Page 1

GE

Grid Solutions

DR60

Digital Recorder

Technical Manual

Platform Hardware Version: A

Platform Software Version: 2

Publication Reference: DR60-TM-EN-2.1A

imagination at work

Page 2

2

DR60-TM-EN-2A

CONTENTS

Chapter 1: Introduction 6

1 Foreword 6

1.1 Target Audience 6

1.2 Nomenclature 6

1.3 Abbreviations 7

2 Product Scope 8

3 Unpacking 8

4 External Indication 8

4.1 DR60 Nameplate 8

5 Key Features 9

6 Compliance 10

7 Functional Overview 10

8 Programs Under the GPL License 10

9 Ordering Options 13

Chapter 2: Safety Information 15

1 Health and Safety 15

2 Symbols 15

3 Installation, Commissioning and Servicing 16

3.1 Lifting Hazards 16

3.2 Electrical Hazards 17

3.3 Fusing Requirements 18

3.4 Equipment Connections 19

3.5 Pre-energization Checklist 20

3.6 Peripheral Circuitry 20

3.7 Upgrading/Servicing 21

4 Decommissioning and Disposal 21

5 Standards Compliance 22

5.1 EMC Compliance: 22

5.2 Product Safety 22

5.3 R&TTE Compliance 23

Chapter 3: Design 25

1 Hardware Architecture 25

2 Mechanical Implementation 25

2.1 DR60 Connections Overview and Indicators 26

3 Frequency Calculation 28

Chapter 4: Configuration 29

1 DR60 Configurator Tool 29

1.1 Main Screen 29

1.2 Configuration Tabs 30

1.3 Status Bar 32

2 Access Levels 32

3 Communication Setup and Configuration Files Use 33

Page 3

DR60

3

DR60-TM-EN-2A

3.1 Configuring Communication Parameters 34

3.2 Creating a New Configuration File 35

3.3 Receiving an Equipment Configuration File 35

3.4 Opening a Pre-existing Configuration File 36

3.5 Saving a Configuration File 36

3.6 Sending a Configuration File for the Equipment 36

4 Tools 36

4.1 LOG 37

4.2 Administrative Tools 37

5 Configuration Tabs 38

5.1 General 38

5.2 Analog 38

5.3 Binary 40

5.4 Communication 41

5.5 Synchronization 48

5.6 Recording 51

5.7 Triggering 53

6 Monitoring and Web Interface 57

7 Alarm and Warning Reporting 58

Chapter 5: Records 61

1 Wave Form Records 61

1.1 Recorded Values 61

1.2 Recording Times by Trigger 61

1.3 Sampling Rate 62

1.4 Trigger Burst Limiter 62

2 Re-trigger and Record Concatenation 62

3 Disturbance and Continuous Disturbance Records 63

3.1 Recorded Values 63

3.2 Recording Times by Trigger 66

3.3 Sampling Rate 67

3.4 Trigger Burst Limiter 67

4 Trend Recorder 67

5 SOE - Sequence of Events Records 67

5.1 Sampling Rate 67

6 Record Format and Naming, and Mass Storage Capacity 67

6.1 Record Format 67

6.2 Record Naming 68

6.3 Mass Storage Capacity 69

7 Record Management and Access 69

7.1 Creating Installations 70

7.2 Creating Devices 70

Chapter 6: PMU 71

1 Synchrophasor Measurement and Broadcast 71

1.1 Reported Values 71

Page 4

4

DR60-TM-EN-2A

1.2 Accuracy Limits 71

1.3 Communication Ports, Transmission Rates 72

1.4 Configuration 72

1.5 Transmission Protocol 74

1.6 Communication Mode 75

1.7 Standards Compliance 75

1.8 PMU Specification 76

Chapter 7: Communications 79

1 Communication Interfaces – Slot B 79

1.1 Electrical and Optical Ethernet 79

1.2 Serial Port 80

2 Communication Ports and Protocols 81

3 Recovering the DR60 IP Address 82

4 Accessing the Equipment 82

4.1 Web Interface Minimum Requirements 82

Chapter 8: Installation 83

1 Handling the Goods 83

1.1 Receipt of the Goods 83

1.2 Unpacking the Goods 83

1.3 Storing the Goods 83

1.4 Dismantling the Goods 84

2 Normal Use of the Equipment 84

3 Mounting the Device 84

3.1 DR60 Mechanical Installation 84

4 Cables and Connectors 85

4.1 Power Supply Connections 86

4.2 Powering Up 87

4.3 Earth Connection 88

4.4 IN SERVICE Contact 89

4.5 Optical IRIG-B Input 90

4.6 Serial ports 90

4.7 I/O Nomenclature 91

4.8 Binary Inputs and Outputs 92

4.9 Voltage and Current Analog Inputs 96

5 Case Dimensions 98

5.1 DR60 Dimensions and Weight 98

5.2 Panel Cutout 99

5.3 Accessories 99

6 DR60 Configurator Tools Installation 100

6.1 Minimal requirements 100

Chapter 9: Maintenance 102

1 Maintenance 102

1.1 Maintenance Checks 102

1.2 Back up and restore settings 103

Page 5

DR60

5

DR60-TM-EN-2A

1.3 Measurement Accuracy 103

1.4 Replacing the Unit 103

1.5 Cleaning 104

1.6 Watchdog 104

2 DR60 Troubleshooting 104

3 DR60 Firmware Update 104

4 Equipment Return 105

5 Instructions for Equipment Repair/Service for Service Personnel 105

Chapter 10: Technical Specifications 107

1 DR60 Specifications 107

1.1 Power Supply 107

1.2 Ethernet Ports 107

1.3 Optical IRIG-Input 108

1.4 Serial Ports 108

1.5 Dry-contact Relay Outputs 109

1.6 Analog Acquisition 110

1.7 Voltage Inputs 110

1.8 Current Inputs 111

1.9 DC Transducer Inputs 112

1.10 Binary Inputs 112

1.11 Binary Outputs 113

1.12 Environmental Conditions 113

1.13 Type Tests DR60 114

1.14 Safety Tests 116

1.15 Environmental tests 116

1.16 Dimensions 117

Chapter 11: Wiring Diagrams 118

1 Connection Diagrams of the Voltage Inputs 118

2 Connection Diagrams of the Current Inputs 120

Appendix A – Equipment Log 123

1 Equipment Log 123

Page 6

6

DR60-TM-EN-2A

DR60

Digital Recorder

Chapter 1: Introduction

This chapter provides some general information about the technical manual and an

introduction to the device(s) described in this technical manual.

1 Foreword

This technical manual provides a functional and technical description of GE Reason

DR60, as well as a comprehensive set of instructions for using the device. The level at

which this manual is written assumes that you are already familiar with protection

engineering and have experience in this discipline. The description of principles and

theory is limited to that which is necessary to understand the product.

We have attempted to make this manual as accurate, comprehensive and user-friendly

as possible. However, we cannot guarantee that it is free from errors. Nor can we state

that it cannot be improved. We would therefore be very pleased to hear from you if you

discover any errors, or have any suggestions for improvement. Our policy is to provide

the information necessary to help you safely specify, engineer, install, commission,

maintain, and eventually dispose of this product. We consider that this manual provides

the necessary information, but if you consider that more details are needed, please

contact us.

All feedback should be sent to our contact center via the following URL:

http://www.gegridsolutions.com/alstomenergy/grid/grid/contactcentre

1.1 Target Audience

This manual is aimed towards all professionals charged with installing, commissioning,

maintaining, troubleshooting, or operating any of the products within the specified

product range. This includes installation and commissioning personnel as well as

engineers who will be responsible for operating the product.

The level at which this manual is written assumes that installation and commissioning

engineers have knowledge of handling electronic equipment. Also, system and

protection engineers have a thorough knowledge of protection systems and associated

equipment.

1.2 Nomenclature

Due to the technical nature of this manual, many special terms, abbreviations and

acronyms are used throughout the manual. Some of these terms are well-known

industry-specific terms while others may be special product-specific terms used by GE.

Page 7

DR60

7

DR60-TM-EN-2A

1.3 Abbreviations

AC - Alternating Current;

COMNAME - IEEE C37.232 Recommended Practice for Naming Time Sequence Data

Files;

COMTRADE - IEEE C37.111 Common Format for Transient Data Exchange;

CID – Configured IED Description

DC - Direct Current;

DFR – Digital Fault Recorder;

EMC - Electromagnetic Compatibility;

FRQ - Frequency;

GOOSE - Generic Object Oriented Substation Events;

GPS - Global Positioning System;

HTML - HyperText Markup Language;

IMB - Imbalance;

IEEE - Institute of Electric and Electronic Engineers;

IEC - International Electrotechnical Commission;

IED - Intelligent Electronic Devices;

IP - Internet Protocol;

IRIG-B -Inter Range Instrumentation Group (Rate Designation B);

KML - Keyhole Markup Language;

MAC - Media Access Control;

MODBUS - Modicon Bus;

PC - Computer;

PMU - Phasor Measurement Unit;

Pst - Short-term flicker severity;

Plt - Long-term flicker severity;

RAM - Random-access Memory;

RFC, DEFLATE - RFC 1951, DEFLATE Compressed Data Format Specification;

RMS - Root Mean Square;

SCADA - Supervisory Control and Data Acquisition;

SCD – Substation Configuration Description

SCL - Edit Configuration File for the GOOSE Configurator;

SNTP - Simple Network Time Protocol;

SOE - Sequence of Events;

SQL - Structured Query Language;

SSD - Solid-state Drive;

TCP - Transmission Control Protocol;

THD - Total harmonic distortion;

TTL – Transistor-transistor-logic;

TW - Travelling Wave;

UDP - User Datagram Protocol;

UTC - Coordinated Universal Time;

VLAN - Virtual Local Area Network;

XML - Extensible Markup Language.

Page 8

8

DR60-TM-EN-2A

2 Product Scope

The DR60 a single-box solution for Digital Recording. The solution is designed for the

acquisition, monitoring and recording of electrical quantities normally associated with

electrical power generation, transmission or distribution equipment. The DR60 is

designed fan-less and no rotating part components. It has a 16-bit acquisition system

that provide an acquisition rate of 256 or 512 samples/cycle synchronized by the IRIG-B

or IEEE 1588 PTPv2.

The DR60 has a very flexible architecture with several different boards with allows the

customer to choose the most cost-effective solution for each application. Depending on

the boards combination, the DR60 can offer: up to 32 analog channels, 96 digital

channels and 48 digital outputs

The DR60 is a native IEC 61850 device, which means that all its internal variables follow

the data models and logical nodes described in the IEC 61850 edition 2. The DR60 is

able to publish and subscribe to GOOSE messages, as well as publish Report control

blocks for supervisory system integration.

It allows communication through the electrical Ethernet ports or optical interfaces.

3 Unpacking

Unpack the equipment carefully and make sure that all accessories and cables are put

away so they will not be lost.

Check the contents against the packing list. If any of the contents listed is missing,

please contact GE immediately (see contact information at the beginning of this

manual).

Examine the equipment for any shipping damage. If the unit is damaged or fails to

operate, notify the shipping company immediately. Only the consignee (the person or

company receiving the unit) can file a claim against the carrier for occasional shipping

damages.

We recommend that the user retain the original packing materials for use in case of

need to transport or ship the equipment at some future time.

4 External Indication

4.1 DR60 Nameplate

Information about the company, power supply, the serial number and part number is

shown on a small nameplate affixed to the rear of the equipment, as shown in figure

below.

Page 9

DR60

9

DR60-TM-EN-2A

Location of Serial Number, Part Number and specifications

5 Key Features

The DR60 presents the following key features:

• Acquisition system:

▪ 16-bit opto-isolated analog-to-digital converters, independent for each

channel (50/60 Hz channels);

▪ 256 and 512 samples/cycle (50/60 Hz channels);

▪ Frequency response of DC to approximately 3.0 kHz;

▪ Opto-isolated digital inputs

▪ Internal time skew compensation;

▪ Sampling rate synchronized to external time reference;

• Channel capacity:

Page 10

10

DR60-TM-EN-2A

▪ Up to 16 voltage inputs;

▪ Up to 16 current inputs;

▪ Up to 16 transducer voltage inputs;

▪ Up to 16 transducer current inputs;

▪ Up to 96 digital inputs;

Note: Maximum capacity of channels depends on boards combination

• Fan-less and no rotating part design

• Waveform recorder at 256 and 512 samples/cycle;

• Disturbance and continuous disturbance at 1, 2 or 4 samples/cycle;

• IRIGB-004 and IEEE 1588 PTPv2

• Trigger using Boolean logic equations;

• GOOSE publisher and subscriber (up to 256 GOOSE inputs)

• MMS report control block publisher

• Cross-trigger using GOOSE messages;

• RS232 serial ports for configuration;

• 1 failsafe contact (normally closed dry contact relay);

6 Compliance

The device has undergone a range of extensive testing and certification processes to

ensure and prove compatibility with all target markets. A detailed description of these

criteria can be found in the Technical Specifications chapter.

7 Functional Overview

It is a single-box solution design for substation environment and offers a very

flexible combination of boards, which allows the customers to have up to 32 analog

inputs and up to 96 binary inputs. These characteristics along with binary outputs options

and two Ethernet ports, make the DR60 ideal to monitor up to 3 bays (considering 8

analog and 16 binary inputs per bay).

The DR60 provides a cost-effective solution for disturbance recording through a

distributed approach. It can be installed locally on a per-feeder basis or interconnected

via peer-to-peer GOOSE messaging that allows cross-triggering to occur without the need

to hard-wire the contacts, providing a scalable solution to station-level recording.

The DR60 complements relays by providing independent, high fidelity waveform

capture. It provides Waveform recorders, SOE and triggered and continuous disturbance

recorders - not typically found even in the most advanced digital relays. It also provides

features such GOOSE publisher and subscriber and MMS report control blocks for

integration with supervisory systems.

8 Programs Under the GPL License

The DR60 uses GPL licenses in its implementation according to the following table:

Page 11

DR60

11

DR60-TM-EN-2A

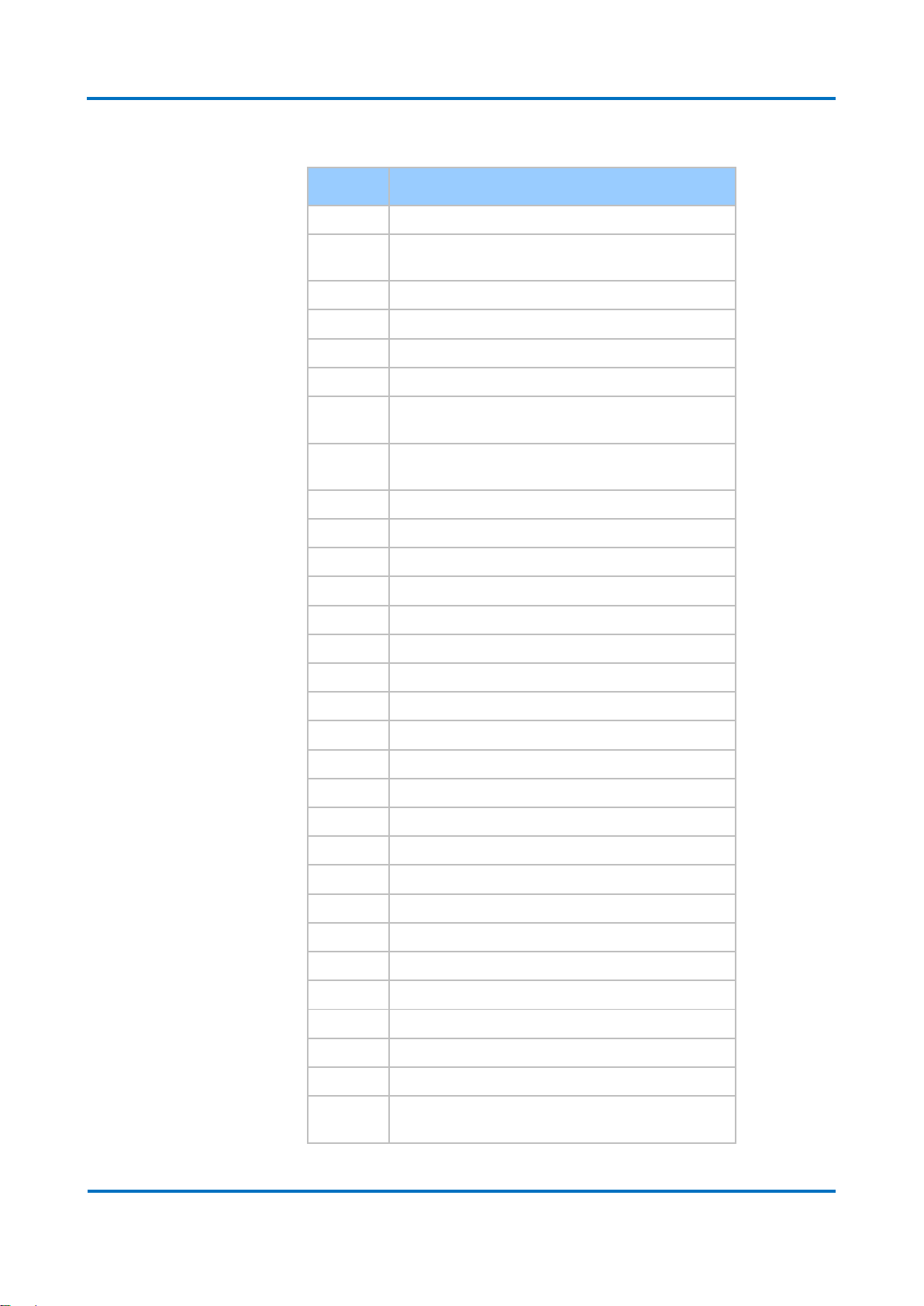

PACKAGE

LICENSE

glibc

GPLv2+ (programs), LGPLv2.1+, BSD-3c, MIT (library)

linux-

headers

GPLv2

bash

GPLv3+

busybox

GPLv2

ncurses

MIT with advertising clause

readline

GPLv3+

e2fsprogs

GPLv2, libuuid BSD-3c, libss and libet MIT-like with

advertising clause

util-linux

GPLv2+, BSD-4c, libblkid and libmount LGPLv2.1+,

libuuid BSD-3c

zlib

zlib license

ethtool

GPLv2

gptfdisk

GPLv2+

htop

GPLv2

irqbalance

GPLv2

lighttpd

BSD-3c

pcre

BSD-3c

mtd

GPLv2

mxml

LGPLv2+ with exceptions

netsnmp

Various BSD-like

openssl

OpenSSL or SSLeay

openssh

BSD-3c BSD-2c Public Domain

parted

GPLv3+

pps-tools

GPLv2+

sudo

ISC BSD-3c

uboot-tools

GPLv2+

vsftpd

GPLv2

linux

GPLv2

kermit

BSD

libiec61850

GPLv3

mms-client

GPLv3

ntp-

internal

ntp license

Page 12

12

DR60-TM-EN-2A

ptpd-

internal

BSD

Page 13

DR60

13

DR60-TM-EN-2A

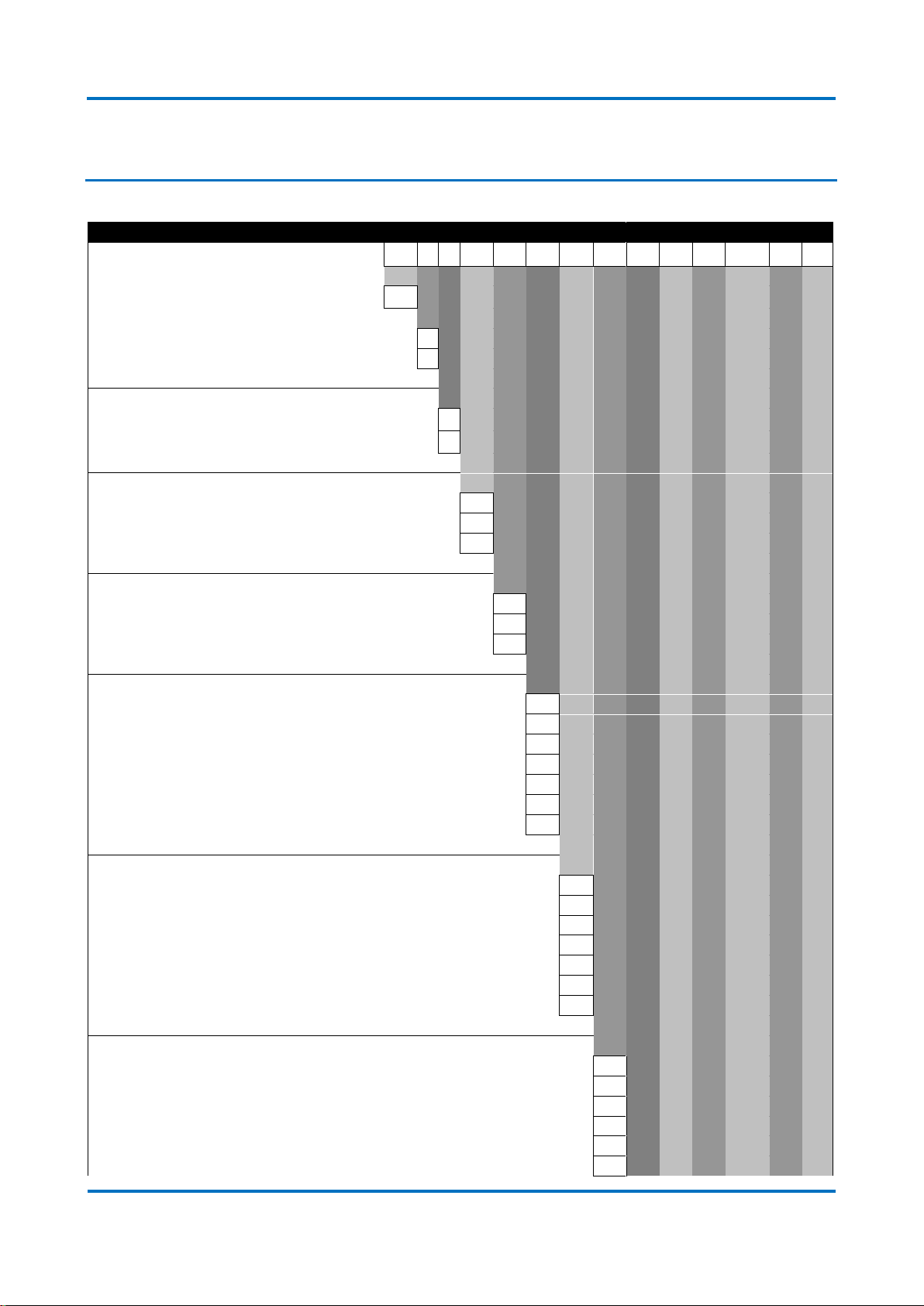

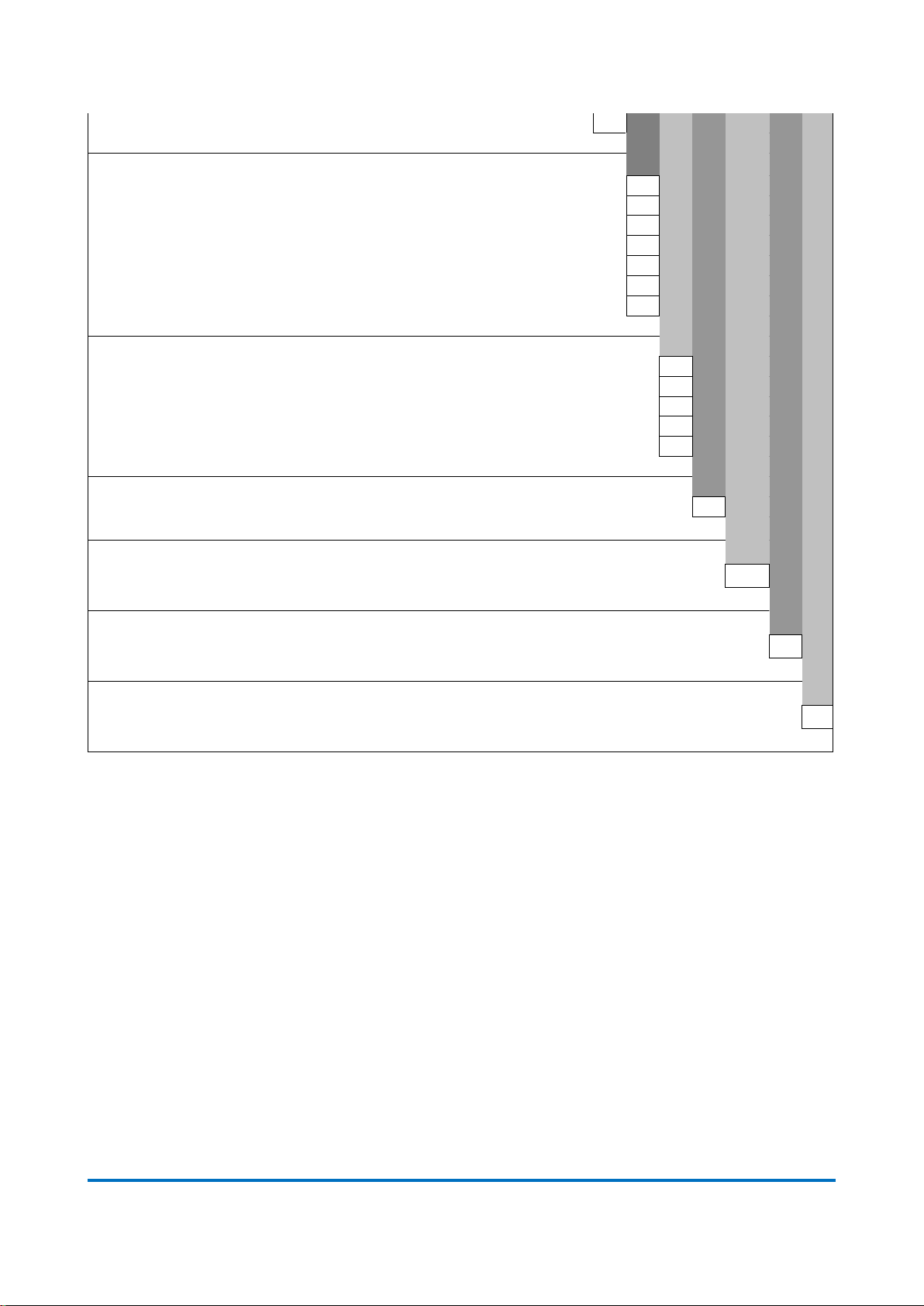

9 Ordering Options

Variants

Order Number

1-4 5 6

7-8

910

1112

1314

1516

1718

1920

21

22-23

24

25

Model type:

DR60 Digital Recorder

DR

60

Slot A - Power Supply

24-48 Vdc

1

100-250 Vdc / 110-240 Vac

3 Slot B - Hardware Options

Processing unit + two RJ45 copper 10/100BASE-TX Ethernet

interfaces

E

Processing unit + two multimode LC-type connector 100BASE-FX Ethernet

interfaces

O

Slot C - Binary I/O

16 x 24/48/125/250 V binary inputs

B1

6 x 24/48/125/250 V binary inputs and 8 x binary outputs

B2

Not installed

XX Slot D - Binary I/O

16 x 24/48/125/250 V binary inputs

B1 6 x 24/48/125/250 V binary inputs and 8 x binary outputs

B2 Not installed

XX

Slot E - Flexible I/O Options

16 x 24/48/125/250 V binary inputs

B1

6 x 24/48/125/250 V binary inputs and 8 x binary outputs

B2

4 x VT 115 V and 4 CT 1/5 A RMS measurement analog inputs

ME

4 x VT 115 V and 4 x CT 1 A RMS protection analog inputs

P1

4 x VT 115V and 4 x CT 5 A RMS protection analog inputs

P5

4 x ±10 Vdc and 4 x 0-20 mAdc transducer inputs

DC

Not installed

XX

Slot F - Flexible I/O Options

16 x 24/48/125/250 V binary inputs

B1 6 x 24/48/125/250 V binary inputs and 8 x binary outputs

B2

4 x VT 115 V and 4 CT 1/5 A RMS measurement analog inputs

ME 4 x VT 115 V and 4 x CT 1 A RMS protection analog inputs

P1 4 x VT 115V and 4 x CT 5 A RMS protection analog inputs

P5 4 x ±10 Vdc and 4 x 0-20 mAdc transducer inputs

DC Not installed

XX

Slot G - Flexible I/O Options

16 x 24/48/125/250 V binary inputs

B1

6 x 24/48/125/250 V binary inputs and 8 x binary outputs

B2

4 x VT 115 V and 4 CT 1/5 A RMS measurement analog inputs

ME

4 x VT 115 V and 4 x CT 1 A RMS protection analog inputs

P1

4 x VT 115V and 4 x CT 5 A RMS protection analog inputs

P5

4 x ±10 Vdc and 4 x 0-20 mAdc transducer inputs

DC

Page 14

14

DR60-TM-EN-2A

Not installed

XX

Slot H - Flexible I/O

Options

16 x 24/48/125/250 V binary inputs

B1 6 x 24/48/125/250 V binary inputs and 8 x binary outputs

B2 4 x VT 115 V and 4 CT 1/5 A RMS measurement analog inputs

ME 4 x VT 115 V and 4 x CT 1 A RMS protection analog inputs

P1 4 x VT 115V and 4 x CT 5 A RMS protection analog inputs

P5

4 x ±10 Vdc and 4 x 0-20 mAdc transducer inputs

DC Not installed

XX

Primary Functions

Phasor Measurement Unit (PMU)

**

Waveform recorder

**

Disturbance Recorder

**

Continuous Disturbance Recorder

**

Trend Recorder

**

Secondary Functions

Standard Issue

1

Firmware Version

Latest available firmware - 02

02

Warranty

Standard warranty

0

Hardware Design Suffix

Initial version

A

Issue B

Page 15

DR60

15

DR60-TM-EN-2A

DR60

Digital Recorder

Chapter 2: Safety Information

This chapter provides information about the safe handling of the equipment. The

equipment must be properly installed and handled in order to maintain it in a safe

condition and to keep personnel safe at all times. You must be familiar with information

contained in this chapter before unpacking, installing, commissioning, or servicing the

equipment.

1 Health and Safety

Personnel associated with the equipment must be familiar with the contents of this

Safety Information.

When electrical equipment is in operation, dangerous voltages are present in certain

parts of the equipment. Improper use of the equipment and failure to observe warning

notices will endanger personnel.

Only qualified personnel may work on or operate the equipment. Qualified personnel

are individuals who are:

• familiar with the installation, commissioning, and operation of the equipment

and the system to which it is being connected.

• familiar with accepted safety engineering practices and are authorized to

energies and de-energies equipment in the correct manner.

• trained in the care and use of safety apparatus in accordance with safety

engineering practices

• trained in emergency procedures (first aid).

The documentation provides instructions for installing, commissioning and operating the

equipment. It cannot, however cover all conceivable circumstances. In the event of

questions or problems, do not take any action without proper authorization. Please

contact your local sales office and request the necessary information.

Each product is subjected to routine production testing for Dielectric Strength and Protective

Bonding Continuity

2 Symbols

Page 16

16

DR60-TM-EN-2A

Throughout this manual you will come across the following symbols. You will also see

these symbols on parts of the equipment.

Caution: Refer to equipment documentation. Failure to do so

could result in damage to the equipment

Risk of electric shock

Ground terminal. Note: This symbol may also be used for a

protective conductor (ground) terminal if that terminal is

part of a terminal block or sub-assembly.

Protective conductor (ground) terminal

Chassis functional earth terminal

Both direct and alternating current

Instructions on disposal requirements

The term 'Ground' used in this manual is the direct equivalent of the European term

'Earth'.

3 Installation, Commissioning and Servicing

3.1 Lifting Hazards

Many injuries are caused by:

• Lifting heavy objects

• Lifting things incorrectly

• Pushing or pulling heavy objects

• Using the same muscles repetitively

Plan carefully, identify any possible hazards and determine how best to move the

product. Look at other ways of moving the load to avoid manual handling. Use the

correct lifting techniques and Personal Protective Equipment (PPE) to reduce the risk of

injury.

Page 17

DR60

17

DR60-TM-EN-2A

3.2 Electrical Hazards

All personnel involved in installing, commissioning, or servicing

this equipment must be familiar with the correct working

procedures.

Consult the equipment documentation before installing,

commissioning, or servicing the equipment.

Always use the equipment as specified. Failure to do so will

jeopardize the protection provided by the equipment.

Removal of equipment panels or covers may

expose hazardous live parts. Do not touch until the

electrical power is removed. Take care when there

is unlocked access to the rear of the equipment.

Isolate the equipment before working on the

terminal strips.

Use a suitable protective barrier for areas with

restricted space, where there is a risk of electric

shock due to exposed terminals.

Disconnect power before disassembling. Disassembly of the

equipment may expose sensitive electronic circuitry. Take

suitable precautions against electrostatic voltage discharge (ESD)

to avoid damage to the equipment.

NEVER look into optical fibers or optical output connections.

Always use optical power meters to determine operation or signal

level.

Testing may leave capacitors charged to dangerous voltage levels.

Discharge capacitors by reducing test voltages to zero before

disconnecting test leads.

If the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be

impaired.

Operate the equipment within the specified electrical and

environmental limits.

Page 18

18

DR60-TM-EN-2A

Before cleaning the equipment, ensure that no connections are

energized. Use a lint free cloth dampened with clean water.

Integration of the equipment into systems shall not interfere with

its normal functioning.

The functioning of the device has been certified under the

circumstances described by the standards mentioned in

Technical Specifications chapter (item Type Tests). Usage of the

equipment in different conditions from the specified in this

manual might affect negatively its normal integrity.

The equipment shall have all their rear connectors attached even

if they are not being used, in order to keep their levels of ingress

protection as high as possible

Never manipulate liquid containers near the equipment even

when it is powered off.

Avoid modification to the wiring of panel when the system is

running.

VT circuits must never be left short circuited.

3.3 Fusing Requirements

A high rupture capacity (HRC) fuse type with a maximum current

rating of 10 Amps and a minimum dc rating of 250 V dc may be

used for the auxiliary supply (for example Red Spot type NIT or

TIA). Alternatively, a miniature circuit breaker (MCB) of type C,

10A rating, compliant with IEC 60947-1 and IEC 60947-3 may be

used.

Digital input circuits should be protected by a high rupture

capacity NIT or TIA fuse with maximum rating of 10 A, or

equivalent MCB as above. For safety reasons, current transformer

circuits must never be fused. Other circuits should be

appropriately fused to protect the wire used.

Reason devices contain an internal fuse for the power supply

which is only accessed by opening the product. This does not

remove the requirement for external fusing or use of an MCB as

previously mentioned. The ratings of the internal fuses are:

DR60 unit: 2 Amp, type T, 250V rating

Page 19

DR60

19

DR60-TM-EN-2A

CTs must NOT be fused since open circuiting them may produce

lethal hazardous voltages.

3.4 Equipment Connections

Terminals exposed during installation, commissioning and

maintenance may present a hazardous voltage unless the

equipment is electrically isolated.

Tighten M3 clamping screws of heavy duty terminal block

connectors to a nominal torque of 1.0 Nm.

Tighten captive screws of header-type (Euro) terminal blocks to

0.5 Nm minimum and 0.6 Nm maximum.

Always use insulated crimp terminations for voltage and current

connections.

Always use the correct crimp terminal and tool according to the

wire size.

In order to maintain the equipment’s requirements for

protection against electric shock, other devices connected to the

DR60 shall have protective class equal or superior to Class I.

Watchdog (self-monitoring) contacts are provided to indicate

the health of the device on some products. We strongly

recommend that you hard wire these contacts into the

substation's automation system, for alarm purposes.

Earth the equipment with the supplied PCT (Protective

Conductor Terminal).

Do not remove the PCT.

The PCT is sometimes used to terminate cable screens. Always

check the PCT’s integrity after adding or removing such earth

connections.

The user is responsible for ensuring the integrity of any

protective conductor connections before carrying out any

other actions.

Page 20

20

DR60-TM-EN-2A

The PCT connection must have low-inductance and be as short

as possible. For best EMC performance, ground the unit using

a 10 mm (0.4 inch) wide braided grounding strap.

All connections to the equipment must have a defined

potential. Connections that are pre-wired, but not used,

should be earthed, or connected to a common grouped

potential.

Pay extra attention to diagrams before wiring the equipment.

Always be sure that the connections are correct before

energizing the circuits.

3.5 Pre-energization Checklist

Check voltage rating/polarity (rating label/equipment

documentation).

Check CT circuit rating (rating label) and integrity of

connections.

Check protective fuse or miniature circuit breaker (MCB)

rating.

Check integrity of the PCT connection.

Check voltage and current rating of external wiring,

ensuring it is appropriate for the application.

3.6 Peripheral Circuitry

Do not open the secondary circuit of a live CT

since the high voltage produced may be lethal to

personnel and could damage insulation. Short

the secondary of the line CT before opening any

connections to it.

Reason devices DO NOT feature any automatic CT shorting feature. Therefore,

external shorting of the CTs is mandatory. Check the equipment documentation

and wiring diagrams carefully.

Page 21

DR60

21

DR60-TM-EN-2A

Where external components such as resistors or voltage

dependent resistors (VDRs) are used, these may present a

risk of electric shock or burns if touched.

Operation of computers and equipment connected to the

DR60 under environmental conditions such as temperature

and humidity that exceed the conditions specified in their

respective manuals can cause malfunctioning or even

irreversible damage to them or the nearby installation.

There might be situations in which the DR60 is operating

within its environmental operational range, but the

computers, equipment connected to them or nearby

equipment are operating outside their operational range.

That situation can cause malfunctioning and/or irreversible

damage to those devices. In that occasion the

communication to the Reason equipment might be

compromised but its recording, operational and safety

capacities will not be affected.

Take extreme care when using external test blocks and

test plugs such as the MMLG, MMLB and P990, as

hazardous voltages may be exposed. Ensure that CT

shorting links are in place before removing test plugs, to

avoid potentially lethal voltages.

3.7 Upgrading/Servicing

Do not insert or withdraw modules, PCBs or expansion

boards from the equipment while energized, as this

may result in damage to the equipment. Hazardous

live voltages would also be exposed, endangering

personnel.

Internal modules and assemblies can be heavy and may

have sharp edges. Take care when inserting or removing

modules into or out of the IED.

4 Decommissioning and Disposal

Page 22

22

DR60-TM-EN-2A

Before decommissioning, completely isolate the

equipment power supplies (both poles of any dc supply).

The auxiliary supply input may have capacitors in

parallel, which may still be charged. To avoid electric

shock, discharge the capacitors using the external

terminals before decommissioning.

Avoid incineration or disposal to water courses. Dispose

of the equipment in a safe, responsible and

environmentally friendly manner, and if applicable, in

accordance with country-specific regulations.

5 Standards Compliance

Compliance with the European Commission Directive on EMC and LVD is demonstrated

using a Technical File.

5.1 EMC Compliance:

Compliance with IEC 60255-26:2013 was used to establish conformity.

5.2 Product Safety

Compliance with IEC 60255-27:2014 was used to establish conformity.

Protective Class

IEC 60255-27:2014 Protective Class 1. This equipment requires a protective conductor

(earth) to ensure user safety.

Installation category

▪ When using the 100-250 Vdc / 110-240 Vac power supply: IEC 60255-27:2013

Installation category III (Overvoltage Category III). Equipment in this category is

qualification tested at 5kV peak, 1.2/50 μS, 500 Ohms, 0.5 J, between all supply

circuits and earth and also between independent circuits.

▪ When using the 24-48 Vdc power supply: IEC 60255-27:2013 Installation category II

(Overvoltage Category II)

Environment

IEC 60068-2-1, IEC 60068-2-2, IEC 60068-2-30, IEC 60068-2-14, IEC 60255-21-1, IEC

60255-21-2. The equipment shall always be installed in a specific cabinet or housing

which will enable it to meet the requirements of IEC 60529 with the classification of

degree of protection IP54 or above.

Page 23

DR60

23

DR60-TM-EN-2A

5.3 R&TTE Compliance

Radio and Telecommunications Terminal Equipment (R&TTE) directive 99/5/EC.

Conformity is demonstrated by compliance to both the EMC directive and the Low

Voltage directive, to zero volts.

Page 24

Page 25

DR60

25

DR60-TM-EN-2A

DR60

Digital Recorder

Chapter 3: Design

This chapter provides information about the hardware design of the products.

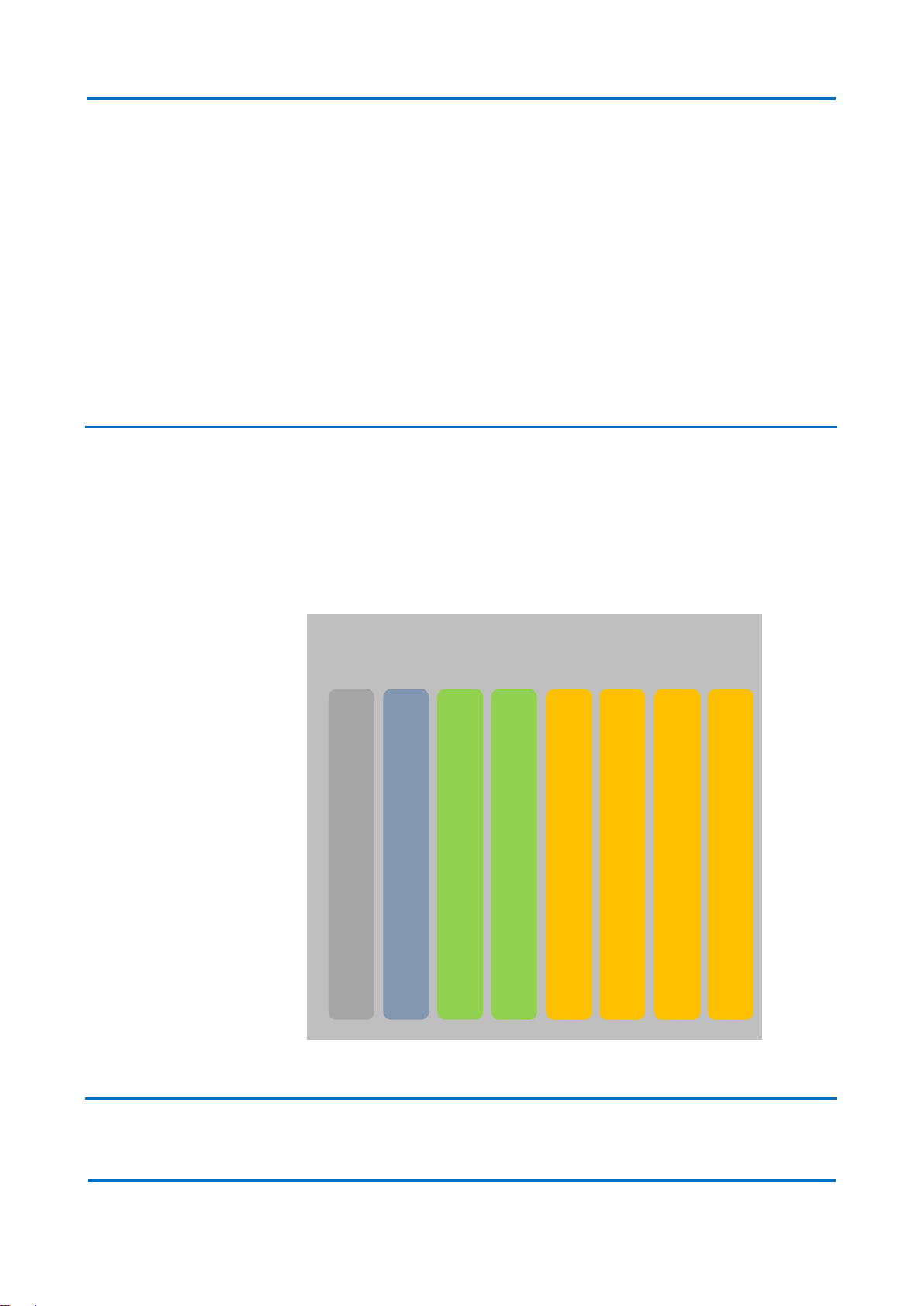

1 Hardware Architecture

The DR60 is composed of up to 8 boards, from slot A to H. A very flexible number of

inputs and outputs can be achieved by the combination of the boards. The slot A is

reserved for power supply; Slot B for CPU, Ethernet and serial connection and IRIGB

synchronization input; Slots C and D are used for binary input/outputs and slots E to H

can be used either for binary I/O or analog inputs. The figure below illustrates the DR60

slots composition. For the complete list of board option, refer to the ordering option in

Chapter 1.

DR60 slots composition

2 Mechanical Implementation

Power Supply

CPU/Communication

Digital Board Digital Board

Analog or Digital Analog or Digital Analog or Digital Analog or Digital

A

C

D E F

G

H

Slots

Page 26

DR60

26

DR60-TM-EN-2A

2.1 DR60 Connections Overview and Indicators

The figure below shows the DR60 front panel with connectors and indicator LEDs.

Front View of the DR60

The diagram and table below show the designation and meaning of each LED.

Power

LED

Indicator LEDs

Alarm

In Service

Trigger

Sync

Failsafe

relay

Power

Supply

Binary I/O

Binary I/O or analog inputs

Ethernet

interfaces

Serial

Interfaces

IRIGB

Input

Page 27

DR60

27

DR60-TM-EN-2A

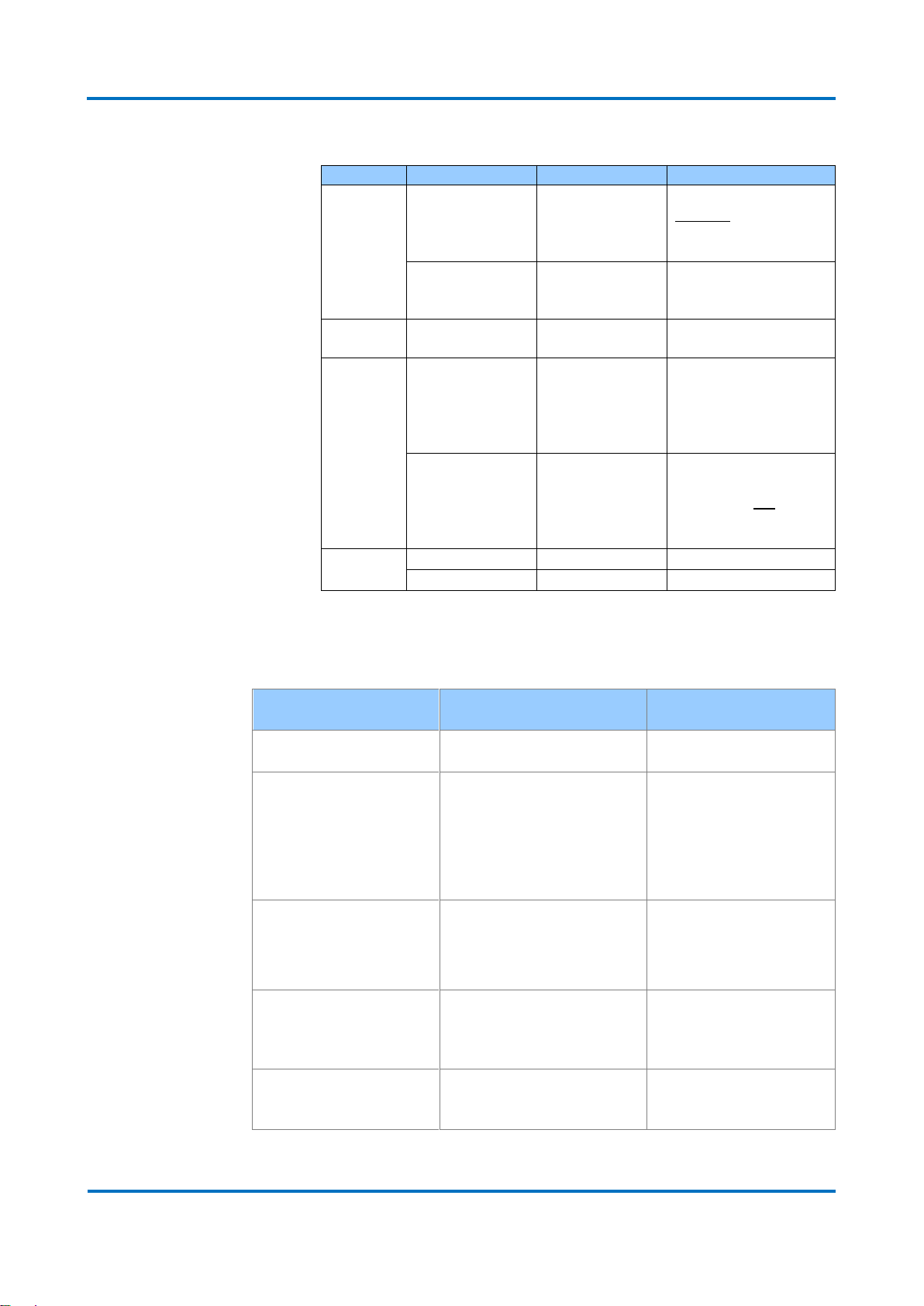

LED

Color

Indicator

Meaning

Alarm

Orange

Warning

An alarm event that

does not compromise

the DR60 functions was

detected

Red

Alarm

An alarm event that

compromised DR60

functions was detected

In Service

Green

In Service

DR60 is working in

perfect conditions

Sync

Green

Global

DR60 is synchronized

with the time reference

clock that is

synchronized with

satellite reference

Orange

Local

DR60 is synchronized

with the time reference

clock that is not

synchronized with

satellite reference

Trigger

Green

Trigger

Any trigger occurred

Orange

Re-trigger

Any trigger reoccurred

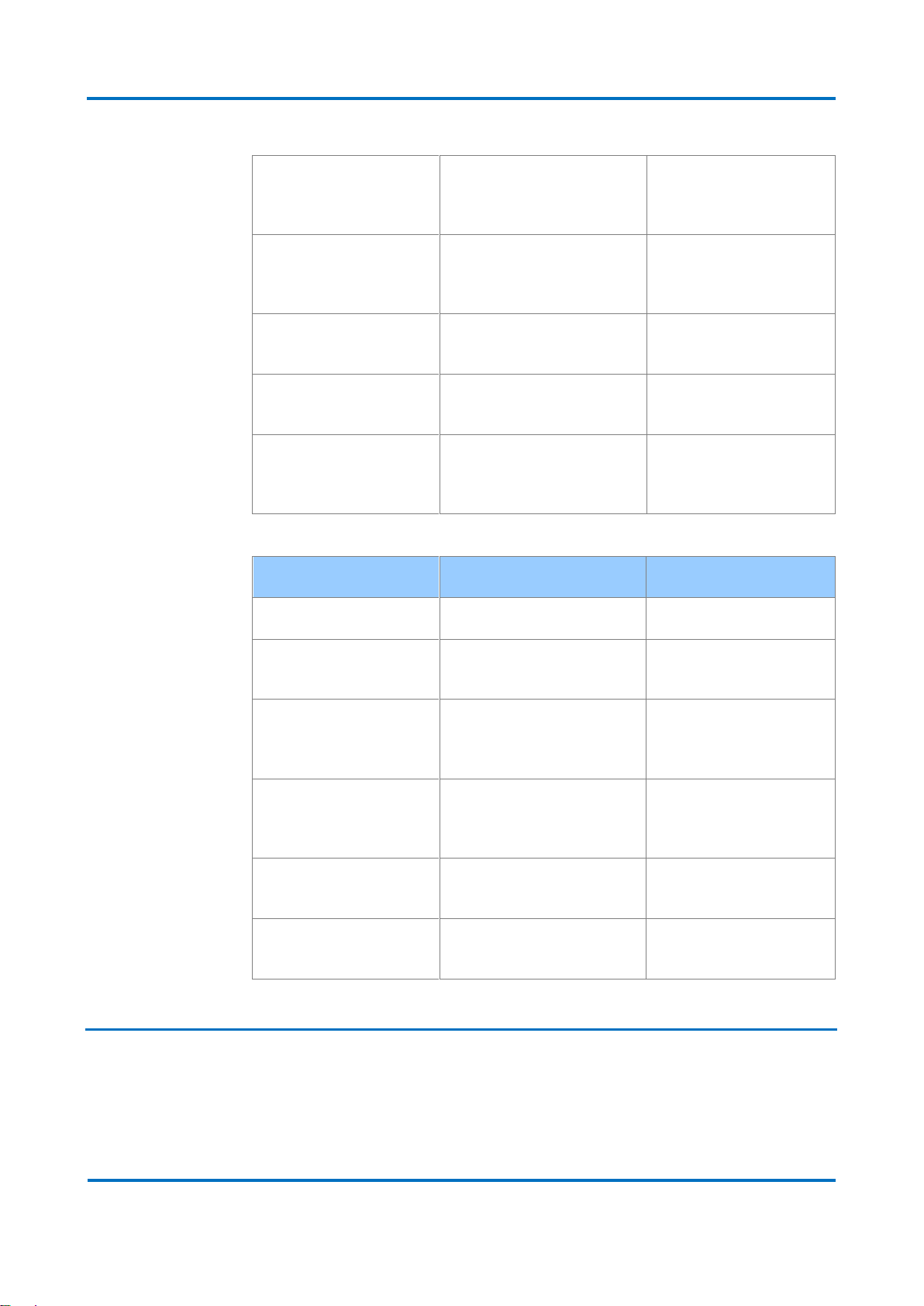

The table below shows which events are considered alarms and warnings.

Alarms

Data Name

Description

Sync NOT OK

BSE/ALARMSGGIO1.Alm1

Card not detected, invalid

or incompatible

BSE/ALARMSGGIO1. Alm2

Happens when there are

discrepancies between the

installed boards and the

device CORTEC

Internal voltage

BSE/ALARMSGGIO1. Alm3

Internal voltage

automonitoring alarm

Internal temperature

BSE/ALARMSGGIO1. Alm4

Internal temperature is

abnormal (Out of -10°C to

60ºC)

No communication

Ethernet interface 1

BSE/ALARMSGGIO1. Alm5

Loss of communication

with ethernet interface 1

Page 28

DR60

28

DR60-TM-EN-2A

Waveform/Fault recorder

memory usage above 98%

BSE/ALARMSGGIO1. Alm6

Happens when the

memory becomes 98% full

for waveform recorder

Disturbance recorder

memory usage above 98%

BSE/ALARMSGGIO1. Alm7

Happens when the

memory becomes 98% full

for disturbance recorder

Trend recorder memory

usage above 98%

BSE/ALARMSGGIO1. Alm8

Records memory exceeds

98% for trend recorder

SOE recorder memory

usage above 98%

BSE/ALARMSGGIO1. Alm9

Records memory exceeds

98% for SOE recorder

GOOSE subscriber failure

or timeout

BSE/ALARMSGGIO1. Alm10

Time for the next expected

GOOSE message to come

exceeded

Warnings

Data Name

Description

Sync OK

BSE/ALARMSGGIO1.Wrn1

Equipment not sync

No communication

Ethernet interface 2

BSE/ALARMSGGIO1. Wrn5

Loss of communication

with ethernet interface 2

Waveform/Fault recorder

memory usage above 90%

BSE/ALARMSGGIO1. Wrn6

Happens when the

memory becomes 90% full

for waveform recorder

Disturbance recorder

memory usage above 90%

BSE/ALARMSGGIO1. Wrn7

Happens when the

memory becomes 90% full

for disturbance recorder

Trend recorder memory

usage above 90%

BSE/ALARMSGGIO1. Wrn8

Records memory exceeds

90% for trend recorder

SOE recorder memory

usage above 90%

BSE/ALARMSGGIO1. Wrn9

Records memory exceeds

90% for SOE recorder

3 Frequency Calculation

The DR60 calculates frequency applying a moving average filter in the derivative of the

angle of the positive sequence voltage, the angle is calculated four times per cycle and

so is the frequency.

.

Page 29

DR60

29

DR60-TM-EN-2A

DR60

Digital Recorder

Chapter 4: Configuration

This chapter includes detailed instructions of how to configure all available features in

the device.

1 DR60 Configurator Tool

The DR60 Configurator the is the DR60’s ICT (IED configuration tool). It allows the

modification of all configurable functionalities of the device, including communication

aspects, recorders, binary I/O etc.

1.1 Main Screen

The figure below shows the main screen of the DR60 Configurator. This screen is

accessed by opening an existing configuration, reading the device configuration or

creating a new configuration.

The DR60 Configurator is available in the following languages:

- English;

- French;

- Spanish and;

- Portuguese.

Page 30

DR60

30

DR60-TM-EN-2A

DR60 Configurator main screen

Below is described the main common menu options on the screen according to the

highlights on the figure above:

A Menu bar: New Configuration.

B Menu bar: Open Configuration.

C Menu bar: Save Configuration.

D Menu bar: Save Configuration As.

E Export Configuration Report: Exports PDF report with the configured parameters.

F Menu bar: Receive Configuration: download configuration from the DR60.

G Menu bar: Send Configuration: send configuration to the DR60.

H Menu bar: User: Shows which level of user is currently connected (Configuration, I

Administration).

I Menu bar: Exit

J Configuration tabs: contain all the device configuration divide by categories.

K Configuration sub-tabs: divide a tab the configuration into groups for ease of

configuration

L IP address of the DR60 currently connected to the DR Configurator.

M Add a new circuit or remove the selected circuit. Selecting a circuit and pressing

delete will also remove the circuit.

N Selects the nominal frequency of the system (50 Hz or 60 Hz)

1.2 Configuration Tabs

L

A B C D E F G

I J KH M

N

Page 31

DR60

31

DR60-TM-EN-2A

The settings tabs contain all configurable parameters of the equipment divided by

categories. There are seven settings tabs, as shown in the figure below.

DR60 Configurator Settings Tabs

Through the setting tabs it is possible to configure all the equipment parameters, as

detailed on the table below. The possible configurations and the procedure to configure

each parameter will be described in the next sections.

Hover the mouse cursor over the text fields of the configurable parameters to show the

range of values or the possible characters.

The table below describes the menu options:

Tab

Sub-tab

Description

General

Physical Device

(LPHD)

Contains the values and parameters of the

Physical Device logical node (LPHD), such

as: Model, Identifier, Location etc.

Analog

Bay

Arrangements

(MMXU/MMXN)

Configures name tags/descriptions and

associates the analog physical terminals to

the measurements circuits, sets the CT/VT

ratios; nominal frequency. Enables

calculations such as: RMS, power,

frequency, symmetrical components, THD,

average values, PMU and impedance fault

location

Generic Sensors

(TGSN)

Configures name parameters for the

transducer inputs ± 10V and 20 mA dc

Binary

Binary Inputs

Configures the voltage level, debouncing

time and polarity of the binary inputs.

GOOSE Inputs

Enables and configures the tags of the

GOOSE inputs

Communication

Physical

Configures parameters related to the

Ethernet and serial ports, such as: PRP

redundancy, IP Address etc.

Dataset

Adds and edits the datasets to be sent via

GOOSE of MMS

GOOSE Publisher

Associates the datasets to GOOSE Control

Blocks to be published.

Page 32

DR60

32

DR60-TM-EN-2A

GOOSE

Subscriber

Configures the GOOSE subscriptions using

the SCL files from the IEDs publishing

GOOSE.

Reports

Associates the datasets to Report Control

Blocks to be published.

C37.118.2-2011

(PMU)

Configures the communication parameters

regarding the PMU streams according to

C37.118.2-2011

DNP3

Configures the communication parameters

of the DNP3 stream

Synchronization

Synchronization

Configure the synchronization

source/protocol, timezone and daylight

saving time parameters.

Recording

Recording

Configures the parameters of the DR60

recorders (Waveform, disturbance,

continuous disturbance and SOE), such as:

pre, post time, sampling rate and others.

Triggering

Thresholds

(RADR)

Contains the thresholds to trigger the

DR60 waveform and disturbance recorder

Equations

Allows the creation of logical equations

using the DR60 variables (inputs, logical

nodes parameters).

Matrix

Configures which thresholds,

binary/GOOSE inputs or equations will

trigger the DR60 recorders. Also,

configures the DR60 binary outputs.

1.3 Status Bar

Status bar presents the software name, the connection status (if it is connected, reading

or sending configurations), and the Ethernet IP address, as shown in the figure below.

DR60 Configurator Status Bar

2 Access Levels

Page 33

DR60

33

DR60-TM-EN-2A

The DR60 Configurator has three access levels, each one with a corresponding user

name.

The MON user is able access the DR60 Logs;

The CFG user is able to access the DR60 logs, to create, receive and send configurations

and to change its own password.

The ADM user is able to do all that CFG user is able to, plus firmware update, device key

change and alter all users’ passwords.

Password is not required to access the web monitoring page

The user names and default password are presented below:

User

Password

CFG

UV@bM8DtqAN

ADM

RX8jg3S&mDx

MON

QcURcm"Gk3P

3 Communication Setup and Configuration Files Use

This section describes how to configure the communications parameters and how to

manipulate configuration files (CID), using the DR60 Configurator.

The initial screen of the DR60 Configurator application is shown in the figure below and

has the following options:

DR60 Configurator initial screen

Page 34

DR60

34

DR60-TM-EN-2A

A <New>: creates a new configuration file.

B <Receive>: receives a configuration file from the DR60 configured in the

Communication menu.

C <Open>: this button opens a file containing a pre-existing configuration.

D <Communication>: this button opens communications parameters for connecting

settings.

E <HMI>: this button opens the window containing information about the device.

F <Administrative Tools>: this button opens the window containing the following

options:

▪ Firmware update;

▪ Key update;

▪ Access control – allows changing the password for each kind of user (CFG,

ADM and MON);

▪ Support file – Downloads a support file containing internal logs used for

diagnosis.

On the initial screen, it is also possible to change the software language by clicking the

icon on the bottom right corner.

3.1 Configuring Communication Parameters

The <Communication> button on the initial screen opens the Communication Setup

screen that allows the configuration of the parameters to connect with the DR60. The

DR60 Configurator can communicate with the DR60 using serial RS232/RS485 or

Ethernet interfaces. The serial ports parameters and the IP address of the to be

connectedDR60.

The following option are available on the screen:

• Serial:

▪ Ports

▪ Speed

▪ Data Bits

▪ Parity

▪ Stop Bits

• Ethernet

▪ IP Address

▪ Name: inserts the identification name of this connection.

▪ Saved Connections: shows the name of the saved connections.

▪ <Add>: this button adds a connection name to the Saved

Connections area.

▪ <Remove>: this button removes a selected connection name from

the Saved Connections area.

Page 35

DR60

35

DR60-TM-EN-2A

3.1.1 IP Address Scanning

The DR60 Configurator is able to scan the Ethernet network and recover the IP

Addresses of the connected DR60s. This tools is useful when the IP Address of the DR60

the user wants to communicate is not known.

The IP Address Scanning tool is located on the Communication setup screen.

3.2 Creating a New Configuration File

In order to create a new configuration, click on the <New> button on the initial screen

of the DR60 Configurator.

It opens a window to configure the order code of the equipment, according to hardware

configuration.

A Order Code: the order code must be created based on the equipment hardware

configuration. On each field insert the configuration of the respective slot. The order

code of the equipment is displayed on the label affixed on the equipment. For

additional information about the formation of the order code, refer to APPENDIX A.

B <Cancel>: this button cancels the order code edition and goes back to the initial

screen of the DR60 Configurator.

C <Ok>: this button confirms the order code edition and opens the main screen of the

DR60 Configurator.

It is also possible to create a new configuration file through the Main Screen of the

DR60 Configurator, by selecting the option New CID on the File menu.

3.3 Receiving an Equipment Configuration File

To receive an online equipment configuration, click on the <Receive> button on the

initial screen of the DR60 Configurator. The configurator will communicate with the IP

Address or serial configuration configured in the Communication Setup screen and

download the DR60 current configuration loading it on the main Screen of the DR60

Configurator.

It is also possible to receive an equipment configuration file from the Main Screen of

the DR60 Configurator, by selecting the option Receive Configuration on the Menu Bar.

After clicking the Receive button, an authentication window will pop up asking for a

user and a password to complete the operation.

The possible user names and passwords are:

Page 36

DR60

36

DR60-TM-EN-2A

User

Password

CFG

UV@bM8DtqAN

ADM

RX8jg3S&mDx

3.4 Opening a Pre-existing Configuration File

In order to open a pre-existing configuration, click on the <Open> button on the initial

screen of the DR60 Configurator.

It opens the Windows© folder where the configuration files are saved:

Choose the configuration file and the Main Screen of the DR60 Configurator will open,

with the selected configuration file loaded.

It is also possible to open a configuration file from the Main Screen of the DR60

Configurator, by selecting the option Open Configuration on the menu on the Menu

Bar.

3.5 Saving a Configuration File

To save an opened configuration, select the option Save Configuration or Save

Configuration As, on the File menu of the Main Screen of the DR60 Configurator.

When saving a configuration, the DR60 Configurator will create three different files:

*.CID file: saves the communication and recorders configuration. The DR60 uses the SCL

schema 3.1 from the IEC 61850 data models;

*.st file: saves the logic equation and the matrix of I/O and triggering configuration

according to the IEC 61131 Structured Text Language (STL).

*extref: saves the external references for the GOOSE subscriber configuration.

3.6 Sending a Configuration File for the Equipment

To send a configuration file to online equipment, select the option Send Configuration,

on the Menu Bar.

4 Tools

The Tools section of the Initial screen presents two different tools:

Log: monitored and downloads the DR60 logs

Administrative Tools: Firmware upgrade, password management, equipment license

upgrade and support file download.

Page 37

DR60

37

DR60-TM-EN-2A

Upon clicking the menus, an authentication window will pop up asking for a user and a

password to complete the operation

The possible user names and passwords are:

User

Password

CFG

UV@bM8DtqAN

ADM

RX8jg3S&mDx

MON

QcURcm"Gk3P

The tools menus are described in the next sections.

4.1 LOG

The equipment maintains a history of the last 10000 system events that can be

downloaded in from the DR60. The logs visualization screen can show up to 2000

events.

The option on the Log screen are described below:

A IED Name: indicates IED Name.

B IP Address: indicates IP of the device that the software is connected to.

C Period: chooses the period of time to be displayed, from oldest to most recent.

D Codes: searches specific logs or time intervals. For example, search a log between 300

and 399, just enter 3??, and to search a list, enter 2??, 507, 700. Codes shall be entered

with 3 digits.

E <Refresh>: this button shows the list of logs according to the filtering parameters.

F <Download>: this button downloads the log files to the folder.

G Time stamp: indicates the date and time of event log (yyyymm-dd hh:mm:ss[.uuuuuu]

± 0000 (UTC time offset).

H Code: indicates the log code.

I Description: describes the log.

4.2 Administrative Tools

This menu allows the user to perform the following configurations:

▪ Access Control – allows changing the password for each kind of user (CFG,

ADM and MON);

▪ Firmware Update;

▪ License Update;

▪ Support File – Downloads a support file containing internal logs used for

diagnosis.

Page 38

DR60

38

DR60-TM-EN-2A

5 Configuration Tabs

5.1 General

The General configuration tab contains information related to the physical device logical

node (LPHD) of the DR60.

On this screen, it is shown the information of the respective device:

▪ Model (CORTEC)

▪ Vendor (General Electric Company)

▪ Hardware Version

▪ Firmware Version

▪ Serial Number

Moreover, the following parameter can be configured:

▪ Identifier: Up to 61 characters. Possible characters: a-z, A-Z, a-9, _.

▪ Location: Up to 255 characters. Possible characters: a-z, A-Z, a-9, _.

▪ Owner: Up to 255 characters. Possible characters: a-z, A-Z, a-9, _.

▪ LPHD Prefix: Up to 11 characters. Possible characters: a-z, A-Z, a-9, _.

▪ Electric Power System: Up to 255 characters. Possible characters: a-z, A-Z, a-9,

_.

▪ Primary Operator: Up to 255 characters. Possible characters: a-z, A-Z, a-9, _.

▪ Secondary Operator: Up to 255 characters. Possible characters: a-z, A-Z, a-9, _.

▪ Master Resource Identification: Up to 255 characters. Possible characters: a-z,

A-Z, a-9, _.

▪ Latitude: Possible characters: 0.0-90.0.

▪ Longitude: Possible characters: 0.0-180.0.

▪ Altitude: Possible characters: 0.0-10000.0

5.2 Analog

The Analog configuration tab contains configurations related to the analog channels and

circuits and it is divided into two sub-tabs: Instrument Transformer (TCTR/TVTR); and

Bay Arrangement (MMXU/MMXN).

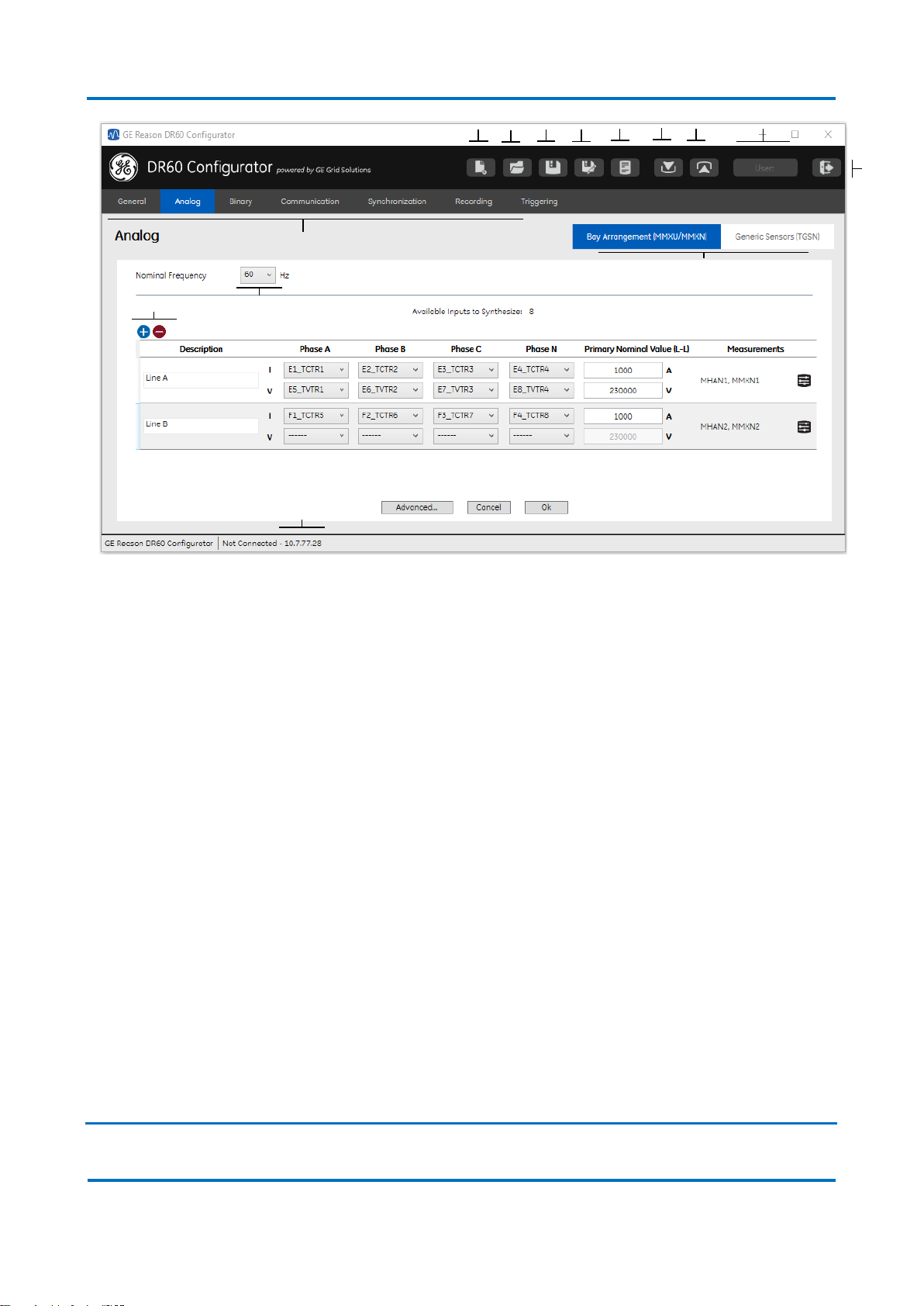

5.2.1 Bay Arrangement (MMXU/MMXN)

This window allows the configuration of the analog inputs. The configuration includes

the circuit description tag, association with physical inputs, nominal values for

Page 39

DR60

39

DR60-TM-EN-2A

instrument transformer ratio calculation; activation of: trend measurement calculation,

PMU calculation and impedance fault location.

The following configurations are available:

Current and Voltage circuits:

▪ Nominal Frequency: Selects the nominal frequency of the system between 50

Hz and 60 Hz

▪ Add a new circuit or remove the selected circuit. Selecting a circuit and

pressing delete will also remove the circuit.

▪ Description: Enters a description for the circuit. Up to 256 of any characters is

allowed.

▪ Phase A, Phase B, Phase C, Phase N: Associate each phase of the circuit with its

respective physical input

▪ Nominal Value: Configures the nominal value of the primary of the instrument

transformers. This value is used for transformer ratio calculation and

thresholds/triggers.

▪ Measurement: Shows all the logical nodes associated with the respective

circuit and by clicking the sign the following window will open.

o This window allows the following configuration:

▪ Trend calculation activation

▪ PMU Class M or P activation. The DR60 supports up to 4

PMUs, each class will count as 1 PMU even if they are from

the same circuit. When a PMU is activated a logical node

associated to it and dataset is automatically created with all

the synchrophasor, frequency and rate of change of

frequency of the respective circuit.

▪ Impedance Fault Locator calculation. The line parameters

are configured in the advanced settings right on the right

side of the window. The fault location is treated according

to the IEC 61850 logical node for fault location: RFLO. The

fault location can be sent via MMS of DNP3 by selecting the

data attribute RFLOxFltDiskm.mag.f within the MX

functional constraint.

▪ Advanced: Allows the following configuration.

▪ Name: Enter name tags for each analog input. Maximum characters: 10.

Possible characters: a-z, A-Z, a-9, _.

Page 40

DR60

40

DR60-TM-EN-2A

▪ Secondary Value: Configures the nominal value of the secondary of the CT/VT.

This configuration is only important when using the high accuracy

measurement board which can be used for 1 A or 5 A.

▪ Ratio: Shows the CT/VT ratio according to the primary and secondary values

configured.

▪ Compensation: Inserts a percentage value onto the DR60 reading of that

specific analog inputs. Possible characters: -100.0% to 100.0%.

For example:

Applied value: 100 V.

Read value: 99 V.

5.2.2 Generic Sensor (TGSN) – Transducer inputs

This subtab configures the transducer inputs.

The signal of the transducer (±10 V or 0-20 mA) is converted in to the desired physical

measurement using a first order transfer function with the parameters of Scale Factor

() and offset () defined by the user:

where is the converted value and is the value read by the DC channel in Volts or

Amps.

The screen allows the user to configure for each channel: a name, the Scale Factor A,

the Offset B and the Unit of the measurement that the transducer represents.

5.3 Binary

This configuration tab contains the parameters to configure the physical binary inputs,

enable/disable GOOSE inputs and set their name tags.

5.3.1 Binary Inputs Subtab

The following aspects related to the physical binary inputs are configured on this

subtab:

Page 41

DR60

41

DR60-TM-EN-2A

▪ Level: Selects the voltage level of the binary inputs. There are two options

available: 24/48Vdc and 125/250Vdc. The operating changes of each level is

shown in the Technical Specification Chapter. Applying voltage signals

incompatible to the Level configuration may damage the inputs.

▪ GGIO_DIGITAL: Shows the index reference of each binary input (Ind1…Indn).

▪ Name: Configures the name tags of each binary input. Maximum characters:

12. Possible characters: a-z, A-Z, a-9, _.

▪ Debouncing Time: The DR60 will only start a record once the binary activation

time (i.e. duration of the HIGH signal for the normal polatiry channels) has

exceeded the debouncing time parameter.

▪ Polarity: chooses the polarity of each input.

- Normal: LOW signals are interpreted as LOW signals and HIGH signals are

interpreted as HIGH signals.

- Inverted: HIGH signals are interpreted as LOW signals and LOW signals are

interpreted as HIGH signals.

Choose the voltage level of the binary inputs accordingly to

the voltage levels applied to them. Choosing 24/48V voltage

level and applying higher voltage levels can damage the

inputs.

The binary inputs acquisition rate is the same as the configured for the waveform

recorder. Then the waveform recorder is not enabled the binary inputs acquisition rate

is 256 samples/cycle.

5.3.2 GOOSE Inputs

This subtab allows enabling/disabling and entering a name tag for each GOOSE input.

The DR60 can handle up to 256 GOOSE inputs to record, cross-trigger and trigger

recorders.

The following parameters are available for configuration:

▪ GGIO_GOOSE: Enables or disables the corresponding GOOSE input.

▪ Name: Configures the name tags of each binary input. Maximum characters:

12. Possible characters: a-z, A-Z, a-9, _.

5.4 Communication

This configuration tab contains all the configuration related to communication to other

devices, such as: Ethernet and serial ports, PMU streams, GOOSE and Report control

blocks, GOOSE subscriber and DNP3 transmission.

5.4.1 Physical

Page 42

DR60

42

DR60-TM-EN-2A

The configuration of the physical communication ports is carried out though this

subtab.

Each Ethernet port, 1 and 2, have different addresses and it is possible to configure for

each of them:

▪ IP Address

▪ Network Mask

▪ Gateway

The Ethernet ports are used to:

Port

Usage

Ethernet 1

Configuration, monitoring, GOOSE

publication/subscription, MMS report control

block publication, firmware upgrade, log and

registers download.

Ethernet 2

Configuration, monitoring, firmware upgrade,

log and registers download.

The default settings are:

Default Setting

Parameter

Ethernet port 1

Ethernet port 2

IP Address

192.168.0.199

192.168.1.199

Network mask

255.255.255.0

255.255.255.0

Gateway

192.168.0.254

192.168.1.254

For the serial ports A (RS232) and B (RS232), the following parameters are

configurable:

▪ Speed

▪ Data Bits

▪ Parity

▪ Stop Bits

5.4.2 Datasets

The Dataset section is used to create a dataset for GOOSE or Report publishing.

The configurable parameters are described below:

▪ Datasets buttons:

▪ <New>: this buttons creates a new dataset. Clicking on this button, the dataset

parameters will appear for editing.

Page 43

DR60

43

DR60-TM-EN-2A

▪ <Edit>: this button edits a selected pre-existing dataset. Clicking on this

button, the dataset parameters will appear for editing.

▪ <Delete>: this button deletes a selected pre-existing dataset. The DigInput1

dataset cannot be deleted.

▪ Functional Constraint: selects the functional constraint that indicates the possible

operating services of a specific DataAttribute. The functional constraints are:

▪ ST: Status Information;

▪ MX: Measurements;

▪ CO: Control;

▪ SP: Setting Point;

▪ SG: Setting Group;

▪ SE: Setting Group Editable

▪ SV: Substitution

▪ CF: Configuration

▪ DC: Description

▪ EX: Extended Definition

▪ Dataset Name: inserts a name for the new dataset. Maximum characters: 32.

Possible characters: a-z, A-Z, a-9, _.

▪ Description: inserts a description for the new dataset. Maximum characters: 64.

Possible characters: except “<” and “>”.

▪ Filter: enables the user to filter the global dataset by DataAttribute names.

Note:

When selecting the data for the dataset, the IEC 61850 name for binary inputs is

DIGITALGGIO and the binary outputs as OUTPUTGGIO.

5.4.3 GOOSE Publisher

To publish GOOSE messages grouped in datasets, it is necessary to create a GOOSE

Control Block (GCB). In the GOOSE Publisher subtab it is possible to create and edit

GOOSE Control Blocks for the GOOSE messages transmission.

Each GCB is associated with one Dataset and the DR60 is able to send up to 16 GCB.

The configurable parameters are described below:

▪ GOOSE Control Block Identification

▪ Message Name: inserts a name for the GOOSE Control Block. The allowed

characters are 0-9, a-z, A-Z and ‘_’. Maximum characters: 32.

▪ Description: inserts a description for the GOOSE Control Block. The not

allowed characters are ‘<’ and ‘>’. Maximum characters: 64.

▪ GOOSE ID: inserts an identification for the GOOSE Control Block. The allowed

characters are 0-9, a-z, A-Z and ‘_’. Maximum characters: 129.

▪ Dataset: selects the dataset for this GOOSE Control Block. In this field will

appear all created datasets.

Page 44

DR60

44

DR60-TM-EN-2A

▪ Network Settings

▪ APP ID: inserts an indication of the message identifier. The identifier must

contain four hexadecimal characters. Characters range 0x0 – 0x3FFF.

▪ MAC-Address: inserts an indication of the MAC address of the originator to be

filtered. The address must be represented as six groups of hexadecimal

characters. The allowed characters are 0-9, a-f, A-F and ‘-‘.’. IEC 61850-8-1

standard recommends the MAC address for GOOSE messages creation as

following:

▪ The first three bytes are 01-0C-CD;

▪ The fourth byte must be 01 for GOOSE;

▪ Thus, the MAC address must be from 01-0C-CD-01-00-00 to 01-0C-CD-01-

01-FF.

▪ VLAN-PRIORITY: selects the VLAN priority. Such priority must be a numeric value

between 0 and 7.

▪ VLAN-ID: inserts the VLAN unique identification. Characters range 0x0 – 0xFFF.

▪ Minimum Time: inserts the maximum delay time allowed for message

transmission, after the change of the state. The range is from 1 ms to 60000 ms.

▪ Maximum Time: inserts the source supervision time. If there is none change of

state, a message is transmitted in this time. The range is from 4 ms to 60000 ms.

5.4.4 GOOSE Subscriber

The DR60 has 256 virtual GOOSE inputs that can be associated with GOOSE Booleans

values.

The configurable parameters are described below:

To associate a GOOSE Control Block with a digital input, do the following:

1 Load the SCL file from the IED sending the messages clicking “Add SCL File”.

2 On the right side, select the GOOSE Boolean that the DR60 shall subscribe to, on the

right side select the GOOSE input that will be associated with that GOOSE boolean. Only

the GOOSE inputs enabled in the Binary configuration tab will be displayed.

3 Click the “>>” button to perform the association and “<<” to undo it.

5.4.5 Reports

This screen allows the user to configure the MMS Report Control Blocks (RCB). The

Report Control Block sends internal variables grouped on a datasheet to the supervisory

system.

Each RCB is associated to one Dataset and the DR60 is able to send up to 15 buffered or

unbuffered Report Control Blocks.

The configurable parameters are described below:

Page 45

DR60

45

DR60-TM-EN-2A

Report Control Block Identification and data

▪ Message Name: inserts a name for the GOOSE Control Block. The allowed

characters are 0-9, a-z, A-Z and ‘_’. Max characters: 32.

▪ Description: inserts a description for the GOOSE Control Block. The not

allowed characters are ‘<’ and ‘>’. Max characters: 64.

▪ Report ID: Optional RCB identifier. The allowed characters are 0-9, a-z, A-Z and

‘_’. Max characters: 74.

▪ Dataset: selects the dataset for this Report Control Block. All the created

datasets will be listed here.

Options

▪ Buffered: internal events (caused by trigger options data-change, quality-

change, and data-update) issue immediate sending of reports or buffer the

events (to some practical limit) for transmission, such that values of data

object are not lost due to transport flow control constraints or loss of

connection.

▪ Buffered Time: specifies the time interval in milliseconds for the buffering of

internal notifications caused by data-change (dchg), quality-change (qchg),

dataupdate (dupd) by the BRCB for inclusion into a single report.

▪ Upon receipt of the first set of internal notification of events of the referenced

data-set, the BRCB starts a timer of the duration buffer time. When the timer

expires, the BRCB combines all internal notifications that have been received

during the time interval into a single report. The next internal notification

following the timer expiration signals the new start of that timer. Range: 1 –

1000 ms. Step 1 ms;

▪ Indexed: When checked the report control block instance names are created

from the RCB name, followed by an index number from 01 up to maximum 15.

▪ Max Instances: To allow multiple clients to receive the same values of data

object, multiple instances of the report control classes shall be made available.

Once a report control block is reserved, by a specific client, no other client

shall have access rights to set the control block attributes. Up to 16 instances

can be configured.

Trigger Options: Specifies the trigger conditions which will be monitored by this

BRCB. The following values are defined:

▪ Data Change(dchg); relates to a change in a value of a DataAttribute

representing the process-related value of the data object

▪ Quality Change(qchg); relates to a change in the quality value of a

DataAttribute.

▪ Data Update (dupd): relates to a freeze event in a value of a DataAttribute

representing a freeze value of the data object (for example, frozen counters)

or to an event triggered by updating the value of a DataAttribute. Data-update

trigger condition may be used to issue sending a report or storing a log entry

into a log when a value of a DataAttribute has updated. Updating may mean

that the value has changed or has been “overwritten” with the same value as

before. The dupd trigger condition can be used as a trigger for statistics values

that may be calculated and updated on a periodic base. Independently of

whether the statistics value has changed or not, the value will be reported or

logged.

Page 46

DR60

46

DR60-TM-EN-2A

▪ General Interrogation: After a request for General Interrogation the BRCB

starts the interrogation process and create a report that includes all

DataAttribute values of the referenced dataset.

▪ Integrity: When integrity reports are enabled, the BRCB shall be notified each

time the value of the time as specified in Integrity Period has expired. The

BRCB then builds a report with the values of all members of the referenced

data-set. Range: 1 – 1000 ms. Step 1 ms.

Note: The general-interrogation is initiated by the client. The integrity report, which

also transmits all values of a data set, is initiated by the BRCB.

Optional Fields:

▪ Sequence Number: Includes the SqNum in the report. The attribute SqNum

specifies the sequence number for each BRCB that has report enable set to

TRUE. This number is incremented by the BRCB for each report generated and

sent.

▪ Dataset: Includes DatSets in the report

▪ Data Reference: Includes the DataRef in the report

▪ Buffer Overflow: Includes the BufOvfls in the report. The parameter BufOvfl

indicates to the client that entries within the buffer may have been lost.

▪ Time Stamp: Includes the time stamp in the report.

▪ Reason Code: Includes the Reason Codes in the report, which means the

reason that generated the report according to Trigger Options

▪ Entry ID: Includes EntryID in the report.

▪ Configuration Revision: Includes the ConfRev in the report. The attribute

ConfRevshall represent a count of the number of times that the configuration

of the data-set referenced by DatSet has been changed.

Note: RMS values and frequency values are calculated and made available for MMS

communication every ¼ cycle.

5.4.6 C37.118.2-2011 (PMU)

This tab allows the configuration of the communication parameters of the PMU

streams.

For each of the 4 separate streams the following configuration is available:

▪ Enable: Enables the transmission of the respective frame

▪ ID: PMU ID according to C37.118-2011. The PMU ID code is set to uniquely

associate the synchrophasor values to the PMU responsible for producing

them. The ID ranges from 1 to 65534.

Page 47

DR60

47

DR60-TM-EN-2A

▪ Dataset: Associates the PMU stream with a PMU dataset. The PMU dataset is

created automatically when the PMU is activated for a circuit in the Analog

configuration tab and it can be edited in the Communication>Dataset tab.

▪ Frame Rate: Selects the frame rate for the respective stream. 60 fps at 60 Hz

and 50 fps at 50 Hz are available.

▪ Communication Mode: Configures the communication or operation mode of

the stream. The configurations available are: Commanded, Spontaneous

Unicast or Spontaneous Multicast.

▪ Protocol: Choses between the UDP/IP or TCP/IP transmission protocols.

▪ Source Port: Chooses the source port of the respective stream. Each stream

needs to have an exclusive port number. Multiple streams cannot be sent with

the same port number.

▪ Destinations Address: Configure the destination IP address and port number

for the spontaneous transmissions.

▪ Output Interface: In case the destination address is not in the same submask

as one of the ethernet ports, the streams will be sent through the Ethertnet 1

interface

5.4.7 DNP3

The DR60 provides DNP3 implementation level 2 for outstation equipment via both

Ethernet or serial communication.

This tab allows the configuration of the communication parameters of the DNP3

streams.

The following configuration parameters are available:

▪ Enabled: Turn on or off the DNP3 streaming.

▪ DNP3 Communication: Selects the physical interfaces that will send DNP3.

Ethernet, Serial port 1 or serial port 2.

▪ Master IP Address: IP address of the equipment reading the DNP3.

▪ Outstation Address: DNP3 address of the DR60 being configured. Range 0 to

65534.

▪ Outstation port: Port number for the DR60 being configured. 20000 is the

default and the port number registered for DNP3 use with the IANA (Internet

Assigned Numbers Authority).

▪ Application Timeout: The timeout for an application layer confirmation in

seconds. Range 0,01 to 40 s.

▪ Link Layer Timeout: The timeout for a data link layer confirmation in seconds.

Range 0,01 to 40 s.

▪ Enable Unsolicited Reporting:

▪ Server address to report to: DNP3 address of the server

(master)show

▪ Class 1, 2, 3

▪ Max Delay: Maximum time the outstation waits until sending the

data pertaining to each class in case no data state change or DNP3

threshold is exceeded.

Page 48

DR60

48

DR60-TM-EN-2A

▪ Max Events: Maximum number of events that can be buffered for

each class. Range 1 to 200.

▪ Mask: Enables the transmission of the respective DNP3 class.

Object Variation

Defines the variation of the respective object to be reported when the master

does not request any specific type.

▪ Object 1 – Binary Inputs - Options: 1 – With status; 2 – Without status

▪ Object 2 – Binary Input Event - Options: 1 – Without timestamp; 2 – With

timestamp; 3 – With relative timestamp

▪ Object 30 – Analog Input - Options: 1 – (32) Integer; 2 – (16) Integer; 3 - (32)

Integer without flag; 4 - (16) Integer without flag

▪ Object 32 – Analog Input Event - Options: 1 – (32) Integer without timestamp;

2 – (16) Integer without timestamp; 3 - (32) Integer with timestamp; 4 - (16)

Integer with timestamp

Input Selection

▪ Binary

▪ Analog

▪ Scale: Scale factor that multiplies the analog measurement

▪ Deadband: An event is triggered when the Analog input changes an

amount greater than the deadband value. A Deadband of zero

permits any change in the analog input value to generate an event,

and a Deadband of full range of the variable prevents generation of

an event

Note: Only float measurement marked with the suffix .f|MX are able to be transmitted via

DNP3.

5.5 Synchronization

5.5.1 Synchronization

The DR60 supports time synchronization with PTP IEEE1588v2 and demodulated IRIGB-

004. It is also possible to configure the DR60 to work with no time sync, just with the

internal clock.

The following parameters are found on this configuration sab:

Time source:

Page 49

DR60

49

DR60-TM-EN-2A

▪ IRIGB: sets the DR60 to be synchronized with IRIGB. No further configuration is

necessary.

▪ PTP: sets the DR60 to be synchronized with PTPv2. The PTP configuration presents

the following parameters:

5.5.2 PTP Configuration

The PTPv2 synchronization source presents the following parameters:

▪ Holdover Time: Period during which the DR60 can maintain the

synchronization quality without an external sync reference, thanks to drift of

the internal clock. Range: 5 – 60s.

▪ Network Interface: Choses the Ethernet port used for the PTP sync.

▪ Profile: Choses between the PTP profiles: Power IEEE C37.238/2011, P2P

default and Custom.

▪ Domain Number: A PTP domain is a collection of one or more PTP subdomains.

A subdomain is a logical grouping of 1588 clocks that synchronize to each

other using the PTP protocol, but that are not necessarily synchronized to PTP

clocks in another PTP subdomain. Subdomains provide a way of implementing

disjoint sets of clocks, sharing a common network, but maintaining

independent synchronization within each set. The domain number can be set

as 0, 1, 2 or 3.