Page 1

GE

Energy

Flame Tracker

Designed for Peak Performance and Reliability

GE Energy’s Silicon Carbide (SiC) Flame Tracker* dramatically

improves gas turbine performance while significantly reducing

maintenance requirements. Standard on all new GE gas turbines,

the Flame Tracker flame sensor’s optical photodiode is designed

for use with multiple fuels, low NO

injection. Reliable turbine operations for oil/steam injection

applications require the sensitivity provided by Flame Tracker.

Advantages include:

High Sensitivity, Fast Response

Flame Tracker, with its patented SiC photodiode, has high sensitivity

to the longer UV wavelengths that easily penetrates the fog of fuel

and steam. This is advantageous over typical flame sensors that

are sensitive to only the short UV wavelengths. In addition, the SiC

sensor has an analog output with a very wide dynamic range and

rapid response time. These features offer the ability to quickly—in

less than 25 milliseconds—track flame dynamics, including flame-

out. This means interruption-free service and improved availability.

Minimal Maintenance

The Flame Tracker flame sensor is equipped with quick disconnect

connectors, allowing sensor replacement time to be reduced from

hours to minutes. Its improved sensor-cooling feature minimizes

the impact of surrounding heat and extends the life of electronics.

Customized Conversion Kits

GE supplies customized flame sensor conversion kits for all turbine

configurations. These sensor enhancements are mechanically and

electrically interchangeable with existing systems. The kit solution

simplifies the upgrade of older, maintenance-intensive systems to

the superior performance of GE Energy’s Flame Tracker.

combustors and steam

x

fact sheet

Multiple Applications

esigned to replace existing sensors, the Flame Tracker is

D

applicable to all land-based and marine-based gas turbines,

regardless of size. In addition, it is internationally approved

for UL and CE applications.

Reliable, Low Voltage Operation

Providing a 4-20 mA industry-standard output signal, the Flame

Tracker operates reliably with any fuel—with or without steam

injection. Unlike older flame sensors that require high voltage for

operation, the Flame Tracker requires low voltage, which elimi-

nates special wiring and explosion-proof conduit requirements.

Performance Benefits

• Provides reliable operation when using any fuel

• Eliminates signal flicker

• Allows full operation during the water wash cycle

• Reduces maintenance time

• Operates on low voltage

• Provides rapid response to flameout

• Produces a wide dynamic range

• Offers easy, customized conversion option

• Customized conversion kits

• Meets all NFPA guidelines for

flame detection on gas turbines

• Delivers 10 times the sensitivity

of tube-style sensors

Page 2

fact sheet

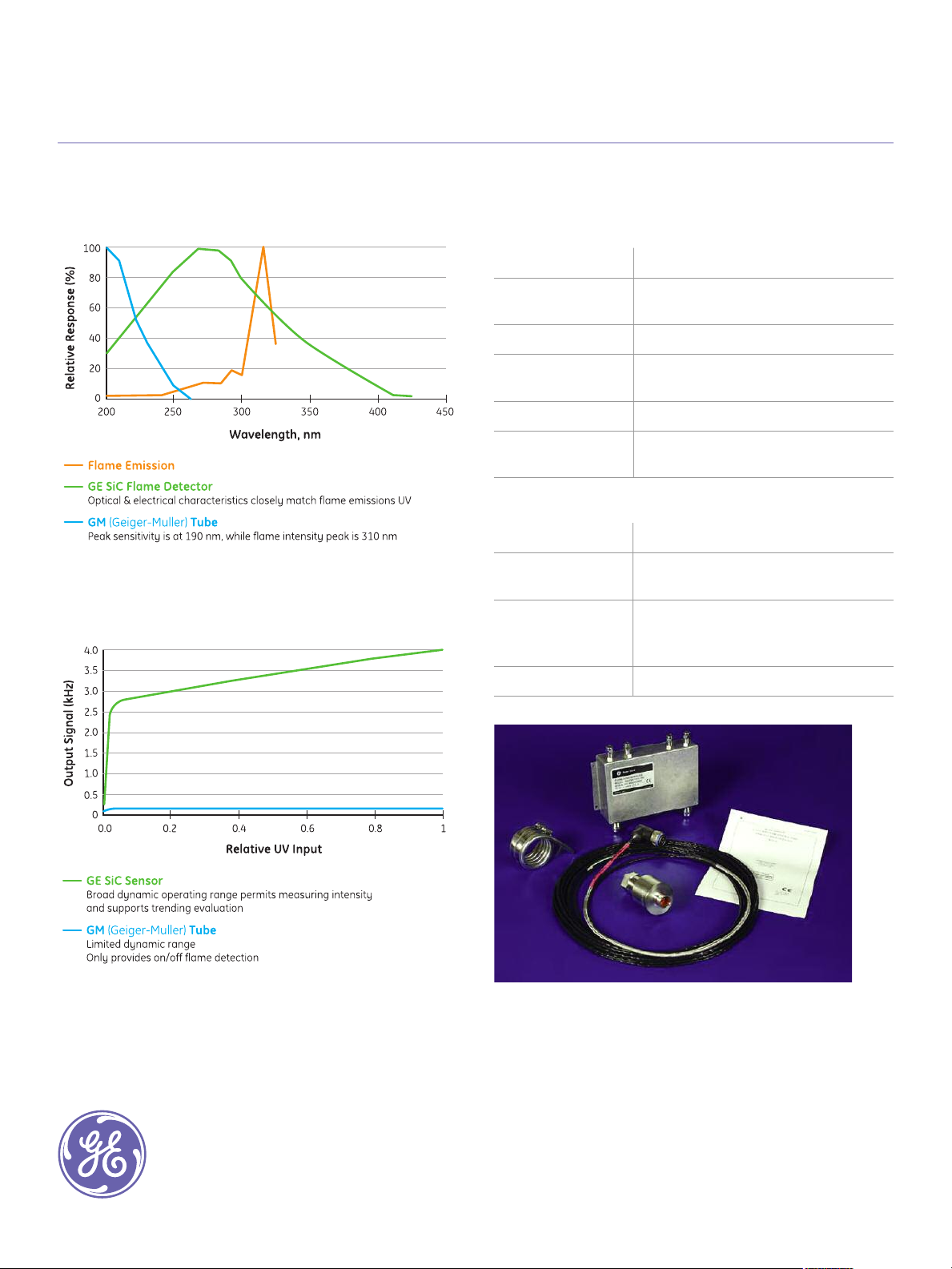

Sensor Responsivity and

ydrocarbon Flame Emission Spectrum

H

Instrument Response at 254 nm for

GE SiC Sensor & GM (Geiger-Muller) Tube

Specifications

Operating

Power Requirements 24 VDC nominal, 12-30 VDC @ 100 mA

Output 4-20 mA (a module to convert output

to other controller inputs is available)

esponse Time < 25 milliseconds

R

Temperature Range -20ºF to +300ºF (-30ºC to +150ºC) 455ºF

(235ºC) with specified water or air cooling

Process Pressure To 400 psig (2.8 MPa)

Sensitive 5 mA @ 1x1010 photons/in2/sec.

@ 310 nm

Material

Body Mount AISI 316 Stainless Steel

Housing AISI 304 Stainless Steel

(sealed and Argon filled)

Connector

– Process

– Electrical

3/4" NPT female

MIL-C-38999 Series III size 15 (5 pin)

Sensor Silicon Carbide (SiC) photodiode

GE Energy

8499 Darrow Road

Twinsburg, OH 44087

1 (330) 425-3755

rsweb@ge.com

www.ge-energy.com/oc

* Flame Tracker is a registered trademark of General Electric Company.

© 2007, General Electric Company. All rights reserved.

GEA-13662C (03/07)

Loading...

Loading...