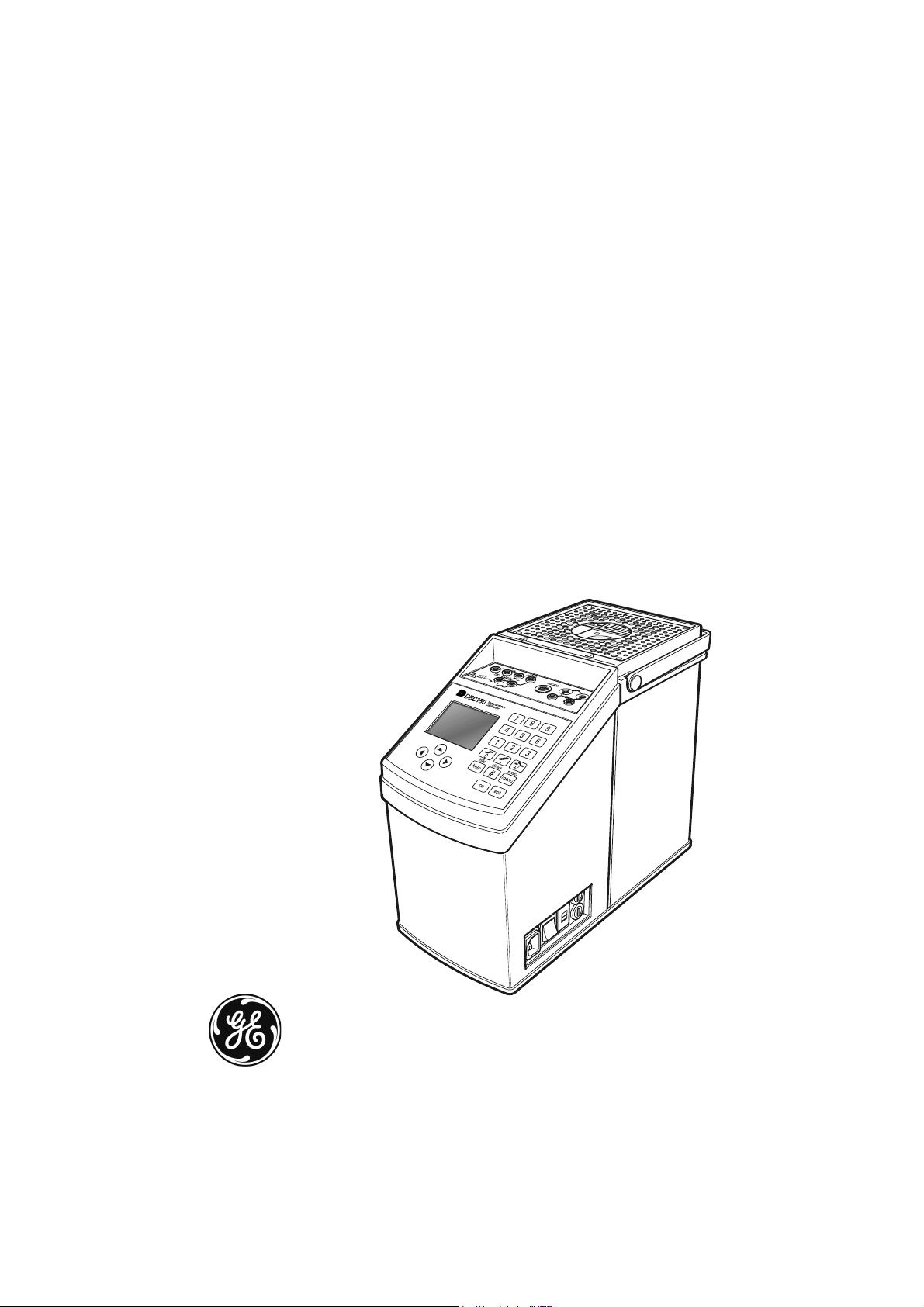

Page 1

GE Infrastructure

Sensing

Druck DBC 150/650 Series

Dry block temperature calibrator

User manual - K400

[EN] English 1 ..... 56

[FR] French TBA

[DE] German TBA

[IT] Italian TBA

[PT] Portuguese TBA

[ES] Spanish TBA

Page 2

© 2005 General Electric Company. All rights reserved.

Page 3

Introduction

• This technical manual provides operating instructions for the Druck

DBC Series of Dry Well Calibrators.

Safety

• The manufacturer has designed this equipment to be safe when

operated using the procedures detailed in this manual. Do not use this

equipment for any other purpose than that stated.

• This publication contains operating and safety instructions that must be

followed to ensure safe operation and to maintain the equipment in a

safe condition. The safety instructions are either warnings or cautions

issued to protect the user and the equipment from injury or damage.

• Use suitably qualified * technicians and good engineering practice for

all procedures in this publication.

Test leads

• Only use the test leads supplied with the instrument, do not use these

test leads with any other equipment.

Power isolation

• Access to the power supply isolator switch must not be obstructed.

Toxic Materials

• There are no known toxic materials used in construction of this

equipment.

Maintenance

• The equipment must be maintained using the procedures in this

publication. Further manufacturer’s procedures should be carried out

by authorized service agents or the manufacturer’s service

departments.

Technical Advice

• For technical advice contact the manufacturer.

*A qualified technician must have the necessary technical knowledge,

documentation, special test equipment and tools to carry out the required

work on this equipment.

This equipment meets the requirements of all relevant

European safety directives. The equipment carries the CE

mark.

K400 Issue No. 1 i

Page 4

TRACEABILITY AND CALIBRATION REPORT

• Each DBC instrument is supplied as standard with a calibration report,

declaring traceability to a National or International standard.

WARRANTY AND LIABILITY

1 Our equipment is guaranteed against defective material and

workmanship during the warranty period. Claims under warranty

can be made by returning the equipment, prepaid, to our factory. The

equipment will be replaced, repaired or adjusted at our discretion.

2 The liability of GE is restricted to that given under our warranty. No

responsibility is accepted for damage, loss or other expense

incurred through the sale or use of our equipment.

3 Under no circumstances will GE be liable for any special incidental

or consequential damage.

Symbols

The following symbols are used to identify hazards on the instrument:

This symbol, on the instrument, indicates that the user

should refer to the user manual.

This symbol, on the instrument, indicates a very hot

surface that must not be touched.

K400 Issue No. 1 ii

Page 5

Safety Instructions

This

instrument

During operation observe the following safety instructions:

1 USE the instrument in vertical position only.

2 DO NOT place any object on the protection grid of the dry well.

3 DO NOT put any liquid into the dry well and/or on the inserts.

4 DO NOT use fluids to clean the dry well and/or the inserts.

5 BEFORE any maintenance activity, WAIT for the instrument to cool

to ambient temperature (keep the instrument switched on, to allow

the cooling fan to operate).

6 DO NOT touch the protection grid until it has cooled to ambient

temperature).

7 The instrument must be at ambient temperature before storing in any

transit case or packing system.

8 DO NOT use this instrument near inflammable liquids or in

Hazardous areas.

9 DO NOT place either your hands, or any other object, into the dry

well.

10 Before use, REMOVE all traces of contamination from the device

under test.

11 During normal operation, this instrument could reach high

temperatures.

12 Always observe all the safety instructions.

*A qualified technician must have the necessary technical knowledge,

documentation, special test equipment and tools to carry out the required

work on this equipment.

should only be used by suitably qualified * technicians

Abbreviations

The following abbreviations are used in this manual; the

abbreviations are the same in the singular and plural.

BLK block ent enter

CJ Cold Junction CJC Cold Junction Compensation

DBC Dry Block Calibrator °C Degrees Centigrade

in inch mA milliampere

mm millimetre mV millivolt

RDG reading RTD Resistive Temperature Device

T/C Thermocouple V Volt

TC Temperature Calibrator TS Temperature Source

K400 Issue No. 1 iii

Page 6

TABLE OF CONTENTS

Introduction .................................................................................. .......... i

Safety .......................................................................................... .......... i

Traceability and Calibration Report.............................................. .......... ii

Symbols ....................................................................................... .......... ii

Safety Instructions........................................................................ .......... iii

Index .......................................................................................... ..........iv

Standard and optional accessories............................................... .......... vii

1 INTRODUCTION ............................................................... ..........1

1.1 Automatic calibration ......................................................... ..........2

1.2 Parts identification ............................................................. ..........2

2 INSTALLATION.................................................................. ..........4

2.1 Preparation .......................................... .............................. ..........4

2.2 Power Supply..................................................................... ..........4

2.3 Temperature Probes........................................................... ..........4

2.4 Electrical Connections........................................................ ..........6

3OPERATION...................................................................... ..........11

3.1 Key-pad Functions ............................................................. ..........11

3.2 Operating Displays............................................................. ..........13

Menu selection screen....................................................... ..........13

System Set-up screen........................................................ ..........13

Working screen................................................................... ..........13

Help/Info screen................................................................. ..........14

Self-test screen.................................................................. ..........14

3.3 Functional Modes............................................................... .......... 15

Reading of the generated temperature.............................. ..........15

Dual display - (generated temperature and an input test).. ..........15

3.4 Temperature Reference Selection...................................... ..........16

Internal reference probe..................................................... ..........16

External reference probe.................................................... ..........16

3.5 System Set-up .................................................................. ..........18

Language settings.............................................................. ..........18

Temperature unit settings................................................... ..........18

Key-pad audio signal.......................................................... ..........19

Digital Interface settings..................................................... ..........19

K400 Issue No. 1 iv

Page 7

Printer settings................................................................... ..........20

Calibration.......................................................................... ..........20

Protection code.................................................................. ..........21

3.6 Testing Modes.................................................................... ..........22

Direct mode........................................................................ ..........22

Step mode.......................................................................... ..........23

Fixed step selection............................................................ ..........23

Programmable step selection............................................. ..........24

Ramp mode........................................................................ ..........25

Preset values mode............................................................ ..........26

3.7 Measuring an Input ............................................................ ..........27

Switch test.......................................................................... ..........27

Thermocouple testing......................................................... ..........28

Internal............................................................................... ..........29

Setting Cold Junction Compensation................................. ..........29

Direct ................................................................................. ..........30

CAL mode.......................................................................... ..........30

Absolute............................................................................. ..........31

% of span............................................................................ ..........31

% of reading....................................................................... ..........32

RTD measurements........................................................... ..........33

Direct ................................................................................. ..........34

CAL mode.......................................................................... ..........34

Absolute............................................................................. ..........35

% of span............................................................................ ..........35

% of reading....................................................................... ..........36

Current measurements....................................................... ..........37

Direct ................................................................................. ..........37

CAL ................................................................................... ..........38

Voltage measurements (high level).................................... ..........39

Direct ................................................................................. ..........39

CAL ................................................................................... ..........40

Voltage measurements (low level)...................................... ..........41

Resistance measurements................................................. ..........42

4 SERIAL COMMUNICATION ............................................. ..........43

K400 Issue No. 1 v

Page 8

4.1 DBC Series - Serial Commands Protocol .......................... ..........43

5 CALIBRATION .................................................................. ..........48

Calibration of the Standard Reference Probe Input ..................... ..........48

Calibration of the External Reference Probe ............................... ..........49

Calibration of the Internal Dry Well Sensor .................................. ..........49

Calibration of the Millivolt Input Range ........................................ ..........50

Calibration of the Volt Input Range .............................................. ..........51

Calibration of the mA Input Range .............................................. ..........51

Calibration of the Ohm Input Range ............................................ ..........52

6 FAULT FINDING ............................................................... ..........53

7 MAINTENANCE................................................................. ..........54

7.1 Cleaning Instructions.......................................................... ..........54

8 TECHNICAL SPECIFICATION ......................................... ..........55

8.1 Standard Specification........................................................ ..........55

8.2 Common Specification ....................................................... ..........55

8.3 Electrical Input Specification (DBC-TC models)................ ..........56

K400 Issue No. 1 vi

Page 9

STANDARD ACCESSORIES DBC-TC series

The DBC-TC series is supplied with the following standard accessories:

• Operating manual

• Set of leads for:

2 test leads and 2 clamps for switch connection

6 test leads and 6 clamps for connection of electrical signal

• Power supply cable

• Removable insert with 3 holes (5, 6.6, 9.8 mm diameter), (3/16, 1/4,

3/8 in. diameter for USA)

• Tool for extraction of removable insert

• RS232 interface cable (1.5 metre, 5 pin/5 pin)

• Traceable calibration certificate

• 2 spare fuses (see page 4 for more information)

OPTIONAL ACCESSORIES DBC-TC series

• Option B1 for DBC 150, reference probe type PT 100, range –50°C

to +400°C

• Option B2 for DBC 650, reference probe type PT 100, range +50°C

to +650°C

• Option B3, temperature probe type PT 100, range –50°C to +650°C.

• Option D, fast cooling device

• Option E, aluminium transit case

• Option C1/C2, insert with 2 holes (5 and 13 mm diameter), (3/16,

1/2 in. diameter for USA)

• Option C3/C4, insert with 4 holes (3.4, 5, 5, 8.2 mm diameter), (1/8,

3/16, 3/16 and 5/16 in. diameter for USA)

• Option C5/C6, blank insert

• Option C7/C8, insert with special holes.

K400 Issue No. 1 vii

Page 10

STANDARD ACCESSORIES DBC-TS series

The DBC-TC series is supplied with the following standard accessories:

• Operating manual

• Set of leads for:

2 test leads and 2 clamps for switch connection

• Power supply cable

• Removable insert with 3 holes (5, 6.6, 9.8 mm diameter), (3/16, 1/4,

3/8 in. diameter for USA)

• Tool for extraction of removable insert

• RS232 interface cable (1.5 metre, 5 pin/5 pin)

• Traceable calibration certificate

• 2 spare fuses (see page 4 for more information)

OPTIONAL ACCESSORIES DBC-TS series

• Option B1 for DBC 150, reference probe type PT 100, range –50°C

to +400°C

• Option B2 for DBC 650, reference probe type PT 100, range +50°C

to +650°C

• Option B3, temperature probe type PT 100, range –50°C to +650°C.

• Option D, fast cooling device

• Option E, aluminium transit case

• Option C1/C2, insert with 2 holes (5 and 13 mm diameter), (3/16,

1/2 in. diameter for USA)

• Option C3/C4, insert with 4 holes (3.4, 5, 5, 8.2 mm diameter), (1/8,

3/16, 3/16 and 5/16 in. diameter for USA)

• Option C5/C6, blank insert

• Option C7/C8, insert with special holes.

K400 Issue No. 1 viii

Page 11

1INTRODUCTION

The DBC series of temperature calibrators test and calibrate temperature devices.

The series comprises two types: a TS (Temperature Source) and a TC

(Temperature Calibrator). Multilingual firmware provides a menu-driven user

interface in English, French, German, Italian, Spanish and Portuguese. An RS232

digital interface, supplied as standard, enables remote operation of the instrument

from a compatible computer.

TS (Temperature Source)

The DBC-TS generates stable temperatures and accurately measures the

temperature of the dry well. It provides an automatic switch test facility.

There are two models of the DBC-TS, providing the same operating capabilities at

different temperature ranges:

• DBC 150-TS : -45°C below ambient temperature to +150°C.

• DBC 650-TS : +50°C to +650°C.

This series of calibrators uses the GE technology temperature controller, providing

high performance temperature stability and accuracy. Temperature generation can

be controlled either in manual mode (direct) or automatic with ramping, stepping or

preset functions. The dry well temperature can be measured either with the internal

probe or with an external certified reference probe. The key-pad, display and

electrical connections enable the user to carry out test procedures for RTD and

thermal switches with a hysteresis calculation.

TC (Temperature Calibrator)

The DBC-TC generates stable temperatures and accurately measures the

temperature of the dry well. It measures process signals from the temperature

devices under test.

There are two models of this series, providing the same operating capabilities at

different temperature ranges:

• DBC 150-TC : -45°C below ambient temperature to +150°C.

• DBC 650-TC : +50°C to +650°C.

This series of calibrators uses the GE technology temperature controller, providing

high performance temperature stability and accuracy. Temperature generation can

be controlled either in manual mode (direct) or automatic with ramping, stepping or

preset functions. The dry well temperature can be measured either with the internal

probe or with an external certified reference probe.

The key-pad, display and electrical connections enable the user to carry out test

procedures for thermocouples, RTD, switches, temperature transmitters and

converters, regulators. Both TC models contain a switch test function with a

hysteresis calculation. This Input/Measure facility enables direct connection and

reading of thermocouples, RTD, Voltages, Current and Resistance: the dual display

can simultaneously show the generated temperature (with internal or external

K400 Issue No. 1 1

Page 12

reference) and a possible electrical feedback from a device under test (i. e.

temperature probes, temperature transmitters). An error calculation, with scaling

function, allows the user to check immediately the accuracy specification of the unit

under test. A 24 V auxiliary excitation provides power for temperature transmitters

under test.

1.1 Automatic Calibration

An RS232 computer interface enables a Calibration Management Software to

provide automatic calibration procedures, typically with the following capabilities:

• Creation of instrument details

• Creation of test procedures and work orders

• Analysis of devices due for calibration

• Printing of calibration reports

• Export functions

Refer to section 4 SERIAL COMMUNICATION for remote control of this instrument.

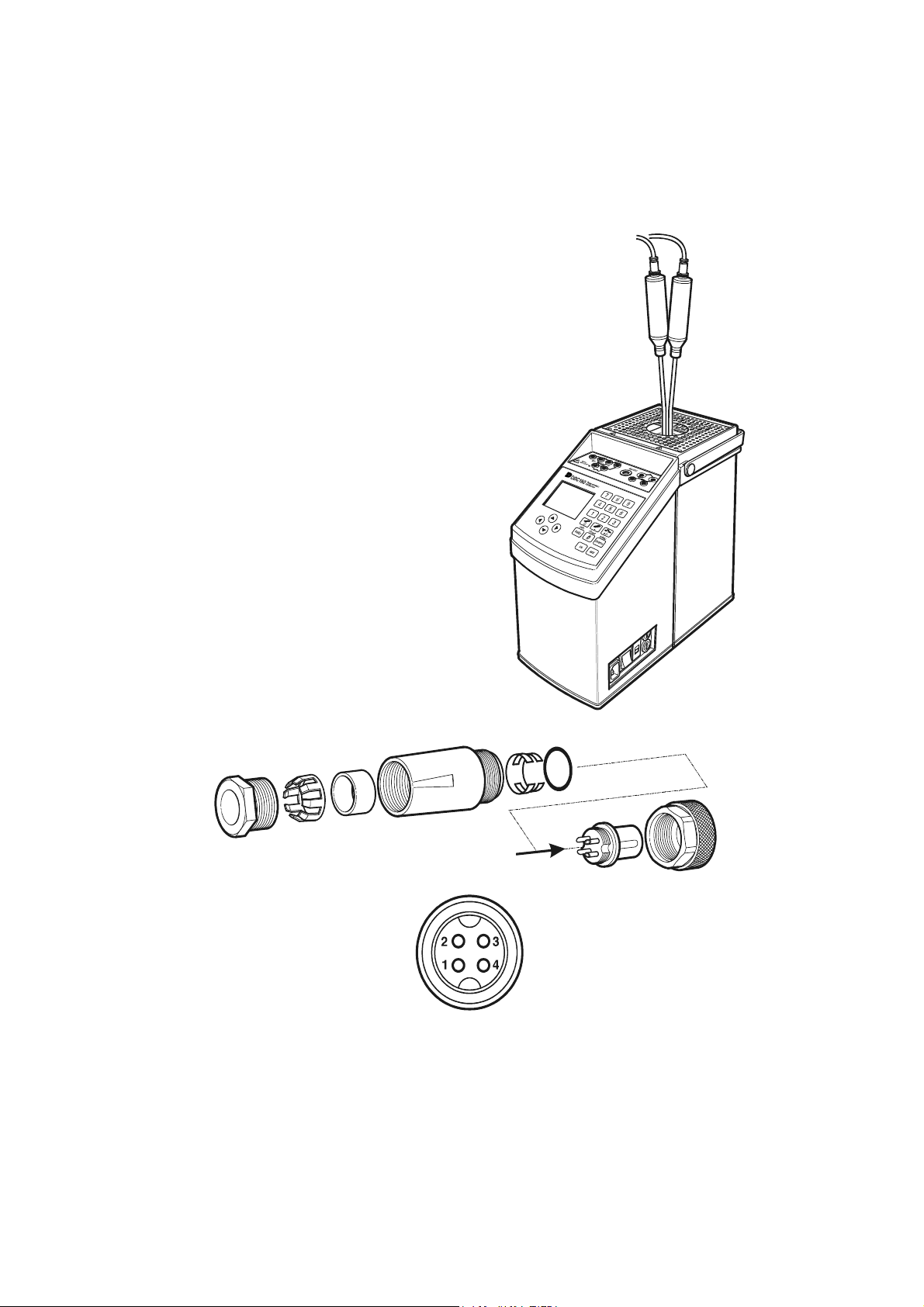

1.2 Parts Identification

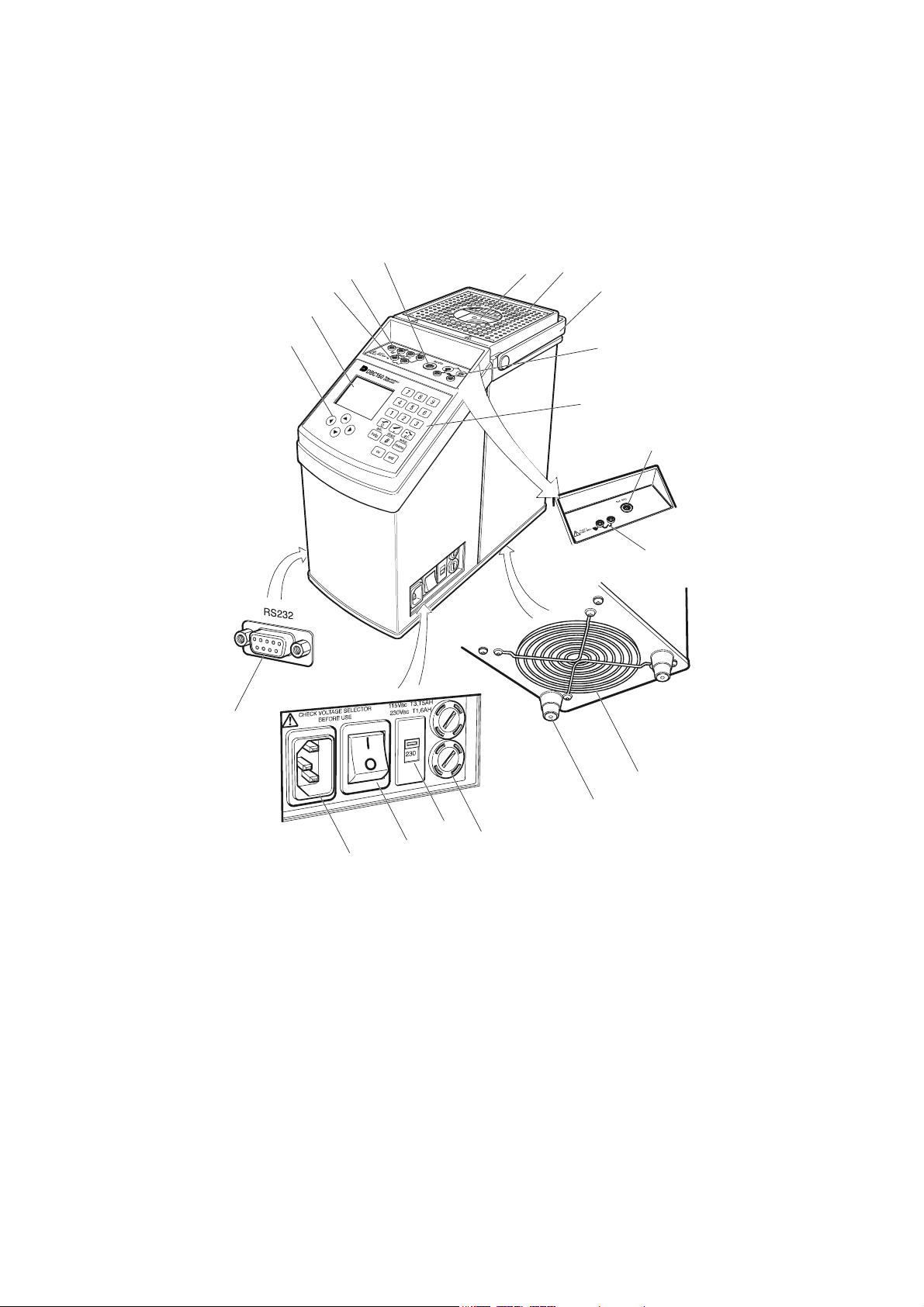

Key to Figure 1-1

Fig no. Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Dry well with insert

Protection grid

Carrying handle

4 mm socket for T/C, RTD and ohm connection, with CJ compensation

Tactile key-pad for direct selection of all the operating function (ramps, steps, preset

values, switch test, help, set-up) and to set temperature values

Cooling fan

Support feet (4)

Protection fuse (115 Vac 2x12.5 AT and 230 Vac 2x6.3 AT for DBC 650

(115 Vac 2x1.6 AT and 230 Vac 2x3.15 AT for DBC 150)

Main power selector 100 - 120 Vac and 220 - 240 Vac, 50/60 Hz

Power supply on/off switch

Main power socket: to connect the standard power cable

RS232 serial communications interface

Cursor (arrow) keys to select operating functions from the main menu and to move the

selection cursor through the menus

Digital display with Multi-language user interface

Switch test connection, suitable to connect test leads supplied as standard

4 mm socket for voltage and current input with 24V dc auxiliary excitation

Lemo connection for external reference probe: suitable for connecting PT 100 probes

with 3 or 4 wires, supplied with standard mating connector ( B1, B2 and B3 options)

2 K400 Issue No. 1

Page 13

17

16

15

14

2

1

3

13

4

5

17

DBC-TS

15

12

6

7

9

11

10

8

Figure 1-1

K400 Issue No. 1 3

Page 14

2INSTALLATION

2.1 Preparation

General

• Remove the instrument from the carrying case and use it on a flat, stable

surface. To avoid any possible damage, either to the instrument or the unit

under test, the dry well of the instrument must be used in the vertical position.

• The fan system at the base of the instrument must be free from any obstruction.

• The dry well must be completely clean.

• Carefully read the SAFETY section of this manual.

2.2 Power Supply

CAUTION:

B

EFORE OPERATING, CHECK THAT THE POWER SUPPLY SELECTOR SWITCH

SETTING MATCHES THE POWER SUPPLY VOLTAGE.

The DBC series of calibrators operate from an a. c. power supply of 100 to 120 Vac

or 220 to 240 Vac, 50-60 Hz.

CAUTIONS:

1T

2T

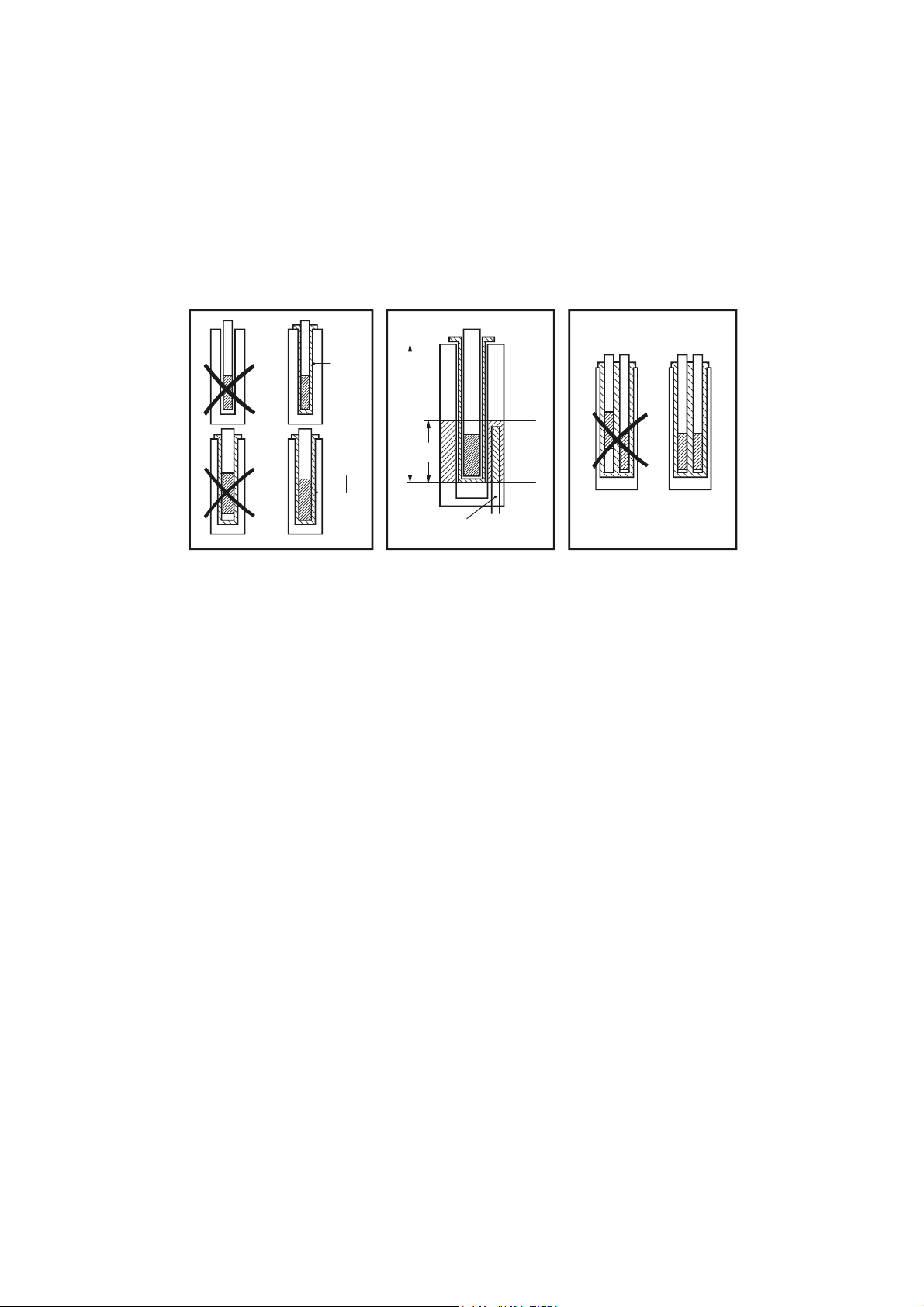

2.3 Temperature Probes

WARNING

The temperature probe to be tested must be correctly placed in the dry well to

produce accurate test results:

HE POWER SUPPLY MUST PROVIDE CONNECTION TO A PROTECTIVE GROUND

TERMINAL.

HE INSTRUMENT MUST, AT ALL TIMES, BE CONNECTED TO THE SUPPLY EARTH

(

GROUND).

AFTER USE, THE PROBES WILL BE VERY HOT. HANDLE WITH

CARE AND WAIT FOR THE PROBES TO COOL COMPLETELY.

• Check the probe diameter and operating range and use reduction inserts with

the correct sized holes (the hole diameter should comply with EA-10/13

guidelines). A large temperature difference between probe and dry well causes

large measuring errors. This difference increases as the difference between

the diameters increases.

• Always clean the probes, before use.

• Do not force the probes into the dry well, insert the probe down to the bottom of

the dry well.

4 K400 Issue No. 1

Page 15

• When testing a probe with a certified reference probe, place both probes close

together and at the same depth.

insert

NO

NO

Reduction

YES

*

YES

160mm

50

mm

Internal reference probe

zone

Calibration

NO YES

* dimension should comply with EA-10/13 guidelines - for temperature

ranges -80° C to +660°C maximum 0.5mm

IMPORTANT NOTE

Reduction inserts with special holes could be necessary when carrying out a

calibration procedure on temperature device with specific mechanical

dimensions. Refer to GE for details of specific application solutions.

K400 Issue No. 1 5

Page 16

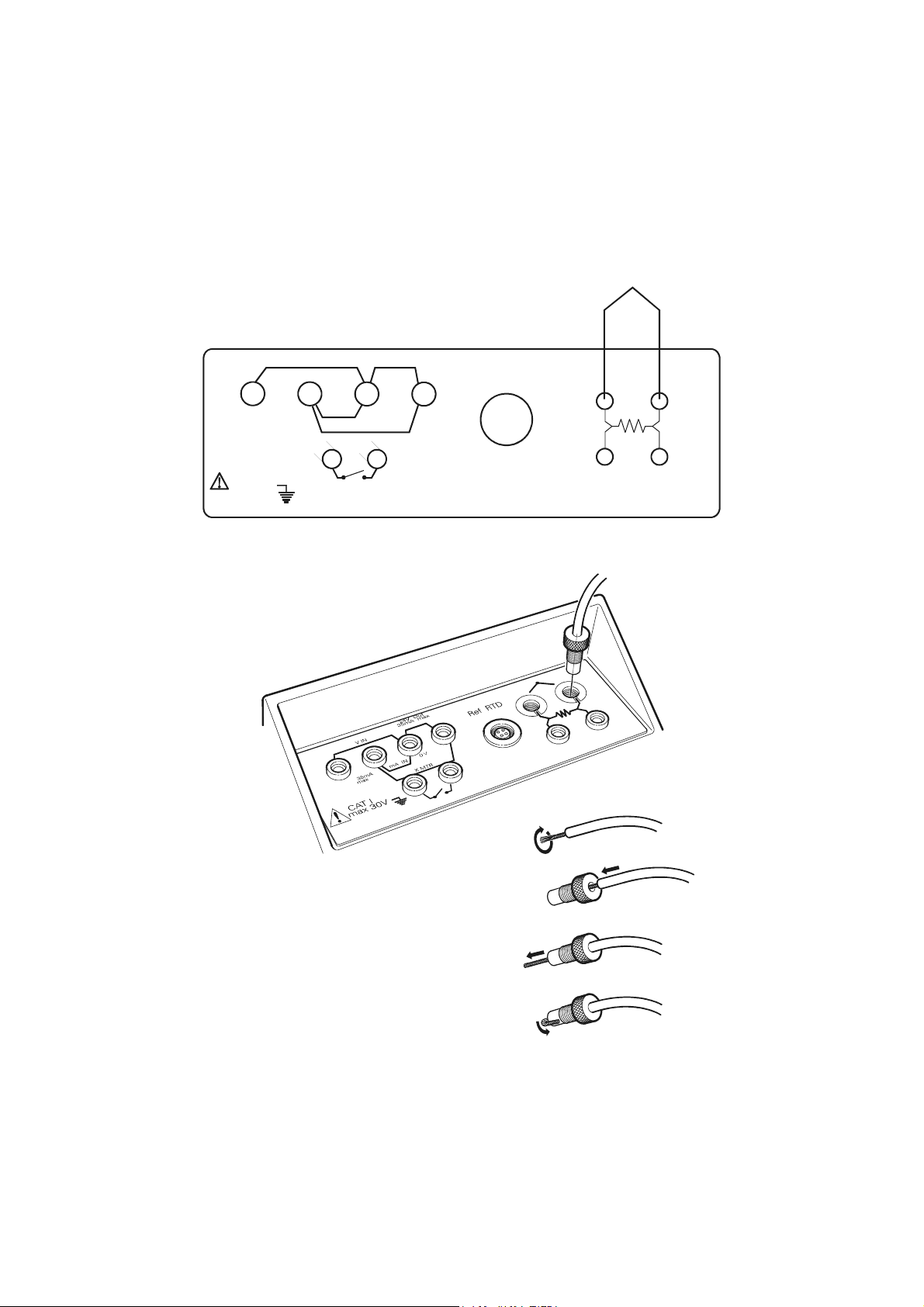

2.4 Electrical Connections

• Connection of a Thermocouple sensor

V IN

24V Out

35mA max

Ref RTD

0V

X MTR

CAT I

max 30V

35mA

max

mA IN

• Use of screw connections for T/C wires

-

+

1

2

3

4

6 K400 Issue No. 1

Page 17

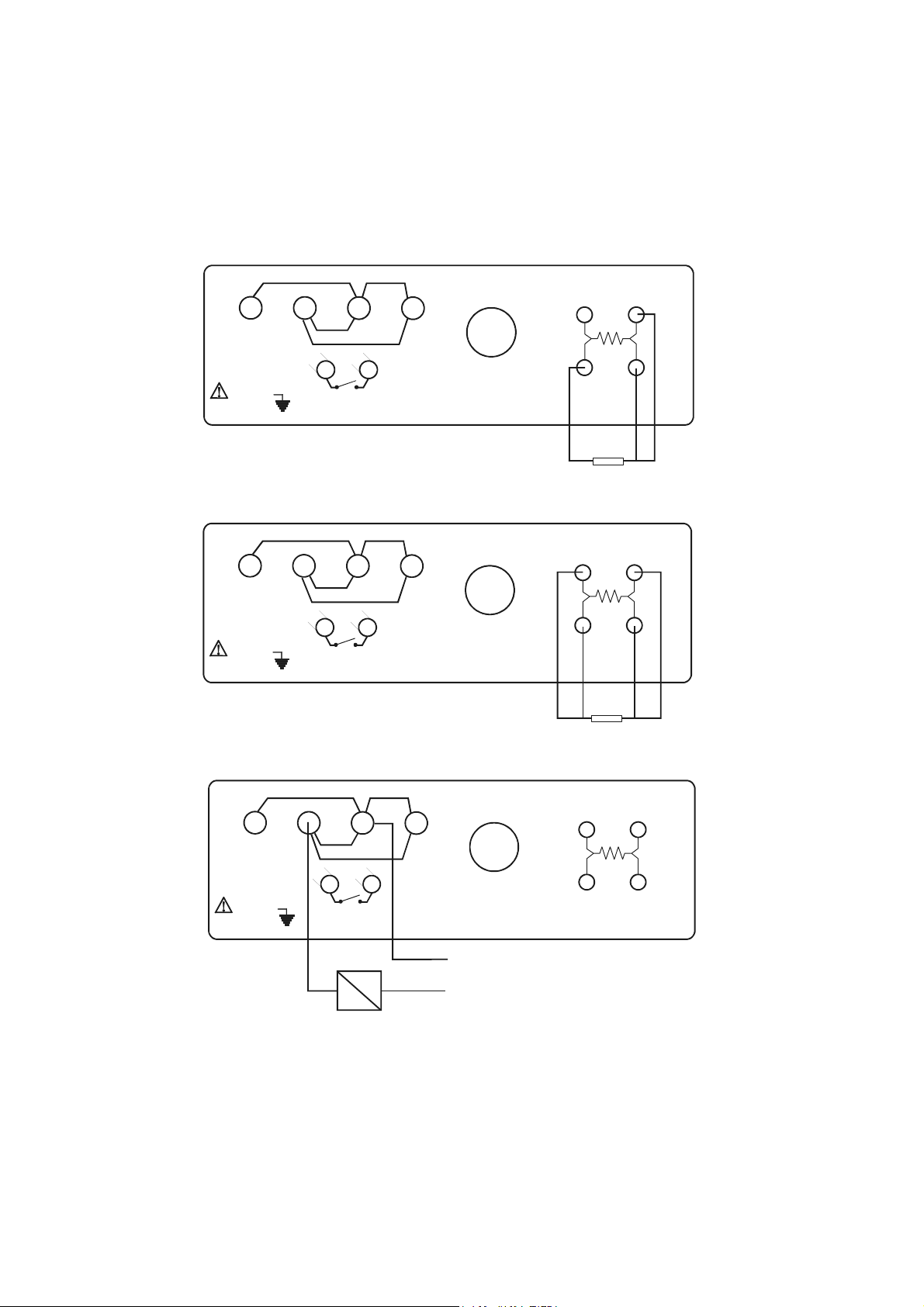

• Connection of a 3-wire RTD.

X MTR

24V Out

35mA max

0V

CAT I

max 30V

35mA

max

V IN

mA IN

• Connection of a 4-wire RTD

X MTR

24V Out

35mA max

0V

CAT I

max 30V

35mA

max

V IN

mA IN

Ref RTD

Ref RTD

• Connection of a 2-wire T/I transmitter

V IN

24V Out

35mA max

(external 24 V dc excitation)

Ref RTD

0V

X MTR

CAT I

max 30V

35mA

max

mA IN

0V user supply (SELV)

I

T

-

K400 Issue No. 1 7

+

24V user supply floating (SELV)

Page 18

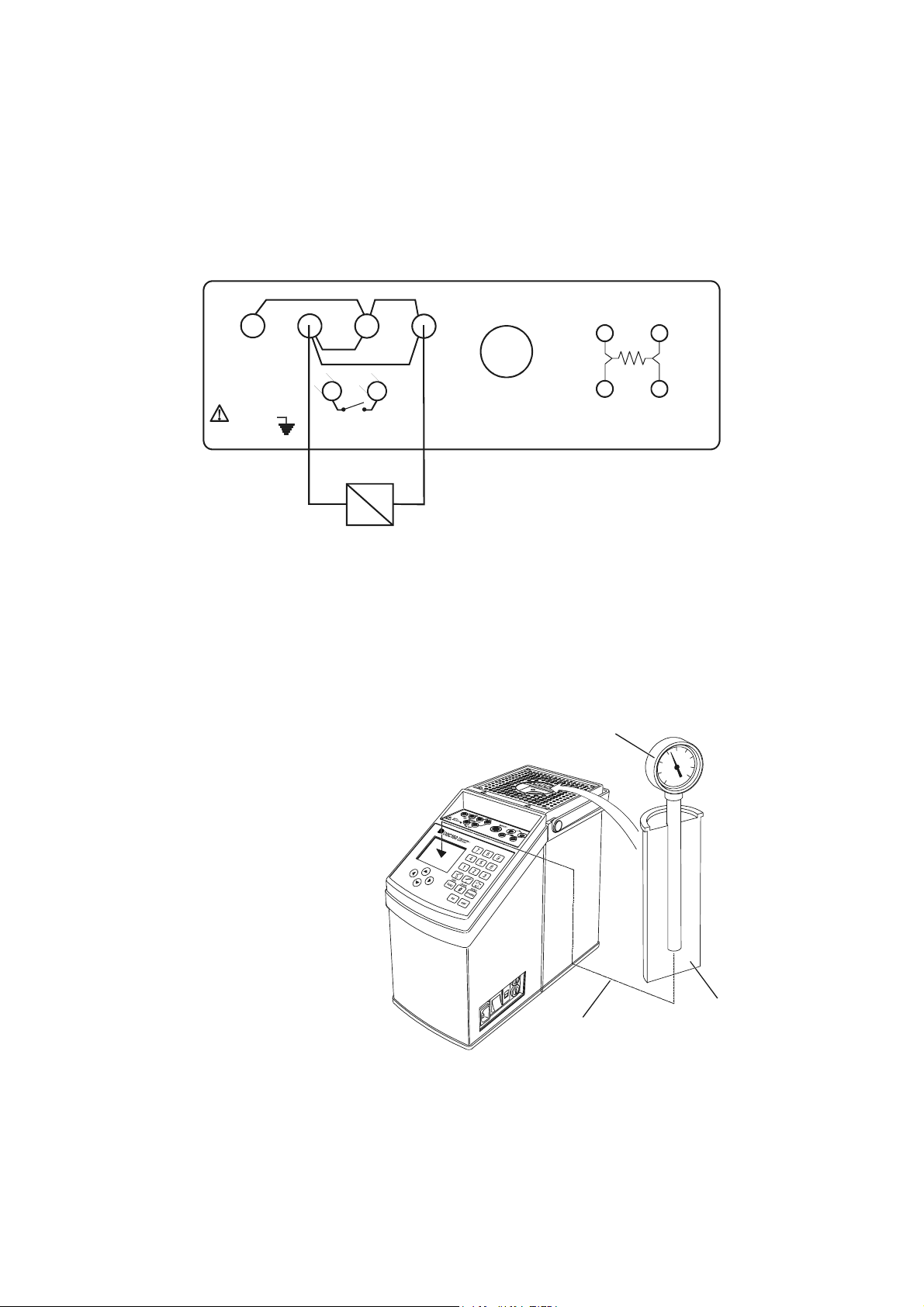

• Connection of a 2-wire T/I transmitter

(with 24 V dc auxiliary excitation)

X MTR

24V Out

35mA max

0V

Ref RTD

CAT I

max 30V

35mA

max

V IN

mA IN

I

T

• General

The temperature probes to be tested fit into an appropriate size reduction insert

located in the 30 mm diameter hole of the dry well. The dry well can be heated by

either cartridge heaters (DBC 650) or Peltier cells (DBC 150). A fan system fitted

on the bottom of the instrument reduces the temperature during cooling operations.

Operating procedure

The DBC Series can be used to carry out comparison test using a variety of

methods:

Reading of temperature calibration with the internal regulation probe

The generated temperature

is considered as reference

value and is shown on the

DBC display: this

temperature is measured

with the standard internal

probe.

Unit under Test

Dry Well

Internal Temperature

Probe

8 K400 Issue No. 1

Page 19

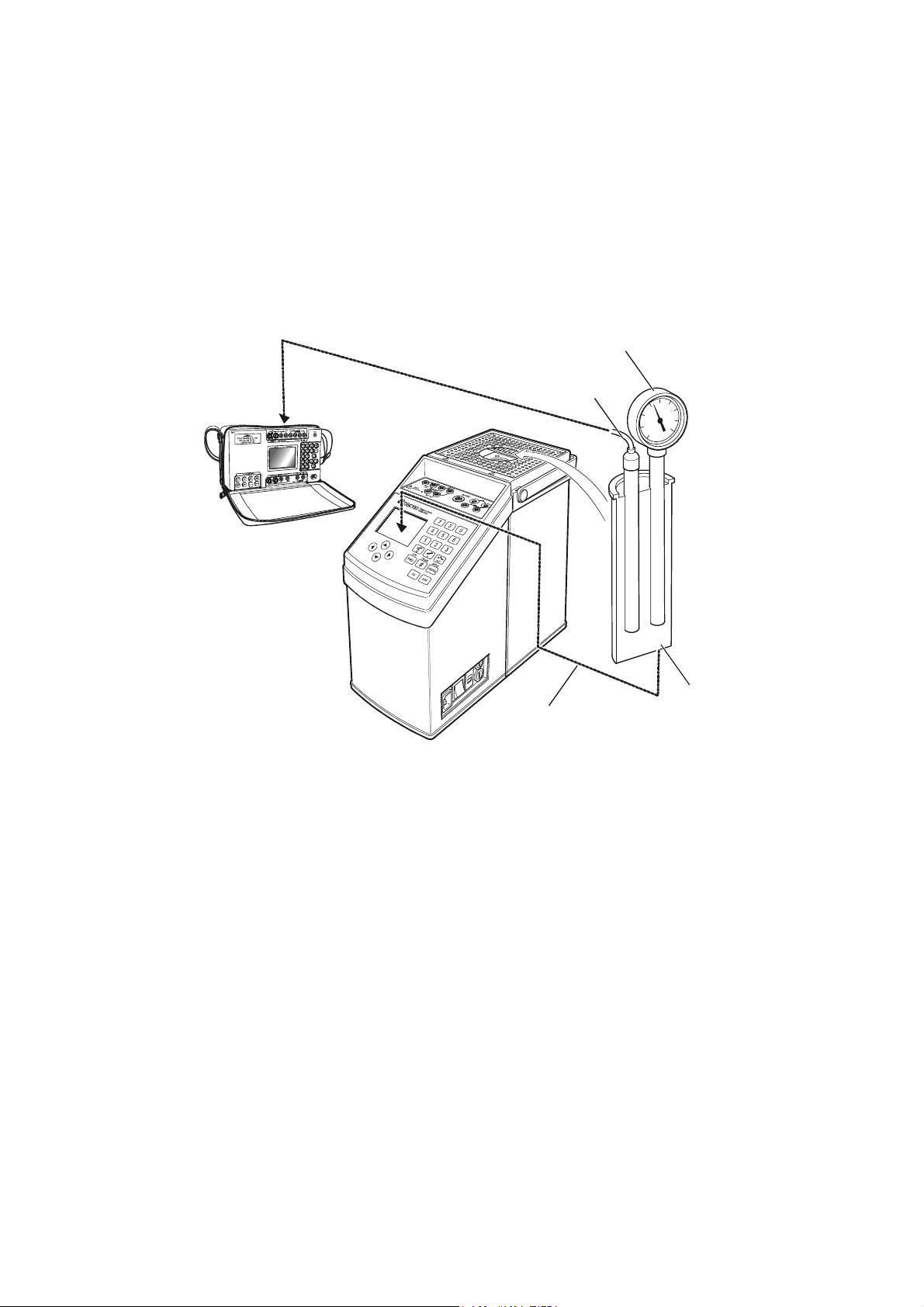

Calibration with external reference probe

l

The temperature value to be considered as standard is measured with an external

and certified reference probe. This measurement reading can be directly shown

either on the DBC display (connecting the reference probe to the REF RTD socket

on the top of the instrument) or with an external, certified electronic calibrator.

Unit under Test

External Certified

Reference Probe

Dry Wel

Internal Temperature

Probe

K400 Issue No. 1 9

Page 20

Power, reading and calibration of devices

under test (

The DBC-TC series has the input capability to

directly measure the electrical signal of unit

under test (T/C, RTD, mA, V, Ohms): using an

error calculation function (with scaling

capability), calibration procedures can be

carried out and the UUT accuracy immediately

measured.

A 24 V auxiliary excitation supply is also

available to power the loop of the device due for

calibration. The generated temperature can be

measured with the internal or the external

reference as described above.

DBC-TC only)

• External probe connections

A

1 Wire 1

2 Wire 1a

3 Wire 2

4 Wire 2a

A

10 K400 Issue No. 1

Page 21

3OPERATI0N

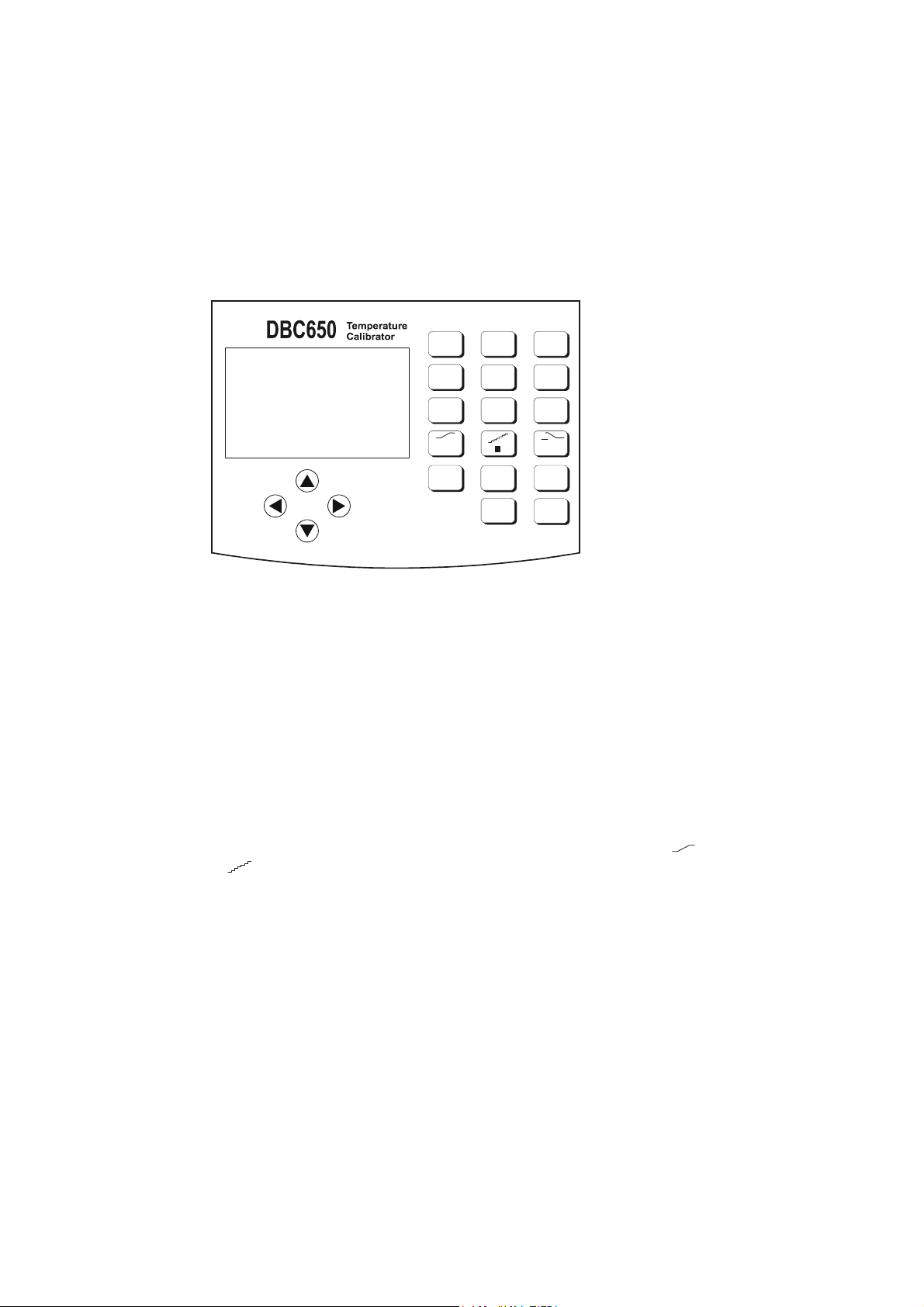

3.1 Key-pad Functions

7

4

1

0

info direct

help

8

5

2

#

ce

9

6

3

+/-

setup

menu

ent

• ent (Enter) key

1. Pressing this key to confirms the selected choices or the temperature set-

point.

•ce (clear entry) key

2. Pressing this key cancels the previous key operation or corrects a typing

error.

•menu/setup key

3. Pressing this key recalls the Menu Selection Screen. Pressing this key after

the # key (2nd function), selects the SETUP menu display.

•# key

4. Pressing this key selects DIRECT temperature generation mode. Pressing

this key with other keys recalls second functions (# + set-up, # + , # +

etc.).

•help/Info key

5 Pressing this key recalls a related display containing more information, either

on the selected function or on the operation to be performed. Pressing this

key after the # key, changes the display containing information relating to the

selected temperature reference or to the selected test function (for example

switch test).

K400 Issue No. 1 11

Page 22

•+/- key

6 Pressing this key changes the sign on working screen. Pressing this key

after the # key, recalls the Switch Test function. Pressing # and +/- again to

return to the working screen.

• key

7 Pressing this key sets the decimal point. Pressing this key after the # key,

recalls the step generation mode, starting from the step selection screen.

•0 key

8 Pressing this key zeroes the display. Pressing this key after the # key, recalls

the ramp generation mode, starting from the Ramp set-up screen.

•1- 9 (numeric) keys

9 Using these numeric keys sets a temperature value or a special generation

mode (ramp limits, programmable steps etc.). Pressing keys 1- 5 after the #

key, recalls specific preset values.

• (arrow) keys

10 Pressing these keys moves the screen cursor either in the horizontal or

vertical direction. When the ramp and step functions are enabled, these keys

can start, stop, hold or recall related values.

12 K400 Issue No. 1

Page 23

3.2 OPERATING DISPLAYS

The DBC-TC series has four operating displays:

• Menu selection screen

REF T.

INTERNAL

SEL RTD

MEASURE

NONE

T/C

RTD

mA

REF T.

INTERNAL

SEL RTD

MEASURE

NONE

T/C

RTD

mA

MEASURE

NONE

DBC-TS

This display shows the measure parameters. The arrow keys move the cursor in

both horizontal and vertical directions.

• System Set-up Screen

Press MENU to select the system set-up menu.

SYSTEM SETUP

LANGUAGE

TEMPERATURE UNIT

KEYBOARD

SERIAL PORT

PRINT

Use the keys to move the cursor up/down and press ent to select.

• Working screen

DBC-TC

T/ C K 23.8° C

RDG: °C

148.50

0.15% SPAN

150.00 DIRECT

BLK

°C

148.00

SWITCH

150.00 DIRECT

BLK

°C

K400 Issue No. 1 13

DBC-TS

148.00

Page 24

This display shows the temperature set-point, the actual temperature (with internal

or external reference) and the current temperature measurement. Use the numeric

key-pad to set the temperature value and, using the second function key, change

the direct function to ramping, stepping and preset.

• Help/Info screen

REF T.

INTERNAL

SEL RTD

MEASURE

NONE

SELECT

ENT TO

CONFIRM

This display shows more information relating to the selected function or test/

measure - (for example selected temperature reference – internal or external -,

switch test, mA reading etc.).

• Self-test screen

Note:

When switched on, the display shows the self-test screen:

• Model

• Firmware release

•EPROM self-test

• Temperature regulator self-test

DBC - 650 - TC

V x. xx - mm/ yyyy

Self test ....................................

Eeprom OK

Temp. Control OK

14 K400 Issue No. 1

Page 25

3.3 Function Modes

• Reading of the generated temperature

REF T.

INTERNAL

SEL RTD

MEASURE

NONE

T/C

RTD

mA

150.00 DIRECT

BLK

148.00

°C

Press the MENU key to recall the Menu Selection Screen from any Working Screen.

Leave the MEASURE (Input) display set to NONE to display the dry well (BLK)

temperature with the temperature set-point shown in small numbers and arrow

symbols indicating either a heating or cooling operation.

• Dual display – (generated temperature and an input (test) option)

REF T.

INTERNAL

SEL RTD

MEASURE

NONE

T/C

RTD

mA

T/ C K 23.8° C

148.50

RDG: °C

0.15% SPAN

150.00 DIRECT

BLK

°C

148.00

From the Menu Selection Screen, use the horizontal and vertical cursor keys move

the cursor through the REF. T and MEASURE displays. Select both the reference

for the temperature to be generated and an input option (measure). The final

working screen, configured as a dual display, shows two sections of equal size, dry

well temperature and the unit under test feedback (with or without scaling

capability).

K400 Issue No. 1 15

Page 26

3.4 Temperature Reference Selection

The DBC series measures the dry well temperature in two different ways:

• Internal reference probe

From the standard working screen, press the menu key to open the menu selection

screen:

REF T.

INTERNAL

SEL RTD

MEASURE

NONE

T/C

RTD

mA

Using the keys, move the selection cursor on the REF. T display. Select

INTERNAL with the keys and press ent to activate the dry well temperature

measure made with the internal regulation probe. The next display allows the

setting-up of the temperature generation mode (Direct, Ramp, Step or Preset).

• External reference probe

From the REF. T display of the Menu Selection Screen select the SEL RTD function

using the keys and press ent.

REF T.

INTERNAL

SEL RTD

MEASURE

NONE

T/C

RTD

mA

The next selection display now appears as follows.

16 K400 Issue No. 1

Page 27

Move the cursor with the keys, to select a REF 1or REF 2 connection and

press ent.

SEL RTD

REF 1

REF 2

The following display allows the set-up of the temperature generation mode. Using

this facility, the user can connect one of two certified probes to the Ref RTD

connector and display the measured dry well temperature.

Note:

For best accuracy, use an optional reference probe (option B1, B2 or B3).

K400 Issue No. 1 17

Page 28

3.5 System Set-up

• Language setting

The DBC series have multi-lingual firmware with a default setting of English. To

select a different language, press the # + menu keys to recall the System Set-up

Screen. Using the keys select the required LANGUAGE (English, French,

German, Italian, Portuguese or Spanish) and press ent. Press ce to return to the

Working Screen.

SYSTEM SETUP

LANGUAGE

TEMPERATURE UNIT

KEYBOARD

SERIAL PORT

PRINT

LANGUAGE

ENGLISH

FRENCH

GERMAN

ITALIAN

PORTUGUESE

• Temperature unit setting

Press the # + menu keys to recall the System Set-up Screen, using the keys,

select TEMPERATURE UNIT and press ent. Select the required temperature unit

and press ent again. Press ce to leave the System Set-up Screen.

SYSTEM SETUP

LANGUAGE

TEMPERATURE UNIT

KEYBOARD

SERIAL PORT

PRINT

TEMPERATURE UNIT

°C

°F

K

18 K400 Issue No. 1

Page 29

•Key-pad audio signal

A

The DBC series can give an audio signal to confirm each key press. To select this

option, press the # + menu keys to recall the System Set-up Screen. Using the

keys select KEYBOARD and press ent. Select the required function (beep

off/on) and press ent again. Press ce to return to the Working Screen.

SYSTEM SETUP

LANGUAGE

TEMPERATURE UNIT

KEYBOARD

SERIAL PORT

PRINT

KEYBOARD

BEEP OFF

BEEP ON

• Digital interface settings

SYSTEM SETUP

LANGUAGE

TEMPERATURE UNIT

KEYBOARD

SERIAL PORT

PRINT

To set the RS232 communication address, select the System Set-up Screen, using

the keys select SERIAL PORT and press ent. To set the communication

address, use the numeric key-pad and press ent. Press ce twice to exit the System

Set-up Screen.

SERIAL PORT

ddress: 1

K400 Issue No. 1 19

Page 30

•Printer settings

To print calibration data via the RS232 interface, press the # + menu keys to recall

the System Set-up Screen. Using the keys, select PRINT and press ent.

Select the parameter to be printed using the keys, (set-point temperature

[SET], dry well temperature [BLK], reference temperature [REF], measure [RDG]).

Use the numeric keys to set the period, in seconds, between each printout and

press ent. Press ce to return to the Working Screen.

SYSTEM SETUP

LANGUAGE

TEMPERATURE UNIT

KEYBOARD

SERIAL PORT

PRINT

PRINT SETUP

Period: 0 sec

SET NO

BLK NO

REF NO

RDG NO.

• Calibration

A PIN code protects the CALIBRATION function. Refer to 5 Calibration, page 47.

SYSTEM SETUP

CALIBRATION

ENTER CODE

ENTER CODE

20 K400 Issue No. 1

Page 31

• Protection code

To set a new PIN code (initial code 4321) open the System Set-up Screen and,

using the keys, select ENTER CODE and press ent. Using the numeric keypad, enter the existing PIN (initial code 4321) and press ent to change the PIN

code.

SYSTEM SETUP

CALIBRATION

ENTER CODE

ENTER CODE

ENTER CODE

4321CODE:

ENTER CODE

Note:

This procedure permanently changes the PIN code.

Using the numeric key-pad, set the new code and press ent to store it.

K400 Issue No. 1 21

Page 32

3.6 Testing Modes

•Direct mode

After switching on and self-test the display automatically changes to the DIRECT

generation working screen. The related display shows the actual dry well

temperature in large characters (from the internal or external probe), temperature

set-point and a possible measurand (i.e. the last selections made).

150.00 DIRECT

BLK

148.00

°C

The status bar shows the temperature set-point, the symbol (indicating a

cooling or heating condition) and the generation mode. To set a new set-point value

and generate a new temperature, use the numeric key-pad and press ent. The

calibrator immediately activates the temperature regulator and the status bar shows

the new set-point, with the symbol indicating the new heating or cooling

condition. On reaching the new set-point, the RDY (ready) message replaces the

symbol.

150.00 RDY DIRECT

BLK

150.00

°C

22 K400 Issue No. 1

Page 33

• Step mode

To set a STEP generation mode from the DIRECT mode display, press the # key

(2nd function) and the key. The display shows the step function selection menu

as follows:

STEPS

PROGRAM

20%

25%

33%

50%

Using the keys, select the required percentage of temperature interval

between each step or, depending on the application, program a variety of values.

• Fixed step selection

STEPS

PROGRAM

20%

25%

33%

50%

Using the keys, select one of the standard percentage steps (20, 25, 33, and

50%) and press ent. The following display allows the temperature range span to

be set-up (e. g.), 0 to 100 %.

20% STEPS

0% = 0.00 °C

100% = 100.00 °C

Using the keys, move the selection cursor in vertical direction, set the required

temperature values (0 and 100 %) and press ent. In the next working screen, use

the keys to increase or decrease the temperature set-point with the selected

percentage difference between each step.

K400 Issue No. 1 23

Page 34

The status bar shows the recalled percentage step, together with the related

temperature set-point, the step symbol ( ) and the heating/cooling arrow

symbols.

20.00 20%

BLK:

19.00

°C

• Programmable step selection

From the display of step setting, select PROGRAM using the keys and press

ent. The next display permits the temperature step size to be set-up (5 maximum).

STEPS

PROGRAM

20%

25%

33%

50%

Using the keys select the number of step to be set and press ent. In the next

display, move the selection cursor using the again and set a specific

temperature value for each step.

STEPS

2

3

4

5

PROGRAMMED STEPS

# 1 = 0.00 °C

# 2 = 100.00 °C

At the end of this operation, press ent to activate the standard working screen. Use

the keys to increase/decrease the step value as described above for the fixed

step capability.

24 K400 Issue No. 1

Page 35

• Ramp mode

The DBC series can generate temperature using programmable temperature ramp

function. To set-up a ramp function from a Direct or Step working screen, press the

# and 0 keys. The next display allows set-up of the ramp temperature limits and the

required temperature gradient (°C/minute), to be used during the generation

(maximum capability 10.0°C/minute).

RAMP

T min: 0.00 °C

T max: 100.00 °C

dt/ dT: 1.00 °C/ min

Move the cursor in vertical direction using the keys and, using the numeric keypad, set the start/finish ramp temperature values (T min and T max) and the

required rate of change for the regulator. Pressing the ent key causes the working

screen to be activated. Use the key to start ramp generation, starting at the

actual dry well temperature and finishing at the T max value. Use the key to start

a negative ramp function (actual dry well temperature to T min). The display shows

the ramp direction, together with a corresponding heating/cooling symbol.

60.00

BLK:

50.00

°

C

To stop the ramp, press the key. Press the keys to restart. The status bar

shows the ramp symbol, the temperature set-point, the symbols and a

HOLD message (if the ramp has been stopped).

K400 Issue No. 1 25

Page 36

•Preset values mode

To set-up temperature generation from the standard working screen, using

PRESET values, the user must assign a temperature set-point value to a specific

numeric key on the key-pad. From the Direct/Step/Ramp working screen, press ce

since the setting menu is already open. Select PRESET using the keys and

press ent.

SET MODE

DIRECT

PRESET

STEPS

RAMP

PRESET

# 1 = 0.00 °C

# 2 = 0.00 °C

# 3 = 0.00 °C

# 4 = 0.00 °C

# 5 = 0.00 °C

The next display allows a specific temperature value to be assigned to each of the

numeric keys (1 to 5) of the key-pad. Use the keys and the numeric key-pad

to set the values. Press ent to leave the set-up display and to open the working

screen.

Pressing the # key followed by one of the numeric keys 1- 5 recalls the set-point

assigned to the numeric key.

Note:

Ramp, Step and Preset functions can also be set starting from the Menu

Selection Screen. In an active standard working screen, press the menu

key to open the Menu Selection Screen and use the keys to select the

required temperature reference from the REF. T display (see next section),

and press ent. The following screen allows set-up of the Ramp, Step and

Preset parameters.

26 K400 Issue No. 1

Page 37

3.7 Measuring an Input

The DBC series has a dual display. By selecting a measurement (input) option from

the menu using the keys and pressing ent, the working screen shows a dual

display with the dry well temperature (at the bottom) and the selected input (at the

top).

Note:

Leaving the MEASURE section of the Menu Selection Screen to NONE, the

final working screen shows only the dry well temperature (with internal or

external reference).

To show the dry well temperature and a thermocouple input (DBC-TC only):

• Select from the menu screen REF .T and then INTERNAL.

• Using the keys, select from the menu screen MEASURE and then T/C.

• Press the ent key, to confirm and set the display.

REF T.

INTERNAL

SEL RTD

MEASURE

NONE

T/C

RTD

mA

T/ C K 23.8° C

RDG: °C

148.50

0.15% SPAN

150.00 DIRECT

BLK

°C

148.00

•Switch Test

A switch test can be carried out by connecting the device under test to the electrical

connections on the top side of the instrument (identified with the symbol).

• Select from the menu screen REF .T and then INTERNAL.

• Using the keys, select from the menu screen MEASURE and then .

• Press the ent key, to confirm and set the display.

REF T.

INTERNAL

SEL RTD

DBC-TC

MEASURE

NONE

T/C

RTD

mA

REF T.

INTERNAL

SEL RTD

DBC-TS

MEASURE

NONE

K400 Issue No. 1 27

Page 38

Selecting the Direct, Step or Preset generation mode, the final working screen

shows the dry well temperature at the bottom (together with the temperature setpoint, the generation mode and the status arrow symbol) and the contact state at

the top (open/close). An audio signal indicates the change of state.

SWITCH

150.00 DIRECT

BLK

°C

148.00

To enable the Switch Test with the indication of open, close and calculated

hysteresis values, the Ramp generation mode must first be selected.

SWITCH

OPENED AT: 145.50 °C

CLOSED AT: 148.00 °C

HIST: 2.50 °C

150.00

BLK:

148.00 °C

The switch test function can be rapidly recalled from any working screen by

pressing the # and +/- keys. Press these keys again to disable Switch Test and to

recall only the dry well temperature measurement.

• Thermocouple Testing

The DBC-TC series can measure the T/C electrical output, directly displaying the

value in the selected temperature units.

From the Menu Selection Screen, select the required dry well temperature

reference into the REF. T display, move the selection cursor on the MEASURE

section using the keys, select T/C using the keys and press ent.

REF T.

INTERNAL

SEL RTD

28 K400 Issue No. 1

MEASURE

NONE

T/C

RTD

mA

Page 39

After the SET MODE selection, a new display allows the T/C type definition.

TYPE

K

J

S

N

R

Using the keys, select the type of probe to be measured and press ent : the

next display sets the compensation method for the T/C cold junction.

COLD J.

INTERNAL

SET CJC

• Internal

This selection activates the internal CJ compensation mode. A temperature sensor

fitted near the T/C electrical connection measures the CJ temperature and activates

the compensation circuit.

• Setting Cold Junction Compensation

This sets the CJ compensation temperature reference to a programmable value

between 0 to 70° C. The T/C reference table uses a CJ temperature of 0° C.

SET CJC

CJC °C: 24.2 °C

Using the keys, select the required CJ compensation method and press ent.

The display shows the mode settings (i.e. how the T/C measurement can be

displayed).

K400 Issue No. 1 29

Page 40

MODE

DIRECT

CAL

•Direct

This screen shows, in the top, a direct reading in the selected temperature unit,

together with the T/C type and the CJ temperature. The bottom part of the screen

shows, the generated temperature value (with internal or external reference), the

temperature set-point, the status arrows symbols and the selected generation

mode.

T/ C K 23.8° C

RDG: °C

148.50

150.00 DIRECT

BLK

°C

148.00

• CAL Mode

This facility performs an error calculation analysis for the unit under test. From the

MODE display select CAL using the and press ent. The next display provides

the setting of T/C span.

SET SPAN

T min : 50.00 °C

T max : 200.00 °C

Using the select the T min value and set the temperature limit using the

numeric key-pad: then, move the cursor on the T max value using the key, set

the related temperature value and press ent to confirm. Press ent again to show

the next display, where the error calculation method can be set.

30 K400 Issue No. 1

Page 41

ERROR

ABSOLUTE

% OF SPAN

% OF RDG

Using the keys, select the required error calculation method and press ent.

• Absolute

The display shows the error calculation as deviation in temperature measurement

units between the reference temperature (internal or external) and the unit under

test measurement.

•% of Span

This selection gives an error calculation referenced to the full-scale value.

T/ C K 23.8° C

148.50

RDG: °C

0.15% RDG

150.00 DIRECT

BLK

°C

148.00

The working screen shows, in the top part, the selected T/C type, the probe

measure directly in the selected temperature unit, the CJ temperature and the error

value.

The bottom part of the screen shows, the generated temperature value (with

internal or external reference), the temperature set-point, the status arrows symbols

and the selected generation mode.

K400 Issue No. 1 31

Page 42

• % of Reading

This selection gives an error calculation referenced to a previously set, specific

measuring point of the temperature span.

T/ C K 23.8° C

148.50

RDG: °C

0.15% RDG

150.00 DIRECT

BLK

°C

The screen shows, in the top part, the selected T/C type, the probe measure directly

in the selected temperature unit, the CJ temperature and the error value.

The bottom part of the screen shows, the generated temperature value (with

internal or external reference), the temperature set-point, the status arrows symbols

and the selected generation mode.

148.00

32 K400 Issue No. 1

Page 43

• RTD Measurements

The DBC-TC series can measure the electrical output of RTD, displaying the value

directly in the selected temperature unit.

REF T.

INTERNAL

SEL RTD

MEASURE

NONE

T/C

RTD

mA

From the Menu Selection Screen, using the select RTD and press ent.

After selection of the generation mode, a new display shows the RTD types that can

be measured.

TYPE

Pt-100

Pt-200

Pt-500

Pt-1000

Ni-100

Using the keys to select the required RTD type and press ent. After this

operation, a new display sets the connection configuration (3 or 4 wires) of the

probe under test.

RTD

3 WIRES

4 WIRES

Using the keys, select the required connection configuration and press ent.

K400 Issue No. 1 33

Page 44

The display shows the mode settings (i.e. how the RTD measurement can be

displayed).

MODE

DIRECT

CAL

•Direct

This screen shows, in the top, a direct reading in the selected temperature unit,

together with the RTD type and the temperature. The bottom part of the screen

shows, the generated temperature value (with internal or external reference), the

temperature set-point, the status arrows symbols and the selected generation

mode.

Pt-100

RDG: °C

148.50

0,15% SPAN

150.00 DIRECT

BLK

°C

148.00

• CAL Mode

This facility performs an error calculation analysis for the unit under test. From the

MODE display select CAL using the and press ent. The next display provides

the setting of RTD span.

SET SPAN

T min : 50.00 °C

T max : 200.00 °C

Using the select the T min value and set the temperature limit using the

numeric key-pad: then, move the cursor on the T max value using the key, set

the related temperature value and press ent to confirm. Press ent again to show

the next display, where the error calculation method can be set.

34 K400 Issue No. 1

Page 45

ERROR

ABSOLUTE

% OF SPAN

% OF RDG

Using the keys, select the required method and press ent.

• Absolute

The display shows the error calculation as deviation in temperature measurement

units between the reference temperature (internal or external) and the unit under

test measurement.

•% of Span

This selection gives an error calculation referenced to the full-scale value.

Pt-100

RDG: °C

148.50

0,15% SPAN

150.00 DIRECT

BLK

°C

148.00

The screen shows, in the top part, the selected RTD type, the probe measure

directly in the selected temperature unit and the error value.

The bottom part of the screen shows, the generated temperature value (with

internal or external reference), the temperature set-point, the status arrows symbols

and the selected generation mode.

K400 Issue No. 1 35

Page 46

• % of Reading

This selection gives an error calculation referenced to a previously set, specific

measuring point of the temperature span.

Pt-100

RDG: °C

148.50

0,15% RDG

150.00 DIRECT

BLK

°C

The screen shows, in the top part, the selected RTD type, the probe measure

directly in the selected temperature unit and the error value.

The bottom part of the screen shows, the generated temperature value (with

internal or external reference), the temperature set-point, the status arrows symbols

and the selected generation mode.

148.00

36 K400 Issue No. 1

Page 47

Current Measurements

The DBC-TC series has an input section for direct measurement of mA signal, for

example, from a DIN temperature transmitter, directly fitted on the probe under test.

REF T.

INTERNAL

SEL RTD

MEASURE

NONE

T/C

RTD

mA

From the Menu Selection Screen, select mA using the and press ent. After

selection of the required generation mode (DIRECT, PRESET, STEP, RAMP), the

measure MODE display will be immediately recalled, allowing solution of how the

mA measurement must be carried out.

MODE

DIRECT

CAL

•Direct

Use the keys and pressing ent, changes the display to the working screen.

The top part of the working screen shows the mA electrical signal from the device

under test (i.e. a temperature transmitter) and the bottom part, the usual generated

temperature parameters.

mA

RDG: mA

20.00

150.00 DIRECT

BLK

°C

K400 Issue No. 1 37

148.00

Page 48

• CAL

Use the keys and pressing ent, changes the display. The new display allows

the setting of a temperature range to the specific mA output of the device under test.

SET SPAN

T min : 50.00 °C

T max : 200.00 °C

Min : 4. 000 mA

Max : 20.000 mA

Using the keys to move the cursor through this display and, using the numeric

key-pad, set a low temperature limit (T min) corresponding to a low input current

limit (Min) and a high temperature limit (T max) corresponding to the high input

current limit (Max) and press ent to confirm the selection and to go to the next

display where the error calculation method can be set, as previously described.

Selecting ABSOLUTE, the final working screen shows, in the top part, the mA

signal from the unit under test, scaled into the selected temperature unit with the

error indication reported as deviation in temperature.

Selecting % OF SPAN or % OF RDG the display shows the error as a percentage

value of full-scale or as a percentage value of specific reading point.

CAL mA

RDG:

148.50 °C

0,15% SPAN

150.00 DIRECT

BLK

38 K400 Issue No. 1

148.00

°C

Page 49

Voltage Measurements (high level)

The DBC-TC series can measure a voltage signal from temperature transmitters

under test.

REF T.

INTERNAL

SEL RTD

MEASURE

mV

Ohm

V

From the Menu Selection Screen, select V in the MEASURE section using the

keys and press ent. After selection of the temperature generation mode to be used,

the next display allows set-up of the voltage measurement method.

MODE

DIRECT

CAL

•Direct

Use the keys and pressing ent, changes the display to the working screen.

The top part of the working screen shows the voltage signal from the unit under test

in the top part and the parameters of the generated temperature in the bottom part.

VOLT

RDG: V

10.00

150.00 DIRECT

BLK

°C

K400 Issue No. 1 39

148.00

Page 50

• CAL

Use the keys and pressing ent, changes the display. The new display allows

the setting of a temperature range to the specific voltage output of the device under

test.

SET SPAN

T min : 50.00 °C

T max : 200.00 °C

Min : 0 V

Max : 10.000 V

Using the keys, move the cursor through this display and set the values with

the numeric key-pad: T min value is the low limit for the UUT temperature range,

related to its low limit output voltage, T max is the full-scale for the UUT temperature

range, related to the high limit of its output voltage. Press ent to confirm and to go

to the next display, where the error calculation mode can be set.

ERROR

ABSOLUTE

% OF SPAN

% OF RDG

Using the keys, select ABSOLUTE and press ent: the final working screen

shows the generated temperature parameters in the bottom part of the display, and

the voltage measurement scaled into the selected temperature unit in the top part.

The error (deviation) calculation is shown with small digit between the two sections

of the display and with a temperature unit value.

If in the ERROR screen, using the keys, the % OF SPAN or % OF RDG

functions are selected, pressing the ent key, the final working screen shows the

error calculation as a percentage deviation related to the full-scale of the device

under test temperature range or to its specific measuring point.

CAL VOLT

RDG:

148.50 °C

0,15% SPAN

150.00 DIRECT

BLK

40 K400 Issue No. 1

148.00

°C

Page 51

Voltage Measurements (low level)

The DBC-TC series can measure the low level signal from a thermocouple device

under test: using this capability, the operator can make a direct verification of the

electrical behaviour for the T/C under test.

REF T.

INTERNAL

SEL RTD

MEASURE

mV

Ohm

V

From the Menu Selection Screen, select mV using the keys and press ent.

After the usual selection of the temperature generation mode to be used (Direct,

Ramp, Preset or Step), the final working screen will be immediately recalled

showing the generated temperature parameters in the bottom part of the display

and the measured millivolt value in the top part of it.

mV

RDG: mV

80.00

150.00 DIRECT

BLK

°C

148.00

K400 Issue No. 1 41

Page 52

Resistance Measurement

The DBC-TC series can directly measure the resistance value of an RTD under test.

REF T.

INTERNAL

SEL RTD

MEASURE

mV

Ohm

V

From the Menu Selection Screen, select Ohm in the MEASURE section using the

keys and press ent. After selection of the temperature generation mode,

the next display sets the connected RTD as a 3 or 4 wire device.

RTD

3 WIRES

4 WIRES

Using the select the required connection and press ent. The final working

screen shows the generated temperature in the lower part of the display and the

measured Ohmic value in the top part.

Ohm

RDG:

138.50

Ω

150.00 DIRECT

BLK

°C

42 K400 Issue No. 1

100.00

Page 53

4 SERIAL COMMUNICATION

Using the standard digital RS232 interface, the calibrator can be controlled from a

remote computer. By sending commands via the RS232 interface, the calibrator

automatically retrieves temperature readings or modifies any parameter settings

(temperature set-point, temperature reference selection, ramp/step/preset

generation etc.).

4.1 DBC Series - Serial Commands Protocol

ABBREVIATIONS:

aa:

par:

R/W:

R:

n.a.:

[ ]:

Two digit DBC address in ASCII format. (i.e.. 01).

Send 00 to overwrite every other address.

Parameter. Command depending format.

Read and Write command

Read Only command

Not Applicable

Every parameter enclosed in square bracket are optional

Command

Flow

Write

Read

Query

Write

Read

Query

Write

Read

Query

Command Parameters Description

*aaEM=par

*aaEM?

!aaEM=par

n.a.

*aaER?

!aaER=par

*aaICc=par

*aaICc?

!aaICc=par

Par = 0 Absolute error °C

1% of span

2% of readings

Par = floating point R – Get Error Value

c =1 Regulator (optional)

2 Measure

par = 0 NONE

1 n.a.

2 T/C +CJ

3 T/C no CJ

4 RTD 3 Wires

5 RTD 4 Wires

6 RES 3 Wires

7 RES 4 Wires

8 mV

9 n.a.

10 n.a.

11 n.a.

12 mA

13 n.a.

14 Switch

15 n.a.

16 n.a.

17 Reference RTD 4 wires

18 V

R/W - Error Computation Mode

(MM command to set CAL mode)TCTC

(Mode selected by EM command)

R/W –Input Channel

No measure

Thermocouple + Cold Junction

Thermocouple without Cold Junct.

Thermoresistors 3 wires

Thermoresistors 4 wires

Resistors up to 400 Ω 3 wires

Resistors up to 400 Ω 4 wires

mV input

mA input

Switch mode

User Thermoresistors 4 wires

Volt Input

Model

(TS/TC)

TC

TC

TS

TC

TS

TC

TC

TS/TC

TS/TC

TC

TC

TC

TC

TS/TC

TS/TC

TS/TC

TC

K400 Issue No. 1 43

Page 54

Command

Flow

Write

Read

Query

Write

Read

Query

Write

Read

Query

Write

Read

Query

Write

Read

Query

Command Parameters Description

n.a.

*aaIRc?

!aaIRc= par

*aaISc=par

*aaISc?

!aaISc=par

*aaCJ[1]=par

*aaCJ[1]?

!aaCJ[1]=par

*aaIUc=par

*aaIUc ?

!aaIUc=par

*aaKB[1]=par

*aaKB[1]?

!aaKB[1]=par

c = 1 Reference RTD

2 Measure

par = floating point value

c = 1 Reference RTD

2 Measure

par = 0 NONE

10 PT100 IEC

11 PT200 IEC

12 PT500 IEC

13 PT1000 IEC

16 Ni100 DIN

19 Reference RTD

20 T/C B IEC

21 T/C E IEC

22 T/C J IEC

23 T/C K IEC

24 T/C N IEC

25 T/C R IEC

26 T/C S IEC

27 T/C T IEC

28 T/C U DIN

29 T/C L DIN

30 T/C C

par = Floating Point R/W –Manual Cold Junction Value

c = 1 Reference RTD

2 Measure

par =98 NONE

80 °F

81 °C

82 °K

60 mA

61 V

62 mV

63 Ω

par = 0 silent keyboard

1 beep on

R – Get Input Measure value TS/TC

R/W –Sensor type

No sensor

(Value in current Temperature Units)

R/W –Input Units

Unit n.a

Fahrenheit

Celsius

Kelvin

Milliampere

Volts

Millivolts

Ohms

R/W –Keyboard bid TS/ TC

Model

(TS/ TC)

TC

TS/ TC

TC

TS/TC

TS/TC

TC

TC

TC

TC

TC

TC

TC

TC

TC

TC

TC

TC

TC

TC

TC

TC

TC

TS/ TC

TC

TS/ TC

TS/ TC

TS/ TC

TS/ TC

TC

TC

TC

TC

TC

44 K400 Issue No. 1

Page 55

Command

Flow

Write

Read

Query

Write

Read

Query

Write

Read

Query

Write

Read

Query

Write

Read

Query

Write

Read

Query

Write

Read

Query

Write

Read

Query

Write

Read

Query

Write

Read

Query

Command Parameters Description

*aaKM[ 1]= par

*aaKM[ 1]?

!aaKM[ 1]= par

*aaMRc= par

*aaMRc?

!aaMRc= par

*aaMM= par

*aaMM?

!aaMM= par

*aaOM[ 1]= par

*aaOM[ 1]?

!aaOM[ 1]= par

*aaOP[ 1]= par

*aaOP[ 1]?

!aaOP[ 1]= par

n. a.

*aaOR[ 1]?

!aaOR[ 1]= par

*aaPB[ 1]= par

*aaPB[ 1]?

!aaPB[ 1]= par

*aaPSc= par

*aaPSc?

!aaPSc= par

*aaRIc?

!aaRIc= par

*aaRM[ 1]= par

*aaRM[ 1]?

!aaRM[ 1]= par

par = 0 keys disabled

1 keys enabled

c = 1 zero scale

2 full-scale

par = floating point value

par = 0 Direct mode

1 Cal mode

par = 0 Direct mode

1 Preset mode

2 Steps mode

3 Ramp mode

par = floating point value R/ W – Point Temperature TS/TC

par = 0 to 99.9

floating point value

par = floating point value

c = 1 preset step #1

2 preset step #2

3 preset step #3

4 preset step #4

5 preset step #5

c = 1 Model

2 Software Version

par = 0 Ramp Down

1 Ramp Up

2 Down Hold

3 Up Hold

R/ W – Local lockout keyboard TS/TC

R/ W – Measure Range

(mA or V in CAL ERROR mode)

R/ W – Measurement mode TC

R/ W – Output mode TS/TC

R – Read Controlled Temperature TS/TC

R/ W – Proportional band TS/TC

R/ W – Preset Set Values TS/TC

R – Read Model and Software Version.

R/ W – Ramp mode TS/TC

Model

(TS/TC)

TC

TC

TC

TS/TC

TS/TC

TS/TC

TS/TC

TS/TC

TS/TC

TS TC

TS/TC

K400 Issue No. 1 45

Page 56

Command

Flow

Write

Read

Query

Write

Read

Query

Write

Read

Query

Write

Read

Query

Write

Read

Query

Write

Read

Query

Write

Read

Query

Write

Read

Query

Write

Read

Query

Write

Read

Query

Write

Read

Query

Command Parameters Description

*aaRRc= par

*aaRRc?

!aaRRc= par

*aaRS[ 1]= par

*aaRS[ 1]?

!aaRS[ 1]= par

*aaSA[ 1]= par

*aaSA[ 1]?

!aaSA[ 1]= par

*aaSL[ 1]= par

*aaSL[ 1]?

!aaSL[ 1]= par

n.a.

*aaSN[ 1]?

!aaSN[ 1]= par

*aaSP[ 1]= par

*aaSP[ 1]?

!aaSP[ 1]= par

*aaSWc= par

*aaSWc?

!aaSWc= par

*aaTD[ 1]= par

*aaTD[ 1]?

!aaTD[ 1]= par

*aaTI[ 1]= par

*aaTI[ 1]?

!aaTI[ 1]= par

*aaTU[ 1]= par

*aaTU[ 1]?

!aaTU[ 1]= par

*aaTRc= par

*aaTRc? !aaTRc= par

par = floating point

c = 1 zero scale

2 full-scale

par r = floating point R/W – Ramp Slope TS/TC

par = 1 to 99 R/W – Station Address TS/TC

par = 0 ENGLISH

1 FRENCH

2 GERMAN

3 ITALIAN

4 PORTUGUESE

5 SPANISH

par = 1 to 65535

par = 1 to 5 - # of step R/W – Number of preset step TS/TC

par = floating point

c = 1 – Opened

2 – Closed

3 - Hysteresis

par = 1 to 255 R/W – Derivative constant TS/TC

par = 1 to 255 R/W – Integration constant TS/TC

par = 80 °F

81 °C

82 °K

par = floating point value

c = 1 low scale

2 full-scale

R/W – Ramp Range TS/TC

R/W – Language TS/TC

R – Serial Number TS/TC

R – Switch test threshold TS/TC

R/W – Temperature units TS/TC

R/ W – Temperature Range

(CAL ERROR mode)

Model

(TS/TC)

TC

46 K400 Issue No. 1

Page 57

Command

Flow

Write

Read

Query

Write

Read

Query

Write

Read

Query

Write

Read

Query

Write

Read

Query

Write

Read

Query

Write

Read

Query

Command Parameters Description

n. a.

*aa. Ac?

!aa. Ac= par

n. a.

*aa. Mc?

!aa. Mc= par

n. a.

*aa. Pc?

!aa. Pc= par

*aaRN = par

*aaRN?

!aaRN = par

n.a.

*aaST?

!aaST = par

*aaCN = par

*aaCN?

!aaCN = par

*aaURc = par

*aaURc?

!aaURc = par

par = floating point

c = 1 regulator channel

2 n. a.

3 calibrator board

par = Exp. floating point

c = 1 regulator temp.

2 REF Probe temp.

3 calibrator value

par = Exp. floating point

c = 1 reg. Sensor mV out

2 REF sensor mV out

3 Cal. Electrical value.

par = integer

0 = REF 1

1 = REF 2

par = integer

0 = Cooling

1 = Heating

2 = Ready

par = integer

0 = 10%

1 = 30%

2 = 50%

3 = 70%

4 = 90%

5 = 100%

par = floating

c = 1 REF 1

c = 2 REF 2

R – Get cold junctions compensation TS/TC

R – Not averaged measures

(diagnostic purposes)

R – Main measures

(diagnostic purposes)

Reference RTD selection TS/TC

Status of controller TS/TC

Select display contrast TS/TC

Ref probe R0 coefficient TS/TC

Model

(TS/TC)

TS/TC

TS/TC

Write

Read

Query

Write

Read

Query

Write

Read

Query

Write

Read

Query

*aaUAc = par

*aaUAc?

!aaUAc = par

*aaUBc = par

*aaUBc?

!aaUBc = par

*aaUCc = par

*aaUCc?

!aaUCc = par

*aa. Tc

*aa. Tc?

!aa. Tc= par

par = floating

c = 1 REF 1

c = 2 REF 2

par = floating

c = 1 REF 1

c = 2 REF 2

par = floating

c = 1 REF 1

c = 2 REF 2

par = integer

c = 1 REF 1

c = 2 REF 2

Ref probe A coefficient TS/TC

Ref probe B coefficient TS/TC

Ref probe C coefficient TS/TC

Ref probe tag number TS/TC

K400 Issue No. 1 47

Page 58

5CALIBRATION

The DBC series of temperature calibrators must be considered as reference

standard: these instruments must be periodically tested and calibrated with a

recommended recalibration period of 12 months. The Service Centres of GE

provide a global calibration service to National and International standards.

Calibration must be carried out by the suitably qualified calibration technicians. The

calibration procedure requires a high-accuracy reference standard (at least 5 times

better than the DBC accuracy) with direct traceability to National or International

Standard (SIT, UKAS etc.).

Press the # and the menu keys to select the set-up display.

SYSTEM SETUP

CALIBRATION

ENTER CODE

ENTER CODE

Use the keys to select CALIBRATION and press ent.

Important Note

A PIN code protects the calibration facility from unauthorised use. Each instrument,

on delivery, contains the factory set PIN (4321). To continue protecting the

calibration facility, the PIN code should be changed as soon as possible.

Enter the correct PIN at the ENTER CODE prompt and press ent. After entering

the PIN number, calibrate the instrument by following the on-screen instructions.

CALIBRATION

REF. RTD INPUT

REF. RTD

CALIBRATION

BLOCK

mV (1)

mV (2)

• Calibration of the standard Reference Probe Input

In the calibration menu, using the cursor keys select the REF. RTD INPUT and

press ent. The display enables the setting of the resistance test value (true value).

48 K400 Issue No. 1

Page 59

Using a decade resistance box, generate the required value (to the Ref. Probe

connection on the electrical panel) and press ent. The microprocessor combines

the two values automatically. The nominal value is the value recommended for the

test.

REF. RTD INPUT

Nominal value:

Ω

300

True value: 300.00

Reading: 298.50

Press ENT or CE ...

• Calibration of the external Reference Probe (DBC-TS and DBC-TC)

By selecting the REF RTD from the calibration menu and pressing ent, a new

display opens to set all the parameters needed for the connected Reference RTD

(Tag number, R0 values, coefficients).

REF RTD

Tag :

R0: 100.00

A: 3.9080e-03

B: -5.8020e-07

C: -4.1830e-12

Ω

Move the cursor with the keys and set the value with the numeric key-pad. In

this way, a characterisation of the specific Reference Probe can be made. Press

ent to return to the calibration menu.

• Calibration of the internal dry well Sensor (DBC-TS and DBC-TC)

Note: Starting this procedure after at least 1 hour of warm-up, achieves a better

accuracy.

CALIBRATION

SET 1: 50.00

REF 1: 50.00

SET 2: 300.00

REF 2: 300.00

SET 3: 400.00

K400 Issue No. 1 49

Page 60

1 To calibrate the dry well regulation, install a suitable reference probe in the

dry well and connect it to the Reference Probe socket in the front panel.

2 Follow the above procedure to insert the coefficients of the probe in use.

3 Change from INTERNAL to SEL RTD, Direct mode. The display shows the

temperature measured by the Reference Probe.

4 Select the CALIBRATION menu and use the PIN to enter the menu. Record

the values of SET1 ...SET4, and REF1 ... REF4.

5 Set the dry well temperature at SET1 value; wait at least 30 minutes at this

temperature. Record the true temperature value on display, identify this

value as READ1.

6 Set the dry well temperature at SET2 value; wait at least 30 minutes at this

temperature. Record the true temperature value on display, identify this

value as READ2. Repeat this procedure for SET3 and SET4 and record

values READ3 and READ4.

7 Enter the Calibration menu, select dry well CALIBRATION.

8 Calculate the NEWREF1 ... NEWREF4 value as follow: NEWREFx= READx-

SETx+REFx.

9 Type in REF1 ...REF4 fields the values NEWREF1 ...NEWREF4.

10 Press ENTER. DBC650 (150) automatically calculates the coefficients.

11 The calibration of the dry well temperature regulator has been completed.

• Calibration of the millivolt input ranges (DBC-TC only)

The DBC-TC series has four different millivolt input ranges to be calibrated,

depending on the type of thermocouple measurements available, the calibration

procedure is the same.

CALIBRATION

REF. RTD INPUT

REF. RTD

CALIBRATION

BLOCK

mV (1)

mV (2)

From the CALIBRATION menu select one of the mV input range to be calibrated

using the and press ent.

50 K400 Issue No. 1

Page 61

mV (1)

Using a certified and high accuracy millivolt simulator, generate a millivolt signal to

the T/C electrical connection on the front panel (nominal value is the recommended

value for the calibration): pressing the ent key causes the microprocessor to

combine the millivolt values (true value and effective reading).

• Calibration of the Volt input range (DBC-TC only)

From the CALIBRATION display, select V INPUT using the keys and press

ent.

V INPUT

Using a certified and high accuracy Volt simulator, apply the calibration signal to the

Voltage electrical connection on the front panel of the instrument (the nominal value

is the recommended value for the test).

Pressing the ent key causes the microprocessor to combine the voltages indication

(True value and Reading).

• Calibration of the mA input range (DBC-TC only)

From the CALIBRATION display, select mA INPUT using the keys and press

ent.

mA INPUT

Using a traceable and high accuracy mA simulator, generate a specific current

value to the related electrical connection on the front panel of the instrument (the

K400 Issue No. 1 51

Page 62

Nominal Value is the recommended value for the test): pressing the ent key causes