Page 1

GE

Sensing

Druck MCX-II

Multi-Calibrator

User Manual K0320

Multi-Calibrator

Multikalibrator

Multi-calibrateur

99 Washington Street

Melrose, MA 02176

Fax 781-665-0780

TestEquipmentDepot.com

Page 2

2

Deutsch

Inhaltsverzeichnis ................................ 4

Français

Table des matières .............................. 6

To measure pressures (optional)

Read pressure module MCX-PM

operation manual

Automatic calibration or testing

(optional)

Read Linkpak-W operation manual

To communicate with ‘smart’

instrumentation (optional)

Read "communicator" operation

manual

Table of Contents

Introduction

The MCX-II calibrator ............................. 8

Pressure Measurements and Calibrations

.............................................................. 8

Automatic Calibration.............................. 8

Digital Communicator ........................... 10

Standard Accessories........................... 10

Optional Accessories ............................ 10

Functionality

Parts identification ................................ 12

Screens to work with ............................ 18

Keys to work with .................................. 20

Power Sources

Power from internal batteries ............... 22

Changing from Alkaline to rechargeable

batteries ................................................. 26

Recharging............................................. 26

Operating from 115 V or 230V line

voltage (50 or 60 Hz) ............................ 28

Set-up

Date and Time Settings ........................ 30

Setting the clock to your local time.. 30

Setting the clock to your local date . 32

Temperature readings .......................... 34

Changing the temperature unit......... 34

Changing the temperature scale ...... 36

Language Setting............................... 38

Setting te language ........................... 38

Access code settings............................ 40

LCD screen viewing adjustments ........ 42

Setting the backlight automatic

shut-off mode ..................................... 42

Backlight on/off operation ................. 44

Screen contrast adjustment.............. 44

Bench or portable use ....................... 46

Keystroking ............................................ 48

Storing a key-pad operation sequence

............................................................ 48

Recalling a key-pad operation

sequence ............................................ 48

Clear key-stroking ............................. 50

To measure signals

General................................................... 52

K0320 Issue No. 1

Page 3

Millivolts ................................................. 52

Volts........................................................ 54

Milliamps/XMTR .................................. 54

Ohms ...................................................... 56

Frequency .............................................. 56

Pulse Counter Mode ............................. 58

Switch position change......................... 60

Circuit continuity tester......................... 62

To measure a thermocouple

Using compensation wires ................... 64

Using the standard test leads

(copper wires)........................................ 66

To measure a RTD

With the remote probe (optional)......... 68

Special Measurement Functions

Scaled readings..................................... 70

Setting up scaled readings (linear

relationship) ....................................... 70

Setting up scaled readings

(flow relationship) .............................. 72

Output of electrical signals

General................................................... 74

Set mode ............................................ 74

Output mode....................................... 76

Changing the output level ................. 76

Millivolts ................................................. 78

Volts........................................................ 80

Milliamps/XMTR .................................... 80

Ohms ...................................................... 82

Frequency .............................................. 82

Counter................................................... 84

To simulate a thermocouple

To start/stop ramp cycling ................ 96

Scaled readings..................................... 96

User Power supplies

Transmitter calibration

Setting up a calibration ....................... 100

To check or calibrate a transmitter ...102

Temperature transmitter simulation

Setting up a simulation ....................... 104

To simulate a transmitter.................... 106

Programmable signal converter

Setting up a signal converter ............. 108

Ce Remarks

Ce Remarks ......................................... 110

Service, Repair and Parts

Recalibration of the MCX-II ................ 112

Cold juntion compensation

calibration ......................................... 114

Lithium cell replacement..................... 118

Fault finding procedures ..................... 120

Opening and closing the calibrator

housing ............................................. 120

Fault finding procedures ..................... 122

Spare parts list................................. 128

Specifications

Protocol for RS232 System Integration

.......................................................... 142

Warranty & Liability

3

RTD Simulation

Excitation current .................................. 88

Special Output Functions

Step Mode .............................................. 92

Ramp Mode............................................ 94

Setting up the ramp mode ................ 94

To start/stop a ‘one shot’ ramp ........ 96

K0320 Issue No. 1

Page 4

Introduction

The MCX-II calibrator

The Multi-Calibrator model MCX-II has

8

been designed for testing and

calibration of process instrumentation

and portable test equipment. The unit

provides data to comply with the

ISO9000 requirements for calibration.

The MCX-II can be used to measure

and output analog and digital signals

often used in an industrial

environment.

Also it can be used to simulate a

wide variety of temperature sensors.

Measurement and output/simulation

functions can be operated and read

simultaneously.

Pressure Measurements and Calibrations

A plug-in Pressure Module model

MCX-PM is optionally available for

pressure measurements and

calibration.

K0320 Issue No. 1

Automatic Calibration

To automate calibration routines and

to store calibration data the unit has

been provided with a memory card

slot.

For the same purpose the unit has a

RS232 cable connector to interface

directly with a Personal Computer.

To perform automatic calibration, in

the field or in the workshop, the MCXII is supported by Intecal software. The

software package and Memory Cards

are optionally available from your local

GE Sales Office or Distributor.

Page 5

Functionallity

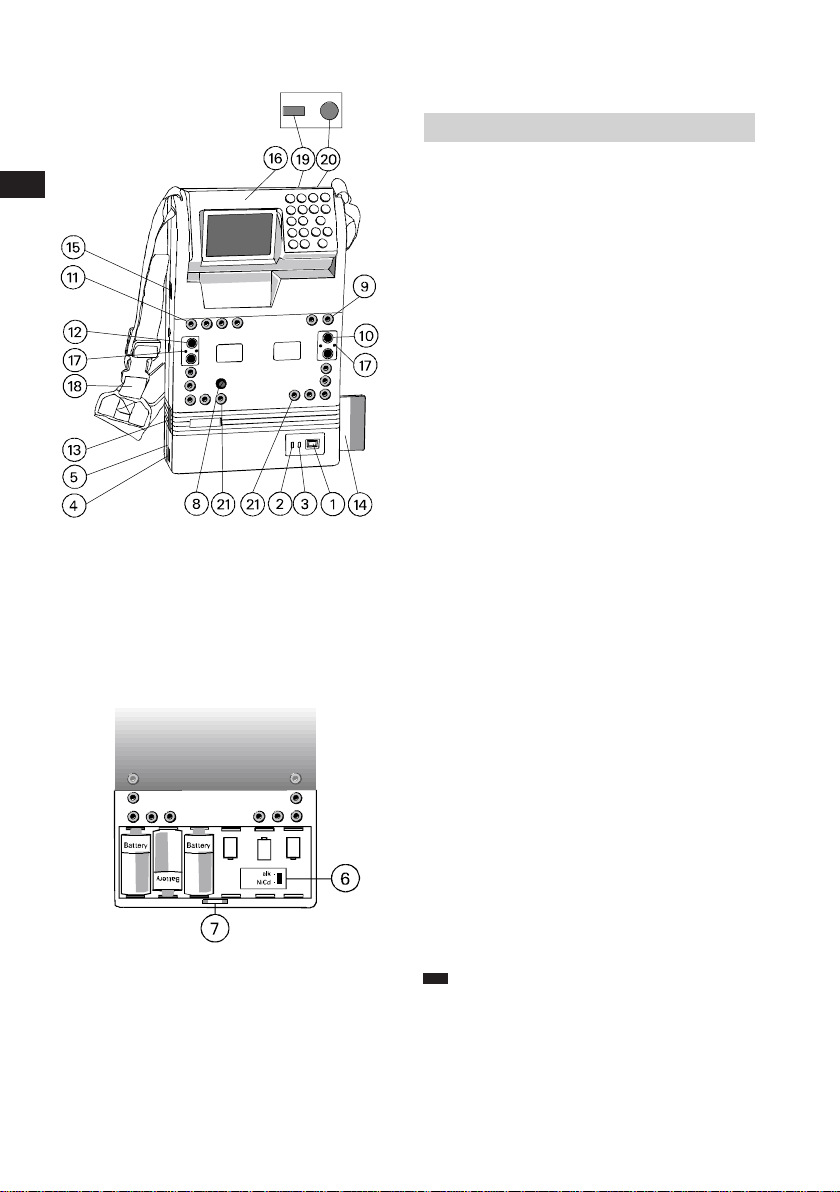

Parts identification

12

1 POWER switch

Switch to put the calibrator

"ON" and "OFF".

2 CHG. (amber LED) charging

indicator

On when batteries are charged.

The indicator should not light

when non-rechargeable

batteries are installed.

3 EXT. (green LED) external

power indicator

On when calibrator is powered

from the optional line

adaptor/charger #13603.

4 EXT. POWER INPUT

Connector for external

power source.

Only suitable for optional line

adaptor/charger #13603.

5 Battery compartment cover

Release screws to get access

to batteries.

K0320 Issue No. 1

6 Battery selector switch

To select Alkaline or

Rechargeable batteries.

Remove protective sticker to

get access to the switch.

IMPORTANT:

Switch position

must comply with installed battery

type.

Page 6

16

Functionallity

15 Pt100 PROBE

4-pole mini DIN female connector

for optional sensor.

16 Control and display panel

Rotatable unit to position best for

bench or portable use.

17 Auxilary Connectors

For use with pressure module

MCX-PM. [Do not make any other

connections to these terminals]

18 Shoulder strap (removable)

For portable use with adjustable

length.

19 VIEWING ANGLE adjustment

knob

To adjust LCD contrast.

20 BACKLIGHT Push button

Switches LCD backlight ON/OFF.

21 COMMUNICATOR TERMINALS

Connections for "smart"

Instrumentation. [Use is optional

with communicator card]

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

K0320 Issue No. 1

FAX 781.665.0780 - TestEquipmentDepot.com

Page 7

18

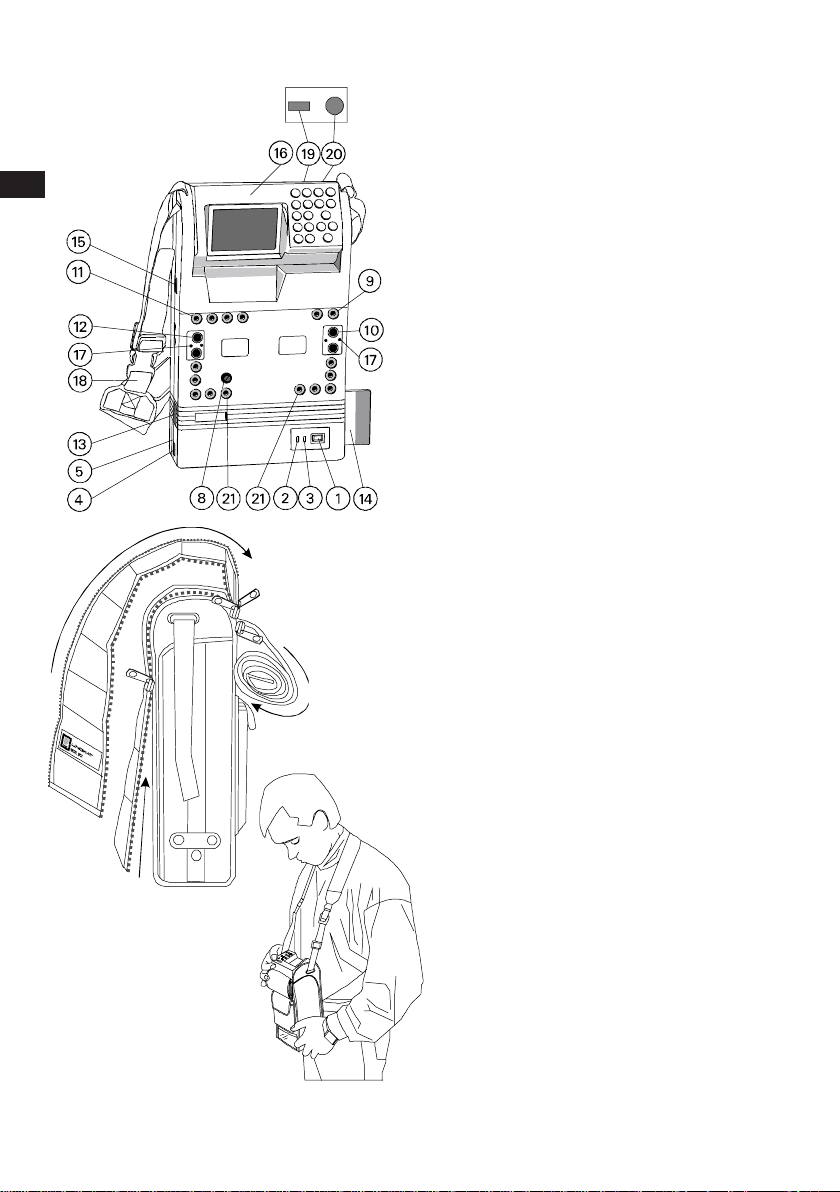

Functionallity

Screens to work with

The MCX-II has four types of screen

display to work with:

• Menu Selection Screen

Offers selection of choices. Move

cursor with arrow keys to your choice.

• Set up Screen

Move cursor with arrow keys to fill in

the blanks.

• Working Screen

Displays readings of measured and

generated values. Output or simulated

temperatures are set with the

numerical key-pad or can be ramped up

and down in different ways.

K0320 Issue No. 1

NOTE:

After switching the calibrator

on, the screen will show:

• Serial Serial Number

• Firmware Firmware version

• Hart Hart Firmware

version

• Battery voltage/switch position

• Days left to next calibration

Page 8

20

Functionallity

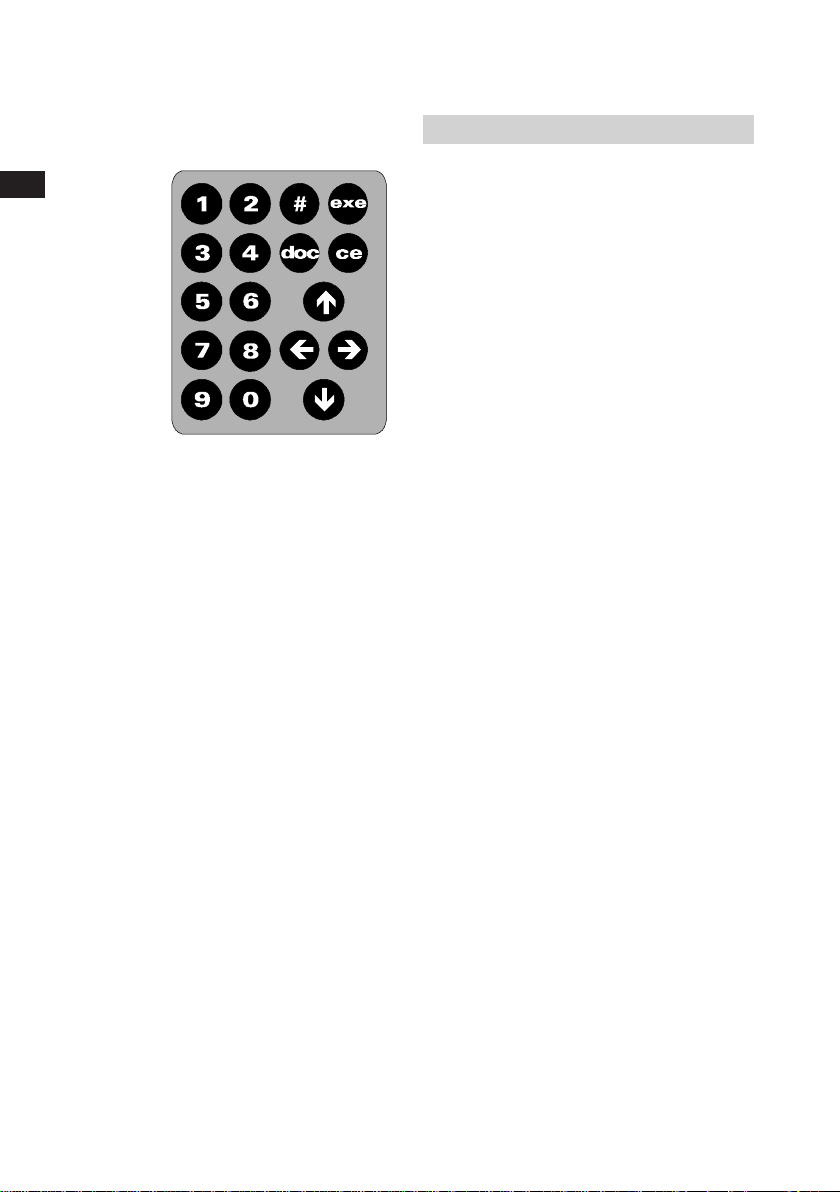

Keys to work with

• The EXE key

Pressing this key will execute choices

or output level adjustments.

• The CE key

Press to cancel your previous key

operation or to correct a typing error.

• The NUMERICAL key-pad

Used to dial output levels or

simulated temperatures. Also used to

fill out levels and time settings for

special functions.

• The ARROW keys

Moves the cursor position and ramps

output levels up or down.

• The # key

Used to open the set-up menu.

K0320 Issue No. 1

• The DOC key

Used to access the documenting

functions.

• The 0 key

Changes the sign when display reads

all zeros.

Page 9

22

Power Sources

Power from internal batteries

Internal power is obtained from

6 x 1.5 V Alkaline batteries or 6 x 1.2 V

Rechargeable batteries, Model R14, Baby

or C size.

• Installation of the batteries

Switch the calibrator off before you

install new batteries. Release both

mounting screws of the battery

compartment cover. Open the

compartment and place the new

batteries in position as indicated

in the compartment. Check for clean

poles and contact plates before you

replace the batteries.

• Use of Alkaline batteries

(supplied as standard)

The calibrator is supplied with one set

of 6x Alkaline batteries. Check that

the Battery Selector Switch is in the

"alkaline" position before replacing the

batteries. Battery switch position will

be confirmed on the screen during

start-up of the calibrator.

Replace batteries when the screen

shows the blinking battery symbol.

K0320 Issue No. 1

Page 10

24

Power Sources

IMPORTANT:

Be sure that batteries are

inserted so that they are

placed correctly with respect

to the (+) and (-) indications in

the battery compartment. If

the batteries are not inserted

correctly, they may leak and

damage the calibrator.

Do not mix old and new

batteries, or batteries of

different types (such as

carbon and alkaline.)

If the calibrator is not to be

used for a long period of time,

take out the batteries.

Remove and dispose of

worn-out batteries.

Never attempt to recharge or

short-circuit the batteries.

K0320 Issue No. 1

Page 11

Power Sources

Changing from Alkaline to

Rechargeable batteries

26

Remove the Alkaline batteries.

Remove the switch protector sticker

and slide the switch to the "Ni-Cd"

position.

Place a new protector sticker to save

the new switch position. Install 6

rechargeable batteries (purchased

locally). Battery switch position will be

confirmed on the screen during startup of the calibrator. Recharge

batteries when the screen shows the

blinking battery symbol.

CAUTION:

Do not fit alkaline or other nonrechargeable batteries after you

have changed the switch position to

"Ni-Cd".

Recharging

Use the Line Adaptor/Charger #13603

only; other equipment may cause

damage to the calibrator. Check the

indicated line volt switch in the

CHARGE position. Connect the

appropriate Adaptor/Charger plugs to

the line and to the calibrator. The

amber led CHG at the calibrator power

panel will now be on. As adaptor and

charger functions are fully

independent from each other, the

calibrator can be used while charging.

Recharging time from complete

discharge to fully charge is 14 hours.

K0320 Issue No. 1

Page 12

28

Power Sources

You may charge for periods longer

than 14 hours. Note that at lower

ambient temperatures the capacity of

Ni-Cd batteries is significantly lower. If

the batteries do not reach their normal

capacity after a 14 hours charging

period, cycle complete discharging

and charging for at least 2 times. If

batteries remain weak they should be

replaced. No particular brand of Ni-Cd

is recommended although cells rated

at 2.0 Ah have preference over

general available 1.8 Ah cells.

Operating from 115 V or 230V line voltage

(50 or 60 Hz)

Use the Line Adaptor/Charger #13603

only; other equipment may cause

damage the calibrator. Check the

indicated line voltage. Connect the

appropriate Line Adaptor/Charger

plugs to the line and to the calibrator.

The green led EXT at the calibrator will

now be on.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

K0320 Issue No. 1

Page 13

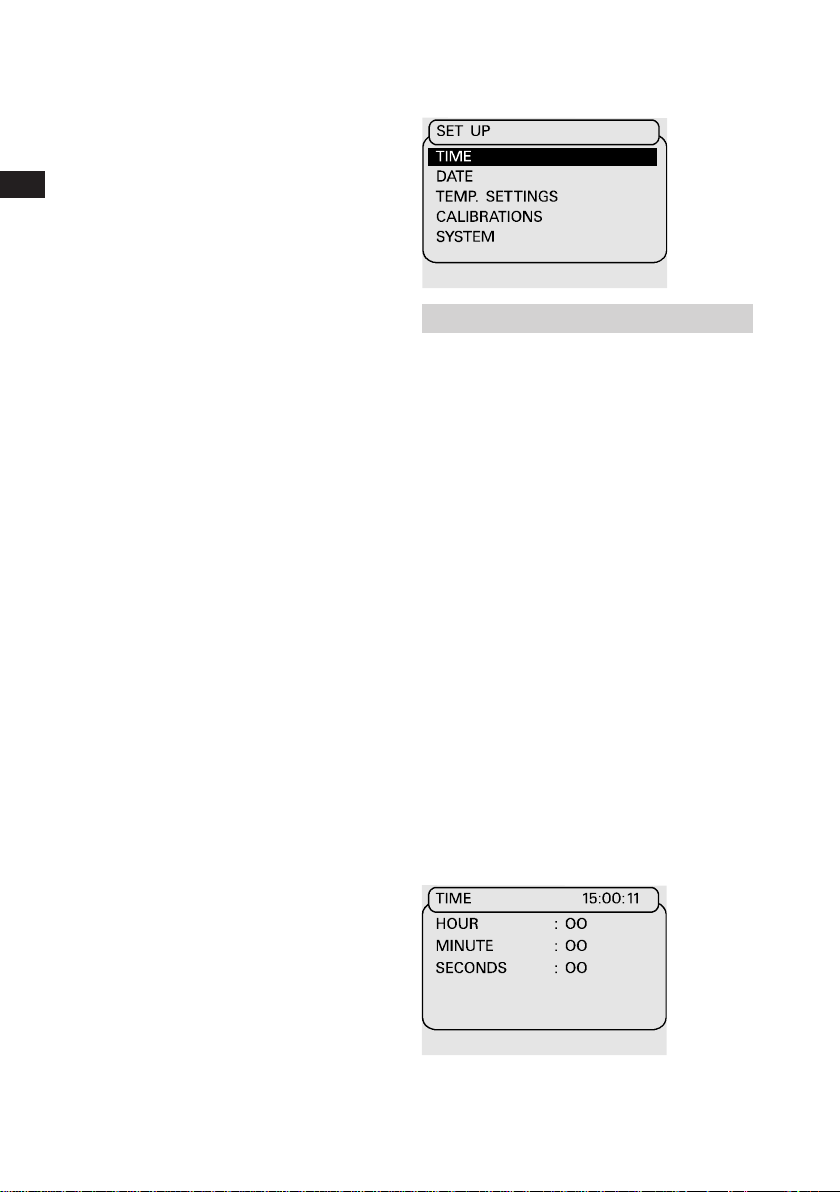

30

Set-up

Date and Time Settings

The MCX-II has been equipped with an

internal clock: to indicate how many

days are left before last calibration

expires and to record date and time

on the memory card. The clock has

been factory set to Paris time at the

date of calibration.

Setting the clock to your local time

Leave the cursor at NONE at the

INPUT and OUTPUT menu and press

the # key to open the set-up menu.

Select TIME. Press EXE again. Enter

the local time. Press EXE to accept

new time or press CE to leave the setup menu.

K0320 Issue No. 1

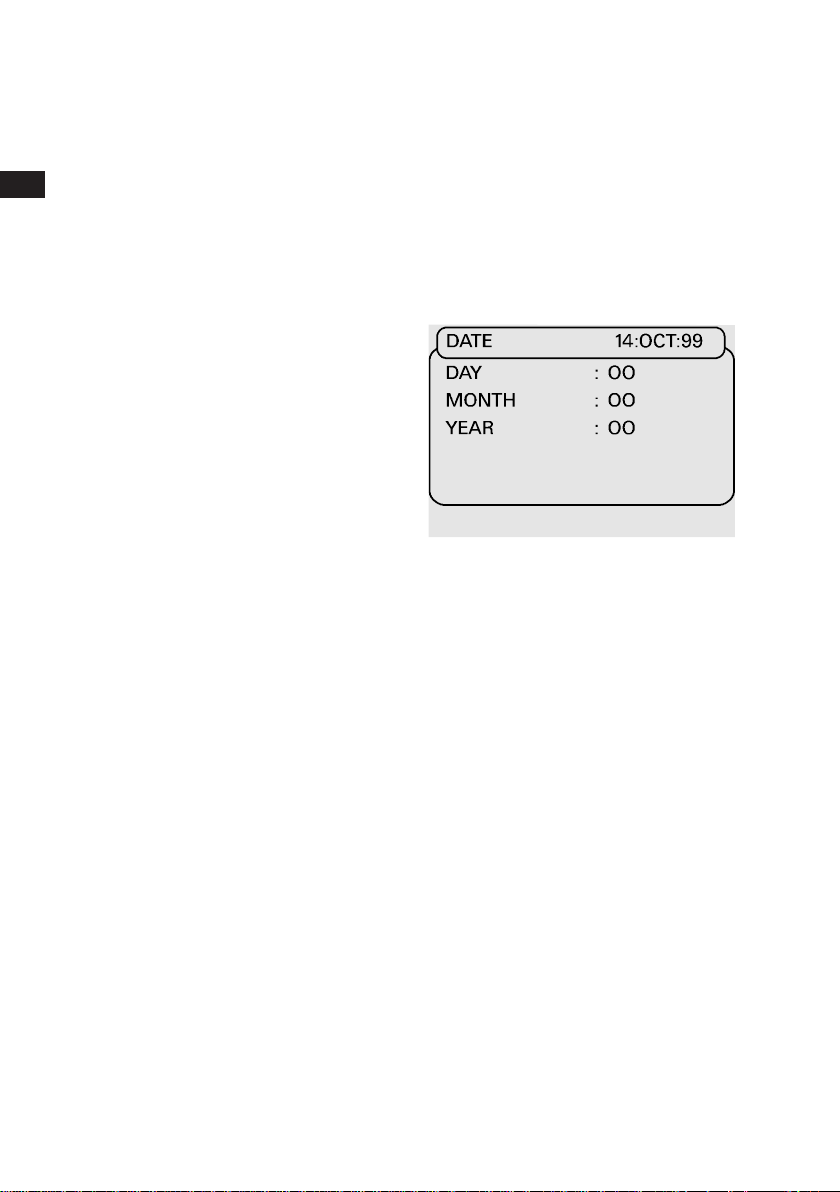

Page 14

32

Set-up

Setting the clock to your local date

Leave the cursor at NONE at the

INPUT and OUTPUT menu and press

the # key to open the set-up menu.

Select DATE. Press EXE again. Enter

date. Press EXE to accept new date or

press CE to leave the set-up menu.

K0320 Issue No. 1

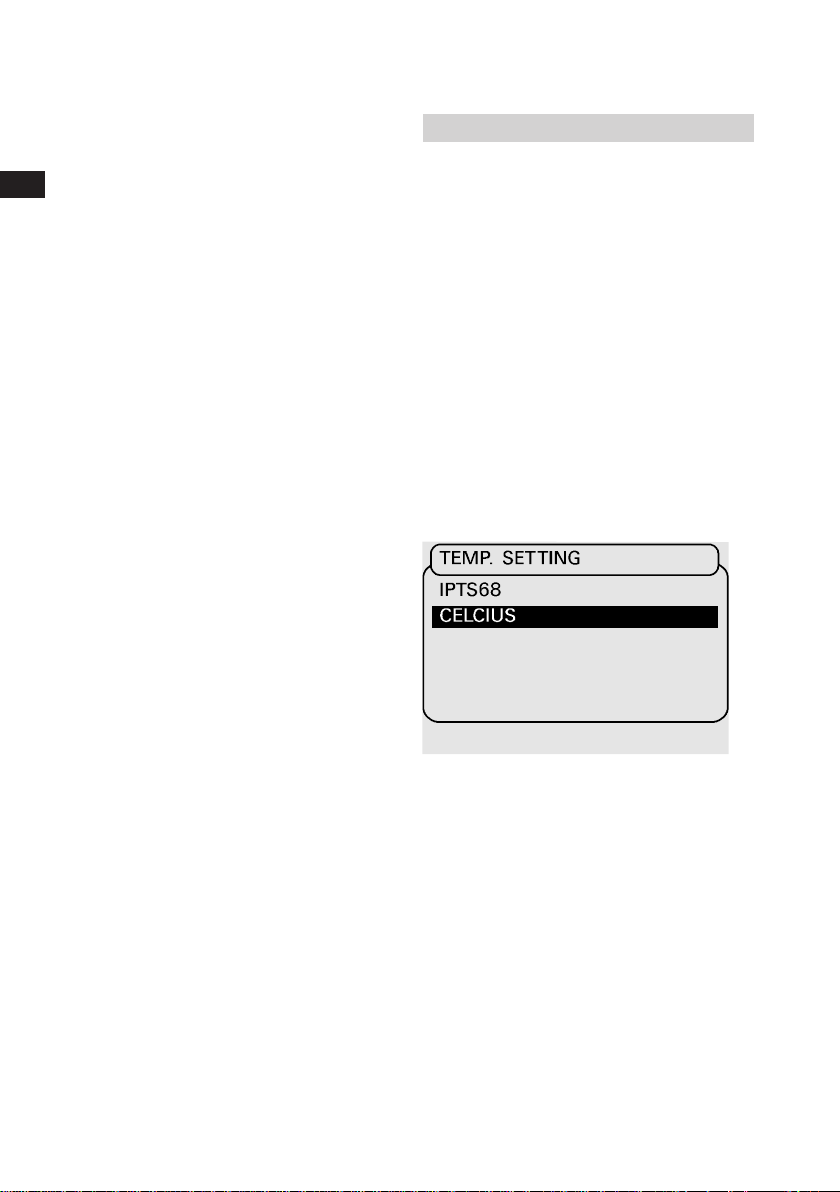

Page 15

34

Set-up

Temperature readings

Temperature simulations and

measurements can be shown in either

Celsius or Fahrenheit units. Factory

setting is Celsius. Readings are based

on either IPTS 68 or ITS 90

temperature scales.

Factory setting is ITS 90.

Changing the temperature unit

Leave the cursor at NONE at the

INPUT and OUTPUT menu and press

the # key to open the setup menu.

Select TEMP.SETTINGS and then the

temperature unit. Press EXE to

change.

K0320 Issue No. 1

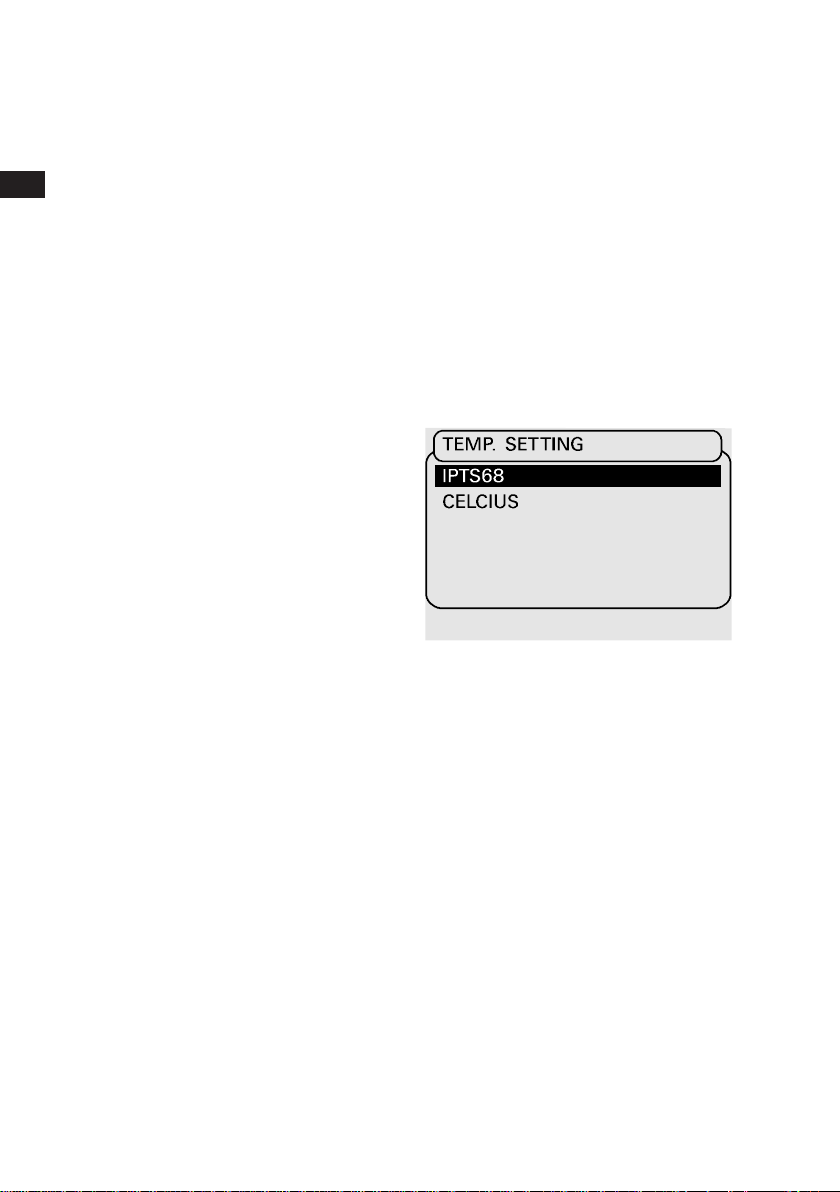

Page 16

36

Set-up

Changing the temperature scale

Leave the cursor at NONE at the

INPUT and OUTPUT menu and press

the # key to open the setup menu.

Select TEMP.SETTING and then

the temperature scale and press

EXE to change.

Select TEMP.SETTING and then

the temperature scale and press

EXE to change.

K0320 Issue No. 1

Page 17

38

Set-up

Language Setting

The MCX-II has multilingual software.

The factory setting is ENGLISH.

Setting the Language

Leave the cursor at NONE at the

measure and source menu and press

# key to open the set-up menu.

Select SYSTEM and then LANGUAGE

and press EXE. Select required

language and press EXE. Press CE to

leave the set-up menu.

K0320 Issue No. 1

Page 18

40

Set-up

Access code settings

The ACCESS CODE is programmable

by the customer. The following menus

are protected by this code;

ACCESS CODE

Calibration menu

(Electrical and pressure)

9410 is standard factory setting.

Leave the cursor at NONE at the

measure and source menu and press

# to open the set-up menu. Select

SYSTEM and press EXE. Select

ACCESS CODE and press EXE to

confirm. You are now in mode where

you can change the code. If applicable

the new code can be typed in and

confirmed by EXE. 0000 as code is

considered as no existing ACCESS

CODE.

NOTE: Registration of the

ACCESS CODE is essential.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

K0320 Issue No. 1

Page 19

42

Set-up

LCD screen viewing adjustments

Setting the backlight automatic shut

off mode

Leave the cursor at NONE at the

INPUT and OUTPUT menu and press

the # key to open the setup menu.

Select system and press EXE. Next

select the BACKLIGHT MODE and

press EXE.

The backlight timer can be set to

30 seconds, 5 minutes or off. select

appropriate choice and press EXE to

acknowledge. Press CE to leave the

setup menu.

NOTE:

It is recommended to

switch the BACKLIGHT MODE on to

save batteries if the unit is mainly

used in the field.

K0320 Issue No. 1

Page 20

44

Set-up

Backlight on/off operation

Press the LIGHT key to switch the

backlight ON or OFF. Each key-pad

operation will postpone shut-off for

another time period.

Screen contrast adjustment

Turn the knob for best screen contrast.

Contrast may alter with different

viewing angles.

K0320 Issue No. 1

Page 21

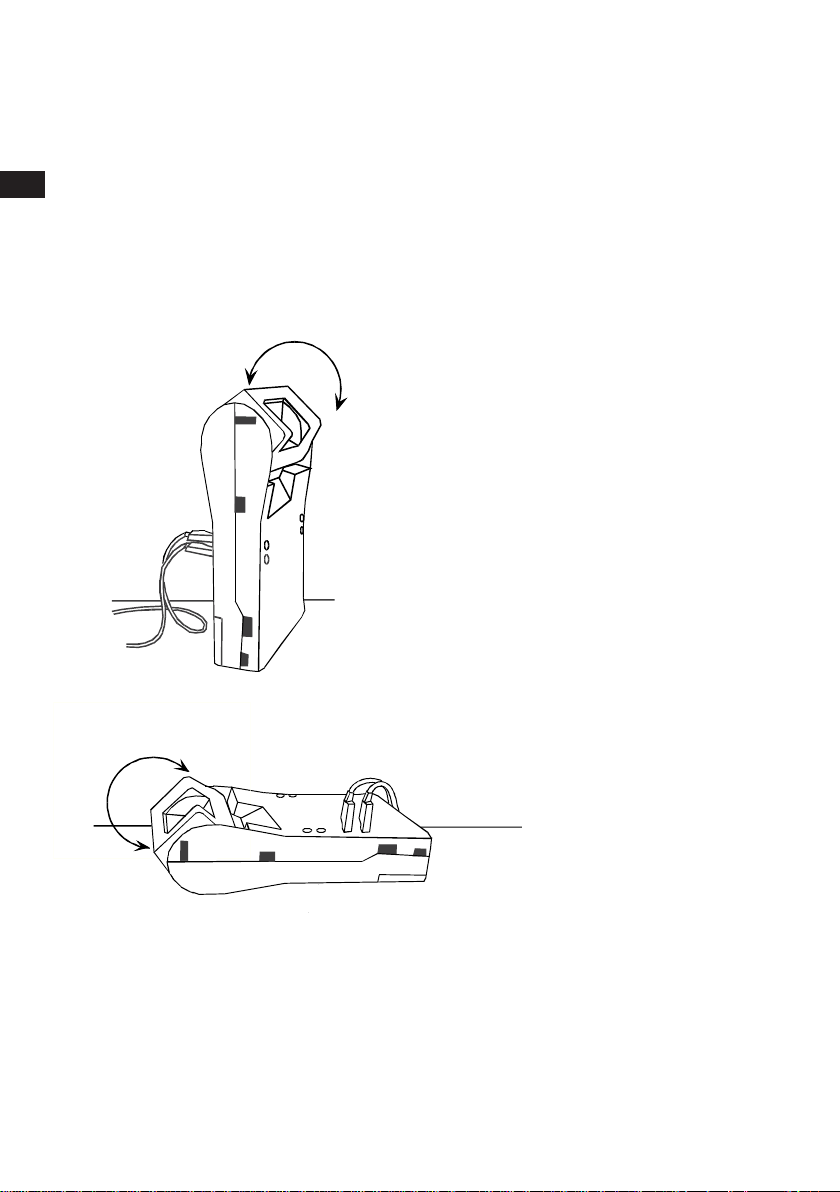

46

Set-up

Bench or portable use

The MCX-II calibrator can be used in

the two ways as shown. Control and

Display Panel can be rotated into

5 different positions for best screen

viewing angle. Input and output

terminals are accessible from front

and back to plug-in the test leads in

the most practical way.

K0320 Issue No. 1

Page 22

48

Set-up

Keystroking

Key-stroking is a solution to eliminate

time consuming key-pad operations for

functions you frequently use. It can

store 10 different sequences of keypad operations. Recalling a sequence

will put you right back into the function

as stored. You can recall a sequence

from any operational situation.

Storing a key-pad operation

sequence

Make all the necessary arrangements

for the function you want to "keystroke". Press # to open the set-up

menu and select key-stroking. Next

select the numerical key under which

you want to store the sequence. To

store a new function under a "used"

key, repeat above procedure to

overwrite the old function.

K0320 Issue No. 1

Recalling a key-pad operation

sequence

Leave the cursor at NONE in the input

and output menu and press the

appropriate numerical key to activate

the "key-stroke".

Page 23

50

Set-up

Clear keystroking

Leave the cursor at NONE at the

measure and source menu and press

the # key to open the set-up menu.

Select CLEAR KEYSTROKING

MEMORY and press EXE. EXE will

clean the KEYSTROKE memory. Press

CE to leave the set-up menu.

K0320 Issue No. 1

Page 24

52

To measure signals

General

Select an input range and select

DIRECT from the menu. It puts you

right in the output mode. For other

modes like scaled readings read the

chapter " Special Output Functions".

The upper part of the screen shows

the window for input functions. Here,

you can read the measured value.

Millivolts

Select mV and DIRECT in the input

menu and press EXE to open the

working screen. The upper window in

the working screen indicates the

measured millivolts reading.

The range is 0-600 mV split into two

(auto) ranges of 0 to 100 mV and

100.000 to 100.01 to 600.00 mV.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

K0320 Issue No. 1

Page 25

54

To measure signals

Volts

Select VOLTS and DIRECT in the

measure menu and press EXE to open

the working screen. The upper window

in the working screen indicates the

measured Volts reading.

The range is 0-60 Volts split into two

(auto)ranges of 0 to 6.0000 Volts and

6.001 to 60.000 Volts.

Milliamps/XMTR

Select mA and DIRECT in the measure

menu and press EXE to open the

working screen. The upper window in

the working screen indicates the

measured milliamps reading.

The percentage of 4-20 mA is indicated

in small size digits to facilitate easy

alarm switch adjustments. The range is

0-52.000 mA.

K0320 Issue No. 1

Page 26

56

To measure signals

Ohms

Select OHMS and DIRECT in the

measure menu and press EXE to open

the working screen. The upper window

in the working screen in the indicates

the measured ohms reading.

The range is 0-2000 Ohms split into

two (auto)ranges of 0.01 to 400.00

Ohm and 400.0 to 2000.0 Ohm. The

exitation current is 0.9 mA.

The wiring can be 2, 3, or 4 wire.

The wire method is a true measurement

of voltage drop across unknown

resistance at a constant excitation

current.

Frequency

Select FREQ in the measure menu

and press EXE. Select FREQ and

DIRECT in the FREQ.menu and enter

a trigger level between 10 mV and 5V.

Press EXE to open the working

screen.

K0320 Issue No. 1

The upper window of the working

screen indicates the measured

frequency reading.

The range is 0-20.000 Hz split into

three (auto)ranges of 0-655 Hz,

655-1310 Hz and 1310-20.000 Hz.

Page 27

58

Counter

Zähler

Compteur

To measure signals

Pulse Counter Mode

There are three different modes

available:

Counts pulses up to

999.999.999

Counts the pulses received in

one minute

Counts the pulses received in

one hour

Select COUNTER in the input menu

and press EXE. Enter a trigger level

between 10 mV and 5.0 Volts. Select

COUNTER, P/MIN or P/HOUR and

press EXE to open the working screen.

Press # to set the trigger level.

K0320 Issue No. 1

NOTE:

The pulse counter starts

on the first (positive) rising edge.

Page 28

60

To measure signals

Switch position change

Connect the switch as indicated.

Select SWITCH in the measure menu.

Generate or simulate the appropriate

source signal from the MCX-II to

activate the switch. The measure

(upper) reading tracks the source

(lower) reading until the switch

position changes. This change will

immediately "freeze" the measure

reading indicating the actual switch

setting. Press the # button to reset.

The measure reading will track the

source reading again.

Make sure that NO or NC contacts are

potential free.

K0320 Issue No. 1

Page 29

62

To measure signals

Circuit continuity tester

To check wiring continuity use the

RTD input terminals identified with SW.

If NONE has been selected in the

output menu and SWITCH has been

selected in the input menu, press EXE

to enter the continuity check mode.

Closing the test loop will activate the

built-in buzzer top prove that the

wiring loop has a resistance of 2200

Ohms or less.

To calculate the switch resistance

press # to open the set-up menu and

select SWITCH RESISTANCE.

NOTE:

Remote temperature

probe should not be connected in

this mode.

K0320 Issue No. 1

Page 30

64

Thermocouples

Thermoelementen

Thermocouples

To measure a thermocouple

Go through the thermocouple input

menu and make the selections as

required. Press EXE to open the

working screen; the measurement

reading is shown in the upper window.

Resolution is 0.1 degrees for most

thermocouple types.

Using compensation wires

It is strongly recommended to use

compensation wires for thermocouple

simulations and measurements. Insert

the compensation wire lead ends into

the wire holes as indicated.

Hand-tight each terminal screw to

secure the wires and make the proper

connections at the instrument side.

Make sure that you use the right type

of wires and that polarities are not

accidentally reversed. Select

INTERNAL to compensate the cold

junction microvolts automatically.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

K0320 Issue No. 1

Page 31

To measure a thermocouple

Using the standard test leads (copper wires)

66

Air probe

Hand-tight the terminal screws

before plugging the test leads in.

Compensation in this case is required

to offset the cold junction

compensation microvolts generated by

the instrument under calibration.

For this we need to measure the

temperature at the instrument

terminals. Instrument terminal

temperatures can be measured by

either a hand-held thermometer or a

remote temperature probe.

• Hand-held thermometer

(not supplied by GE)

Read the thermometer while holding it

close to the instrument terminals.

Select MANUAL and open the screen

to fill out the obtained reading. Press

EXE to enter.

Note that in this mode temperature

changes at the instrument terminals

can easily create calibrations errors.

• Remote temperature probe

(optional)

Plug-in the Pt100 probe as shown and

select EXTERNAL in the menu.

Position the sensor tip as close as

practically possible to the instrument

terminals.

K0320 Issue No. 1

Page 32

68

Air probe

To measure a RTD

Go through the RTD input menu and

make the selections as required.

Press EXE to open the working

screen; the measurement reading is

shown in the upper window.

Resolution is 0.1 or 0.01 degree

depending on selected RTD type. The

excitation current is 0.9 mA. Wiring

can be 2, 3 or 4 wire.

The 4 wire method is a true

measurement of voltage drop across

the unknown resistance at a constant

excitation current.

With the remote probe (optional)

With the optional available

temperature probe or with any other

suitable type of Pt100 sensor, you can

measure temperatures easily. Select

PROBE in the input menu and press

EXE to open the working screen; the

measurement reading is shown in the

upper window when the probe has

been plugged-in as indicated. See the

connection diagram if you use other

Pt100 sensors.

Pt100

PROBE

CONNECTOR

4 POLES, MINI-DIN

K0320 Issue No. 1

Page 33

70

Special Measurement Functions

Scaled Readings

Except in temperature measure ranges

all readings can be presented in a

number of 5 digits and a sign.

This number could represent an

engineering unit like gallons/hour,

revolutions/minute or any other

relationship. This facility is available

on both measurement and source

functions. The original signal reading

is still displayed in smaller sized digits.

Setting up scaled readings

(linear relationship)

Select SCALE to open the set up

screen. Fill out the high- and low-limits

for the span (preset at 4 and 20 mA in

the milliamp ranges). Fill out both

scale ends for the new scale. Press

EXE to show the working screen.

K0320 Issue No. 1

NOTE:

Scaling in lower ranges only

when auto ranging.

Page 34

72

Special Measurement Functions

Setting up scaled readings

(flow relationship)

Only available on the mA ranges.

Select SCALE and FLOW to open the

set-up screen. High- and low-limits for

the span are preset at 4 and 20 mA.

Change span if necessary. Fill out

both scale ends for the new scale.

Press EXE to show the working

screen.

NOTE:

Readings are flow related

when simulating or reading

dP-transmitters measuring across

an orifice plate.

K0320 Issue No. 1

Page 35

74

Output of electrical signals

General

Select an output range and select

DIRECT from the menu. It puts you

right in the output mode. For other

modes read section "Special Output

Functions". The lower part of the

screen shows the window for output

functions. Here, you can read the

output level labelled with either SET

or OUTPUT.

Set mode

In the SET mode you change the

output reading without changing the

actual output at the terminals. Once

you press EXE, the output will change.

to the new setting.

K0320 Issue No. 1

Page 36

76

Output of electrical signals

Output mode

In the OUTPUT mode you change both

the output reading and the actual

output at the terminals. Entering a new

value through the numerical key-pad

brings you back into the SET mode.

Changing the output level

Use the

and keys to ramp the

output signal manually. Holding the

key down will gradually accelerate

the adjustment speed.

Enter a new output value through the

numerical key-pad and press EXE to

activate the signal at the output

terminals. Entered values outside the

range will prompt the message

OUTSIDE RANGE.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

K0320 Issue No. 1

Page 37

78

Output of electrical signals

Millivolts

Go to millivolts in the DIRECT mode to

output any signal between -10 mV and

100 mV. Adjustments are made with

1 microvolt resolution.

If the adjusted output level cannot be

maintained the screen will prompt the

warning CHECK LOOP.

NOTE:

‘Terminal to test lead’

junctions may create e.m.f.

microvolts causing an offset in the

actual output signal.

Millivolts output

Millivolt Geben

Sortie millivolts

K0320 Issue No. 1

Page 38

80

Volts output

Volt Geben

Sortie volt

Transmitter (XMTR) Simulation

Simulieren 2-Leiter Transmitter

Simuler un transmitter 2-fils

Output of electrical signals

Volts

Go to Volts in the DIRECT mode to

output any signal between zero and

12 Volts. Adjustments are made with

100 microvolts. If the adjusted output

level cannot be maintained the screen

will prompt the warning CHECK LOOP.

Milliamps/XMTR

Use mA terminals to source a current

into a resistor (active mode). Use

XMTR terminals to simulate a 2-wire

transmitter (passive mode). Go to

milliamps in the DIRECT mode to

output any signal between 0 and

24 mA. Adjustments are made with

1 microamps resolution. If the

adjusted output level cannot be

maintained the screen will prompt the

warning CHECK LOOP. To output

fixed 0, 4, 8, 12, 16 and 20 mA levels,

press

key to change to fixed steps.

Use

and keys to adjust the output

current. Press

key to return to

normal output mode.

K0320 Issue No. 1

Page 39

82

Output of electrical signals

Ohms

Go through the OHM menu and select

either the 0-400 or the 0-2000 Ohms

range and enter the DIRECT mode.

Resistance is simulated across the two

terminals as shown. Connecting a third

or fourth wire adapts the simulation to

3 or 4 wire input. Adjustment

resolution is respectively 0.01 Ohms

and 0.1 Ohms.

Frequency

Pulses are symmetrical square wave

and -70 mV zero based. Frequency is

set by the

and keys or numerical

key-pad. Resolution is 0.1 Volt and

amplitude is default set to 5.0 Volts.

With frequency set at 0 Hz this

function becomes available as a

voltage adjustable and regulated DC

supply. Frequency output can take

loads up to 34 mA at 24 Volts

maximum.

K0320 Issue No. 1

Frequency range 0-100 Hz

Go to pulse DIRECT mode to output any

pulse signal between zero and 100 Hz.

Adjustments are made with 0.01 Hz

resolution.

Page 40

84

Output of electrical signals

Frequency range 0-20 kHz

Go to pulse DIRECT mode to output any

pulse signal between zero and 20.000 Hz.

Adjustments are made with 1 Hz resolution.

Frequency range 0-6000 P./Min.

Same as 0-100 Hz but reads in

Pulses/Minute

Pulse output range

0 - 99 999 P./Hour

Same as 0-100 Hz but reads in

Pulses/Hour

Counter

Go to the pulse PRESET mode and

set the amplitude. Press EXE to proceed

to the working screen. Use the and

keys to move the cursor from upper to

lower line and vice versa. Fill out the

number of pulses to be transmitted as

well as the Baud rate (max. 18 000

pulses/seconds). Press EXE to start the

pulse transmission.

K0320 Issue No. 1

Page 41

86

To simulate a thermocouple

Go through the thermocouple menu

and make the selections as required.

Select the DIRECT mode to simulate

any temperature within the range of

the chosen thermocouple type.

Adjustment resolution is 0.1 degree.

For cold junction compensation

considerations and different wiring

methods read section "To measure

thermocouples" in this book.

K0320 Issue No. 1

Page 42

88

2 wire

2 Leiter

2 fils

3 wire

3 Leiter

3 fils

RTD Simulation

Go through the RTD menu and make

the selections as required. Select

DIRECT mode to simulate any

temperature within the range of the

chosen RTD type. Adjustment

resolution is 0.1 or 0.01 degree

depending on RTD type.

See specifications for details.

Resistances representing

temperatures are simulated across the

two terminals as shown. Connecting a

third or a fourth wire adapts the

simulation to 3 or 4 wire inputs.

Excitation current

The excitation current to source a

resistance should be between 0.175

and 3.500 mA. Excitation currents may

be intermittent as with some smart

temperature transmitters.

4 wire

4 Leiter

4 fils

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

K0320 Issue No. 1

Page 43

90

Special Output Functions

Step Mode

In the step mode the MCX-II can

generate preset output levels in three

different ways;

INPUT

OHM

FREQ.

COUNT ER

SWI TCH

BATT ERY

OUT P UT

mA/ XMT

mV

VOLT

T/ C

RT D

K0320 Issue No. 1

Page 44

92

Special Output Functions

• Free programmable,

Select PROGR

Number of steps (2 to 10) and levels

are free programmable.

STEP

PROGR.

10 %

20%

30%

• 10% Divisions, Select 10%

Free programmable span is

automatically divided in 10

steps of 10% each.

• 20% Divisions, Select 20%

Free programmable span is

automatically divided in 5 steps

of 20% each.

K0320 Issue No. 1

• 25% Divisions, Select 25%

Free programmable span is

automatically divided in 4 steps

of 25% each.

Stepping through the fixed levels

can either be performed manually

or automatically.

Page 45

94

Special Output Functions

Ramp Mode

The MCX-II can generate automatically

a time linear increasing or decreasing

output signal. Signal limits are free to

set within any of the available output

ranges. Time scales can be set

between 1 and 9999 seconds.

NOTE:

The automatic ramp mode

cannot be used together with the

frequency measurement mode and

the pulse count mode.

INPUT

OHM

FREQ.

COUN TER

SWI TCH

BAT TERY

OUT P UT

mA/ XMT

mV

VOLT

T/ C

RT D

Setting up the ramp mode

Select RAMP and fill out the set-up

screen. The high-end value sets the

maximum output. The low-end value

sets the minimum output. Fill out the

required travel and dwell time in

seconds and press EXE.

K0320 Issue No. 1

Page 46

96

Special Output Functions

To start/stop a ‘one shot’ ramp

Press to start a one shot ramp for

signal increase and press

to start

this ramp for signal decrease.

Press

and simultaneously to

‘freeze’ the ramp action.

To restart press

or . Press CE to

cancel the ramping operation.

To start/stop ramp cycling

Press

and direct after each other

to start a continuous up and down

ramp cycling with dwelling at the high

and low ends. The first arrow key hit

determines the take-off direction.

Press

and simultaneously to

‘freeze’ the ramp action. To restart

press

or . Press CE to cancel the

ramping operation.

K0320 Issue No. 1

Scaled readings

Dial directly in scaled readings to SET

a related output signal as set-up.

Press EXE to actually output the signal.

The and key functions are

available to fine adjust the output.

Page 47

98

User Power supplies

Power supplies available for the user

are designed to power transmitters,

control and transducer wheatstone

bridges. The following power supplies

are available at the terminals as

indicated:

24 VDC fixed, combined with the

mA input terminals, current limited at

32 mA.

24 VDC fixed, combined with the

mA output terminals, current limited

at 32 mA.

0-24 VDC adjustable, combined with

the frequency output terminals.

Resolution is 0.1 Volt. With frequency

set at 0 Hz, output becomes available

as a voltage adjustable and regulated

power supply.

Current limited at 34 mA.

K0320 Issue No. 1

Page 48

100

Transmitter calibration

In this function transmitter source and

measure readings are both scaled in

engineering units for quick comparison.

Transmitter may be a linearized, nonlinearized, 4-20 or 0-20 mA model for

thermocouples or RTD’s.

Setting up a calibration

Leave the cursor on NONE in the

input menu and select the required

output function.

Go through the menu and make the

selections as required. In the mode

screen, select CAL to calibrate a

transmitter. Proceed to select all

transmitter characteristics.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

K0320 Issue No. 1

Page 49

102

Transmitter calibration

To check or calibrate a transmitter

All normal key-pad functions are

available to change the output. Use

the

key to change to fixed steps.

Use and keys to step through

0%, 25%, 50%, 75% and 100% of

the span as set-up. Press

to

return to the normal key-pad functions.

An ideal transmitter will show

equal readings. The difference of

both readings is expressed in % of

the transmitter span or reading and

is shown in the upper window in

small size digits.

K0320 Issue No. 1

Page 50

104

0-20 mA

4-20 mA

mA out

Control system

Regelsystem

Système de régulation

4-20 mA

XMTR

Control system

Regelsystem

Système de régulation

Temperature transmitter

simulation

User can dial a temperature in

degrees to output a 4-20 mA or 0-20

mA signal. This signal can be used to

simulate transmitters at control system

input terminals. The simulated

transmitter may be linearized or nonlinearized. Function is available for all

type of temperature sensors supplied

as standard in the MCX-II.

Setting up a simulation

Leave the cursor on NONE in the input

menu and select the required RTD or

T/C function (ignore the

CJ compensation menu). In the mode

screen, select SIM to simulate a

transmitter and proceed to select all

transmitter characteristics. Fill-out the

transmitter span and press EXE to

open the working screen. The lower

windows shows the MCX-II output

milliamps in small digits.

K0320 Issue No. 1

Page 51

106

Temperature transmitter simulation

To simulate a transmitter

All normal key-pad functions are

available to change the (mA) output.

Use the

key to move to fixed steps.

Use and keys to step through

0%, 25%, 50%, 75% and 100% of

the span as set-up. Press

to

return to the normal key-pad functions.

Next to the simulated temperature the

lower window shows the MCX-II

output milliamps in small size digits.

K0320 Issue No. 1

Page 52

108

Programmable signal

converter

With this unique feature any input

signal (including the probe) can be

converted into any on the MCX-II

available output signals with full

galvanic isolation. Zero and span

settings for both input and output are

fully programmable.

Setting up a signal converter

Make all input and output selections

as you would do when you use input

and output functions separately in the

DIRECT output mode. When the

normal working screen is displayed

press # to open the set-up screen and

select convert. Fill out the input- and

output span and press EXE again to

proceed to the signal converter

working screen. Actual input and

output signals are now displayed.

K0320 Issue No. 1

NOTE:

The signal converter

function can not be used in pulse

counting ranges.

Page 53

110

Ce Remarks

Ce Remarks

The MCX-II prompts EMI (ElectroMagnetic Interference) whenever the

functionality is influenced by

electromagnetic disturbances. The

results obtained during this state are

unreliable.

The MCX-II is protected against

failures by fast transient/burst. It

restarts itself whenever this situation

occurs and returns to the main screen.

K0320 Issue No. 1

In this way a save state of operation

can be assumed.

Page 54

112

Service, repair and parts

Recalibration of the MCX-II

Leave the cursor at NONE in the

INPUT and OUTPUT menu and press

the # key to open the settings menu.

Select CALIBRATION and press EXE.

Fill out the access code and press

EXE to open the calibration menu.

The access code is fixed at 9410

and works as an barrier to prevent

accidental access to MCX-II

calibration ranges.

The calibration menu shows all

relevant ranges to calibrate. Each

range can be recalibrated independent

of any other range. Only the cold

junction compensationsystem is

influenced by millivolts recalibration.

Select the ranges to be calibrated and

press EXE. Follow the instructions on

the next screens. Fill out the

calibration readings and press EXE to

confirm or to return to the calibration

menu.

Select an other range to continue

recalibration or press CE to leave

the calibration menu.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

K0320 Issue No. 1

FAX 781.665.0780 - TestEquipmentDepot.com

Page 55

114

Service, repair and parts

Cold Junction Compensation

Calibration

To recalibrate or check the cold

junction measurement system for both

input and output, use an electronic

thermometer with a maximum error of

±0.07°C (0.13°F). Remove the

compensation wire fixation screws

from the T/C terminals. Insert the

thermometer probe in the appropriate

T/C terminal hole and make sure a

good thermal contact is made down at

the bottom of the terminal. Take

measurements samples of both

terminals and calculate the average

temperature. Enter this temperature

to recalibrate. Do not use thermal

conductivity gel as this can not easily

be removed from the terminal.

K0320 Issue No. 1

Page 56

116

Service, repair and parts

NOTES:

1. Calibration standards should

have a valid calibration

certification and should be at

least 3 times more accurate as

the published accuracies for

the MCX-II for each range.

2. As derived from electrical

parameters, temperature

sensor ranges do not require

any individual recalibration.

3. Be sure that you use the test

leads, as standard supplied

with the MCX-II or other low

e.m.f. test leads.

4. The MCX-II should be powered

from the on board batteries

during recalibration.

5. Recalibration must be carried

out at reference ambient

temperature and humidity.

MCX-II must be exposed to this

condition for at least 2 hours

before the actual recalibration

starts.

6. Recalibrate mV ranges before

starting recalibration of the

Cold Junction Compensation

system.

7. When accessing the calibration

menu the temperature unit is

set to °C and the temperature

scale is set to IPTS 68.

8. Calibration is recommended

between 12 and 14 months.

K0320 Issue No. 1

Page 57

118

Processor board p/n 25100

Processorkarte p/n 25100

Carte processeur p/n 25100

Service, repair and parts

Replacing the lithium battery

Clock problems are in most cases

caused by a weak lithium cell. To

replace the cell, open the unit as

described under chapter “fault finding

procedures”. Use a small screwdriver

to lift the cell from its socket. Remove

the cell by sliding it away. Replace by

3 Volts cell type CR2025 only.

K0320 Issue No. 1

Page 58

Service, repair and parts

120

Fault finding procedures

Opening and closing the

calibrator housing

Remove the batteries and disconnect

the unit from other equipment. Take

the four T/C wire screws out and

release all visible Phillips screws at

the back and inside the battery

compartment. Lift gently the

housing upper half off and put it away.

Disconnect the power cable from the

board and the cable to the rotatable

unit. The electronic board assembly

and the rotatable unit can now be

taken out of the lower half of the

housing.

To open the rotatable unit release the

two screws at the same half on each

side.

To close the calibrator housing in

reverse order the following must be

considered;

1. Place the rotatable unit back in the

click mechanism slots as found before.

2. Make sure that the cable between base

unit and rotatable unit is correctly

routed as indicated.

3. Put the three printed circuit board

spacers in place. Left-hand and righthand spacers have brass wire guide

tubes; make sure they fit into the mV

terminals correctly.

4. Check the "battery type" selector switch

position before turning the unit on.

K0320 Issue No. 1

Page 59

122

Service, repair and parts

Fault finding procedures

When the MCX-II doesn’t work

properly or doesn’t work at all, it is

recommended to return the unit to one

of the GE Service Centres or to your

local distributor after you have

checked the following;

Most of the problems with portable

instruments are related to power

supply defects, blown fuses or

displaced connectors.

The unit doesn’t work at all.

1. When normally line powered,

change to battery operation to

check the line adaptor.

2. When normally battery

powered, check the contact

springs for corrosion and

spring force.

K0320 Issue No. 1

3. Check total battery voltage

with a voltmeter. Alkaline

should read around 9 Volts

and NiCd’s should read

around 7.2 Volts when new or

fully charged.

4. Open the MCX-II as described

in the previous paragraph and

check whether the PCB

interconnecting plugs are still

in position.

Page 60

124

Input board p/n 25102

Eingangskarte p/n 25102

Platine d'entrée p/n 25102

Power board p/n 25101

Versorgungskarte p/n 25101

Platine alimentation p/n 25101

Service, repair and parts

5. The unit doesn’t measure

milliamps.

Check the fuse accessible

from the front. Replace fuse

only by p/n 13119 or Littelfuse

No. 217.400.

6. The unit doesn’t measure

Ohms or RTD’s

Open the MCX-II and check the

fuse on the input board.

Replace fuse only by p/n 13119

or Littelfuse No. 217.400.

7. The Optional “Communicator”

doesn’t work.

Open the MCX-II and check the

fuse on the power board.

Replace fuse only by p/n 13119

or Littelfuse No.217.400.

Most other fault symptoms are not

logically related to just one possible

defect.

When you have spare printed circuit

boards available, you could replace

board by board to find the faulty

board. Note that a board replacement

requires a recalibration. Note that this

procedure may also create a problem

in a new healthy board by specific

defects in a original board.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

K0320 Issue No. 1

Page 61

Kundendienst, Reparatur und Ersatzteile Maintenance, répartions et pièces détachées

5. Das Gerät mißt keine

Milliampere

Prüfen Sie die von der

Vorderseite erreichbare

Sicherung. Ersetzen Sie sie

gegebenenfalls nur durch eine

p/n 13119 oder Littelfuse Nr.

217.400.

6. Das Gerät mißt keine Ohm

oder

Widerstandsthermometer

Öffnen Sie den MCX-II und

prüfen Sie die Sicherung auf

der Eingangskarte. Ersetzen

5. L'appareil ne mesure pas le

millampères

Vérifier le fusible accessible à

l'avant. Le remplacer

uniquement par un fusible réf.

13119 ou un fusible

"Littelfuse" N

0

217.400.

6. L'appareil ne mesure pas

les ohms ou les RTD.

Ouvrir le MCX-II et vérifier le

fusible sur la carte d'entrée.

Le remplacer uniquement par

un fusible réf. 13119 ou on

fusible "Littelfuse" N

0

217.400.

Sie sie gegebenenfalls nur

durch eine p/n 13119 oder

Littelfuse Nr. 217.400.

7. Die Option "Communicator"

funktioniert nicht

Öffnen Sie den MCX-II und

prüfen Sie die Sicherung auf

der Versorgungskarte. Ersetzen

Sie sie gegeben enfalls nur

durch eine p/n 13119 oder

Littelfuse Nr. 217.400.

7. La carte de communication

optionelle ne fonctionne

pas.

Ouvrir le MCX-II

précédemment et vérifier le

fusible sur la carte

alimentation. Le remplacer

uniquement par un fusible réf.

13119 ou un fusible

"Littelfuse" N

0

217.400.

125

Die meisten anderen Fehlersymptome

stehen nicht in einer logischen

Beziehung zu einem einzigen

möglichen Fehler. Wenn Sie

Ersatzkarten zur Verfügung haben,

können Sie Karte für Karte ersetzen

und so die Fehlerhafte finden.

Bedenken Sie, daß der Austausch

einer Karte eine Neukalibrierung

erfordert. Bedenken Sie ferner, daß

durch diese vorgehensweise ein

Fehler in einer neuen intakten Karte

entstehen kann, verursacht durch

einen bestimmten Fehler in einer

Originalkarte.

La plupart des autres symptômes

peuvent avoir plusieurs causes. Si des

cartes de rechange sont disponibles,

remplacer les cartes une à une afin

d'identifier la carte défectueuse. A

noter qu'en cas de remplacement

d'une carte, il faut réétalonner

l'appareil.

Il se peut aussi que cette opération

crée un problème dans une carte

neuve saine du fait de défauts propres

à la carte d'orgine.

K0320 Issue No. 1

Page 62

Service, repair and parts

The following boards are

accommodated in the MCX-II:

126

• Power supply board p/n 25101

• Processor board p/n 25100

• Input board p/n 25102

• Output board p/n 25103

• Digital communicator board

(Optional) p/n 25107

• LCD/Key-pad processor board (in

rotatable panel) p/n 25105

• Key-pad board (in rotatable panel) p/

n 25106

For GE Sales and Service Points

see back cover.

K0320 Issue No. 1

Page 63

128

Service, repair and parts

Spare parts list

Part No.

Power board Assy 152

Processor board Assy 149

Input board Assy 153/II

Output board Assy 154

LCD display 22500

LCD display board Assy 156/II

Key-pad board Assy 157

Board spacers (3X) 25207

T/C terminal screws (2X) 25301

6x Test leads, 6x clips Assy 162

2x Switch protectors

Operating Manual 25500

Line adaptor/charger

115VAC 13603/115

Line adaptor/charger

230VAC 13603/230

Pt100 hand-held probe Assy 170

Switch protector (3X) 24003

Battery compartment

cover 25204

Set of battery

contact springs 13013/16

LCD display window 25125

Set of fuses (10X) 13119

Fuse holder 13118

Carrying case 24005

Shoulder strap 24007

Lithium cell 13183

K0320 Issue No. 1

Page 64

Electrical functions

Measure millivolts

auto.ranging

Output millivolts

130

Measure Volts

auto.ranging

Output Volts

Measure milli-ampére

Output milli-ampére

Simulate 2-wire XMT

Measure Ohms

auto.ranging

Simulate Ohms

Simulate Ohms

Measure frequency

auto.ranging

auto.ranging

Counter

Counts/minute

Counts/hour

Output frequency

Output pulses preset

Temperature functions

Pt1000 Measure

Pt500 Measure

Pt200 Measure

Pt100 Measure

Pt50 Measure

D-100 Measure

Ni100 Measure

Ni120 Measure

Cu10 Measure

Measure/Simulation TC - J

Measure/Simulation TC - L

Measure/Simulation TC - K

Measure/Simulation TC - T

Measure/Simulation TC - U

Measure/Simulation TC - B

Measure/Simulation TC - R

Measure/Simulation TC - S

Measure/Simulation TC - E

Measure/Simulation TC - N

Measure/Simulation TC - C

Measure/Simulation TC - D

Simulation

Simulation

Simulation

Simulation

Simulation

Simulation

Simulation

Simulation

Simulation

Specifications

Range

+ 0...100mV

+100...600mV

-10...100mV

+ 0...6V

+ 6...60V

0...12V

+ 0...52mA

0...24mA

4...24mA

0...400Ω

400...2000Ω

0...400Ω

0...2000Ω

0...655Hz

655...1310Hz

1310...10.000Hz

0...99999999

600000

9999999

0...100Hz

6000 p/min

0...10000Hz

99999 p/hour

0...99999999

Range

-200/400°C -328/752°F

-200/400°C -328/752°F

-200/850°C -328/1562°F

-200/850°C -328/1562°F

-200/850°C -328/1562°F

-200/850°C -328/1562°F

-200/850°C -328/1562°F

-200/850°C -328/1562°F

-200/850°C -328/1562°F

-200/850°C -328/1562°F

-200/649°C -328/1200°F

-200/649°C -328/1200°F

-60/250°C -76/482°F

-60/250°C -76/482°F

-80/260°C -112/500°F

-80/260°C -112/500°F

-200/260°C -328/500°F

-200/260°C -328/500°F

-210/1200°C -346/2192°F

-200/900°C -328/1652°F

-200/1372°C -328/2502°F

-270/-200°C -454/-328°F

-75/400°C -103/752°F

-180/-75°C -292/-103°F

-270/-180°C -454/-292°F

-100/600°C -184/1112°F

-200/-100°C -328/-184°F

1200/1820°C 2192/3308°F

500/1200°C 932/2192°F

250/500°C 482/932°F

50/250°C 122/482°F

300/1769°C 572/3216°F

-50/300°C -58/572°F

400/1769°C 752/3216°F

100/400°C 212/752°F

-50/100°C -58/212°F

-150/1000°C -238/1832°F

-270/-150°C -454/-238°F

-20/1300°C -4/2372°F

-200/-20°C -328/-4°F

-270/-200°C -454/-328°F

0/1500°C 32/2732°F

1500/2000°C 2732/3632°F

2000/2320°C 3632/4208°F

0/1700°C 32/3092°F

1700/2200°C 3092/3992°F

2200/2495°C 3992/4523°F

Resolution

0.001

0.01

0.001

0.0001

0.001

0.0001

0.001

0.001

0.001

0.01

0.1

0.01

0.1

0.01

0.1

1

1

1

1

0,01

1

1

1

1

Resolution

0.1°C 0.2°F

0.1°C 0.2°F

0.1°C 0.2°F

0.1°C 0.2°F

0.1°C 0.2°F

0.1°C 0.2°F

0.03°C 0.06°F

0.03°C 0.06°F

0.06°C 0.11°F

0.06°C 0.11°F

0.03°C 0.06°F

0.03°C 0.06°F

0.1°C 0.2°F

0.1°C 0.2°F

0.1°C 0.2°F

0.1°C 0.2°F

0.3°C 0.6°F

0.3°C 0.6°F

0.1°C 0.2°F

0.1°C 0.2°F

0.1°C 0.2°F

0.2°C 0.4°F

0.1°C 0.2°F

0.1°C 0.2°F

0.1°C 0.2°F

0.1°C 0.2°F

0.1°C 0.2°F

0.1°C 0.2°F

0.2°C 0.4°F

0.3°C 0.6°F

0.5°C 1.0°F

0.1°C 0.2°F

0.2°C 0.4°F

0.1°C 0.2°F

0.2°C 0.4°F

0.2°C 0.4°F

0.1°C 0.2°F

0.1°C 0.2°F

0.1°C 0.2°F

0.1°C 0.2°F

0.2°C 0.4°F

0.1°C 0.2°F

0.1°C 0.2°F

0.2°C 0.4°F

0.1°C 0.2°F

0.1°C 0.2°F

0.2°C 0.4°F

K0320 Issue No. 1

Page 65

1 year accuracy

0.004% Rdg. + 0.004% f.s. +1 lsd

0.005% Rdg. + 0.005% f.s. +1 lsd

0.003% Rdg. + 0.004% f.s. +1 lsd

0.009% Rdg. + 0.003% f.s. +1 lsd

0.009% Rdg. + 0.003% f.s. +1 lsd

0.004% Rdg. + 0.002% f.s. +1 lsd

0.010% Rdg. + 0.003% f.s. +1 lsd

0.010% Rdg. + 0.005% f.s. +1 lsd

0.010% Rdg. + 0.005% f.s. +1 lsd

0.005% Rdg. + 0.008% f.s. +1 lsd

0.01Hz

0.1Hz

1 Hz

infinite

1 c/min

1 c/hour

0.01Hz

1 p/min

1Hz

36 p/hour

infinite

0.012% f.s. +1 lsd

0.012% f.s. +1 lsd

0.010% f.s. +1 lsd

1 year accuracy + (abs. + 1lsd)

0.1°C 0.2°F

0.1°C 0.2°F

0.1°C 0.2°F

0.1°C 0.2°F

0.2°C 0.4°F

0.3°C 0.5°F

0.15°C 0.27°F

0.12°C 0.22°F

0.25°C 0.45°F

0.20°C 0.36°F

0.15°C 0.27°F

0.12°C 0.22°F

0.1°C 0.2°F

0.1°C 0.2°F

0.1°C 0.2°F

0.1°C 0.2°F

1.0°C 1.8°F

1.5°C 2.7°F

0.1°C 0.2°F

0.1°C 0.2°F

0.1°C 0.2°F

0.3°C 0.6°F

0.1°C 0.2°F

0.2°C 0.4°F

0.5°C 0.9°F

0.1°C 0.2°F

0.2°C 0.4°F

0.4°C 0.7°F

0.7°C 1.3°F

1.5°C 2.7°F

2.0°C 3.6°F

0.5°C 0.9°F

1.0°C 1.8°F

0.5°C 0.9°F

0.8°C 1.5°F

1.0°C 1.8°F

0.1°C 0.2°F

0.3°C 0.6°F

0.1°C 0.2°F

0.4°C 0.7°F

1.0°C 1.8°F

0.2°C 0.4°F

0.3°C 0.7°F

0.6°C 1.1°F

0.2°C 0.4°F

0.4°C 0.7°F

1.1°C 2.0°F

Remarks

R - input > 20MΩ

R - input > 20MΩ

R - output < 0.2Ω

R - input > 1MΩ

R - input > 1MΩ

R - output < 0.2Ω

R - input 2,5Ωfused

R - max. 900Ω

V-max. 56 Volts

at 0.9mA excitation

at 0.9mA excitation

at 1.0mA excitation

at 1.0mA excitation

R - input > 300kΩ

R - input > 300kΩ

R - input > 300kΩ

R - input > 300kΩ

R - input > 300kΩ

R - input > 300kΩ

0 - 24V / 34mA max.

0 - 24V / 34mA max.

0 - 24V / 34mA max.

0 - 24V / 34mA max.

0 - 24V / 34mA max.

Remarks

IEC 751

IEC 751

IEC 751

IEC 751

IEC 751

IEC 751

IEC 751

IEC 751

IEC 751

IEC 751

JIS C1604 1989

JIS C1604 1989

DIN 43760 Aug. 1985

DIN 43760 Aug. 1985

Minco 7

Minco 7

Minco 16 - 9

Minco 16 - 9

IEC 584-1

DIN 43710 Dec. 1985

IEC 584-1

IEC 584-1

IEC 584-1

IEC 584-1

IEC 584-1

DIN 43710 Dec. 1985

DIN 43710 Dec. 1985

IEC 584-1

IEC 584-1

IEC 584-1

IEC 584-1

IEC 584-1

IEC 584-1

IEC 584-1

IEC 584-1

IEC 584-1

IEC 584-1

IEC 584-1

IEC 584-1

IEC 584-1

IEC 584-1

ASTM E988-96

ASTM E988-96

ASTM E988-96

ASTM E988-96

ASTM E988-96

ASTM E988-96

131

K0320 Issue No. 1

Page 66

Special functions

132

Specifications

1 Steps; 10 programmable, 10%, 20%,

25% div. stepping by key or adj. timer

2 Ramp; programmable travel time for

up/down and dwell

3 Scaling; in 5 digits and sign on all

electrical ranges

4 Temp. XMT cal.; both input and output

readings in temp. units.

Cal.function extended for all output

functions.

5 Temp. XMT sim.; mA output reads in

temperature units

6 Signal converter; any input into any

output, fully isolated

Note: Thermocouple accuracies do not include cold junction compensation errors

Reference 22°C ±1, RH 45% ±15

Calibration Traceable to National Standards

Accuracies For 17°C to 27°C; outside these

Cold Junction error ±0.4°C (0.8 °F) max. in transient

Long term drift after 1 year 0.005% / year or 1000 hours operating

Cold Junction modes Automatic, Manual, Remote sensor

Temperature scale Selectable IPTS68 or ITS90

Warm up time 2 minutes for rated accuracies

Re-calibration From key-pad (no inside trimmers)

Operating temp. -10°C to 50°C (14°F to 122°F)

Storage temp. -20°C to 70°C (-4°F to 158°F)

Relative humidity 0 - 90% non-condensing

In-/output isolation 500VDC continuous

Electrical protection 50 Volts, 30 sec. max.

Output mismatch Displays " check loop"

limits 0.0005% / °C typical on mV

±0.2°C (0.4°F) max. when steady

Recommended for each year

Ohms out to ground; 5 Volts max.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

K0320 Issue No. 1

Page 67

Overrange Displays ">>>>> "

Underrange Displays "<<<<< "

Readings Temp. °C or °F

Batteries (LR14 or C) 6x 1.5V alkaline or 1.2V NiCd

Battery life Alkaline; 22 hours at 20°C (68°F)

Battery life 20 mA out Alkaline; 12 hours at 20°C (68°F)

Low battery warning Flashes a battery symbol

Line power With optional adaptor 115 - or 230VAC,

Recharge NiCd's With optional adaptor 115 - or 230VAC,

User terminals Gold plated, standard 4mm plugs

T/C comp.wire terminals Screw fixable, 2mm diameter max.

Protection IP 53

Housing Textured high-impact ABS plastic

Control panel Rotatable, 5 clicks of 30°

Size 265 x 160 x 56/80mm without case

Carrying case Black Cordura

Weight 2.2kg (5.5lbs) with batteries

Keystroking 10 operation sequences storage

Contact change detect. Reading freezes on open or close

Date and time Recorded when PCMCIA card is used

PCMCIA station PCMCIA card type 1 or 2

Detect. level freq.in Adjustable; 10mV to 5.0 Volts

Pulse output level Adjustable; 0 - 24 Volt, 0.1V resolution,

Pulse output form Symmetrical square, zero based - 70mV

Pulse output speed Adjustable in Hz or Baud rate

Remote sensor input Mini DIN Suitable for Pt100 (385 curve)

LCD display Full graphic, with contrast control and

Ohms simulation 0.18 to 3.5mA excitation current

Ohms input terminals 2, 3 or 4 wire automatic mode select.

Auxiliary connectors For use with optional pressure module

Dig. communicator board Slot supplied as standard for electronic

20 mA out NiCd; 7 hours at 20°C (68°F)

NiCd; 14 hours at 20°C (68°F)

green LED indicator

amber LED indicator

(10.6 x 6.4 x 2.2 /3.2) inch

2% accuracy

full range, 3 or 4 wire

backlight timer

either polarity

True 4 - wire system

board

133

K0320 Issue No. 1

Page 68

Specifications

Protocol for RS232 System Integration

142

Serial port settings

Bauds: 9600

Parity: none

Bits: 8

Stop: 1

Hardware handshake: none

K0320 Issue No. 1

Page 69

144

Warranty & Liability

Our equipment is warranted against

defective material and workmanship

for a period of 18 months from date of

shipment. Claims under warranty can

be made by returning the equipment

prepaid to our factory. The equipment

will be replaced, repaired or adjusted

at our option. The liability of GE is

restricted to that given under our

warranty. No responsability is

accepted for damage, loss or other

expense incurred through sale or use

of our equipment. Under no condition

shall GE be liable for any special,

incidental or consequential damage.

NOTE: Units with defects caused by

battery electrolyte from leaking

batteries are definitely excluded for

repair or replacement under

warranty.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

K0320 Issue No. 1

Loading...

Loading...