g

GE Consumer Home Services T raining

TECHNICAL SERVICE GUIDE

Triton XL

Dishwashers

MODEL SERIES:

EDW4000

EDW4060

GSD6200

GSD6300

GSD6600

GSD6660

GSD6700

PUB # 31-9085 09/01

PDW7300

PDW7700

PDW7800

PDW7880

!

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in

connection with its use.

WARNING

T o a void personal injury , disconnect power bef ore servicing this product. If electrical power is required for diagnosis or test purposes,

disconnect the power immediately after performing the necessary

checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to

complete a path to ground are removed for service, they must be

returned to their original position and properly fastened.

GE Consumer Home Services Training

Technical Service Guide

Copyright © 2001

All rights reserved. This service guide may not be reproduced in whole or in part

in any form without written permission from the General Electric Company.

Table of Contents

Table of Contents

Introduction ......................................................................................................... 2

Nomenclature ...................................................................................................... 3

Control Panel Features5

Profile Models ................................................................................................. 4

GE Models ....................................................................................................... 6

Component Locator Views..................................................................................9

Dishwasher Components 5

Door Components ........................................................................................ 13

Escutcheon Keypad Assembly .................................................................... 13

Control Module ............................................................................................. 14

Detergent/Rinse Module ............................................................................. 14

Stainless Steel Bowed Panel (on some models) ...................................... 15

Door Interlock Switch ................................................................................... 16

Bottom Door Seal ......................................................................................... 17

Drain System ................................................................................................. 17

Circulation System .......................................................................................18

Fill Funnel......................................................................................................20

Calrod

Turbidity Sensor ........................................................................................... 21

Water Valve and Flood Switch ..................................................................... 22

Active Vent .................................................................................................... 23

®

Heating Element ............................................................................. 20

Flashing Display Lights X.................................................................................. 24

Service Mode X.................................................................................................. 25

Factory Test Mode X.......................................................................................... 26

Washability Complaints......................................................................................27

Cycle Progression Charts................................................................................. 28

Wiring Diagram X................................................................................................ 29

Parts List............................................................................................................. 30

Reviewz .............................................................................................................. 38

Warrantyx

Profile Models ............................................................................................... 39

GE Models ..................................................................................................... 40

– 1 –

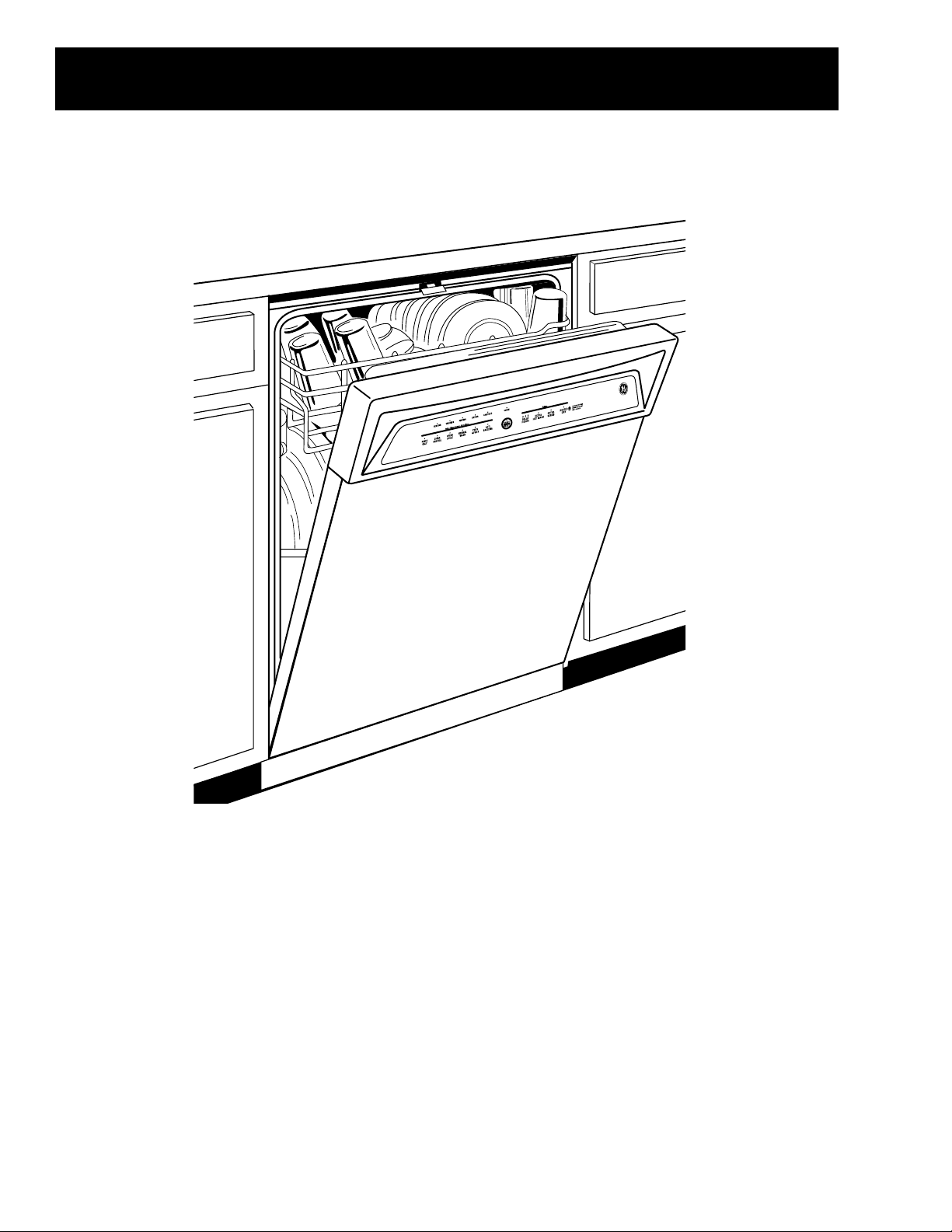

Introduction

The new Triton XL Dishwashers are packed with

features to get your dishes cleaner, pots and pans

spotless, and keep your kitchen quieter... and with

a power usage of 477 kWhr/yr, they have an

“EnergyStar” rating.

The Triton XL Dishwashers have 3 wash arms that

provide complete coverage, eliminating prerinsing, soaking, and scrubbing. The ExtraClean

TM

sensor incorporates a thermistor Auto Temp

control and measures the water turbidity in 5

levels of cleanliness. The 100% triple-water filtration, with extra fine filter, eliminates recirculating

food particles. The PiranhaTM hard food disposer

grinds and pulverizes any other food particles.

Triton XL Dishwashers run quieter thanks to our

QuietPower

TM

motor, P ermaTuf® tub, and the

QuietP ower IV sound insulation, Thinstall.

The dual wattage Calrod

®

heater draws 835 W

when it is wet to heat the water faster and, during

the drying cycle, drops to 700 W for gentler drying.

The information on the following pages will help

you service these new Triton XL Dishwashers

effectively and efficiently.

– 2 –

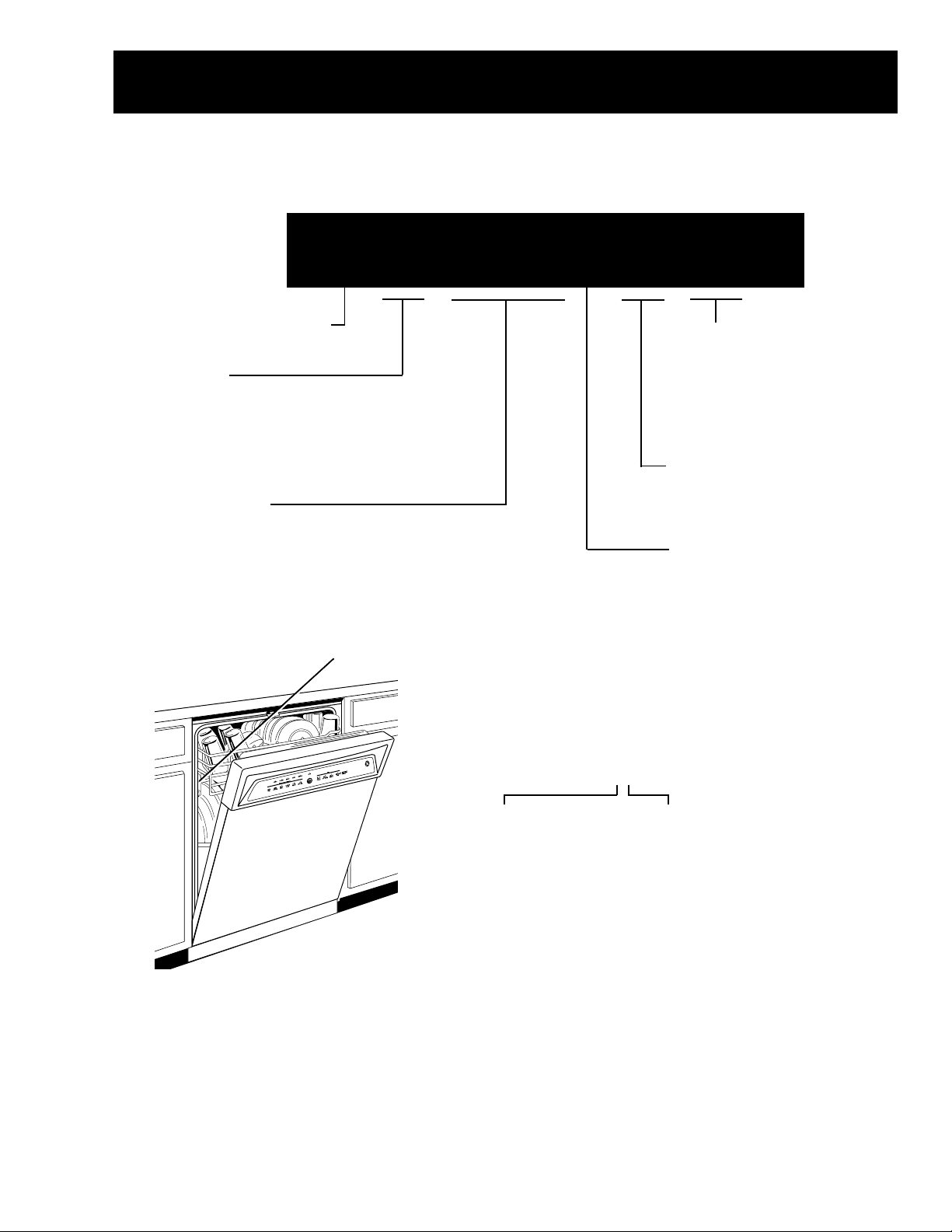

Nomenclature

Model Number

P D W 7 3 0 0 G 0 0 W W

Brand

P = Profile

E = General Electric - NA TM

G = General Electric

Product Type

CD - Counter To p DW = Dishwasher

SD = Standard SC = Convertable

SM = Spacemaker SS = Compact (18 in.)

RF = Retrofit HD = Home Depot Derivative

Model Designator

Designates features–the higher

the number, the more features.

Exterior Color

BB = Black

CC = Bisque

SS = Stainless Steel

WW = White

Engineering Model Suffix

Model Year Designator

Nomenclature

The serial plate of your dishwasher is

located on the tub wall just inside the

door.

Serial Number

The first two characters of the serial number

identify the month and year of manufacture.

Example: AA123456S = January , 2001

A - J AN 2005 - H

D - FEB 2004 - G

F - MAR 2003 - F

G - APR 2002 - D

H - MA Y 2001 - A

L - JUN 2000 - Z

M - JUL 1999 - V

R - AUG 1998 - T

S - SEP 1997 - S

T - OCT 1996 - R

V - NOV 1995 - M

Z - DEC 1994 - L

Note: The service information sheet is located

under the control panel.

The letter designating the

year repeats every 12

years.

Example:

T - 1974

T - 1986

T - 1998

– 3 –

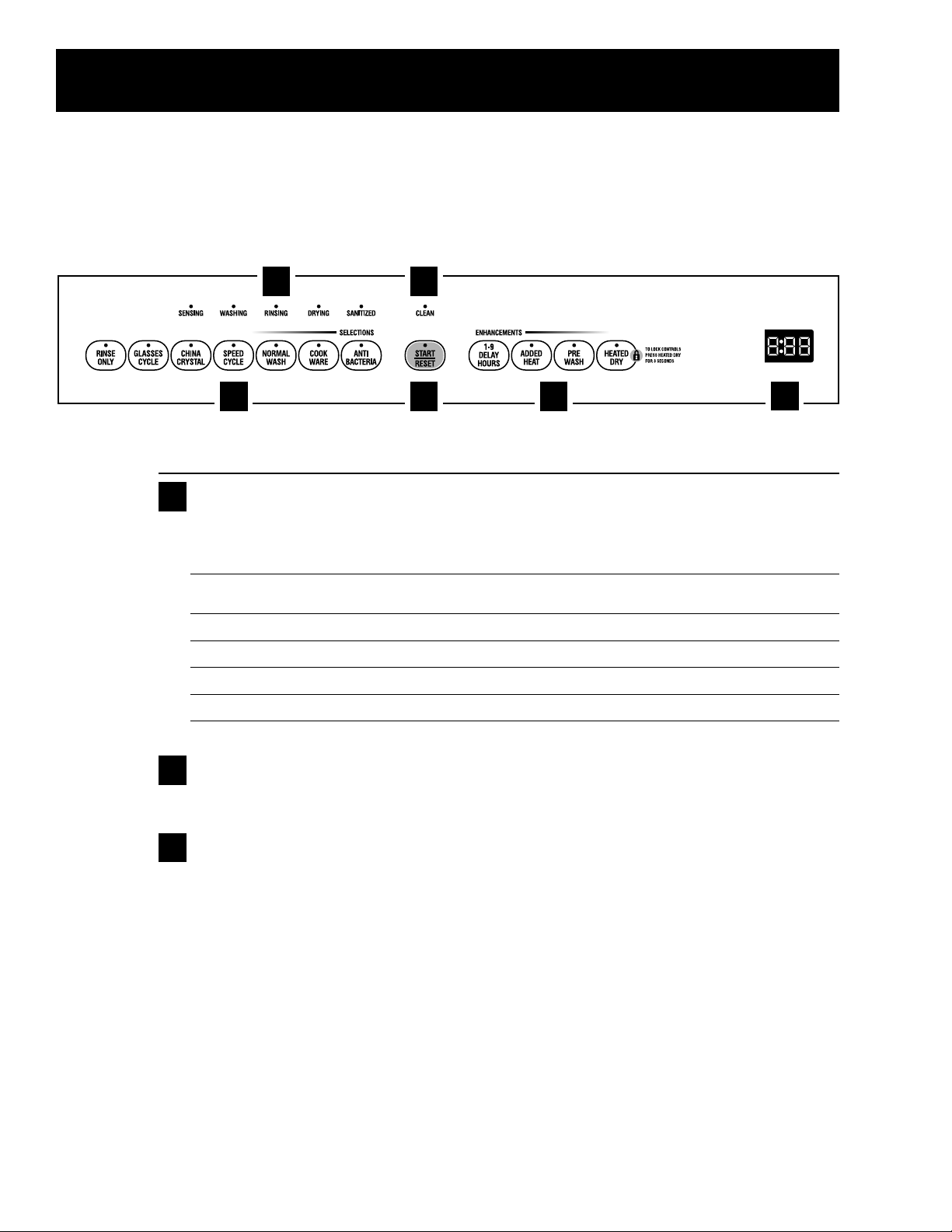

Control Panel Features

Control Settings

Status Indicator Lights

The Status display tells you what’s happening while the dishwasher is in operation and may flash,

indicating a malfunction (see page 6). The lights will come

ON

indicating the sequence of

operation the dishwasher is in.

SENSING Displayed while the ExtraClean™ Sensor is measuring the amount of soil and temperature of water.

The dishwasher will adjust the selected cycle to achieve optimal performance.

WASHING Displayed during prewash and main wash periods.

RINSING Displayed during rinse periods.

DRYING Displayed during

HEATED DRY

.

SANITIZED Displayed when cycle has met sanitization conditions. Light remains ONuntil door is opened.

CLEAN Displayed when a wash cycle is complete. The light will remain

ON

until door is opened.

Time Remaining Display

(on some models)

Displays the minutes remaining until the cycle is complete. The display may adjust the remaining

time while the Sensing light is on.

Selections

The light above the selected pad will be ON to indicate which WASH CYCLE has been selected.

ANTI-BACTERIA Heavy 10.0 gal., 93 min.

Medium 8.6 gal., 90 min.

Light 7.2 gal., 90 min.

This cycle raises the water temperature in the final rinse to sanitize your dishware. The cycle

length will vary depending on the temperature of your inlet water.

NOTE: The Anti-Bacteria cycle is monitored for sanitization requirements. If the cycle is

interrupted during or after the main wash portion or if the incoming water temperature is so low

that adequate water heating cannot be achieved, the sanitizing conditions may not be met. In

these cases, the sanitized light will not illuminate at the end of the cycle.

NOTE: NSF certified residential dishwashers are not intended for licensed food establishments.

1

2

1 6

2

453

3

Profile Models

Throughout this manual, features and appearance may vary from your model.

TIME REMAINING

8

– 4 –

COOK Heavy 11.4 gal., 95 min.

WARE Medium 10.0 gal., 71 min.

Light 10.0 gal., 66 min.

This cycle is meant for heavily soiled dishes or cookware with dried-on or baked-on soils. This

cycle may not remove burned-on foods. Everyday dishes are safe to be used in this cycle.

NORMAL WASH Heavy 9.9 gal., 74 min.

Medium 7.0 gal., 61 min.

Light 5.6 gal., 48 min.

This cycle is for medium/heavily soiled dishes and glassware.

SPEED CYCLE Heavy 9.3 gal., 36 min.

Medium 7.2 gal., 36 min.

Light 5.7 gal., 33 min.

This cycle is for everyday dishes and glassware.

CHINA CRYSTAL Heavy 10.0 gal., 49 min.

Medium 7.2 gal., 36 min.

Light 7.2 gal., 36 min.

This cycle is for lightly soiled china and crystal.

GLASSES Heavy 10.0 gal., 45 min.

(on some models) Medium 7.2 gal., 33 min.

Light 7.2 gal., 32 min.

This cycle is specifically designed for glasses.

RINSE ONLY Heavy 2.9 gal., 7 min.

Light 1.4 gal., 3 min.

For rinsing partial loads that will be washed later. Do not use detergent with this cycle.

NOTE:

This dishwasher is equipped with an ExtraClean™Sensor with automatic temperature

control; therefore cycle length and time may vary depending on soil and temperature conditions.

NOTE:

Only the Anti-Bacteria cycle has been designed to meet the requirements of Section 6,

NSF 184 for soil removal and sanitization efficacy

.

Enhancements

The light above the selected pad will be ON to indicate which ENHANCEMENT has been selected.

PRE For use with heavily soiled and/or dried-on, baked-on soils. This option

MUST

be selected

WASH

PRIOR

to starting the cycle.

This option adds 16 minutes to the cycle time. NOTE:

Cannot

be selected with

RINSE ONLY

cycle.

HEATED DRY Shuts off the drying heat option. Dishes air dry naturally and energy is saved. For faster air dry,

Light OFF

you can prop the door open after the

CLEAN

light illuminates.

HEATED DRY Turns the heater on for fast drying. This will extend the time to your wash cycle by 8 minutes

Light ON

for the

SPEED CYCLE

and 20 minutes for all other cycles.

NOTE:

Cannot be selected with

RINSE ONLY

cycle.

LOCK

You can lock the controls to prevent any selections from being made. Or you can lock the

controls after you have started a cycle.

Children cannot accidentally start dishwasher by touching pads with this option

selected.

To unlock the dishwasher controls, press and hold the

HEATED DRY

pad for 3 seconds. To lock

the dishwasher, press and hold the

HEATED DRY

pad for 3 seconds. The light above the

LOCK

pad will turn off.

ADDED HEAT When selected, the

NORMAL WASH

cycle will run longer with heating elements on to

improve both wash and dry performance.

NOTE:

Cannot be selected with

RINSE ONLY

cycle.

4

– 5 –

Start

Close the dishwasher door and select the

cycle and desired enhancements. Touch the

START/RESET

pad to begin the cycle. Water fill

begins, and approximately 60 seconds later the

wash action begins.

NOTE:

The dishwasher remembers your last cycle so

you don’t have to reprogram each time. When the

dishwasher door is fully closed, the control panel

lights will display the last settings you selected.

If you don’t want to change any of the settings,

simply touch the

START/RESET

pad to begin the

cycle.

If the door is closed the indicator lights will turn off

if the

START/RESET

pad is not selected within two

minutes. To activate the display, open and close the

door or press any pad.

Also, if a power failure occurs,

NORMAL

and

HEATED

DRY

will automatically be programmed. Make any

new selections and touch the

START/RESET

pad to

begin the cycle.

Clean

The

CLEAN

light is illuminated when a wash cycle is

complete. The light will stay

ON

until the door is

opened.

5

6

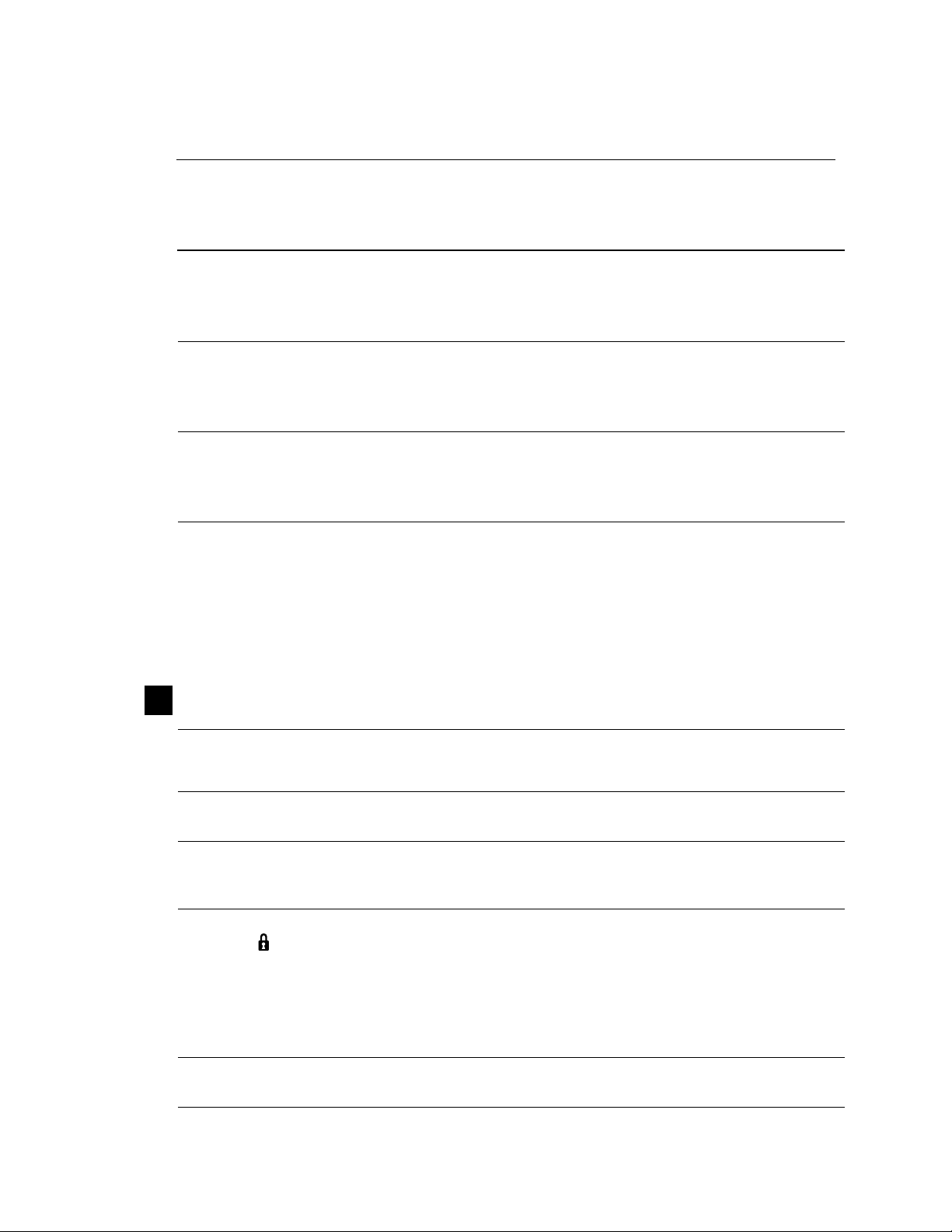

GE Models

DELAY HOURS You can delay the start of a wash cycle for up to 9 hours (on some models). Press the

DELAY

HOURS

pad to choose the number of hours you want to delay the start of the cycle, then press

START/RESET

. The machine will count down and start automatically at the correct time.

Pressing

START/RESET

a second time will cancel the

DELAY START

selection.

NOTE:

If you forget to fully close the door a reminder signal will beep until you do so.

RESET To change a cycle after washing starts, touch the

START/RESET

pad to cancel the cycle.

The

START/RESET

light will flash while the water is pumped out if needed. This takes

approximately 90 seconds. When the light stops flashing, the dishwasher can be reprogrammed

and restarted.

You can locate your model number on the tub wall just inside the door.

Throughout this manual, features and appearance

may vary from your model.

Control Settings

Status Indicator Lights

The Status display tells you what’s happening while the dishwasher is in operation and may flash,

indicating a malfunction (see page 6). The lights will come

ON

indicating the sequence of

operation the dishwasher is in.

SENSING Displayed while the ExtraClean™ Sensor is measuring the amount of soil and temperature of water.

(on some models)

The dishwasher will adjust the selected cycle to achieve optimal performance.

WASHING Displayed during prewash and main wash periods.

(on some models)

RINSING Displayed during rinse periods.

(on some models)

DRYING Displayed during

HEATED DRY

.

(on some models)

SANITIZED Displayed when cycle has met sanitization conditions. Light remains ONuntil door is opened.

CLEAN Displayed when a wash cycle is complete. The light will remain

ON

until door is opened.

1

1 5

3

4

2

8

– 6 –

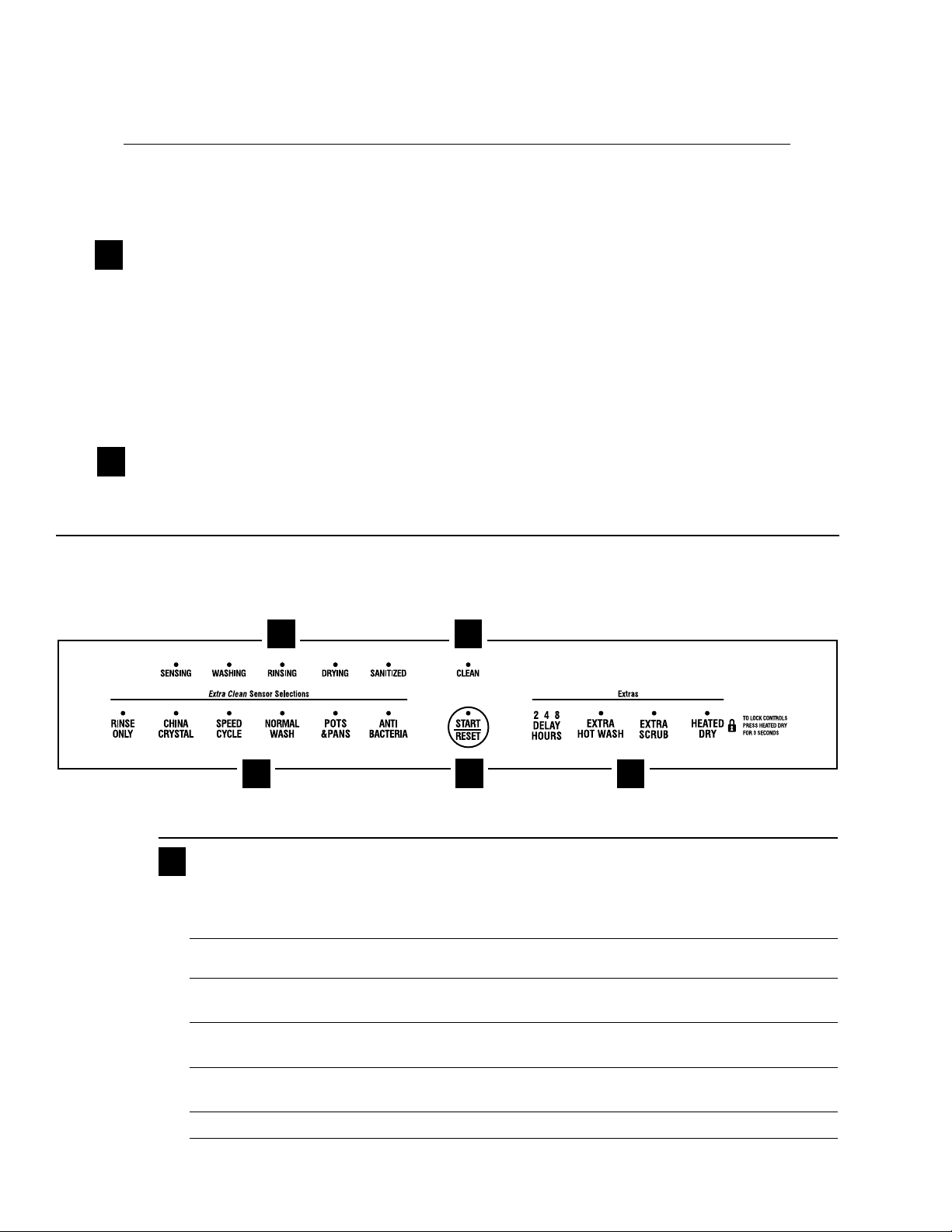

ExtraClean™ Sensor Selections

The light above the selected pad will be ON to indicate which ExtraClean™ Sensor Selection has been

selected.

ANTI-BACTERIA Heavy 10.0 gal., 93 min.

Medium 8.6 gal., 90 min.

Light 7.2 gal., 90 min.

This cycle raises the water temperature in the final rinse to sanitize your dishware. The cycle

length will vary depending on the temperature of your inlet water.

NOTE: The Anti-Bacteria cycle is monitored for sanitization requirements. If the cycle is

interrupted during or after the main wash portion or if the incoming water temperature is so low

that adequate water heating cannot be achieved, the sanitizing conditions may not be met. In

these cases, the sanitized light will not illuminate at the end of the cycle.

NOTE: NSF certified residential dishwashers are not intended for licensed food establishments.

POTS Heavy 11.4 gal., 95 min.

& PANS Medium 10.0 gal., 71 min.

Light 10.0 gal., 66 min.

This cycle is meant for heavily soiled dishes or cookware with dried-on or baked-on soils. This

cycle may not remove burned-on foods. Everyday dishes are safe to be used in this cycle.

NORMAL WASH Heavy 9.9 gal., 74 min.

Medium 7.0 gal., 61 min.

Light 5.6 gal., 48 min.

This cycle is for medium/heavily soiled dishes and glassware.

2

SPEED CYCLE Heavy 9.3 gal., 36 min.

or Medium 7.2 gal., 36 min.

SPEED WASH Light 5.7 gal., 33 min.

This cycle is for everyday dishes and glassware.

CHINA CRYSTAL Heavy 10.0 gal., 49 min.

(on some models) Medium 7.2 gal., 36 min.

Light 7.2 gal., 36 min.

This cycle is for lightly soiled china and crystal.

RINSE ONLY Heavy 2.9 gal., 7 min.

Light 1.4 gal., 3 min.

For rinsing partial loads that will be washed later. Do not use detergent with this cycle.

NOTE:

This dishwasher is equipped with an ExtraClean™Sensor with automatic temperature

control; therefore cycle length and time may vary depending on soil and temperature conditions.

NOTE:

Only the Anti-Bacteria cycle has been designed to meet the requirements of Section 6,

NSF 184 for soil removal and sanitization efficacy

.

Extras

The light above the selected pad will be ON to indicate which EXTRA has been selected.

EXTRA For use with heavily soiled and/or dried-on, baked-on soils. This option

MUST

be selected

SCRUB

PRIOR

to starting the cycle.

This option adds 16 minutes to the cycle time. NOTE:

Cannot

(on some models) be selected with

RINSE ONLY

cycle.

HEATED DRY Shuts off the drying heat option. Dishes air dry naturally and energy is saved. For faster air dry,

Light OFF

you can prop the door open after the

CLEAN

light illuminates.

HEATED DRY Turns the heater on for fast drying. This will extend the time to your wash cycle by 8 minutes

Light ON

for the

SPEED CYCLE

and 20 minutes for all other cycles.

NOTE:

Cannot be selected with

RINSE ONLY

cycle.

3

– 7 –

LOCK

You can lock the controls to prevent any selections from being made. Or you can lock the

controls after you have started a cycle.

Children cannot accidentally start dishwasher by touching pads with this option

selected.

To unlock the dishwasher controls, press and hold the

HEATED DRY

pad for 3 seconds. To lock

the dishwasher, press and hold the

HEATED DRY

pad for 3 seconds. The light above the

LOCK

pad will turn off.

EXTRA When selected, the

NORMAL WASH

cycle will run longer with heating elements on to

HOT WASH improve both wash and dry performance.

NOTE:

Cannot be selected with

RINSE ONLY

cycle.

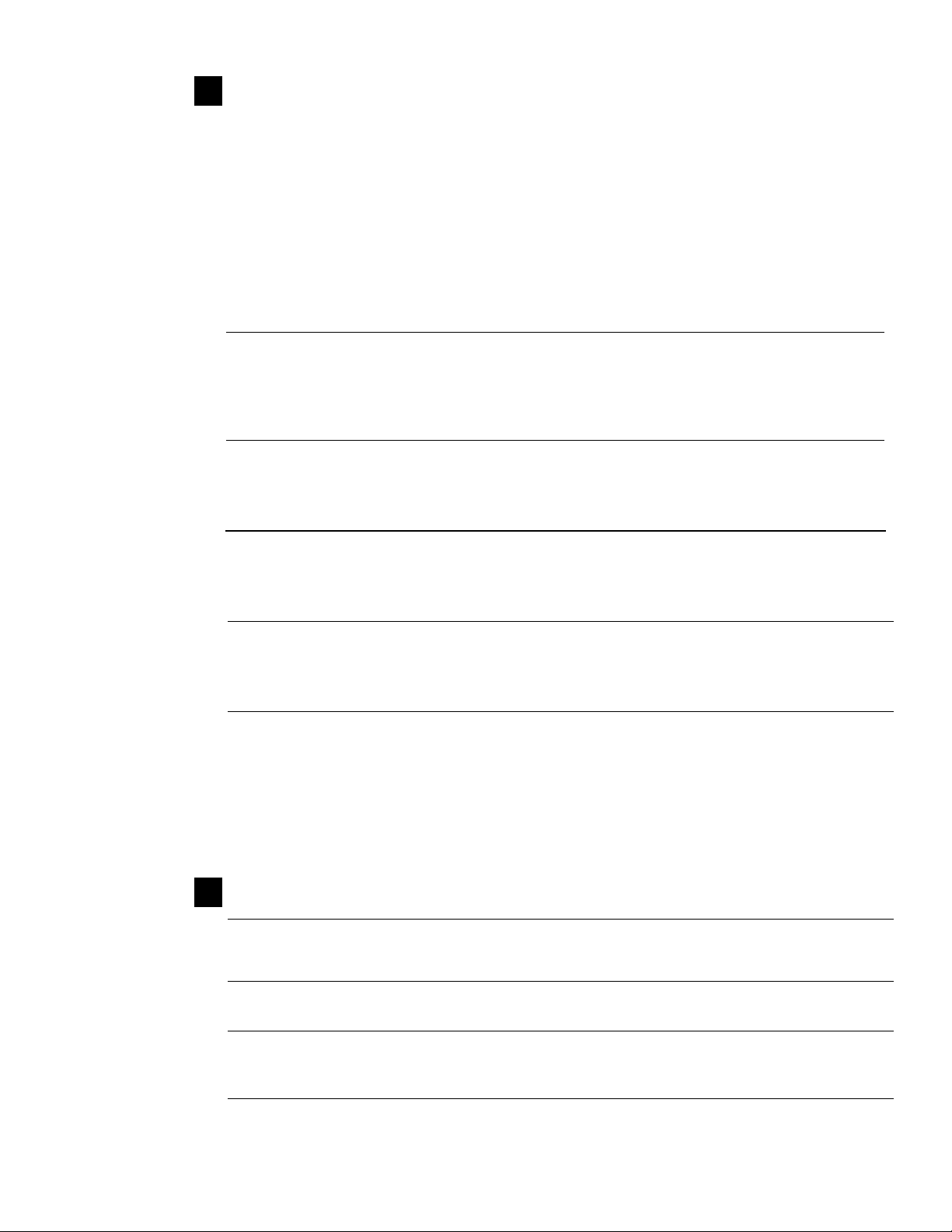

DELAY HOURS You can delay the start of a wash cycle for up to 8 hours (on some models). Press the

DELAY

HOURS

pad to choose the number of hours you want to delay the start of the cycle, then press

START/RESET

. The machine will count down and start automatically at the correct time.

Pressing

START/RESET

a second time will cancel the

DELAY START

selection.

NOTE:

If you forget to fully close the door a reminder signal will beep until you do so.

RESET To change a cycle after washing starts, touch the

START/RESET

pad to cancel the cycle.

The

START/RESET

light will flash while the water is pumped out if needed. This takes

approximately 90 seconds. When the light stops flashing, the dishwasher can be reprogrammed

and restarted.

Start

Close the dishwasher door and select the

cycle and desired enhancements. Touch the

START/RESET

pad to begin the cycle. Water fill

begins, and approximately 60 seconds later the

wash action begins.

NOTE:

The dishwasher remembers your last cycle so

you don’t have to reprogram each time. When the

dishwasher door is fully closed, the control panel

lights will display the last settings you selected.

If you don’t want to change any of the settings,

simply touch the

START/RESET

pad to begin the

cycle.

If the door is closed the indicator lights will turn off

if the

START/RESET

pad is not selected within two

minutes. To activate the display, open and close the

door or press any pad.

Also, if a power failure occurs,

NORMAL

and

HEATED

DRY

will automatically be programmed. Make any

new selections and touch the

START/RESET

pad to

begin the cycle.

Clean

The

CLEAN

light is illuminated when a wash cycle is

complete. The light will stay

ON

until the door is

opened.

4

5

FLASHING DISPLAY LIGHTS

Status Indicator Lights What It Means

START/RESET

CLEAN

Cycle has been interrupted by pressing the

flashing after the dishwasher automatically drains out the water.

Unit has no water. Check the water supply. If water is turned on call for service.

– 8 –

START/RESET

keypad. Light will quit

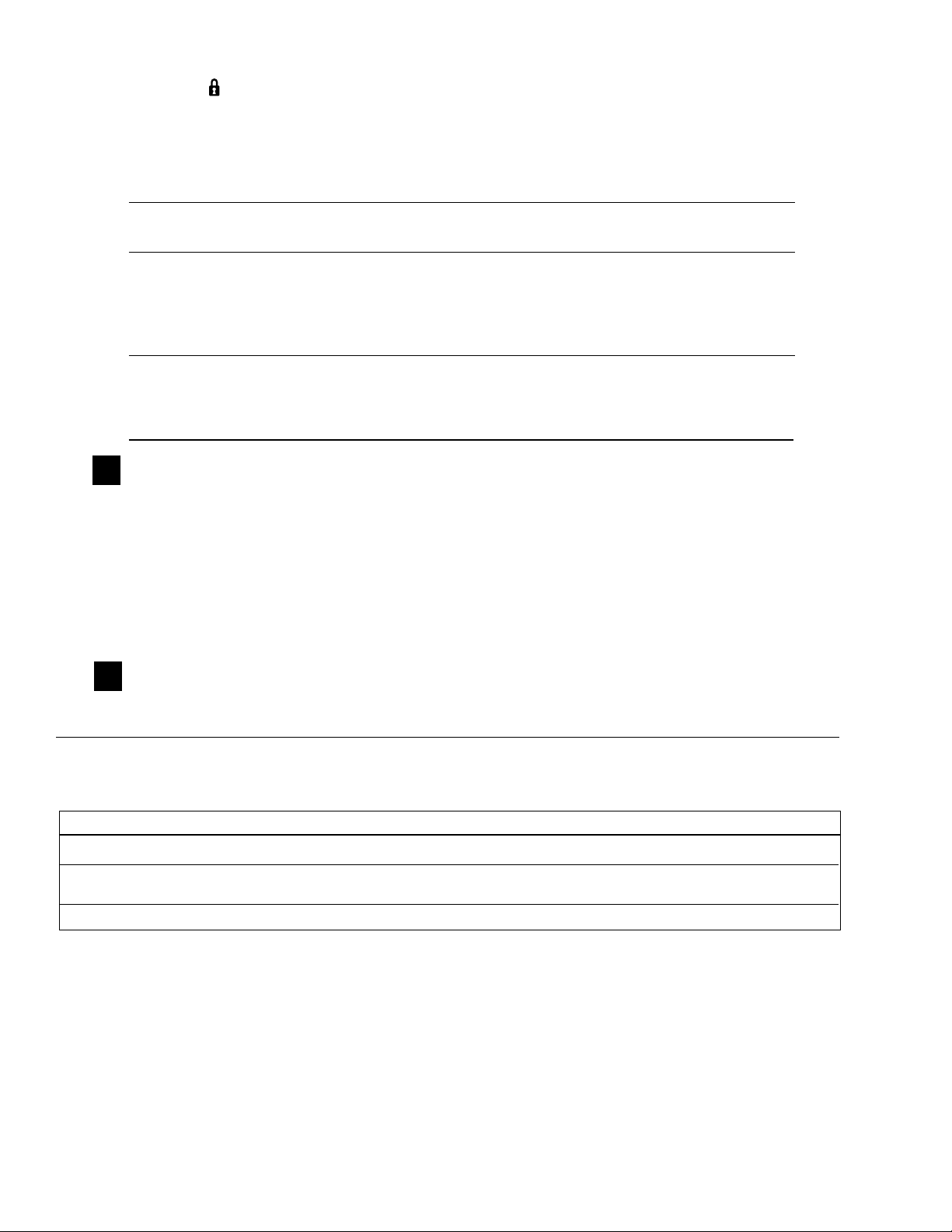

Component Locator Views

Door View (Panel and Escutcheon Removed)

Detergent/

Rinse Agent

Module

Flapper

(Active V ent)

Vent Driver

(Active V ent)

Door Interlock

Switch

Control Module

Flood Switch

Circulation Pump

– 9 –

Factory Test

Cable

House Electrical Supply

Junction Box

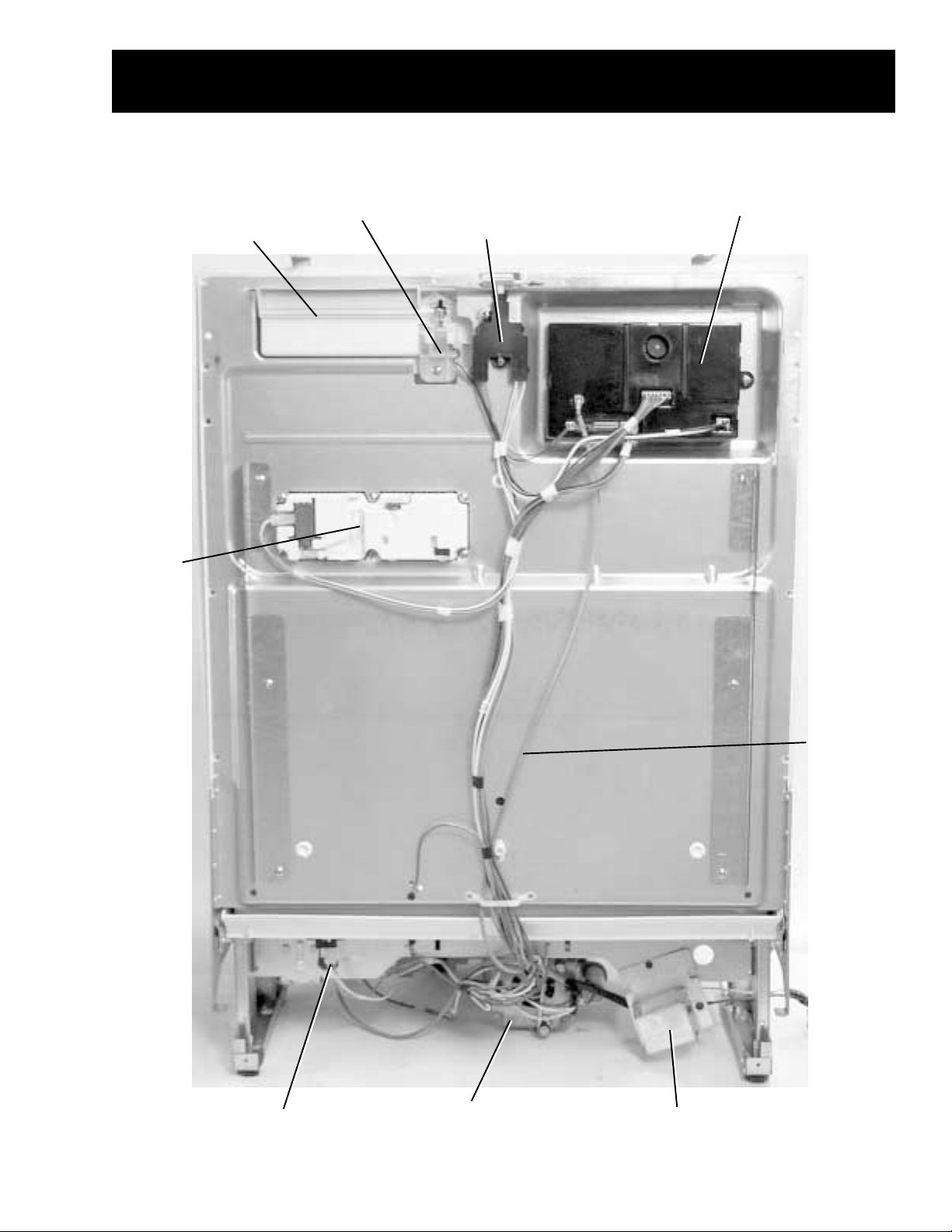

Door View

(Front Panel ONLY Removed)

Escutcheon Keypad

Active V ent

Latch Handle

Control Module

Assembly

Bottom View

FRONT

Water Valve

Factory

T est Cable

Connector

Flood Switch

Circulation Pump

Motor

Junction Box

FRONT

Drain Line

Check Valve

BACK

Drain Pump

High Drain Loop

– 10 –

Heating

Element

Retaining

Nuts

T urbitity

Sensor

BACK

Sump

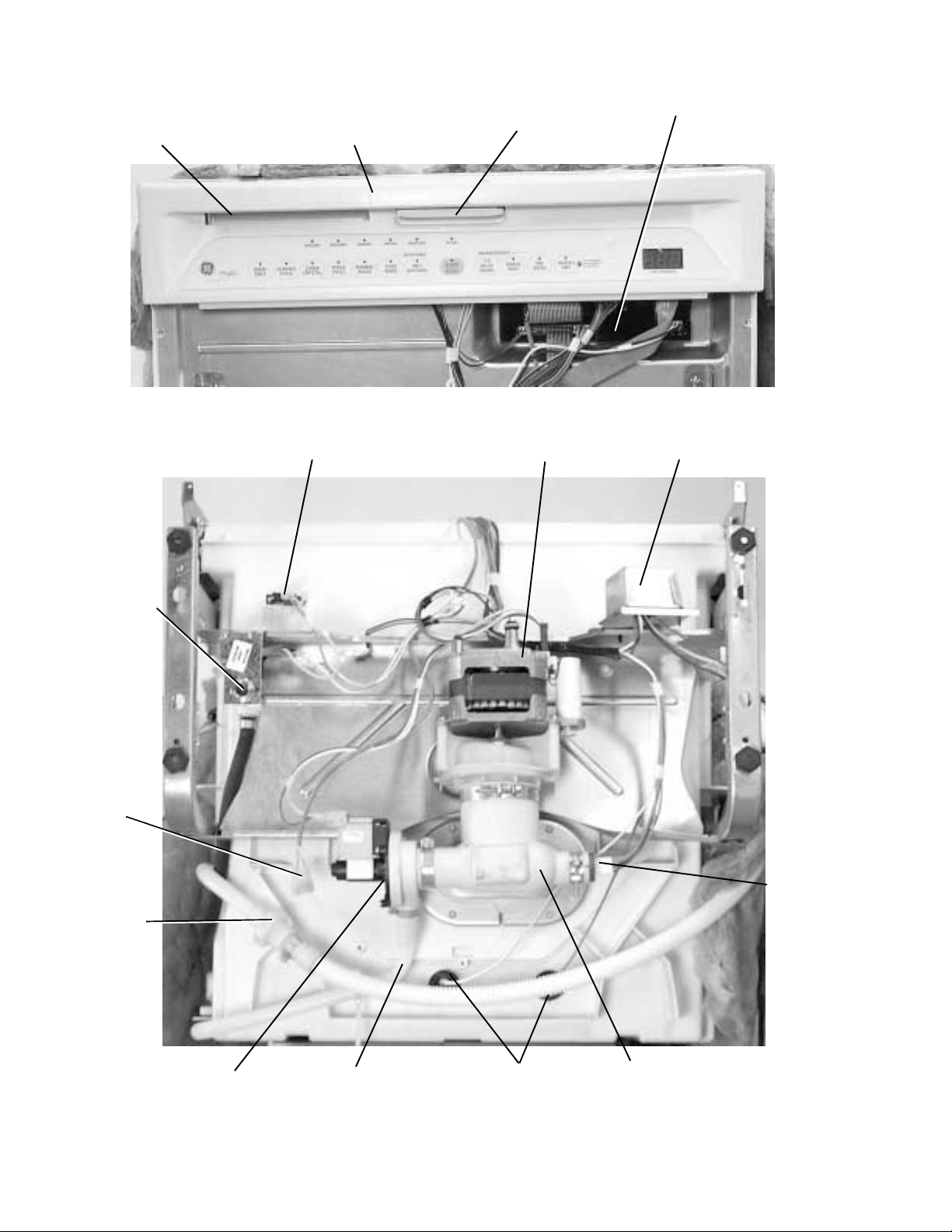

Inside View

Upper

Spray

Arm

Middle Spray Arm

Water Supply Connection

Main Conduit

Lower Spray

Arm

Inside

Door

View

Fine Filter

Heating Element

Inlet Cover

Hub

Detergent/Rinse

Module

Detergent

Compartment

P0003687

– 11 –

Vent

(Active V ent)

Side View

Drain Tube

Assembly

Fill

Funnel

Fill

Hose

Drain Line

Check Valve

Door

Spring

Water

Valve

P0003689

– 12 –

Dishwasher Components

Door Components

The door components are accessible by removing

3 Phillips screws from each side of inner door and

2 T20 torx screws from the bottom of the door.

Carefully separate the inner door panel from the

outer door panel. To access the active vent,

flapper , and door interlock switch, the escutcheon

keypad assembly must be removed.

Escutcheon Keypad Assembly

The keypad and 2 ribbon cables are a permanent

part of the escutcheon and are replaced as a unit.

Disassembly

Caution: After removing the screws from the

escutcheon keypad assembly, the assembly is

still attached to the control module by 2 ribbon

cables. Dropping or rough handling of the

escutcheon will cause the ribbon cable to tear, and

the entire escutcheon keypad assembly will need

to be replaced.

Interlock

Switch

Assembly

Detergent

Module

Figure 5

Flapper

Active Vent

Electronic

Control

Harness

Control Module

1. Remove the outer door panel

nents

).

(see

Door Compo-

2. Open the door, support the escutcheon

keypad assembly, and remove 6 screws from

the back side of the escutcheon keypad assembly .

3. Remove the 2 ribbon cable connectors from the

control module and remove the escutcheon

keypad assembly.

Assembly

IMPORTANT: When reassembling, the active vent

flapper must be closed before the escutcheon

keypad assembly is installed. Close the active vent

flapper by turning the worm gear by hand. Failure

to do so will cause a misalignment and an

increase in noise level.

1. While supporting the escutcheon keypad assembly, connect the 2 ribbon cable connectors

to the control module.

Escutcheon Keypad Assembly

Active V ent

Active V ent

Worm Gear

Worm Gear

2. Open the door . Align the escutcheon and inst all

6 screws from the back side of the escutcheon

keypad assembly.

3. Install the outer door panel

nents

).

(see

Door Compo-

– 13 –

Control Module

Cover

latch

Pre-wash

section

Main

wash

section

Cover

Indicator

window

Dispenser cap

Rinse

agent

adjuster

Removal

2 T abs

1 Screw

1. Remove the outer door panel

nents

).

(see

Door Compo-

2. Open the door and remove the 3 screws from

the back on the right side of the escutcheon

keypad assembly.

3. Remove 1 screw from the right side of the

control module and slide the module out.

4. Unplug the connectors from the module.

Installation

Note: The gray cable is a factory test cable (see

photo) and may be removed when servicing

control module.

1. Plug connectors into control module.

2. Insert the tabs on the left side of the control

module into the slots on the inner door panel

and secure the module with 1 screw.

3. Install 3 screws on the right side of the escutcheon and replace the outer door panel

Components

).

(see

Door

P0003697

Factory

T est Cable

Detergent/Rinse Module

The door panel must be removed to access the

detergent/rinse module. Refer to the

nent

section.

The detergent/rinse module can be activated using

service mode. Refer to the

Service Mode

The detergent/rinse module automatically dispenses both the detergent and the rinse agent at

the appropriate times. The module is activated 2

times during a wash cycle.

The first time the module is activated (1), the lever

slides up the right-hand path of the connecting rod.

This action releases the detergent cover. When

deactivated (2), the lever returns down the lefthand path and comes to rest under the notch in

the center of the connecting rod. At the second

activation (3), the lever lifts the connecting rod by

the notch. This action lifts the rinse dispenser

plunger and releases the rinse agent. When

deactivated, the lever returns to its original starting

position.

Door Compo-

chapter .

1

L1 V oltage from J2-6

DETERGENT MODULE

J2-6

RY

1200-2800

23

DOOR

WR

INTERLOCK

NONCOM

WX

– 14 –

Stainless Steel Bowed Panel

(On Some Models)

Disassembly

1. Open the dishwasher door to the fully open (89

degrees open) position.

2. Remove 8 screws (4 screws per side) which

hold the outer panel to the door assembly. Be

careful not to remove the 2 screws which hold

the escutcheon to the door assembly.

3. Slowly close the door.

4. Once the door is closed, remove the 2 screws

that connect the bottom of the outer panel to the

hinge arms.

5. While holding the outer panel against the door

assembly , slowly open the door to about 15

degrees open so the top of the outer panel is in

front of the kitchen countertop. If the dishwasher is not installed, the door does not have

to be opened.

Do not remove

this screw from

either side.

6. Rotate the bottom of the outer panel out such

that the panel is now vertical.

7. Lift up on the stainless steel outer panel such

that top corner flanges lift up over the corner

cutouts in the escutcheon. Move the panel

forward and over the escutcheon so that the

panel is totally separated from the door. (See

photos of escutcheon and outer panel below .)

Assembly

1. Open the door to about 15 degrees open so that

the top of the outer panel is in front of the

kitchen countertop. If the dishwasher is not

installed, the door does not have to be opened.

2. Lift the outer panel up in the vertical position and

hang the outer panel over top of the escutcheon.

Take care to ensure that the stainless steel

panel corner flanges go over and around the

escutcheon corner cutouts.

3. While holding the outer panel to the escutcheon,

slowly close the door.

4. With the panel hanging over the escutcheon,

rotate the bottom of the stainless steel outer

panel back so it is flush with the door assembly.

Make sure that the sides of the outer panel fit

around the hinge arms.

5. Look at the fit between the escutcheon and the

stainless steel outer panel front opening. Make

– 15 –

sure that the protruding ribs from the escutcheon fit inside the stainless steel front opening.

Adjust the position of the outer panel up or

down, left or right to center the panel with the

escutcheon.

6. Once the panel is centered, install the 2 screws

in the bottom of the panel to connect the stainless steel outer panel to the hinge arms. Recheck to make sure the escutcheon ribs are

protruding through the panel opening.

7. While holding the outer panel against the door

assembly , slowly open the door to about 45

degrees open so that the remaining 8 panel

screws can be installed (4 screws on each

side).

Door Interlock Switch

The door interlock switch opens the L1 circuit and

Neutral circuit when the door is open.

Caution: After removing the screws from the

escutcheon keypad assembly, the assembly is

still attached to the control module by 2 ribbon

cables. Dropping or rough handling of the

escutcheon will cause the ribbon cable to tear, and

the entire escutcheon keypad assembly will need

to be replaced.

1. Remove the escutcheon keypad assembly (see

Escutcheon Keypad Assembly

).

2. Remove 2 screws and the switch from the door.

3. Carefully remove the cover from the switch and

unplug the blade connectors.

Note: The wire color code is on the switch cover.

DOOR INTERLOCK SWITCH

J2-7

J2-8

J1-3

BW

BX

DOOR

NO COM

BXBW

WX

N

COM

DOOR

WR

NO

J1-1

2 Screws

2 Screws

P0003703

P0003705

L1

– 16 –

Bottom Door Seal

DRAIN PUMP

J2-5

M

RX

WR

30

NONCOM

WX

DOOR

INTERLOCK

The bottom door seal is replaceable by removing

the outer door panel (see

Door Components

). With

the door closed, insert a flat-blade screwdriver

under the bottom of the door into the channel and

twist to break the bead. Open the door and pull the

seal from the channel. To install the seal, snap the

seal into the channel, working from one side of the

door to the other , until the entire bead is complete

and the seal slides freely in the channel.

Drain System

Bottom Door Seal

The drain system consists of the following

components:

• Inlet cover

• Sump

• Drain pump (includes motor and one-way check

valve)

• Drain pipe

• Check valve (in line with drain pipe)

The inlet cover prevents large particles from

entering the sump. Water entering the drain pump

is not filtered by the fine filter (metal) or by the

sump filter (plastic). The drain pump is mounted

on the sump and contains a one-way check valve.

The drain pump is controlled by the control module

and can be activated using service mode (refer to

the

Service Mode

chapter). The drain pump

pushes the drain water out into the drainpipe. The

drainpipe contains a one-way check valve.

Inlet Cover and Sump

Caution: Use care to avoid breaking the clip on

the hub when removing the main conduit from hub.

Clip

Fine Filter

Drain Pump

Main Conduit

One Way

Check Valve

INLET

Bottom

Door

Seal

Inlet Cover

Inlet Cover

(sump filter is

(sump filter is

under inlet cover)

under inlet cover)

Hub

Remove the lower wash arm and main conduit to

gain access to the inlet cover and sump.

Drain Pump

The dishwasher must be removed from its instal-

lation to gain access to the drain pump. The drain

pump can be activated using service mode (refer

to the

Service Mode

chapter). The drain pump

contains a one way check valve. Refer to schematic or strip circuit for motor resistance value.

Drain Pipe and Check V alve

The dishwasher must be removed from its instal-

lation to gain access to the check valve that is inline with the drainpipe.

Check Valve

L1 Output from J2-5

– 17 –

(in-Line)

OUTLET

Drainpipe

Sump

Drain Pump

Dishwasher Doesn’t Drain

YES

Check for clogged:

inlet cover

sump

drain pump

drain pipe

one-way check valve

(in drain pipe)

L1 Output from J2-5

Attempt

to activate drain

pump using service mode

(refer to Service Mode

chapter).

Pump activate?

YES

DRAIN PUMP

J2-5

voltage

present at pump?

Note: Perform this test

with wiring connected

pump under

RX

NO

Is L1

and

load.

DOOR

INTERLOCK

M

30

NO

WR

NONCOM

WX

Check pump for open/

shorted motor winding or

for stalled/clogged

condition.

Circulation System

The circulation system consists of the following

components:

• Inlet Cover

• Fine filter and sump filter

• Sump

• Circulation pump

• Hub

• Lower spray arm

• Main conduit

• Middle spray arm

• Upper Spray arm

The inlet cover prevents large particles from

entering the sump. The fine filter (metal) and

sump filter (plastic) prevent fine particles from

entering the circulation-pump part of the sump

(water entering the drain pump is not filtered by the

fine filter or by the sump filter). The circulation

pump is controlled by the control module and can

be activated using service mode (refer to

Mode

chapter). The pump pushes water up

Service

Clip

Fine Filter

Check for open circuit between

control module and pump or

between pump and door interlock

switch. If circuits OK, replace

control module.

Circulation

Pump

Main Conduit

Sump

Inlet Cover

Inlet Cover

(sump filter is

(sump filter is

under inlet cover)

under inlet cover)

Hub

– 18 –

through the hub to the lower spray arm and to the

Conduit Carrier

Hub

Middle

Spray

Arm

Mid

Bracket

Nut

Bearing

Upper Rack

Tab

Mid Conduit

Screw

(Optional)

y arm for bits of

her foreign

-Level

CIRCULATION PUMP

J2-1

M

WR

NX

10

NO COM

WX

DOOR

INTERLOCK

N

main conduit. The main conduit supplies water to

the middle and upper spray arms.

Inlet Cover

Caution: Use care to avoid breaking the clip on

the hub when removing the main conduit from hub.

Remove the lower wash arm and main conduit to

gain access to the inlet cover and sump.

Fine Filter, Sump Filter, and Sump

The dishwasher must be removed from its instal-

lation to gain access to the sump. The sump

must be removed to allow removal of the fine filter

and sump filter.

Circulation Pump

Note: It is extremely important that the self-tapping

ground-wire screw on the circulation pump is

tightened securely .

The dishwasher must be removed from its installation to gain access to the circulation pump. The

circulation pump can be activated using service

mode (refer to the

Service Mode

chapter). Refer to

schematic or strip circuit for motor resistance

value.

L1 Output from J2-1

Lower Wash Arm

Lift and rotate (ccw) the lower spray arm to re-

move it from the hub. Clean the screen on the

water return if necessary.

Middle Wash Arm

Refer to illustration for disassembly.

Upper Wash Arm

Remove screw, plastic bearing, and upper wash

arm.

– 19 –

No Water Circulation

YES

Attempt

to activate

circulation pump using

service mode (refer to Service

Mode chapter).

Does pump

activate?

NO

Check for clogged:

hub (remove lower wash arm)

inlet cover

fine filter

sump/sump filter

Check pump for open/

shorted motor winding.

YES

L1 Output from J2-1

CIRCULATION PUMP

J2-1

YES

Pump is stalled/clogged.

Disconnect power and

attempt to turn pump using

cooling fins.

Motor capacitor is open/

shorted.

Important:

Self tapping

ground-wire screw

on pump must be tightened

Is L1 voltage present at pump?

NX

securely.

Note: Perform test with

wiring connected and

pump under

load.

M

10

WR

DOOR

INTERLOCK

NO COM

NO

WX

Does

the pump

hum?

NO

N

Check for an open

circuit between control

module and pump or

between pump and door

interlock switch. If

circuits OK, replace

control module.

Fill Funnel

The fill funnel is removable with a quarter turn

clockwise. There is an O-ring seal between the fill

funnel and the dishwasher tub.

Calrod® Heating Element

The heating element can be activated using

service mode. Refer to the

The dual wattage Calrod

835 W when it is wet to heat the water faster and,

Service Mode

®

heating element draws

chapter.

Rotate clockwise 1/4 turn to remove.

– 20 –

O-ring

during the drying cycle, drops to 700 W for gentler

Figure 4

Tub

Nut

Heating Element

Support

Heating

Element

Heater

Grommet

1

2

3

4

GY

NX

SX

OX

NTC

TURBIDITY SENSOR

drying.

Water inlet temperature must be at least 120 °F for

proper drying. Low water inlet temperature will

prevent proper convection air movement and

increase drying time substantially .

If the complaint is the dishes are not drying correctly , don’t overlook the rinse agent. A rinse agent

will improve the water sheeting action and drying

performance.

Replacement

Note: The heating element nuts are located on the

underside of the washer, near the back. Ample

force is required to remove the nuts. Removing the

dishwasher from installation may be required.

1. Disconnect power and remove wire leads from

heating element.

2. Unscrew 2 heating element nuts.

3. Remove 2 screws, 2 heating element supports,

and the heating element.

HEATING ELEMENT

J2-3

J2-4

VX

HEATING ELEMENT

19.4-19.8

DOOR

INTERLOCK

WR

NONCOM

WX

Turbidity Sensor

The turbidity sensor measures the amount of

suspended particles in the wash water in the sump.

As the sump water lays between the 1/4- to 3/8inch gap between the LED transmitter and the

receptor during the first fill, the baseline reading is

taken. Successive turbidity measurements are

supplied to the control module and used to determine whether any prewash or rinse cycles can be

skipped. Decisions are based on a comparison of

clean water measurements at the beginning of the

first fill, measurements taken at selected fills, and

water temperature. By measuring the turbidity level,

the control module can conserve energy on lightly

soiled loads by skipping unnecessary cycles.

Note: If the turbidity sensor circuit fails open or

shorted, the sensing LED on the control panel will

not light and the unit will operate for the maximum

amount of time, using the maximum number of

wash and rinse fills for the selected cycle.

The turbidity sensor also contains the thermisteor

for automatic temperature control.

Turbidity Sensor Test

Heating

Element Nuts

(Bottom View)

T urbidity Sensor

T urbidity Sensor

Factory test mode is the most accurate way to test

the turbidity sensor circuit (circuit contains control

module, wiring, and turbidity sensor). Refer to the

Factory Test Mode

chapter.

– 21 –

Refer to

Wiring Diagram

for voltages and pin-outs.

Replacement

To remove the turbidity sensor from the side of the

sump, loosen the screw and slide the retaining

clamp back. Remove turbidity sensor from the

sump and unplug connector from the turbidity

sensor.

Note: When installing the turbidity sensor, align

the key on the sensor with the keyway on the

sump.

Water Valve and Flood Switch

Screw

Screw

T urbidity

sensor

shown

partially

removed.

Keyway and Key

The water valve is a 120 V AC (L1) solenoid valve

that is switched on/off by the control module. The

flood switch acts as a safety switch only and does

not control normal operation of the water valve.

The flood switch opens the L1 side of the water

valve circuit.

Water Valve Replacement

The water valve can be replaced with the dish-

washer installed.

WARNING: Disconnect power to dishwasher

before proceeding.

1. Turn off water supply to dishwasher.

2. Remove toekick.

3. Disconnect house plumbing from dishwasher.

4. Remove 2 screws and valve from dishwasher

frame.

5. Disconnect connector.

6. Move clamp up, away from valve, and remove

valve from hose.

WA TER VA LVE AND

FLOOD SWITCH

L1 voltage from J2-2

SWITCH

J2-2

PX YX

C

FLOOD

WATER VALVE

Screws

725-1200

DOOR

INTERLOCK

WR

NONO

WX

COM

Flood Switch

N

Note: To prevent leaks after installation, ensure

that hose-to-valve connection is good and that

clamp is in place.

Water Valve Test

1. Attempt to activate water valve using service

mode (see

Service Mode

chapter). Pump out

water as necessary using service mode. If an

intermittent failure is suspected, activate water

valve 5 times using service mode. Water valve

should stay on for 50 - 71 seconds per activation and should not turn on and off during the

50 - 71 second activation time.

2. If the water valve is not operating properly or

Water Valve

Clamp

Water Valve

Connector

– 22 –

water level is low, check the following:

• Flood switch, flood switch float, and float stem

- Flood switch should open when water level is

approximately 1/4 in. above the base (bottom)

of the float dome.

• Resistance through the water valve solenoid

coil - Check from yellow wire at flood switch to

white/red wire at door interlock switch (Escutcheon keypad assembly must be removed,

refer to

Escutcheon Keypad Assembly

section).

• Clogged screen in water valve.

Caution: After removing the screws from the

escutcheon keypad assembly, the assembly is

still attached to the control module by 2 ribbon

cables. Dropping or rough handling of the

escutcheon will cause the ribbon cable to tear, and

the entire escutcheon keypad assembly will need

to be replaced.

Active Vent

Float Dome

Water Level

Float

Float Dome

(removed)

The active vent helps to reduce the noise level and

heat loss when in the closed position. The control

module supplies +/- 12 VDC to the motor. The

control module reverses polarity to drive the motor

in a clockwise or counterclockwise (open or

closed) direction. The vent is closed during the

wash cycle and open during the drying cycle

(heated and non-heated) and when the unit is not

in use. If the vent is closed and the door is opened

during the wash cycle, the vent will open. When

the door is closed again, the vent will remain open

for seven (7) seconds, then close again to finish

the cycle.

It is normal for steam to come through the active

vent during the dry cycle.

The active vent can be opened and closed using

the service mode. Refer to the

Service Mode

chapter.

The active vent can be accessed by removing the

escutcheon keypad assembly (see

Keypad Assembly

section).

Escutcheon

Flapper

ACTIVE VENT

V ent Drive

+ or – 12 VDC at J5-1

+ or – 12 VDC at J5-2

BX

RX

ACTIVE

M

MOTOR

VENT

J5-1

J5-2

IMPORTANT: When reassembling, the active vent

flapper must be closed before the escutcheon

keypad assembly is installed. Close the active vent

flapper by turning the worm gear by hand. Failure

to do so will cause a misalignment and an

increase in noise level.

– 23 –

Flashing Display Lights

The status display tells you what’s happening while the dishwasher is in operation and may flash, indicating a malfunction. The lights will come on indicating the sequence of operation the dishwasher is in.

FLASHING DISPLAY LIGHTS

Status Indicator Lights What It Means

START/RESET

CLEAN

Cycle has been interrupted by pressing the

flashing after the dishwasher automatically drains out the water.

Unit has no water. Check the water supply. If water is turned on call for service.

START/RESET

keypad. Light will quit

– 24 –

Service Mode

Opens Active Vent

THIS DISHWASHER IS PROGRAMMED WITH A SERVICE MODE TO AID THE TECHNICIAN IN TROUBLESHOOTING THE DISHWASHER. EACH COMPONENT MAY BE CYCLED TO DETECT IF IT IS FUNCTIONING CORRECTLY. COMPONENTS ARE CYCLED BY

PRESSING KEYPADS TO THE RIGHT OR LEFT OF THE START/RESET KEYPAD. DETERMINE WHICH TYPE OF CONTROL PANEL IS

PRESENT (FLAT OR BOWED) AND THEN USE THE MATRIX BELOW TO DETERMINE HOW TO CYCLE EACH COMPONENT.

FLAT PANEL

4L

5L

Indicates Keypad Used Only on Some Models

2L

3L

TO ENTER SERVICE MODE :

PRESS THE COOKWARE (POTS & PANS ON SOME MODELS)

AND THE HEATED DRY KEYPAD SIMULTANEOUSLY FOR 3

SECONDS.

START

1L

RESET

1R

2R 3R

4R

TO EXIT SERVICE MODE :

PRESS THE START/RESET KEYPAD AT ANYTIME TIME TO EXIT.

TRITON XL SERVICE MODE TEST MATRIX *

KEYPAD

CONTROL DESCRIPTION TIME in seconds**

PAD TYPE

Keypads to the left of the Start/Reset keypad (Selections)

1L

2L

3L

4L

5L

START/RESET Used to EXIT Service Mode

Keypads to the right of the Start/Reset keypad (Enhancement/Extras)

1R FLAT Start/Reset and Option LEDs; 3 seconds each cycle

2R

3R

FLAT Activates Drain Pump

BOWED Activates Detergent Module

FLAT Activates Detergent Module

BOWED Activates Main Pump

FLAT Activates Main Pump

BOWED Activates Heating Element

FLAT Activates Heating Element

BOWED Activates Drain Pump

FLAT Activates Water Valve

BOWED

(Length of time is model dependent)

Activates the following in order:

Status LEDs; Wash LEDs;

BOWED finally “888” will be shown

on the 3 digit display

(some models)

FLAT

Closes Active Vent

BOWED

FLAT

BOWED

Opens Active Vent

Closes Active Vent

BOWED PANEL

T

R

TA

5L

3L

2L

1L

Indicates Keypad Used Only on Some Models

75

60

75

300

50 or 71

S

4L

1R

T

E

S

E

R

*NOTE : Service mode may

be used for 30 minutes

maximum. After 30 minutes

the service mode will

automatically turn off.

**NOTE : Component will be

activated for indicated

time. Component may be

deactivated by pressing

the same keypad that was

pressed to activate the

component.

4R

3R

2R

– 25 –

Factory Test Mode

Factory test mode is the most accurate way to test the turbidity sensor circuit (circuit contains control

module, wiring, and turbidity sensor). Factory test mode will test the thermistor (used for Automatic

Temperature Control) that is contained in the turbidity sensor and will test the transmitter that is contained in the turbidity sensor .

Entering Factory Test Mode

Note: This mode can only be entered within the

first 2 minutes after power-up. After 2 minutes,

factory test mode is unavailable.

1. Disconnect power from dishwasher. Wait 10

seconds and connect power to dishwasher.

2. Press the NORMAL WASH keypad and POTS &

PANS (or COOK WARE) keypad at the same

time for 5 seconds (This step must be

performed within 2 minutes of power-up).

3. The following sequence should occur:

a. All LEDs illuminate for a short period of time.

b. Water valve activates. The dishwasher will fill

for the appropriate amount of time.

c. Circulation pump activates. The dishwasher

will circulate for approximately 1 minute.

d. Turbidity sensor check. The control module

will check the thermistor circuit, the turbidity

(transmitter) circuit, and calibrate itself to the

turbidity sensor (transmitter). The turbidity

sensor check lasts for 20 to 30 seconds.

module will beep continuously and the Lock

LED will be illuminated. The control

module, wiring, and turbidity sensor are

suspect if the turbidity sensor check fails.

Press any keypad to stop the control

module beeping and move to the next step

in the factory test mode sequence.

• If the turbidity sensor check passes, the

control module will automatically move to

the next step in the factory test mode

sequence.

e.Drain pump activates. Allow the dishwasher

to pump out all water (approximately 75

seconds). After the water has been pumped

out, the dishwasher will begin to fill again.

Press the START/RESET keypad while the

dishwasher is filling. The dishwasher will then

pump out for approximately 2 minutes and

then return to normal operation. The

dishwasher will automatically exit factory test

mode 1 hour and 10 minutes after the test

was initiated if the START/RESET keypad is

not pressed to exit.

• If the turbidity sensor check fails, the control

– 26 –

Washability Complaints

Cover

latch

Pre-wash

section

Main

wash

section

Cover

Rinse

agent

Hot Water – Ample supply of water at a minimum

temperature of 120 °F is necessary. Do not use

dishwasher soon after using clothes washer or

filling bath tub.

Loading – Consult Owner’s Manual on loading

procedures.

Amount of Water – Make sure dishwasher is

level. Check water level, allowing dishwasher to fill

normally for first fill. The water level should be

to the base (bottom) of the float dome. If water

level is low, check for clogged screen in water

valve and check flood switch. Refer to the

Valve and Flood Switch

Detergent/Rinse Module Leakage – Some

moisture in cup is normal. Detergent must not be

soaking wet, oozing out and down the inner door

panel. If a leak is detected, check the detergent/

rinse module door lid, latch operation, and gasket

seal. Also refer to the

section.

section.

Detergent/Rinse Module

Water

Float Dome

Water Level

Proper Amount of Detergent – Use full detergent

cup of fresh detergent in hard water. Use only

enough detergent to get good wash performance

in soft water.

Rinse Agent – Use rinse agent if spotting or

drying is a problem. A rinse agent will improve the

water sheeting action and drying performance.

Water Valve – Refer to the

Switch

Spray Arm – Check to be sure all 3 spray arms

spin freely and jets are not clogged. Check to be

sure the middle spray arm water conduit is connecting properly to the main conduit.

Drying – Water inlet temperature must be at least

120 °F for proper drying. Low water inlet temperature will prevent proper convection air movement

and increase drying time substantially .

A rinse agent will improve the water sheeting

action and drying performance.

section.

Water Valve and Flood

Detergent/Rinse Module

– 27 –

Cycle Progression Chart

d

third rinse exten

t

n

third rinse exten

MAX TEMP

FIRST FILL

detergent cupafter 3 minutes no no no no no no no

detergent cup no no no no no no no no

SECOND FILL

THIRD FILL

detergent cup no no no no no no no -

detergent cupyes (rinse aid) - - - - no - -

FOURTH FILL

POWER

PRE-SOAK

detergent cup

OPTION

detergent cup - yes yes yes yes yes yes -

MAIN WASH

W EXTEND

detergent cup - no no no no no no -

FIRST RINSE

detergent cup - no no no no no no -

SECOND RINSE

THIRD RINSE

OPTION

HI-TEMP

NORMAL WASH

SPEED GLASSES CHINA POTS & ANTI- RINSE

(CLEAN) (DIRTY) CYCLE CYCLE CRYSTAL PANS BACTERIA ONLY

140 °F* 130 °F* 130 °F* 145 °F*140 °F* 140 °F*

fill time 49 / 70 sec 49 / 70 sec 50 / 71sec 50 / 71sec 50 / 71sec 50 / 71sec 50 / 71sec 50 / 71sec

fill quantity 1.4 gal 1.4 gal 1.43 gal 1.43 gal 1.43 gal 1.43 gal 1.43 gal 1.43 gal

160 °F* -

calrod after 3 minutes no yes yes yes yes yes no

cycle time 19 minutes 1 - 8 minutes1 - 2 minutes 1 - 2 minutes 1 minute 1 - 8 minutes 1 minute 1 minute

fill time 49 / 70 sec 49-50 / 70-71 50 / 71 sec 49-50 / 70-71 49-50 / 70-71 50 / 71 sec 50 / 71 sec 50 / 71 sec

fill quantity 1.4 gal 1.4 - 1.43 gal 1.43 gal 1.4 - 1.43 gal 1.4 - 1.43 gal 1.43 gal 1.43 gal 1.43 gal

calrod no no yes yes yes yes yes no

cycle time 5 minutes 1 - 8 minutes1 - 2 minutes 1 - 8 minutes 1 - 8 minutes 1 - 8 minutes 1 minute 1 minute

fill time 49 / 70 sec 49 / 70 50 / 71 sec 49-50 / 70-71 49-50 / 70-71 50 / 71 sec 50 / 71 sec -

fill quantity 1.4 gal 1.4 gal 1.43 gal 1.4 - 1.43 gal 1.4 - 1.43 gal 1.43 gal 1.43 gal -

calrod no no yes yes yes yes yes -

cycle time 5 minutes 1 - 8 minutes1 - 2 minutes 1 - 8 minutes 1 - 8 minutes 1 - 8 minutes 1 - 8 minutes -

fill time 49 / 70 sec - - - - 50 / 71 sec - -

fill quantity 1.4 gal - - - - 1.43 gal - -

calrod yes - - - - yes - -

cycle time 9 minutes - - - - 1 - 10 minutes - -

fill time

fill quantity

calrod

cycle time

fill time - 49-50 / 70-71 50 / 71 sec 50 / 71 sec 50 / 71 sec 50 / 71 sec 50 / 71 sec -

fill quantity - 1.4 - 1.43 gal 1.43 gal 1.43 gal 1.43 gal 1.43 gal 1.43 gal -

calrod - ye s yes yes yes yes yes -

cycle time - 15 - 30 minutes7 - 10 minutes 5 minutes 5 minutes 20 - 40 minutes 5 minutes -

if temp not

reached, main

wash enters

extend time

fill time - 49 / 70 sec 50 / 71 sec 50 / 71 sec 50 / 71 sec 50 / 71 sec 50 / 71 sec -

fill quantity - 1.4 gal 1.43 gal 1.43 gal 1.43 gal 1.43 gal 1.43 gal -

#

#

#

#

#

50 / 71 sec 50 / 71 sec 50 / 71 sec 50 / 71 sec 50 / 71 sec 50 / 71 sec 50 / 71 sec

1.43 gal 1.43 gal 1.43 gal 1.43 gal 1.43 gal 1.43 gal 1.43 gal

no no no no no no no

yes yes yes yes yes yes yes

13 minutes 13 minutes 13 minutes 13 minutes 13 minutes 13 minutes 13 minutes

- 130 F - - 110 F 140 F 130 F -

- 15 minutes - - 10 minutes 15 minutes 15 minutes -

-

calrod - no yes yes yes yes yes -

cycle time - 5 minutes 5 minutes 6 minutes 6 minutes 5 minutes 5 minutes -

fill time - 49 / 70 sec 50 / 71 sec 50 / 71 sec 50 / 71 sec 50 / 71 sec 50 / 71 sec -

fill quantity - 1.4 gal 1.43 gal 1.43 gal 1.43 gal 1.43 gal 1.43 gal -

calrod - no yes yes yes yes yes -

cycle time - 5 minutes 5 minutes 2 minutes 5 minutes 5 minutes 5 minutes -

fill time - 49 / 70 sec - 50 / 71 sec 50 / 71 sec 50 / 71 sec 50 / 71 sec -

fill quantity - 1.4 gal - 1.43 gal 1.43 gal 1.43 gal 1.43 gal -

rinse aid - yes - yes yes yes yes -

calrod - ye s - yes yes yes yes -

-

cycle time - 9 minutes - 8 minutes 9 minutes 9 minutes 1 - 60 minutes -

cycle time

fourth fill extended

to 25 minutes

third rinse ex

to 25 minutes

second rinse

extended to 14

minutes

third rinse exte

22 minutes

25 minutes

25 minutes

no effect, third rinse

run time is determined

by sanitation

requirements

-

* When maximum temperature is reached and the calrod is on the calrod will be cycled on and off.

**Heater is on for the first 6 minutes then cycles.

#

The CLEAN NORMAL run will insert the pre-soak after 3 minutes into the first fill. The cycle will be a NORMAL with dirty water where the

DRY

30 minutes** 30 minutes** 8 minutes** 30 minutes** 30 minutes** 30 minutes**

first fill is 3 minutes, and the second and third fills are skipped.

– 28 –

15 minutes cool

15 minutes dry**

-

Wiring Diagram

K

E

Y

P

A

D

CONTROL CIRCUIT BOARD

3-DIGIT DISPLAY

M

ACTIVE

VENT

MOTOR

BX

RX

J7

KEYPAD

1

23

4

5

6789

10

1

23

1

234

5

6

7

8

1

2

J5

ACTIVE

VENT

3-DIGIT DISPLAY

J8

PQA

J10

POWER SWITCHING

J2

1

2

3

1

2

3

4

TURBIDITY/

TEMPERATURE

SENSOR

J3

---THIS CIRCUIT NOT IN

ALL MODELS

J1

POWER

SUPPLY

1

2

3

4

NTC

RECEIVER EMITTER

TRANSMITTER

CATHODE

Vcc

GY

NX

SX

OX

M

M

BW

NO COM

BX

DOOR

INTERLOCK

NO COM

WX

DOOR

INTERLOCK

WR

DETERGENT MODULE

RY

WR

WR

WR

WR

NX

WR

CIRCULATION

PUMP

GY

NL1

WX

BX

PX YX

FLOOD

SWITCH

CNO

WATER VALVE

725-1200

19.4-19.8

VX

HEATING ELEMENT

RX

DRAIN PUMP

1200-2800

G

10

COLOR CODE

LETTERS COLOR

LETTERS COLOR

THE "X" INDICATES ONE SOLID COLOR- NO

TRACER. WIRES WITH TRACER SHOW

BOTH COLORS. EXAMPLE -WR IS WHITE

WITH RED TRACER.

AX

BX

CX

NX

OX

PX

LT. BLUE

BLACK

BROWN

DK. BLUE

ORANGE

PINK

RX

SX

TX

VX

WX

YX

RED

GRAY

TAN

PURPLE

WHITE

YELLOW

30

1

2

3

4

GY

NX

SX

OX

NTC

TURBIDITY SENSOR

COLOR CODE

LETTERS COLOR

LETTERS COLOR

THE "X" INDICATES ONE SOLID COLOR- NO

TRACER. WIRES WITH TRACER SHOW

BOTH COLORS. EXAMPLE -WR IS WHITE

WITH RED TRACER.

AX

BX

CX

NX

OX

PX

LT. BLUE

BLACK

BROWN

DK. BLUE

ORANGE

PINK

RX

SX

TX

VX

WX

YX

RED

GRAY

TAN

PURPLE

WHITE

YELLOW

WARNING: Power must be disconnected before servicing the appliance.

CONTROL MODULE

CONN. INPUT/OUTPUT COMPONENT

J1-1 Neutral House Supply

J1-3 L1 Input House Supply

J2-1 L1 Output Circ. Pump

J2-2 L1 Output Water Valve

J2-3 L1 Output Heating Elem.

J2-4 L1 Output Heating Elem.

J2-5 L1 Output Drain Pump

J2-6 L1 Output Det. Module

J2-7 L1 Input Door Interlock

J2-8 L1 Input Door Interlock

J3-1 Input (thermistor) Turbity Sensor

J3-2 Input (turbidity) Turbity Sensor

J3-3 0 to 5 VDC output* Turbity Sensor

J3-4 5 VDC output* Turbity Sensor

J5-1 + or - 12 VDC* Active Vent

J5-2 + or - 12 VDC* Active Vent

*Measure voltage with black test lead

connected to J10-1.

– 29 –

Door

Part s List

Note: The components shown in this

drawing may differ from the components in

your unit. Refer to the microfiche or GEA

IPC for the component and part number

for your unit.

– 30 –

Body Parts

Note: The components shown in this

drawing may differ from the components in

your unit. Refer to the microfiche or GEA

IPC for the component and part number

for your unit.

– 31 –

Upper Rack

Note: The components shown in this

drawing may differ from the components in

your unit. Refer to the microfiche or GEA

IPC for the component and part number

for your unit.

– 32 –

Lower Rack

Note: The components shown in this

drawing may differ from the components in

your unit. Refer to the microfiche or GEA

IPC for the component and part number

for your unit.

– 33 –

Pumps and Filters

Note: The components shown in this

drawing may differ from the components in

your unit. Refer to the microfiche or GEA

IPC for the component and part number

for your unit.

– 34 –

Note: The components shown in this drawing may differ from the components in your unit. Refer to the

microfiche or GEA IPC for the component and part number for your unit.

Ref # Part # Description Qty

1 31-30365 PM SHEET MINI MANUAL 1

1 31-30530 PM INSTRUCTION INST ALL 1

1 49-5908 PM MANUAL USE & CARE 1

30 WD03X10014 SPRING 2

42 WZ4X376D SCR 10-16X3/4 #8 HX SSTL 3

50 WD13X10006 KEEPER LA TCH ASM 1

51 WD02X10066 SCR 10-24X1/2 TT TRR S 1

70 WD02X0320 SCREW LEVEL 4

101 WD05X10005 ELEMENT HEA TING ASM 1

104 WD01X10097 NUT TOWER HEATER 2

109 WD01X10094 GROMMET HEA TER 2

1 12 WD01X10098 SUPPORT HEATER 2

302 WD12X10051 DOME FLOA T 1

305 WD12X10047 FLOAT 1

306 WD12X10048 STEM FLOA T 1

308 WD12X10043 HOUSING FLOOD SWITCH 1

309 WD12X10058 SHIELD FLOOD SW 1

310 WD26X10015 MECHANISM ASM 1

321 WD21X10118 SENSOR TURBIDITY 1

325 WD26X10016 PUMP DRAIN ASM 1

330 WD01X10103 CLAMP 1

331 WD01X10104 CLAMP 1

332 WD01X10105 CLAMP 1

401 WD03X0767 WASHER ST STL 8

414 WD02X0444 SCREW MECH HANGER 4

420 WD01X10093 HANGER MECH ASM 1

425 WD01X10101 GROMMET 3

428 WD12X10060 RING SUCTION 1

429 WD19X10032 KIT IMPELLER ASM 1

450 WD18X10009 HUB VENTURI ASM 1

452 WD01X1392 CLAMP , SUMP 1

453 WD01X10107 BEARING SPRAY ARM LOW 1

454 WD12X10061 NUT HUB FINE FIL TER 1

455 WD18X10010 CONNECTOR PUMP ASM 1

456 WD01X10106 RING SUMP 2

462 WD24X10014 HOSE DRAIN 1

463 WD24X10020 TUBE DRAIN ASM 1

490 WD21X10119 SWITCH FLOOD 1

494 WD01X10088 HOUSING SPECIAL -DRAIN 1

501 WD22X10030 ARM SPRAY LOW ASM 1

502 WD22X10029 FILTER COARSE 1

505 WD18X10008 SUMP INLET 1

506 WD12X10049 COVER INLET 1

507 WD12X10050 FILTER FINE ASM 1

508 WD22X10028 FILTER SUMP 1

568 WD01X10108 BEARING SPRA Y ARM MID 1

569 WD02X10068 SCR 8-16 B HXW 1.08 SS 1

570 WD22X10027 ARM SPRAY UPPER ASM 1

575 WD12X10056 FUNNEL FILL 1

576 WD24X10019 HOSE FILL 1

577 WD08X10020 GASKET FUNNEL FILL 1

– 35 –

Note: The components shown in this drawing may differ from the components in your unit. Refer to the

microfiche or GEA IPC for the component and part number for your unit.

Ref # Part # Description Qty

585 WD12X10057 CONDUIT MAIN 1

586 WD12X10059 CONE DOCKING 1

610 WD12X10066 HUB SPRA Y ARM MID 1

61 1 WD01X10102 BEARING SPRAY ARM UP 1

612 WD01X10109 NUT HUB MID 1

615 WD28X10074 RACK UPPER ROLL ASM 1

616 WD28X10012 SHELF MULTI PURPOSE 2

617 WD12X10052 CONDUIT SPRA Y ARM MID 1

618 WD22X10031 ARM SPRAY MID ASM 1

619 WD28X10013 GRIPPER STEMWARE 2

620 WD12X10053 BRACKET SPRA Y ARM MID 1

621 WD12X10054 CONDUIT CARRIER MID 1

622 WD02X10067 SCR 8-16 HXW 1/2 SS 1

623 WD12X10062 FINGER INDEXER 1

650 WD30X0098 RACK SLIDE 2

652 WD12X0344 RACK SLIDE END CAP 4

654 WD12X0332 ROLLER STUD ASM 8

692 WD28X10064 COMB LOWER RACK ASM 2

694 WD28X10060 COMB UPPER RACK ASM 1

695 WD28X10061 COMB UPPER RACK ASM 1

698 WD28X10062 RETAINER COMB 6

699 WD28X10063 RETAINER COMB 2

701 WD28X10073 RACK LOW ROLL ASM 1

705 WD12X10065 ROLLER SIDE 4

709 WD01X101 13 INSULATION P ANEL FRONT 1

710 WD01X10095 INSULA TION 1

710 WD01X10100 INSULA TION 1

710 WD01X101 14 INSULATION P ANEL 1

71 1 WD31X10029 PANEL FRONT BOWED WH 1

714 WD02X10083 SCR 8-18 B HXW .480 S 4

715 WD02X10086 SCR 8-18 B 1HW 1/2 S N 2

716 WD14X10009 LINK HINGE ARM 2

733 WD16X10009 PULLEY BRACKET ASM 1

741 WD12X10055 BRACKET J BOX ASM 1

743 WD12X448 COVER JUCTION BOX 1

744 WD15X10004 VAL VE WA TER INLET 1

746 WD2X248D SCR 10-24X3/8 TT HEX 2

755 WZ4X44D SCREW 4

756 WD34X10566 BRACE TOEKICK WH 1

759 WD27X10086 TOEKICK ASM WH 1

761 WD28X10058 BASKET 7 PC ASM 1

762 WD28X10038 BASKET SILVERW ARE END 2

763 WD28X10037 BASKET SIL VER WARE MIDDLE 1

764 WD28X10039 HANDLE BASKET 1

765 WD28X10066 LID BASKET 1

766 WD28X10067 LID BASKET 1

767 WD28X10068 LID BASKET 1

775 WD02X10055 SCREW 10-16 X 5/8 HXW 2

775 WD02X5166 SCR 10-16X1/2 AB HXW S 2

776 WZ5X222D SCR 10-32 T HEX 7/16 S 3

777 WD01X10089 INSULA TION TUB BLANKET 1

– 36 –

Note: The components shown in this drawing may differ from the components in your unit. Refer to the

microfiche or GEA IPC for the component and part number for your unit.

Ref # Part # Description Qty

790 WD01X10065 CLAMP HOSE 1

790 WH01X2036 CLAMP HOSE 1

801 WR02X10585 SPRING RECESS DOOR 1

802 WD13X10010 HANDLE LA TCH WH 1

803 WD21X10121 SWITCH INTERLOCK ASM 1

804 WD13X10008 ACTUA TOR HANDLE 1

805 WD13X10009 RETAINER HANDLE 1

807 WD31X10027 INNER DOOR & HINGE ASM 1

808 WD01X10110 CLIP HARNESS 1

809 WD02X10084 SCR 10-32GX FL T25 .615 S 2

810 WD02X0322 SCR 8-18X7/8 BT 6

81 1 WD12X10046 MODULE RINSE ASM 1

815 WD12X10045 VENT 1

817 WD01X0550 SCR 8-32 PNT 1/2 S 2

817 WD02X0445 SCR 10-32 T HEX .7 S 1

833 WD01X10099 CABLE PULLEY ASM 2

833 WD02X0295 SCR 8-16X2 SS 4

842 WD08X10023 TRIM TUB FLANGE WH 2

843 WD08X10018 GASKET TUB 1

844 WD08X10024 TRIM TUB FLANGE 2

845 WD08X10019 SEAL SHORT BOT DOOR 1

864 WD12X10067 FLAPPER VENT 1

888 WD01X10090 BRACKET COUNTER SIDE RH 1

888 WD01X10091 BRACKET COUNTER SIDE LH 1

901 WD34X10565 ESCUTCHEON KEYP AD ASM WH 1

905 WD21X10017 MODULE CONTROL ASM 1

905 WD35X10015 MODULE CONTROL ASM 1

905 WD21X10131 MODULE CONTROL ASM 1

918 WD21X10120 VENT DRIVER ASM 1

943 WZ5X219D SCREW ESCUTCHEON 1

– 37 –

1. The incoming water temperature must be

_________.

Review

2. The dishwasher has a ______ year parts

warranty.

The electronic module has a _____ year

_________________ warranty .

3. The dishwasher has a ______ year labor

warranty.

4. If the bearing washer (item #61 1) on the top

rack, bottom wash arm is left out, then:

a. washability can be affected.

b. glassware can be broken.

c. excessive wear will occur.

d. all of the above will occur.

e. none of the above will occur , the part is really

not needed.

6. The high drain loop, mounted on the side of the

tub, can be removed if needed.

T or F

7. A blinking START/RESET keypad light indicates:

a. Sequence switch problem.

b. Cycle was interrupted and dishwasher will

drain and stop.

c. There is a problem with the heater circuit.

d. There is a problem with the water valve

circuit.

8. A blinking Clean light indicates:

a. The unit has no water .

b. There is a problem with the turbidity sensor

circuit.

5. Circle the button(s) which must be pushed to

enter Service Mode.

FLAT PANEL

4L

5L

Indicates Keypad Used Only on Some Models

2L

3L

START

1L

RESET

1R

2R 3R

4R

BOWED PANEL

5L

3L

2L

1L

Indicates Keypad Used Only on Some Models

START

RESET

1R

4L

4R

3R

2R

c. The water was not heated properly on sani-

cycle models.

d. Dishwasher is in Extended Wash Mode.

9. The detergent/rinse agent dispenser is activated

with _____ volts ____ times during the cycle.

10. If the turbidity sensor fails, the dishwasher

stops, beeps, drains, and terminates the cycle.

T or F

– 38 –

Profile Models

For The Period Of: GE Will Replace:

One Year Any part

of the dishwasher which fails due to a defect in materials or workmanship. During this

full

From the date of the one-year warranty,

GE will also provide,

free of charge,

all labor and in-home service to replace the

original purchase

defective part.

Second Year Any part

of the dishwasher which fails due to a defect in materials or workmanship.

From the date of the

During this

second-year limited warranty,

you will be responsible for any labor or in-home

original purchase

service costs.

Five Years The dishwasher rack (nylon coated only–not vinyl coated),

if it should rust, or

the electronic control

From the date of the module

if it should fail due to a defect in materials or workmanship. During this

five-year limited

original purchase warranty,

you will be responsible for any labor or in-home service costs.

All warranty service provided by our Factory Service Centers,

or an authorized Customer Care

®

technician. To schedule service,

on-line, 24 hours a day, visit us at GEAppliances.com, or call

800.GE.CARES (800.432.2737).

Staple your receipt here.

Proof of the original purchase

date is needed to obtain service

under the warranty.

What GE Will Not Cover:

Lifetime of Product The PermaTuf®tub or door liner,

if it fails to contain water due to a defect in materials or

workmanship. During this

full warranty,

GE will also provide,

free of charge,

all labor and in-home

service to replace the defective part.

■Service trips to your home to teach you how to use the

product.

■Improper installation.

■Failure of the product if it is abused, misused, or used for

other than the intended purpose or used commercially.

■Replacement of house fuses or resetting of circuit

breakers.

■Damage to the product caused by accident, fire, floods or

acts of God.

■Incidental or consequential damage caused by possible

defects with this appliance.

■Cleaning or servicing of the air gap device in the drain

line.

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home

use within the USA. Proof of original purchase date is needed to obtain service under the warranty. In Alaska, the

warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state. To know what your

legal rights are, consult your local or state consumer affairs office or your state’s Attorney General.

Warrantor: General Electric Company. Louisville, KY 40225

W arranty

– 39 –

What GE Will Not Cover:

Lifetime of Product The PermaTuf®tub or door liner,

if it fails to contain water due to a defect in materials or

workmanship. During this

full warranty,

GE will also provide,

free of charge,

all labor and in-home

service to replace the defective part.

■Service trips to your home to teach you how to use the

product.

■Improper installation.

■Failure of the product if it is abused, misused, or used for

other than the intended purpose or used commercially.

■Replacement of house fuses or resetting of circuit

breakers.

■Damage to the product caused by accident, fire, floods or

acts of God.

■Incidental or consequential damage caused by possible

defects with this appliance.

■Cleaning or servicing of the air gap device in the drain

line.

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home

use within the USA. Proof of original purchase date is needed to obtain service under the warranty. In Alaska, the

warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state. To know what your

legal rights are, consult your local or state consumer affairs office or your state’s Attorney General.

Warrantor: General Electric Company. Louisville, KY 40225

For The Period Of: GE Will Replace:

One Year Any part

of the dishwasher which fails due to a defect in materials or workmanship. During this

full

From the date of the one-year warranty,

GE will also provide,

free of charge,

all labor and in-home service to replace the

original purchase

defective part.

Second Year Any part

of the dishwasher which fails due to a defect in materials or workmanship.

From the date of the

During this

second-year limited warranty,

you will be responsible for any labor or in-home

original purchase

service costs.

Five Years The dishwasher rack (nylon coated only–not vinyl coated),

if it should rust, or

the electronic control

From the date of the module