ddcc611ithrhecTrn6ace.

Duagecan*d

afuaaluy.

This

wananty

is exEnded

b the

odginal

purchaser

and any

succeeding otmterfor

producF purchased

for home

use wihin

the USA ln

Naska, the

wamnty

excludes the

cost

of

shipping or

sevice

calls tu

your

home.

Some

states do not

allow the

exclusion

or limihtion of

incidenbl

or consequential

damages.

This

wamnty

gives

you

specific legal rigtrfs,

and

you

may also have

other dghb vthich

vary from stafe to s'trite. To

know

vdrat

your

Iegal

ights

are,

consuft,your

local

or ffite consumer

affairs

office

oryour

*teb

Ammey

Genenl.

Warnntu:

@twal Eleic

furpry.

buisviile, NV M

-30-

Loading...

Loading...