Page 1

Druck ADTS 405

Air Data Test Systems

User Manual K114

GE

Sensing

DRUCKADTS 405

ATEXCOMPLIANT

HANDTERMINAL

DONOT DISCONNECT WHEN

ENERGIZEDIN THE HAZARDOUS AREA

Ps

1013. 25 mbar

Aim

1013. 25<

Pt

3199. 91 mbar

Aim

3200. 00

D

O

N

O

T

D

IS

C

O

N

N

E

C

T

W

H

EN

E

N

E

R

G

IZ

ED

IN

TH

E

H

A

ZA

R

D

O

U

S

A

R

E

A

D

R

U

CK

AD

TS

405

ATE

X

C

O

M

P

LIA

N

T

H

AN

D

T

ER

M

IN

AL

Page 2

© General Electric Company. All rights reserved.

Page 3

K114 Issue No. 9

D

R

UC

K

AD

TS

405

ATE

X

COM

PLIAN

T

H

AND

TER

M

INA

L

D

O

NO

T

D

IS

C

O

N

N

ECT

W

H

EN

E

NER

G

IZED

IN

T

H

E

HA

Z

AR

D

O

U

S

AR

E

A

Ps 1013. 25 mbar

Aim 1013. 25<

Pt 3199. 91 mbar

Aim 3200. 00

Druck ADTS 405

Air Data Test Systems

User Manual

K114

DO

NOT

DISCONNECTW

HEN

ENERGIZED

IN

THE

HAZARDOUS

AREA

D

RUCKADTS

405

ATEX

CO

MPLIANT

HAN

D

TERM

INAL

Page 4

K114 Issue No. 9

Page 5

i

K114 Issue No. 9

Introduction

This technical manual provides operating instructions for the Air Data Test System compatible

with the requirements of first line servicing.

Scope

This technical manual contains a brief description, operation and testing procedures for the

user of this equipment.

Safety

The manufacturer has designed this equipment to be safe when operated using the

procedures detailed in this manual. Do not use this equipment for any other purpose

than that stated.

This publication contains operating and safety instructions that must be followed to

make sure of safe operation and to maintain the equipment in a safe condition. The

safety instructions are either warnings or cautions issued to protect the user and the

equipment from injury or damage.

Use qualified* technicians and good engineering practice for all procedures in this

publication.

Pressure

Do not apply pressure greater the maximum safe working pressure to the equipment.

Toxic Materials

There are no known toxic materials used in this equipment.

Maintenance

The equipment must be maintained using the manufacturer’s procedures and should

be carried out by authorised service agents or the manufacturer’s service

departments.

Technical Advice

For technical advice contact the manufacturer or subsidiary.

* A qualified technician must have the necessary technical knowledge, documentation,

special test equipment and tools to carry out the required work on this equipment.

Druck ADTS 405 User Manual

This product meets the essential protection requirements of the relevant EEC directives.

Further details of applied standards may be found in the product specification.

CE

Page 6

ii

K114 Issue No. 9

Associated Publications

This lists the Druck manuals and publications referenced in this manual.

Maintenance Manual K244

Air Data Test System ADTS 405

Calibration Manual K199

Air Data Test System ADTS 405

IEEE 488 OPT 2 Manual K154

Air Data Test System ADTS 405

SCPI IEEE 488 Manual K157

Air Data Test System ADTS 405

User Manual K170

Altimeter Encoder Option

User Manual K185

ARINC 429 Option

User Manual K220

Line Switching Unit LSU 100/101

User Manual K222

Line Switching Unit LSU 200

Operating and Communications Manual K223

Line Switching Unit LSU Series

TPM Programming and Communications Manual K230

Test Program Manager Version 4 for Windows

TPM User Manual K250

Test Program Manager Version 4 for Windows

Symbols

This symbol, on the instrument, indicates that the user should refer to the user manual.

This symbol, on the instrument, indicates do not throw-away in domestic bin,

hazardous material, dispose correctly in accordance with local regulations.

This symbol, on the instrument, indicates d.c.

Page 7

iii

K114 Issue No. 9

Table of Contents

Preliminary pages

Introduction ............................................................................................................................................................ i

Scope ............................................................................................................................................................ i

Associated Publications ........................................................................................................................................................ ii

Symbols ............................................................................................................................................................ ii

Table of contents (this table) ............................................................................................................................................. iii

Abbreviations ............................................................................................................................................................ viii

Glossary ............................................................................................................................................................ ix

Returned Goods Procedure for Europe ......................................................................................................................... xi

Returned Materials Procedure for USA .......................................................................................................................... xii

Approved Service Agents ..................................................................................................................................................... xii

ATEX Certified ADTS Hand Terminal ................................................................................................................................ xiii

Pressure Units and Conversion Factors ........................................................................................................................xiv

Section page

1 DESCRIPTION

1.1 Introduction ................................................................................................................................................. 1-1

1.2 Operating Range and Performance ................................................................................................ 1-3

1.3 Operating Limits ........................................................................................................................................ 1-3

2 INSTALLATION

2.1 Packaging ..................................................................................................................................................... 2-1

2.2 Packaging for Storage and Transportation .................................................................................2-1

2.3 Electrical Connection .............................................................................................................................. 2-5

2.4 Pneumatic Pressure Connections ..................................................................................................... 2-7

2.5 Positioning of the ADTS 405 ................................................................................................................. 2-8

2.6 Positioning of the ADTS 405F .............................................................................................................. 2-9

3 OPERATION

3.1 Preparation .................................................................................................................................................. 3-1

3.2 Display Functions and Units of Measure ...................................................................................... 3-2

3.3 Quick Reference ......................................................................................................................................... 3-3

3.4 First Time Operators ................................................................................................................................ 3-4

3.5 Operation and Example Procedures ............................................................................................... 3-10

3.5.1 Checks Before Use .................................................................................................................... 3-10

3.5.2 Operating Procedures ............................................................................................................. 3-10

3.6 Power-up ....................................................................................................................................................... 3-10

3.7 Control or Measure Parameter .......................................................................................................... 3-11

3.8 Leak Testing the ADTS 405 ................................................................................................................... 3-12

3.9 Displays ......................................................................................................................................................... 3-15

3.10 Rate Timer Displays ................................................................................................................................. 3-17

3.11 Pt Only Display ........................................................................................................................................... 3-18

3.12 Changing the Display ............................................................................................................................. 3-18

3.13 Changing the Units .................................................................................................................................. 3-19

3.14 Limit Checking ............................................................................................................................................ 3-19

Aircraft System Protection ...................................................................................................................3-21

Mach Test and Constant Mach .......................................................................................................... 3-21

CONTENTS

Page 8

iv

K114 Issue No. 9

Table of Contents (contd)

Section page

True Airspeed ..............................................................................................................................................3-21

Airspeed Switch Test ............................................................................................................................... 3-22

Engine Pressure Ratio (EPR) ................................................................................................................. 3-23

3.15 Testing Aircraft Systems or UUT ....................................................................................................... 3-24

3.15.1 Go to Ground and Shut-Down ............................................................................................ 3-24

3.16 Options ........................................................................................................................................................... 3-25

SCPI IEEE 488 Option ............................................................................................................................... 3-25

Altimeter Encoder Option ..................................................................................................................... 3-25

ARINC 429 Option ..................................................................................................................................... 3-25

3.17 SETUP and CONFIGuration ...................................................................................................................3-26

3.18 Quick Reference ......................................................................................................................................... 3-26

4 MAINTENANCE

4.1 Introduction ................................................................................................................................................. 4-1

4.2 Materials........................................................................................................................................................ 4-2

4.3 Maintenance Tasks .................................................................................................................................. 4-3

4.4 Routine Maintenance .............................................................................................................................. 4-4

5 TESTING AND FAULT FINDING

5.1 Introduction ................................................................................................................................................. 5-1

5.2 Standard Serviceability Test ............................................................................................................... 5-2

5.3 Self-test Errors ............................................................................................................................................ 5-4

5.4 Venting after Over-pressure ............................................................................................................... 5-4

5.5 Fault Diagnosis .......................................................................................................................................... 5-5

5.6 Further Testing ........................................................................................................................................... 5-8

Test Environment and Preliminary Operations .......................................................... 5-8

Pressure Leak Check ...............................................................................................................5-8

Vacuum Leak Check ................................................................................................................ 5-9

Controller Stability .................................................................................................................... 5-10

5.7 Testing an Option Facility .....................................................................................................................5-11

Testing the IEEE 488 Facility................................................................................................................ 5-11

Configuring and Enabling the IEEE 488 Facility ......................................................................... 5-11

Programming a Test of the IEEE 488 Facility .............................................................................. 5-12

Connection of the IEEE 488 Facility ................................................................................................. 5-13

Testing the Altimeter Encoder Option............................................................................................. 5-14

Configuring and Enabling the Altimeter Encoder Option...................................................... 5-14

Optional cable (AAU-32) ......................................................................................................................... 5-15

Testing the ARINC 429 Option ............................................................................................................ 5-16

Configuring and Enabling the ARINC 429 Option ..................................................................... 5-16

5.8 Fault Finding ................................................................................................................................................ 5-17

5.8.1 Error Messages ...........................................................................................................................5-17

5.8.2 Warning Messages ................................................................................................................... 5-18

6 REFERENCE and SPECIFICATION

6.1 Introduction ................................................................................................................................................. 6-1

6.2 Main Pressure Display ............................................................................................................................ 6-1

F1 - F4 ............................................................................................................................................. 6-1

ALT Ps .............................................................................................................................................. 6-2

Druck ADTS 405 User Manual

Page 9

v

K114 Issue No. 9

Table of Contents (contd)

Section page

SPEED Qc ....................................................................................................................................... 6-2

MACH Pt ......................................................................................................................................... 6-3

EPR .................................................................................................................................................... 6-4

ROC Ps RATE ................................................................................................................................ 6-4

RATE TIMER ................................................................................................................................... 6-4

HOLD ............................................................................................................................................... 6-5

RATE ................................................................................................................................................. 6-6

LEAK MEASURE/CONTROL ..................................................................................................... 6-6

GROUND ........................................................................................................................................ 6-7

PORT ................................................................................................................................................ 6-9

REMOTE .......................................................................................................................................... 6-9

PRINT ............................................................................................................................................... 6-9

EXECUTE TEST PROGRAM ...................................................................................................... 6-10

HELP ................................................................................................................................................. 6-12

or (nudge keys) .................................................................................................................. 6-12

0 to 9 ................................................................................................................................................ 6-12

-000 .................................................................................................................................................. 6-13

CLEAR/QUIT .................................................................................................................................. 6-13

ENTER .............................................................................................................................................. 6-14

CLEAR/QUIT + ENTER (ABORT) .............................................................................................................6-14

6.3 SET-UP ............................................................................................................................................................ 6-15

FULL SET-UP ................................................................................................................................................ 6-15

SETUP, [UNITS] ............................................................................................................................ 6-16

SETUP, [LIMITS] ........................................................................................................................... 6-16

SETUP, [OSC] ................................................................................................................................ 6-17

SETUP, [MORE], [CONTROL],[Ps Pt DUAL] ....................................................................... 6-17

SETUP, [MORE], [DISPLAYS/OPTIONS],[DISPLAY TYPE] ............................................. 6-18

SET-UP, [MORE], [DISPLAYS/OPTIONS],[OPTIONS]...................................................... 6-20

SETUP, [MORE], [CLOSE OUTPUT VALVES]...................................................................... 6-20

SETUP, [MORE], [OPEN OUTPUT VALVES] ....................................................................... 6-20

SET-UP, [MORE], [SYSTEM SELF TEST]............................................................................... 6-20

SET-UP, ALT .................................................................................................................................. 6-21

SET-UP, SPEED [AUTO ZERO] ................................................................................................ 6-21

SET-UP, SPEED [CAS/TAS] ...................................................................................................... 6-21

SET-UP, SPEED [Pt TEMPERATURE] .................................................................................... 6-23

SET-UP, MACH ............................................................................................................................. 6-23

SET-UP, RATE TIMER ................................................................................................................................. 6-23

SET-UP, RATE ............................................................................................................................... 6-23

SET-UP, LEAK MEASURE CONTROL, [AUTO LEAK] ....................................................... 6-24

SET-UP, LEAK MEASURE CONTROL, [AUTO LIMIT] ...................................................... 6-24

SET-UP, GROUND .......................................................................................................................6-24

SET-UP, PORT ............................................................................................................................... 6-24

SET-UP, PRINT,[DATE/TIME]................................................................................................... 6-2

4

SET-UP, EXECUTE TEST PROGRAM ..................................................................................... 6-24

SET-UP, HELP ............................................................................................................................... 6-25

SET-UP,

or (nudge keys) ................................................................................................ 6-25

CONTENTS

Page 10

vi

K114 Issue No. 9

Table of Contents (contd)

Section page

MINIMUM SET-UP ............................................................................................................................................................ 6-26

SETUP, [UNITS], [AERO] ........................................................................................................... 6-26

SETUP, [UNITS], [PRESS] ..........................................................................................................6-26

SETUP, [LIMITS] ........................................................................................................................... 6-26

SETUP, ALT/Ps.............................................................................................................................. 6-27

SETUP, PORT ................................................................................................................................. 6-27

SETUP, HELP ................................................................................................................................. 6-27

6.4 CONFIGURATION ....................................................................................................................................... 6-28

Procedure...................................................................................................................................... 6-28

Functions ....................................................................................................................................... 6-28

CONFIG,[UNITS] .......................................................................................................................... 6-29

CONFIG, [LIMITS],[EDIT LIMITS],[EDIT EXISTING] ..........................................................6-29

NAME ............................................................................................................................................... 6-30

MIN ALT,MAX ALT, MIN CAS, MAX CAS ............................................................................. 6-30

MAX MACH .................................................................................................................................... 6-30

MAX ROC, MAX RATE CAS ....................................................................................................... 6-30

MIN Ps, MAX Ps, MIN Qc, MAX Qc ....................................................................................... 6-30

MAX RATE Ps, MAX RATE Qc.................................................................................................. 6-30

ARINC LIMITS ............................................................................................................................... 6-30

ALTITUDE CORRECTION ..........................................................................................................6-31

SAVING LIMITS ............................................................................................................................. 6-31

CONFIG, [LIMITS],[EDIT LIMITS],[MAX LIMITS] ................................................................ 6-32

CONFIG, [LIMITS],[EDIT LIMITS],[EDIT NEW] ................................................................... 6-32

CONFIG, [LIMITS],[CLEAR LIMITS] ........................................................................................6-32

CONFIG, [LIMITS],[LOCK AIRCRAFT] ...................................................................................6-32

CONFIG, [LIMITS],[DEFAULT AIRCRAFT] ........................................................................... 6-32

CONFIG, [MORE],[CONTROL],[CONTROL MODE] .......................................................... 6-32

CONFIG, [MORE],[CONTROL],[CONTROL LOCK] ...........................................................6-32

CONFIG, [MORE],[DISPLAY/OPTIONS],[DISPLAY TYPE] .............................................. 6-32

CONFIG, [MORE],[DISPLAY/OPTIONS],[OPTIONS] ........................................................ 6-32

CONFIG, [MORE],[DATE/FORMAT] ....................................................................................... 6-32

CONFIG, [MORE],[SETUP MODE] .......................................................................................... 6-33

FULL ................................................................................................................................................. 6-33

MINIMUM ....................................................................................................................................... 6-33

OFF ................................................................................................................................................... 6-33

CONFIG, SPEED,[AUTO ZERO] ............................................................................................... 6-33

CONFIG, SPEED,[CAS/TAS] ..................................................................................................... 6-33

CONFIG, SPEED,[Pt TEMPERATURE] ................................................................................... 6-33

CONFIG, RATE TIMER ................................................................................................................6-33

CONFIG, RATE .............................................................................................................................. 6-33

CONFIG, LEAK MEASURE, [AUTO LEAK ON/OFF] .........................................................6-33

CONFIG, LEAK MEASURE, [AUTO LEAK LOCK] ..............................................................................6-33

CONFIG, LEAK MEASURE, [AUTO LIMIT ON/OFF] ......................................................................... 6-33

CONFIG, LEAK MEASURE, [AUTO LIMIT LOCK] ..............................................................................6-33

CONFIG, GROUND ..................................................................................................................................... 6-33

Druck ADTS 405 User Manual

Page 11

vii

K114 Issue No. 9

Table of Contents (contd)

Section page

CONFIG, PORT ............................................................................................................................. 6-34

CONFIG, REMOTE ....................................................................................................................... 6-34

CONFIG, ETP,[AUTO RUN] ....................................................................................................... 6-34

CONFIG, ETP,[ERASE PROGRAMS] ...................................................................................... 6-34

CONFIG, ETP,[RESULT] ............................................................................................................. 6-34

CONFIG,

or (nudge keys) ............................................................................................... 6-34

CONFIG, 000 ................................................................................................................................................ 6-34

6.5 Specification ................................................................................................................................................ 6-35

Zone 2 Hazardous Area Definition ................................................................................................... 6-42

List of Illustrations

Figure page

Figure 1-1 ADTS 405 General View.......................................................................................................................... 1-2

Figure 1-2 ADTS 405F General View ....................................................................................................................... 1-2

Figure 2-1 Equipment and Parts .............................................................................................................................. 2-3

Figure 2-2 ADTS 405 Altitude Reference .............................................................................................................. 2-8

Figure 2-3 ADTS 405F Altitude Reference ............................................................................................................ 2-9

Figure 2-4 ADTS 405 General View.......................................................................................................................... 2-10

Figure 2-5 ADTS 405 Rear Panel View ................................................................................................................... 2-11

Figure 2-6 ADTS 405F General View ....................................................................................................................... 2-12

Figure 3-1 Front Panel ................................................................................................................................................... 3-2

Figure 3-2 Main Pressure Display (Leak Measure Mode) .............................................................................. 3-12

Figure 3-3 Main Pressure Display (Control Mode)............................................................................................ 3-13

Figure 3-4 Single Display ............................................................................................................................................. 3-15

Figure 3-5 Dual Display ................................................................................................................................................ 3-16

Figure 3-6 Triple Display .............................................................................................................................................. 3-16

Figure 3-7 Rate Timer Display Aeronautical Units .......................................................................................... 3-17

Figure 3-8 Rate Timer Display Pressure Units ................................................................................................... 3-17

Figure 3-9 Pt Only Display ........................................................................................................................................... 3-18

Figure 5-1 Fault Finding Chart .................................................................................................................................. 5-6

Figure 6-1 Altitude Correction Rack Mounting .................................................................................................. 6-22

Figure 6-2 Altitude Correction On-aircraft .......................................................................................................... 6-22

Figure 6-3 ARINC 565 Operating Limits ................................................................................................................ 6-31

List of Tables

Table page

2-1 Parts List ........................................................................................................................................................ 2-4

4-1 Maintenance Chart .................................................................................................................................. 4-1

4-2 Materials List ............................................................................................................................................... 4-2

4-3 Tool and Test Equipment Requirements ....................................................................................... 4-2

5-1 Fault Finding ................................................................................................................................................ 5-7

5-2 Error Messages .......................................................................................................................................... 5-17

5-3 Warning Messages ................................................................................................................................... 5-18

Page 12

viii

K114 Issue No. 9

Druck ADTS 405 User Manual

Abbreviations

The following abbreviations are used in this manual; the abbreviations are the same in the singular and plural.

A Ampere

abs Absolute

a.c. Alternating current

ALT Altitude

ATEX Equipment for Use in Potentially Explosive Atmosheres

CAS Calibrated airspeed

d.c. Direct current

e.g. For example

EOC End of conversion

EPR Engine pressure ratio

EPROM Electrically programmable read only memory

etc. And so on

Fig. Figure

ft Foot

g Gauge

Hg Mercury

Hz Hertz

IAS Indicated airspeed

i.e. That is

IEEE 488 Institute of Electrical and Electronic Engineers standard 488 data

in Inch

kg Kilogram

LED Light emitting diode

m Metre

mA Milliampere

max Maximum

mbar Millibar

min Minute or minimum

mm Millimetre

mV Millivolts

No. Number

N.m. Newton metre

Para. Paragraph

Ps Static pressure

psi Pounds per square inch

Pt Total pressure

Qc Differential pressure Ps-Pt

QFE Local atmospheric pressure

QNH Barometric pressure at sea level

ROC Rate of climb

SCPI Standard commands for programmable instruments

TAS True airspeed

TE Test equipment

V Volts

Vc Calibrated velocity

Vt True velocity

+ve Positive

-ve Negative

°C Degrees Celsius

°F Degrees Fahrenheit

Page 13

ix

K114 Issue No. 9

Glossary

Terminology

The terminology used in this manual is specific and individual interpretation must not be

introduced. The terms are defined as follows:

Adjust To bring to a more satisfactory state; to manipulate controls, levers, linkages,

etc. to return equipment from an out-of-tolerance condition to an in-tolerance

condition.

Align To bring into line; to line up; to bring into precise adjustment, correct relative

position or coincidence.

Assemble: To fit and secure together the several parts of; to make or form by combining

parts.

Calibrate: To determine accuracy, deviation or variation by special measurement or by

comparison with a standard.

Check: Make a comparison of a measure of time, pressure, temperature, resistance,

dimension or other quality with a known figure for that measurement.

Disconnect: To detach the connection between; to separate keyed or matched equipment

parts.

Dismantle: To take apart to the level of the next smaller unit or down to all removable parts.

Examine: To perform a critical visual observation or check for specific conditions; to test the

condition of.

Fit: Correctly attach one item to another.

Inspect: Review the work carried out by Specialists to make sure it has been performed

satisfactorily.

Install: To perform operations necessary to properly fit an equipment unit into the next

larger assembly or system.

Maintain: To hold or keep in any particular state or condition especially in a state of

efficiency or validity.

Make sure: To confirm that a proper condition exists; to find out with certainty.

Operate: Make sure that an item or system functions correctly as far as possible without

the use of test equipment or reference to measurement.

Power-up: To perform operations necessary to switch on a system ready for use.

Glossary

Page 14

x

K114 Issue No. 9

Power-down: To perform operations necessary to safely switch off a system after use.

Readjust: To adjust again; to move back to a specified condition; to bring back to an

in-tolerance condition.

Reconnect: To rejoin or refasten that which has been separated.

Refit: Fit an item which has previously been removed.

Remove: To perform operations necessary to take an equipment unit out of the next larger

assembly or system. To take off or eliminate. To take or move away.

Repair: To restore damaged, worn out or malfunctioning equipment to a serviceable,

usable or operable condition.

Replace: Remove an item and fit a new or a serviced item.

Reset: To put back into a required position, adjustment or condition.

Service: To perform such operations as cleaning, lubricating and replenishing to prepare for

use.

Test: Ascertain by using the appropriate test equipment that a component or system

functions correctly.

Druck ADTS 405 User Manual

Page 15

xi

K114 Issue No. 9

Returned Goods Procedure

for Europe

Should the unit become unserviceable and require repair it can be returned to the Druck

Service Department.

Please contact our Service Department, either by 'phone, fax or e-mail to obtain a Returned

Goods Authorization (RGA) number, providing the following information:

Product (i.e. ADTS 405)

Pressure medium (i.e. air, nitrogen)

Serial number

Details of defect/work to be undertaken

Operating conditions

Safety Precautions

You must also tell us if the product has been in contact with anything hazardous or toxic and

the relevant COSH references and precautions to be taken when handling.

Important notice

Service by unauthorized sources will affect the warranty and may not guarantee further

performance.

Page 16

xii

K114 Issue No. 9

Returned Material Procedure

for USA

Should the equipment become unserviceable it can be returned to the Druck Service

Department.

Please contact our Service Department, either by 'phone, fax or e-mail to obtain a Returned

Material Authorization (RMA) number, providing the following information:

Product (i.e. ADTS 405)

Pressure medium (i.e. air, nitrogen)

Serial number

Details of defect/work to be undertaken

Operating conditions

Safety Precautions

You must also tell us if the product has been in contact with anything hazardous or toxic and,

the relevant MSDS references and precautions to be taken when handling.

Important notice

Service by unauthorized sources will affect the warranty and may not guarantee further

performance.

Approved Service Agents

For the list of service centres visit our web site:

www.gesensing.com

Page 17

xiii

K114 Issue No. 9

ATEX Certified ADTS Hand Terminal

CONDITIONS OF USE

The ATEX certified ADTS hand terminal supplied with the ADTS 405 can be used in zone 2

hazardous areas in accordance with the ATEX certification document and schedule.

ATEX Certificate of Conformity

No. Baseefa05ATEX0192

BASEEFA being an Approved Certification Body, in accordance with Article 14 of the Council

Directive of the European Communities of 18th December, 1975 (76/117/EEC) certifies that

the apparatus has been found to comply with harmonised European Standards:

EN 60079-15: 2003

and has successfully met the examination and test requirements recorded in confidential

report number:

05(C)0154 (Baseefa) dated 12th October 2005

NOTE: Refer to pages 2/2 of the Certificate of conformity for electrical connection parameters.

Rated Voltage = 32Vdc.

Marking detail:

ADTS Hand Terminal

Baseefa05ATEX0192

II 3G IP54

Baseefa05ATEX0192 (EC type examination certificate number)

EEx nA nL IIC T4 (-25°C

<T

amb

<=55°C)

Druck, LE6 0FH, UK

6 - 32V

Power

3W Max

SPECIAL CONDITION OF USE

• The power supplies must be isolated when connecting the ADTS hand terminal in the

hazardous area.

• The ADTS hand terminal must not be disconnected when energized in the hazardous

area.

• The ADTS hand terminal is a non-serviceable component. If the ADTS hand terminal

becomes unserviceable it can only be replaced by another ATEX compliant hand

terminal.

Page 18

xiv

K114 Issue No. 9

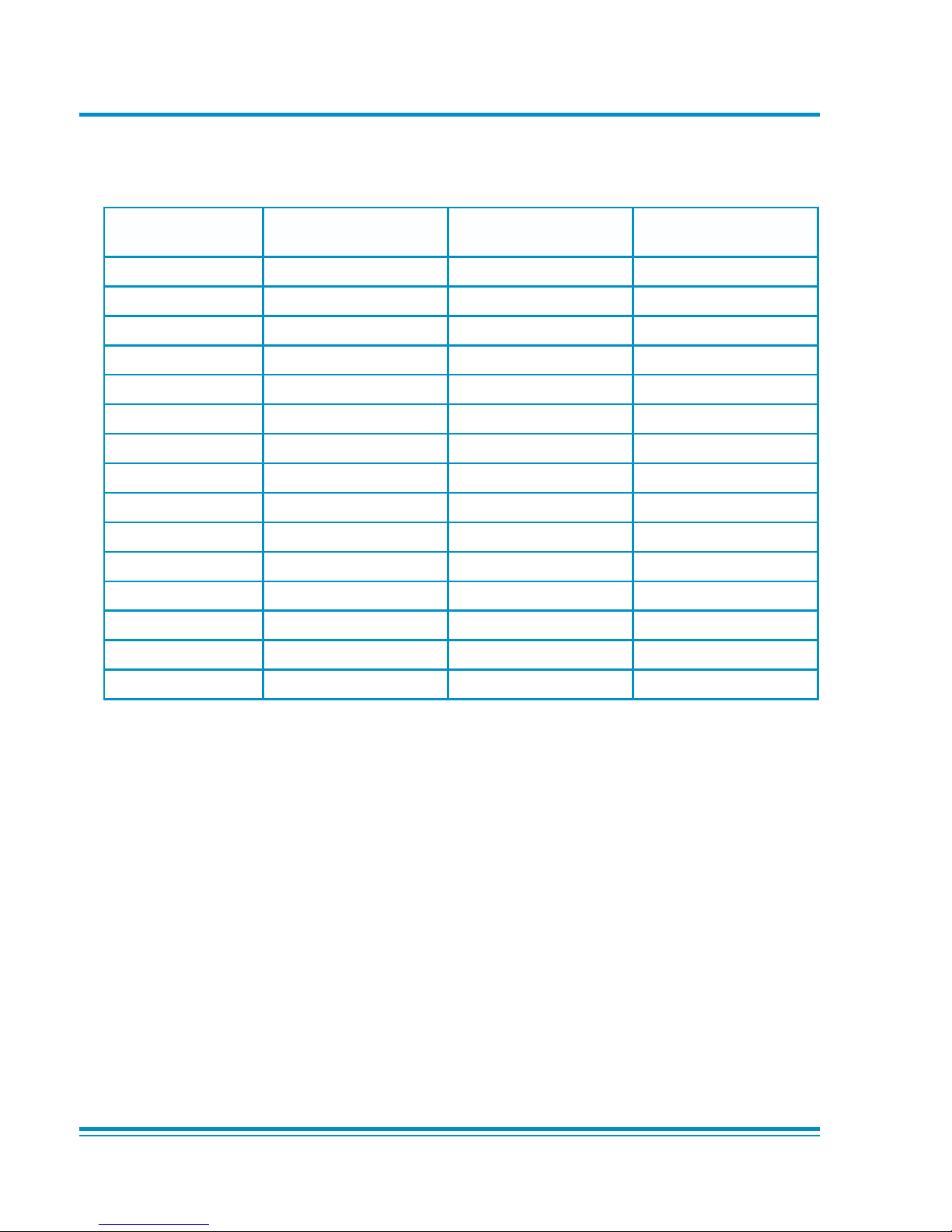

Table of pressure units and conversion factors

Unit Conversion

To convert FROM pressure VALUE 1 in pressure UNITS 1

TO pressure VALUE 2 in pressure UNITS 2, calculate as follows:

VALUE 2 = VALUE 1 x

FACTOR 1

FACTOR 2

Note

The conversion factor for pressure units referenced [1] are calculated for a water temperature of 4°C.

Pressure units referenced [2] are calculated for a water temperature of 68°F these units are normally

used in the USA.

tinuerusserP )slacsaP(rotcaF tinuerusserP )slacsaP(rotcaF

rab000001tf/fbl

2

3088.74

ni/fbl

2

)isp(67.4986gHni93.6833

Hm

2

O56.6089Hni

2

]1[O980.942

rabm001Htf

2

]1[O70.9892

mc/fgk

2

5.66089mta0.523101

m/fgk

2

56608.9tf/ldp

2

61884.1

gHmm223.331mc/nyd

2

1.0

gHmc22.3331rabh00000001

gHm0.223331tf/fnot

2

)KU(0.252701

H/mm

2

]1[O56608.9ni/fnot

2

)KU(00344451

H/mc

2

]1[O5660.89Hni

2

]2[)ASU(O53146.842

m/N

2

1Htf

2

]2[)ASU(O3896.3892

aPh001mm/pk

2

0566089

aPk0001mc/pk

2

5.66089

aPM0000001m/pk

2

56608.9

rrot223.331

Pressure units and conversion factors

Page 19

1 - 1Description

K114 Issue No. 9

1

1 DESCRIPTION

1.1 Introduction

There are two versions of the ADTS 405, a 19", 6U high (10½”) rack-mounted unit and a

flight line unit.

The ADTS 405 is a rack-mounted system and, with external pressure and vacuum supplies

connected, provides measurement and control for leak checks, calibration accuracy

checks and functional tests of air data instruments, components and systems.

The ADTS 405F is a self-contained flight-line air data test system providing complete

pressure and vacuum measuring and control for on-aircraft sense and leak testing,

calibration accuracy checks and functional tests of air data instruments, components and

systems. The unit comprises an electronics rack and pump rack enclosed in a high density,

polyethylene case.

The ADTS 405 displays and operates in either units of pressure measurement or aeronautical

units. In the control mode, the rate that the pressures change towards new set-points can

be controlled in true aeronautical rate units.

There are two independent pneumatic channels connect to the aircraft or instrument

systems, one for static and one for pitot. They can be operated as measure only channels

with leak testing facility or each can be control channels producing true pressure

conditions for altitude and airspeed.

To protect sensitive instruments and equipment a `ground' facility automatically and

safely controls both channels to atmospheric pressure at the previously entered rates of

change and then informs the operator when both channels are safely at `ground'.

The operator interface is either an ATEX certified hand terminal connected to the front

panel or the key pad and display on the front panel. Both provide information and control

selections for the user through the keys and display. The unit can also be controlled

remotely using the IEEE 488 communications interface. The front panel contains the

operate switch and a mimic panel with LED indicators showing the operation of the

solenoid-operated pneumatic valves.

The pump rack, on the ADTS 405F, produces pressure and vacuum supplies for the

electronics rack and for external services. Located on the front panel, the external

connectors provide for external pressure and vacuum supplies (EXT PRESSURE and EXT

VACUUM) and an auxiliary static (vacuum) output (AUX). The rack is cooled by a fan located

under a protective cover on the front panel. The power supply connection for the ADTS

405F is located on the front panel.

Page 20

Druck ADTS 405 User Manual

1 - 2

K114 Issue No. 9

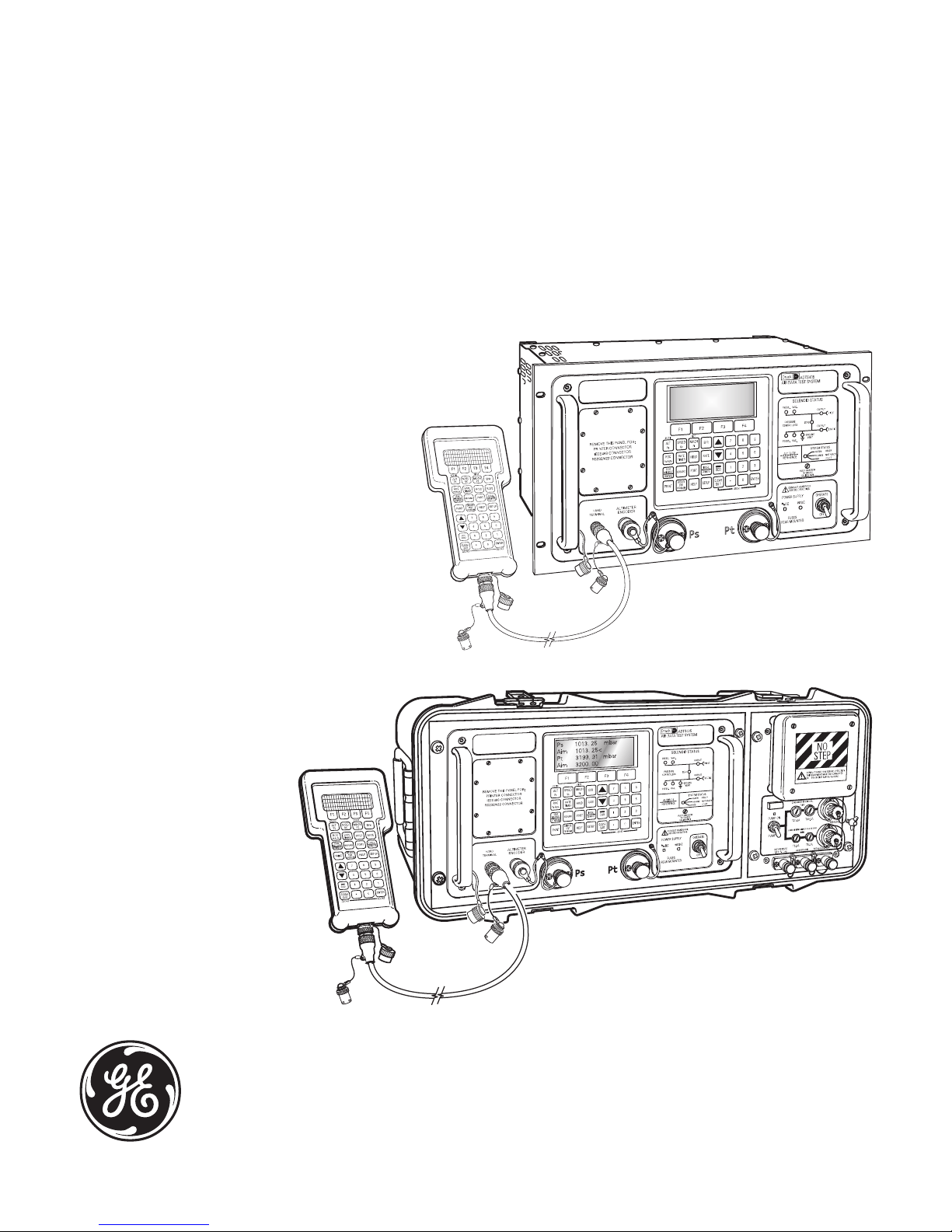

FIGURE 1-2 ADTS 405F GENERAL VIEW

FIGURE 1-1 ADTS 405 GENERAL VIEW

DRUCKADTS 405

ATEXCOMPLIANT

HANDTERMINAL

DONOT DISCONNECT WHEN

ENERGIZEDIN THE HAZARDOUS AREA

Ps 1013. 25 mbar

Aim 1013. 25<

Pt 3199. 91 mbar

Aim 3200. 00

DONOT DISCONNECT WHEN

ENERGIZEDIN THE HAZARDOUS AREA

DRUCKADTS 405

ATEXCOMPLIANT

HANDTERMINAL

Page 21

1 - 3Description

K114 Issue No. 9

1

1.2 Operating Range and Performance

The ADTS 405 is supplied in one of two full-scale ranges (850 knots or 1000 knots) for

measurement and control of the pitot pressure channel.

Operating limits are set, pre-defined tabular limits known as STANDARD, CIVIL and MAX

these can be selected through the SETUP menu (see Reference section 6). Operators

may also configure the display to aeronautical or pressure units but should be aware

that when units of pressure are selected, wider full-scale pressure limits will be enabled

for some parameters.

1.3 Operating Limits

The following sets of operating limits are supplied with the ADTS 405.

850 knot range operating limits

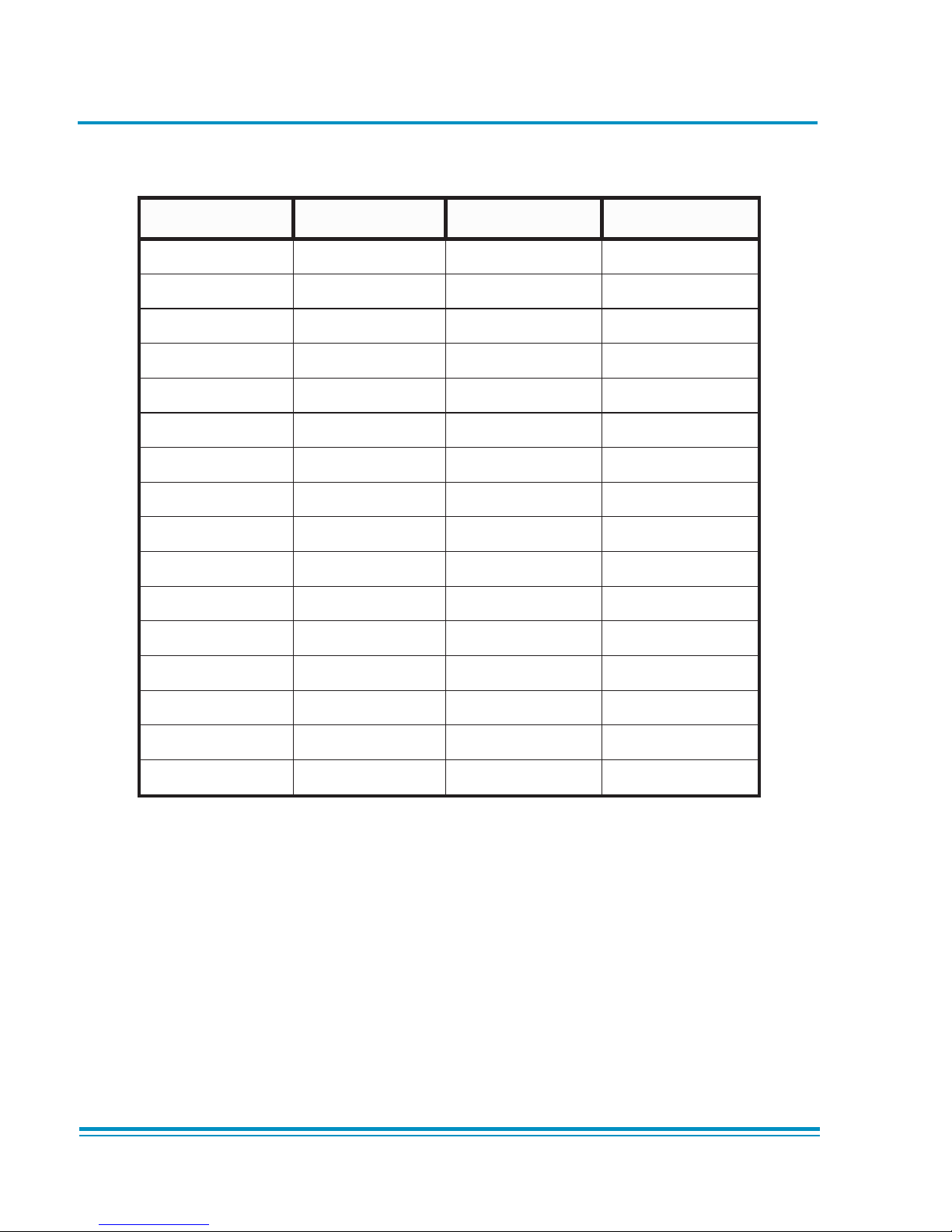

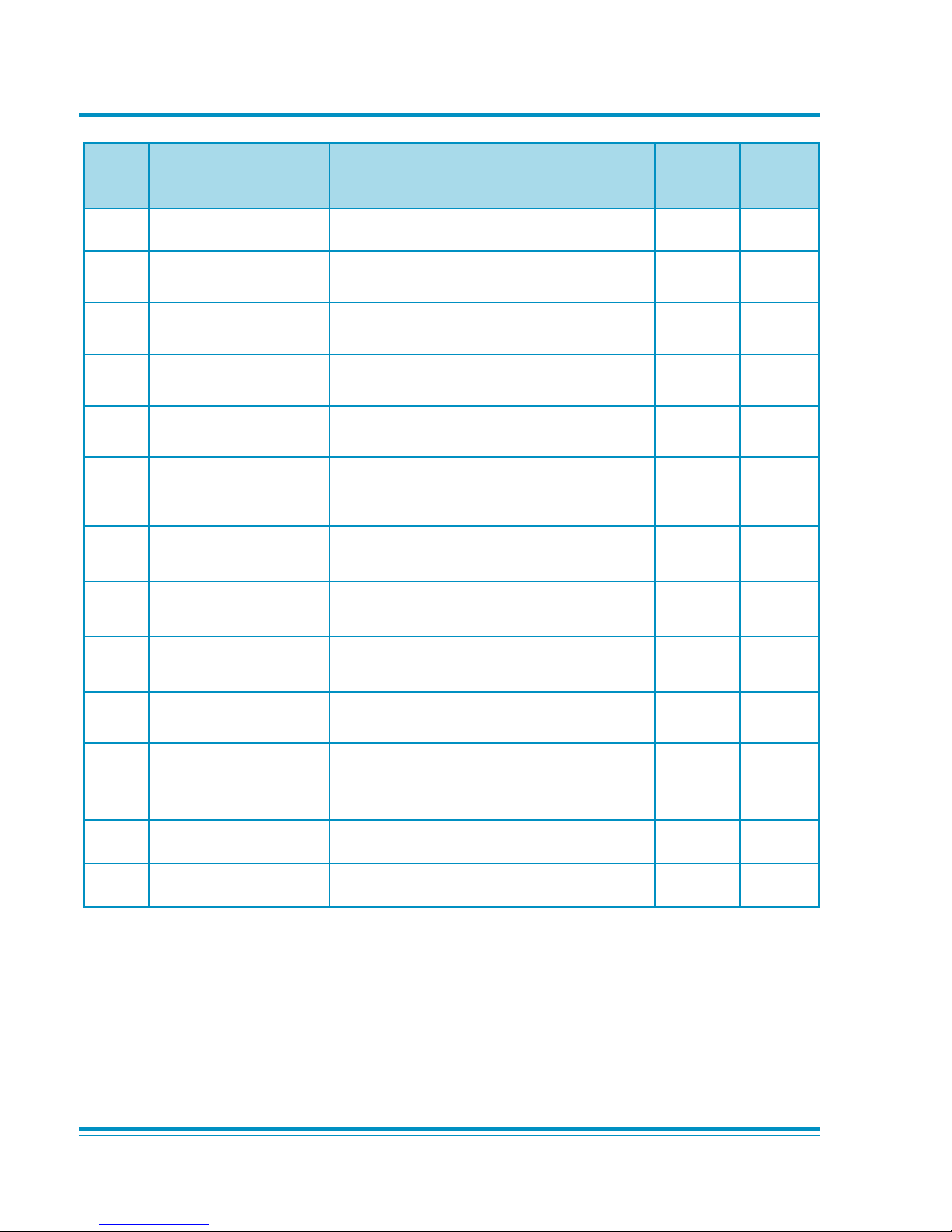

retemaraP stimiLxaM stimildradnatS stimilliviC

tlAniMtf000,3-tf000,2-tf000,1-

tlAxaMtf000,501tf000,08tf000,05

SACniMstk001-stk0.0stk0

SACxaMstk058stk05

8stk054

sPniMrabm0.3rabm516.72rabm279.511

sPxaMrabm00.5531rabm756.8801rabm604.0501

cQniMrabm00.253,1-rabm0.0rabm0

c

QxaMrabm00.007,1rabm00.8861rabm10.863

hcaMxaM53.215.21

CORxaMnim/tf000,001nim/tf000,9nim/tf000,6

SACetaRxaMnim/stk

000,2nim/stk006nim/stk006

sPetaRxaMnim/rabm00.000,01nim/rabm00.002nim/rabm00.001

cQetaRxaMnim/rabm00.000,01nim

/rabm00.002nim/rabm00.001

stimiLCNIRAFFOFFOFFO

noitcerroCtlAtf0tf0tf0

Page 22

Druck ADTS 405 User Manual

1 - 4

K114 Issue No. 9

retemaraP stimiLxaM stimildradnatS stimilliviC

tlAniMtf000,3-tf000,3-tf000,1-

tlAxaMtf000,501tf000,08tf000,05

SACniMstk001-stk0stk0

SACxaMstk000,1stk00

0,1stk054

sPniMrabm0.3rabm516.72rabm279.511

sPxaMrabm00.5531rabm920.821,1rabm604.0501

cQniMrabm00.253,1-rabm303.6

1-rabm0

cQxaMrabm00.005,2rabm05.094,2rabm10.863

hcaMxaM79.4151

CORxaMnim/tf000,001nim/tf000,51nim/tf000,6

SACetaRxa

Mnim/stk000,2nim/stk007nim/stk006

sPetaRxaMnim/rabm00.000,01nim/rabm00.002nim/rabm00.001

cQetaRxaMnim/rabm00.0

00,01nim/rabm00.002nim/rabm00.001

stimiLCNIRAFFOFFOFFO

noitcerroCTLAtf0tf0tf0

1000 knot range operating limits

Page 23

K114 Issue No. 9

Installation 2 - 1

2

2 INSTALLATION

2.1 Packaging

Packaging List - ADTS 405

i) Rack ADTS 405

ii) Power supply cable

iii) User Manual (this publication)

iv) Output, hose, 2.5m, red, AN6 - open

v) Output, hose, 2.5m, blue, AN4 - open

vi) Input, hose, 2.5m, green, AN6 - open

vii) Input, hose, 2.5m, yellow, AN4 - open

viii) Spare fuses (2 off)

ix) Plug, expansion port

Packaging List - ADTS 405F

i) Flight line ADTS 405F

ii) Accessory bag

iii) Power supply cable

iv) Hand terminal

v) Hand terminal cable - 2 m

vi) Hand terminal cable - 18 m

vii) Output, hose, 2.5m, red, AN6 - open

viii) Output, hose, 2.5m, blue, AN4 - open

ix) User Manual (this publication)

x) Spare fuses (2 off)

2.2 Packaging for Storage or Transportation

To store the unit or to return the unit for calibration or repair carry out the following

procedures:

1. Pack the unit as detailed in the following procedure.

2. To return the unit for calibration or repair complete the return goods procedure

as detailed in the preliminary pages.

On receipt of the ADTS 405 check the contents of the packaging against the following

lists:

Page 24

K114 Issue No. 9

2 - 2 Druck ADTS 405 User Manual

Procedure

The unit should be at zero/ambient pressure. Disconnect the hose assemblies and

stow in the shoulder bag.

Switch OFF and disconnect from the electrical power supply. Disconnect the

power supply cable and the hand terminal cable. Disconnect the hand terminal

cable from the hand terminal.

Stow the power supply cable, hand terminal cable and the hand terminal in the

ADTS 405F lid. For ADTS 405 rack units these items should be placed in a sealed

polythene bag.

Fit the lid to the unit.

If available, use the original packing material. When using packing materials other

than the original, proceed as follows.

Wrap unit in polyethylene sheeting.

Select a double-wall cardboard container. Inside dimensions must be at least

15 cm greater than the equipment. The carton must meet test strength

requirements of >125 kg.

Protect all sides with shock-absorbing material to prevent equipment movement

within the container.

Seal carton with approved sealing tape.

Mark carton “FRAGILE” on all sides, top, and bottom of shipping container.

Environment

The following conditions apply for both shipping and storage:

Temperature Range-40° to +70°C (-40° to +158°F)

Altitude......................... Up to 15,000 feet (4,570 metres)

Page 25

K114 Issue No. 9

Installation 2 - 3

2

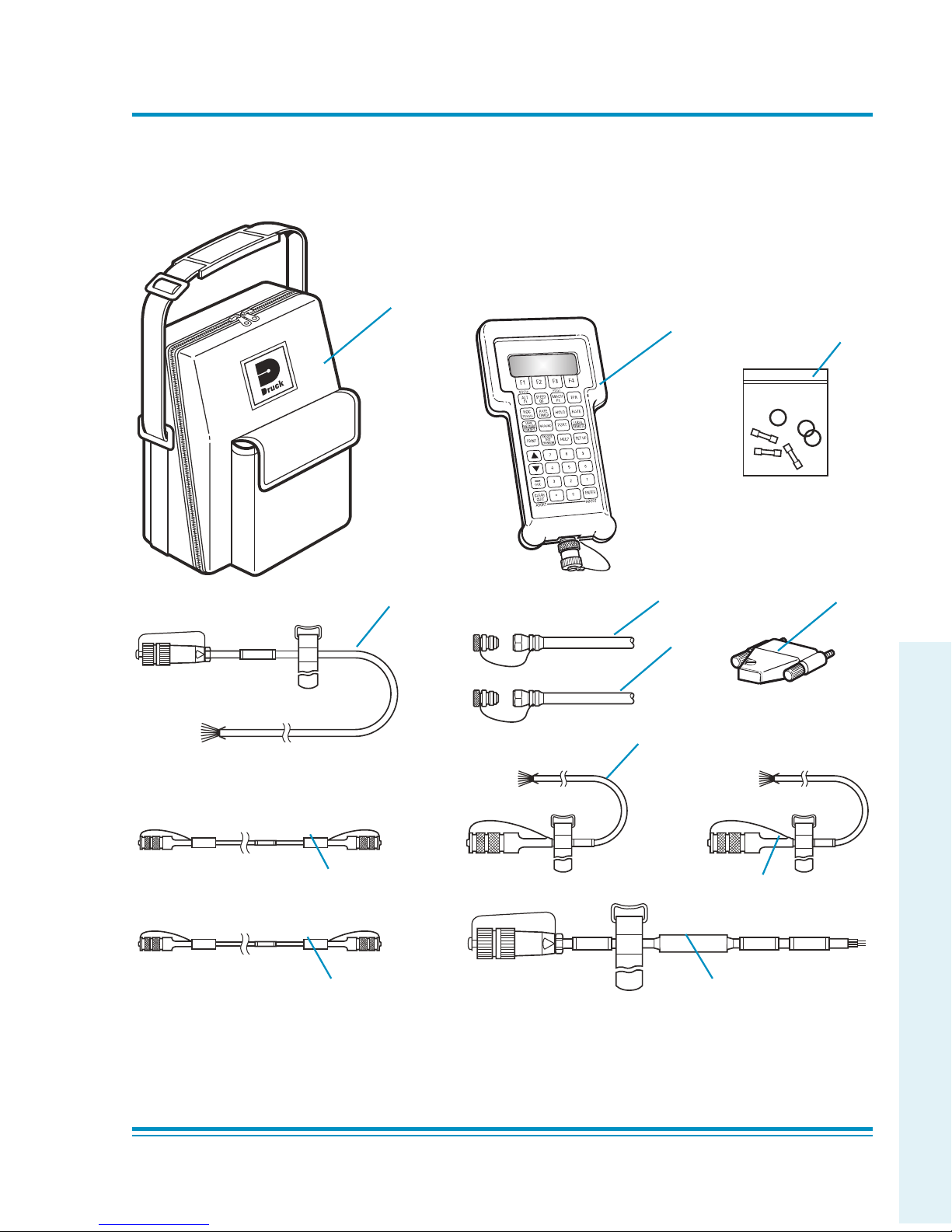

DONOT DISCONNECT WHEN

ENERGIZEDIN THE HAZARDOUS AREA

DRUCK ADTS 405

ATEXCOMPLIANT

HAND TERMINAL

FIGURE 2.1 EQUIPMENT AND PARTS

1

4

8

2

6

11a

5

12

10

2m

18m

9

3

13

Page 26

K114 Issue No. 9

2 - 4 Druck ADTS 405 User Manual

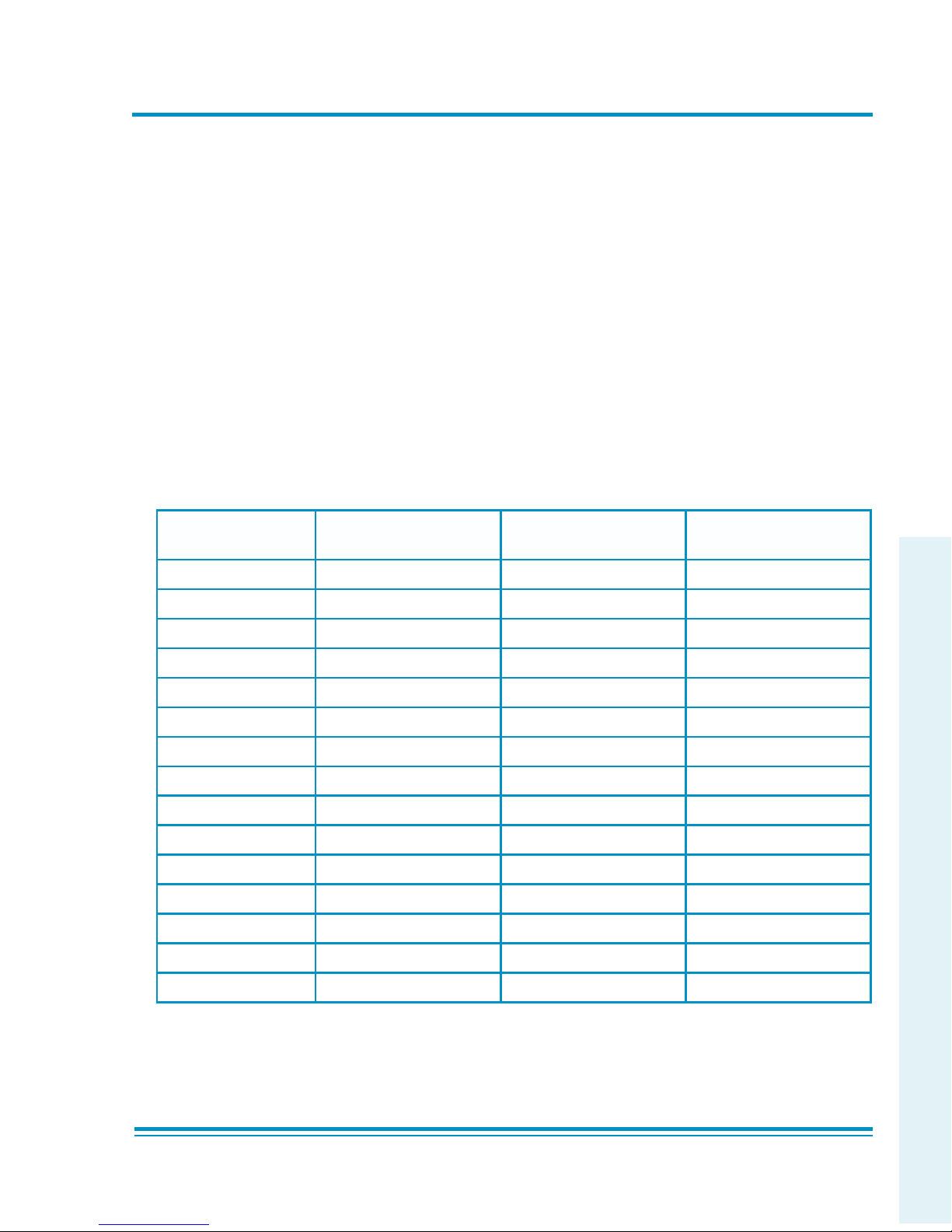

TABLE 2-1 PARTS LIST

oN rebmuNtraP noitpircseD nOdesU

repytQ

yssa

1

0M-93-8271-504STDAredluohS,gaB

F504STDA

1

2

0M-63-8271-504STDAgniR-O/esuF,tiK

F504STDA

dna

504STDA

1

3

1M-73-8271-504STDA,lanimretdnaH

F504STDA

dna

504STDA

1

4

0M-74-8271-504STDA)dnEnepOV062(M5,rewoPCA,elbaC

F504STDA

dna

504STDA

1

5

0M-82-8271-504STDAM2lanimretdnaH,elbaC

F504STDA

dna

504STDA

1

a6

0M-72-8271-504STDAM81lanimretdnaH,elbaC

F504STDA

dna

504STDA

1

*b6

0M-92-8271-504STDA)noitpO(M03lanimretdnaH,elbaC

1

*7

0M-25-9271-504STDA)nepO/TSNAM5.2x2(rotpadaesoh,tiK

F504STDA

dna

504STDA

1

8

0M-16-9271-504STDA6NA,NPO/TS,der,)sP(citatS,esoH

)elbaliavasnoitpolaicepS(

F504STDA

dna

504STDA

1

9

0M-26-9271-504STDA4NA,NPO/TS,eulb,)tP(totiP,esoH

)elbaliavasnoitpolaicepS(

F504STDA

dna

504STDA

1

01

0M-43-8271-504STDA)dnEnepO()rotcennoCralucriC(CNIRA,elbaC

)noitpO(

F504STDA

dna

504STDA

1

a11

0M-53-8271-504STDA)dnEnepO(M6,redocnEretemitlA,elbaC

)noitpO(

F504STDA

dna

504STDA

1

*b11

0M-16-1981-504STDA)sretemitla23-UAA(M6,elbaCredocnEretemitlA

)noitpO(

1

21

0M-84-8271-504STDA)noitpO(M5,rewoPCD,elbaC

F504STDA

1

31

0M-22-1981-504STDAtropnoisnapxe,gulP

504STDA

1

ATEX certified

Page 27

K114 Issue No. 9

Installation 2 - 5

2

2.3 Electrical Connection

WARNINGS: 1 VOLTAGES IN EXCESS OF 30 VOLTS (RMS) AC OR 50VOLTS DC,

IN CERTAIN CIRCUMSTANCES, CAN BE LETHAL. CARE MUST BE TAKEN

WHEN WORKING ON LIVE, EXPOSED CONDUCTORS.

2 DO NOT DISCONNECT THE HAND TERMINAL WHEN ENERGIZED IN THE

HAZARDOUS AREA.

Power Supply Connection

The unit must be connected to the correct electrical power supply as stated, adjacent

to the power connector.

CAUTIONS:

1T

HE SUPPLY MUST PROVIDE CONNECTION TO A PROTECTIVE GROUND TERMINAL. THE UNIT

MUST

, AT ALL TIMES, BE CONNECTED TO THE SUPPLY EARTH (GROUND).

2T

HE POWER SUPPLY CABLE AND CONNECTOR MUST BE CORRECTLY RATED FOR THE POWER

SUPPLY

.

Note: The ADTS 405 is normally supplied with an approved power supply cable

for use in the country of delivery. This can limit the maximum supply

voltage that can be safely used.

e.g. a NEMA 5-15P terminated cable, for use in the U.S.A., is approved for a

maximum of 125 V ac; it must be replaced for a higher supply voltage.

ADTS 405 rack mounted units

Make sure that the power supply is off before connecting the power cable .

If required, connect the hand terminal to the connector using either the 2 metre or 18

metre cable.

Note: Connecting the hand terminal disables the front panel key-pad.

Fit the expansion port plug (item 13, Table 2-1) to the rear panel expansion port.

Note: For units used with the Druck PV 103 Pump Unit connect the expansion cable, supplied

with the PV 103, to the expansion port.

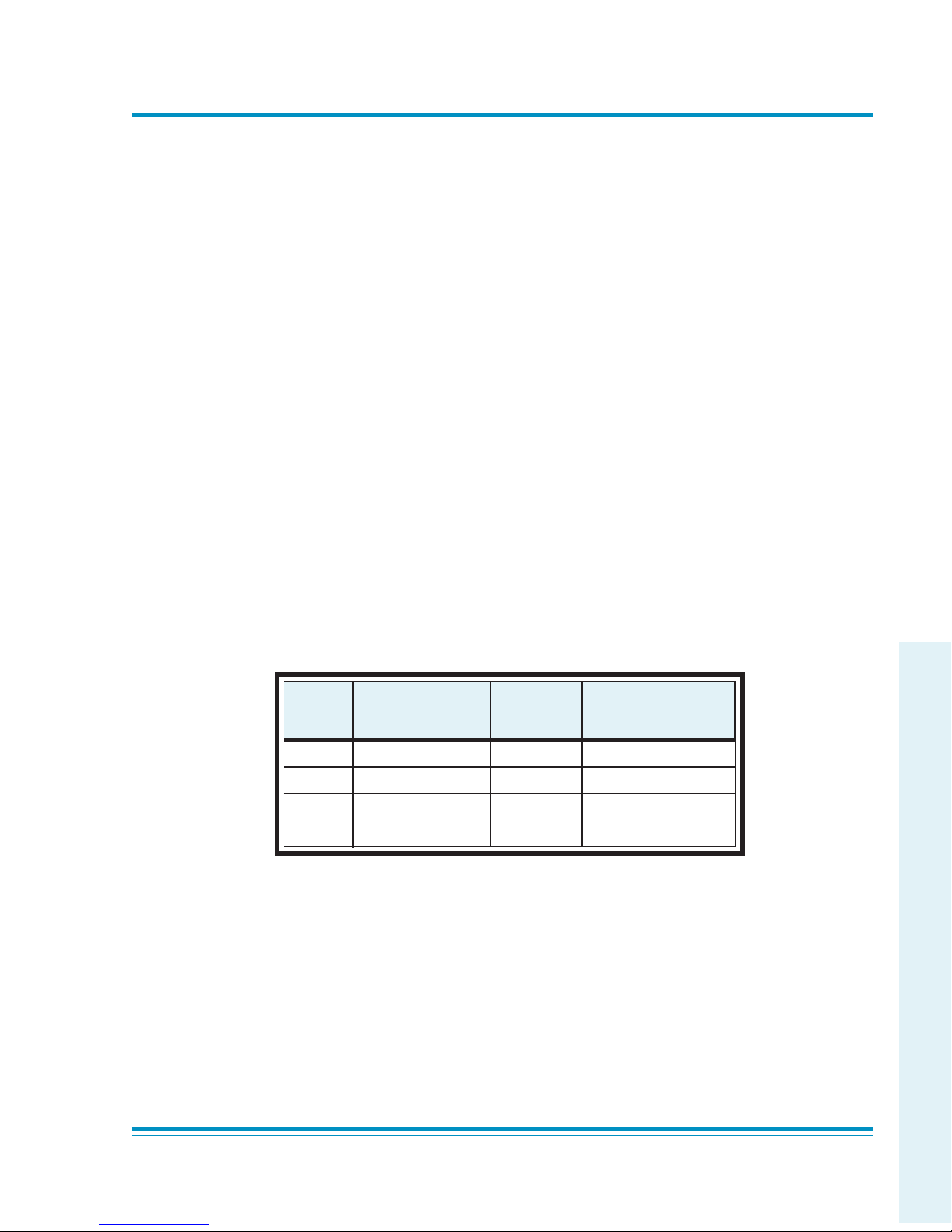

Pin European U.S. Function

Colour Color

1 Brown Black Live

4 Blue White Neutral

Centre Green/Yellow Green Protective Earth

(Ground)

Page 28

K114 Issue No. 9

2 - 6 Druck ADTS 405 User Manual

Note: The unit will not be damaged if AC power and DC power are connected at the same time.

Flight line units

Make sure that the power supply is off before connecting the power cable and hand

terminal cable.

Note: The flight line version power cable supplies both the electronics and pump racks.

If required, connect the hand terminal to the connector on the front panel using either

the 2 metre or 18 metre cable.

Note: Connecting the hand terminal disables the front panel key-pad.

The two fuses, located in the holders and mounted on the front panel, protect the

Electronics Rack and the Pump Rack. The fuses are connected in the live supply circuit

and are rated at:

5A anti-surge HBC 250V

An external earth (ground) cable may be connected to the stud on the front panel of

the pump rack to ensure integrity of the earth (ground) connection.

DC Power Option

The DC power option (nominal 28 V DC), can be an alternative power supply using an

additional connector. This is located on the rear of the rack (ADTS 405) or on the pump

front panel (ADTS 405F) both have the same connector details.

Pin European U.S. Function

Colour Color

1 Grey Gray +28V

2 White White 0V Return

Protective Earth Protective Ground Protective Earth

(Ground) (Ground)

Page 29

K114 Issue No. 9

Installation 2 - 7

2

2.4 Pneumatic Pressure Connections

ADTS 405 rack-mounted unit

Static (Ps) ............................................................................................................................ AN-6 37° flare

Pitot (Pt) ............................................................................................................................ AN-4 37° flare

Pressure supply ....................................................................................................................... AN-4 37° flare

Vacuum supply ........................................................................................................................ AN-6 37° flare

Connect pressure and vacuum supplies to the rear panel PRESSURE and VACUUM

connectors. The pressure supply should be clean, dry gas, nitrogen or air refer to the

specification.

Connect the Unit Under Test (UUT) to either the front panel or optional rear panel Ps

(static) and Pt (pitot) output connectors.

Note: Blanking caps must be fitted on unused front or rear outputs.

ADTS 405F flight line

Static (Ps) ............................................................................................................................ AN-6 37° flare

Pitot (Pt) ............................................................................................................................ AN-4 37° flare

Pressure supply ....................................................................................................................... AN-4 37° flare

Vacuum supply ........................................................................................................................ AN-6 37° flare

Auxiliary vacuum supply ..................................................................................................... AN-4 37° flare

In normal operation make sure that the correct blanking caps are fitted to the external

connectors.

The external pressure and vacuum connections are used when an external pump unit

supplies the pressure and vacuum. This may increase the maximum achievable rates

of change when connected to large volume systems.

The auxiliary vacuum, AUX VACUUM, can be used to supply the suction-type static

adaptors and provides a nominal 100 mbar (3 inHg) absolute vacuum. When not in

use, a blanking cap must be fitted.

Note: A leak of this blanking cap affects the performance of the ADTS 405F.

Page 30

K114 Issue No. 9

2 - 8 Druck ADTS 405 User Manual

Single channel operation

For single pipe testing of airspeed indicators or similar, requiring only Pt (pitot), connect

the UUT to Pt (pitot). The Ps (static) output must be left open to atmosphere (no

blanking cap) to provide a reference pressure.

Note: The Pt ONLY mode of operation must be used in this configuration.

For single pipe testing of altimeters or similar, requiring only Ps (static), connect the

UUT to Ps (static). The Pt (pitot) output should be left with a blanking cap fitted.

Note: The Ps ONLY mode of operation must be used in this configuration.

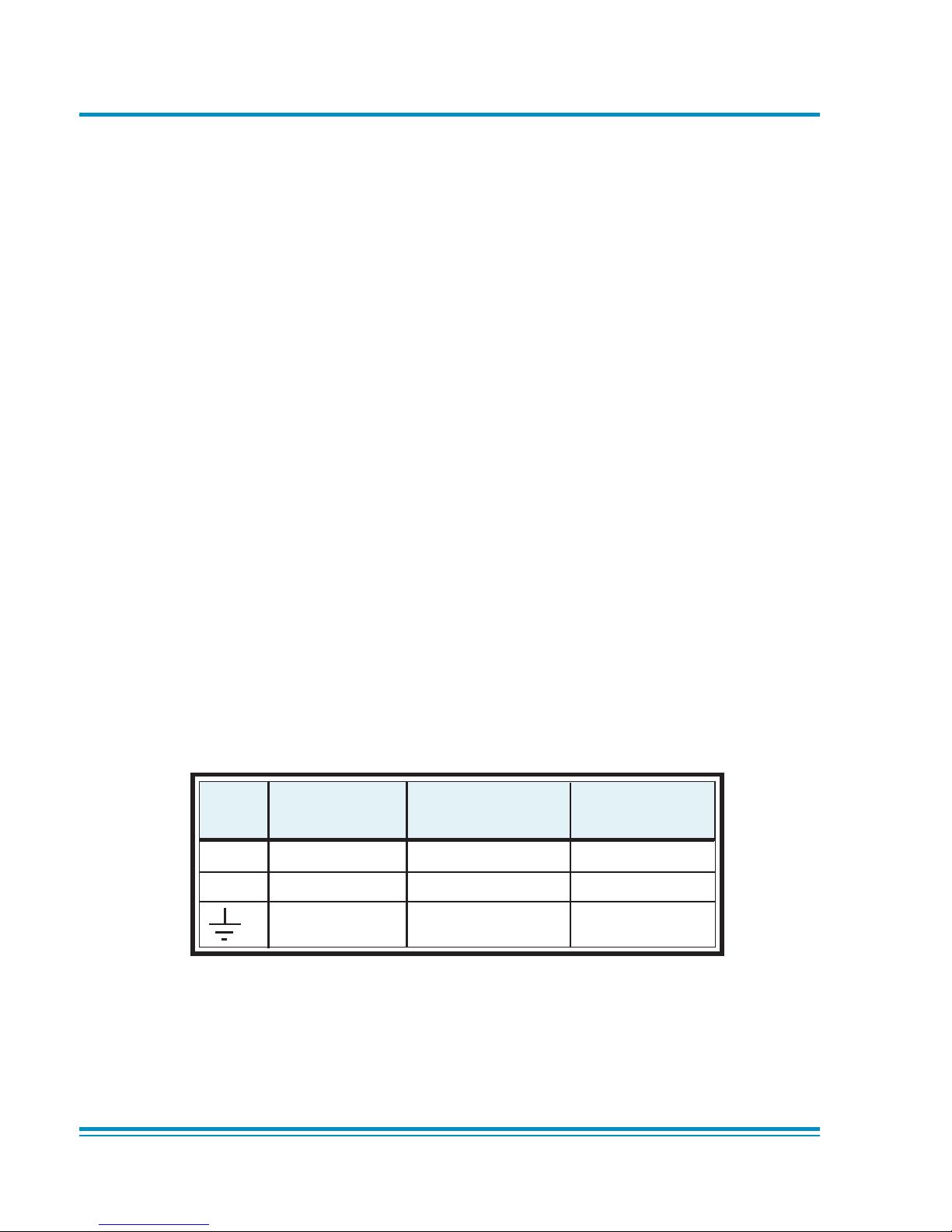

2.5 Positioning of the ADTS 405

It is important that the position of the ADTS 405 in relation to the components under

test is known. An altitude correction must be made to allow for the difference in height

between the reference level, indicated on the mimic panel, and the components under

test. The Reference section contains details of altitude correction (SETUP, ALTITUDE).

FIGURE 2-2 ADTS 405 ALTITUDE REFERENCE

WARNING: OBSERVE THE APPROPRIATE SAFETY

INSTRUCTIONS AND PROCEDURES DETAILED IN

THE COMPONENT MAINTENANCE MANUALS.

Page 31

K114 Issue No. 9

Installation 2 - 9

2

reference level

inst

AIR DATA

COMPUTER

STATIC

PITOT

reference level

altitude

correction

value

Corrected altitude = Altitude measurement - Altitude correction value

Zone 2 defined hazardous area

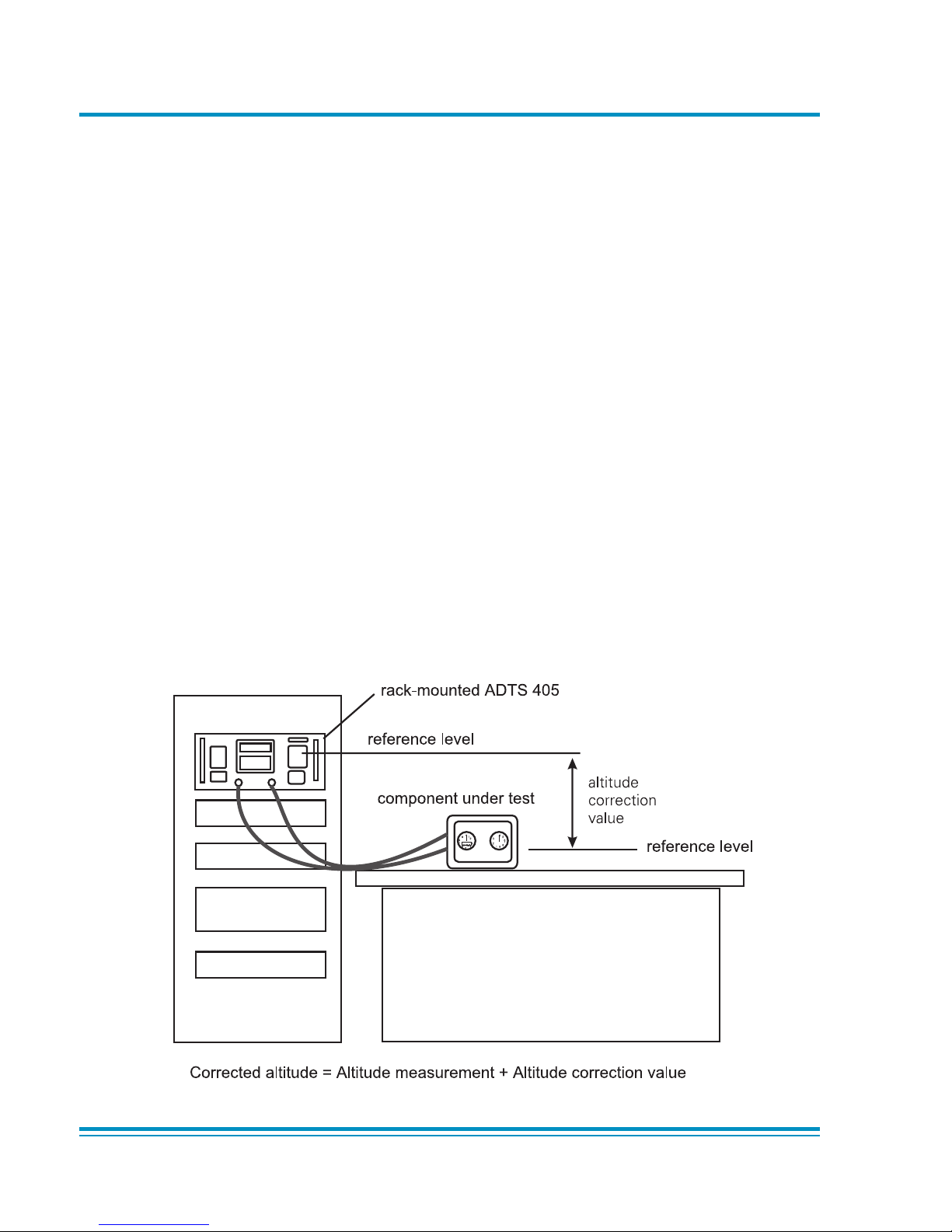

2.6 Positioning of the ADTS 405F

WARNING: DO NOT DISCONNECT THE ATEX CERTIFIED HAND TERMINAL WHEN

ENERGIZED IN THE HAZARDOUS AREA. THIS CAN CAUSE AN EXPLOSION.

To operate safely, the ADTS 405F must be placed outside the user defined zone 2

hazardous area. Only the ATEX certified hand terminal may be used inside the defined

zone 2 hazardous area (refer to section 6.5 for a definition).

It is important that the position of the ADTS 405F in relation to the aircraft altitude

sensors is known. An altitude correction must be made to allow for the difference in

height between the reference level and the aircraft's altitude sensors. The Reference

section contains details of altitude correction.

WARNING: OBSERVE THE APPROPRIATE SAFETY

INSTRUCTIONS AND PROCEDURES DETAILED IN

THE AIRCRAFT MAINTENANCE MANUALS.

F

IGURE 2-3 ADTS 405F ALTITUDE REFERENCE

Page 32

K114 Issue No. 9

2 - 10 Druck ADTS 405 User Manual

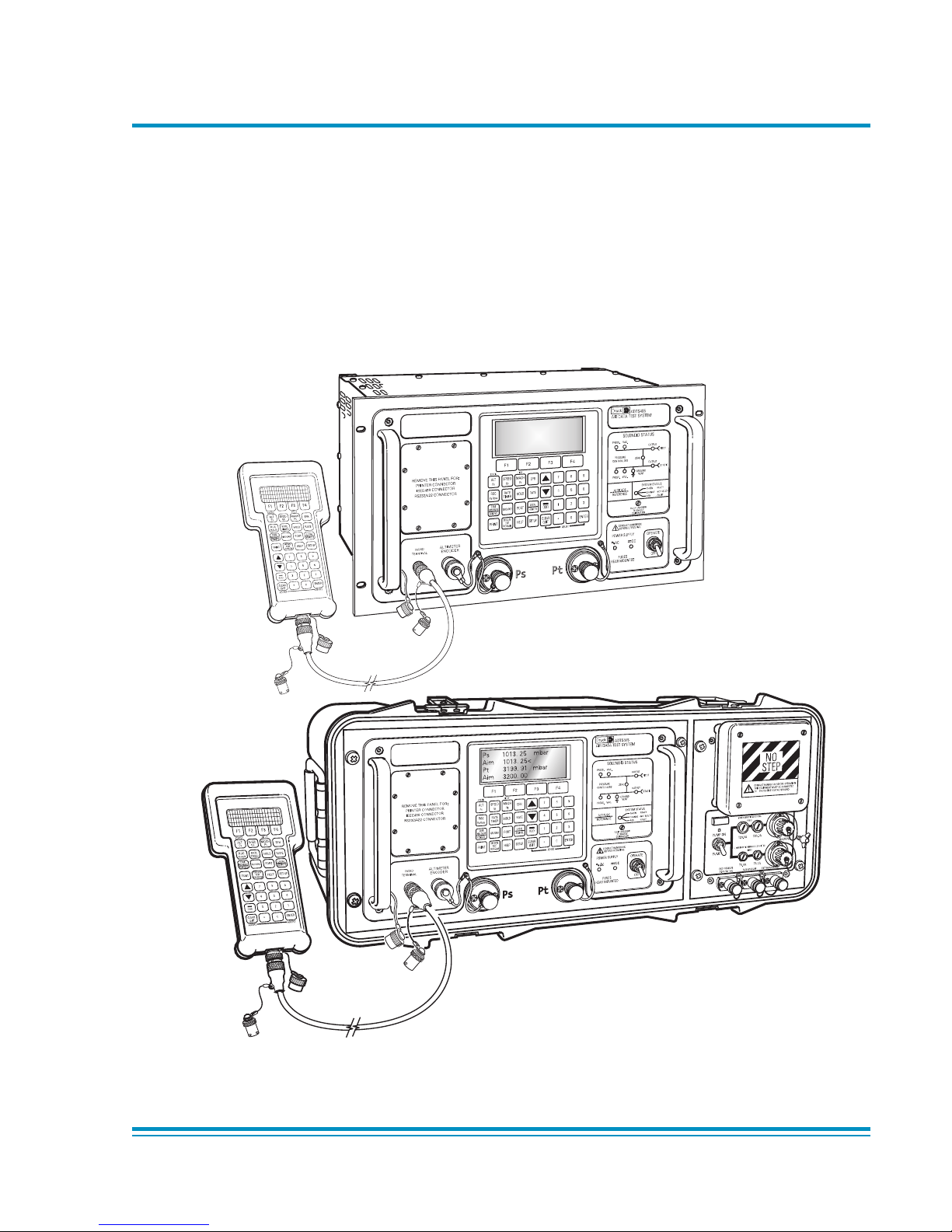

FIGURE 2-4 ADTS 405 GENERAL VIEW

Page 33

K114 Issue No. 9

Installation 2 - 11

2

FIGURE 2-5 ADTS 405 REAR PANEL VIEW

Page 34

K114 Issue No. 9

2 - 12 Druck ADTS 405 User Manual

FIGURE 2-6 ADTS 405F GENERAL VIEW

DONOT DISCONNECT WHEN

ENERGIZEDIN THE HAZARDOUS AREA

System

status

indicator

Solenoid

valve status

indicator

Key-pad

and

display

Cover plate

for option

connectors

Static

output

connector

Connector cable

(2m or 18m)

Hand

terminal

Pitot

output

connector

Altitude

reference

Auxiliary

Vacuum

input

connector

Vacuum

input

connector

Calibration

enable

switch

Power

supply

switch

Pump

switch

ARINC 429/

Altimeter

encoder

connector

(optional)

AC power

supply

connector

DC power

supply

connector

(optional)

DC and

AC power

supply

fuses

Pressure

input

connector

Fan

outlet

cover

Elapsed

time

indicator

DRUCK ADTS 405

ATEXCOMPLIANT

HAND TERMINAL

Page 35

K114 Issue No. 9

Druck ADTS 405 User Manual 3 - 1

3

3 OPERATION

3.1 Preparation

WARNING:

OBSERVE SAFETY PRECAUTIONS STATED IN LOCAL ORDERS AND THE

AIRCRAFT OR EQUIPMENT SERVICING PROCEDURES.

Make sure the electrical and pneumatic connectors, electrical cables and pipes and

positioning of the ADTS 405 comply with the instructions and requirements in Section 2

Installation.

Carry out the following before use:

If necessary, carry out the maintenance task detailed in Section 4.

Make sure the air data test system power supply switch on the front panel is set

to OFF. Connect the air data test system to the electrical supply, make sure the

supply includes a connection to a protective earth.

Inspect the pneumatic hoses for damage, ingress of dirt and moisture. Make

sure the aircraft adaptors are serviceable.

Connect, to the air data test system, the hoses necessary for the test procedures to be

carried out: red hose to the STATIC output (Ps), blue hose to the PITOT output (Pt).

Temporarily seal the free ends of the hoses.

Note: When connected, take care not to kink or stand on the hoses.

Connect the hand terminal to the air data test system through the HAND TERMINAL

connector on the front panel. If necessary, connect the hand terminal through the

extension cable.

Before use, the ADTS 405 should be tested, for first time users see section 3.4, for users

requiring more operating detail see section 3.5.

This section contains a quick reference chart showing all the functions of the key-pad.

Further quick reference charts show the set-up and configuration settings for each

key-pad function.

Review and become familiar with the whole procedure before starting the test process

on an aircraft or component.

Page 36

K114 Issue No. 9

3 - 2 Operation

3.2 Display Functions and Units of Measure

When operating in either pressure measuring or pressure controlling modes, the ADTS

405 can display the following information:

Aeronautical Functions Display Abbreviation Displayed Units

(if applicable)

Altitude ALT ft, m

Calibrated and True Airspeed CAS, TAS kts, km/h, mph

Mach MACH Rate of Climb ROC ft/m, m/m, m/s, hm/m

Rate of Airspeed Rt CAS, kts/m, km/h/m, mph/m

Rate of Mach RtMCH Mach/m

Pressure Functions Display Abbreviation Displayed Units

(if applicable)

Static (Absolute) Ps [P]

Pitot (Absolute) Pt [P]

Dynamic or Impact (Differential) Qc [P]

Engine Pressure Ratio EPR Rate of Ps Rt Ps [P] /m

Rate of Pt Rt Pt [P] /m

Rate of Qc Rt Qc [P] /m

Rate of EPR Rt EPR EPR/m

Where [P] is the currently selected pressure units from the following list:

mbar, inHg, mmHg, inH2O (4°C), inH2O (20°C), psi, hPa, kPa, inH2O (60°F), kg/cm2, %FS

FIGURE 3-1 FRONT PANEL

Page 37

K114 Issue No. 9

Druck ADTS 405 User Manual 3 - 3

3

the display shows the main pressure display (Leak Measure or Control mode).

KEY-PAD FUNCTION

F1-F4

ALT Ps

SPEED Qc

MACH Pt

EPR

ROC Ps RATE

RATE TIMER

F1

F2

F3

HOLD

RATE

LEAK MEASURE/CONTROL

GROUND

[GO TO GROUND]

[DISPLAY QFE]

[DISPLAY QNH]

PORT

REMOTE

PRINT

[ALPHA]

[BACK]

data entry

EXECUTE TEST PROGRAM

[NEXT]

[PREV]

[RUN]

F1

F2

HELP

SETUP

See QUICK REFERENCE -

SETUP or MINIMUM SETUP

SETUP + F1

See QUICK REFERENCE - CONFIG

(nudge up)

(nudge down)

0-9

-000

CLEAR/QUIT

ENTER

CLEAR/QUIT + ENTER

Function keys for menus

Altitude (Aeronautical units) or Ps (Pressure units)

Airspeed (Aeronautical units) or Qc (Pressure units)

Mach (Aeronautical units) or Pt (Pressure units)

Engine Pressure Ratio (pressure units only)

Rate of Climb (Aeronautical units) or Rate of Ps (Pressure units)

Start timing rate of change

Wait and time choice 1

Wait and time choice 2

Wait and time choice 3

Hold pressure at present value - Press again to release

Rate of change of Pitot parameter - Press Pitot parameter then RATE

Switches between measure mode (for leak testing) and control mode

Controls Ps to atmospheric pressure and Qc to zero at current rates of

change

Display local atmospheric (ground) pressure

Display sea level equivalent of local atmospheric pressure

See Line Switching Unit User Manual

Switches (toggles) between remote and local operation

Prints current parameter values

Inserts alphabet character in user text

Deletes last character of user text

Numeric entry for user text

Execute down-loaded Test Programs

Select next listed test program

Select previous listed test program

Execute selected test program

Execute all tests in the test program

Selects and executes a specific test program

Press HELP then other key for further information

Temporary set-up - lost at power down

Configuration - changes power-up defaults

Hold F1 while pressing SETUP - then enter PIN

Increases aim value

Decreases aim value

Number entry

Minus sign for first number entry 000 (thousand) if not first number of entry

Clear number entry - quit from menu or clear warning message

Complete number entry

ABORT - restart with power-up

Key/selection Function and comments

3.3 Quick Reference

The quick reference chart shows normal operation key functions. In the key/selection column the following applies:

ALT - Key.

[NEXT] - Item in menu (soft key).

(SINGLE DOUBLE) - Sequence of parameters selected by NEXT key.

(craft1 craft2...) - Sequence of names selected by NEXT key.

data entry - Enter number from key-pad.

Page 38

K114 Issue No. 9

3 - 4 Operation

3.4 First Time Operators

The following sequences of operation should be used by first time operators and by

operators that use the equipment occasionally. For regular users, familiar with the

equipment, go to section 3.5. Set the power supply switch to OPERATE and the powerup routine starts.

(1) The display, on the front panel or hand-terminal, shows:

DK126 Iss 1.xx

Display Power Up

Please Wait

(2) After a short time the display shows:

DRUCK

ADTS 405

DK263

VER 6.xx

Note:

Where x is the current issue number of the software.

(3)

Last Calibration

dd/mm/yy (dmy)

RPT Transducer

PLEASE WAIT

Note:

Date format can be changed in configuration.

For units fitted with the Solartron transducer, the display shows Solartron Transducer in

place of RPT Transducer.

(4)

Self Test

PLEASE WAIT

Page 39

K114 Issue No. 9

Druck ADTS 405 User Manual 3 - 5

3

(5) The system opens the zero valves and after approximately 7 seconds the valves close

and the routine continues with the display shows:

Measuring Ground

Pressures

PLEASE WAIT

(6) The system opens the output valves and controls pressures at the original measured

values.

Equalising System

Pressures

(Valves May Pulse)

PLEASE WAIT

(7) At switch on, check the hand-held terminal display.

Note:

The ADTS 405 is a continuous, self-monitoring system. If the system detects an error, the

display shows an error message. Lists of errors are detailed in Section 5, Fault Finding

and Testing.

ALT 0 ft

Leak Measure

WARMUP

Note:

Wait 15 minutes, before continuing, to allow the system to get to thermal stability. The

wait time can be reduced to 5 minutes if the system has been re-powered after a short

time.

Operating modes

The air data test system can now be set for a variety of functions and modes. In the

following, examples of measure mode, control mode, leak measure mode and go-toground show the key presses and selections required for each mode.

Page 40

K114 Issue No. 9

3 - 6 Operation

Measure Mode

SPEED

Qc

or or

ft

Measured

parameter

"leak-measure" when

measure mode selected

Measured value

ALT

Ps

STATIC

MACH

Pt

PITOT

Units of

measurement

SETUP

SETUP

Change display

dual or triple

press:

single,

Change units from aeronautical

to pressure:

[MORE]

[CONTROL]

[DISPLAYS/OPTIONS]

[OPTIONS]

[Ps Pt DUAL]

[DISPLAY TYPE]

[UNITS]

[SAVE]

[PREV]

[NEXT]

To select the measured parameter press:

kts

CAS

Alt

350

10000

Leak Measure

Leak Measure

Page 41

K114 Issue No. 9

Druck ADTS 405 User Manual 3 - 7

3

Control Mode

Page 42

K114 Issue No. 9

3 - 8 Operation

Leak Measure Mode

Note: Compressing a gas generates heat. Gas heated or cooled in an enclosed volume

causes a pressure change. It is important, especially for leak testing, to allow enough

time for the heated gas to cool and the pressure to stabilize. When setting the rate

timer consider three factors:

1 The volume of the system to be tested (large volumes take longer to stabilize).

2 The pressure change (the higher the change the greater heat generated).

3 The ambient air temperature.

Page 43

K114 Issue No. 9

Druck ADTS 405 User Manual 3 - 9

3

Go to Ground

Page 44

K114 Issue No. 9

3 - 10 Operation

3.5 Operation and Example Procedures

3.5.1 Checks Before Use

Inspection and Cleaning

Inspect the external of the ADTS 405, and its associated equipment, for damage, dirt,

and the ingress of moisture. If necessary, use foam cleaner and a lint-free cloth to

clean the external surfaces.

Inspect the pressure outlet ports for ingress of dirt and moisture, clean if necessary

with a lint-free cloth.

3.5.2 Operating Procedures

The procedures show the steps required to make sure the ADTS 405 is serviceable and

the settings required to test an aircraft system or component. For further information

refer to the quick reference charts, at the end of this section, and Section 6 - Reference

and Specification.

In the following:

All key presses are highlighted in bold and shown as identified on the key-pad.

Key presses inside brackets e.g., [MORE], are soft key presses (i.e., function key

selections {F1 to F4} indicated on the display screen).

Help System

The help information includes further details of the function and details associated

functions, also see the Reference Section 6.

3.6 Power-up

Check the power indicator is illuminated and set the front panel power switch to

OPERATE.

The display shows the following sequence:

a. Display power-up screen.

b. ADTS 405 power-up screen.

c. Date of the last calibration and type of main transducer fitted.

d. Self-test message.

e. Measuring ground pressure message.

f. Equalising system pressures message.

g. Display shows Leak Measure mode and the number of parameters last selected in

configuration.

The ADTS 405 always powers-up in Leak Measure mode with the pressure controllers

off. When changing to Control Mode the pump unit must be switched on and