Page 1

GasDryer

5O

I If you have any questions, carl 1-800-GECARES (US) or 1-800-361-3400 (Canada)

or Visit our Web site at: www. GEAppliances.com

BEFOREYOU BEGIN

Read these instructions completely and carefully.

IMPORTANT -Savethese

instructions for local inspector's use.

IMPORTANT =Observeall

governing codes and ordinances.

Note to Installer - Be sure to leave these instructions with

the customer

Note to Customer - Keep these instructions with your Use

and Care Book for future reference.

This dryer must be exhausted to the outdoors.

Before the old dryer is removed from service or discarded,

remove the dryer door.

Service Information and the wiring diagram are located in

the control console.

Service of this dryer must be performed by a qualified

installer,service agency, or the gas supplier.

Do not allow children on or in the appliance. Close

supervision of children is necessary when the appliance is

used near children.

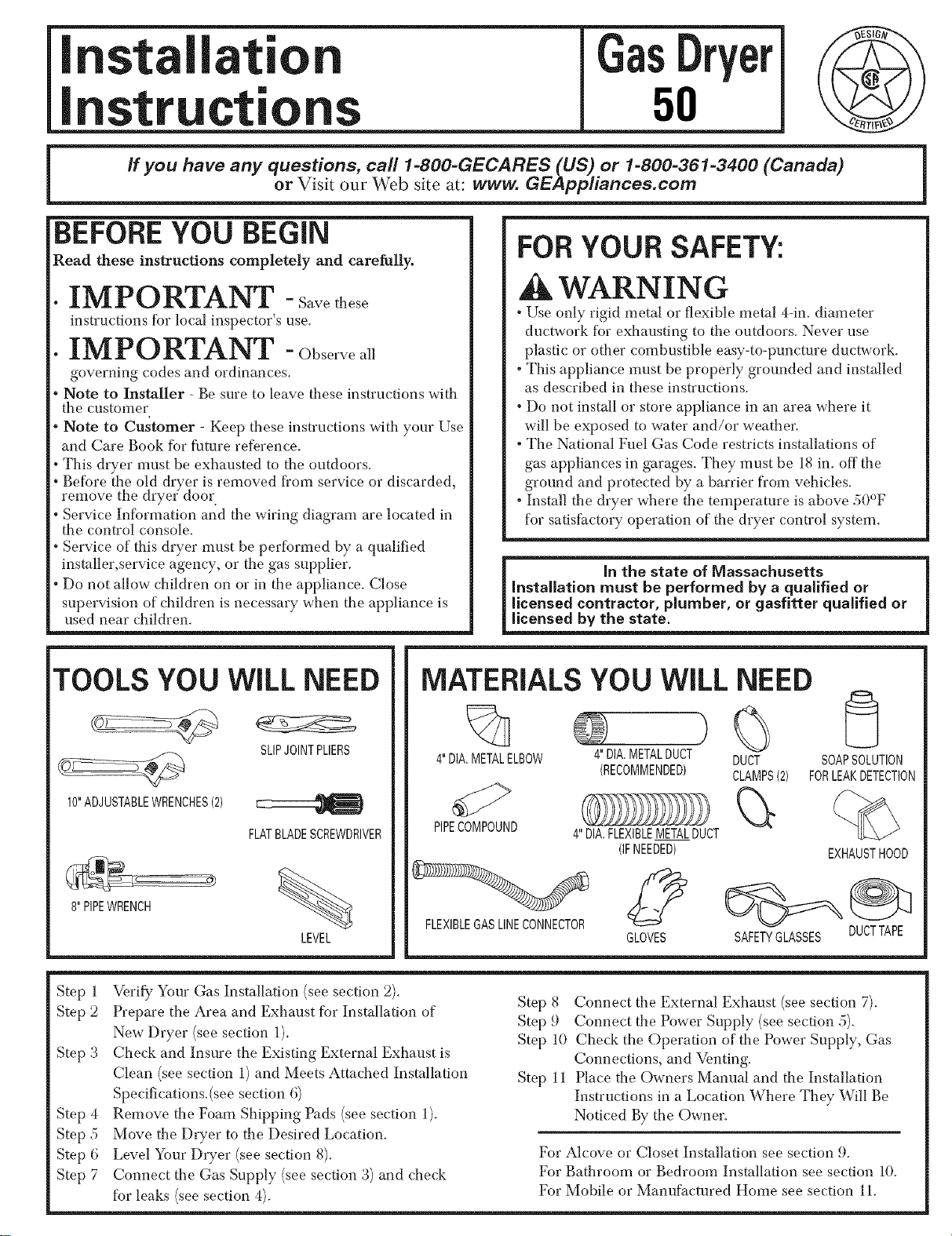

TOOLS YOU WiLL NEED

MATERIALSYOU WiLL NEED

FORYOUR SAFETY:

WARNING

• Use only rigid metal or flexible metal 4-in. diameter

ducrwork for exhausting to the outdoors. Never use

plastic or other combustible easy-to-puncture ductwork.

• This appliance must be properly grounded and installed

as described in these instructions.

• Do not install or store appliance in an area where it

will be exposed to water and/or weather.

• The National Fuel Gas Code restricts installations of

gas appliances in garages. They must be 18 in. off the

ground and protected by a barrier from vehicles.

• Install the dryer where the temperature is above 50°F

for satisfactory operation of the dryer control system.

licensed by the state.

10"ADJUSTABLEWRENCHES(2)

8"PIPEWRENCH

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

Verify Your Gas Installation (see section 2).

Prepare the Area and Exhaust for Installation of

New Dryer (see section 1).

Check and Insure the Existing External Exhaust is

Clean (see section 1) and Meets Attached Installation

Specifications.(see section 6)

Remove the Foam Shipping Pads (see section 1).

Move the Dryer to tile Desired Location.

Level Your Dryer (see section 8).

Connect tile Gas Supply (see section 3) and check

for leaks (see section 4).

SLIPJOINTPLIERS

FLATBLADESCREWDRIVER

%

LEVEL

%

4"DIA,METALELBOW

PIPECOMPOUND

FLEXIBLEGASLINECONNECTOR

Step 8 Connect the External Exhaust (see section 7).

Step 9 Connect the Power Supply (see section 5).

Step 10 Check the Operation of the Power Supply, Gas

Step 11 Place the Owners Manual and the Installation

For Alcove or Closet Installation see section 9.

For Bathroom or Bedroom Installation see section 10.

For Mobile or Manufactured Home see section 11.

4"DIA,METALDUCT

4"DIA.FLEXIBLEMETALDUCT

Connections, and Venting.

Instructions in a Location Where They _rill Be

Noticed By the Owner.

(RECOMMENDED)

(IFNEEDED)

GLOVES

DUCT SOAPSOLUTION

CLAMPS(2) FORLEAKDETECTION

EXHAUSTHOOD

SAFETYGLASSES DUCTTAPE

Page 2

Installation instructions

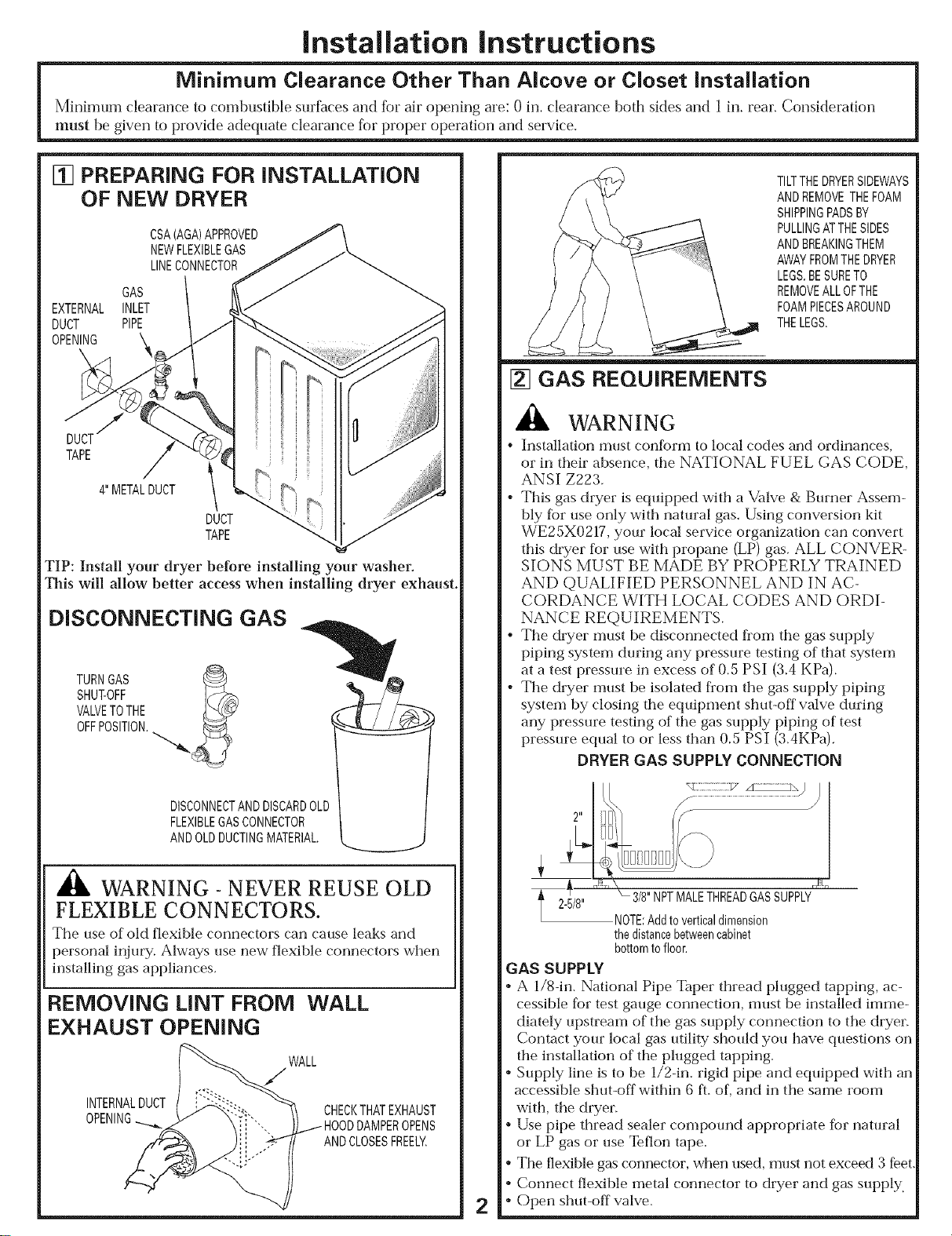

Minimum Clearance Other Than Alcove or Closet Installation

Minimum clearance to combustible surfaces and fox'air opening are: 0 in. clearance both skies and 1 in. rear. Consideratkm

must be given to provkte adequate clearance for proper operation and service.

[] PREPARING FOR iNSTALLATiON

OF NEW DRYER

CSA(AGA)APPROVED

NEWFLEXIBLEGAS

LINECONNECTOR

GAS

EXTERNAL

DUCT

OPENING

TAPE

TIP: Install your dryer before installing your washer.

This will allow better access when installing dryer exhaust.

INLET

PIPE

4"METALDUCT

DUCT

TAPE

DiSCONNECTiNG GAS

SHUT-OFF

VALVETOTHE

OFFPOSITION.

TURNGAS . .__

TILTTHEDRYERSIDEWAYS

ANDREMOVETHEFOAM

SHIPPINGPADSBY

PULLINGATTHESIDES

ANDBREAKINGTHEM

AWAYFROMTHEDRYER

LEGS,BESURETO

REMOVEALLOFTHE

FOAMPIECESAROUND

THELEGS.

[] GAS REQUIREMENTS

WARNING

. Installation must conform to local codes and ordinances,

or in their absence, the NATIONAL FUEL GAS CODE,

ANSI Z223

. This gas dryer is equipped with a Valve & Burner Assem-

bly for use only with natural gas. Using conversion kit

WE25X0217, your local service organization can convert

this dryer fox' use with propane (LP) gas. ALL CONVER-

SIONS MUST BE MADE BY PROPERLY TRAINED

AND QUALIFIED PERSONNEL AND IN AC-

CORDANCE WITH LOCAL CODES AND ORDI-

NANCE REQUIREMENTS.

. The dryer must be disconnected fl'om the gas supply

piping system during any pressure testing of that system

at a test pressure in excess of 0.5 PSI (3.4 KPa).

. The dryer must be isolated fl'om the gas supply piping

system by closing the equipment shut-off valve during

any pressure testing of the gas supply piping of test

pressure equal to or less than 05 PSI (3.4KPa).

DRYER GAS SUPPLY CONNECTION

DISCONNECTANDDISCARDOLD

FLEXIBLEGASCONNECTOR

ANDOLDDUCTINGMATERIAL.

Z_

WARNING - NEVERREUSE OLD

FLEXIBLE CONNECTORS.

The use of old flexible connectors can cause leaks and

personal injury. Always use new flexible connectors when

installing gas appliances.

REMOVING LiNT FROM WALL

EXHAUST OPENING

WALL

/

INTERNALDUCT CHECKTHATEXHAUST

OPENING OPENS

ANDCLOSESFREELY,

A ..............1_ J J

24/8" 3/8"NPTMALETHREADGASSUPPLY

NOTE:Addtoverticaldimension

thedistancebetweencabinet

bottomtofloor.

GAS SUPPLY

A 1/8-in. National Pipe Taper thread plugged tapping, ac-

cessible for test gauge connection, must be installed imme-

diately upstream of the gas supply connection to the dryer.

Contact your local gas utility should you have questions on

the installation of the plugged tapping.

Supply line is to be 1/2-in. rigid pipe and equipped with an

accessible shut-offwithin 6 ft. of, and in the same room

with, the dryer.

Use pipe thread sealer compound appropriate for natural

or LP gas or use Teflon tape

The flexible gas connector, when used, must not exceed 3 feet.

Connect flexible metal connector to dryer and gas supply.

Open shut-off valve.

2

Page 3

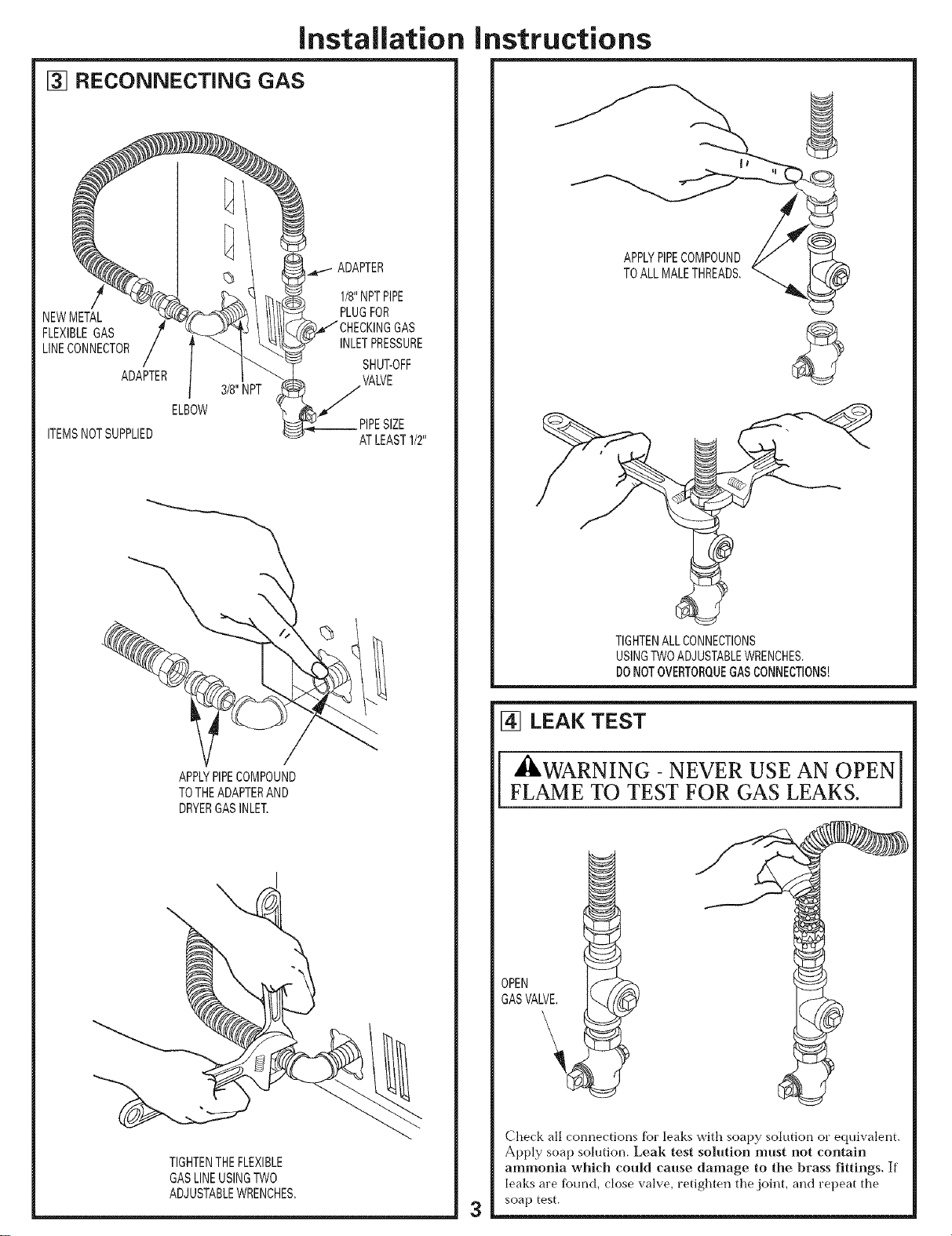

[] RECONNECTING GAS

NEWMETAL

FLEXIBLEGAS

LINECONNECTOR

ADAPTER

3/8"NPT

ELBOW

ITEMSNOTSUPPLIED

Installation

1/8"NPTPIPE

PLUGFOR

GAS

INLETPRESSURE

SHUTOFF

VALVE

X

__PIPE SIZE

ATLEAST1/2"

Instructions

APPLYPIPECOMPOUND

TOALLMALETHREADS.

APPLYPIPECOMPOUND

TOTHEADAPTERAND

DRYERGASINLET.

\

TIGHTENALLCONNECTIONS

USINGTWOADJUSTABLEWRENCHES.

DONOTOVERTORQUEGASCONNECTIONS!

[] LEAK TEST

[ ,d_WARNING - NEVER USE AN OPEN

FLAME TO TEST FOR GAS LEAKS.

OPEN

GASVALVE.

TIGHTENTHEFLEXIBLE

GASLINEUSINGTWO

ADJUSTABLEWRENCHES.

Check all connections fbr leaks with soapy solution oi" equivalent.

Apply soap solution. Leak test solution must not contain

ammonia which could cause damage to the brass fittings. If

leaks are found, close valve, retighten the joint, and repeat the

soap test.

Page 4

Installation

instructions

[] ELECTRICAL CONNECTION

iNFORMATiON

WARNING- TO REDUCE THE RISK OF

FIRE, ELECTRICAL SHOCK, AND PERSONAL

INJURY:

DO NOT USE AN EXTENSION CORD OR AN

ADAPTER PLUG WITH THIS APPLIANCE.

Dryer must be electrically grounded in accordance with

local codes and ordinances, or in the absence of local

codes, in accordance with the NATIONAL ELECTRI-

CAL CODE, ANSI/NFPA NO. 70.

ELECTRICAL REQUIREMENTS

This appliance must be supplied with 120V, 60Hz, and connected

to a properly grounded branch circuit, protected by a 15- or 20-

amp circuit breaker or time-delay fuse. If electrical supply provid-

ed does not meet the above specifications, it is reconnnended that

a licensed electrician install an apt)roved outlet.

_WARNING - THIS DRYER IS EQUIPPED

A THREE-PRONG (GROUNDING) PLUG FOR

YOUR PROTECTION AGAINST SHOCK

HAZARD AND SHOULD BE PLUGGED

DIRECTLY INTO A PROPERLY GROUNDED

THREE-PRONG RECEPTACLE. DO NOT CUT

OR REMOVE THE GROUNDING PRONG

FROM THIS PLUG.

[] EXHAUST iNFORMATiON

A

_WARNING - USE ONLY METAL 4-IN. DUCT.

DO NOT USE DUCT LONGER THAN SPECIFIED

IN THE EXHAUST LENGTH TABLE.

Exhaust longer than specified will:

• Increase the drying times and the energy cost.

" Reduce the dryer life.

• Accunmlate lint, creating a potential fire hazard.

The correct exhaust installation is your responsibility.

Problems due to incorrect installation a,,e not covered

by the warranty.

The MAXIMUM ALLOWABLE length of the exhaust system

depends upon the type of duct, number of turns, the type of

exhaust hood (wall cap), and all conditions noted below-. Both

rigid and flexible metal duct are shown in the table below:

EXHAUST LENGTH

RECOMMENDED MAXIMUM LENGTH

Exhaust HoodTypes

Recommended

No. of 90 °

Elbows

0

1

2

3

4

5

If using flexible metal duct, please refer to page 6.

Rigid Flexible

Metal Metal

150 Feet 55 Feet

135 Feet 52 Feet

125 Feet 49 Feet

115 Feet 46 Feet

105 Feet 43 Feet

95 Feet 40 Feet

Use onlyfor short

run installations

4" DIA.

Rigid Flexible

Metal Metal

125 Feet 45 Feet

115 Feet 42 Feet

105 Feet 39 Feet

95 Feet 36 Feet

85 Feet 33 Feet

75 Feet 30 Feet

ENSURE PROPER GROUND EXISTS BEFORE USE.

?-

IFLOCALCODESPERMIT,

ANEXTERNALGROUNDWIRE

(NOTPROVIDED},WHICHMEETS

LOCALCODES,MAYBEADDED

BYATTACHINGTOTHEGREEN

GROUNDSCREWONTHEREAR

OFTHEDRYER,ANDTOA GROUNDED

METALCOLDWATERPIPEOROTHER

ESTABLISHEDGROUND.

EXHAUST SYSTEM CHECK LiST

HOOD OR WALL CAP

•Terminate in amanner to prevent back drafts or entry of birds or

other wildlife.

•Termination should present minimal resistance to the exhaust air flow

and should require little or no maintenance to prevent clogging.

•Never install a screen in or over the exhaust duct.

•Wall caps must be installed at least 12 in. above ground level or any other

obstruction with the opening pointed down.

•If roof vents or louvered plenmns are used, they must be equivalent to a

4-in. dampened wall cap in regard to resistance to air flow, prevention of

back drafts, and maintenance required to prevent clogging.

SEPARATION OF TURNS

Fox'best performance, separate all turns by at least 4 fL of straight duct,

including distance between last turn and dampened wall cap.

TURNS OTHER THAN 90°

• One turn of 45 or less may be ignored.

•Two 45 turns should be treated as one J0 turn.

•Each turn over 45oshould be treated as one ,)0 turn.

SEALING OF JOINTS

"All joints should be tight to avoid leaks. The male end of each section of

duct must point away fi'om the dryer.

•Do not assemble the ductwork with fasteners that extend into the duct.

They will serve as a collection point for lint.

•Duct joints should be made air-and moisture-tight by wrapping the

overlapped joints with duct tape.

•Horizontal runs should slope down towm'ds outdoors 1/2 inch pet"fbot,

INSULATION

•Duct work that runs through an unheated area or is near air conditioning

4

should be insulated to reduce condensation and lint build up_

o

o

( o

o

Page 5

Installation

[] EXHAUST CONNECTION

_WARNING -TO REDUCE THE RISK

OF FIRE OR PERSONAL INJURY:

*This dryer must be exhausted to the outdoors.

*Use only metal duct.

*Do not terminate exhaust in a chimney, any gas vent,

under an enclosed floor (crawl space), or into an attic.

The accumulated lint could create a fire hazard.

*Provide an access for inspection and cleaning of the

exhaust system, especially at turns. Inspect and clean at

least once a year.

* Never terminate the exhaust into a common duct with a

kitchen exhaust. A combination of lint and grease could

create a fire hazard.

* Do not obstruct incoming or exhausted air.

WE RECOMMEND THAT YOU INSTALL YOUR DRYER

BEFOREYOUR WASHER. THIS WILL PERMIT DIRECT

ACCESS FOR EASIEREXHAUST CONNECTION

THIS DRYERCOMES READY FORREAREXHAUSTING. IF

SPACEIS LIMITED, USE THE INSTRUCTIONS IN SECTION

12 TO EXHAUST DIRECTLYFROM THE LEFTSIDE OR

BOTTOM OF THE CABINET.

Instructions

FORSTRAIGHT

LINEINSTALLATION,

CONNECTTHE ELBOWHIGHLY

DRYEREXHAUST -_ RECOMMENDED.

TOTHEWALLUSING

DUCTTAPE.

RECOMMENDED

CONFIGURATION

TOMINIMIZE

EXHAUST

BLOCKAGE,

ELBOWHIGHLY

RECOMMENDED,-

NOTE: ELBOWS WILL PREVENT DUCT

KINKING AND COLLAPSING.

STANDARD REAR EXHAUST

[] LEVELING DRYER

LEVEL

FRONT-TO-BACK.

4LEVELINGLEGS

_. LEVEL

SIDE-T0-SIDE

WESTRONGLYRECOMMENDTHEUSEOF

RIGIDMETALEXHAUSTDUCT.IFUSING

FLEXABLEMETALDUCT,CUTITTOTHEPROPER

LENGTHANDAVOIDBUNCHINGOFTHEDUCT

BEHINDTHEDRYER.

STANDTHEDRYERUPRIGHTNEARTHE

2ANTI-TIPLEGS

FINALLOCATIONANDADJUSTTHE4LEVELING

LEGSTOMATCHTHEHEIGHTOFYOURWASHER,

ADJUSTTHE2ANTI-TIPLEGSTOCONTACT

THEFLOOR.

Page 6

Installation instructions

USING FLEXIBLE METAL DUCTS

If rigid all-metal duct cannot be used, then flexible all-metal

venting can be used, but it will reduce the maximum

recommended duct length. In special installations when it is

impossible to make connection with the above recommendations,

then UL-listed clothes dryer transition duct may be used as

transition venting between the dryer and wall connection only. The

use of this ducting will affect dry time.

If flexible transition duct is necessary, the following directions Ernst

be followed.

• Use the Shortest Length Possible.

• Stretch the Duct to Its Maxinmm Length.

• Do Not (;rush or Collapse.

° Never Use Transition Duct Inside the Wall or

Inside the DryeI:

° Avoid Resting the Duct on Sharp Objects.

° Venting Must Conform to Local Building Codes.

[] ALCOVE OR CLOSET INSTALLATION

• If your dryer is approved for installation in an alcove or

closet, it will be stated on a label on the dryer back.

° The dryer MUST be vented to the outdoors. See the

EXHAUST INFORMATION section.

° Minimum clearance between dryer cabinet and adjacent

walls or other surfaces is:

0 in. either side

3 in. front and rear

° Minimum vertical space from floor to overhead cabinets,

ceiling, etc. is ,52 in.

° Closet doors must be louvered or otherwise ventilated and

must contain a minimum of 60 sq. in. of open area equally

distributed. If the closet contains both a washer and a

dryer, doors must contain a minimum of 120 sq. in. of open

area equally distributed.

° The closet should be vented to the outdoors to prevent gas

pocketing in case of a gas leak in the supply line.

• No other fuel-burning appliance shall be installed in the

same closet with the dryer.

[] BATHROOM OR BEDROOM

INSTALLATION

ELBOWHIGHLY

RECOMMENDED

ELBOWSHIGHLY

RECOMENDED -_

DONOTUSE

EXCESSIVE

)(

,

_. CRUSH

FLEXIBLE

DONOT

_I EXHAUST

_ AGAINST

--WAL,%

° The dryer MUST be vented to the outdoors. See

EXHAUST INFORMATION section 6.

° The installation must conform with local codes or, in the

absence of local codes, with the NATIONAL FUEL GAS

CODE, ANSI Z223.

[] MOBILE OR MANUFACTURED

HOME INSTALLATION

° Installation must conform to the MANUFACTURED

HOME CONSTRUCTION & SAFETY STANDARD,

TITLE 24, PART 32-80 or, when such standard is not

applicable, with AMERICAN NATIONAL STANDARD

FOR MOBILE HOME, NO. 501B.

• The dryer MUST be vented to the outdoors with the

termination securely fastened to the mobile home

structure. (See EXHAUST INFORMATION section 6.)

• The vent MUST NOT be terminated beneath a mobile or

manufactured home.

° The vent duct material MUST BE METAL.

° KIT 14-D3A6-33 MUST be used to attach the dryer

securely to the structure.

• The vent MUST NOT be connected to any other duct,

vent, or chinmey.

• Do not use sheet metal screws or other refastening

devices which extend into the interior of the exhaust vent.

° Provide an opening with a flee area of at least 25 sq. in.

for introduction of outside air into the dryer room.

6

Page 7

Installation

nstructions:

[] DRYER EXHAUST TO BOTTOM

CABINET

,_ WARNING - BEFORE PERFORMING

THIS EXHAUST INSTALLATION, BE SURE

TO DISCONNECT THE DRYER FROM ITS

ELECTRICAL SUPPLY. PROTECT YOUR

HANDS AN DAR MS FROM SHARP EDGES

WHEN WORKING INSIDE TH E CABINET.

BE SURE TO WEAR GLOVES

REMOVE

SCREW

ANDSAVE.

REMOVE

DESIRED

KNOCKOUT

(ONEONLY).

Detach and remove the bottom, right or left side knockout

as desired. Remove the screw inside the dryer exhaust duct

and save. Pull the duct out of the dryer.

FIXINGHOLE

ADDING NEW DUCT

FIXING

HOLE

Reconnect the cut portion (A) of the duct to the blower

housing. Make sure that the shortened duct is aligned with

the tab in the base. Use the screw saved previously to secure

the duct in place through the tab on the appliance base.

• Apply duct tape as shown on the joint between the dryer

internal duct and the elbow;

DUCT

B A

14 9"

Cut the duct as shown and keep portion A.

TAB LOCATION

BENDTAB

UP450

Through the rear opening, locate the tab in the middle of

the appliance base. till the tab to about 45°using a fiat

blade screwdriver"

II

CAUTION:

Internal duct joints must be

secured with tape, otherwise

they may separate and cause

a safety hazard.

Page 8

Installation

instructions

ADDING ELBOW FOR EXHAUST

THROUGH BOTTOM OF CABINET

• Insert the elbow through tile rear opening and connect it to

the dryer internal duct.

• Apply duct tape on the joint between the dryer internal

duct and elbow, as shown on page 7.

CAUTION:

internal duct joints must be secured with tape,

otherwise they may separate and cause a

safety hazard.

ADDING COVER PLATE TO REAR

OF CABINET

[] CHANGING DIRECTION OF

DOOR OPENING

REMOVE4HOLEPLUGSAND

REMOVE4

HINGESCREWS.

PLACETHEMINTHEHOLES

ONTHEOPPOSITESIDE.

PLATE

(KITWE1M454)

Connect standard metal elbows and ducts to complete the

exhaust system. Cover back opening with a plate (Kit

WE1M454) available from your local service provider.

Place dryer in final location.

I _kWARNING. NEVER LEAVE THE

BACK_OPENING WITHOUT THE PLATE.

ROTATEDOOR1800

ANDREINSTALL.

[] SERVICING

,_ WARNING- LABEL ALL WIPES

PRIOR TO DISCONNECTION WHEN

SERVICING CONTROLS. WIRING

ERRORS CAN CAUSE IMPROPER AND

DANGEROUS OPERATION AFTER

SERVICING/INSTALLATION.

For Questions on Installation, Call: 1-800-626-2000 (US) or

:,oo',Isvpo:,o 1-800-3614400 (Canada). Pub. # 31-16110 8

For replacement parts and other information, refer to

Owner's Manual for servicing phone numbers.

Loading...

Loading...