Page 1

GE Oil & Gas

.

t

Dresser* Micro Corrector - IMC/W2

Integral Volume Correction Differential Pressure (DP) Monitoring

Versions: ptz-dp + LOG, T-dp + LOG, ptz + LOG, P + LOG, and T + LOG

GE Oil & Gas offers an integrated solution,

the Dresser Differential Pressure (DP) Micro Corrector,

which monitors meter health by continuous

measurement of the differential pressure

drop across the meter. The Dresser Micro

Corrector DP is capable of learning the

differential pressure curve for an individual

meter. During the learning period, DP is

monitored using the values present in the

Differential Test Acceptance Calculator (DTAC).

The Dresser Micro Corrector DP retains the last

valid average differential pressure measurement on

the LCD of the corrector along with the date when

this occurred. It also displays the average line pressure,

average line temperature and meter flow rate for that

same date. The differential pressure test information

required to be in compliance with state Public Utility

Commission (PUC) requirements is available with the

push of a button.

This offers operating efficiencies as the number of

return trips to the meter set is reduced, and reduces

the need for venting gas during periods of low

consumption. Differential pressure test results are

also logged in the data logs.

Developed from the proven IMC/W platform, the

Dresser Micro Corrector provides volume correction

through a simple-to-use interface. Features such as

improved low flow accuracy, enhanced data logging

capability, and reduced accuracy test times combine

to offer a complete solution to major customers.

The Dresser Micro Corrector, model IMC/W2,

an integral corrector rated for Division 1 hazardous

locations by the Canadian Standards Association (CSA)

and ATEX.

rrector,

nt on

hen

Dresser Meter with IMC/W2,

Model ptz-dp + LOG

Features

■

Monitors meter health

■

Reduces unnecessary scheduled maintenance

■

Aids in regulatory compliance of DP testing,

where applicable

■

Last valid DP measurement displayed on

LCD and live data screen

■

Real-time differential pressure measurement

■

Compatible with Dresser Series A (LMMA),

Series B, and Romet meters

■

DP measurement is independent of volume correction

■

Remote monitoring capability with Dresser Micro

Modems - GSM/GPRS modems

■

dp + LOG units feature faults for high DP and meter

lock-up

Dresser GSM/GPRS Micro Modem

Page 2

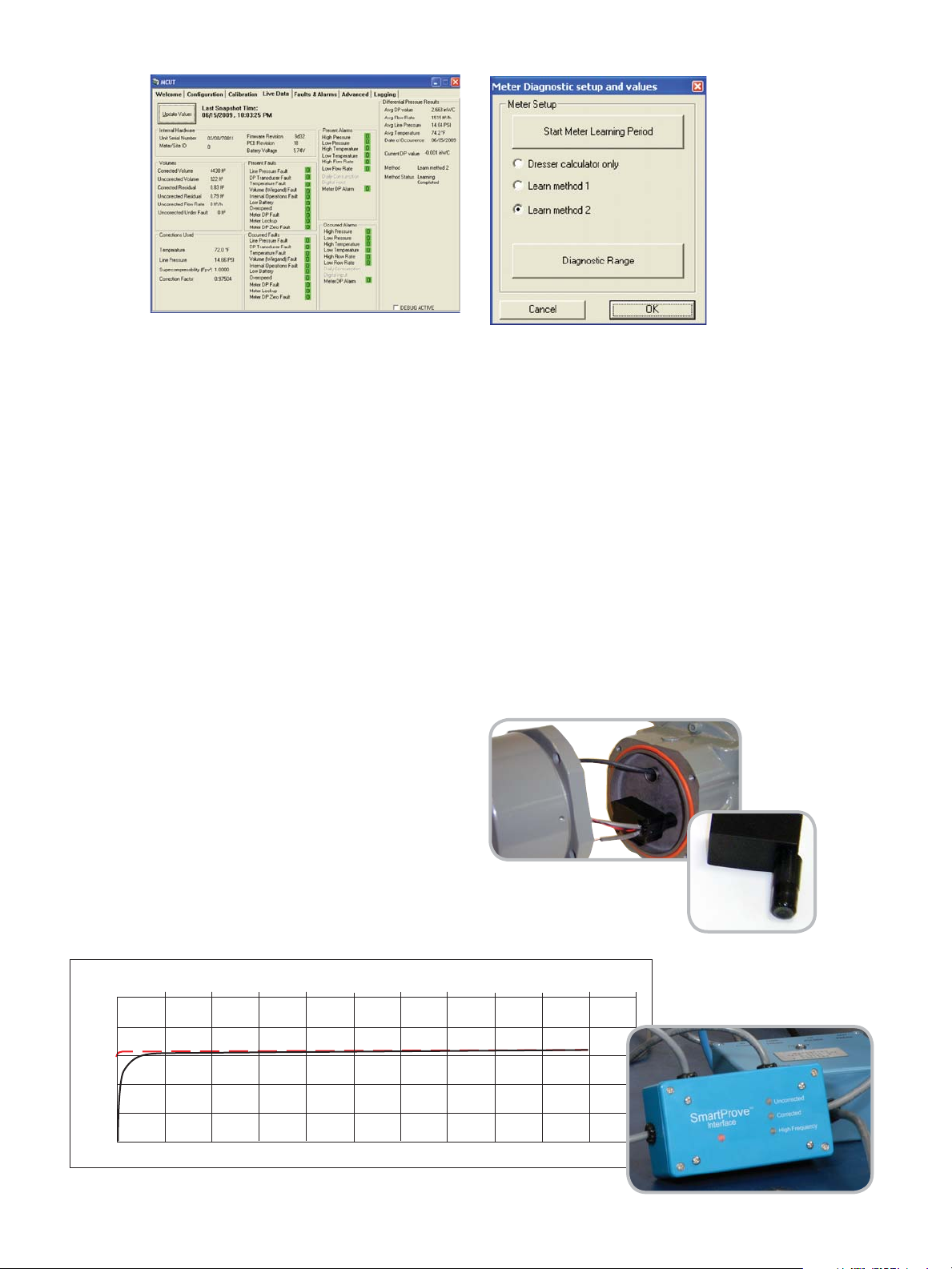

Live data screen displays current DP read, as well as last

valid DP read, pressure, temperature and fl ow rate with

date of occurrence.

Features

■

Rotating index offers ease of meter reading, especially

in non-typical installations

■

Uncorrected instantaneous flow rate displayed on

LCD can help meter differential testing in the field

Maximum uncorrected peak fl ow also

displayed on LCD

■

The SmartProve* Interface reduces meter and

corrector test times by as much as 90%, and allows

the meter and corrector to be tested as a complete

measurement system.

■

User selectable trim table improves rotary meter

accuracy at flow rates less than 10% of meter Qmax

■

Micro Generator* adds years to main battery life,

extending the interval between battery changes

■

User terminal software allows for configuration,

calibration and data log downloads

■

1 to 3 data logs provide for years of historical

information and are configurable in increments from

1 minute to 1 month. Data logs include the option to log

live battery voltage

■

Audit log maintains a record of configuration and

calibration changes

■

Available with your choice of sealed alkaline or

lithium battery pack

Learning methods are customer selectable

in the user terminal software.

■

Alarms notify the user of over-range conditions for

pressure, temperature, and flow rate

■

On units with DP transducer installed, alarms are present

for higher than normal differential pressure

■

Alarm & fault activity is displayed in the data log and

audit log reports, and the live data screen

■

E2PROM provides non-volatile storage of recorded

data and corrector configuration regardless of

battery condition

■

Uncorrected volume under fault register in E2PROM

replicates a backup mechanical index

■

MS Excel® formatted reports allow for manipulation and

sharing of information

Micro Generator

0.0

102

101

100

.99

ACCURACY - %

.98

.97

Trim Table

.5 1.0

ACCURACY CURVE

1.5

2.0 2.5 3.0

RATE-MCFH at INLET CONDITIONS

3.5

4.5

5.0

5.5

5.0

Dresser SmartProve Interface

Page 3

Performance

3 Fully Programmable Pulse Outputs

Resolution

Volume

Pressure

Temperature

Supercompressibility

2

)

(Fpv

Correction Factor

Accuracy over

Operating Temperature

Range

Line Pressure

Line Temperature

Differential Pressure

IMC/W2-PTZ

IMC/W2-P

I MC/W2-T

Long Term Stability

Pressure

Temperature

Meter Trim Table

Meter Accuracy

Correction Range

E2PROM Data Log Memory

Time-stamped Entries

Parameters Logged

3

(0.01 m3)

0.01 ft

0.01 psi (1 mbar)

0.1 ºF (0.1 ºC)

0.0001

0.00001

-40 °F to 140 °F (-40 °C to 60 °C)

0.4% reading

0.9 °F (0.5 °C)

0.1 in. WC

0.5% corrected volume

0.45% corrected volume

0.25% corrected volume

0.1% FS/yr non-cumulative

0.3 ºF (0.2 ºC)/yr non-cumulative

0.3% to 10% Qmax

Up to 32,161 (depending on the

number of Parameters logged)

Corr Vol; Uncorr Vol; Fault Vol; Corr

Factor; Supercomp; Avg and Peak Corr

Flow Rate; 4 Pressures – Min, Max, Avg

and Ending; 4 Temps – Min, Max, Avg

and Ending; Batt Voltage; Differential

pressure test results on units fitted

with DP transducer

Corrected, Uncorrected, and Alarm/Fault

Loop Voltage

Loop Current

Pulse Width

Switch Off Resistance

Switch On Resistance

Isolation

5-15 VDC

10 mA maximum

62.5, 125, 187, or 312 ms

> 2 Mohms

<10 ohms

2,500 VDC

Environment

Operating

-40º F to 140º F (-40º C to 60º C)

Temperature

Storage Temperature

Humidity

-58º F to 176º F (-50º C to 80º C)

Up to 95% sustained outdoor exposure

Enclosure

NEMA 4X (IP66)

Intrinsic Safety

Class 1, Division 1,

CSA Approval No. 1224451

Group D

Zone 0

Class-I, Division-1,

EEX ia IIC T4 Tamb = -40º C to 60º C

BAS98ATEX 1083

Group A, B, C, D

Electromagnetic/Radio Frequency Immunity

FCC Class B

Meets EMI/RFI immunity at 10 V/m,

0.1 to 1,000 MHz

EN50081-1 and EN5088-2

Other

ISO-9001, CE Mark

Battery - Alkaline

Sealed Pack - Alkaline

Low Battery Reserve Alkaline

Battery - Lithium

Sealed Pack

Low Battery Reserve

Inputs

Volume

Pressure

Temperature

5-years nominal life

3-months approximately

15-years nominal life

1.5-years

High speed magnetic pickup in meter

magnet cup

Proprietary semiconductor strain

gauge

ITS-90 Platinum 100Ω RTD = 0.00385

Dresser Micro Corrector also available in

ID and wall mount versions.

Page 4

Ordering Information

The IMC/W2 with or without DP can be ordered

as either:

■

An integral part of a new meter.

■

As a kit to convert existing Dresser Series-A (LMMA),

Series-B (TQM), or Romet meters.

For P and PTZ versions

The IMC/W2 is available in the following pressure

transducer ranges:

Transducer Range Gauge Absolute

30 psi (2bar) X X

180 psi (12 bar) X X

350 psi (24 bar) X

1000 psi (70 bar) X X

1500 psi (100 bar) X

■

The 350 psi (24 bar), 1000 psi (70 bar), and 1500 psi

(100 bar) transducers would typically be used for

high pressure meter applications

■

The IMC/W2 can be ordered with either an external

or internal pressure connection

■

IMC/W2’s for Series-A meters, 23M - 56M high

capacity meters, and high pressure meters require

external pressure connections

■

Optional piping kits are available for convenient

connection of external pressure connections

For PTZ and T versions

■

All 23M - 56M high capacity meters, and high pressure

meters require an external temperature probe and

thermowell.

The probes are available with 5 ft or 10 ft

armored cables and in 2” or 8-1/2” in insertion lengths

■

Thermowells are available in sizes 1/4-NPT x 2, 1-NPT x

2, 1-NPT x 4, and 1-NPT x 6; all dimensions are in inches

A variety of pulse output connectors are available

■

Metal 6-pin circular twist lock connectors

■

Plastic cable-gland connectors

■

Conduit fittings and other special connectors are

available upon request

The IMC/W2 will be shipped with a factory standard

configuration unless the customer specifies otherwise.

A sealed battery pack is included and provides a nominal

5 years of reliable corrector operation. Adding the

optional Micro Generator may extend battery life to

7 years or more.

New users will want to order the user terminal software

and one or more communication cables to allow local

configuration, calibration, and data retrieval. The cables

are available in 6, 25, and 50 ft. lengths. Special cables

are available for proving the meter and corrector with

the Dresser Model-5 Transfer Prover. See TS: Dresser

SmartProve for further details.

Pressure Piping Kits for Non-DP versions

Approved for use

to 350 psig G

Length of SS Tubing Part Number Part Number

32” 051416-320 051416-310

84” 051416-420 051416-410

120” 051416-520 051416-510

■

For IMC/W2-dp version, the following piping kits

Approved for use to

1480 psig G

are available:

Length of SS Tubing Part Number

36” 051416-600

36” with Pipe Plugs 051416-610

36” with Test Plugs 051416-620

Battery Packs

Sealed Alkaline Pack - P/N 055362-000

Sealed Lithium Pack - P/N 060587-000

Circular Conduit Plug

Communication Cables

PC (Serial) to IMC

Length of Cable Part Number

6.6’ 057135-001

25’ 057135-002

50’ 057135-003

PC (USB) to IMC

6.4’ 060506-000

Cable Gland

GE Oil & Gas

16240 Port Northwest Dr., Suite 100

Houston, Texas 77041-2645

Inside US Ph: 800.521.1114

Inside US Fax: 800.335.5224

Outside US Ph: +1 832.590.2303

Outside US Fax: +1 832.590.2494

Email: rootsmeters.inquiries@ge.com

Visit us online at:

www.ge.com/energy

© 2012 General Electric Company

All Rights Reserved

*Denotes trademarks of General

Electric Company

GEA19164_Dresser Micro Corrector_IMC/W2

Rev. 9.2012

Loading...

Loading...