GE DNCD450EG9WC, GHDX100EM0WW, GRDN510EM0WS, GRDN510EM2WS, GRDN510GM2WS Installation Guide

...Page 1

Installation

ElectricDryer

Instructions

Questions on installation? calk 1-800-GECARES (US)

or Visit our Web site at: www.GEAppliunces.com (US)

BEFORE YOU BEGIN

Readtheseinstructionscompletelyandcarefully.

•IMPORTANT- Save these instructionsfor

localinspector'suse.

•IMPORTANT- Observeall governingcodes

andordinances.

• Note to Installer - Besureto leavethese

instructionswith the customer.

• Note to Customer - Keeptheseinstructions

with your Useand CoreBookforfuture

reference.

• Beforethe old dryeris removedfrom serviceor

discorded,removethe dryerdoor.

• Inspectthe dryerexhaustoutlet andstraighten

the outlet wallsif they arebent.

• Serviceinformation andthe wiringalia-gram

arelocated inthe controlconsole.

• Do notallowchildrenon or inthe appliance.

Closesupervisionofchildren isnecessary

whenthe applianceis usednearchildren.

• Installthe dryerwherethe temperature is

above50°Ffor satisfactory operationof the

dryercontrol system.

O5

WARNING ruSKOFFree

, Toreduce the risk of severe injury or death, follow all installation

instructions.

, Clothes dryer installation must be performed by a qualified installer.

, Install the clothes dryer according to these instructions and in

accordance with local codes.

, Thisdryer must be exhausted to the outdoors.

, Useonly 4" rigid metal ducting for exhausting the clothes dryer to the

outdoors.

, DO NOTinstall a clothes dryer with flexible plastic ducting materials.

If flexible metal (semi-rigid orfoil-type) duct is installed, it must be

ULlisted and installed in accordance with the instructions found in

"Connecting The Dryer To House Vent" on page 5 of this manual.

Flexible venting materials are known to collapse, be easily crushed,

and trap lint. These conditions will obstruct dryer airflow and increase

the risk of fire.

, Do not install or store this appliance in any location where it could be

exposed to water and or weather.

, Save these instructions. (Installers: Besure to leave these instructions

with the customer).

NOTE: Installation and service of this dryer requires basic

mechanical and electrical skills. It is your responsibility to

contact a qualified installer to make the electrical connections.

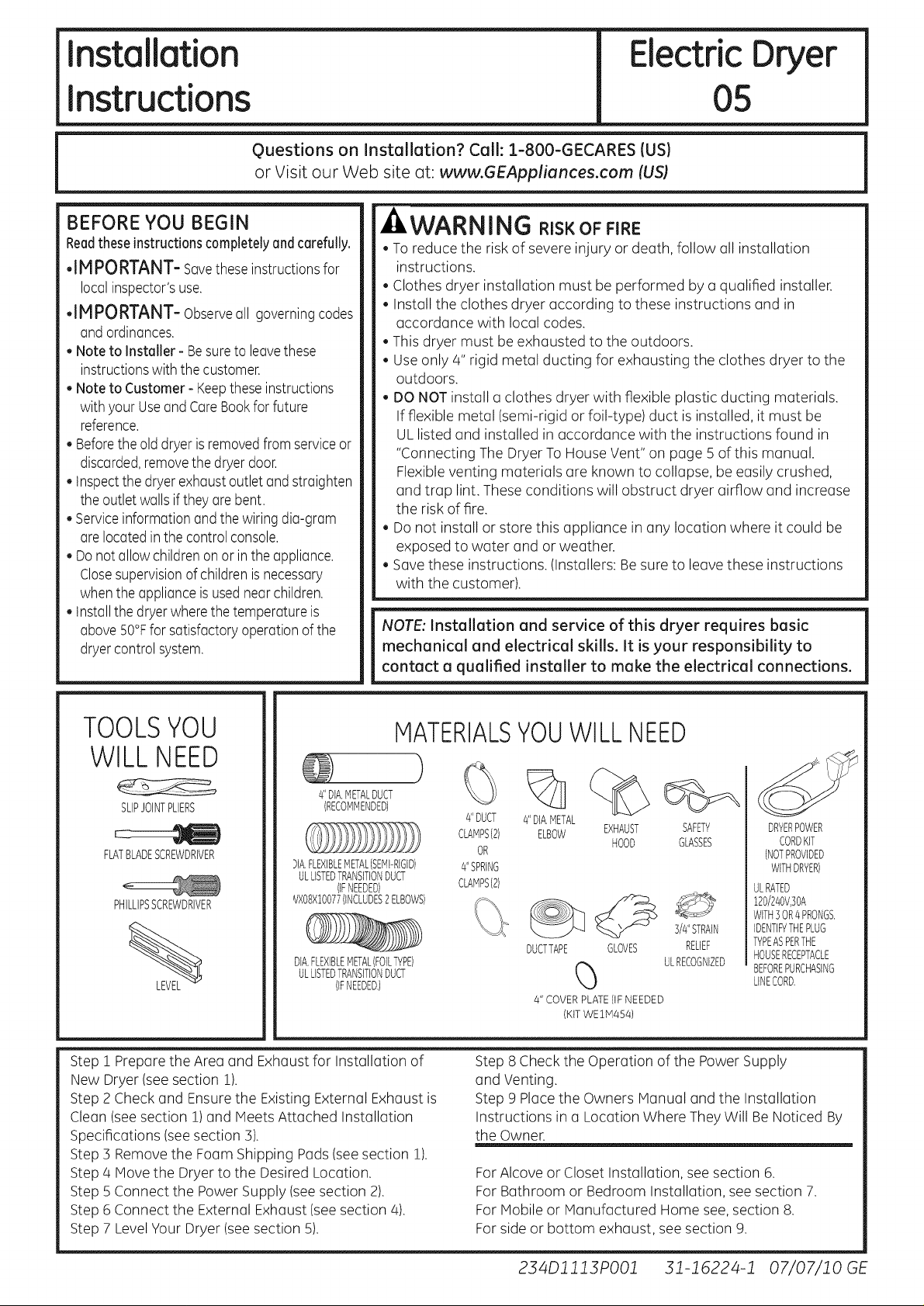

TOOLSYOU

MATERIALSYOUWILL NEED

WILLNEED

)

4IIDIA,METALDUCT

SLIPJOINTPLIERS

FLATBLADESCREWDRIVER

PHILLIPSSCREWDRIVER

Step 1 Prepare the Area and Exhaust for Installation of

New Dryer (seesection 1).

Step 2 Check and Ensurethe Existing External Exhaust is

Clean (seesection 1) and Meets Attached Installation

Specifications (seesection 3).

Step 3 Remove the Foam Shipping Pads(seesection 1).

Step 4 Move the Dryer to the Desired Location.

Step 5 Connect the Power Supply (see section 2).

Step 6 Connect the External Exhaust (see section 4).

Step 7 LevelYour Dryer (see section 5).

(RECOMMENDED)

}IA.FLEXIBLEMETAL(SEMI-RIGID)

ULLISTEDTRANSITIONDUCT

(IFNEEDED)

_,/XO8XlO077(INCLUDES2ELBOWS)

DIA.FLEXIBLEMETAL(FOETYPE)

ULLISTEDTRANSITIONDUCT

(IFNEEDED,)

%

4'IDUCT

CLAMPS(2) EXHAUST

4"SPRING

CLAMPS(2)

Step 8 Check the Operation of the Power Supply

and Venting.

Step 9 Place the Owners Manual and the Installation

Instructions in a Location Where They Will Be Noticed By

the Owner.

For Alcove or Closet Installation, see section 6.

For Bathroom or Bedroom Installation, see section 7.

For Mobile or Manufactured Home see, section 8.

For side or bottom exhaust, see section 9.

OR

4'1DIA,METAL

ELBOW

DUCTTAPE GLOVES RELIEF

4" COVERPLATE(IFNEEDED

(KITWEIM454)

HOOD

%

SAFETY

GLASSES

3/4"STRAIN

ULRECOGNIZED

DRYERPOWER

CORDKIT

(NOTPROVIDED

WITHDRYER)

ULRATED

120/240V,]OA

WITH3OR4PRONGS.

IDENTIFYTHEPLUG

TYPEASPERTHE

HOUSERECEPTACLE

BEFOREPURCHASING

LINECORD,

234Dll13PO01 31-16224-1 07/07/10 GE

Page 2

Installation instructions

Minimum Clearance Other Than Alcove or Closet Installation

Minimum clearance to combustible surfaces and for air opening are: 0 in. clearance both sides and 1in. rear.

Consideration must be given to provide adequate clearance for installation and service.

ri] PREPARING FOR INSTALLATION

OF NEW DRYER

TIP:Install your dryer before installing your washer.

This will allow better access when installing dryer

exhaust.

REMOVING LINT FROM WALL

EXHAUST OPENING

. Remove and discard existing plastic or metal foil

transition duct and replace with UL listed transition

duct.

WALL

/

INTERNALDUCT

OPENING i HOODDAMPEROPENS

CHECKTHATEXHAUST

ANDCLOSESFREELY.

TILTTHE DRYERSIDEWAYS

AND REMOVETHE FOAM

SHIPPING PADS BY

PULLING ATTHE SIDES

AND BREAKING THEM

AWAY FROM THE DRYER

LEGS, BE SURE TO

REMOVEALL OF THE

FOAM PIECESAROUND

THE LEGS,

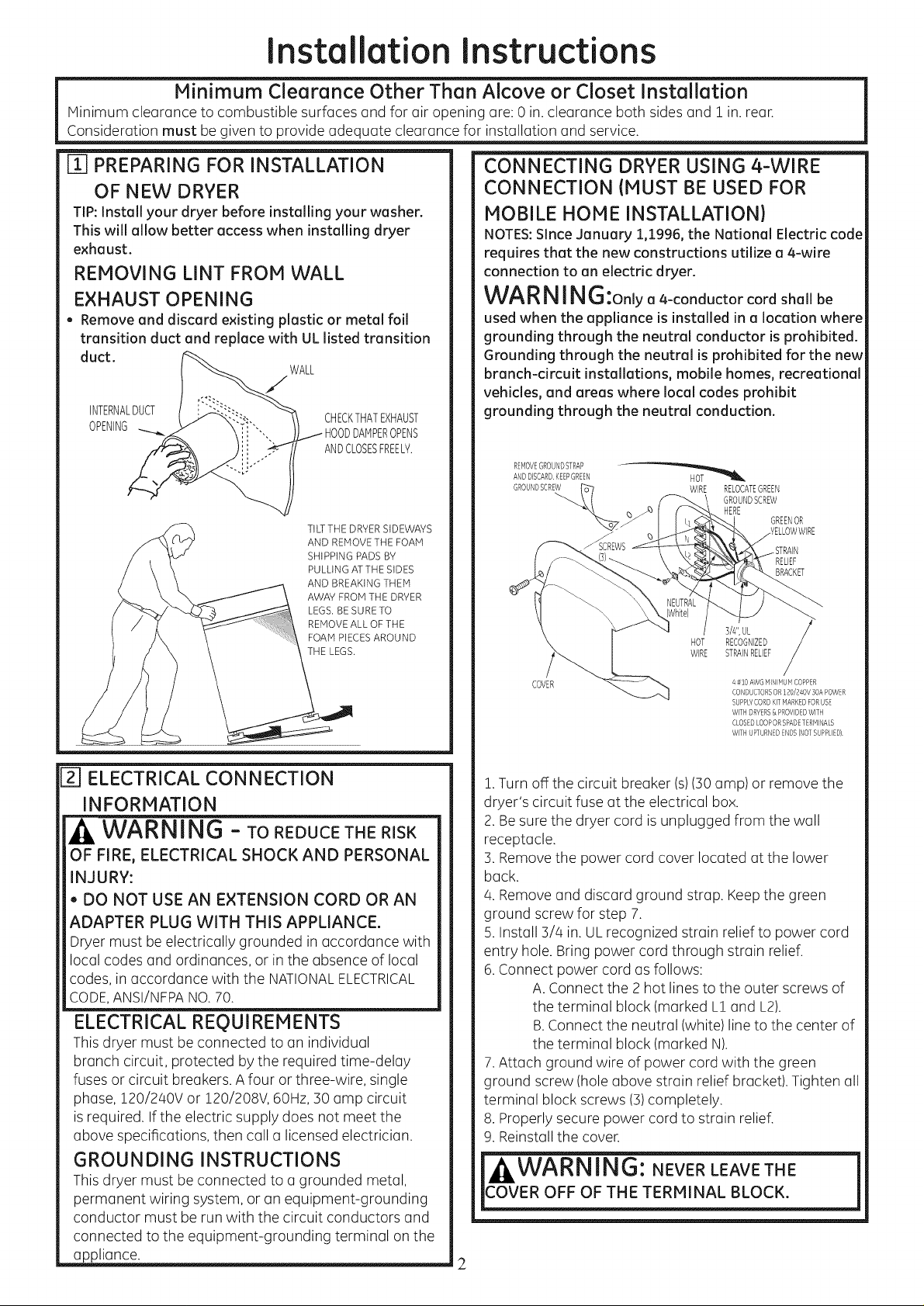

CONNECTING DRYER USING 4-WIRE

CONNECTION (MUST BE USED FOR

MOBILE HONE INSTALLATION)

NOTES:Since January 1,1996, the National Electric code

requires that the new constructions utilize a 4-wire

connection to an electric dryer.

WARNING:onlya4-conductorcordshallbe

used when the appliance is installed in a location where

grounding through the neutral conductor is prohibited.

Grounding through the neutral is prohibited for the new

branch-circuit installations, mobile homes, recreational

vehicles, and areas where local codes prohibit

grounding through the neutral conduction.

REivIOVEGROUNDSTRAP

ANDDISCARDKEEPGREEN

GROU"@SCREW ('_-/ WIRE RELOCATEGREEN

-_::::::_:3 _ HERE GREENOR

COVER

GROUNDSCREW

HOT

RECOGNIZED

STRAINRELIEF

WIRE

s/4",UL

N#10 AWG HR'_iHUIVICOPPER

CONDUCTORSOR120/240V 30APOWER

SUPPLYCORDKITHARKEDFORUSE

WITHDRYERS& PROVIDEDWITH

CLOSEDLOOPORSPADETERHINALS

WITHUPTURNEDENDS(NOTSUPPLIED)

RELIEF

BRACKET

[_] ELECTRICAL CONNECTION

INFORMATION

WARNING - ToREDUCETHERISK

OF FIRE, ELECTRICAL SHOCK AND PERSONAL

INJURY:

, DO NOT USE AN EXTENSION CORD OR AN

ADAPTER PLUG WiTH THiS APPLIANCE.

Dryer must be electrically grounded inaccordance with

local codes and ordinances, or in the absence of local

codes, in accordance with the NATIONALELECTRICAL

CODE,ANSI/NFPANO.70.

ELECTRICAL REQUIREMENTS

This dryer must be connected to an individual

branch circuit, protected by the required time-delay

fuses or circuit breakers. A four or three-wire, single

phase, 120/240V or 120/208V, 60Hz, 30 amp circuit

is required. If the electric supply does not meet the

above specifications, then call a licensed electrician.

GROUNDING INSTRUCTIONS

This dryer must be connected to a grounded metal,

permanent wiring system, or an equipment-grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal on the

appliance.

1.Turn off the circuit breaker (s)(30amp) or remove the

dryer's circuit fuse at the electrical box.

2. Besure the dryer cord is unplugged from the wall

receptacle.

3. Removethe power cord cover located at the lower

back.

4. Remove and discard ground strap. Keepthe green

ground screw for step 7.

5. Install 3/4 in. UL recognized strain relief to power cord

entry hole. Bring power cord through strain relief.

6.Connect power cord as follows:

A. Connect the 2 hot lines to the outer screws of

the terminal block (marked L1 and L2).

B.Connect the neutral (white) line to the center of

the terminal block (marked N).

7.Attach ground wire of power cord with the green

ground screw (hole above strain relief bracket). Tighten all

terminal block screws (3)completely.

8. Properly secure power cord to strain relief.

9. Reinstall the cover.

,

2

Page 3

Installation instructions

CONNECTING DRYER USING 3-WIRE

CONNECTION

IFREQUIRED,BYLOCALCODE,

iNSTALLEXTERNALGROUND

(NOTPROVIDED)TOGROUNDED

METAL,COLDWATERPIPE,OR GREEN GROUND

OTHERESTABLISHEDGROUND GROUND STRAP

DETERMINEDBYAQUALiFiED SCREW

ELECTRiCiAN. HOT

COVER

WiRE STRAINRELIEF

NEUTRAL

(White) HOT

] #10AWGMINIMUMCOPPER

CONDUCTORSOR120/240V30APOWER

SUPPLYCORDKiTMARKEDFORUSE

WiTHDRYERS&PROVIDEDWiTHCLOSED

LOOPORSPADETERMINALSWiTH

UPTURNEDENDS(NOTSUPPLIED}.

BRACKET

WIRE

3/#',UL

RECOGNIZED

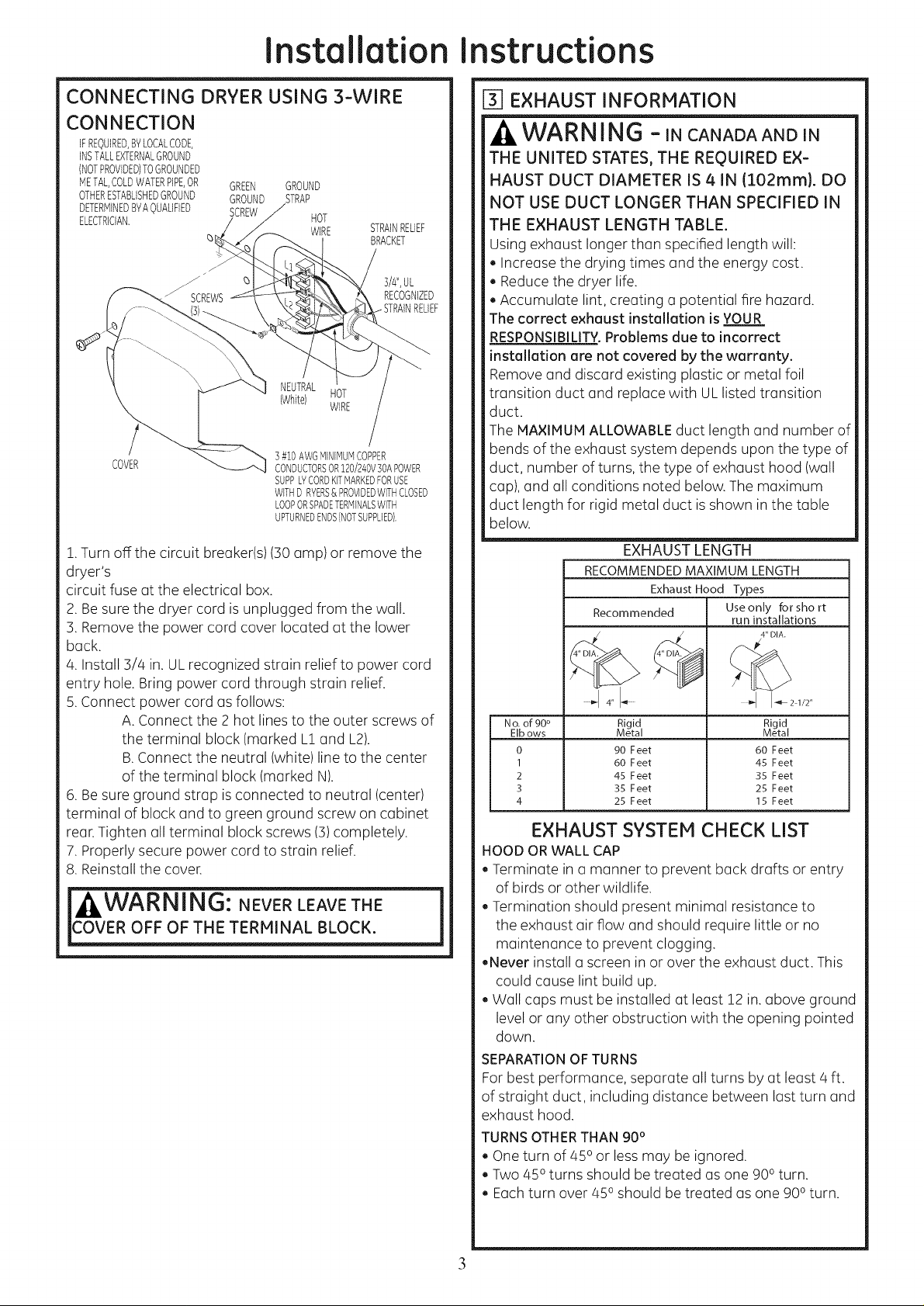

EXHAUST INFORMATION

WARNING -IN CANADAANDIN

THE UNITED STATES, THE REQUIRED EX-

HAUST DUCT DIAMETER IS 4. IN (102mm). DO

NOT USE DUCT LONGER THAN SPECIFIED IN

THE EXHAUST LENGTH TABLE.

Using exhaust longer than specified length will:

, Increase the drying times and the energy cost.

, Reducethe dryer life.

, Accumulate lint, creating a potential fire hazard.

The correct exhaust installation is YOUR

RESPONSIBILITY.Problems due to incorrect

installation are not covered by the warranty.

Remove and discard existing plastic or metal foil

transition duct and replace with ULlisted transition

duct.

The MAXIMUM ALLOWABLE duct length and number of

bends of the exhaust system depends upon the type of

duct, number of turns, the type of exhaust hood (wall

cap), and all conditions noted below. The maximum

duct length for rigid metal duct is shown in the table

below.

1.Turn off the circuit breaker(s)(30amp) or remove the

dryer's

circuit fuse at the electrical box.

2. Besure the dryer cord isunplugged from the wall.

3. Removethe power cord cover located at the lower

back.

4. Install 3/4 in. ULrecognized strain relief to power cord

entry hole. Bring power cord through strain relief.

5.Connect power cord as follows:

A. Connect the 2hot lines to the outer screws of

the terminal block (marked L1 and L2).

B.Connect the neutral (white) line to the center

of the terminal block (marked N).

6. Besure ground strap isconnected to neutral (center)

terminal of block and to green ground screw on cabinet

rear.Tighten all terminal block screws (3)completely.

7. Properly secure power cord to strain relief.

8. Reinstall the cover.

j|WARNING'. NEVER LEAVE THE j

COVER OFF OF THE TERMINAL BLOCK.

EXHAUST LENGTH

RECOMMENDED MAXIMUM LENGTH

Exhaust Hood Types

Recommended

4" I-_ I-4_ 2 1/2"

No.of 90 ° Rigid Rigid

EIbows Metal Metal

0 90 Feet 60 Feet

1 60 Feet 45 Feet

2 45 Feet 35 Feet

3 35 Feet 25 Feet

4 25 Feet 15 Feet

Useonly for sho rt

run installations

4" DIA.

EXHAUST SYSTEM CHECK LIST

HOOD ORWALL CAP

, Terminate in a manner to prevent back drafts or entry

of birds or other wildlife.

, Termination should present minimal resistance to

the exhaust air flow and should require little or no

maintenance to prevent clogging.

,Never install a screen inor over the exhaust duct. This

could cause lint build up.

, Wall caps must be installed at least 12 in. above ground

level or any other obstruction with the opening pointed

down.

SEPARATIONOF TURNS

Forbest performance, separate all turns by at least 4 ft.

of straight duct, including distance between last turn and

exhaust hood.

TURNSOTHERTHAN 90°

, Oneturn of 45oor less may be ignored.

, Two 45oturns should be treated as one 90oturn.

, Eachturn over 45o should be treated as one 90oturn.

3

Page 4

Installation

Instructions

EXHAUST INFORMATION (cont)

SEALING OFJOINTS

, AIIjoints should be tight to avoid leaks. The male end of

each section of duct must point away from the dryer.

, Do not assemble the ductwork with fasteners that

extend into the duct. Theywill serve as a collection

point for lint.

, Duct joints can be made air and moisture-tight by

wrapping the overlapped joints with duct tape.

, Horizontal runs should slope down toward the outdoors

1/2inch per foot

INSULATION

Duct work that runs through an unheated area or is

near air conditioning should be insulated to reduce

condensation and lint build-up.

[_ EXHAUST CONNECTION

_ZI,WARNING - TOREDUCE

THE

RISK OF FIRE OR PERSONAL INJURY:

, Thisclothes dryer must be exhausted to the outdoors.

, Useonly 4" rigid metal ducting for the home exhaust

duct.

, Useonly 4" rigid metal or UL-listed flexible metal

(semi-rigid or foil-type) duct to connect the dryer

to the home exhaust duct. It must be installed

in accordance with the instructions found in

"Connecting The Dryer To House Vent" on page 5 of

this manual.

, Donot terminate exhaust in a chimney, a wall,

a ceiling, gas vent, crawl space, attic, under an

enclosed floor, or in any other concealed space of

a building. The accumulated lint could create a fire

hazard.

, Neverterminate the exhaust into a common duct

with a kitchen exhaust system. A combination of =

grease and lint creates a potential fire hazard.

, Donot use duct longer than specified in the exhaust

length table. Longer ducts can accumulate lint,

creating a potential fire hazard.

, Never install a screen inor over the exhaust duct. This

will cause lint to accumulate, creating a potential fire

hazard.

, Donot assemble ductwork with any fasteners

that extend into the duct. These fasteners can

accumulate lint, creating a potential fire hazard.

, Donot obstruct incoming or exhausted air.

, Provide an access for inspection and cleaning of

the exhaust system, especially at turns and joints.

Exhaust system shall be inspected and cleaned at

least once a year.

THIS DRYER COMES READY FOR REAR

EXHAUSTING. IF SPACE IS LIMITED, USE

THE INSTRUCTIONS IN SECTION 9 TO

EXHAUST DIRECTLY FROM THE SIDES OR

BOTTOM OF THE CABINET.

STANDARD REAR EXHAUST

(Vented at all floor level}

FOR STRAIGHT LINE INSTALLATION,

CONNECT THE DRYER EXHAUST TO

THE EXTERNAL EXHAUST HOOD

USING DUCT TAPE OR CLAMP.

EXTERNAL

DUCT

OPENING

DUCT TAPE OR

DUCT CLAMP

4" METAL DUCT

(CUT TO PROPER

LENGTH) DUCT TAPE OR

NOTE: WE STRONGLY RECOMMEND SOLID METAL EXHAUST DUCTING.

HOWEVER, IF FLEXIBLE DUCTING IS USED IT MUST BE UL-LISTED METAL

NOT PLASTIC.

ELBOWHIGHLY

RECOMMENDED-

DUCT CLAMP

STANDARD REAR EXHAUST

(Vented above floor level)

ELBOWHIGHLY

_ RECOMMENDED

RECOMMENDED

CONFIGURATION

TOMINIMIZE

EXHAUST

BLOCKAGE.

NOTE:ELBOWSWILL PREVENTDUCT

KINKINGAND COLLAPSING.

[_ LEVELING AND STABILIZING YOUR DRYER

STAND THE DRYER UPRIGHT NEAR THE FINAL LOCATION AND ADJUST

THE 4 LEVELING LEGS, AT THE CORNERS, TO ENSURE THAT THE DRYER

IS LEVEL FROM SIDE TO SIDE AND FRONT TO REAR.

LEVEL

FRONT TO-BACK

LEVEL

SOETO-SDE

RLEVELNGLEGS

2ANTTPLEGS

4

Page 5

Installation instructions

CONNECTING THE DRYERTO HOUSEVENT

RIGIDMETALTRANSITIONDUCT

• Forbest dryingperformance,a rigid metaltransition duct is

recommended.

• Rigidmetaltransitionsducts reducethe riskof crushingand

kinking.

UL-LISTEDFLEXIBLEMETAL(SEMI-RIGID}TRANSITIONDUCT

• tf rigid metalduct cannot beused,thenUL-listedflexiblemetal

(semi-rigid)ducting can beused(KitWX08XZ0077).

• Neverinstallflexible metalduct inwalls,ceilings,floorsor

otherenclosedspaces.

Total lengthofflexiblemetal duct shouldnot exceed8 feet

(2.4m).

Formany applications,installingelbowsat both the dryer

andthe wallishighlyrecommended(seeillustrationsbelow).

Elbowsallow the dryerto sitcloseto the wallwithout kinking

andor crushingthetransition duct, maximizingdrying

performance.

•Avoidrestingtheduct on sharpobjects.

UL-LISTEDFLEXIBLEMETAL(FOIL-TYPE}TRANSITIONDUCT

• tn specialinstallations,itmaybenecessaryto connectthe

dryerto the houseventusinga flexiblemetal(foil-type)duct.

A UL-listedflexiblemetal (foil-type)ductmay beusedONLY

in installationswhererigid metalor flexiblemetal(semi-rigid)

ductingcannot beusedANDwherea4" diameter can be

maintainedthroughout theentire lengthof the transition

duct.

• tn Canadaandthe UnitedStates,onlythe flexiblemetal(foil-

type)ductsthat complywith the"Outlinefor ClothesDryer

TransitionDuct Subject2158A"shallbe used.

• Neverinstallflexible metalduct inwalls,ceilings,floorsor

otherenclosedspaces.

Total lengthofflexiblemetal duct shouldnot exceed8 feet

(2.4m).

•Avoidrestingtheduct on sharpobjects.

Forbest dryingperformance:

1.Slideoneend ofthe ductoverthe clothesdryeroutlet pipe.

2.Securetheduct with a clamp.

3.With thedryer initspermanentposition,extendthe duct

to its full length.Allow2"ofductto overlapthe exhaust pipe.

Cutoff and removeexcessduct. Keepthe duct asstraight as

possiblefor maximum airflow.

/4.Securetheduct to the exhaustpipewith theother clamp.

rssmq

EXCESSLVE

EXHAUST _}LENG_ .................................................EXHAUSTAGALNSTFLEXLBLEDOCRUSHNOT

ALCOVE OR CLOSET INSTALLATION

• tfyour dryerisapprovedfor installationinan alcoveor closet,

itwill bestatedon a labelon the dryerback.

•ThedryerMUSTbeventedto the outdoors.Seethe EXHAUST

INFORMATIONsections3 &/4.

• Minimumclearancebetweendryercabinetand adjacentwalls

or other surfacesis:

0 in.eitherside

3 in.front and rear

Minimumvertical spacefromfloorto overheadcabinets,

ceiling,etc.is 52in.

Closetdoorsmustbe Iouveredor otherwiseventilated and

mustcontaina minimum of60 sq.in.of openareaequally

distributed,tf theclosetcontainsbotha washerand a dryer,

doorsmust containaminimum of 120sq.in. ofopen area

equallydistributed.

[-7]BATHROOM OR BEDROOM INSTALLATION

• The dryer MUST be vented to the outdoors. See

EXHAUSTINFORMATIONsection 3 & 4.

, The installation must conform with local codes or, in the

absence of local codes, with the NATIONAL ELECTRICAL

CODE,ANSI/NFPA NO. 70.

ELBOW HIGHLY

RECOMMENDED

u___LA _t_ S HIGHLY

RECOMMENDED

i-8-_MOBILE OR MANUFACTURED HOME

INSTALLATION

• installationMUSTconform to the MANUFACTUREDHONE

CONSTRUCTION& SAFETYSTANDARD,TITLE24,PART32-80

or,when suchstandardisnotapplicable,with AMERICAN

NATIONALSTANDARDFORMOBILEHOME,ANSI/NFPANO.

501B.

• ThedryerMUSTbeventedto the outdoorswiththe

termination securelyfastenedto the mobilehome structure.

(SeeEXHAUSTINFORMATIONsection3&/4).

• Thevent MUSTNOTbe terminatedbeneathamobileor

manufactured home.

• Thevent ductmaterialMUSTBEMETAL.

• Donot usesheet metalscrewsor other fasteningdevices

which extendintothe interior of theexhaustvent.

• Seesection2for electricalconnectioninformation.

5

Page 6

Instollotion instructions

F9]DRYER EXHAUST TO RIGHT, LEFT

OR BOTTOM CABINET

THIS EXHAUST INSTALLATION, BE SURE

TO DISCONNECT THE DRYER FROM ITS

ELECTRICAL SUPPLY. PROTECT YOUR HANDS

AND ARMS FROM SHARP EDGES WHEN

WORKING INSIDE THE CABINET. BE SURE TO

WEAR GLOVES

REMOVE

SCREW

ANDSAVE.

REMOVEjO

DESIRED

KNOCKOUT

(ONEONLY).

Detach and remove the bottom, right or left side knockout

as desired. Remove the screw inside the drger exhaust duct

and save. Pull the duct out of the drger.

Note: Only 4" round rigid metal ducting allowed inside

dryer. FIXINGHOLE

I

B A

ADDING NEW DUCT

FIXING

HOLE

PORTION"A"

RIGHTOR

LEFTSIDE

EXHAUST

Reconnect the cut portion (A)of the duct to the blower

housing. Make sure that the shortened duct is aligned with

the tab in the base. Use the screw saved previouslg to secure

the duct in place through the tab on the appliance base.

ADDING ELBOW AND DUCT FOR

EXHAUST TO LEFT OR RIGHT SIDE OF

CABINET

. Preassemble 4" elbow with 4" duct. Wrap duct tape

around joint.

. Insert duct assembly, elbow first, through the side

opening and connect the elbow to the dryer internal

duct.

CAUTION: Be sure not to pull or damage the

electrical wires inside the dryer when inserting the

duct.

Cut the duct as shown and keep portion A.

TAB LOC, )N

BENDTAB

UP45°

Through the rear opening, locate the tab in the middle of

the appliance base. Lift the tab to about 45ousing a flat

blade screwdriver.

EXHAUSTCAN

BEADDEDTO

LEFTORRIGHTSIDE

\

DUCT

TAPE

6

Page 7

Installation instructions

. Apply duct tape as shown on the joint between the

dryer internal duct and the elbow.

DUCT

CAUTION:

Internal duct joints must be

secured with tape, otherwise

they may separate and cause

a safety hazard.

ADDING ELBOW FOR EXHAUST

THROUGH BOTTOM OF CABINET

. Insert the elbow through the rear opening and connect

it to the dryer internal duct.

. Apply duct tape on the joint between the dryer internal

duct and elbow, as shown on page 6.

.J

CAUTION:

Internal duct joints must besecured with tape,

otherwise they may separate and cause a

safety hazard.

ADDING COVER PLATE TO REAR

CHANGING DIRECTION OF

DOOR OPENING

1.Open the door and remove the filler plugs opposite

the hinges.With the door completely open, remove the

bottom screws from each hinge on the dryer face. Insert

these screws about half way into the TOPholes,for each

hinge on the opposite side (where you removed the filler

plugs).Apply firm pressure to get the screw started.

2.Loosen the top screws from each hinge on the dryer

face half way. With one hand holding the top of the door

and the other hand holding the bottom, remove the door

from the dryer by lifting it UP and OUT.

3.Rotate the door 1800. Insert the door on the opposite

side of the opening by moving the door IN and DOWN

until the top hinge and the bottom hinge are resting on

the top screws inserted in step 1.

4. Remove the remaining screws from the side of the

opening from which the door was removed. With these

screws secure each hinge at the bottom. Tighten the two

top screws on each hinge. Reinsert the plastic plugs on

the side from which the door was removed.

REMOVE THE

BOTTOM SCREW LOOSEN THE TOP SCREWS

FROM EACH HINGE FROM EACH HINGE ON

ON THE DRYER FACE THE DRYER FACE

HALF WAY

OF CABINET {SIDES AND BOTTOM

EXHAUST}

PLATE

(KITWE1M454)

Connect standard metal elbows and ducts to complete

the exhaust system. Cover back opening with a plate (Kit

WE1M454) available from your local service provider.

Placedryer in final location.

WARNING-NEVER LEAVE THE BACK

OPENING WITHOUT THE PLATE. {Kit

WEIM454}

MOVE THE DOOR IN AND

DOWN UNTIL THE TOP HINGE SECURE EACH HINGE

AND THE BOTTOM HINGES ARE AT THE BOTTOM AND

RESTING ON THE TOP SREWS TIGHTEN THE TWO TOP

INSERTED IN STEP 1 SCREWS OF EACH HINGE

7

7

Page 8

Installation

Instructions

[] CONNECTING INLET HOSES

(onsome models)

To produce steam, the dryer must connect to the cold

water supply. Since the washer must also connect to the

cold water, a ",7"connector is inserted to allow both inlet

hoses to make that connection at the same time.

NOTE:Use the new inlet hoses provided; never

use old hoses.

1.Turn the cold water faucet off. Removethe washer inlet

hose from the washer fill valve connector (cold).

2. Ensurethe rubber fiat washer isin place and screw

the female coupling of the short hose onto the washer fill

valve connector. Tighten by hand until firmly seated.

3. Attach the female end of the '"7" connector to the male

coupling of the short hose. Ensure the rubber fiat washer

is in place. Tighten by hand until firmly seated.

4. Insert the filter screen in the coupling of the washer's

inlet hose. If a rubber fiat washer

isalready in place remove it before installing

the filter screen. Attach this coupling to one male end of

the "`7"connector. Tighten by hand until firmly seated.

5. Ensure the rubber fiat washer is in place and attach

the dryer's long inlet hose to the other mule end of the

"`7"connector. Tighten by hand until firmly seated.

6. Ensure the rubber fiat washer is in place and attach

the other end of the dryer's long inlet hose to the fill valve

connector at the bottom of the dryer back panel. Tighten

by hand until firmly seated.

[] CONNECTING INLET HOSES (cont.)

8. Turn the water faucet on.

9. Check for leaks around the "`7"connector,

faucet and hose couplings.

WATER SUPPLY REQUIREMENTS

Hot and cold water faucets MUSTbe installed within/42

in, (107 cm) of your washer's water inlet. The faucets

MUSTbe 3//4 in. (1.9cm)garden hose-type so inlet hoses

can be connected. Water pressure IvlUSTbe between 10

and 120 pounds per square inch. ,Tourwater department

can advise you of your water pressure.

NOTE:A water softener is recommended to reduce

buildup of scale inside the steam generator if the home

water supply is very hard.

[] SERVICING

WARNING - LABELALLWIRES

PRIOR TO DISCONNECTING WHEN SERVICING

CONTROLS. WIRING ERRORS CAN CAUSE

IMPROPER AND DANGEROUS OPERATION

AFTER SERVICING/INSTALLATION.

Forservicing phone numbers for replacement parts, and

other information, refer to Owner's Manual or visit our

Web site.

7. Using pliers, tighten all the couplings with

an additional two-thirds turn.

NOTE:Do not overtighten. Damage to the couplings may

result.

TO REGISTER YOUR DRYER

CALL TOLL-FREE

1-888-269-1192

Prompt registration confirms your right to protection

under the terms of your warranty.

www.GEAppliances.com (US)

For Questions on Installation, Call: !-800-GECARES (US)

8

Loading...

Loading...