Page 1

GE

g

READ THOROUGHLY BEFORE INSTALLING

Save instructions for future use.

Lighting Solutions

WARNING

Risk of electric shock

• To prevent risk of electrical shock,

deactivate/disconnect power supply

before installing or relamping fixture.

• This fixture should be installed by qualified

technicians in strict accordance with the

National Electrical Code and any local

requirements.

GEH-5967

INSTRUCTIONS

Food Pro™ II Series, Installation,

Operations and Maintenance

GENERAL

1. Before installing check the carton label and fixture label

to insure that you have correct fixture and voltage.

2. BEFORE INSTALLING, MAKE CERTAIN THAT THE

CIRCUIT IS DEACTIVATED.

3. This fixture is factory-sealed to prevent moisture entry.

Removal of the seal may result in leakage.

MAINTENANCE

CAUTION

Disconnect the supply circuit before

opening or relamping the fixture.

To relamp, loosen four (4) lens frame screws, open

lens frame, replace lamp, then replace lens frame.

As a factory-sealed unit, no routine maintenance is

required to keep this fixture functional. It is recommended

that the plastic refractor be kept clean for optimum lighting

output.

These instructions do not purport to cover all details or variations in equipment nor to provide for every possible contingency to be met in connection with installation, operation or

maintenance. Should further information be desired or should particular problems arise which are not covered sufficiently for the purchaser’s purposes, the matter should be referred

to GE Lighting Solutions.

Page 2

INSTALLATION

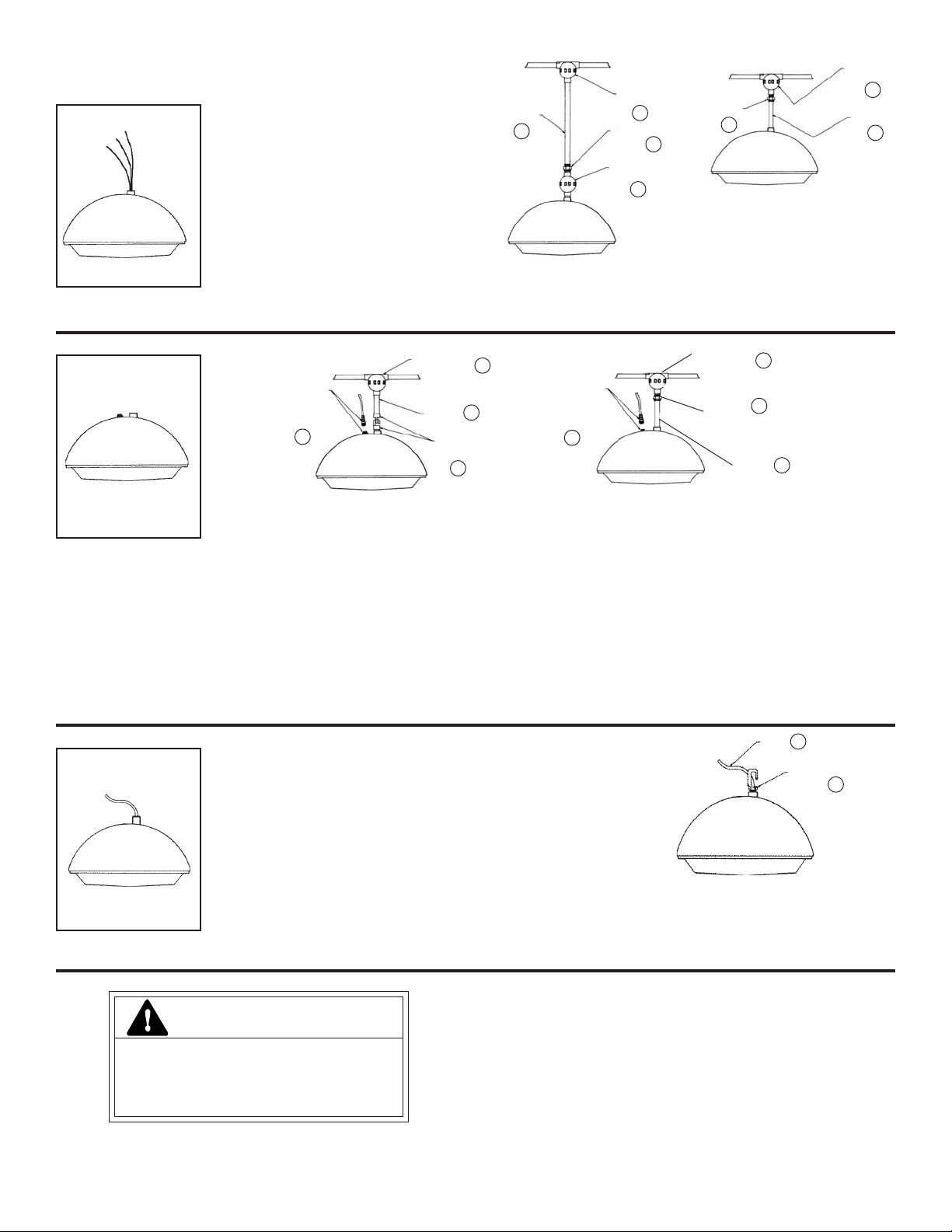

SEALED FIXTURE AS IT COMES

FROM THE FACTORY

STANDARD

FIXTURE

RIGID PENDANT MOUNT

1. Install conduit (A) into junction box (B).

Pull incoming power supply leads

through conduit (A) and close junction

box (B).

2. Install union (D) to water tight junction

box (C) and conduit stem(A).

3. Feed wires from top of fixture into

junction box (C), then install junction

box (C) on fixture.

4. Connect fixture to conduit stem (A) at

union.

5. Connect wires and close junction box (C).

CONDUIT

A

Rigid Pendant Mount

with Long Conduit

Hard Wired

STANDARD

JUNCTION BOX

B

STANDARD

UNION

D

STANDARD

JUNCTION BOX

C

STANDARD

JUNCTION BOX

STANDARD

UNION

D

CONDUIT

Rigid Pendant Mount

with Short Conduit

Hard Wired

Note: For short conduit, fixture

wire can be pulled through union

and conduit. Wires can then be

connected in junction box.

B

A

STANDARD

SEALED FIXTURE AS IT COMES

FROM THE FACTORY

FIXTURE WITH

MINI-RECEPTACLE OPTION

OPTION

MINI-PLUG

ELECTRICAL

DISCONNECT

E

Hanger Mount

with Quick Disconnect

JUNCTION BOX B

CONDUIT A

OPTION

HANGER

HANGER MOUNT WITH QUICK DISCONNECT

1. Install hanger (G) to hub on fixture and secure with set screws.

2. Install conduit (A) into junction box (B).

3. Install hanger (G) to conduit (A).

4. Install fixture, engaging both hangers.

5. Install mini-connector cord (E) to junction box (not shown).

6. Connect mini-connector plug to mini-connector receptacle.

SEALED FIXTURE AS IT COMES

FROM THE FACTORY

FIXTURE WITH

CABLE OPTION

HANGER MOUNT

1. Feed cable (F) through hanger(G).

2. Thread hanger (G) into fixture hub.

3. Secure with set screw.

4. Attach male plug at the end of cable (F).

5. Install fixture by means of hanger (G).

6. Hanger MUST be sealed where cable exits hanger to prevent

accumulation of water.

7. Plug in the fixture into receptable.

STANDARD

JUNCTION BOX B

OPTION

MINI-PLUG

ELECTRICAL

DISCONNECT

E

C

STANDARD D

UNION

CONDUIT A

Rigid Pendant

with Quick Disconnect

RIGID PENDANT MOUNT WITH QUICK DISCONNECT

1. Feed fixture wires through conduit (A), then install conduit

stem (A) in fixture hub.

2. Attach union (D) to conduit (A) and junction box (B).

3. Attach conduit/fixture to junction box (B) at union.

4. Install mini-connector cord (E) to junction box (not shown)

and wire mini-connector cord (E) with incoming wires.

5. Connect mini-connector plug to mini-connector receptacle.

CABLE F

OPTION

HANGER C

Hanger Mount

with Sealed Cable

CAUTION

All vertical conduit must be secured

with lock nuts or set screws to keep

fixture from rotating.

Page 3

GE

g

Lighting Solutions

Luminaires série Food Pro™ II

Installation, utilisation et entretien

LIRE ATTENTIVEMENT AVANT D'INSTALLER

Conserver ces instructions pour référence future.

AVERTISSEMENT

Risque d'électrocution

• Pour éviter les risques d'électrocution,

désactiver/déconnecter l'alimentation

électrique avant d'installer ce luminaire

et avant d'en remplacer la lampe.

• Ce luminaire doit être installé par

un technicien qualifié respectant

rigoureusement les normes électriques

nationales et locales.

GÉNÉRALITÉS

1. Avant de commencer l'installation, vérifiez l'étiquette de la

boîte et du luminaire pour vous assurer que vous avez le

luminaire approprié et qu'il est conçu pour la tension

électrique disponible.

2. AVANT L'INSTALLATION, ASSUREZ-VOUS QUE LE

CIRCUIT EST DÉSACTIVÉ.

3. Ce luminaire a été hermétiquement fermé en usine pour

éviter toute entrée d'humidité. L'enlèvement du joint

hermétique peut permettre des infiltrations.

GEH-5967

INSTRUCTIONS

Puisque cet appareil a été hermétiquement fermé en usine,

aucun entretien routinier n'est nécessaire pour qu'il demeure

fonctionnel. Pour que la puissance d'éclairage demeure

optimale, il est recommandé que le réfracteur en plastique

soit maintenu propre.

ENTRETIEN

ATTENTION

Avant d'ouvrir ou remplacer la lampe de

ce luminaire, le circuit d'alimentation

doit être déconnecté.

Pour remplacer la lampe du luminaire, desserrez les

quatre (4) vis du châssis de la lentille, ouvrez le

châssis, remplacez la lampe et réinstallez le châssis.

™ Trademark of General Electric Company

Ces instructions n'ont pas pour destination de couvrir tous les détails ou variantes de l'équipement, ni de répondre à toutes les éventualités que vous pourriez rencontrer pendant l'installation,

le fonctionnement ou l'entretien. Si vous souhaitez des informations complémentaires, ou si vous rencontrez un problème particulier qui ne soit pas adressé de votre point de vue d'acheteur,

le sujet doit être remonté jusqu'à la société GE Lighting Solutions

Page 4

INSTALLATION

LUMINAIRE HERMÉTIQUEMENT

FERMÉ EN USINE

LUMINAIRE

STANDARD

MONTAGE PENDANT RIGIDE

1. Installez le conduit (A) dans la boîte de

jonction (B).Tirez les fils d'alimentation

dans le conduit (A) et fermez la boîte de

jonction (B).

2. Installez le raccord union (D) sur la boîte de

jonction étanche (C) et sur le tuyau du

conduit (A).

3. Faites passer les fils depuis le haut du

luminaire dans la boîte de jonction (C), puis

installez la boîte de jonction (C) sur le

luminaire.

4. Connectez le luminaire sur le tuyau du

conduit (A) sur le raccord union.

5. Connectez les fils électriques et fermez la boîte

de jonction (C).

CONDUIT

A

Montage pendant

rigide avec conduit

long câblé

BOÎTE DE JONCTION

STANDARD

RACCORD UNION

STANDARD

BOÎTE DE

JONCTION STANDARD

C

B

D

Remarque: Dans le cas d'un conduit

court, le câble du luminaire peut être

tiré dans le raccord union et le

conduit. Les fils peuvent ensuite être

connectés dans la boîte de jonction.

RACCORD

UNION

STANDARD

D

Montage pendant

rigide avec conduit

court câblé

BOÎTE DE JONCTION

STANDARD

CONDUIT

A

B

BOÎTE DE JONCTION

LUMINAIRE HERMÉTIQUEMENT

FERMÉ EN USINE

LUMINAIRE AVEC

MINI-RÉCEPTACLE OPTIONNEL

MINI-CONNECTEUR

ÉLECTRIQUE

OPTIONNEL

E

avec déconnexion rapide

Montage suspendu

STANDARD

CONDUIT

BRIDE DE

SUSPENSION

OPTIONNELLE

MONTAGE SUSPENDU À DÉCONNEXION RAPIDE

1. Installez la bride de suspension (C) sur le connecteur du luminaire

et fixez avec des vis d'arrêt.

2. Installez le conduit (A) sur la boîte de jonction (B).

3. Installez la bride de suspension (C) sur le conduit (A).

4. Installez le luminaire, en emboîtant les deux brides de suspension.

5. Installez un cordon avec mini-connecteur (E) sur la boîte de jonction

(non illustrée).

6. Connectez la mini-fiche de connexion sur le mini-réceptacle

correspondant.

LUMINAIRE HERMÉTIQUEMENT

FERMÉ EN USINE

LUMINAIRE AVEC

CÂBLE DISPONIBLE EN OPTION

MONTAGE SUSPENDU

1. Faites passer le câble (F) dans la bride de suspension (C).

2. Enfilez la bride de suspension (C) dans le connecteur du luminaire.

3. Fixez avec une vis d'arrêt.

4. Installez le connecteur mâle à l'extrémité du câble (F).

5. Installez le luminaire avec l'aide de la bride de suspension (C).

6. La bride de suspension DOIT être hermétiquement fermée à la sortie

du câble pour éviter toute accumulation d'eau.

7. Connectez le luminaire dans le réceptacle.

BOÎTE DE JONCTION

B

MINI-CONNECTEUR

ÉLECTRIQUE

A

C

OPTIONNEL

E

STANDARD

B

RACCORD UNION

STANDARD

D

CONDUIT

A

Montage pendant

rigide avec déconnexion rapide

MONTAGE PENDANT RIGIDE AVEC DÉCONNEXION

RAPIDE

1. Faites passer les fils d'alimentation dans le conduit (A), puis installez le

tuyau de conduit (A) sur le connecteur du luminaire.

2. Fixez le raccord union (D) sur le conduit (A) et la boîte de jonction(B).

3. Fixez le conduit/luminaire sur la boîte de jonction (B) au niveau du raccord

union.

4. Installez un cordon avec mini-connecteur (E) sur la boîte de jonction (non

illustrée), puis reliez les fils du cordon avec mini-connecteur (E) aux fils

d'alimentation.

5. Connectez la mini-fiche de connexion sur le mini-réceptacle correspondant.

F

CÂBLE

BRIDE DE SUSPENSION

OPTIONNELLE

Montage suspendu avec

câble étanche

C

g

ATTENTION

Tout le conduit vertical doit être

retenu par des écrous de blocage

ou des vis d'arrêt pour éviter que le

luminaire puisse tourner.

GE Lighting Solutions • 1-888-MY-GE-LED • www.gelightingsolutions.com

GE Lighting Solutions is a subsidiary of the General Electric Company. Evolve and other trademarks belong to GE Lighting Solutions. The GE brand and logo are trademarks of the General Electric Company.

© 2011 GE Lighting Solutions. Information provided is subject to change without notice. All values are design or typical values when measured under laboratory conditions.

16943533----888

35-201578-159 (GELS 11/05)

Loading...

Loading...