GE DCCB330GJ2WC, DCCB330GJ3WC, DCCB330GJ4WC, DMCD330GJ3WC, DMCD330GJ4WC Installation Guide

...Page 1

Installation

Gas Dryer

instructions

Questions? Call800.GE.CARES 1800.432.2737)or visitour Web siteat:GEAppliances.com

i

BEFORE YOU BEGIN

Readthese instructions completely and

carefully.

, IMPORTANT- savethese instructions for

local inspector's use.

. IMPORTANT- Observe all governing

codes and ordinances.

, Note to Installer - Be sure to leave these

instructions with the customer.

, Note to Customer- Keepthese instructions with

your Owner's Manualfor future reference.

, Before the old dryer is removed from service or

discarded, remove the dryer door.

, Inspect the dryer exhaust outlet and straighten

the outlet walls if they are bent.

, Service information and the wiring diagram

are located in the control console.

, Do not allow children on or in the appliance.

Close supervision of children is necessary

when the appliance is used near children.

, Install the dryer where the temperature is

above 50°F for satisfactory operation of the

dryer control system.

, Product failure due to improper installation is

not covered under the Warranty.

IN THE COMMONWEALTH OF MASSACHUSETTS

. This product must be installed by a licensed

plumber or gas fitter.

. When using ball-type gas shut-offvalves, they

shall be the T-handle type.

. A flexible gas connector, when used, must not

exceed 3 feet.

InCanada, call1.800.561.3344or visitwww.GEAppliances.ca i

02

WARNING RISKOFFIRE

. To reduce the risk of severe injury or death, follow all installation

instructions.

. Clothes dryer installation must be performed by a qualified installer.

. Install the clothes dryer according to these instructions and in

accordance with local codes.

. California SafeDrinking Water and Toxic Enforcement Act

This act requires the governor of California to publish a list of

substances known tothe state to causecancer,birth defects or other

reproductive harm and requires businesses to warn customers of

potential exposure to such substances. Gas appliances can cause

minor exposure to four of these substances, namely benzene,

carbon monoxide, formaldehyde and soot, caused primarily by the

incomplete combustion of natural gas or LPfuels. Properly adjusted

dryers will minimize incomplete combustion. Exposure to these

substances can be minimized further by properly venting the dryer

to the outdoors.

. Thisdryer must be exhausted to the outdoors.

. Useonly rigid metal 4" diameter ductwork inside the dryer cabinet

and use only ULapproved transition ducting between the dryer and

the home duct.

. DO NOTinstall aclothes dryer with flexible plastic ducting

materials. Ifflexible metal (semirigid or foil-type) duct is installed, it

must beULlisted and installed in accordance with the instructions

found in"Connecting The Dryer ToHouse Vent" on page 5 of this

manual. Flexible venting materials are known to collapse, be easily

crushed, and trap lint. These conditions will obstruct dryer airflow

and increase the risk of fire.

. Do not install orstore this appliance in any location where it could

be exposed to water and or weather.

. Savethese instructions. (Installers: Be sure to leave these

instructions with the customer).

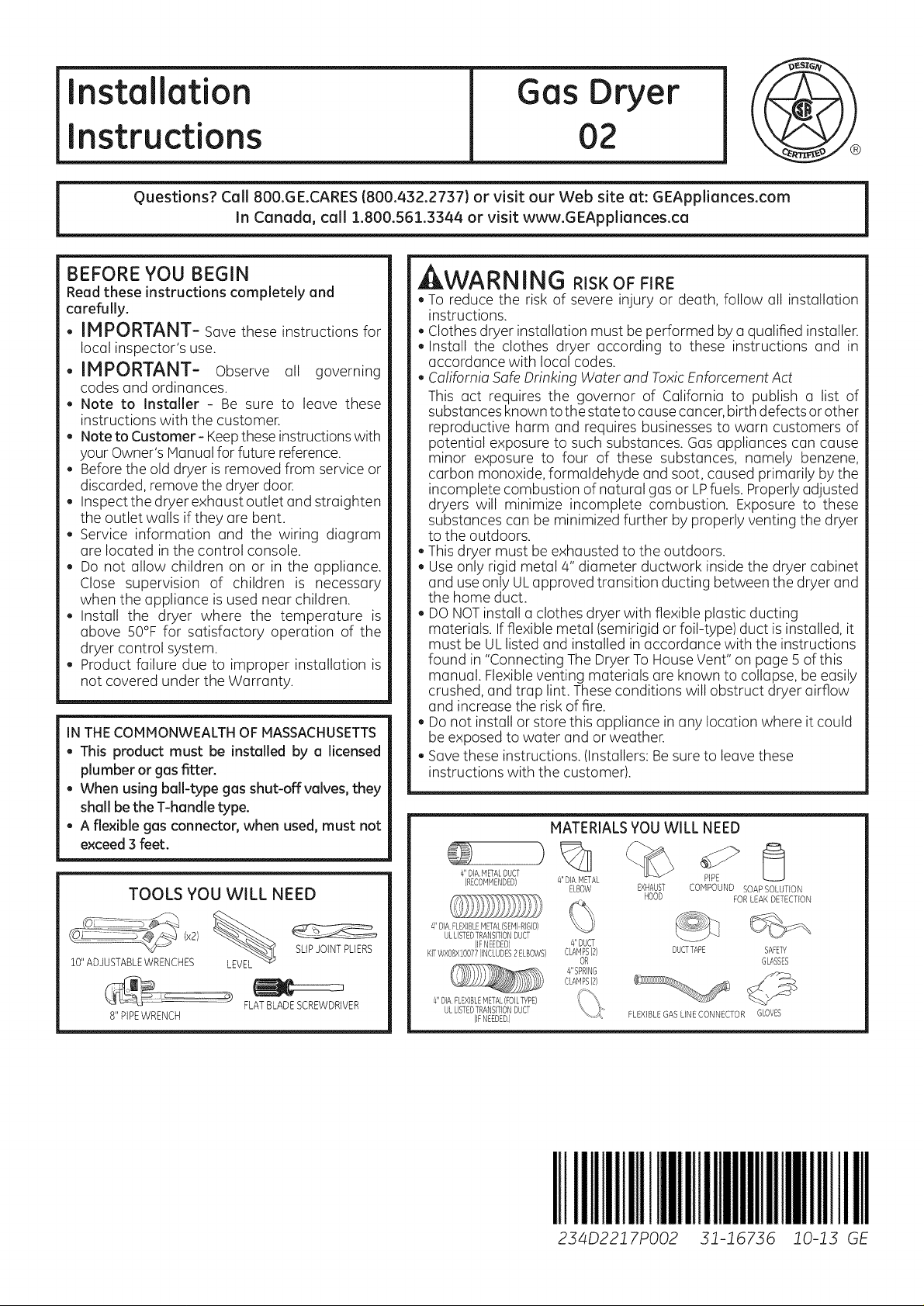

MATERIALSYOUWILL NEED

TOOLS YOU WILL NEED

10"ADJUSTABLEWRENCHES LEV_EL SLIPJOINTPLIERS

8" PIPEWRENCH

FLATBLADESCREWDRIVER

4I1DIA.METALDUCT

(RECOMMENDED)

4HDIA.FLEXIBLEMETAL(SEMI-RIGID)

ULLISTEDTRANSITIONDUCT

KITWX08XI0077(INCLUDES2ELBOVVS}

(IFNEEDED)

4"DIAFLEXIBLEMETAL(FOILTYPE)

ULLISTEDTRANSITIONDUCT

IIFNEEDED)

4"DIAMETAL PIPE

ELBOW EXHAUST COMPOUND SOAP SOLUTION

4"DUCT

CLAMPS(B)

OR

4"SPRING

CLAMPS(2)

IIIIIIIIIIII!11

234D2217P002

HOOD FORLEAKDETECTION

DUCTTAPE SAFETY

FLEXIBLEGASLINECONNECTOR GLOVES

GLASSES

IIII!11111IIII

31-16736 10-13 GE

Page 2

Installation Instructions

Minimum Clearance Other Than Alcove or Closet Installation

Minimum clearance to combustible surfaces and for air opening are: 0 in.clearance both sides and ! in. rear.

Consideration must be given to provide adequate clearance for installation and service.

m PREPARING FOR INSTALLATION

OF NEW DRYER

TIP:Install your dryer before installing your washer.

This will allow better access when installing dryer

exhaust.

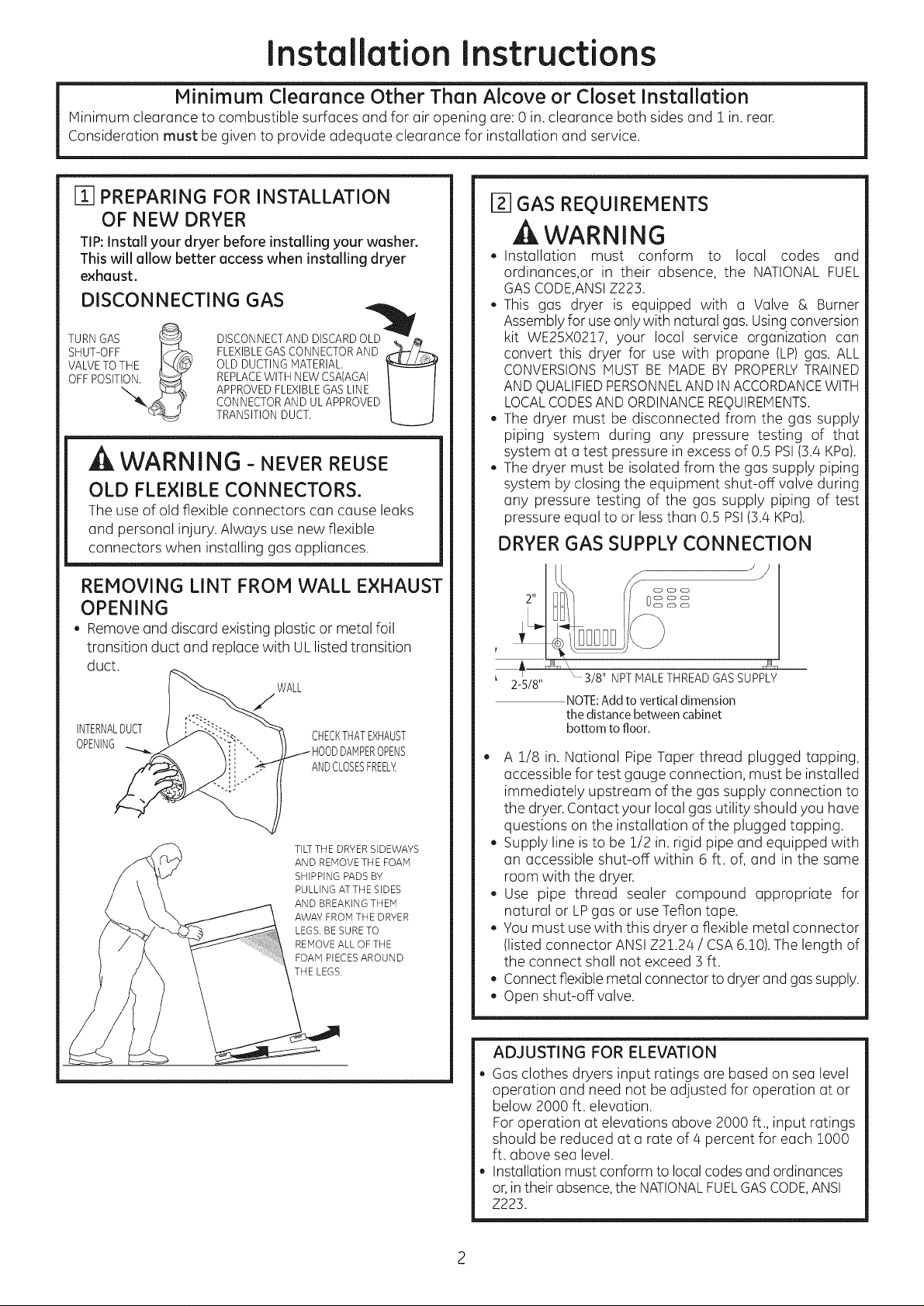

DISCONNECTING GAS

TURN GAS _ DISCONNECTAND DISCARDOku'_ _

SHUT-OFF J¢_ FLEXIBLEGASCONNECTORAND _/_

VALVETOTHE _'_L_ OLD DUCTINGMATERIAL.

APPROVEDFLEXIBLEGASLINE

CONNECTORAND UL APPROVED

TRANSITIONDUCT.

U

WARNING - NEVERREUSE

OLD FLEXIBLE CONNECTORS.

The use of old flexible connectors can cause leaks

and personal injury. Always use new flexible

connectors when installing gas appliances.

REMOVING LINT FROM WALL EXHAUST

OPENING

, Remove and discard existing plastic or metal foil

transition duct and replace with ULlisted transition

duct.

WALL

INTERNALDUCT

OPENING DPENS

CHECKTHATEXHAUST

ANDCLOSESFREELY

TILTTHE DRYERSIDEWAYS

AND REMOVE THE FOAM

SHIPPING PADS BY

PULLING ATTHE SIDES

AND BREAKING THEM

AWAY FROM THE DRYER

LEGS. BESURETO

REMOVEALL OFTHE

FOAM PIECESAROUND

THE LEGS.

12]GAS REQUIREMENTS

WARNING

. Installation must conform to local codes and

ordinances,or in their absence, the NATIONAL FUEL

GASCODE,ANSIZ223.

• This gas dryer is equipped with a Valve & Burner

Assembly for useonly with natural gas. Using conversion

kit WE25X02!7, your local service organization can

convert this dryer for use with propane (LP)gas. ALL

CONVERSIONSMUSTBE MADE BY PROPERLYTRAINED

AND QUALIFIEDPERSONNELAND INACCORDANCEWITH

LOCALCODESANDORDINANCEREQUIREMENTS.

, The dryer must be disconnected from the gas supply

piping system during any pressure testing of that

system at a test pressure inexcess of 0.5 PSI(3.4KPa).

, The dryer must be isolated from the gas supply piping

system by closing the equipment shut-off valve during

any pressure testing of the gas supply piping of test

pressure equal to or less than 0.5 PSI(3.4 KPa).

DRYER GAS SUPPLY CONNECTION

)

2"

2-5/8"

A 1/8 in. National Pipe Taper thread plugged tapping,

accessible for test gauge connection, must be installed

immediately upstream of the gas supply connection to

the dryer. Contact your local gas utility should you have

questions on the installation of the plugged tapping.

, Supply line is to be !/2 in. rigid pipe and equipped with

an accessible shut-off within 6 ft. of, and in the same

room with the dryer.

, Use pipe thread sealer compound appropriate for

natural or LPgas or use Teflon tape.

, You must use with this dryer a flexible metal connector

(listed connector ANSI Z2!.24 / CSA6.!0). The length of

the connect shall not exceed 3ft.

, Connect flexible metal connector to dryer and gassupply.

, Open shut-off valve.

" 3/8" NPT MALETHREAD GAS SUPPLY

NOTE:Add to vertical dimension

the distance between cabinet

bottom to floor,

ADJUSTING FOR ELEVATION

, Gas clothes dryers input ratings are based on sea level

operation and need not be adjusted for operation at or

below 2000 ft. elevation.

Foroperation at elevations above 2000 ft., input ratings

should be reduced at a rate of 4 percent for each 1000

ft. above sea level.

, Installation must conform to local codes and ordinances

or,intheir absence,the NATIONALFUELGASCODE,ANSI

Z223.

Page 3

Installation instructions

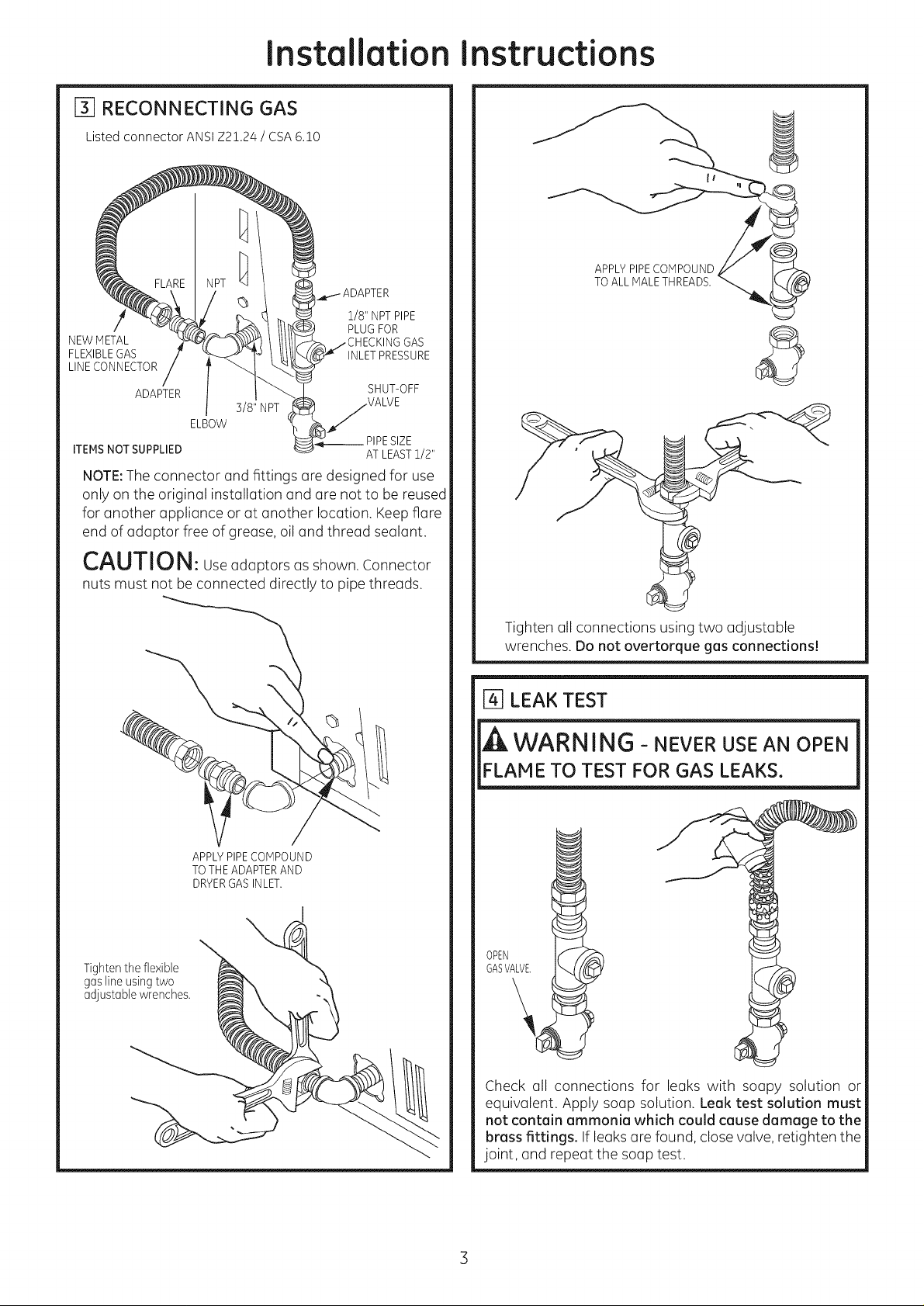

[_ RECONNECTING GAS

Listed connector ANSI Z2!.24 / CSA 6.!0

1/8" NPTPIPE

NEWMETAL GAS

FLEXIBLEGAS INLETPRESSURE

LINECONNECTOR

ADAPTER SHUT-OFF

3/8" NPT

ELBOW

ITEMSNOT SUPPLIED AT LEAST1/2"

NOTE:The connector and fittings ore designed for use

only on the original installation and ore not to be reused

for another appliance or at another location. Keep flare

end of odoptor free of greose, oil ond threod seolont.

PLUGFOR

__ PIPESIZE

APPLYPIPECOMPOUND

TOALL MALETHREADS.

/

CAUTION: UseodoptorsosshownConnector

nuts must not be connected directly to pipe threads.

APPLYPIPECOMPOUND

TOTHEADAPTERAND

DRYERGASINLET.

Tighten the flexible

gas line using two

adjustable wrenches.

Tighten oil connections using two adjustable

wrenches. Do not overtorque gas connections!

[_] LEAK TEST

WARNING- NEVER USE AN OPEN

FLAME TO TEST FOR GAS LEAKS.

GASVALVE.

OPEN

Check oil connections for leaks with soapy solution or

equivalent. Apply soap solution. Leak test solution must

not contain ammonia which could cause damage to the

brass fittings. If leaks ore found, closevalve, retighten the

joint, and repeat the soap test.

Page 4

Installation

Instructions

[] ELECTRICAL CONNECTION

iNFORMATiON

A WARNING - TOREDUCETHE

RISK OF FIRE, ELECTRICAL SHOCK,

AND PERSONAL INJURY:

• DO NOT USE AN EXTENSION CORD

OR AN ADAPTER PLUG WITH THIS

APPLIANCE.

Dryer must be electrically grounded in accordance

with local codes and ordinances, or in the absence

of local codes, in accordance with the NATIONAL

ELECTRICALCODE,ANSI/NFPANO.70.

ELECTRICAL REQUIREMENTS

This appliance must be supplied with 120V, 60Hz, and

connected to a properly grounded branch circuit,

protected by a 15- or 20-amp circuit breaker or time

delay fuse. if electrical supply provided does not meet

the above specifications, it is recommended that a

licensed electrician install an approved outlet.

WARNING - THIS DRYERIS

EQUIPPED WITH A THREE-PRONG

(GROUNDING) PLUG FOR YOUR

PROTECTIONAGAINSTSHOCKHAZARD

AND SHOULD BE PLUGGED DIRECTLY

INTO A PROPERLYGROUNDED THREE-

PRONG RECEPTACLE. DO NOT CUT OR

REMOVE THE GROUNDING PRONG

FROM THIS PLUG.

[_] EXHAUST INFORMATION

WARNING - IN CANADA AND IN

THE UNITED STATES, THE REQUIRED EXHAUST

DUCT DIAMETER IS 4 in (102ram). DO NOT

USE DUCT LONGER THAN SPECIFIED IN THE

EXHAUST LENGTH TABLE.

Using exhaust longer than specified length will:

, Increase the drying times and the energy cost.

, Reducethe dryer life.

, Accumulate lint, creating a potential fire hazard.

Thecorrect exhaust installation is YOURRESPONSIBILITY.

Problems due to incorrect installation are not covered

by the warranty.

Remove and discard existing plastic or metal foil

transition duct and replace with ULlisted transition duct.

The MAXIMUM ALLOWABLEduct length and number of

bends of the exhaust system depends upon the type of

duct, number of turns, the type of exhaust hood (wall

cap), and all conditions noted below. The maximum duct

length for rigid metal duct is shown in the table below.

EXHAUSTLENGTH

RECOMMENDEDMAXIMUM LENGTH

Exhaust Hood Types

Recommended run installations

i @ . 4"°'A_L

NO.of 90° Rigid Rigid

Elbows Metal Metal

0 90 Feet 60 Feet

1 60 Feet 45 Feet

2 45 Feet 35 Feet

3 35 Feet 25 Feet

4 25 Feet 15 Feet

, Forevery extra 90°elbow,reducethe allowable vent system

length by 10 ft.

, Two 45° elbows will be treated likeone 90° elbow.

, Forthe sideexhaust installations, add one 90°elbow to the

chart.

,The total vent system length includes all the straight

portions and elbows of the system (transition duct included).

Use only for short

1/2"

ENSURE PROPER GROUND EXISTS BEFORE USE

LOCAL CODES PERMIT,

q EXTERNALGROUND WIRE

OT PROVIDED), WHICH rV]EETS

)CAL CODES, rvlAYBEADDED

' ATTACHING TO THE GREEN

_OUND SCREW ON THE REAR

: THE DRYER,AND TO A GROUNDED

ETALCOLDWATER PIPE OR OTHER

;TABLISHED GROUND.

EXHAUST SYSTEM CHECK LIST

HOODORWALLCAP

, Terminate in a manner to prevent back drafts or entry of

birdsor other wildlife.

, Termination should present minimal resistance to the

exhaust airflow andshouldrequire littleor no maintenance

to prevent clogging.

, Never install a screen in or over the exhaust duct. This

could cause lint build up.

, Wall caps must be installed at least 12 in. above ground

level or any other obstruction with the opening pointed

down.

SEPARATIONOFTURNS

For best performance, separate allturns by at least 4 ft. of

straight duct, including distance between last turn and

exhaust hood.

TURNSOTHERTHAN90°

, One turn of 450or lessmay be ignored.

, Two 45oturns should be treated as one 90oturn.

, Eachturn over45oshould be treated as one 90oturn.

4

Page 5

Installation

Instructions

SEALING OFJOINTS

, Alljoints should be tight to avoid leaks.The male end of

each section of duct must point away from the dryer.

, The duct shall not be assembled with screws or other

fastening means that extend into the duct and catch

lint.

, Duct joints can be made air and moisture-tight by

wrapping the overlapped joints with duct tape.

, Horizontal runs should slope down toward the outdoors

1//4inch per foot.

INSULATION

Duct work that runs through an unheated area or is near air

conditioning should be insulated to reduce condensation

and lint build-up.

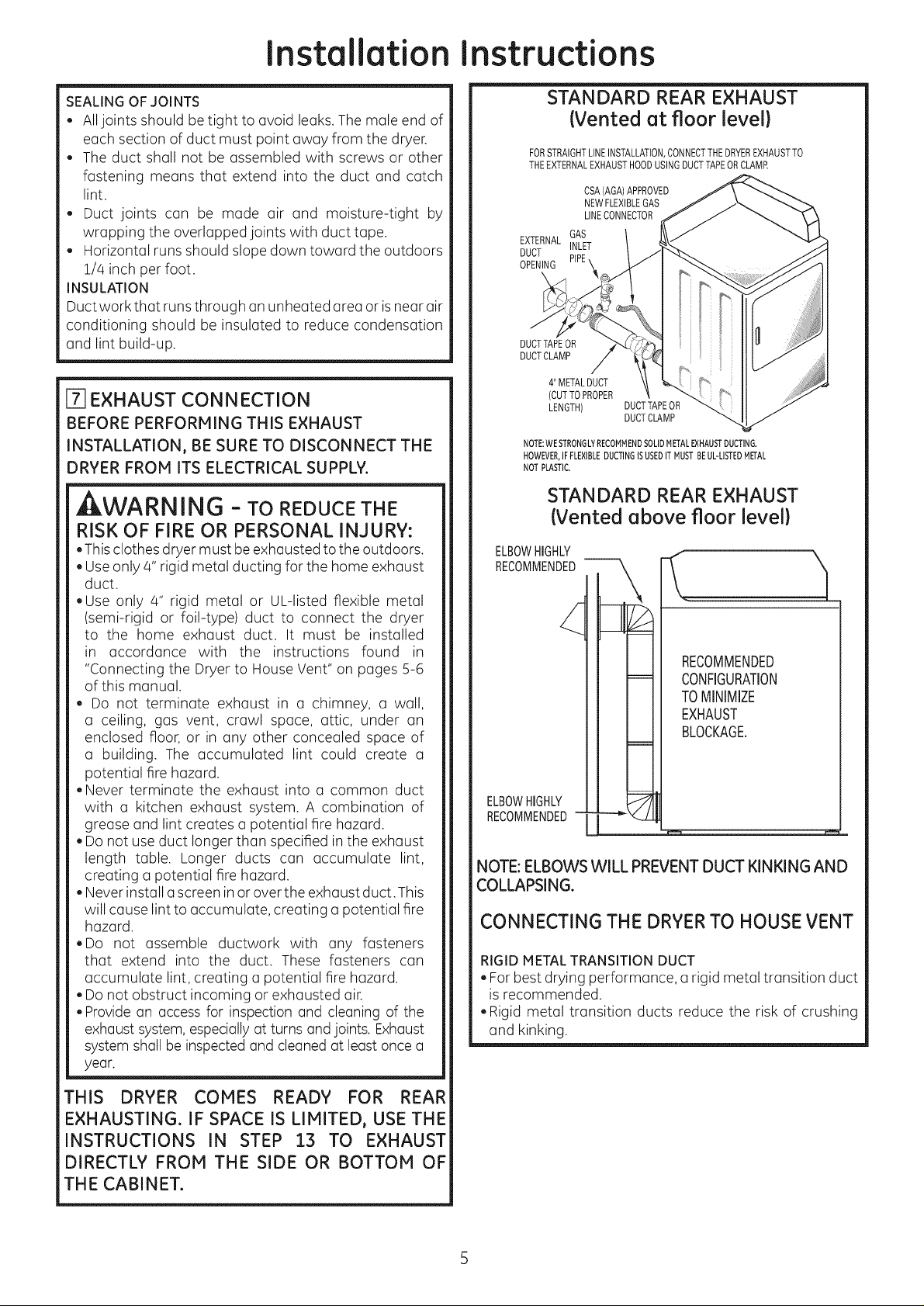

[] EXHAUST CONNECTION

BEFORE PERFORMING THIS EXHAUST

INSTALLATION, BE SURE TO DISCONNECT THE

DRYER FROM ITS ELECTRICAL SUPPLY.

, WARNING - TO REDUCE THE

RISK OF FIRE OR PERSONAL INJURY:

,This clothes dryer must be exhausted to the outdoors.

, Useonly 4" rigid metal ducting for the home exhaust

duct.

,Use only 4" rigid metal or UL-listed flexible metal

(semi-rigid or foil-type) duct to connect the dryer

to the home exhaust duct. It must be installed

in accordance with the instructions found in

"Connecting the Dryer to House Vent" on pages 5-6

of this manual.

, Do not terminate exhaust in a chimney, a wall,

a ceiling, gas vent, crawl space, attic, under an

enclosed floor, or in any other concealed space of

a building. The accumulated lint could create a

potential fire hazard.

,Never terminate the exhaust into a common duct

with a kitchen exhaust system. A combination of

grease and lint creates a potential fire hazard.

, Do not use duct longer than specified inthe exhaust

length table. Longer ducts can accumulate lint,

creating a potential fire hazard.

, Never install a screen in or over the exhaust duct. This

will cause lint to accumulate, creating a potential fire

hazard.

,Do not assemble ductwork with any fasteners

that extend into the duct. These fasteners can

accumulate lint, creating a potential fire hazard.

, Do not obstruct incoming or exhausted air.

, Provide an accessfor inspection and cleaning of the

exhaust system, especially at turns and joints. Exhaust

system shall be inspected and cleaned at least once a

year.

STANDARD REAR EXHAUST

{Vented at floor level}

FORSTRAIGHTLINEINSTALLATION,CONNECTTHEDRYEREXHAUSTTO

THEEXTERNALEXHAUSTHOODUSINGDUCTTAPEORCLAMR

CSA(AGA)APPROVED

NEWFLEXIBLEGAS

LINECONNECTOR

EXTERNAL

DUCT

OPENING

DUCTTAPEOR

DUCTCLAMP

GAS

INLET

4" METALDUCT

(CUTTOPROPER

LENGTH) DUCTTAPEOR

NOTE:WE STRONGLYRECOMMENDSOUDMETALEXHAUSTDUCTING.

HOWEVER,IFFLEXIBLEDUCTINGISUSEDIT MUSTBEUL-LISTEDMETAL

NOTPLASTIC.

DUCTCLAMP

STANDARD REAR EXHAUST

{Vented above floor level}

ELBOWHIGHLY

RECOMMENDED

RECOMMENDED

CONFIGURATION

TOMINIMIZE

EXHAUST

BLOCKAGE.

ELBOWHIGHLY

RECOMMENDED-

NOTE: ELBOWS WILL PREVENT DUCT KINKING AND

COLLAPSING.

CONNECTING THE DRYERTO HOUSE VENT

RIGIDMETALTRANSITION DUCT

, For best drying performance, a rigid metal transition duct

is recommended.

, Rigid metal transition ducts reduce the risk of crushing

and kinking.

THIS DRYER COMES READY FOR REAR

EXHAUSTING. IF SPACE IS LIMITED, USE THE

INSTRUCTIONS IN STEP 13 TO EXHAUST

DIRECTLY FROM THE SIDE OR BOTTOM OF

THE CABINET.

Page 6

Installation Instructions

UL-LISTED FLEXIBLE METAL (SEMI-RIGID) TRANSITION

DUCT

, If rigid met(]l duct c(]nnot be used, then UL-listed flexible

met(]l (semi-rigid) ducting can be used (KitWX08X10077).

, Never install flexible met(]l duct in w(]lls, ceilings, floors or

other enclosed sp(]ces.

,Total length of flexible metal duct should not exceed 8 feet

(2.4m).

, Form(]ny (]pplic(]tions, inst(]lling elbows (It both the dryer

(]nd the w(]ll is highly recommended (see illustr(]tions

below). Elbows (]llow the dryer to sit close to the w(]ll

without kinking (]nd or crushing the tr(]nsition duct,

m(]ximizing drying Derform(]nce.

,Avoid resting the duct on sh(]rp objects.

UL-LISTEDFLEXIBLEMETAL(FOIL-TYPE)TRANSITIONDUCT

, In speciol installations, it may be necessary to connect the

dryer to the housevent usingo flexible metol (foil-type)duct.

A UL-listedflexible metol (foil-type)duct moy be used ONLY

in instollotions where rigid metol or flexible metol (semi-rigid)

ducting cannot be used AND where a 4" diameter con be

mointoinedthroughout the entire lengthof thetransition duct.

, In Conodo ond the United Stotes, only the flexible metol

(foil-type) ducts thot comply with the "Outline for Clothes

Dryer Tronsition Duct Subject 2158A" sholl be used.

, Never instoll flexibl_ metol duct in wolls, ceilings, floors or

other enclosed sp(]ces.

,TotGI length of flexible metol duct should not exceed 8 feet

(2.4m).

, Avoid resting the duct on shGrpobjects.

For best drying performonce:

1.Slide one end of the duct over the clothes dryer outlet pipe.

2.Secure the duct with o clomp.

3.With the dryer in its permGnent position, extend the duct

to its full length. Allow 2" of duct to overlGp the exhGust

pipe. Cut off ond remove excess duct. Keep the duct os

stroight os possible for moximum oirflow.

4.Securethe duct to the exh(]ust pipe with the other cl(]mp.

LEVELING DRYER

LEVEL

FRONTT0-BACK,

4LEVELINGLEGS

LEVEL

SIDE-TO-SIDE,

L

STANDTHEDRYERUPRIGHTNEARTHE

FINALLOCATIONANDADJUSTTHE4LEVELING

LEGSTOMATCHTHEHEIGHTOFYOURWASHER,

ADJUSTTHE2ANTI-TIPLEGSTOCONTACT

THEFLOOR,

ALCOVE OR CLOSET INSTALLATION

, If your dryer is (]pproved for inst(]ll(]tion in (in (]lcove or

closet, it will be stated on o I(]bel on the dryer b(]ck.

,The dryer MUST be vented to the outdoors. See the

EXHAUSTINFORMATIONstep 6.

,Minimum clear(]nce between dryer c(]binet (]nd

(]dj(]cent w(]lls or other surf(Ices is:

0 in. either side

3 in.front

3 in. re(it

, Minimum vertic(]l sp(]ce from floor to overhead c(]binets,

ceiling, etc. is 52 in.

, Closet doors must be Iouvered or otherwise ventil(]ted

(]nd must cont(]in (] minimum of 60 sq. in. of open (]re(]

equ(]lly distributed. If the closet cont(]ins both (] w(]sher

(]nd (] dryer, doors must cont(]in (] minimum of 120 sq.

in. of open (]re(] equ(]lly distributed.

,The closet should be vented to the outdoors to prevent

g(]s pocketing in c(]se of (] g(]s le(]k in the supply line.

, No other fuel-burning (]ppli(]nce sh(]ll be inst(]lled in the

s(]me closet with the dryer.

2ANTI-TIPLEGS

[] BATHROOM OR BEDROOM

INSTALLATION

,The dryer MUSTbevented to the outdoors. SeeEXHAUST

INFORMATIONstep 6.

, The inst(]ll(]tion must conform with Ioc(]l codes or, in the

(]bsence of Ioc(]l codes, with the NATIONALELECTRICAL

CODE,ANSI/NFPANO.70.

6

Page 7

Installation instructions

[] MOBILE OR MANUFACTURED HOME

INSTALLATION

.Installation must conform to the MANUFACTURED

HOMECONSTRUCTION& SAFETYSTANDARD,TITLE24,

PART32-80 or, when such standard is not applicable,

with AMERICAN NATIONAL STANDARD FOR MOBILE

HOME,ANSI/NFPANO.501B.

.The dryer MUSTbe vented to the outdoors with the

termination securely fastened to the mobile home

structure. (SeeEXHAUSTINFORMATIONsection 6).

.The vent MUSTNOTbe terminated beneath a mobile or

manufactured home.

.The vent duct material MUSTBEMETAL.

.KIT 14-D346-33 MUST be used to attach the dryer

securely to the structure.

.The vent MUST NOTbe connected to any other duct,

vent, or chimney.

. Donot usesheet metal screws or other fastening devices

which extend into the interior of the exhaust vent.

. Provide an opening with a free area of at least 25 sq. in.

for introduction of outside air into the dryer room.

.Stacking of a gas dryer is not permitted in a mobile

home or manufactured home.

r_ GARAGE INSTALLATION (IF ALLOWED

BY LOCAL CODES)

. Dryers installed in garages must be elevated 18 inches

(46cm) above the floor.

[_ DRYER EXHAUST TO LEFT OR

BOTTOM

, ,WAR NING- BEFOREPERFORMING

THIS EXHAUST INSTALLATION, BE SURE

TO DISCONNECT THE DRYER FROM ITS

ELECTRICAL SUPPLY. PROTECT YOUR

HANDS AND ARMS FROM SHARP EDGES

WHEN WORKING INSIDE THE CABINET.

BESURE TO WEAR GLOVES.

TAB LOCATION

BENDTAB

Up/45°

Through the rear opening, locate the tab in the middle of

the appliance base. Lift the tab to about 450 using a flat

blade screwdriver.

ADDING NEW DUCT

FIXING

HOLE

Reconnect the cut portion (A) of the duct to the blower

housing. Make sure that the fixing hole is aligned with the

tab in the base. Use the screw saved previously to secure

the duct in place through the tab on the appliance base.

PORTION"A"

LEFTSIDE

EXHAUST

ADDING ELBOW AND DUCT FOR

EXHAUST TO LEFT SIDE OF CABINET

. Preassemble 4" elbow with 4"duct. Wrap duct tape

around joint.

. Insert duct assembly, elbow first, through the side

opening and connect the elbow to the dryer internal

duct.

REMOVE

SCREW

AND SAVE,

Detach and remove the bottom or left side knockout as

desired. Removethe screw inside the dryer exhaust duct

and save.Pullthe duct out of the dryer. Protect sharp edges

around the knockout and exhaust opening with the tape.

FIXINGHOLE

I-' 9"

Cut the duct as shown and keep portion A.

CAUTION: Besure not to pullor damage the

electrical wires inside the dryer when inserting the duct.

DUCT

TAPE

. Apply duct tape as shown on the joint between the

dryer internal duct and the elbow.

DUCT CAUTION:

Internal duct joints must be

secured with tape, otherwise

they may separate and cause a

_ safety hazard.

Page 8

Installation

Instructions

ADDING ELBOW FOR EXHAUST

THROUGH BOTTOM OF CABINET

, Insert the elbow through the rear opening and connect

itto the dryer internal duct.

,Apply duct tope on the joint between the dryer internal

duct and elbow, as shown above.

ADDING COVER PLATE TO REAR OF

CABINET

Connect standard metal elbows and ducts to complete

the exhaust system. Cover back opening with a plate

(KitWEIM454) available from your local service provider.

Placedryer in final location.

CAUTION:

Internal duct joints must be secured with tape,

otherwise they may separate and cause a

safety hazard.

LOOSEN EACH TOP HINGE

SCREW HALF WAY AND LIFT

THE DOOR UP AND OFF

3. Removethe blind plate from

the hinge side of the dryer

by removing its two screws.

Removethe strike plate from

the opposite side ofthe dryer

by removing its two screws, pLATE

Reinstall the plates, on the

opposite sides, using two

screws in each plate.

4.Rotate the door 1800. Insert the door on the opposite

side of the opening by moving the door ON and DOWN

until the top hinge and the bottom hinge are resting on

the top screws inserted in step 1.

TON TOP HINGESCREWS

PLATE

(KITWE1M454)

,iI_WARNING-NEVER LEAVE THE

BACK OPENING WITHOUT THE PLATE

{KIT WEIM454).

114]CHANGINGDIRECTIONOFDOOROPENING

1.Open the door and remove the filler plugs opposite the

hinges. With the door completely open, remove the

bottom screw from each hinge on the dryer face. Insert

these screws about half way into the TOPholes, for each

hinge on the opposite side (where you removed the filler

plugs). Apply firm pressure to get the screws started.

REMOVE 4 PLUGS AND KEEP

FOR INSERTION INTO

THE OPPOSITE SIDE

REMOVEBOTTOMSCREWFROMEACHHINGE

AND INSTALL HALF WAY INTO EACH TOP OF

//

ROTATE DOOR 180 ° AND HANG

5.Remove the remaining screws from the side of the

opening from which the door was removed. With these

screws secure each hinge at the bottom. Tighten the

two top screws oneach hinge. Reinsert the plastic plugs

on the side from which the door was removed.

INSTALLANDTIGHTEN BOTTOM INSERT PLUGS

SCREWS AND TIGHTEN TOP INTO HOLES ON

_._OPPOSITE SIDE

SERVICING

WARN !NG-LABEL ALL WIRES PRIOR

TO DISCONNECTING WHEN SERVICING

CONTROLS. WIRING ERRORS CAN CAUSE

IMPROPER AND DANGEROUS OPERATION

AFTER SERVICI NG/I NSTALLATION.

2. Loosen the top screw from each hinge on the dryer face

halfway. With one hand holding the top of the door and

the other hand holding the bottom, remove the door

from the dryer by lifting it UP and OFF.

REGISTERYOUR NEW APPLIANCE TO RECEIVE

ANY IMPORTANTPRODUCT NOTIFICATIONS.

Please go to www.GEAppliunces.com or mail in

your product registration card.

For questions on installation, call: 800.626.2000 (US)or

800-561-3344 (Canada).

8

Loading...

Loading...