Page 1

GE

Grid Solutions

TM

DMC490

Microgrid Controller

Software Configuration Guide

SWM0091

Version 1.00, Revision

GE

Information

3

Page 2

Copyright Notice

are trademarks and service marks of

©2016, General Electric Company. All rights reserved.

The information contained in this online publication is the exclusive property of General Electric Company, except as otherwise indicated. You

may view, copy and print documents and graphics incorporated in this online publication (the “Documents”) subject to the following: (1) the

Documents may be used solely for personal, informational, non-commercial purposes; (2) the Documents may not be modified or altered in any

way; and (3) General Electric Company withholds permission for making the Documents or any portion thereof accessible via the internet. Except

as expressly provided herein, you may not use, copy, print, display, reproduce, publish, license, post, transmit or distribute the Documents in

whole or in part without the prior written permission of General Electric Company.

The information contained in this online publication is proprietary and subject to change without notice. The software described in this online

publication is supplied under license and may be used or copied only in accordance with the terms of such license.

Trademark Notices

GE and

* Trademarks of General Electric Company.

Cisco is a registered trademark of Cisco Corporation. Hyperterminal is a registered trademark of Hilgraeve, Incorporated. IEC is a registered

trademark of Commission Electrotechnique Internationale. IEEE and POSIX are registered trademarks of the Institute of Electrical and Electronics

Engineers, Inc. Internet Explorer, Microsoft, and Windows are registered trademarks of Microsoft Corporation. JAVA is a registered trademark of

Oracle Corporation, Modbus is a registered trademark of Schneider Automation, Inc. Netscape is a registered trademark of Netscape

Communications Corporation. SEL is a registered trademark of Schweitzer Engineering Laboratories, Inc.

Other company or product names mentioned in this document may be trademarks or registered trademarks of their respective companies.

General Electric Company.

Security Notice

Many of the DMC490’s network services are unauthenticated and unencrypted (for example, DNP3/TCP Master). It

is the user’s responsibility to ensure these services are protected from unauthorized use.

Even though the DMC490 includes a host firewall, it is recommended that an external network firewall be placed

on the electronic security perimeter as an additional layer of protection.

Page 3

Purpose

This guide provides detailed information on how to configure the software of the Multilin

DMC490 Microgrid Controller.

Intended Audience

This document is a resource for utility personnel and system engineers who are

implementing the DMC490 for a microgrid, and protection engineers who are controlling

network devices. It is intended for readers who have knowledge of substation automation

equipment and applications.

About this Document

Additional Documentation

For further information about the DMC490, refer to the following documents.

• D400 Substation Gateway Instruction Manual (994-0089)

• D400 Substation Gateway Software Configuration Guide (SWM0066 V5.2)

• D400 V5.20 online Help (includes D400 configuration tool online Help)

How to Use this Guide

For most operational features, refer to the documents listed above.

For information specific to the Microgrid Controller (MGC) feature, see the details provided in

this manual (SWM0091).

The DMC490 employs sophisticated applications that contain many advanced features and

capabilities. To successfully configure and operate the DMC490 for your environment, it is

highly recommended that you work through this entire guide and the D400 Substation

Gateway Software Configuration Guide (SWM0066 V5.2).

If you need assistance, contact General Electric Company GE Grid Solutions Technical

Support.

In configuration tables, “N/A” in the “Default” column indicates there is no default setting

provided, and “X” indicates the number is automatically incremented.

Page 4

Document Conventions

This guide uses the Systeme International (SI) and the Microsoft® Manual of Style as a basis

for styles and conventions.

The following typographic conventions are used throughout this manual.

Bold face is used for:

– Names of software program menus, editors, and dialog boxes; also for the names of

menu commands, keyboard keys, icons and desktop shortcuts, and buttons and

fields in editors and dialog boxes

– Names of hardware components

– User input that must be typed exactly

Italic face is used for:

– Emphasis

– Cross-references to sections, figures and tables within this manual and for titles of

other documents

– File and directory names; examples of directory paths are generally given in the

Windows form

– Placeholders for user input that is specific to the user. May also include angle

brackets around the placeholder if the placeholder is already in italic text. For

example, c:\<product>\product.def

– References to a setting or field value shown

The software-related procedures in this guide are based on using a computer running

®

Windows

XP. Some steps and dialog boxes may vary slightly if you are using another version

of Windows.

Safety words and definitions

Before attempting to install or use the device, review all safety indicators in this document to

help prevent injury, equipment damage or downtime.

The following safety and equipment symbols are used in this document:

Indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

Indicates a hazardous situation which, if not avoided, could result in death

or serious injury.

Indicates a hazardous situation which, if not avoided, could result in minor

or moderate injury.

Indicates practices that are not related to personal injury.

Page 5

If you need help with any aspect of your GE Grid Solutions product, you can:

• Access the GE Grid Solutions Web site

• Search the GE Technical Support library

• Contact Technical Support

GE Grid Solutions Web Site

The GE Grid Solutions Web site provides fast access to technical information, such as

manuals, release notes and knowledge base topics.

Visit us on the Web at: http://www.gegridsolutions.com

GE Technical Support Library

Product Support

This site serves as a document repository for post-sales requests. To get access to the

Technical Support Web site, go to: http://sc.ge.com/*SASTechSupport

Contact Technical Support

The GE Grid Solutions Technical Support is open 24 hours a day, seven days a week for you to

talk directly to a GE representative.

In the U.S. and Canada, call toll-free: 1 800 547 8629

International customers, please call: +1 905 927 7070

or email to multilin.tech@ge.com

Have the following information ready to give to Technical Support:

• Ship to address (the address that the product is to be returned to)

• Bill to address (the address that the invoice is to be sent to)

• Contact name

• Contact phone number

• Contact fax number

• Contact e-mail address

• Product number / serial number

• Description of problem

Technical Support will provide you with a case number for your reference.

Page 6

Page 7

Table of Contents

DMC490 Overview ..................................................................................................................................................................... 8 Chapter 1 -

Application Overview ............................................................................................................................................................................................. 8

Microgrid Overview................................................................................................................................................................................................. 9

Microgrid Controller Setup ............................................................................................................................................................................... 16

DMC490 Configuration ......................................................................................................................................................... 17 Chapter 2 -

DMC490 Operation Modes .............................................................................................................................................................................. 17

Configuration Overview .................................................................................................................................................................................... 18

Configure Electrical Assets .............................................................................................................................................................................. 20

Configure Thermal Assets ................................................................................................................................................................................ 34

Configure System Settings .............................................................................................................................................................................. 40

Health Status and Monitoring .......................................................................................................................................... 45 Chapter 3 -

Forecasts ..................................................................................................................................................................................... 46 Chapter 4 -

Common Forecast Settings ............................................................................................................................................................................. 46

Forecasts for Renewables ............................................................................................................................................................................... 47

Forecasts for Electrical Load .......................................................................................................................................................................... 47

Forecasts for Grid Buy Price ........................................................................................................................................................................... 48

Forecasts for Grid Sell Price ............................................................................................................................................................................ 48

Forecasts for Heat Load ................................................................................................................................................................................... 48

Forecast Value Update Procedure .............................................................................................................................................................. 48

vii

Page 8

DMC490 Overview Chapter 1 -

The DMC490 Microgrid Controller:

• Controls and monitors a microgrid

• Optimizes the dispatch of electrical generation, thermal generation, and energy storage to minimize

operating cost

Application Overview

The Microgrid Controller optimizes the dispatch of electrical generation, thermal generation, and energy

storage to minimize operating cost. It operates in a supervisory mode, issuing on/off and dispatch commands

every few minutes. The MGC works in a grid-connected or standalone microgrid.

Up to 32 electrical and heating resources are supported, including the following:

• Renewable, such as wind turbines, hydro, solar panels

• Dispatchable generators, such as diesel generators

• Combined heat and power (CHP) generation, or cogeneration

• Heating elements, such as boilers

• Storage, specifically hydrogen-based and batteries

• Utility grid connections

The block diagram of Figure 1 shows the microgrid approach. When the resources include Modbus server

functionality, the UR controllers are unnecessary. For example, when a wind turbine is added to the microgrid

and it has Modbus server capability, a UR controller is not needed for it.

Figure 1 Microgrid approach – Block Diagram

The storage can be short or long-term:

• Short-term storage functions of the MGC help in step-load changes resulting from load-generation

variations or in transferring to an islanded microgrid.

• Long-term storage from tens of minutes to several hours helps during peak demand periods and in

shifting power generation to environmentally-friendly renewable sources.

8

Page 9

DMC490 Overview

Microgrid Overview

The Microgrid Controller controls microgrid generation and storage assets to optimize operation for the lowest

cost based on load and renewable forecasts.

A microgrid is a distribution network that operates with local (distributed) generation or islanded (grid

connection open). Both types can include renewable sources, such as wind, photovoltaics, and hydro. Because

the output from renewable sources can be intermittent and variable, and energy from these resources is not

always available when needed, renewable sources can be better utilized when there is storage in the

microgrid, such as an electrolyzer/fuel cell system or conventional battery storage.

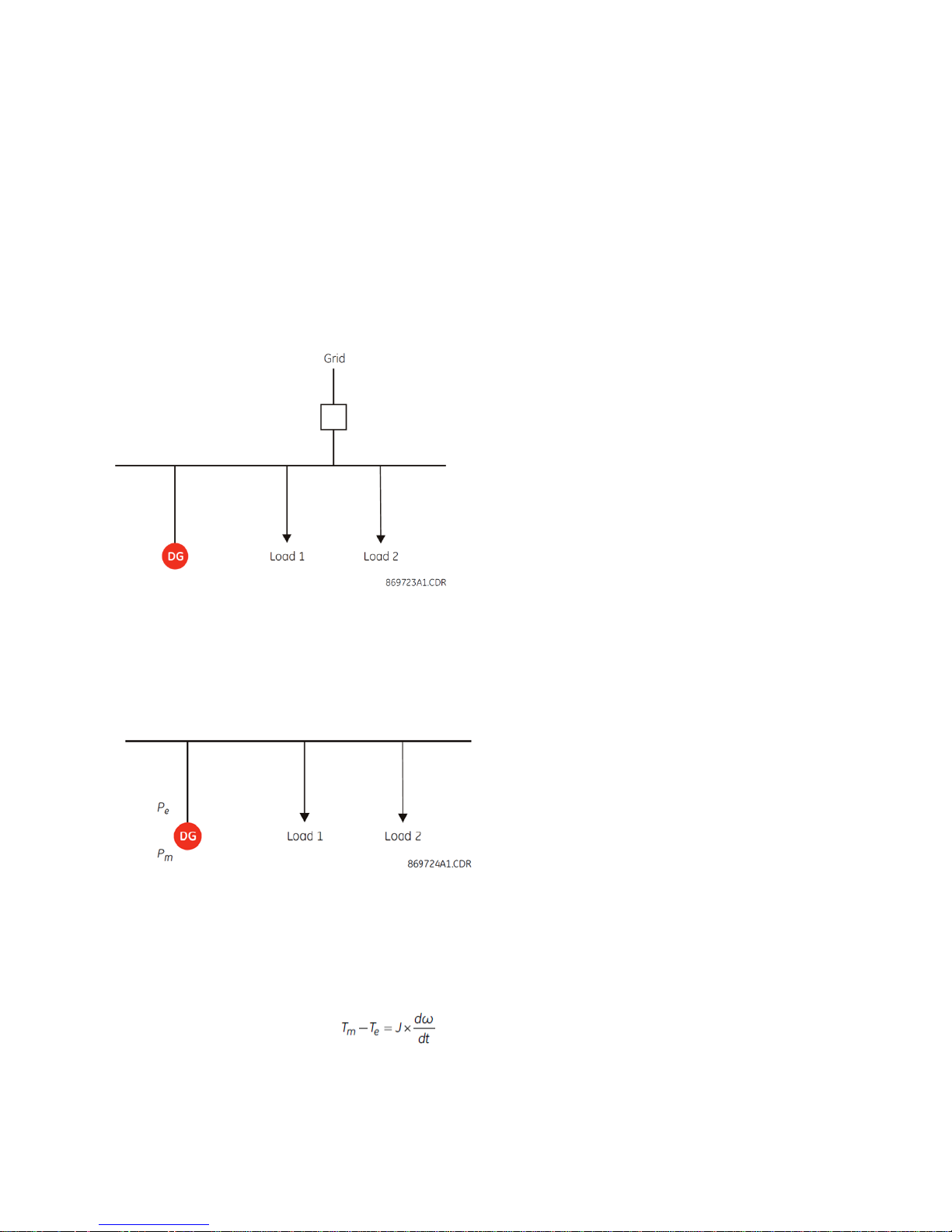

Figure 2 shows a typical Microgrid where DG represents a Diesel Generator.

Figure 2 Typical microgrid

Islanded Power System Operation

Within any power system, the generated power must match the demand. The loading in the system is variable.

Consider the single-generator power system shown in Figure 3.

Figure 3 Single-generator power system

and Pm result from multiplying the torque with the angular velocity (speed).

P

e

Where:

is the electrical power

P

e

is the mechanical power

P

m

The basic torque balance equation for the generator is:

Eq. 1

9

Page 10

DMC490 Microgrid Controller Software Configuration Guide

Where:

T

is the mechanical torque provided by the prime mover

m

is the electrical torque exerted by the loading of the power system

T

e

J is the inertia constant of the machine, and

ω is the rotational speed.

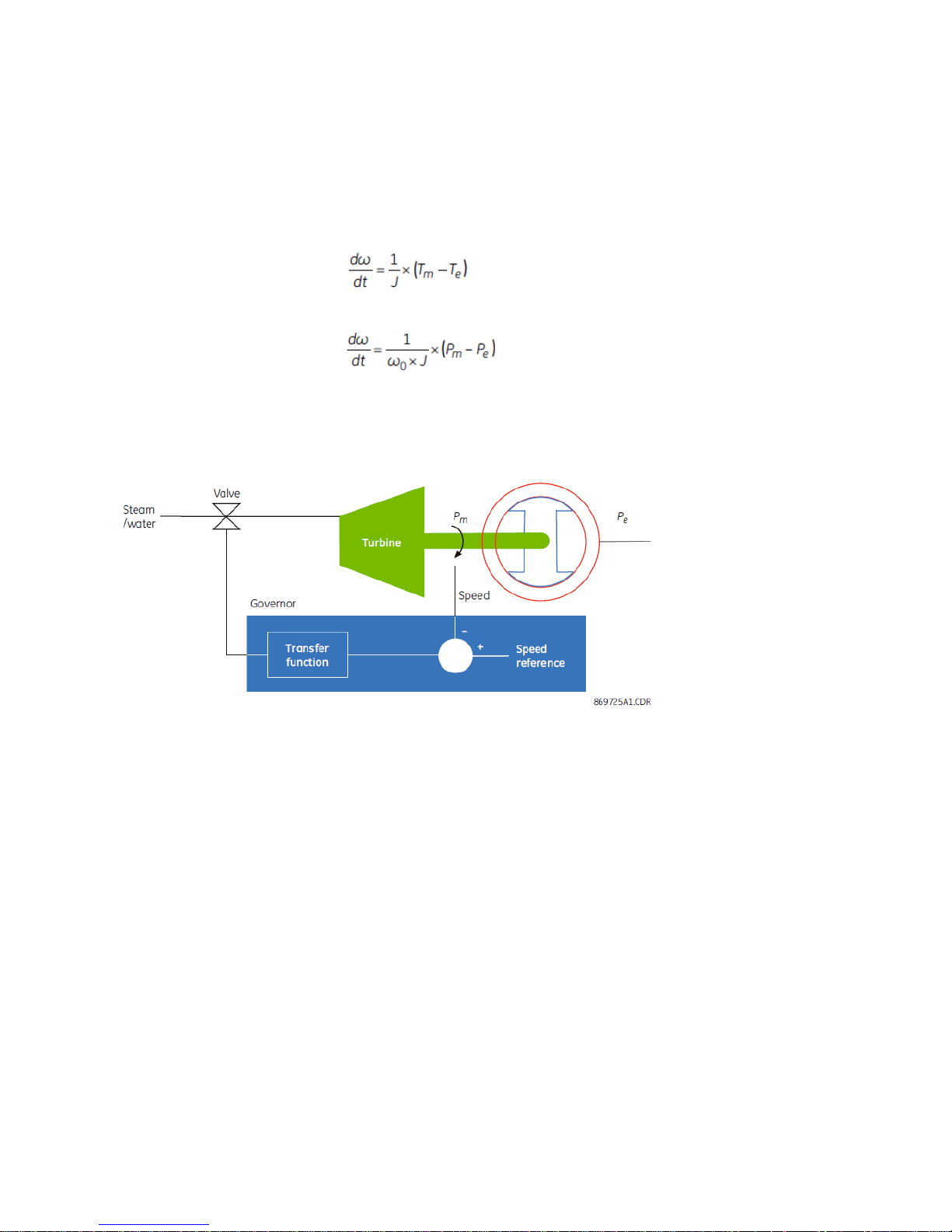

Solving for dω/dt, the result is:

Eq. 2

Multiplying by the top and bottom of this equation by rated speed, ω0, the result is:

Eq. 3

Speed is constant (dω/dt = 0) whenever mechanical power matches electrical power. This fact allows us to

control a generator to supply the required load by regulating the speed of the generator at a fixed value. This

method is known as isochronous control and is shown in Figure 4.

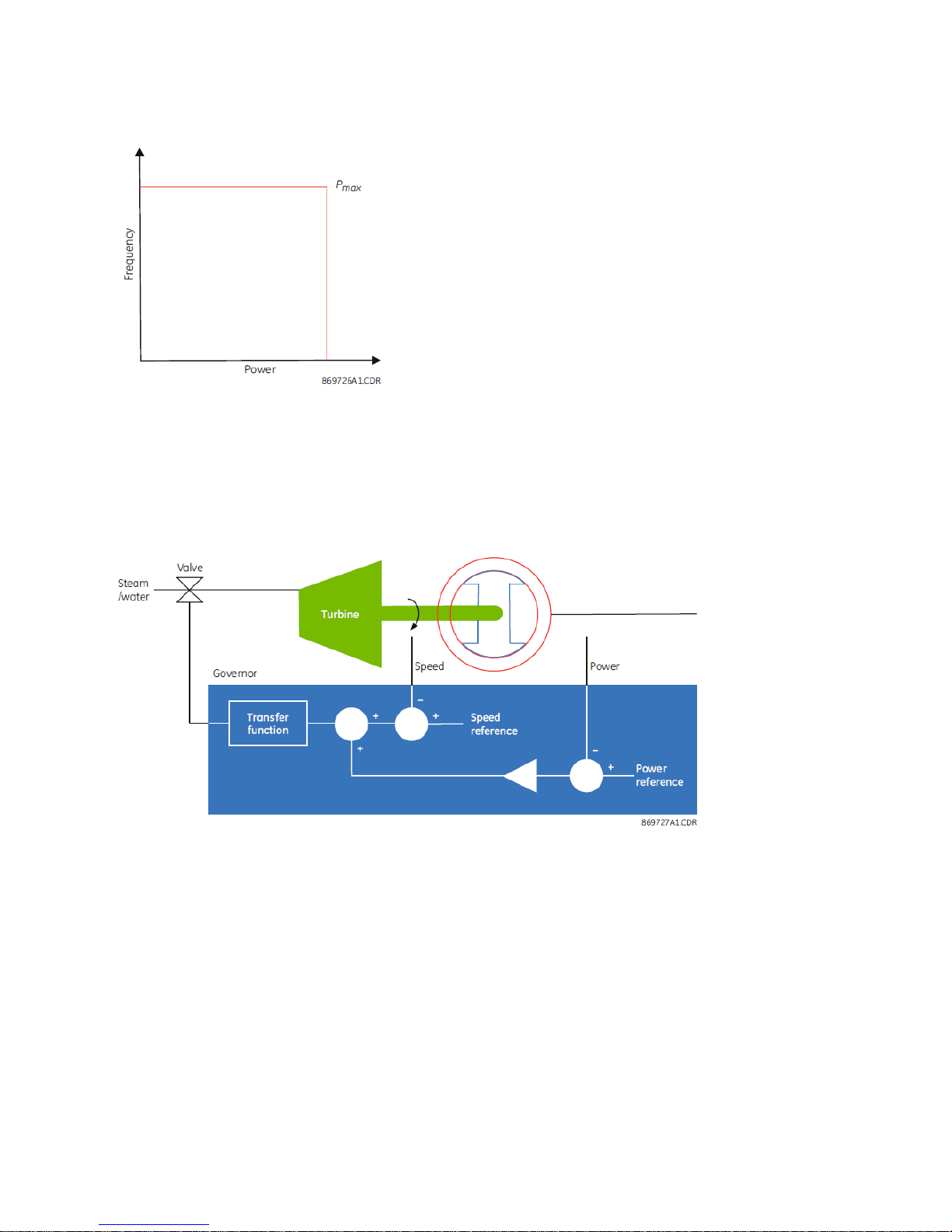

Figure 4 Isochronous control

Assume that electrical and mechanical power are initially equal and speed is equal to the reference speed.

When the loading of the system increases, then P

becomes greater than Pm. As seen in the previous equation,

e

the machine speed drops. The governor takes a measurement of machine speed and compares it with a

reference speed (nominal speed). The difference is an error signal that is applied to a transfer function (typically

a proportional/integral regulator). The output of the governor drives an actuator (for instance a valve in the

case of a steam turbine). This acts to increase the flow of steam to the turbine, increasing the mechanical

power to balance the electrical power.

The operating characteristic of an isochronous generator is shown in the plot of frequency (proportional to

mechanical speed) and power; see Figure 5.

10

Page 11

DMC490 Overview

Figure 5 Isochronous operating characteristic

An isochronous machine maintains a constant frequency for any value of power up to its maximum rating.

Having more than one generator operating in isochronous control creates a challenge. Measurement error

results in each machine having a slightly different idea of the actual system frequency, and each machine tries

to bring this value to the nominal frequency. To resolve this potential conflict, one machine is typically operated

in isochronous mode and the remaining generators are operated in droop control, resulting with the machine

receiving an additional power signal that it compares to a power reference.

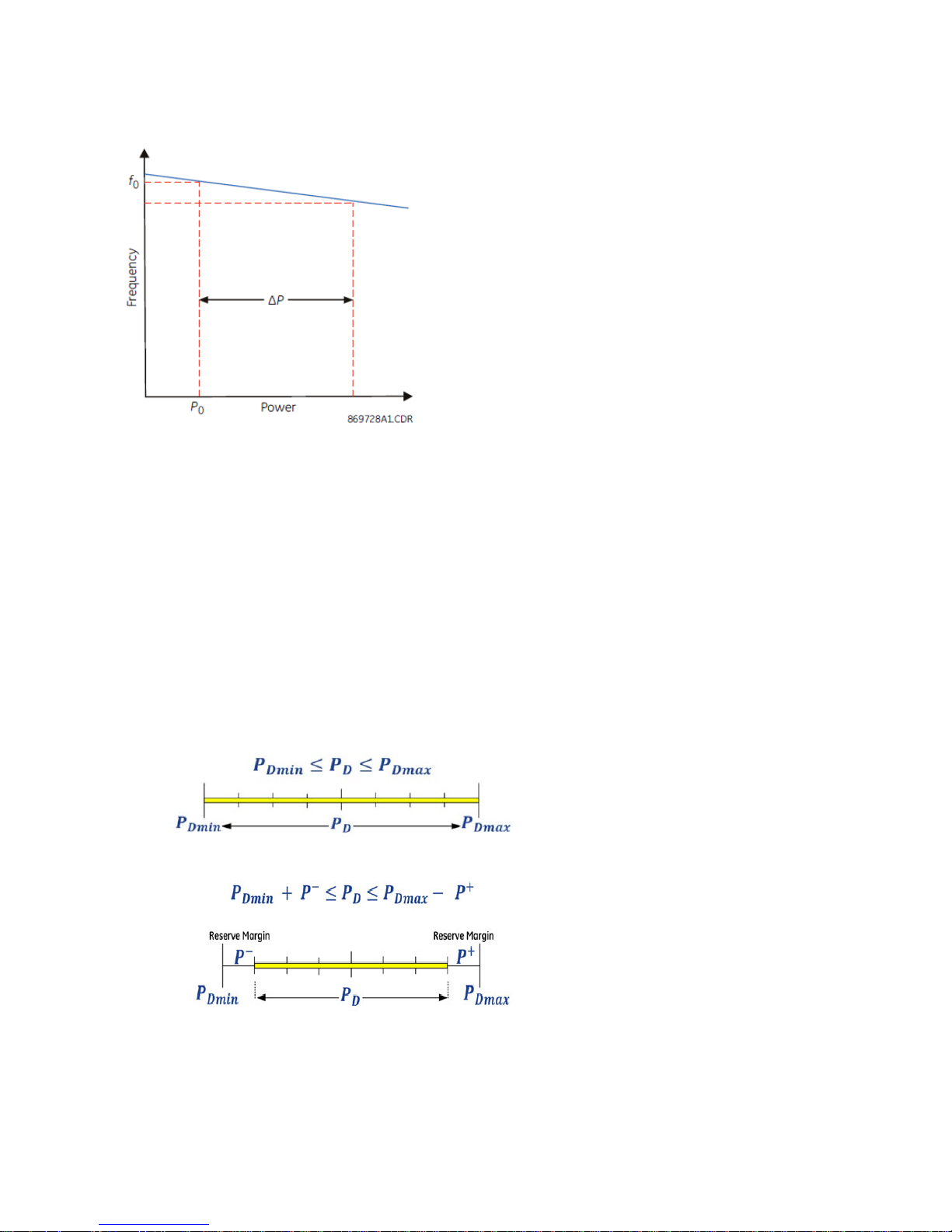

Figure 6 Droop control used for two or more sources of power

At nominal frequency, the level of power output is determined by the power reference command because the

speed error signal is zero. When there is a drop in frequency, the generator increases output power according

to its droop setting. For example, a generator with a droop setting of 5% produces a 100% change in output

power for a 5% change in frequency.

Taken together the power and speed signals produce a sloped operating characteristic as shown in Figure 7.

11

Page 12

DMC490 Microgrid Controller Software Configuration Guide

Figure 7 Droop control operating characteristic

In grid-connected microgrids, the grid compensates for any imbalance between load and generation in the

microgrid, behaving like an isochronous machine for the microgrid. However, for islanded microgrids, there is a

need for an isochronous machine to maintain load-generation balance, and stabilize the frequency around the

nominal value in response to instantaneous load and renewable generation variations above or below the

forecasted values. Such an isochronous machine provides reserve margins in both positive and negative

directions to address the deficit or surplus of power, respectively. These margins are defined as a percent of the

total load in the microgrid.

Isochronous/non-isochronous operation of a generator impacts the behavior of the MGC in the process of

optimally dispatching the generation/storage devices in the microgrid. Thus, generating power of a

dispatchable generator (genset) operating in non-isochronous mode can pick any value between its lower and

upper bounds; however, for an isochronous dispatchable genset, lower and upper bounds of generating power

need to be changed in the optimization problem solved by the MGC so that the reserve margins are respected.

These concepts are demonstrated in Figure 8 and Figure 9, where the highlighted regions specify the intervals

that the generating power (P

) is allowed to change. PD

D

and PD

min

represent the lower and upper bounds of

max

dispatchable generating power.

Figure 8 Demonstration of non-isochronous operation of a dispatchable generator

Figure 9 Demonstration of the isochronous operation of a dispatchable generator

A diesel or a CHP unit can usually operate in isochronous mode due to the non-variable nature of their fuel

source, while highly-intermittent renewable power sources such as wind or solar cannot fulfill the requirements

of an isochronous machine. However, the MGC supports the isochronous operation of renewable power

generation units that are relatively less intermittent, such as run-of-the-river hydro units with reservoirs. In

order to support such a feature, a parameter entitled Renewable Capability is defined in the setup program.

12

Page 13

DMC490 Overview

This is a parameter between 0 and 1, multiplied by the upper bound of renewable power generation unit, and

decided by the operator based on meteorological observation data.

Optimal Dispatch

The primary function of the MGC is optimal dispatch, which is the process of allocating the required load

demand among the available resources such that the cost of operation is minimized. The MGC minimizes cost

of electricity and/or heat in a microgrid, for example daily, and the prediction horizon can extend up to 48

hours.

Within a microgrid, resources include conventional generators and storage devices. The cost of operation is

typically defined by fuel cost but can include maintenance and other costs.

An optimal dispatch algorithm is used to minimize the total operational cost of the microgrid. This cost is the

sum of the fuel cost required to run the non-renewable generators, cost of electricity, which needs to be

bought from a grid when one exists, and the operational cost of renewable and storage devices. Other factors

include maintenance, start-up/shut-down costs, cost/revenue components associated with

importing/exporting power to the grid, minimum energy/power requirements for various generation assets and

minimum up/down times for some of the assets. The power bought from the grid plus the power generated

internally must equal the total load and the power exported to the grid at any instant of time. The algorithm

does not treat loads as dispatchable except to avoid situations of grid instability associated with imbalance

between supply and demand. In other words, the microgrid always supplies enough power to satisfy its loads

provided that this is physically possible given the power limits on the generators.

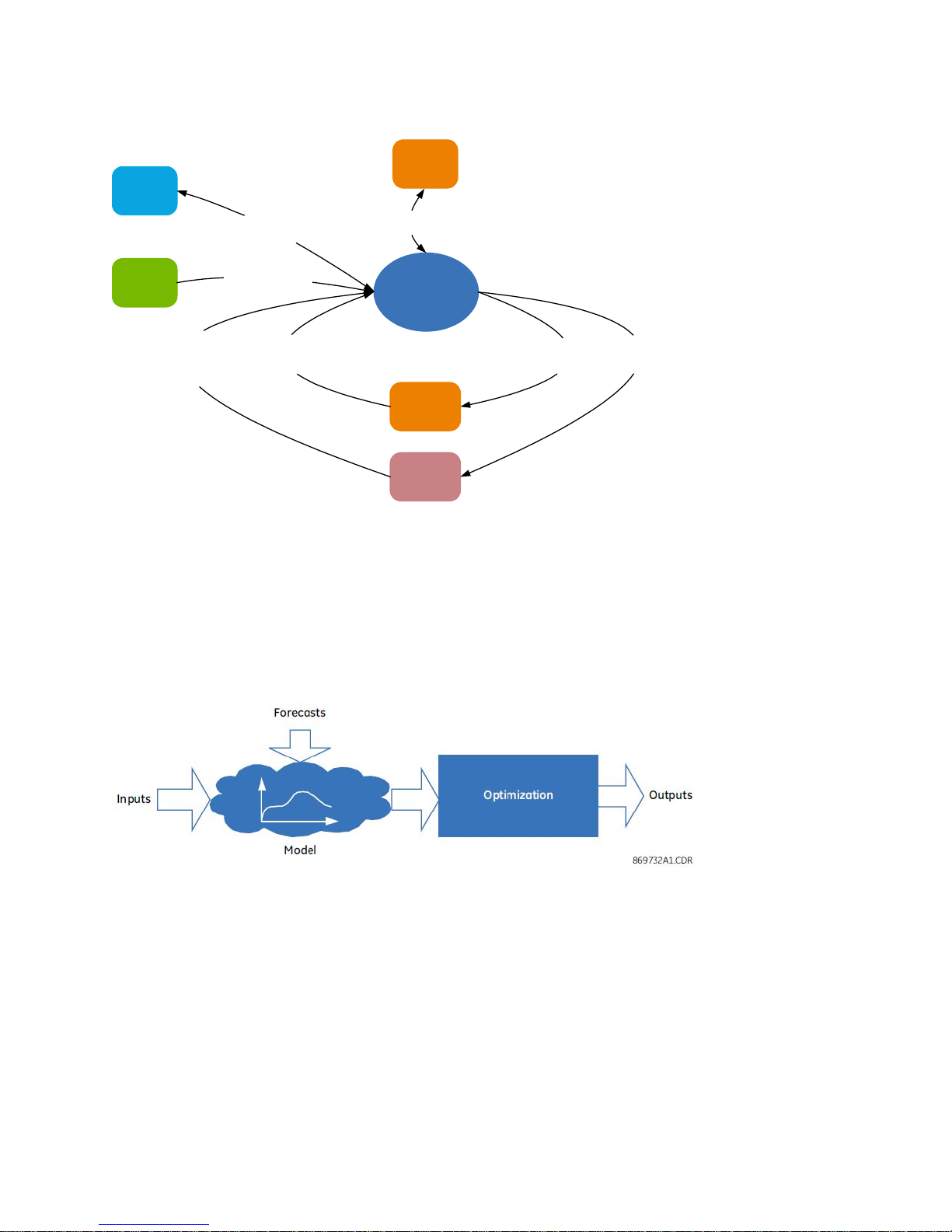

The optimal dispatch algorithm uses a technique known as model predictive control. It makes use of historical

data as follows: daily, weekly, and annual load profiles; hydro, wind, and solar forecasts; and fuel or electricity

market pricing information (when a bulk grid connection exists). Given this information, the algorithm

determines the cost of operation for a fixed period in the future, typically 24 hours. It then solves the

optimization problem with the objective to minimize the total costs and to determine the required control

actions. These control actions include selecting the best machines to be operated at any given time, by issuing

start/stop commands and sending proper isochronous or non-isochronous commands to dispatchable or

renewable power generation units. It determines when energy is stored and when it is supplied to the system.

Finally, it determines the best power reference point for each droop (non-isochronous) machine and for each

storage device. Figure 10 shows data flow between the MGC and the different component devices within the

microgrid.

13

Page 14

DMC490 Microgrid Controller Software Configuration Guide

DMC490

Microgrid Controller

System

Loads

Renewable

generators

Power generated

Online status

Availability

Power consumed

Online status

Dispatchable

generators

Power generated

Online status

Availability

Storage

devices

Start/stop

Input preferences

Output preferences

Power generated

Power consumed

State of charge

Online status

Availability

Setup tool

Operational

parameters (settings)

Start/stop

Isochronous/droop

Output preferences

Figure 10 Data flow for a system with dispatchables, renewables, and storage

Model Predictive Control

Model predictive control (MPC) is used for optimal dispatch in the microgrid. In this method, a model of the

process to be controlled is used to evaluate the behavior of process outputs in response to control inputs. The

model response is evaluated for a finite period extending into the future, known as a prediction horizon. The

outputs are optimized over this period in order to arrive at the ideal values of outputs to be applied at the

current time.

Figure 11 Model predictive control

Applied to the dispatch challenge, inputs represent internal physical states of the process such as

offline/online, availability, isochronous operation, storage state of charge, and metered power of the devices.

Generators and storage devices are modeled by their power ratings and efficiency curves. Forecasts model the

loading of the power system, the contribution of renewable sources, and the price of grid power (if one exists).

Finally, outputs take the form of start/stop commands and power reference commands applied to generators

and storage devices.

Generation must match load in a stable power system. Dispatchable generation including the storage equals

the total load minus the total power supplied by renewable sources. These resources are assumed to have

local controllers that are designed to maximize the use of available renewable energy.

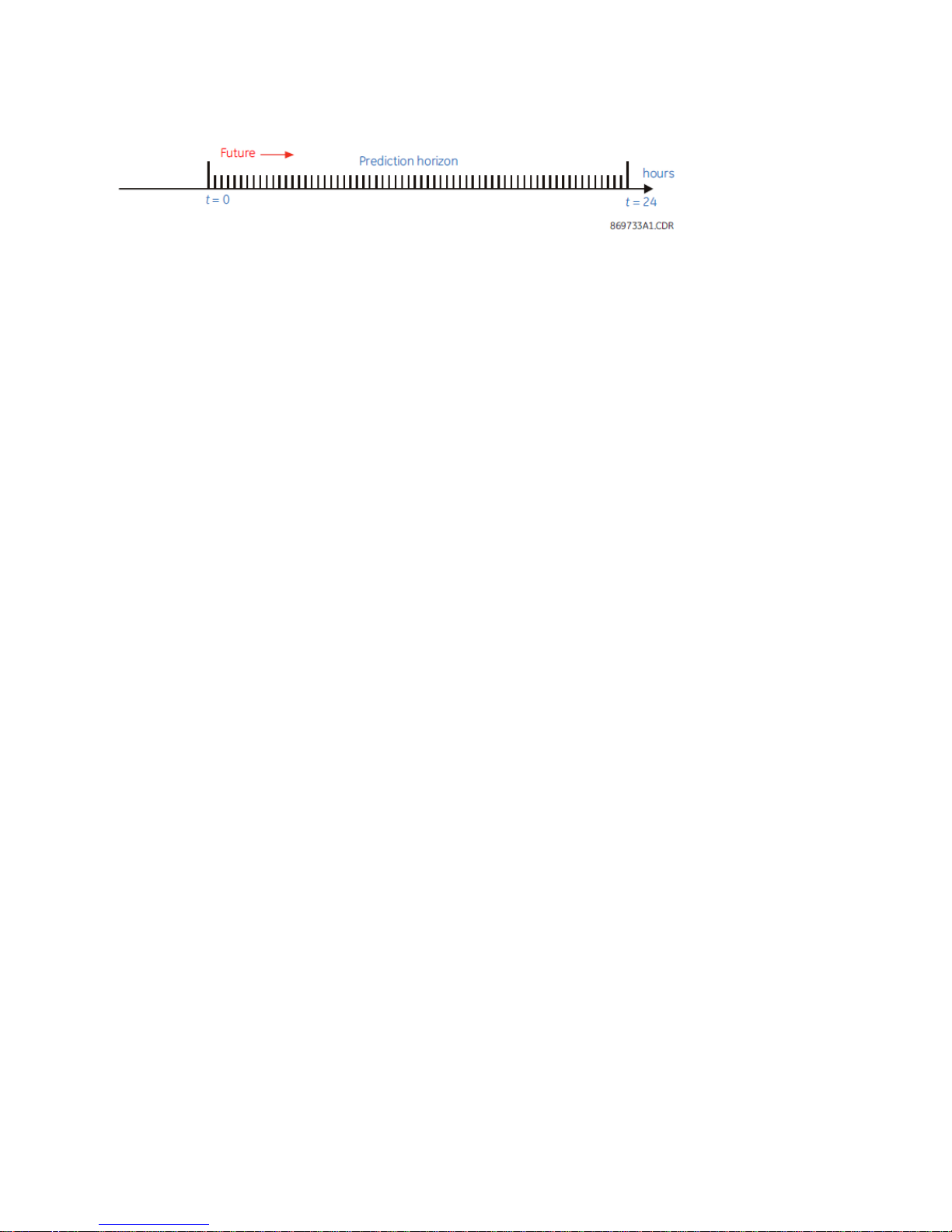

The problem to be solved by the MGC is a multi-interval optimization problem. As shown in Figure 12, an

assumed prediction horizon of 24 hours is divided into multiple time steps/intervals, such as 120 twelve-minute

or 240 six-minute time intervals.

14

Page 15

DMC490 Overview

Figure 12 Prediction horizon

Different routines within the optimization framework are formulated and solved at each time step (for example,

12 minutes) over the prediction horizon (24 hours) based on load, renewable resources, and price forecasts. In

this framework, a variety of operational considerations are factored in. These include and are not limited to the

support of a hydro unit in isochronous mode, minimum up/down times required for storage charging,

interaction with the grid, and support of manual-start dispatchable generators.

The objective function of the optimization problem can, in general, include the following terms:

• Fuel/operation costs of all power generation devices in the microgrid

• Cost/incentive terms for storage device charging/discharging. These are more subjectively

determined, being driven by the requirement to prevent simultaneous charging and discharging and

the need to limit storage cycling.

• Penalty terms mainly related to those generation/storage devices allowed to have their limits on

minimum powers violated (that is, having soft constraints)

• Power importing/exporting costs/revenues when the microgrid is grid-connected

Also, the constraints of the optimization problem capture the following limitations for both electrical and

thermal systems:

• Minimum and maximum values of generated power with the consideration of their isochronous or

non-isochronous operation, and the microgrid reserve margin requirements

• Limits on importing/exporting powers considering the microgrid reserve power requirements (for grid-

connected microgrids)

• Power balance in the microgrid considering the contribution of power generation/storage devices,

load, and any grid

• Minimum, maximum, and initial values of storage devices state of charge

• Limits on storage input and output powers

• The energy balance equation of storage devices representing the storage state of charge in each time

step based on its value in the previous time step as well as charging and discharging powers with the

consideration of the related efficiencies and standby losses

When the prediction horizon is long enough, the algorithm can determine when to charge storage, because it

can anticipate times when the loads are large and when the stored power can be utilized. The optimal dispatch

algorithm implemented within the microgrid controller can be configured for up to 32 resources. Assuming a

worst-case scenario where all resources are committed, the optimization problem can have on the order of

20,000 variables and 40,000 constraints.

Incorporation of CHP Plants

Combined heat and power (CHP) is the generation of electricity and heat in a single process. Inclusion of CHP

plants in the microgrid significantly increases the overall efficiency of the system by using the hot exhaust

gases from the gas turbine to heat water. Recovered heat can also be used for district heating or covering the

heat demand requirement of the system. The incorporation of CHP plants introduces another energy source

(natural gas) and another energy carrier (heat) into the system.

A CHP plant can be modeled by constant conversion ratios. The conversion ratios indicate efficiency. For

example, a gas-to-electricity conversion ratio of 0.35 means that 35% of the energy content of natural gas is

converted to electricity and the remainder is in the form of heat. Two dimensionless conversion ratios for gasto-electricity (rge) and gas-to-heat (rgh) are defined as shown in the following figure. Typical values of rge and

rgh are 0.35 and 0.45, respectively, considering a 20% parasitic loss.

15

Page 16

DMC490 Microgrid Controller Software Configuration Guide

related configuration.

Figure 13 Representation of the co-generator model

Note: Different energy source and carriers, meaning natural gas, electricity, and heat, are involved, and that

they are all represented in terms of a common unit (kW). Note too that P

independently controlled. Also, fuel consumption rate of a CHP unit reflected in the objective function is

assumed to be an affine function of its generated electric power; this is similar to all dispatchable units

in the microgrid.

Similar to dispatchable generators, CHP units can also operate in isochronous mode to cover the electric

system reserve requirements.

CHPe

and P

CHPh

are not

Microgrid Controller Setup

The Microgrid Controller is set up for microgrid operation and control from the DMC490 HMI.

» To connect and configure a microgrid, perform the following tasks:

1. Set up communication between Assets controller or Asset of the Microgrid to the DMC490 using Data

Collection Application; see Chapter 17 - Configure IED/Device Blocks (Clients) of the SWM0066 D400

Software Configuration Guide.

2. Follow the configuration procedure provided in Chapter 2 – DMC490 Configuration of this manual.

Using SGConfig to Configure the DMC490

SGConfig (v9.0 or later) can be used to configure LogicLinx for a DMC490.

The following SGConfig features are not supported and will fail if you attempt to use them

to configure a DMC490:

• Offline editor

• Bulk editing

• Import/export

If you attempt to use the offline editor and commit the changes, you will lose the MGC-

16

Page 17

DMC490 Configuration

Boilers

8

CHPs

8

Dispatchables (auto-start)

16

Grids

1

Heat Loads

16

Loads

16

Renewables

16

Storage

16

DMC490 Configuration Chapter 2 -

You specify the number of dispatchable generators, loads, boilers for heat, renewable resources, and so on in

the DMC490 Configuration Tools.

Up to 32 resources can be connected in the microgrid, with maximum per device type as follows.

Maximum configuration by device type

Resource Maximum number (up to total of 32)

DMC490 Operation Modes

The MGC optimization function has different modes of operations, which determine whether optimization is on

or off.

Modes of Operation

The modes of operation are:

• Legacy (Off) — Off — In this mode, no optimization takes place and no communication occurs with the

resources and assets in the microgrid. When a user selects this mode, the microgrid continues to operate

using the last configured values. For example, when a diesel generator is on, and the user activates Legacy

(Off) mode, the diesel generator continues to operate.

The Analog Value code for this mode is 0.

• Auto — On — In this mode, Optimization occurs and the optimal solution is communicated to the resources

and assets.

The analog value code for this mode is 1.

• Advisory — On — In this mode, Optimization occurs, but the optimal solution is not communicated to the

resources and assets. When there is a problem in the microgrid, the unit automatically switches to this

mode to prevent commands from being sent to devices. To fix this issue, inspect the system, including

generation and storage devices, local controllers, and communication links.

The analog value code for this mode is 2.

Note:: Delay is associated in the Process of transitioning between the modes. The mode cannot be abruptly

changed from off to Auto; it first switches to Advisory mode, and if the optimization problem is feasible,

and an optimal solution is found, the operation mode changes from Advisory to Auto at the end of the

problem-solving phase. This transition is indicated by "Running Optimal Dispatch" on the main HMI

pane.

17

Page 18

DMC490 Microgrid Controller Software Configuration Guide

View and Switch Modes

» To view the state of Optimizer Operation Mode:

1. Navigate to the MGC application Point details page on the HMI:

Point Summary > Applications > Microgrid Controller> Analog Input

2. Use the Analog Input pseudo point MGC Current state from the MGC point summary page.

» To switch between different Optimizer Operation modes:

1. Navigate to the MGC application Point details page on the HMI:

Point Summary > Applications > Microgrid Controller> Analog Output

2. From the Analog Output tab, access pseudo point MGC Change Current state.

3. Choose a desired mode based on the Analog codes given for each mode.

» To view the time remaining until the next cycle of Optimization is executed:

1. Navigate to the MGC application Point details page on the HMI:

Point Summary > Applications > Microgrid Controller> Analog Input

2. From the Analog Output, access pseudo point MGC Change Current state.

3. See the status for the Time to Next Advice point.

Configuration Overview

Microgrid Assets

» To configure and map microgrid assets:

1. Click the Configuration Power Bar button and select the MGC tab.

Result: The Electrics pane appears.

2. Select: Electrics (Electrical Assets) tab or the Thermal (Thermal Assets) tab.

3. If Electrics or Thermal is selected, click + to add an asset.

Result: The Create Asset window appears.

4. Select the Asset type:

• Electrical Assets

o Renewable Asset

o Dispatchable Asset

o Storage Asset

o Load Asset

o Grid Asset

• Thermal Assets

o Thermal CHP Asset

o Boiler Asset

o Heat Load Asset

18

Page 19

DMC490 Configuration

Result: The settings pane appears on the right-hand side; for example, Dispatchable Asset1.

5. Configure the Electrical Assets and Thermal Assets Point settings. Refer to the Configure Electrical Assets

section on page 20 for more details.

6. Add digital/analog inputs and digital/analog outputs for the assets.

7. Set the time periods for the forecasts: System (Settings > Economic Dispatch setup.

8. Configure annunciator alarms (Configuration > Alarm tab > Alarm Points tab) that are viewed on the

Active Alarms page.

9. Set the operating mode of the MGC assets (that is, Renewable assets, Dispatchable Assets, and Thermal

CHP Assets

10. Configure forecast settings for optimization.

11. Map the Electrical Assets and Thermal Assets status points to the Datalogger (click: Data Logger

powerbar button) so that you can analyze decisions made by the Optimizer over the logging period.

12. Repeat steps 1 to 11 for each microgrid asset.

System Settings

» To configure microgrid system settings:

1. Click the Configuration Power Bar button and select the MGC tab.

Result: The Electrics pane appears.

2. Select the Settings (System Settings) tab.

3. Select the System Settings group:

• System Settings

• Economic Dispatch

• Command Scheduler

o Dispatchable Units

o Storage Units

Result: The settings pane appears on the right-hand side; for example, System Settings.

19

Page 20

DMC490 Microgrid Controller Software Configuration Guide

Setting

Description

Range

Default

Enabled

Rated Power

(kW)

Specify the maximum power generation capacity in kW

depending on the availability of the renewable resource.

0 to 1,000,000

kW

Operating

Specify the operating cost of the equipment in dollars per

$0 to

$0

Isochronous

Mode3

Configure Electrical Assets

» To configure Electrical Settings:

Navigate to Configuration > MGC > Electrics >

• Renewable asset

• Dispatchable asset

• Storage asset

• Load asset

• Grid asset

Renewable Asset

Configure each renewable resource with settings such as power generating capacity and operating cost of a

photovoltaic array.

Renewable resources of the same type that are co-located are considered one device.

Point Settings

Asset ID Unique asset ID assigned by the DMC490 MGC.

Name Specify the name of the asset.

Enabled

Cost ($/kWh)

Isochronous

Operation

Mode1

Operation

Mode2

Isochronous

Operation

Specify if the asset is to be included in the microgrid

optimization calculations.

kWh. Include operations, maintenance, and (any) fuel costs.

The cost is in dollars; for other currencies simply enter that

value and be consistent in all fields involving the currency.

Specify if isochronous or droop (non-isoch) mode is to be

used for the renewable resources in each of the microgrid

operation modes.

The numbers 1 to 4 for this setting refer to operation modes

for the microgrid. Depending on the type of isochronous

machine and how the reserve margins are provided, four

different operation modes can be considered for the

microgrid. The following modes are some examples that can

be used:

4 to 20

characters

Disabled

$1,000,000

Isoch

Droop

Renewable

Asset_

Enabled

250 kW

Droop

20

Page 21

DMC490 Configuration

Isochronous

• Dispatchable/CHP isochronous load sharing

Setting

Description

Range

Default

Asset ID

Unique asset ID assigned by the DMC490 MGC.

Name

Specify the name of the asset.

4 to 20

Dispatch

Operation

Mode4

• Hydro in isochronous

• Single dispatchable/CHP in isochronous

• Grid in isochronous

For example, assume in a particular microgrid, one big hydro

generator (such as a run-of-the-rive hydro unit with a

reservoir) can operate in isochronous mode.

This corresponds to Operation Mode 2; however, any of the

four operation modes can be assigned to a single hydro unit

in isochronous. If the operator follows the suggested

operation-mode assignment (that is, Operation Mode 2 is

hydro in isochronous) and Hydro 1 is supposed to be the

isochronous machine, the following are set for this machine:

• Operation Mode 1 = Droop

• Operation Mode 2 = Isoch

• Operation Mode 3 = Droop

• Operation Mode 4 = Droop

In this manner, if you select the second mode to be the active

mode for the microgrid, then Hydro 1 can run in isochronous

mode by receiving the isochronous command from the

DMC490 MGC.

For the other microgrid operation modes, Hydro 1 is in nonisochronous mode (as set by zero values).

Status Points

The following field mappings apply to the status/control and read-only inputs that are to be mapped to the

Microgrid controller > Renewable Asset configuration page:

• Online: This field indicates if the renewable resource is online or offline.

• Isoc Mode: This field indicates if the resource is in droop or isochronous mode.

• Net Meter Power: This field indicates the power generation values (in kW) read from different

renewable generators in the system.

• Operation mode: This is an Analog output which refers to the current microgrid operation mode of the

asset (as explained in section System Settings on page 19, see the Active Mode setting).

• Watchdog: This is a Digital Output command used to inform the asset that the MGC controller is

active. A Digital Output command is sent on this point with the value toggling between 0 and 1 every

10 seconds.

Dispatchable Asset

Configure each dispatchable resource with settings such as operating capacity, operating cost, and minimum

operating period of an auto startup diesel generator.

Point Settings

characters

able

Asset_

21

Page 22

DMC490 Microgrid Controller Software Configuration Guide

Specify if the asset is to be included in the microgrid optimization

Enabled

Rated Power

Specify the maximum power generation capacity of the

0 to

250 kW

Start Cost ($)

Specify the cost to power up the resource. Include the costs that

$0 to

$10

Specify the cost to power down the resource. The cost is in dollars;

$0 to

Fuel Cost ($/L)

Specify the cost of fuel that operates the dispatchable generator, in

$0 to $100

$1

Enabled

(kW)

Minimum

Power (kW)

Efficiency

Maximum

(kWh/kg)

Efficiency

Minimum

(kWh/kg)

calculations.

dispatchable resource in kW.

Specify the preferred minimum power, in kW. For example, some

generators need to be operated at a minimum of 30 percent of their

rated power, expressed in kW.

Specify the efficiency at maximum generator power, in kWh per kg

of fuel consumed. Calculate the number using the related curves for

your generator. If the dispatchable efficiency at maximum power is

available in terms of percent, this setting can simply be determined

by multiplying the percent value with the higher heating value or

energy content of the input fuel in terms of kWh/kg. Higher heating

values for different fuel sources can be found in the related

handbooks or the Internet.

Specify the efficiency at minimum generator power, in kWh per kg

of fuel consumed. Generators are usually less efficient when

operating at low loads. Calculate the number using the related

curves for your generator. If the dispatchable efficiency at minimum

power is available in terms of percent, this setting can simply be

determined by multiplying the percent value with the higher heating

value or energy content of the input fuel in terms of kWh/kg. Higher

heating values for different fuel sources can be found in the related

handbooks or the Internet.

Disabled

1,000,000

kW

0 to

1,000,000

kW

0 to 1,000

kWh/kg

0 to 1,000

kWh/kg

Enabled

50 kW

0.75

kWh/kg

0.55

kWh/kg

Stop Cost ($)

Fuel Density

(kg/L)

you think are important based on your experience with the

microgrid. The cost is in dollars; for other currencies simply enter

that value and be consistent in all fields involving the currency.

for other currencies simply enter that value and be consistent in all

fields involving the currency.

dollars per liter. For example, enter the price for a liter of diesel fuel

or gasoline. The volume of gaseous fuels is usually expressed in

terms of Normal cubic meter (Nm3). Therefore, Fuel Cost of

dispatchable generation resources running on gaseous fuels can

also be expressed in terms of dollars per Nm3; however, in this

case, Fuel Density also needs to be in terms of kg per Nm3. The cost

is in dollars; for other currencies simply enter that value and be

consistent in all fields involving the currency.

Specify the specific gravity of fuel in kg per liter. Values differ based

on the fuel type, such as natural gas and diesel. Use reference

books or the Internet to determine this value. Examples are 0.832

kg/L for diesel, 0.745 kg/L for ethanol-free gasoline, 0.71 to 0.77

kg/L for gasoline, and 0.41 to 0.5 kg/L for liquefied natural gas (LNG).

Fuel Density can also be expressed in terms of kg/Nm3, which is

common for gaseous is case, Fuel Cost also needs to be expressed

in terms of $/Nm3. The unit of volume in both Fuel Cost and Fuel

Density settings need to be the same.

$1,000,000

$1,000,000

0 to 1,000

kg/L

$10

0.85 kg/L

22

Page 23

DMC490 Configuration

Constraint

Soft constraint means that the generator is allowed to violate its

Minimum

Use this setting in conjunction with Constraint Mode. This setting

and be consistent in all fields involving the currency.

0 to 1,000

Isochronous

Specify if isochronous or droop (non-isoch) mode is to be used for

Isochronous

Isochronous

Mode

Power Penalty

($/kWh)

Operation

Mode1

Operation

Mode2

Isochronous

Operation

Mode3

Operation

Mode4

minimum power generation level but at the cost of a penalty in the

objective function. Having the possibility of going below the

minimum power (soft constraint) can positively affect the feasibility

of the microgrid optimization problem.

Hard constraint means that the generator is not allowed to go

below its minimum power generation level.

Use this setting in conjunction with Minimum Power Penalty.

puts a numerical value on the minimum power violation. When the

violation from minimum power is critical, set a high value here.

The cost is in dollars; for other currencies simply enter that value

the renewable resources in each of the microgrid operation modes.

Operation mode numbers 1 to 4 refer to operation modes for the

microgrid. Depending on the type of isochronous machine and how

the reserve margins are provided, four different operation modes

can be considered for the microgrid.

For example the following mode numbers can be used:

1. Dispatchable/CHP isochronous load sharing

2. Hydro in isochronous

3. Single dispatchable/CHP in isochronous

4. Grid in isochronous

Assume in a particular microgrid, one big hydro generator

(such as a run-of-the-rive hydro unit with a reservoir) can

operate in isochronous mode. This corresponds to Operation

Mode 2; however, any of the four operation modes can be

assigned to a single hydro unit in isochronous. If the operator

follows the suggested operation-mode assignment (that is,

Operation Mode 2 is hydro in isochronous) and Hydro 1 is

supposed to be the isochronous machine, the following are set

for this machine:

• Operation Mode 1 = Droop

• Operation Mode 2 = Isoch

• Operation Mode 3 = Droop

• Operation Mode 4 = Droop

In this manner, if you select the second mode to be the active

mode for the microgrid, then Hydro 1 can run in isochronous

mode by receiving the isochronous command from DMC490.

For the other microgrid operation modes, Hydro 1 is in nonisochronous mode (as set by zero values).

Hard

Soft

$/kWh

Isoch

Droop

Hard

0 $/kWh

Droop

Status Points

The following field mappings apply to the status and read only inputs that are to be mapped to the Microgrid

controller > Dispatchable Asset configuration page:

• Online: This field indicates if the resource is online or offline. It is not necessarily the same as being

available for use in the MGC optimization calculations.

• Input Isoch Mode: This field indicates if the resource is to be in droop or isochronous mode. There is an

input and output isoch mode. The input isoch mode is advice produced by the optimizer and issued to

the dispatchable asset. The output isoch mode is the actual operating mode of the dispatchable asset.

23

Page 24

DMC490 Microgrid Controller Software Configuration Guide

Setting

Description

Range

Default

Asset ID

Unique asset ID assigned by the DMC490 MGC.

4 to 20

characters

Storage

Asset_

Input Enabled

This setting indicates if the storage input/charging is set to be

Disabled

Enabled

Assuming that the dispatchable resource follows the advice of the optimizer, the modes are usually

the same.

• Availability: Availability is declared by the generator. This field indicates if the generator can be

controlled by the MGC and included in the optimization problem solved by the MGC. An online

generator is not necessarily an available generator. The availability signal is built by the generator’s

local controller based on some parameters and is read by the MGC.

• Net Meter Power: This field indicates the power generation values in kW read from different

dispatchable generators in the system.

The following field mappings apply to the AO/DO control points that are to be mapped to the Microgrid

controller > Dispatchable Asset configuration page:

• Start: Start/stop is a command. When the MGC sends the start command, the generator comes online

after some time.

• Output Isoch Mode: This field indicates if the resource is in droop or isochronous mode.

For isochronous mode, there is an input and output isoch mode:

o The input isoch mode is advice produced by the optimizer and issued to the dispatchable

asset.

o The output isoch mode is the actual operating mode of the dispatchable asset.

Assuming that the dispatchable resource follows the advice of the optimizer, the modes are usually

the same.

• Power Ref: This field refers to the power reference points of dispatchable generators, in kW. Their

values are computed by the MGC dispatch algorithm.

• Operation mode: This is an Analog output which refers to the current microgrid operation mode of the

asset (as explained in section System Settings on page 19, see the Active Mode setting).

• Watchdog: This is a Digital Output command used to inform the asset that the MGC controller is

active. A Digital Output command is sent on this point with the value toggling between 0 and 1 every

10 seconds.

Storage Asset

Configure each electrical storage installation with settings such as capacity and cost.

Storage devices of the same type that are co-located are considered one storage device.

Point Settings

Name Specify the name of the asset.

included in the microgrid optimization calculations by the

DMC490. When storage input is offline and the optimal

dispatch result indicates storage input usage above the

minimum storage input for equal to or longer than the

Charging Minimum Up Time, then the storage input is started.

For hydrogen storage, which is interpreted as the combination

of electrolyzer, high-pressure storage cylinders, and fuel cell,

enabling the input translates to enabling the electrolyzer.

Enabled

24

Page 25

DMC490 Configuration

This setting indicates if the storage output/discharge is set to

Storage Type

Specify if the storage is batteries or a hydrogen-based system,

Hydrogen

Battery

Minimum

Charging power for a storage device cannot be below a

0 to 1,000,000

efficiency of the storage cylinders is close to unity.)

Discharging

This setting describes how efficient the stored energy is

0% to 100%

55%

Output Enabled

Maximum

Discharging

Power (kW)

Minimum

Discharging

Power (kW)

Maximum

Charging Power

(kW)

Charging Power

(kW)

Charging

Efficiency (%)

be included in the microgrid optimization calculations by the

DMC490. For hydrogen storage, which is interpreted as the

combination of electrolyzer, high-pressure storage cylinders,

and fuel cell, enabling the output translates to enabling the

fuel cell.

such as the combination of electrolyzer, high-pressure storage

cylinders, and fuel cell.

Specify the maximum electrical power in kW that the storage

unit can discharge to the microgrid. For hydrogen storage,

which is interpreted as the combination of electrolyzer, highpressure storage cylinders, and fuel cell, this setting refers to

the rated power of a fuel cell.

Specify the minimum electrical power in kW that the storage

unit is to discharge to the microgrid. For hydrogen storage,

which is interpreted as the combination of electrolyzer, highpressure storage cylinders, and fuel cell, this setting refers to

the minimum fuel cell output power.

Specify the maximum input/charging power of the storage

unit in kW. For hydrogen storage, which is interpreted as the

combination of electrolyzer, high-pressure storage cylinders,

and fuel cell, this setting refers to the rated power of the

electrolyzer.

certain level, so Specify the minimum input/charging power of

the storage unit. This power level is related to the technology

and specifications of the storage device itself and it does not

depend on other dispatchable or renewable devices in the

system. For hydrogen storage, which is interpreted as the

combination of electrolyzer, high-pressure storage cylinders,

and fuel cell, this setting refers to the minimum input power of

the electrolyzer.

For example, for a 300 kW alkaline electrolyzer, this setting

can be in the range of 120 to 130 kW.

This setting describes how efficient the input or charging

power over time contributes in increasing the state of charge.

Charging efficiency depends on the input/charging power and

storage state of charge. However, it is assumed here to be a

fixed setting, which is acceptable in most applications. For

hydrogen storage, which is interpreted as the combination of

electrolyzer, high-pressure storage cylinders, and fuel cell, this

setting refers to the electrolyzer efficiency. (The charging

Disabled

Enabled

Enabled

Battery

0 to 1,000,000

50 kW

kW

0 to 1,000,000

25 kW

kW

0 to 1,000,000

50 kW

kW

25 kW

kW

0% to 100% 50%

Efficiency (%)

converted back to the microgrid. Discharging efficiency

depends on the output/discharging power and storage state

of charge. However, it is assumed here to be a fixed setting,

which is acceptable in most applications. For hydrogen

storage, which is interpreted as the combination of

electrolyzer, high-pressure storage cylinders, and fuel cell, this

setting refers to the fuel cell efficiency. (The discharging

efficiency of the storage cylinders is close to unity.)

25

Page 26

DMC490 Microgrid Controller Software Configuration Guide

State Of Charge

This setting is the maximum capacity of the storage device. It

0 to 1,000,000

State Of Charge

Specify the minimum level of storage state of charge, in kWh.

0 to 1,000,000

50 kWh

Lower

This setting is the upper boundary of the minimum acceptable

example one to five percent (that is, 0.01 to 0.05).

0 to 1 kW

0 kW

Lower

This setting is the lower boundary of the minimum acceptable

0 to 1 kW

0 kW

Maximum (kWh)

specifies the maximum level of storage state of charge (SOC),

in kWh.

300 kWh

kWh

Minimum (kWh)

Upper

Boundary Store

Device1 (kW)

Lower

Boundary Store

Device2 (kW)

Due to lifetime considerations, SOC cannot usually go below a

certain limit. This is referred to as maximum depth of

discharge (DOD). For example, for a 100kWh storage device

with 80% DOD, State Of Charge Minimum is set to 20 kWh.

Storage state of charge needs to be always above State Of

Charge Minimum and below State Of Charge Maximum.

However, a variety of practical complexities, such as storage

standby loss, delay in issuing the charging/discharging

commands, measurements errors, and startup or

environmental conditions, lead to the violation of these limits

and can render the real-time microgrid optimization problem

infeasible. Apart from the infeasibility of the optimization

problem, there is also a chance of an undesired phenomenon

occurring, which is frequent charging and discharging (cycling)

of storage devices. These undesired outcomes (that is,

infeasibility and cycling) are avoided in the DMC490 MGC by

having some pre and post processing units outside of the

optimization core to modify the commands issued by the

controller, such as storage stop/start, or to change some input

readings, such as SOC. This also requires defining some small

regions around State Of Charge Maximum and State Of

Charge Minimum.

Thus, two regions below State Of Charge Maximum, and two

regions on either side of State Of Charge Minimum are

defined as shown in the following figure. If SOC is located in

region E, no action is required; however, if SOC is within any of

four regions A to D, its measured value is appropriately

changed together with issuing some necessary

charging/discharging commands.

Upper Boundary Store Dev1 is the upper boundary of the

maximum acceptable charging level. Configure it to be within

a few percent of storage maximum capacity State Of Charge

Minimum, for example one to five percent (that is, 0.01 to

0.05).

Refer to Figure 14 for more details

This setting is the lower boundary of the maximum acceptable

charging level. Configure it to be within a few percent of

storage maximum capacity (State Of Charge Minimum), for

example one to five percent (that is, 0.01 to 0.05).

kWh

0 to 1 kW 0 kW

0 to 1 kW 0 kW

Boundary Store

Device1 (kW)

Boundary Store

Device2 (kW)

charging level. Configure it to be within a few percent of

storage minimum capacity (State Of Charge Minimum), for

charging level. Configure it to be within a few percent of

storage minimum capacity (State Of Charge Minimum), for

example one to five percent (that is, 0.01 to 0.05).

26

Page 27

DMC490 Configuration

Constraint

Soft constraint means that the storage device is allowed to

Charging Cost

This setting is the cost to charge the storage device in dollars

0 to 1,000

10 $/kWh

consistent in all fields involving the currency.

Mode

violate its minimum capacity State Of Charge Minimum but at

the cost of a penalty in the objective function. Having the

possibility of going below the minimum capacity (soft

constraint) can positively affect the feasibility of the microgrid

optimization problem but can also result in charge/discharge

cycling.

Hard constraint means that the storage is not allowed to go

below its minimum capacity (State Of Charge Minimum).

Use this setting in conjunction with State Of Charge Penalty,

State Of Charge Minimum Incentive and State Of Charge

Penalty.

($/kWh)

per kWh. Determine the cost based on your knowledge of the

microgrid or initial simulation studies. Including such costs

helps to prevent simultaneous charging and discharging and

helps to limit charge/discharge cycling. The cost is in dollars;

for other currencies simply enter that value and be consistent

in all fields involving the currency.

Discharging

Cost ($/kWh)

This setting is the cost to discharge power from the storage

unit in dollars per kWh. Determine the cost based on your

knowledge of the microgrid or initial simulation studies.

Including such costs helps to prevent simultaneous charging

and discharging and helps to limit charge/discharge cycling.

The cost is in dollars; for other currencies simply enter that

value and be consistent in all fields involving the currency.

Charging

Incentive

($/kWh)

This setting is the financial incentive to charge storage, in

dollars per kWh. In some jurisdictions, utilities are required to

store a percent of energy and incentives can be available for

such a program.

The incentive can be used to set this parameter for gridconnected microgrid configurations. In the absence of such an

incentive program, some simulation studies can be needed to

fine-tune this setting given the requirement to prevent

simultaneous charging and discharging and the need to limit

storage cycling.

The cost is in dollars; for other currencies simply enter that

value and be consistent in all fields involving the currency.

Discharging

Incentive

($/kWh)

This setting is the financial incentive to discharge storage, in

dollars per kWh. In the absence of incentive programs for gridconnected microgrids, some simulation studies can be needed

to fine-tune this setting given the requirement to prevent

simultaneous charging and discharging and the need to limit

storage cycling.

The cost is in dollars; for other currencies simply enter that

value and be consistent in all fields involving the currency.

State Of Charge

Penalty

($/kWh2)

This setting promotes discharging and lower values of SOC.

Both State Of Charge Penalty and State Of Charge Incentive

settings are provided to allow you more freedom to configure

the system based on your operational knowledge. The cost is

in dollars; for other currencies simply enter that value and be

Hard

Soft

$/kWh

0 to 1,000

$/kWh

0 to 1,000

$/kWh

0 to 1,000

$/kWh

0 to 1,000

$/kWh2

Hard

5 $/kWh

0 $/kWh

0 $/kWh

0 $/kWh2

27

Page 28

DMC490 Microgrid Controller Software Configuration Guide

State Of Charge

This incentive promotes more charging and higher values of

0 to 1,000

State Of Charge

The setting is the penalty when storage is allowed to violate its

0 to 1,000

0 $/kWh2

The DMC490 MGC supports input up-time, down-time, and

Charging

When the Hysteresis field is set to On, this is the minimum

0 to 720

0 minutes

Charging

When the Hysteresis field is set to On, this is the minimum off

at least this length of time.

0 to 720

0 minutes

Incentive

($/kWh2)

SOC. Both State Of Charge Penalty and State Of Charge

Incentive settings are provided to allow you more freedom to

configure the system based on your operational knowledge.

The cost is in dollars; for other currencies simply enter that

value and be consistent in all fields involving the currency.

0 $/kWh2

$/kWh2

Minimum

Penalty

($/kWh2)

Hysteresis

Minimum Up

Time (minutes)

Minimum Down

Time (minutes)

minimum level (that is, soft constraint is set for Constraint

Mode. The greater the violation from State Of Charge

Minimum, the greater the penalty cost in the objective

function.

The cost is in dollars; for other currencies simply enter that

value and be consistent in all fields involving the currency.

cycle-per-day hysteresis. When Hysteresis is On, a set of

appropriate parameters is in place to prevent excessive

switching and cycling. Support for hysteresis is required for

storage input to overcome high-frequency on/off cycling of

the electrolyzer because it lowers performance and decreases

the life of the device. The hysteresis mostly targets the

electrolyzer (hydrogen-based storage), but it is available for all

storage devices.

running time of the electrolyzer, in minutes. If the electrolyzer

is turned on, it runs for at least this length of time. When

storage input is offline and the optimal dispatch result

indicates storage input usage above the minimum storage

input (Minimum Charging Power) for equal to or longer than

the Charging Minimum Up Time, then the storage input is

started with the calculated setpoint.

time of the electrolyzer, in minutes. When the electrolyzer is

on and receives an off command, it turns off and stays off for

$/kWh2

On

Off

minutes

minutes

On

28

Page 29

DMC490 Configuration

Charging Limit

Yes means that the storage local controller provides the

Feedback

maximum value of discharging power for the DMC490 MGC to

read. No means that the value read by the DMC490 MGC is

disregarded.

For storage devices we have maximum charging power and

maximum discharging power; these are settings and fixed

values. However, for particular storage technologies, these

maximum powers are not fixed; they depend on the state of

charge (SOC). For example, we have a setting of 100 kW for

maximum discharging power but if SOC is below a certain limit

we cannot approach this maximum 100-kW limit. For these

particular storage devices, the maximum charging or

discharging powers are declared by their local controllers;

they have mathematical functions that calculate the

maximum power depending on the value of SOC; these values

are published so that an external device like the DMC490 can

read them.

Given this, the DMC490 has two related settings for storage

devices: Charging Limit Feedback and Discharging Limit

Feedback. For example, when the Charging Limit Feedback is

Yes, it means that the storage local controller provides the

maximum value of charging power (this is read by the

DMC490 and used in the optimization calculation). In this case,

the value read by the DMC490 is replaced with the maximum

value already set by the user. In other words, setting value for

maximum charging power is overwritten based on the value

provided by the storage local controller and read by the

DMC490.

When the Charging Limit Feedback is set to No, then the value

read by the DMC490 is disregarded.

False

True

False

29

Page 30

DMC490 Microgrid Controller Software Configuration Guide

Discharging

Yes means that the storage local controller provides the

Commitment1

Used by Unit

Commitment2

Used by Unit

Used by Unit

relatively high dissipation.

Limit Feedback

maximum value of discharging power for the DMC490 to read.

No means that the value read by the DMC490 is disregarded.

For storage devices we have maximum charging power and

maximum discharging power; these are settings and fixed

values. However, for particular storage technologies, these

maximum powers are not fixed; they depend on the state of

charge (SOC). For example, we have a setting of 100 kW for

maximum discharging power but if SOC is below a certain limit

we cannot approach this maximum 100-kW limit. For these

particular storage devices, the maximum charging or

discharging powers are declared by their local controllers;

they have mathematical functions that calculate the

maximum power depending on the value of SOC; these values

are published so that an external device like the DMC490 can

read them. Given this, the DMC490 has two related settings

for storage devices: Charging Limit Feedback and Discharging

Limit Feedback. For example, when the Charging Limit

Feedback is Yes, it means that the storage local controller

provides the maximum value of charging power (this is read

by the DMC490 and used in the optimization calculation). In

this case, the value read by the DMC490 is replaced with the

maximum value already set by the user. In other words,

setting value for maximum charging power is overwritten

based on the value provided by the storage local controller

and read by the DMC490. When the Charging Limit Feedback

is set to No, then the value read by the DMC490 is disregarded.

Used by Unit

Select yes to have storage contribution considered in the Unit

Commitment (UC) routine of the optimization problem.

The Unit Commitment problem is the task of determining a

combination of power generation units each with a certain

capacity and operation cost so as to minimize the total

Commitment3

Commitment4

operation costs while satisfying the electricity-demand

requirement of the microgrid in each time period.

The numbers 1 to 4 specify whether or not to consider the

contribution of storage devices in the Unit Commitment (UC)

routine in each of the four microgrid operation modes.

Charging

Dissipation

(kWh/h)

This setting represents energy loss from the storage device

over time. It specifies the rate of charge dissipation, or standby

loss of the storage, in kWh/h. You set this value based on your

knowledge of the storage technology used in the microgrid.

For example, some storage technologies, such as hydrogen,

have low standby losses while battery storage systems have

False

True

False

True

0 to 1,000

kWh/h

False

False

0 kWh/h

30

Page 31

DMC490 Configuration

Status Points

The following field mappings apply to the status and read only inputs that are to be mapped to the Microgrid

controller > Storage Asset configuration page:

• Input Online: This field indicates if the storage input is online or offline. For hydrogen storage, which is

interpreted as the combination of electrolyzer, high-pressure storage cylinders, and fuel cell, Input

Online represents the offline/online status of the electrolyzer. Being online is not necessarily the same

as being available for use in the MGC optimization calculations.

• Output Online: This field indicates if the storage output is online or offline. For hydrogen storage,

which is interpreted as the combination of electrolyzer, high-pressure storage cylinders, and fuel cell,

Output Online represents the offline/online status of the fuel cell. Being online is not necessarily the

same as being available for use in the MGC optimization calculations.

• Input Availability: Input availability is declared by the storage device. It indicates if the storage input

can be controlled by the MGC and included in the optimization problem solved by the MGC. The

availability signal is built into the storage local controller based on some parameters and is read by the

MGC. For hydrogen storage, which is interpreted as the combination of electrolyzer, high-pressure

storage cylinders, and fuel cell, Input Availability represents the availability of the electrolyzer. An

online storage resource is not necessarily an available storage resource.

• Output Availability: Output availability is declared by the storage device. It indicates if the storage

output can be controlled by the MGC and included in the optimization problem solved by the MGC. The

availability signal is built into the storage local controller based on some parameters and is read by the

MGC. For hydrogen storage, which is interpreted as the combination of electrolyzer, high-pressure

storage cylinders, and fuel cell, Output Availability represents the availability of the fuel cell. An online

storage resource is not necessarily an available storage resource.

• Net Meter Power In: This is the net metered input power, in kW. It indicates the input/charging power

value read from the storage device. For hydrogen storage, which is interpreted as the combination of

electrolyzer, high-pressure storage cylinders, and fuel cell, Net Meter Power In represents the

measured value of the electrolyzer input/charging power.

• Net Meter Power Out: This is the net metered output power, in kW. This field indicates the

output/discharging power value read from the storage device. For hydrogen storage, which is

interpreted as the combination of electrolyzer, high-pressure storage cylinders, and fuel cell, Net Meter

Power Out represents the measured value of the fuel cell output/discharging power.

• SOC: This field indicates storage state of charge, in kWh.

The following field mappings apply to the AO/DO control points that are to be mapped to the Microgrid

controller > Storage Asset configuration page:

• Input Start: This field represents the start command for storage charging. For hydrogen storage,

which is interpreted as the combination of electrolyzer, high-pressure storage cylinders, and fuel cell,

Input Start corresponds to the electrolyzer start command.

• Output Start: This field represents the start command for storage discharging. For hydrogen storage,

which is interpreted as the combination of electrolyzer, high-pressure storage cylinders, and fuel cell,

Output Start corresponds to the fuel cell start command.

• Power Ref In: This field reflects the reference input power of the storage device. It is the value decided

by the MGC for the storage charging power. For hydrogen storage, which is interpreted as the

combination of electrolyzer, high-pressure storage cylinders, and fuel cell, Power Ref In represents the

command for electrolyzer input/charging power.

• Power Ref Out: This field reflects the reference output power of the storage device. It is the value

decided by the MGC for the storage discharging power. For hydrogen storage, which is interpreted as

the combination of electrolyzer, high-pressure storage cylinders, and fuel cell, Power Ref Out

represents the command for fuel cell output/discharging power.

31

Page 32

DMC490 Microgrid Controller Software Configuration Guide

Setting

Description

Range

Default

Asset ID

Unique asset ID assigned by the DMC490 MGC.

Enabled

• Operation mode: This is an Analog output which refers to the current microgrid operation mode of the

asset (as explained in section System Settings on page 19, see the Active Mode setting).

• Input Watchdog: This is a Digital Output command used to inform the charge controller in the Storage

asset that the MGC controller is active. A Digital Output command is sent on this point with a value

toggling between 0 and 1 every 10 seconds.

• Output watchdog: This is a Digital Output command used to inform the discharge controller in the

Storage asset that the MGC controller is active. A Digital Output command is sent on this point with a

value toggling between 0 and 1 every 10 seconds.

Figure 14 Upper Boundary Store – State of Charge

Load Asset

Configure each load for the use of the electricity, such as which forecast to use.

Point Settings

Name Specify the name of the asset. 4 to 20 characters Load Asset_

Enabled

Status Points

The following field mappings apply to the status/control and read only inputs that are to be mapped to the

Microgrid controller > Load Asset configuration page:

• Online: This field indicates if the load is online or offline, meaning consuming electricity or not.

• Net Meter Power: This field indicates the values of demanding powers in kW read from different loads

in the system.

• Operation mode: This is an Analog output which refers to the current microgrid operation mode of the

asset (as described in section System Settings on page 19, see the Active Mode setting).

• Watchdog: This is a Digital Output command used to inform the asset that the MGC controller is

active. A Digital Output command is sent on this point with the value toggling between 0 and 1 every

10 seconds.

Specify if the asset is to be included in the microgrid

optimization calculations.

Disabled

Enabled

32

Page 33

DMC490 Configuration

Setting

Description

Range

Default

Export

Specify if exporting from the microgrid to the grid is enabled.

and Export Enabled to Disabled.

Disabled

Enabled

Minimum

Minimum amount of electricity to import from the grid to the

0 to 1,000,000

50 kW