Page 1

GE

Measurement & Control

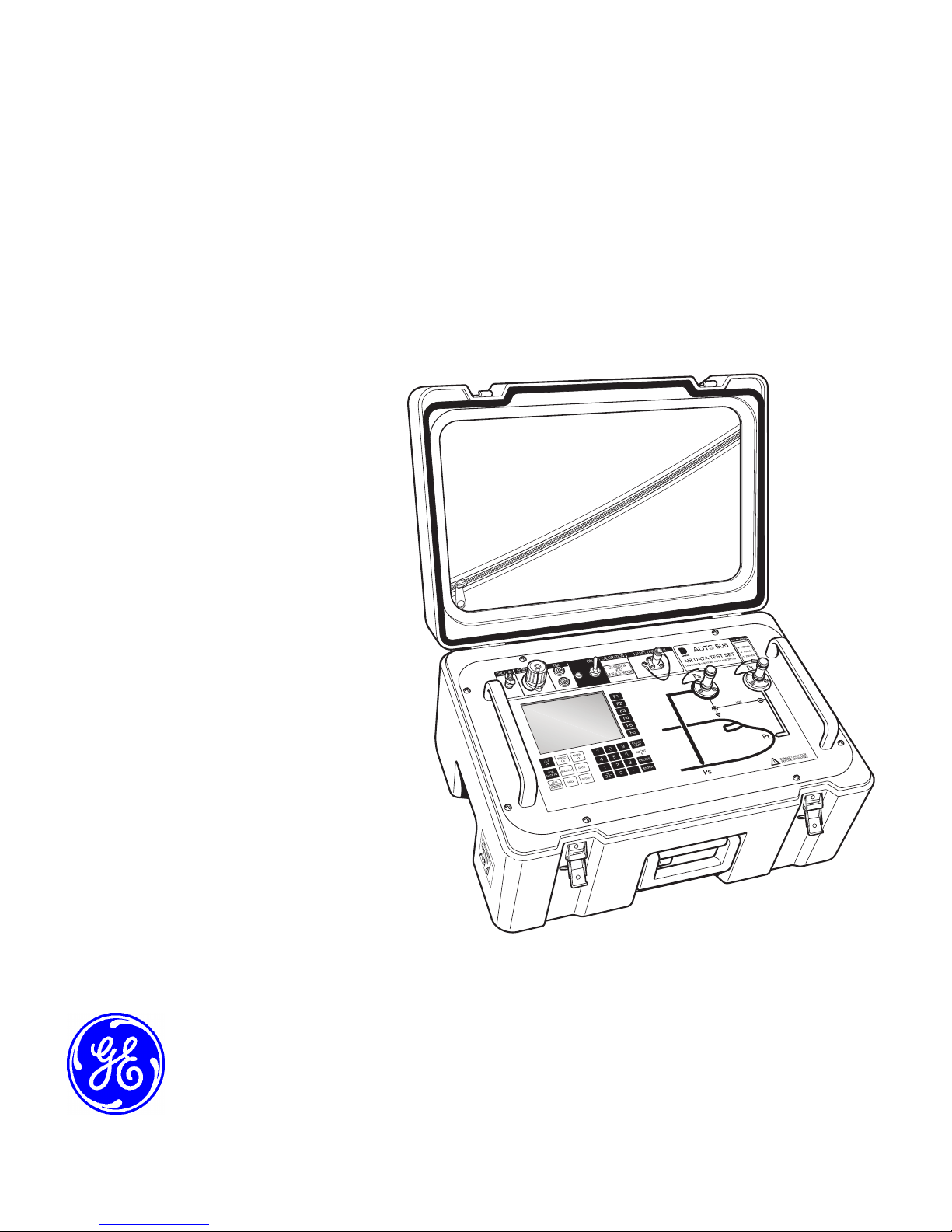

Druck ADTS 505 Air Data Test Set

User Manual K0260

Page 2

© 2013 General Electric Company. All Rights Reserved. Specifications are subject to change without notice. GE is a

registered trademark of General Electric Company. Other company or product names mentioned in this document may

be trademarks or registered trademarks of their respective companies, which are not affiliated with GE.

Page 3

i

K0260 Issue No. 8

Introduction

This technical manual provides operating instructions for the Air Data Test System compatible

with the requirements of first line operation for the technician and supervisor.

Scope

This technical manual contains a brief description, operation and testing procedures for the

user of this equipment with software version V1.08.

Safety

The manufacturer has designed this equipment to be safe when operated using the

procedures detailed in this manual. Do not use this equipment for any other purpose than that

stated, the protection provided by the equipment may be impaired.

This publication contains operating and safety instructions that must be followed to make sure

of safe operation and to maintain the equipment in a safe condition. The safety instructions are

either warnings or cautions issued to protect the user and the equipment from injury or

damage.

Use qualified* technicians and good engineering practice for all procedures in this publication.

PIN Protection

The ADTS 505 contains two protected menus, the operating limits (described in this manual)

and the maintain calibration menu (described in the calibration manual).

The factory set PIN codes are contained in an envelope addressed to the Supervisor.

IMPORTANT NOTE

Change these codes for authorised access. Unauthorised access to these two menus can make

this system inaccurate and could, in control mode, cause excessive rates of pressure change.

Pressure

Do not apply pressure greater than the maximum safe working pressure to the equipment.

Toxic Materials

There are no known toxic materials used in this equipment.

Maintenance

The equipment must be maintained using the manufacturer’s procedures and should be

carried out by authorized service agents or the manufacturer’s service departments

Technical Advice

For technical advice contact the manufacturer or subsidiary.

* A qualified technician must have the necessary technical knowledge, documentation, special test

equipment and tools to carry out the required work on this equipment.

Page 4

ii

K0260 Issue No. 8

Associated Publications

This lists the manuals and publications referenced in this manual.

Calibration Manual K272

Air Data Test Set ADTS 505

Quick Reference Guide K274

Air Data Test Set ADTS 505

Approved Service Agents

Markings and Symbols

This equipment meets the requirements of all relevant European safety directives. The

equipment carries the CE mark.

This symbol, on the instrument, indicates that the user should refer to the user manual. This

symbol, in this manual, indicates a hazardous operation.

Do not dispose of this product as household waste. Use an approved organisation that

collects and/or recycles waste electrical and electronic equipment. For more information,

contact one of these:

• our customer service department (contact us at www.ge-mcs.com)

• your local government office

Approved Service Agents

For a list of approved service agents, visit our website: www.ge-mcs.com

Internet www.ge-mcs.com

Druck ADTS 505 User Manual

Page 5

iii

K0260 Issue No. 8

Table of Contents

Preliminary pages

Introduction .................................................................................................................................................................................. ............... i

Scope .................................................................................................................................................................................. ............... i

Associated Publication................................................................................................................................................................... ............... ii

Approved Service Agents.............................................................................................................................................................. ............... ii

Table of contents (this table)....................................................................................................................................................... ............... iii

Abbreviations .................................................................................................................................................................................. ............... vii

Glossary .................................................................................................................................................................................. ............... ix

Pressure units and conversion factors................................................................................................................................. ...............xi

Section Title page

1 DESCRIPTION

1.1 Introduction......................................................................................................................................................... ............... 1-1

1.2 Operating Limits............................................................................................................................................... ............... 1-3

2INSTALLATION

2.1 Packaging ........................................................................................................................................................... ...............2-1

2.2 Packaging for Storage and Transportation....................................................................................... ............... 2-1

2.3 Return Goods Procedure............................................................................................................................. ............... 2-3

2.4 Electrical Connection..................................................................................................................................... ............... 2-6

2.5 Pneumatic Pressure Connection............................................................................................................. ............... 2-7

2.6 Positioning of the ADTS 505....................................................................................................................... ...............2-8

3OPERATION

3.1 Preparation.......................................................................................................................................................... ............... 3-1

3.2 Display Functions and Units of Measure............................................................................................. ............... 3-2

3.3 Quick Reference............................................................................................................................................... ............... 3-3

3.4 First Time Operators....................................................................................................................................... ............... 3-4

3.4.1..... Operating Modes............................................................................................................................ ............... 3-6

3.5 Operation and Example Procedures..................................................................................................... ............... 3-10

3.5.1..... Operating Procedures.................................................................................................................. ............... 3-10

3.5.2..... Power-up............................................................................................................................................. ............... 3-10

3.5.3..... Control or Measure Parameter................................................................................................ ............... 3-11

3.5.4..... Leak Testing the ADTS 505......................................................................................................... ...............3-11

3.5.5..... Changing the Units of Measurement.................................................................................... ............... 3-13

3.5.6..... Setting Limits..................................................................................................................................... ............... 3-13

3.6 Tests Before Use.............................................................................................................................................. ............... 3-15

3.6.1..... Aircraft System Protection......................................................................................................... ...............3-15

3.7 Testing Aircraft Systems or UUT.............................................................................................................. ............... 3-15

3.7.1..... Testing the Aircraft Static System........................................................................................... ............... 3-16

3.7.2..... Testing the Aircraft Pitot System............................................................................................. ............... 3-17

3.7.3..... Combined Testing of the Aircraft Pitot and Static Systems........................................ ............... 3-18

3.7.4..... Mach Test and Constant Mach................................................................................................ ...............3-19

3.7.5..... Leak Testing....................................................................................................................................... ............... 3-20

3.7.6..... Airspeed Switch Test..................................................................................................................... ............... 3-21

3.7.7..... Engine Pressure Ratio (EPR)....................................................................................................... ............... 3-22

3.7.8..... Go To Ground.................................................................................................................................... ............... 3-23

CONTENTS

Page 6

iv

K0260 Issue No. 8

Table of Contents (contd)

Section Title page

3.8 Manual Venting of the Aircraft Pitot and Static Systems............................................................. ............... 3-24

3.9 ADTS 505 Options............................................................................................................................................ ...............3-24

3.10 Set-up Reference............................................................................................................................................. ...............3-25

4MAINTENANCE

4.1 Introduction......................................................................................................................................................... ............... 4-1

4.2 Materials and Tools......................................................................................................................................... ............... 4-2

4.3 Maintenance Tasks......................................................................................................................................... ...............4-3

4.4 Routine Maintenance..................................................................................................................................... ............... 4-4

5 TESTING AND FAULT FINDING

5.1 Introduction......................................................................................................................................................... ............... 5-1

5.2 Standard Serviceability Test...................................................................................................................... ............... 5-2

5.3 Fault Diagnosis................................................................................................................................................. ............... 5-3

5.4 Warnings and Self-test Errors.................................................................................................................. ............... 5-3

5.5 Further Testing.................................................................................................................................................. ...............5-6

5.6 Fault Finding....................................................................................................................................................... ............... 5-14

6 REFERENCE and SPECIFICATION

6.1 Introduction......................................................................................................................................................... ............... 6-1

6.2 Key-pad Selections and Functions......................................................................................................... ............... 6-1

F1 - F6................................................................................................................................................................... ............... 6-1

ALT/Ps................................................................................................................................................................... ............... 6-2

SPEED Qc.............................................................................................................................................................. ............... 6-2

MACH..................................................................................................................................................................... ............... 6-3

ROC Ps RATE........................................................................................................................................................ ............... 6-3

RATE....................................................................................................................................................................... ............... 6-4

LEAK MEASURE/CONTROL.......................................................................................................................... ............... 6-5

GROUND................................................................................................................................................................ ............... 6-5

0 to 9...................................................................................................................................................................... ............... 6-6

-000........................................................................................................................................................................ ............... 6-6

CLEAR/QUIT......................................................................................................................................................... ............... 6-6

DELETE................................................................................................................................................................... ............... 6-6

HELP....................................................................................................................................................................... ............... 6-7

ENTER.................................................................................................................................................................... ............... 6-7

CLEAR/QUIT + ENTER (ABORT)................................................................................................................... ............... 6-7

Main Menu........................................................................................................................................................... ............... 6-8

[Rate Timer]......................................................................................................................................................... ............... 6-8

[Units].................................................................................................................................................................... ............... 6-9

[EPR]....................................................................................................................................................................... ............... 6-10

[Hold]..................................................................................................................................................................... ............... 6-10

Nudge [ or ]............................................................................................................................................... ............... 6-10

6.3 SETUP .................................................................................................................................................................... ............... 6-11

6.3.1..... Set-up 1 of 2....................................................................................................................................... ............... 6-11

...............[Display],[Single, Dual, Quad, Hand Term]........................................................................... ............... 6-11

Druck ADTS 505 User Manual

Page 7

v

K0260 Issue No. 8

Table of Contents (contd)

Section Title page

[Units].................................................................................................................................................................... ............... 6-12

[Limits]................................................................................................................................................................... ............... 6-13

[Alt. Corr.].............................................................................................................................................................. ............... 6-15

[Date Format]..................................................................................................................................................... ...............6-16

6.3.2..... Set-up 2 of 2....................................................................................................................................... ............... 6-17

...............[Operational Hours]....................................................................................................................... ............... 6-17

...............[Software Versions]........................................................................................................................ ............... 6-17

...............[Security].............................................................................................................................................. ...............6-17

...............[Maintain Calibration]................................................................................................................... ............... 6-17

...............[Auto Leak].......................................................................................................................................... ...............6-18

6.4 Other Features................................................................................................................................................... ............... 6-19

Elapsed Time Counter.................................................................................................................................... ............... 6-19

...............Auto Zero............................................................................................................................................. ............... 6-19

...............Hand Terminal Option A.............................................................................................................. ............... 6-19

...............Hand Terminal Option B.............................................................................................................. ............... 6-19

............... ...............Template Format for Creating Test Sequence Files....................................... ............... 6-32

............... ...............Option B Advanced Hand Terminal Specification........................................... ...............6-41

6.5 Specification........................................................................................................................................................ ............... 6-42

CONTENTS

Page 8

vi

K0260 Issue No. 8

Table of Illustrations

Figure Title page

1-1 ADTS 505 General View............................................................................................................................... ............... 1-2

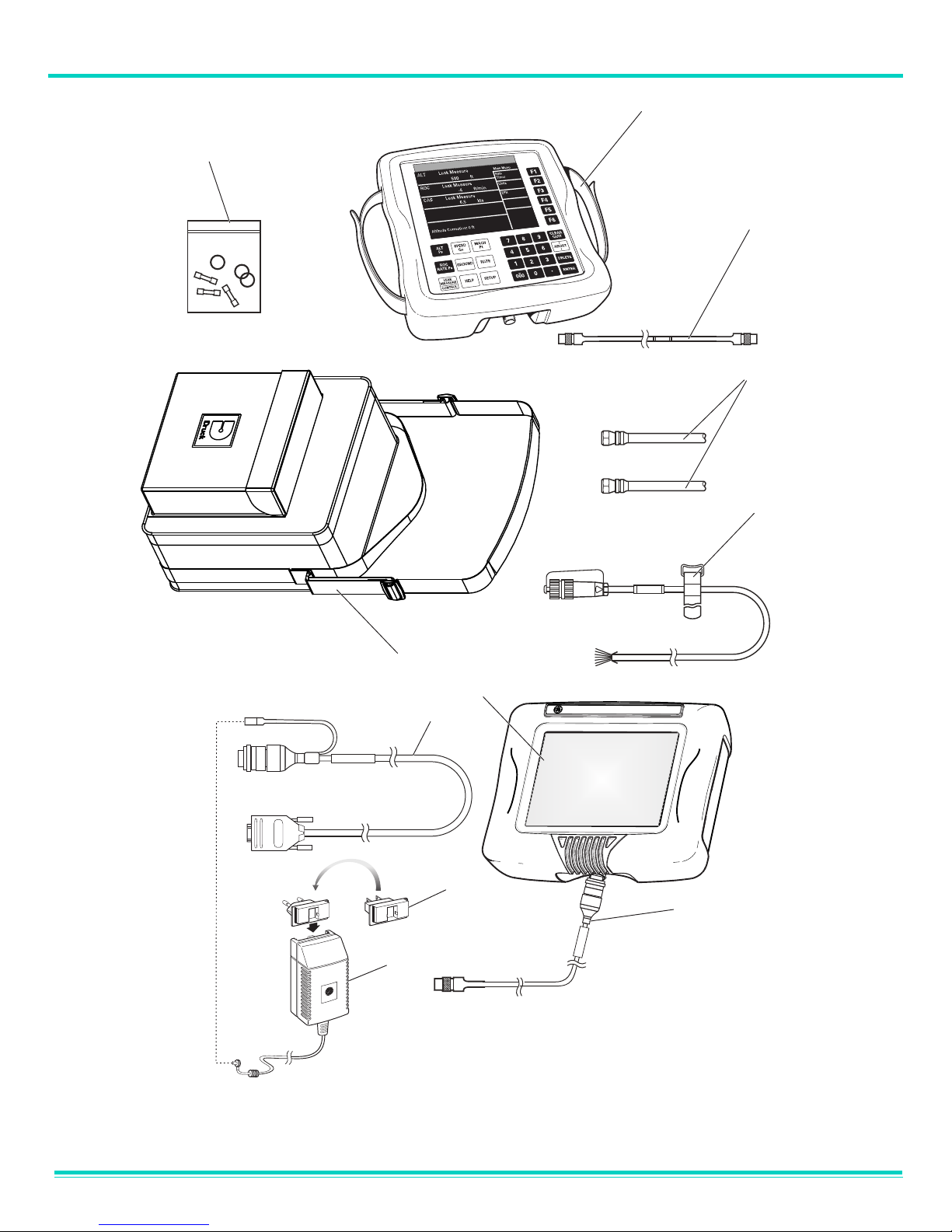

2-1 ADTS 505 Accessories................................................................................................................................... ............... 2-4

2-2 ADTS 505 Altitude Correction On-aircraft........................................................................................... ...............2-9

2-3 ADTS 505 Altitude Correction Off-aircraft........................................................................................... ............... 2-9

2-4 ADTS 505 General View............................................................................................................................... ............... 2-10

3-1 Key-pad and Display...................................................................................................................................... ............... 3-3

4-1 Fuse Replacement........................................................................................................................................... ............... 4-5

5-1 Fault Finding Chart......................................................................................................................................... ............... 5-4

5-2 System Screen for Diagnosis.................................................................................................................... ............... 5-7

5-3 System Screen................................................................................................................................................... ............... 5-9

5-4 Key-pad Test Display..................................................................................................................................... ............... 5-10

6-1 ARINC 565 Limits Graph.............................................................................................................................. ............... 6-14

6-2 Altitude Correction On-aircraft................................................................................................................ ............... 6-15

6-3 Altitude Correction Off-aircraft................................................................................................................ ............... 6-16

6-4 Interconnection................................................................................................................................................ ............... 6-20

6-5 Power-up Displays.......................................................................................................................................... ............... 6-21

6-6 Main Menu Screen.......................................................................................................................................... ...............6-22

6-7 Main Menu Structure..................................................................................................................................... ............... 6-23

6-8 Manual Control Selections......................................................................................................................... ............... 6-24

6-9 Set-up Menu Selections............................................................................................................................... ............... 6-27

6-10 Test Sequence Selections........................................................................................................................... ............... 6-30

6-11 Customer Test Sequence File Selections............................................................................................. ............... 6-31

6-12 System Status..................................................................................................................................................... ............... 6-38

6-13 Example Error Screen.................................................................................................................................... ............... 6-39

List of Tables

Table Title page

2-1 Parts List............................................................................................................................................................... ............... 2-5

4-1 Maintenance Chart......................................................................................................................................... ............... 4-1

4-2 Materials List....................................................................................................................................................... ............... 4-2

4-3 Tool and Test Equipment Requirements.............................................................................................. ............... 4-2

5-1 Fault Finding ...................................................................................................................................................... ............... 5-5

5-2 System Screen Information....................................................................................................................... ............... 5-8

5-3 Error Messages................................................................................................................................................. ...............5-14

5-4 Warning Messages......................................................................................................................................... ............... 5-15

Druck ADTS 505 User Manual

Page 9

vii

K0260 Issue No. 8

Abbreviations

The following abbreviations are used in this manual; the abbreviations are the same in the singular and plural.

AAmpere

abs Absolute

a.c. Alternating current

ADTS Air Data Test Set

ALT Altitude

ARINC Air Radio Incorporated

ASI Airspeed indicator

CAS Calibrated airspeed

COSHH Control of Substances Hazardous to Health Regulations

cm Centimetre

d.c. Direct current

Def Define

e.g. For example

EPR Engine pressure ratio

etc. And so on

°F Degrees Fahrenheit

Fig. Figure

ft Foot

g Gauge

hHour

HBC High breaking capacity

Hg Mercury

hm Hecto metre

Hz Hertz

IAS Indicated airspeed

i.e. That is

in Inch

kg Kilogram

km Kilometre

kts Knots

LCD Liquid crystal display

mMetre

mA Milliampere

max Maximum

mbar Millibar

min Minute or minimum

mm Millimetre

mph Miles per hour

MSDS Material safety data sheet

mV Millivolts

No. Number

PIN Personal identification number

Ps Static pressure

psi Pounds per square inch

Pt Total pressure (Pitot)

Qc Differential pressure Ps-Pt

QFE Local atmospheric pressure

QNH Barometric pressure at sea level

Abbreviations

Page 10

viii

K0260 Issue No. 8

Abbreviations (contd)

RGA Return Goods Authorization (Druck procedure)

RH Relative humidity

RMS Root mean square

ROC Rate of climb

Rt Rate

SST Standard serviceability test

VVolts

+ve Positive

-ve Negative

°C Degrees Celsius

°F Degrees Fahrenheit

Druck ADTS 505 User Manual

Page 11

ix

K0260 Issue No. 8

Glossary

Terminology

The terminology used in this manual is specific and individual interpretation must not be

introduced. The terms are defined as follows:

Adjust To bring to a more satisfactory state; to manipulate controls, levers, linkages, etc. to return equipment

from an out-of-tolerance condition to an in-tolerance condition.

Align

To bring into line; to line up; to bring into precise adjustment, correct relative position or coincidence.

Assemble

:To fit and secure together the several parts of; to make or form by combining parts.

Calibrate

: To determine accuracy, deviation or variation by special measurement or by comparison with a

standard.

Check:

Make a comparison of a measure of time, pressure, temperature, resistance, dimension or other

quality with a known figure for that measurement.

Disconnect

:To detach the connection between; to separate keyed or matched equipment parts.

Dismantle

:To take apart to the level of the next smaller unit or down to all removable parts.

Examine

: To perform a critical visual observation or check for specific conditions; to test the condition of.

Fit

: Correctly attach one item to another.

Inspect

: Review the work carried out by Specialists to ensure it has been performed satisfactorily.

Install

: To perform operations necessary to properly fit an equipment unit into the next larger assembly or

system.

Maintain

: To hold or keep in any particular state or condition especially in a state of efficiency or validity.

Operate

: Make sure that an item or system functions correctly as far as possible without the use of test

equipment or reference to measurement.

Readjust

: To adjust again; to move back to a specified condition; to bring back to an in-tolerance condition.

Reconnect

:To rejoin or refasten that which has been separated.

Refit

: Fit an item which has previously been removed.

Glossary

Page 12

x

K0260 Issue No. 8

Remove: To perform operations necessary to take an equipment unit out of the next larger assembly or

system. To take off or eliminate. To take or move away.

Repair

: To restore damaged, worn out or malfunctioning equipment to a serviceable, usable or operable

condition.

Replace

: Remove an item and fit a new or a serviced item.

Reset

: To put back into a desired position, adjustment or condition.

Service

: To perform such operations as cleaning, lubricating and replenishing to prepare for use.

Test

: Ascertain by using the appropriate test equipment that a component or system functions correctly.

Druck ADTS 505 User Manual

Page 13

xi

K0260 Issue No. 8

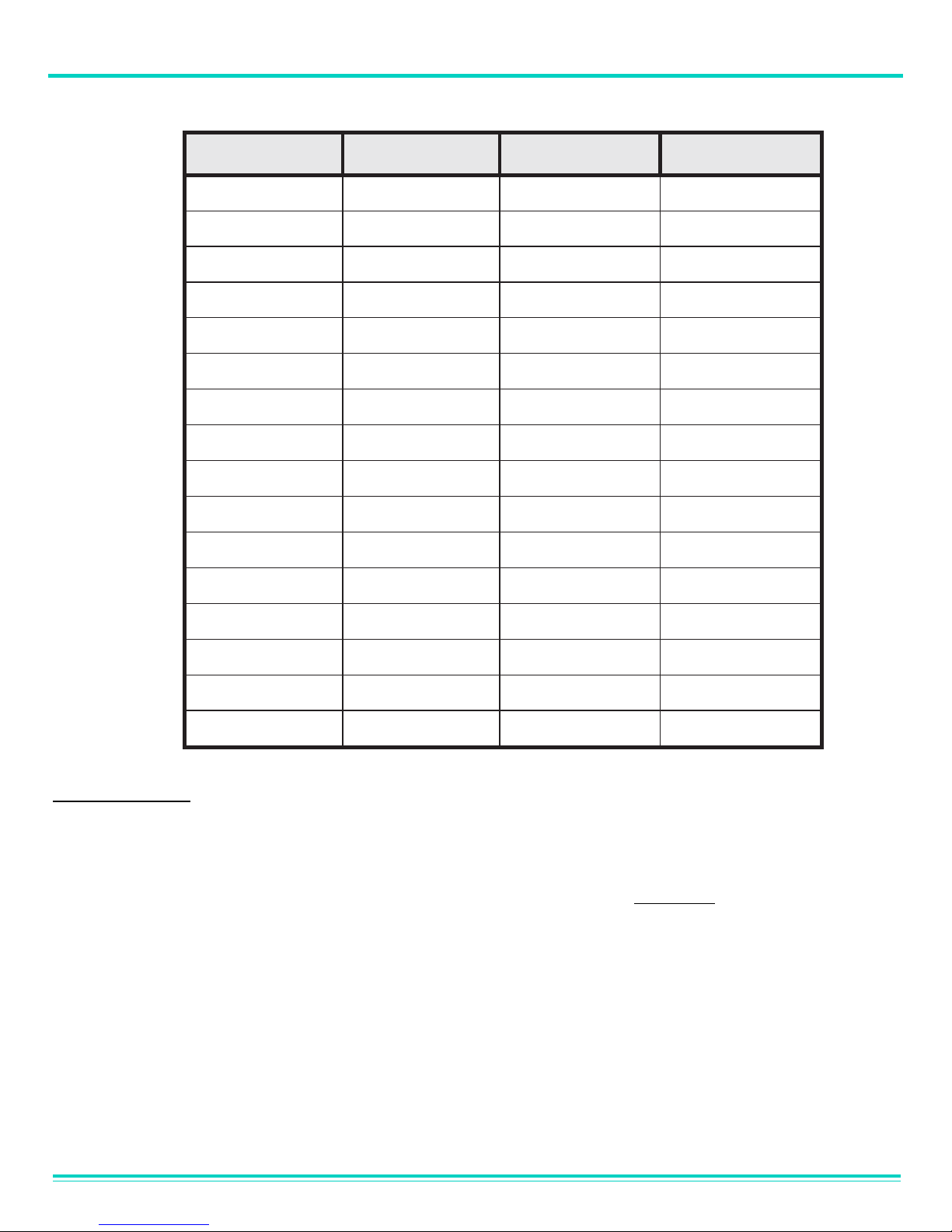

Table of pressure units and conversion factors

Unit Conversion

To convert FROM pressure VALUE 1 in pressure UNITS 1

TO pressure VALUE 2 in pressure UNITS 2, calculate as follows:

VALUE 2 = VALUE 1 x FACTOR 1

FACTOR 2

Note:

The conversion factor for pressure units referenced [1] are calculated for a water temperature

of 4°C. Pressure units referenced [2] are calculated for a water temperature of 68°F these units

are normally used in the USA.

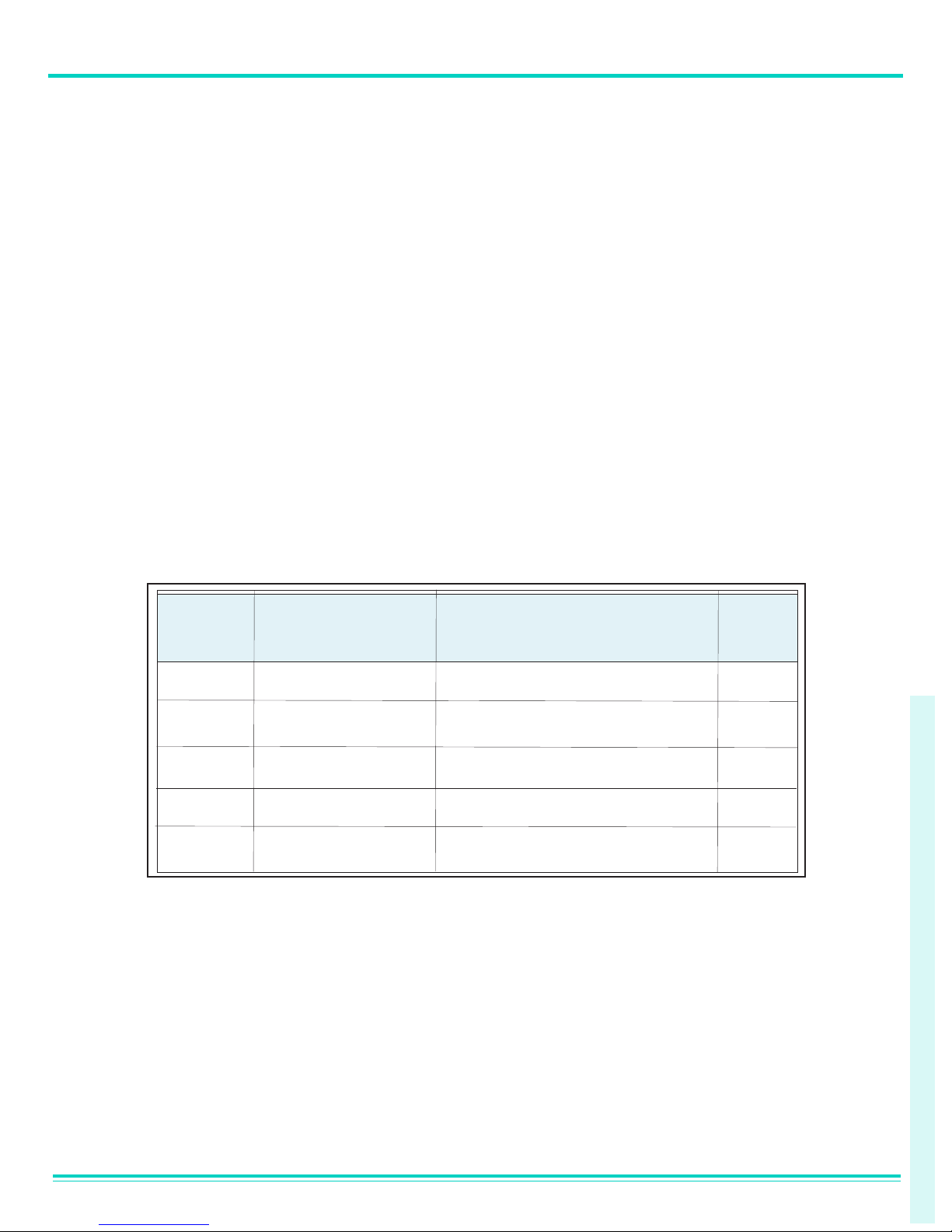

tinuerusserP )slacsaP(rotcaF tinuerusserP )slacsaP(rotcaF

rab000001tf/fbl

2

3088.74

ni/fbl

2

)isp(67.4986gHni93.6833

Hm

2

O56.6089Hni

2

]1[O980.942

rabm001Htf

2

]1[O70.9892

mc/fgk

2

5.66089mta0.523101

m/fgk

2

56608.9tf/ldp

2

61884.1

gHmm223.331mc/nyd

2

1.0

gHmc22.3331rabh00000001

gHm0.223331tf/fnot

2

)KU(0.252701

H/mm

2

]1[O56608.9ni/fnot

2

)KU(00344451

H/mc

2

]1[O5660.89Hni

2

]2[)ASU(O53146.842

m/N

2

1Htf

2

]2[)ASU(O3896.3892

aPh001mm/Pk

2

0566089

aPk0001mc/Pk

2

5.66089

aPM0000001m/Pk

2

56608.9

rrot223.331

Page 14

xii

K0260 Issue No. 8

Druck ADTS 505 User Manual

Page 15

Description 1 - 1

K0260 Issue No. 8

1

1INTRODUCTION

1.1 Introduction

The ADTS 505 is a self-contained flight-line air data test system, enclosed in an ABS case. The

unit provides complete pressure and vacuum measuring and control for on-aircraft sense and

leak testing, functional tests of air data instruments, components and systems.

The ADTS 505 displays and operates in either units of pressure measurement or aeronautical

units. In the control mode, the rate that the pressures change towards new set-points can be

controlled in true aeronautical rate units.

There are two independent pneumatic channels connect to the aircraft or instrument systems,

one for static and one for pitot. They can be operated as measure only channels with leak

testing facilities or each can be control channels producing true pressure conditions for altitude

and airspeed. Two pneumatic outlet ports, on the front panel and identified as Ps (static) and

Pt (pitot) provide connection to the aircraft system or unit under test.

To protect sensitive instruments and equipment a `ground' facility automatically and safely

controls both channels to atmospheric pressure at the previously entered rates of change and

then informs the user when both channels are safely at `ground'.

Pre-defined sets of limits, stored in the system, prevent excessive pressures and rates

damaging aircraft systems and components. A further five sets of operating limits can be

defined by the supervisor or quality assurance engineer. The user can select sets of limits but

cannot change the values.

The user interface is either the key-pad and display on the front panel or one of two types of

optional hand terminal connected to the front panel. The two types of hand terminal are

identified as option A and option B.

The option A hand terminal contains all the facilities of the front panel key-pad and display.

The key-pad contains fixed function keys used to select various parameters, modes and enter

numeric values. The display shows various menus, each menu provides selections using six

menu-defined function keys.

The option B advanced hand terminal is a computer-based device that contains all the facilities

of option A on a touch-sensitive, Windows® display, colour screen. It also up-loads and downloads user-defined test programs and displays the resulting test data.

The integral pumps of the ADTS 505, produce pressure and vacuum supplies for the unit's

controlling requirements. The power supply connection for the unit is located on the front panel.

Page 16

1 - 2 Druck ADTS 505 User Manual

K0260 Issue No. 8

FIGURE 1-1 ADTS 505 GENERAL VIEW

Option A Hand Terminal

Option B Hand Terminal

Air DataTest Set - HandTerminal

Leak Measur

e

LEAK MEASURE MODE

Mach

0.001

Mach

DO NOT

OBSTRUCT

THESE VENTS

WATER

DRAIN

Advanced Hand TerminalAdvanced Hand Terminal

g

T5.0A

250V

HBC

Page 17

Description 1 - 3

K0260 Issue No. 8

1

1.2 Operating Limits

The ADTS 505 is supplied with the following pre-defined operating limits.

Civil Limits

Parameter Limit

MIN ALT -1,000 ft

MAX ALT 50,000 ft

MIN CAS 0.0 knots

MAX CAS 450.0 knots

MAX MACH 1.000 Mach

MAX ROC 6,000 ft/min

ARINC LIMITS OFF

ALT CORRECTION 0 ft

MIN Ps 115.972 mbar

MAX Ps 1050.406 mbar

MIN Qc 0.0 mbar

MAX Qc 368.01 mbar

MAX Rate Ps 109.85 mbar/min

MAX Rate Qc 109.85 mbar/min

Standard Limits

Parameter Limit

MIN ALT -2,000 ft

MAX ALT 60,000 ft

MIN CAS 0.0 knots

MAX CAS 650.0 knots

MAX MACH 1.732 Mach

MAX ROC 10,000 ft/min

ARINC LIMITS OFF

ALT CORRECTION 0 ft

MIN Ps 65.00 mbar

MAX Ps 1088.6 mbar

MIN Qc 0.0 mbar

MAX Qc 866.00 mbar

MAX Rate Ps 200 mbar/min

MAX Rate Qc 200 mbar/min

Page 18

1 - 4 Druck ADTS 505 User Manual

K0260 Issue No. 8

Max Limits

Parameter Limit

MIN ALT -2,000 ft

MAX ALT 60,000 ft

MIN CAS 0.0 knots

MAX CAS 650.0 knots

MAX MACH 2.800 Mach

MAX ROC 40,000 ft/min

ARINC LIMITS OFF

ALT CORRECTION 0 ft

MIN Ps 10.90 mbar

MAX Ps 1355.00 mbar

MIN Qc -1355.00 mbar

MAX Qc 2490.00 mbar

MAX Rate Ps 1000 mbar/min

MAX Rate Qc 1000 mbar/min

EPR Limits

Parameter Limit

MIN INLET 27.0 mbar

MAX INLET 1355.0 mbar

MIN OUTLET 27.0 mbar

MAX OUTLET 2500.0 mbar

MIN EPR 0.1

MAX EPR 10.0

MIN INLET RATE 0

MAX INLET RATE 1000 mbar/min

MIN EPR RATE 0

MAX EPR RATE 60 EPR/min

Page 19

Druck ADTS 505 User Manual 2 - 1

K0260 Issue No. 8

2

2 INSTALLATION

2.1 Packaging

On receipt of the ADTS 505 check the contents of the packaging against the following lists:

i) ADTS 505 Air Data Test Set

ii) Power supply cable - 5 m, no line plug (regional line plugs require option C)

iii) Option A

comprising:

Hand terminal

Hand terminal cable - 18 m (option A only)

5 m hose - red

5 m hose - blue

Accessory Bag

iv) Option B

comprising:

Advanced hand terminal

Hand terminal cable - 18 m (option B only)

Cable, communications

Cable, power supply

Power pack

Accessory Bag

v) 3 m hose - red

vi) 3 m hose - blue

vii) User Manual (this publication)

viii) Quick Reference Guide K0274

ix) Kit, fuse/o-ring (also see Figure 2-1, item1)

2.2 Packaging for Storage or Transportation

To store the unit or to return the unit for calibration or repair carry out the following procedures:

1. Pack the unit as detailed in the following procedure.

2. To return the unit for calibration or repair complete the return goods procedure as

detailed in 2.3.

Page 20

2 - 2 Installation

K0260 Issue No. 8

Procedure

The unit should be at zero/ambient pressure. Disconnect the hose assemblies and stow in the

lid.

• Switch OFF and disconnect from the electrical power supply. Disconnect the power

supply cable and the hand terminal cable. Disconnect the hand terminal cable from the

hand terminal.

• Fit the lid to the unit.

• The power supply cable, hand terminal cable and the hand terminal should be placed

in the original packing material.

If available, use the original packing material. When using packing materials other than the

original, proceed as follows.

• Wrap unit in polyethylene sheeting.

•

Select a double-wall cardboard container. Inside dimensions must be at least 15 cm

greater than the equipment. The carton must meet test strength requirements of >

125 kg.

• Protect all sides with shock-absorbing material to prevent equipment movement within

the container.

Seal carton with approved sealing tape.

Mark carton “FRAGILE” on all sides, top, and bottom of shipping container.

To return the unit for calibration or repair complete the return goods procedure as detailed in 2.3.

Environment

The following conditions apply for both shipping and storage:

• Temperature Range........... ............-20 to +70°C (-4 to +158°F)

• Altitude......... ............Up to 15,000 feet (4,570 metres)

Page 21

Druck ADTS 505 User Manual 2 - 3

K0260 Issue No. 8

2

2.3 Returned Goods Procedure

Should the unit require calibration or become unserviceable it can be returned to the Druck

Service Department.

Please contact our Service Department, either by 'phone, fax or E-mail, to obtain a Returned

Goods Authorization (RGA) number or (Return Material Authorization [RMA] in USA), providing

the following information:

Product (i.e. ADTS 505)

Serial number

Details of defect/work to be undertaken

Calibration traceability requirements

Operating conditions

Safety Precautions

You must also tell us if the product has been in contact with anything hazardous or toxic and,

the relevant COSHH (MSDS in USA) references and precautions to be taken when handling.

IMPORTANT NOTICE

Service or calibration by unauthorized sources will affect the warranty and may not guarantee

further performance

Page 22

2 - 4 Installation

K0260 Issue No. 8

FIGURE 2-1 ADTS 505 ACCESSORIES

Air Data Test S

et - Hand T

erminal

Leak Measure

LMEAK EASURE MODE

M

ach

0

.0

0

1

Mach

Advanced Hand TerminalAdvanced Hand Terminal

g

191-198

2

1

5

18m

3A

6

9

12

13

11

Note: Item 13 supplied for the country of use

10

18m

4

Page 23

Druck ADTS 505 User Manual 2 - 5

K0260 Issue No. 8

2

# not illustrated † alternative

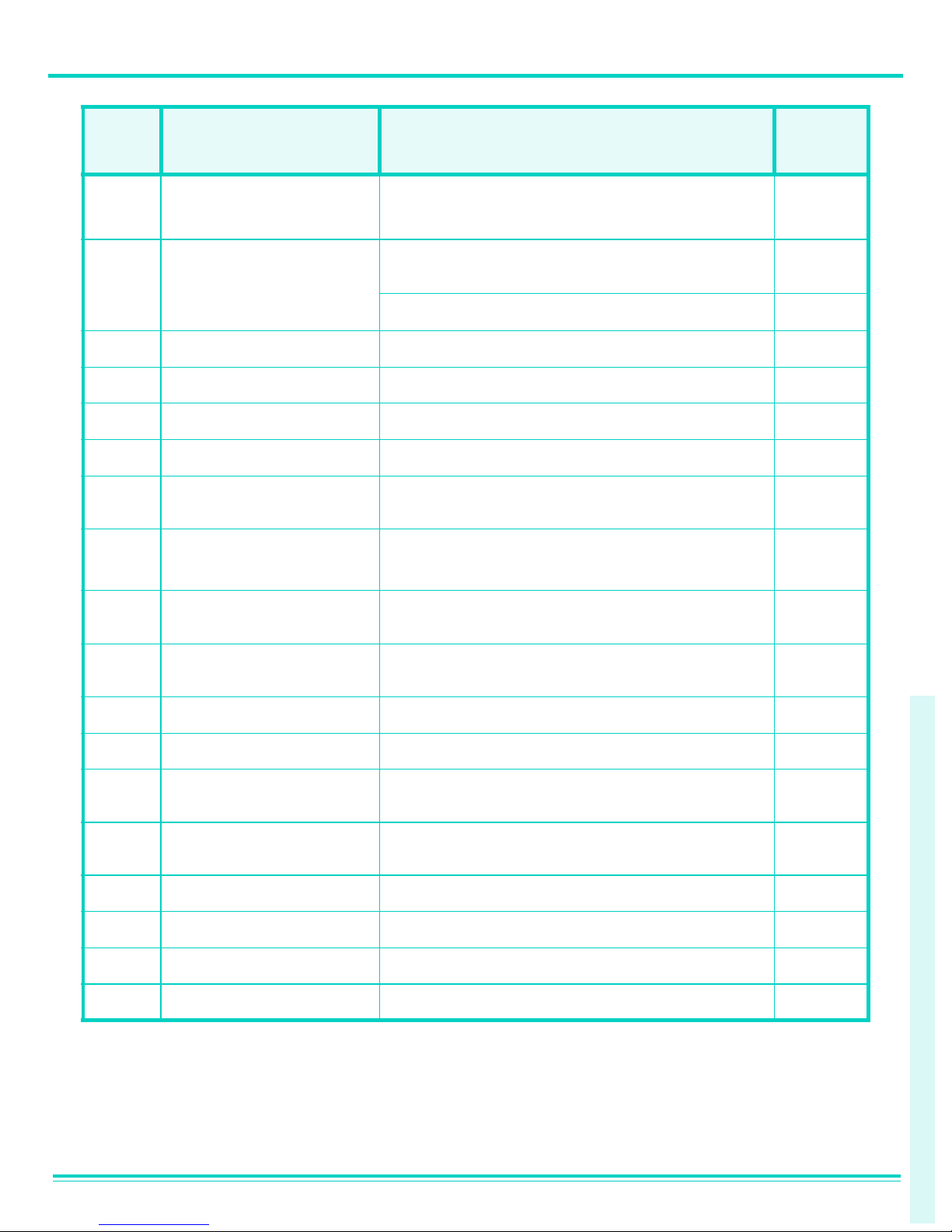

TABLE 2-1 PARTS LIST

No Part Number Description

Qty per

assy

1

AS505-18-3124M0

Kit, fuse/o-ring comprising:

o-ring AN4

fuse, T5.0A/250V HBC

1

2

AS505-53-3124M0

comprising:

Hose, red, ST/OPN, AN4, 3m

1

Hose, blue, ST/OPN, AN4, 3m

1

3A

AS505-40-3124M0 Cable, AC Power, 5M (open end)

1

3B#

AS505-40-3124M0 † Cable, AC Power, 5M (250V UK plug)

1

3C#

AS505-41-3124M0 † AC Power, 5M (115V US plug)

1

3D#

AS505-42-3124M0 † AC Power, 5M (250V European plug)

1

4

AS505-56-3124M0

Option A

Hand terminal Assembly

1

4.1#

-

Option A and B

Hose, red, 5M

Hose, blue, 5M

1

5

AS505-54-3124M0

Option A

Cable, Hand terminal 18M (option)

1

6

AS505-57-3124M0

Option A and B

Bag, Accessory, Hand Terminal

1

7#

AS505-60-3124M0 Handbook, User Manual, K0260

1

8#

AS505-61-3124M0 Handbook, Calibration Manual, K0272

1

9

AS505-56-3124M1

Option B

Hand terminal, Advanced

1

10

AS505-54-3124M1

Option B

Cable, Hand terminal 18M, Safety marking (option)

1

11

AS204-06-3435M0 Cable, Communications PC

1

12

AS204-07-3435M0 Power pack

1

13

- part of item 12 -Adaptor, power pack (comprising: 4)

1

14

AS204-10-3435M0 Stylus, pack (comprising: 3)

1

Page 24

2 - 6 Installation

K0260 Issue No. 8

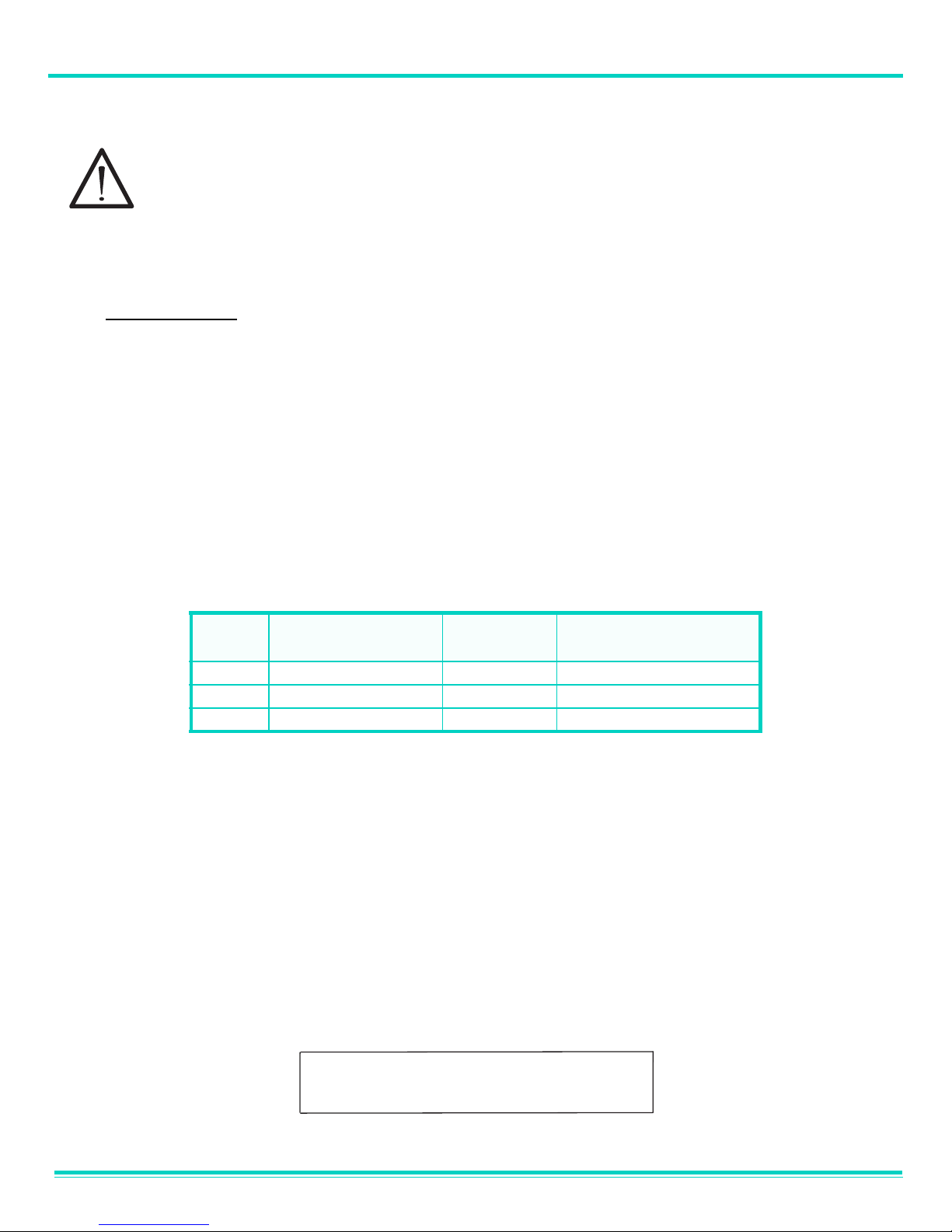

2.4 Electrical Connection

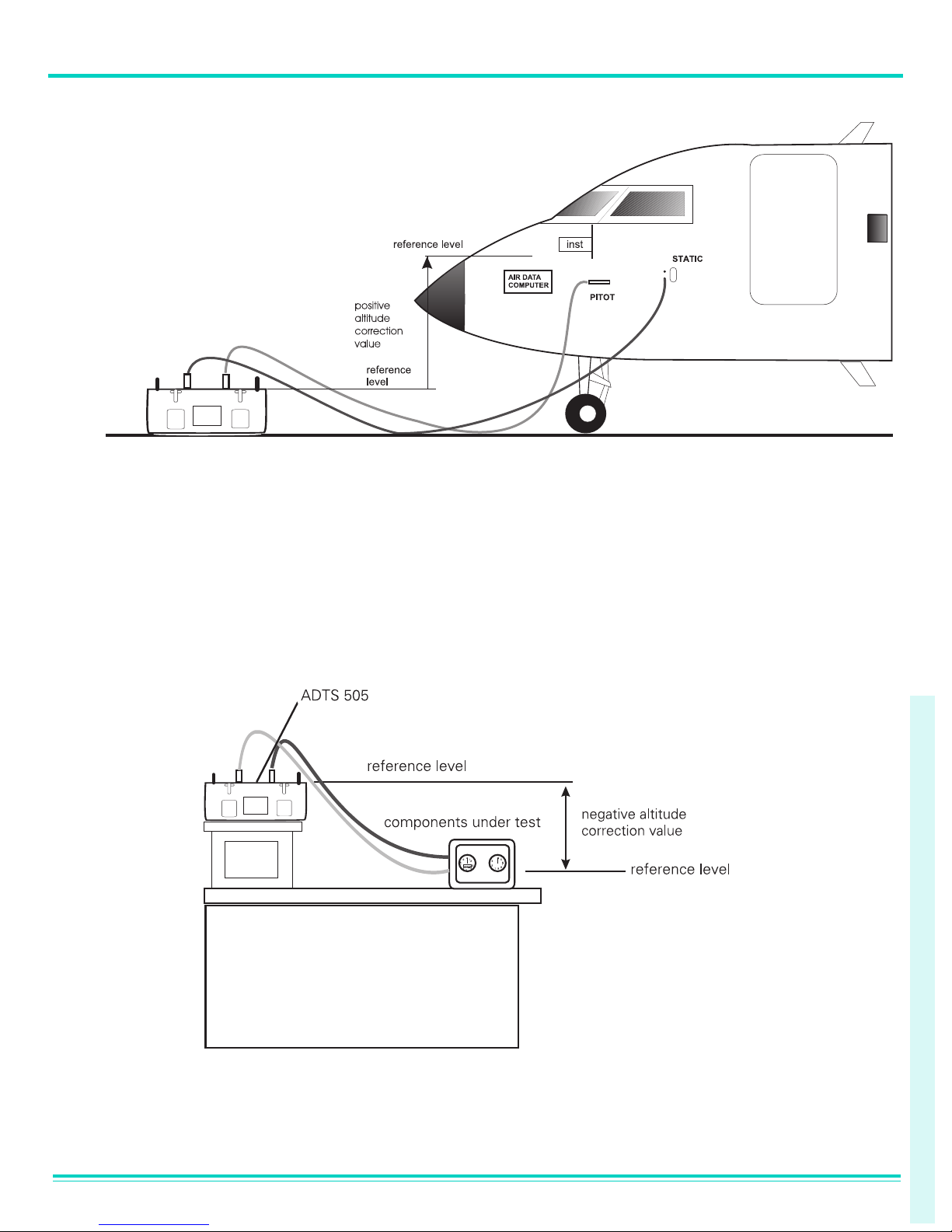

WARNING: VOLTAGES IN EXCESS OF 30 VOLTS (RMS) AC OR 50 VOLTS DC, IN CERTAIN

CIRCUMSTANCES, CAN BE LETHAL. CARE MUST BE TAKEN WHEN WORKING ON LIVE,

EXPOSED CONDUCTORS.

Power Supply Connection

The unit must be connected to the correct electrical power supply as stated, adjacent to the

power connector.

Open end cables

Only a qualified technician (see page i) must fit a connector to a cable supplied by GE (see Table 2-1,

item 3).

CAUTIONS:

1T

HE SUPPLY MUST PROVIDE CONNECTION TO A PROTECTIVE GROUND TERMINAL. THE UNIT MUST, AT

ALL TIMES, BE CONNECTED TO THE SUPPLY EARTH (GROUND).

2T

HE POWER SUPPLY CABLE AND CONNECTOR MUST BE CORRECTLY RATED FOR THE POWER SUPPLY.

Note: The ADTS 505 is normally supplied with an approved power supply cable for use in the country

o f d e li ve ry . T hi s c an li mi t t he ma xi mu m s up pl y v ol ta ge th at ca n b e s af el y u se d.

e.g. a NEMA 5-15P terminated cable, for use in the U.S.A., is approved for a maximum of 125 V

ac; it must be replaced for a higher supply voltage.

Make sure that the power supply is off before connecting the power cable.

If required, connect the hand terminal to the connector on the front panel.

Note: Connecting the hand terminal to the unit disables the front panel key-pad.

Fuses

The two fuses, located in the holders and mounted on the front panel, protect the unit. The

fuses are connected in the live and neutral supply circuit and are T5.0A/250V HBC type.

Note: Only replace the fuses with the correct type, see Figure 2-1 item1, to replace see section 4-5.

External earth/ground connection

An external earth (ground) cable may be connected to the stud on the front panel of the unit

providing integrity of the earth (ground) connection.

F

IGURE 2-2 POWER SUPPLY LABEL

Pin

(ADTS)

European

Colour

U.S.

Color

Function

1

Brown Black Live

4

Blue White Neutral

Centre

Green/Yellow Green Protective Earth (Ground)

100 / 120 / 230V ~ 50 / 60Hz 200VA

115V ~ 400Hz 200VA

Page 25

Druck ADTS 505 User Manual 2 - 7

K0260 Issue No. 8

2

Connection

• The ADTS 505 provides a power supply to the advanced hand terminal when connected to the

hand terminal connector on the front panel.

• The power supplies must be isolated when connecting the advanced hand terminal in the

hazardous area.

Using the advanced hand terminal when not connected to the ADTS 505

Using the advanced hand terminal with a pc to create test scripts.

• The unit must be connected to the correct electrical power supply, see paragraph 2.4.

• Before use, make sure the SELV power adaptor supplied with the instrument is correct for the

power supply voltage. The Safety Extra Low Voltage (SELV) power adaptor complies with

EN61010 (including safety requirements for laboratory instruments).

Note: The instrument can be powered from other DC power supplies of the correct voltage range. It

is the user’s responsibility to make sure the power supply is safe.

Make sure that the power supply is off before connecting the power cable.

Communications Connection

Communications cable - parts list item 11

2.5 Pneumatic Pressure Connections

Ps (static)- AN4 (MS33656-4)

Pt (pitot)- AN4 (MS33656-4)

When not in use, a blanking cap must be fitted.

Note: When carrying out a leak test, a leak of this blanking cap affects the performance of the ADTS 505.

Pin No.

ADTS

1

2

BLK

BLK-W

Function

Connector

Cable

Colour

0V

+ VIN

Jack plug outer

Jack plug inner

3

5

4

RED

RS232 Tx

PIN 2

PIN 3

PIN 5

BLK

GRN

RS232 0V

RS232 Rx

Page 26

2 - 8 Installation

K0260 Issue No. 8

2.6 Positioning of the ADTS 505

WARNING: IN AN ENCLOSED AREA WITH FUEL VAPOUR PRESENT THIS EQUIPMENT MUST BE

PLACED AT LEAST 0.5 METRES ABOVE FLOOR LEVEL. THIS EQUIPMENT CONTAINS A

D.C. MOTOR WITH BRUSHES THAT COULD CAUSE A SPARK.

C

AUTION:TO OPERATE, PLACE THE UNIT ON A HORIZONTAL SURFACE (FRONT PANEL UPPERMOST) OR VERTICALLY

(

POWER SUPPLY CONNECTOR UPPERMOST) THIS ALLOWS THE WATER IN THE WATER FILTER TO VENT.

W

ATER COULD CONTAMINATE THE CONTROLLER MANIFOLD AND AFFECT CONTROLLER PERFORMANCE.

Note: In control mode, the water drain, located at one end of the unit near the carrying handle, produces

a flow of air and some water. The amount of water depends on the humidity and the operating

time in control mode.

C

AUTION:BEFORE USE, CHECK THE WATER DRAIN PIPE, IT MUST BE FREE OF OBSTRUCTION. WHEN IN CONTROL

MODE CHECK THAT A SMALL FLOW OF AIR COMES OUT OF THE DRAIN PIPE.

Notes:

1 When checking for a small flow of air do not block the drain pipe completely this causes a back-

pressure in the pipe and controller instability.

2 If no air flows from the drain pipe, when in control mode, switch off and start again. If no air

flows after a re-start, switch off and do not use the ADTS 505, return the unit to the repair depot.

C

AUTION: THE SIDE VENTS MUST NOT BE OBSTRUCTED, THIS UNIT REQUIRES AN AIRFLOW FOR THE INTERNAL COOLING FANS.

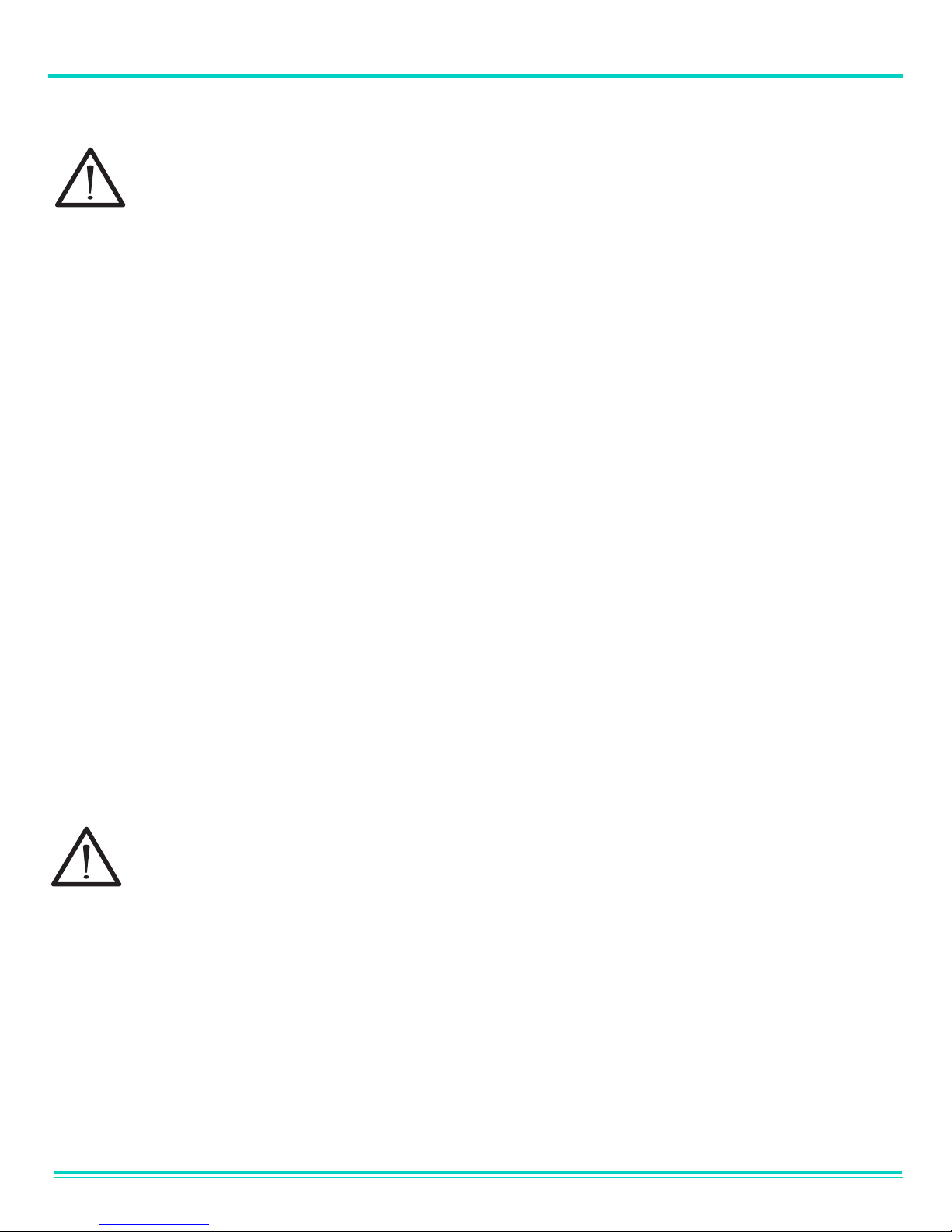

It is important that the position of the ADTS 505 in relation to the aircraft altitude sensors is

known. An altitude correction must be made to allow for the difference in height between the

reference level and the aircraft's altitude sensors (Figures 2-2 and 2-3). The Reference section

contains details of altitude correction.

WARNING: OBSERVE THE APPROPRIATE SAFETY INSTRUCTIONS AND TESTING PROCEDURES

DETAILED IN THE AIRCRAFT MAINTENANCE MANUALS AND COMPONENT

MAINTENANCE MANUALS.

Page 27

Druck ADTS 505 User Manual 2 - 9

K0260 Issue No. 8

2

FIGURE 2-2 ADTS 505 ALTITUDE CORRECTION ON-AIRCRAFT

FIGURE 2-3 ALTITUDE CORRECTION OFF-AIRCRAFT

Page 28

2 - 10 Installation

K0260 Issue No. 8

Power supply

fuses

Power supply

switch

Hand terminal

connector (option)

Ps (static)

connector

Pt (pitot)

connector

Power supply

connector

G

()

stud

round

Earth

Key-pad

and display

Air

vent

Water

drain

DO

NOT

OBSTRUCT

THESE

VENTS

WAT

E

R

D

R

A

IN

T5.0A

250V

HBC

FIGURE 2-4 ADTS 505 GENERAL VIEW

Page 29

Druck ADTS 505 User Manual 3 - 1

K0260 Issue No. 8

3

3OPERATION

3.1 Preparation

WARNING:

OBSERVE SAFETY PRECAUTIONS STATED IN LOCAL ORDERS AND THE AIRCRAFT OR

EQUIPMENT SERVICING PROCEDURES.

Make sure the electrical and pneumatic connectors, electrical cables and pipes and positioning of

the ADTS 505 comply with the instructions and requirements in Section 2 Installation.

Carry out the following before use:

If necessary, carry out the maintenance task detailed in Section 4.

Make sure the air data test system power supply switch on the front panel is set to

OFF. Connect the air data test system to the electrical supply, make sure the supply

includes a connection to a protective earth.

Inspect the pneumatic hoses for damage, ingress of dirt and moisture. Make sure the

aircraft adaptors are serviceable and the pipe connections are air-tight.

Note: Do not connect the air data test system to a contaminated aircraft system. Inspect the static

vents and pitot probes for dirt and debris before connecting. If necessary, check the pitot-static

system water drain traps.

Connect, to the air data test system, the hoses necessary for the test procedures to be carried out:

STATIC output (Ps), PITOT output (Pt). Temporarily seal the free ends of the hoses.

Note: When connected, take care not to kink or stand on the hoses.

Before use, the ADTS 505 should be tested, for first time users see section 3.4, for users requiring

more operating detail see section 3.5.

This section contains a quick reference chart detailing all the functions of the key-pad. Further

quick reference charts, at the end of this section, detail the set-up menu.

Review and become familiar with the whole procedure before starting the test process on an

aircraft or component.

Page 30

3 - 2 Operation

K0260 Issue No. 8

3.2 Display Functions and Units of Measure

When operating in either pressure measuring or pressure controlling modes, the ADTS 505 can

display the following information:

Aeronautical Functions

Display Abbreviation Displayed Units

(if applicable)

Altitude ALT ft, m

Calibrated Airspeed CAS kts, km/h, mph

Mach MACH Rate of Climb ROC ft/min, m/min, m/s, hm/min

Rate of Airspeed Rt CAS kts/min, km/h/min, mph/min

Pressure Functions Display Abbreviation Displayed Units

(if applicable)

Static (Absolute) Ps [P]

Pitot (Absolute) Pt [P]

Dynamic or Impact

(Differential) Qc [P]

Engine Pressure Ratio EPR Rate of Ps Rt Ps [P] /min

Rate of Pt Rt Pt [P] /min

Rate of Qc Rt Qc [P] /min

Rate of EPR Rt EPR EPR/min

Where [P] is the currently selected pressure units from the following list:

mbar, inHg, mmHg, inH2O (4°C), inH2O (20°C), inH2O (60°F), psi, hPa, kPa.

Operating Range and Performance

The ADTS 505 is supplied with a full-scale range of 650 knots for measurement and control of the

pitot pressure channel. The unit can measure altitude up to 105,000 ft; altitude control depends

on the performance of the pump, the integral pump is capable of achieving -2000 to 60,000 ft.

Refer to section 6 for more details of performance and specification.

Sets of factory-defined limits known as ARINC565, Standard, Military, Max and EPR can be selected

through the SETUP menu (see Reference section 6). Operators may also define up to five sets of

additional limits for different aircraft types. When configuring the display to aeronautical or

pressure units operators should be aware that when units of pressure are selected, wider full-scale

pressure limits will be enabled for some parameters.

Page 31

Druck ADTS 505 User Manual 3 - 3

K0260 Issue No. 8

3

3.3 Quick Reference

Key/selection Function and comments

FIGURE 3-1 KEY-PAD AND DISPLAY

KEY-PAD FUNCTION

the display shows the main pressure display (Leak Measure or Control mode) with

normal operation key functions.

F1-F6

Function keys for menus

ALT/Ps

Altitude (Aeronautical units) or Ps (pressure units)

SPEED Qc

Airspeed (Aeronautical units) or Qc (pressure units)

EPR

Engine Pressure Ratio (pressure units only)

ROC/RATE Ps

Rate of Climb (Aeronautical units) or Rate of Ps (pressure units)

LEAK MEASURE/CONTROL

Switches between measure mode (for leak testing) and control mode

RATE

Rate of change of Pitot or Mach parameter, press parameter then RATE (read only)

GROUND

Controls Ps to atmospheric pressure and Qc to zero both at current rates of change

SETUP

Changes functions, limits and units, if [save/lock] pressed changes are permanent

HELP

Press HELP for further information on current selection/display

0-9

Number entry

-/000

Minus sign for first number entry 000 (thousand) if not first number of entry

CLEAR/QUIT

Clear number entry - quit from menu, HELP screen or clear warning message

ENTER

Complete number entry

DELETE

Removes the last number or character entered

CLEAR/QUIT + DELETE =

ABORT, all operations stop, the ADTS 505 restarts from a normal power-up

sequence, including safe equalising of pressures between the test set and the

connected system

100 / 120 / 230V ~ 50 / 60Hz 200VA

115V ~ 400Hz 200VA

T5.0A

250V

HBC

Page 32

3 - 4 Operation

K0260 Issue No. 8

3.4 First Time Operators

The following sequences of operation should be used by first time operators and by operators that

use the equipment occasionally. For regular users, familiar with the equipment, go to section 3.5.

Set the power supply switch to ON and the power-on routine starts.

(1) The display first shows:

(2) After approximately five seconds the display shows

the start of the power-on sequence, the system

carries out a self test. If the test finds a fault, the

display shows an error message, refer to Section 5,

Fault Finding and Testing.

(3) The display messages show a sequence of

pneumatic and internal system checks:

(4) After a successful self-test sequence the system changes to measure mode. The display changes

to the Leak Measure mode display showing the parameters selected in set-up.

ALTPsSPEEDQcMACH

Pt

ROC

RATE Ps

GROUND

RATE

7

F6

F5

F4

F3

F2

F1

4

1

_

000

8

5

2

0

9

6

3

.

CLEAR

QUIT

ABORT

DELETE

ENTER

LEAK

MEASURE

CONTROL

HELP SETUP

SYSTEM STARTING

PLEASE WAIT

ALTPsSPEEDQcMACH

Pt

ROC

RATEPs

GROUND

RATE

7

F6

F5

F4

F3

F2

F1

4

1

_

000

8

5

2

0

9

6

3

.

CLEAR

QUIT

ABORT

DELETE

ENTER

LEAK

MEASURE

CONTROL

HELP SETUP

ADTS 505

Software Version1.06

LAST CALIBRATED[DD/MM/YYYY]

THERMAL TESTPLEASE WAIT

ALTPsSPEEDQcMACH

Pt

ROC

RATEPs

GROUND

RATE

7

F6

F5

F4

F3

F2

F1

4

1

_

000

8

5

2

0

9

6

3

.

CLEAR

QUIT

ABORT

DELETE

ENTER

LEAK

MEASURE

CONTROL

HELP SETUP

Software Version1.06

LAST CALIBRATED[DD/MM/YYYY]

CHECKING FOR VACUUMLEAKS

ADTS 505

ALTPsSPEEDQcMACH

Pt

ROC

RATEPs

GROUND

RATE

7

F6

F5

F4

F3

F2

F1

4

1

_

000

8

5

2

0

9

6

3

.

CLEAR

QUIT

ABORT

DELETE

ENTER

LEAK

MEASURE

CONTROL

HELP SETUP

Software Version1.06

LAST CALIBRATED[DD/MM/YYYY]

CHECKING FOR PRESSURE LEAKS

ADTS 505

ALTPsSPEEDQcMACH

Pt

ROC

RATEPs

GROUND

RATE

7

F6

F5

F4

F3

F2

F1

4

1

_

000

8

5

2

0

9

6

3

.

CLEAR

QUIT

ABORT

DELETE

ENTER

LEAK

MEASURE

CONTROL

HELP SETUP

Software Version1.06

LAST CALIBRATED[DD/MM/YYYY]

PRESSURIZING PUMPS

ADTS 505

ALTPsSPEEDQcMACH

Pt

ROC

RATEPs

GROUND

RATE

7

F6

F5

F4

F3

F2

F1

4

1

_

000

8

5

2

0

9

6

3

.

CLEAR

QUIT

ABORT

DELETE

ENTER

LEAK

MEASURE

CONTROL

HELP SETUP

KEEP SIDEAIR VENTS CLEAR

FINDING VALVEBIAS 1 OF 4...

ADTS 505

ALTPsSPEEDQcMACH

Pt

ROC

RATEPs

GROUND

RATE

7

F6

F5

F4

F3

F2

F1

4

1

_

000

8

5

2

0

9

6

3

.

CLEAR

QUIT

ABORT

DELETE

ENTER

LEAK

MEASURE

CONTROL

HELP SETUP

KEEP SIDEAIR VENTS CLEAR

GROUND SENSORS

ADTS 505

ALTPsSPEEDQcMACH

Pt

ROC

RATEPs

GROUND

RATE

7

F6

F5

F4

F3

F2

F1

4

1

_

000

8

5

2

0

9

6

3

.

CLEAR

QUIT

ABORT

DELETE

ENTER

LEAK

MEASURE

CONTROL

HELP SETUP

KEEP SIDEAIR VENTS CLEAR

OPEN VALVES

ADTS 505

Page 33

Druck ADTS 505 User Manual 3 - 5

K0260 Issue No. 8

3

(5) The system is now ready for use.

NOTES

1 The ADTS 505 is a continuous, self-monitoring system. If the system detects an error, the display

shows an error message. Lists of errors are detailed in Section 5, Fault Finding and Testing.

2 The display at power-up will be [QUAD] format (see above) unless changed in SETUP and [Save

Settings] selected.

(6) The connection of an optional hand terminal (option A or B) causes the front panel display to show

one of two messages:

or

To change between

these two displays, see

SETUP and

[Display], [Hand Term],

[Monitor] or [Message].

See paragraphs 3.4.1

and 3.9.

ALTPsSPEEDQcMACH

Pt

ROC

RATE Ps

GROUND

RATE

7

F6

F5

F4

F3

F2

F1

4

1

_

000

8

5

2

0

9

6

3

.

CLEAR

QUIT

ABORT

DELETE

ENTER

LEAK

MEASURE

CONTROL

HELP SETUP

REMOTE

HAND

TERMINAL

OPERATING

Page 34

3 - 6 Operation

K0260 Issue No. 8

3.4.1 Operating Modes

The air data test system can now be set for a variety of functions and modes. In the following,

examples of measure mode, control mode, leak measure mode and go-to-ground show the key

presses and selections required for each mode.

Measure Mode

The system automatically enters measure mode after a successful self-test. To c hange the di splay

press:

To store display for the next power-up press:

To return to measure mode press:

To set the display to show [Monitor]

or [Message] press F6. This switches

between the two settings and

operates only when the hand

terminal is connected.

Page 35

Druck ADTS 505 User Manual 3 - 7

K0260 Issue No. 8

3

Checking the Limits

Before use on aircraft systems or components check that the limits are within the values stated

in the appropriate maintenance manual. There are sets of factory-defined limits:

Civil, Standard, Max or EPR (refer to Section 1 for details)

At each power-up sequence the default set of limits "CIVIL" become active. The "CIVIL" limit set

contains the lowest ranges and values. To see the name of the set of limits in use, press SETUP the

display shows the [name] in the F3 limits field. To see the value of limits in use proceed as follows:

The current selected limits can be viewed by pressing F3. To select and use one of the factorydefined limit sets or define one of five sets of user-defined limits, see 3.5.6. The selected set of limits

remain active until the selection of another set of limits or until power supply switch-off.

Limits

t

s

View

Details

Select

Limits

Enter

PIN

ALTPsSPEEDQcMACH

Pt

ROC

RATE Ps

GROUND

RATE

7

F6

F5

F4

F3

F2

F1

4

1

_

000

8

5

2

0

9

6

3

.

CLEAR

QUIT

ABORT

DELETE

ENTER

LEAK

MEASURE

CONTROL

HELP SETUP

USER 1

USER 2

USER 3

USER 4

USER 5

MAX

STANDARD

CIVIL

Active Limit Set: CIVIL

Available Preset Limits

Available User Limits

t

s

Select

Limit

Limits

Save

Settings

Modify

Details

Modify

Name

User

Supervisor

ALTPsSPEEDQcMACH

Pt

ROC

RATE Ps

GROUND

RATE

7

F6

F5

F4

F3

F2

F1

4

1

_

000

8

5

2

0

9

6

3

.

CLEAR

QUIT

ABORT

DELETE

ENTER

LEAK

MEASURE

CONTROL

HELP SETUP

Min ALT -1000 ft

Min CAS

Max Mach 1.0 Mach

Max ROC 6,000 ft/min

Max ALT 50,000 ft

0.0 knots

Max CAS 450 knots

Alt Cor. 0 ft

ARINC Limits OFF

Page #1

Details

Next

Page

Next

Page

User

Supervisor

t

s

Details

Modify

Units

Detail

more

(2 of 2)

more

(1 of 2)

m km/h

m/min

ft kts

ft/min

mbar

mbar/min

ALTPsSPEEDQcMACH

Pt

ROC

RATE Ps

GROUND

RATE

7

F6

F5

F4

F3

F2

F1

4

1

_

000

8

5

2

0

9

6

3

.

CLEAR

QUIT

ABORT

DELETE

ENTER

LEAK

MEASURE

CONTROL

HELP SETUP

Rt

Min Ps 115.97 mbar

Max Ps 1050.41 mbar

Min Qc 0.0 mbar

Max Qc 368.01 mbar

Ps 100.00 mbar/min

Rt Qc 100.0 mbar/min

Page #2

Details

Next

Page

User

Page 36

3 - 8 Operation

K0260 Issue No. 8

Control Mode

When the system is in measure mode, to enter control mode press:

The display changes to:

Note: The number of parameters displayed depends on the settings made in set-up, see previous page.

New set-point

To change the Aim value, press the required parameter key and, using the numeric keys, set the

new Aim value. If necessary, use DELETE to remove the last digit set in the Aim value display field.

The display shows each numeric key press, a beep sounds with each key press. When the display

shows the new Aim value press ENTER.

The display shows the parameter changing as the system controls to the set-point, at the set rate

of change.

Page 37

Druck ADTS 505 User Manual 3 - 9

K0260 Issue No. 8

3

Go to GROUND

When the system is in control mode press:

Note: Go to ground does not operate in measure mode.

The ALT Aim value immediately changes to the current

ground pressure (local airfield altitude) and the system

safely controls to the GROUND value stored from

power-up. The CAS Aim value immediately changes to

zero and the system safely controls to zero:

The altitude and airspeed decreases at the rate set in

ROC and RtCAS.

When the altitude and airspeed are at ground and zero

the display changes to:

At ground and zero the display shows safe at ground for 5

seconds then the ADTS 505 system closes the output valves

to isolate the aircraft system and goes into a system datum

check routine (includes operation of the pump and control

valves) go to 3.7.8 for more details.

After completion of the system datum check routine the

display shows safe at ground and the message "Press Clear/

Quit to continue".

It is now safe to continue testing or to switch off and

disconnect the aircraft system.

When familiar with these procedures go to 3.5.4 to leak test

the ADTS 505.

ALTPsSPEEDQcMACH

Pt

ROC

RATEPs

GROUND

RATE

7

F6

F5

F4

F3

F2

F1

4

1

_

000

8

5

2

0

9

6

3

.

CLEAR

QUIT

ABORT

DELETE

ENTER

LEAK

MEASURE

CONTROL

HELP SETUP

SAFE

AT

GROUND

Page 38

3 - 10 Operation

K0260 Issue No. 8

3.5 Operation and Example Procedures

3.5.1 Operating Procedures

The procedures show the steps required to mak e sure th e ADTS 505 is serviceable and the settings

required to test an aircraft system or component. For further information refer to the Section 6 Reference and Specification.

In the following:

All key presses are highlighted in bold and shown as identified on the front panel.

Key presses inside brackets e.g., [MORE], are soft key presses (i.e., function key selections {F1 to F6}

indicated on the screen).

Help System

The help information includes further details of the function and details associated functions, also

see Section 6 - Reference and Specification.

3.5.2 Power-up

Set the front panel power switch to ON and check the power indicator lights.

The display shows the following sequence:

a. ADTS 505 power-up screen with the software version and the last calibration date.

b. Sequence of system and pneumatic tests:

i. Thermal test.

ii. Testing for vacuum leaks.

iii. Testing for pressure leaks.

iv. Pressurizing pumps.

v. Finding valve bias.

vi. Measuring ground pressure.

vii. Equalising system pressures.

c. Display shows Leak Measure mode and the number of parameters last selected in

display set-up.

Make sure that the ADTS 505 performs a self-test with no errors reported refer to Testing and Fault

finding Section 5, for details of errors.

The ADTS 505 always powers up in Leak Measure mode with the pressure controllers off. When

changing to Control Mode the pump unit must be producing the correct pressure and vacuum.

The ADTS 505 system is now ready for use. After approximately 15 minutes, the system may be

used with full specification accuracy and stability.

Page 39

Druck ADTS 505 User Manual 3 - 11

K0260 Issue No. 8

3

3.5.3 Control or Measure Parameter

To change the displayed Measure parameters:

Press SETUP [Displays], [Single, Dual, Quad], press CLEAR/QUIT repeatedly until the display goes

to Leak Measure Mode.

Measure parameters:

Press the parameter key

e.g., press SPEED/Qc to display airspeed.

To change the displayed rate parameter:

Press the associated parameter key followed by the rate key.

e.g., display airspeed rate, press SPEED/Qc then RATE.

ROC/RATE Ps may be directly pressed without first pressing ALT/Ps.

In Leak Measure mode, pressing the parameter and rate keys changes the order that the display

shows the parameters.

Control Aim

A new control aim can be entered using the numeric keys. Each digit is displayed as it is pressed.

The existing aim is replaced when the first digit of the new aim is pressed. If an error is made during

the entry of data, press CLEAR/QUIT to restore the original aim.

Press ENTER to action the new aim.

Note 1:The -/000 key can be used as a quick way of entering thousands. If this key is pressed first (i.e.

before a number is entered) the value becomes negative, press again the value becomes positive.

Note 2:The ADTS 505 must be in control mode to enter a new aim (current aim displayed). If the aim

field shows "Leak Measure" press LEAK MEASURE/CONTROL to enter control mode.

3.5.4 Leak Testing the ADTS 505

It is important to check that the ADTS 505 and the connecting hoses do not leak. Before use, a leak

check should be carried out as follows:

Connect the Pitot and static hoses (to front panel of ADTS 505). Temporarily seal the free ends of

the hoses.

Set the display to quad, see 3.4.1. Set the units to feet and knots, see 3.5.5.

Page 40

3 - 12 Operation

K0260 Issue No. 8

Press LEAK MEASURE/CONTROL to select Control mode.

Using the set-up menu, choose the limits set for the aircraft or UUT, see 3.5.6.

Press CLEAR/QUIT repeatedly until the display shows control mode.

Set ROC/RtPs to 5000ft/min, enter an altitude aim of 1000 ft and an airspeed of 200 knots.

Wait until the system achieves the aim values and press LEAK MEASURE/CONTROL to

change to Leak Measure mode.

Leak Measurement

Note: Compressing a gas generates heat. Gas heated or cooled in an enclosed volume causes a

pressure change. It is important, especially for leak testing, to allow enough time for the heated

gas to cool and the pressure to stabilize.

In Leak Measure mode, select from the main menu [Rate Timer], and enter a wait time in minutes

and seconds F3 - [Set Wait] 00m.30Secs. Enter a leak measure time in minutes and seconds F4 [Set Time] 00m.30Secs. If necessary, press F5 to save these times for future use.

Select [Start Timer] F1, as the rate timer starts, the display shows the count down (in seconds) of

the wait time and then the count down of the timing. The status message at the bottom of the

screen changes in this order LEAK MODE: WAIT: TIMING: RATES AVAILABLE: Wait until rate timer

has completed, the rate parameters on the display changes from "Leak Measure" to "Timed Leak

Measure" and shows the results in units/min.

• Check ROC is less than ±25 ft/min and Rt CAS is less than ±0.25 kt/min.

• Press CLEAR/QUIT to return to the main menu.

• Press LEAK MEASURE/CONTROL to return to Control mode.

• Press GROUND, to go to atmospheric pressure.

• Wait until the display shows safe at ground (atmospheric pressure).

After a successful leak test, the ADTS 505 is now ready to be connected to an aircraft system or

unit under test.

After an unsuccessful, first-time leak test, leave the system to achieve thermal stability for a further

five minutes, press CLEAR/QUIT and repeat the leak test. If the leak test is now successful, the

ADTS 505 is now ready to be connected to an aircraft system or unit under test.

After another unsuccessful leak test, disconnect both hoses, check the condition of the o-rings on

the Ps and Pt connectors as detailed in the maintenance section and firmly replace the blanking

caps. Press CLEAR/QUIT and repeat the leak test procedure.

After a successful leak test without hoses connected, replace or repair the faulty hose(s) and test

again. If the ADTS 505 fails the leak test without hoses connected, switch off and return the unit

to the repair depot.

Page 41

Druck ADTS 505 User Manual 3 - 13

K0260 Issue No. 8

3

3.5.5 Changing the Units of Measurement

The units of measurement can be changed

to units of pressure measurement or

aeronautical units.

To change the units:

• Select, from the main menu, [Units].

• Select from the Units Menu:

• Select [Save Settings] to store as the

units used at the next power up.

• Press CLEAR/QUIT to return to the

main pressure display.

• In set-up, more units of pressure

measurement can be selected for

each parameter.

3.5.6 Setting Limits

All data entered is checked against minimum and maximum values set for the particular limit set

in use. If these limits are exceeded, the display shows a warning message "Changed aim to current

limit". Press CLEAR/QUIT the system automatically modifies the aim values so that the limits are

not exceeded. All limits of associated parameters are checked, if these limits are exceeded the

display shows the warning message and the parameter modified. Similarly, if an ARINC 565 limit

is exceeded when entering a value and, ARINC limits are enabled, the display shows a warning

message. Refer to Section 6 for details of the factory-defined operating envelope ARINC565.

In the SETUP function, previously stored sets of limits can be selected for use. Each set of limits is

stored under name or number up to a maximum of 10 characters. To enable other sets of limits

or enter additional sets of limits requires the supervisor PIN.

F1

F2

F3

F4

F5

F6

F2

Units

Main Menu

ft kts

ft/min

m km/h

m/min

mbar

mbar

/min

Save

Settings

Units

Page 42

3 - 14 Operation

K0260 Issue No. 8

To select a limit set (User)

Press SETUP, the display shows Setup, [Limits]

[xxxxxx], where xxxxxx is the current name of

the selected limit set. Select [Limits] [xxxx] F3.

The display highlights the current set of limits

in use by the name in the list. The current limit

values can be inspected by pressing [View

Details] F4. The display shows the current

limit values and divides these values into

aeronautical (Page #1) and pressure (Page

#2).

The ARINC 565 limit can be selected ON or