Page 1

Druck DPI 610

Portable Pressure Calibrator

Aeronautical version

User manual - K0237

GE

Measurement & Control Solutions

Advanced Test Equipment Rentals

www.atecorp.com 800-404-ATEC (2832)

®

E

s

t

a

b

l

i

s

h

e

d

1

9

8

1

Page 2

© The General Electric Company. All rights reserved

Page 3

Safety

The manufacturer has designed this equipment to be safe when operated using the

procedures detailed in this manual. Do not use this equipment for any other purpose

than that stated.

This publication contains operating and safety instructions that must be followed to

ensure safe operation and to maintain the equipment in a safe condition. The safety

instructions are either warnings or cautions issued to protect the user and the equipment

from injury or damage.

Use suitably qualified * technicians and good engineering practice for all procedures in

this publication.

Pressure

Do not apply pressures greater than the safe working pressure to this equipment.

Maintenance

The equipment must be maintained using the procedures in this publication. Further

manufacturer’s procedures should be carried out by authorized service agents or the

manufacturer’s service departments.

www.gesensinginspection.com

For technical advice contact the manufacturer.

* A qualified technician must have the necessary technical knowledge,

documentation, special test equipment and tools to carry out the required work

on this equipment.

Symbols

This equipment meets the requirements of all relevant European safety

directives. The equipment carries the CE mark.

This symbol, on the instrument, indicates that the user should refer to

the user manual. This symbol, in this manual, indicates a hazardous

operation.

This symbol, on the instrument, indicates do not throw-away in

domestic bin, hazardous material, dispose correctly in accordance with

local regulations.

i K0237 Issue No. 2

Page 4

Specification

Safe working pressure

2 x full-scale

Ranges

Altitude -3000 to 50,000ft

Airspeed 0 to 600 knots

Precision

over the airspeed range:

200 knots ±3 knots

400 knots ±0.7 knots

over the altitude range:

sea level ±14 ft

10,000ft ±18 ft

30,000ft ±36 ft

Precision includes linearity, hysteresis and repeatability, 12 months measurement stability

Temperature Effects

±0.004% of reading/°C (averaged over -10° to +40°C w.r.t. 20°C)

±0.002% of reading/°F (averaged over +14° to 104°F w.r.t. 68°F)

Power supply

Batteries 6 x 1.5 V C cells, alkaline (up to 60 hours nominal use at 20°C)

Rechargeable NiCad battery pack (20 hours nominal use) supplied with charger/

adaptor, supplies power to instrument while charging batteries.

Environment

Operating Temperature: -10°C to 50°C (+14°F to 122°F)

Calibrated Temperature: -10°C to 40°C (+14°F to 104°F)

Sealing

Sealed to IP54 (NEMA 4)

Physical

Size: 300 x 170 x 140 mm (11.8” x 6.7” x 5.5”)

Weight: 3 kg (6.6lb)

For further general specification and functionality details refer to the standard DPI

610/615 Series Portable Calibrator data sheet.

Introduction 1

Pneumatic Controls 2

Electical Connections 2

Operation 3

Altitude Switch Tests 3

Altitude Leak Tests 6

Airspeed Switch Tests 8

Airspeed Leak Tests 10

K0237 Issue No. 2 ii

Contents

Page 5

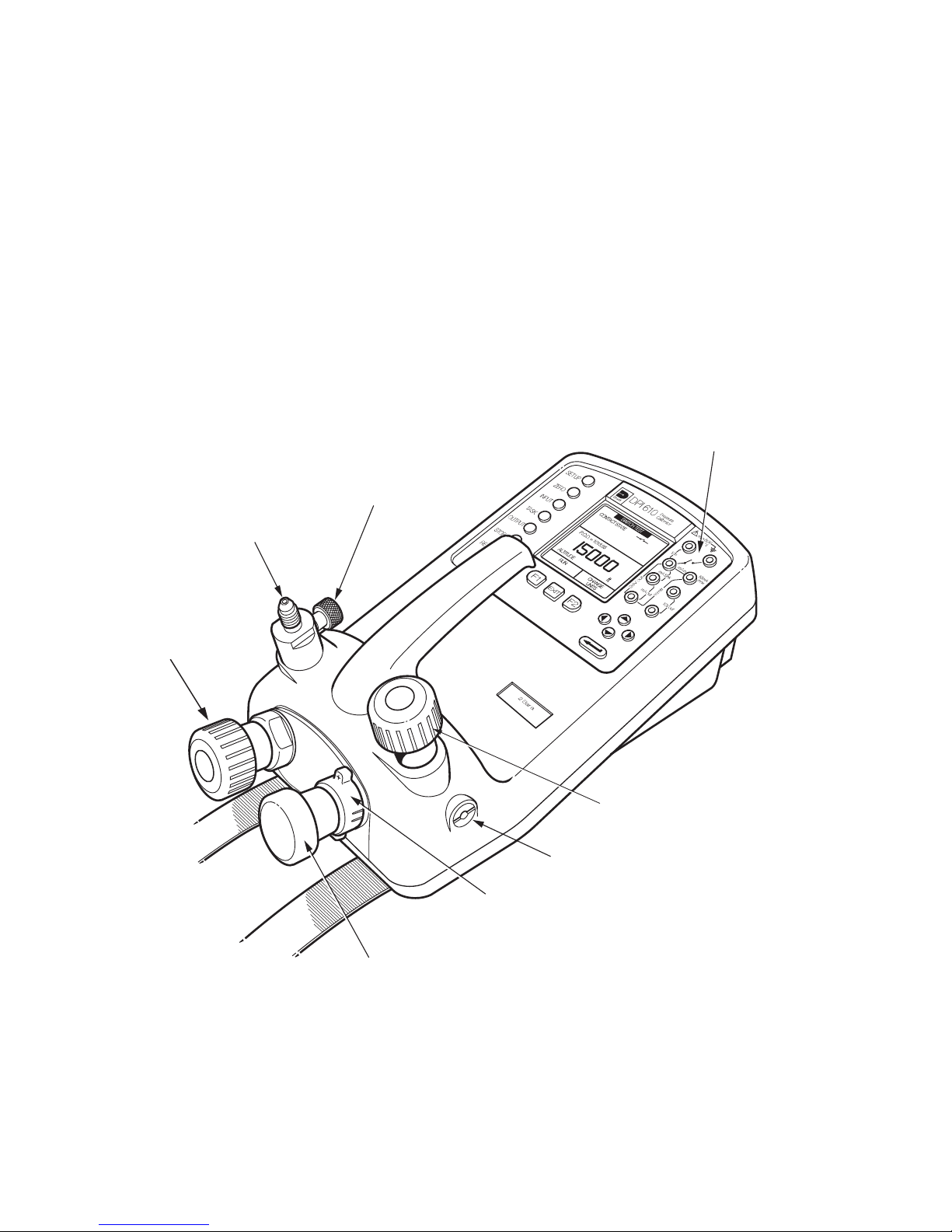

Introduction (Figure C1)

This 2 bar absolute (59 inHg absolute) version of the DPI 610 provides manual generation

of pressure and vacuum for testing of aircraft Pitot and Static systems. It has a special

pneumatic manifold and output port assembly, the regulated output of the hand-pump

prevents overpressure/vacuum of the aircraft’s Pitot and Static systems.

The generated pressure or vacuum vents to atmosphere through the vent port, the user

controls the vent rate to protect the aircraft’s systems and instruments using the release

valve.

A manual let-down valve, fitted directly in the output port, allows the system to be

manually vented (returned to ground level) by the user when the pressure or vacuum has

vented to a safe operational level i.e. < 1500 ft. The aeronautical option (AERO) can be

accessed only from the TASK menu. All other functions and tasks of the DPI 610 are

available on this version of the DPI 610 instrument.

Electrical (switch)

inputs

Manual let-down

Output port (AN4)

To pitot or static

system

valve

Fine adjustment of

either positive (pitot)

or negative (static)

pressure

Selects either

or negative (static) pressure

Hand-pump

Generates either positive (pitot)

or negative (static) pressure

Release Valve

Releases system pressure/vacuum

at a controlled rate

Vent port

positive (pitot)

Figure C1 Aeronautical Option Controls

1 K0237 Issue No. 2

Page 6

Pneumatic Controls (Figure C2)

An AN4 connector provides the output connection.

Note:

The instrument is designed to operate with 5 metres of 6mm bore pipe attached.

CLOSE

OPEN

Figure C2 - Pneumatic Controls

Electrical Connections

Refer to publication K0415 pages 6 and 7 for the fitting of batteries and the charging of

batteries.

Maximum Instrument Ratings

The following table shows the maximum measurement ratings of the standard

instrument that should not be exceeded. Pressure over range (120% of FS) is indicated

by a flashing pressure display. Voltage or current over range (110% of max) causes

either the voltage or current display to flash.

Note:

When the AERO task is selected, the display flashes if the voltage or current input over

ranges by 110% of the above maximum values. The pressure display flashes at altitudes

below -3000 ft and above 50,000 ft or at airspeeds greater than 600 knots, depending on

the mode selected.

K0237 Issue No. 2 2

Page 7

Operation

Using this version of the DPI 610 instrument, a switch test and leak test can be carried

out on an aircraft pitot or static system.

WARNING:

OBSERVE SAFETY PRECAUTIONS STATED IN LOCAL ORDERS AND

THE AIRCRAFT OR EQUIPMENT SERVICING PROCEDURES.

To select the aeronautical option from task menu, proceed as follows:

TASK

TASKS

BASIC

P-I

P-P

P-V

I-P

SELECT TASK

TASKS

ADVANCED

AERO

USER TASKS

SELECT TASK

Altitude Switch Tests

Select TASK, AERO:

Select ALTITUDE, SWITCH TEST as follows:

If necessary, SELECT AERO UNITS as follows.

ft

m

hm

3 K0237 Issue No. 2

Page 8

If required, apply pressure of the day correction (POD), by selecting POD ADJUST

as follows:

SELECT OPTION SELECT OPTION

SETUP

SETUP

BACKLIGHT

STORE MODE

CONTRAST

SETTINGS

DRY CELL LEVEL

SETTINGS

UNITS

CALIBRATION

LANGUAGE

RS232

POWERDOWN

CALIBRATION

POD ADJUST

Apply QFE pressure reading as POD correction as follows:

Note: The display can show either: POD = Off or POD = current value (QFE pressure

reading). The POD RESET key (F2) sets the current POD correction to Off.

POD=Off

POD Correction

WARNING

VENT SYSTEM

BEFORE SETTING POD

CHANGE POD

VALUE

mbar

POD RESET

POD=Off

POD Correction

WARNING

VENT SYSTEM

BEFORE SETTING POD

CHANGE POD

VALUE

ENTER VALUE

mbar

POD RESET

POD = 1002.85

POD Correction

WARNING

VENT SYSTEM

BEFORE SETTING POD

CHANGE POD

VALUE

POD RESET

Method (accessible switch contacts)

(1) Connect the instrument to the static system and connect the altitude switch as

shown. Ensure that the pitot system is vented to atmosphere before starting the test:

Note:

Contacts must be potential free.

Applied Static System Pressure

Vent Pitot System (Atmospheric Pressure)

Altitude Switch

S

mbar

Figure C3 - Altitude Switch Test Connections

(2) Select negative pressure and close the release valve.

K0237 Issue No. 2 4

Select

Negative (-)

Pressure

CONTACT STATE

POD = 1008.63

ALTITUDE

RUN

SWITCH TEST

ft

F2F1

Page 9

(3) Close the manual let-down valve.

(4) Press the RUN key (F1) and operate the hand-pump, continue until the switch

operates:

SWITCH TEST SWITCH TEST SWITCH TEST

CONTACT STATE

POD=Off

CONTACT STATE

CLOSED AT 5550 ft

POD=Off

CONTACT STATE

CLOSED AT 5550 ft

OPENED AT 5325

HYSTERESIS 225ftft

POD=Off

MANUAL

ft

ALTITUDE

STOP

OPERATION

ft

MANUAL

ALTITUDE

RUN

ft

ALTITUDE

STOP

OPERATION

(5) Carefully open the release valve and allow altitude to decrease until the switch

operates again. The display shows the operating pressures and hysteresis.

(6) Record the displayed operating data.

(7) Allow the indicated altitude to decrease until it is below 1500ft.

(8) Slowly open the manual let-down valve to return the system to ground level.

(9) To perform another switch test press RUN (F1).

(10) To cancel switch test mode, press TASK.

Method (non-accessible switch contacts)

When the altitude switch contacts cannot be connected to the instrument, an external

indicator or annunciator must be used as the indication of pressure switch operation.

The user, on receipt of an indication of switch operation, presses the MANUAL OPERATION

(F2) key:

(1) Connect the instrument to the static system.

to atmosphere before starting the test:

(2) Select negative pressure and close the release valve.

(3) Close the manual let-down valve.

(4) Press the RUN key (F1) and operate the hand-pump, continue until indication of

switch operation and immediately press (F2).

(5) Carefully open the release valve and allow the altitude to decrease until the

indication of switch operation and immediately press (F2).

Ensure that the pitot system is vented

5 K0237 Issue No. 2

Page 10

(6) Record the displayed operating data.

(7) Allow the indicated altitude to decrease until it is below 1500ft.

(8) Slowly open the manual let-down valve to return the system to ground level.

(9) To perform another switch test, press RUN (F1).

(10) To cancel switch test mode, press TASK.

Altitude Leak Tests

Select TASK, AERO:

Select ALTITUDE LEAK TEST:

If necessary, SELECT AERO UNITS:

Method

(1) Connect the instrument to the static system and, if required, apply a pressure

correction value of the pressure of the day (POD) as detailed on page 6.

(2) Close the release valve and manual let-down valve, using the hand-pump,

generate the required altitude.

(3) Set WAIT and DURATION of the leak test times:

ALTITUDE

WAIT

DURATION

CION

START ALT.

STOP ALT.

ALT. CHANGE

LEAK RATE

CHANGE

VALUE

ft

60

secs

secs

60

ft

ft

ft

ft/m

RUN

SET WAIT TIME SET DURATION

ALTITUDE

WAIT

DURATION

CION

START ALT.

STOP ALT.

ALT. CHANGE

LEAK RATE

CHANGE

VALUE

ft

60

secs

secs

60

ft

ft

ft

ft/m

RUN

K0237 Issue No. 2 6

Page 11

(4) When ready, press the RUN key (F2):

Initially, the WAIT period counts-down, followed by the TIMING period. The START

ALT is recorded as soon as the timing period starts. At the end of the test the

display shows the complete details of the test.

(5) Record the displayed operating data.

(6) To perform another leak test, use the hand-pump to generate a new system

altitude and press RUN (F2) again.

(7) On completion of the test, allow the altitude to decrease until it is below 1500 ft.

(8) Slowly open the manual let-down valve to return the system to ground level.

(9) To exit or cancel leak test mode, press TASK.

7 K0237 Issue No. 2

Page 12

Airspeed Switch Tests

Select TASK, AERO:

Select AIRSPEED SWITCH TEST:

If necessary, SELECT AERO UNITS:

Method (accessible switch contacts)

(1) Connect the instrument to the pitot system and connect the airspeed switch as shown:

Ensure that the static system is vented to atmosphere before starting the test.

Note:

Contacts must be potential free.

Applied Pitot System Pressure

Vented Static System

(Atmospheric Pressure)

CONTACT STATE

AIRSPEED

SWITCH TEST

RUN

AIRSPEED

SWITCH

P

S

kts

SELECT

POSITIVE (+)

PRESSURE

Figure C4 - Airspeed Switch Test Connections

K0237 Issue No. 2 8

F2F1

Page 13

(2) Ensure that positive pressure is selected and close the release valve.

(3) Close the manual let-down valve.

(4) Zero the airspeed reading by pressing the ZERO key.

(5) Press the RUN key (F1) and operate the hand-pump, continue until the switch

operates:

(6) Carefully open the release valve and allow airspeed to decrease until the switch

operates again. The display shows the operating airspeeds and hysteresis.

(7) Record the displayed operating data.

(8) Allow the airspeed to decrease until it is below 80 kts.

(9) Slowly open the manual let-down valve to return system to zero (ground level).

(10) To perform another switch test, press RUN (F1) and repeat the above procedure.

(11) To cancel switch test mode, press TASK.

Method (non-accessible switch contacts)

When the airspeed switch contacts cannot be connected to the instrument, an external

indicator or annunciator must be used as indication of airspeed switch operation. The

user, on receipt of an indication of switch operation, presses the MANUAL OPERATION (F2)

key:

(1) Connect the instrument to the pitot system as shown in Figure C4. Ensure that

the static system is vented to atmosphere before starting the test.

(2) Ensure that positive pressure is selected and close the release valve.

(3) Close the manual let-down valve.

(4) Zero the airspeed reading by pressing the ZERO key.

9 K0237 Issue No. 2

Page 14

(5) Press the RUN key (F1) and operate the hand-pump, continue until the switch

operates and immediately press (F2).

(6) Carefully open the release valve and allow the airspeed to decrease until the

switch operates again and immediately press (F2). The display shows the

operating airspeeds and hysteresis.

(7) Record the displayed operating data.

(8) Allow the airspeed to decrease until it is below 80 kts.

(9) Slowly open the manual let-down valve to return system to zero (ground level).

(10) To perform another switch test, press RUN (F1).

(11) To cancel switch test mode, press TASK.

Airspeed Leak Tests

Select TASK, AERO:

Select AIRSPEED LEAK TEST:

If necessary, SELECT AERO UNITS:

Method

(1) Connect the instrument to the pitot system as shown in Figure C4. Ensure that

the static system is vented to atmosphere before starting the test.

(2) Close the release valve and manual let-down valve and, using the hand-pump,

generate the required airspeed.

K0237 Issue No. 2 10

Page 15

(3) Set WAIT and DURATION of leak test times:

(4) When ready, press the RUN key (F2):

Initially, the WAIT period counts down, followed by the timing period. The START

SPEED is recorded as soon as the timing period starts. At the end of the test the

display shows the complete details of the test.

(5) Record the displayed operating data.

(6) Allow the airspeed to decrease until it is below 80 kts.

(7) Slowly open the manual let-down valve to return the system to zero (ground

level).

(8) To perform another leak test, use the hand-pump to generate a new airspeed

and press RUN (F2) again.

(9) To exit or cancel leak test mode, press TASK.

11 K0237 Issue No. 2

Page 16

intentionally left blank

K0237 Issue No. 2 12

Page 17

Page 18

Loading...

Loading...