Page 1

MANUAL

GraviMaster-FGB-M05 (S)

Gravimetric Blender

Serial No. ...................

ISO 08.01.02.064.GB

986731

Rev. May 2001

Page 2

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 1

Gravimetric Blender

1.0 INTRODUCTION

2.0 CONTROLS

2.1 Blender startup

2.2 Blender status

2.3 Machine-mode

2.4 Production-modes

2.5 Mixer-mode

2.6 Dispense modes

2.7 Batch handling

2.7.1 Production control

2.7.2 Recipe to weight calculation

2.7.2.1 Method Standard

2.7.2.2 Method Percentage

2.7.3 Adding extra materials

2.7.4 Additive to regrind

2.7.5 Regrind control

2.7.5.1 Empty regrind Control

2.7.5.2 Stock Silo Control

2.7.6 Dispensing

2.7.7 Calculations

2.8 Datalogging

2.9 Certifi cates

3.0 USER INTERFACE

3.1 Operator-interface

3.1.1 Keyboard

3.1.2 User control

3.2 Recipes

3.2.1 Change components

3.2.2 Add/change recipes

3.2.3 Change current recipe

3.3 Timely information

3.3.1 Production screen

3.3.2 Material usage screen

3.3.3 Input & Output monitor

3.4 Adjustment of the gravimetric blender

3.4.1 Calibration of the weighbin

3.4.2 Tare of the weighbin

3.4.3 Hardware-reactiontime

3.5 Overview of parameters

3.5.1 Public parameters

3.5.2 Protected parameters

3.6 Reports and overviews

Page 3

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 2

Gravimetric Blender

3.7 Settings of the user-interface

3.7.1 Change the rights of an operator

3.7.2 Change entrycode

3.7.3 Change date and time

3.7.4 Revision code of the system

3.8 Menu hierarchy

4.0 INSTALLATION

4.1 Demanded connections

4.2 Attaching

5.0 ALARMS

5.1 Alarm reports and solutions

6.0 MAINTENANCE AND REPAIR

6.1 Maintenance

6.2 Replacement of parts

6.2.1 Replacement of printed circuit

6.3 Cleaning the machine

6.4 Transportation of the GraviMaster

7.0 TECHNICAL INFORMATION

7.1 General machine specifi cations

7.1.1 Safety measures

7.2 User-interface specifi cations

7.3 Valves specifi cations

7.4 Air pressure cylinders specifi cations

7.5 Electrical diagrams

Page 4

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 3

Gravimetric Blender

1.0 INTRODUCTION

GRAVIMETRIC FEEDING

An effi cient materials blending system is an essential feature of the modern plastics

processing industry. Dosing each component on the basis of weight shows distinct

advanta ges over traditional volumetric systems. The quantity of material delivered is

precise and unaffected by variations in bulk density, fl ow characteristics and particle size.

Ferlin Plastics Automation now have a range of more than twenty blenders that deliver

the benefi ts of gravimetric blending at a price that makes other gravimetric ... and most

volumetric systems ... look distinctly expensive.

FGB SERIES GRAVIMETRIC BLENDERS

“GraviMaster” blending systems are available in more than twenty diffe rent models with a

throughput capacity range from 10 to 750 kg/hr for the standard units. The number of

components on the standard unit is two to six. But purpose-built units may designed for

additional feeds up to a maximum of ten and a throughput capacity up to 1500 kg/hr.

The blending units may either fl ow-control-valve design or have a combination with

auger-feeders. The proven “GraviMaster” blending systems are being used successfully in

Injection-moulding, Blow-moulding, Sheet-extrusion and Film-extrusi on.

ACCURATE WEIGH SYSTEM

Each component is dispensed into a weigh-pan using one set of load cells. When all the

components are correctly weighed, the blend is discharged into a mixing chamber. A high

effi ciency horizontal mixer is programmed to give a uniform blend which discharges to a

storage bin with suction device, or directly into the processing machine hopper.

The system is capable of extremely accurate measurements of additive, even at very small

percentages or ratios. Load cells of the highest accuracy are used, weighing to within

0.01 gm. The accuracy of the process is enhanced by the software system which is

designed to compensate in a subsequent batch for any errors arising in a prece ding batch.

Overall accuracy of 0.1% can be achieved.

COMPACT AND MODULAR CONSTRUCTION

The units are designed and built as a modular construction using standard components

where possible, so that all components are readily obtainable. All components which

are in contact with the raw material are made in stainless steel. This includes hoppers,

valves, augers, weigh pan, mixer and mixing chamber. When auger feeders are instal led,

these can be quickly accessed for easy cleaning. The mixing chamber and weigh pan can

be removed easily for cleaning and access. The construction is in accordance with the

essential require ments under the CE regulations.

Page 5

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 4

Gravimetric Blender

RELIABLE PROCESS CONTROL

The FGB control system incorporates the latest in computer and micro processor

technology for total automation of recipe entry and stora ge, inventory control and process

monitoring. The control panel (user-interface) is provi ded with a micro-controller and

industrial PC with LCD-display, functional keyboard, fi ber optic communication cable (or

RS-422) and parallel printer port.

Features are:

• data storage of all plant raw materials.

• easy call up of materials for the formulation of recipes.

• fast identifi cation of recipes and call up for machine operation.

• automatic regrind control within chosen limits, so that regrind generation is matched

with usage.

• automatic additive to regrind control.

• a fi xed weight of blended material can be produced according to any of the stored

formulations.

• screen display of all process operation.

• reports of material used and batch histories can be printed on an optional printer

regularly.

• storage facility for components and recipes.

• functions are menu driven and take the operator through the required sequence of

actions with simple instructions.

• the software is pre-programmed with many options for the future, these are blenders

you won’t outgrow.

Options are:

• automatic stock silo control.

• extra level control of the blender hoppers.

• extra level control of the machine hopper.

• control and data for materials management systems.

• different language on the display.

• automatic loading of the hoppers can be provided separately with Ferlin loaders or

others of your choice.

• several blenders may be linked to a central user-interface to give integrated inventory

control over the whole process.

Page 6

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 5

Gravimetric Blender

2.0 CONTROLS

When all components are available the dispense of a batch starts. The cycle begins with

closing the weigh-pan. Then each of the requested components is dispensed and weighed in

the weigh-pan. When all the components of the recipe are correctly weighed, the blend is

dischar ged into the mixing-chamber. A horizontal mixer mixes the compo nents to a

uniform blend which discharges to a storage bin, or direct ly into the machine hopper.

2.1 Blender start-up

In this section is a short description of the normal start-up action of the blending system.

More details of the controls are described in the following sections. An emergency stop

can be made to shut-down the machine by pushing the button as indicated in drawing

1 in § 7.7.1.

Steps to follow for the start-up of the blending system:

[1] Plug the communication cable into the user-interface and control box on the blender.

[2] Connect air pressure to the blender and turn it on, 6 bar is recommended.

[3] Turn on the power. On the user-interface and control-box.

[4] Select the right language. The selected language is indicated.

Select a different language through key <↑> or <↓> and press <ENTER>.

[5] If necessary adjust date and time.

[6] Select the blender to be started.

[7] Select on the interface the desired recipe from the menu (F1)

‘controller / select recipe’

[8] Be sure there is no alarm active.

[9] Start the blender, press <START>.

The blender will now operate automatically on the select recipe.

2.2 Blender status

The control of the blender is based on a number of status. Each status gives an exact

description in which situation the controller is. The controller knows the following status:

Inactive

At the start-up of the blender several internal tests will be done automatically if the controller

can’t fi nd a recipe. In this status the blender will not start until a recipe is edited.

Standby

The blender is complete in rest but can be started any moment by giving the start-command.

In this status recipes, parameters and debug-commands can be sent to the controller.

Operating

The blender will now produce a blend for the selected recipe.

Page 7

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 6

Gravimetric Blender

Pause

When the pause-command is given for a temporary stop the blender will stop after the

cycle is complete.

Stop requested

The blender is operating but has received a stop-command. The stop-command will be

executed at the end of a batch-cycle. This status will be replaced automatically with ‘standby’

if nothing is done. If a start-command is given during the status ‘stop requested’ the status

will be ‘operate’ again.

Error

The controller has detected an error and therefore the system will stop. In a sub-menu at

the operator-interface the error will be displayed. The error situation can be recovered using

the <ENTER> command. The error must be solved then.

2.3 Machine-mode

The controller can be in two modes: Automatic and Manual. The operator can change the

mode using the menu item ‘controller’. This changing of mode is only possible while the

blender has status ‘standby’.

If a controller is in Automatic-mode, the recipe will be executed without the need of

an operator. This mode is used for production purposes and is only dependent on the

settings ‘production-mode’.

In automatic mode the keys mentioned below mean:

F5 Start-command (start-key)

F6 Stop-command (stop-key)

F7 Pause-command

F8 Continue-command (clear pause)

After a start-command in Manual-mode one batch will be executed. After this the machine status will be ‘standby’ again. The weighbin and mixbin-valve can be controlled manually.

In manual mode the keys mentioned below meaning:

F5 Step-command (One component of a batch)

F6 Reset-command (Back to the fi rst component of a batch)

F7 Empty weighbin

F8 Empty mixbin

Page 8

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 7

Gravimetric Blender

2.4 Production-modes

The production-mode of the blender indicates how the production will stop in automatic mode. This parameter can be changed using the menu (F1) ‘controller / public parameters’.

The production-mode has three options:

Continue

The blender will not stop automatically after the start-command. The blender will continue

the production, unless the blender runs out of material or an error occurs.

Weight->Alarm

If ‘Weight->Alarm’ has been chosen, a requested weight has to be given. After a start the

requested weight will be compared with ‘produced-weight’. If both are the same or the

‘produced-weight’ higher, the controller will send an alarm to the operator-interface. The

production will continue.

The alarm can be recovered setting the ‘production-weight’ to zero (0). This command is part

of the option-menu (F2) of the status screen.

Weight->Error

When using the option ‘Weight->Error’ a weight has to be given. After a start the requested

weight will be compared with ‘production-weight’. If both are the same or the

‘production-weight’ higher, the controller will send an error to the operator-interface. The

production will not continue in this case.

2.5 Mixer-mode

When all components are dispensed, the contents of the weighbin will be emptied. The

mixer in the mixing chamber, which contains the dispensed components, can be put in

different modes. Choose the menu (F1) ‘controller/public parameters’.

Normal

The mixer is off during production. If the components are dumped from the weighbin into the

mixer chamber the mixer will be on for a predefi ned number of seconds, defi ned by

‘mixerOnTime’. This parameter can only be changed if this option is chosen.

Pulsing

The mixer will pulse during production. Both on- and off-time ca be defi ned using the

parameters mixerPulseOnTime (time on) and mixerPulseOffTime (time off). These

parameters can only be changed if this option is chosen.

Off

The mixer is always off.

On

The mixer is always on, when the machine status is active.

Page 9

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 8

Gravimetric Blender

2.6 Dispense modes

The blender has two ways of dispensing: gravimetric and volumetric. One mode can be

selected or a combination of both. This can be defi ned choosing menu (F1) ‘controller /

public parameters’.

Gravimetric

All component of the batch are dispensed and measured separately. Gravimetric is more

accurate than volumetric, but takes more production time, ie., lower output.

Volumetric

All components of the batch are dispensed at the same time using the dispense time of each

component (calculated by the system). The components are dumped directly in the mixer

chamber. No measurement is done in this mode. Therefore this method is less accurate, but

the production time is faster, ie., maximum output

Combination

When combination is defi ned, one gravimetric will be followed by a defi ned number of

volumetric dispenses. This is defi ned by the parameter combinationRatio. This parameter can

only be defi ned if ‘combination’ is chosen. This mode has the best of gravimetric and

volumetric.

Use: normally the defi ned combination will be done (ex. 1:3). However, if the mixer chamber

is full, the process will automatically do a gravimetric dispense instead of a (possible)

volumetric one.

2.7 Batch handling

2.7.1 Production control

If a start command is given the controller will check if the blender actually can start. If a

hopper has a low-indication (optional) the controller will alarm.

Also the parameters are checked. These can be in confl ict with the recipe to be executed.

The following items will be checked (if applicable):

* Empty Regrind control

- The controlled hopper must contain regrind (according to recipe)

* Stock silo control (optional)

- Controlled hopper must contain regrind (according to recipe)

* Additive to regrind

- Controlled hopper must contain additive (according to recipe)

The blender will not start unless all conditions are met. A message will be sent to the user interface.

Page 10

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 9

Gravimetric Blender

2.7.2 Recipe to weight calculation

After a start-command the controller will calculate the requested weights of all components

of the selected recipe.

A recipe can be defi ned in two ways: ‘Standard’ and ‘Percentage’. These methods can

be defi ned in the recipe choosing menu (F1) ‘recipes / edit recipes’. The methods

‘Standard’ end ‘Percentage’ defi ne the relation of the components (Regrind, Natural and

Additive) in a recipe.

2.7.2.1 Method Standard

The different components are defi ned as follows:

Regrind : Percentage of the batch weight

Natural : Relation between other naturals

Additive : Percentage of the totals of all naturals

Example

Batchweight 2000.0 gr.

Regrind 20.0%

Natural 1 4

Natural 2 1

Additive 5.0%

Regrind : 20.0% of 2000.0 gr. 400.0

Naturals : naturals + additive = 80.0%

naturals + (0,05 * naturals) = 80.0%

naturals = 80.0/1.05 = 76.2%

natural 1 = 4/5 * 76.2 = 61.0% 1220.0

natural 2 = 1/5 * 76.2 = 15.2% 304.0

Additive : 80.0 - 61.0 - 15.2 = 3,8% 76.0

TOTAL 2000.0

Page 11

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 10

Gravimetric Blender

2.7.2.2 Method Percentage

The different component are defi ned as follows:

Regrind : Percentage of the batch weight

Natural : Percentage of the batch weight

Additive : Percentage of the batch weight

Total sum must be 100%.

Example

Batchweight 2000 gr.

Regrind 20.0%

Natural 1 60.0%

Natural 2 15.0%

Additive 5.0%

Regrind : 20.0% of 2000.0 400.0

Natural 1 : 60.0% of 2000.0 1200.0

Natural 2 : 15.0% of 2000.0 300.0

Additive : 5.0% of 2000.0 100.0

TOTAL 2000.0

2.7.3 Adding extra materials

The defi ned amount of the component defi ned in the recipes can be changed external

using some special parameters. The controller has two methods: ‘Additive to regrind’ and

‘Regrind Control’.

IMPORTANT

Addition of extra material using ‘Additive to regrind’ and ‘Regrind Control’ is only

possible when a ‘standard’ recipe is used.

Page 12

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 11

Gravimetric Blender

2.7.4 Additive to regrind

It is possible to dispense more additive in relation to the amount of regrind. Choose for

this defi nition menu (F1) ‘controller / public parameters’. A maximum of two hoppers

(additive) can be defi ned (additiveToRegrindHopper). The defi nition must be completed

defi ning the requested percentage (additiveToRegrindPerc).

ADDITIVE TO REGRIND

Not activated Activated with 2.0%

Component Recipe Weight (g) Recipe Weight (g)

Regrind 20.0% 400.0 20.0% 400.0

Natural 1 4 1219.0 4 1213.0

Natural 2 1 304.8 1 303.2

Additive 5.0% 76.2 5.0% + 2.0% 83.8

2.7.5 Regrind control

The fl ow of ‘regrind’ is very often not continuous due to the process. There are two

methods to adjust the amount of regrind to the actual process: ‘Empty Regrind’ or ‘Stock

Silo’.

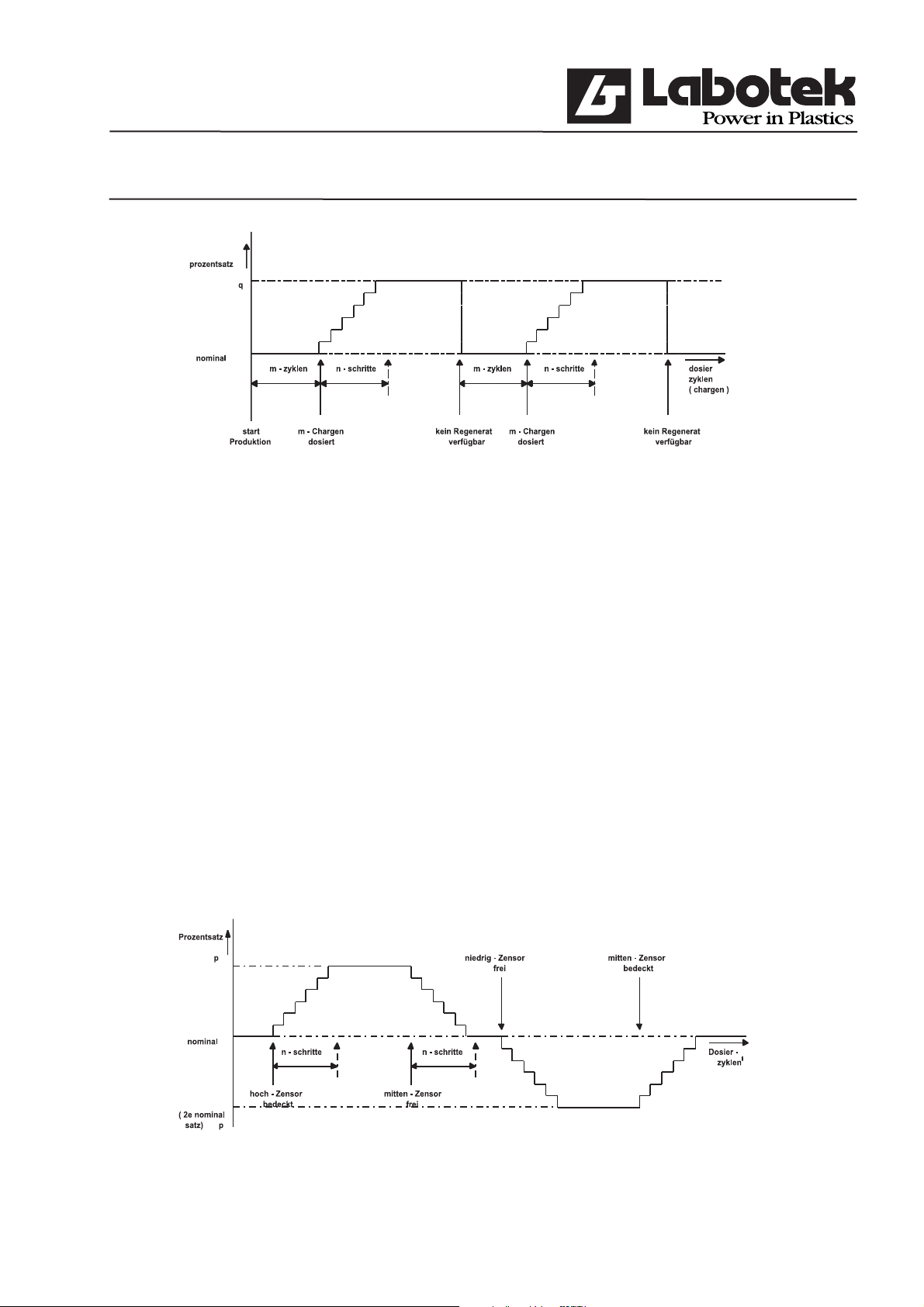

2.7.5.1 Empty regrind Control

Empty regrind control means: keep the regrind-hopper empty. The material must be

dispensed, because otherwise another parts of the process can be destroyed (regrind return

mechanism).

Through menu (F1) ‘controller / protected parameters’ the process can be activated. After

the process is started a defi ned amount of batches (Empty regrind wait count) must be

awaited before the percentage will be increased. The percentage will be increased in

the defi ned number of steps (Dispensevariation cycl.) until the requested percentage is

reached (Dispense increase).

If not enough material can be dispensed from the regrind hopper, then regrind will be reset

to the original setting (recipe).

Page 13

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 12

Gravimetric Blender

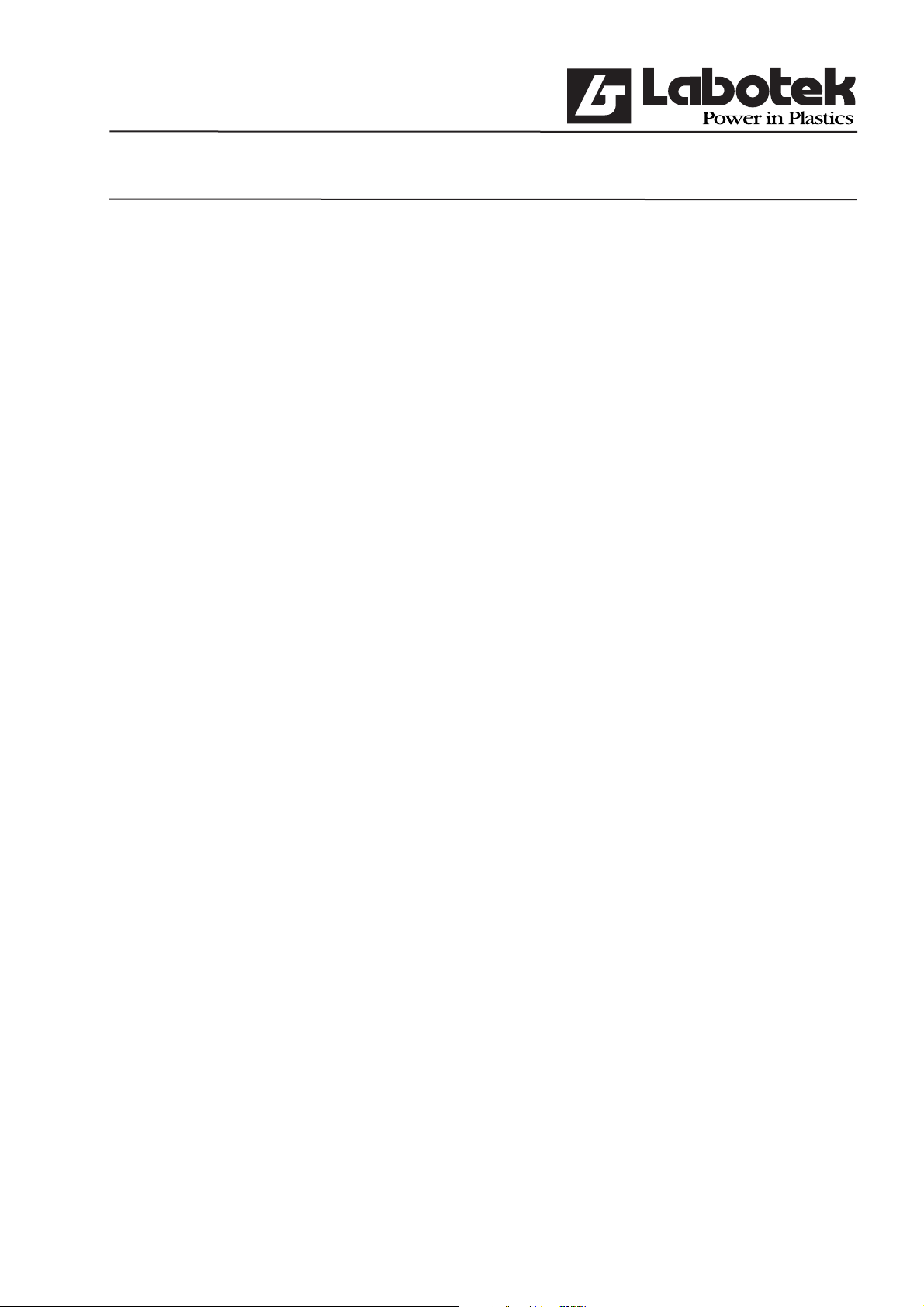

2.7.5.2 Stock Silo Control

A regrind silo can have (optional) three sensors to detect high- low- and middle. If the

controller has these sensors, ‘Stock-Silo’ regrind control can be activated, choosing menu

(F1) ‘controller / protected parameters’.

If the high-sensor is true, the silo is almost full. Therefore more regrind will be dispensed.

This is the same as described in ‘empty regrind control’. This will be done until the middle

sensor is not true anymore. In a defi ned number of steps the process will dispense the

original setting of the recipe.

If the low-sensor is true, the silo is almost empty. Therefore less regrind will be dispensed.

This is the inverse as described in ‘empty regrind control’. This will be done until the

middle sensor will become true. In a defi ned number of steps the process will dispense

the original setting of the recipe.

Page 14

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 13

Gravimetric Blender

2.7.6 Dispensing

Dispensing of the different components will start after the calculation of the related weights.

The components are dispensed in the order as defi ned in the recipe (gravimetric only). In

volumetric mode all components are dispensed at the same time.

Every mechanical valve has a reaction time. The controller uses the ‘Hardware Reaction

Time’ to calculate the time which the dispense valve must be activated. The ‘Hardware

Reaction Time’ is the maximum active time of the valve when no material is dispensed. The

controller uses a pulse of 5ms in the following algorithm:

OpenTime = Weight [g] / dipenseSpeed [g/s]

OpenPulses = (OpenTime [s] / 0.005 [s]) + HardwareReactionTime [Puls]

After every dispense cycle the weight is measured. The weight bin must be stable before

the weight can be measured, therefore a time delay is inserted between dispense and

measuring. When the controller starts measuring the signal must be stable for at least 1 sec.

(signal within the ‘Weighbin-variationband’)

After measuring the weight of the fi rst dispense some calculations can be done, and with

the results parameters can be changed. Result is a more accurate next dispense. After the

fi rst dispense of a material one of the following situation occurs:

Dispense is correct

The difference between calculated- and measured weight is less then the dispense accuracy.

In this case extra dispense tries of this material are not necessary.

Dispense not correct (too little)

The difference between calculated- and measured weight is more than the dispense

accuracy but there is less dispensed (measured) than calculated. In this case the controller

reacts according to the chosen ‘alarm-type’. The following ‘alarm-types’ are possible:

IGNORE No extra dispense-tries. Relations within the recipe will corrected by

re-calculations.

WARNING The controller tries to reach the dispense-accuracy by extra dispenses. The

extra dispenses are limited by the parameter ‘dispenseTry’. When after a

maximum number of dispense tries, the accuracy is not reached the controller

sends a warning only to the user (= The controller continues with the next

material).

ERROR The reaction of the controller is equal to ‘WARNING’ only an error is sent

to the user when the accuracy is not reached. Now the controller waits for a

confi rmation (enter) to initiate new dispense tries of the same material. This

process goes on until the dispense accuracy is reached.

Page 15

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 14

Gravimetric Blender

Dispense not correct (too much)

To much material has been dispensed so there is nothing the controller can do. Of course

the relations within the recipe will corrected by re-calculations.

After the fi rst dispense try in all of the above mentioned cases a new dispense rate will

be calculated. If the measured dispenserate (measured weight / dispense time) differs from

the used dispenserate a correction can be made. A correction is only made if the difference

between the measured- and used dipenserate is less then the boundary

(dispenseRateVarBand). This method prevents the controller calculating incorrect values

e.g. if a hopper runs out of material. The new dispenserate is calculated by the next

algorithm:

dispenseRate = ((4 * dispenseRate) + (measuredWeight/dispenseTime))/5

When all components of a recipe are dispensed the contents of the weighbin is dumped

in to the mixer chamber. The weighbin dumps the material by opening a valve for a given

time. This time (weighbinDumpTime) is a parameter which can be changed. It is also

possible to start the mixer at this time (see mixer-mode). There are two conditions for

opening the weighbin valve:

Condition 1. The mixbin-vale may not be open (if present)

Dispensed material must be mixed fi rst before it can be used. Therefore the mixbin-valve

and weighbin-valve may not be open at the same time.

Condition 2. The mixerchamber may not be full

If the input-device indicates a full mixerchamber no material may be dumped into it (it

is full)

2.7.7 Calculations

In order to be able to dispense with high accuracy, the actual measured weights will be

used to recalculate the requested weight of the next component. The dispense will be

optimised if possible in order to guarantee a good batch (good relation).

IMPORTANT

Best dispense order is:

Regrind, Natural, Additive

Page 16

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 15

Gravimetric Blender

2.8 Datalogging

Some production data is stored. This is shown at the user interface and can also be printed.

* Batch data

- measured weight (each component)

- dispenserate of each component

- recalculation to recipe

* Total data

- Sum of batch data

* Material usage

- dispensed amount of each hopper

- percentages

The controller saves all data in battery-backup memory.

Page 17

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 16

Gravimetric Blender

2.9 EQ-Net Certifi cate

Page 18

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 17

Gravimetric Blender

2.10 ISO Certifi cat

Page 19

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 18

Gravimetric Blender

3.0 USER INTERFACE

3.1 Operator-interface

3.1.1 Keyboard

Description:

F1 Open main menu. All other sub-menu’s can be selected

F2 Open option menu. The contents is dependent of the actual screen.

F3 Will be used during calculation

F4 Choose node number

The function keys F5 up to F8 is dependent of the machine mode (automatic, manual).

FUNCTION KEY IN MACHINE-MODE

Function key Automatic Manual

F5 Start production Dispense one component

F6 Stop production Mixer

F7 Pause Dump weightbin

F8 Start after pause Dump mixer chamber

Page 20

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 19

Gravimetric Blender

Besides the function key there are some special keys:

DIRECT MACHINE-CONTROL KEYS

Key Description

# or F4 Select FGB

START Start command, the same as F5

STOP Stop command, the same as F6

DATA ENTRY KEYS

Key Description

0-9 Entry of numbers

+/- Increase and decrease function (value of fi eld can be changed by step)

ENTER Select function. (choise is made and entered values are saved)

. Decimal point

ESC Escape, Leave menu without choice

(Home) (Arrow up with line) Jump to fi rst element of row

(End) (Arrow down with line) Jump to last element of row

INS Insert function to add recipes and components

DELL Delete function to delete recipes and components

← Backspace (above DELL-key) delete the character left of the cursor

← ↑ → ↓

Cursor-keys, move cursor and menu-items

Page 21

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 20

Gravimetric Blender

3.1.2 User control

The user-interface consists of several screens which can be selected by a menu. A screen

consists of objects only one object in a screen is active (selected). By using the ↓ en ↑

arrow keys the actual selected object can be changed. Pressing <ENTER> activates the

selected object.

Button

After activating the button a command (or set of commands) is (are) executed. The name of

the button represents the functionality of the button.

Number input fi eld

When a number input fi eld is selected it can be activated by either the <ENTER> key or

just typing the numbers. The activated input fi eld shows a cursor at the position where

the next number will be placed. To deactivate (leave) the input fi eld use one of the the

following keys <ENTER>, <ESC>, ↓ or ↑

Text input fi eld

The text input fi eld is equal to a number input fi eld but it also accepts characters. Because

the keyboard doesn’t have character-keys a special method is implemented to enter

characters.

To enter a character in a text inputield fi rst activate the object with the <ENTER> key.

When the input fi eld is activated a cursor is shown at the fi rst position. At this moment it

possible to select a character with the <+> and <-> keys. After a character is chosen the

next position can be selected with the → arrow key.

Option fi eld

Option fi elds are objects with a toggle function (yes/no) or (true/false). When the button

according to the option fi eld is activated the value is toggled. The actual value of the option

fi eld is displayed by a cross. When the cross is visible the object has the value ‘yes’ or

‘true’ otherwise the value is ‘no’ or ‘false’.

Optionlist

Optionlist fi elds are fi elds that can contain a limited set of values. The optional values

become visible as the object is activated. Now the required value can be selected by using

the ↑ and ↓ key and select it with <ENTER>.

3.2 Recipes

Recipes constitute the core of the controller. They contain all information about the

material to be produced. By the menu (F1) ‘recipes / edit recipes’ it is possible to add

recipes to the controller. One recipe consists of one or more (max 12) components which

can be changed independently.

Page 22

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 21

Gravimetric Blender

3.2.1 Change components

There is a components list available in the controller. The list can be used by the operator

to defi ne recipes. The components list stores the name and type of a component and is

maximised to 100 components. The operator is free to chose a name for a component.

There are only three options namely:

Regrind Scrap-material

Natural Basic-material

Additive Additive-material (e.g. masterbatch)

One component of every type is already present in the list. These components have the

name ‘no name’ and can not be deleted from the list.

To add or modify components chose the menu (F1) ‘recipes / edit components’. The next

screen will be displayed:

[0]OPERATING AUTO[ ] [ ] [ ]

STATN:[0] FGB#00: (No name) STATUS OPERATING

MODE: AUTOMATIC

------------------------ [Edit components]

Name Type

SCR GARDEN CHAIR REGRIND

ADEG-2RN NATURAL

ADEG-4RN NATURAL

ANTISTATIC ALU ADDITIVE

<ENTER> = edit component

<INSERT> = insert component

<DELETE> = delete component

F1Menu F2Option F3 F4Clear F5Start F6Stop F7Pauze

F8Cont.

Page 23

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 22

Gravimetric Blender

In the screen it is possible to select a component with the arrow keys. After a component has

been activated by <ENTER> the name and type can be changed. If the fi eld type has been

activated an option list will appear. One of the options (Regrind, Natural or Additive) must be

chosen.

By pressing the <INS> insert-button a new component will be added to the list. The controller

places a standard name and type into the fi elds. The operator now can change these fi elds to

the correct name and type.

Deleting a component from the list can be done by pressing the <DEL> delete-key. The

component pointed to by the highlighted line will be deleted from the list.

The option-key (F2) contains two functions in the screen ‘edit components’: print components

and search components, activate one of them by selecting and push <ENTER>.

Example: Add a new component

Goal: Component with he name “WHITE” and type “ADDITIVE”

Actions:

Step: Menu (F1) ‘recipes’ <ENTER>

Step: ‘edit components’ <ENTER> (By using the arrow-keys)

Name Type

Step: Press <INS> key (INS = insert)

Name Type

< > [NATURAL]

Step: Search for the character W by using the + or - key:

<+> Starts with special characters and numbers then the alphabet

<-> Starts at the end of the alphabet

When the + or - key is hold down the character will change fast.

Page 24

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 23

Gravimetric Blender

If the character W has been found the ? key is pressed.

Name Type

<W> ? [NATURAL]

Step: Repeat the same procedure for the character H, I, T and E. When the whole name is

given press <ENTER>. Now the name ‘WHITE” is stored.

Name Type

?WHITE? [NATURAL]

Step: Press the ? key again to select the type-fi eld.

Name Type

[WHITE] NATURAL ?

Step: Press <ENTER> to activate the fi eld.

Name Type

[WHITE] [NATURAL ]

REGRIND

NATURAL

ADDITIVE

Step: Select ADDITIVE by using the arrow keys and confi rm by pressing <ENTER>.

Name Type

[WHITE] ?ADDITIVE ?

Step: To confi rm the new component press the arrow key ? or use the <ESC> key.

Now the “ADDITIVE” component “WHITE” is added to the list. The maximum number of

components is 100.

Page 25

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 24

Gravimetric Blender

3.2.2 Add/change recipes

The terminal has the capacity for 340 recipes. This space is divided into 4 spices so every

connected FGB can contain 85 recipes. If the menu item (F1) ‘recipes / edit recipes’ is

chosen a list with recipes will be displayed.

Now recipes can be added, changed or deleted. The <DEL>-key deletes the current recipe of

course there will be a conformation for the operator. By adding <INS>-key or changing

<ENTER> the current recipe the same screen is used.

[0]OPERATING AUTO[ ] [ ] [ ]

STATN:[0] FGB#00: (No name) STATUS OPERATING MODE: AUTOMATIC

+--------------------------EDIT RECIPE

Number : [ 10]

Name : CRATE

Colour : [YELLOW ]

Batch : [ 2]Kg.

Interpretation : [STANDARD ]

H# Component Quant Alarm Rate (g/s)

1 noname (r) 50.0 IGNORE 957.2

2 noname (n) 2.0 IGNORE 891.4

3 noname (n) 2.0 IGNORE 875.5

5 noname (a) 4.0 IGNORE 8.3

4 <ENTER> = edit line

5 <INSERT> = insert line

6 <DELETE> = delete line

7 <HOME> = sort up

8 <END> = sort down

9

10

11

12

+-------------------------------------------------------------------------

F1Menu F2Option F3 F4Clear F5Start F6Stop F7Pauze

F8Cont.

All fi elds of the recipe are visible in the screen. By selecting the objects with the arrow-keys

and activate them with the <ENTER>-key it is possible the change the them. Below a list is

given with every fi eld of the recipe giving some extra information about the fi eld.

Page 26

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 25

Gravimetric Blender

FIELD OF A RECIPE

Fields Description

Number Unique recipe number

Name Recipe name

Colour Characterfi eld for the colour-name

Batch Total batchweight

Interpretation Recipe calculation

Component Link hopper to component

The screen can be left by pressing the <ESC>-key. Now the terminal checks the recipe and if

it is correct it will be stored. If the recipe is not correct the operator can chose either changing

the recipe or discard all changes.

The option-key (F2) contains other functions in the screen ‘edit recipes’. The next functions

are available:

OPTION MENU IN EDIT-RECIPE

Option Description

Copy recipe Copies the recipe to the same or other terminal.

Find number Searches for the recipe with the given number.

Find colour Searches for the recipe with the given colour.

Find name Searches for the recipe with the given name.

Print recipe Sends the current recipe to the printer.

Print all recipes Prints all recipes of the actual controller.

Example: Add a new recipe

Goal: Add a 2 kg standard recipe .

Remark: The required component names should have been added.

Page 27

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 26

Gravimetric Blender

Actions:

Step: Menu (F1) ‘recipes’ <ENTER>

Step: ‘edit recipes’ <ENTER>

Name Nr. Colour

Step: Press the <INS> key (INS = insert)

Number: [1]

Name: ? ?

Colour: [ ]

Batch: [ 2.0] kg

Interpretation: [ STANDARD ]

H# Component Quantity. Alarm Speed (g/s) 1 2 : : 10 11 12

The name and colour of the recipe is entered in the same way as the components name

(§ 3.2.1).

Step: Press the arrow key <↓> to select the batch.

Batch: < 2.0> kg

When the batchweight must be changed it can be done by the use of the numeric-keys

IMPORTANT Never enter a batchweight higher then the standard value.

Page 28

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 27

Gravimetric Blender

Step: Press the arrow-key <↓> once

Interpretation: < STANDARD>

Step: When the interpretation must be changed into PERCENTAGE press the <ENTER>

key. Now select PERCENTAGE with the arrow keys and confi rm with <ENTER>.

Interpretation: STANDARD

PERCENTAGE

Step: Press the arrow key <↓> once.

H# Component QTY Alarm Speed (g/s)

1

2

:

12

Step: Select the hopper you want to edit with the arrow-keys and press <ENTER> to

activate.

H# Component Quantity Alarm Speed (g/s)

1

2

:

12

Step: Press <ENTER>.

Name Type

Noname REGRIND

Noname NATURAL

Noname ADDITIVE

WHITE ADDITIVE

Page 29

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 28

Gravimetric Blender

Step: Use the arrow-keys <↓> to select a component and press <ENTER>.

Use the arrow-key <?> to select Quantity. Enter the quantity and press <ENTER>.

Use the arrow-key <→> to select Alarmtype and press <ENTER>.

Alarm

Ignore

Ignore

Warning

Error

Step: Select an alarm type by using the arrow-keys and press <ENTER>.

It is not necessary to enter a speed (g/s) because the terminal already has entered

standard values and the GraviMaster calculates new speeds and updates the recipe.

Step: Press the arrow-key <ο> to select the next hopper number.

Depending on the model, it is possible to use upto 12 hoppers.

The terminal has a keyboard but the keyboard doesn’t contain characters. Therefore it is

possible to connect a standard AT keyboard to the terminal. This keyboard must connect to

a connector which is placed on the PCB in the terminal. When using a AT keyboard, than:

• Switch power off the terminal

• Disconnect the internal keypath from the PC board

• Connect the AT keyboard on the PC board

• Switch on the terminal

Now you can use the AT-keyboard. When you are ready, than connect the terminal-keyboard

again. This has to be done when the terminal is switched off.

3.2.3 Change current recipe

When an operator wishes to produce a new product a change of the current recipe must be

done. To change the current recipe select menu (F1) ‘controller / select recipe’. The terminal

now shows a list with all recipes. The recipe which is marked with an <↓> is the actual

recipe, this recipe is also loaded in the controller.

IMPORTANT

When a new recipe is selected be sure that all hoppers are fi lled with material. The controller

calculates new dispense-rates by a fast algorithm in the fi rst 5 batches.

Page 30

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 29

Gravimetric Blender

3.3 Timely information

It is possible to get an over view of one of the connected controllers. Therefore three screens

are available on the terminal: production-screen, material usage-screen and input/output screen.

3.3.1 Production screen

The production-screen can be reached by selecting menu (F1) ‘production / production

status’. The production-screen displays information about the current controller. The

information on the screen is updated every 0.3 sec.

Page 31

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 30

Gravimetric Blender

OPERATING AUTO[ ] [ ] [ ]

STATUS:[0] FGB#00: (No name) STATUS OPERATING MODE: AUTOMATIC

PRODUCTION STATUS]

Production mode :

CONTINUE Dispense mode: GRAVIMETRIC

Name: PIR-HOUSING Mix mode : PULSE

Recipe CRATES YELLOW

[current] [previous] [total]

H# Type Recipe Requested Dispensed Recipe Dispensed Recipe Dispensed

1 REG [ 20.0] 400.0 20.0 400.0 20.0 1600

2 NAT [ 1.0] 1523.8 1.0 1523.8 1.0 6095

3 ADD [ 5.0] 76.2 5.0 76.2 5.0 305

4

5

6

7

8

9

10

11

12

totals

[ACCEPT] [UNDO CHANGES] 0.1 2000.0 8000

Produced weight: 82000

F1Menu F2Option F3 F4Node F5Start F6Stop F7Pauze

F8Cont.

During production it is possible to change the recipe without a change of the current recipe.

The recipe can be changed in the production-screen by selecting a fi eld (arrow-keys). Next

enter a new value and press <ENTER> to confi rm. Now the recipe is changed but the

controller uses the new values at the start of a new batch.

3.3.2 Material usage screen

The material usage screen menu (F1) ‘production / material usage’ displays the total

quantity of material witch is used ordered by hopper number. The quantities which are stored

doesn’t depend on the current recipe. The material usage screen is erased from memory by

one of the following actions:

* Command given by the operator

* After a operator prints the screen.

This is possible by using option-key (F2) and selecting the option you require and pressing

<ENTER>.

Other values witch are stored in the material usage screen are: date of the last erase-action,

number of batch-cycles and production speed (kg/hour).

Page 32

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 31

Gravimetric Blender

3.3.3 Input & Output monitor

The input & Output screen menu (F1) ‘controller / digital I/O monitor’ displays all digital

input and output lines. Every object in the screen can be selected by using the arrow-keys.

When a output line is selected and <ENTER> is given the digital output will toggle. The

operator has control of the digital outputs when the controller is in ‘manual mode’.

3.4 Adjustment of the gravimetric blender

The controller has some system-parameters. These parameters must be entered during the

installation of the GraviMaster. The controller uses these parameters to read the weigh bin

signal correctly, to open the weigh bin-valve, control the dispense-valves or motors etc.

3.4.1 Calibration of the weigh bin

The controller uses two known (entered) calibration-points to calculate a weighline. The

controller uses this line to fi nd a weight by every input-signal. The two calibration-points

must be entered by the operator by the menu (F1) ‘controller / calibration / loadcell’.

The calibration-procedure of the loadcell has two steps. Extra information is given to the

operator by every step. This information is displayed at the top of the screen. First be sure

that the weighbin is empty and press (F3). The weight of the empty weighbin is measured

and stored by the controller. Next step is to fi ll the weighbin with a reference-weight and be

sure that the input fi eld on the terminal has the same value. Now press (F3) again and the

second calibration-point is measured and stored. The calibration-procedure is now ready.

IMPORTANT

The second calibration-point must be greater then the fi rst one.

3.4.2 Tare of the weighbin

Due to temperature, age, overload etc. it is possible that the weighline of the controller

‘moves’. When the line has moved a zero-weight will be displayed that isn’t zero. To move

the weightline back it is possible to start a new calibration procedure. But the calibration procedure takes a lot of time and the weightline is correct (it only moved). The tare-function

moves the line back to its zero-point. To start the tare function enter menu (F1) ‘controller

/ calibration / loadcell-tarration’.

Page 33

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 32

Gravimetric Blender

3.4.3 Hardware-reactiontime

The adjustment of the number of pulses is very important for the autopulse system of the

FGB-M05. When dosing less than 8 gram of material, the GraviMaster will switch over to the

autopulse system. In the hardware-reactiontime the opening time can be adjusted by increasing

the clockpulses. One clockpulse is 5 ms (0,005 s).

The autopulse system does not caculate the rate in g/s but in g/puls. It calculates how many

pulses he needs for an amount of material. This is why it is very important that the opening time

of the pulse is not too long, because it cannot dose accurate anymore.

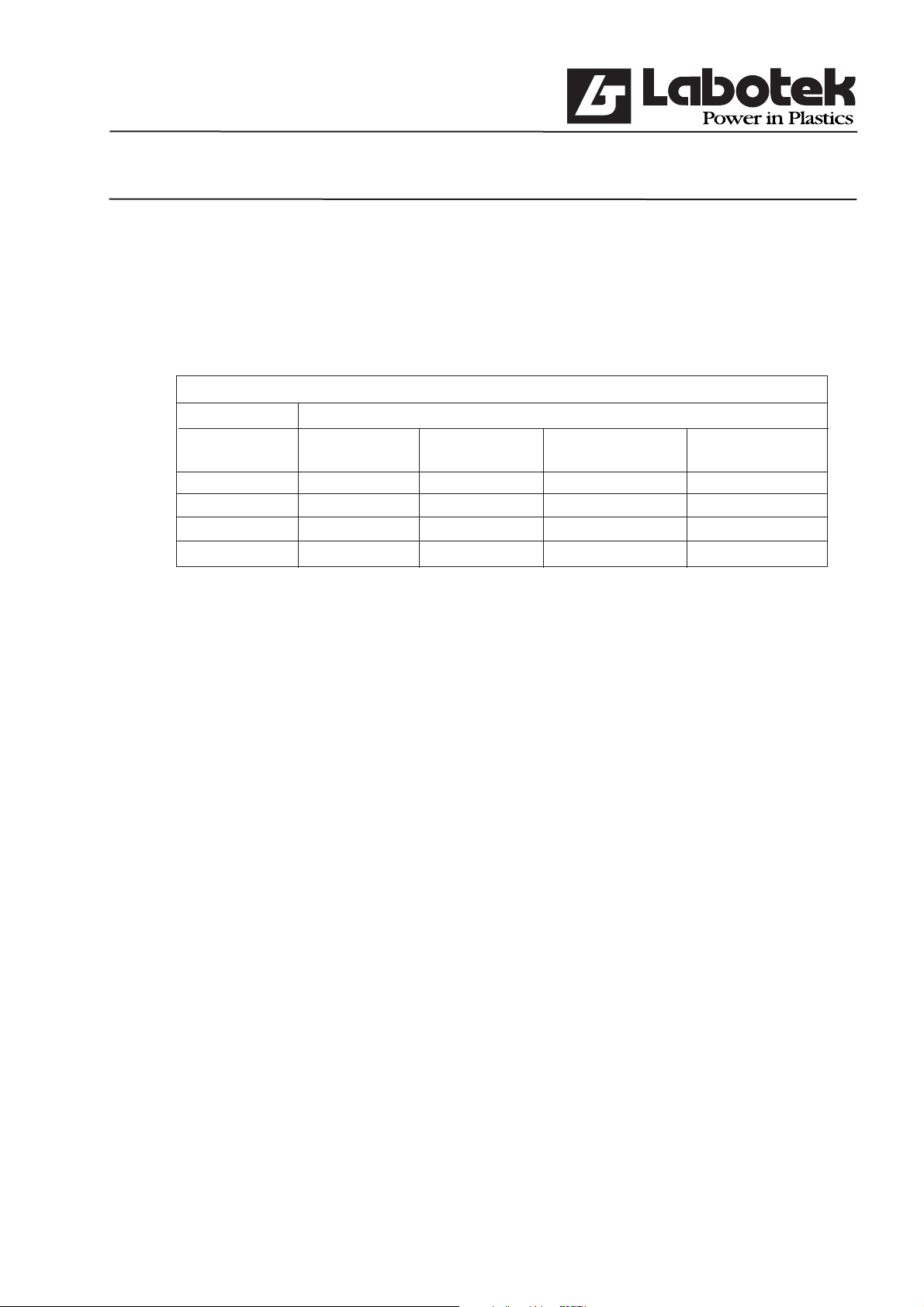

Standard adjustment:

Hopper

Clockpulses

Time (s)

1 3 0,015

2 4 0,020

3 4 0,020

4 3 0,015

3.5 Overview of parameters

The controller has a great number of parameters. The parameters are necessary to control

the machine with all its features. The parameters are broken down into two groups; public parameters and protected-parameters. Free parameters may be changed by an operator,

protected parameters may only be changed if the password is given.

3.5.1 Public parameters

Below a list is given of all parameters which are attainable by the menu (F1) ‘controller /

public parameters’.

Page 34

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 33

Gravimetric Blender

PUBLIC PARAMETERS

Parameter Description Init

AlarmReport Indicates if alarm-reports must be printed. No

ProductionReport Indicates if production-reports must be printed. No

*)

*)

If so the parameter interval-time must be given also.

Interval

BatchReport Indicates if batch-reports must be printed. No

Pauze (time) before printing the next production-report.

01:00.00

*)

ProductionMode Actual production-mode. There are three possible CONTINUE

modes; CONTINUE, WEIGHT and ALARM_

WEIGHT. If the mode WEIGHT os ALARM_

WEIGHT has been selected the parameter production

Weight must also be given.

ProductionWeight The FGB stops his production when the production 100 [Kg]

Weight is reached. (productionMode must be

WEIGHT or ALARM_WEIGHT).

DispenseMode Actual dispense-mode. There are three possible GRAVIMETRIC

modes; GRAVIMETRIC, VOLUMETRIC and

COMBINATION. If the mode COMBINATION is

chosen the parameter combinationRatio must be given.

CombinationRatio Relation between the volumetric and gravimetric 3

dispenses. (one gravimetric dispense and x

volumetric dispenses).

MixMode Actual mixermode. There are four possible modes; PULSE

ON, OFF, NORMAL and PULSE. In normal-mode

the parameter mixerOnTime must be given. In the

mode pulse the parameters mixerPulseOnTime and

mixerPulseOffTime must be given.

MixerOnTime Time the mixer is activated after the material is 10 [s]

dumped out of the weighbin.

MixerPulseOnTime Time the mixer is activated in pulse-mode. 5 [s]

MixerPulseOffTime Time the mixer is not activated in pulse-mode. 15 [s]

AdditiveToRegrind Percentage additive to regrind which must be added. 0 [%]

Percentage 1/2

AdditiveToRegrind Hoppernumber in which the additive is. Hopper 5

Hopper 1/2

WeighbinDumpTime Time the weighbinvalve is activated (dumping of 4 [s] 0,5 kg unit

material into the mixerchamber). 6 [s] 1,2,5 and

25 kg unit

LevelControlWaitTime Time between the full signal of the mixerchamber 8 [s]

sensor and opening the mixerchamber-valve.

LevelControlDumpTime Time between the free signal of the mixerchamber

sensor and closing the mixerchamber-valve. 1 [s]

*) No = [ ], Yes = [X]

Page 35

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 34

Gravimetric Blender

For example if the alarm report must be activated. First select the option fi eld by using the

up- and down-keys. Now press <ENTER> to activate the option fi eld. If the option fi eld

displays a [X] the alarm report is activated. The parameters must be updated into the

controller, so select the OK button and activate it by pressing <ENTER>. Updating the

parameters into the controller must be done for every parameter.

3.5.2 Protected parameters

Below a list is given of all parameters with are attainable by the menu (F1) ‘controller /

protected parameters’.

Page 36

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 35

Gravimetric Blender

PROTECTED PARAMETERS

Parameter Description Init

BatchWeight Total weight of one batch. This value is copied into 0,5 [kg]

every recipe when it is created.

DispenseTry Maximum number of tries per component to reach 4

maximum accuracy

DispenseAccuracy Minimum accuracy for each component. 25 [%]

DispenseRate Maximum deviation when a re-calculation of the 30 [%]

CorrectionBand dispense-speed is done

SiloPresent Indicates the ‘Stock-Silo’ regrind control process No

is activated.

MaximumTare Maximum absolute deviation from the zeropoint 40 [g]

Variation of the weighbin.

SiloHighCount Number of batches with the highness activated 100

before the controller initiates an alarm.

SiloLowCount Number of batches with the lowsensor not activated 100

before the controller initiates an alarm.

EmptyRegrind Indicates the ‘Empty Regrind’ regrind control No

process is activated.

EmptyRegrindHopper Indicates the hopper which is used in the empty Hopper 1

regrind process

EmptyRegrindCycles Number of batches empty regrind waits before 1

increasing regrind (startprocess)

Dispense inc/dec Maximum percentage for the regrind control 10 [%]

processes

Dispense Number of steps in whitch the maximum must 10

VariationCycles be reached.

LoadcellGain Amplifi cation-factor for the loadcell signal 16

LoadcellOverload Maximum weight in the weighbin. The controller 800 [g]

initiates an error on this point.

LoadcellSettleTime Time between the dispense of the last component 1 [s]

and reading the weigbin-signal.

(to eliminate vibrations).

LoadcellWeight To read a correct weight 8 samples must fi t to this 10 [g]

BandWidth absolute band.

FGB-Name/Nr. Name of the controller; This name is used in the

user-interface of the terminal.

Page 37

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 36

Gravimetric Blender

3.6 Reports and overviews

There is the possibility of printing several reports and overviews. Underneath a list is made

with the reports and overviews with behind them the section and page where instructions for

printing are given.

* batch report § 3.5.1

* production report § 3.5.1

* material usage report § 3.3.2

* error report § 3.5.1

* recipe overview § 3.2.2

* component overview § 3.2.1

* alarm overview § 5.1

3.7 Settings of the user-interface

3.7.1 Change the rights of an operator

The terminal has some area’s which are protected by a password; protected-parameters, debug monitor etc. Before an operator can use, modify or see these area’s he has to perform a login

procedure. This procedure starts by choosing menu (F1) ‘system / login’ the controllers asks

now for an ID (see below). When the ID is correct the menu item login changes to logout.

To lock the system select menu (F1) ‘system / logout’ the menu item changes to login again.

3.7.2 Change entrycode

To change ID chose menu (F1) ‘system / change ID’.

IMPORTANT

Standard the ID is set to 1234. After it is changed the ID 1234 can’t be used.

There is no way to display the current ID so store the actual ID in a safe place.

When you lost the new code, please contact your dealer.

Page 38

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 37

Gravimetric Blender

3.7.3 Change date and time

Date and time of the terminal can be changed by entering menu (F1) ‘system / time and date’.

3.7.4 Revision code of the system

The terminal has the possibility to display the revision and those of the connected controllers.

This information can be important for system-errors when you inform the dealer. To display

this information chose menu (F1) ‘system / revision’

3.8 Menu hierarchy

PRODUCTION CONTROLLER RECIPES SYSTEM

Production status Select recipe Edit recipes Login/logout

Change ID

Material usage Public parameters Edit components

Protected parameters Time and date

Revision

Alarm history

Cablibration >>>

Hardware reaction time

Digital I/O Loadcell

monitor Loadcell tarration

Select automatic

mode

Select manual mode

Page 39

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 38

Gravimetric Blender

Reference to section:

Production

Production status § 3.3.1

Material usage § 3.3.2

Controller

Select recipe § 2.1

Public parameters § 3.5.1

Protected parameters § 3.5.2

Alarm history § 5.1

Calibration

Hardware reaction time § 3.4.3

Load cell § 3.4.1

Load cell tarration § 3.4.2

Digital I/O monitor § 3.3.3

Select automatic mode § 2.3

Select manual mode § 2.3

Recipes

Edit recipes § 3.2.2

Edit components § 3.2.1

System

Login/logout § 3.7.1

Change ID § 3.7.2

Time and date § 3.7.3

Revision § 3.7.4

Page 40

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 39

Gravimetric Blender

4.0 INSTALLATION

4.1 Services

For installation 1ph or 3ph supply is required dependent on type of unit and a 1/4” air supply

with a minimum 6bar.

4.2 Mounting

There are several ways where to place the GraviMaster, namely

- on a frame

- on a mezzanine

- on the machine

Before mounting the unit fi rst open the front panel and take out the mixing chamber.

Make sure nothing is connected yet.

The front panel can be opened by opening the fasteners.

You can take out the mixer chamber and the weigh bin when the frontdoor is open.

s

4.2. Mountingplate

Page 41

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 40

Gravimetric Blender

The foot plate of the GraviMaster should be attached on a steel attachment plate on the frame

or mezzanine or fl ange pertinent to the machine.

The mounting holes are 9 mm and are positioned as shown in drawing 4.2

The unit should be mounted as stably as possible, in connection with the accuracy of the

loadcell.

Now mixer chamber, the weighbin and the front panel can be replaced.

Connect the air pressure to the regulator (max. 12 bar). Put the plugs of the GraviMaster and

the user interface in the sockets (220 V), these should be “clean”, without fl uctuations and it

must not be drawn off a 400 V wire. Then the communication cable should be plugged into

the user-interface and the control-box.

The raw material supply should be connected to the hoppers. For startup refer to section 1

of chapter 2.

Page 42

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 41

Gravimetric Blender

5.0 Alarms

5.1 Alarm reports and solutions

The operating system sends a message to the terminal when a failure is detected. The

message will be displayed and stored with date and time in the alarm history. Underneath is

a list of all possible messages, with the solutions.

Page 43

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 42

Gravimetric Blender

ALARMS

Alarm-message Description Action to cancel alarm

Press enter Alarm already cancelled Press enter

Operator must confi rm

No control voltage No 24V control voltage present Turn on the main-switch

or check fuses

Covers open Security cover not present or mixerchamber Place security-cover /

removed mixer-chamber

Production weight producedWeight equals produktionweight Reset the

reached producedWeight

No weighbin or Zero weight of the weighbin is greater then Loadcell must be

calibrate ‘maximumTareVariation’ calibrated or a tare

procedure must be done.

Parameters corrupted The controller can’t read his parameters Check the parameters

*)

correctly. All parameters will be fi lled with

standard values.

Data corrupted The controller can’t read the productiondata Confi rm

*)

(production-screen). The data will be cleared.

Hopper low The hoppersensor (optional) indicates that a Fill hopper with material

hopper runs out of material.

Hopper empty No material is dispensed so the controller

indicates that a hopper must be empty.

Fill hopper with material and

press the start-button.

***)

Loadcell not calibrated The controller can’t read the loadcell Calibrate the weighbin

parameters correctly.

Loadcell overload Weight of the weighbin is greater than the Remove material out of

loadcellOverload parameter. the weigbin.

Check in recipe the

Loadcell not stable Weightsignal from the loadcell doesn’t fi t Press enter

*) **)

the band.

Loadcell need Controller needs more samples to generate a Press enter

*)

more samples stable weight.

Loadcell boundary error

To much weight-samples doesn’t fi t the band. Press enter

*)

Silo high Silo supply hopper is full for several batches. Counter will

(High sensor is activated) automaticaly cleared.

Regrind process par Given hoppernumbers doesn’t contain regrind Check the regrind

confl ict or percentage control parameters

Additive regrind par Given hoppernumber doesn’t contain additive Check the

confl ict AdditiveToRegind

parameters

Page 44

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 43

Gravimetric Blender

*) If this error occurs frequently contact your dealer

**) Other problems which initiate this error are:

- The weighbinDumpTime too short

- Weighbin valve touches the material when mixerchamber is full

When the second problem occurs the position of the mixerchamber-sensor must be set

lower. This actions affects the total production capacity of your system.

***) Through a too short dispense valve opening time, the machine could think that there is

no material in the hopper. There are three possible reasons for this.

-1 dispense accuracy is too narrow

-2 dispense speed is too high

-3 number of dispense attempts is too low solutions:

-1 increase dispense accuracy (§ 3.5.2)

-2 adjust speed in recipe (§ 3.2.2)

-3 increase number of attempts (§ 3.5.2)

An error message on the terminal must be confi rmed by pressing the <ENTER>-key. The

terminal stores all error messages these can be displayed by the menu (F1) ‘controller / alarm

history’. This screen shows the last 256 errors and the number of times the error occurred. The

error-list can de cleared by pressing (F2) option button and choose clear, with this button it is

also possible to print a report of alarms, select ‘print alarm history’ and push <ENTER>.

Page 45

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 44

Gravimetric Blender

[0]OPERATING AUTO[ ] [ ] [ ]

STATUS:[0] FGB#00: (No name) STATUS OPERATING

----------------------------[ALARM HISTORY]

No control voltage 1 Loadcell overload 0

Covers are open 1 Loadcell not stable 0

Production weight reached 0 Loadcell needs more samples 0

No Weighbin / Need calibration 0 Loadcell boundary error 0

Parameters are corrupted 0 Silo full error 0

Production data corrupted 0 Silo empty error 0

Hopper number (n) is empty 0 Confl ict with regrind parameter 0

Loadcell is not calibrated 0 Confl ict with addi.-regr.param 0

1 Date: 06-04-94 Time: 13:14:00 No control voltage

0 Date: 06-04-94 Time: 13:14:00 Covers are open

<Home>top of list

<↑> scroll up

<↓> scroll down

F1Menu F2Option F3 F4Clear F5Start F6Stop

F7Pauze F8Cont.

If your problems can not be solved by these directives, please contact your dealer.

Page 46

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 45

Gravimetric Blender

6.0 MAINTENANCE AND REPAIR

Make sure ,when maintenance or repair is carried out, the power is shut off (by pulling the

plugs out) and the air pressure (by disconnecting the air pressure).

6.1 Maintenance

Everything is set right and tested in the factory, adjustments should only be carried out if a

part of the machine is not working correctly

Air pressure: Set air pressure to about 6 bar for best accuracy. However, lower

pressure will work. If your plant air fl uctuates, set the regulator to the

low end so that the dispense valves always see a consistent pressu re.

Level sensor: The sensor should protrude into the mixer chamber about 1 cm past

the inside surface of the stainless mounting plate. If it protrudes too

far, it will sense the mixer blades. If it does not protrude far enough, it

will sense the mounting plate itself.

Adjusting sensor sensitivity:

At the end of the sensor is a small screw, with this the sensitivity is adjustable.

step1: fi ll the mixer chamber until the sensor is covered.

step2: turn screw counter-clockwise until the led goes on (if the led already

is on, then turn clockwise until led goes off and proceed with step 4).

step3: turn screw clockwise until led goes off.

step4: turn screw another 3/4 turn clockwise.

step5: Empty the mixer chamber and check to be sure the sensor does not

react on the mixer blades.

Weighbin dump valve:

The weighbin dump valve should open and close smoothly. Two

airfl ow regula tors are attached on the cylinder. This can be adjusted

by the screw that is on top of it.

Page 47

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 46

Gravimetric Blender

6.2 Replacement of parts

6.2.1 Replacement of printed circuit

For the replacement of the printed circuit of the control-box, the cover should be removed

by unscrewing the bolts. unplug the connectors which are attached to the printed circuit.

Now unscrew all M3 bolts and remove the circuit. It is important to fi rst disconnect the

connectors and then unscrew the bolts. attach the new printed circuit in the same way,

but in reverse.

It is wise to use a wrist band with ground cord which is connected with earth (PE). This

because of the of static electricity.

6.3 Cleaning the machine

The frequency of cleaning will depend on the number of times the raw material is changed.

For cleaning the machine the front panel, the mixer chamber, the weighbin and the mixer

should be removed (as described in section 4.2). Disconnect the electrical power and

air supply.

Clean the machine by using air pressure. Use safety-goggles when cleaning. After it has

been cleaned, put it back together in the reverse way of stripping it.

6.4 Transportation of the GraviMaster

The weigh bin should be removed, before moving the GraviMaster, this can be done as

described in the previous section. The weigh bin should be removed to prevent damaging

the loadcell. The machine can now be transported on a fi rm pallet.

Page 48

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 47

Gravimetric Blender

7.0 TECHNICAL INFORMATION

7.1 General machine specifi cations

Connecting voltage : 1-phase 240 V

Communication cable : Fiber optic cable (or RS–422)

Air pressure : max. connecting pressure: 12 bar (+/- 170 psi)

working pressure: 4-6 bar (+/- 57-86 psi)

Sound level : < 70 dB (A)

Surroundings temperature : -18°C to +50°C

Batch weight : 0,5 kg

Machine weight : 25 kg

Machine dimensions : 450 x 450 x 640 mm

7.1.1 Safety measures

The GraviMaster is secured by 1 safety switch, which is positioned on the frontdoor. When

the frontdoor is opened, the machine will stop.

7.2 User-interface specifi cations

Connecting voltage : 240 V

Printer connection : Parallel port

7.3 Valves specifi cations

The machine is supplied with valves from the brand MAC, type 45A-SC1-DDAJ-1KJ. The

number of valves is similar to the number of hoppers + 1 for the weighbin + 1 for the

mixer chamber valve (optional).

The connection: (drawing 7 and 7.1) The valve of the weighbin is sealed at W1, so

connection on W2 is the only possibility. Connecting dispenser valves

H1 and H2 is as follows;

* H1-1 onto C1, as H2-1 onto C1 etc.

* H1-2 onto C2, as H2-2 onto C2 etc.

H1-1 and H1-2 should be connected to the cylinder under hopper 1,

H2-1 and H2-2 to the one under hopper 2 etc.

If there is a mixer chamber valve, it should be connected to B-1 and

B-2, one of the lines is numbered, like one side of the cylinder.

Connect the concordant ones.

Page 49

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 48

Gravimetric Blender

Drawing 7.1 Cylinder

Maschine

1

2

W H 1 H 2 B

W= Wiegeschalenanschluss

H1= Dosierschieber 1

H2= Dosierschieber 2

B= Mischkammerschieber

Option

(

Drawing 7.2 Topview valves

)

7.4 Air pressure cylinders specifi cations

See specifi cations on cylinder.

Ein

Page 50

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 49

Gravimetric Blender

7.5 Electrical diagrams

Page 51

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 50

Gravimetric Blender

Page 52

Rev. May 2001 GraviMaster-FGB-M05 (S) Page 51

Gravimetric Blender

Loading...

Loading...