GE DSKP333EC0WH, DSKP333EC0WW, DSKP333EC2WW, DSKP333EC3WW, DSKP333EC4WW Installation Guide

...Page 1

MODELS DSKS433 AND DSKS333 MUST BE INSTALLED WITH CONTROL PANEL AT BOTTOM IN ORDER TO OPERATE ADEQUATELY.

Installation Instructions (USA onlg) !

Questions? Call: 800.GE.CARES (US) or visit our web site at: www.GEAppliances.com (US)

BEFORE YOU BEGIN

Reed these instructions completely end cerefullg.

• IMPORTANT- Save these instructions for local

inspector's use.

• IMPORTANT- Observe all governing codes and

ordinances.

• Note to Instoller - Be sure to leave these instructions

with the customer.

• Note to Customer - Keep these instructions with your

Owner's Manual for future reference.

• Before the old dryer is removed from service or

discarded, remove the dryer door.

• Service information and the wiring diagram are located

in the control console.

• Do not allow children on or in the appliance. Close

supervision of children is necessary when the appliance

is used near children.

• Install the dryer where the temperature is above 50°F

for satisfactory operation of the dryer control system.

• Product failure due to improper installation is not

covered under the Warranty.

• Dryers installed in garages (if allowed by local codes)

must be elevated 18 inches (46 cm) above the floor.

-4LWARNING RISK OF FIRE

• To reduce the risk of severe injury or death, follow all

installation instructions.

• Clothes dryer installation must be performed by a qualified

installer.

• Install the clothes dryer according to these instructions and

in accordance with local codes. In the absence of local codes,

installation must comply with the NATIONAL ELECTRICALCODE

ANSI/NFPA NO. 70.

• This dryer must be exhausted to the outdoors.

• Use only 4" rigid metal ducting for exhausting the clothes dryer to

the outdoors.

• DO NOT install a clothes dryer with flexible plastic ducting

materials. If flexible metal (semi-rigid or foil-type) duct is

installed, it must be UL listed and installed in accordance with

the instructions found in "Connecting The Dryer To House Vent"

on page/4 of this manual. Flexible venting materials are known

to collapse, be easily crushed, and trap lint. These conditions will

obstruct dryer airflow and increase the risk of fire.

• Do not install or store this appliance in any location where it

could be exposed to water and or weather.

• Save these instructions. (Installers: Be sure to leave these

instructions with the customer).

DETERMINE ELECTRICAL REQUIREMENTS FOR YOUR DRYER MODEL

• This dryer must be connected to an individual branch circuit of proper voltage and frequency as specified on Rating Plate (located inside

dryer door) with no other appliances or fixtures attached.

EXCEPTION:

• A 120V receptacle is located on the back on the dryer and isavailable only for use with a washer that isaffixed to the dryer with a

WDF-85 kit. It may not be used for any other appliance or any conditions other than slated above (208V& 240V models only).

• Branchcircuit mustbeprotected bythe requiredtime-delayfusesorcircuitbreakers208Vor 240Vinstallation-30 amps 120Vinstallation15or20 amps.

• The electrical installation must conform to the national and local codes.

208V AND 240V MODELS ARE NOT APPROVED FOR 120V INSTALLATION.

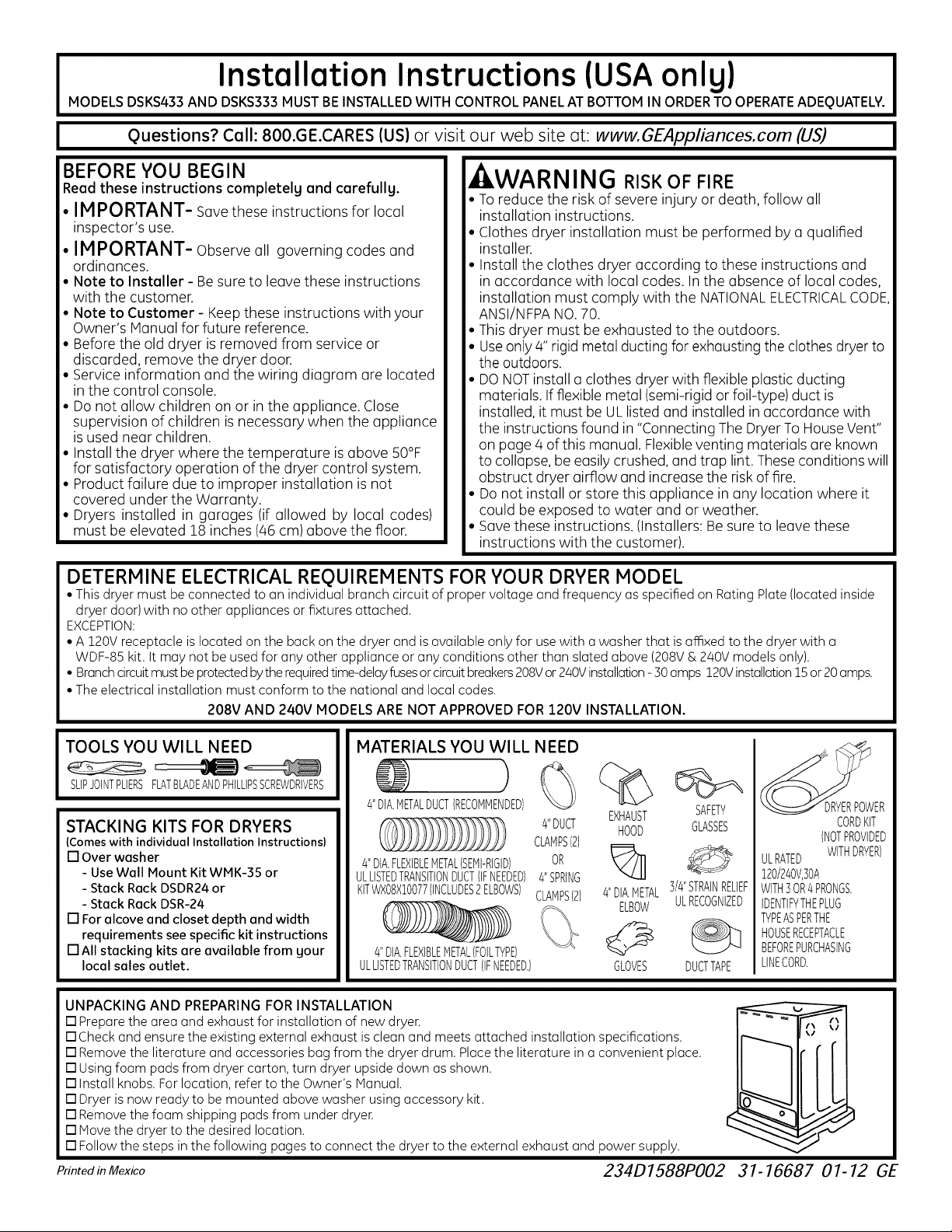

TOOLS YOU WILL NEED

SLIPJOINTPLIERSFLATBLADEANDPHILLIPSSCREWDRIVERS

STACKING KITS FOR DRYERS

(Comeswith individuol Instollotion Instructions)

[] Over wosher

- Use Woll Mount Kit WHK-35 or

- Stock Rock DSDR24or

- Stock Rock DSR-24

[] For olcove ond closet depth ond width

requirements see specific kit instructions

[]All stocking kits ore ovoiloble from sour

Iocol soles outlet.

UNPACKING AND PREPARING FOR INSTALLATION

[] Prepare the area and exhaust for installation of new dryer.

[]Check and ensure the existing external exhaust is clean and meets attached installation specifications.

[] Remove the literature and accessories bag from the dryer drum. Place the literature in aconvenient place.

[] Using foam pads from dryer carton, turn dryer upside down as shown.

[] Install knobs. For location, refer to the Owner's Hanual.

[] Dryer is now ready to be mounted above washer using accessory kit.

[] Remove the foam shipping pads from under dryer.

[] Move the dryer to the desired location.

[] Follow the steps inthe following pages to connect the dryer to the external exhaust and power supply.

MATERIALS YOU WILL NEED

4"DIA.METALDUCT(RECOMMENDED)

4"DUCT

CLAMPS(2)

4"DIA.FLEXIBLEMETAL(SEMI-RIGID) OR

ULLISTEDTRANSITIONDUCT(IFNEEDED)4"SPRING

KITWXO8X10077(INCLUDES2ELBOWS)CLAMPS12)

4"DIA.FLEXIBLEMETAL(FOILTYPE)

ULLISTEDTRANSITIONDUCT(IFNEEDED.)

EXHAUST

HOOD

%

4"DIA.METAL

ELBOW

GLOVES

%

SAFETY

GLASSES

3/4"STRAINRELIEF

ULRECOGNIZED

DUCTTAPE

)RYERPOWER

CORDKIT

(NOTPROVIDED

ULRATED WITHDRYER)

120/240V,]OA

WITH3OR4PRONGS.

IDENTIFYTHEPLUG

TYPEASPERTHE

HOUSERECEPTACLE

BEFOREPURCHASING

LINECORD.

PrintedinMexico 234D1588PO02 31-16687 01- 12 GE

Page 2

ELECTRICAL CONNECTION DETAILS

OBSERVE ALL GOVERNING CODES AND ORDINANCES

GROUNDING INSTRUCTIONS

•The operating voltage (Volts),Amperage (Amps) and

Frequency (Hz)of this dryer are indicated on the Rating

Plate located to the right of the loading port.

• Connect this dryer to acircuit corresponding to that

indicated on Rating Plate and protected by fuses or a

circuit breaker in accordance with local codes.

• Use a power supply cord kit marked for usewith clothes

dryer. For208V and 240Vmodels, use a power supply cord

kit marked for use with clothes dryers.

I O NOTUSEEXTENSIONCORDWITH THISAPPLIANCE

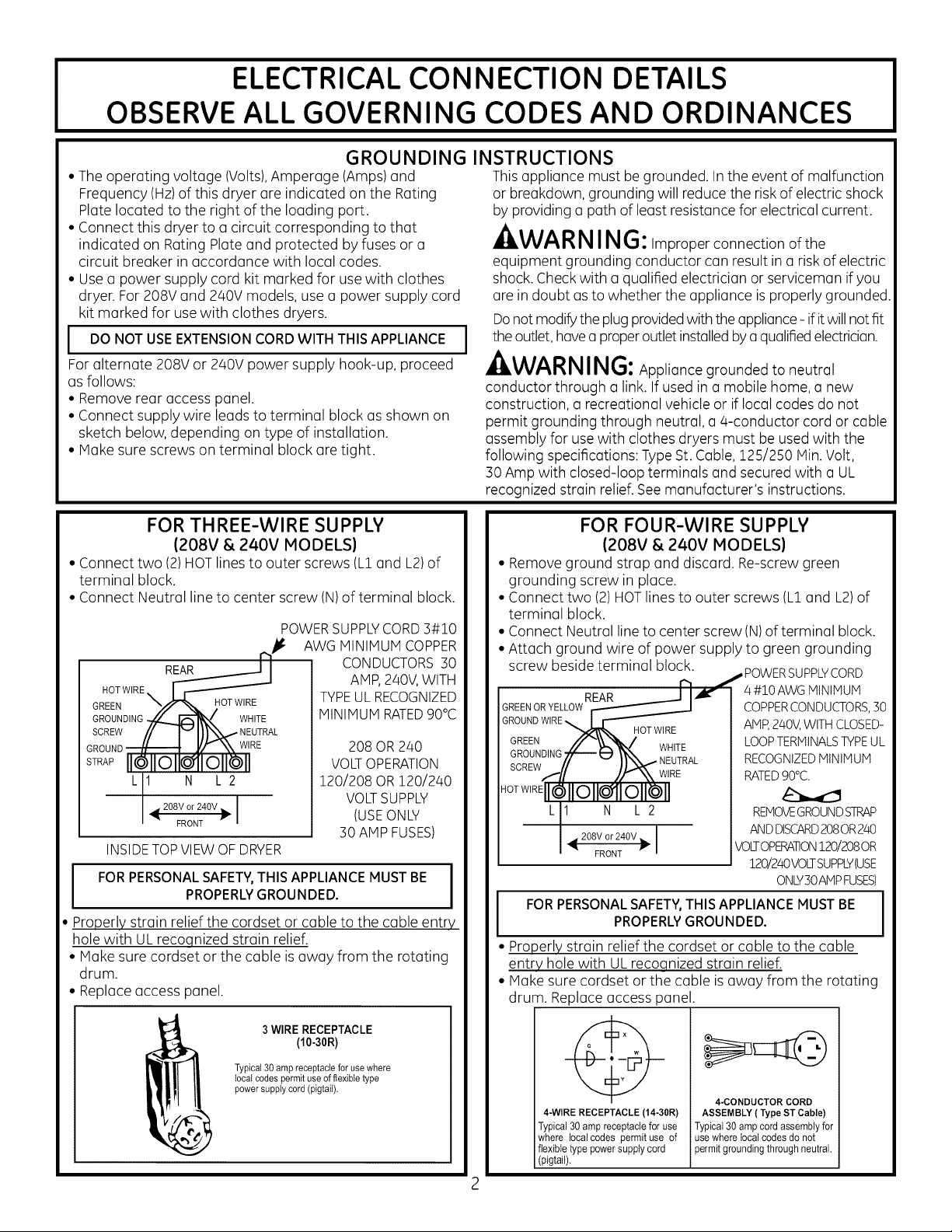

For alternate 208V or 240V power supply hook-up, proceed

as follows:

• Remove rear access panel.

• Connect supply wire leads to terminal block as shown on

sketch below, depending on type of installation.

• Make sure screws on terminal block are tight.

This appliance must begrounded. Inthe event of malfunction

or breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electrical current.

WARN ING:Improperconnection of the

equipment grounding conductor can result in a riskof electric

shock. Check with a qualified electrician or serviceman if you

are in doubt as to whether the appliance isproperly grounded.

Donot modify the plugprovidedwith theappliance-if it will notfit

the outlet,havea proper outlet installedbya qualified electrician.

I

, WARNING: Appliance grounded to neutral

conductor through a link. Ifused in a mobile home, a new

construction, a recreational vehicle or if local codes do not

permit grounding through neutral, a 4-conductor cord or cable

assembly for use with clothes dryers must be used with the

following specifications: TypeSt. Cable, 125/250 Min. Volt,

30 Amp with closed-loop terminals and secured with a UL

recognized strain relief. Seemanufacturer's instructions.

FOR THREE-WIRE SUPPLY

(208V & 240V MODELS)

• Connect two (2)HOTlines to outer screws (L1 and L2)of

terminal block.

• Connect Neutral line to center screw (N) of terminal block.

POWER SUPPLY CORD 3#10

_- AWG MINIMUM COPPER

REAR

HOT WIRE \

GREEN HOT WIRE

GROUNDING WHITE

SCREW _ NEUTRAL

GROUND WIRE

STRAP

N L 2 120/208 OR120/240

2o8vor24ov I VOLTSUPPLY

_f

FRONT _ I (USEONLY

INSIDETOP VIEW OF DRYER

FOR PERSONAL SAFETY,THISAPPLIANCE MUST BE I

PROPERLY GROUNDED.

• Properly strain relief the cordset or cable to the cable entry

hole with UL recoqnized strain relief.

• Make sure cordset or the cable is away from the rotating

drum.

• Replace access panel.

CONDUCTORS 30

AMP, 240V, WITH

TYPE UL RECOGNIZED

MINIMUM RATED 90°C

208 OR 240

VOLTOPERATION

30AMP FUSES)

I

FOR FOUR-WIRE SUPPLY

{208V & 240V MODELS}

• Remove ground strap and discard. Re-screw green

grounding screw in place.

• Connect two (2)HOTlines to outer screws (L1 and L2)of

terminal block.

• Connect Neutral line to center screw (N)of terminal block.

• Attach ground wire of power supply to green grounding

screw beside terminal block.

GREEN / WHITE

GROUNDING.___: _ WHITE

SCREWf// /_ WIRE

II v I1\\ JNEUTRAL

p POWERSUPPLYCORD

/4#10 AWG MINIMUM

COPPERCONDUCTORS,30

AMP,240V, WITH CLOSED-

LOOP TERMINALSTYPEUL

RECOGNIZEDMINIMUM

RATED90°C.

OTW'REII¢IIOII : IIOI1 11

REMOVEGROUNDSTRAP

LItN L21

_, 208V or240V _.

"_ FRONT

FOR PERSONAL SAFETY, THIS APPLIANCE MUST BE

PROPERLYGROUNDED.

Properly strain relief the cordset or cable to the cable

entry hole with UL recoqnized strain relief.

• Make sure cordset orthe cable is away from the rotating

drum. Replace access panel.

ANDDISCARD208OR240

VOLTOPERATION120/208OR

120/240VOLTSUPPLY(USE

ONLY30AMPFUSES)

3 WIRE RECEPTACLE

(10-30R)

Typical 30 amp receptacle for use where

local codes permit use of flexible type

power supply cord (pigtail).

4-WIRE RECEPTACLE (14-30R)

Typical 30 amp receptacle for use

where local codes permit use of

flexible type power supply cord

(pigtail).

4-CONDUCTOR CORD

ASSEMBLY (Type ST Cable)

Typical30 amp cord assembly for

use where local codes do not

permit grounding through neutral.

2

Page 3

EXHAUST INFORMATION

-&WARNING -IN CANADAANDINTHE

UNITED STATES, THE REQUIRED EXHAUST DUCT

DIAMETER IS4 in (102ram). DO NOT USEDUCT LONGER

THAN SPECIFIED IN THE EXHAUST LENGTH TABLE.

Using exhaust longer than specified length will:

• Increase the drying times and the energy cost.

• Reduce the dryer life.

• Accumulate lint, creating a potential fire hazard.

- WARNING - BEFORE PERFORMING THIS

EXHAUST INSTALLATION, BE SURE TO DISCONNECT

THE DRYER FROM ITS ELECTRICAL SUPPLY.

The correct exhGust instGllation is YOURRESPONSIBILITY.Problems

due to incorrect instGllation are not covered bg the wGrrGntg.

Remove and discard existing plastic or metal foil transition duct and

replace with UL-listed transition duct.

The MAXIMUM ALLOWABLEduct length and number of bends of

the exhaust system depends upon the type of duct, number of

turns, the type of exhaust hood (wall cap), and all conditions noted

below. The maximum duct length for rigid metal duct isshown in

the table on the next page.

EXHAUST SYSTEM CHECK LIST

HOOD OR WALL CAP

• Terminate in a manner to prevent back drafts or entry of birds or

other wildlife.

• Termination should present minimal resistance to the exhaust

air flow and should require little or no maintenance to prevent

clogging.

• Never install a screen in or over the exhaust duct. This could

cause lint build up.

• Wall caps must be installed at least 12 in.above ground level or any

other obstruction with the opening pointed down.

SEPARATION OF TURNS

For best performance, separate all turns by at least/4 ft. of straight

duct, including distance between last turn and exhaust hood.

TURNS OTHER THAN 90 °

• One turn of/45°or lessmay be ignored.

• Two/45 ° turns should be treated asone 90° turn.

• Each turn over/45 ° should be treated as one 90° turn.

SEALING OF JOINTS

° All joints should be tight to avoid leaks. The male end of each

section of duct must point away from the dryeE

• The duct shall not be assembled with screws or other fastening

means that extend into the duct and catch lint.

• Duct joints can be made air and moisture-tight by wrapping the

overlapped joints with duct tape.

• Horizontal runs should slope down toward the outdoors 1/4 inch

per foot.

INSULATION

Ductwork that runs through an unheated area or is near air conditioning

should be insulated to reduce condensation and lint build-up.

EXHAUST CONNECTION

- WARNING - TO REDUCE THE RISK

OF FIRE OR PERSONAL INJURY:

° This clothes dryer must be exhausted to the outdoors.

• Use only 4" rigid metal ducting for the home exhaust duct.

• Use only 4" rigid metal or UL-listed flexible metal (semi-rigid or

foil-type) duct to connect the dryer to the home exhaust duct.

It must be installed in accordance with the instructions found in

"Connecting the Dryer to House Vent" on page/4 of this manual.

• Do not terminate exhaust in a chimney, a wall, a ceiling, gas

vent, crawl space, attic, under an enclosed floor, or in any other

concealed space of a building. The accumulated lint could create

a potential fire hazard.

• Never terminate the exhaust into a common duct with a kitchen

exhaust system. A combination of grease and lint creates a

potential fire hazard.

• Do not use duct longer than specified inthe exhaust length table.

Longer ducts can accumulate lint, creating a potential fire hazard.

• Never install a screen in or over the exhaust duct. Thiswill cause

lint to accumulate, creating a potential fire hazard.

• Do not assemble ductwork with any fasteners that extend into the

duct. These fasteners can accumulate lint, creating a potential

fire hazard.

• Do not obstruct incoming or exhausted air.

• Provide an access for inspection and cleaning of the exhaust

system, especially at turns and joints. Exhaust system shall be

inspected and cleaned at least once a year.

ALTERNATE EXHAUST INSTRUCTIONS

IF YOUR DRYER COMES WITH REAR EXHAUST,

TO CHANGE TO SIDE OR BOTTOM EXHAUST:

• Remove access panel at back of dryer to gain access to

internal ducts.

• Disconnect duct exhaust from blower housing (remove

tape securing duct).

FORSIDE EXHAUST:

• Remove desired knockout plate (either right or left side).

• Cut a 115 mm (/4½")length of 100 mm (/4")dia. rigid

duct as shown (remove burrs from cut edge).

• Attach this extension duct to blower housing duct.

° Attach a 90° elbow facing desired opening.

° Attach a section of 100 mm (4")dia. rigid duct

to elbow to protrude through side of cabinet.

° Seal all joints with duct tape.

° Reinstall rear access panel.

FORBOTTOM EXHAUST:

° Remove cover plate at bottom of dryer.

° Install a 90° elbow.

° Seal all joints with duct tape.

° Reinstall rear access panel.

° Placecover plate (removedfrom bottom

of dryer) over rear exhaust opening.

295 mm '_- For Rear Exhaust

115 mm I'_-II_l - ForSide Exhaust

k _ ._' J2_ Metallic

_ EXTENSION DUCT

It is importat to replace the ground clip after

cutting the exhaust duct, (on rear exhaust model) duct as shown (remove burrs from cut edge).

DRYER TOP VIEW

152 mm

Left knockout _.

Blower

2

Right knockout • "° I I

20-_33mm

Bottom

knockout

_(_/_89 mm

Ductlng

IF YOURDRYERCOMESWITH TOP EXHAUST,

TO CHANGETO SIDE OR REAREXHAUST:

• Remove rear access panel.

• Disconnect retaining plate and 90° elbow by removing

mounting screw from the chassis and remove tape

securing elbow to blower housing.

• Remove cover plate from rear access panel and place

over top exhaust opening.

FORSIDEEXHAUST:

• Remove desired knockout plate (either right or left side).

,,)

• Take the duct previously removed and cut a 115 mm

(/4½")length of 100 mm (/4")dia. rigid duct as shown

(remove burrs from cut edge).

• Attach this extension duct to blower housing duct.

• Attach the 90° elbow facing desired opening.

• Attach a section of 100 mm (/4")dia.rigid duct to elbow

to protrude through side of cabinet.

• Seal all joints with duct tape.

• Reinstall rear access panel.

FORREAREXHAUST:

• Cut a 295 mm (11 ½ ")length of 100 mm (/4")dia. rigid

• Attach this extension duct to blower housing.

• Seal alljoints with duct tape. Reinstall near access panel.

Page 4

EXHAUST LENGTH CALCULATION

RIGID (Preferred)

Parts are available from your local service organization:

WX8X63 4"X1' Duct WX8X51 Elbow

WX8X64 4"X2' Duct WX8Xg9 Aluminum hood

RECOMMENDED MAXIMUM LENGTH

Exhaust Hood Types

Recommended Use only for short

o"l-

No. of g0 °

Elbows

0

£

2

3

Total length of flexible metal duct shall not exceed 8 ft (2.4 m).

The following kit is available from you local service organization:

Kit WX08X10077 - 4" dia. flexible metal (semi-rigid) UL-listed

transition duct (includes 2 elbows).

Rigid

Metal

£a m (46 ft)

11 m (37 ft)

9 m (30 ft)

7 m (23 ft)

FLEXIBLE

run installations

4" DIA.

--_ I-,_, 2_112,,

Rigid

Metal

11m(37ft)

9 m (30 ft)

6.5 m (22 ft)

4.5m(15ft)

ALCOVE OR CLOSET INSTALLATION

• Ifyour dryer is approved for installation in an alcove or closet,

it will be stated on a label on the dryer back. The installation

must conform to the following specifications:

ILWARNING: TOPREVENTLARGEAMOUNTS

OFL,NTANDMO,STUREFROMACCUMULAT,NGANDTO

MAINTAIN DRYER EFFICIENCY, THIS MACHINE MUST BE

EXHAUSTED OUTDOORS.

• Minimum clearances between dryer cabinet and adjacent

walls or other surfaces are:

Alcove Closet

Sides 0" 1"

Top 1" 1"

Front 3"

Rear 3" 3"

• Minimum vertical space from floor to overhead cabinets,

ceiling, etc. is 52 in.

• Closet doors must be Iouvered or otherwise ventilated and must

contain atleast 60 square inches of open area equally distributed. If

the closet contains both a washer and adryer, doors must contain

at least 120square inches of open area equally distributed.

sideration must be given to the tgpe accessory kit used

NOTE: The clearances stated above are minimums. Con- |

with dryer. Refer to the specific kit instruction for details.

!

CONNECTING THE DRYERTO HOUSE VENT

RIGID METALTRANSITION DUCT

• For best drying performance, a rigid metal transition duct is

recommended.

• Rigid metal transition ducts reduce the risk of crushing and

kinking.

UL-LISTEDFLEXIBLEMETAL(SEMI-RIGID)TRANSITIONDUCT

• If rigid metal duct cannot be used, then UL-listed flexible met-

al (semi-rigid) ducting can be used (KitWX08X10077).

• Never install flexible metal duct in walls, ceilings, floors or

other enclosed spaces.

• Total length of flexible metal duct should not exceed 8 feet

(2.4m).

• For many applications, installing elbows at both the dryer

and the wall is highly recommended (see illustrations below).

Elbows allow the dryer to sit close to the wall without kinking

and or crushing the transition duct, maximizing drying

performance.

• Avoid resting the duct on sharp objects.

NOTE TO INSTALLER - AFTERINSTALLATIONCHECK

THE FOLLOWING:

[] EXHAUSTDUCT- Must meet specs on page 3. No excessive

turns. No kinks or obstructions to air flow.

[] EXHAUSTHOOD- Should work freely and open downward.

[] GROUNDING- Dryer must be properly grounded to conform to

local codes and ordinance requirements.

[] OPERATION- Turn dryer on and check for heat.

[] HAND CUSTOMERTHEOWNER'SMANUAL- Give instructions on

operating the dryer - Answer any questions.

[] GIVETHESEINSTALLATIONINSTRUCTIONSto the customer.

UL-LISTED FLEXIBLE METAL (FOIL-TYPE) TRANSITION DUCT

• In special installations, it may be necessary to connect the

dryer to the house vent using a flexible metal (foil- type) duct.

A UL-listed flexible metal (foil-type) duct may be used ONLY

in installations where rigid metal or flexible metal (semi-rigid)

ducting cannot be used AND where a 4" diameter can be

maintained throughout the entire length of the transition duct.

• In Canada and the United States,only the flexible metal (foil-

type) ducts that comply with the "Outline for Clothes Dryer

Transition Duct Subject 2158A" shall be used.

• Never install flexible metal duct in walls, ceilings, floors or

other enclosed spaces.

• Total length of flexible metal duct should not exceed 8 feet

(2.4m).

• Avoid resting the duct on sharp objects.

For best drying performance

1 Slideone end of the duct over the clothes dryer outlet pipe.

2.Secure the duct with a clamp.

3.With the dryer in its permanent position, extend the duct to

its full length. Allow 2" of duct to overlap the exhaust pipe.

Cut off and remove excess duct. Keep the duct as straight as

possible for maximum airflow.

4.Secure the duct to the exhaust pipe with the other clamp.

WHEN INSTALLED IN MANUFACTURED (MOBILE) HOMES

Dryer must be exhausted to the outside. Exhaust MUSTNOTbe

terminated beneath mobile home. Exhaust material MUSTNOT

support combustion. Installation MUSTconform to Manufactured

Home Construction & Safety Standard, Title 24 CFR,Part 32-80

or when such standard is not applicable, the American National

Standard of Mobile Homes, ANSI/NFRA No. 501B-1977. For electrical

connection, see "Connecting dryer using 4 wire connection".

USE OF CASTERS (120V PORTABLE MODELS ONLY)

Fora portableinstallationscrewcastersinto the holesonthe bottomof the

dryer.Referto the "InstallationInstructionsfor casterassembly"sheetto

installcasters.

Loading...

Loading...