Page 1

GE Oil & Gas

Dresser* Micro Corrector - MC2

Models ptz + LOG, pt + LOG and t + LOG

This second generation Micro Corrector (MC) takes the

proven MC platform and adds features to enhance the

user experience, functions that can deliver data logging,

and lower operation and maintenance efficiencies, while

retaining the features of the original product.

The Dresser Micro Corrector, Model MC2, can function

as an instrument drive (ID) or wall mount corrector. As a

wall mount model, it can also function as an economical

pressure and/or temperature recorder. Rated for Division

I hazardous locations by Canadian Standard Association

(CSA) and ATEX.

the

the

gging,

, while

tion

. As a

mical

Division

iation

Features

■

1 to 3 data logs provide years of historical

information and are configurable in increments

from 1 minute to 1 month

■

Audit log maintains a record of configuration

and calibration changes

■

Available with your choice of lithium or

alkaline sealed battery pack

■

A larm and fault activity is displayed in the

data log and audit log reports

■

E2PROM provides non-volatile storage of recorded

data and corrector configuration, regardless of

battery condition

Dresser Micro Corrector, Model ptz + LOG, ID Mount Version

Other available Dresser Micro Corrector Model - IMCW2

Page 2

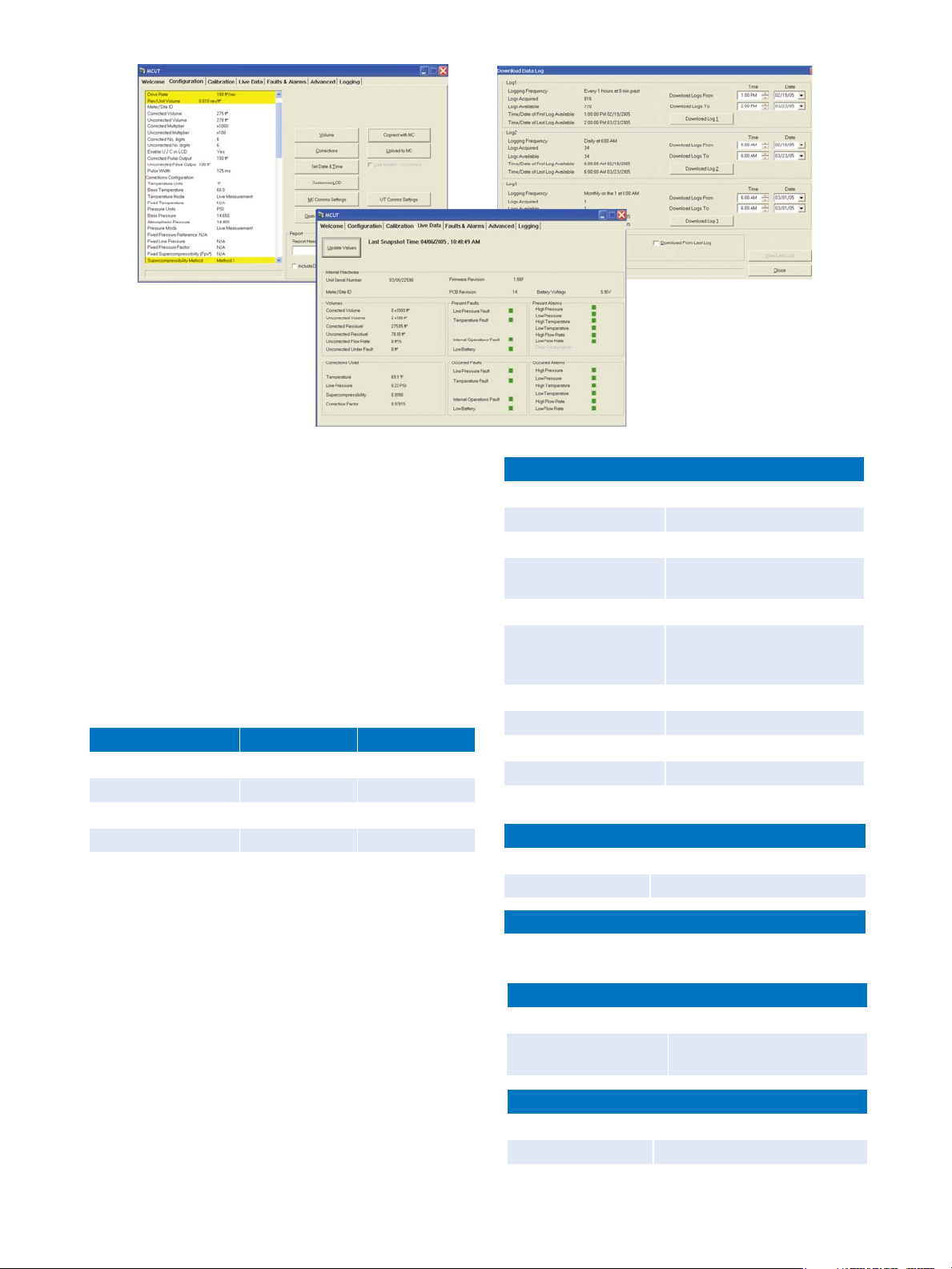

Confi guring the MC2

Live data screen

■

MS Excel® formatted reports allow manipulation

and sharing of information

■

Simple user terminal software allows for ease of

configuration, calibration and data downloads

■

Live data screen allows you to query the corrector

either serially or via a modem to see the current

conditions at the meter site, including a real time

display of the corrector’s battery pack voltage

Available Pressure Transducers

Micro Correctors fitted with pressure transducers are

available with either gauge or absolute transducers in

the following ranges:

Transducer Range Gauge Absolute

30 psi (2bar) X X

180 psi (12 bar) X X

350 psi (24 bar) X

1000 psi (70 bar) X X

1500 psi (100 bar) X

Temperature Probes

Two different temperature probes are available,

either of which can be fitted with a 5 or 10 foot long

armored cable. The smaller 2 inch probe can be installed

in the differential tap of the rotary meter or in small

diameter pipe. For large diameter piping, an 8-1/4 inch

probe is also available.

Resolution

Volume

Pressure

Temperature

Supercompressibility

(Fpv2)

Correction Factor

Accuracy over

Operating Temperature

Range

Line Pressure

Line Temperature

MC2-PTZ

MC2-P

MC2-T

Long Term Stability

Pressure

Temperature

E2PROM Data Log Memory

Time-stamped Entries

Battery - Alkaline

Sealed Pack - Alkaline

Low Battery Reserve Alkaline

Downloading data logs

0.01 ft3 (0.01 m3)

0.01 psi (1 mbar)

0.1º F (0.1 ºC)

0.0001

0.00001

-40 °F to 140 °F

(-40 °C to 60 °C)

0.4% reading

0.9 ºF (0.5 ºC)

0.5% corrected volume

0.45% corrected volume

0.25% corrected volume

0.1% FS/yr non-cumulative

0.3 ºF (0.2 ºC)/yr non-cumulative

up to 32161 (depending on the

number of Parameters logged)

5-years nominal life

3-months approximately

Battery - Lithium

Sealed Pack

Low Battery Reserve

15-years nominal life

1.5-years

Page 3

Inputs

Volume

Instrument Drive

Must specify CW or CCW rotation,

compatible with rotary, turbine and

diaphragm meters.

Wall Mount

Form-A switch, mechanical reed

or Weigand, compatible with all

Dresser low frequency pulsers.

Pressure

Proprietary semiconductor strain

gauge

Temperature

ITS-90 Platinum 100Ω RTD = 0.00385

LCD Display

18 user selectable parameters

3 Fully Programmable Pulse Outputs

Corrected, Uncorrected, and Alarm/Fault

Loop Voltage

Loop Current

Pulse Width

Switch off Resistance

Switch on Resistance

Isolation

Environment

Operating Temperature

5-15 VDC

10 mA maximum

62.5, 125, 187, or 312 ms

> 2 Mohms

<10 ohms

2,500 VDC

-40 ºF to 140 ºF (-40 ºC to 60 ºC)

Ordering

The MC2 can be ordered as either:

■

An instrument drive mount version corrector

■

A wall or pipe mount version corrector

For P and PTZ versions:

■

Optional piping kits are available for convenient

connection of external pressure connections

■

We offer piping kits with various lengths of stainless

steel tubing and two different pressure ratings

Pressure Piping Kits for Non-DP versions

Approved for use

to 350 psig G

Length of SS Tubing Part Number Part Number

32” 051416-320 051416-310

84” 051416-420 051416-410

120” 051416-520 051416-510

For P & T and T versions:

■

Temperature probes are available with 5 foot or 10

foot long armored cables, and with 2 inch or 8-1/2 inch

insertion lengths

■

Thermowells available in sizes 1/4-NPT x 2, 1-NPT x 2,

1-NPT x 4, and 1-NPT x 6. All dimensions are in inches

A variety of pulse output connectors are available:

One metal 6-pin Mil-Spec twist lock connector.

One plastic cable-gland connector.

Approved for use

to 1480 psig G

Storage Temperature

Humidity

-58 ºF to 176 ºF (-50 ºC to 80 ºC)

Up to 95% sustained outdoor

exposure

Enclosure

NEMA 4X (IP66)

Intrinsic Safety

Class 1, Division 1,

CSA Approval No. 1224451

Group D

Zone 0

Class-I, Division-1,

EEX ia IIC T4 Tamb = -40º C to 60º C

BAS98ATEX 1083

Group A, B, C, D

Electromagnetic/Radio Frequency Immunity

FCC Class B

Meets EMI/RFI immunity at 10 V/m,

0.1 to 1,000 MHz

EN50081-1 and EN5088-2

Other

ISO-9001, CE Mark

Battery Packs

Sealed Alkaline Pack - P/N 055362-000

Sealed Lithium Pack - P/N 060587-000

Circular Conduit Plug

Cable Gland

The MC2 will be shipped with a factory standard

configuration.

Please consult your customer service representative for

a copy of our customer configuration worksheet.

A sealed battery pack is included and will provide a

nominal five years of reliable corrector operation.

New users may want to order the user terminal software

and one or more communication cables to allow for

local configuration, calibration, and data log retrieval.

The cables are available in 6, 25, and 50 ft. lengths.

Communication Cables

PC (Serial) to IMC

Length of Cable Part Number

6.6’ 057135-001

25’ 057135-002

50’ 057135-003

PC (USB) to IMC

6.4’ 060506-000

Page 4

GE Oil & Gas

16240 Port Northwest Dr., Suite 100

Houston, Texas 77041-2645

Inside US Ph: 800.521.1114

Fax: 800.335.5224

Outside US Ph: +1 832.590.2303

Fax: +1 832.590.2494

Email: rootsmeters.inquiries@ge.com

Visit us online at:

ge.com/energy

© 2012 General Electric Company

All Rights Reserved

*Denotes trademarks of General

Electric Company

GEA19163 Dresser Micro Corrector

4.12

Loading...

Loading...