Page 1

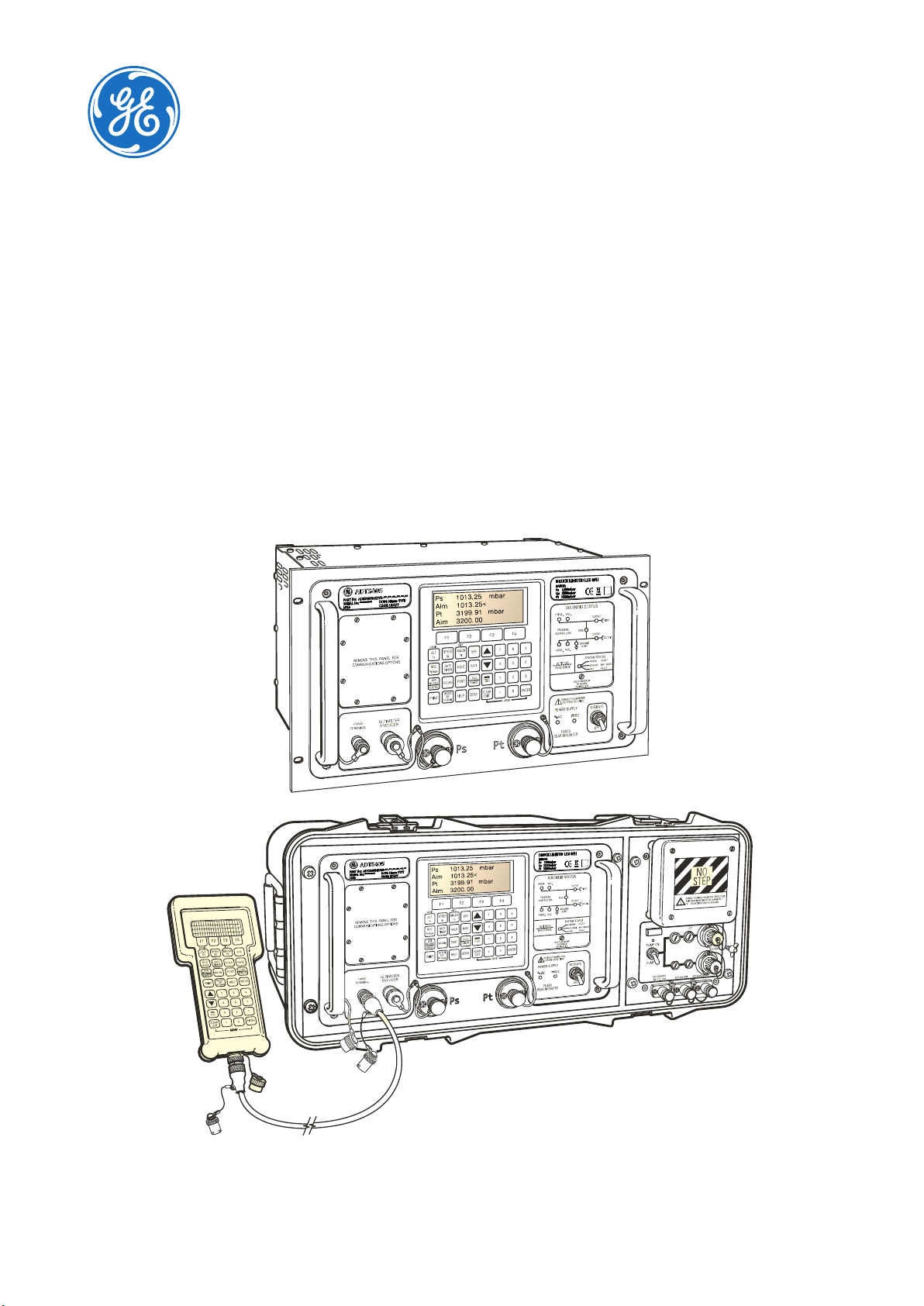

Druck

ADTS 405 R/F Mk2

Air Data Test Set

Instruction Manual

ADTS HAND TERMINAL

GE Data Classification: Public

500VA

POWERSUPPLY24-30V

FUSES

T32A

T20A

POWERSUPPLY

100/120/230V~50/60Hz500VA

115~400Hz500VA

FUSES

T5.0A250VHRC

www.gemeasurement.com

Page 2

Page 3

INTRODUCTION

This technical manual provides operating instructions for the Druck Air Data Test System ADTS 405

Mk 2 series.

SCOPE

This technical manual contains a brief description, operation and testing procedures for the user of this

equipment.

SAFETY

The manufacturer has designed this equipment to be safe when operated using the procedures

detailed in this manual:

• Do not use this equipment for any other purpose than that stated.

the protection given by the equipment from working.

• See Product Safety and Installation Guide 124M8686, also supplied, for essential operating

and Safety instructions that must be followed to ensure safe operation.

• Use suitably qualified Technicians and good engineering practice for all procedures in this

publication.

*A qualified technician must have the necessary technical knowledge, documentation,

special test equipment and tools to carry out the required work on this equipment.

Incorrect use can prevent

PRESSURE

Do not apply pressure greater than the maximum safe working pressure specified in this manual

when using the ADTS405 Mk 2 series.

TOXIC MATERIALS

There are no known toxic materials used in this equipment.

MAINTENANCE

The equipment must be maintained using the manufacturer’s procedures and should be carried out

by authorized service agents or the manufacturer’s service departments.

For technical advice contact GE or subsidiary manufacturer of this product.

© 2015 General Electric Company – All rights reserved. ADTS 405 Mk2 Instruction Manual-English | i

Page 4

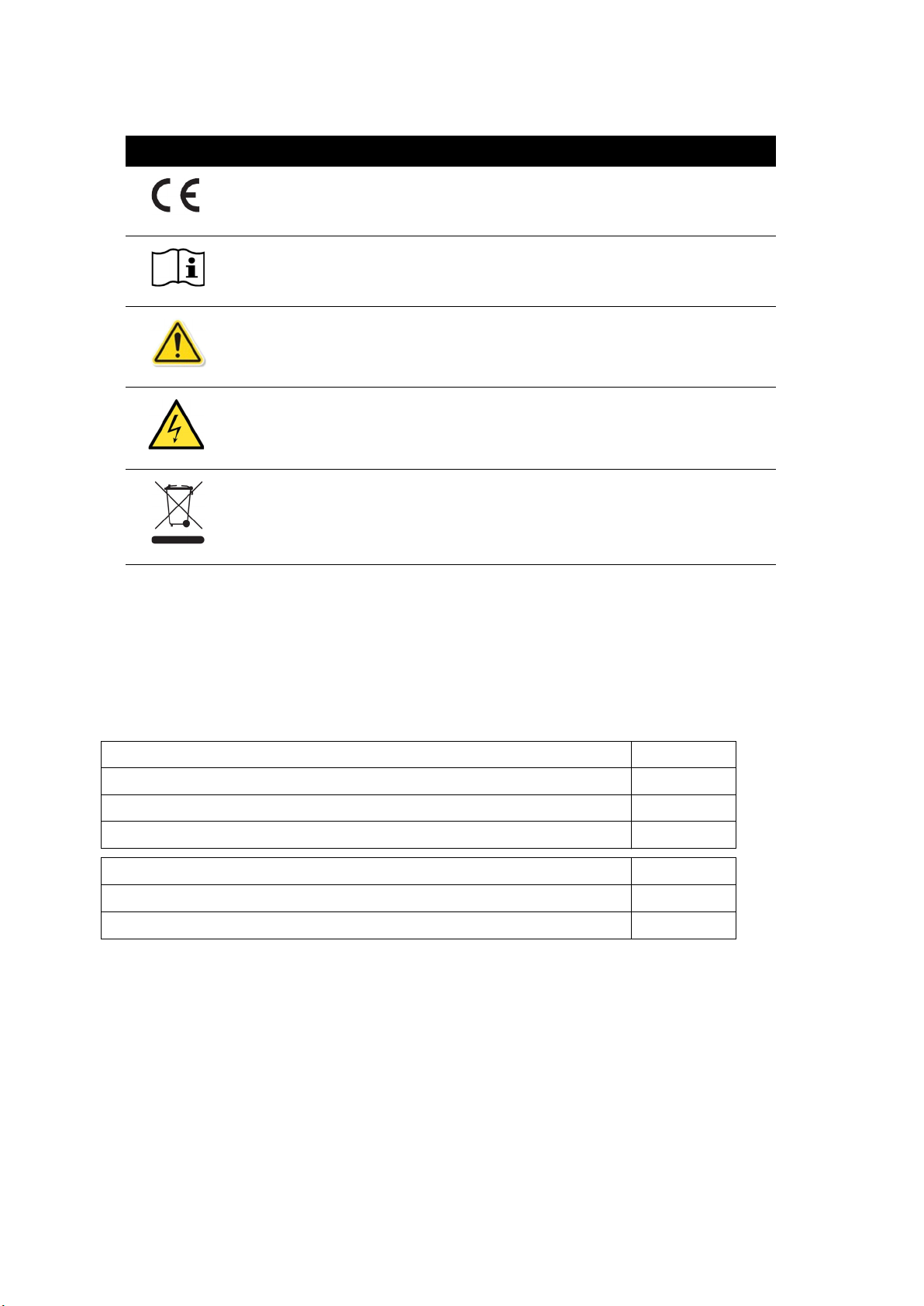

MARKS AND SYMBOLS ON THE EQUIPMENT

Symbol Description

This equipment meets the requirements of all relevant European safety

directives. The equipment carries the CE mark.

This symbol on the equipment indicates that the user should refer to the

user manual.

This symbol on the equipment indicates a warning and that the user should

refer to the user manual.

This symbol warns the user of the danger of electric shock.

Do not dispose of this product as household waste. Use an approved

organization that collects and/or recycles waste electrical and electronic

equipment. For more information contact your Customer Service using the

details shown at the back, or your local Government Office.

For the list of approved GE service centers go to: www.gemeasurement.com

ASSOCIATED PUBLICATIONS

The following table lists the Druck publications referenced in this manual:

Safety and Installation Guide - Air Data Test Systems ADTS 405F/ 405R 124M8686

Calibration Manual -

IEEE 488 OPT 2 Manual -

SCPI IEEE 488 Manual -

User Manual -

User Manual -

Operating and Communications Manual -

Altimeter Encoder Option K0170

Line Switching Unit LSU 100/101

Air Data Test System ADTS 405

Air Data Test System ADTS 405

Air Data Test System ADTS 405

Line Switching Unit LSU Series

K0199

K0154

K0157

K0220

K0223

ii | ADTS 405 Mk2 Instruction Manual-English © 2015 General Electric Company – All rights reserved.

Page 5

ABBREVIATIONS

The following abbreviations are used in this manual; the abbreviations are the same in the singular

and plural.

Abbreviation Description

A Ampere

abs Absolute

a.c. Alternating current

ALT Altitude

CAS Calibrated airspeed

d.c. Direct current

e.g. For example

EOC End of conversion

EPR Engine pressure ratio

EPROM Electrically programmable read only memory

etc. And so on

Fig. Figure

ft Foot

g Gauge

Hg Mercury

Hz Hertz

IAS Indicated airspeed

i.e. That is

IEEE 488 Institute of Electrical and Electronic Engineers standard 488 data

in inch

kg Kilogram

LED Light emitting diode

(M) Magnesium alloy

m Meter

mA Milliampere

max Maximum

mbar Millibar

mV Millivolts

No. Number

N.m. Newton meter

Para. Paragraph

Ps Static pressure

psi Pounds per square inch

© 2015 General Electric Company – All rights reserved. ADTS 405 Mk2 Instruction Manual-English | iii

Page 6

Abbreviation Description

Pt Total pressure (pitot)

Qc Differential pressure Pt-Ps

QFE Local atmospheric pressure

QNH Barometric pressure at sea level

ROC Rate of climb

Vc Calibrated velocity

Vt True velocity

+ve Positive

-ve Negative

°C Degrees Celsius

iv | ADTS 405 Mk2 Instruction Manual-English © 2015 General Electric Company – All rights reserved.

Page 7

GLOSSARY

The terminology used in this manual is specific and individual interpretation must not be

introduced. The terms are defined as follows:

Item Description

Adjust To bring to a more satisfactory state; to manipulate controls, levers, linkages, etc. to

return equipment from an out-of-tolerance condition to an in-tolerance condition.

Align To bring into line; to line up; to bring into precise adjustment, correct relative

position or coincidence.

Assemble To fit and secure together the several parts of; to make or form by combining parts.

Calibrate To determine accuracy, deviation or variation by special measurement or by

comparison with a standard.

Check Make a comparison of a measure of time, pressure, temperature, resistance,

dimension or other quality with a known figure for that measurement.

Disconnect To detach the connection between; to separate keyed or matched equipment parts.

Dismantle To take apart to the level of the next smaller unit or down to all removable parts.

Ensure To confirm that a proper condition exists; to find out with certainty.

Examine To perform a critical visual observation or check for specific conditions; to test the

condition of.

Fit Correctly attach one item to another.

Inspect Review the work carried out by Specialists to ensure it has been performed

satisfactorily.

Install To perform operations necessary to properly fit an equipment unit into the next

larger assembly or system.

Maintain To hold or keep in any particular state or condition especially in a state of efficiency

or validity.

Operate Ensure that an item or system functions correctly as far as possible without the use

of test equipment or reference to measurement.

Readjust To adjust again; to move back to a specified condition; to bring back to an in-

tolerance condition.

Reconnect To rejoin or refasten that which has been separated.

Refit Fit an item which has previously been removed.

Remove To perform operations necessary to take an equipment unit out of the next larger

assembly or system. To take off or eliminate. To take or move away.

Repair To restore damaged, worn out or malfunctioning equipment to a serviceable, usable

or operable condition.

Replace Remove an item and fit a new or a serviced item.

Reset To put back into a desired position, adjustment or condition.

Service To perform such operations as cleaning, lubricating and replenishing to prepare for

use.

Test Ascertain by using the appropriate test equipment that a component or system

functions correctly.

© 2015 General Electric Company – All rights reserved. ADTS 405 Mk2 Instruction Manual-English | v

Page 8

RETURNED GOODS PROCEDURE

If the unit is unserviceable and requires a repair return to a GE Service Centre. Contact the GE

Service Centre, either by 'phone, fax or e-mail to obtain a Returned Goods Authorization (RGA)

number, providing the following information:

• Product (i.e. ADTS 405)

• Pressure medium (i.e. air, nitrogen)

• Serial number

• Details of defect/work to be undertaken

• Operating conditions

SAFETY PRECAUTIONS

See Safety and Installation Guide 124M8686

Note: Do not use unauthorized sources to service this equipment as this will affect the

warranty and may not guarantee further performance.

PRESSURE UNITS AND CONVERSION FACTORS

Pressure units Factor (hPa) Pressure units Factor (hPa)

mbar 1.0 cmH

bar 1000.0 mH

Pa (N/m2)0.01 kg/m

hPa 1.0 kg/cm

kPa 10.0 torr 1.333223684

MPa 10000.0 atm 1013.25

mmHg @ 0°C 1.333223874 psi 68.94757293

cmHg @ 0°C 13.33223874 lb/ft

mHg @ 0°C 1333.223874 inH

inHg @ 0°C 33.86388640341 inH2O @ 20°C 2.486413

mmH

O @ 4°C 0.0980665 inH2O @ 60°F 2.487641558

2

O @ 20°C 0.978903642

2

O @ 20°C 97.8903642

2

2

2

2

O @ 4°C 2.4908891

2

0.0980665

980.665

0.4788025898

O @ 4°C 0.980665 ftH2O @ 4°C 29.8906692

cmH

2

O @ 4°C 98.0665 ftH2O @ 20°C 29.836983

mH

2

mmH

vi | ADTS 405 Mk2 Instruction Manual-English © 2015 General Electric Company – All rights reserved.

O @ 20°C 0.097890364 ftH2O @ 60°F 29.8516987

2

Page 9

Unit Conversion

To convert FROM pressure Value 1(in pressure Units)1 TO pressure Value 2 in pressure

Units: Calculate as follows:

Value 2 = Value 1 x Factor 1 ÷ Factor 2

© 2015 General Electric Company – All rights reserved. ADTS 405 Mk2 Instruction Manual-English | vii

Page 10

viii | ADTS 405 Mk2 Instruction Manual-English © 2015 General Electric Company – All rights reserved.

Page 11

Contents

1. DESCRIPTION 1

1.1 Introduction 1

1.2 Operating Range and Performance 1

1.3 Operating Limits 2

2. INSTALLATION 5

2.1 List of Parts 5

2.2 Packaging for Storage or Transportation 5

2.3 Power Supply 9

2.3.1 405R Rack-mounted version 9

2.3.2 405F Flightline version 9

2.4 Positioning of the ADTS 10

2.4.1 405R Rack-mounted version 10

2.4.2 405F Flightline version 10

3. OPERATION 15

3.1 Preparation 15

3.2 Start-up 15

3.2.1 Connections 15

3.2.2 Power-up 16

3.2.3 Units of Measure 18

3.3 Operation quick reference 19

3.4 Operating modes 20

3.5 Operating Procedures 24

3.5.1 Control or Measure Parameter 24

3.5.2 Aim 28

3.5.3 Leak Measure 29

3.5.4 Aircraft system protection 31

3.5.5 Limit Checking 31

3.5.6 Changing Parameters 33

3.5.7 Engine Pressure Ratio (EPR) 34

3.6 Testing Aircraft Systems or UUT 35

3.6.1 Go To Ground and Shut-down 35

3.6.2 SETUP and CONFIGuration options 36

3.7 Communications panel options 45

3.7.1 Ethernet System 45

3.7.2 Access ADTS files 47

3.7.3 Connection of the IEEE 488 Facility 48

3.8 Enabling the Altimeter Encoder Option 49

4. MAINTENANCE 51

4.1 Introduction 51

4.2 Materials 51

© 2015 General Electric Company – All rights reserved. ADTS 405 Mk2 Instruction Manual-English | ix

Page 12

4.3 Maintenance Tasks 52

4.4 Routine Maintenance 53

4.4.1 Servicing Procedures 53

4.4.2 Replacing the output connector o-ring 53

4.4.3 Fuse Replacement 53

4.5 Cable tests 56

5. TESTING AND FAULT FINDING 59

5.1 Introduction 59

5.2 Error messages 59

5.3 Standard Serviceability Test 60

5.3.1 Procedure 60

5.3.2 Fault Finding 61

5.4 Fault Diagnosis 62

5.5 Ventilating after Overpressure 63

5.6 Further Testing 65

5.6.1 Environmental and preliminary operations 65

5.6.2 Pressure Leak check 65

5.6.3 Vacuum leak check 66

5.6.4 Range Check 66

5.6.5 Controller Stability 66

5.6.6 Testing of Standard and Optional External Communication Ports 67

5.6.7 Testing of IEEE 488 Facility 68

5.6.8 Testing the Altimeter Encoder Option 69

6. REFERENCE AND SPECIFICATION 71

6.1 Introduction 71

6.2.1 F1 - F4 72

6.2.2 ALT/Ps 72

6.2.3 SPEED/Qc 72

6.2.4 MACH/Pt 73

6.2.5 EPR 73

6.2.6 ROC/Ps RATE 73

6.2.7 RATE TIMER 73

6.2.8 HOLD 74

6.2.9 RATE 75

6.2.10 LEAK MEASURE/CONTROL 75

6.2.11 GROUND 76

6.2.12 [GO TO GROUND] 76

6.2.13 [DISPLAY QFE] 76

6.2.14 [DISPLAY QNH] 77

6.2.15 PORT 77

6.2.16 REMOTE 77

6.2.17 PRINT 77

6.2.18 EXECUTE TEST PROGRAM 78

6.2.19 HELP 79

6.2.20 or (Nudge Keys) 79

6.2.21 Number 0 to 9 79

6.2.22 -000 80

x | ADTS 405 Mk2 Instruction Manual-English © 2015 General Electric Company – All rights reserved.

Page 13

6.2.23 CLEAR/QUIT 80

6.2.24 ENTER 80

6.2.25 CLEAR + ENTER (ABORT) 80

6.2.26 SETUP 81

6.2.27 FULL SET-UP 81

6.2.28 SETUP, [UNITS] 81

6.2.29 SETUP, [LIMITS] 82

6.2.30 SETUP, [OSC] 82

6.2.31 SETUP, [MORE], [CONTROL], [Ps Pt DUAL] 83

6.2.32 SETUP, [MORE], [DISPLAYS/OPTIONS], [DISPLAY TYPE] 83

6.2.33 SETUP, [MORE], [DISPLAYS/OPTIONS], [OPTIONS] 85

6.2.34 SETUP, [MORE], [CLOSE OUTPUT VALVES] 85

6.2.35 SETUP, [MORE], [OPEN OUTPUT VALVES] 85

6.2.36 SETUP, [MORE], [SYSTEM SELF TEST] 85

6.2.37 SETUP, ALT (Figures 6-5 and 6-6) 86

6.2.38 SETUP, SPEED, [AUTO ZERO] 86

6.2.39 SETUP, SPEED, [CAS/TAS] 86

6.2.40 SET-UP, SPEED, [Pt TEMPERATURE] 87

6.2.41 SET-UP, MACH 87

6.2.42 SET-UP, RATE TIMER 88

6.2.43 SET-UP, RATE 88

6.2.44 SETUP, LEAK MEASURE CONTROL, [AUTO LEAK] 88

6.2.45 SETUP, LEAK MEASURE CONTROL, [AUTO LIMIT] 88

6.2.46 SETUP, GROUND 88

6.2.47 SETUP, [PORT] 88

6.2.48 SETUP, PRINT, [DATE/TIME] 88

6.2.49 SETUP, EXECUTE TEST PROGRAM 89

6.2.50 SETUP, HELP 89

6.2.51 SETUP, or (Nudge keys) 89

6.2.52 MINIMUM SETUP 89

6.2.53 SETUP, [UNITS], [AERO] 89

6.2.54 SETUP, [UNITS], [PRESS] 89

6.2.55 SETUP, [LIMITS] 90

6.2.56 SETUP, HELP 90

6.2.57 CONFIGURATION 90

6.2.58 CONFIG, [UNITS] 91

6.2.59 CONFIG, [LIMITS], [EDIT LIMITS], [EDIT EXISTING] 91

6.3 ADTS 405R/F Specification 97

6.4 Measurement and Control Range Specifications 99

© 2015 General Electric Company – All rights reserved. ADTS 405 Mk2 Instruction Manual-English | xi

Page 14

xii | ADTS 405 Mk2 Instruction Manual-English © 2015 General Electric Company – All rights reserved.

Page 15

Figures

Figure Page

2-1 Equipment and Parts 7

2-2 ADTS 405R Altitude Reference 10

2-3 ADTS 405F Altitude Reference 11

2-4 ADTS 405R Front Panel View 11

2-5 ADTS 405R Rear Panel 12

2-6 ADTS 405F General View 13

3-1 Front Panel 18

3-2 Single Display 25

3-3 Dual Display 25

3-4 Triple Display 26

3-5 Rate Timer Display Aeronautical Units 26

3-6 Rate Timer Display Pressure Units 27

3-7 Pt Only Display 27

3-8 Set-up example 36

3-9 Configuring Windows For ADTS Subnet IP Address 45

3-10 Ping Test From Windows Command Prompt 46

3-11 PuTTY Configuration 46

3-12 Changing the default password 47

3-13 WinSCP Login Screen 47

3-14 ADTS File System Directories Screen 48

4-1 Output Connector O ring Seal 53

4-2 ADTS 405F AC Fuse Positioning 54

4-3 ADTS 405F DC Fuse Positioning 55

4-4 ADTS 405R AC Fuse Positioning 56

5-1 Fault Finding Chart 62

5-2 External Communications 67

6-1 Altitude Correction Rack Mounting 87

6-2 ALTITUDE CORRECTION ON-AIRCRAFT 87

6-3 ARINC 565 OPERATING LIMITS 93

© 2015 General Electric Company – All rights reserved. ADTS 405 Mk2 Instruction Manual-English | xiii

Page 16

xiv | ADTS 405 Mk2 Instruction Manual-English © 2015 General Electric Company – All rights reserved.

Page 17

Tables

Table Page

2-1 ADTS MK2 SPARES AND ACCESSORIES LIST 8

2-2 DC Input Connector 10

3-1 Units of Measure 18

3-2 Warning Messages 32

3-3 IEEE 488 facility 49

4-1 Maintenance Chart 51

4-2 Materials List 51

4-3 Tool and Test Equipment Requirements 52

4-4 AC Input Connector 57

4-5 DC Input Connector 57

5-1 Error Messages 59

5-2 Fault Advice and Action 63

5-3 Optional cable (AAU-32 units) 69

6-1 Aeronautical Units Dual Display 83

6-2 Pressure Units Dual Display 84

6-3 Aeronautical units triple display 84

6-4 Pressure units triple display 85

© 2015 General Electric Company – All rights reserved. ADTS 405 Mk2 Instruction Manual-English | xv

Page 18

xvi | ADTS 405 Mk2 Instruction Manual-English © 2015 General Electric Company – All rights reserved.

Page 19

Introduction

1. DESCRIPTION

1.1 Introduction

There are two versions of this Air Data Test System, a 19", 6U high (10½”) rack-mounted unit (ADTS

405R) and a flight line unit (ADTS 405F).

The ADTS 405R is a rack-mounted system and, with external pressure and vacuum supplies

connected, provides measurement and control of pitot and static systems and components. The

unit can be used for leak checks, calibration accuracy checks and functional tests of air data

instruments, components and systems.

The ADTS 405F is a self-contained flight-line air data test system providing complete pitot and

static measurement and control. The unit can be used for on-aircraft sense and leak testing,

calibration accuracy checks and functional tests of air data instruments, components and systems.

The ADTS 405F comprises an electronics rack and pump rack enclosed in a high density,

polyethylene case.

The ADTS 405 displays and operates in either units of pressure measurement or aeronautical units.

In the control mode, the rate that the pressures change towards new set-points can be controlled

in true aeronautical rate units.

There are two independent pneumatic channels connect to the aircraft or instrument systems, one

for static and one for pitot. They can be operated as measure only channels with leak testing facility

or each can be control channels producing true pressure conditions for altitude and airspeed.

To protect sensitive instruments and equipment a “ground” facility automatically and safely

controls both channels to atmospheric pressure at the previously entered rates of change and then

informs the operator when both channels are safely at “ground”.

The operator interface is either a hand terminal connected to the front panel or the key pad and

display on the front panel. Both provide information and control selections for the user through the

keys and display. The keypad has a back-light for improved operation in poor light conditions. The

unit can also be controlled remotely using the IEEE488 communications interface. The front panel

contains the operate switch and a mimic panel with LED indicators showing the operation of the

solenoid-operated pneumatic valves.

The pump rack, on the ADTS 405F, produces pressure and vacuum supplies for the electronics rack

and for external services. Located on the front panel, the external connectors provide for external

pressure and vacuum supplies (EXT PRESSURE and EXT VACUUM) and an auxiliary static (vacuum)

output (AUX). The rack is cooled by a fan located under a protective cover on the front panel. The

power supply connection for the ADTS 405F is located on the front panel.

1.2 Operating Range and Performance

The ADTS 405 is supplied in one of two full-scale ranges (850 knots or 1000 knots) for

measurement and control of the pitot pressure channel.

Operating limits are set, pre-defined tabular limits known as STANDARD, CIVIL and MAX these can

be selected through the SETUP menu (see Reference section 6). Operators may also configure the

display to aeronautical or pressure units but should be aware that when units of pressure are

selected, wider full-scale pressure limits will be enabled for some parameters.

© 2015 General Electric Company – All rights reserved. ADTS 405 Mk2 Instruction Manual-English | 1

Page 20

Chapter 1. DESCRIPTION

1.3 Operating Limits

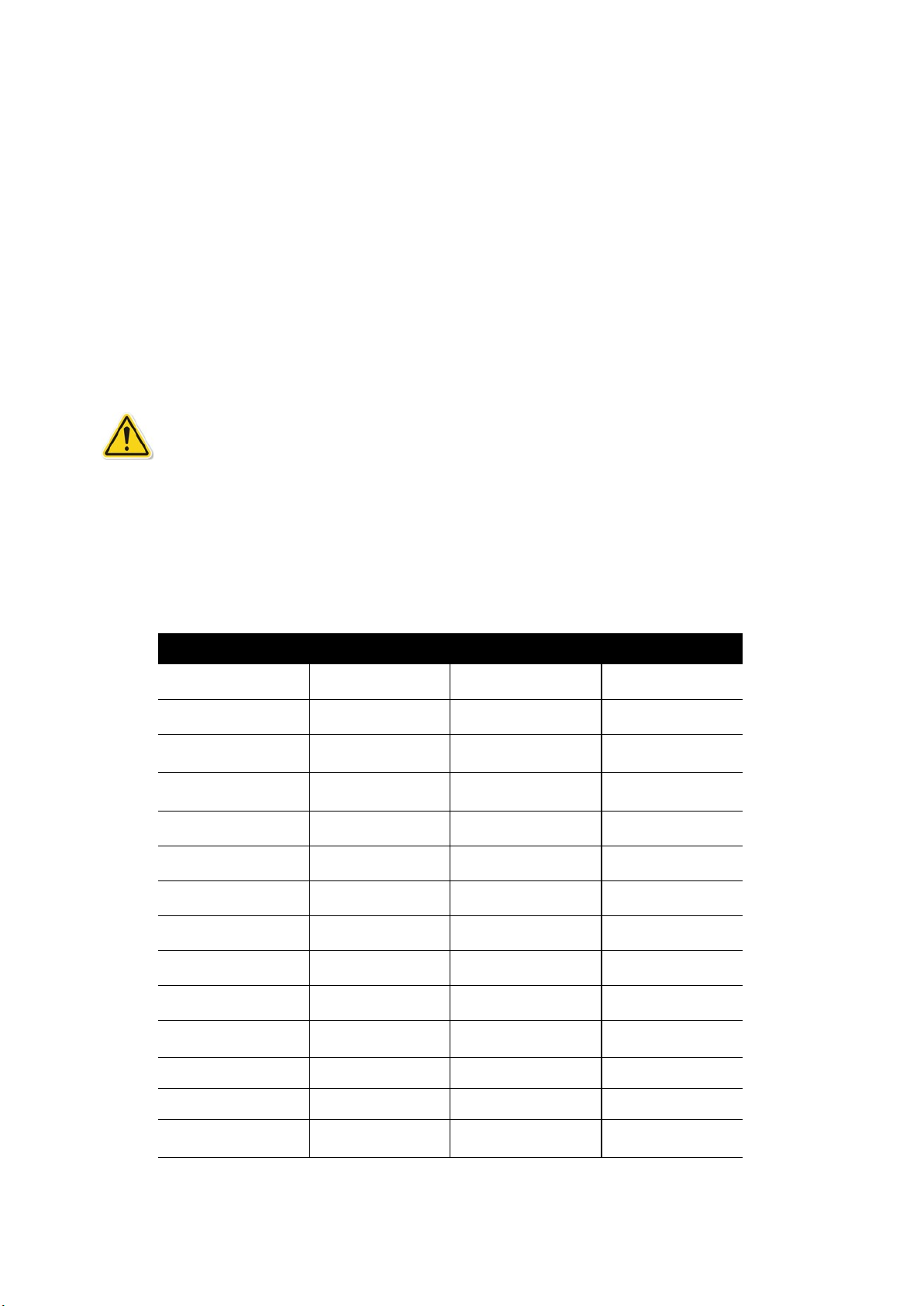

The following sets of operating limits are supplied with the ADTS 405.

850 knot range operating limits

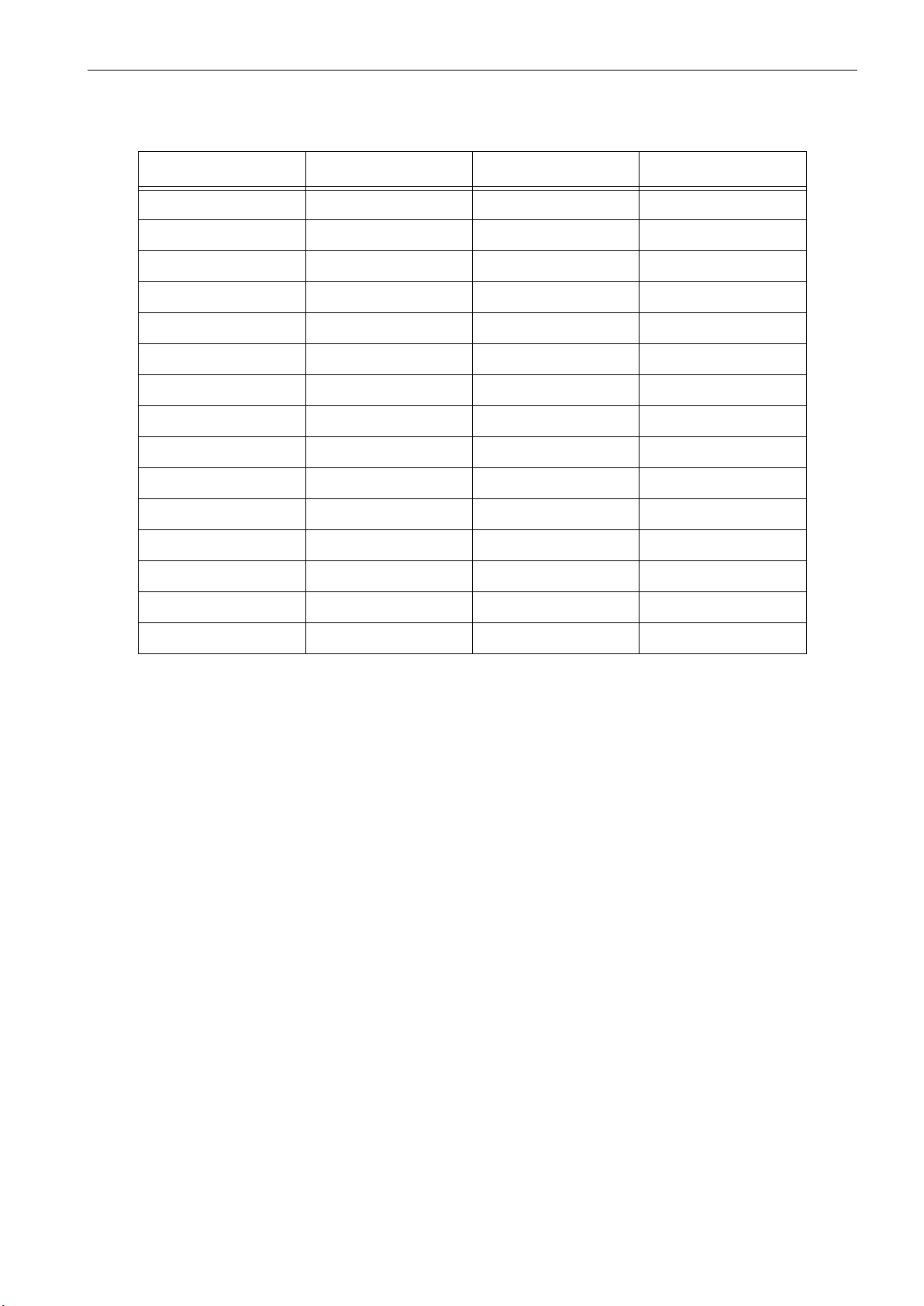

Parameter Max Limits Standard Limits Civil Limits

Min Alt -3,000 ft -2,000 ft -1,000 ft

Max Alt 105,000 ft 80,000 ft 50,000 ft

Min CAS -100 kts 0.0 kts 0 kts

Max CAS 850 kts 850 kts 450 kts

Min Ps 3.0 mbar 27.615 mbar 115.972 mbar

Max Ps 1355.00 mbar 1088.657 mbar 1050.406 mbar

Min Qc -1,352.00 mbar 0.0 mbar 0.0 mbar

Max Qc 1,700.00 mbar 1688.00 mbar 368.01 mbar

Max Mach 12.35 2.5 1

Max ROC 100,000 ft/min 9,000 ft/min 6,000 ft/min

Max Rate CAS 2,000 kts/min 600 kts/min 600 kts/min

Max Rate Ps 10,000.00 mbar/min 200.00 mbar/min 100.00 mbar/min

Max Rate Qc 10,000.00 mbar/min 200.00 mbar/min 100.00 mbar/min

ARINC Limits OFF OFF OFF

Alt Correction 0 ft 0 ft 0 ft

2 | ADTS 405 Mk2 Instruction Manual-English © 2015 General Electric Company – All rights reserved.

Page 21

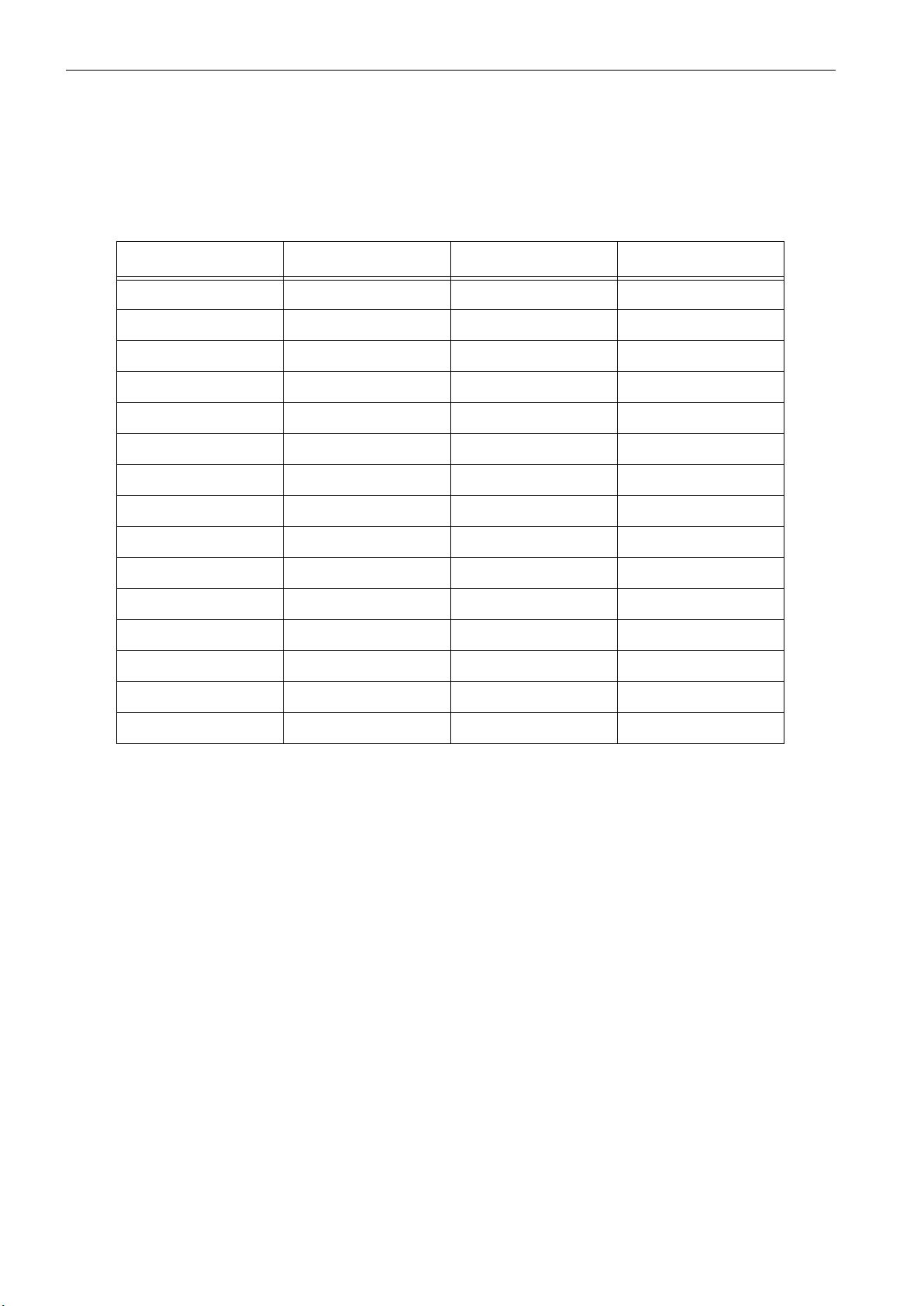

Operating Limits

1000 knot range operating limits

Parameter Max Limits Standard Limits Civil Limits

Min Alt -3,000 ft -3,000 ft -1,000 ft

Max Alt 105,000 ft 80,000 ft 50,000 ft

Min CAS -100 kts 0.0 kts 0 kts

Max CAS 1,000 kts 1,000 kts 450 kts

Min Ps 3.0 mbar 27.615 mbar 115.972 mbar

Max Ps 1355.00 mbar 1,128.029 mbar 1050.406 mbar

Min Qc -1,352.00 mbar -16.303 mbar 0 mbar

Max Qc 2,500.00 mbar 2,490.50 mbar 368.01 mbar

Max Mach 14.97 5 1

Max ROC 1000,000 ft/min 15,000 ft/min 6,000 ft/min

Max Rate CAS 2,000 kts/min 700 kts/min 600 kts/min

Max Rate Ps 10,000.00 mbar/min 200.00 mbar/min 100.00 mbar/min

Max Rate Qc 10,000.00 mbar/min 200.00 mbar/min 100.00 mbar/min

ARINC Limits OFF OFF OFF

Alt Correction 0 ft 0 ft 0 ft

© 2015 General Electric Company – All rights reserved. ADTS 405 Mk2 Instruction Manual-English | 3

Page 22

Chapter 1. DESCRIPTION

4 | ADTS 405 Mk2 Instruction Manual-English © 2015 General Electric Company – All rights reserved.

Page 23

List of Parts

2. INSTALLATION

Special request

Please keep the special packing boxes so that the ADTS can be safely shipped for calibration, repair

or storage.

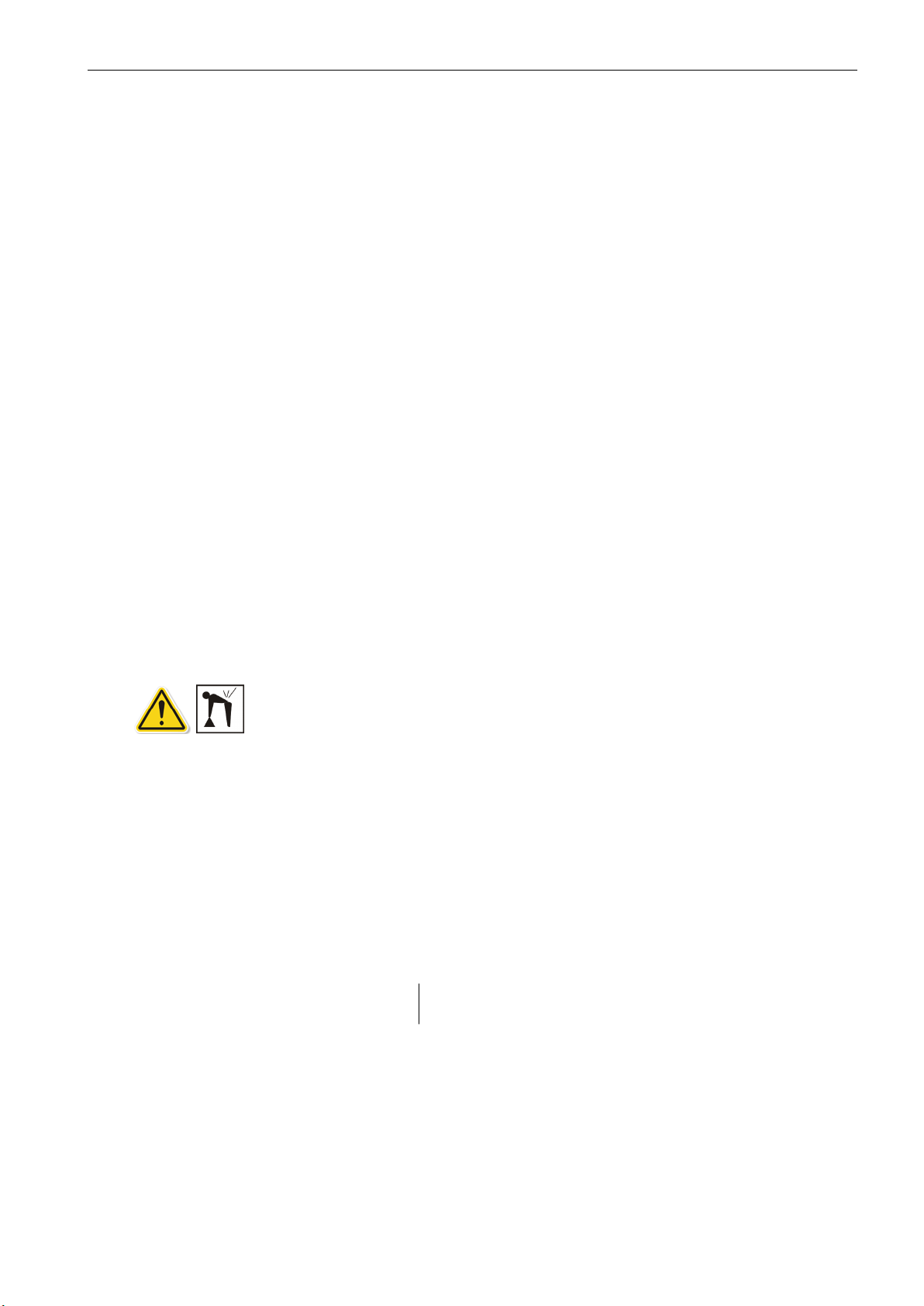

2.1 List of Parts

On receipt of the ADTS 405 check the contents of the packaging against the following lists:

Standard Packaging List - ADTS 405F Standard Packaging List - ADTS 405R

i) Flight line ADTS 405F i) Rack ADTS 405R

ii) Accessory bag ii)

Power supply cable 2m or 10m (regional plug

iii)

as per order)

iv) Hand terminal (optional) iv) Input, hose, 15m, green, AN6 - open

v) Hand terminal cable - 2 m (optional) v) Input, hose, 15m, yellow, AN4 - open

vi) Hand terminal cable - 18 m (optional) vi) Kit, fuse/o-ring

vii) User Manual K0572 (this publication) vii) Plug, expansion port

viii) Kit, fuse/o-ring viii) Safety and Installation Guide 124M8686

Power supply cable 2.5m (regional plug as per

order)

iii) User Manual K0572 (this publication)

ix) Safety and Installation Guide 124M8686

2.2 Packaging for Storage or Transportation

WARNING THE FLIGHT-LINE UNIT CAN BE MOVED BY USE OF THE HANDLE AND

WHEELS, BUT IF IT IS TO BE LIFTED, IT IS A TWO PERSON LIFT.

Environment

The optimum conditions for ADTS405 Mk2 equipment during transit, preparation for calibration and

repair and when being storage are detailed as below. Items in storage are defined as being nonoperational. If the ADTS becomes exposed to moisture or very high humidity, dry as soon as

possible and temporarily store in a low humidity area. The following conditions apply for storage or

shipping:

Temperature Range -51° to 70°C (-60° to +158°F)

Altitude Up to 50,000 feet (15,240 metres)

Procedure

1. The unit should be at zero/ambient pressure.

2. Disconnect all hose assemblies and stow them in the shoulder bag.

3. Switch power OFF and disconnect from the electrical power supply.

4. Disconnect the power supply cable and the hand terminal cable.

5. Disconnect the hand terminal cable from the hand terminal.

© 2015 General Electric Company – All rights reserved. ADTS 405 Mk2 Instruction Manual-English | 5

Page 24

Chapter 2. INSTALLATION

When using packing materials other than the original, proceed as follows:

1. Wrap unit in polyethylene sheeting.

2. Select a double-wall cardboard container. Inside dimensions must be at least 15 cm

greater than the equipment. The carton must meet test strength requirements of >125 kg.

3. Protect all sides with shock-absorbing material to prevent equipment movement within

the container.

4. Seal carton with approved sealing tape.

5. Mark carton “FRAGILE” on all sides, top, and bottom of shipping container.

Note: For ADTS 405R rack units loose or peripheral items should be placed in a

sealed polythene bag. For ADTS 405F stow the power supply cable, hand

terminal cable and the hand terminal in the ADTS 405F lid. Fit the lid to the

unit.

6 | ADTS 405 Mk2 Instruction Manual-English © 2015 General Electric Company – All rights reserved.

Page 25

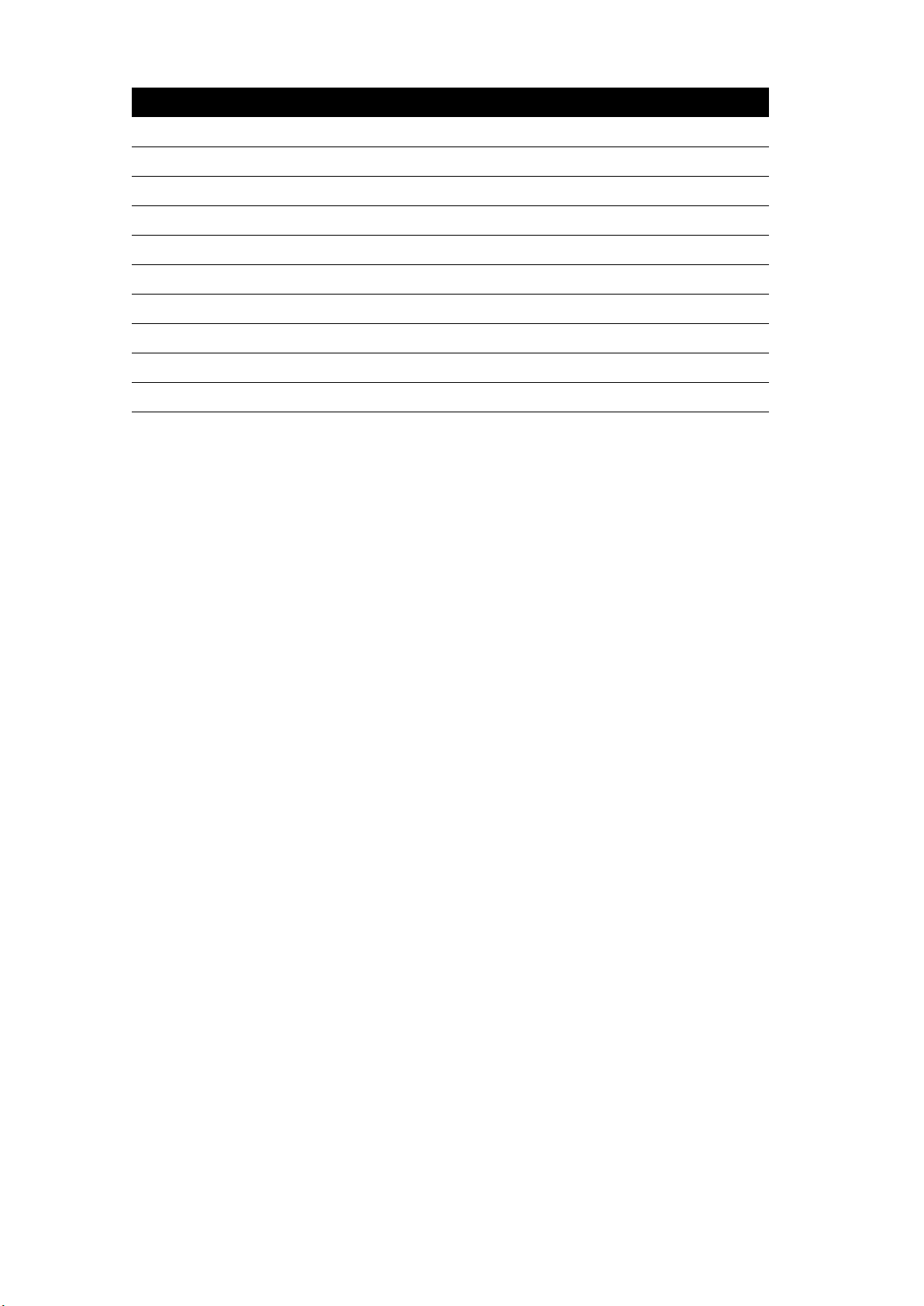

SHOULDER BAG

Packaging for Storage or Transportation

HAND TERMINAL

ADTS 405F

2

ADTS 405R

A

4a-h

5a-p

REGIONAL LINE PLUG

AC CABLE (ADTS 405F)

6

7

HAND TERMINAL CABLES

3

2.5mREGIONAL LINE PLUG

AC CABLE (ADTS 405R)

2m or 10m

2m

18m

IEC

1

ACCESSORIES

8

EXPANSION PORT DONGLE

(ADTS 405R ONLY)

9a-d

OPTIONAL CONFIGURABLE

ORDER ITEMS

AIRCRAFT HOSES

(Ps / Pt, RED / BLUE)

10

ALTIMETER ENCODER CABLE (OPTION)

11

SERVICE KIT

12

SERVICES HOSES (ADTS 405R ONLY)

PRESSURE / VACUUM, YELLOW / GREEN

15m

13

DC CABLE (OPTION)

A

Figure 2-1: Equipment and Parts

© 2015 General Electric Company – All rights reserved. ADTS 405 Mk2 Instruction Manual-English | 7

Page 26

Chapter 2. INSTALLATION

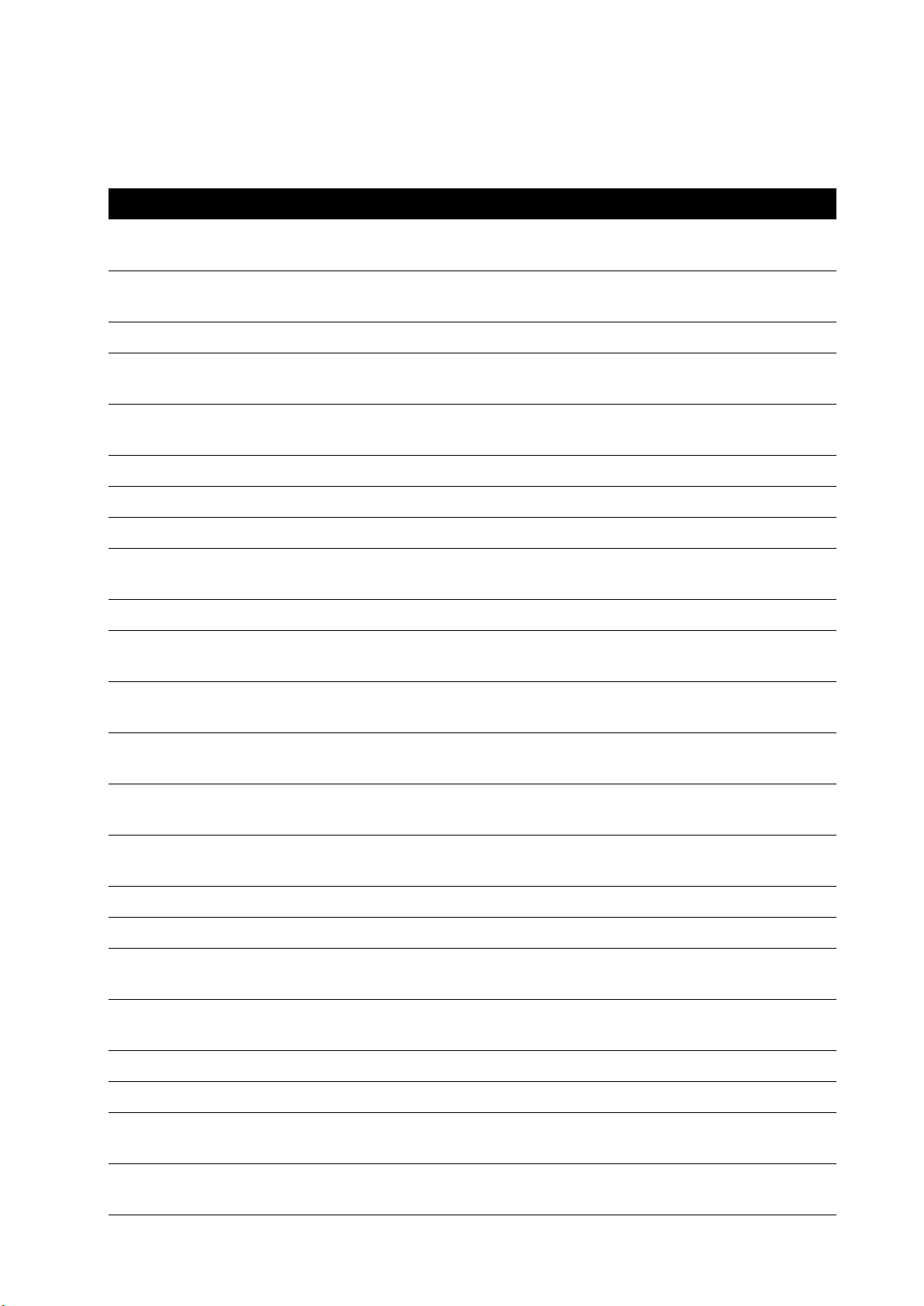

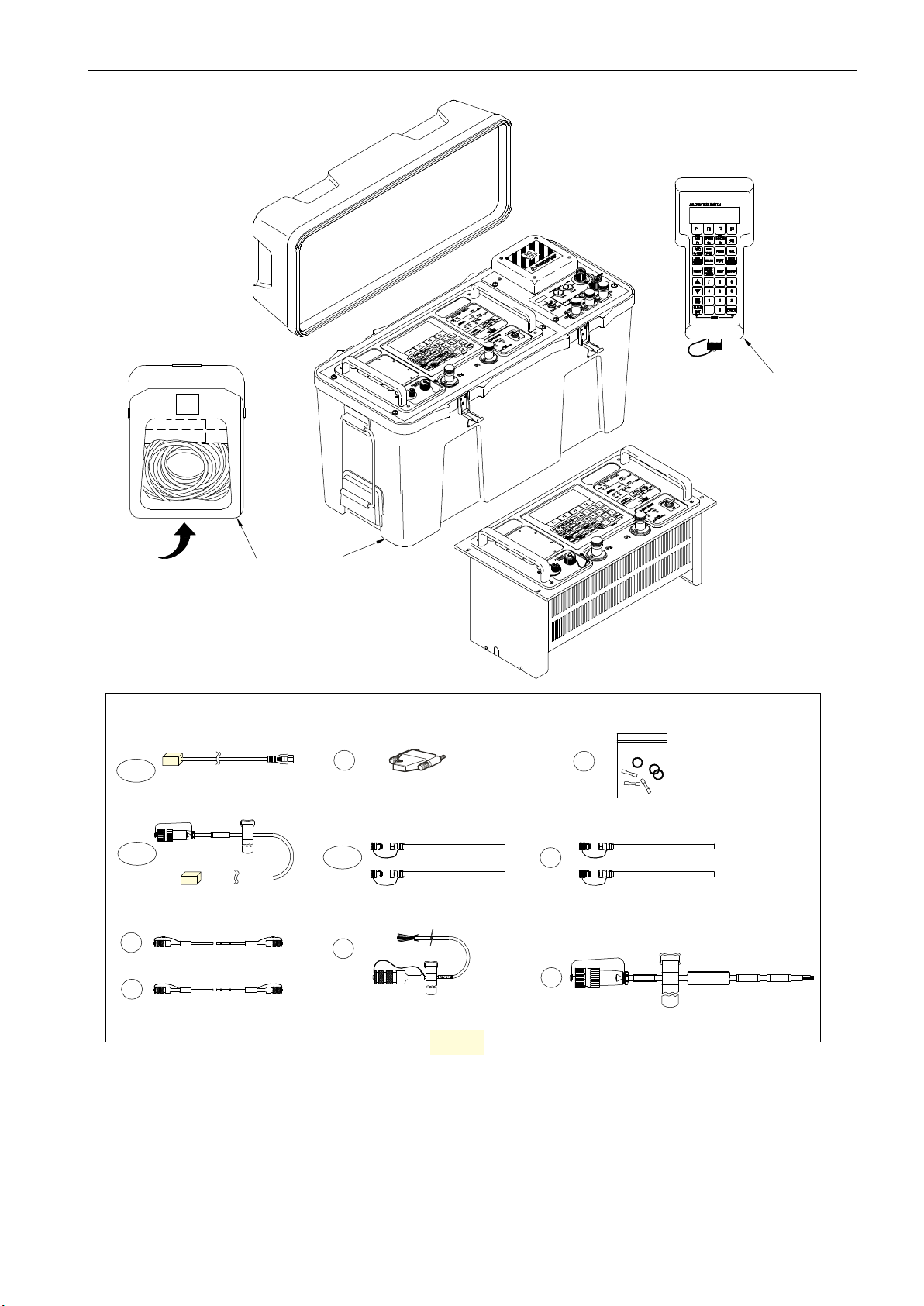

Table 2-1: ADTS MK2 SPARES AND ACCESSORIES LIST

Item Part Number Description Used On

1 - FLIGHTLINE ASSEMBLY (configured order item)

2 AS405-111-1728M0

3 AS505-57-3124M0 Accessory Bag

4a

†4b*

†4c*

†4d*

†4e*

†4f

†4g*

†4h*

5a

5b

5c

5d

5e

5f

5g

5h

5i

5j

5k

5l

5m

5n

5o

5p

6

7*

8

9a

9b

9c

9d

10

11

12

13

AA405F-23

AA405F-24

AA405F-25

AA405F-26

AA405F-27

AA405F-28

AA405F-29

AA405F-30

AA405F-1

AA405F-2

AA405F-3

AA405F-4

AA405F-5

AA405F-6

AA405F-7

AA405F-8

AA405F-9

AA405F-10

AA405F-11

AA405F-12

AA405F-13

AA405F-14

AA405F-15

AA405F-16

AS405-33-1891M0

AS405-34-1891M0

AS405-22-1891M0 EXPANSION PORT DONGLE ADTS 405R

AA500F-19

AA500F-20

AA500F-22

AA500F-23

AS405-60-1891M0

AS405-82-1891M0

AS405-53-1729M0 /

AS405-54-1729M0

AS405-31-1891M0 POWER CABLE DC (OPTION) ADTS 405F

* not illustrated

† option

HAND TERMINAL ASSEMBLY ADTS 405F/R

IEC 60320 to UK Style, BS1363

IEC 60320 to USA/Canada style, NEMA 5-15P

IEC 60320 to European style, Schuko CEE 7/7

IEC 60320 to Australia/New Zealand style, AS/NZS4417

(AS3112)

IEC 60320 to India style, IS 1293 (IA16A3, BS546)

IEC 60320 to China style, GB 15934 (GB 2099, GB1002)

IEC 60320 to South Africa style, SANS 164-1

(SANS 60799, BS546)

IEC 60320 to Japan style, JIS 8303 (NEMA 5-15P)

LEAD, AC POWER, UK, 2m

LEAD, AC POWER, UK, 10m

LEAD, AC POWER, USA, 2m

LEAD, AC POWER, USA, 10m

LEAD, AC POWER, EUROPE, 2m

LEAD, AC POWER, EUROPE, 10m

LEAD, AC POWER, NEW ZEALAND, 2m

LEAD, AC POWER, NEW ZEALAND, 10m

LEAD, AC POWER, INDIA, 2m

LEAD, AC POWER, INDIA, 10m

LEAD, AC POWER, CHINA, 2m

LEAD, AC POWER, CHINA, 10m

LEAD, AC POWER, SOUTH AFRICA, 2m

LEAD, AC POWER, SOUTH AFRICA, 10m

LEAD, AC POWER, JAPAN, 2m

LEAD, AC POWER, JAPAN, 10m

LEAD, HAND TERMINAL 2 M

LEAD, HAND TERMINAL 18 M

HOSE, RED (state length in metres)

HOSE, BLUE (state length in metres)

CONNECTOR, HOSE, AN4 FEMALE

CONNECTOR, HOSE, AN6 FEMALE

ALTIMETER ENCODER CABLE

FUSE/O-RING KIT

HOSE SET, PRESS. / VAC. YELL. / GRN.

ADTS 405F

ADTS 405F

ADTS 405R

ADTS 405F

ADTS 405F/R

ADTS 405F/R

ADTS 405F/R

ADTS 405F/R

ADTS 405F/R

ADTS 405F/R

ADTS 405F/R

ADTS 405F/R

ADTS 405R

Examine all equipment to be used, paying particular attention to electrical leads and connectors

and pneumatic pipes and connectors.

CAUTION DO NOT USE ANY EQUIPMENT THAT IS KNOWN TO BE OR SUSPECTED TO BE

DAMAGED OR FAULTY.

8 | ADTS 405 Mk2 Instruction Manual-English © 2015 General Electric Company – All rights reserved.

Page 27

2.3 Power Supply

See Safety and Installation Guide 124M8686 for full details.

AC Input

AC power supply

100 / 120 / 230V ~ 50 / 60Hz

115V ~ 400Hz 500VA

DC Input (Option ADTS405 F only)

DC power supply

24 - 30V

500VA

2.3.1 405R Rack-mounted version

Power Supply

1. The unit must be connected to the correct electrical power supply as stated, beside the

power connectors on the rear panel.

2. Install an easily accessible isolator in the power supply circuit.

3. The power supply connector on the rear panel of the unit will not be accessible when fitted

in the equipment rack.

Note: The power supply switch on the front panel is not classified as a

disconnecting device.

On the ADTS 405R, two 20mm High Breaking Capacity fuses are located in the holder mounted on

the power input connector on the rear of the rack and protect the entire unit. The fuses are

connected in the live and neutral supply circuit and are: T5A/250V HRC type. Only replace the fuses

with the correct type, see Figure 2-1 item 11 section 4-4.

2.3.2 405F Flightline version

1. The power switch on the front panel is not a power isolator as defined by EN61010. To

isolate the power supply disconnect the power supply connector.

Fuses AC Power

The fuses fitted in the fuse holders on the front panel are: T5A/250V HRC type. Only replace a fuse

with the correct type, see Figure 2-1, item 11. To replace a fuse see Section 4-4.

Fuses DC Power

The fuses fit in the fuse holders on the front panel are either: T20.0A/250V HRC type (on the left) or

T32A/250V HRC type (on the right). The DC power option (nominal 28 V DC), can be an alternative

power supply using an additional connector located on the pump front panel. Only replace a fuse

with the correct type, see Figure 2-1, item 11 To replace a fuse see, Section 4-4.

© 2015 General Electric Company – All rights reserved. ADTS 405 Mk2 Instruction Manual-English | 9

Page 28

Chapter 2. INSTALLATION

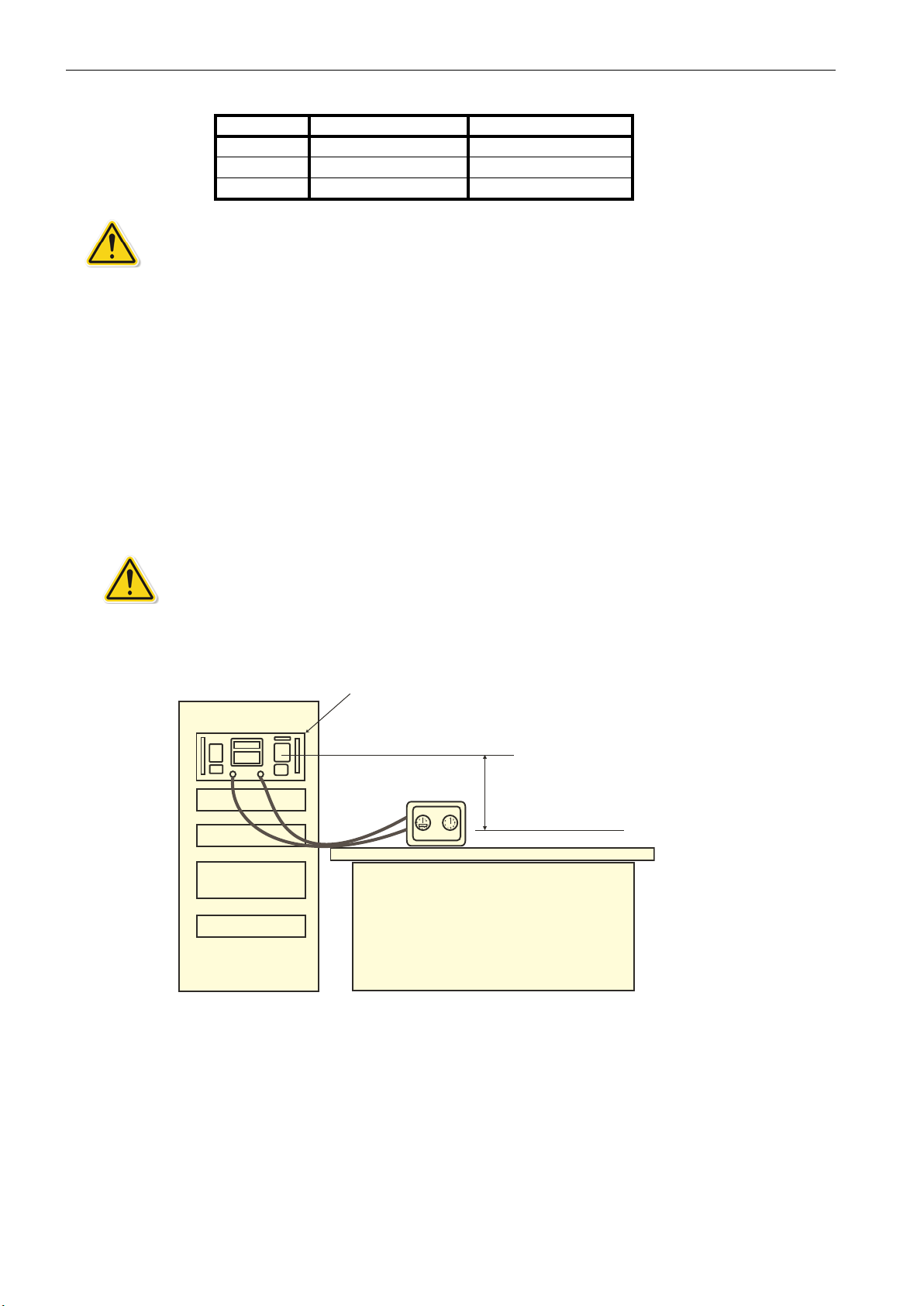

Table 2-2: DC Input Connector

ADTS Pin Cable Colour Function

1 Grey + 28V

2 White 0V Return

EARTH Green Protective Ground

CAUTION A protective EARTH connection must also be made for DC operation or

specified EMC performance may be impaired.

2.4 Positioning of the ADTS

2.4.1 405R Rack-mounted version

It is important that the position of the ADTS 405 in relation to the UUT is known. An altitude

correction must be made to allow for the difference in height between the reference level, indicated

on the mimic panel, and the UUT. The Reference section contains details of altitude correction

(SETUP, ALTITUDE).

WARNING OBSERVE THE APPROPRIATE SAFETY INSTRUCTIONS AND PROCEDURES

DETAILED IN THE AIRCRAFT MAINTENANCE MANUAL AND COMPONENT MAINTENANCE

MANUALS.

rack-mounted ADTS 405R

ADTS panel marked reference level

requires negative

UUT

Corrected altitude output = true altitude output increased by height difference

Figure 2-2: ADTS 405R Altitude Reference

altitude correction value

entered when below ADTS

UUT reference level

2.4.2 405F Flightline version

It is important that the position of the ADTS 405F in relation to the aircraft altitude sensors is

known. An altitude correction must be made to allow for the difference in height between the

reference level and the aircraft's altitude sensors. The Reference section contains details of altitude

correction (SETUP ALTITUDE).

10 | ADTS 405 Mk2 Instruction Manual-English © 2015 General Electric Company – All rights reserved.

Page 29

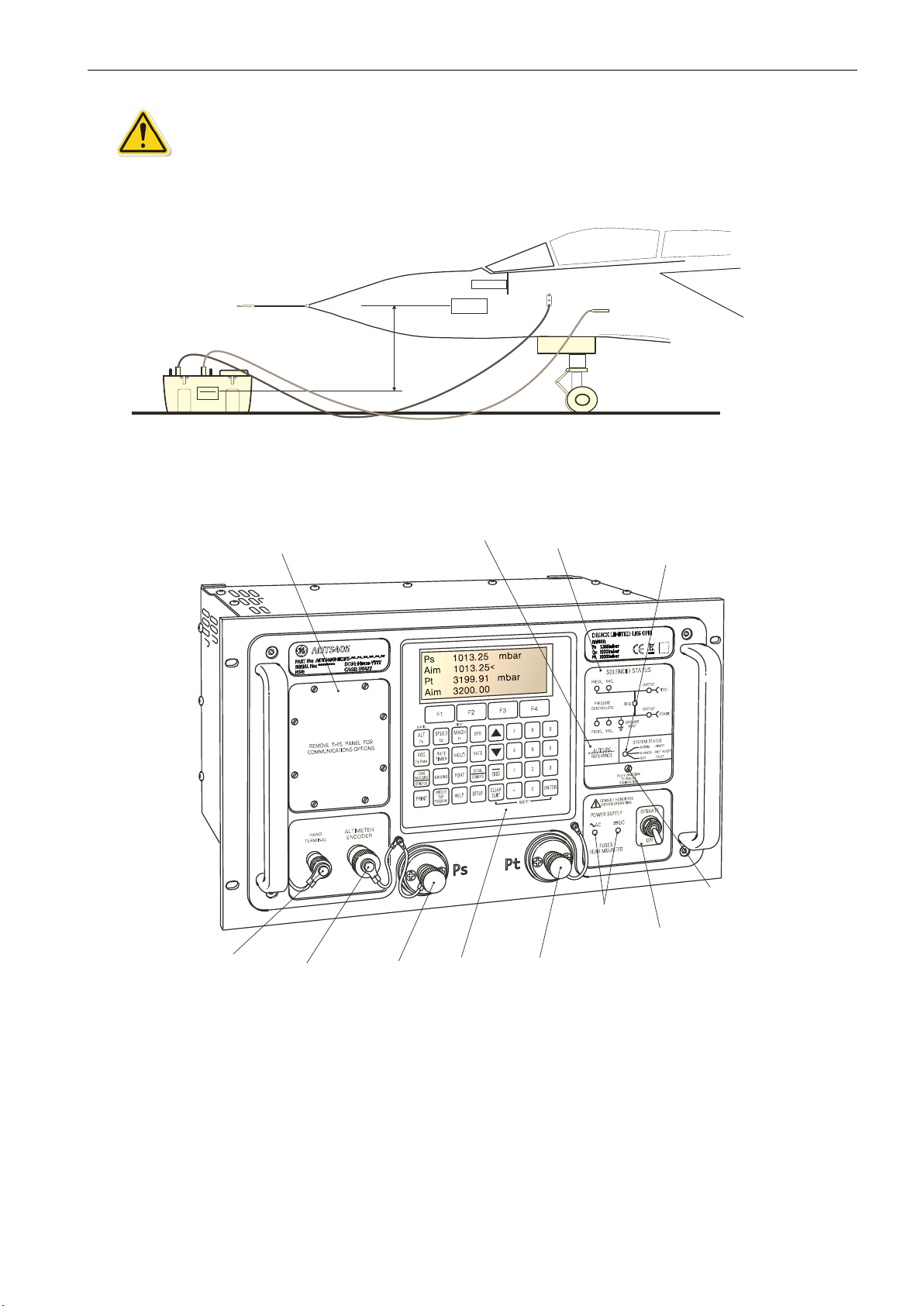

Positioning of the ADTS

WARNING THE ADTS SHOULD NOT BE PLACED IN CONTACT WITH HAZARDOUS FUEL

VAPOUR CONCENTRATIONS.

Instruments

Aircraft reference level

requires positive

altitude correction value

entered when above ADTS

ADTS reference level

Air Data

Computer

Corrected altitude output = true altitude output decreased by height difference

Figure 2-3: ADTS 405F Altitude Reference

STATIC

PITOT

Cover plate for

communications

connectors

Hand

terminal

connector

Altimeter

encoder

connector

(option)

Static

output

connector

Altitude sensor

datum height

Key-pad

and

display

Solenoid valve

status indicator

Pitot output

connector

Figure 2-4: ADTS 405R Front Panel View

Power

connection

indicators

System

status

indicator

Calibration

enable

switch

Power supply

switch

© 2015 General Electric Company – All rights reserved. ADTS 405 Mk2 Instruction Manual-English | 11

Page 30

Chapter 2. INSTALLATION

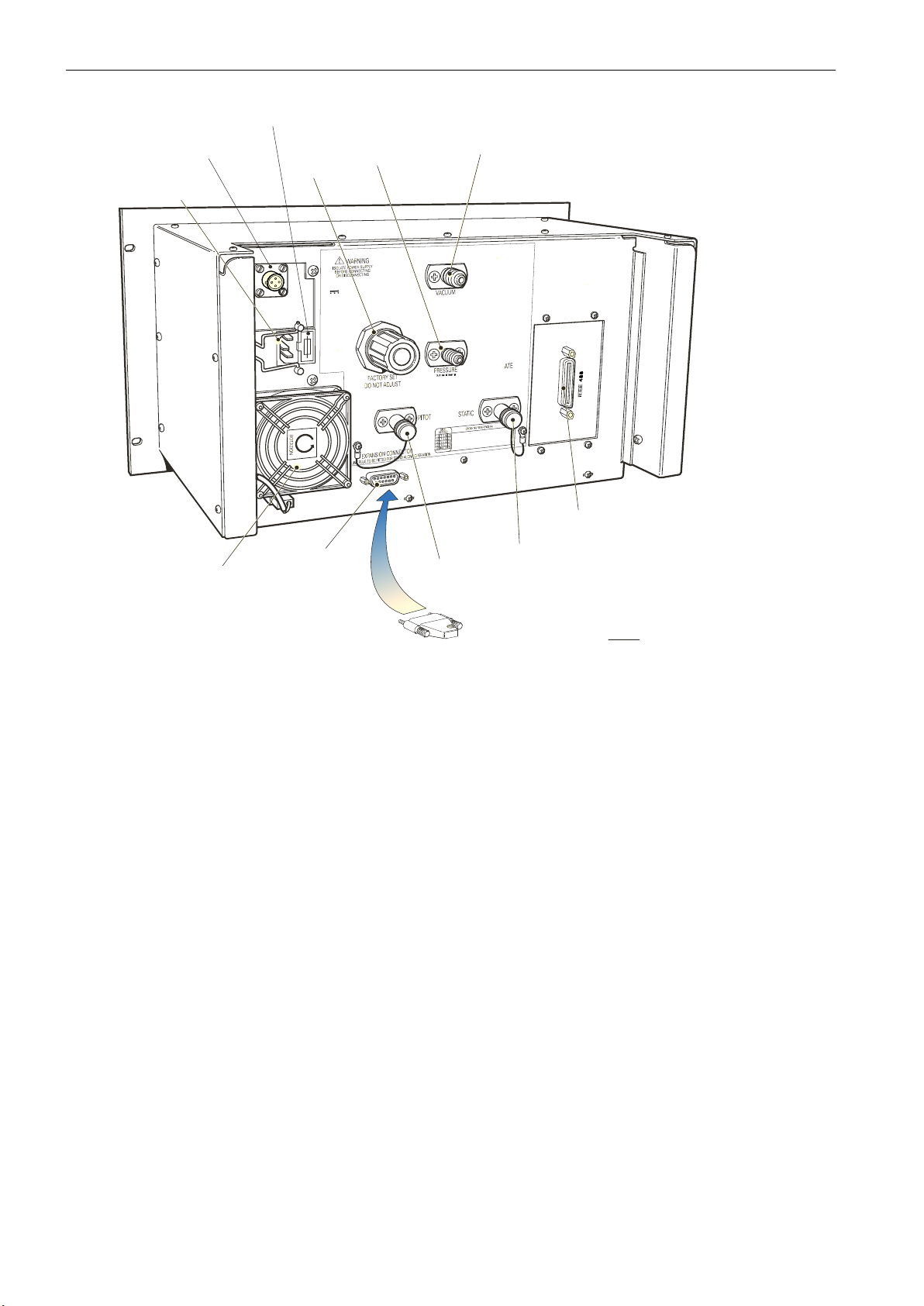

AC fuses holder

DC power supply

Connector (option)

AC power supply

connector

Pressure

regulator

Source Pressure

Input connector

DC

INPUT

24-30V

400VA

AC

~

INPUT

100/120/230V~50/60Hz

115V~400Hz

400VA

FUSED2x

T5A250VHRC

Source Vacuum

Input connector

Cooling fan

air intake

Expansion port

(used with GE

PV103R pump unit)

Figure 2-5: ADTS 405R Rear Panel

Pitot

output

connector

IEEE 488

interface

Static

output

connector

Note:

When port not used with other equipment

the Expansion Port Plug

connector

MUST

be fitted.

12 | ADTS 405 Mk2 Instruction Manual-English © 2015 General Electric Company – All rights reserved.

Page 31

Positioning of the ADTS

ADTS HAND TERMINAL

Cover plate

for option

Remote

hand terminal

Connector cable

(2m or 18m)

Key-pad

and display

Solenoid

valve status

indicator

System

status

indicator

Elapsed

time

indicator

Pump

switch

Calibration

enable

switch

Altimeter

encoder

connector

Static

output

connector

Pitot

output

connector

Altitude sensor

datum height

Power

supply

switch

(optional)

Figure 2-6: ADTS 405F General View

Fan

outlet

cover

POWERSUPPLY24-30V

FUSES

T20A

POWERSUPPLY

100/120/230V~50/60Hz500VA

115~400Hz500VA

FUSES

T5.0A250VHRC

Pressure

input

connector

DC power

Supply fuses

500VA

T32A

AC power

Supply fuses

DC power

supply

connector

(optional)

Cross bonding

connector

AC power

supply

connector

Vacuum

input

connector

Auxiliary

Vacuum

output

connector

© 2015 General Electric Company – All rights reserved. ADTS 405 Mk2 Instruction Manual-English | 13

Page 32

Chapter 2. INSTALLATION

14 | ADTS 405 Mk2 Instruction Manual-English © 2015 General Electric Company – All rights reserved.

Page 33

Preparation

3. OPERATION

WARNING OBSERVE SAFETY PRECAUTIONS STATED IN LOCAL ORDERS AND THE

AIRCRAFT OR EQUIPMENT SERVICING PROCEDURES.

Make sure the electrical and pneumatic connectors, electrical cables, pipes and positioning of the

ADTS 405 comply with the instructions in this manual and local regulatory requirements.

3.1 Preparation

WARNING THE ELECTRICAL SUPPLY MUST INCLUDE A CONNECTION TO A PROTECTIVE

EARTH. SEE SAFETY AND INSTALLATION GUIDE 124M8686 FOR START-UP SAFETY CHECKS

AND INFORMATION.

Carry out the following before use:

a. If necessary, carry out the maintenance detailed in Section 4.3 “Maintenance Tasks”.

b. Make sure the air data test system power supply switch on the front panel is set to OFF.

c. Connect the air data test system to the electrical supply.

d. Inspect the pneumatic hoses for damage, ingress of dirt and moisture. Make sure the

aircraft adapters are serviceable.

3.2 Start-up

Before use, the ADTS 405 should be tested. Review and become familiar with the overall operating

states and test procedures before starting any test process on an aircraft or component.

3.2.1 Connections

a. Connect the hoses for the test procedures to the air data test system:

• Red hose to the STATIC output (Ps)

• Blue hose to the PITOT output (Pt)

b. Temporarily seal the free ends of the hoses.

Note: When connected take care not to restrict air flow to the hoses.

c. Connect the hand terminal to the air data test system through the hand terminal

connector on the front panel. If necessary, connect the hand terminal through the

extension cable.

© 2015 General Electric Company – All rights reserved. ADTS 405 Mk2 Instruction Manual-English | 15

Page 34

Chapter 3. OPERATION

3.2.2 Power-up

a. Check the power indicator is illuminated and set the front panel power switch to

OPERATE.

b. The display will show the following sequence:

1. Power-up screen.

2. ADTS 405 power-up screen.

3. Date of the last calibration and type of main transducer fitted.

4. Self-test message.

5. Measuring ground pressure message.

6. Equalizing system pressures message.

7. Display shows Leak Measure mode and the number of parameters last selected in

configuration.

i. The display, on the front panel or

hand-terminal, shows:

SYSTEM STATUS

DK425 V.xx

Display Power Up

Please Wait

Note: V.xx will display the current software version number.

ii. After a short time the display

shows:

SYSTEM STATUS

DRUCK

ADTS 405

DK415

VER.xx

RED - FAULT

ORANGE - NOT READY

Last Calibration

dd/mm/yy (dmy)

RPT Transducer

PLEASE WAIT

iii. Date format can be set to a leading value of day or month in SETUP.

16 | ADTS 405 Mk2 Instruction Manual-English © 2015 General Electric Company – All rights reserved.

Page 35

Start-up

iv. Self test and front panel LED status:

SYSTEM STATUS

Self Test

PLEASE WAIT

GREEN - READY

v. The system opens the zero valves and after approximately 7 seconds the valves

close and the routine continues. The display shows:

Measuring Ground

Pressures

PLEASE WAIT

vi. The system opens the output valves, Ps and Pt port pressures will safely remain at

the original measured values:

Equalising System

Pressures

(Valves May Pulse)

PLEASE WAIT

vii. At power on check the hand-held terminal display.

ALT 0 ft

Leak Measure

CAS 0 kts

Leak Measure WARMUP

The ADTS 405 system may now be used but for full specification accuracy and stability, wait the

“WARMUP” period of 15 minutes. The display shows “WARMUP” in the lower right hand corner, this

message clears automatically after the time period.

Note:

(1)The ADTS 405 is a continuous, self-monitoring system. If the system detects an

error, the display shows an error message. Lists of errors are detailed in Section 5,

Fault Finding and Testing.

(2) The display at power-up can be changed, see CONFIGuration (Pg. 3-27).

© 2015 General Electric Company – All rights reserved. ADTS 405 Mk2 Instruction Manual-English | 17

Page 36

Chapter 3. OPERATION

3.2.3 Units of Measure

When operating, in either pressure measure or pressure control modes, the ADTS 405 can display

the following unit information:

Table 3-1: Units of Measure

Aeronautical Functions

Altitude ALT ft, m

Calibrated and True Airspeed CAS, TAS kts, km/h, mph

Mach MACH Rate of Climb ROC ft/m, m/m, m/s, hm/m

Rate of Airspeed Rt CAS, kts/m, km/h/m, mph/m

Rate of Mach RtMCH Mach/m

Display

Abbreviation

Displayed Units

(if applicable)

Pressure Functions

Static (Absolute) Ps [P]

Pitot (Absolute) Pt [P]

Dynamic or Impact (Differential) Qc [P]

Engine Pressure Ratio EPR Rate of Ps Rt Ps [P]/m

Rate of Pt RtPt [P]/m

Rate of Qc Rt Qc [P]/m

Rate of EPR Rt EPR EPR/m

Where [P] is the currently selected pressure units from the following list:

mbar, inHg, mmHg, inH2O (4°C), inH2O (20°C), psi, hPa, kPa, inH2O (60°F), kg/cm2,%FS

Display

Abbreviation

Displayed Units

(if applicable)

Figure 3-1: Front Panel

18 | ADTS 405 Mk2 Instruction Manual-English © 2015 General Electric Company – All rights reserved.

Page 37

Operation quick reference

3.3 Operation quick reference

The quick reference chart shows normal operation key functions. See Section 6. ‘Reference and

Specification’ for detailed descriptions of ADTS 405Mk2 functions.

In the key/selection column the following applies:

ALT - Key.

[NEXT] - Item in menu (soft key).

(SINGLE DOUBLE) - Sequence of parameters selected by NEXT key.

(craft1 craft2...) - Sequence of names selected by NEXT key.

data entry - Enter number from key-pad.

The display shows the main pressure display (Leak Measure or Control mode).

Key/selection Function and comments

F1-F4

ALT Ps

SPEED Qc

MACH Pt

EPR

ROC Ps RATE

RATE TIMER

F1

F2

F3

HOLD

RATE

LEAK MEASURE/CONTROL

GROUND

[GO TO GROUND]

[DISPLAY QFE]

[DISPLAY QNH]

PORT

REMOTE

PRINT

[ALPHA]

[BACK]

data entry

EXECUTE TEST PROGRAM

[NEXT]

[PREV]

[RUN]

F1

F2

HELP

SETUP

See QUICK REFERENCE SETUP or MINIMUM SETUP

SETUP + F1

See QUICK REFERENCE -

CONFIG

(nudge up)

(nudge down)

0-9

-000

CLEAR/QUIT

ENTER

CLEAR/QUIT + ENTER

Function keys for menus

Altitude (Aeronautical units) or Ps (Pressure units)

Airspeed (Aeronautical units) or Qc (Pressure units)

Mach (Aeronautical units) or Pt (Pressure units)

Engine Pressure Ratio (pressure units only)

Rate of Climb (Aeronautical units) or Rate of Ps (Pressure units)

Start timing rate of change

Wait and time choice 1

Wait and time choice 2

Wait and time choice 3

Hold pressure at present value - Press again to release

Rate of change of Pitot parameter - Press Pitot parameter then RATE

Switches between measure mode (for leak testing) and control mode

Controls Ps to atmospheric pressure and Qc to zero at current rates of change

Display local atmospheric (ground) pressure

Display sea level equivalent of local atmospheric pressure

See Line Switching Unit User Manual

Switches (toggles) between remote and local operation

Prints current parameter values to a stored text file

Inserts alphabet character in user text

Deletes last character of user text

Numeric entry for user text

Execute down-loaded Test Programs

Select next listed test program

Select previous listed test program

Execute selected test program

Execute all tests in the test program

Selects and executes a specific test program

Press HELP then other key for further information

Temporary set-up - lost at power down

Configuration - changes power-up defaults

Hold F1 while pressing SETUP - then enter PIN

Increases aim value

Decreases aim value

Number entry

Minus sign for first number entry 000 (thousand) if not first number of entry

Clear number entry - quit from menu or clear warning message

Complete number entry

ABORT - restart with power-up

© 2015 General Electric Company – All rights reserved. ADTS 405 Mk2 Instruction Manual-English | 19

Page 38

Chapter 3. OPERATION

3.4 Operating modes

CAUTION Once initialised wait 15 minutes to allow the pressure measurement system

to reach a stable operating temperature. The “Warm-up” period can be reduced to 5

minutes if the system has been powered following a short period of inactivity.

The air data test system can now be set for a variety of functions and modes that follow:

1. Pressure measurement mode

2. Pressure control mode

3. Timed leak rate measurement

4. Control to local ground pressure

The ADTS 405 always powers-up in Measure mode with the pressure controllers off. When

changing to Control Mode the pump unit must be switched on and producing the correct pressure

and vacuum.

Each operating function shows the required key presses to set displays and selections.

Measure Mode (Pressure measurement mode)

To select the measured parameter press:

STATIC

ALT SPEED MACH

Ps Qc Pt

Measured

parameter

or or

Measured value Units of measurement

Alt 10000

Leak Measure

CAS 350 kts

“leak-measure” when

measure mode selected

Change display single,

dual or triple press:

Leak Measure

PITOT

ft

Change units from

aeronautical to pressure:

SETUP

[MORE]

[CONTROL]

[Ps Pt DUAL]

[DISPLAYS/OPTIONS]

[DISPLAY TYPE]

[OPTIONS]

20 | ADTS 405 Mk2 Instruction Manual-English © 2015 General Electric Company – All rights reserved.

SETUP

[UNITS]

[NEXT]

[PREV]

[SAVE]

Page 39

Control Mode (Pressure control mode)

For ADTS 405F set the pump switch to PUMP ON

PUMP ON

PUM

From leak measure press:

Operating modes

Alt

Leak Measure

Return to leak measure at new altitude

0

LEAK

MEASURE

CONTROL

ft

Aim of 5000 ft press

LEAK

MEASURE

CONTROL

5

Alt

Aim

Alt

Leak Measure

5000

5000 <

5000

Alt

Aim 0<

000

ft

ft

0

ft

ENTER

© 2015 General Electric Company – All rights reserved. ADTS 405 Mk2 Instruction Manual-English | 21

Page 40

Chapter 3. OPERATION

Leak measure mode (Timed average leak rate measurement)

Static channel altitude 5000 ft,

measure leak:

Set rate timer:

wait 05.00 miutes

test 01.00 minutes

RATE

TIMER

Alt

Leak Measure

Display shows alternating time

countdown and TIMING message

WAIT

F1 00:00

F2 00:00

F3 05:00

4996

00:30/TIMING

Alt

Leak Measure

TIME

00:30

01:00

01:00

ft

ROC

RtCAS

-15.00T

-1.97T

5000

Display shows alternating wait time

countdown and WAITING message

ft

Alt

Leak Measure

ft/m

kts/m

4996

04:36/WAITING

Display

rate timer

ft

shows

result

Timed Rates

Note: Compressing a gas generates heat. Gas heated or cooled in an enclosed

volume causes a pressure change. It is important, especially for leak testing, to

allow enough time for the heated gas to cool and the pressure to stabilize.

When setting the rate timer consider three factors:

1. The volume of the system to be tested (large volumes take longer to stabilize).

2. The pressure change (the higher the change the greater heat generated).

3. The ambient air temperature.

22 | ADTS 405 Mk2 Instruction Manual-English © 2015 General Electric Company – All rights reserved.

Page 41

Go to Ground (Control to local ground pressure)

Operating modes

Alt

Leak Measure

CAS 350

Leak Measure

Dual parameter display

Aim Ground <

CAS = 350.0

Aim 0.0

5000

Alt

Aim Ground <

CAS = 0.0

Aim 0.0 kts

120 ft

kts

ft

kts

(USER MODE)

GO TO GROUND

F1

F2

DISPLAY QFE

F3

DISPLAY QNH

LEAK

MEASURE

CONTROL

GROUND

Alt

5000 <ft

ft

Leak Measure

Single parameter display

Note:

In leakMeasure use F2 and F3 for

QFE and QNH information.

F1 invalid in this mode.

Alt

5000

Aim Ground <

Alt

Aim

120 <

Ground

ft

Checking Ground

PLEASE WAIT

Equalising System

Pressures

(Valves May Pulse)

PLEASE WAIT

Safe At Ground

Press CLEAR/QUIT

to continue..

Note:

This ground value will not be

zero and depends on local

atmospheric pressures and

aireld altitude.

Note:

Safe to disconnect pipes and adaptors

from the aircraft or component under test.

© 2015 General Electric Company – All rights reserved. ADTS 405 Mk2 Instruction Manual-English | 23

Page 42

Chapter 3. OPERATION

3.5 Operating Procedures

WARNING See Safety and Installation Guide 124M8686 for guidance on safety and

standard operating conditions.

The procedures show the steps required to make sure the ADTS 405 is serviceable and of the

settings required to test an aircraft system or component in the following notation:

1. All key presses are highlighted in bold and shown as identified on the key-pad.

2. Key presses inside brackets e.g., [MORE], are soft key presses (i.e, function key selections

{F1 to F4} indicated on the display screen).

For further information on a particular ADTS function and using the Help System refer to Section 6 Reference and Specification. The help information includes further details of the function and

details associated functions.

For a summary of Set-up and Configuration procedures refer to the quick reference charts, at the

end of this section.

3.5.1 Control or Measure Parameter

To change the (displayed) parameter:

a. Value parameters: Press the parameter key e.g, press SPEED/Qc to display airspeed.

b. Rate parameter: Press the associated parameter key followed by the rate key for that

channel. e.g, display airspeed rate, press SPEED/Qc then RATE. ROC/Ps Rate may be

directly pressed without first pressing ALT/Ps.

Note: The displayed parameters depend on the last keys pressed.

To display two parameters:

a. Press each value parameter in turn, e.g, display altitude and airspeed together, press ALT/

Ps then SPEED/Qc.

b. In control mode, an arrow, at the right-hand end of the aim value, indicates the last

parameter selected. This can be changed by entering a new value.

To display a value parameter together with its rate:

a. Press the parameter key followed by the associated rate key, e.g, display airspeed and rate

of speed together, press SPEED/Qc then RATE.

Note: If ROC/Ps Rate is pressed, the display automatically shows ALT and ROC.

See “SETUP RATE”, section 6.3, for display details.

Display Functions (Fig 3.2, Fig 3.3 and Fig 3.4)

The display normally shows pressures and rates or aeronautical equivalents. It can be set-up to

show, at the same time, one parameter (single), two parameters (dual) or three parameters (triple).

24 | ADTS 405 Mk2 Instruction Manual-English © 2015 General Electric Company – All rights reserved.

Page 43

Operating Procedures

The triple display always shows altitude and airspeed; with pressure units selected, the display

always shows Ps and either Qc, Pt or EPR. When ALT or CAS are selected the display shows the aim

and measured values of ALT and CAS as a dual display. With any other selected parameter the

display shows the measured values of altitude and airspeed and, the aim and measured value of the

other selected parameter. Additional display modes are available for certain options.

Note: The ADTS 405 automatically returns to the pressure display if left

inactive in any set-up or menu type display for a period of more than one

minute.

Controlled

or measured

parameter

Measured value

Alt

10000

Aim

Aim (set-point or target)

or “leak-measure” when

controller selected o

T for timed rate

of change

10000

Pointer for

parameter

Figure 3-2: Single Display

Measured values T for timed rate

of change

Units of

measurement

ft

WARMUP

Special

messages

Controlled

or measured

parameters

Alt

Aim

CAS

Aim

Aim (set-point or target)

or “leak-measure” when

controller selected o

10000

10000

582.0

600.0

Pointer for primary

parameter - aim that

changes on data entry

Figure 3-3: Dual Display

ft

Units of

measurement

kts

Special

message

© 2015 General Electric Company – All rights reserved. ADTS 405 Mk2 Instruction Manual-English | 25

Page 44

Chapter 3. OPERATION

Figure 3-4: Triple Display

Measured values T for timed rate

of change

Constant

indication

of values

Current

changing

parameter

Aim (set-point or target)

or “leak-measure” when

controller selected o

Alt

CAS

ROC

Aim

10000

582.0

2995

3000

Pointer for primary

parameter - aim that

changes on data entry

ft

kts

ft/min

Special

message

Units of

measurement

Rate Timer Displays (Fig 3.5 and Fig 3.6)

When in Leak Measure mode and, after completing a rate timing, the system generates the rate

timer displays. These displays are independent of the display mode (single, dual, triple or option).

Note: There is no pointer for the primary parameter, values cannot be entered

in the rate timer displays.

Pressing a parameter key (ALT, ROC, etc) or CLEAR/QUIT exits the rate timer displays.

Parameters

Measured

Timed

values

ROC

Rt CAS

-17.25 T

-0.52 T

T for timed rate

of change

ft/m

Kts/m

Timed Rates

Special

message

Figure 3-5: Rate Timer Display Aeronautical Units

Units of

measurement

26 | ADTS 405 Mk2 Instruction Manual-English © 2015 General Electric Company – All rights reserved.

Page 45

Operating Procedures

Parameters

Measured

Rt Ps

Rt Pt

Rt Qc

Timed

values

0.637 T

0.341 T

-0.224 T

T for timed rate

of change

mbar/m

mbar/m

mbar/m

Timed Rates

Special

message

Figure 3-6: Rate Timer Display Pressure Units

Pt Only Display (Fig 3.7)

The Pt only display overrides the other display modes (single, dual and triple). The measured

altitude and the CAS are produced from Ps in measure mode.

Alt always

shown

Measured

altitude

T for timed rate

of change

Units of

measurement

Alt

Selected

parameter

Pt Only

CAS

Aim

Aim (set-point or target)

or “leak-measure” if

Pitot controller selected o

3.5.1.1 Change display units:

a. Press SETUP.

b. Select [MORE].

c. Select [DISPLAYS/OPTIONS].

d. Select [DISPLAY TYPE].

407

0.0

0.0

Pointer for

parameter

Figure 3-7: Pt Only Display

ft

kts

Special

messages

e. Using [NEXT] or [PREV].

f. Select either SINGLE, DUAL or TRIPLE, ENCODER (more display types with options fitted).

g. Press [SAVE] to accept.

h. Press CLEAR/QUIT repeatedly to return to user display.

© 2015 General Electric Company – All rights reserved. ADTS 405 Mk2 Instruction Manual-English | 27

Page 46

Chapter 3. OPERATION

3.5.1.2 Change the display for Pt Only:

a. Press SETUP.

b. Select [MORE].

c. Select [Control], [Ps Pt Dual].

d. Select [Pt Only Mode].

e. Press CLEAR/QUIT repeatedly to return to user display.

3.5.1.3 Change measurement units:

In Full Set-up Mode any set of aeronautical or pressure units can be selected.

a. Press the SETUP key.

b. Select [UNITS].

c. Use [NEXT] and [PREV] keys to select the required units.

d. Select [SAVE] to accept.

e. Press CLEAR/QUIT repeatedly to return to the main pressure display.

• In Minimum Setup Mode only the default aeronautical and pressure units can be

selected.

• If Set-up Mode is switched off, units cannot be changed.

3.5.1.4 Change the unit type

a. Press the SETUP key.

b. Select [UNITS TYPE].

c. Select either [AERO] or [PRESS] to select the unit type.

d. Select [SAVE] to accept.

e. Press CLEAR/QUIT repeatedly to return to the main pressure display.

• The default pressure and aeronautical units are defined in the CONFIGuration

mode.

• Display cannot be changed with SETUP switched off or in minimum mode.

3.5.2 Aim

The ADTS 405 must be in control mode to set a new aim (current aim displayed). If the aim field

shows “Leak Measure” press LEAK MEASURE/CONTROL to enter control mode.

A new aim can be entered using the numeric keys. The existing aim is replaced when the first digit

of the new aim is pressed. Each digit is displayed as it is pressed, If an error is made during the entry

of data, press CLEAR/QUIT to restore the original aim.

Press ENTER to action the new aim.

Note: The 000 key can be used as a quick way of entering thousands.

28 | ADTS 405 Mk2 Instruction Manual-English © 2015 General Electric Company – All rights reserved.

Page 47

Operating Procedures

3.5.3 Leak Measure

a. Press LEAK MEASURE/CONTROL to return to Leak Measure mode.

b. Press RATE TIMER, F3 - [Wait 05:00, Time 01:00].

Note: Different wait and time periods can be selected by pressing F1 or F2.

c. Wait until rate timer has completed and the results displayed.

d. Check rate of climb is less than ±100 ft/min and rate of airspeed (CAS) is less than ±1 kt.

e. Press LEAK MEASURE/CONTROL to return to Control mode.

f. Press GROUND, F1, [Go to Ground].

g. Wait until for the display shows “Safe At Ground”.

3.5.3.1 ADTS 405 Leak Test

It is important to check that the ADTS 405 and the connecting equipment does not leak.

a. Before use a leak check should be carried out as follows:

b. Connect the pitot and static hoses (to front panel of ADTS 405F).

c. Temporarily seal the free ends of the hoses.

d. Set the display to dual display, see 3.9, Display.

e. Set the units to feet and knots, see 3.13, Changing the Units.

f. Using the SETUP menu, choose the limits set for the aircraft or UUT, see 3.14, Limit

Checking.

i. Press SETUP, [LIMITS], and [NEXT] until required wait is shown/set.

ii. Press [SEL] to save and then press CLEAR/QUIT until the main pressure screen

shown below is displayed.

ALT 125 ft

Leak Measure

CAS 0.0 kts

Leak Measure WARMUP

Note: The numeric value of the parameters displayed change with each powerup sequence. The amount of change depends on local atmospheric pressure

conditions at the time of power-up.

g. Press the LEAK MEASURE/CONTROL key to turn on the pressure controllers.

© 2015 General Electric Company – All rights reserved. ADTS 405 Mk2 Instruction Manual-English | 29

Page 48

Chapter 3. OPERATION

Example

To apply an altitude of 5000 ft at a rate of climb of 6000 ft/min and an airspeed of 300 kts at a rate

of 600 kts/min:

i. SPEED/Qc then RATE to select rate of change of speed.

ii. 6, 0, 0, ENTER to set the rate.

iii. SPEED/Qc to select airspeed.

iv. 3, 0, 0, ENTER to set an airspeed of 300 kts (airspeed [CAS] now starts increasing).

v. ROC/Ps Rate to select rate of climb.

vi. 6, 0, 0, 0, ENTER to set the rate of climb.

vii. ALT/Ps to select the altitude.

viii. 5, 0, 0, 0, ENTER to set altitude ([Alt] altitude now starts increasing).

ix. SPEED/Qc to view altitude and airspeed together.

Note: When altitude and airspeed are changing at the same time, and

automatic airspeed rate is enabled, the system automatically adjusts the

airspeed rate so that the aim points are reached at the same time. The airspeed

rate will not exceed the entered aim value.

Wait for the aim values to be achieved. Observe over a period of 1 minute that the value of Alt stays

within ±10 ft and the value of CAS with ±1 kt.

ALT 4050 ft

Aim 5000

CAS 289.0 kts

Aim 300.0 <

After a successful leak test, the ADTS 405 is ready to be connected to an aircraft system or unit

under test.

If the preliminary leak test is unsuccessful:

h. Leave the system to achieve thermal stability for a further five minutes, press CLEAR/

QUIT and repeat the leak test.

i. After another unsuccessful leak test:

j. Disconnect both hoses, check the condition of the o-rings on the Ps and Pt connectors as

detailed in the maintenance section and firmly replace the blanking caps.

k. Press CLEAR/QUIT and repeat the leak test procedure.

l. After a successful leak test without hoses connected:

m. Replace or repair the faulty hose(s) and re-test.

n. If the ADTS 405 fails the leak test without hoses connected, switch off and return the unit

to the repair depot.

Note: Compressing a gas generates heat. Gas heated or cooled in an enclosed

volume causes a pressure change. It is important, especially for leak testing, to

allow enough time for the heated gas to cool and the pressure to stabilize.

30 | ADTS 405 Mk2 Instruction Manual-English © 2015 General Electric Company – All rights reserved.

Page 49

Operating Procedures

3.5.4 Aircraft system protection

The ADTS 405 protects the aircraft system against user error and leaks in the aircraft system.

Note: The pumps must be switched on.

The system protection operates by:

• Limit checking of user entered set-points.

• Automatic regain of control if leak rate is over limit during leak testing.

• Automatic regain of control if a leak takes the system pressures outside of limits.

3.5.4.1 Auto recovery facilities

The pressure controllers in the ADTS 405 can “feed” a leak in an aircraft system. When first testing

an aircraft system, a leak test must be carried out at low altitude and airspeed.

• If, during a leak test, a leak in the system produces a rate of climb greater than the

rate set in limits or a rate of change of airspeed greater than the rate set in limits,

then the pressure controllers automatically regain control to minimise damage to

the aircraft system. This AUTO LEAK RECOVERY facility can be disabled.

• If a leak causes the system pressures to exceed any limit during a leak test, the

pressure controllers automatically regain control. This AUTO LIMIT RECOVERY

facility can be disabled.

• If negative airspeed (or Qc) occurs in measure mode, the zero valve is

automatically opened for one second to balance the airspeed. This only applies

when the minimum CAS (or Qc) limit is zero.

• Limits cannot be changed with SETUP switched off or Limit Lock enabled.

3.5.5 Limit Checking

The system checks all data entered against minimum and maximum limits set for the particular

limit set in use. If these limits are exceeded, the data entry is ignored and a warning message

displayed showing the minimum and maximum values that can be entered. The system also checks

all limits of associated parameters. If these limits are exceeded when a new value is entered, the

display shows the name of the associated parameter, e.g. If a Mach limit is exceeded when entering

an airspeed value the display shows “Mach” and the equivalent maximum and minimum limits as

airspeed values.

Similarly, if an ARINC 565 limit is exceeded when entering a value and ARINC limits are enabled, the

display shows `ARINC'.

3.5.5.1 Select the limits in use:

a. Press SETUP.

b. Select [LIMITS].

c. Use [NEXT] or [PREV] to select the limits required. Each set of limits is identified by its

name, including the pre-defined sets of limits (“Standard“, “Civil” and “Max” see section 1.3,

Operating Limits).

d. Select [SEL] to select the limits.

e. Press QUIT/CLEAR to return to the pressure display.

© 2015 General Electric Company – All rights reserved. ADTS 405 Mk2 Instruction Manual-English | 31

Page 50

Chapter 3. OPERATION

Table 3-2: Warning Messages

The following table lists the warning messages with the possible cause and action to be taken.

No. Message Probable Cause Action

2 INVALID USER

INPUT

3 OPERATE CAL

ENABLE ON

STATUS PANEL

4 ONLY VALID IN

CONTROL MODE

210 Ps SOFT START

TIMEOUT

212 Ps PRESSURE FAIL The Ps controller has detected loss of supply

213 Ps VACUUM FAIL The Ps controller has detected loss of supply

220 Pt SOFT START

TIMEOUT

222 Pt PRESSURE FAIL The Pt controller has detected loss of supply

223 Pt VACUUM FAIL The Pt controller has detected loss of supply

301 LEAK RATE TOO

HIGH REGAINING

CONTROL

302 OUTSIDE LIMITS

REGAINING

CONTROL

303 ZERO OFFSET TOO

LARGE

304 INITIALIZING

SYSTEM

305 OUTSIDE LIMIT GO

TO GROUND

306 SWITCH PUMPS ON Cannot select control mode with pumps off. Switch pumps on.

307 COMMUNICATION

RING FAULT-

PACKET IS

CORRUPT

308 UPDATING SYSTEM Software upgrade. Wait 1 minute.

309 CANNOT CONTROL Failed pump test. Check system limits.

310 PUMP TEST FAILED Pump not achieving limits. Set lower limits.

The numeric value entered was outside the

allowed range

Calibration started before removing calibration

enable plate on the front panel

Selection not allowed in Leak measure mode Select controller on.

The Ps controller has failed to go into control

mode

pressure and automatically switched all channels

to measure mode. This can occur at very high

rates of pressure change in large volume systems

if the pumps cannot produce enough pressure.

vacuum and automatically switched all channels

to measure mode. This can occur at very high

rates of pressure change in large volume systems

if the pumps cannot produce enough vacuum.

The Pt controller has failed to go into control

mode.

pressure and automatically switched all channels

to measure mode. This can occur at very high

rates of pressure change in large volume systems

if the pumps cannot produce enough pressure.

vacuum and automatically switched all channels

to measure mode. This can occur at very high

rates of pressure change in large volume systems

if the pumps cannot produce enough vacuum.

Control mode automatically regained for aircraft

safety as leak rates too high.

Control mode automatically regained for aircraft

safety as the measures values have drifted

outside the operating limits due to leaks.

The zero offset measured during auto-zero was

outside.

This only occurs on main system software

upgrade.

Measured pressure is outside new limits selected

or power-up limits.

Internal error. If the fault can be repeated, return to

Re-enter value within allowed range.

Refer to main fault finding chart in the

service manual.

Select CONTROL again. If fails again,

refer to main fault finding chart in the

service manual.

Restore pressure supply BEFORE going

to control mode again. Refer to main

fault finding chart in the service manual.

Restore vacuum supply BEFORE going to

control mode again. Refer to main fault

finding chart in the service manual

Select CONTROL again. If fails again,

refer to main fault finding chart in the

service manual.

Restore pressure supply BEFORE going

to control mode again. Refer to main

fault finding chart in the service manual.

Restore vacuum supply BEFORE going to

control mode again.

Correct leak and retest.

Correct leak and retest. If leak Ps,

ensure that normal Qc pressure is

applied (e.g. 200 kts to avoid negative

airspeed).

Return to maintenance depot for

calibration.

If message occurs during normal

operation, return to maintenance depot.

Control pressure to within limits.

maintenance depot.

32 | ADTS 405 Mk2 Instruction Manual-English © 2015 General Electric Company – All rights reserved.

Page 51

Operating Procedures

Using the CONFIGuration function, new sets of limits can be created and existing sets of limits can

be edited. In addition, the set of limits in use at power-up can be selected. If required, this selection

can be locked to prevent unauthorised changing of the limits.

Using the SETUP function, previously stored sets of limits can be recalled for use. Each set of limits

is stored under an aircraft name. Three pre-defined sets of limits “Standard“, “Civil” and “Max” limits

are supplied with the ADTS 405.

Note: The ADTS 405, when delivered, contains “Standard” and “Civil” limits; to

set and store “Max” limits, for the first time, enter configuration. The “Max”

limits depend on the range of the pitot channel either 850 or 1000 knots, see

section 1.3, Operating Limits.

3.5.6 Changing Parameters

3.5.6.1 Mach Test and Constant Mach

To go to 0.8 Mach, enter Control Mode and proceed as follows:

a. Press SPEED then RATE to select rate of change of airspeed.

b. Enter required rate, e.g. 300 kts/min.

c. Press MACH.

d. Enter 0.8.

e. Wait for the Mach to be achieved.

Note: If the altitude changes the system automatically adjusts the airspeed to

keep the Mach value constant.

3.5.6.2 True Airspeed

The normal airspeed parameter is Calibrated Airspeed (CAS) (equivalent to IAS for testing

purposes).

The airspeed parameter may be changed to True Airspeed (TAS) as follows:

a. Press SETUP then SPEED.

b. Select [CAS/TAS].

c. Select [TAS].

d. Press QUIT/CLEAR repeatedly to exit set-up.

e. Press SPEED.

The display now shows the airspeed parameter as TAS.

Note: Airspeed parameter type can only be changed in Full Set-up mode. Rate of

change of airspeed will still be shown as Rate CAS.

Pitot temperature (Θt) is used in the calculation of TAS. Pitot temperature can only be changed in

Full Set-up mode. To enter (Θt):

a. Press SETUP.

b. Press SPEED.

c. Select [Pt TEMPERATURE].

d. Enter the temperature measured by the aircraft's Pitot temperature sensor.

e. Press QUIT/CLEAR three times to return to user display.

© 2015 General Electric Company – All rights reserved. ADTS 405 Mk2 Instruction Manual-English | 33

Page 52

Chapter 3. OPERATION

3.5.6.3 Airspeed Switch test

The following example shows how an airspeed switch can be functionally checked.

Note: For low airspeed switches (i.e. 130 knots) the Pt Only facility could be used.

Example

a. Press LEAK MEASURE/CONTROL to enter control mode. Press SPEED/Qc.

b. If necessary, press RATE and enter a change of airspeed low enough to observe switch

operation.

c. Enter an Aim value below the operating limits of the switch (i.e., airspeed switch operating

at 130 knots ±2 knots set 127 knots).

d. Press ENTER and observe the airspeed changing.

e. Using the nudge facility, set to an appropriate step value, increase the Aim value.

f. Increase the Aim until the switch operates (contacts close) and record the value.

g. Change the Aim to above the airspeed operating range (i.e. 133 knots). Repeat the steps 3

to 5, decreasing the Aim value until the airspeed switch operates (contacts open) and

record value.

This procedure can be repeated. If many operations of a switch are required use the oscillating

facility detailed in Full Set-up, see 6.2.30. The above method (steps a. to g.) can be applied for the

other parameters:

Examples:

Altitude switch

• Low altitude warning

• Landing gear configuration warning

• Height lock

Mach switch

• Speed brake scheduling

• Mach cruise lock

3.5.7 Engine Pressure Ratio (EPR)

The ADTS 405 may be used to check EPR sensors and indicators. Use Ps for INLET pressure and Pt

for OUTLET pressure. To carry out an EPR check, the display

mbar or in Hg.

must be showing pressure units e.g,

3.5.7.1 Example EPR

To enter an EPR of 1.8 with inlet pressure of 500 mbar (15 inHg), proceed as follows:

a. If the display shows “Leak Measure”, press LEAK MEASURE/CONTROL to regain control.

Note: The pressure/vacuum pumps must be switched on.

b. Press ROC/Ps RATE to select rate of change of static.

c. Enter required rate of change e.g, 1000 mbar/min, (30 inHg/min).

34 | ADTS 405 Mk2 Instruction Manual-English © 2015 General Electric Company – All rights reserved.

Page 53

Testing Aircraft Systems or UUT

d. Press EPR then RATE to select EPR rate.

e. Enter required value e.g, 5 EPR/min and press ENTER.

f. Press ALT/Ps.

g. Enter 500 mbar (15 inHg) and press ENTER.

h. Press EPR.

a. An EPR of 1.8 will quickly be achieved.

Note: EPR testing can also be performed by specifying the actual INLET and

OUTLET values.

3.6 Testing Aircraft Systems or UUT

WARNING OBSERVE THE APPROPRIATE SAFETY INSTRUCTIONS AND PROCEDURES

DETAILED IN THE AIRCRAFT MAINTENANCE MANUALS OR COMPONENT MAINTENANCE

MANUALS.

a. Connect the applicable hoses and adapters to the aircraft system or UUT.

b. Do a leak test detailed in the appropriate aircraft or component manual, to make sure that

the connections to the aircraft system or UUT are not leaking.

3.6.1 Go To Ground and Shut-down

At the end of testing and, before disconnecting from the aircraft system or UUT, the pressures in

the system must be taken to the local atmospheric pressure (ground) with zero airspeed, as

follows:

a. If the display shows “Leak Measure”, press LEAK MEASURE/CONTROL.

b. Press GROUND, F1, [Go To Ground].

c. Wait for the display to show “Safe At Ground”.

d. It is now safe to disconnect the aircraft system or UUT.

The pressure in the system changes towards ground. The ground pressure or “Ground” replaces the

static or altitude aim value.

3.6.1.1 While Going to Ground

If required, new rates of change can be entered while going to ground.

• To change the ROC or static rate, press ROC/Ps Rate and enter the new value.

• To change the airspeed or Qc rate, press SPEED/Qc then RATE and enter the new

value.