Page 1

Installation

Built-In

Dishwasher

Instructions

If you have questions, call 800-GECARES or visit our website at: www.GEAppliances.com

READ CAREFULLY.

KEEP THESE INSTRUCTIONS.

PDW8100 Series

PDW8200 Series

PDW8500 Series

PDW8600 Series

PDW8700 Series

Page 2

Installation Preparation

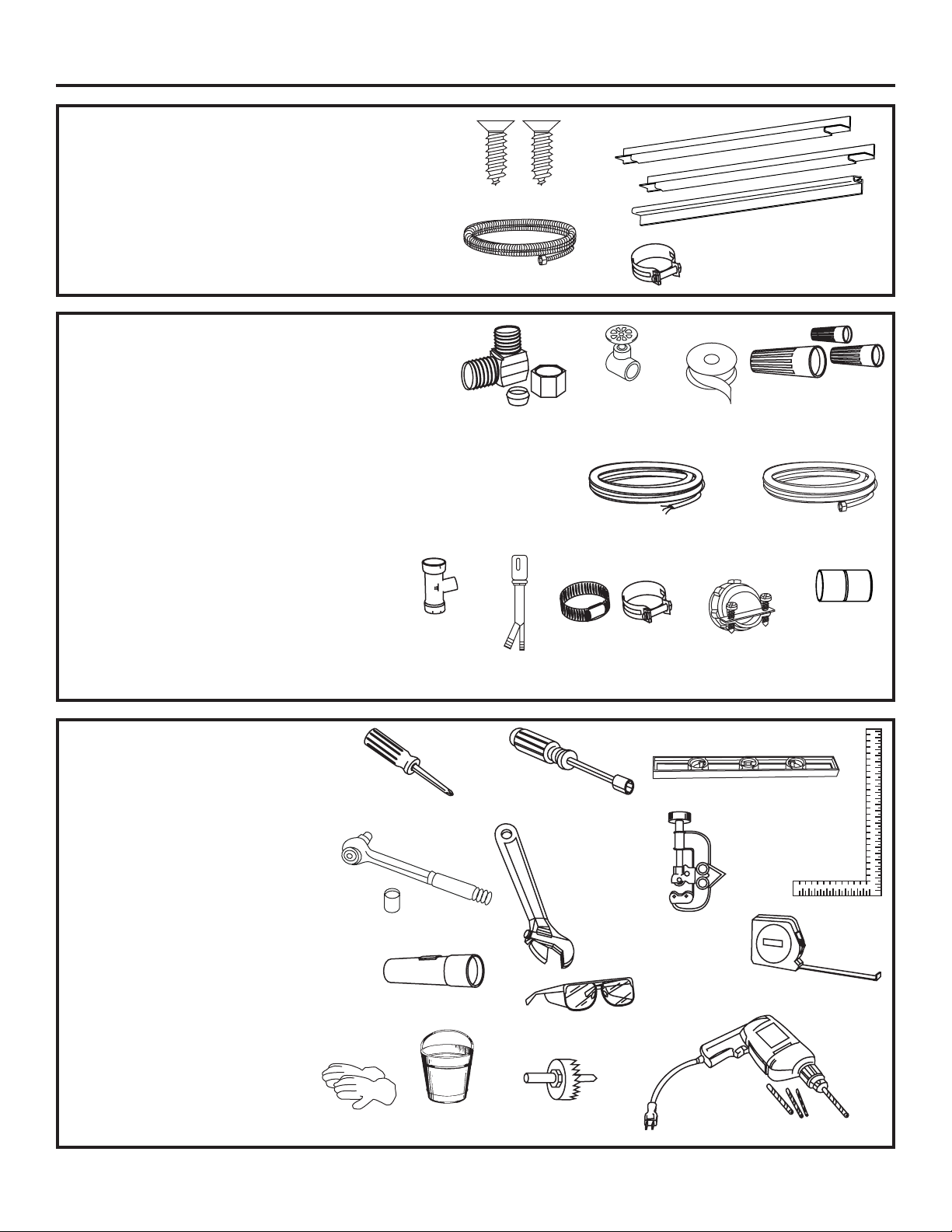

PARTS SUPPLIED:

Two #8 Phillips flat head wood screws, 5/8" long to

secure dishwasher to underside of countertop or

sides of cabinetry. (Taped to top or side of dishwasher.)

Side and top trim pieces

Trim Panel Accessory Kit (not shown).

Model PDW9700 only

Drain Hose and Hose Clamp

MATERIALS YOU WILL NEED :

Ferrule, compression nut and 90° Elbow (3/8"NPT external

thread on one end, opposite end sized to fit water supply)

Thread seal tape

UL Listed wire nuts (3)

Materials For New Installations Only:

Air gap for drain hose, if required

Waste tee for house plumbing, if applicable

Electrical cable or power cord, if applicable

Screw type hose clamps

Strain relief for electrical connection.

Hand shut-off valve

Water line 3/8" min. copper

Coupler for extending drain line, if applicable

Waste Tee

2 Wood Screws

Drain Hose

90° Elbow,

Ferrule and

Compression Nut

Air Gap

Hose Clamp

Hand

Shut-Off

Valve

Electrical Cable

(or Power Cord, if applicable)

Screw Type

Hose Clamps

Thread

Seal Tape

Strain Relief

Trim Pieces

(some models)

Wire Nuts (3)

Hot Water line

Coupler

TOOLS YOU WILL NEED:

Phillips head screwdriver

5/16" and 1/4" nutdriver

6" Adjustable wrench

Level

Carpenters square

Measuring tape

Safety glasses

Flashlight

Bucket to catch water when flushing the line

15/16" socket (optional for skid removal)

Gloves

For New Installations Only:

Tubing cutter

Drill and appropriate bits

Hole saw set

Phillips

Head

Screwdriver

15/16" Socket

Gloves

Flashlight

Bucket

2

1/4"

and 5/16"

Nutdriver

Safety Glasses

Hole Saw Set

6" Adjustable

Wrench

Level

Carpenters

Square

Tubing Cutter

Measuring Tape

Drill and Bits

Page 3

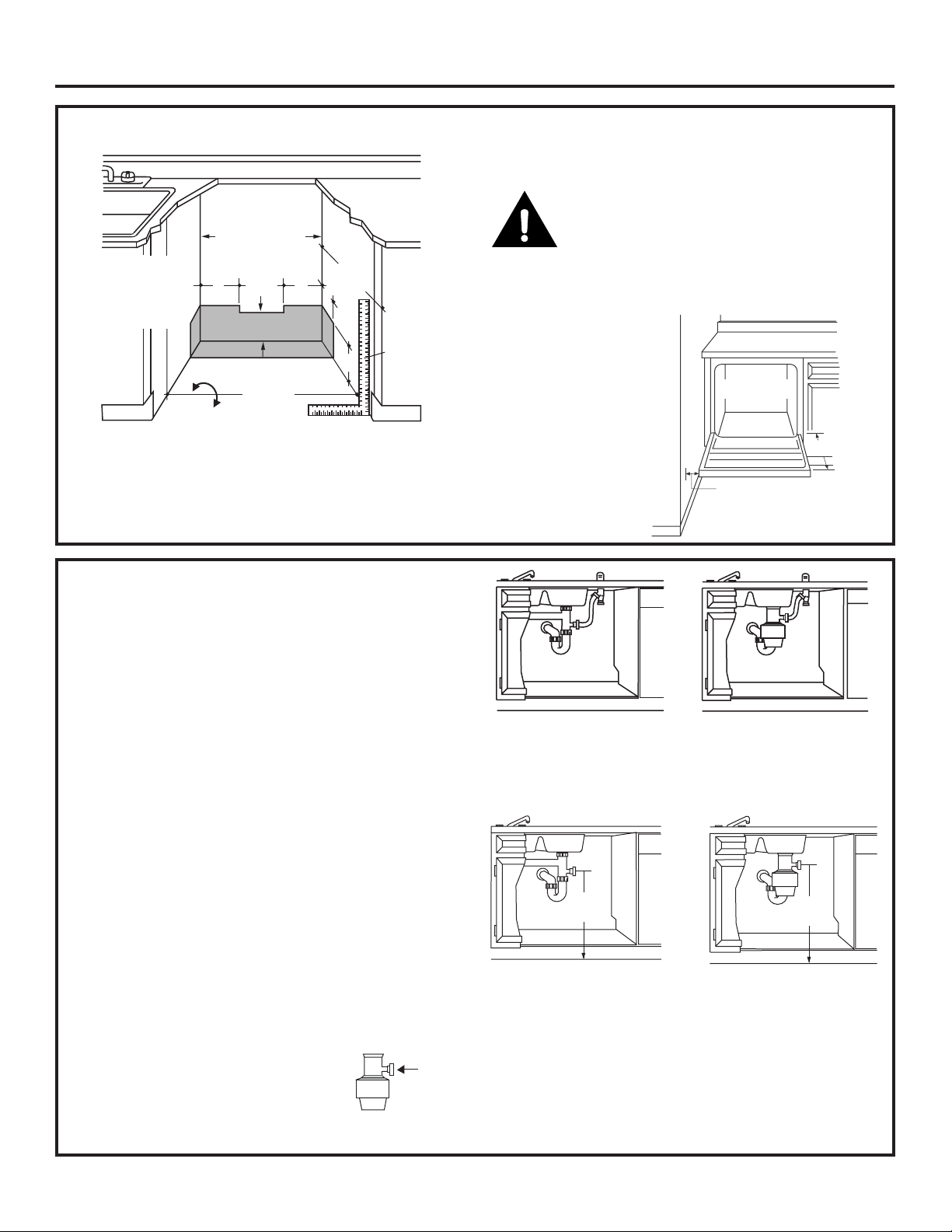

Installation Preparation

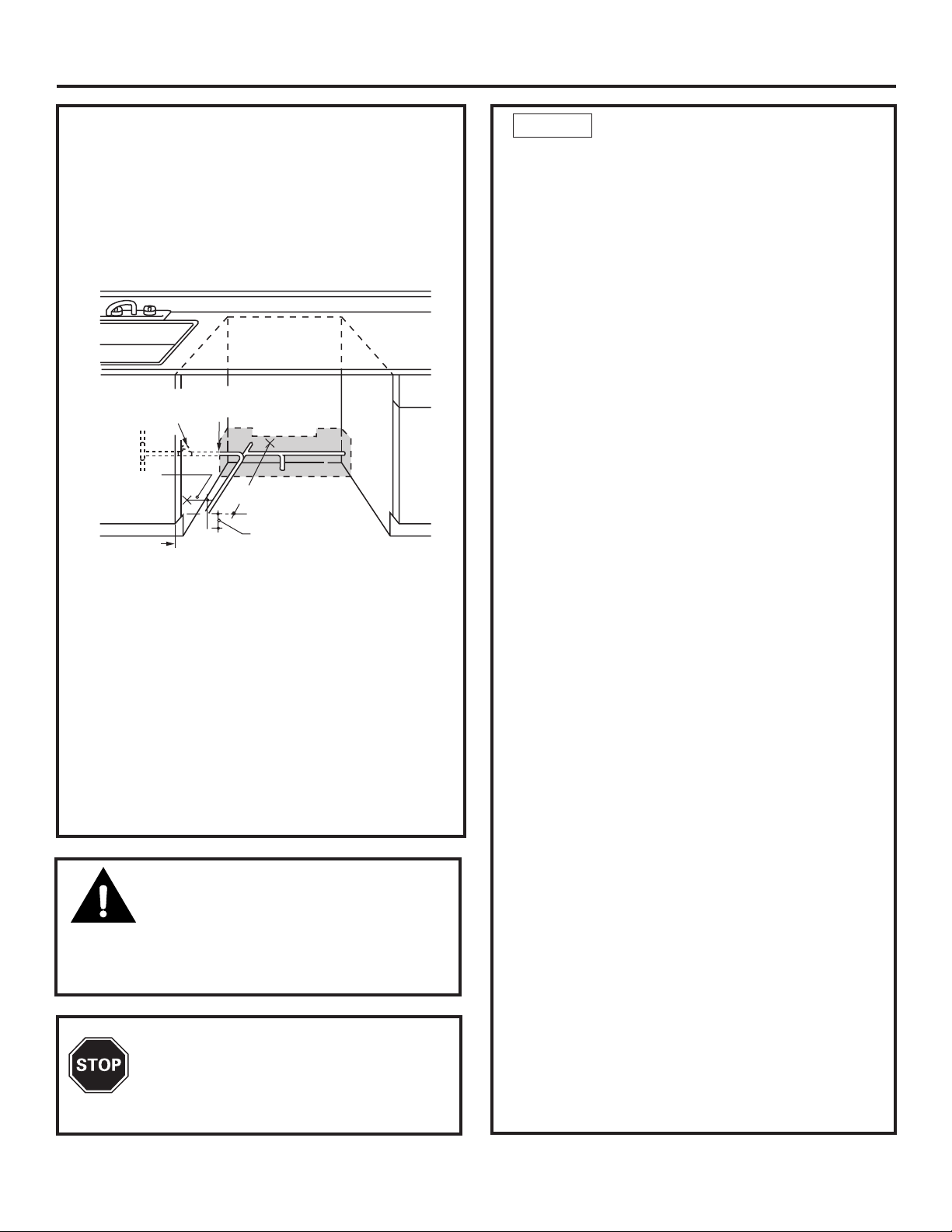

PREPARE DISHWASHER ENCLOSURE

This Wall Area

must be Free of

34-1/2"±1/4"

Pipes or wires

Underside of

5" 5"

4"

Countertop

to Floor

24" Min.

Floor MUST

Figure A

be Even with

Room Floor

Plumbing and Electric Service

Must Enter Shaded Area

• The rough cabinet opening must be at least 24" deep,

24" wide and approximately 34-1/2" high from floor to

underside of the countertop.

24"

Min.

4"

Cabinets

Square

6"

and

Plumb

• The dishwasher must be installed so that drain hose is

no more than 10 feet in length for proper drainage.

WARNING

To reduce the risk of electric shock, fire, or injury to

persons, the installer must ensure that the dishwasher

is completely enclosed at the time of installation.

CLEARANCES: When

installed into a corner,

allow 2" min. clearance

between dishwasher and

adjacent cabinet, wall or

other appliances. Allow

28-3/8" min. clearance

from the front of the

dishwasher for door

opening. Figure B

Countertop

Dishwasher

28-3/8"

Clearance for Door

Opening 2" Minimum

Figure B

DRAIN REQUIREMENTS

• Follow local codes and ordinances.

• Do not exceed 10 feet distance to drain.

• Do not connect drain lines from other devices

to the dishwasher drain hose.

NOTE: This dishwasher is equipped with a high drain

loop. There is no minimum height required for drain hose

routing. However, 18" minimum from floor to center of

waste tee or disposer inlet is required. See Figure D.

DETERMINE DRAIN METHOD

The type of drain installation depends on the following

question.

Do local codes or ordinances require an air gap?

Is waste tee less than 18" above floor?

If the answer to either question is YES, Method 1 MUST

be used.

• If the answers are NO, either method may be used.

CABINET PREPARATION

• Drill a 1-1/2" dia. hole in the cabinet wall within the

shaded areas shown in Figure A for the drain hose

connection. The hole should be smooth with no sharp

edges.

IMPORTANT: When connecting

drain line to disposer, check to be

sure that drain plug has been

removed. DISHWASHER WILL NOT

DRAIN IF PLUG IS LEFT IN PLACE.

Remove

Hopper

Plug

Figure C

Method 1 – Air Gap with Waste Tee or Disposer

An air gap must be used when required by local codes and ordinances.

The air gap must be installed according to manufacturers instructions.

18"

Min.

Figure D

Method 2 – Built-in “High Drain Loop” with Waste Tee or

Disposer

18"

Min.

3

Page 4

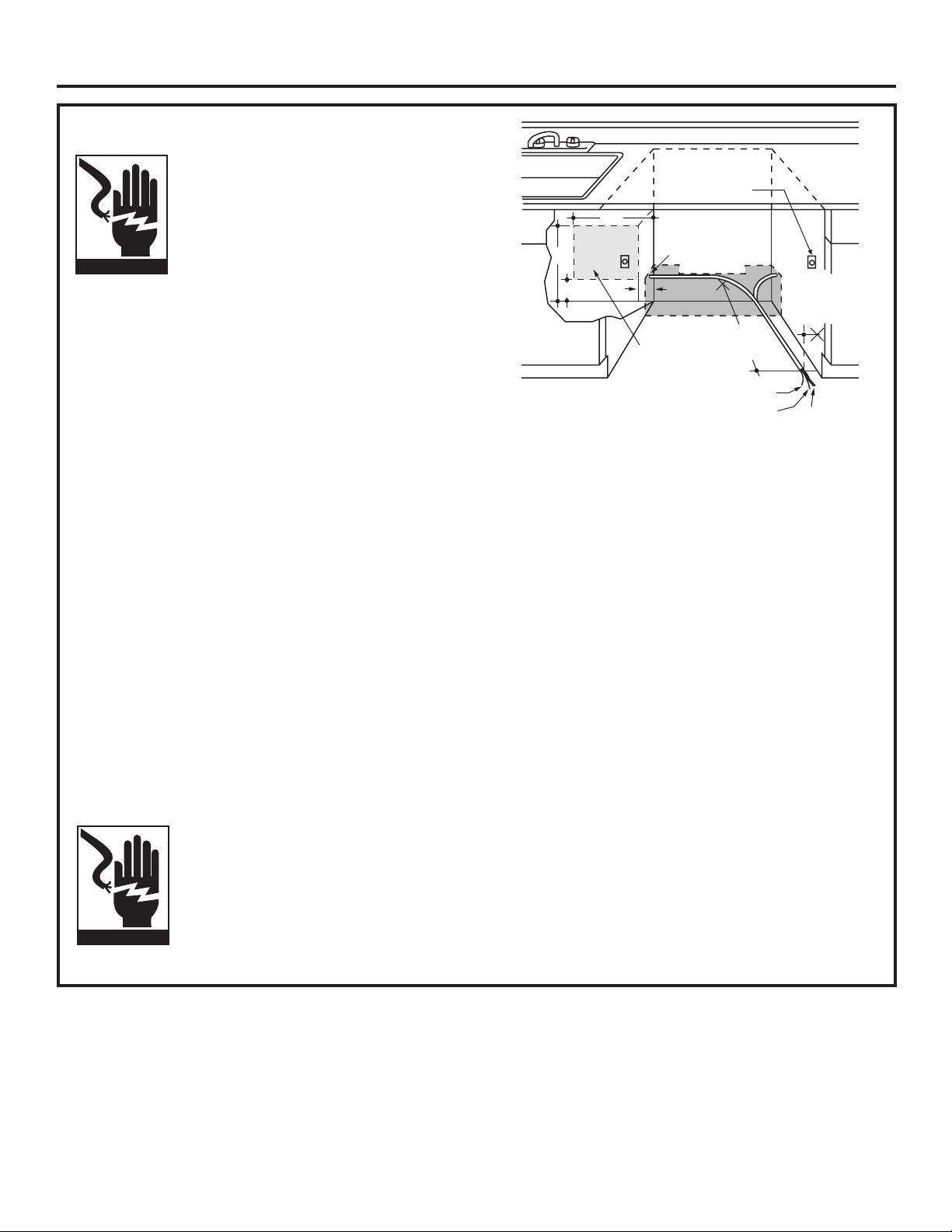

Installation Preparation

White

18"

6"

24"

from Wall

3"

from

Cabinet

Alternate

Receptacle

Location

Ground

Black

1-1/2" Dia.

Hole (Max.)

18"

6"

Receptacle

Location

Area

PREPARE ELECTRICAL WIRING

WARNING

FOR PERSONAL SAFETY: Remove

house fuse or open circuit breaker

before beginning installation. Do not

use an extension cord or adapter plug

with this appliance.

Electrical Requirements

• This appliance must be supplied with 120V, 60 Hz., and

connected to an individual properly grounded branch

circuit, protected by a 15 or 20 ampere circuit breaker

or time delay fuse.

• Wiring must be 2 wire with ground and rated for 75°C

(176°F).

• If the electrical supply does not meet the above

requirements, call a licensed electrician before

proceeding.

Grounding Instructions–Cable Direct

This appliance must be connected to a grounded metal,

permanent wiring system, or an equipment grounding

conductor must be run with the circuit conductors and

be connected to the equipment grounding terminal or

lead on the appliance.

Grounding Instructions–Power Cord Models

This appliance must be grounded. In the event of a

malfunction or breakdown, grounding will reduce the

risk of electric shock by providing a path of least resistance for electric current. This appliance is equipped

with a cord having an equipment grounding conductor

and a grounding plug. The plug must be plugged into an

appropriate outlet that is installed and grounded in

accordance with all local codes and ordinances.

WARNING

The improper connection of the

equipment grounding conductor can

result in a risk of electric shock. Check

with a qualified electrician or service

representative if you are in doubt that

the appliance is properly grounded.

Figure E

For models equipped with power cord: Do not modify the

plug provided with the appliance; if it will not fit the outlet,

have a proper outlet installed by a qualified technician.

Cabinet Preparation & Wire Routing

• The wiring may enter the opening from either side, rear

or the floor within the shaded area.

• Cut a 1-1/2" max. dia. hole to admit the electrical cable.

Cable direct connections may pass through the same

hole as the drain hose and hot water line, if convenient.

If cabinet wall is metal, the hole edge must be covered

with a bushing. NOTE: Power cords with plug must pass

through a separate hole.

Electrical Connection to Dishwasher

Electrical connection is on the right front of dishwasher.

• For cable direct connections the cable must be routed

as shown in Figure E. Cable must extend a minimum of

24" from the rear wall.

• For power cord connections, install a 3-prong grounding

type receptacle in the sink cabinet rear wall, 6" min. or

18" max. from the opening, 6" to 18" above the floor.

4

Page 5

Installation Instructions

PREPARE HOT WATER LINE

• The line may enter from either side, rear or floor

within the shaded area shown in Figure F.

• The line may pass through the same hole as the

electrical cable and drain hose. Or, cut an additional

1-1/2" dia. hole to accommodate the water line. If

power cord with plug is used, water line must not

pass through power cord hole.

Valve

2"

1-1/2" Dia.

Hole

19" From Wall

2" From Floor

Shut-off

Hot

From

Cabinet

Cabinet Face

Figure F

Water Line Connection

• Turn off the water supply.

• Install a hand shut-off valve in an accessible location,

such as under the sink. (Optional, but strongly recommended and may be required by local codes.)

• Water connection is on the left side of the dishwasher.

Install the hot water inlet line, using no less than 3/8"

O.D. copper tubing. Route the line as shown in Figure F

and extend forward at least 19" from rear wall.

• Adjust water heater for 120°F to 150°F temperature.

• Flush water line to clean out debris.

• The hot water supply line pressure must be 20-120 PSI.

STEP 1 CHECK DOOR BALANCE

• With dishwasher on the wood skid, check the door

balance by opening and closing the door.

• If the door drops when released, increase the spring

tension. If the door rises when released, decrease the

tension.

• Position the spring for increased or decreased tension

as required.

• Model families have different spring mounting holes

and tension adjustment methods. Refer to the appropriate figure for your model.

PDW8100-PDW8800 Series

Figure G

CAUTION:

Do not remove wood base until you are

ready to install the dishwasher. The dishwasher will tip

over when the door is opened if the wood base is

removed.

BEFORE YOU BEGIN

Locate and set aside the 2 Phillips head

mounting screws wrapped with yellow tape

and stuck to the top or side of the dishwasher.

TIP: If door does not open easily or falls too quickly,

check the spring cable routing. Check that the cable is

properly aligned on the pulley (as shown).

5

Page 6

Installation Instructions

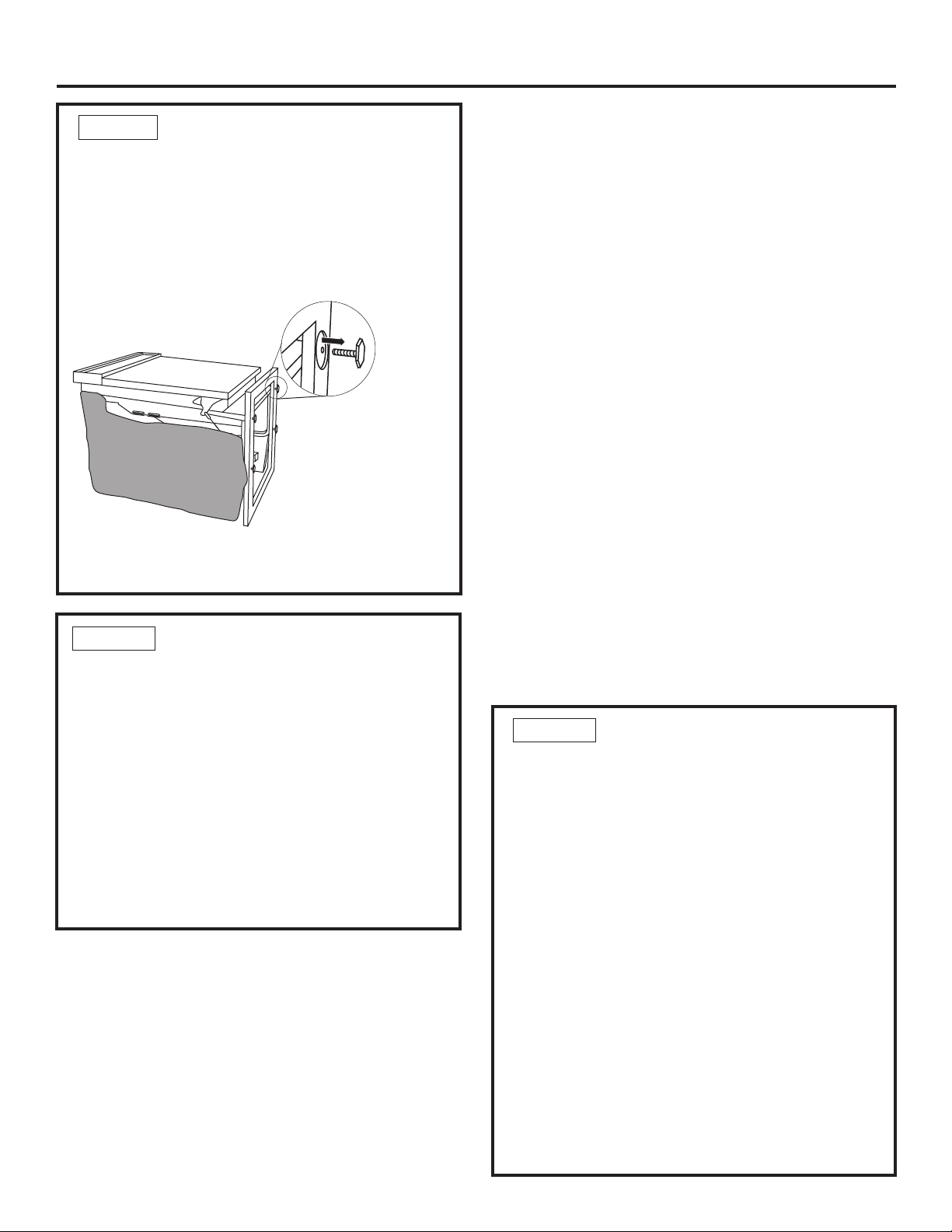

STEP 2 REMOVE WOOD BASE,

INSTALL LEVELING LEGS

IMPORTANT – Do not kick off

wood base! Damage will occur.

• Move the dishwasher close to the installation

location and lay it on its back.

• Remove the four leveling legs on the underside of

the wood base with an adjustable

wrench or 15/16" socket.

• Discard base.

Figure J

• Screw leveling legs back into the dishwasher

frame, approximately 1/4" from frame as shown.

STEP 3 REMOVE TOEKICK

• Remove the two toekick screws.

Figure K

STEP 5 INSTALL 90° ELBOW

• Wrap 90° elbow with thread seal tape.

• Install a 90° elbow onto the water valve.

Figure M

• Do not over tighten 90° elbow, water valve bracket

could bend or water valve fitting could break.

• Position the end of the elbow to face the rear of the

6

dishwasher.

Page 7

Installation Instructions

STEP 6 POSITION WATER LINE

AND HOUSE WIRING

• Position water supply line and house wiring on the

floor of the opening to avoid interference with base

of dishwasher and components under dishwasher.

Figure N

STEP 7

INSTALL DRAIN HOSE,

GUIDE THROUGH CABINET

• Remove tape and wire tie holding the clamp to the

drain hose. Be careful not to damage the drain hose.

• Stand the dishwasher

upright.

• Slip the supplied

hose clamp over the

small end of the hose.

Do not tighten.

Figure O

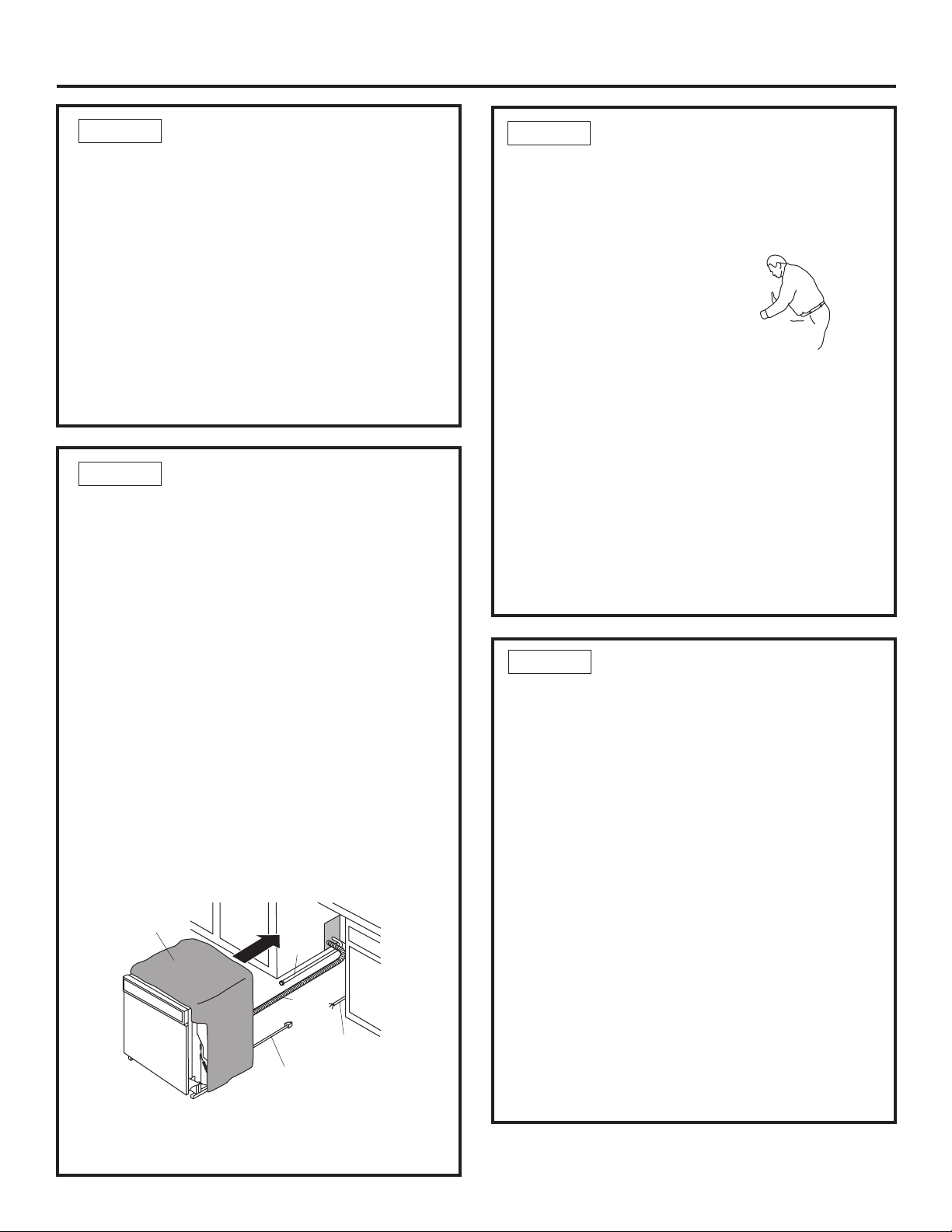

STEP 8 SLIDE DISHWASHER

PARTIALLY INTO CABINET

DO NOT PUSH AGAINST FRONT PANEL WITH KNEES.

DAMAGE WILL OCCUR.

• Slide dishwasher into the opening a few inches at a

time.

Figure Q

• As you proceed, pull the drain hose through the opening under the sink. Stop pushing when the dishwasher

is a few inches forward of adjacent cabinetry.

• Make sure drain hose is not kinked under the dishwasher and there is no interference with the water

line and wiring or any other component.

STEP 9 INSTALL TRIM PIECES

Skip this step if trim is not supplied with the

dishwasher.

• Locate trim strips inside dishwasher.

• Press trim onto the tub flange on each side. Start with

the top edge, pressing on as you move towards the

bottom.

• Press the two top trim pieces on each side of the latch.

• Open and close the door to check that trim does not

bind and does not interfere with door latch.

Insulation

Blanket

• Position the dishwasher in front of the opening.

Insert drain hose into the cabinet side. If power cord

is used, guide the end through a separate hole.

Water

Line

Drain

Hose

House

Wiring

Power Cord

(If Used)

Figure R

7

Page 8

Installation Instructions

STEP 10 POSITION DISHWASHER UNDER COUNTERTOP

• Push the dishwasher into the cabinet.

• Push at the sides with your hands. Do not use your

knee against the door since door damage will occur.

• Check that the tub insulation blanket does not get

“bunched-up” or interfere with the springs as you

slide it into the cabinet.

• Center the dishwasher in the opening.

• Check that the edges of the dishwasher door are

behind the cabinet frame and aligned with the front

face of the cabinet as shown.

• Carefully open and close the door to ensure that the

door panel does not catch or rub on the cabinet

frame.

• If the door catches or rubs on the frame, reposition

and/or level the unit (see Step 11) until the door

moves freely and does not contact the cabinet frame.

Figure S

Positioning for

PDW9200-PDW9800 Series

The controls on these models are designed to be

hidden by your countertop. Align the dishwasher as

shown.

NOTE: If the drain hose gets “bunched-up” behind the

unit it can prevent the controls from being hidden by

the countertop.

NOTE: If this dishwasher is replacing an existing

dishwasher, the old countertop bracket screw holes

may not be in the correct position to accept a topcontrol model. New holes may be required.

TIP: The leveling legs can be used to increase or

decrease the amount of gap between the controls and

the countertop affecting the visibility of the controls.

IMPORTANT – Leave enough gap

between the controls and the countertop brackets so

that the screwheads do not contact and scratch the

controls.

Figure T

Page 9

Installation Instructions

STEP 11 LEVEL DISHWASHER

IMPORTANT – Dishwasher must

be level for proper dish rack operation and wash

performance.

• Place level on

door and rack

track inside the

tub as shown to

check that the

dishwasher is

level.

Figure X

• Level the dishwasher

by adjusting the

four leveling legs

individually.

• If adjustment to the

right rear leveling leg

is required, gain

access by loosening

junction box bracket

screw (through the

access hole) and

rotate bracket clockwise.

TIP: Pull lower rack out, about halfway. Check to

be sure the rack does not roll forward or back into

dishwasher. If the rack rolls in either direction, the

dishwasher must be leveled again.

• If door hits the tub, the dishwasher is not installed

correctly. Adjust leveling legs to align door to tub.

Figure Y

The dishwasher must be secured to the countertop or

the cabinet sides. When countertops are made of wood,

use Method 1. When countertops are granite or other

materials that will not accept screws, use Method 2 to

secure dishwasher at the sides.

Figure AA

9

Figure BB

Page 10

Installation Instructions

STEP 13 CONNECT WATER SUPPLY

Connect water supply line to 90° elbow.

• Slide compression nut, then ferrule over end of

water line.

• Insert water line into 90° elbow.

• Slide ferrule against elbow and secure with compres-

sion nut.

IMPORTANT – Check to be sure

that door spring does not rub or contact the fill hose or

water supply line. Test by opening and closing the door.

Re-route the lines if a rubbing noise or interference

occurs.

Figure CC

STEP 14 CONNECT DRAIN LINE

FOLLOW ALL LOCAL CODES AND ORDINANCES.

The drain hose molded end will fit 5/8", 3/4" or 1"

diameter connections on the air gap, waste tee or

disposer. Cut on the marked line as required for your

installation.

Cutting Lines

3/4"

1"

IMPORTANT: Do not cut corrugated

portion of hose

• If a longer drain hose is required, add up to 42" of

length for a total of 10 ft. to the factory installed hose.

Use 5/8" or 7/8" inside diameter hose and a coupler to

connect the two hose ends. Secure the connection

with hose clamps.

5/8"

Figure DD

DRAIN LINE INSTALLATION

• Connect drain line to air gap, waste tee or disposer

using either previously determined method.

Method 1 – Air gap with waste tee or disposer

Waste Tee Installation

Method 2 – Built-in “High drain loop” with waste tee or

disposer

Figure FF

Disposer Installation

Figure EE

• Secure the drain hose to the air gap, waste tee or

disposer with clamps.

NOTE: TOTAL DRAIN HOSE LENGTH MUST NOT EXCEED

10 FEET FOR PROPER DRAIN OPERATION.

Waste Tee Installation

Figure GG

Disposer Installation

IMPORTANT –

When connecting drain line to

disposer, check to be sure that drain

plug has been removed. DISHWASHER WILL NOT DRAIN IF PLUG IS LEFT IN PLACE.

TIP: Avoid unnecessary service call charges. Always be

sure disposer drain plug has been removed before

attaching dishwasher drain hose to the disposer.

10

Page 11

Installation Instructions

STEP 16 PRE-TEST CHECK LIST

Review this list after installing your dishwasher to

avoid charges for a service call that is not covered

by your warranty.

Check to be sure power is OFF.

Open door and remove all foam and paper

packaging.

Locate the Owner’s Manual in the literature

package.

Read the Owner’s Manual for operating

instructions.

Check door opening and closing. If door does not

open and close freely or tends to fall, check spring

cable routing and spring adjustments. See Step 1.

Check to be sure that wiring is secure under the

dishwasher, not pinched or in contact with door

springs or other components. See Steps 8 and 10.

Figure HH

Check door alignment with tub. If door hits tub,

level dishwasher. See Step 11.

Pull lower rack out, about half way. Check to be

sure it does not roll back or forward on the door.

If the rack moves, adjust leveling legs. See Step 11.

Check door alignment with cabinet. If door hits

cabinet, reposition or relevel dishwasher. See

Steps 10, 11 and 12.

Check that door spring does not contact water

line, fill hose, wiring or other components. See

Step 13.

Verify water supply and drain lines are not kinked

or in contact with other components. Contact with

motor or dishwasher frame could cause noise. See

Steps 6 and 8.

Turn on the sink hot water faucet and verify waterep 11. Read ret 8w9 T4oaet withurn on the sink hot waterT*03 Tf-1.090.3is an1f-0.8945 0 TD0.0004 Tw( Readrn on the sink w4l dD0 Tw AdD0ek w4l dD0 Tw AdD0ek w4l dD3b0 136 an door hits)Tj0.1964L8945 0 TD (eai uTjskt( Read re 4 T09 rc19 ek w4l dD3b0 136 an door hits)Tj0.19erating)Tj-6.333333333333333333333333333333333333333333333333333333333333333333333333333333333333333333333333333333333333333333333333333333.oic1 T5A()Tb-1.0909 -1.ij/ao on3333330n9ose p0ek833333333333333c 4333 w4l relevel dish6rhot watp9n35.TJ( an1f-0.8 i.ts)cw4l Rir1p66.e/33339ssd

11

Page 12

Installation Instructions

STEP 17 DISHWASHER WET TEST

Turn on power supply (or plug power cord into

outlet, if equipped).

Start the unit to check for leaks.

PDW8100-PDW8800 Series:

– Latch door

– Push RINSE ONLY pad

– Push START/RESET pad

PDW9200-PDW9800 Series:

– Push RINSE ONLY pad

– Push START/RESET pad

– Close door

Push “Rinse Only” button.

Push start/reset pad once.

Check to be sure that water enters the dishwasher.

If water does not enter the dishwasher, check to be

sure that water and power are turned on.

Check for leaks under the dishwasher. If a leak is

found, turn power supply off, then tighten connections. Restore power after leak is corrected.

Check for leaks around the door. A leak around the

door could be caused by door rubbing or hitting

against adjacent cabinetry. Reposition the dishwasher if necessary. See Step 12.

STEP 18 REPLACE TOEKICK

• Place toekick against the legs of the dishwasher.

Figure JJ

• Align the toekick with the bottom edge and make

sure it is against the floor.

• Insert and tighten the two toekick attachment

screws. The toekick should stay in contact with the

floor.

TIP: Make sure toekick is against floor to minimize

noise.

The dishwasher will drain and turn off about 5

minutes after i.7(c1minu5h.H3 Twafter ithe)]TJ0.19rEnot()9cT,e9rEn-0.0000003 Tw[c6e5-15.02 reSBT/F3 1 Tf14 0 0 14 51.48 695.04 Tm/GS2 gs48 695.h2 is c48 1t02 Twr.196/F2c7p2 1t02 Twr.196/F A 1minu1arog/F6eeJ- 5

STEP 19 LITERATURE

• Be sure to leave complete literature package and

installation instructions with the consumer.

Page 13

Specification Created 7/03

250202

TM

PDW9700JII – GE Profile™Fully Integrated Built-In Dishwasher

24

24

†††

21-1/4

2-3/4

4 (Adjustable)

33-13/16" MIN.

adj. to 35"

27-1/2

22-1/2

†††

Add 3/4" for custom panel and additional room

for custom handle

Built-In Dishwasher Dimensions (in inches)

Electrical Rating

Voltage AC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Hertz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Total connected load amperage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.1

Calrod®heater watts max. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 875

For use on adequately wired 120-volt, 15-amp circuit having 2-wire service

with a separate ground wire. This appliance must be grounded for

safe operation.

For answers to your Monogram,

®

GE Profile™or

GE®appliance questions, visit our website at

GEAppliances.com or call

GE Answer Center®service, 800.626.2000.

R

Listed by

Underwriters

Laboratories

As an ENERGY STAR®partner,

GE has determined that this product

meets the ENERGY STAR

®

guidelines for energy efficiency.

Dishwasher Rough-In Information

Note: Dishwasher must not be installed more than ten feet

from sink for proper drainage. All plumbing and electrical

work must be in accordance with local codes.

Note: If a flush look is needed, a 25" base cabinet needs

to be used (except Profile and Triton XL models).

The power cord and connections must comply with the

National Electrical Code Section 422 and/or local codes

and ordinances. The cord must be no longer than six feet

from the junction box to the receptacle.

This wall area

must be free of

pipes or wires

Countertop

4

6

Hot

water

line on

left

44

2

Plumbing and electrical

service must enter

inside shaded area

24" From wall

24" MIN.

90°

19" MIN. from wall

24"

MIN.

6

34" to 34-3/4"

Underside

of countertop

to floor

55

90°

Electrical

wiring on

right

Electrical

wiring is

3" from

cabinet

Custom Panel for Model PDW9700JII

Dishwasher comes panel-ready.

Installation Information (in inches)

B

A

Custom

Panel Size

Floor

Cabinets

Side

View

Countertop

3/4" Max.

Bottom of

Adjacent Cabinetry

The most common panel dimensions are 30-1/4"H

and 23-3/4"W.

STEP A: Determine custom panel height

1. Measure Dimension A from underside of

countertop to bottom of adjacent cabinets.

2. Subtract 1/4". This allows a 1/4" clearance gap

between the underside of the countertop and

the top of the dishwasher door.

Height is equal to A minus 1/4"

STEP B: Determine custom panel width

1. Measure dimension B, the rough opening width.

2. Subtract 1/4" for clearance (1/8" on each side).

Width is equal to B minus 1/4"

Note: 23-1/8" min. panel width and 26-1/4" min.

panel height is required to cover the door frame.

Panel height varies depending on installation.

Consideration must be given to door swing

clearance above the toekick.

Page 14

2-9/32"

Trim Around Dotted Line

11-5/16"

Top of Panel Top of Panel

11-5/16"

Trim Around Dotted Line

2-9/32"

Drill 3/32"

Pilot Hole

3/32" Deep

25-9/16"

3/4" Thick Custom Panel

Template Instructions

For PDW9700J Series

The custom panel should be sized to your installation situation. See Step 1. For easier

installation the custom panel and custom handle should be attached before installing the

dishwasher. Use this template to locate mounting scr

IMPORTANT

• A custom handle must be installed onto the custom panel. Install the custom handle 4-1/2" max.

from the top of the panel.

STEP 1 DETERMINE CUSTOM PANEL SIZE

A: Determine custom panel height

1. Measure dimension A, from the underside of

the countertop to the bottom of adjacent

cabinets.

2. Subtract 1/4". This allows a 1/4" clearance

gap between the underside of the countertop

and the top of the dishwasher door.

HEIGHT = A – 1/4"

Note: 30-1/16" minimum panel height is required to cover

the door frame. Panel height varies depending on

installation. Consideration must be given to door swing

clearance above the toekick.

B: Determine custom panel width

1. Measure dimension B, the rough opening

width.

2. Subtract 1/4" for clearance (1/8" on each

side).

WIDTH = B – 1/4"

STEP 2 DRAW CENTERLINE

• Place the custom panel on a flat surface with appearance

side down.

• Locate the vertical center of the panel at the top.

• Use a carpenters square to draw a centerline from top to

bottom.

STEP 3 ALIGN TEMPLATE TO PANEL

• Trim template on the dotted line along all sides.

• Place the template on the panel aligned with the top edge

and the centerline. Use tape to hold in place.

• Use an awl to mark the screw hole locations indicated on

the template. Remove the template.

STEP 4 INSTALL MOUNTING SCREWS AND SPACERS

If the panel is less than 3/4" thick, shorter screws must

be used. Use #8 x 1/2" screws for 1/2" thick panels (not

supplied).

• Use a 3/32" drill bit to drill pilot holes 3/32" deep in the

marked locations.

Note: The custom panel is secured to the dishwasher door

with the spacers and screws provided. The spacer will slip

into the keyhole slots on the dishwasher door.

• Drive the supplied #8 x 3/4" hex washer head wood screws

through the spacer and into the panel.

• Install remaining spacers and screws as indicated in the

marked locations.

ews and spacers on the custom panel.

PARTS INCLUDED:

(4) Spacers

(4) #8 x 3/4" Hex washer head wood screws

(3) #8 x 1-3/4" Phillips truss head stainless steel

wood screws

(2) Heavy duty springs

Custom

Countertop

Panel Size

Cabinets

Side

A

View

Floor

3/4" Max.

Bottom of

Adjacent Cabinetry

Note: The most common panel dimensions are 30-1/4" H

and 23-3/4" W.

B

Screw

Spacer

Mark Center

Screw Holes

STEP 5 INSTALL CUSTOM HANDLE

A custom handle must be installed onto the

panel before the panel is secured to the dishwasher door.

• The handle should be installed so that it aligns

with adjacent drawer handles, or 4-1/2" max.

from the top of the panel. Secure the handle in

the same manner as cabinet handles. Screws

must be countersunk into the panel.

STEP 6 INSTALL ASSEMBLED PANEL

• Secure the panel to the door by inserting the

top and bottom mounting screws with spacers

into the matching keyhole slots.

• Make sure all 4 spacers engage the keyhole

slots.

• Press the panel against the door and push

downwards until the spacers are fully engaged

into the key hole slots. The panel should align

evenly with the top and sides.

• Stand the dishwasher upright.

• Open dishwasher door and drive the supplied

#8 x 1-3/4" truss head screws. Drive one screw

at the top and one on each side as shown,

through the inner door and into the custom

panel.

WARNING: Do not overtighten screws.

Excessive tightening of the screws could damage

door edges.

STEP 7 INSTALL DOOR SPRINGS

The dishwasher is shipped from the factory with a

temporary set of balance springs. Use the heavy

duty springs provided to balance the door after

the custom panel is installed onto the dishwasher.

The door balance system is designed to accommodate a wide variety of custom panels. Use the

holes on the cable to make major adjustments.

Use the holes in the leg for minor adjustments to

the door balance.

• With the dishwasher on the wood skid, close

and latch the door.

• Remove and discard both door springs.

• Attach the new heavy duty door springs. Engage

the end with the short hook into the support

leg and the long hook into the cable.

• Open and close the door.

• If the door drops open when released, increase

spring tension. If the door closes when released, decrease tension.

Screws Must

Be Countersunk

Into Panel

Custom

Door Panel

Dishwasher

Door

Custom

Panel

Note: To increase tension, move spring up one

hole. To decrease tension use lower hole. Adjust

one or both springs until door is correctly

balanced.

Pulley

Shoulder

Check Spring

Cable Routing

IMPORTANT: If the door does not open easily or

falls too quickly, check spring cable routing. The

cable is held in place by “shoulders” on the pulley.

Check to be sure the cable has not slipped over the

pulley shoulders.

Make Minor

Spring Tension

Adjustment Here

4-1/2" Max.

Handle

Custom

Panel

Shoulder Washers

Engage Keyhole

From Top

of Panel

Slots

INCREASE

DECREASE

Adjust Here

to Increase or

Decrease Spring

Tensi on

25-9/16"

Drill 3/32"

Pilot Hole

3/32" Deep

Drill 3/32"

Pilot Hole

3/32" Deep

Trim Around Dotted Line

Pub. No. 31-30558

Dwg. No. 206C1559P098

N.D. 694 3/03

Trim Around Dotted Line

Drill 3/32"

Pilot Hole

3/32" Deep

Page 15

Specification Created 7/03

250202

TM

PDW9700JII – GE Profile™Fully Integrated Built-In Dishwasher

T

I

M

E

R

E

M

A

I

N

I

N

G

Loading...

Loading...