Page 1

GEAppliances

Part Install Instructions

Dryer DeKalb Motor Replacement To NIDEC Motor Kit:

WE17X22216, WE17X22217, WE17X23355, WE17X23463,

WE17X23464, WE17X23465, *WE17X10002 or *WE17X23618

To avoid a risk of electrical shock, disconnect power prior to servicing.

Follow all steps and safety information in these instructions to avoid a risk of personal injury, [death], or property damage. This part should only

be installed by persons with adequate backgrounds of electrical and mechanical experience. Any attempt to repair a major appliance can result

in personal injury and property damage. The manufacturer or seller cannot be responsible for the interpretation of this information, nor can it

assume any liability in connection with its use.

Parts Included

• NIDEC Motor and Pulley Assembly

• Harness Jumper • Label

• Wire Tie • Instruction Sheet

Overview

Installation of the new motor requires the use of a harness jumper included in this kit. The new

motor will mount in the motor bracket as the previous motor. These instructions show how to

correctly complete the installation of the new motor and jumper.

Note: Install the jumper harness to the motor before installing it into the motor bracket.

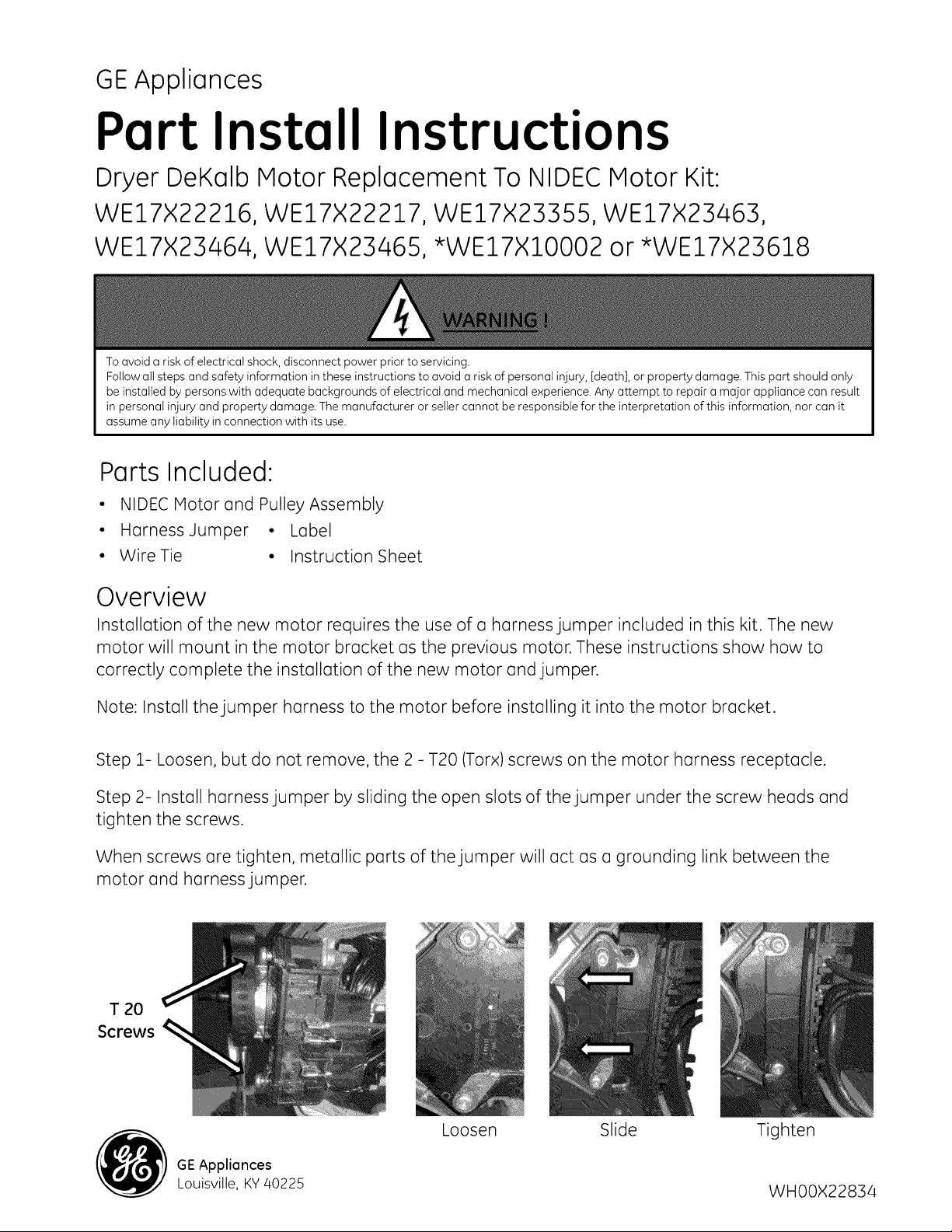

Step Z- Loosen, but do not remove, the 2- T20 (Torx) screws on the motor harness receptacle.

Step 2- Install harness jumper by sliding the open slots of the jumper under the screw heads and

tighten the screws.

When screws are tighten, metallic parts of the jumper will act as a grounding link between the

motor and harness jumper.

T 20

Screws

GEAppliances

Louisville, KY40225

Loosen Slide Tighten

WHOOX22834

Page 2

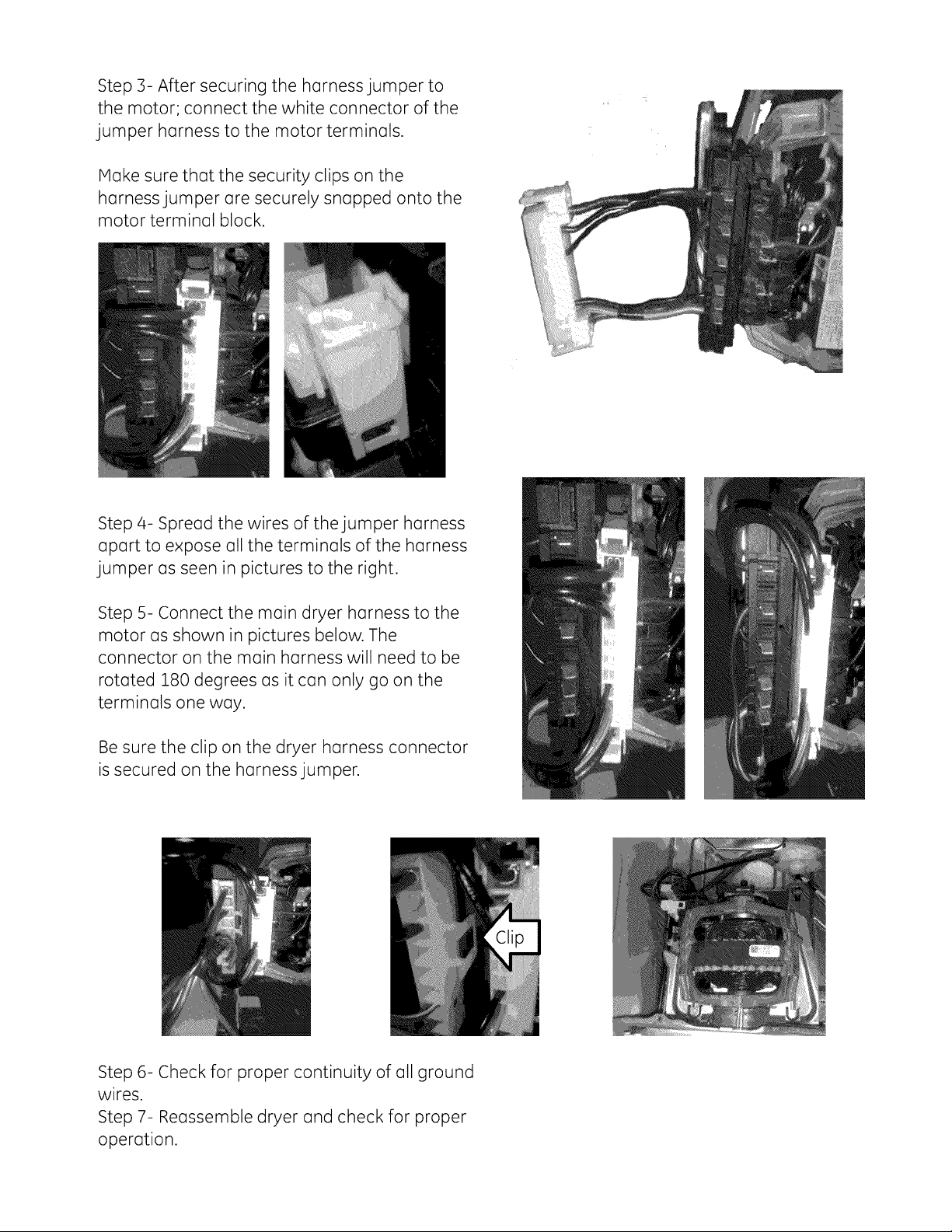

Step 5- After securing the harness jumper to

the motor; connect the white connector of the

jumper harness to the motor terminals.

Hake sure that the security clips on the

harness jumper are securely snapped onto the

motor terminal block.

Step 4- Spread the wires of the jumper harness

apart to expose all the terminals of the harness

jumper as seen in pictures to the right.

Step 5- Connect the main dryer harness to the

motor as shown in pictures below. The

connector on the main harness will need to be

rotated 180 degrees as it can only go on the

terminals one way.

Besure the clip on the dryer harness connector

is secured on the harness jumper.

Step 6- Check for proper continuity of all ground

wires.

Step 7- Reassemble dryer and check for proper

operation.

Page 3

* Fordryersrequiringmotor kitWE17X10002,themotor needsto beinstolledot on opproximote

45°ongtetoword the right cobinetponel. Thisisrequiredsothe hornessdoesnot rub onthe

drum.

Ifinstollingincommerciolstockeddryers,the

existingwiretie willneedto be removedthot

securesthe hornessto themountingbrocket.Use

o newwiretie whenreinstollingthe newmotor.

* Wheninstollingmotor kitWE17X23618in models,DSKP333EC3WW,DSKS333EC3WW,

DSKS433EB4WW,PCKS443EB4WW,PSKP333EB3WWond PSKS333EB3WW,themotorwill needto

berototedso the hornessconnectorfocesthe right sidelookingot the motorfrom the front of the

dryer.

Alsothe hornessgroundwirewill needto be movedfrom the motor brocketto the cobinetbose.

Oncethe motor ond hornessjumperore instolledon thesemodels,the hookon the motor brocket

connot beusedto holdthe idlerorm. tnstotlthe Iobelprovidedonthe blower housingto notify

futuretechsthot o servicemotor hosbeeninstotled.

Brocket Hook

New Ground Screw Locotion

doesn't allow the idler arm to be secured to the

I ATTENTION: Service motor installed on this unit |

motor bracket during drum removal

Label

J

Page 4

GEAppliances

Part Install Instructions

Dryer DeKalb Motor Replacement To NIDEC Motor Kit:

WE17X22216, WE17X22217, WE17X23355, WE17X23463,

WE17X23464, WE17X23465, *WE17X10002 or *WE17X23618

To avoid a risk of electrical shock, disconnect power prior to servicing.

Follow all steps and safety information in these instructions to avoid a risk of personal injury, [death], or property damage. This part should only

be installed by persons with adequate backgrounds of electrical and mechanical experience. Any attempt to repair a major appliance can result

in personal injury and property damage. The manufacturer or seller cannot be responsible for the interpretation of this information, nor can it

assume any liability in connection with its use.

Parts Included

• NIDEC Motor and Pulley Assembly

• Harness Jumper • Label

• Wire Tie • Instruction Sheet

Overview

Installation of the new motor requires the use of a harness jumper included in this kit. The new

motor will mount in the motor bracket as the previous motor. These instructions show how to

correctly complete the installation of the new motor and jumper.

Note: Install the jumper harness to the motor before installing it into the motor bracket.

Step Z- Loosen, but do not remove, the 2- T20 (Torx) screws on the motor harness receptacle.

Step 2- Install harness jumper by sliding the open slots of the jumper under the screw heads and

tighten the screws.

When screws are tighten, metallic parts of the jumper will act as a grounding link between the

motor and harness jumper.

T 20

Screws

GEAppliances

Louisville, KY40225

Loosen Slide Tighten

WHOOX22834

Page 5

Step 5- After securing the harness jumper to

the motor; connect the white connector of the

jumper harness to the motor terminals.

Hake sure that the security clips on the

harness jumper are securely snapped onto the

motor terminal block.

Step 4- Spread the wires of the jumper harness

apart to expose all the terminals of the harness

jumper as seen in pictures to the right.

Step 5- Connect the main dryer harness to the

motor as shown in pictures below. The

connector on the main harness will need to be

rotated 180 degrees as it can only go on the

terminals one way.

Besure the clip on the dryer harness connector

is secured on the harness jumper.

Step 6- Check for proper continuity of all ground

wires.

Step 7- Reassemble dryer and check for proper

operation.

Page 6

* Fordryersrequiringmotor kitWE17X10002,themotor needsto beinstolledot on opproximote

45°ongtetoword the right cobinetponel. Thisisrequiredsothe hornessdoesnot rub onthe

drum.

Ifinstollingin commerciolstockeddryers,the

existingwiretie willneedto be removedthot

securesthe hornessto themountingbrocket.Use

o newwiretie whenreinstollingthe newmotor.

* Wheninstollingmotor kitWE17X23618in models,DSKP333EC3WW,DSKS333EC3WW,

DSKS433EB4WW,PCKS443EB4WW,PSKP333EB3WWond PSKS333EB3WW,themotorwill needto

berototedso the hornessconnectorfocesthe right sidelookingot the motorfrom the front of the

dryer.

Alsothe hornessgroundwirewill needto be movedfrom the motor brocketto the cobinetbose.

Oncethe motor ond hornessjumperore instolledon thesemodels,the hookon the motor brocket

connot beusedto holdthe idlerorm. tnstotlthe Iobelprovidedonthe blower housingto notify

futuretechsthot o servicemotor hosbeeninstotled.

Brocket Hook

New Ground Screw Locotion

doesn't allow the idler arm to be secured to the

I ATTENTION: Service motor installed on this unit |

motor bracket during drum removal

Label

J

Loading...

Loading...