Installation Instructions

27” Drop In Ranges

Questions?

In Canada, call 1.800.561.3344 or visit GEAppliances.ca

BEFORE YOU BEGIN

Read these instructions completely and

carefully.

•

IMPORTANT — Save these

instructions for local inspector’s use.

•

IMPORTANT — Observe all

governing codes and ordinances.

• Note to Installer – Be sure to leave these

instructions with Consumer.

ATTENTION INSTALLER: All electric drop-ins must be hard-wired (direct-wired) into

an approved junction box. A plug and receptacle is NOT permitted on these products.

FOR YOUR SAFETY:

If you did not receive an anti-tip bracket with your purchase,

call 1.800.626.8774 to receive one at no cost. (In Canada,

call 1.800.561.3344.) For installation instructions of the bracket,

visit: GEAppliances.com. (In Canada, GEAppliances.ca.)

MATERIALS YOU MAY NEED

Junction Box

Wire Nuts

Strain Relief Clamp for 1/2” Conduit

REMOVE PACKAGING MATERIALS

1

Failure to remove packaging materials could result in damage to the appliance. Remove all packing

parts from oven, racks and heating elements. Remove protective film and labels on the outer door

and control panel. Also, remove plastic on trims and panel and all tape around the oven. Open oven

door and remove literature pack and oven racks. Remove the bottom trim from the side of the oven.

It will be installed at the end of the installation process. The trim is wrapped separately in a plastic

bag which also contains the five screws to secure the bottom trim and the 4 anti-tip screws used to

secure the product to the countertop. The plastic bag is taped to the side of the unit.

Call 1.800.GE.CARES (1.800.432.2737) or visit GEAppliances.com

• Note to Consumer – Keep these instructions

for future reference.

• Skill level – Installation of this appliance

requires a qualified installer or electrician.

• Proper installation is the responsibility

of the installer.

• Product failure due to improper installation

is not covered under Warranty.

WARNING

A child or adult can tip the range and be killed.

Verify the anti-tip bracket has been properly

installed and engaged.

Ensure the anti-tip bracket is re-engaged when

the range is moved.

Do not operate the range without the anti-tip bracket

in place and engaged.

Failure to follow these instructions can result in

death or serious burns to children or adults.

Tip-Over Hazard

Anti-Tip Bracket

Kit Included

WARNING

Before beginning

the installation, switch power off at

service panel and lock the service

disconnecting means to prevent power

from being switched on accidentally.

When the service disconnecting

means cannot be locked, securely

fasten a prominent warning device,

such as a tag, to the service panel.

TOOLS YOU MAY NEED

1/8” Drill Bit and Electric or Hand Drill

Phillips Screwdriver

Wire Strippers

Hand or Saber Saw

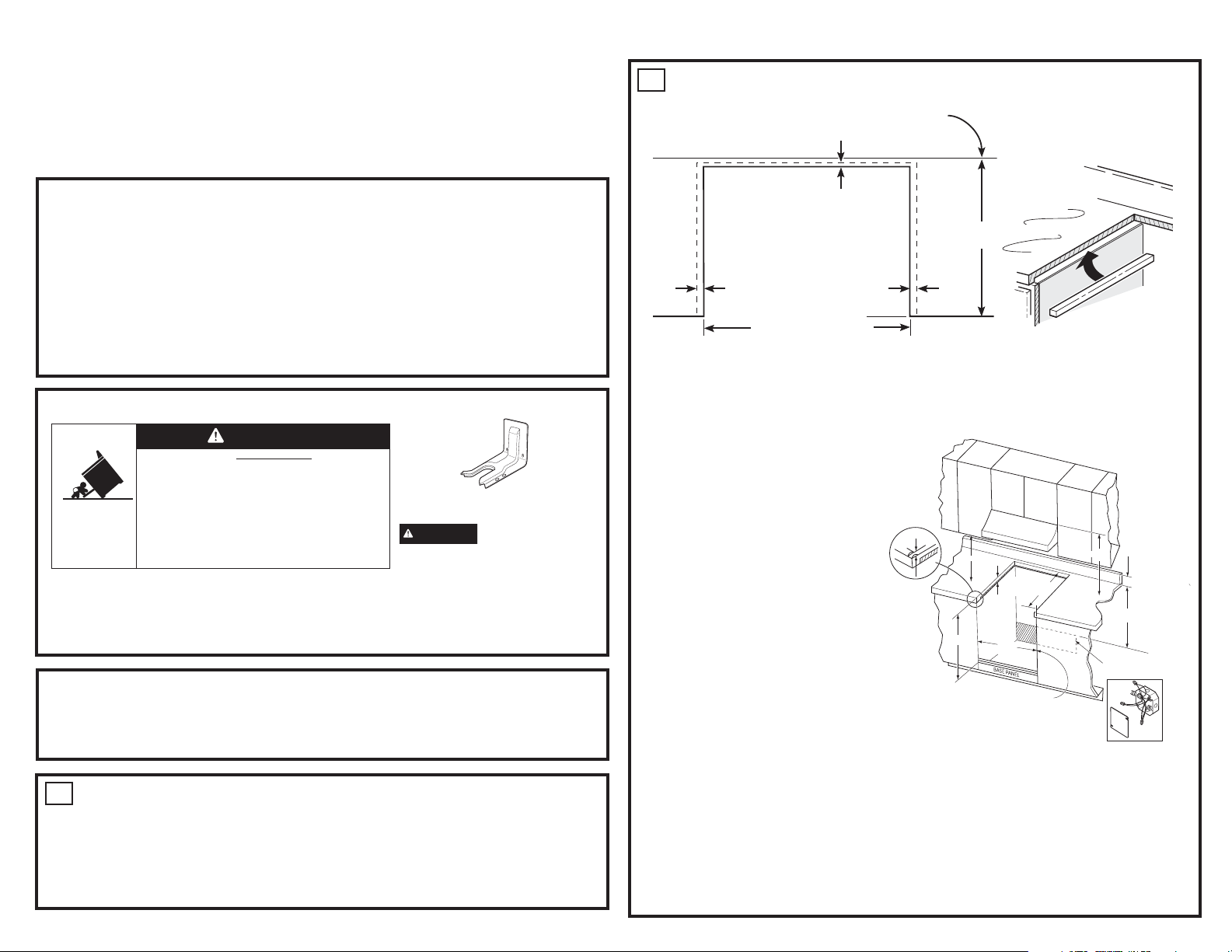

PREPARING THE OPENING (FOR INDOOR USE ONLY)

2

See the Illustrations for all rough dimensions. The range may be placed with 0” clearance at the

side cabinet.

9/16” min.

flat

26-1/4” smooth cut

3/8” min.

flat

9/16” min.

flat

Wall

25”

typically

Range support

Countertop

Brace

Countertop thickness 1-1/2” min. is required to support the product. Countertop width 1-1/2” min. is

required to properly support the 3/4” anti-tip screw.

Braces must be installed between the underside of the countertop and the cabinet if required to

obtain 1-1/2” minimum thickness (each side)

Make sure the wall coverings, counters and cabinets around the oven can withstand the heat (up to

200°F [93.3°C]) generated by the oven.

This range is designed to hang from

the counter top. It does not rest on the

cabinet. The range must not be installed

on a floor or sub structure (2” x 4”

support)

•

Allow 30” minimum clearance between

surface units and bottom of unprotected

wood or metal cabinet, or allow a 24”

minimum when bottom of wood or metal

cabinet is protected by no less than 1/4”

thick flame retardant millboard covered

with not less than No 28 MSG sheet

metal, (.015”), .015” thick stainless steel,

13/32”

TRIM SECTION FOR

COUNTERTOP WITH

POST FORMED OR

RAISED FRONT EDGE

18” Min.

28-7/16”

*

21-3/4” CABINET

FACE TO REAR OF

CUT-OUT

27”

BETWEEN

CABINETS

MOULDING MAY BE FITTED TO

THE OVEN TRIM FOR A MORE

CUSTOM APPEARANCE

30” MIN.

4” MAX.

28-1/2”

MIN.

JUNCTION BOX LOCATION

(BOX MUST NOT EXTEND MORE THAN

3” OFF THE PLANE OF THE WALL)

.024” aluminium or .020” copper.

•

This appliance has been approved for 0”

spacing to adjacent surfaces above the cooktop. However, a 6” minimum spacing to surfaces less

than 15” above the cooktop and adjacent cabinet is recommended to reduce exposure to steam,

grease splatter and heat.

• To reduce the risk of burns or fire when reaching over hot surface elements, cabinet storage space

above the cooktop should be avoided. If cabinet storage space is to be provided above the cooktop, the risk can be reduced by installing a range hood that projects at least 5” beyond the front of

the cabinets. Cabinets installed above the cooktop must be no deeper than 16”.

Locate a wiring junction box at the rear of the cutout. The dimension from the top of the wiring junction box to the countertop must be a minimum of 28-1/2”. The box must not extend more that 3” off

the plane of a wall. The junction box must be located where it will allow considerable slack in the

range conduit, so that the range can be pulled for servicing if necessary.

ELECTRICAL REQUIREMENTS

3

WARNING

• This appliance must be properly grounded.

• Do not use an extension cord.

• Before installing range, switch power off at the service panel and lock the service disconnecting

means

cannot be locked, securely fasten a prominent warning device, such as a tag, to the service panel.

Failure to follow these instructions may result in serious injury or death.

WARNING

Improper connection of aluminum house wiring to copper leads can result in an electrical or fire hazard.

If residence leads are aluminum, use only connectors designed for joining copper to aluminum and

follow the manufacturer’s recommended procedure closely. Failure to do so may result in serious injury

or death.

We recommend you have the electrical wiring and hookup of your appliance connected by a

qualified electrician. After installation, have the electrician show you how to disconnect power from

the appliance.

You must use a single-phase, 120/208 VAC or 120/240 VAC, 60 Hertz electrical system.

Effective January 1, 1996, the National Electrical Code requires that new construction (not existing)

utilize a four-conductor connection to an electric oven. When installing an electric oven in new

construction, a mobile home, recreational vehicle or an area where local codes prohibit grounding

through the neutral conductor, refer to the section on four-conductor branch circuit connections.

Check with your local utilities for electrical codes which apply

in your area. Failure to wire your oven according to governing

codes could result in a hazardous condition. If there are no

local codes, your oven must be wired and fused to meet

the National Electrical Code, NFPA No. 70 – latest edition,

available from the National Fire Protection Association.

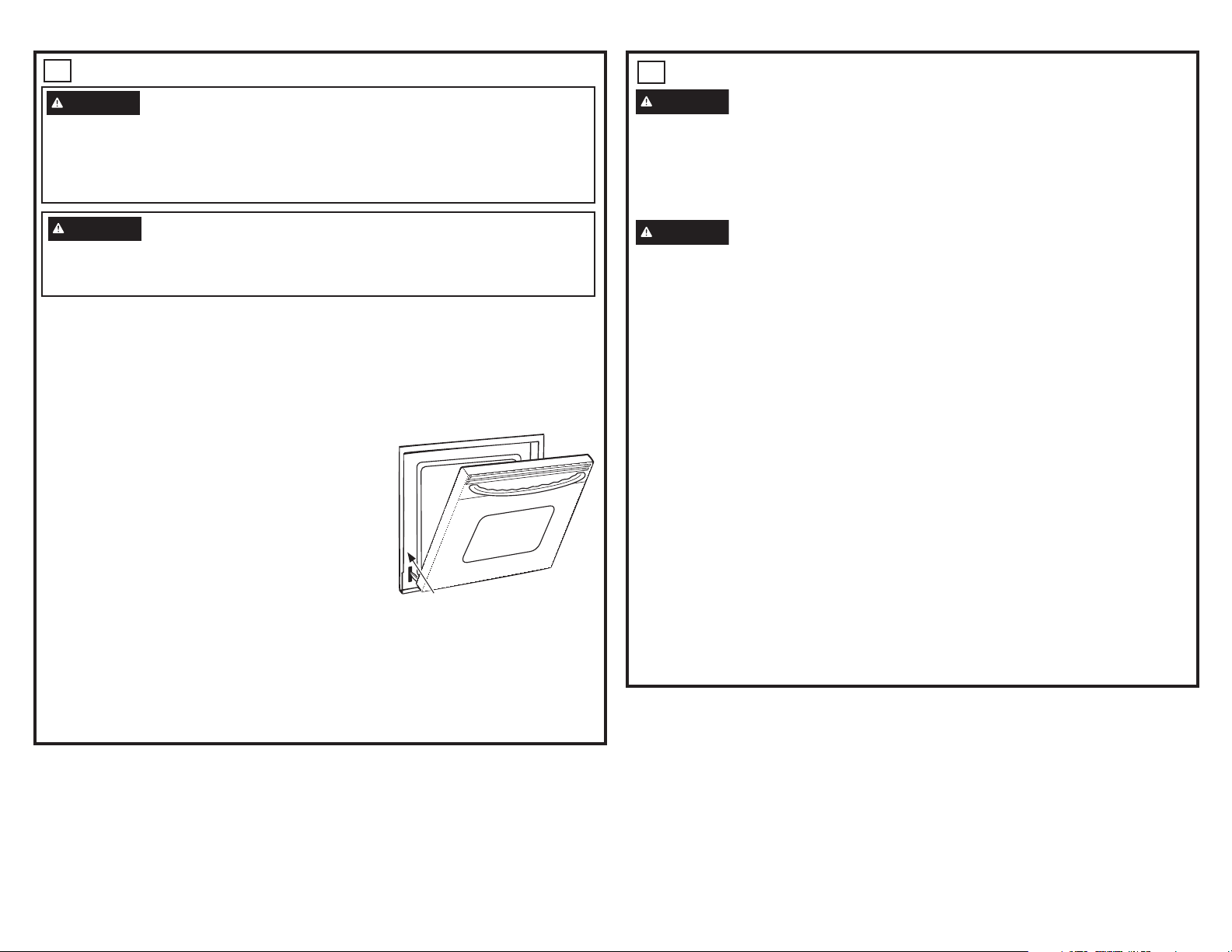

Rating plate is located on oven front frame and is visible

when oven door is open.

This appliance must be supplied with the proper voltage and

frequency, and connected to an individual, properly grounded,

40 amp (minimum) branch circuit protected by a circuit

breaker or time-delay fuse.

DO NOT shorten the flexible conduit. The conduit strain relief

clamp must be securely attached to the junction box and the flexible conduit must be securely

attached to the clamp. If the flexible conduit will not fit within the clamp, do not install the oven until

a clamp of the proper size is obtained.

The 3 power leads supplied with this appliance are suitable for connection to heavier gauge

household wiring. The insulation of these 3 leads is rated for temperatures much higher than

the temperature rating of the household wiring. The current-carrying capacity of the conductor is

governed by the wire gauge and the temperature rating of the insulation around the wire.

Electric Shock Hazard

to prevent power from being switched on accidentally. When the disconnection means

Fire Hazard

Rating Plate Location

4

ELECTRICAL REQUIREMENTS

WARNING

• This appliance must be properly grounded.

• Do not use an extension cord.

• Before installing range, switch power off at the service panel and lock the service

disconnecting means to prevent power from being switched on accidentally. When the

disconnection means cannot be locked, securely fasten a prominent warning device, such

as a tag, to the service panel.

Failure to follow these instructions may result in serious injury or death.

WARNING

Improper connection of aluminum house wiring to copper leads can result in an electrical

or fire hazard. If residence leads are aluminum, use only connectors designed for joining

copper to aluminum and follow the manufacturer’s recommended procedure closely. Failure

to do so may result in serious injury or death. We recommend you have the electrical wiring

and hookup of your range connected by a qualified electrician. After installation, have the

electrician show you how to disconnect power from the range.

We recommend you have the electrical wiring and hookup of the appliance connected by a qualified

electrician. After installation, have the electrician show you how to disconnect power from the appliance.

You must use a single-phase, 120/208 VAC or 120/240 VAC, 60 Hertz electrical system.

Effective January 1, 1996, the National Electrical Code requires that new construction (not existing)

utilize a four-conductor connection to an electric oven. When installing an electric oven in new

construction, a mobile home, recreational vehicle or area where local codes prohibit grounding

through the neutral conductor, refer to the section on four-conductor branch circuit connections.

Check with your local utilities for electrical codes which apply in your area. Failure to wire your oven

according to governing code could result in a hazardous condition. If there are no local codes, your

oven must be wired and fused to meet the National Electrical Code, NFPA No. 70-latest edition,

available from the National Fire Protection Association.

Rating plate is located on oven front frame and is visible when oven door is open.

This appliance must supplied be with the proper voltage and frequency, and connected to an individual,

properly grounded, 40 amp (minimum) branch circuit protected by a circuit breaker or time-delay fuse.

DO NOT shorten the flexible conduit. The conduit strain relief clamp must be securely attached to

the junction box and the flexible conduit must securely attached to the clamp. If the flexible conduit

will not fit within the clamp, do not install the oven until a clamp of the proper size is obtained.

The 3 power leads supplied with this appliance are suitable for connection to heavier gauge

household wiring. The insulation of these 3 leads is rated for temperatures much higher than

the temperature rating of the household wiring. The current-carrying capacity of the conductor is

governed by the wire gauge and the temperature rating of the insulation around the wire.

Electric Shock Hazard

Fire Hazard

4

ELECTRICAL REQUIREMENTS (Cont.)

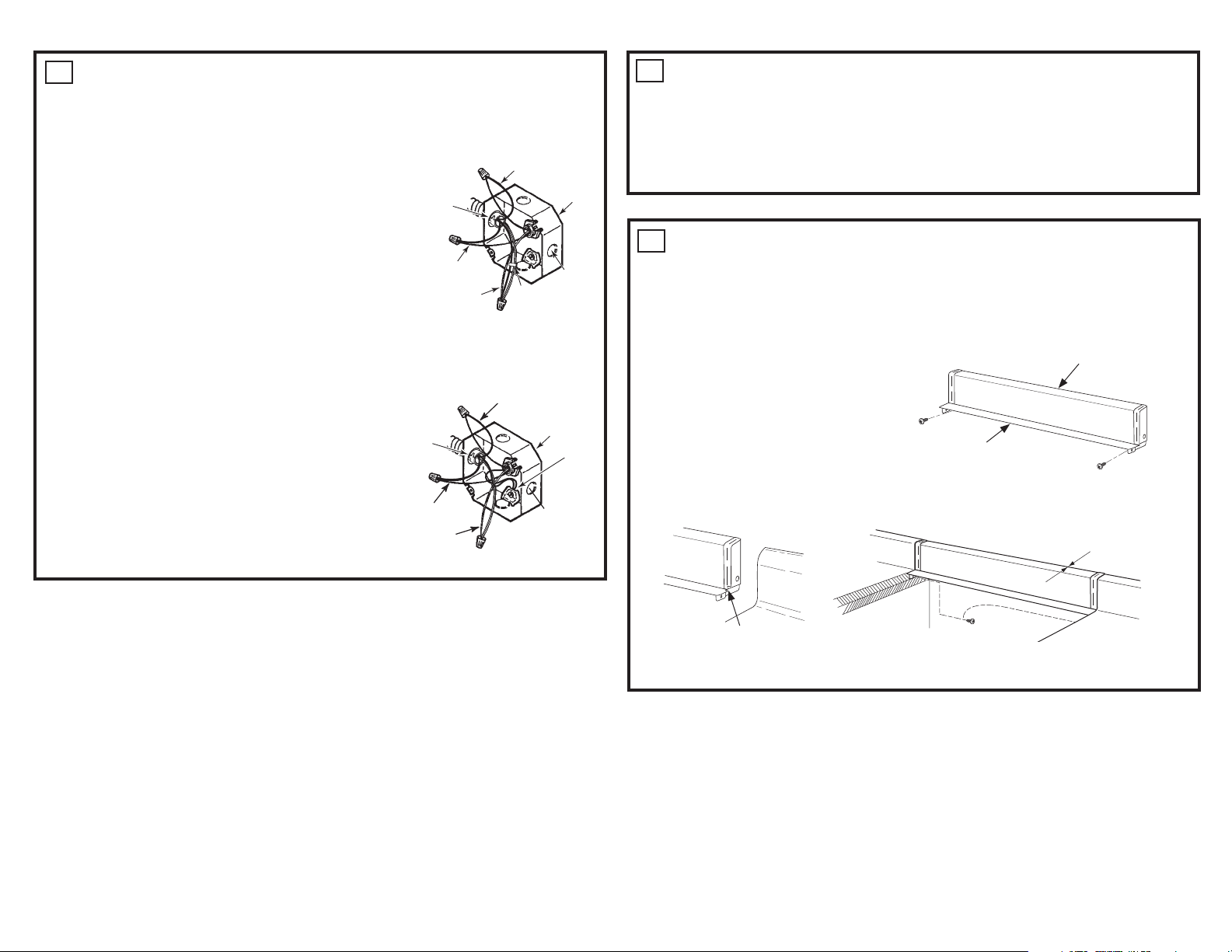

MAKE ELECTRICAL CONNECTIONS

Place the unit on a platform or table even with the cutout opening. The platform must support

200 lbs. (91 kg). Connect the flexible conduit to the electrical junction box as follows:

THREE-CONDUCTOR BRANCH CIRCUIT CONNECTION

NOTE: If residence leads are aluminum conductors, see

WARNING in section 4A, Electrical Requirements.

When connecting to a three-conductor branch circuit, if local codes

permit:

1. Connect the oven ground conductor along with the neutral

Range

conduit

snaps

into box

Black

(white) lead to the branch circuit neutral (white or gray in color),

using a wire nut.

2. Connect the oven red lead to the branch circuit red lead, and the

oven black lead to the branch circuit black lead in accordance

with local codes, using wire nuts.

3. Install proper strain relief clamp.

4. Install junction box cover.

Red

Ground

and neutral

wires (white)

Tape or

Crimp

Neutral wire

connection

FOUR-CONDUCTOR BRANCH CIRCUIT CONNECTION

NOTE: If residence leads or ground are aluminum conductors, see WARNING in section 4,

Electrical Requirements.

When connecting to a four-conductor branch circuit, if local codes permit:

1. Free the neutral (white) lead from being restrained to any

other wires. If necessary, cut the neutral (white) lead and

then re-strip it to expose the proper length of conductor.

2. Attach the appliance grounding lead (green or bare copper)

Range conduit

snaps into box

Black

Branch

circuit

in accordance with local codes.

3. Connect the oven neutral (white) lead to the branch circuit

neutral (white or gray) in accordance with local codes,

using a wire nut.

4. Connect the oven red lead to the branch circuit red lead

and the oven black lead to the branch circuit black lead in

ac cor dance with local codes, using wire nuts.

Red

White

Alternate

knockout

5. Install proper strain relief clamp.

6. Install junction box cover.

Branch

circuit

Alternate

knockout

Ground

wires

5

CHECK FOR PROPER INSTALLATION OF ANTI-TIP

SCREWS

• Raise lift-up cooktop and support it with cooktop support rod so anti tip screws are visible. (see

Section 7)

• Lower the oven door and gently apply a medium force to the inside of the door at the handle end.

• Properly installed screws will prevent any movement of the range when force is applied to the

door. If movement occurs, refer to “Mounting the range in the opening” section.

WHEN INSTALLING RANGE IN COUNTERTOP WHICH IS

6

CUT OUT TO THE WALL

If you have an existing 27” wide cutout that goes all the way to the wall, you may want to buy a

backsplash kit for your range. Order Kit JX27RWH (White) or Kit JX27RBK (Black). This kit will fill in

the space between the back of the range and the wall.

BACKSPLASH KIT FOR 27” DROP-IN RANGES

This kit contains:

1 Backsplash

2 Screws

1 Maintop Filler

2 Wood Screws

NOTE: The backsplash attaches to the

counter. The range slides into position after the

backsplash is in place.

Follow the instructions packed with the backsplach kit.

Filler

Backsplash with End Caps

Screw

Possible Gap May Occur

31-10830-3 10-20 GEA

Trim for any interference

with postformed backsplash on countertop.

Wood Screws Provided

Loading...

Loading...