Page 1

Safety warnings

The use of these products requires awareness of the following safety issues:

GE Consumer & Industrial

Lighting

Warning

• Risk of electric shock - isolate from power supply before changing lamp

• Strong magnetic elds may impair lamp performance

and worst case can lead to lamps shattering

Use in enclosed fixtures to avoid the following:

• Risk of re.

• A damaged lamp emits UV radiation which may cause eye/skin injury

• Unexpected lamp shattering may cause injury, re, or property damage

Caution

• Risk of burn when handling hot lamp

• Lamp may shatter and cause injury if broken

• Arc tube ll gas contain Kr-85

Always follow the supplied lamp operation and handling instructions.

ConstantColor™ CMH™

Ceramic Metal Halide Lamps

Single Ended G8.5

Product Information

Lamp technology

ConstantColor CMH™ lamps combine HPS technology

(providing stability, efficiency & uniformity) and Metal Halide

Technology (providing bright white quality light) to produce

highly efficient light sources with good colour rendering and

consistent colour performance through life. This is achieved

by using the ceramic arc tube material from the Lucalox™

lamp, which minimises the chemical changes inside the

lamp through life. When combined with the halide doses

used in Arcstream™ Metal Halide lamps then the quality

and stability of the dose maintains the colour consistency.

Hence the name ConstantColor CMH™.

Metal halide lamps, traditionally made with quartz arc tubes,

are prone to colour shift through life and lamp-to-lamp

colour variation. Some of the dose, e.g. sodium, (an

important component of metal halide lamps), can migrate

through quartz to cause colour shift and loss of light through

life. The ceramic arc tube resists this material loss, can be

manufactured to tighter tolerances and withstands a higher

temperature to provide a more constant colour.

Single ended format

Single ended Ceramic Metal Halide lamps are designed to

provide symmetrical beam distribution using the axial configuration of the discharge arc.

A variety of beam angles are possible and adjustable beam

control can be built into the luminaire.

This compact lamp shape enables luminaire size to be

minimised and the bi-pin lamp base enables easy changing

with front access.

Applications areas

DATASHEET

www.ge.com/eu/lighting

and General Electric are both registered trademarks

of the General Electric Company

GE Lighting is constantly developing and improving its products. For this reason, all product descriptions in this brochure are intended as a

general guide, and we may change specifications time to time in the interest of product development , without prior notification or public announcement. All descriptions in this publication present only general particulars of the goods to which they refer and shall not form part of any

contract. Data in this guide has been obtained in controlled experimental conditions. However, GE Lighting cannot accept any liability arising

from the reliance on such data to the extent permitted by law. CMH Single Ended G8.5 Product Information for OEMs 17th July, 2007

Features

• Consistent colour over life

• Good colour uniformity lamp to lamp

• Bright light – in a very compact size

• Excellent colour rendition

• Improved reliability due to 3 part design

• Up to 97 Lumen per Watt (LPW) efcacy

• Up to 15,000 Hr life

• UV control

• Colour temperatures 3000K, 4200K

• Retail

• Ofces

• Stage/Studio

• Architectural lighting

• Display Cabinet

• Hotels

Page 2

2

3

Specification summary*

Specification summary*

Ordering Information

Description

CMH20/T/UVC/U/830/G8.5 Plus 20 3000K

CMH35/T/UVC/U/830/G8.5 Plus 35 3000K

CMH35/TC/UVC/U/842/G8.5 35 4200K

CMH70/TC/UVC/U/830/G8.5 Plus 70 3000K

CMH70/T/UVC/U/942/G8.5 70 4200K

20W

Units

Product code 39858 43273 26348 43274 26349

Nominal Wattage

Format

Bulb type

Bulb diameter

Bulb material

Bulb finish

Arc Gap

Base

W 20 35 35 70 70

mm 14.5 14.5 14.5 14.5 14.5

mm 3.35 4.65 4.3 7.4 5.5

3000K

T4.5 T4.5 T4.5 T4.5 T4.5

G8.5 G8.5 G8.5 G8.5 G8.5

Wattage Colour Product Code

39858

43273

26348

43274

26349

35W

3000K Plus

35W

4200K

Single ended

UVC Quartz

Clear

70W

3000K Plus

70W

4200KGeneral

Operating Conditions

20W

Photometric Characteristics

Product code 39858 43237 26348 43274 26349

100 hrs Lumens

Typical Lumen change

with burning position

– vertical to horizontal

Typical voltage change

with burning position

– vertical to horizontal

Correlated Colour Temperature

Chromaticity X

Chromaticity Y

Colour Rendering Index

Luminous efficacy

Base

lm

lm 100-150

V 8

K

Ra

lm/W

3000K

1650 3400 3150 6200 6000

3000 3000 4200 3000 4200

0.435 0.435 0.475 0.435 0.475

0.400 0.400 0.370 0.400 0.370

80+ 84+ 88+ 80+ 90+

85 86 80 86 83

35W

3000K Plus

35W

4200K

G8.5

70W

3000K Plus

70W

4200K

Starting and Warm-up Characteristics*

Time to start ( at 25 °C )

Time to start - Cold box test at -30 °C

Hot restart time

Warm-up time (for 90% lumens)

* Typical values (actual values are ballast and ignitor dependent)

sec. < 2 < 2 < 2 < 2 < 2

sec. < 2 < 2 < 2 < 2 < 2

min. < 3 < 3 15 15 15

min. 1.2 1.2 3 3 3

Burning position

Luminaire characteristics

Notes:

1) Lamp voltage in the luminaire should not increase by more than 5V when compared to lamp voltage in free air.

2) Ballast protection required, according to IEC61167.

3) 35W & 70W data is based on operation from a conventional magnetic ballast. Improved performance can be achieved using an electronic ballast.

4) 35W 4200K CMH lamp is based on operation from an electronic ballast. Lamps can run on conventional ballast with a small reduction in performance.

5) 20W designed for operation only from an electronic ballast.

Universal

Enclosed

Electrical Characteristics *

Lamp power

Lamp voltage

Lamp current

Max. Ignition Voltage

Min. Ignition Voltage

Extinction voltage

(% of rated input voltage)

* The specication provides typical performance data for 35W & 70W operating from a 50Hz mains sinewave supply at nominal power. Actual values depend on ballast,

supply voltage and application 20W to be used only with an electronic ballast

*** See additional notes on electronic ballast requirements for 20W

W 20 39 39 72 72

V 90 90 90 90 90

A 0.226 0.50 0.50 0.98 0.98

kV *** 5.0 5.0 5.0 5.0

kV *** 3.5 3.5 3.5 3.5

% *** 90 (Max.) 90 (Max.) 90 (Max.) 90 (Max.)

Through life Performance*

Lumen maintenance

at 40% rated life (mean lumens)

Average rated life

* Life data measured in Vertical Base up position. Performance can be greatly increased in horizontal position.

% 68 68 85 71 77

h 12000 15000 12000 15000 15000

Maximum Operating temperatures**

Maximum allowed bulb temperature

(horizontal orientation, thermocouple

attached above burner)

Maximum pinch temperature

(vertical base up orientation)

* The specication provides typical performance data for 35W & 70W operating from a 50Hz mains sinewave supply at nominal power. Actual values depend on ballast, supply

voltage and application 20W to be used only with an electronic ballast – see later for additional notes on electronic ballast requirements.

** Temperatures above which lamp performance or reliability is impaired. Additionally, voltage rise when operated in luminaire should not exceed 5V

*** Photometric characteristics refer to lamp performance after 100hrs burning.

°C

°C

500 500 500 550 550

300 300 300 300 300

Page 3

4

5

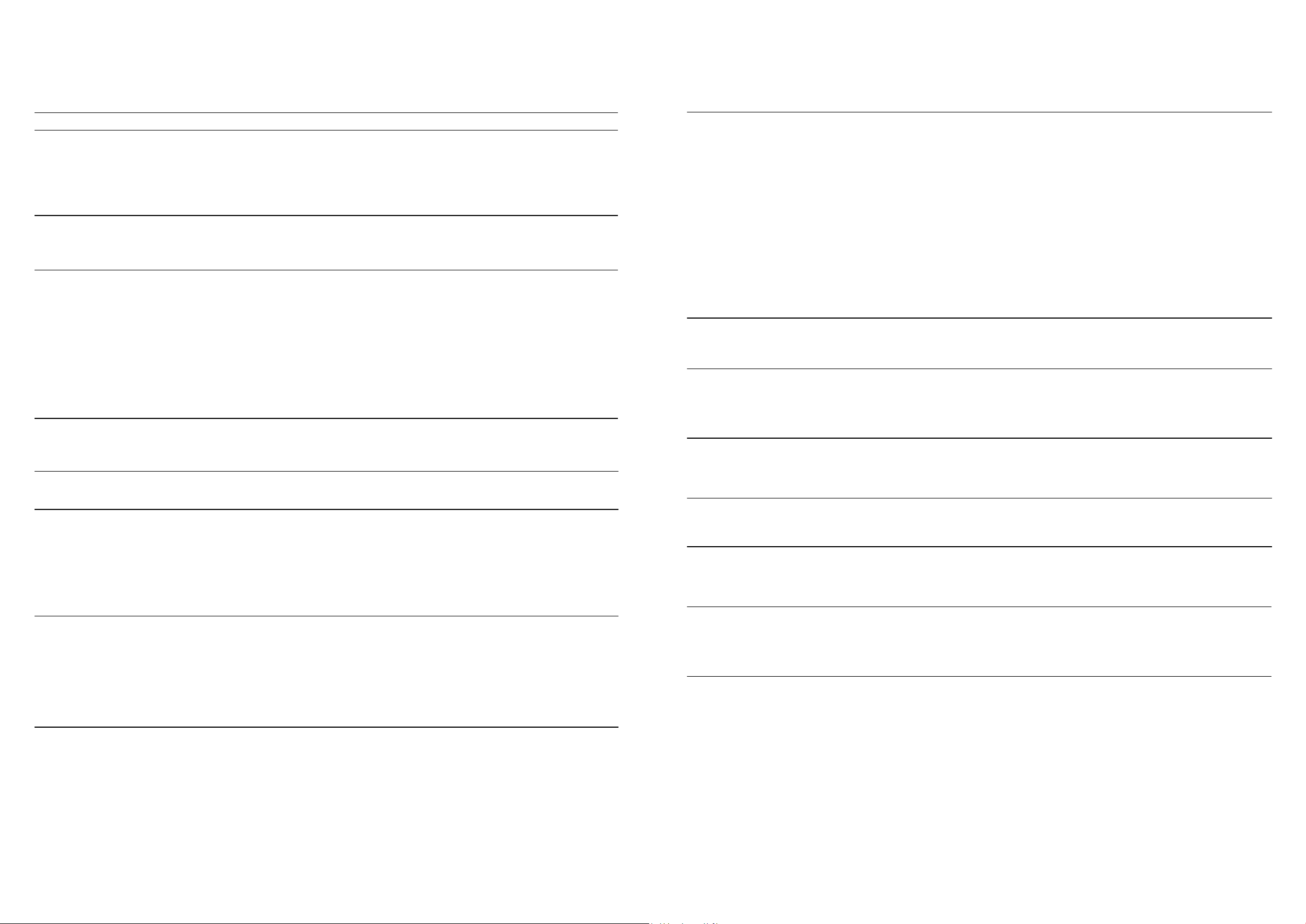

Dimension

40%

20%

0%

60%

80%

100%

4 6 8 10 120 2

Burning times (thousand hours)

% Lamp survival

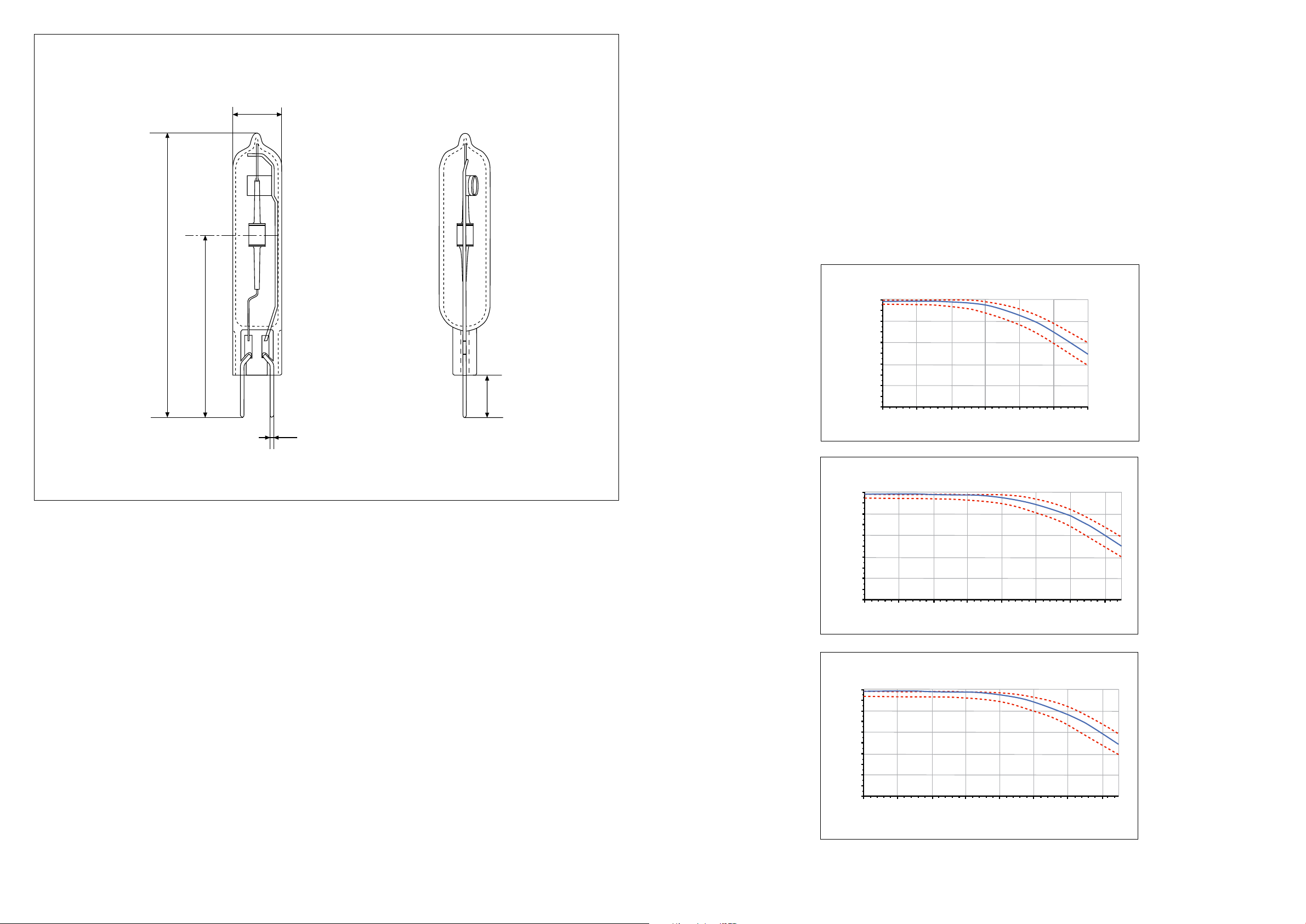

CMH 20W G8.5 3000K

40%

20%

0%

60%

80%

100%

4 6 8 10 12 140 2

Burning times (thousand hours)

% Lamp survival

CMH 35W G8.5 3000K and 4200K

40%

20%

0%

60%

80%

100%

4 6 8 10 12 140 2

Burning times (thousand hours)

% Lamp survival

CMH 70W G8.5 3000K and 4200K

85 mm MAX

LCL 52 ± 1.0 mm

14.5 mm

Lamp life

Life survival graphs are shown for statistically representative batches of lamps operated under controlled nominal conditions

with a 7 hours per start switching cycle. Declared lamp life is the median value, i.e. when 50% of lamps from a large sample

batch would have failed. Lamp life in service is affected by a number of parameters, including supply voltage variation,

switching cycle, operating position, ballast impedance tolerance, luminaire design and mechanical vibration.

The information provided is intended to be a practical guide for comparison with other lamp types. Determination of lamp

replacement schedules will depend upon relative costs of spot or group replacement and acceptable reduction in lighting

levels.

Note: Representative curves are shown for Vertical Base-Up lamp orientation unless otherwise specied. Life performance is

significantly increased in the Horizontal burning position.

1.0 mm

12.0 mm

Page 4

6

7

Lumen maintenance

Burning time (thousand hours)

% of Initial

Lumen Maintenance 70W G8.5 4200K

40

20

0

60

80

100

2 4 6 8 10 12 14 160

Burning time (thousand hours)

% of Initial

Lumen Maintenance 70W G8.5 3000K

40

20

0

60

80

100

2 4 6 8 10 12 14 160

Burning time (thousand hours)

% of Initial

Lumen Maintenance 35W G8.5 3000K

40

20

0

60

80

100

2 4 6 8 10 12 14 160

85

80

75

70

65

60

90

95

100

2 4 6 8 10 120

Lumen Maintenance 35W G8.5 4200K

Burning time (thousand hours)

% of Initial

85

80

75

70

65

60

90

95

100

2 4 6 8 10 120

Lumen Maintenance 20W G8.5 3000K

Burning time (thousand hours)

% of Initial

Spectral Power Distribution [3000K]

0

20

30

40

50

60

0

70

10

WWaavveelleennggtthh