Page 1

FVR-C9S-7UX

Instruction Manual

FVR-C9S-7UX Drive Series

Single-phase 240 V AC Input Type

1

Page 2

FVR-C9S-7UX

CAUTION

• Make sure that you read this instruction manual thoroughly

before installing, wiring, operating and inspecting this drive.

• Please make sure that this instruction manual accompanies the

drive to the end user.

• Keep this instruction manual so that it will always be available

for the duration of the drive’s operating life.

• Product specifications are subject to change without notice.

2

Page 3

FVR-C9S-7UX

Thank you for purchasing the Fuji “FVR-C9S” drive marketed by GE Fuji Drives USA, Inc. This

instruction manual is included with the drive and equipment and is provided for the convenience of the end user. Please be sure it accompanies the drive.

CONTENTS

0. Safety Precautions .................................... 4

1. Inspection Upon Receipt .......................... 6

2. Part Names ............................................... 7

3. Warning and Caution ................................ 7

4. Specifications ........................................... 8

5. External Dimensions ............................... 10

6. Installation Instructions ........................... 12

7. Wiring ...................................................... 12

8. Basic Wiring Diagrams............................ 14

9. Application of Wiring and Equipment ..... 16

10. Terminal Function Explanation ................ 17

11. Operation ................................................ 19

12. Keypad Panel .......................................... 21

13. Function Explanation .............................. 23

14. Protective Functions ...............................34

15. Warranty Parts and Service .................... 35

16. Electromagnetic Compatibility ................ 37

17. EC Declaration of Conformity ................. 40

3

Page 4

0. Safety Precautions

FVR-C9S-7UX

Before carrying out installation, wiring, maintenance or inspection of the drive, read this instruction manual thoroughly to gain a full understanding of the correct operation procedures.

Make sure that you have read all product details,

safety information, warnings and cautions before

use. The following classifications for warnings

and cautions are used throughout this manual.

WARNING:

Denotes operating procedures and practices that

may result in severe injury or loss of life if not

correctly followed.

CAUTION:

Denotes operating procedures and practices

that, if not strictly observed, may result in personal injury or damage to the equipment.

WARNING:

FIRE AND PERSONAL INJURY HAZARD

This drive is designed for variable-speed operation of three-phase induction motors. It cannot

be used with single-phase motors or for any

other applications, otherwise fire may result.

The drive cannot be used by itself for elevators,

life-preservation equipment or other equipment

which is directly related to human safety. In such

situations, sufficient consideration should be

given to overall system configuration, not just to

the drive, otherwise serious accidents could

result.

inside the drive or onto the cooling fins, otherwise fire or problems with operation may result.

AC input fuses are required to validate UL listing

of this device.

Do not install and operate the drive if it is damaged or if some of the parts are missing. Doing

so may result in severe personal injury.

Do not touch the drive cooling fin because the

cooling fin reaches high temperatures during

operation, otherwise personal injury may result.

Install the drive in the environment of pollution

degree 2. If environment is pollution degree 3 or

4, the drive should be installed in a cabinet of

IP54.

Required for CE Certification.

WIRING

WARNING:

FIRE AND ELECTRIC SHOCK HAZARD.

When connecting the drive to a power supply, be

sure to connect it via a circuit breaker, a leakage

current breaker or a fuse, otherwise fires may

result.

AC input fuses are required to validate the UL

listing of the drive.

Use only fuses and circuit breakers with rated

capacities that are suitable for use with the drive.

Failure to do so may result in fire.

Connect the drive with a secure ground, otherwise electric shocks or fires may result.

INSTALLATION

WARNING:

FIRE AND PERSONAL INJURY HAZARD

Install the drive to a non-flammable surface such

as a metal surface, otherwise fires may result.

Do not place the drive near flammable materials,

otherwise fires may result.

Do not hold the drive by its cover when transporting. Otherwise the drive could be damaged

and cause injury to personnel.

Do not let any scraps of thread, paper, sawdust,

dirt, metal shavings or other foreign objects get

Wiring work should only be carried out by suitably qualified personnel, otherwise electric

shocks may result.

Make absolutely sure that the power supply is

turned off (open) before wiring, otherwise electric

shocks may result.

Wiring work should only be carried out after the

drive has been installed, otherwise electric

shocks or injury may result.

4

Page 5

FVR-C9S-7UX

CAUTION:

Check that the phase and voltage of the AC

power supply being connected matches the

input phase and rated input voltage of the drive.

Using an improper power supply may cause

injury or damage to the equipment.

Do not connect AC power to the output terminals (U, V, W) otherwise injury may result.

The drive, motor and wiring produce electromagnetic noise during operation. Make sure that this

does not interfere with the operation of sensors

or other equipment nearby, otherwise accidents

may result.

OPERATION

WARNING:

ELECTRIC SHOCK HAZARD

Always install the drive cover before turning on

the power supply. In addition, do not remove the

drive cover while the power is on. Failure to

observe these precautions may result in electric

shocks.

Do not operate any of the switches with wet

hands, otherwise electric shocks may result.

WARNING:

FIRE AND PERSONAL INJURY HAZARD

CAUTION:

Do not touch the cooling fins, as they become

hot during drive operation.

Because it is relatively easy to set the drive to

high speed operation, be sure to check the

capacity of the motor and the equipment being

operated before changing the drive function

setting.

The drive braking function cannot be substituted

for mechanical means. Attempting to do so may

result in injury.

MAINTENANCE, INSPECTION AND PART

REPLACEMENT

WARNING:

ELECTRIC SHOCK HAZARD

Wait at least five minutes after turning off the

power before carrying out inspection. Check that

the charge indication lamp has gone out. Do not

touch the drive parts if the lamp is still lit, otherwise electric shocks may result.

Maintenance, inspection and parts replacement

should only be carried out by suitably qualified

personnel. Remove any metallic accessories

such as watches and rings before starting work,

and use only properly insulated tools, otherwise

electric shocks may result.

If the retry function has been activated and a trip

occurs, the drive will restart automatically depending on the cause of the trip. Make sure that

the system is set up properly so that there will be

no danger to personnel when the drive starts.

The STOP key is only effective when keypad

panel operation has been selected in the function settings. A separate switch should be

installed for emergency stopping purposes.

If an alarm reset is carried out while a run signal

(FWD/REV) is being input, the drive will suddenly

restart. Always check that the run signal is not

being input before carrying out the alarm reset,

otherwise accidents may occur.

Never touch the drive terminals while the power

is fed to the drive, regardless of whether the

drive is running or not.

DISPOSAL

CAUTION

Disposal of the drive should be entrusted to a

suitably-qualified disposal agency, otherwise

injury may result.

PACKING

CAUTION

Do not stand or sit on the drive as injury may

result.

The number of packing cartons that can be

stacked together is printed on the packing

container. Do not stack the containers any higher

than this or injury may result.

5

Page 6

FVR-C9S-7UX

UL/CSA

WARNING / AVERTISSEMENT

Hazard of electrical shock. Disconnect incoming

power before working on this control.

Risque de choc electrique. Couper l’alimentation

avant le depannage de sette commande.

More than one live circuit. See diagram. Cet

equipment renferme plusieurs circuits sous

tension. Voir le schema

CAUTION ATTENTION

Dangerous voltage exists until charge light is off.

Prede tensions dangereuses tant que le voyant

n’est pas eteint.

Suitable for use on a circuit capable of delivering

not more than 5,000 rms symmetrical amperes.

240V maximum.

• Use 60/75° C copper wire only.

• Use Class 1 wire only.

• Open type equipment

• Tightening torque and wire range for field

␣ ␣ ␣ wiring terminals are as follows:

Model Required Wire

torque (N.m) range

FVRF12C9S-7UX 0.98 14

FVRF25C9S-7UX 0.98 14

FVRF50C9S-7UX 0.98 14

FVR001C9S-7UX 0.98 14

FVR002C9S-7UX 0.98 14

Control board

terminal 0.7 24

Use the listed quick-acting fuse in series. Factory recommendation is a Bussman type JKS or

equivalent. Fuses are required to validate the UL

and CSA listings.

Field wiring connection shall be made by a UL

listed and CSA Certified closed-loop terminal

connector sized for the wire gauge involved.

Connector must be fixed using the crimp tool

specified by the connector manufacturer.

OTHER

WARNING:

FIRE AND PERSONAL INJURY HAZARD

Do not carry out any modifications to the drive.

Doing so may result in electric shock and injury.

GENERAL CAUTION

All of the illustrations in this instruction manual

show the drive with the covers and other protective equipment removed in order to facilitate

explanation of detailed parts of the drive. Be

absolutely sure to return all covers and protective

equipment to the prescribed positions before

operating the drive, and make sure that all operations are carried out in accordance with the

instructions in this manual.

1. Inspection Upon Receipt

Please inspect the following items upon receipt

of your drive.

• Check the name plate to insure the specifications correspond to those ordered.

• Inspect the unit for damage which may have

occurred during shipping.

If you have any problems or questions regarding

the drive, please contact the nearest Fuji sales

office or the distributor where the unit was

purchased.

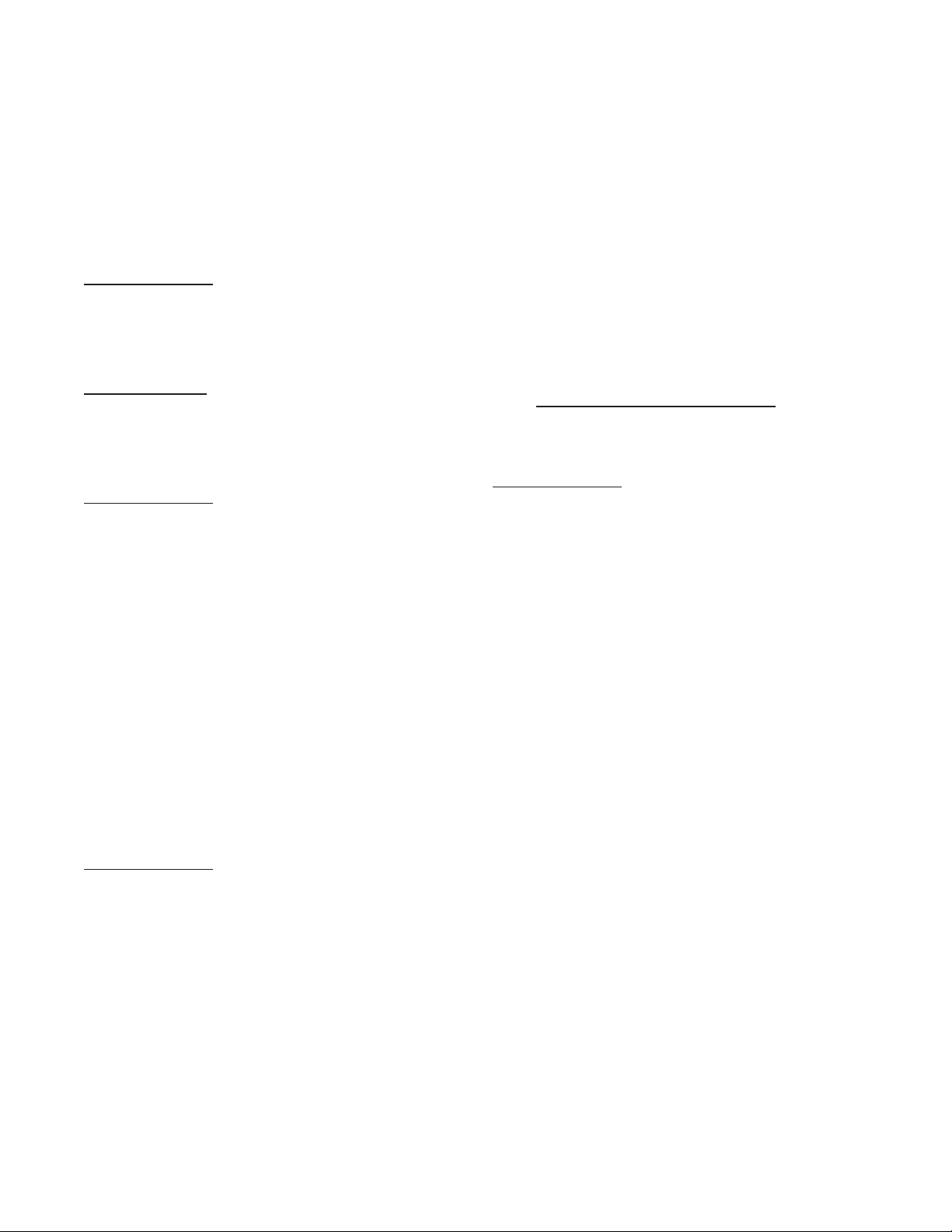

Nameplate

Model Dist. fuse size,600V

FVRF12C9S-7UX 20

FVRF25C9S-7UX 20

FVRF50C9S-7UX 20

FVR001C9S-7UX 20

FVR002C9S-7UX 30

TYPE

SOURCE

OUTPUT

SER. NO.

FVRF 12C9S-7UX

1PH 200-240V 1.7A 50/60 HZ

3PH 200-230 0.66A 1/8HP 1-120HZ

Fuji Electric Co. Inc. Japan

1

2 3 4

5 6 7

8

6

Page 7

FVR-C9S-7UX

1. Type

Drive Series

F V R F 2 5 C 9 S 7 U X

Power Series: 200V UX Series

Applicable motor output (Hp)

2. Phase: 1AC - Single-phase

3. Voltage range: 220V - 240V

AC200V Series

4. Frequency: 50/60Hz

5. Rated output capacity

6. Rated output current

7. Output frequency range: 1- 120 Hz

8. Serial No.

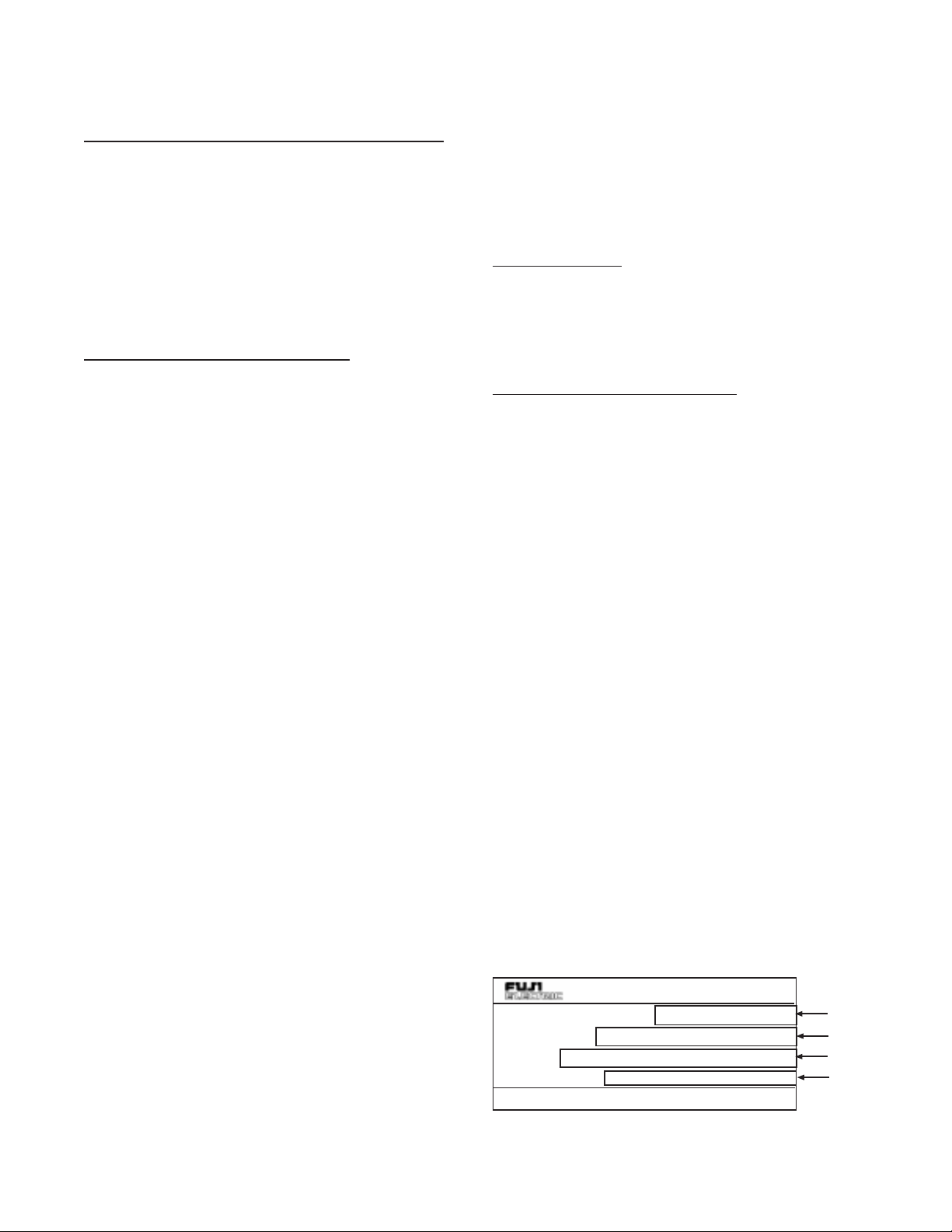

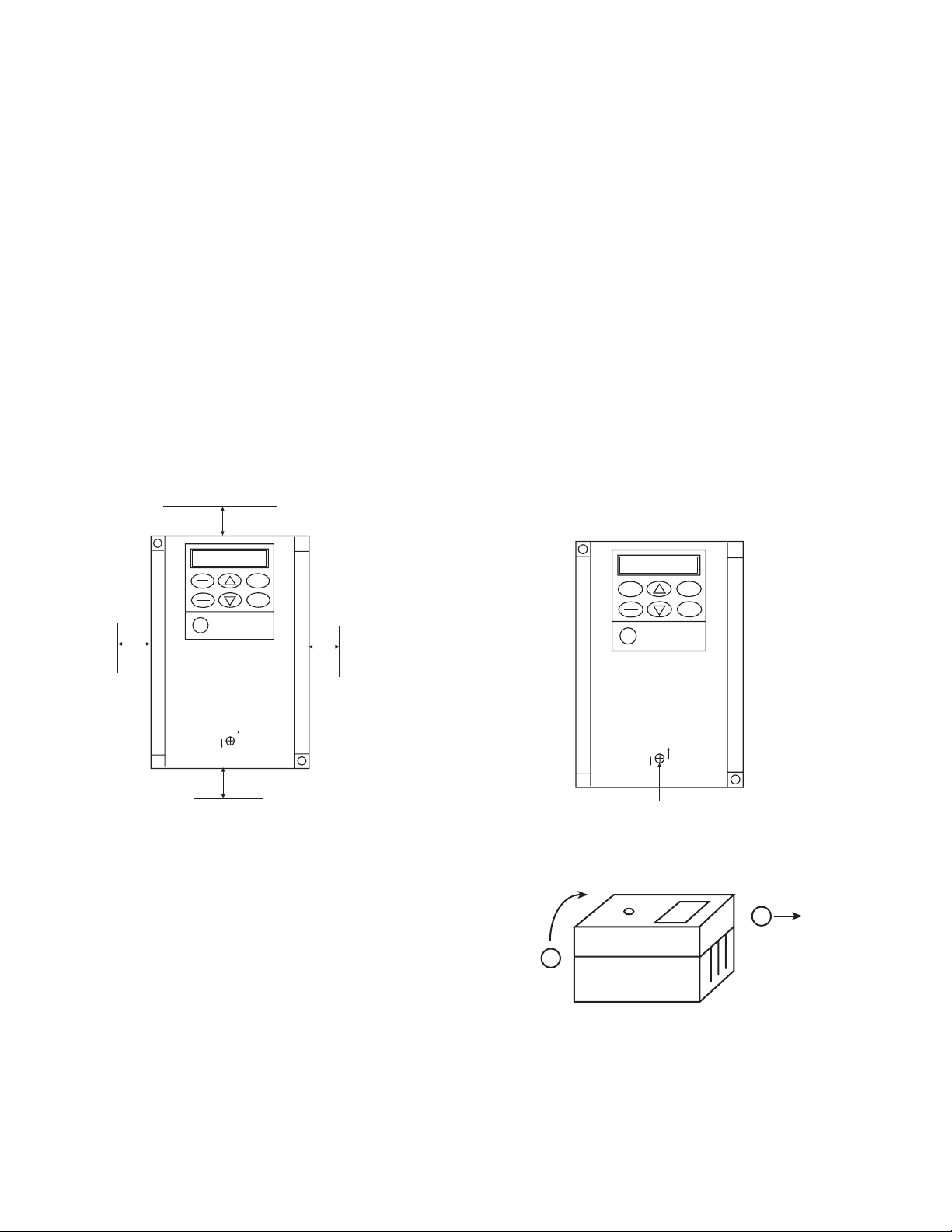

2. Part Names

4

3. Warning and Caution

Improper wiring will result in damage to, and

failure of the unit. Please carefully note the

items listed below, and use the unit as indicated.

WARNING AND CAUTION

1. Do not connect the power supply to

voltage that exceeds the standard specification voltage with permissible fluctuation. (Permissible voltage: AC220V 240V)

2. Do not connect power supply to the drive

output terminals (U, V, W). Connect

power supply only to the power terminals

(L1, L2)

3. Whenever removing the drive cover,

always switch off the power supply. Do

not switch on the power supply to the

drive with the drive cover removed.

PRG

RESET

FUNC

DATA

1

CLOSED

1. Drive Cover

2. Keypad Panel

3. Frequency Setting VR

4. Mounting Screw Holes

5. Drive Cover Screw

RUN

STOP

FVR-C9S

OPEN

5

2

4. Do not touch the live part until the CRG

lamp located above the main circuit

terminals goes out.

5. Avoid using a magnetic contactor (ON/

OFF) installed in the line side of the drive

for RUN and STOP. Use the FWD-CM

3

(forward) and REV-CM (reverse) terminals

for RUN and STOP.

6. Do not connect a power factor correcting

capacitor to the output side of the drive.

7. Do not perform a megger test between

the drive terminals or on the control

4

circuit terminals.

7

Page 8

FVR-C9S-7UX

ge,

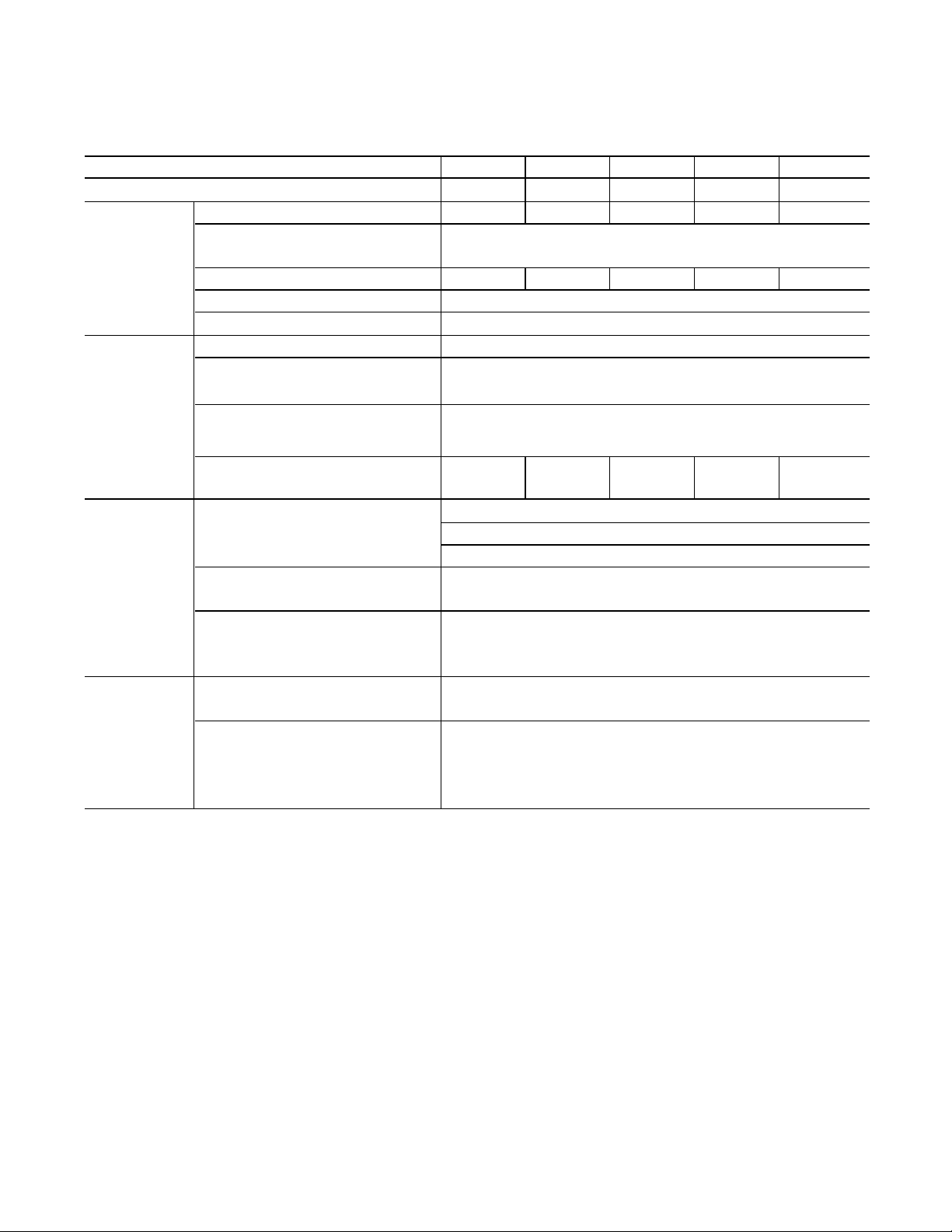

4. Specifications

Type (FVR _ _ _ C9S-7UX) F12 F25 F50 001 002

Applicable motor output

1

Rated capacity

2

Voltage [V] Three-phase 220-240V 50/60 Hz (Output voltage is proportional

Output Rating Rated current [A] 0.66 1.2 2.1 3.7 6.4

Overload current rating 150% 1 min.

Rated frequency [Hz] 50/60 Hz

Phase, voltage, frequency Single-phase 220-240V 50/60 Hz

Allowable variation in

Input power

supply

voltage/frequency

Instantaneous voltage drop

withstanding capacity

Required power supply

capacity

Adjustment Max. freq.4 [Hz]

Base freq. [Hz]

Starting freq. [Hz]

Output Accuracy Analog setting: ±1.0% of max. frequency (25±10°C)

frequency Digital setting: ±0.01% of max. frequency (-10 - +50°C)

Setting resolution Analog setting:1/255 of max. frequency

Control method Sine wave PWM control

Control Operation Keypad operation: Operation control by RUN/STOP keys

1) "Applicable motor" indicates a standard 4-pole motor.

2) "Rated capacity" indicates a capacity at 240V rating.

3) This applies to the case where momentary power failure occurs under such conditions that rated voltage is

inputted and load factor is 85%.

4) Shows the case where an applicable motor equipped with an AC reactor (option) on the input side is used.

[Hp] 1/8 1/4 1/2 1 2

[kVA] 0.27 0.5 0.87 1.5 2.7

to input voltage)

Voltage: =10 - 15% Frequency: 15% (Imbalance in power

supply voltage: 3%)

Drive is kept running if voltage is 165V or more. If voltage drops

more than 165V from rated volta

drive is run for 15ms.

3

[kVA] 0.3 0.6 1.0 1.7 3.1

50-120 Hz Setting variable (in increments of 1 Hz)

50-120 Hz Setting variable (in increments of 1 Hz)

1-6 Hz Setting variable (in increments of 1 Hz)

(ex. 0.25 Hz / 60 Hz, 0.5 Hz / 120 Hz)

Digital Setting: 0.1 Hz (99.9 Hz max) 1 Hz (100-120 Hz)

(Extremely low noise by high frequency carrier)

Terminal strip: Forward command. Reverse command.

Coast-to-stop command. Reset.

External alarm.

C92-7-13

8

Page 9

FVR-C9S-7UX

Type (FVR _ _ _ C9S-7UX) F12 F25 F50 001 002

Applicable motor output

1

Frequency setting Key operation: Setting with UP/DOWN keys

Display Run mode Output frequency is displayed. (3 digit LED)

Acceleration/Deceleration time 0-60s (Variable setting) Acceleration time and deceleration

Control

Voltage frequency characteristics

Restart after momentary power failure "Automatic restart" setting makes it possible to keep motor

High Limiter & Low Limiter

Bias setting

Jump frequency

Torque boost

Starting torque [%] 150% for 60 seconds.

Braking torque

5

Braking DC brake Brake starting frequency: 3 Hz (fixed)

Overload Detects overload current and stops drive.

Momentary overcurrent Protects drive In case of ground fault (detects at start) and

Overvoltage Detects overvoltage of DC bus and stops drive.

Protection Overheating of cooling element Detects abnormal temp. rise of cooling element and stops drive.

Motor protection Protects standard 4-pole motor and forced-air cooled motor by

Alarm protection Outputs contact signal in case of a trip for protection

Installation location Indoor at an altitude of 3283 feet (1000m) or less and free of

Ambient temperature -10 to 50°C

Ambient humidity 20 -90% RH (There shall be no dew condensation)

Environment Vibration 19 feet/s

Storage temperature -25 to 65°C

Atmospheric pressure Operation/storage: min 900 mb (equivalent to 3283 feet (1000m)

Enclosure IP20

Cooling method Self-cooling (up to 1 Hp), forced-air cooling (2 Hp)

5) This indicates average braking torque of a single motor. (Value varies according to motor efficiency.

[Hp] 1/8 1/4 1/2 1 2

Potentiometer: Terminal for 1-5K ohm VR is provided

Analog signal: 0-5 VDC 0-10 VDC (resistance = 12k ohm)

4-20 mA (resistance = 250 ohm)

Fault mode Cause of fault is displayed.

Other LED comes on with charging voltage applied.

time can be set independently.

Setting of maximum frequency/base frequency is variable.

running and restart drive in case of a momentary power failure.

Upper limit and lower limit of frequency can be set.

Bias setting is possible with respect to analog frequency setting.

Three jump points and one jump width can be set.

Setting variable in 32 steps.

[%] 150% 1 min. 100% 1 min. 50% 1 min.

Setting of braking current / braking time is variable.

short circuit of output circuit.

means of electronic thermal overload relay.

(1c contact capacity: AC250V 0.3A cos = 0.3)

dust, corrosive gas and oil mist.

2

(5.9m/s2) or less

Vibration frequency: 5 - 55 Hz

Transport: min 660 mb (equivalent to 10720 feet (3265m)

C92-7-14

9

Page 10

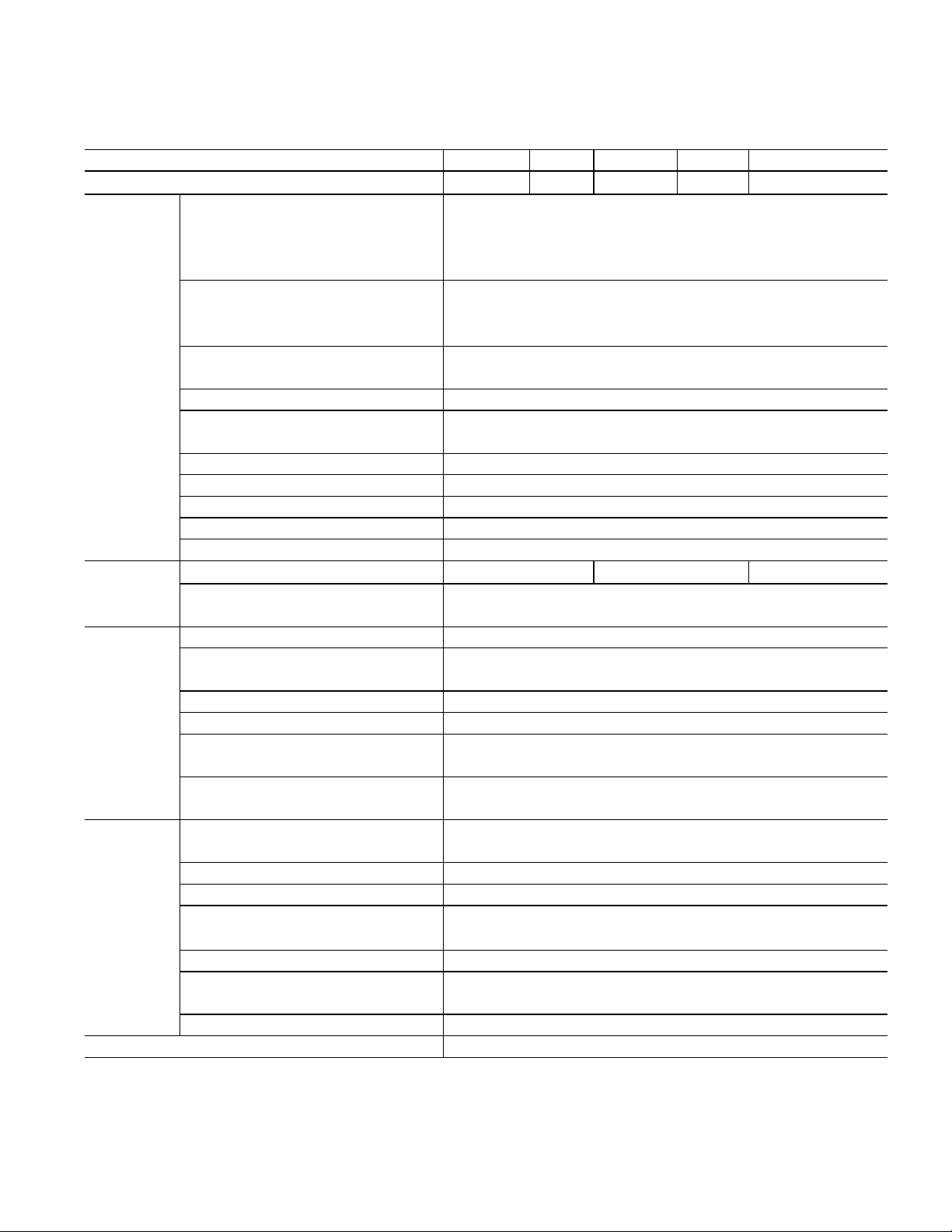

5. External Dimensions

FVR-C9S-7UX

0.24 (6.2) D

0.26 (6.5)

0.06 (1.5)

4.72 (120)

1.97 (50)2.76 (70)

3.15 (80)

2.64 (67)

2 - 0.20 X 0.24

(2 - 5 X 6.2)

0.43 (11)

0.26 (6.5)

0.06 (1.5)

0.20 (5)

4.33 (110)

0.20 (5)

D2

0.06 (1.5)

0.39 (10)

0.24 (6.2)

3.94 (100)

TERMINAL M3.5

0.39 (10)

D1

10

2.36 (50)0.39 (10) 0.39 (10)

DWG 1: FVRF12C9S-7UX to FVROO1C9S-7UX

Rated Current External Dimensions: inches (mm) DWG No.

Type [A] D D1 D2

FVRF12C9S-7UX 0.66 3.37 (85.5) 0.89 (22.5) 0.39 (10)

FVRF25C9S-7UX 1.2 3.56 (90.5) 1.08 (27.5) 0.59 (15) DWG 1

FVRF50C9S-7UX 2.1 3.96 (100.5) 1.48 (37.5) 0.98 (25)

FVR001C9S-7UX 3.7 5.53 (140.5) 2.46 (62.5) 1.97 (50)

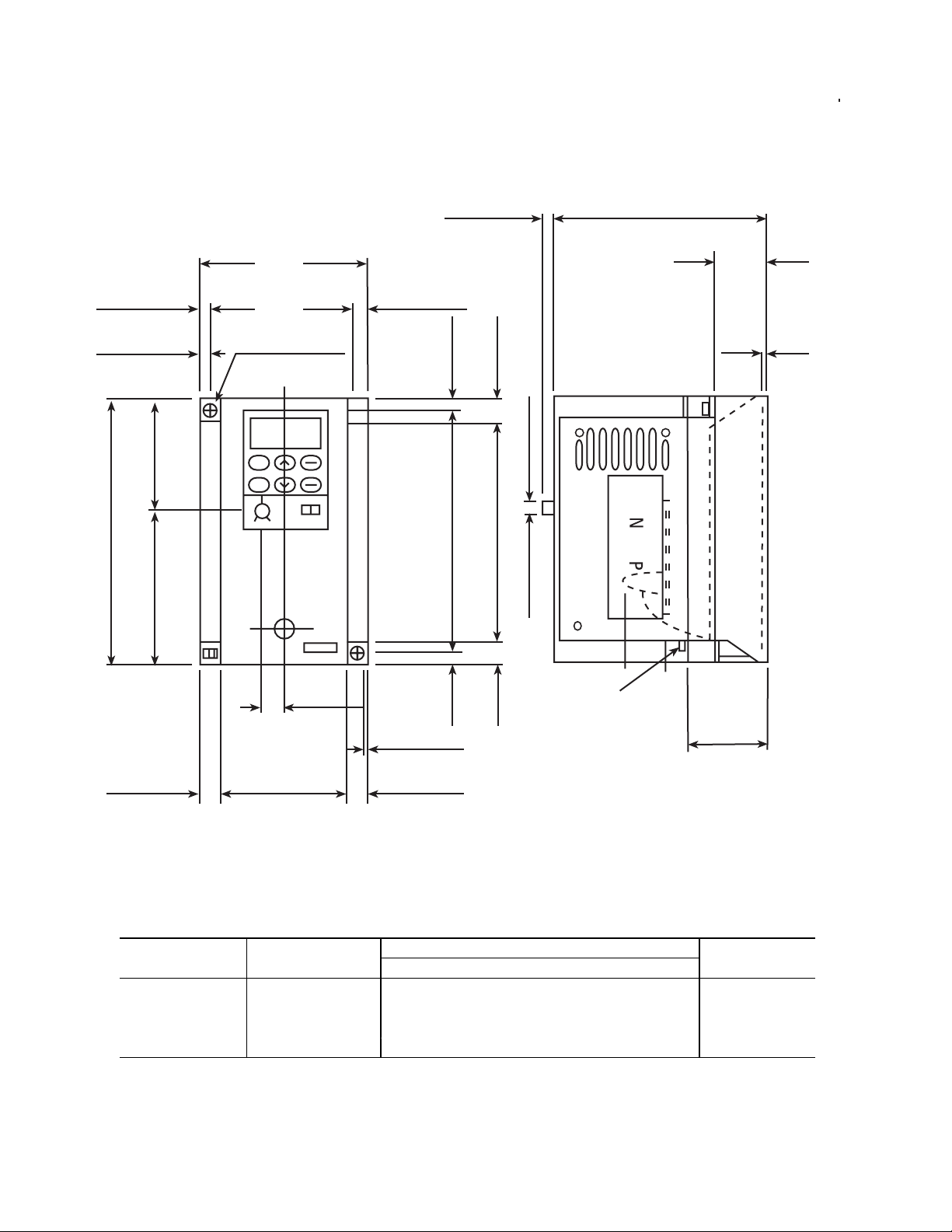

Page 11

4.33 (110)

FVR-C9S-7UX

0.24 (6.2) D

D2

0.24 (6.2)

2 - dia. 0.20

(2 - dia. 5)

5.12 (130)

1.97 (50)3.15 (80)

0.20 (5)

3.86 (98)

0.18 (4.5)

0.43 (11)

0.24 (6.2)

0.24 (6)

4.65 (118)

0.24 (6.2)

0.45 (11.5)

4.21 (107)

0.45 (11.5)

0.24 (6.2)

0.24 (6.2)

TERMINAL M3.5

D1

0.45 (11.5)

3.43 (87)

0.45 (11.5)

DWG 2: FVR002C9S-7UX

Rated Current External Dimensions: inches (mm) DWG No.

Type [A] D D1 D2

FVR002C9S-7UX 6.4 5.53 (140.5) 3.05 (77.5) 2.56 (65) DWG 2

7-'005

11

Page 12

FVR-C9S-7UX

6. Installation Instructions

Installation Conditions

Install the drive in a location which meets the

following requirements:

• The ambient temperature should be be-

tween -10°C and +50°C.

• Install the drive in the environment of

pollution degree 2. If environment is pollution degree 3 or 4, the drive should be

installed in a cabinet of IP54.

• Install the drive in the atmospheric pressure of 900mbar or more.

• Install the drive in the vibration of 232

inches/s2 (5.9m/s2) or less.

Mounting Direction and Space

3.94”

(10cm)

Mounting plate: Heat sink temperature will

reach +90°C during operation. Please use

thermostable material for drive mounting

plate.

Multi-mounting: When 2 or more drives are

installed within the drive switchboard, arrange them side by side, keeping space

(shown in the above figure) between each

drive. If the drives must be lined up vertically,

provide adequate ventilation so that the hot

air from each drive will not affect the one

above it.

7. Wiring

Perform wiring in accordance with the following procedure:

1) Remove the cover mounting screw at the

center of the cover.

0.394”

(1cm)

PRG

RESET

FUNC

DATA

CLOSED

FVR-C9S

OPEN

3.94”

(10cm)

RUN

STOP

0.394”

(1cm)

NOTICE: The durability and reliability of the

drive will be affected by the ambient temperature. Do not place the unit where ambient temperature is not proper.

Direction: Insert M4 size screws in the

mounting screw holes in the left upper and

right lower of the drive, and install the drive

with these screws. Install the drive vertically.

Horizontal or other positional installation will

cause the drive to overheat.

PRG

RESET

FUNC

DATA

CLOSED

Cover Mounting Screw

RUN

STOP

FVR-C9S

OPEN

2) Hold the lower end of the cover, lift it up

and remove the cover

2

1

Side view of inverter

12

Space: The drive will generate heat during

operation. Allow sufficient space around the

unit as shown in the above figure.

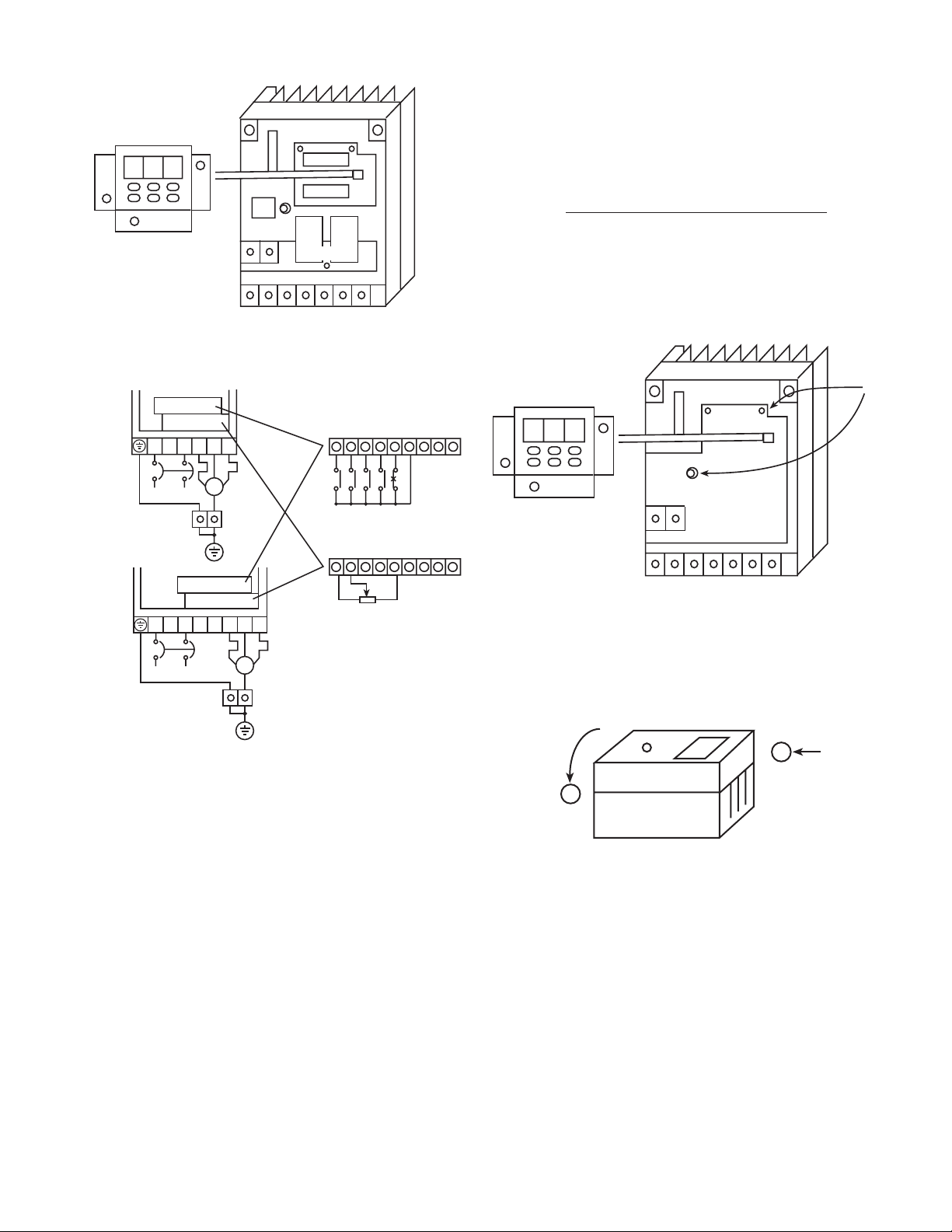

3) Remove the keypad panel from the main

unit, and disconnect the harness from the

CN2 at the same time.

Page 13

8. 8. 8.

Disconnect

CN 1

FVR-C9S-7UX

CN 2

Note 3) Connect the power supply of over

voltage category II. If the power

supply is over voltage category III,

place the devices to limit the over

voltage below 2.5kV.

Required for CE Certification.

4) Arrange the main circuit and the control

circuit wiring as follows.

L1

Power Supply

FVRF12C9S-7UX to FVR001C9S-7UX

L1 L2 U V W

Power Supply

FVR002C9S-7UX

L2 U V W

M

3-Phase

motor

Cabinet PE

terminals

M

Cabinet PE

3-Phase

motor

terminals

CRG Lamp

B

X

1

1

1

6

5) Reinstall the cover. Connect the harness

of the keypad panel to the CN2 on the main

unit, then reinstall the keypad panel fitting it

onto the guide pins.

Connect

R

R

F

T

3

S

E

W

HRC

T

V

D

3 5 7742

1

1

3

2

6 76

3

O

O

M

C

B

Note 1

3

O

F

A

M

Note 2

8. 8. 8.

CN 1

CN 2 CN 2

Guide Pin

6) As shown below, reinstall the cover onto

the drive main unit, and fix it with the mounting screw.

1. Motor coast-to-stop

2. Reset signal

3. Reverse-direction operation command

4. Forward-direction operation command

5. External alarm

6. Frequency setting VR

7. Combined alarm relay output

Note 1) FWD and THR are connected to CM

at the factory. In this condition,

starting/stopping can be performed

via RUN/STOP keys on the keypad

panel.

Note 2) In case of using an external potenti

ometer, remove the connector

which the keypad panel and the

CN2 on the drive main unit are

connected.

1

2

Side view of inverter

13

Page 14

FVR-C9S-7UX

8. Basic Wiring Diagram

1) Keypad Panel Operation

From the factory, the drive is set for frequency control by means of the potentiometer control

knob on the keypad panel. The RUN/STOP function of the drive is controlled by the RUN/

STOP keys on the keypad panel.

FAB

Power Supply

AC220 - 240V

50/60 Hz

1-phase

L1

L2

13

12

11

C1

FWD

REV

8 8 8

CN2

E(G)

Fault

U

V

W

M

★

PE

30A

30B

30C

14

RST

BX

CM

THR

FM

10V 1mA

* PE terminal blocks for the drive and motor should be provided in the cabinet in which the

drive is installed in.

Page 15

FVR-C9S-7UX

2) External Signal Operation

Ensure that the connection is as shown in the following diagram in case of operating the drive

by means of external frequency setting potentiometer or contact signal.

Power supply

AC220-240V

50/60Hz

1 Phase

Potentiometer for

frequency setting

Forward-direction operation command

Reverse-direction operation command

Motor coast-to-stop command

Alarm reset

FAB

E(G)

L1

L2

13

12

11

C1

FWD

REV

BX (X2)

RST

888

CN2

U

V

W

E(G)

Fault

Thermal Relay

M

x

★

PE

30A

30B

30C

External alarm input

Analog monitor

10V 1mA

CM

THR (X1)

FVR-C9S

FM

Note 1) Set function F02 to 1.

Note 2) In case of using an external frequency setting potentiometer, disconnect the potentiometer connector (CN2) from the keypad panel. Use of an external potentiometer together

with the potentiometer on the keypad panel may result in damage to the drive.

* PE terminal blocks for the drive and motor should be provided in the cabinet in which the

drive is installed in.

15

Page 16

FVR-C9S-7UX

CAUTION:

The control circuit terminal wiring should be

kept as far as possible from the main circuit

wiring to prevent operational error due to

noise interference. Never install them in the

same duct or conduit. (A separation distance

of 4 inches [10cm] or more is recommended.) If the control circuit wiring must

cross the main circuit wiring, make sure it

crosses at a right angle.

Use shielded, twisted wire for the control

circuit wiring , which should be as short as

possible (65 feet [20m] or less).

Install a surge absorber in parallel with any

magnet contactors, solenoids, relays or

timer coils, which are close to the drive.

Long wiring lengths between the motor and

the drive will result in increased capacitance

and leakage current. This may cause earlier

activation of such protective functions as:

overcurrent protection, overheating protection and electronic thermal overload, or the

error in current detection may become large.

To avoid these, adjust the length of wiring

between the drive and the motor so that is

does not exceed the length shown below.

FVRF12C9S-7UX : 165 feet (50m)

FVRF25 to 002C9S-7UX : 325 feet (100m)

9. Application of Wiring and Equipment

Applicable motor output [Hp] 1/8 1/4 1/2 1 2

Drive type FVRF12 FVRF25 FVRF50 FVRF001 FVRF002

C9S-7UX C9S-7UX C9S-7UX C9S-7UX C9S-7UX

Output rated capacity [kVA] 0.27 0.5 0.87 1.5 2.7

Applicable wire size Main circuit 14 12

(AWG) Contol circuit 24

MCCB 6 10 16 20

ELCB 6 10 16 20

Listed fuse* 20 30

* The use of quick-acting fuses is required to validate UL listing. The factory

recommendation is Bussman type JKS or equivalent.

C92-7-15

16

Page 17

FVR-C9S-7UX

10. Terminal Function Explanation

Terminal Function Explanation

Classi-

fication

Terminal Code Terminal Name Explanation of Function

Main

Circuit

Frequency

Setting

Control

Input

L1, L2

U, V, W

E (G) Drive Grounding Terminals

13

12 Frequency Setting Voltage Input DC 0 - +10V / 0 - 100% (Input resistance: 22K ohm)

11*

C1

FWD

REV

Commercial power supply input

terminals

Drive Output Terminals For connection of a 3-Phase motor

Power Supply for Frequency

Setting

Frequency Setting Common

Terminal

Frequency Setting

Current Input (+)

Forward/Stop Command Input

Terminal

Reverse/Stop Command Input

Terminal

For connection of 1-Phase 220 to 240V commercial power

supply

Grounding terminal of drive chassis (case). Be sure to ground

the drive to prevent electric shock or to lower noise

Used as a power supply for frequency setter (variable

resistor: 1 - 5K ohm) (DC + 10V, 10mA max)

Common terminal for frequency setting signals 12 and 13

DC4 to 20 mA / 0 to 100% (Input resistance: 250 ohm)

Forward-direction operation takes place when FWD-CM is

closed. Drive decelerates and stops when FWD-CM is

opened

Reverse-direction operation takes place when REV-CM is

closed. Drive decelerates and stops when REV-CM is opened

BX

THR External Alarm Input Terminal

RST Alarm Reset Terminal When RST-CM is closed, the drive fault is reset.

CM* Control Input Common Terminal Common terminal for control input signals

* Electric potential of 11 terminal is identical with that of CM terminal.

Motor Coast-to-Stop Input

Terminal

•Drive output is cut off instantly and motor will coast-tostop when BX-CM is closed. Alarm signal is not outputted.

•This functions as multistep frequency selection terminal X2

when changing function.

•When THR-CM is opened during operation, drive output is

cut (motor will coast-to-stop) and an alarm signal is

outputted. This signal is latched and reset by RST input.

•This functions as multistep frequency selection terminal X1

when changing functions.

C92-7-03

17

Page 18

FVR-C9S-7UX

Terminal Function Explanation cont.

Terminal Function Explanation

Classi-

fication

Output for

Motor

Terminal Code Terminal Name Explanation of Function

FM Analog Monitor

Outputs + 10VDC between FM and CM terminals. When

frquency setting is equal to the maximum frequency setting,

outputs + 10VDC at 150% current when monitoring output

current.

• Two DC voltmeters (internal resistance of 10K ohm or

greater) can be connected.

• In case of DC ammeter (1mA full scale), it is necessary to

add series resistance of 10K ohm (1/2W)

• This output is a pulse output constant frequency (38. 1 Hz)

which has a variable duty.

Contact

Output

30A, B, C

Combined Alarm Output

Terminals

Output via no volt signal (contact1c) to indicate that the

drive's protective function has been activated by an alarm.

• Contact capacity (DC48V. 0.3A)

C92-04

18

Page 19

FVR-C9S-7UX

11. Operation

Pre-Operation Inspection

• Check for wiring errors.

• Check that all loose wire stands, metal

chips and unnecessary screws, etc. have

been removed.

• Check that no screws, terminals, etc. are

loose.

• Check that the wire ends of crimp terminal

are not in contact with other terminals.

Test Run Check Points

• Smooth rotation and correct rotation

direction.

• No abnormal vibrations and noise from

the motor.

• Smooth acceleration and deceleration.

• The drive is shipped with a factory installed jumper, between FWD-CM. Only

forward operation is possible. To enable

reverse operation, remove the jumper

from FWD/CM and install the jumper

between REV-CM.

• RUN/STOP by terminal operation (F02 : 1)

Note: Open FWD and REV terminals when

changing F02 data. Data cannot be changed

if not open.

Frequency

Frequency Setting Method

• Frequency setting by potentiometer control (factory preset at the time of shipment; F01:1). As wired at the factory,

frequency setting can be performed by

turning the potentiometer control knob on

the keypad panel. Turn the potentiometer

control knob clockwise to increase frequency.

• Frequency setting by digital signal (F01 :

0). With the function F01 set to 0, frequency can be increased or decreased by

the

UP/DOWN) keys on the keypad panel.

UP: Frequency up

DOWN: Frequency down

RUN/STOP Method

• RUN/STOP by keypad panel operation

(Factory preset at the time of shipment

F02:0).

RUN

Frequency

FWD-CM

REV-CM

STOP

Forward

ON

Time

Reverse

ON

19

Page 20

FVR-C9S-7UX

g

g

Selecting Operation Method

With the FVR-C9S Series, the following

methods can be selected to input the

RUN/STOP signals and for frequency

setting.

RUN/STOP

Keypad panel

1

operation

RUN/STOP Keys

2

F

02= 0 F01= 1

Terminal operation

3

(operation by external

signal, FWD/REV

terminals)

4

F

02= 1 F01= 1

* The frequency setting rate of change increases when FUNC/DATA key and UP/DOWN keys

are pressed simultaneously

Frequency Settin

UP/DOWN Keys*

Analog signal (DC0 - 10V)

UP/DOWN Keys*

Analog signal (DC0 - 10V)

Function Code settin

F01= 0

F01= 0

C92-07

20

Page 21

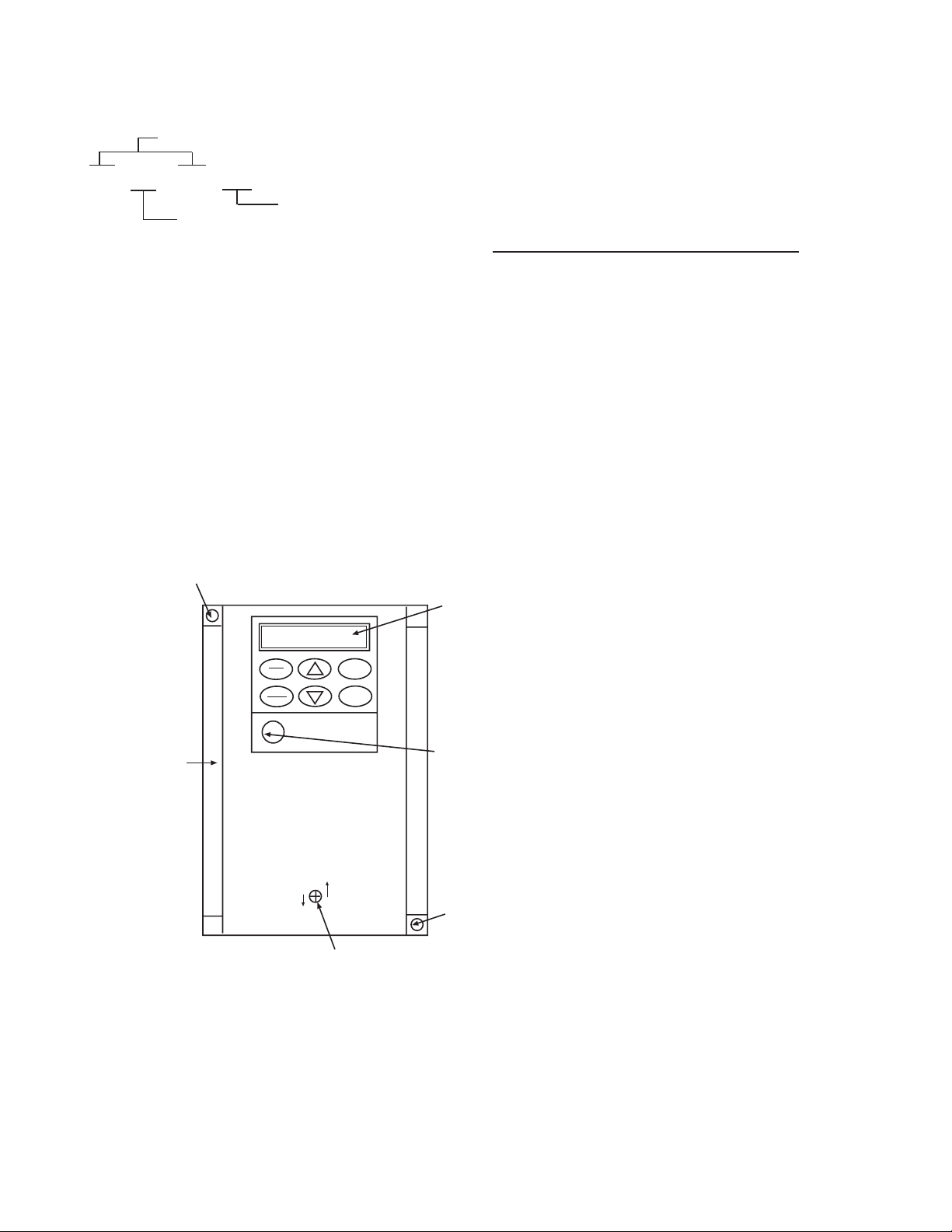

12. Keypad Panel

Part Names and Functions

FVR-C9S-7UX

Digital monitor:

In program mode, the keypad displays the various

function codes and data

values. During operation, it

displays the output frequency, current, voltage,

etc. If a fault occurs, the

causes of the problem will

be displayed as a code.

PROGRAM key (RESET

key): Normal mode or

program setting mode

select key. If a fault occurs,

this key is used to reset the

fault.

FUNCTION key (DATA key):

During normal mode, this key can be used to

change the display unit (frequency display

and output current display) while operation is

either stopped or running. During the program setting mode, this key can be used to

read and write the function codes and data.

8. 8. 8.

PRG

RESET

FUNC

DATA

RUN key: This key is used

for starting operation. The

LED (green) lights up during

operation. This key does

not function when terminal

operation control F02_ _ 1

RUN

is selected.

STOP

STOP key: This key is used

for stopping operation. This

FVR-C9S

UP/DOWN keys: These keys increase or

decrease the frequency. When unit is in

program setting mode, they change the

function code or data values.

key does not function when

terminal operation control

F02 _ _1 is selected.

Controlling Method for Keypad Panel

FUNC

1) Monitor change

During the normal mode, frequency display and

output current display can be changed by

pressing the FUNC/DATA key.

2) Run/Stop

When F02 is _ _ 0): Press RUN to run drive; press STOP to stop drive.

3) Frequency change

When F01 is _ _ 0: Press UP to increase frequency; press DOWN to decrease frequency.

Note) If FUNC/DATA is pressed while pressing UP or DOWN, frequency changing speed

increases.

4) Function setting method

6 0. 0

DATA

1. 2 A

FUNC

DATA

21

Page 22

FVR-C9S-7UX

Method Operation Procedure Display

1 PRG/RESET

2 UP/DOWN

3 FUNC/DATA

4 UP/DOWN

Press this key to switch to the

program setting mode.

Press UP key or DOWN key to

select function code

Press this key to display function

code.

Press UP key or DOWN key to

change function code data.

5 FUNC/DATA Press this key to store data.

6

Change other

function code

PRG/RESET

Press this key to cancel program

mode

60.0

F00

F01

1

1

F02

60.0

C92-06

22

Page 23

Function Code Tables

Function

Code

Function Date Code Range Unit

FVR-C9S-7UX

Min.

Set.

Factory

Setting

Change

During

Operation

F00 Data protection

F01

F02

F03

F04 Base Frequency 50 - 120 Hz Hz 1 60 Hz No

F05 Acceleration TIme 0.0 - 60s (0.0 setting = 0.01s) s 0.1 6.0s Yes

F06 Deceleration Time 0.0 - 60s (0.0 setting = 0.01s) s 0.1 6.0s Yes

F07 Torque Boost 0 - 31 (code) — — 13 Yes

F08

Frequency

Command

Operation

Command

Maximum

Frequency

Electronic Thermal

Overload Relay

Operation

0: Data change possible

1: Data change not possible

0: Keypad panel (UP/DOWN keys)

1: Analog input (VR, DC0 - 10V or DC4 - 20mA)

0: Keypad panel operation (RUN/STOP keys)

1: External signal operation (FWD/REV terminals)

50 - 120 Hz Hz 1 60 Hz No

0: Inactive

1: Active (standard 4-pole motor)

2: Active (forced-air cooled motor)

—— 0 No

—— 1 No

—— 0 No

—— 0 No

Electronic Thermal

F09

F10

F11

F12

F13 DC Brake (Time) 0.0 (inactive) 0.1 - 30s s 0.1 0.1s Yes

F14 Starting Frequency 1 - 6 Hz Hz 1 1 Hz No

Overload Relay

Level

Restart after

Momentary Power

Failure

Gain for Frequency

Setting Signal

DC Brake (Level

Setting)

30 - 105% of rated current of drive % 1 100% No

0: Inactive

1: Active (Restart drive in 0.5s after power failure)

0: For 0 - 10 V

1: For 0 - 5 V

0 - 100% — 1 50% Yes

—— 0 No

—— 0 No

C92-01

23

Page 24

Function Code Tables

Function

Code

Function Date Code Range Unit

FVR-C9S-7UX

Min.

Set.

Factory

Setting

Change

During

Operation

F15

F16 Fault Memory

F17 Data Initialization

F18 Retry

F19

F20

F21 Jump Frequency 1 0 - 120Hz Hz 1 0 Yes

F22 Jump Frequency 2 0 - 120 Hz Hz 1 0 Yes

F23 Jump Frequency 3 0 - 120 Hz Hz 1 0 Yes

F24 High Limiter 0 - 100% % 1 100 Yes

Motor Running

Sound

Motor

Characteristics

Jump Frequency

Range

0 - 5 (code) — — 5 Yes

The current and previous 3 fault events are displayed

in order of occurrence

0: Inactive

1: Reset to the initial value (value set at factory)

0: Inactive

1: Active (Retry times fixed at 5, Retry starts in

.05s after trip)

0 - 10 — — 4 Yes

0 - 10Hz Hz 1 3 Yes

—— — No

—— 0 No

—— 0 No

F25 Low Limiter 0 - 100% % 1 0 Yes

F26 Bias Setting 0 - 100% % 1 0 Yes

F27

F28

F29

F30

F31

F32 Meter Adjustment

F33

*1 Frequency can be set in increments of 0.1 Hz within a range of 0.0 to 99.9 Hz, and can be set in increments of 1 Hz

THR Terminal

Function

BX Terminal

Function

Multistep Speed

Setting 1

Multistep Speed

Setting 2

Multistep Speed

Setting 3

Meter Output

selection

0: External alarm input

1: Multistep speed selection (X1)

0: Motor coast-to-stop command input

1: Multistep speed selection (X2)

0.0 - 120 Hz Hz 1* 10.0 Hz Yes

0.0 - 120 Hz Hz 1* 20.0 Hz Yes

0.0 - 120 Hz Hz 1* 30.0 Hz Yes

0 - 99 (Full scale DC 6.5 - 10.5V)

0: Output frequency monitor

1: Output current monitor

—— 0 No

—— 0 No

— 1 85 Yes

— 1 0 Yes

C92-02

24

Page 25

FVR-C9S-7UX

Base

frequency

V

1

Maximum

voltage

Detailed Explanation of Each Function Code

F 0 0 Data Protection

The set data can be locked so that it will not be changed by mistake.

0 Data change possible

1 Data change not possible

To change data simultaneously press the STOP key and either the UP/DOWN key.

F 0 1 Frequency Command

Either of the following two frequency setting methods can be selected.

0 Keypad panel setting (UP/DOWN keys)

1 Analog input (setting by volume control, 0 -10VDC or 4 - 20mA)

F 0 2 Operation Command

Either of the following two control methods can be selected.

0 Keypad panel operation (RUN/STOP keys)

1 External signal operation (FWD/REV keys)

F 0 3 Maximum Frequency

Sets the maximum value for the output frequency

50

120

Multipurpose motors and other motors which are designed to operate at

low speed can be damaged if operated at high frequency. Be sure to set the

frequency to match the characteristics of the motor.

F 0 4 Base Frequency

Sets the base frequency (the frequency which is the divergent point of the specified torque characteristics

and the specified output characteristics).

50

120

Frequency can be set in increments of 1 Hz within a range of 50 to 120 Hz

Frequency can be set in increments of 1 Hz within a range of 50 to 120 Hz

V

1

Maximum

frequency

— Set to match the characteristics of the motor.

—

Although the base frequency may exceed the maximum

frequency, in that case the voltage will be decreased accordingly.

F 0 5 Acceleration Time

F 0 6 Deceleration Time

0. 0

60.0

Note: 0.0s setting is taken for 0.01s for acceleration and 0.1s for deceleration.

The time required to reach the maximum output frequency can be set within a range of

0.0s to 60s (in increments of 0.1s).

25

Page 26

FVR-C9S-7UX

F 0 7 Torque Boost

Can be set from among 32 different levels in accordance with the type of load, the

characteristics of the motor, etc.

0

For a reduced torque load (fan, pump, etc.)

1

2 Low

Output

voltage

High

3 1 High

8 Set to match this when using a Fuji FV motor designed for use with a drive.

F 0 8 Electronic Thermal Overload Relay

Either of the following two can be selected.

0 Inactive

1 Active (electronic thermal overload relay protection) For a standard 4-pole motor

2 Active (electronic thermal overload relay protection) For a Fuji FV motor

F 0 9 Electronic Thermal Overload Relay Level

Sets the operation level for the electronic thermal overload relay.

30

105

Setting value (%) = K X X 100

Setting range: 30 to 105% (increments of 1%)

Motor's rated current

Drive's rated current

Low

Output frequency f

26

Drive Capacity Wiring Length : feet

0 130 165 325 655

F12C9S-7UX K = 1.2 External thermal OL relay is recommended

F25C9S-7UX K = 1 K = 1.1 K = 1.2

F50C9S-7UX K = 1 K = 1.1

001C9S-7UX K = 1

002C9S-7UX

C97-10

Page 27

FVR-C9S-7UX

Derating characteristics for the continuously allowable current

1) For a standard 4-pole motor _ _ 1 2) for a forced-air cooled motor _ _ 2

110 -

100 -

90 80 70 60 50 40 30 20 10 -

0 -

Continuously allowable current

0 10 20 30 40 50 60 70 8 0

Setting value

Drive frequency (Hz)

105%

30%

110 -

100 -

90 80 70 60 50 40 30 20 10 -

0 -

Continuously allowable current

0 10 20 30 40 50 60 70 8 0

Setting value

Drive frequency (Hz)

105%

30%

27

Page 28

FVR-C9S-7UX

Drive Model F12 F25 F50 001 002

Time(s) 0.7 0.7 1.4 1.4 4.0

F 1 0 Restart After Momentary Power Failure

It is possible to select whether or not to restart operation when power supply is resumed after

momentary power failure.

0 Inactive While stopped: Stopped condition is maintained even after power supply

has been restored.

While running: After power supply has been restored. LU is lit and an alarm

is outputted.

1 Active Operation is restarted in 0.5s after power supply has been restored.

(When drive is stopped, it is maintained in the stopped condition even after

power supply has been restored).

This is valid only if power supply is restored while LU is lit. The length of

time that LU will remain lit after a power failure occurs is as follows.

F 1 1 Gain for Frequency Setting Signal

Outputs a frequency which is a proportional ratio of the analog frequency setting.

Selects an analog input signal level when F O 1 is _ _ 1.

0 Maximum frequency is outputted at 10V

1 Maximum frequency is outputted at 5V

When used together with the frequency setting bias,

this frequency setting gain takes priority, and the

bias applied to the frequency after the gain has

been applied.

100%

1

Frequency setting

5V 10V

Analog input

F 1 2 DC Brake

The current level of DC brake can be set.

Taking the rated current of the drive as 100%, this current level can be set in increments of 1%.

F 1 3 DC Brake (Braking Time)

The DC braking time can be set.

0.0 Inactive

0.1 - 30.0 Braking time can be set within a

range of 0.1 to 30s (in increments of 0.1s)

0

28

Output

frequency

3 Hz

Output

voltage

Time

1 DC braking

Page 29

FVR-C9S-7UX

F 1 4 Starting Frequency

The starting frequency can be set in increments of 1 Hz within a range of 1 to 6 Hz. Note that stopping will

also occur at the frequency set by this function.

1 1 Hz

6 6 Hz

Set to 2 Hz when using a high speed motor.

F 1 5 Motor Running Sound

The sound of the motor operation can be changed by changing the carrier frequency.

0

Select from among 5 levels in accordance with the usage conditions.

5

Data code

0 Low carrier frequency

5 High carrier frequency (low noise)

Output

frequency

Starting

frequency

1

F 1 6 Fault Memory

The current and previous 3 fault events are stored in memory.

The data for each can be displayed by using the DOWN key.

The procedure for displaying the data is as follows:

No. Procedure

1

Press FUNC/DATA Key

2

Press DOWN Key

3

Press DOWN Key

4

Press DOWN Key

5

Press DOWN Key

6

Display

F16 F16

Press UP Key

F01

Press UP Key

OH2

Press UP Key

OC1

Press UP Key

---

End

Display

(ex) Remarks

The information for the latest

trip will be displayed

The information for the first

preceding trip will be displayed

The information for the second

preceding trip will be displayed

The information for the third

preceding trip will be displayed.

(in this example, there is no

history of a third preceding trip).

C92-12

The information for any new trip will be stored in the area for the "information for the latest trip" shown

above, each trip history will be removed downward and the "information for the third preceding trip"

will be erased.

29

Page 30

FVR-C9S-7UX

F 1 7 Data Initialization

Reset the data for all of the functions to the value set at the factory.

0

Inactive

1

Resets to the value set at the factory.

From the _ _ 0 display, by simultaneously pressing STOP and UP, the display will change to _ _ 1.

By pressing FUNC/DATA in this state, the data will be reset to the value set at the factory, and the mode

will automatically change to the 6 0. 0 frequency display mode.

F 1 8 Retry

The number of times of retry for automatic restart after the drive has been tripped can be set.

0

The number of retry times is fixed at 5. Retry takes place in 0.5s after trip

1

Note that the retry takes place only in the case where the drive is tripped due to overcurrent or

overvoltage applied during operation.

F 1 9 Motor Characteristics

Used to compensate for output current instability.

F 2 0 Jump Frequency Range

F 2 1 Jump Frequency 1

F 2 2 Jump Frequency 2

F 2 3 Jump Frequency 3

Frequency is jumped so that the mechanical common point of load and the output frequency of drive do not

coincide with each other.

Jump

Width

Output

frequency

50X

50X

Jump frequency 1

Jump frequency 2

Jump frequency 3

30

Set frequency

Jump width is changeable within

0-10 Hz range in a unit of 1 Hz.

Page 31

FVR-C9S-7UX

F 2 4 High Limiter

F 2 5 Low Limiter

The upper and lower and lower limits of the output frequency can be set.

0

Set as a percentage of the maximum frequency in increments of 1% within a range of 0 to 100%

100

If the value set for low limiter is higher than that set for the

high limiter, the high limiter will take priority and the low

limiter will be ignored. Thus, operation will always be in

accordance with the high limiter value regardless of the

frequency setting.

F 2 6 Bias Frequency

Outputs a bias frequency with respect to the analog frequency setting.

0

Set as a percentage of the maximum frequency in increments of 1% within a range of 0 to 100%

100

100%

100%

Output

frequency

High

limiter

Low limiter

100%

Frequency

setting

Output

frequency

Bias

Frequency

setting

100%

F 2 7 THR Terminal Function

This function enables terminal THR to be used for two different functions by changing the data

code as follows:

0

External alarm input

1

Multistep speed selection (X1)

This function data cannot be changed during operation. (Possible to change only in STOP mode).

F 2 8 BX Terminal Function

This function enables terminal BX to be used for two different functions by changing the data code as follows:

0

Motor coast-to-stop command input

1

Multistep speed selection (X2)

This function data cannot be changed during operation. (Possible to change only in STOP mode).

31

Page 32

FVR-C9S-7UX

F 2 9 Multistep Speed Setting 1 (Speed 1)

F 3 0 Multistep Speed Setting 2 (Speed 2)

F 3 1 Multistep Speed Setting 3 (Speed 3)

Multistep speeds can be set within a range of 0 to 120 Hz only by changing the contact signal from outside.

(X1-CM X2-CM). Setting of speed of optional step is possible within a range of 0 to 120 Hz during drive

operation

(Note1) X1 or X2 terminal is selected via THR/BX terminal function change (F27, F28)

(Note 2) In selecting THR/BX terminal function (F27, F28) individual setting is possible.

Terminal / Function Code F27 : 1 F27: 0 F27: 1 F27: 0

F28: 0 F28: 1 F28: 1 F28: 0

THR X1 External Alarm input X1 External alarm imput

BX

Speed 0 Frequency setting is made by either the analog signal or the keypad panel.

Motor coast-to-stop

command imput

X2 X2

Speed 1

Speed 2

Speed 3

Speed 0

Motor coast-to-stop

command imput

C92-09

32

THR-CM (X1)

BX-CM (X2)

FWD-CM

ON

Time

ON

ON

ON

Page 33

FVR-C9S-7UX

F 3 2 FM Terminal Output Level Calibration

Adjust the level of the voltage output to terminal FM for the frequency meter.

0

Approximate DC 6.5V at full scale

99

Note: The FM terminal output is a pulse output of which frequency is constant (38.1 Hz) and duty is variable.

F 3 3 FM Terminal Function Selection

With regard to the data outputted to the FM terminal, either the output frequency or the output current

can be selected.

Approximate DC 10.3V at full scale

0

Output frequency

1

Output current

FM

CM

33

Page 34

14. Protective Functions

FVR-C9S-7UX

Function

Momentary

Overcurrent

Protection

Overvoltage

Protection

Undervoltage

Protection

Protection against

overheating of

cooling element

External Alarm Input

Electronic Thermal

Overload

Drive Overload Detects overload of drive and stops drive. OLU Yes

Stops drive to protect it against overcurrent .

OC1 = During acceleration

OC2 = During deceleration

OC3 = During constant speed operation

Detects overvoltage of DC intermediate circuit and stops drive. OU Yes

Detects undervoltage of DC intermediate circuit and stops drive. LU Yes*

Detects abnormal temperature rise of cooling element and stops drive OH1 Yes

Stops drive by input of an external signal. OH2 Yes

Detects overload of motor and stops drive. OL Yes

Explanation

Display

OC1

OC2

OC3

Alarm Output

Yes

Memory Error Stops drive in case of memory error Er1 Yes

CPU Error Stops drive in case of a CPU error Er3 Yes

* This output is selectable by F10

C92-05

34

Page 35

FVR-C9S-7UX

15. Warranty Parts and Service

The purpose of the following section to

provide specific instructions to the user of

the FVR-C9S-7UX drive regarding warranty

administration and how to obtain assistance

on both in-warranty and out-of-warranty

equipment.

If assistance is required to determine warranty status call:

Technical Services

GE Fuji Drives USA, Inc.

1-540-387-5739

24-hour Emergency 1-540-387-8292

Warranty Coverage

The warranty set forth in Section 1 of

FN-1090 (1/91) of GE’s Condition of Sale

covers all major parts of the drive such as

the main printed circuit boards, transistor

modules, etc. The warranty covers replacement of the entire drive.

“Warranty period is 12 months after installation or 18 months after shipment from the

Company, whichever occurs first.”

Before calling the number at left to determine warranty status, the drive serial number

will be required. This is located on the drive

nameplate. If the drive is still under warranty,

further information will be required per the

“In-Warranty Failure Checklist” shown on

page 36 of this instruction book.

Out-of-Warranty Procedures

If a defective drive is out-of-warrant contact

an Authorized GE Fuji Service Provider for

repair or an Authorized GE Fuji Distributor

for replacement.

Motors

Repairs on motors are generally handled by

the motor manufacturer. For specific instructions on your motor, call the distributor from

which it was purchased and be prepared to

furnish complete nameplate data.

35

Page 36

FVR-C9S-7UX

In-Warranty Failure Checklist

To assist with warranty troubleshooting, the following information is required. This data is needed to evaluate

the cause in an effort to eliminate any further failures.

Model No.:

Serial No.:

Start-Up Date:

Failure Date:

Status When Failure Occurred (check one):

Power-Up Running Accel Decel

Explanation of Failure:

Application Information (check Yes or No)

Input Transformer: Yes No

If Yes: KVA

L1 Volts L2 Volts L3 Volts

Power Factor Correction Capacitors: Yes No

If Yes: Microfarad

Other Equipment on Same Power Yes No

If Yes, what?

Line Reactor on Input Yes No

Input Starter Yes No

Output Starter Yes No

Motor Overloads Yes No

Control Terminals Used (circle if used)

THR X1 X2 X3 30A 30B 30C

RST/BX FWD REV C1 11 12 13

RUN RT1

Function Codes Different From Factory Settings

Function Code Setting Function Code Setting

36

Failure Message (see Section 5)

Latest Fault Previous Faults: No Message

Hz 1.

A2.

V3.

After all of the Checklist information is acquired, contact the following Service Center number for assistance:

540-387-5739 (8am - 5pm Central Standard time Monday thru Friday).

540-387-8292 (24-hour emergency)

When you return the unit for warranty you need to get a RMA number from your Service Center.

Page 37

FVR-C9S-7UX

16. Electromagnetic Compatibility (EMC)

1. General

In accordance with the provisions described

in the European Commission Guidelines

Document on Council Directive 89/336/EEC,

Fuji Electric Co., Ltd. has chosen to classify

the FVR-C9S-7UX range of drives as “Complex Components”. Classification as “Complex Components” allows a product to be

treated as “apparatus”, and thus permits

compliance with the essential requirements

of the EMC Directive to be demonstrated to

both an integrator of FVR drives and to his

customer or the installer user. FVR drives up

to 2 Hp are supplied “CE-marked”, signifying

compliance with EC Directive 89/336/EEC

when fitted with specified filter units installed

and earthed in accordance with this sheet.

This specification requires the following

performance criteria to be met.

Immunity : EN50082-2

Emissions : EN50081-1

2. RFI Filters

It is strongly recommended that the appropriate FVR input filter is used, as shown in

the followings, to limit RF current flowing

into the main supply circuit. Without an input

filter a FVR installation may not meet statutory requirement. FVR drives contain high

power semi-conductor devices which are

switched at high speeds to synthesis a nearsinusoidal current waveform across the

frequency range of the output. Rapidlychanging voltages and currents will generate

some degree of electromagnetic emission.

Emissions will be predominantly conducted

through the motor and the mains supply

cables, although some radiated emissions

will be detected in close proximity to the

drive system. It is essential that precautions

are taken both at the design stage and at the

time of installation to prevent radio frequency interference (RFI) from the drive

system affecting sensitive equipment in

close proximity.

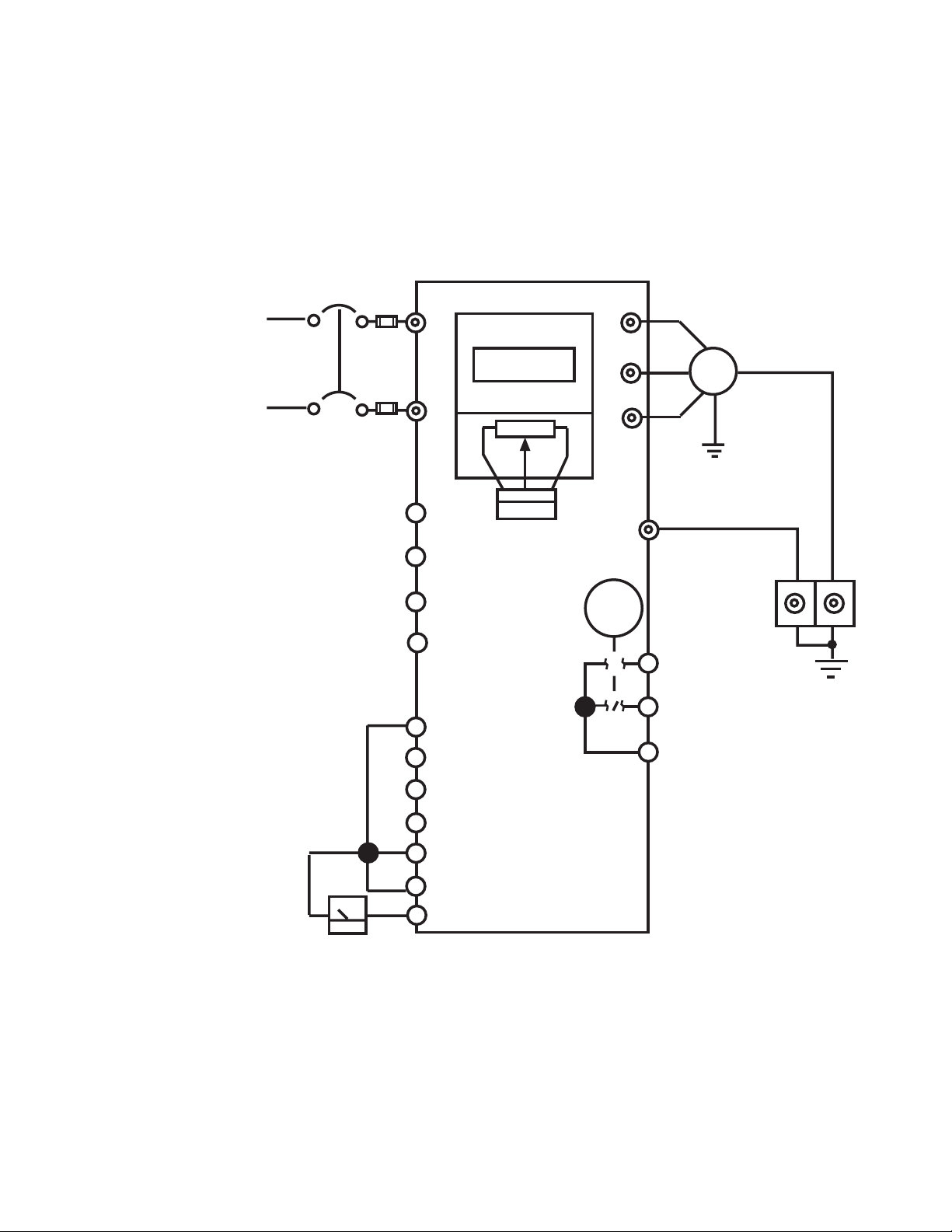

3. Recommended Installation Instructions

It is necessary that to conform to the EMC

Directive, these instructions must be followed. Follow the usual safety procedures

when working with electrical equipment. All

electrical connections to the filter, drive and

motor must be made by a qualified electrical

technician.

1) Check the filter rating label to ensure that

the current, voltage rating and part number

are correct.

2) The back panel of the wiring cabinet of

board should be prepared for the mounting

dimensions of the filter. Care should be

taken to remove any paint etc. from the

mounting holes and face area around the

hole of the panel. This will ensure the best

possible earthing of the filter.

3) The filter should then be securely

mounted in position, and the drive mounted

to the front of the filter with the screws

provided.

4) Connect the incoming mains supply to the

filter terminals marked “LINE” and earth any

cables to the earth stud provided. And fit the

Input Ferrite Ring (if required two ferrite

rings, refer to table 1), then connect the filter

terminals marked “LOAD” to the mains input

of the drive using short length of appropriate

gauge wire.

5) Fit the Output Ferrite Ring as close to the

drive as possible and connect the motor.

Armored or screened cable should be used

with the 3 phase conductors only passing

twice through the center of the Output Ferrite Ring. The earth conductor should be

securely earthed at both drive and motor

ends. The screen should be connected to

enclosure.

37

Page 38

FVR-C9S-7UX

6) It is important that all lead length are kept

as short as possible and that incoming

mains and outgoing motor cables are kept

well separated.

7) Segregate power cables from control

wiring as possible as you can, and avoid

parallel cable runs to minimize “noise coupling”. Wherever runs of power and control

cable must cross, try to achieve this at right

angles.

Mains input

terminals

Earth Stud

L

8) FVR drives should be installed, and are

designed to operate, within an electrically

shielded metal enclosure.

The RFI filters range are designed especially

for the FVR drive and help to ensure EMC

compliance of machinery an installations

using the drives. The drives may be mounted

on top of the filter using the integral fixing

positions, the intention being that valuable

space inside wiring cabinets may be saved.

(Refer to Fig. 1 and Table 1)

N

LINE

Drive fixing

positions

L’

LOAD

Y

N’

L

Earth Stud

Load terminals

to drive

input

X

Fig. 1 RFI Filters

H

W

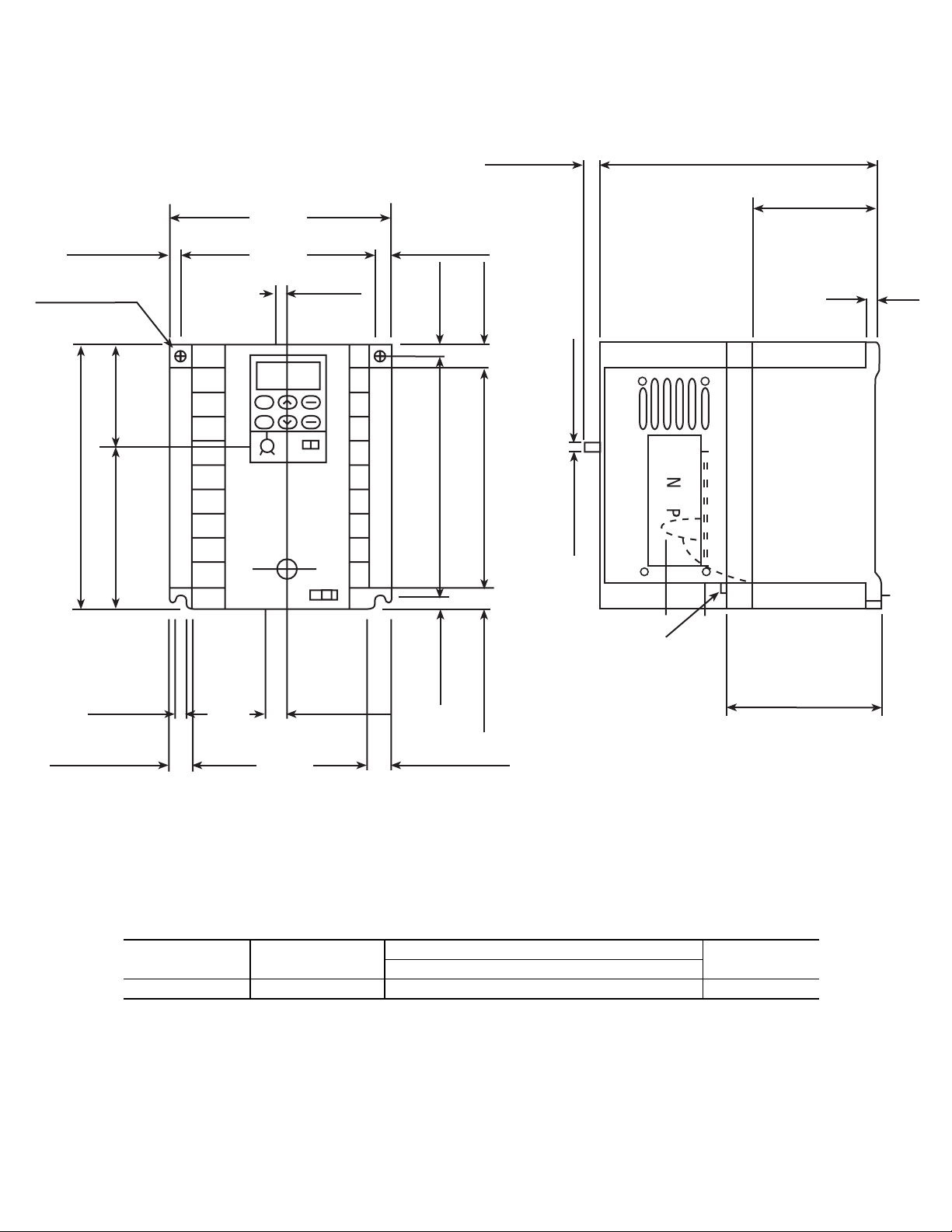

Table 1 RFI Filter Dimensions Conforms to EN55011 Class B

Filter Applied Rated Max Rated Dimensions inches Drive Sub

Part No. Drive Current Voltage L x W x H X Y Fixings Filters

EFL-0.2C9-7 FVRF12C9S-7UX 3A 6.69 x 3.35 x 1.38 1.97 6.1 M4 0.16 Ferrite

FVRF25C9S-7UX x0.63 (2pcs.) OC1x (1 pcs.)

EFL-0.75C9-7 FVRF50C9S-7UX 10A 1-Phase 6.69 x 3.35 x 1.38 1.97 6.10 M4 0.16

FVR001C9S-7UX 240 VAC x0.63 (2 pcs.)

EFL-2.2C9-7 FVR002C9S-7UX 16A 7.09 x 4.53 x 1.38 3.50 6.50 M4 0.16 Ferrite

x0.63 (4 pcs.) OC2x (1 pcs.)

7-'006

38

Page 39

Basic Standards: EN55011 Class B

FVR-C9S-7UX

Input

Single

contactor

Enclosure

phase

50/60 Hz

power

supply

HRC Fuses

or circuit

breaker

Noise filter

(foot mounted)

L

L’

Ferrite ring

Drive

L1

1 turn

U

Screen

V

N

N’

L2

W

PE

*2

*1

Screening must be electrically continuous and earthed at the enclosure and the motor.

E

*1and *2: These connections are to be as short as possible and earth conductor should

be as thick as possible.

39

Page 40

Power supply

single-phase

220-240V

50/60 HZ

FVR-C9S-7UX

RFI

FILTER

L

N

PE

Alarm Signal

L’

N’

L1

L2

30C

30B

30A

U

V

W

Ferrite

ring

Enclosure

Housing

Motor

M

E

Armored or

screened cable

Frequency

setting

Potentiometer

Analog

frequency

meter

3

2

1

[13]

[12]

[11]

(CM)

(FWD)

(REV)

(THR)

(EX)

[FM]

(RST)

[CM]

Fig. 3 Recommended installation detail inside the enclosure

Control

input

40

Page 41

FVR-C9S-7UX

41

Page 42

FVR-C9S-7UX

17. EC Declaration of Conformity

We Fuji Electric Co., Ltd. Suzuka Factory

5520 Minami tamagaki-cho Suzuka-city Mie-ken JAPAN

declare under our sole responsibility that the following products

Product identification

• Product : Inverter

• Brand : Fuji Electric

• Model/Type : FVRO.1C9S-7xxx to FVR1.5C9S-7xxx

(xxx stands for A to Z)

to which this declaration relates is in conformity with the EMC requirements of the following

standard(s):-

Immunity : EN50082-2 “Generic immunity standard

Part 2 (Industrial Environment)”

Emission : EN50081-1 “Generic emission standard

Part 1 (residential, commercial and light industrial)”

and conforms to the protection requirements of Council Directive :-

89/366/EEC

relating to Electromagnetic Compatibility.

When : Wired and earthed in accordance with the installation instructions. Installed

within a steel enclosure. Used in conjunction with power input filter and ferrite

rings which are recommended by Fuji Electric.

A. OKUBO

General Manager

Inverter Design Department

Suzuka Factory

42

Dated: November 20, 1997

Page 43

FVR-C9S-7UX

EC Declaration of Conformity

We Fuji Electric Co., Ltd. Suzuka Factory

5520 Minami tamagaki-cho Suzuka-city Mie-ken JAPAN

declare under our sole responsibility that the following products

Product Identification

• Product : Inverter

• Brand : Fuji Electric

• Model/Type : FVRO.1C9S-7xxx to FVR1.5C9S-7xxx

(xxx stands for A to Z)

to which this declaration relates is in conformity with the low voltage requirements of the

following standard(s) :

DIN VDEO160/1988

Category : Overvoltage category II/Pollution degree 2 and conforms to the protection

requirements of Council Directive :

73/23/EEC relating to Low Voltage.

When : Wired and earthed in accordance with the installation instructions. Installed

within a steel enclosure satisfied “Pollution degree 2”. Used in conjunction with

1AC power supply (Line) whose line is earthed for -7xxx series.

A. OKUBO

General Manager

Inverter Design Department

Suzuka Factory

Dated: November 20, 1997

43

Page 44

FVR-C9S-7UX

44

GE Fuji Drives USA, Inc.

1501 Roanoke Blvd. Suite 435

Salem, VA 24153

1-800-543-6196

Internet Address: http://www.ge.com

INR Si47-0459 b-E Printed in Japan

Loading...

Loading...