GE DPVH891EK0WW, DPVH890GJ2MV, DPVH890GJ2MG, DPVH890GJ1WW, DPVH890GJ1MV Owner’s Manual

...

GEAppliances.com

Safety Instructions ........... 2-4

Operating Instructions

Controls ........................... 5-8

Cycle Options .................... 9, 10

Demand Response ................. 13

Dryer Features.................. 10,11

Quick Start Guide .................... 5

SettingsOption ..................... 10

Usingthe Dryer ..................... 12

DPVH891

DPVH890

UPVH890

S ,cheuses

Installation Instructions

Before You Begin ................ 14, 15

Connecting the Inlet Hoses ......... 17

Connecting a Gas Dryer ........ 18-21

Connecting an

Electric Dryer ................... 22-24

Exhausting the Dryer ........... 25-31

Final Setup .......................... 32

Installing the Pedestal .......... 42-44

Location of your Dryer .......... 15, 16

Reversing the Door Swing ...... 33-38

Stacking the Washer

and Dryer ....................... 39-41

Troubleshooting Tips ...... 45-48

Consumer Support

ConsumerSupport ....... BackCover

Warranty (Canada) ................. 50

Warranty (U.S.)..................... 49

Profile

La section frangaise commence _ la page 51

Secadoras

Profile

La secci6n en espafiol empieza en la p_gina :103

SAVETHESEINSTRUCTIONS

Write the model and serial

numbers here:

Model #

Serial #

Theg are on the label on the front

of the drger behind the door.

175D1807P632 49-90367 05-09 JR

IMPORTANTSAFETYINFORMATION.

READALL INSTRUCTIONSBEFOREUSING.

WARNING!

Forgour safety, the information in this manual must be followed to minimize the risk

of fire or explosion, electric shock, or to prevent property damage, persona/injury,

or death.

• Do not store or usegasoline or other

flammable vapors and liquids in the

vicinity of this or ang other appliance.

• Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

WHAT TODO IF VOUSMELLGAS:

mO.onot try to light a match, or

cigarette, or turn on any gas or

electrical appliance.

r2] Do not touch any electrical switch;

do not use any phone in your building.

[_] Clear the room, building or area

of all occupants.

California Safe Drinking Water and Toxic Enforcement Act

Thisact requiresthegovernor of Californiato publish a list of substances known to the state to cause cancer,

birth defects or other reproductive harm and requiresbusinessesto warn customers of potential exposureto

such substances.

Gosopplioncescon couse minor exposuretofour ofthese substonces,nomely benzene,corbon monoxide,

formoldehyde ond soot, coused primorily by the incompletecombustion of noturol gos or LPfuels.

Properly adjusted dryers will minimize incomplete combustion. Exposureto these substances can be

minimized further by properly venting the dryer to the outdoors.

r_ Immediately call your gas supplier

from a neighbor's phone. Follow the

gas supplier's instructions carefully.

[_] If you cannot reach your gas supplier,

call the fire department.

PROPERINSTALLATION

This dryer must be properly instolled ond Iocoted in occordonce with the Instollotion Instructions

before it is used. Instollotion Instructions ore included in the buck of this monuol.

• Properly ground dryer to conform with all ExhauslYDucting

governing codes and ordinances. Follow details

in Installation Instructions.

Installor store where it will not be exposed to

temperatures below freezing or exposed to water

or weather.

• Connectto a properly rated, protected and sized

power supply circuit to avoid electrical overload.

• Removeallsharp packing items and disposeof

olishipping moteriols properly.

2

I--_-1DryersMUSTbeexhausted to the outside to

prevent large amounts of moisture and lint from

being blown into the room.

rz1 use only rigid metol 4" diometer ductwork inside

the dryer cobinet. Useonly rigid metol or flexible

metol 4-in diometer ductwork for exhousting to

the outdoors. Neveruse plosticor other

combustible, eosy-to-puncture ductwork.

Forcomplete detoils,follow the Instollotion

Instructions.

A WARNING!

YOUR LAUNDRY AREA

GEAppliances.com

Keepthe area underneath and around your

appliances free of combustible materials,

(lint, paper,rags,etc.),gasoline,chemicals

and other flammable vapors and liquids.

Keepthe floor around your appliances clean

and dry to reducethe possibility of slipping.

Closesupervisionis necessary if this appliance is

used by or near children. Do not allow children to

play on,with or insidethis or any other appliance.

WHEN USING YOURDRYER

Neverreach into the dryer while the drum is

moving. Beforeloading, unloading or adding

clothes,wait until the drum has completely

stopped.

Cleanthe lint filter before each load to prevent lint

accumulation insidethe dryer or in the room. DO

NOTOPERATETHEDRYERWITHOUTTHELINT

FILTERIN PLACE.

Donot wash or dry articles that have been

cleaned in,washed in,soaked in or spotted

with combustible or explosivesubstances(such as

wax, oil,paint, gasoline, degreasers,dry-cleaning

solvents,kerosene,etc.).Thesesubstances give

off vapors that may ignite or explode. Donot add

these substances to the wash water. Do not use

or place these substancesaround your washer

or dryer during operation.

Donot place items exposed to cooking oilsin

your dryer. Items contaminated with cooking oils

may contribute to a chemical reaction that could

cause a clothes load to catch fire.

Any article on which you have used a cleaning

solvent or that contains flammable materials

(suchas cleaning cloths, mops,towels used in

beauty salons,restaurants or barber shops,etc.)

must not be placed in or near the dryer until

solvents or flammable materials have been

removed.Thereare many highly flammable items

usedin homes such asacetone, denatured alcohol,

gasoline, kerosene,some household cleaners,some

spot removers,turpentines, waxes, wax removers

and products containing petroleum distillates.

Keepthe area around the exhaust opening

and adjacent surrounding areas freefrom the

accumulation of lint, dust and dirt.

Keepall laundry aids(suchas detergents,

bleaches,etc.)out of the reach of children,

preferably in a locked cabinet. Observeall

warnings on container labelsto avoid injury.

• Neverclimb on or stand on the dryer top.

Thelaundry process can reduce the flame

retardancy of fabrics. Toavoid such a result,

carefully follow the garment manufacturer's

careinstructions.

Donot dry articles containing rubber,plastic

or similar materials such as padded bras,tennis

shoes,galoshes, bath mats, rugs, bibs,baby pants,

plastic bags, pillows,etc.that may melt or burn.

Somerubber materials, when heated, can under

certain circumstances producefire by spontaneous

combustion.

Donot store plastic, paper or clothing that may

burn or melt on top ofthe dryer during operation.

Garments labeled Dry Away from Heat or Do Not

TumbleDry (suchaslifejackets containing Kapok)

must not be put in your dryer.

Donot dry fiberglass articles in your dryer.

Skinirritation could result from the remaining

particles that may be picked up by clothing

during subsequent dryer uses.

Tominimizethe possibility of electric shock, unplug

this appliance from the power supply or disconnect

the dryer at the household distribution panel by

removing the fuse or switching off the circuit

breaker before attempting any maintenance or

cleaning (exceptthe removal and cleaning of the

lint filter).NOTE:PressingSTART/PAUSEor POWER

doesNOTdisconnect the appliance from the power

supply.

Ifyou seewater on the floor around the dryer,

callfor service.

IMPORTANTSAFETYINFORMATION.

READALL INSTRUCTIONSBEFOREUSING.

WARNING!

WHEN USING YOURDRYER(cont.)

Neverattempt to operate this appliance if it is •

damaged, malfunctioning, partially disassembled,

or has missing or broken parts, including a

damaged cord or plug. •

Theinterior of the machine and the exhaust duct

connection insidethe dryer should be cleaned at

least once a year by a qualified technician. See

the Sorting and Loading Hintssection on page 12.

Ifyours isa gas dryer,it isequipped with an

automatic electric ignition and does not have

a pilot light.DO NOTATTEMPTTOLIGHTWITH

A MATCH.Burnsmay result from having your hand

in the vicinity ofthe burner when the automatic

ignition turns on.

Donot open the dryer door during steam cycles.

Thesteam isvery hot and it will continue to

exhaust from the port for severalseconds after

opening. Donot touch the steam port after a

steam cycle.

Donot usea steam cycle with items such

aswool, leather,silk,lingerie, foam products

or electric blankets.

Donot usesteam cycles on new clothes without

first washing.

Youmay wish to soften your laundered fabrics

or reduce the static electricity in them by using

a dryer-applied fabric softener or an anti-static

conditioner.We recommend you useeither

a fabric softener in the wash cycle, according

to the manufacturer's instructions for those

products, or try a dryer-added product for which

the manufacturer giveswritten assurance on

the package that their product can be safely

used in your dryer.Serviceor performance

problems caused by useof these products are

the responsibility of the manufacturers of those

products and are not covered under the warranty

of this appliance.

Neverattempt to usethe Steam Dewrinkleor

Steam Refreshcycles without clothesin the drum.

Additionally, it ishighly recommended to select

the appropriate load sizefor best results.Selecting

large load cycles for small loads may result in

wetting of clothes, and selecting small load cycles

for large loads may result in poor dewrinkling

performance.

WHEN NOT USING YOURDRYER

Graspthe plug firmly when disconnecting this

appliance to avoiddamage to the cord while

pulling. Placethe cord away from traffic areas

so itwill not be stepped on, tripped over or

subjected to damage.

Donot attempt to repair or replaceany part of

this appliance or attempt any servicing unless

specificallyrecommended in this Owner's Manual

or in publisheduser-repairinstructionsthat you

understand and havethe skillsto carry out.

• Beforediscarding a dryer, or removing it from

service,removethe dryer door to prevent children

from hiding inside.

• Do not tamper with controls.

READANDFOLLOWTHISSAFETYINFORMATIONCAREFULLY.

SAVETHESEINSTRUCTIONS

/4

About the dryer controlpanel. GEAppliances.com

WARNING! To_d__h__ko_,__ _ho_ko__j_y_on_o__od_h_,_o_

SAFETY INSTRUCTIONS before operating this appliance.

Throughout this monuol, features ond oppeoroncemog vorg from gout model.

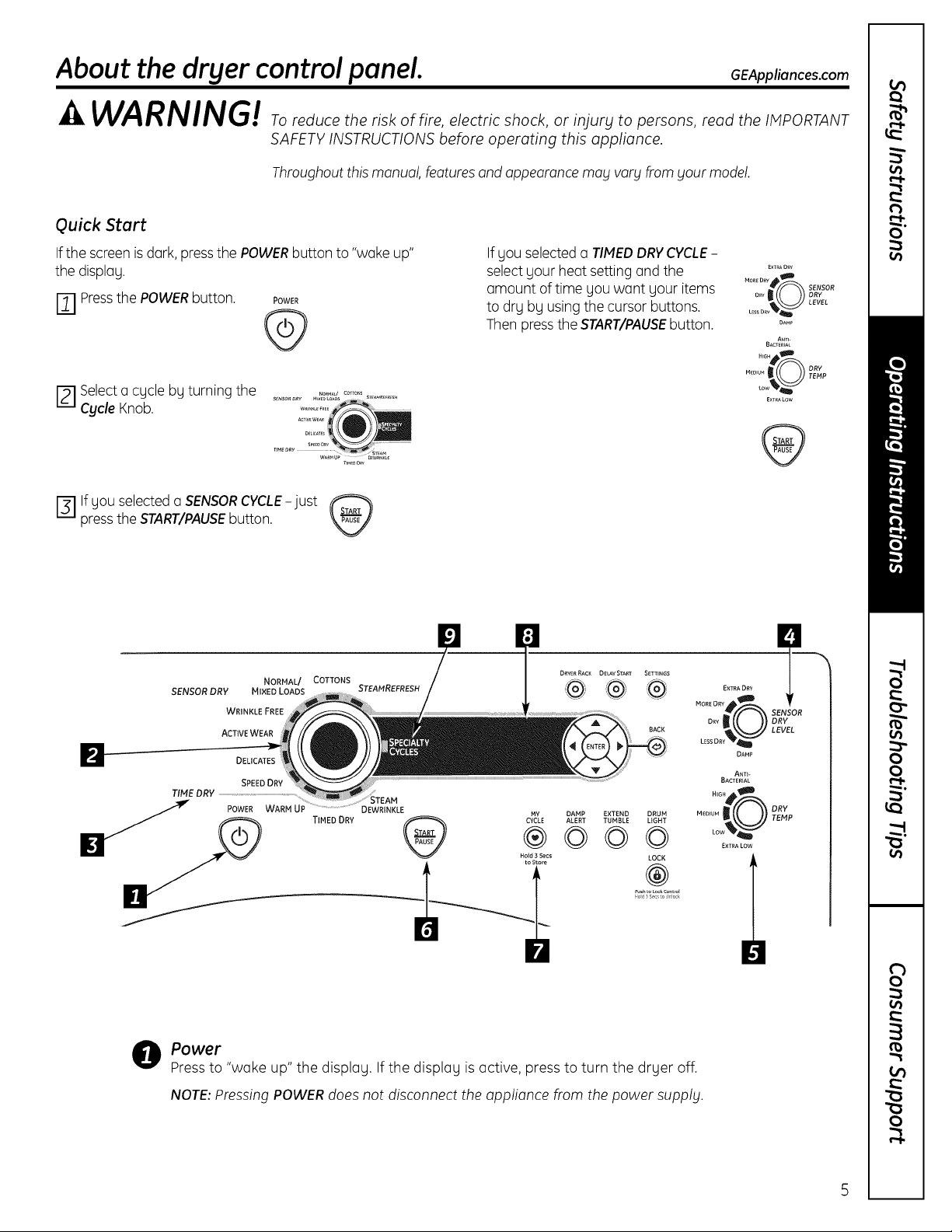

Quick Start

Ifthe screen isdork, pressthe POWERbutton to "woke up"

the displog.

[_ Pressthe POWERbutton. POWER

@

E] Selecto cgcle bg turning the

Cycle Knob.

press the START/PAUSEbutton.

lf gou selected o SENSOR CYCLE-just

SENSOR DRY

TIME DRY ..........................................................................................

_WARM UP DEWRINKL_

MIXED LOADS

WRINKLE FREE

ACTIVEWEAR

DELICATES

SPEEDDRY

NORMAL/ COTTONS

STEAMREFRESH

TIMED DRY CyMcYE

If gou selected o TIMEDDRYCYCLE-

selectgour heot setting ond the

omount oftime gou wont gour items

to drg bg using the cursor buttons.

Then pressthe START/PAUSEbutton.

DRYER RACK DELAY START SETTINGS

BACK

MORELEsIRDDRY(OR SENSORLEvELDRY

®

,t,Z4o_t__

DAMP EXTEND DRUM

ALERT TUMBLE UGHT

©©©

LOCK

M..... _ _ TD6RYI_p

®

od _s_c o Jock

EXTRA DRY

ANTI-

BACTERIAL

N_G_ _D

o_

EXTRA LOW

DAMP

E×T_AORV

MORED_Y_

DAM_

A_rl-

BACTER_At

....s_

M_ou_I _ DRY

E×TRALOW

TEMPow'_

O Power

Pressto "woke up" the displog. If the displog is octive, press to turn the drger off.

NOTE:Pressing POWER does not disconnect the applionce from thepower supplg.

About the dryer controlpanel.

Dry Cycles

The dry cycle controls the cycle time for the drying process.The chart below will help you match

the dry setting with the loads.

Sensor Cycles

COTTONS For cottons and most linens.

NORMAL/ For loads consisting of cottons and poly-blends.

MIXED LOAD

WRINKLE FREE For wrinkle-free/easy care and permanent press items.

ACTIVEWEAR Clothing worn for active sports exercise and some casual wear. Fabrics include new

technology finishes and stretch fibers such as Spandex.

DELICATES For lingerie and special-care fabrics.

SPEEDDRY For small loads that are needed in a hurry, such as sports or school uniforms. Can also be

used if the previous cycle left some items damp, such as collars or waistbands.

Timed Dry Cycles

STEAM

REFRESH

STEAM For use with larger loads than STEAMREFRESH.Ideal for loads left in dryer for an extended

DEWRINKLE time. Selecting a larger cycle than needed (e.g.,selecting Large Load for a half-full dryer)

WARM UP Provides 10 minutes of warming time to warm up clothes.

My Cycle (on some models)

MY CYCLE Pressto use, create or modify custom dry cycles.

Timed Dry

0

Use to set your own dry time. TINED DRYis also recommended for small loads.

To use TINED DRV:

1. Turn dry cycle dial to TINED DRV.

2. Select the drying time by pressing the • and • buttons. You can increase the time in lO-minute

increments up to 2V2 hours.

3. Select the DRV TEMP.

For slightly wrinkled dry garments. Significantly reduces wrinkles on 1-5 garments.

Selecting a higher number of garments for the cycle (e.g.,selecting S-garment load

for a 1-garment load) may result in excessive wetting of clothes. After the SteamRefresh

Cycle, the unit will beep and display "Garments Ready" and "0:00." If the unit is not turned

off or if the door is not opened, the dryer will continue to tumble for 30 minutes. At the end

of 30 minutes, it will display "0:00" and "Cycle Complete."

Asingle extremely light fabric item may need to have an additional item included

in the steam refresh cycle to achieve optimum results.

may result in excessive wetting of clothes.

4. Close the door.

5. Press START/PAUSE.

O Sensor Dry Level

The sensor continuously monitors the amount of moisture in the load. When the moisture in your

clothes reaches your selected dry level, the dryer will stop.

EXTRADRY Usefor heavy-duty fabrics or items that should be very dry, such as towels.

MORE DRY Usefor heavy or mixed type of fabrics.

DRY Usefor normal dryness level suitable for most loads. This isthe preferred cycle

for energy saving.

LESSDRY Use for lighter fabric (ideal for ironing).

DAMP For leaving items partially damp.

6

Dry Temp

You can change the temperature of your dry cycle.

GEAppliances.com

ANTI-BACTERIAL

HIGH

MEDIUM

LOW

EXTRA LOW

START/PAUSE

0

Pressto start o dry cycle. If the dryer is running, press it once and it will pause the dryer.

Pressit again to restart the dry cycle.

MY MUgCycle (onsomemodels)

0

CYCLE

Set up your favorite combination of settings and save them here for one touch recall.

These custom settings can be set while a cycle is in progress.

This option may only be used with COTTONSor MIXED LOAD cycles. This option reduces

certain types of bacteria by 99.9%, including: Staphylococcus oureus, Pseudomonos

oeruginoso and Ktebsiettopneumonioe*. The anti-bacterial process occurs when high

heat is used during a portion of this drying cycle.

NOTE:Do not use this cycle on delicate fabrics.

* The Anti-Bacterial Cycle is Certified by NSFinternational (formerly National Sanitation

Foundation) to NSFProtocol P154 Sonitizotion Performance of Residential Clothes Dryers.

Sanitization Pert_brmance ot

Residential Clothes Dryers

For regular to heavy cottons.

For synthetics, blends and items labeled permanent press.

For delicates, synthetics and items labeled Tumble Dry Low.

For lingerie and special-care fabrics.

To store u MY CYCLEcombinution of settings:

1. Select your drying cycle.

2. Change DRY TEMPand SENSORDRYLEVEL settings to fit your needs.

3. Select any drying OPTIONSyou want.

4. Pressand hold the MYCYCLEbutton for 3 seconds to store your selection. A beep will sound

and the button will light up.

To recull gour stored MY CYCLEcombinution:

Pressthe MY CYCLEbutton before drying a load. The light around the button will light up when

MYCYCLEis selected.

To chunge your stored MY CYCLE combinution:

Follow Steps 1-4 in "To store u MY CYCLE combinution of settings."

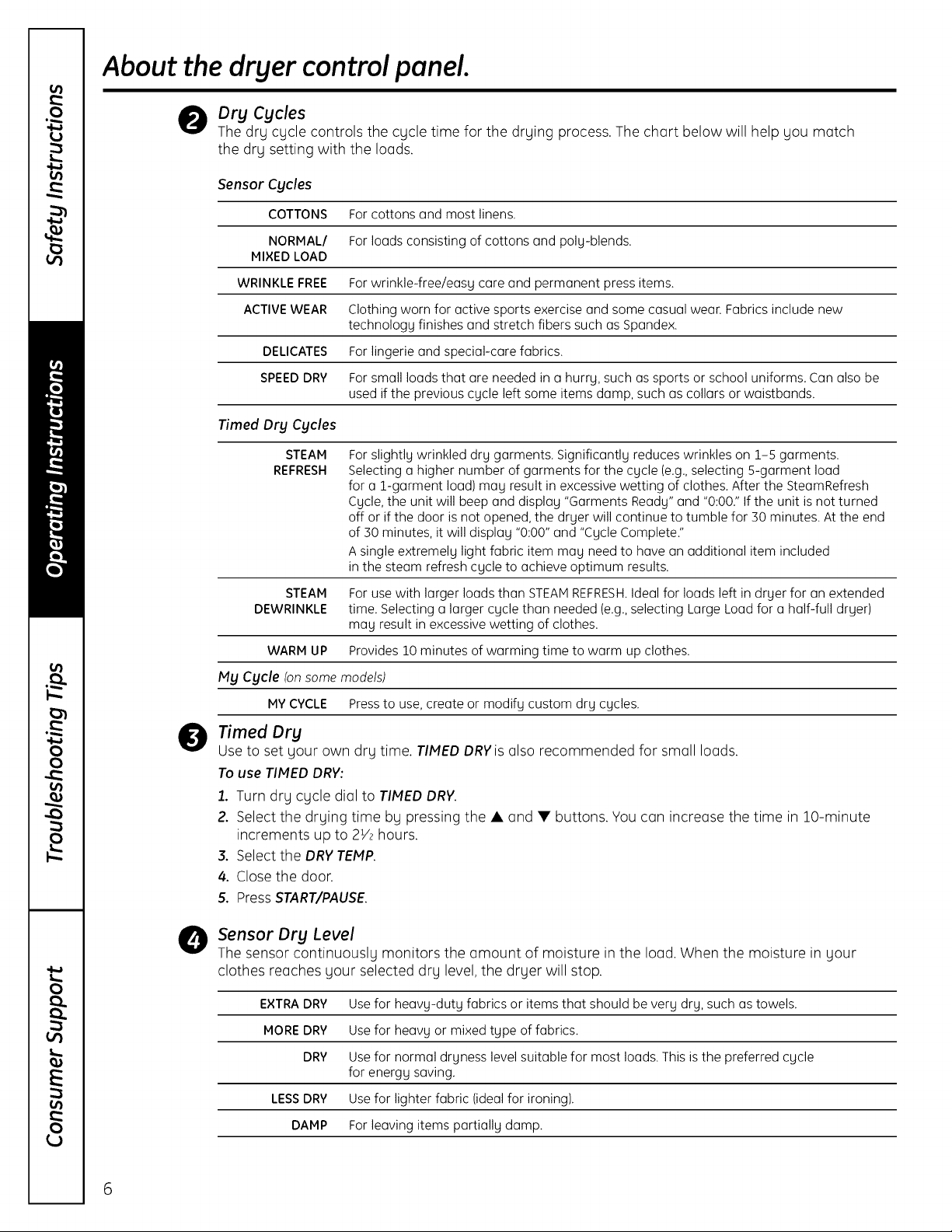

Displag

SpecialCycleStatusOR

DryerRackORTimedDry

Est.CycleTime

ORTimlt0 Dry

4(

LintFilterStatus DELAYTIME

Status Screen

"CLEAN LINT FILTER" (message)

This message stays onfor 15 minutes after the cycle finishes. This message isonlg a reminder.

About the dryer controlpanel.

Specialty Cycles

0

1. Turn the CYCLEknob to SPECIALCYCLES.Alist of cycle options will appear in the display.

2. Using the cursor buttons, select a CATEGORY.

3. Using the cursor buttons, select a CYCLE.

Pressthe BACK button to take you back to the CATEGORIES.

4. PressENTERto select.

5. Press the START/PAUSEbutton.

SPECIALTVCVCLESinclude:

Garments

• Coots

• Hosiery/Bras (use mesh bag)

•Jeans

• Khakis

Bed and Bath

• Blankets (Cotton)

• Comforters

• Sheets

• Towels

Other Specialty

• Air Fluff

• Dryel

• Fleece

• Fragile Cotton

• Performance Fabrics

• Pet Bedding

• Play Clothes

• Sleeping Bags

• Rack Dry

• Throw Rugs

Washer Communicated Cycles

Toturn on communication, pressthe

SETTINGSbutton on the washer control

panel. When "DRYERLINK"appears in the

display, press ENTER.Using the arrow keys,

select ON;then press ENTER.

When the washer cycle is completed, the

washer will communicate with the dryer

when any button on the control panel is

touched or the door isopened.

The washer will display, "TRANSFERRING

CYCLEINFORMATIONTOTHE DRYER"and

the dryer will display, "RECEIVINGCYCLE

INFORMATIONTOTHEDRYER".

8

The dryer will only communicate with the

washer if the dryer is not running a cycle.

If the washer starts a new cycle before the

dryer has a chance to communicate with

it, the information will be lost.

About cycle options.

NOTE: Not all features are available on all dryer models. GEAppliances.com

EXTEND

TUMBLE

ALERT

i i i i

DRUM

LIGHT

Extend Tumble

Minimizeswrinkles bg adding approximatelg

60 minutes of no-heat tumbling after clothes

are drg.

Thelight around the button will light up when

EXTENDTUMBLEison.

Damp Alert

Thisoption causesthe dryer to beep when

clothes havedried to a damp level.Remove

itemsthat gou wish to hang drg.The DAMP

ALERTwillonlg beepwhen this option is

selected.

Drum Light

Pressthis button to turn on the light in the

drger.

Pressthe button again to turn the light off.

ExtendTumble isautomaticallg selected

for the SteamRefreshcgcle and cannot

be deselected. Drgerwill beep and displag

"Garments Ready"when SteamRefreshis

complete. Thedryer will continue in Extend

Tumble until the door isopened.

Removingclothes and hanging them when

theg are damp can reducethe needto iron

some items.

The light around the button will light up when

DAMPALERTison.

The light around the button will light up when

DRUMLIGHTison.

Thisonlg controls the light when the door

isshut. NOTE:Thelight will turn off by itself

after oneminute when thedoor is shut.

When the door isopened,the light comes

on outomoticollg.

Delay Start

DELAYSTAR

Useto delog the start of gour drger.

1. Choose gour drg cgcle and ong options.

2. PressDELAVSTART.Youcon change the

3. PresstheSTART/PAUSEbuttontostart

Thecountdowntimewillbeshown inthe

ESTIMATEDTIMEREMAININGdisploy.

Lock

LOCK

Youcan lock the controls to prevent ang

selectionsfrom being made. Or gou can lock

the controls after gou have started a cgcle.

delog time in 1/2-hour increments,using

the• or• arrowpads,

thecountdown,

NOTES:

• If the door is opened while the drger is

in DELAY, the countdown time will not

restart unless the door is closed and

START/PAUSEbutton has been pressed

again.

• You can delag the start of a drg cgcle up

to 24 hours,

Thelight around the button will light up when

DELAYSTARTison.

Tolock the drger, pressthe LOCKbutton.

Tounlock the drger,press and hold the LOCK

button for 3 seconds.

_iI ii i

Press to lock control.

Hold 3 seconds to unlock.

Children cannot accidentallg start the drger

bg touching pads with this option selected.

Thelight around the LOCKbutton will light up

when the controls ore locked.

Eventhough the controls ore locked,the

POWERbutton isstill active in case gou hove

to turn the unit off.

9

About cycle options.

NOTE: Not all features are available on all dryer models.

Settings

SETTINGS

About dryer features.

Under the SETTINGSoption, you can

adjust the volume or the brightness of

the display.

VOLUME

• End of Cycle (signal) volume can be set

from HIGH, MED, LOW or OFF.

• Control Sounds volume can be set from

HIGH, MED,LOW or OFF.

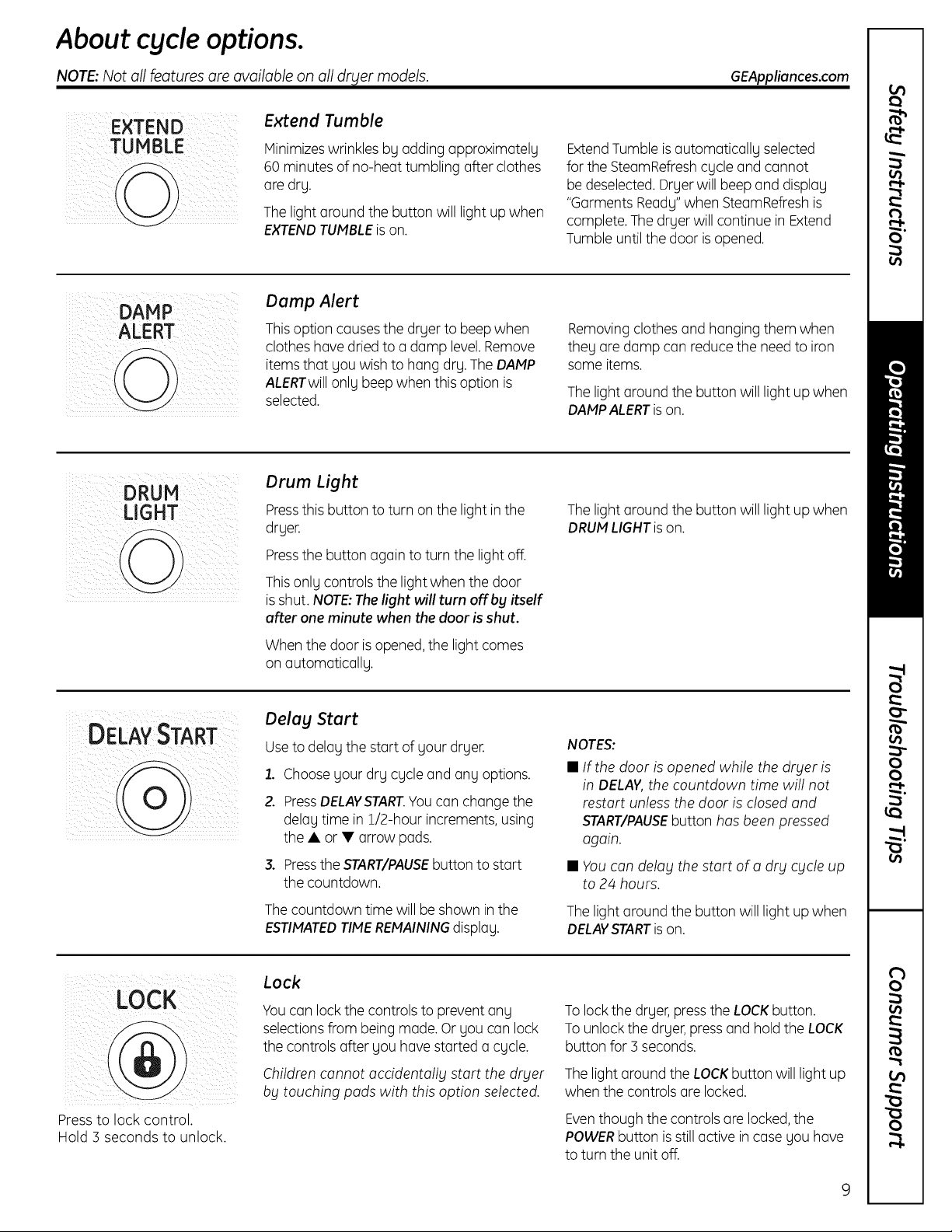

Drum Lamp

Before replacing the light bulb, be sure to unplug the dryer power cord or

disconnect the dryer at the household distribution panel by removing the

fuse or switching off the circuit breaker. Reach above dryer opening from

inside the drum. Removethe bulb and replace with the same size bulb.

DISPLAV BRIGHTNESS can be set from

HIGH, MED or LOW.

After you have made your selection,

press ENTER.

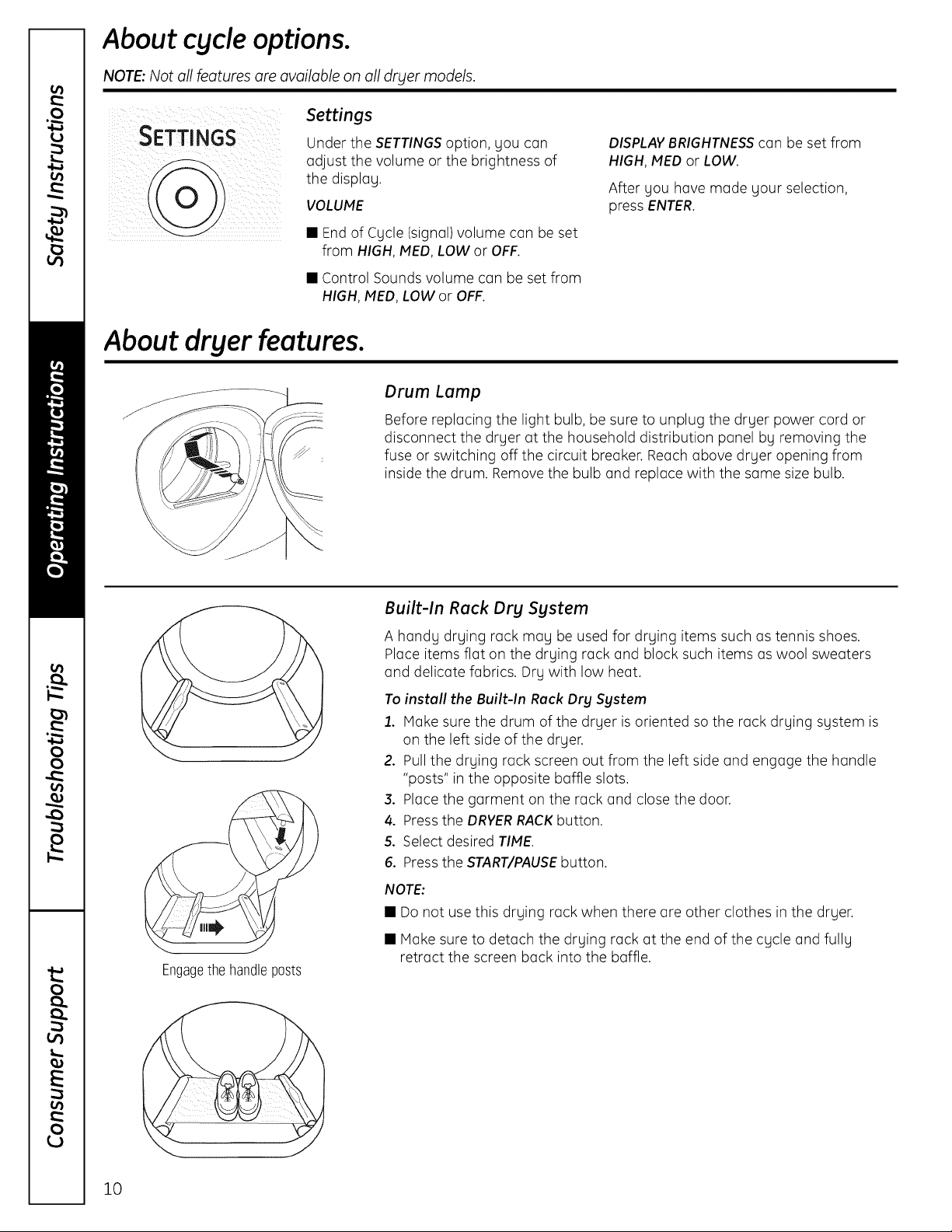

Engagethehandleposts

Built-In Rack Dry System

A handy drying rack may be used for drying items such as tennis shoes.

Place items flat on the drying rack and block such items as wool sweaters

and delicate fabrics. Dry with low heat.

To install the Built-In Rack Dry System

1. Hake sure the drum of the dryer is oriented so the rack drying system is

on the left side of the dryer.

2. Pull the drying rack screen out from the left side and engage the handle

"posts" in the opposite baffle slots.

3. Place the garment on the rack and close the door.

4. Press the DRVERRACKbutton.

5. Select desired TIME.

6. Press the START/PAUSEbutton.

NOTE:

• Do not use this drying rack when there are other clothes in the dryer.

• Make sure to detach the drying rack at the end of the cycle and fully

retract the screen back into the baffle.

10

GEApplionces.com

To Use the Built-In Hook

for Hanging Garments

1. Make sure the drum of the drger is

oriented so the hook is on the top

center of the drger.

2. Using gour finger, pull the hook out

of the baffle.

3. Hang the garment on a hanger,

hang the hanger on the hook and

close the door.

4. Pressthe DRYERRACKbutton.

5. Select the desired time.

6, Pressthe START/PAUSEbutton.

Reverse Tumble TM

All Profile front-load matching drgers are equipped with the Reverse TumbleT"

feature, as part of the Duo Drg Plussgstem T'.Bg reversing the direction

of drum rotation during the drging cgcle, gour drger will tangle the clothes

load less,drg more evenlg and improve drging times. Tgpical loads such

as bed and bath mixed loads, where sheets, towels and pillow cases are

laundered together, benefit from this capabilitg. When the drger reverses

direction, there will be a slight pause and sound change. This is normal.

All drger cgcles utilize this feature, except when the rack drg option is selected,

in which case the drum does not tumble.

11

Using the dryer.

Always follow fabric manufacturer's care label when laundering.

Sorting and Loading Hints

Aso general rule,if clothes ore sorted

properly for the washer,they ore sorted

properly for the dryer.Try also to sort items

according to size.Forexample, do not dry

o sheet with socksor other small items.

Do not odd fabric softener sheetsonce

the load has become worm. They may

cause fabric softener stains. Bounce®

Fabric Conditioner Dryer Sheets hove

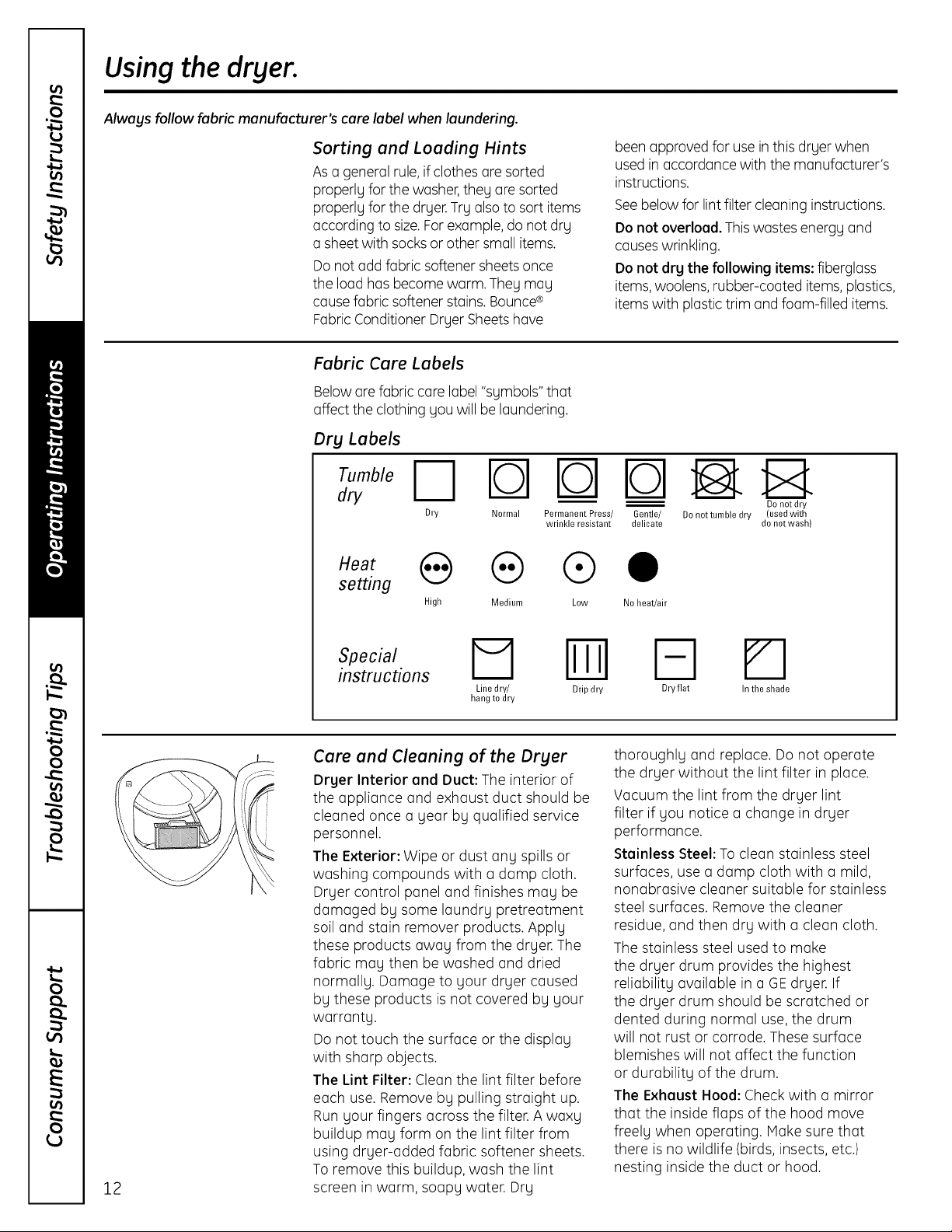

Fabric Care Labels

Belowore fabric care label "symbols" that

affect the clothing you will be laundering.

Dry Labels

dry

Dry Normal Permanent Press/

wrinkle resistant

setting

High Medium Low

been approved for use inthis dryer when

used in accordance with the manufacturer's

instructions.

Seebelow for lintfilter cleaning instructions.

Do not overload. Thiswastes energy and

causeswrinkling.

Do not dry the following items: fiberglass

items,woolens, rubber-coated items, plastics,

items with plastictrim and foam-filled items.

b-qE

Gentle/ De net tumble dry (used with

delicate do not wash)

0

No heat/air

Do not dry

12

instructions

rq Iml

Line dry/ Drip dry

hang to dry

Care and Cleaning of the Dryer

Dryer Interior and Duct: The interior of

the appliance and exhaust duct should be

cleaned once o year by qualified service

personnel.

The Exterior: Wipe or dust any spills or

washing compounds with o damp cloth.

Dryer control panel and finishes may be

damaged by some laundry pretreotment

soil and stain remover products. Apply

these products away from the dryer. The

fabric may then be washed and dried

normally. Damage to your dryer caused

by these products isnot covered by your

warranty.

Do not touch the surface or the display

with sharp objects.

The Lint Filter: Clean the lint filter before

each use. Remove by pulling straight up.

Run your fingers across the filter. A waxy

buildup may form on the lint filter from

using dryer-added fabric softener sheets.

To remove this buildup, wash the lint

screen in warm, soapy water. Dry

Fq

Dry flat

thoroughly and replace. Do not operate

the dryer without the lint filter in place.

Vacuum the lint from the dryer lint

filter if you notice a change in dryer

performance.

Stainless Steel: To clean stainless steel

surfaces, use a damp cloth with a mild,

nonabrasive cleaner suitable for stainless

steel surfaces. Remove the cleaner

residue, and then dry with a clean cloth.

The stainless steel used to make

the dryer drum provides the highest

reliability available in a GEdryer. If

the dryer drum should be scratched or

dented during normal use, the drum

will not rust or corrode. These surface

blemishes will not affect the function

or durability of the drum.

The Exhaust Hood: Check with o mirror

that the inside flaps of the hood move

freely when operating. Hake sure that

there isno wildlife (birds, insects, etc.)

nesting inside the duct or hood.

In the shade

Demand Response. (onsome models) GEAppliunces.com

ModelDPVH891iscompatiblewith the GEDemandResponse

(DR)modulewhich can be purchasedseparately.Contactyour

localutility or visit www.GEApptionces.com/demondresponse

to seeif your area is usingDRtechnology.

Thefollowing demand responsefeaturesare availableas part

of a pilottest program with the local utility company to help

consumersreducepeakelectricity usageinthe home.

Instollotion

Thepreferredlocationfor the module installationison top

ofthe clothesdryer.

Detailson howto connectthe cablesto the moduleare

in the instructionsthat comewith the module.

Wait 5 minutes;then pressthe Settingsbutton.Scrolland

lookfor the energy management screen as seen below.

Settings Menu

PressSETTINGS;then select Energg Management.

OelogEcoOverride

If gouare starting a cgcle ina Criticalor HighutilitNrate,this

option allowsthe unit to automaticallNrunon an EcoCgcle.This

settingwill operatewith lessenergNthan normal cgcles.Default

setting isYES.

Auto-ExtendOelo_lS

Ifatimed delaNisselected,this option allowsfor the scheduled

start to extend ifthe utilitNrate isCriticalor High at the

scheduledstart. Thedefaultsettingwill automaticallNextend

thesecgcles.

Er_er.gy !"!anager__e.r_t.

Thisscreenmeansthe moduleisattached correctlgand

gou canbeginto use gour DR-enabledappliancefollowing

the instructionsbelow.

If the EnergyManagementScreenisnot available,refer to

the DRmoduletroubleshootingguide.

Quick Guide

Thereare 4 power levelsavailable:Critical,High,Mediumand

Low.Onthe Mediumand Low levels,the unit runsas normal.

Thefollowing stepsshow howthe unit reactsduringstartup

at Criticaland Highpowerlevels.

Option1 (Oelo_lEco)

Duringstartupsat Criticaland Highlevels,the unitwill delag

starting untilthe levelbecomesMediumor Low.Pressthe

START/PAUSEbutton.

Option2 (OverrideOelo_lEco)

Tostart the unitwhen DelaNEcoisshown,pressthe DELAY

STARTbuttonto turn the delaNoff.ThenpressSTART/PAUSE

to beginthe cgcle.

TimedOralEcoOption

Ifthe unit is running inTimed DrNModeandthe utilitNrate

switchesto Critical or High,the unitwill conserveenergNbN

decreasingheatif YES(default)isselected.IfNOisselected,the

unitwill operatenormallN.

NOTE:When YES(default)isselected,gour loadmaNbedamp

at the end ofthe cgcle.

Inorderfor the demandresponsefeatureson the applianceto

work,additionalequipment isrequiredto be installedto interface

with the local utilitN.SuchequipmentmaNbe soldseparatelN

and/or isavailablethroughgour utilitNaspart of the pilottest

program.Checkwith gour utilitNcompanNto seeif a pilottest

programisavailablein gour area and for full details.

PLEASENOTE:Atthe conclusionof the pilottest programor if

goumoveto an areawherethe program isnotavailable,the

demandresponsefeaturescannot be activatedand utilizedon

the appliance.Theappliance willfunction as normalafter the

demandresponseequipment has beendeactivatedor

disconnected.

ii

13

Installation

Dryer

Instructions

In Canada, call 1.800.561.3344 or visit www.GEAppliances.ca

I uestions? Call 800.GE.CARES (800.432.2737) or visit our Web site at: GEAppliances.com

BEFORE YOU BEGIN

Readthese instructions completely and carefully.

• IMPORTANT-Save theseinstructionsforlocal

electrical inspector's use.

• IMPORTANT-Observe all governing codes and

ordinances.

• Installthe clothes dryer according to the manufacturer's

instructions and local codes.

• Note to Installer- Besure to leave these instructions

with the Consumer.

• Note to Consumer - Keepthese instructions for future

reference.

• Clothes dryer installation must be performed by a

qualified installer.

• This dryer must be exhausted to the outdoors.

• Beforethe old dryer is removed from service or

discarded, remove the dryer door.

• Service information and the wiring diagram are located

in the control console.

• Donot allow children on or in the appliance. Close

supervision of children isnecessary when the appliance

is used near children.

• Proper installation isthe responsibility of the installer.

• Product failure due to improper installation is not

covered under the Warranty.

• Install the dryer where the temperature is above 50°F

for satisfactory operation of the dryer control system.

• Removeand discard existing plastic or metal foil duct

and replace with UL-listed duct.

CALIFORNIA SAFE DRINKING WATER AND

TOXIC ENFORCEMENT ACT

This act requires the governor of California to publish a

list of substances known to the state to cause cancer,

birth defects or other reproductive harm and requires

businesses to warn customers of potential exposure to

such substances. Gasappliances can cause minor

exposure to four of these substances, namely benzene,

carbon monoxide, formaldehyde and soot, caused

primarily by the incomplete combustion of natural gas

or LPfuels. Properly adjusted dryers will minimize

incomplete combustion. Exposure to these substances

can be minimized further by properly venting the dryer

to the outdoors.

DPVH891o DPVH890o

FOR YOUR SAFETY:

_aWA RNING- .is,o,Fire

• To reduce the risk of severe injury or death, follow

all installation instructions.

• Clothes dryer installation must be performed by a

qualified installer.

• Install the clothes dryer according to these

instructions and in accordance with local codes.

This dryer must be exhausted to the outdoors.

Use only 4" rigid metal ducting for exhausting the

clothes dryer to the outdoors.

DO NOT install a clothes dryer with flexible plastic

ducting materials. If flexible metal (semi-rigid or

foil-type) duct is installed, it must be UL-listed and

installed in accordance with the instructions found

in "Connecting the Dryer to House Vent" on page 26

of this manual. Flexible ducting materials are known

to collapse, be easily crushed and trap lint. These

conditions will obstruct dryer airflow and increase

the risk of fire.

• Do not install or store this appliance in any location

where it could be exposed to water and/or weather.

• Save these instructions. (Installers: Be sure to leave

these instructions with the customer.)

FOR GAS MODELS ONLY:

NOTE: Installation and service of this dryer must be

performed bg a qualified installer, service agency or

the gas supplier.

In the Commonwealth of Massachusetts:

• This product must be installed bg a licensed

plumber or gas fitter.

• When using ball-type gas shut-off valves, they

shall be T-handle-type.

• A flexible gas connector, when used, must not

exceed 3 feet.

UPVH890

I

14

Installation Instructions

UNPACKING YOUR DRYER

Tilt the dryer sideways and remove the foam

shipping pads by pulling at the sides and breaking

them away from the dryer legs. Be sure to remove

all of the foam pieces around the legs.

Remove the bag containing the literature and serial

cable.

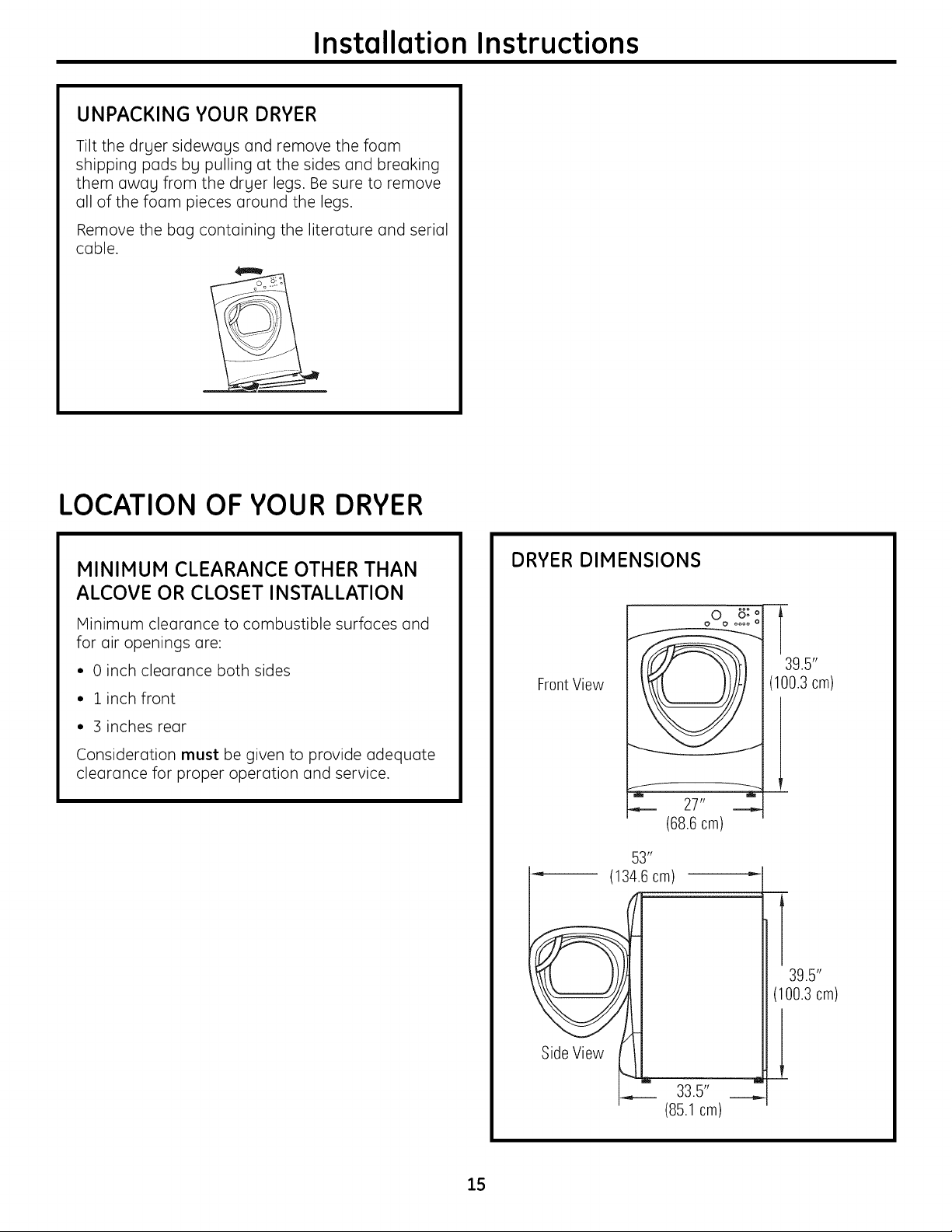

LOCATION OF YOUR DRYER

MINIMUM CLEARANCE OTHER THAN

ALCOVE OR CLOSET INSTALLATION

Minimum clearance to combustible surfaces and

for air openings are:

• 0 inch clearance both sides

• 1 inch front

• 3 inches rear

Consideration must be given to provide adequate

clearance for proper operation and service.

DRYER DIMENSIONS

FrontView

f _

(68.6cm)

53 _'

'_ (134.6cm)

oO_ 8: o

27"

oooo o

T

39.5"

(100.3 cm)

15

39.5"

(100.3cm)

Side View

33.5" __,,,

(85.1 cm)

Instollotion Instructions

REQUIREMENTS FOR ALCOVE OR

CLOSET INSTALLATION

• Your dryer is approved for installation in

an alcove or closet, as stated on a label on

the dryer back.

• The dryer MUST be vented to the outdoors. See

the EXHAUSTING THE DRYERsection.

• Minimum clearance between dryer cabinet and

adjacent walls or other surfaces is:

0" either side

::3"front and rear

• Minimum vertical space from floor to overhead

shelves, cabinets, ceilings, etc., is 52".

• Closet doors must be Iouvered or otherwise

ventilated and have at least 60 square inches

of open area equally distributed. If the closet

contains both a washer and a dryer, doors must

contain a minimum of 120 square inches of open

area equally distributed.

• The closet should be vented to the outdoors

to prevent gas pocketing in case of gas in the

supply line.

• No other fuel-burning appliance shall be

installed in the same closet with the dryer

(gas models only).

NOTE: WHEN THE EXHAUST DUCT IS LOCATEDAT

THE REAROF THE DRYER, MINIMUM CLEARANCE

FROM THE WALL IS 5.5 INCHES.

BATHROOM OR BEDROOM

INSTALLATION

• The dryer MUST be vented to the outdoors. See

EXHAUSTING THE DRYER.

• The installation must conform with local codes or,

in the absence of local codes, with the NATIONAL

ELECTRICALCODE, ANSI/NFPA NO. 70 (for electric

dryers) or NATIONAL FUEL GAS CODE, ANSI Z223

(for gas dryers).

MOBILE OR MANUFACTURED HOME

INSTALLATION

• The installation must conform to the

MANUFACTURED HOME CONSTRUCTION & SAFETY

STANDARD, TITLE 24, PART:32-80 or, when such

standard isnot applicable, with AMERICAN

NATIONAL STANDARD FOR MOBILE HOME,

NO. 50lB.

• The dryer MUST be vented to the outdoors with

the termination securely fastened to the mobile

home structure. (See EXHAUSTING THE DRYER.)

• The vent MUST NOT be terminoted beneoth o

mobile or manufactured home.

• The vent duct moteriol MUST BE METAL.

• FOR GAS MODELS ONLY: KIT 14-D346-33 MUST be

used to ottoch the dryer securely to the structure.

• FOR GAS MODELS ONLY: The vent MUST NOT be

connected to any other duct, vent or chimney.

• Do not use sheet metol screws or other

refustening devices which extend into the interior

of the exhaust vent.

• Provide an opening with u free urea of at least

25 sq. in. for introduction of outside air into the

dryer room.

16

Installation Instructions

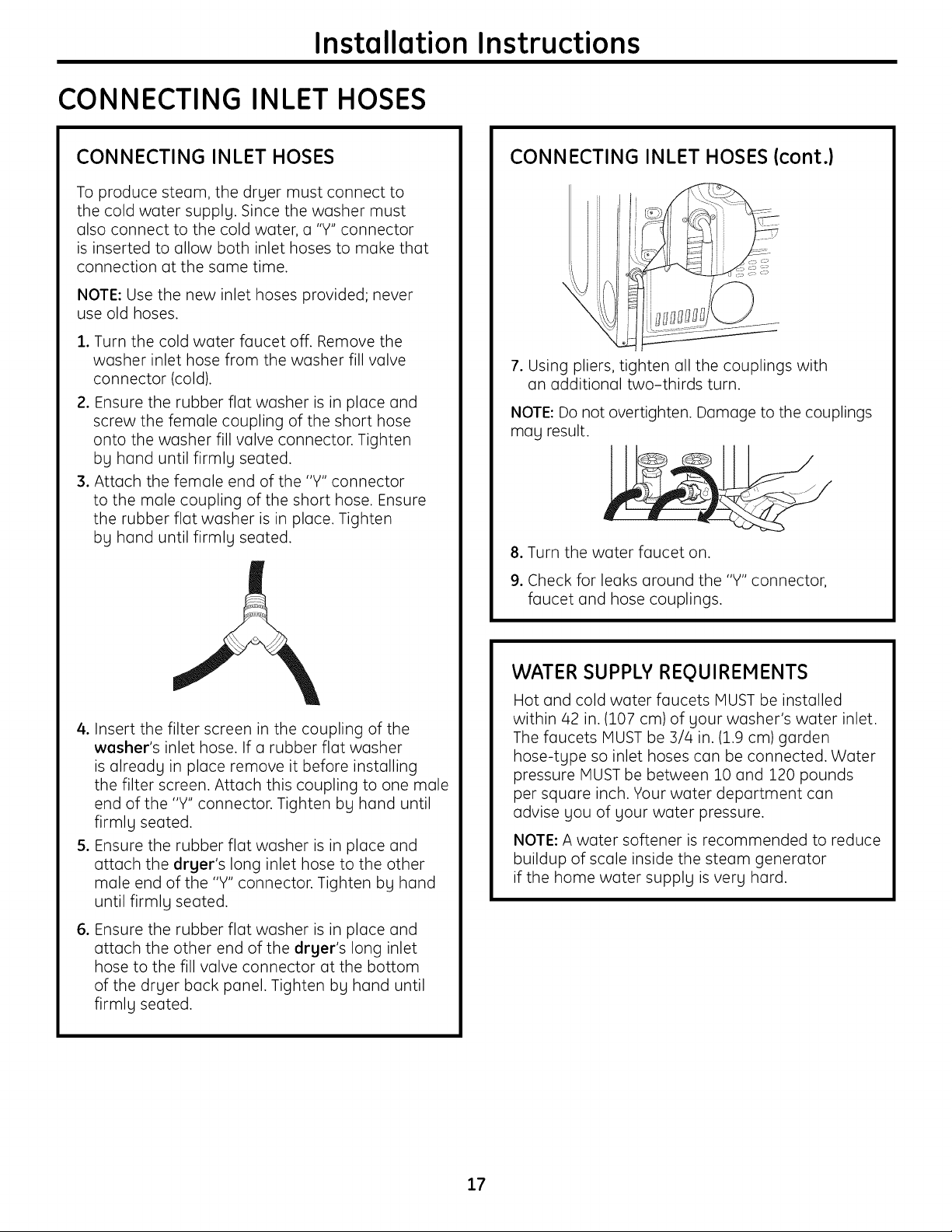

CONNECTING INLET HOSES

CONNECTING INLET HOSES

To produce steam, the dryer must connect to

the cold water supply. Since the washer must

also connect to the cold water, a "Y" connector

is inserted to allow both inlet hoses to make that

connection at the same time.

NOTE: Use the new inlet hoses provided; never

use old hoses.

, Turn the cold water faucet off. Remove the

washer inlet hose from the washer fill valve

connector (cold).

2. Ensure the rubber flat washer is in place and

screw the female coupling of the short hose

onto the washer fill valve connector. Tighten

by hand until firmly seated.

3. Attach the female end of the "Y" connector

to the male coupling of the short hose. Ensure

the rubber flat washer is in place. Tighten

by hand until firmly seated.

CONNECTING INLET HOSES {cont.}

7. Using pliers, tighten all the couplings with

an additional two-thirds turn.

NOTE: Do not overtighten. Damage to the couplings

may result.

8. Turn the water faucet on.

9. Check for leaks around the "Y" connector,

faucet and hose couplings.

4. Insert the filter screen in the coupling of the

washer's inlet hose. If a rubber flat washer

is already in place remove it before installing

the filter screen. Attach this coupling to one male

end of the "Y" connector. Tighten by hand until

firmly seated.

5. Ensure the rubber flat washer is in place and

attach the dryer's long inlet hose to the other

male end of the "Y" connector. Tighten by hand

until firmly seated.

,

Ensure the rubber flat washer is in place and

attach the other end of the dryer's long inlet

hose to the fill valve connector at the bottom

of the dryer back panel. Tighten by hand until

firmly seated.

WATER SUPPLY REQUIREMENTS

Hot and cold water faucets MUST be installed

within/42 in. (107 cm) of your washer's water inlet.

The faucets MUST be ::3//4in. (1.9 cm) garden

hose-type so inlet hoses can be connected. Water

pressure MUST be between 10 and 120 pounds

per square inch. Your water department can

advise you of your water pressure.

NOTE: A water softener is recommended to reduce

buildup of scale inside the steam generator

if the home water supply is very hard.

17

Installation Instructions

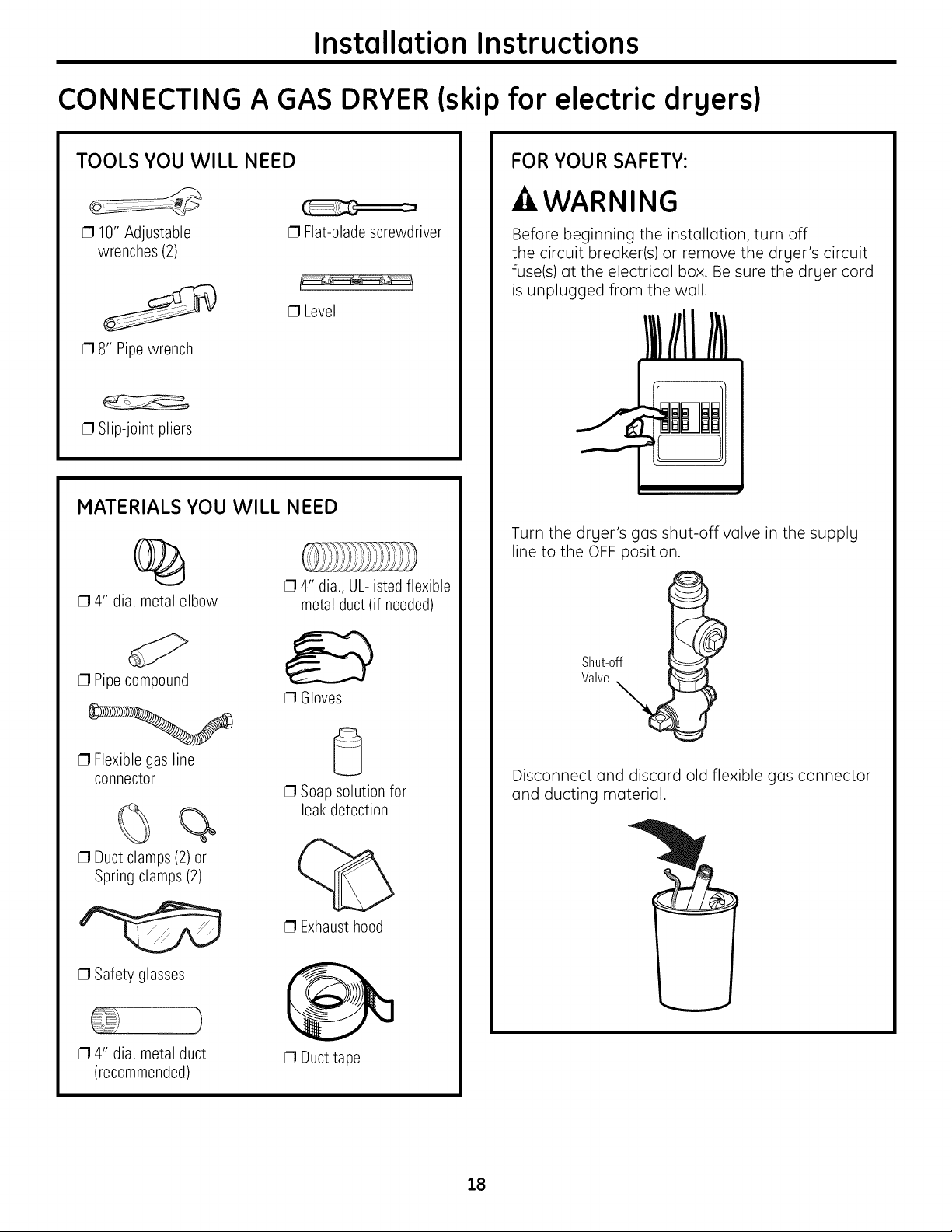

CONNECTING A GAS DRYER(skip for electric dryers)

TOOLS YOU WILL NEED

[] 10" Adjustable

wrenches (2)

[] 8" Pipe wrench

[] Slip-joint pliers

[] Flat-blade screwdriver

[] Level

MATERIALS YOU WILL NEED

%

[] 4" dia. metal elbow

[] 4" dia., UL-listedflexible

metal duct (if needed)

FOR YOUR SAFETY:

-AWARNING

Before beginning the installation, turn off

the circuit breaker(s) or remove the dryer's circuit

fuse(s) at the electrical box. Be sure the dryer cord

is unplugged from the wall.

Turn the dryer's gas shut-off valve in the supply

line to the OFF position.

[] Pipecompound

[] Flexible gas line

connector

%

[] Duct clamps(2) or

Spring clamps (2)

[] Safety glasses

[] 4" dia. metal duct

(recommended)

[] Gloves

[] Soap solution for

leakdetection

[] Exhausthood

[] Duct tape

Shut-off

Valve

Disconnect and discard old flexible gas connector

and ducting material.

18

Installation Instructions

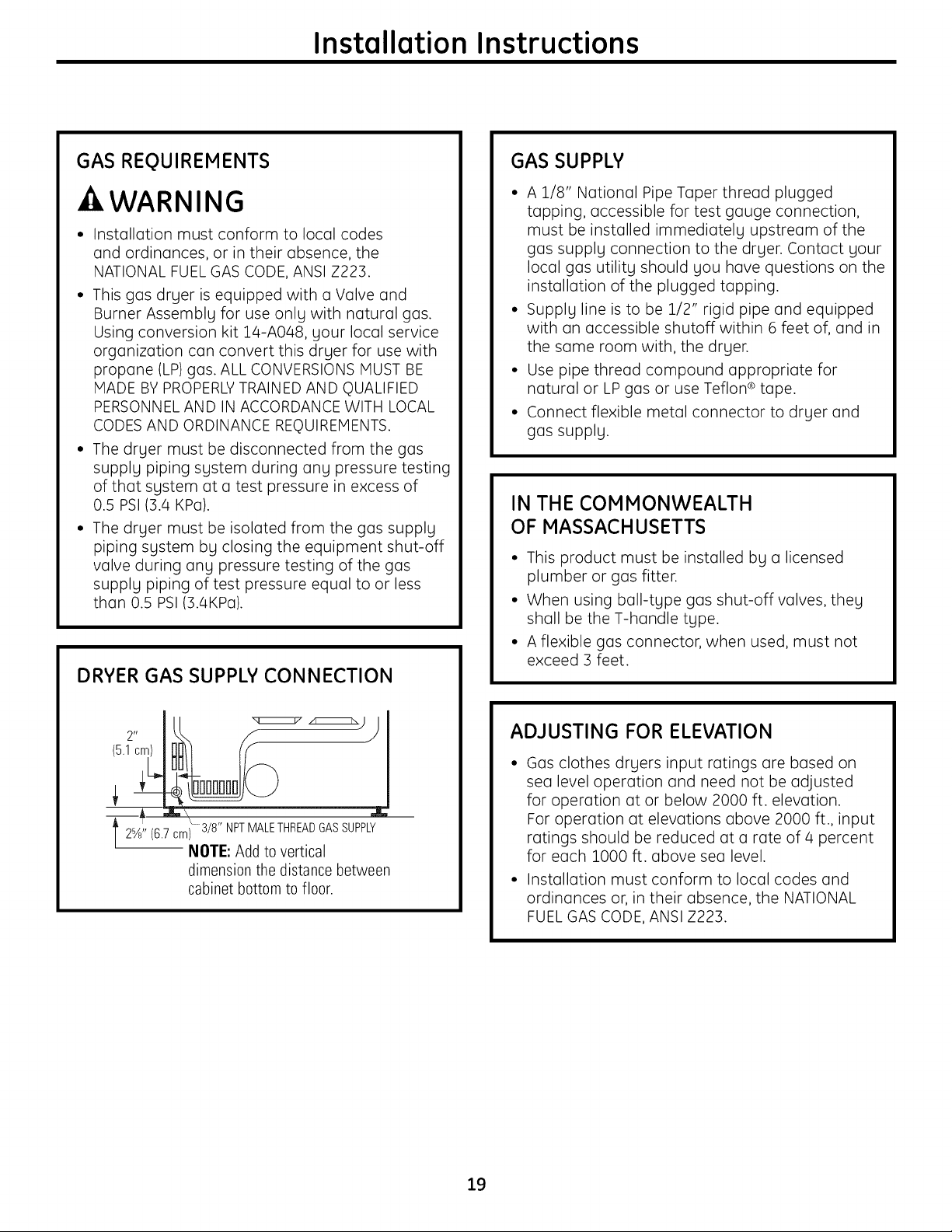

GAS REQUIREMENTS

-AWARNING

Installation must conform to local codes

and ordinances, or in their absence, the

NATIONAL FUELGAS CODE, ANSI Z223.

• This gas dryer is equipped with a Valve and

Burner Assembly for use only with natural gas.

Using conversion kit ]_4-A048, your local service

organization can convert this dryer for use with

propane (LP)gas. ALL CONVERSIONS MUST BE

MADE BY PROPERLYTRAINED AND QUALIFIED

PERSONNEL AND IN ACCORDANCE WITH LOCAL

CODES AND ORDINANCE REQUIREMENTS.

• The dryer must be disconnected from the gas

supply piping system during any pressure testing

of that system at a test pressure in excess of

0.5 PSi (3.4 KPa).

The dryer must be isolated from the gas supply

piping system by closing the equipment shut-off

valve during any pressure testing of the gas

supply piping of test pressure equal to or less

than 0.5 PSi(3.4KPa).

DRYER GAS SUPPLY CONNECTION

GAS SUPPLY

• A 1/8" National Pipe Taper thread plugged

tapping, accessible for test gauge connection,

must be installed immediately upstream of the

gas supply connection to the dryer. Contact your

local gas utility should you have questions on the

installation of the plugged tapping.

• Supply line is to be 1/2" rigid pipe and equipped

with an accessible shutoff within 6 feet of, and in

the same room with, the dryer.

• Use pipe thread compound appropriate for

natural or LPgas or use Teflon ®tape.

• Connect flexible metal connector to dryer and

gas supply.

IN THE COMMONWEALTH

OF MASSACHUSETTS

• This product must be installed by a licensed

plumber or gas fitter.

• When using ball-type gas shut-off valves, they

shall be the T-handle type.

• A flexible gas connector, when used, must not

exceed 3 feet.

2- lu

2%' (6.7.cm) 3/8" NPTMALETHREADGASSUPPLY

/

NOTE: Add to vertical

dimension the distance between

cabinet bottom to floor.

ADJUSTING FOR ELEVATION

Gas clothes dryers input ratings are based on

sea level operation and need not be adjusted

for operation at or below 2000 ft. elevation.

For operation at elevations above 2000 ft., input

ratings should be reduced at a rate of/4 percent

for each 1OOOft. above sea level.

Installation must conform to local codes and

ordinances or, in their absence, the NATIONAL

FUEL GAS CODE, ANSI Z223.

19

Installation Instructions

CONNECTING A GAS DRYER (cont.)

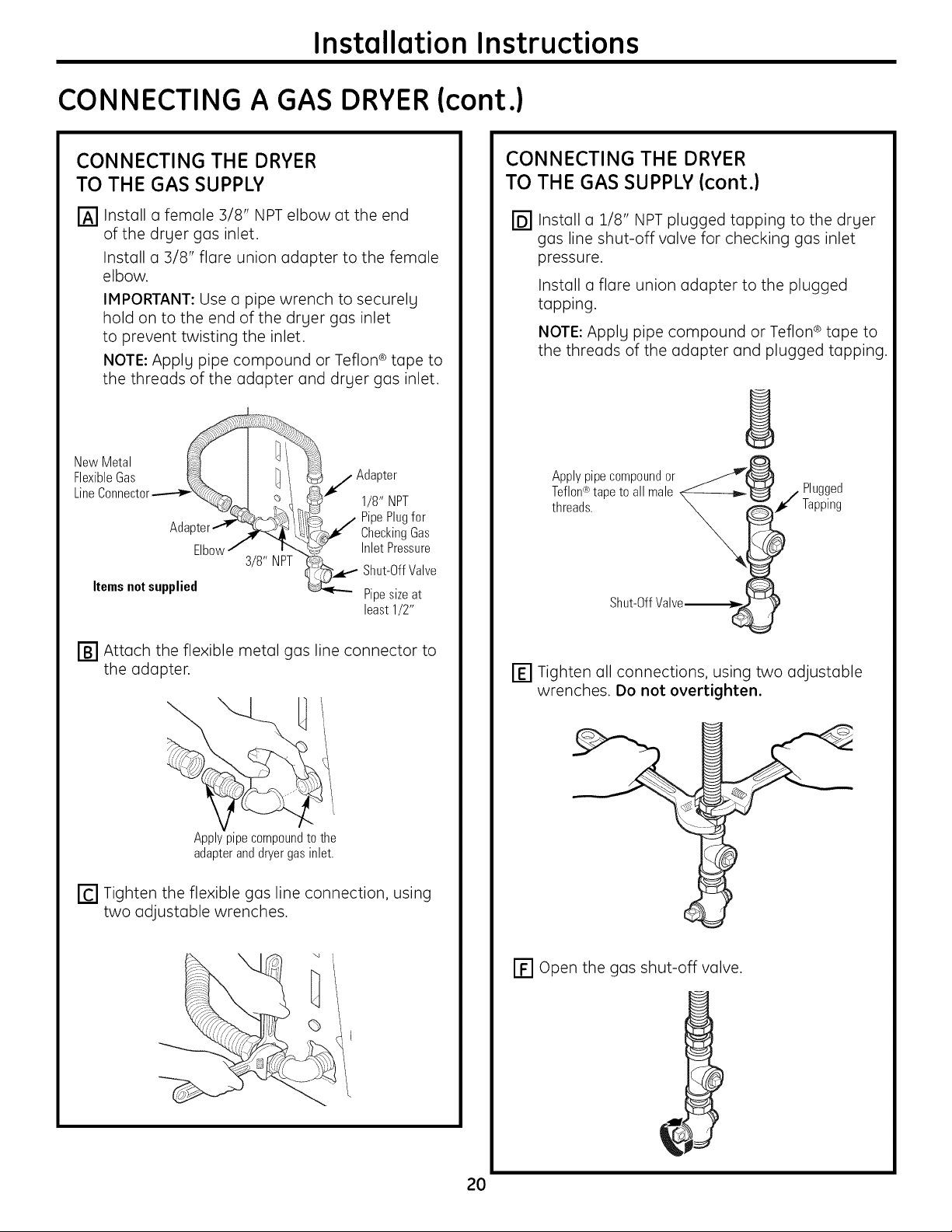

CONNECTING THE DRYER

TO THE GAS SUPPLY

Install a female 3/8" NPT elbow at the end

of the drger gas inlet.

Install a 3/8" flare union adapter to the female

elbow.

IMPORTANT: Use a pipe wrench to securelg

hold on to the end of the drger gas inlet

to prevent twisting the inlet.

NOTE: Applg pipe compound or Teflon ® tape to

the threads of the adapter and drger gas inlet.

NewMetal

FlexibleGas _ I ]I /Adapter

LineConnector___ I _ i "_ 1/8" NPT

Adapter [_1¢" Checking Gas

Elbow/ ix. _ InletPressure

3/8" NPT i%_.. -- Shut-OffVave

Itemsnotsupplied _ Pipesizeat

least1/2"

CONNECTING THE DRYER

TO THE GAS SUPPLY (cont.)

@Install a 2/8" NPT plugged tapping to the dryer

gas line shut-off valve for checking gas inlet

pressure.

Install a flare union adapter to the plugged

tapping.

NOTE: Apply pipe compound or Teflon ® tape to

the threads of the adapter and plugged tapping.

Applypipecompoundor _w'_

Teflon®tapeto all male N_---------b_'_ / Plugged

threads. _ _1¢ Tapping

Shut-OffValve__ !

IB1 Attach the flexible metal gas line connector to

the adapter.

Applypipecompoundtothe

adapteranddryergasinlet.

[] Tighten the flexible gas line connection, using

two adjustable wrenches.

' "4

_j

I-_ Tighten all connections, using two adjustable

wrenches. Do not overtighten.

[] Open the gas shut-off valve.

2O

Installation Instructions

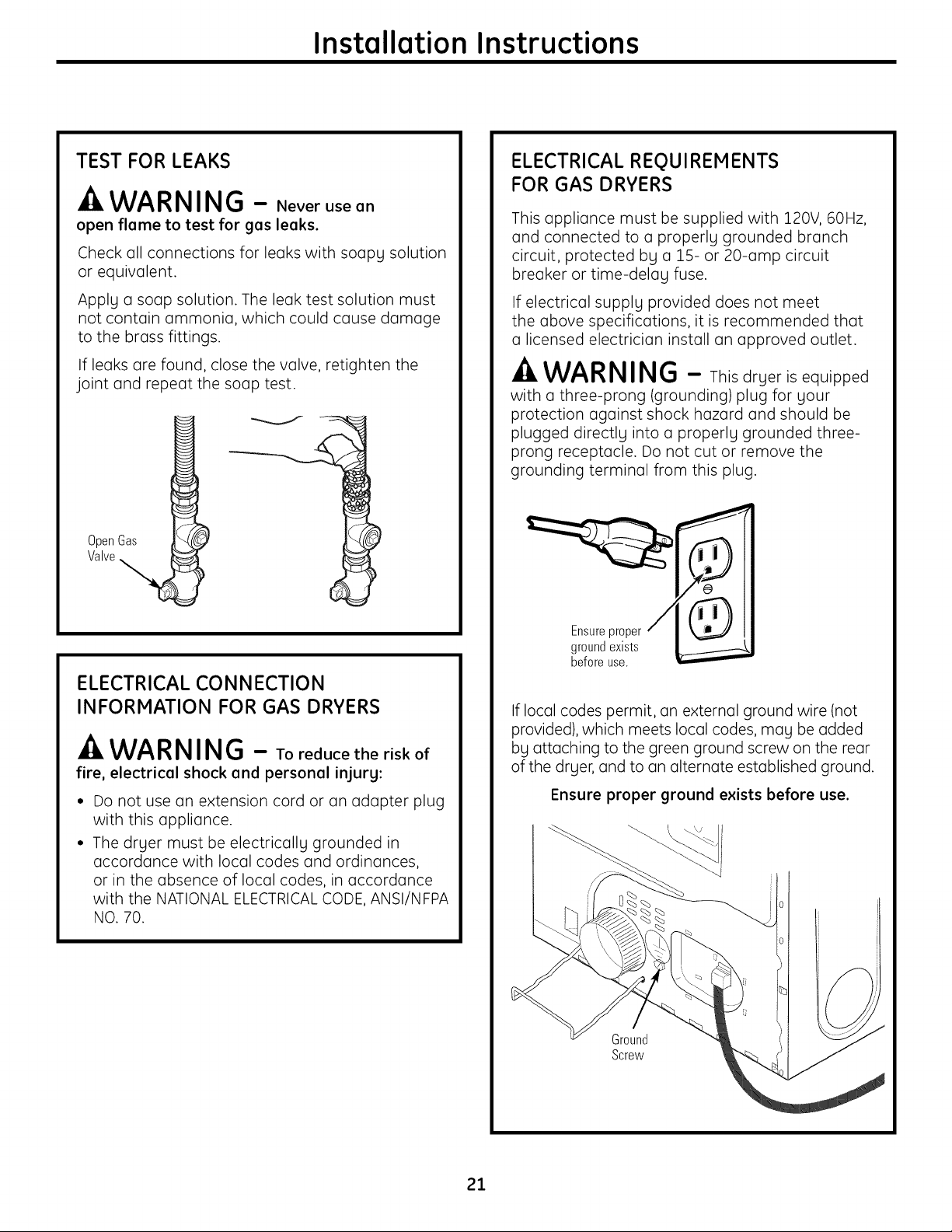

TEST FOR LEAKS

WARNING - Neverusean

open flame to test for gas leaks.

Check all connections for leaks with soapy solution

or equivalent.

Apply a soap solution. The leak test solution must

not contain ammonia, which could cause damage

to the brass fittings.

If leaks are found, close the valve, retighten the

joint and repeat the soap test.

OpenGas

Valve

ELECTRICAL REQUIREMENTS

FOR GAS DRYERS

This appliance must be supplied with 120V, 60Hz,

and connected to a properly grounded branch

circuit, protected by a 15- or 20-amp circuit

breaker or time-delay fuse.

If electrical supply provided does not meet

the above specifications, it is recommended that

a licensed electrician install an approved outlet.

WARNING - Thisdryerisequipped

witha three-prong(grounding)plugforyour

protectionagainstshock hazard and should be

plugged directlyintoa properlygrounded three-

prong receptacle.Do not cutor remove the

groundingterminalfrom thisplug.

ELECTRICAL CONNECTION

INFORMATION FOR GAS DRYERS

-A WARNING - Toreducetheriskof

fire, electrical shock and personal injury:

Do not use an extension cord or an adapter plug

with this appliance.

The dryer must be electrically grounded in

accordance with local codes and ordinances,

or in the absence of local codes, in accordance

with the NATIONAL ELECTRICAL CODE, ANSI/NFPA

NO. 70.

Ensureproper

groundexists

beforeuse.

If local codes permit, an external ground wire (not

provided), which meets local codes, may be added

by attaching to the green ground screw on the rear

of the dryer, and to an alternate established ground.

Ensure proper ground exists before use.

Ground

Screw

21

Installation Instructions

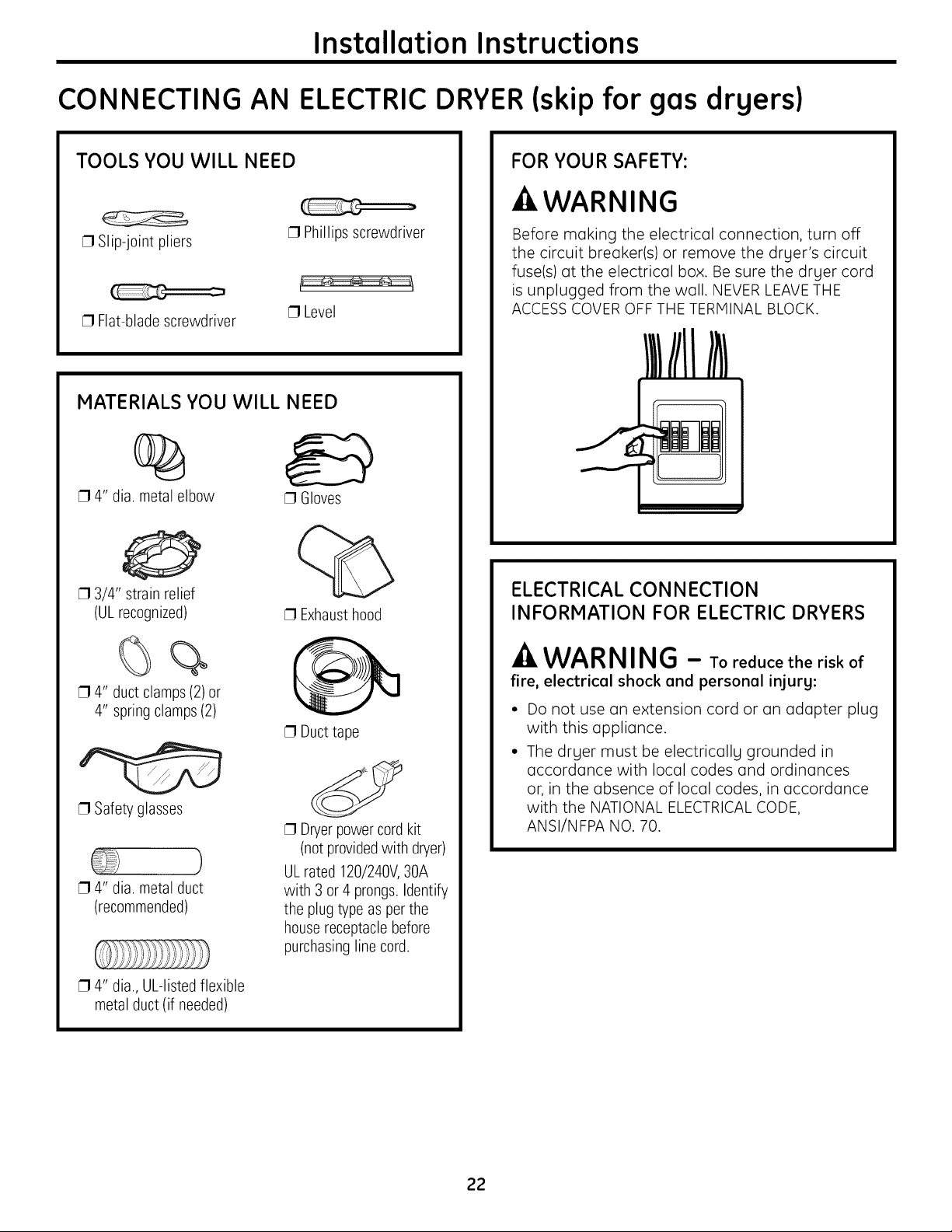

CONNECTING AN ELECTRICDRYER(skip for gas drgers)

TOOLS YOU WILL NEED

[] Slip-joint pliers

[] Flat-blade screwdriver

MATERIALS YOU WILL NEED

[] Phillips screwdriver

[] Level

%

[] 4" dia. metal elbow

[] 3/4" strain relief

(ULrecognized)

[] Gloves

[] Exhausthood

FOR YOUR SAFETY:

-AWARNING

Before making the electrical connection, turn off

the circuit breaker(s) or remove the dryer's circuit

fuse(s) at the electrical box. Be sure the dryer cord

is unplugged from the wall. NEVER LEAVETHE

ACCESSCOVEROFF THE TERMINAL BLOCK.

ELECTRICAL CONNECTION

INFORMATION FOR ELECTRIC DRYERS

%%

[] 4" duct clamps (2) or

4" spring clamps (2)

[] Safety glasses

)

[] 4" dia. metal duct

(recommended)

[] 4" dia., UL-listedflexible

metal duct (if needed)

[] Duct tape

[] Dryerpowercord kit

(notprovidedwith dryer)

ULrated 120/240V,30A

with 3 or 4 prongs.Identify

the plug type as per the

housereceptaclebefore

purchasinglinecord.

-A WARNING - Toreducetheriskof

fire, electrical shock and personal injury:

• Do not use an extension cord or an adapter plug

with this appliance.

• The dryer must be electrically grounded in

accordance with local codes and ordinances

or, in the absence of local codes, in accordance

with the NATIONAL ELECTRICALCODE,

ANSI/NFPA NO. 70.

22

Installation Instructions

ELECTRICAL REQUIREMENTS

FOR ELECTRIC DRYERS

This dryer must be connected to an individual

branch circuit, protected by the required time-

delay fuses or circuit breakers. A three- or four-

wire, single-phase, 120/240V, 60Hz, 30-amp

circuit is required.

If the electric supply does not meet the above

specifications, then call a licensed electrician.

GROUNDING INSTRUCTIONS

This dryer must be connected to a grounded metal,

permanent wiring system, or an equipment-

grounding conductor must be run with the circuit

conductors and connected to the equipment

grounding terminal on the appliance.

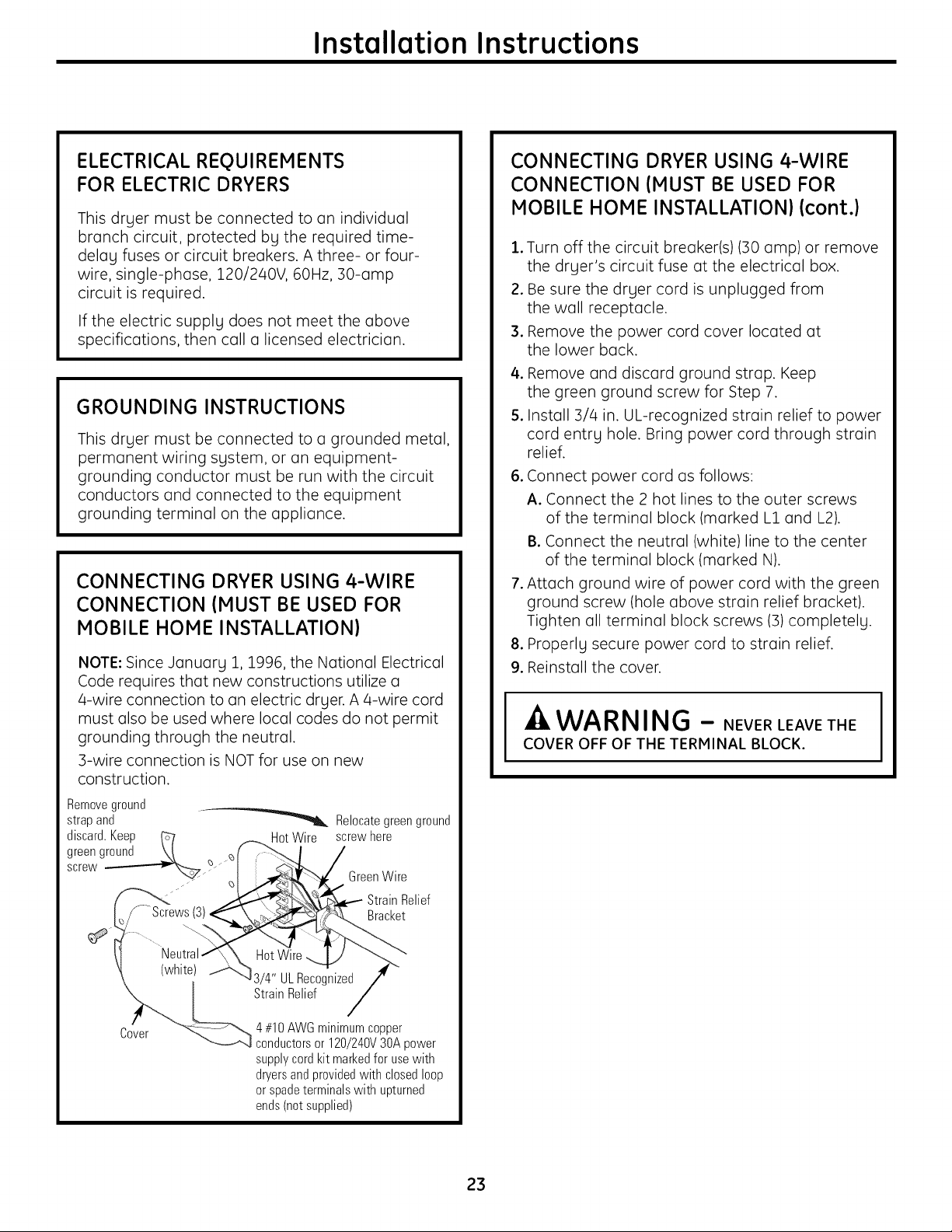

CONNECTING DRYER USING 4-WIRE

CONNECTION (MUST BE USED FOR

MOBILE HOME INSTALLATION}

NOTE: Since January 1, 1996, the National Electrical

Code requires that new constructions utilize a

a-wire connection to an electric dryer. A 4-wire cord

must also be used where local codes do not permit

grounding through the neutral.

3-wire connection is NOT for use on new

construction.

Removeground

strap and "_ Relocate green ground

discard.Keep _7 HotWire screwhere

greenground \/ _f J_.. I /

CONNECTING DRYER USING 4-WIRE

CONNECTION (MUST BE USED FOR

MOBILE HOME INSTALLATION} (cont.}

.

Turn off the circuit breaker(s)(30 amp) or remove

the dryer's circuit fuse at the electrical box.

2.

Be sure the dryer cord is unplugged from

the wall receptacle.

3.

Remove the power cord cover located at

the lower back.

4.

Remove and discard ground strap. Keep

the green ground screw for Step 7.

5.

Install 3/4 in. UL-recognized strain relief to power

cord entry hole. Bring power cord through strain

relief.

.

Connect power cord as follows:

A. Connect the 2 hot lines to the outer screws

of the terminal block (marked L1 and L2).

B.Connect the neutral (white)line to the center

of the terminal block (marked N).

.

Attach ground wire of power cord with the green

ground screw (hole above strain relief bracket).

Tighten all terminal block screws (3) completely.

.

Properly secure power cord to strain relief.

9.

Reinstall the cover.

WARNING - NEVERLEAVETHE

COVER OFF OF THE TERMINAL BLOCK.

screw __ GreenWire

_ __\\_\P-_d-. _ StrainRelief

I_/ Screws(3)_:_X__£._ Bracket

(white_ UL Reco_ized /"

_ [ ..... StrainRelief /

" "_--_ 4#10AWGminimumcopper

_cver _'_-----.A_ conductorsor 120/240V30Apower

supplycordkit markedfor usewith

dryersandprovidedwithclosedloop

or spadeterminalswith upturned

ends(net supplied)

23

Installation Instructions

CONNECTING AN ELECTRICDRYER(cont.)

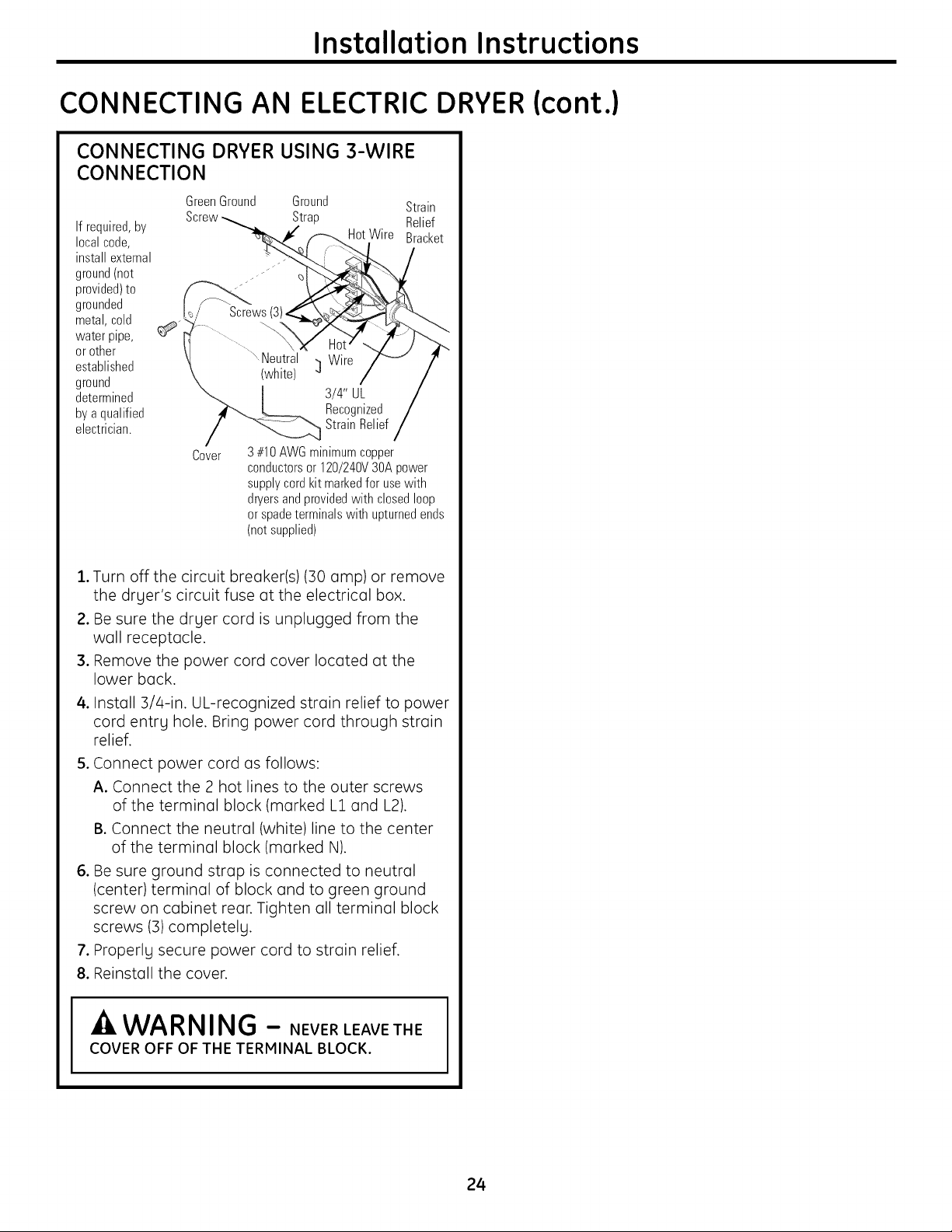

CONNECTING DRYER USING 3-WIRE

CONNECTION

GreenGround Ground Strain

Ifrequired,by

localcode,

installexternal

ground(not

provided)to

grounded

metal,cold

water pipe,

or other

established

ground

determined

bya qualified

electrician.

Screw Strap Relief

HotWire Bracket

Screws

.Neutral Wire

(white) ]

3/4" UL

Recognized

StrainRelief

Cover

3#10AWGminimumcopper

conductorsor 120/240V3OApower

supplycordkit markedfor usewith

dryersandprovidedwith closedloop

or spadeterminalswith upturnedends

(notsupplied)

1.Turn off the circuit breaker(s)(30 amp) or remove

the dryer's circuit fuse at the electrical box.

2. Be sure the dryer cord is unplugged from the

wall receptacle.

3. Remove the power cord cover located at the

lower back.

4. Install 3/4-in. UL-recognized strain relief to power

cord entrg hole. Bring power cord through strain

relief.

5. Connect power cord as follows:

A. Connect the 2 hot lines to the outer screws

of the terminal block (marked L1 and L2).

B.Connect the neutral (white)line to the center

of the terminal block (marked N).

6. Be sure ground strap is connected to neutral

(center) terminal of block and to green ground

screw on cabinet rear. Tighten all terminal block

screws (3) completely.

7. Properly secure power cord to strain relief.

8. Reinstall the cover.

WARNING - NEVERLEAVETHE

COVER OFF OF THE TERMINAL BLOCK.

24

Installation Instructions

EXHAUSTING THE DRYER

-A WARNING - Toreducethe

risk of fire or personal injury:

• This clothes dryer must be exhausted to the outdoors.

• Use only 4" rigid metal ducting for the home

exhaust duct.

• Use only 4" rigid metal or UL-listed flexible metal

(semi-rigid or foil-type) duct to connect the dryer

to the home exhaust duct. It must be installed

in accordance with the instructions found in

"Connecting the Dryer to House Vent" on page 26

of this manual.

• Do not terminate exhaust in a chimney, a wall, a

ceiling, gas vent, crawl space, attic, under an

enclosed floor, or in any other concealed space of

a building.

• Never terminate the exhaust into a common duct

with a kitchen exhaust system. A combination of

grease and lint creates a potential fire hazard.

• Do not use duct longer than specified in the exhaust

length table. Longer ducts can accumulate lint,

creating a potential fire hazard.

• Never install a screen in or over the exhaust duct.

This will cause lint to accumulate, creating a

potential fire hazard.

• Do not assemble ductwork with any fasteners that

extend into the duct. These fasteners can

accumulate lint, creating a potential fire hazard.

• Do not obstruct incoming or exhausted air.

• Provide an access for inspection and cleaning of

the exhaust system, especially at turns and joints.

Exhaust system shall be inspected and cleaned at

least once a year.

• This dryer comes ready for rear exhausting. If space

is limited, use the instructions on pages 29-:31 to

exhaust directly from the sides or bottom of the

cabinet.

EXHAUST SYSTEM CHECKLIST

HOOD OR WALL CAP

• Terminate in a manner to prevent back drafts or

entry of birds or other wildlife.

• Termination should present minimal resistance to

the exhaust airflow and should require little or no

maintenance to prevent clogging.

• Never install a screen in or over the exhaust duct.

• Wall caps must be installed at least 12" above

ground level or any other obstruction with the

opening pointed down.

SEPARATIONOF TURNS

• For best performance, separate all turns by

at least 4 ft. of straight duct, including distance

between last turn and dampened wall cap.

SEALING OF JOINTS

• All joints should be tight to avoid leaks. The male

end of each section of duct must point away

from the dryer.

• Do not assemble the ductwork with fasteners that

extend into the duct. They will serve as a collection

point for lint.

• Duct joints should be made air- and moisture-tight

by wrapping the overlapped joints with duct tape

or aluminum tape.

• Horizontal runs should slope down towards the

outdoors 1/4" per foot.

INSULATION

• Ductwork that runs through an unheated area

or is near air conditioning should be insulated

to reduce condensation and lint buildup.

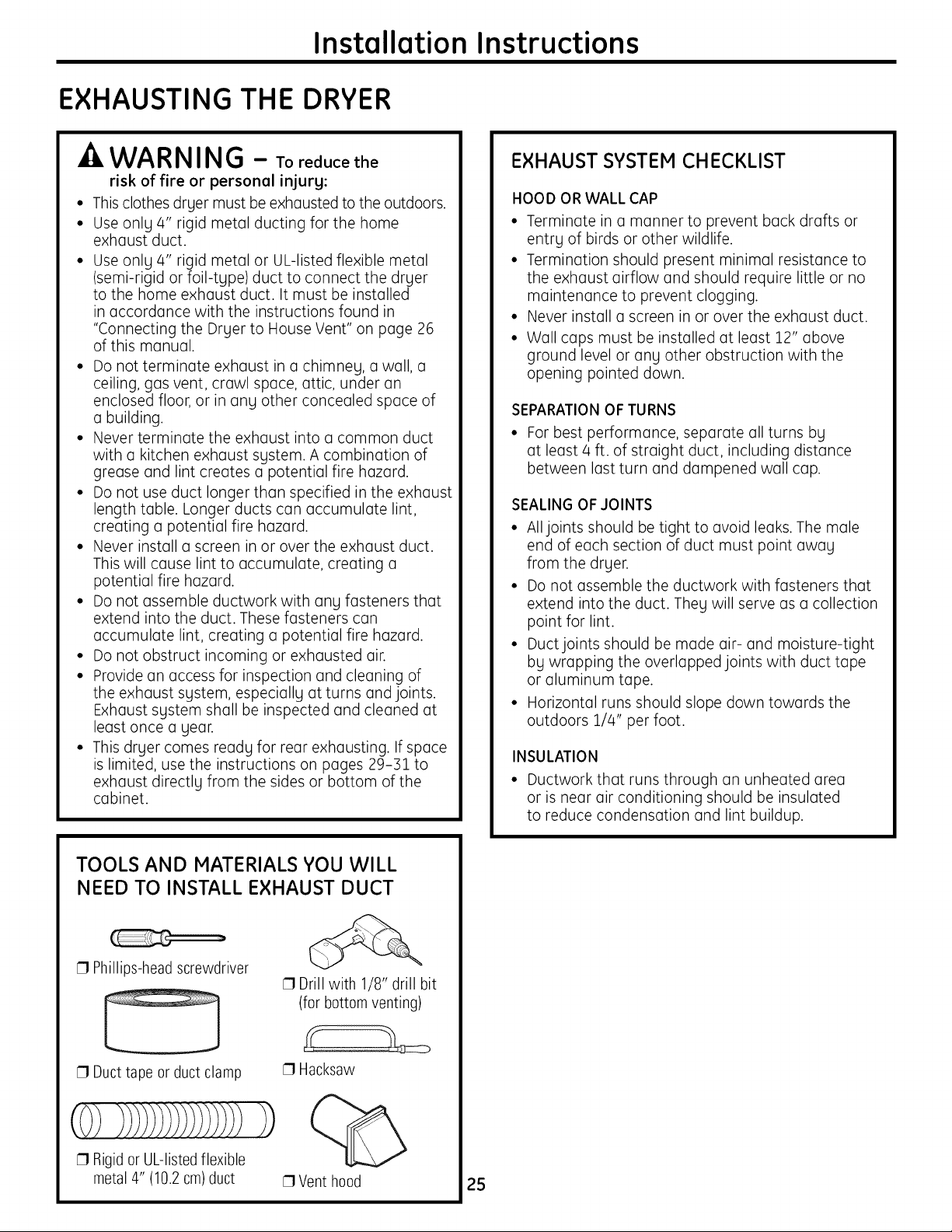

TOOLS AND MATERIALS YOU WILL

NEED TO INSTALL EXHAUST DUCT

[] Phillips-head screwdriver

[] Drill with 1/8" drill bit

(for bottom venting)

[] Ducttape or duct clamp

[] Hacksaw

1)

[] Rigidor UL-listed flexible

metal 4" (10.2cm)duct

[] Vent hood

25

Installation Instructions

EXHAUSTING THE DRYER (cont.)

CONNECTING THE DRYER TO

HOUSE VENT

RIGID METAL TRANSITION DUCT

• For best drying performance, a rigid metal

transition duct is recommended.

• Rigid metal transition ducts reduce the risk of

crushing and kinking.

UL-LISTED FLEXIBLE METAL (SEMI-RIGID)

TRANSITION DUCT

• If rigid metal duct cannot be used, then ULdisted

flexible metal (semi-rigid)ducting can be used

(Kit WX08X10077).

• Never install flexible metal duct in walls, ceilings,

floors or other enclosed spaces.

• Total length of flexible metal duct should not

exceed 8 feet (2.4 m).

• For many applications, installing elbows at both

the dryer and the wall is highly recommended (see

illustrations at right). Elbows allow the dryer to sit

close to the wall without kinking and/or crushing

the transition duct, maximizing drying performance.

• Avoid resting the duct on sharp objects.

UL-LISTED FLEXIBLE METAL (FOIL-TYPE)

TRANSITION DUCT

In special installations, it may be necessary to

connect the dryer to the house vent using a flexible

metal (foil-type)duct. A UL-listed flexible metal

(foil-type) duct may be used ONLY in installations

where rigid metal or flexible metal (semi-rigid)

ducting cannot be used AND where a 4" diameter

can be maintained throughout the entire length

of the transition duct.

In Canada and the United States, only the flexible

metal (foil-type) ducts that comply with the "Outline

for Clothes Dryer Transition Duct Subject 2158A"

shall be used.

Never install flexible metal duct in walls, ceilings,

floors or other enclosed spaces.

Total length of flexible metal duct should not

exceed 8 feet (2.4 m).

Avoid resting the duct on sharp objects.

For best drying performance:

1.Slide one end of the duct over the clothes

dryer outlet pipe.

2. Secure the duct with a clamp.

3. With the dryer in its permanent position,

extend the duct to its full length. Allow 2" of

duct to overlap the exhaust pipe. Cut off and

remove excess duct. Keep the duct as straight

as possible for maximum airflow.

4. Secure the duct to the exhaust pipe with the

other clamp.

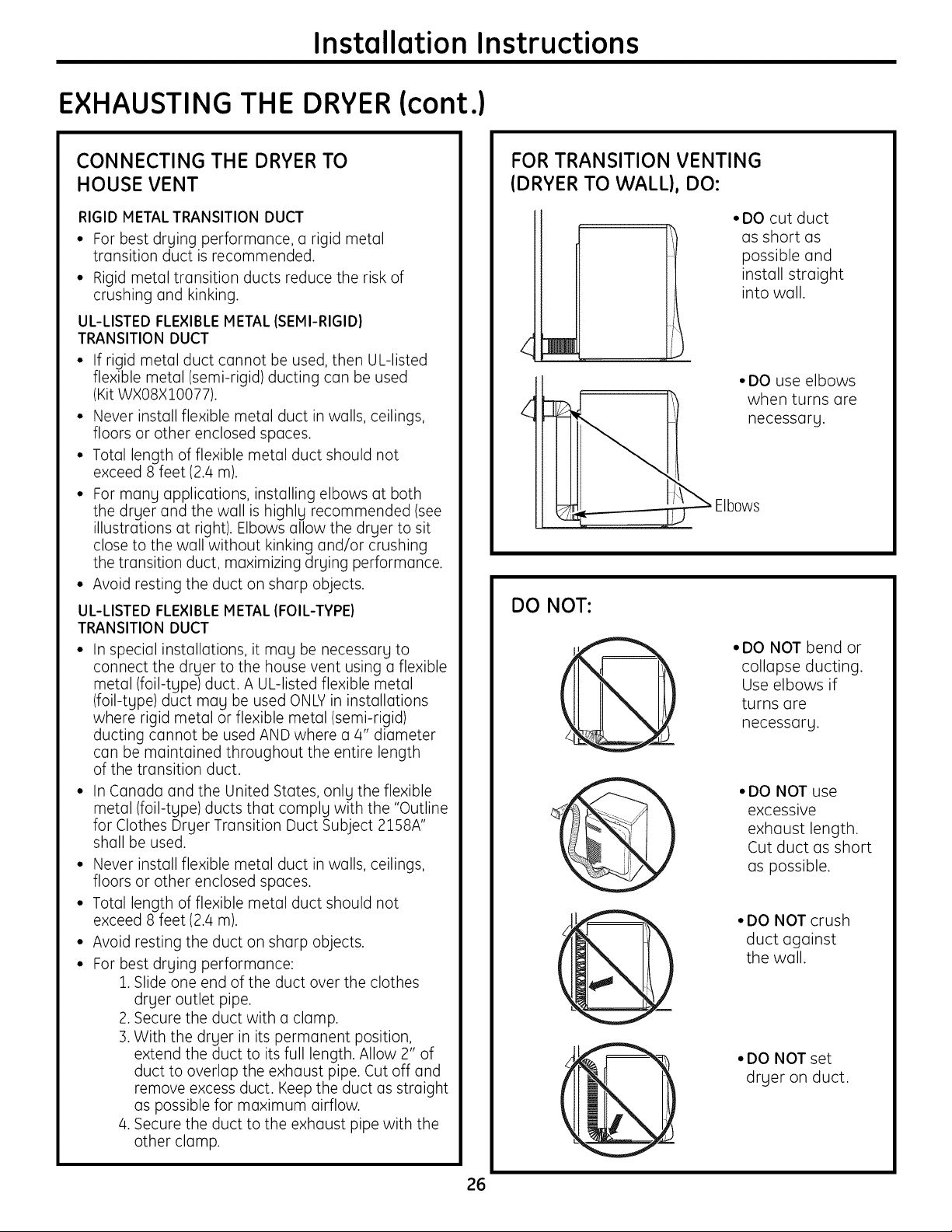

FOR TRANSITION VENTING

(DRYER TO WALL}, DO:

• DO cut duct

DO NOT:

• DO NOT bend or

'@

@

@

@

as short as

possible and

install straight

into wall.

• DO use elbows

when turns are

necessary.

collapse ducting.

Use elbows if

turns are

necessary.

• DO NOT use

excessive

exhaust length.

Cut duct as short

as possible.

•DO NOT crush

duct against

the wall.

• DO NOT set

dryer on duct.

26

Installation Instructions

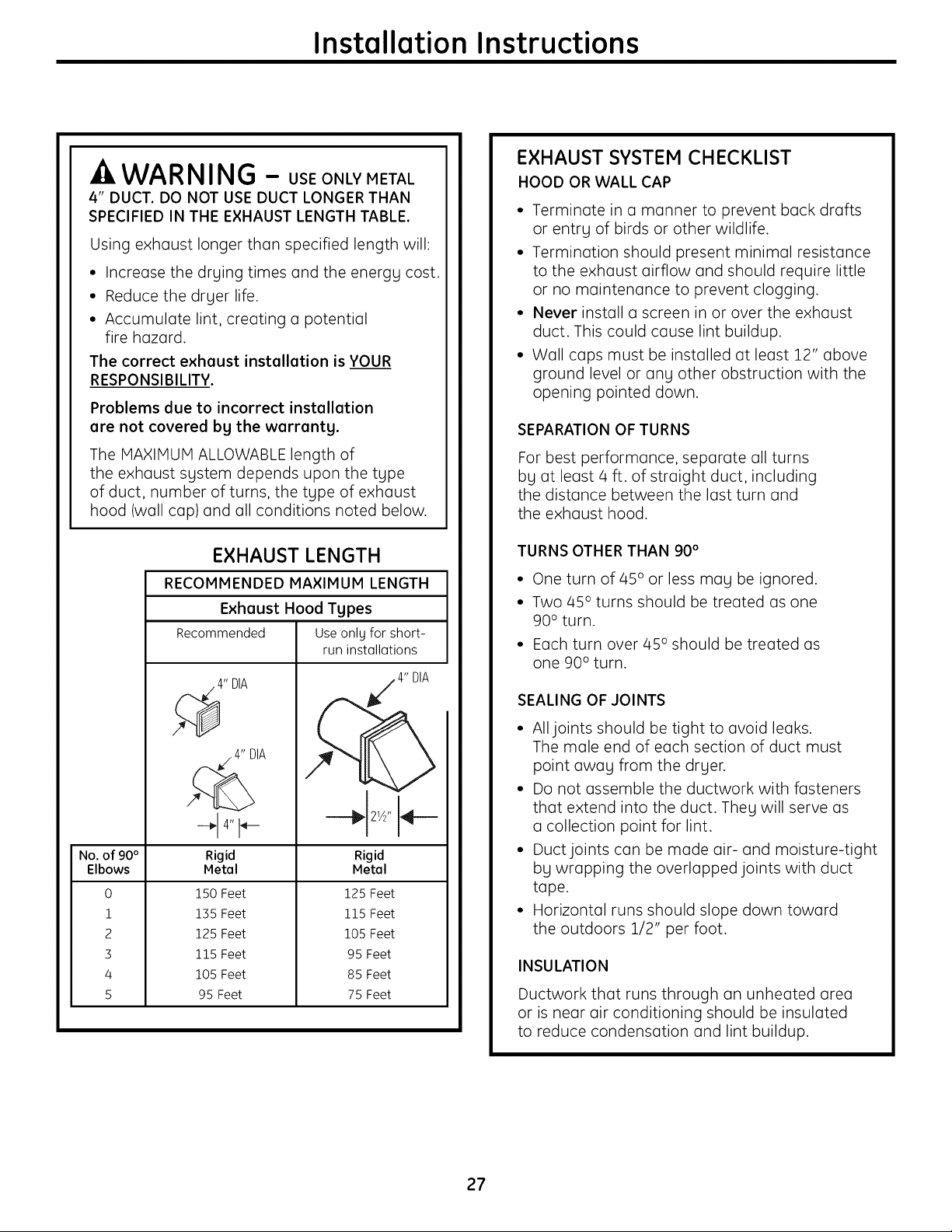

-A WARNING - USEONLYMETAL

4" DUCT. DO NOT USE DUCT LONGER THAN

SPECIFIED IN THE EXHAUST LENGTH TABLE.

Using exhaust longer than specified length will:

• Increase the drging times and the energg cost.

• Reduce the drger life.

• Accumulate lint, creating a potential

fire hazard.

The correct exhaust installation is YOUR

RESPONSIBILITY.

Problems due to incorrect installation

are not covered bg the warrantg.

EXHAUST SYSTEM CHECKLIST

HOOD OR WALL CAP

• Terminate in a manner to prevent back drafts

or entry of birds or other wildlife.

• Termination should present minimal resistance

to the exhaust airflow and should require little

or no maintenance to prevent clogging.

• Never install a screen in or over the exhaust

duct. This could cause lint buildup.

• Wall caps must be installed at least 12" above

ground level or ang other obstruction with the

opening pointed down.

SEPARATION OF TURNS

The MAXIMUM ALLOWABLE length of

the exhaust sgstem depends upon the tgpe

of duct, number of turns, the tgpe of exhaust

hood (wall cap) and all conditions noted below.

EXHAUST LENGTH

RECOMMENDED MAXIMUM LENGTH

Exhaust Hood Types

Recommended Useonlg for short-

run installations

4" DIA

_. 4" DIA

-_ 4" I_---

No. of 90°

Elbows

0

1

2

3

4

5

Rigid

Metal

150 Feet

135 Feet

125 Feet

115 Feet

105 Feet

95 Feet

Rigid

Metal

125 Feet

115 Feet

105 Feet

95 Feet

85 Feet

75 Feet

4" DIA

For best performance, separate all turns

bg at least/4 ft. of straight duct, including

the distance between the last turn and

the exhaust hood.

TURNS OTHER THAN 90 °

• One turn of 45° or less may be ignored.

• Two 45° turns should be treated as one

90 ° turn.

• Each turn over 45 ° should be treated as

one 90° turn.

SEALING OF JOINTS

• All joints should be tight to avoid leaks.

The male end of each section of duct must

point awag from the drger.

• Do not assemble the ductwork with fasteners

that extend into the duct. Theg will serve as

a collection point for lint.

• Duct joints can be made air- and moisture-tight

bg wrapping the overlapped joints with duct

tape.

• Horizontal runs should slope down toward

the outdoors 1/2" per foot.

INSULATION

Ductwork that runs through an unheated area

or is near air conditioning should be insulated

to reduce condensation and lint buildup.

27

Installation Instructions

EXHAUSTING THE DRYER (cont.)

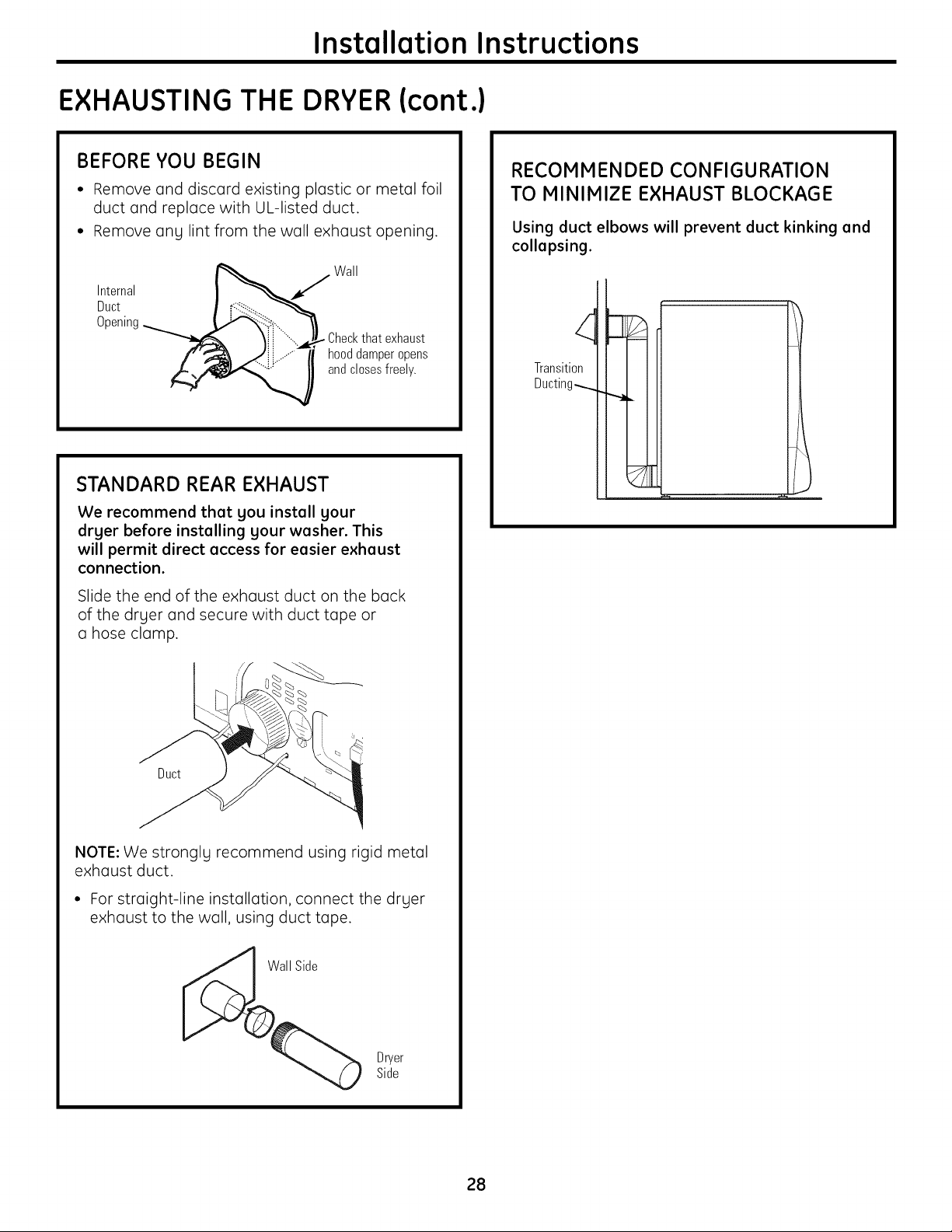

BEFORE YOU BEGIN

• Remove and discard existing plastic or metal foil

duct and replace with UL-listed duct.

• Remove ang lint from the wall exhaust opening.

Wall

Internal

Duct

Opening

"__ Checkthat exhaust

and closes freely.

hooddamperopens

STANDARD REAR EXHAUST

We recommend that gou install gour

drger before installing gour washer. This

will permit direct access for easier exhaust

connection.

Slide the end of the exhaust duct on the back

of the druer and secure with duct tape or

a hose clamp.

RECOMMENDED CONFIGURATION

TO MINIMIZE EXHAUST BLOCKAGE

Using duct elbows will prevent duct kinking and

collapsing.

Transition

Ducting_

Duct

NOTE: We strongly recommend using rigid metal

exhaust duct.

• For straight-line installation, connect the dryer

exhaust to the wall, using duct tape.

Dryer

Side

28

Installation Instructions

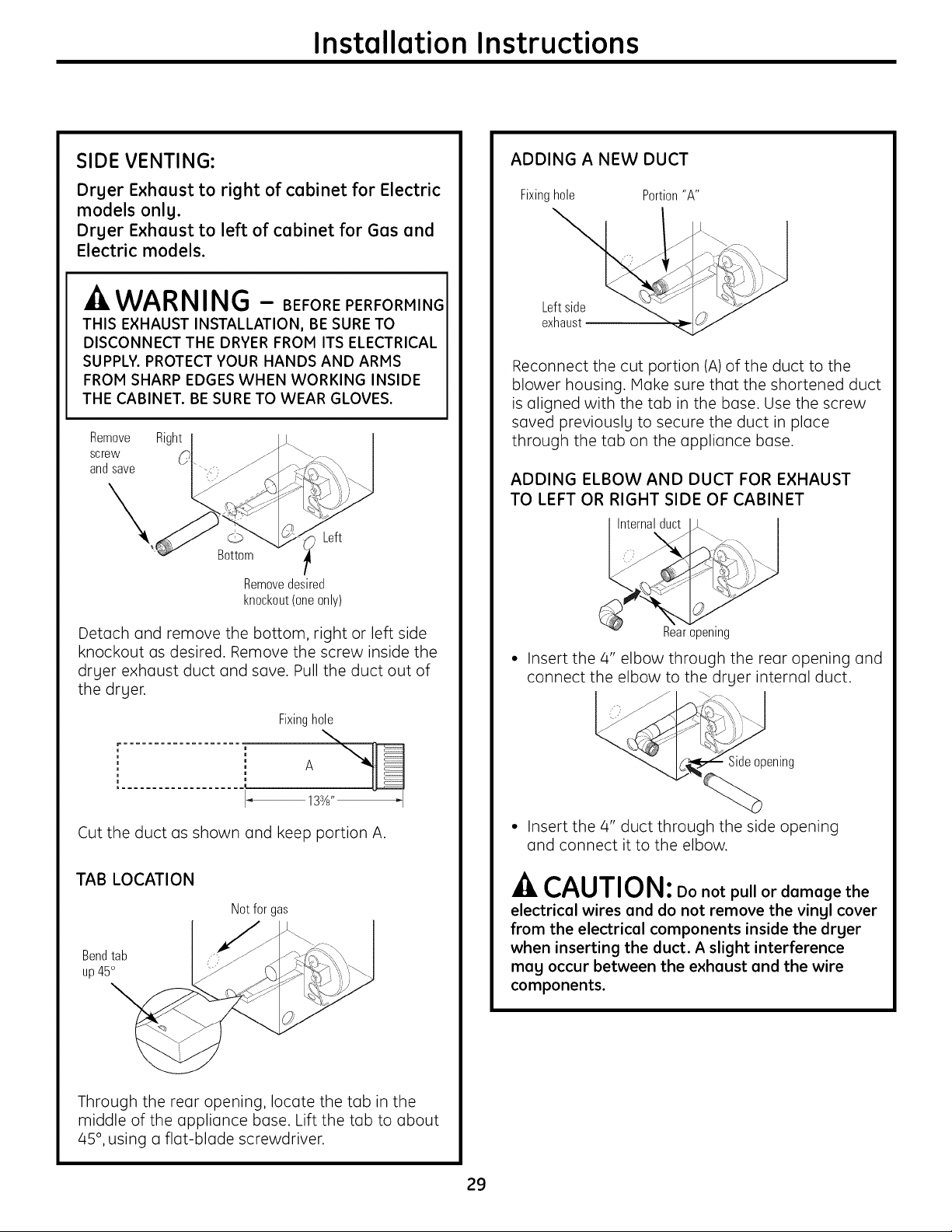

SIDE VENTING:

Dryer Exhaust to right of cabinet for Electric

models only.

Dryer Exhaust to left of cabinet for Gas and

Electric models.

-A WARNING - BEFOREPERFORMING

THIS EXHAUST INSTALLATION, BE SURE TO

DISCONNECT THE DRYER FROM ITS ELECTRICAL

SUPPLY. PROTECT YOUR HANDS AND ARMS

FROM SHARP EDGES WHEN WORKING INSIDE

THE CABINET. BE SURE TO WEAR GLOVES.

Remove

screw

and save

Right

Left

Bottom

Removedesired

knockout(oneonly)

ADDING A NEW DUCT

Fixinghole Portion"A"

Reconnect the cut portion (A)of the duct to the

blower housing. Make sure that the shortened duct

is aligned with the tab in the base. Use the screw

saved previously to secure the duct in place

through the tab on the appliance base.

ADDING ELBOW AND DUCT FOR EXHAUST

TO LEFT OR RIGHT SIDE OF CABINET

Internalduct

Detach and remove the bottom, right or left side

knockout as desired. Remove the screw inside the

dryer exhaust duct and save. Pull the duct out of

the dryer.

Fixinghole

Cut the duct as shown and keep portion A.

TAB LOCATION

Notfor gas

Bendtab

up45°

Rear opening

• Insert the 4" elbow through the rear opening and

connect the elbow to the dryer internal duct.

Sideopening

• Insert the 4" duct through the side opening

and connect it to the elbow.

-A CAUTION: Do not pull or damage the

electrical wires end do not remove the vingl cover

from the electrical components inside the drger

when inserting the duct. A slight interference

meg occur between the exhaust end the wire

components.

Through the rear opening, locate the tab in the

middle of the appliance base. Lift the tab to about

/45°, using a flat-blade screwdriver.

29

Installation Instructions

EXHAUSTING THE DRYER (cont.)

SIDE VENTING (cont.)

ADDING ELBOW AND DUCT FOR EXHAUST

TO LEFT OR RIGHT SIDE OF CABINET (cont.)

• Apply duct tape as

shown on the joint

between the dryer

internal duct and

the elbow, and also

the joint between the "

elbow and the side duct.

Duct

-ACAUTION:

Internal duct joints must be secured with tape;

otherwise, they may separate and cause a safety

hazard.

ADDING COVER PLATE TO REAR OF CABINET

(SIDE EXHAUST)

BOTTOM VENTING:

Drger Exhaust to the bottom of cabinet

for Gas and Electric models.

WARNING - BEFOREPERFORMING

THIS EXHAUST INSTALLATION, BE SURE TO

DISCONNECT THE DRYER FROM ITS ELECTRICAL

SUPPLY. PROTECT YOUR HANDS AND ARMS

FROM SHARP EDGES WHEN WORKING INSIDE

THE CABINET. BE SURE TO WEAR GLOVES.

Remove

screw

and save

Bottom

Removedesired

knockout(oneonly)

Remove the screw inside the dryer exhaust duct

and save. Pull the duct out of the dryer. Detach

and remove the bottom knockout.

Connect standard metal elbows and ducts to

complete the exhaust system. Cover back opening

with a plate (Kit WEllVl4S4) available from your

local service provider. Place dryer in final location.

WAR NING - NEVERLEAVE

THE BACK OPENING WITHOUT THE PLATE.

(Kit WEIM454)

Fixinghole

123_'' _1

Cut the duct as shown and keep portion A.

3O

Loading...

Loading...